Lignin iron powder ball compound adhesive and preparation method thereof

A technology of lignin and binder, which is applied in the field of lignin iron powder pellet composite binder and its preparation, can solve the problems of decreased mechanical strength, damage and pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

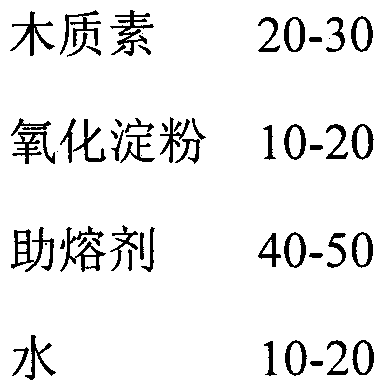

Embodiment 1

[0013] A certain mass of alkali lignin is taken and dissolved in 1% NaOH solution according to the solid-to-liquid ratio of 1:50 (m / v). Adjust the pH value of the lignin solution to 10, filter to remove insoluble impurities, and concentrate with an ultrafiltration membrane with a molecular weight cut-off of 10,000 Da to obtain a large molecular weight lignin solution. Adjust the pH of the large molecular weight lignin solution to 3 with HCl solution, centrifuge and wash the lignin precipitate to remove sodium chloride, and obtain a large molecular weight lignin raw material free of sulfur and alkali metal. Fully stir and mix lignin, oxidized starch and flux according to the ratio of: 25 parts of lignin, 15 parts of oxidized starch, 25 parts of lime powder, 8 parts of magnesium oxide, 7 parts of magnesium chloride, and 20 parts of water to obtain 20% water content Iron powder pellet binder. The above-mentioned binder is added into the iron powder according to 12% of the mass o...

Embodiment 2

[0015] A certain mass of alkali lignin is taken and dissolved in 1% NaOH solution according to the solid-to-liquid ratio of 1:50 (m / v). Adjust the pH value of the lignin solution to 9, filter to remove insoluble impurities, and concentrate with an ultrafiltration membrane with a molecular weight cut-off of 10,000 Da to obtain a large molecular weight lignin solution. Adjust the pH of the large molecular weight lignin solution to 2 with HCl solution, centrifuge and wash the lignin precipitate to remove sodium chloride, and obtain a large molecular weight lignin raw material free of sulfur and alkali metals. Fully stir and mix lignin, oxidized starch and flux according to the ratio of: 30 parts of lignin, 10 parts of oxidized starch, 25 parts of lime powder, 10 parts of magnesium oxide, 10 parts of magnesium chloride and 15 parts of water to obtain 15% water content Iron powder pellet binder. The above-mentioned binder is added into the iron powder according to 10% of the mass ...

Embodiment 3

[0017] A certain quality of ethanol lignin is taken and dissolved in 2% NaOH solution according to the solid-to-liquid ratio of 1:40 (m / v). Adjust the pH value of the lignin solution to 9, filter to remove insoluble impurities, and concentrate with an ultrafiltration membrane with a molecular weight cutoff of 6000 Da to obtain a large molecular weight lignin solution. Adjust the pH of the large molecular weight lignin solution to 2 with HCl solution, centrifuge and wash the lignin precipitate to remove sodium chloride, and obtain a large molecular weight lignin raw material free of sulfur and alkali metals. Fully stir and mix lignin, oxidized starch and flux according to the ratio of: 25 parts of lignin, 15 parts of oxidized starch, 20 parts of lime powder, 15 parts of magnesium oxide, 10 parts of magnesium chloride and 15 parts of water to obtain 15% water content Iron powder pellet binder. Add the above-mentioned binder into the iron powder according to 7% of the mass of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com