Preparation method of formed semicoke for calcium carbide

A technology of semi-coke and calcium carbide, which is applied in the field of preparation of molded semi-coke for calcium carbide, can solve the problems of semi-coke powder reuse, etc., and achieve the effects of reusing, good cold strength, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Raw materials for preparing semi-coke

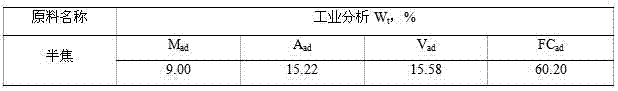

[0023] 1. Semi-coke: The semi-coke used was analyzed by the industrial analysis method of GB / T212-2008 coal, and the results are as follows:

[0024]

[0025] 2. Quicklime: The used quicklime is analyzed for loss on ignition according to GB / T 15057.10-1994, and the loss on ignition content is 5.55%.

[0026] 2. Preparation of semi-coke by double-roll forming process

[0027] 1. Handling of raw materials:

[0028] The semi-coke is made into semi-coke powder with a particle size of less than 3 mm, and the quicklime is made into lime powder with a particle size of less than 1 mm.

[0029] 2. Preparation of molding semi-coke binder:

[0030] Weigh quicklime with a particle size of <1 mm, and add excess water to fully mature the lime. After about 40-50 minutes, filter the supernatant liquid, and take out the lower layer of slurry, that is, the slaked lime slurry, which is used as the forming semi-coke binder.

[0031] 3. The...

Embodiment 2

[0038] Example 2: The raw materials include: semi-coke powder and binder, the addition amount (g) is: 3120 and 880 respectively; the addition ratio (%) is respectively: 78% and 22%; drop strength / %, 1m For: 91.79. Others are the same as in Example 1.

Embodiment 3

[0039] Example 3: The raw materials include: semi-coke powder and binder, the addition amount (g) is: 3040 and 960 respectively; the addition ratio (%) is respectively: 76% and 24%; drop strength / %, 1m For: 78.47. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com