Binder additive and method for preparing calcium carbide by applying binder additive

A technology of binder and additive, applied in the field of binder additive and its application to prepare calcium carbide, can solve problems such as affecting the normal production of new calcium carbide process, low thermal strength of pellets, large amount of binder, etc., and achieve excellent bonding Performance, wide range of sources, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

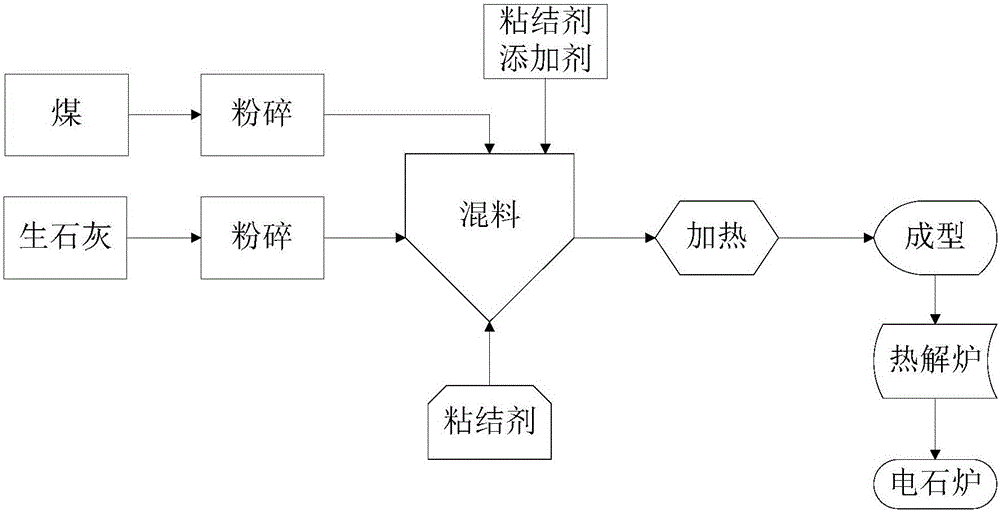

Method used

Image

Examples

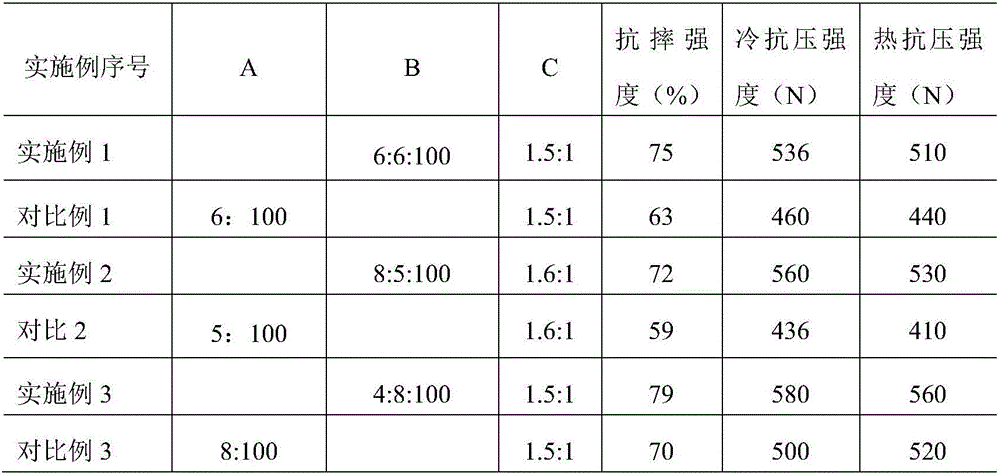

Embodiment 1

[0053] The binder additive is anthracene oil;

[0054] The mass ratio of binder additive: binder: mixture = 6:6:100.

[0055] Weigh a certain amount of long-flame coal powder and quicklime powder, wherein the size of long-flame coal powder and quicklime powder is ≤100 mesh, the mass ratio of quicklime powder and long-flame coal powder=1.5:1, and evenly mix the above two raw materials 10 minutes; add the binder accounting for 6% of the mass of the above mixture and the binder additive anthracene oil accounting for 6% of the mass of the mixture (note: the anthracene oil needs to be heated to 100 ℃ before adding), and continue to stir for 10 minutes; take out the above pellets The raw materials are put into a forming press to prepare forming pellets, the pressure of the forming equipment is 12MPa, the forming pellets are put into a pyrolysis furnace for pyrolysis to obtain pyrolysis pellets, and the pyrolysis temperature is 400°C.

[0056] After cooling, the drop strength, cold ...

Embodiment 2

[0065] The binder additive is made of waste nitrile rubber powder;

[0066] The mass ratio of binder additive: binder: mixture = 8:5:100.

[0067] Weigh a certain amount of long-flame coal powder and quicklime powder, wherein the size of long-flame coal powder and quicklime powder is ≤100 mesh, and the mass ratio of quicklime powder and long-flame coal powder=1.5:1, and evenly mix the above two raw materials 10 minutes; add binder that accounts for 5% of the mass of the above mixture and waste nitrile rubber powder of the binder additive that accounts for 8% of the mass of the above mixture (Note: the waste nitrile rubber powder should be crushed to less than 0.5mm before adding), continue to stir 10 minutes; put it into a heating screw with a temperature of 150 ° C for preheating for 10 minutes, and finally put it into a forming press to prepare forming pellets, the pressure of the forming equipment is 12 MPa, and the forming pellets are placed in a pyrolysis furnace Pyrolys...

Embodiment 3

[0077] The binder additive is made of recycled phenolic resin particles;

[0078] Binder additive: Binder Z: mass ratio of mixture = 4:8:100.

[0079] Weigh a certain amount of long-flame coal powder and quicklime powder, wherein the size of long-flame coal powder and quicklime powder is ≤100 mesh, and the mass ratio of quicklime powder and long-flame coal powder=1.5:1, and evenly mix the above two raw materials 10 minutes; add the binder accounting for 8% of the mass of the above mixture and the regenerated phenolic resin particles of the binder additive accounting for 4% of the mass of the above mixture (note: the regenerated phenolic resin particles need to be crushed to less than 0.2mm before adding), and continue to stir for 10 minutes; Put it into a heating screw with a temperature of 150 ° C for preheating for 10 minutes, and finally put it into a molding press to prepare molding pellets. The pellets were pyrolyzed, and the pyrolysis temperature was 600°C.

[0080] Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com