Industrial briquette and technique for producing the same

A technology for production process and briquette, applied in the field of industrial briquette and its production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The components and weight percentages of the industrial briquette are: bituminous coal 62%, coking coal 15%, clay 10%, and sodium humate 13%.

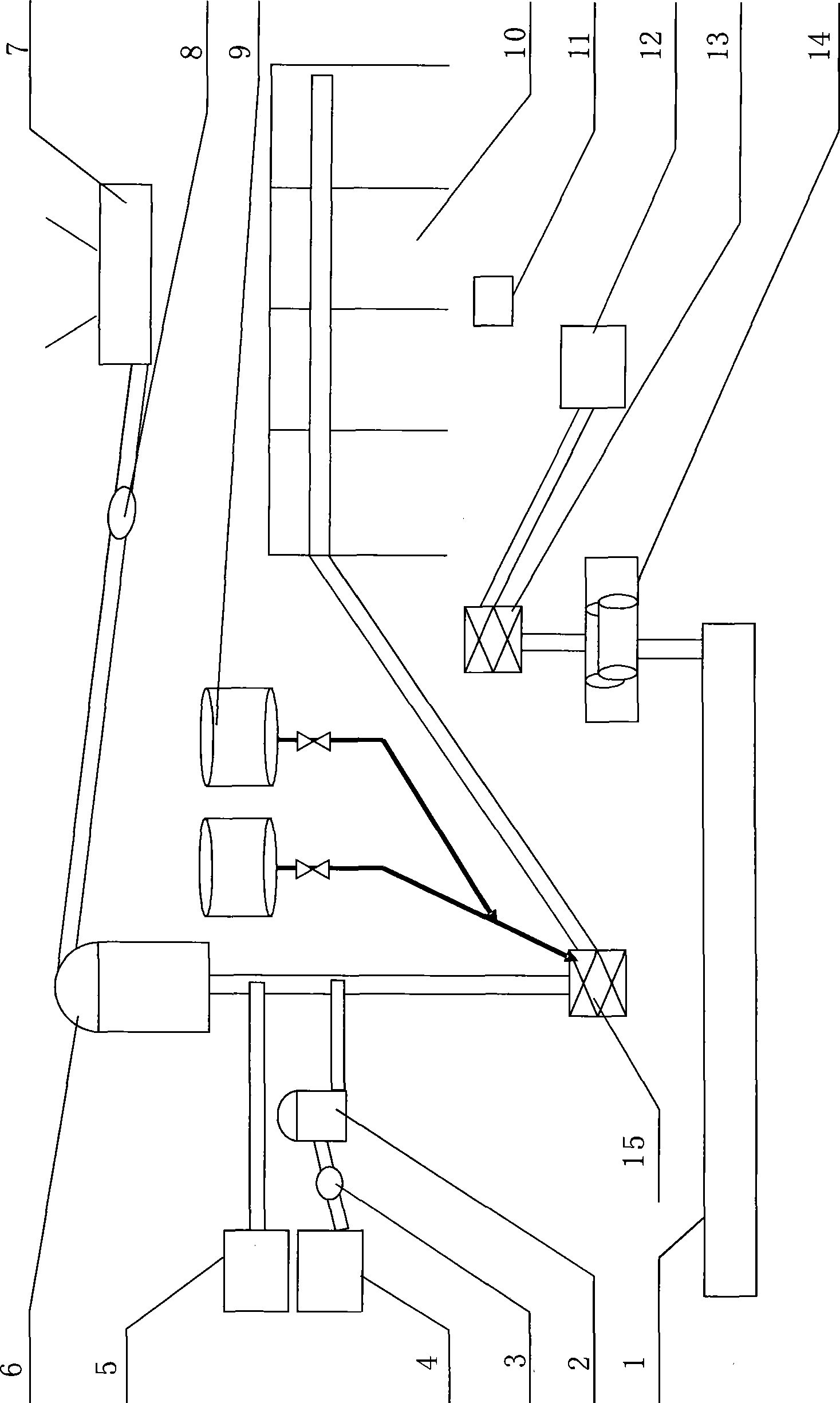

[0016] Bituminous coal of 9.3 tons / hour rationed by the raw coal quantitative feeder 7 is transported by the belt, and the iron is removed by the raw coal iron remover 8, and then sent to the raw coal crusher 6, crushed to the pulverized coal below 3mm, and transported to the mixer B15 by the belt ; 1.5 tons / hour of clay is sent out by clay quantitative feeder 5, and sent to the crushed pulverized coal belt through belt; 2.25 tons / hour of coking coal is sent out by coking coal quantitative feeder 4, conveyed by belt, and passed through coking coal iron remover 3. After removing the iron, it is sent to the coking coal crusher 2 for crushing, and the crushed coking coal is conveyed to the crushed pulverized coal belt with a belt; after the sodium humate is prepared into a sodium humate solution in the sodium humate reactor 9, it is...

Embodiment 2

[0018] The components and weight percentages of the industrial briquette are: bituminous coal 72%, coking coal 10%, clay 8%, and sodium humate 10%.

[0019] Bituminous coal of 10.8 tons / hour rationed by the raw coal dosing feeder 7 is transported by the belt, and the iron is removed by the raw coal iron remover 8, and then sent to the raw coal crusher 6, crushed to the pulverized coal below 3mm, and transported to the mixer B 15 by the belt 1.2 tons / hour of clay is sent out by clay quantitative feeder 5, and sent to the crushed pulverized coal belt through belt; 1.5 tons / hour of coking coal is sent out by coking coal quantitative feeder 4, conveyed by belt, removed by coking coal After the iron is removed from the iron device 3, it is sent to the coking coal crusher 2 for crushing, and the crushed coking coal is conveyed to the crushed pulverized coal belt with a belt; after the sodium humate is prepared into a sodium humate solution in the sodium humate reactor 9, it is contro...

Embodiment 3

[0021] The components and weight percentages of the industrial briquette are: bituminous coal 82%, coking coal 7%, clay 5%, and sodium humate 6%.

[0022] Bituminous coal of 12.3 tons / hour rationed by the raw coal quantitative feeder 7 is transported by belt, and iron is removed by the raw coal iron remover 8, and then sent to the raw coal crusher 6, crushed to the pulverized coal below 3mm, and transported to the mixer B 15 by the belt Inside; 0.75 t / h of clay is sent out through clay dosing feeder 5 and sent to the crushed pulverized coal belt through belt; 1.05 t / h coking coal is sent out through coking coal dosing feeder 4, conveyed through belt, removed by coking coal After the iron is removed from the iron device 3, it is sent to the coking coal crusher 2 for crushing, and the crushed coking coal is conveyed to the crushed pulverized coal belt with a belt; after the sodium humate is prepared into a sodium humate solution in the sodium humate reactor 9, it is controlled by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com