Multistation punch for producing fomed semi-finsished casting coke product

A semi-finished, multi-station technology, used in material forming presses, presses, manufacturing tools, etc., can solve the problems of no fixed block size of finished products, many recycling equipment, limited cupolas, etc., to achieve uniform quality and reduce tons The effect of coal power consumption and gas resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

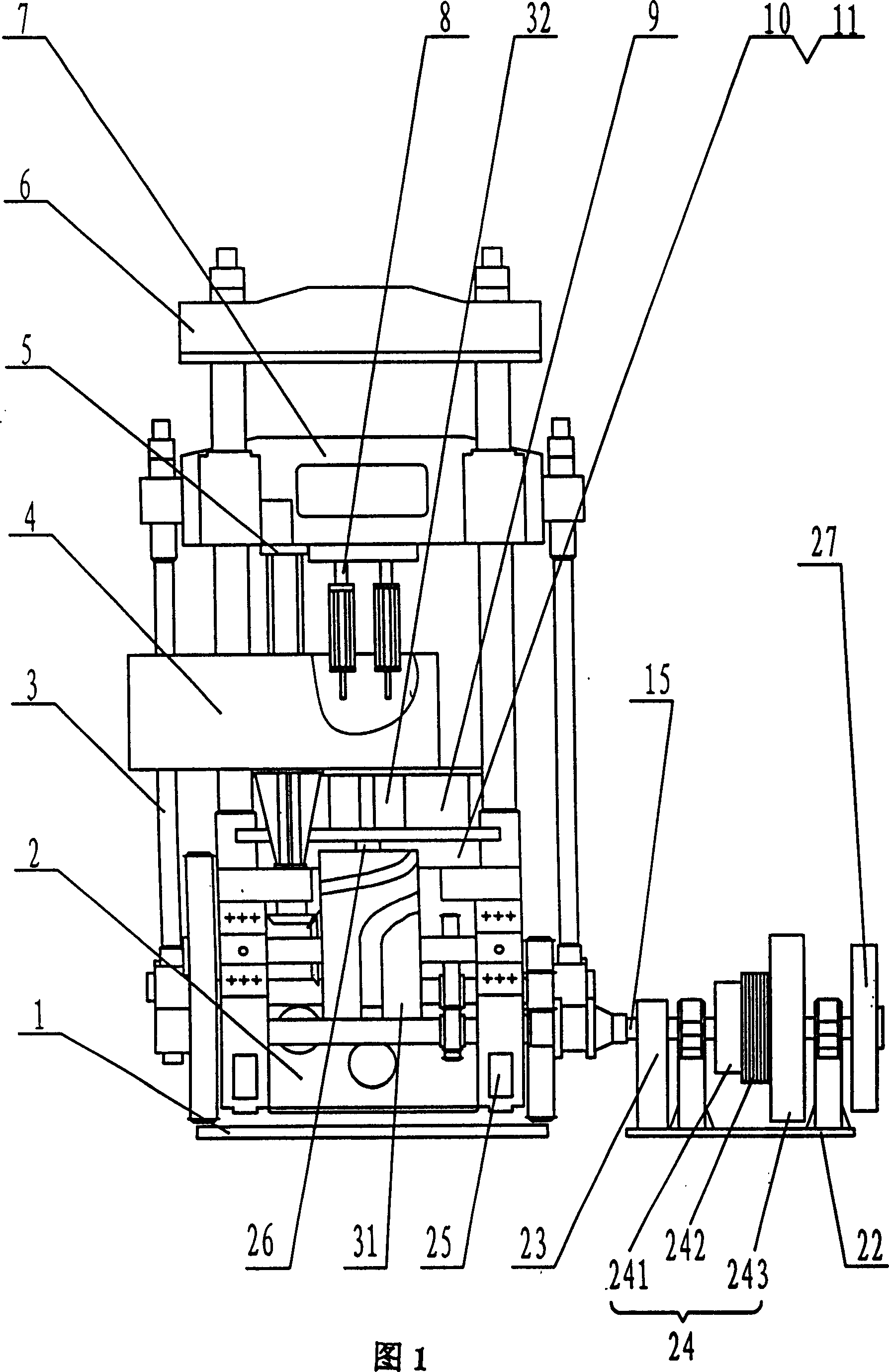

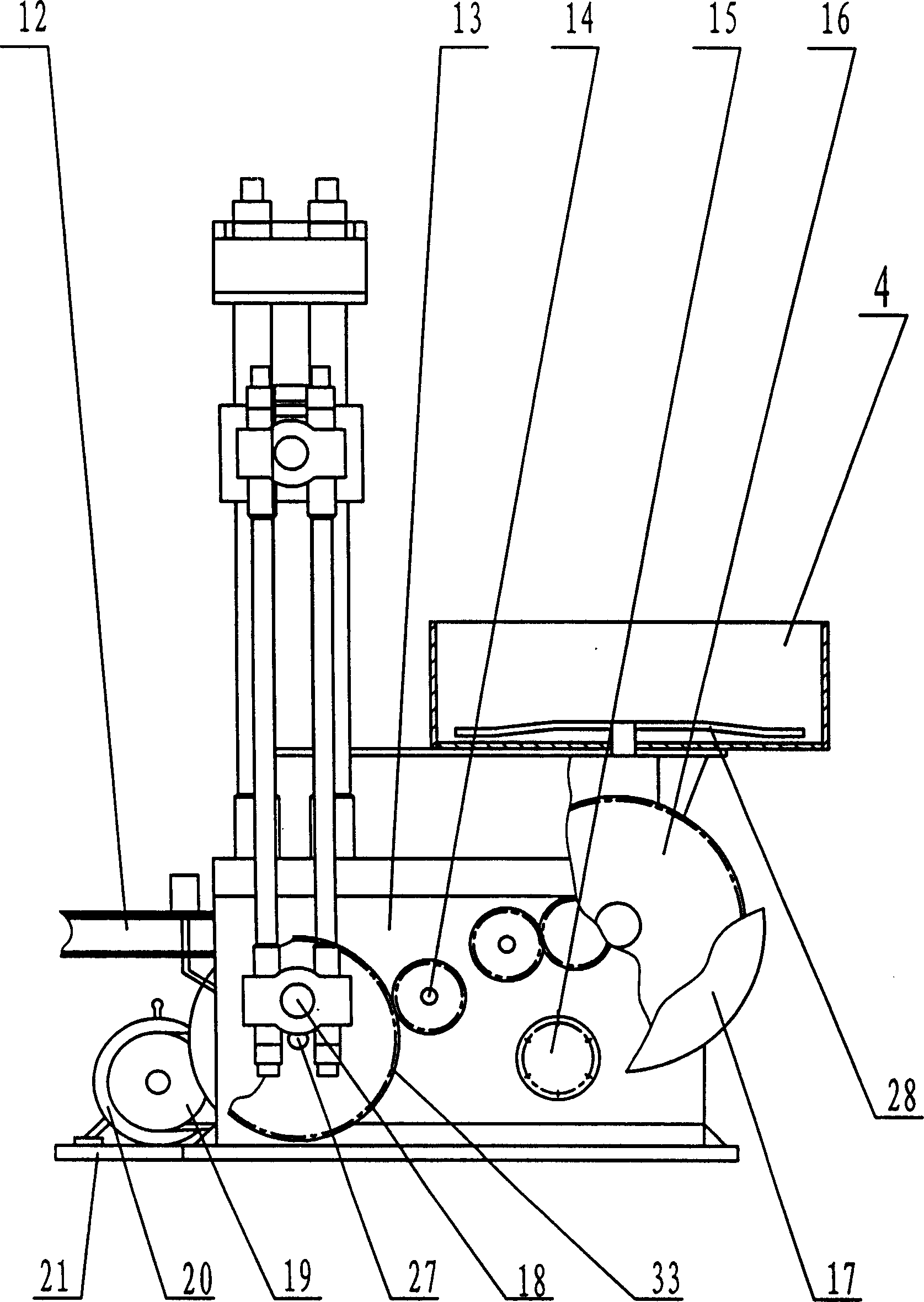

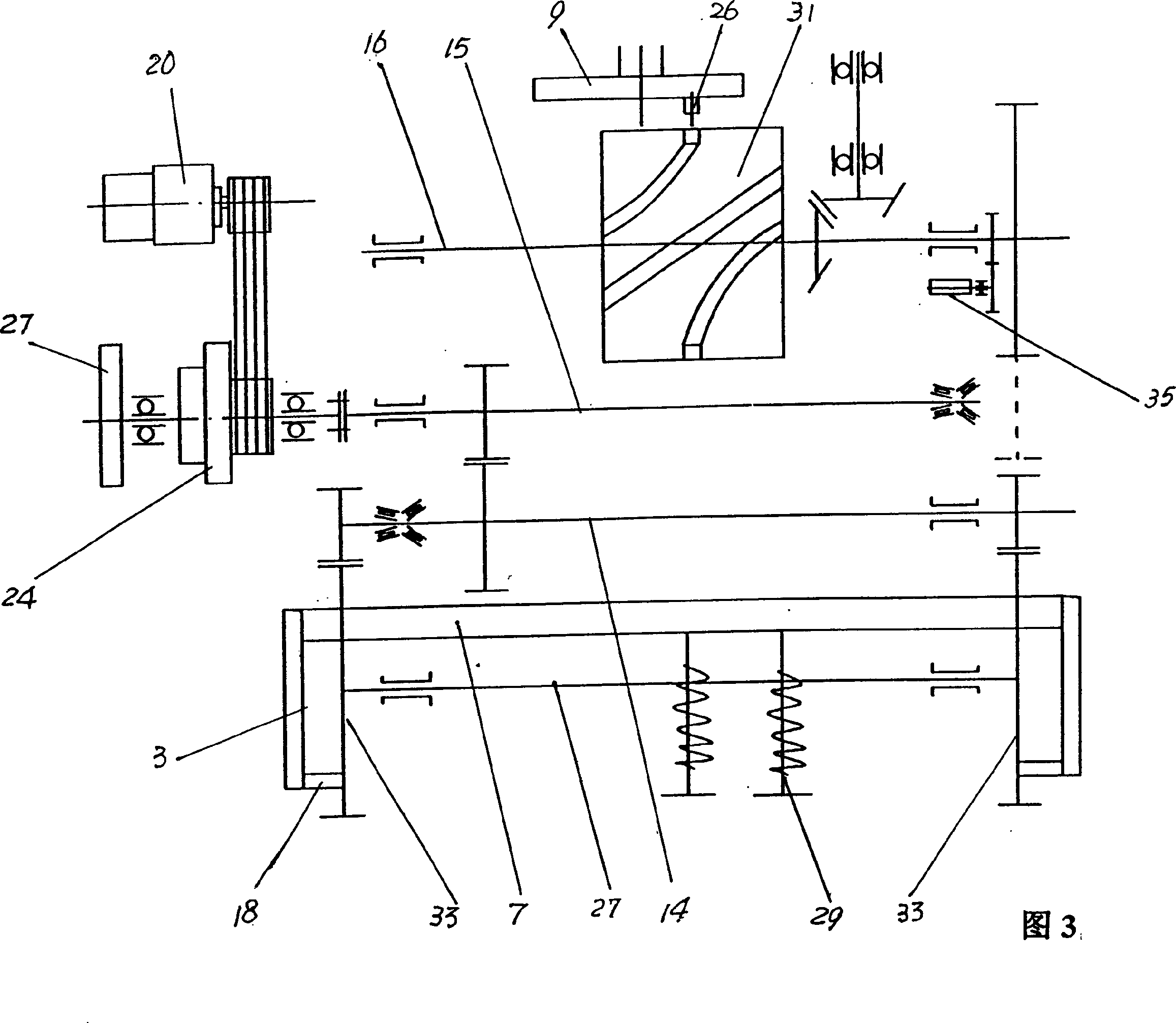

[0035] Drawing No.:

[0036] 1. Frame base 2. Rear frame 3. Link

[0037] 4. Distributing tray 5. Demolding device 6. Guide device

[0038] 7. Punching arm device 8. Die 9. Turning disc device

[0039] 10. Fixed plate 11. Mold support 12. Discharge belt

[0040] 13. Side frame B 14. No. 2 shaft

[0041] 15. No. 1 shaft (main shaft) 16. Camshaft 17. Shield

[0042] 18. Crank shaft 19. Motor pulley 20 Motor

[0043] 21. Motor seat 22. Base 23. Electromagnetic brake

[0044] 24. Drive wheel device 241. Pulley 242. Electromagnetic clutch 243. Flywheel

[0045] 25. Side frame A 26. Roller shaft 27. No. 3 shaft

[0046] 28. Dial wing 29. Punch

[0047] 291. Round nut 292. Spring 293. Spring seat

[0048] 294. Punch rod 295. Press plate 296. Punch needle

[0049] 297. Punch 298. Screw head

[0050] 30. Safety device 301. Round head screw 302. Hexagon socket head screw

[0051] 304. Rear bearing seat 306. Removable safety pin sleeve 307. Pulley

[0052] 308. Safety pin sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com