Patents

Literature

797results about How to "High pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

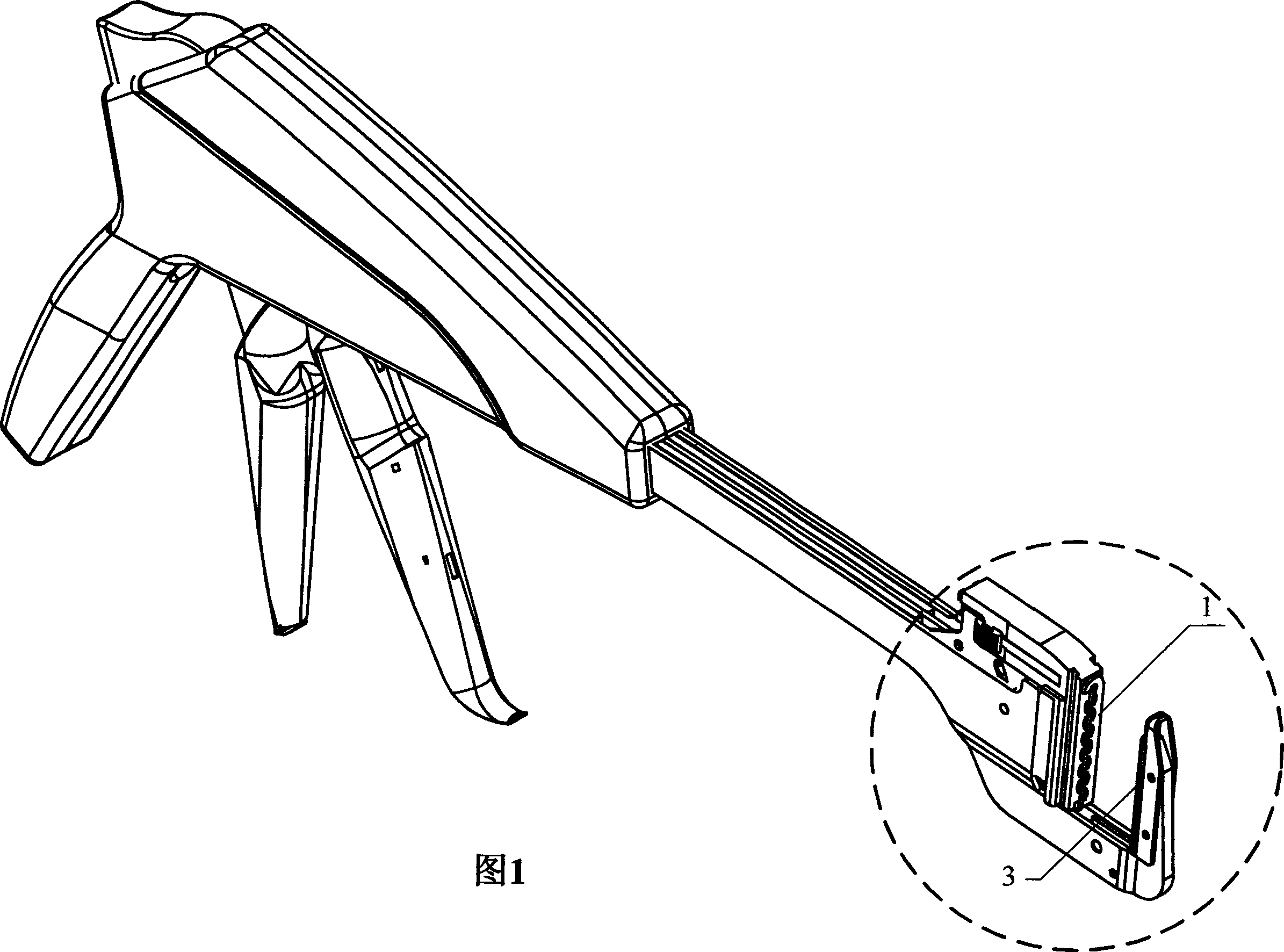

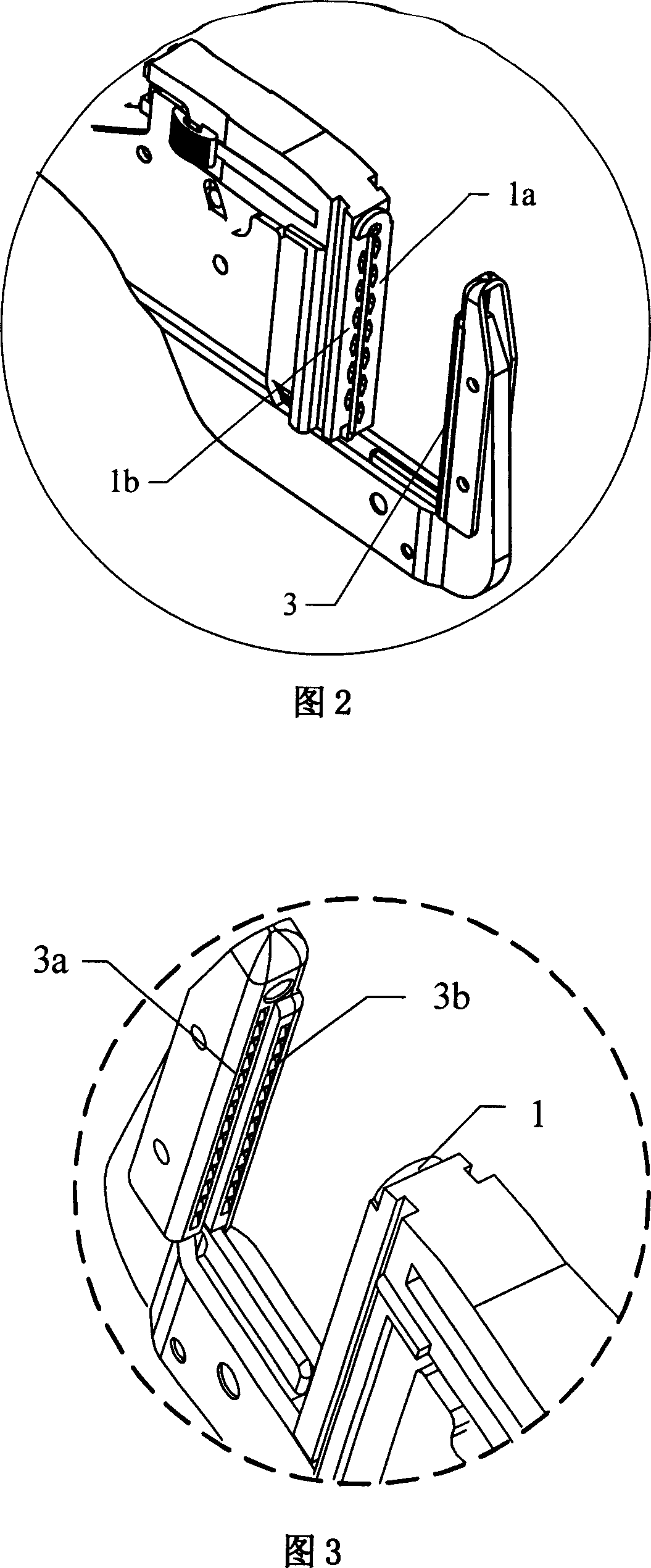

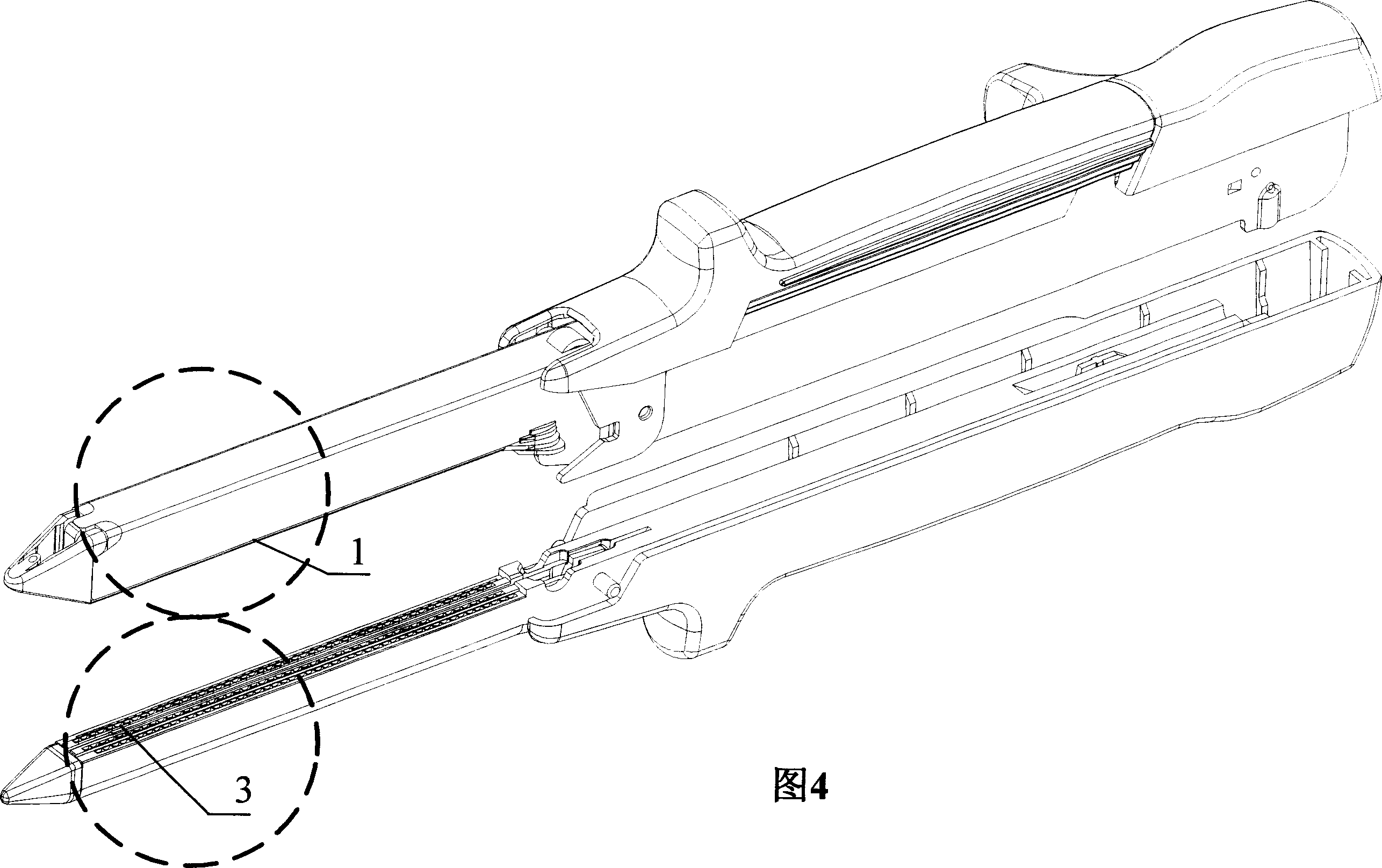

Surgical binding instrument binding mechanism

The invention relates to a binding mechanism of a surgical binding apparatus, which is placed at the head of the surgical binding apparatus and includes a nail pin, a nail pushing plate and a nail block. The nail pushing plate and the nail pin are installed inside the binding apparatus body. The positions of the nail block and the nail pushing plate are opposite. The invention is characterized in that the working faces of nail pin, the nail pushing plate and the nail block are not at the same plane and at least present a step-type fall distributed structure. When the structure is adopted to form an anastomoses opening, the distance between two lines of nails is enlarged; the elasticity of the anastomoses opening which is formed in the operation is increased and is more close to the physiological characteristic of the tissue, which is in favor of the prompt recovery of the tissue. When the nail block is set out from an anastomoses ring or a content object is put through the anastomoses ring after binding, the elasticity of the anastomoses ring becomes larger to allow the nail block or the content object pass through and reduce the probability of damaging the anastomoses ring.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

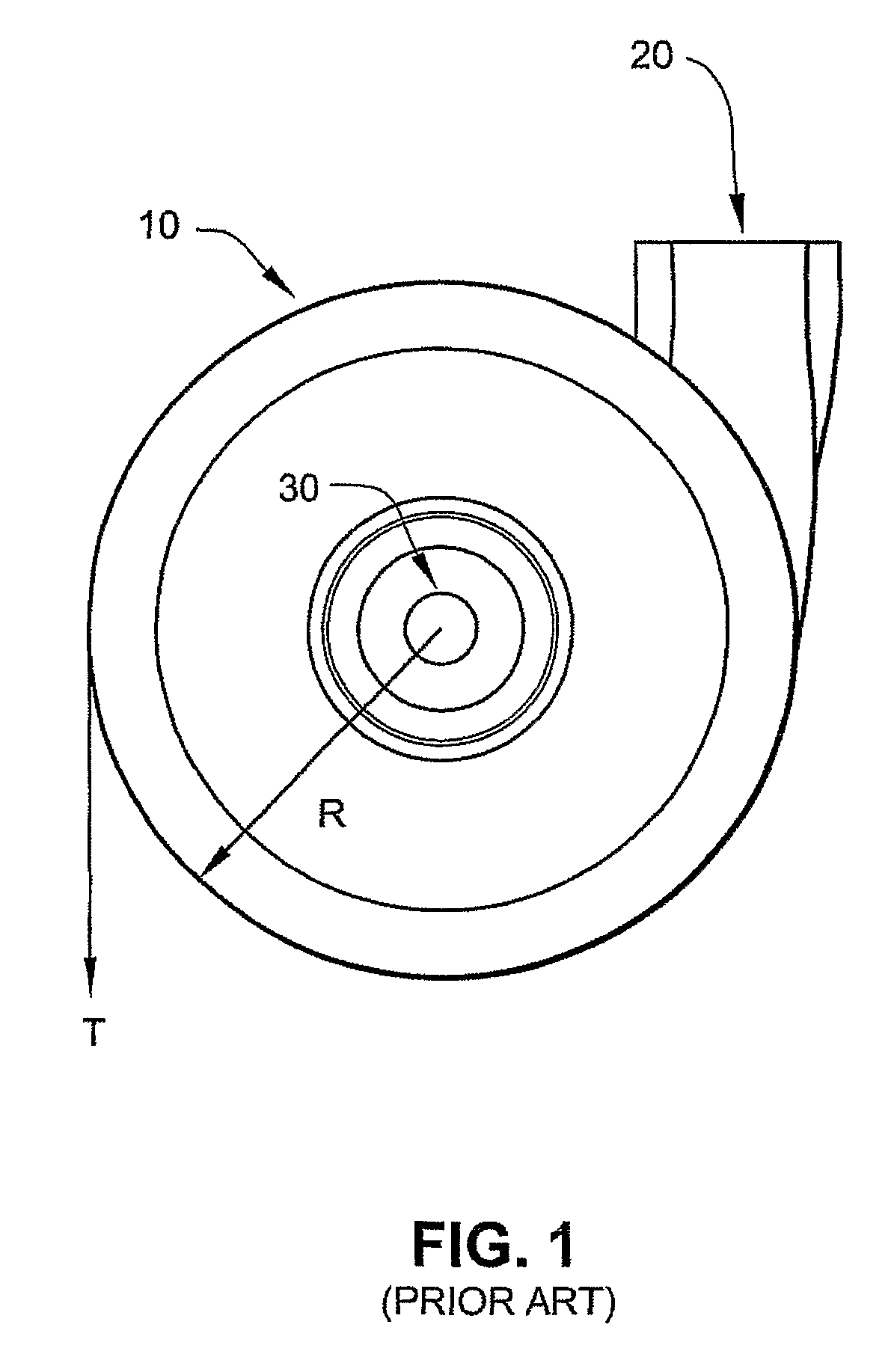

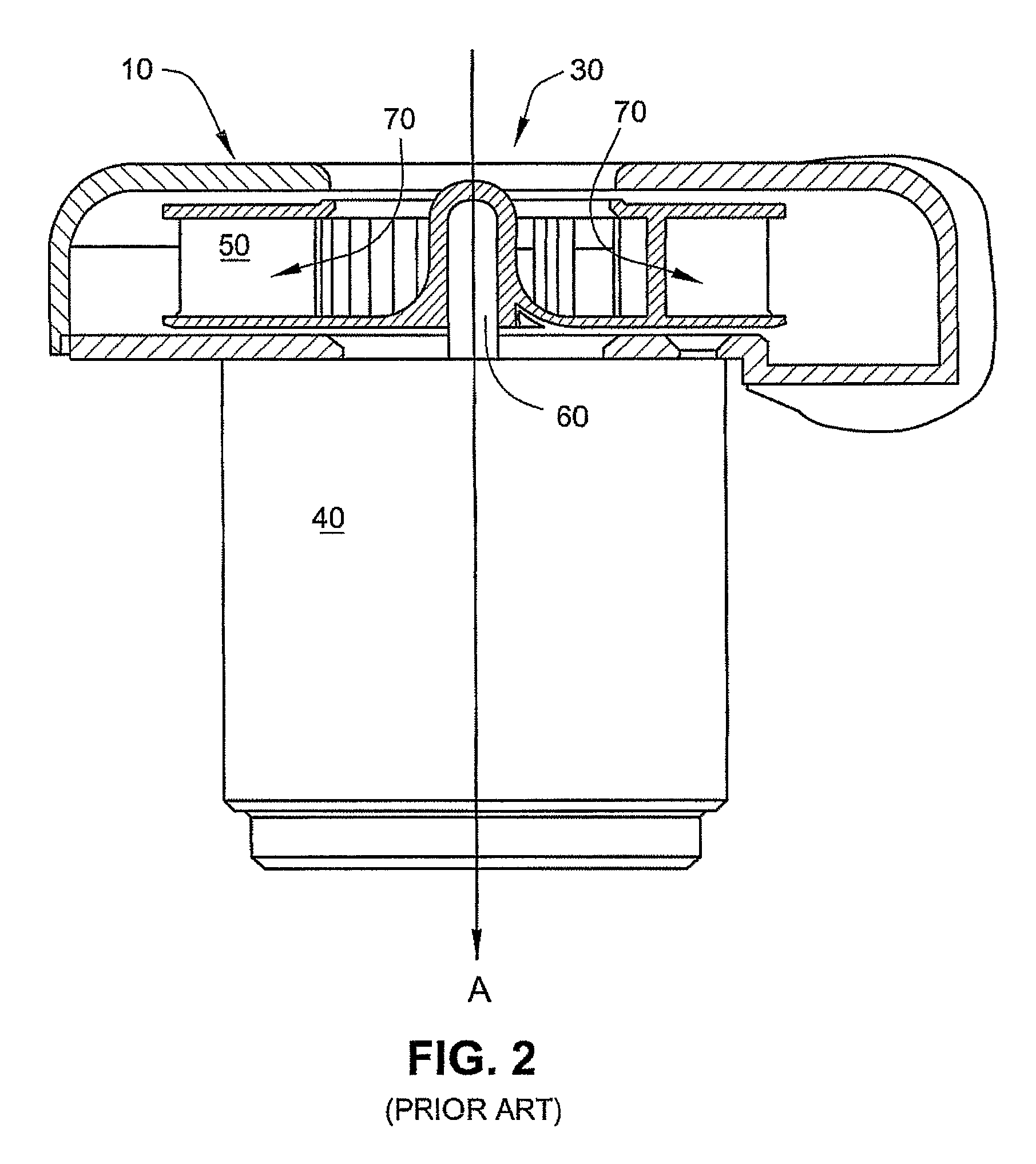

Compact low noise efficient blower for CPAP devices

Owner:RESMED MOTOR TECH

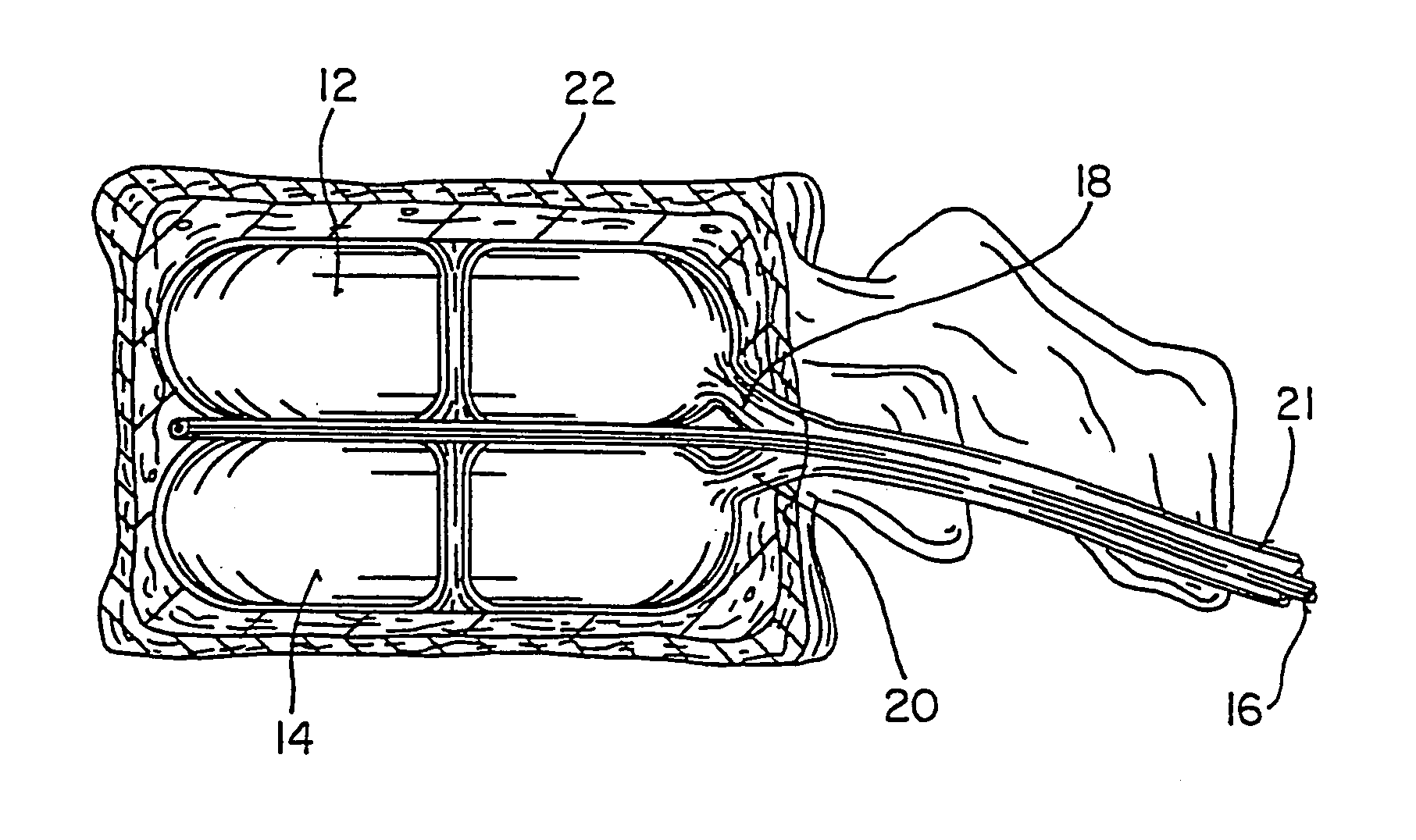

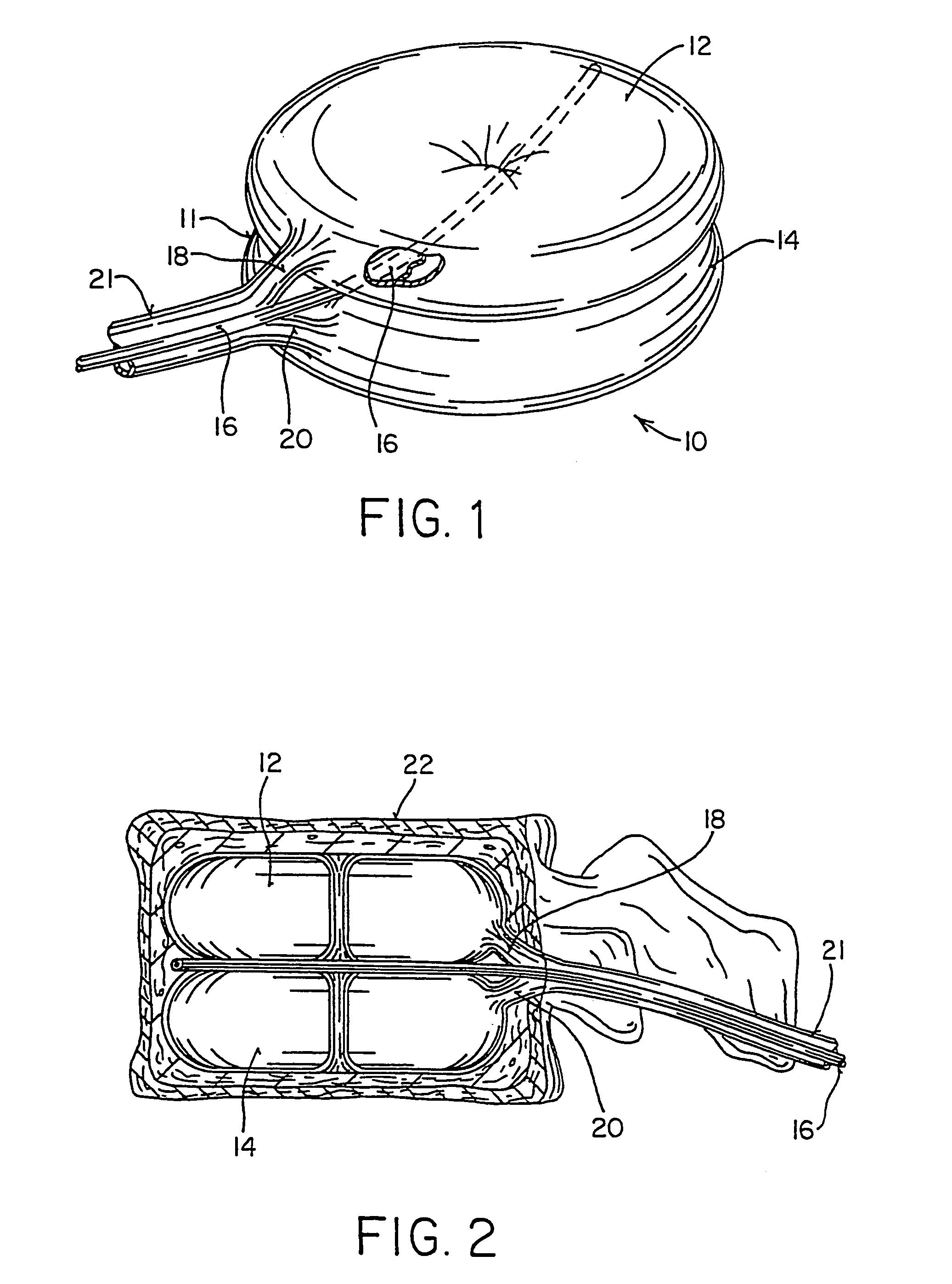

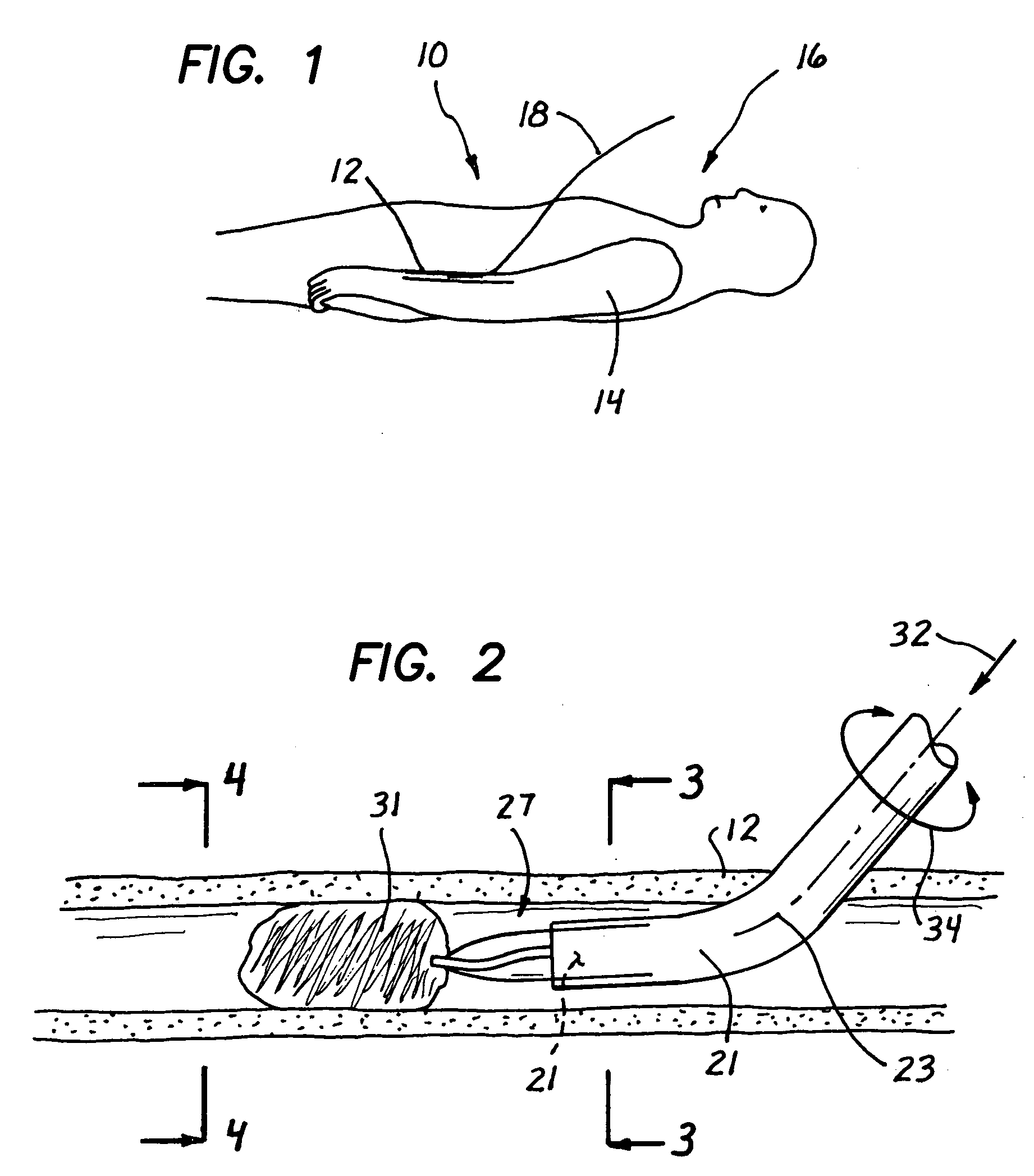

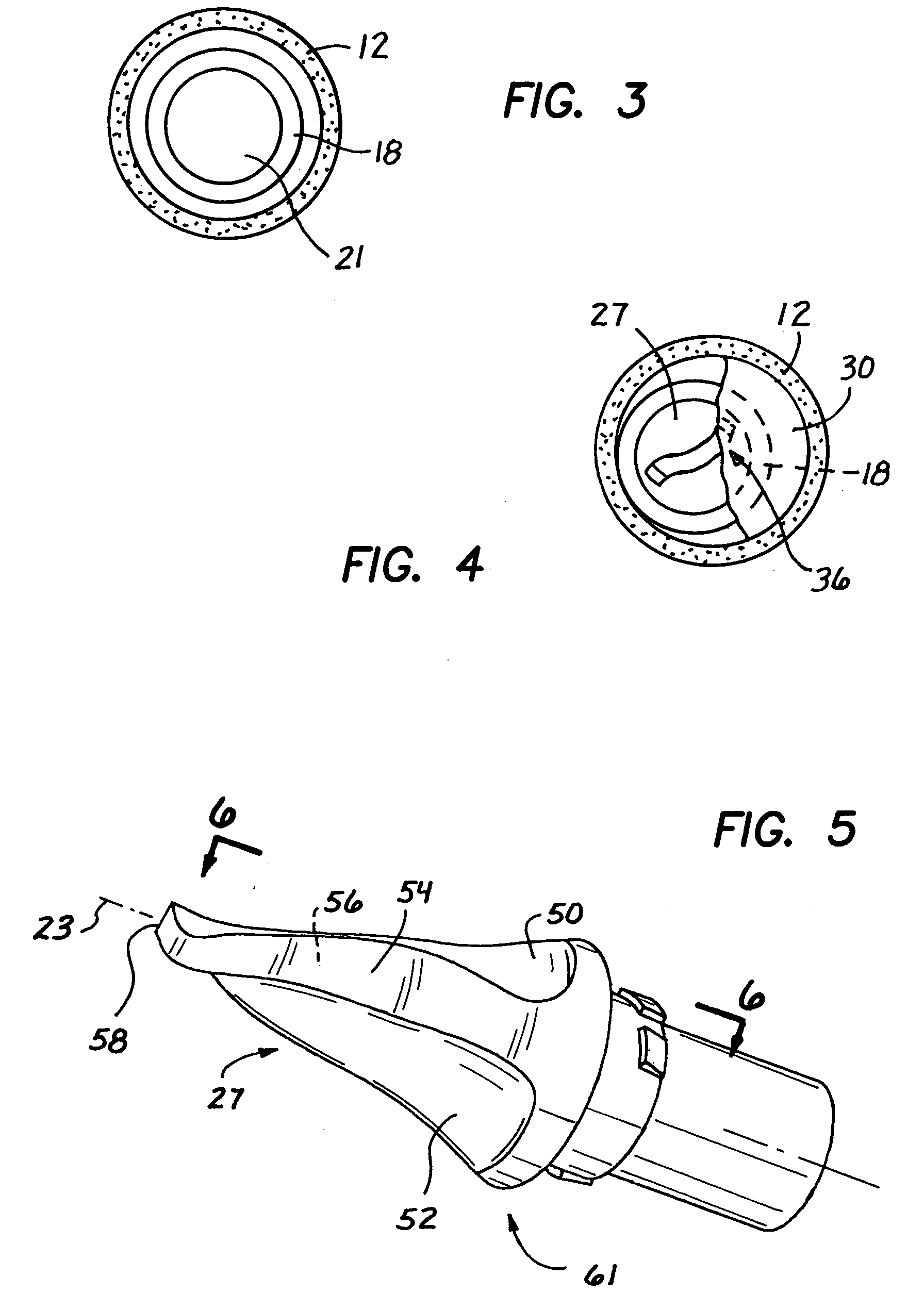

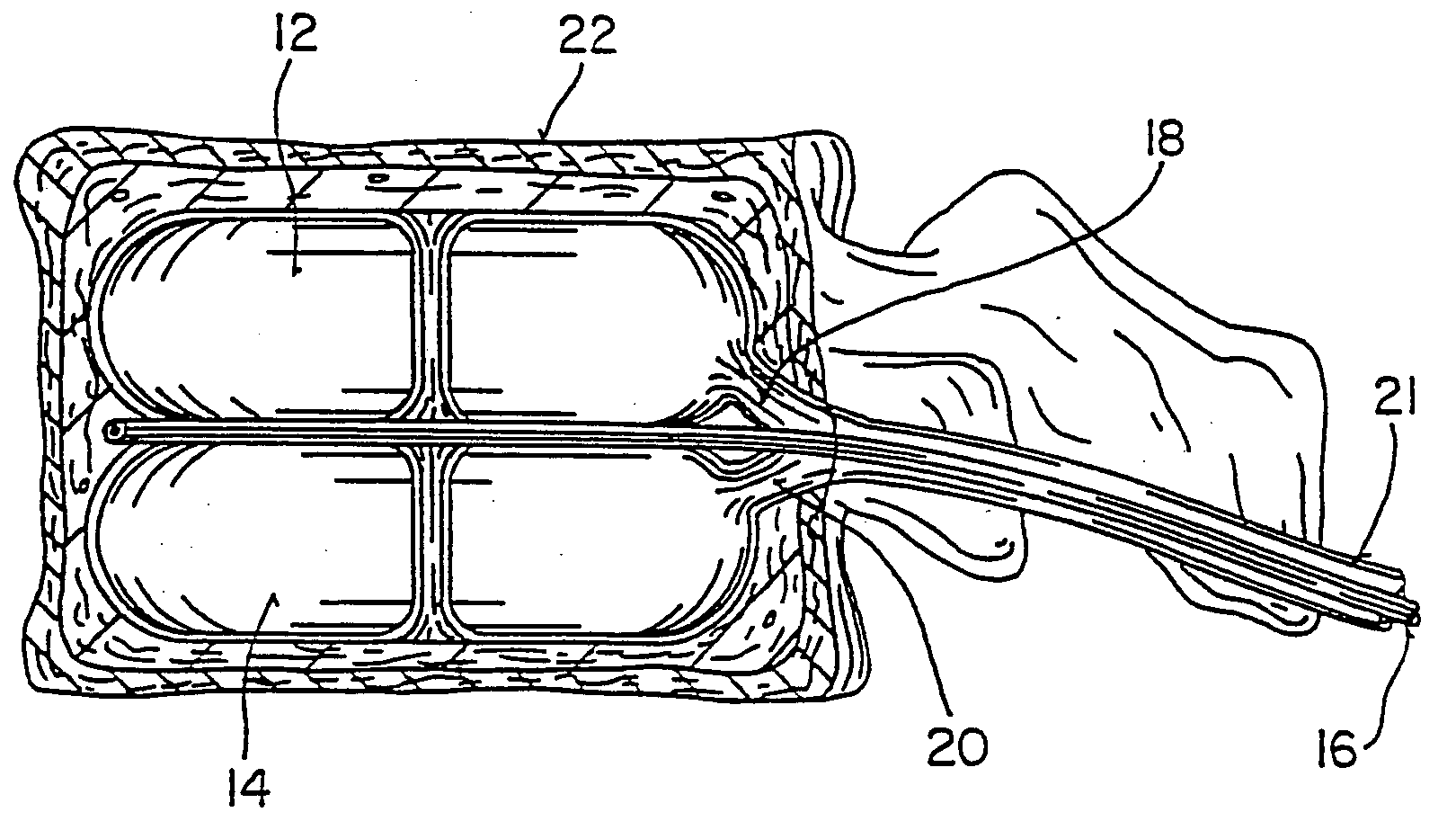

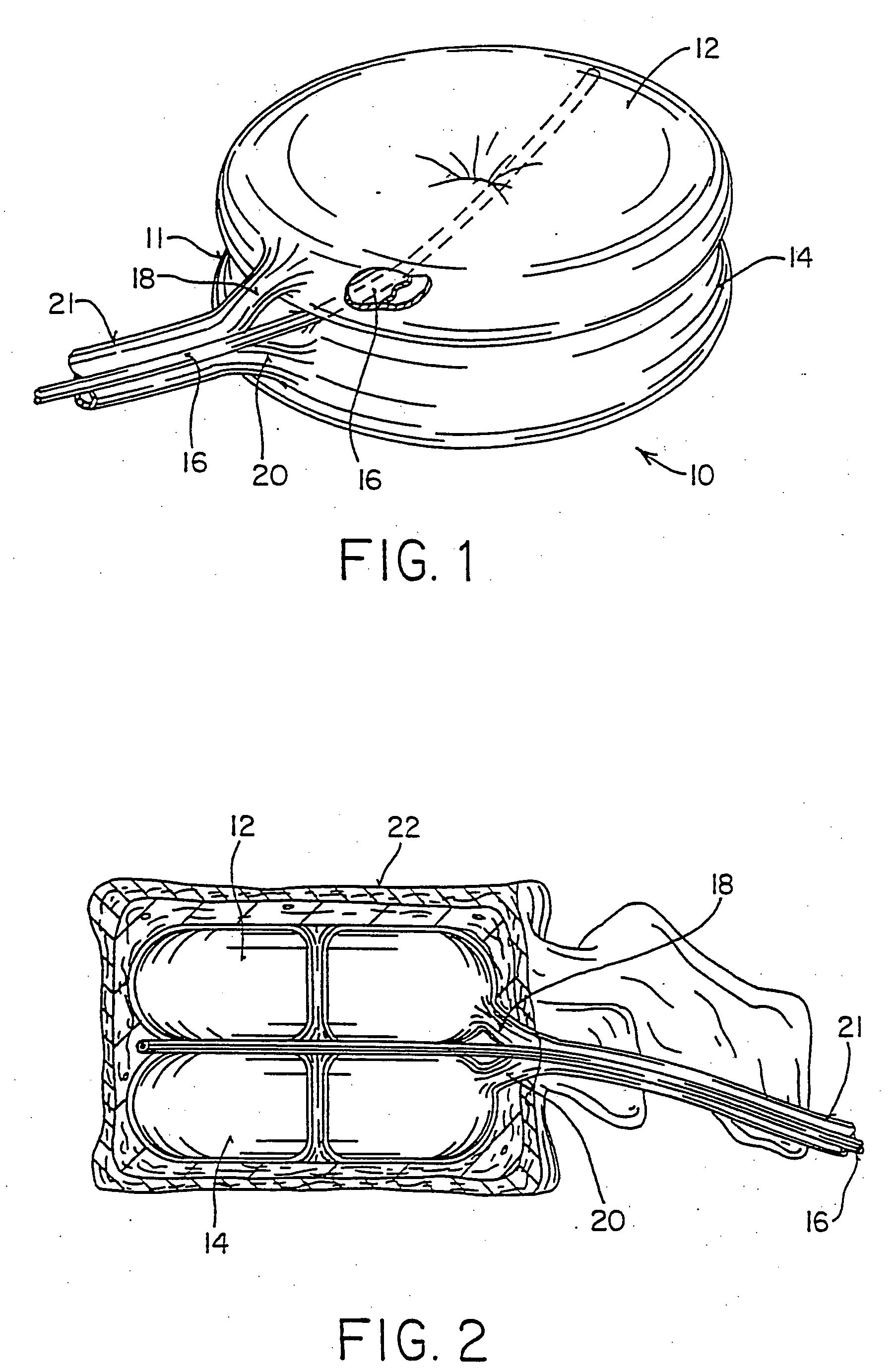

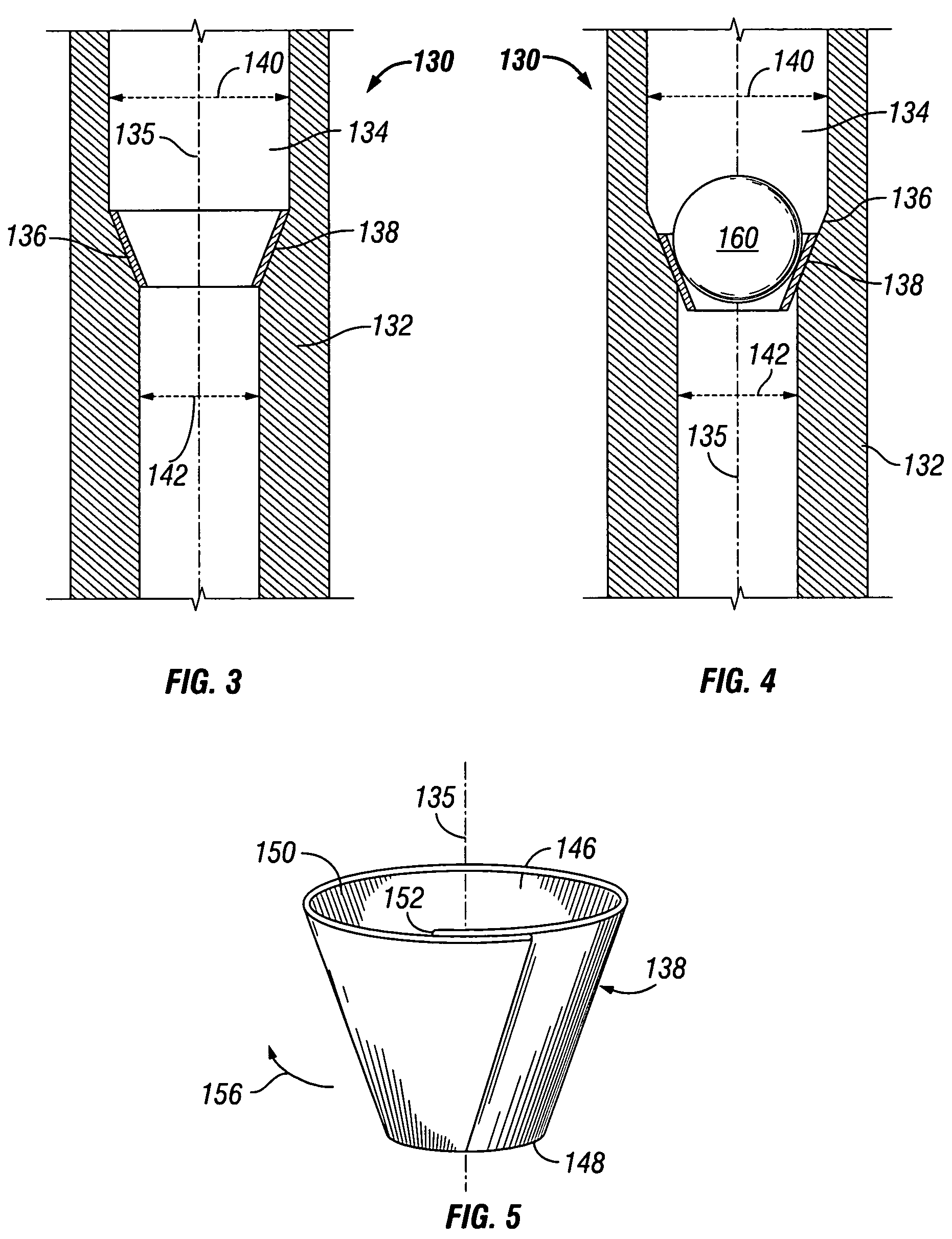

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS6981981B2Improve clinical outcomesWorsen conditionSurgical furnitureInternal osteosythesisFilling materialsCancellous bone

Systems for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide a first tool, a second tool, and a third tool. The first tool establishes a percutaneous access path to bone. The second tool is sized and configured to be introduced through the percutaneous access path to form a void that occupies less than the interior volume. The third tool places within the void through the percutaneous access path a volume of filling material. Related methods for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide establishing a percutaneous access path to bone. A tool is introduced through the percutaneous access path and manipulated to form a void that occupies less than the interior volume. A volume of filling material is then placed within the void through the percutaneous access path.

Owner:ORTHOPHOENIX

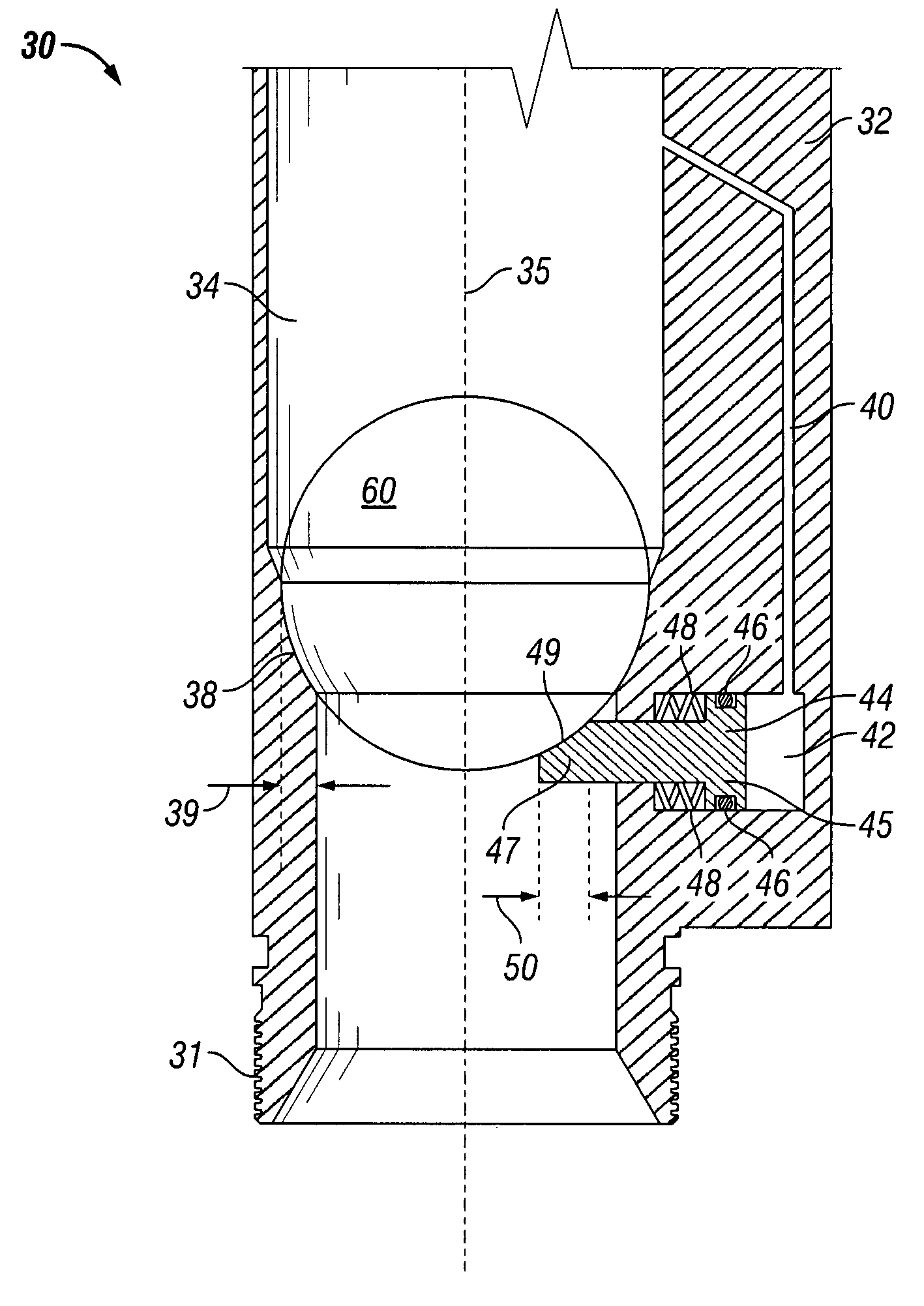

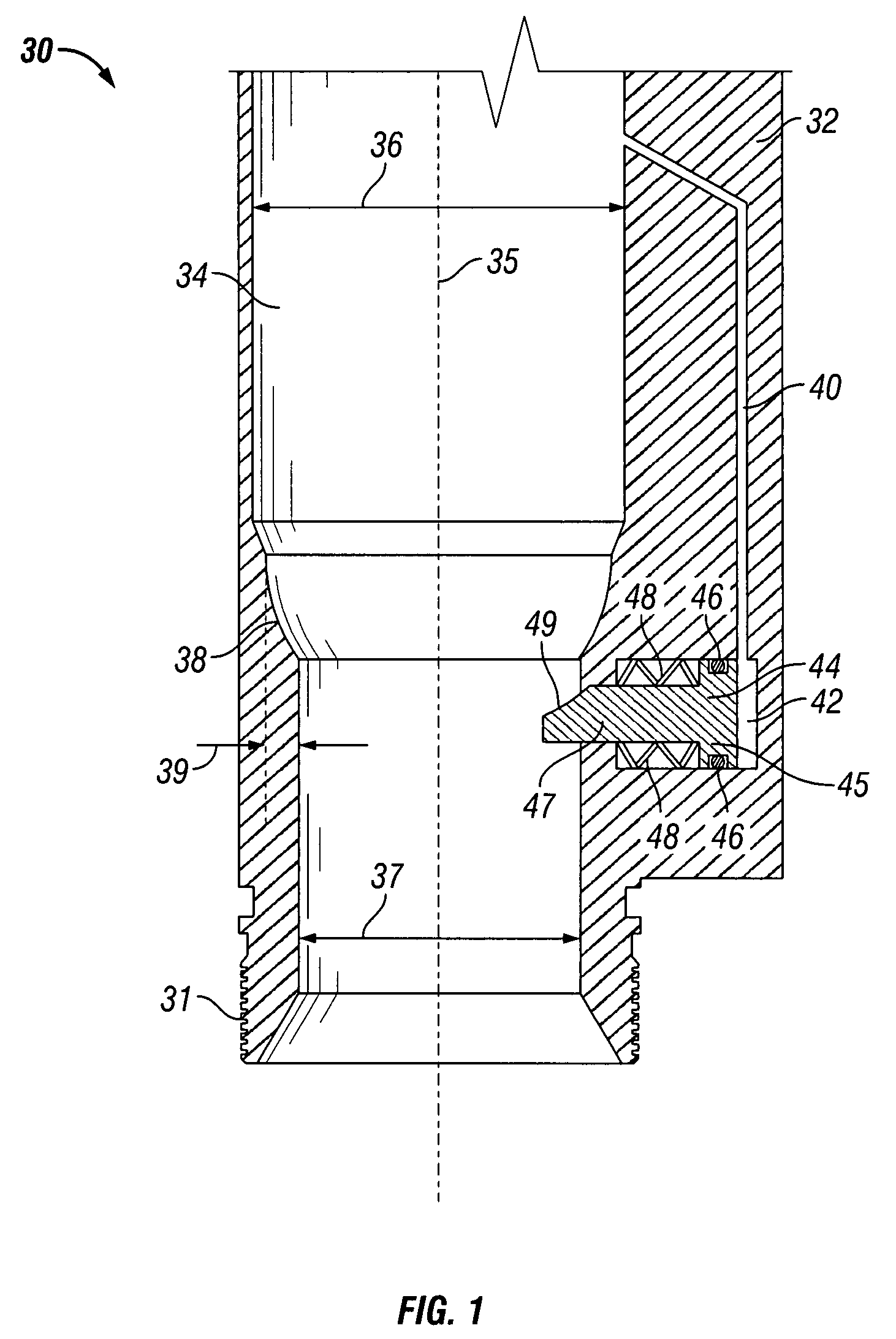

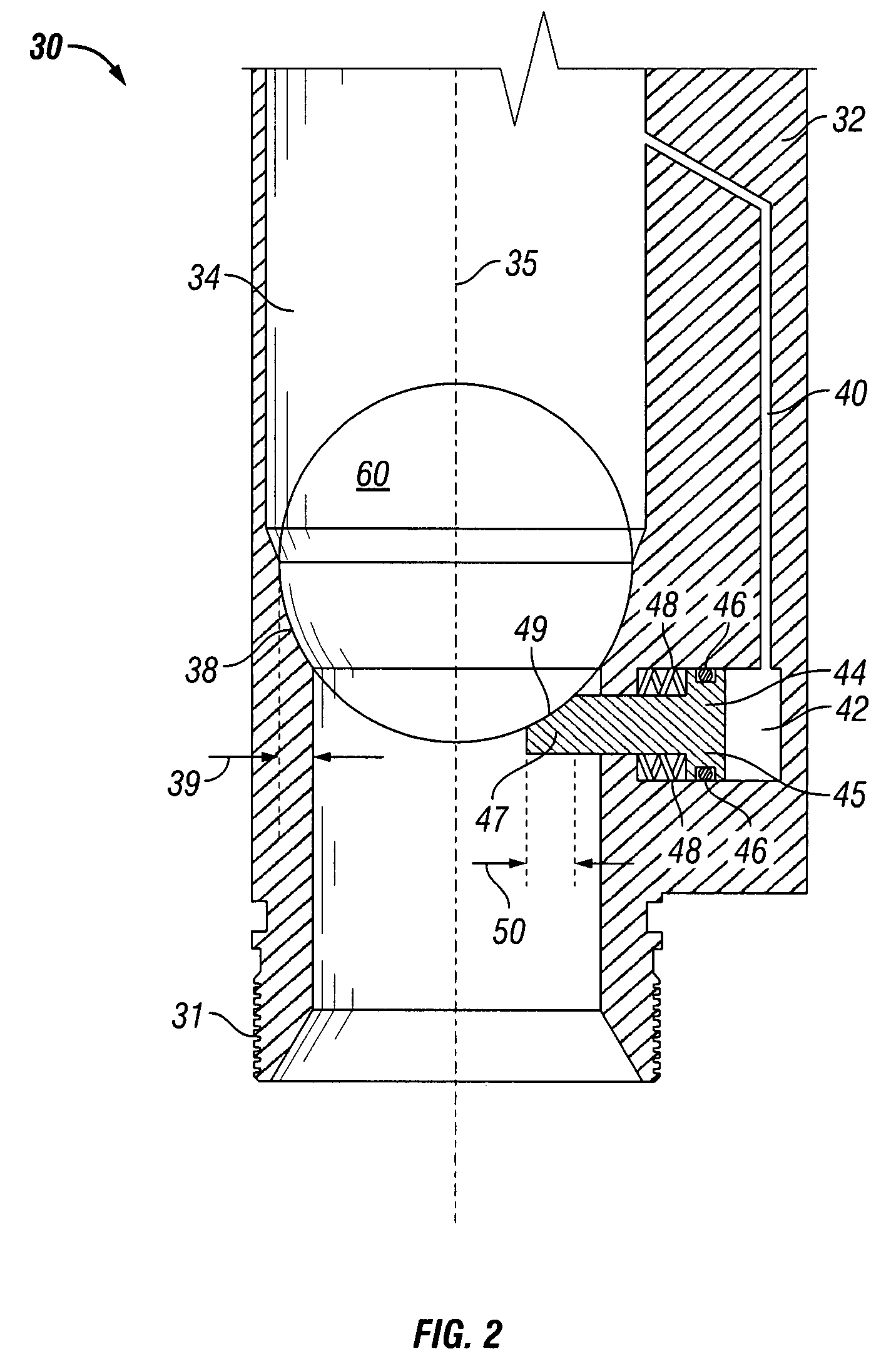

Ball seat having segmented arcuate ball support member

ActiveUS20090159289A1Increase pressureReduce the possibilityFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Owner:BAKER HUGHES INC

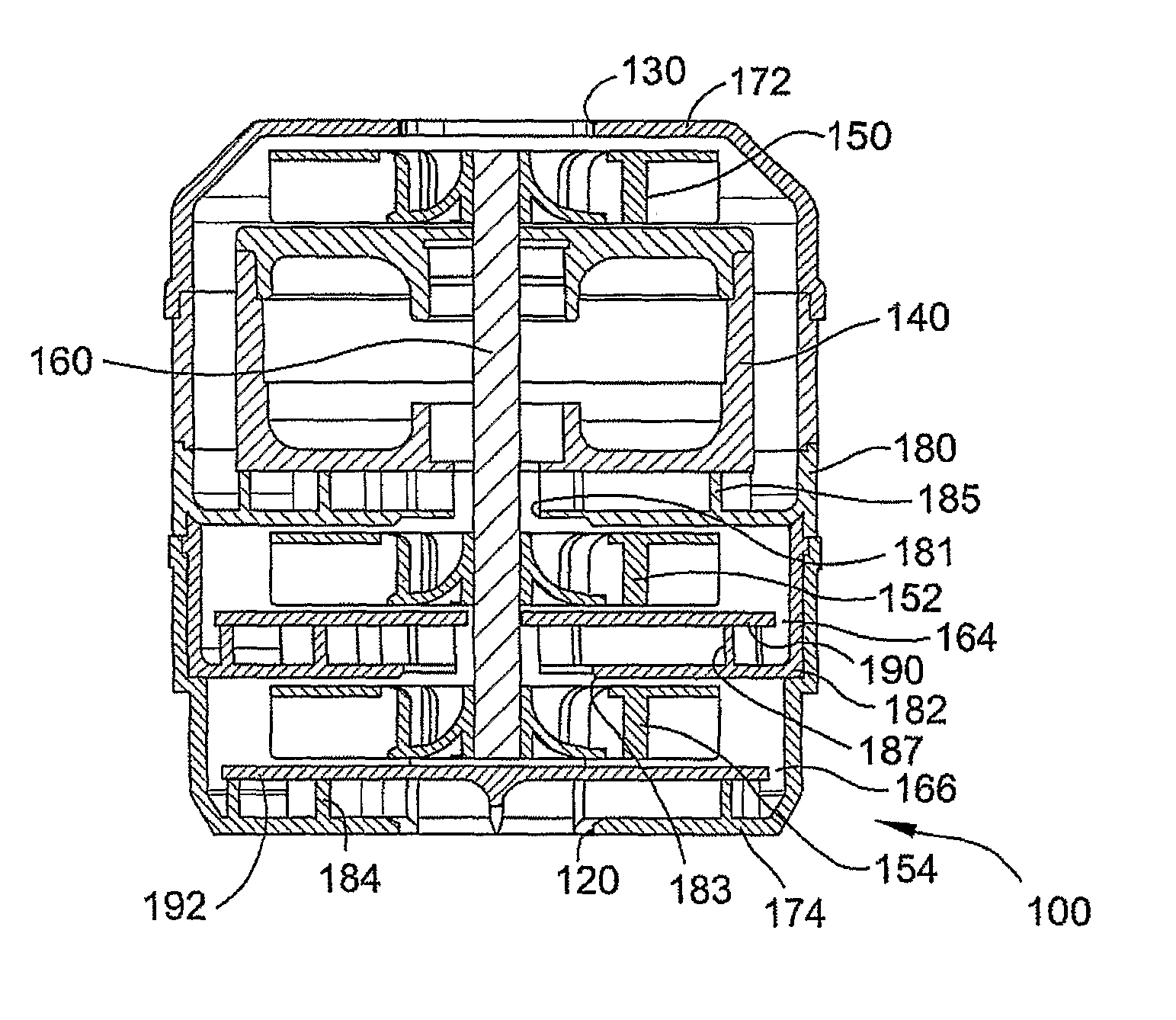

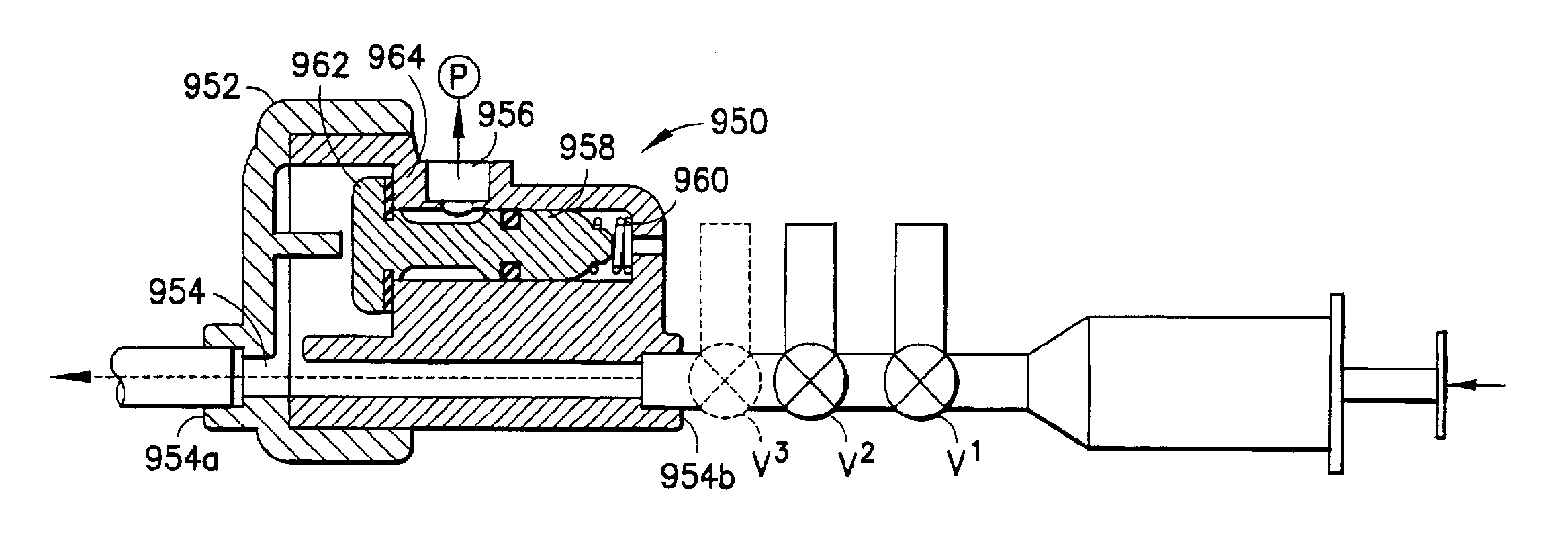

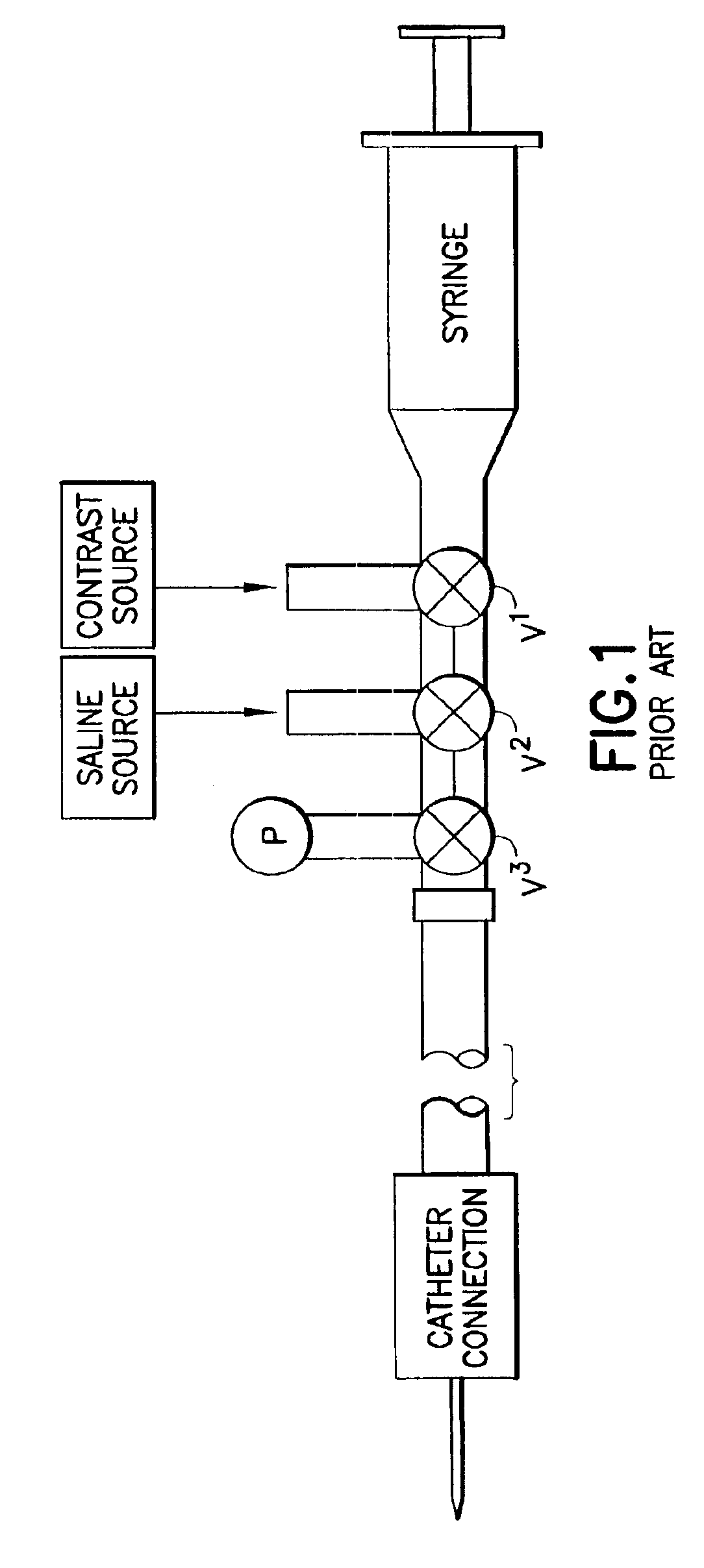

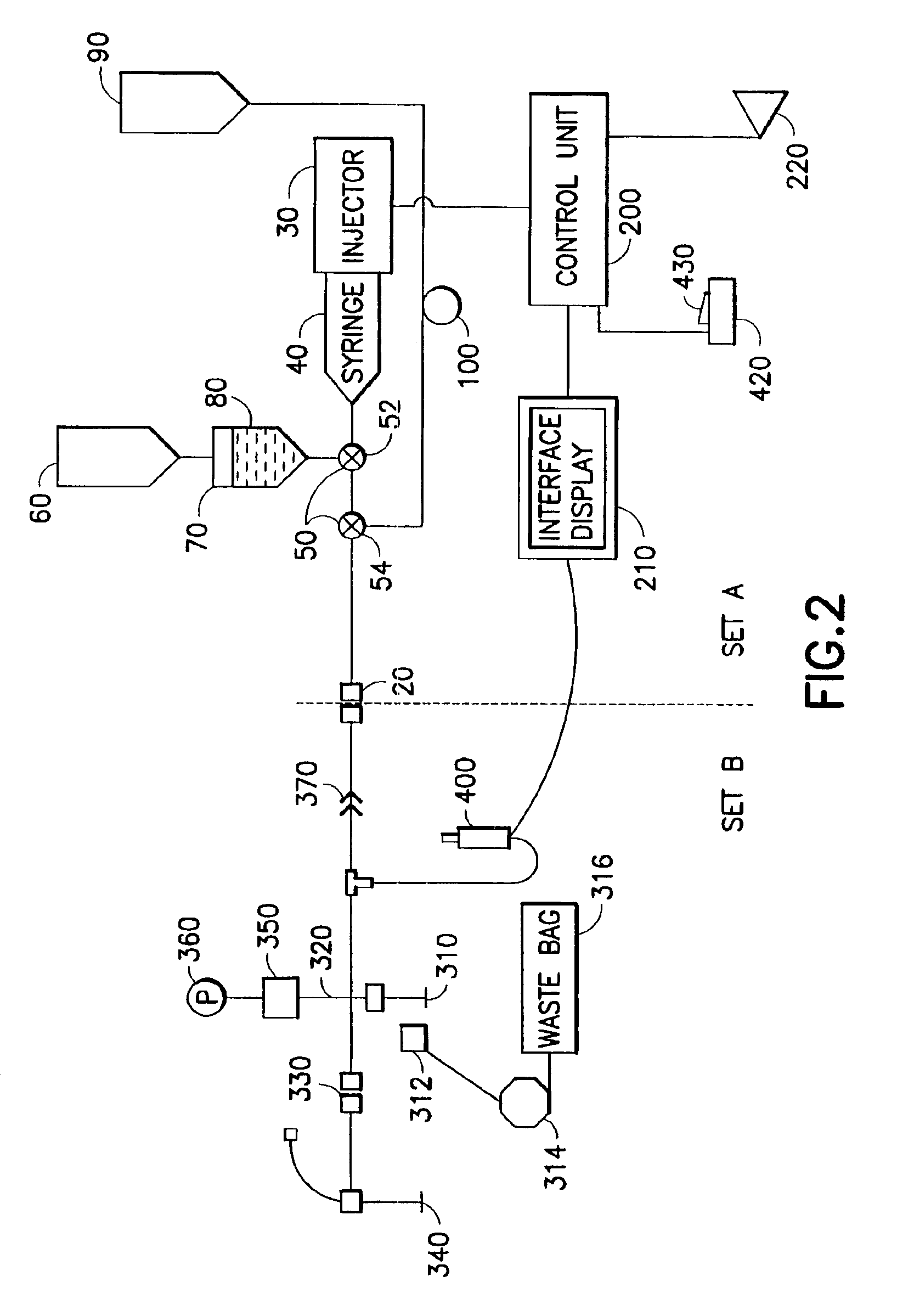

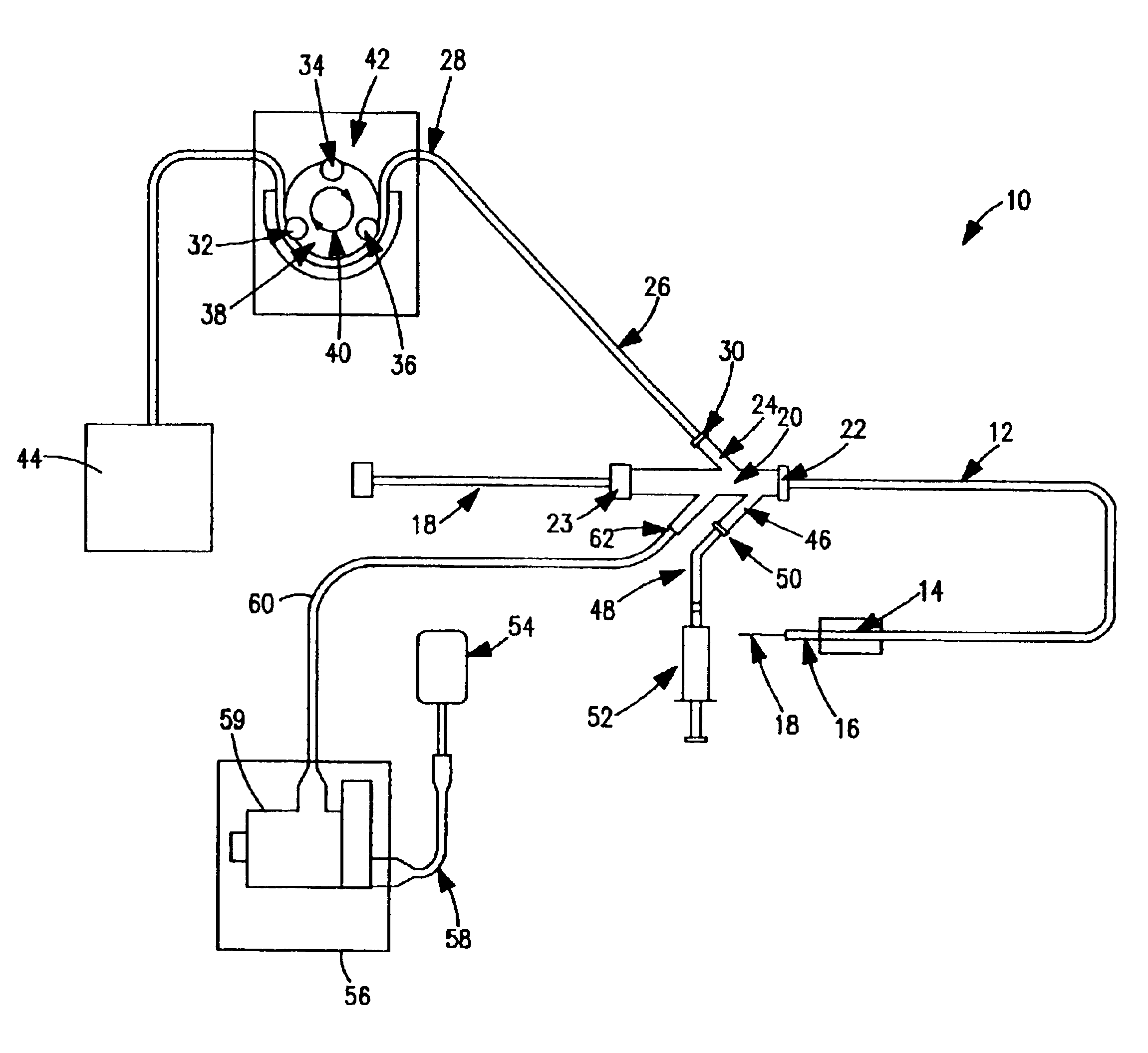

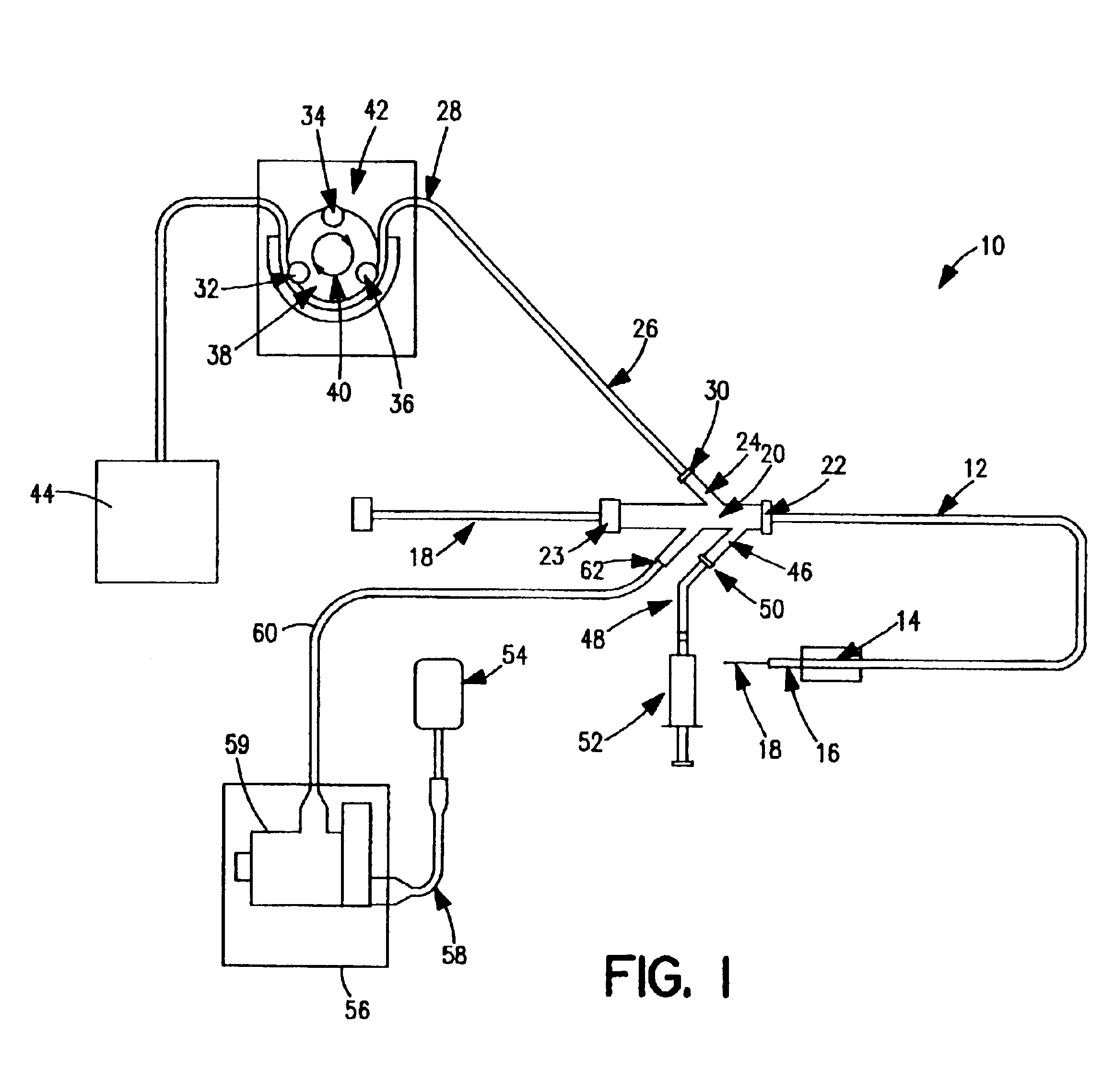

Pressure isolation mechanisms and fluid delivery systems including pressure isolation mechanisms

InactiveUS6866654B2Reduce and eliminate flowSmall sizeMedical devicesPressure infusionTransducerEngineering

A pressure isolation mechanism for use in a medical procedure includes a lumen, an isolation port in fluid connection with the lumen, and a valve having a first state and a second state. The first state occurs when the lumen and the isolation port are connected. The second state occurs when the lumen and the isolation port are disconnected. The lumen remains open for flow of fluid therethrough in the first state and in the second state. The valve is preferably spring-biased in the first state and is switchable to the second state when fluid pressure in the lumen reaches a predetermined pressure level. Alternately, an actuator can control the state of the valve. A pressure transducer can be in fluid connection with the isolation port of the pressure isolation mechanism. A fluid delivery system includes a syringe and a pressure isolation mechanism as described above.

Owner:MEDRAD INC.

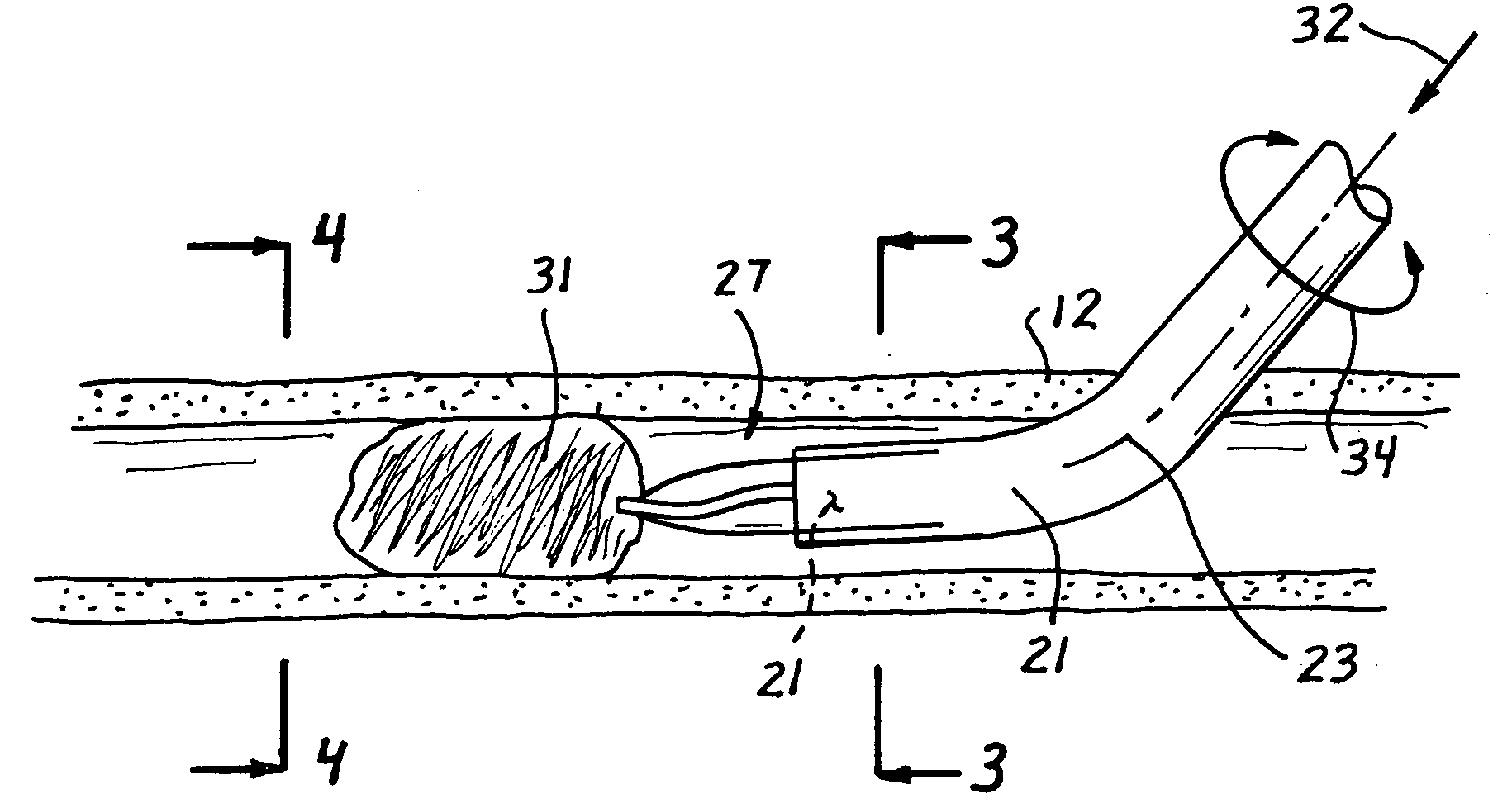

Catheter with conduit traversing tip

InactiveUS20050149096A1Improve scalabilityHigh pressureSurgical needlesDilatorsDistal portionEndoscope

A catheter facilitating traversal of restrictions in body conduits includes a shaft having a distal tip with a shape that is non-conical, radially twisted, and rectangular in radial cross section. An outer surface of the tip includes at least one side section extending from a blunt point radially outwardly with progressive positions proximally along an axis of the tip. The side section includes a proximal portion in proximity to the shaft, and a distal portion twisted radially with respect to the proximal portion. The catheter can be adapted for placement over a guidewire and can be made transparent thereby facilitating visualization through an endoscope in the catheter.

Owner:APPL MEDICAL RESOURCES CORP

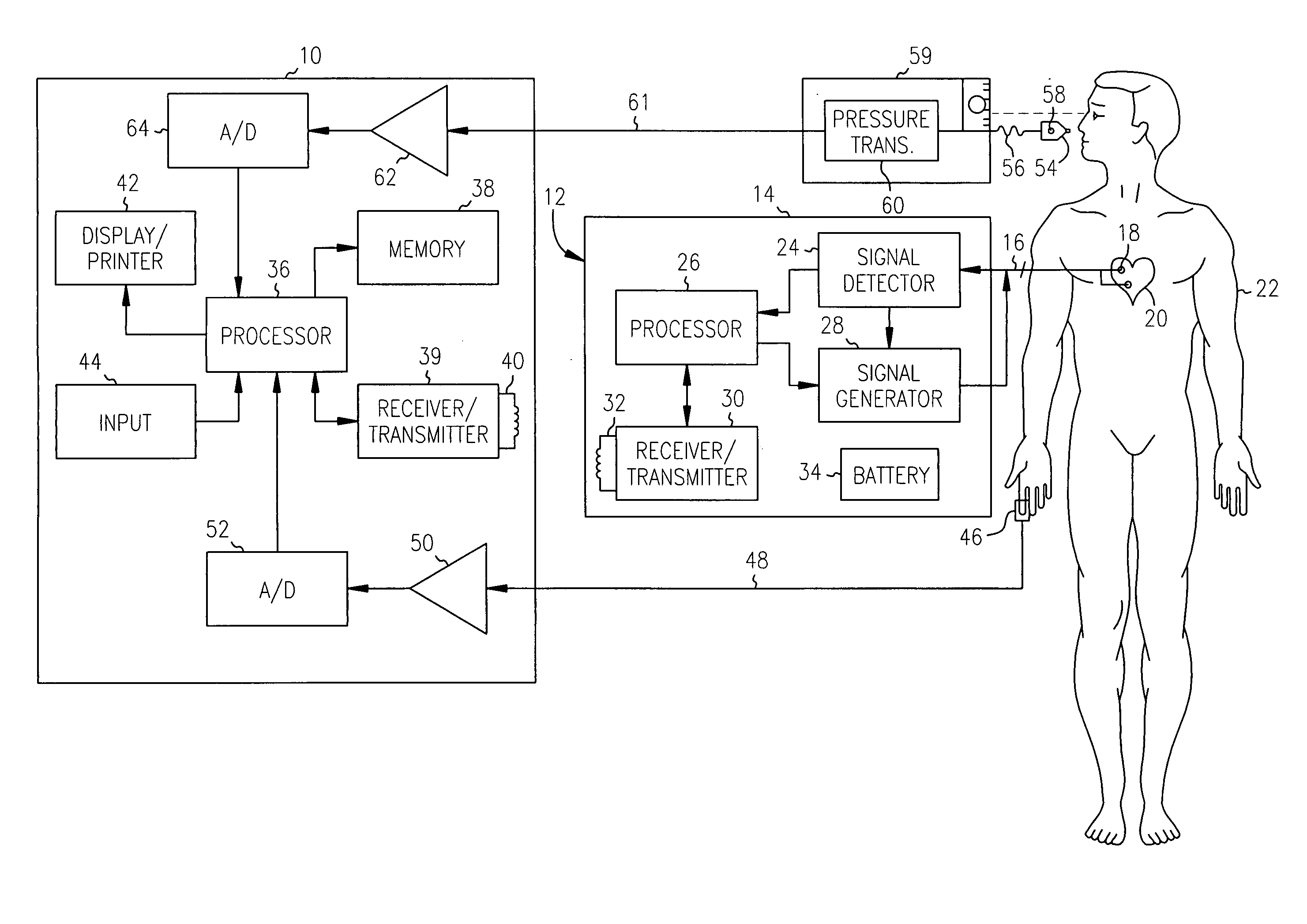

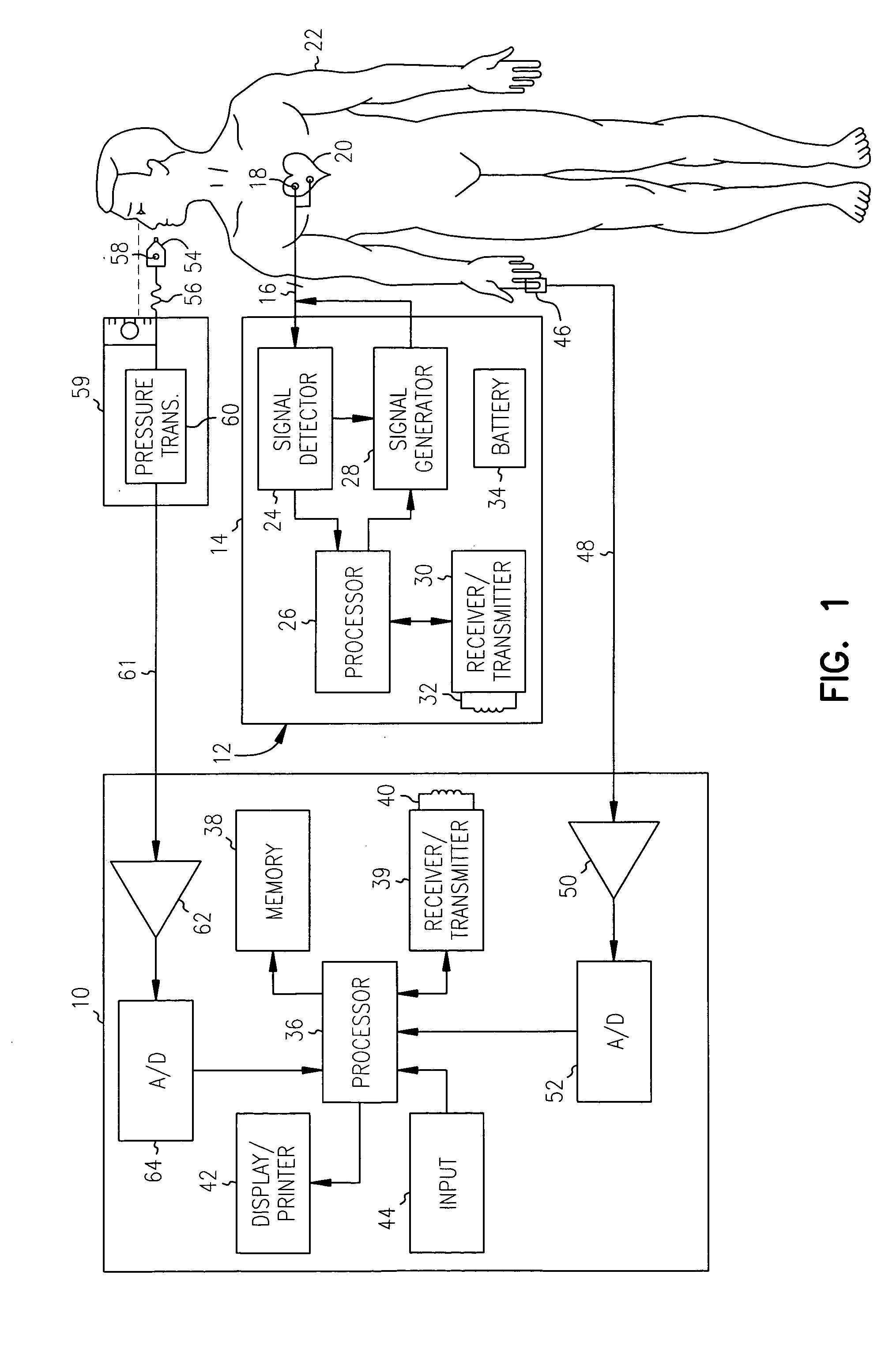

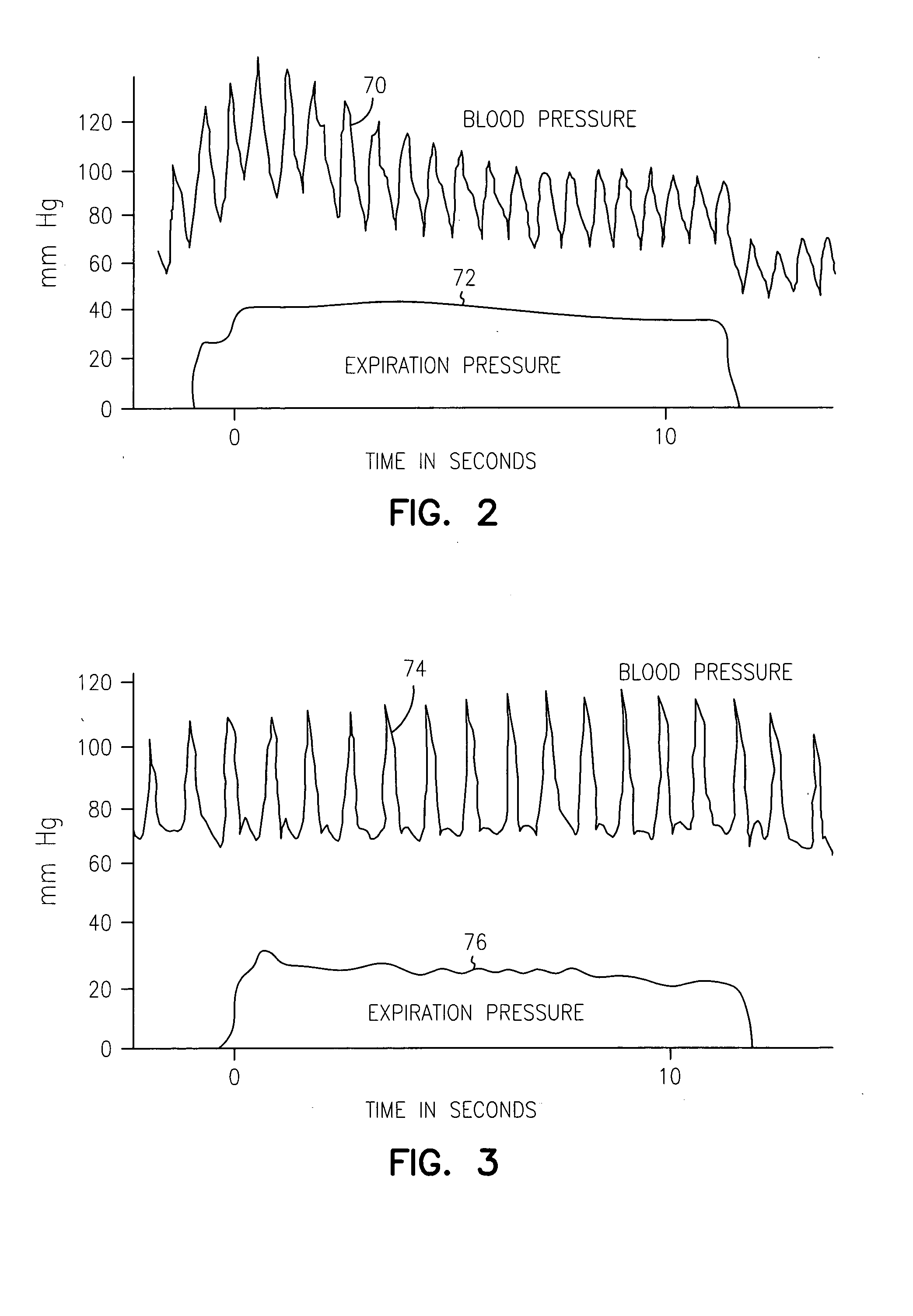

Non-invasive method and apparatus for cardiac pacemaker pacing parameter optimization and monitoring of cardiac dysfunction

InactiveUS20050043767A1Uniform peak amplitudeEasy to detectHeart stimulatorsCardiac dysfunctionAmplitude response

A plethysmogram signal is sensed from a patient and provided to a programmer device for monitoring the condition of the patient and for optimizing pacing parameters of a cardiac device implanted in the patient. The programmer device analyzes the plethysmogram signal for cardiac performance associated with different pacing parameters. The cardiac performance is indicated by, for example, a pulse amplitude response, a degree of pulsus alternans, or irregularity in the pressure pulses detected in an atrial fibrillation patient. The pacing parameters resulting in the best cardiac performance are selected as the optimum pacing parameters. In one embodiment, the programmer device monitors a Valsalva maneuver performed by a patient. Optimum pacing parameters are derived by analysis of the plethysmogram signals obtained during performance of the Valsalva maneuver while the patient is paced using different pacing parameters.

Owner:CARDIAC PACEMAKERS INC

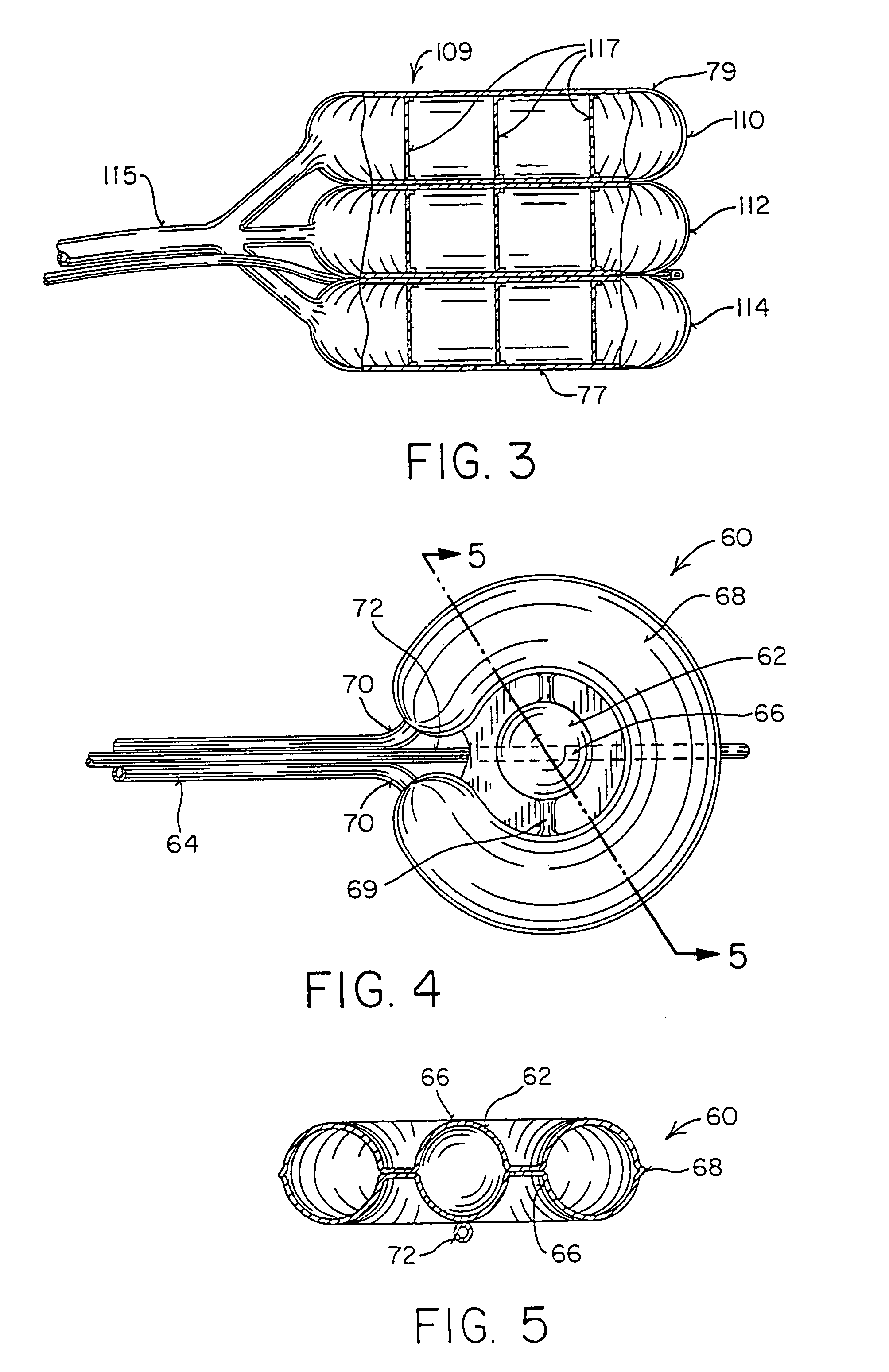

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS20060100635A1High pressureEasy to doStentsBalloon catheterFilling materialsCancellous bone

Systems for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide a first tool, a second tool, and a third tool. The first tool establishes a percutaneous access path to bone. The second tool is sized and configured to be introduced through the percutaneous access path to form a void that occupies less than the interior volume. The third tool places within the void through the percutaneous access path a volume of filling material. Related methods for treating a bone, e.g. a vertebral body, having an interior volume occupied, at least in part, by cancellous bone provide establishing a percutaneous access path to bone. A tool is introduced through the percutaneous access path and manipulated to form a void that occupies less than the interior volume. A volume of filling material is then placed within the void through the percutaneous access path.

Owner:ORTHOPHOENIX

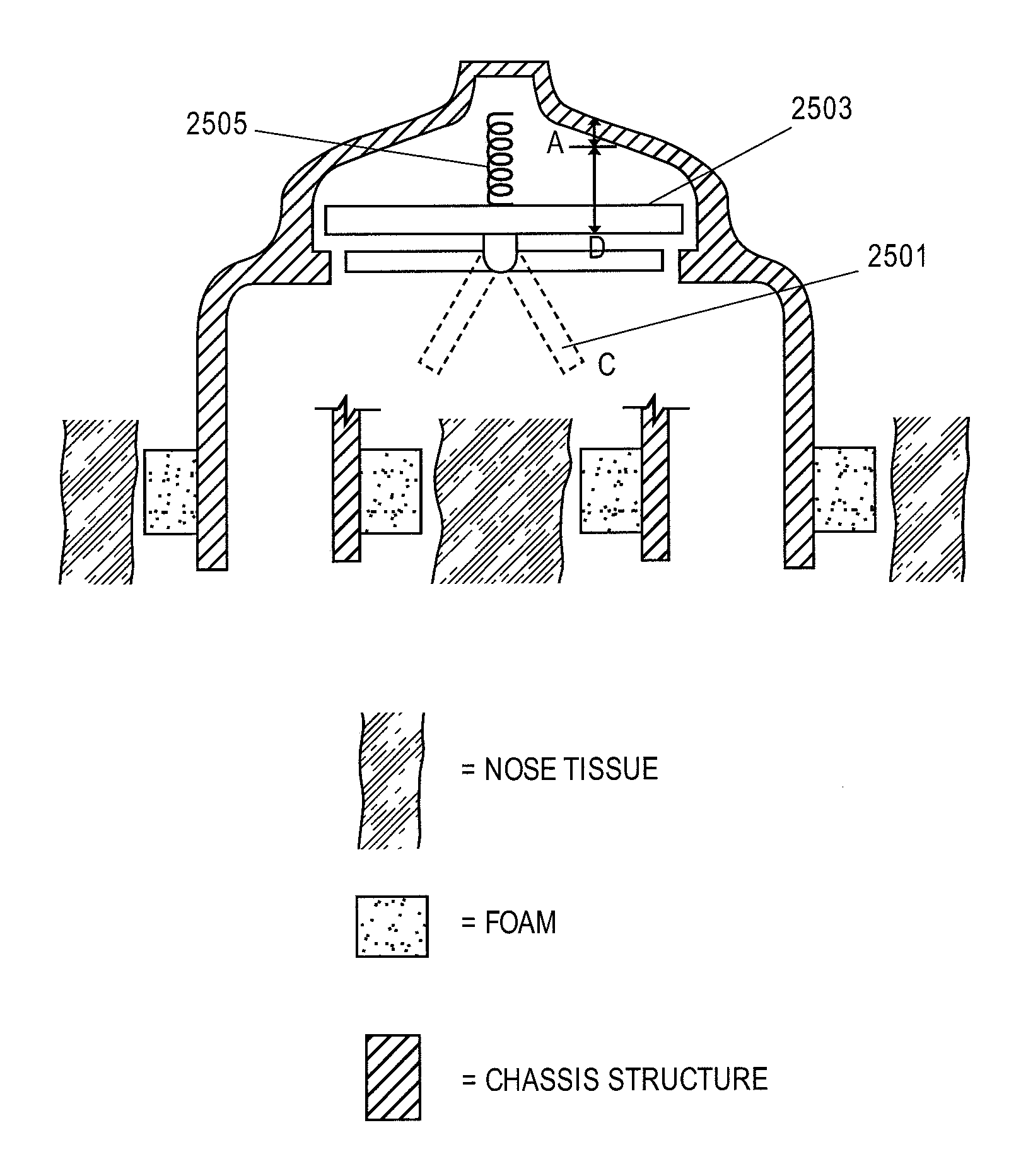

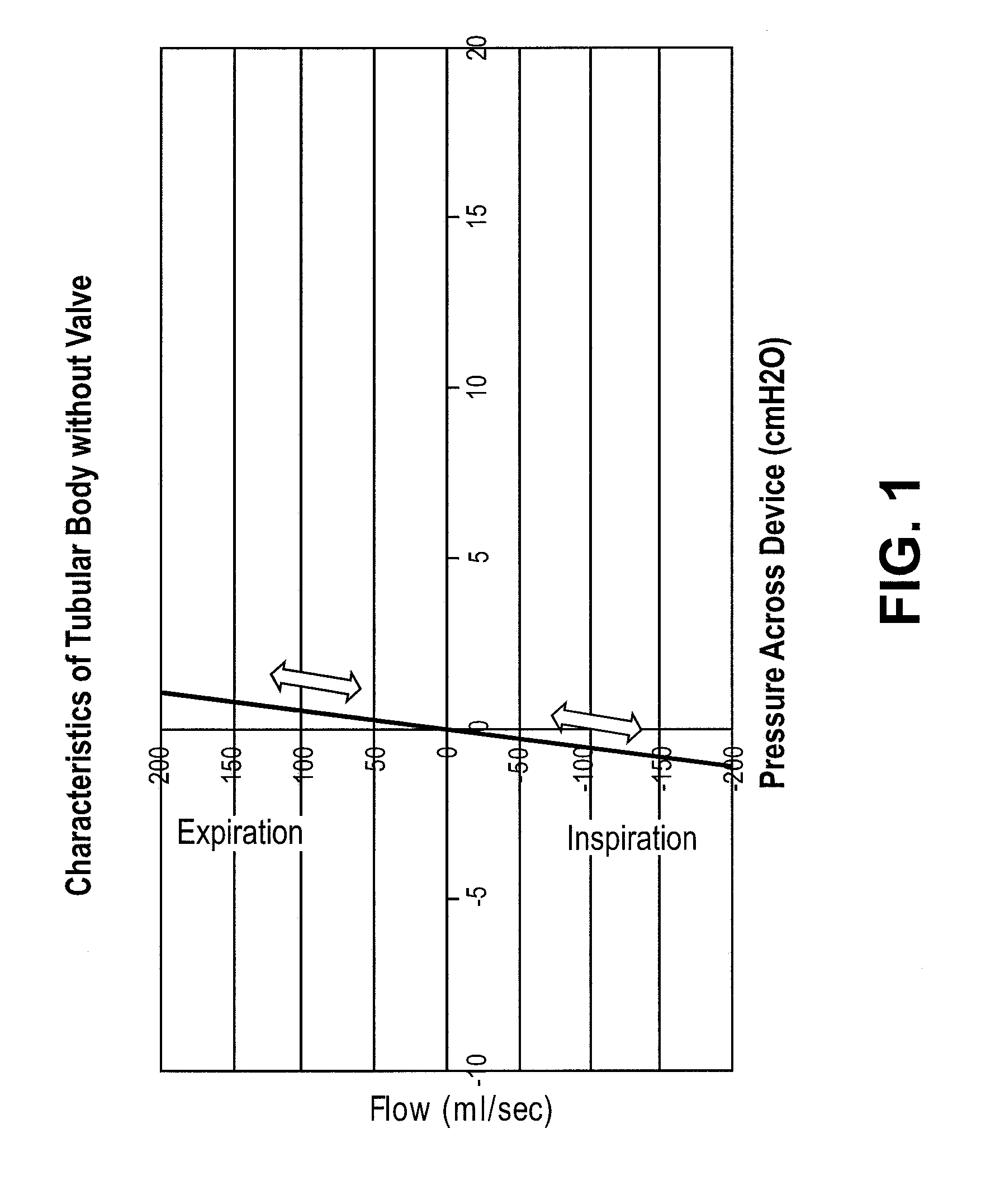

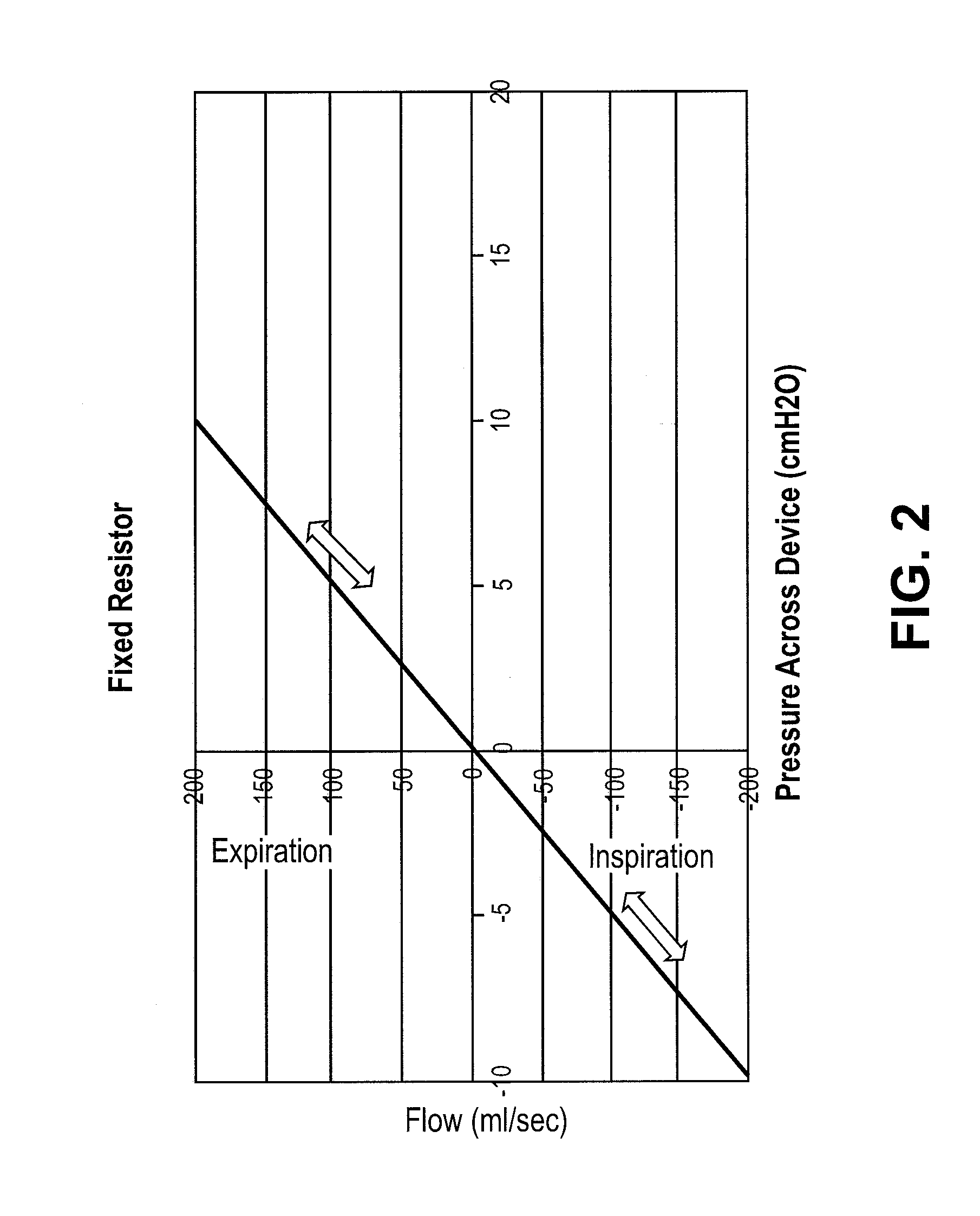

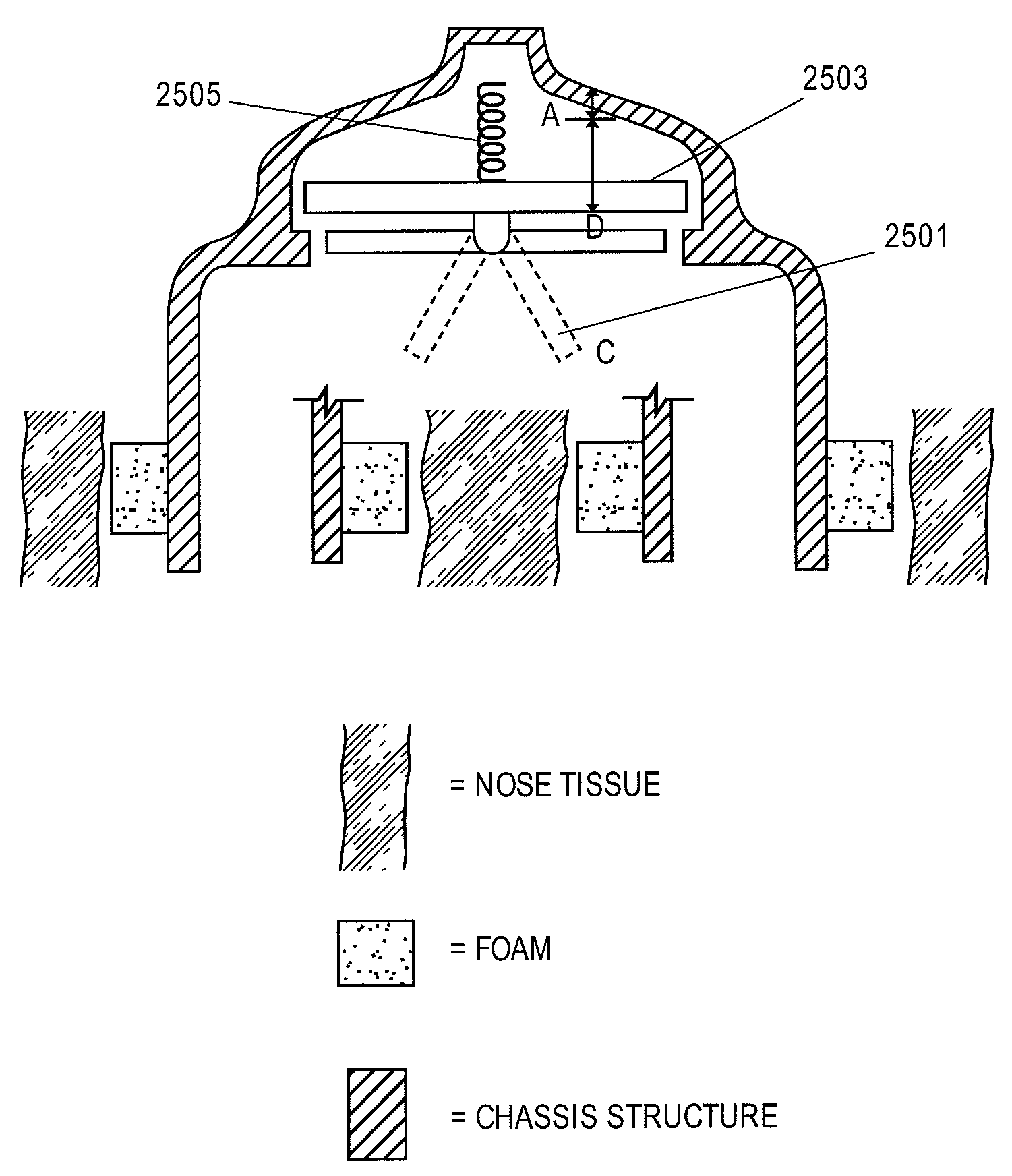

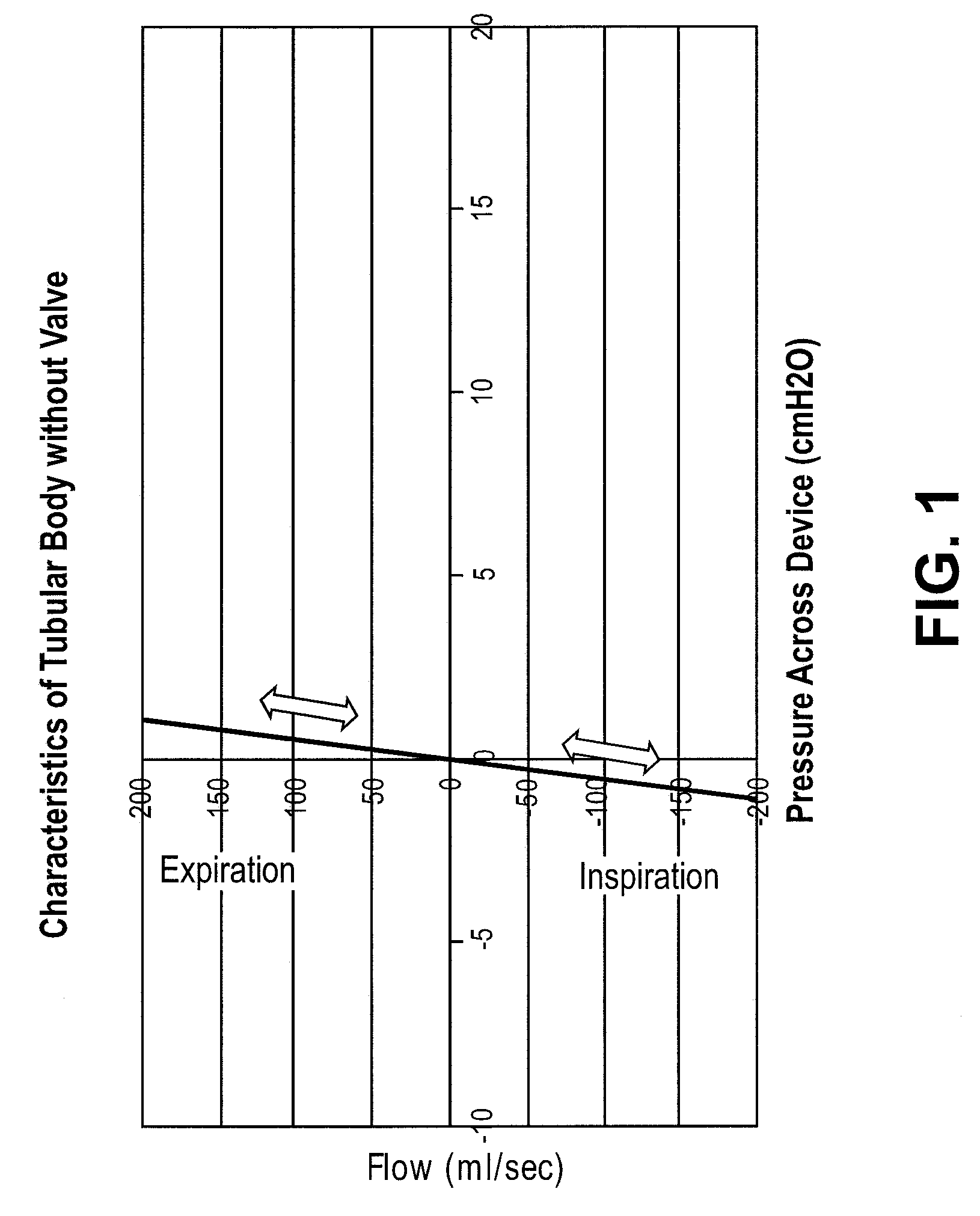

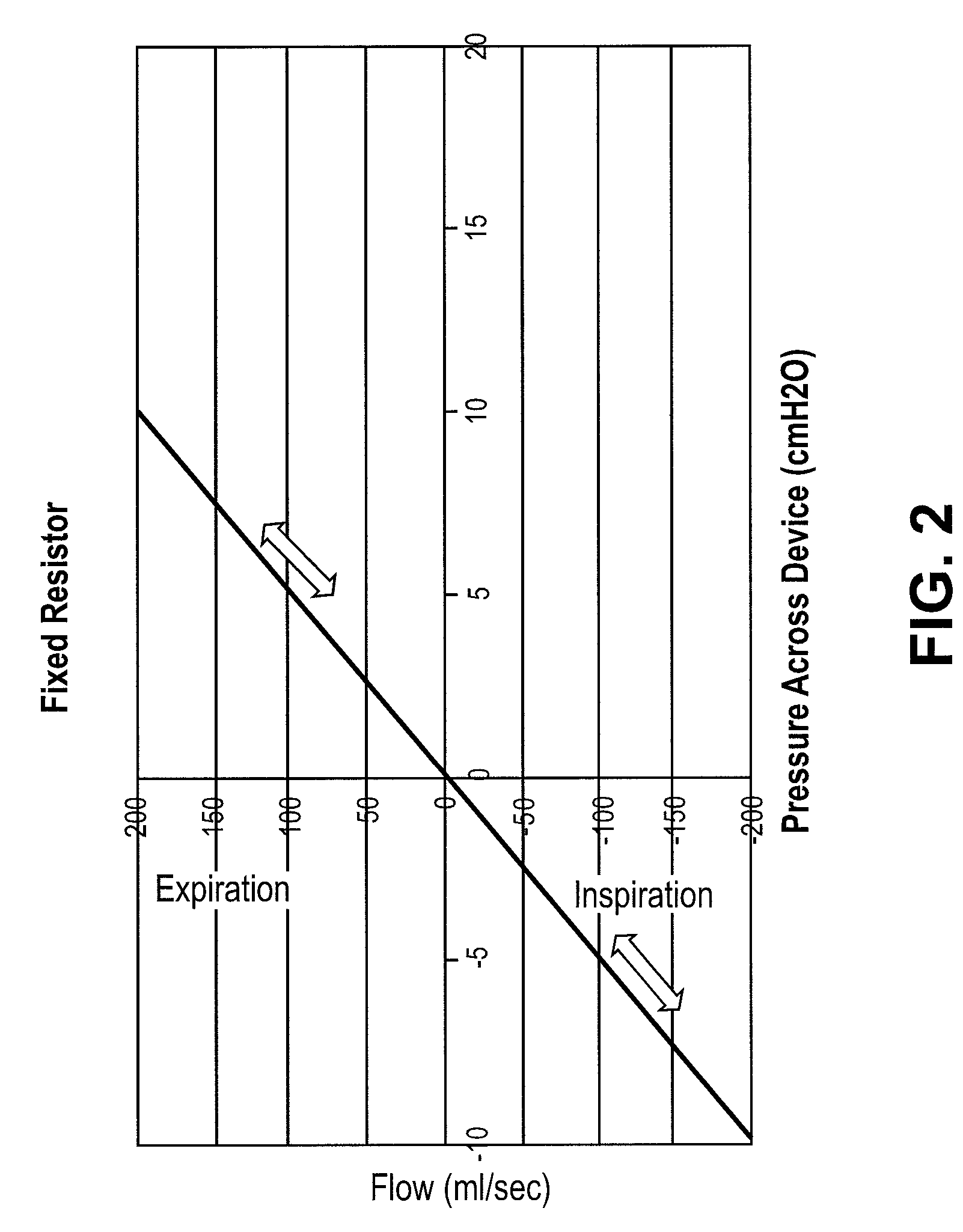

Nasal respiratory devices for positive end-expiratory pressure

InactiveUS20070295338A1Improve toleranceLarge peep pressureRespiratorsOperating means/releasing devices for valvesDuring expirationEnd-expiration

Described herein are nasal respiratory devices, in particular, nasal respiratory devices configured to achieve positive end-expiratory pressure (PEEP) in a subject wearing the device. PEEP devices may have a threshold pressure for opening during expiration. In some variations, these devices have a threshold pressure for closing during expiration.

Owner:THERAVENT

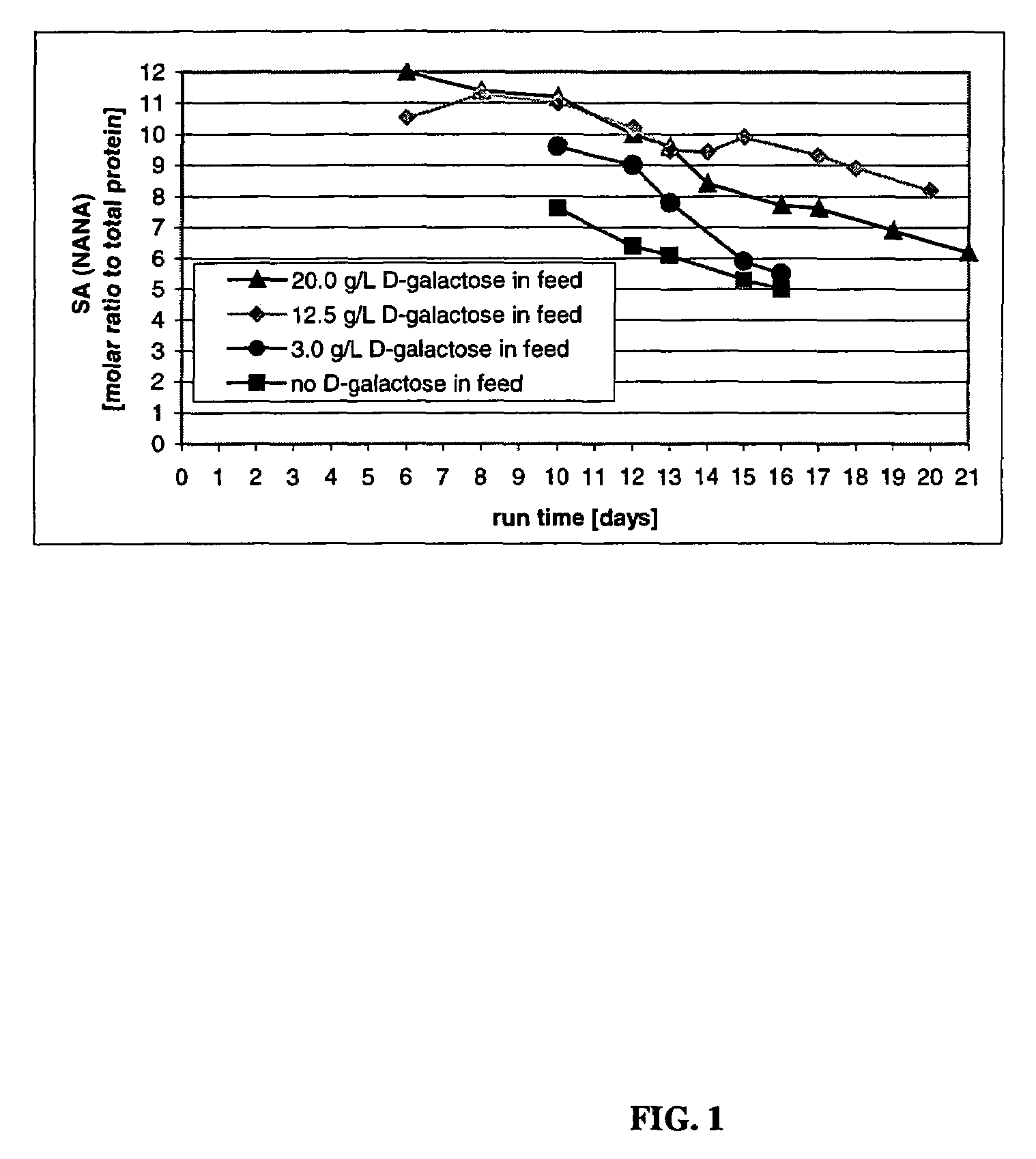

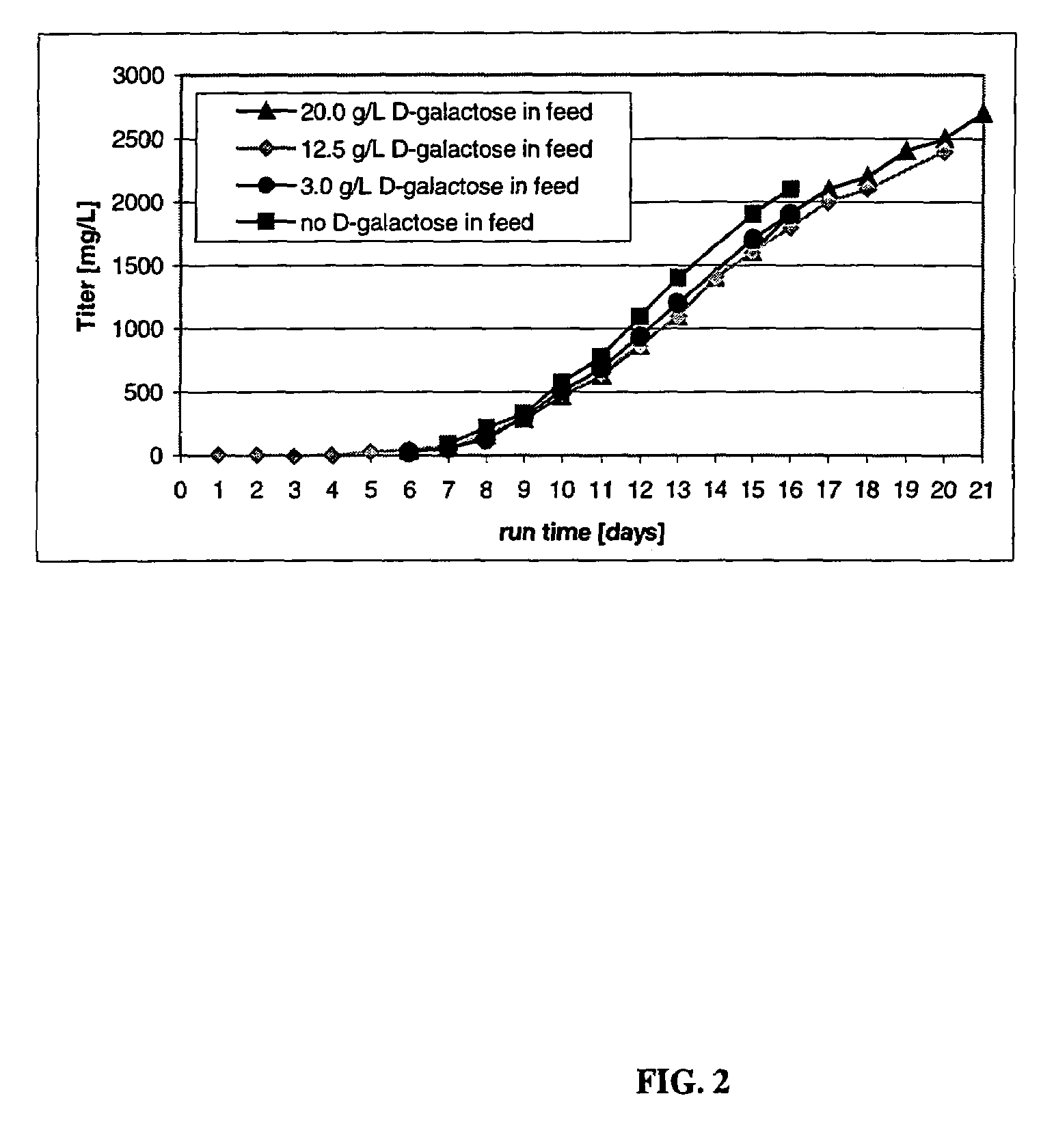

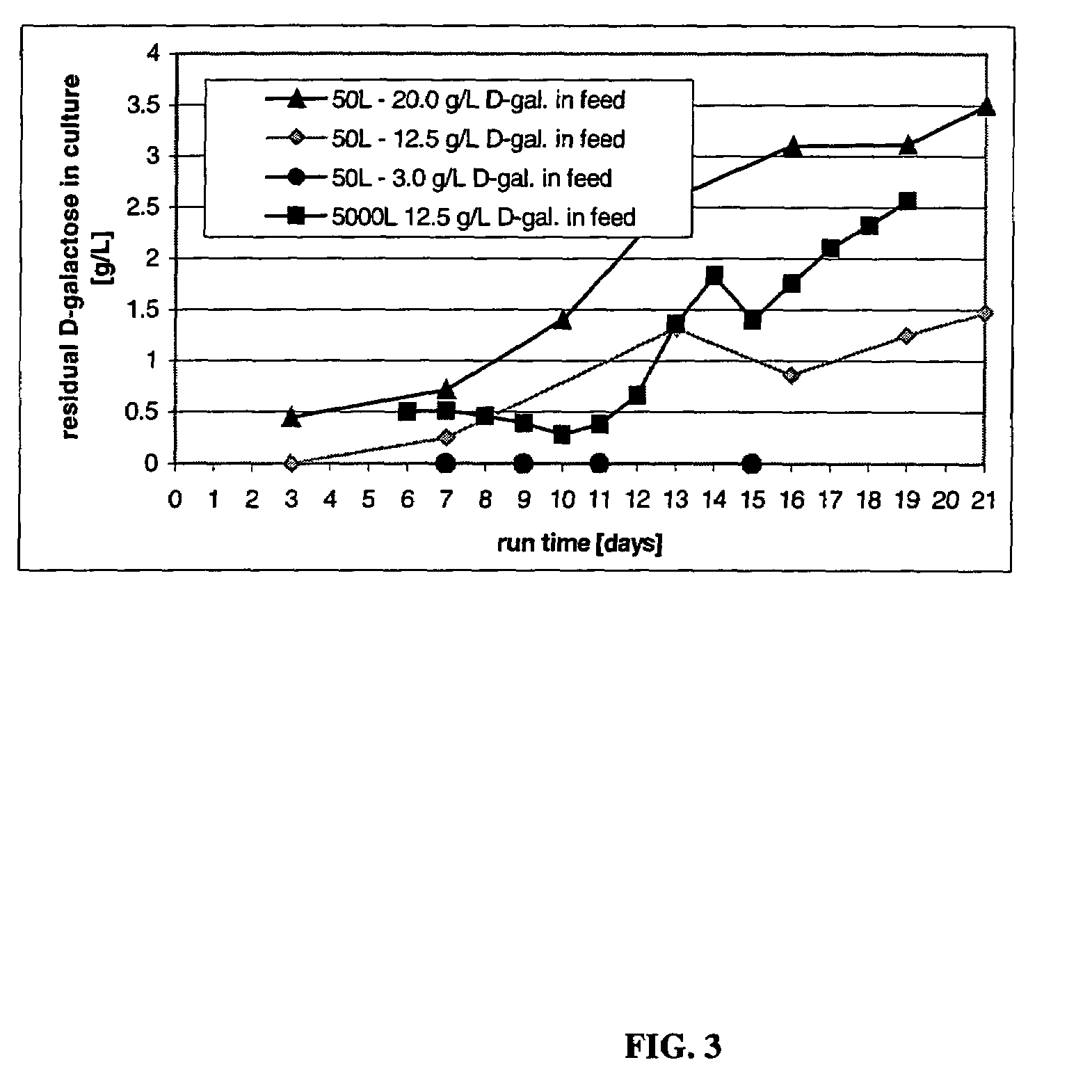

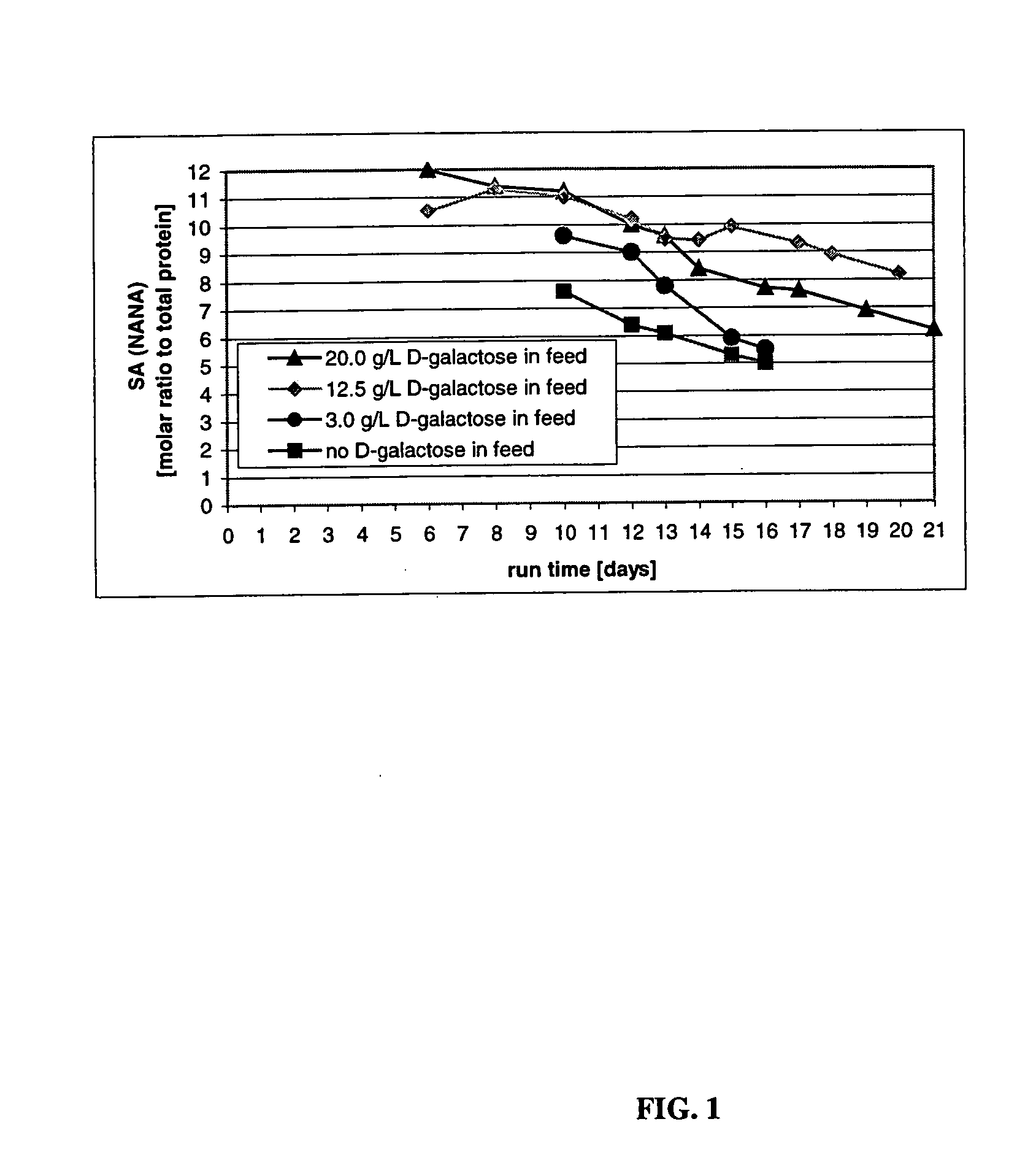

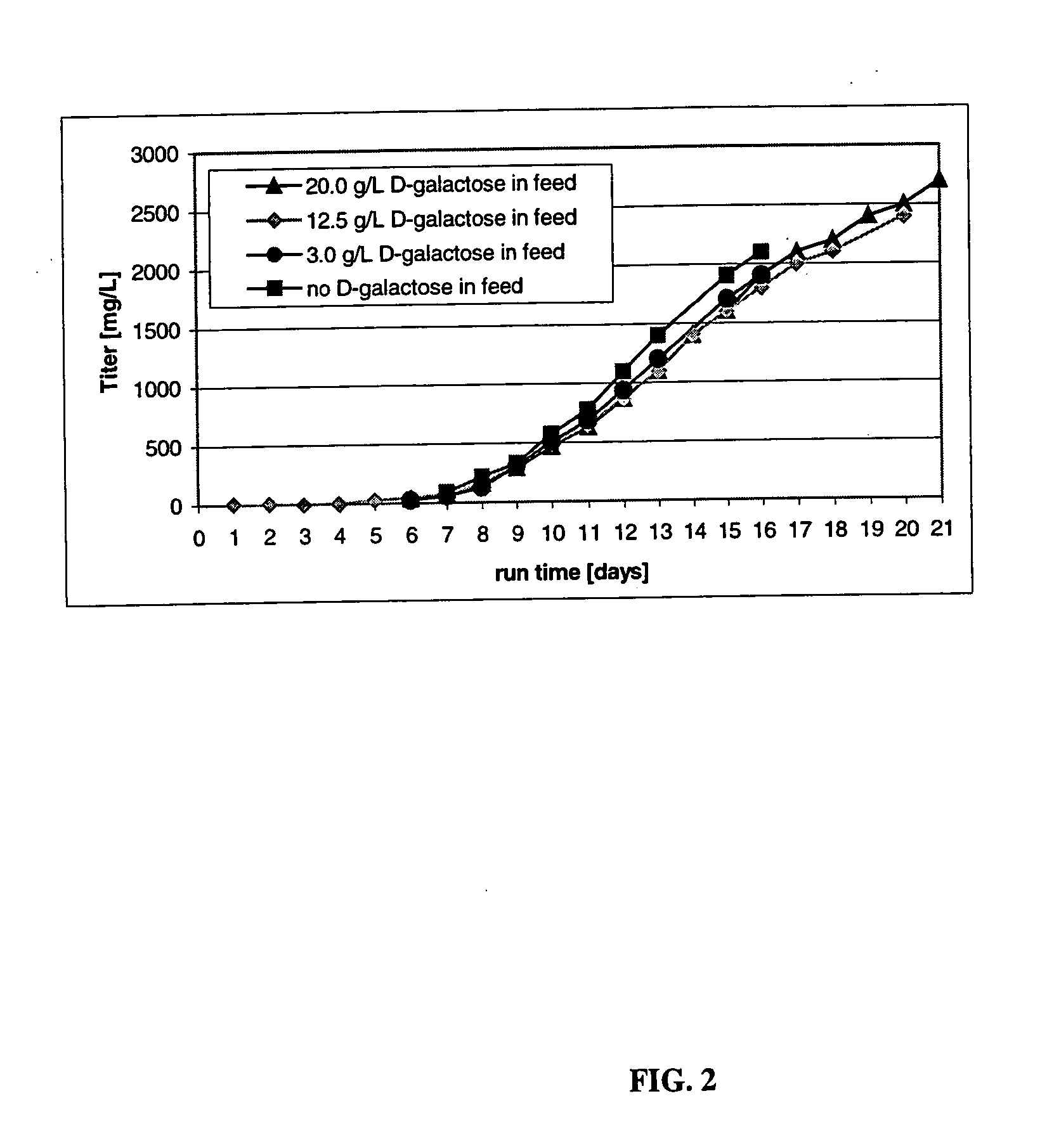

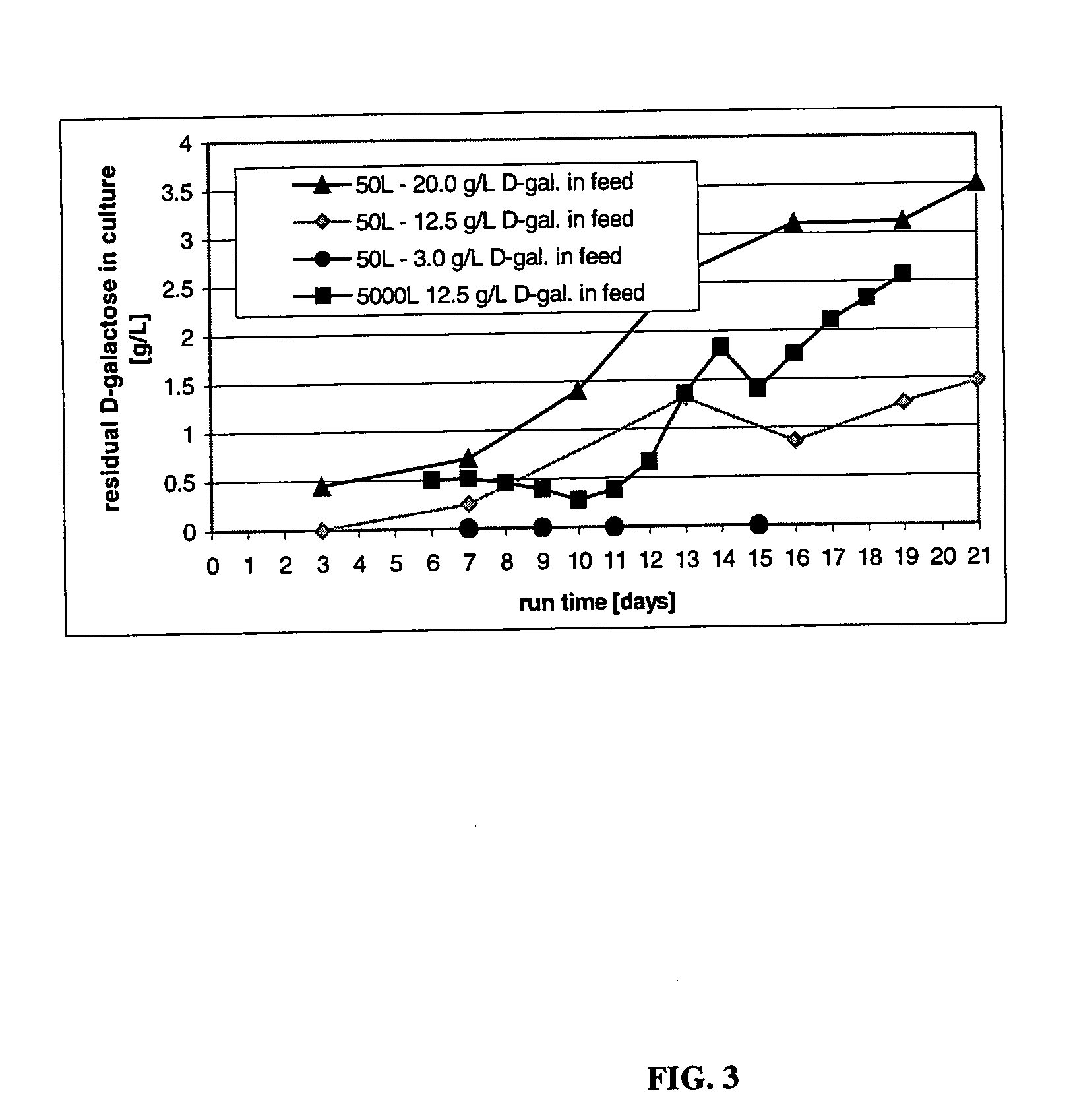

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS7332303B2Low production costQuality improvementAnimal cellsCell receptors/surface-antigens/surface-determinantsHigh cellBiotechnology

Owner:BRISTOL MYERS SQUIBB CO

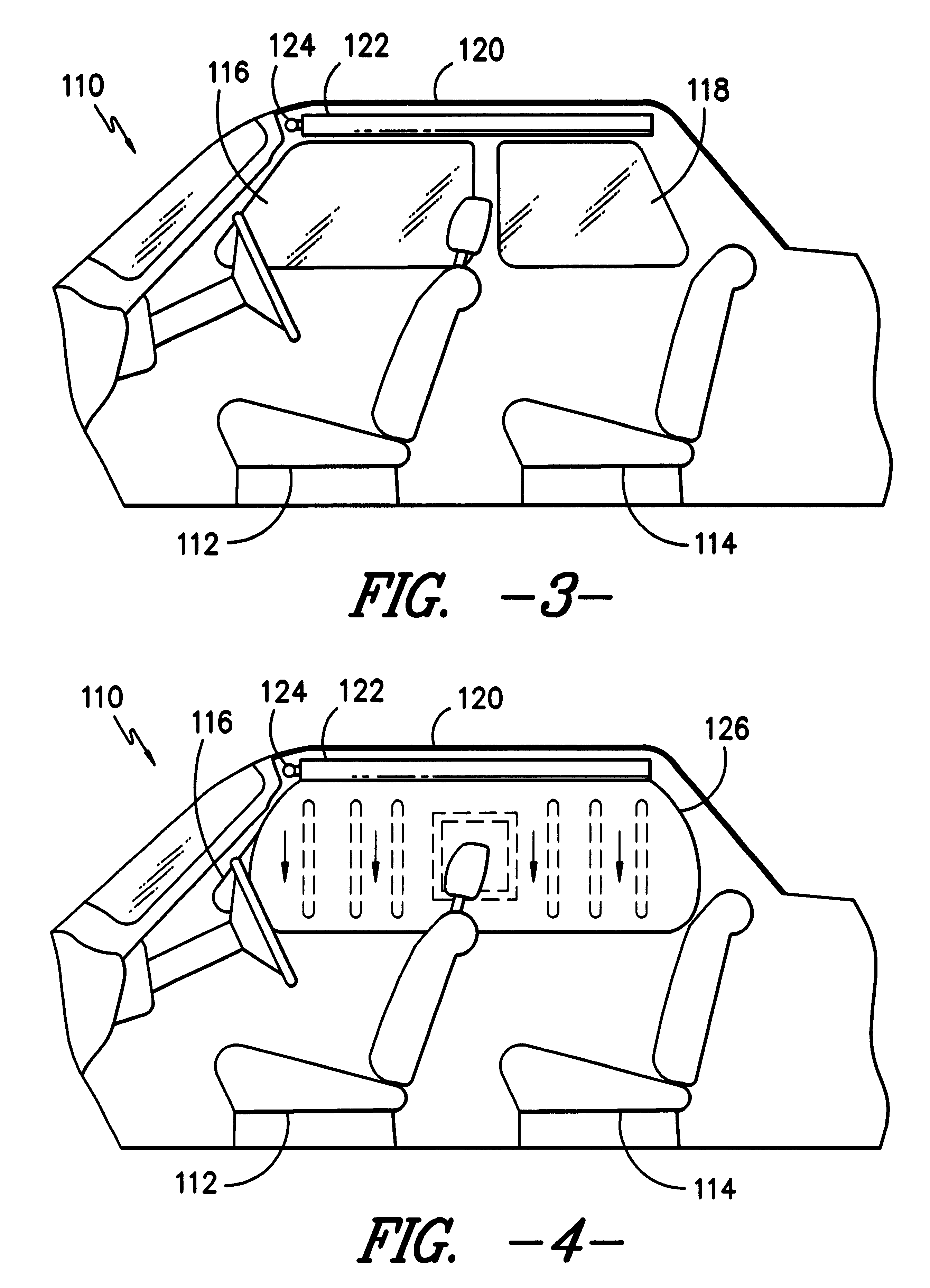

Safe correlator system for automatic car wash

InactiveUS20080028974A1Reduce wearExtended service lifeCleaning apparatus with conveyorsTramway railsAxial displacementEngineering

A correlator system for automatic car wash has roller assemblies for supporting the front left and right wheels of a vehicle entering a car wash line. A set of guide rails or bars cooperate with the roller assemblies to adjust axial displacement and angular misalignment between the vehicle's front end and a conveyor track transporting the vehicle through the car wash facility. The rollers in the roller assembly rotate freely with minimal friction, axially displacing the front end of the vehicle and adjusting the angular misalignment of the front wheels. The low friction, easy-to-rotate rollers are provided with a plurality of braking elements that generate friction against the rollers, retarding their rotation when a worker steps thereon. The friction generated by the braking elements is insufficient to prevent roller rotation during alignment of the front end with the conveyor track. Injuries to car wash personnel caused by loss of balance when stepping on the rollers are virtually eliminated, and an accurate alignment of the vehicle's front end with the car wash conveyor track is reliably achieved.

Owner:BIANCO ARCHANGEL J

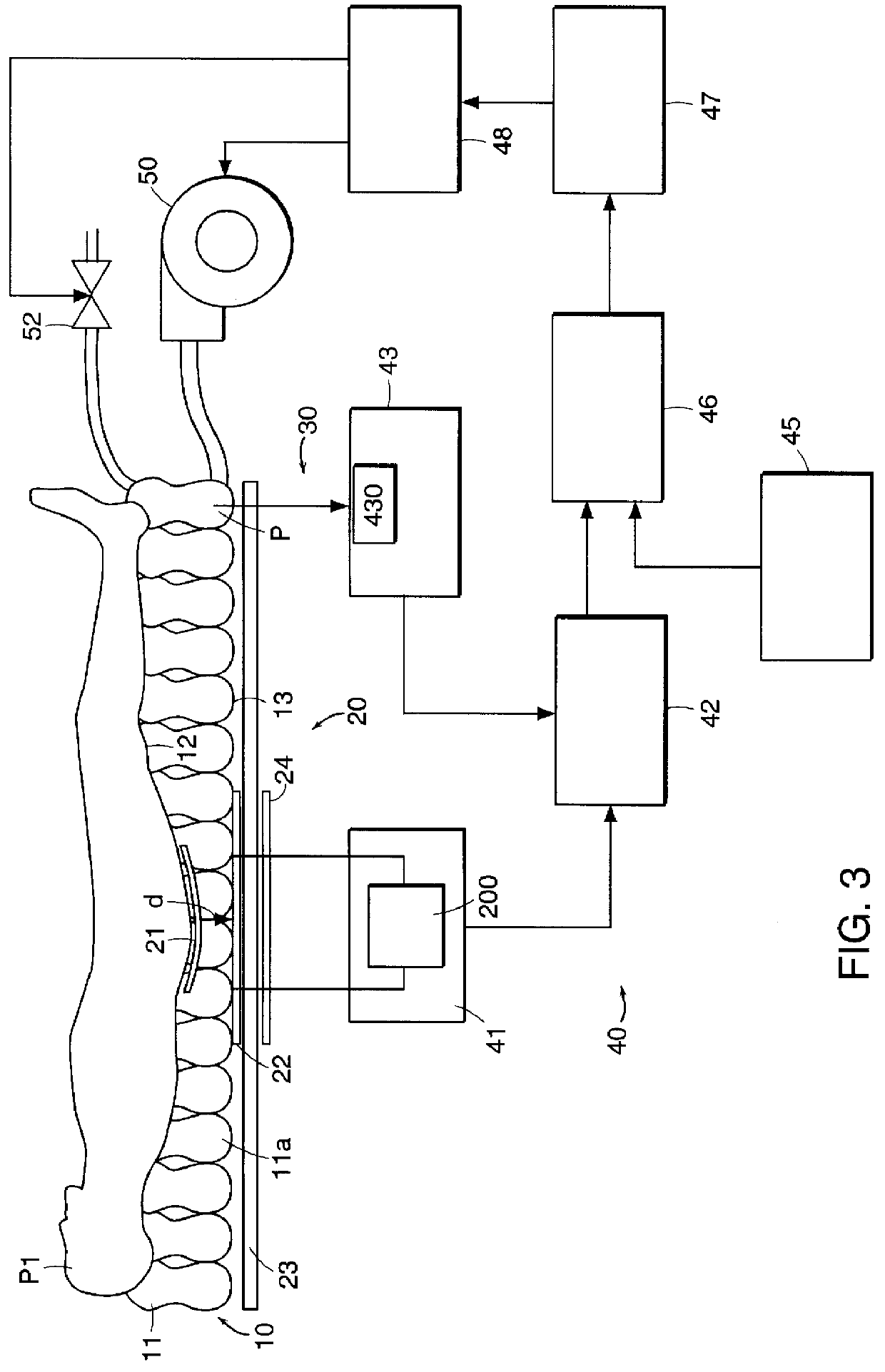

Method and apparatus for supporting an element to be supported, in particular the body of a patient, making it possible to support said element at a predetermined float line

InactiveUS6009580AHigh pressureStuffed mattressesSpring mattressesControlled releaseMeasurement device

The present invention relates to a method and apparatus for supporting a body element. The apparatus includes at least one support device with at least one closed or controlled-release chamber, a filling device and an emptying means device for filling said chamber with a filling fluid and emptying the fluid from the chamber, and a distance-measurement device for measuring the distance between a top face and a bottom face of the chamber. The apparatus further includes a reaction-measurement device for measuring the reaction of the support device relative to the morphological data of the body element to be supported, and a control system including a combination device for combining the measurement of the penetration distance d provided by the distance-measurement device and the measurement of the reaction provided by the reaction-measurement device. This combination is advantageously constituted by summing the two obtained measurements. The invention makes it possible to support the element to be supported substantially in a position of equilibrium corresponding substantially to a predetermined float line.

Owner:HILL ROM INDS

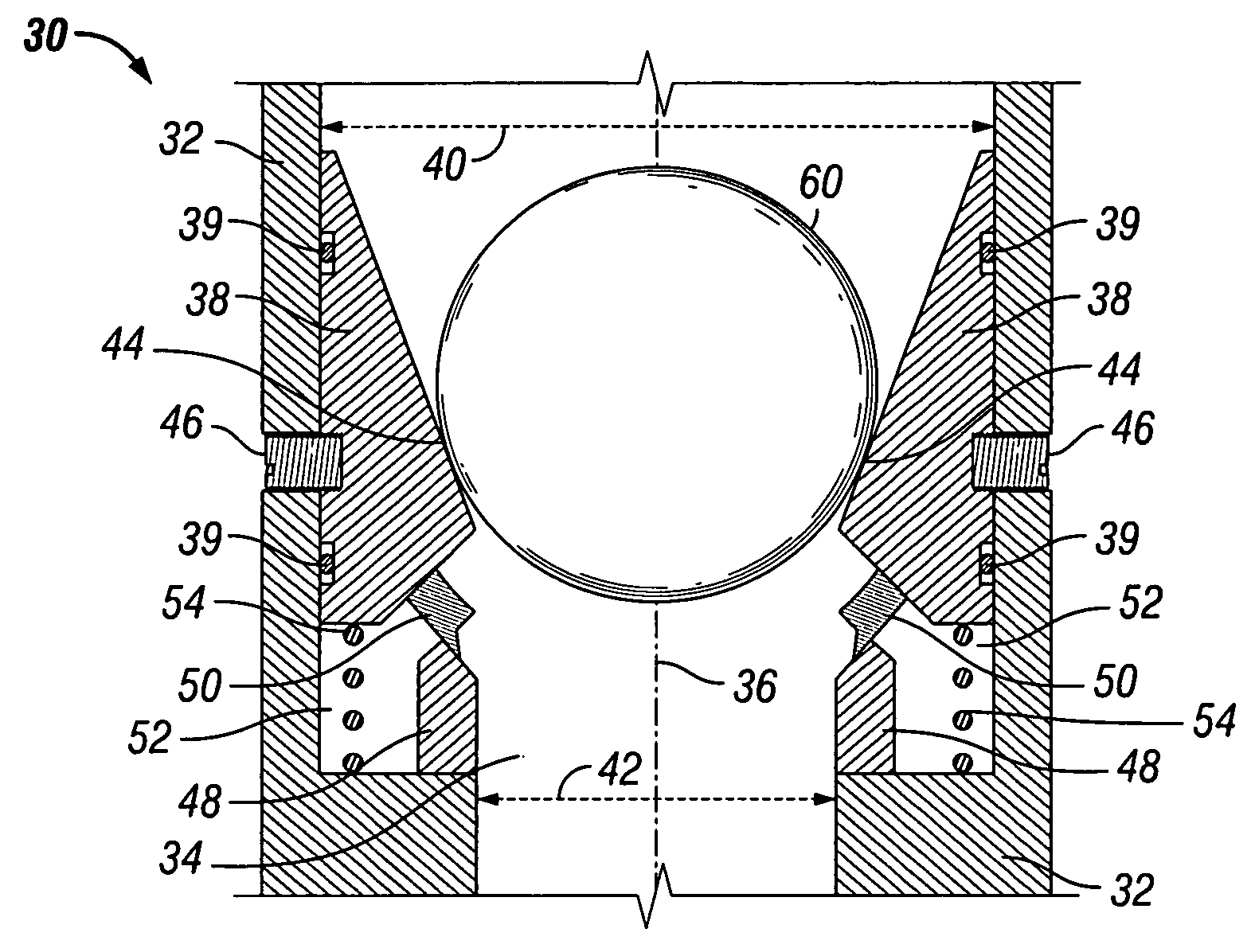

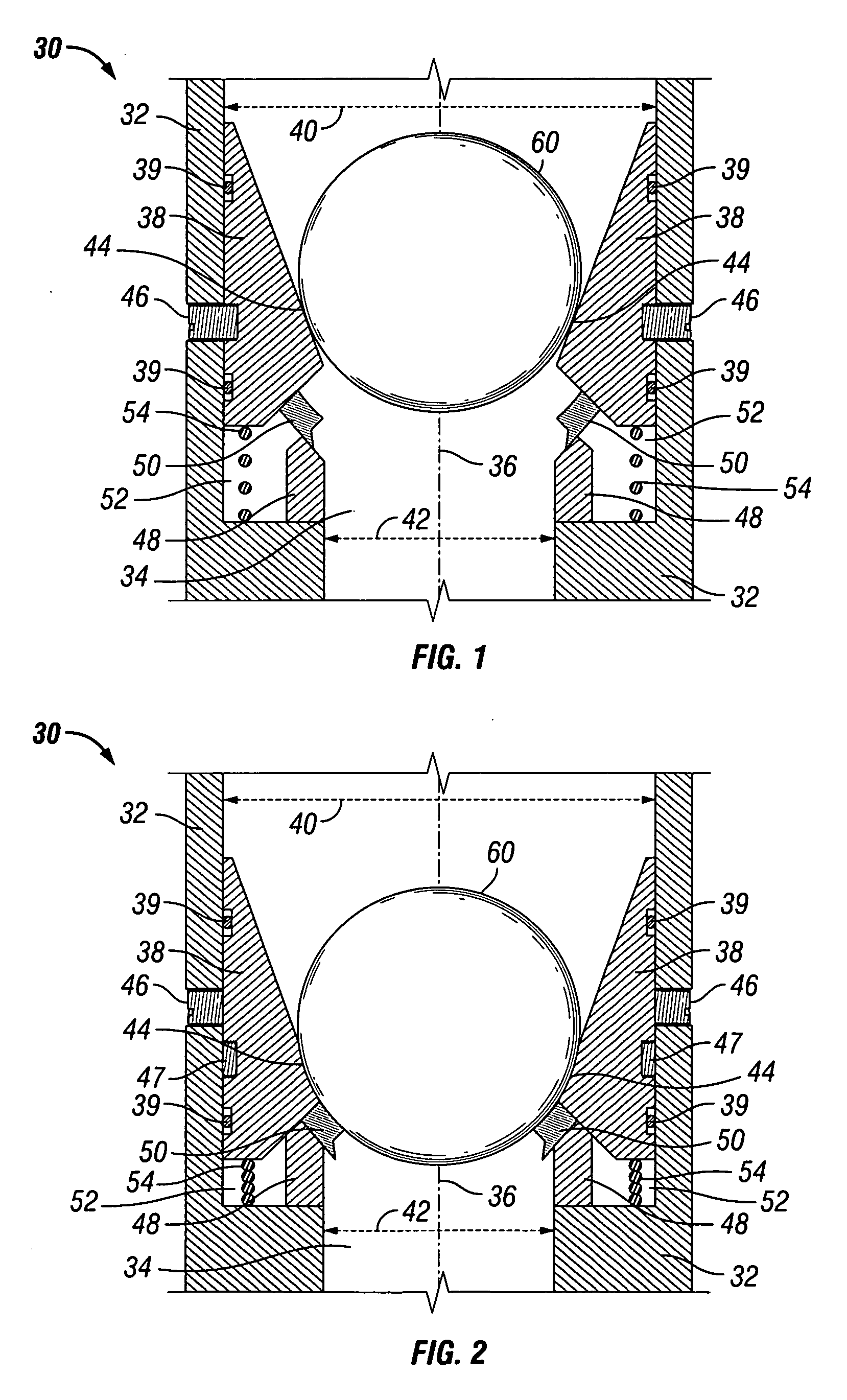

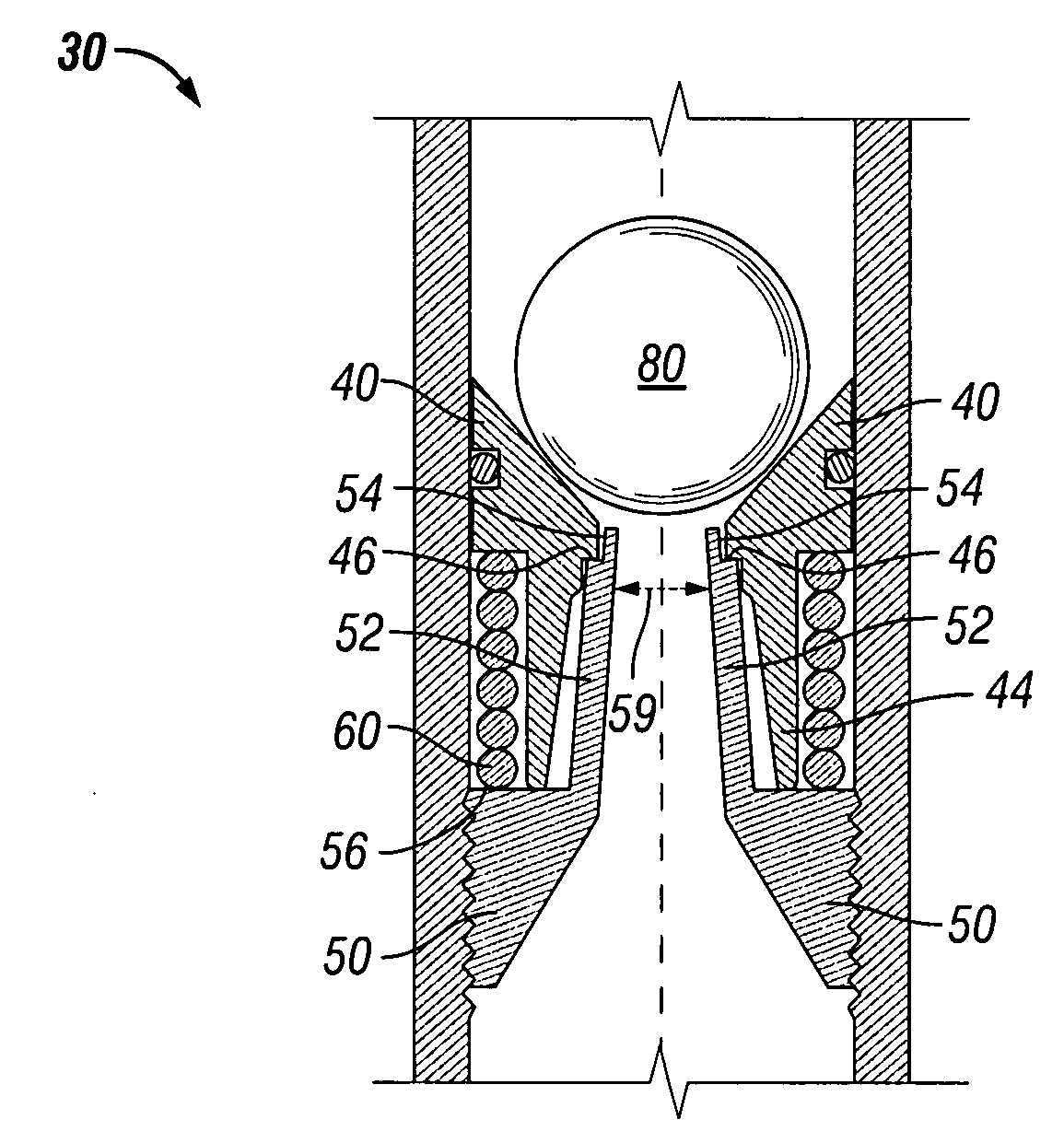

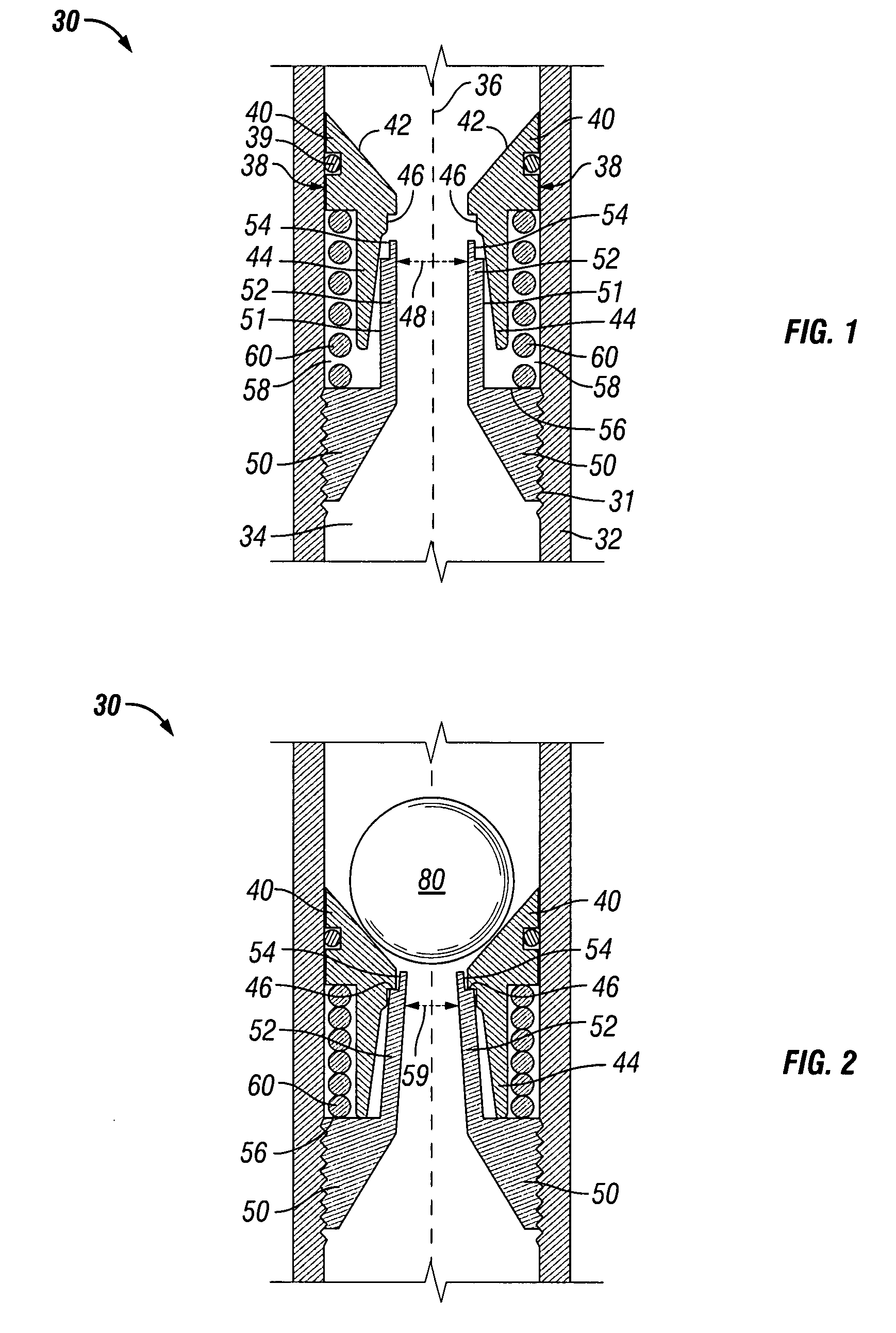

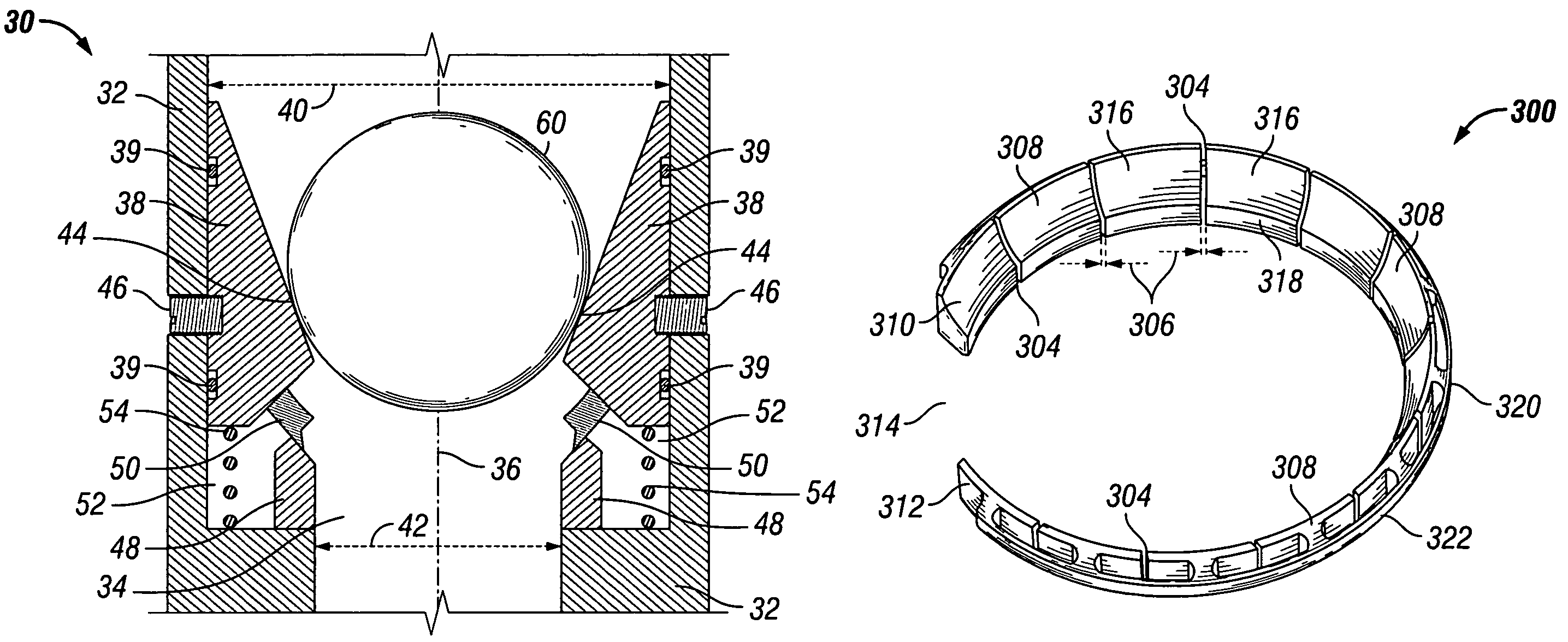

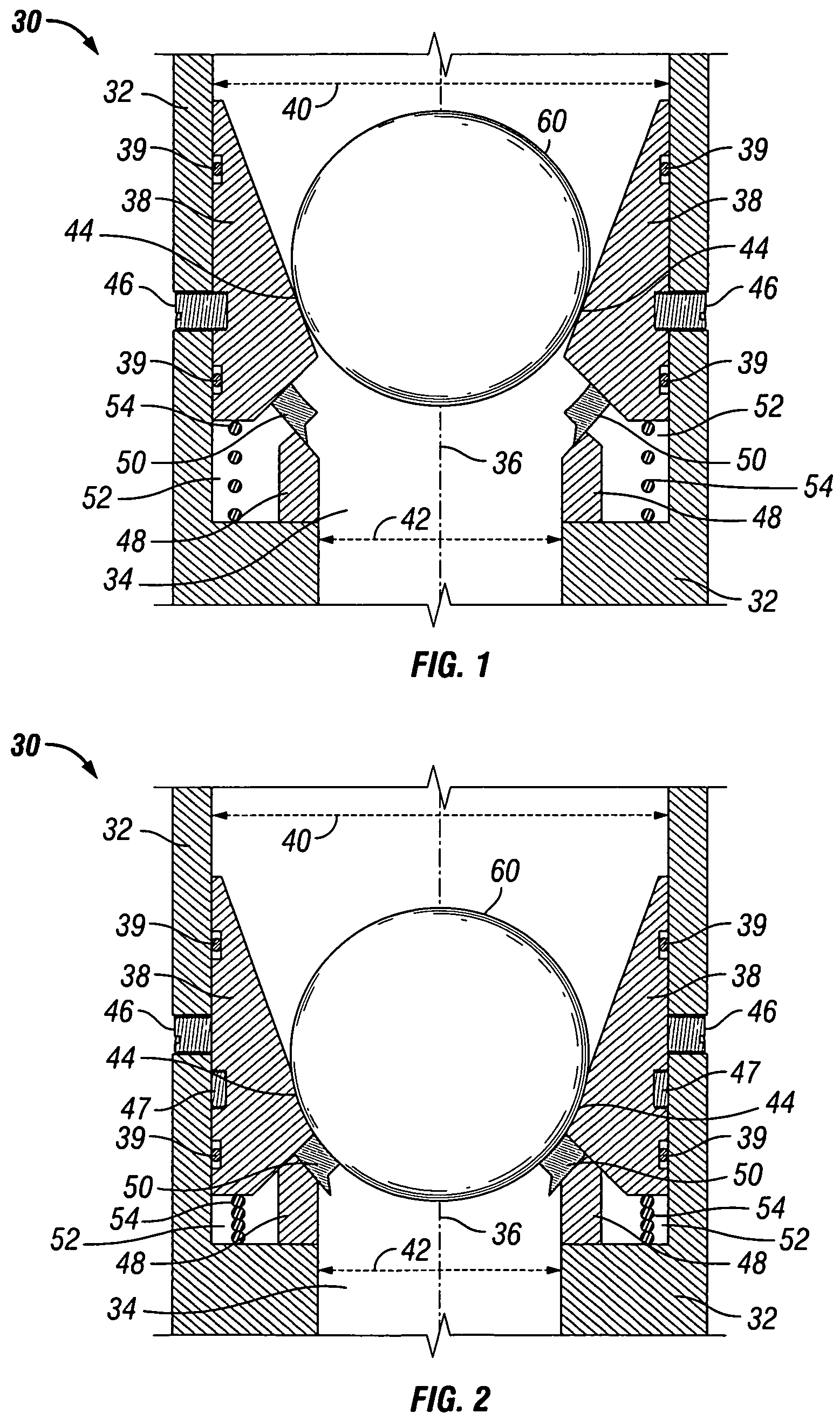

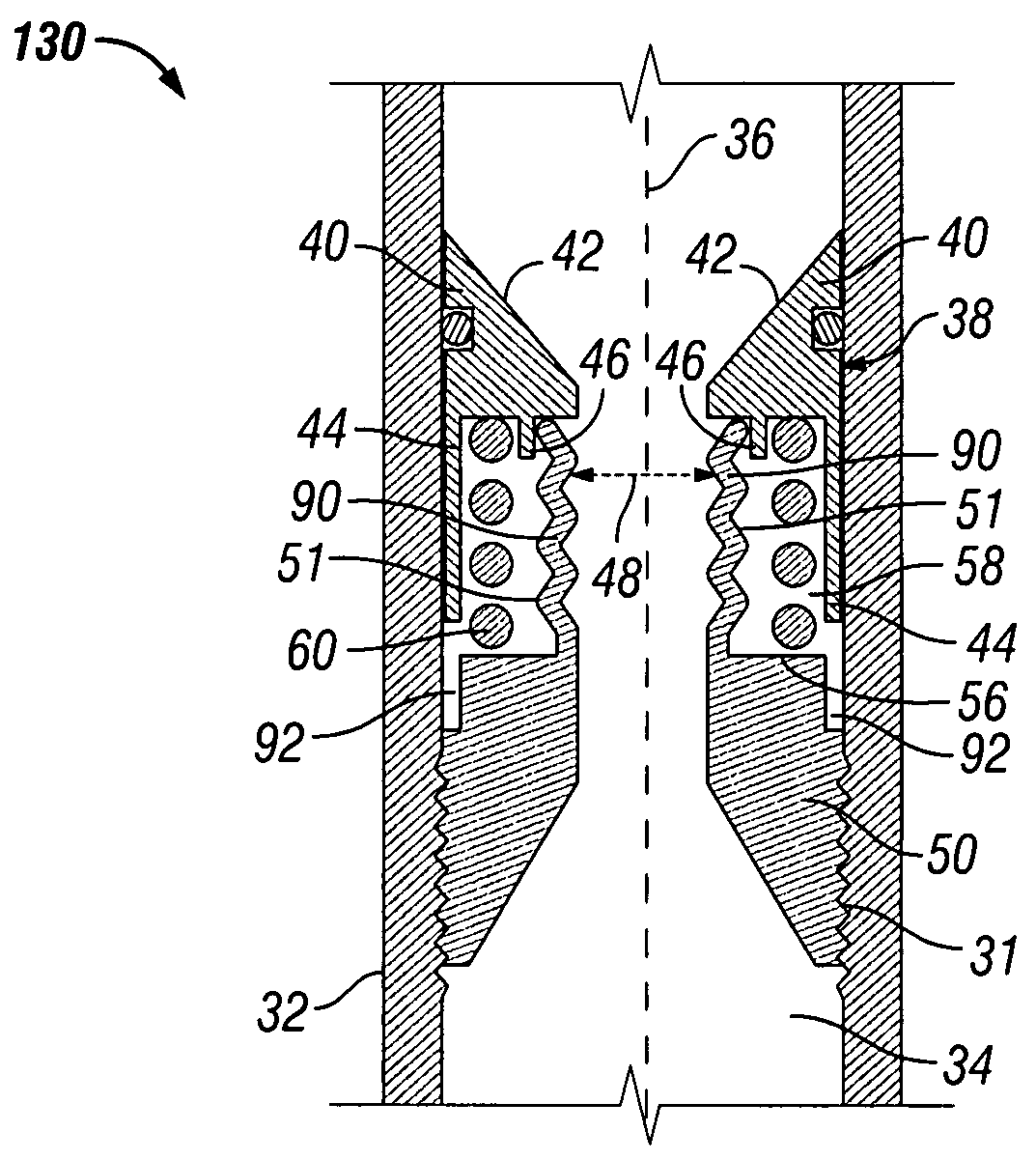

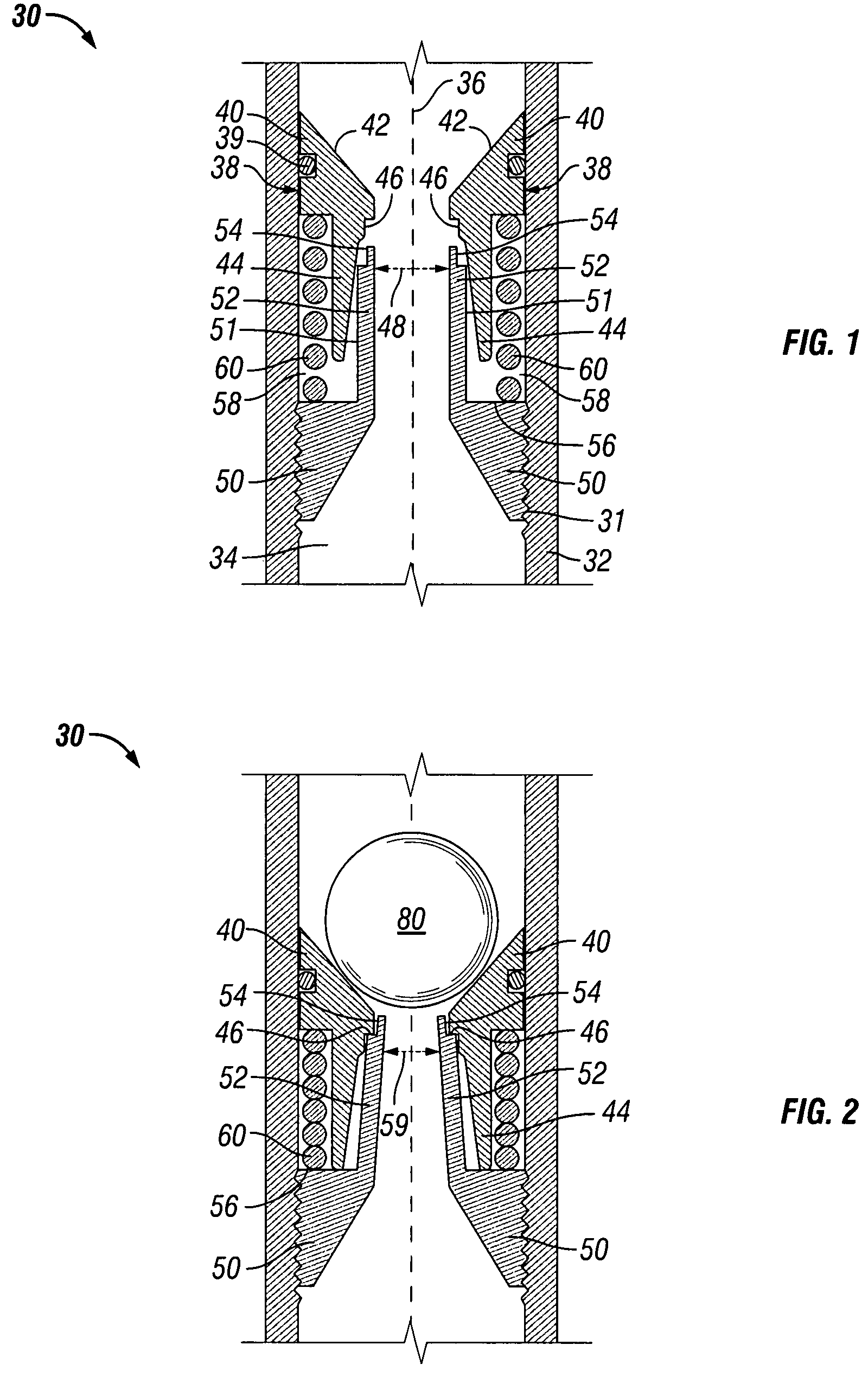

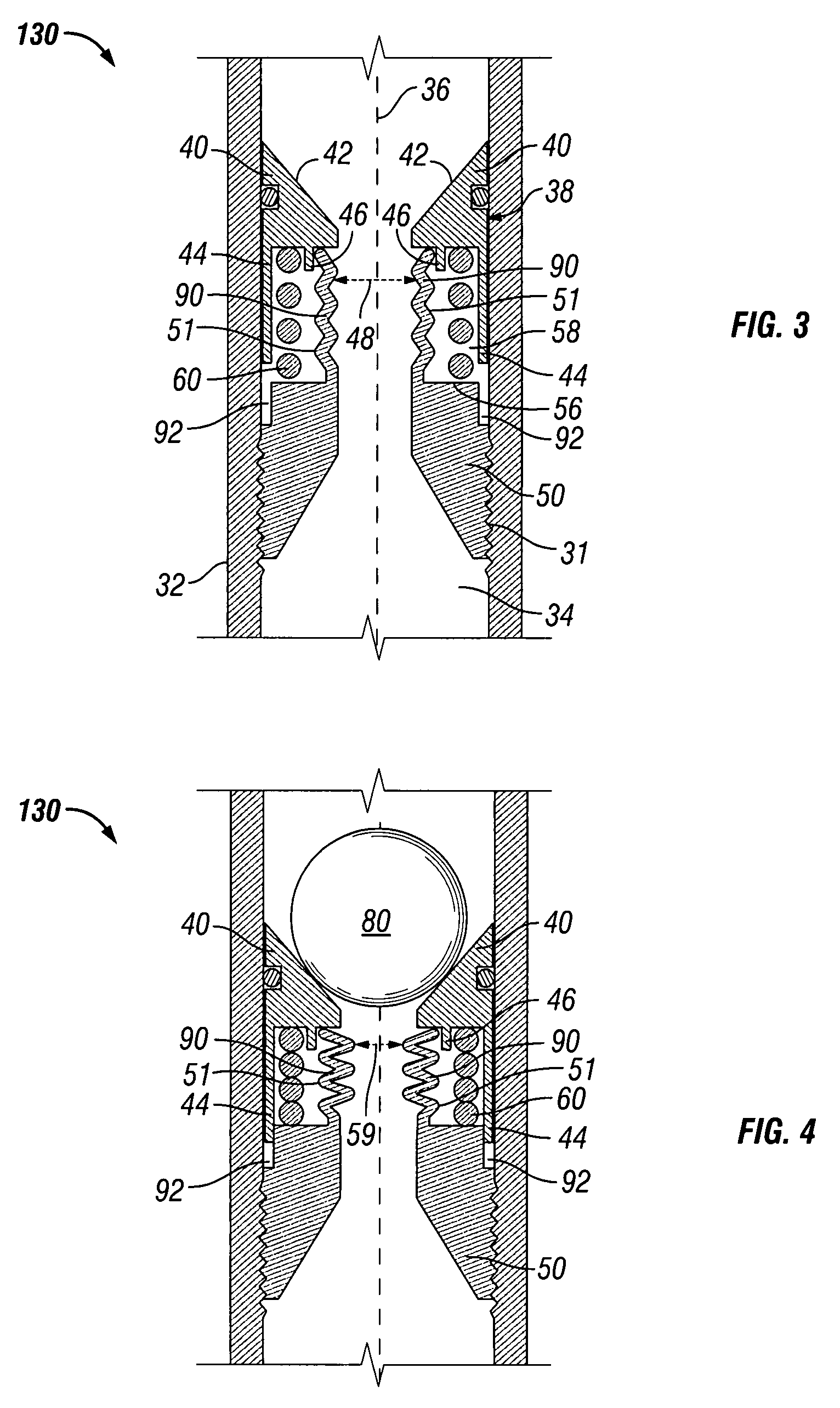

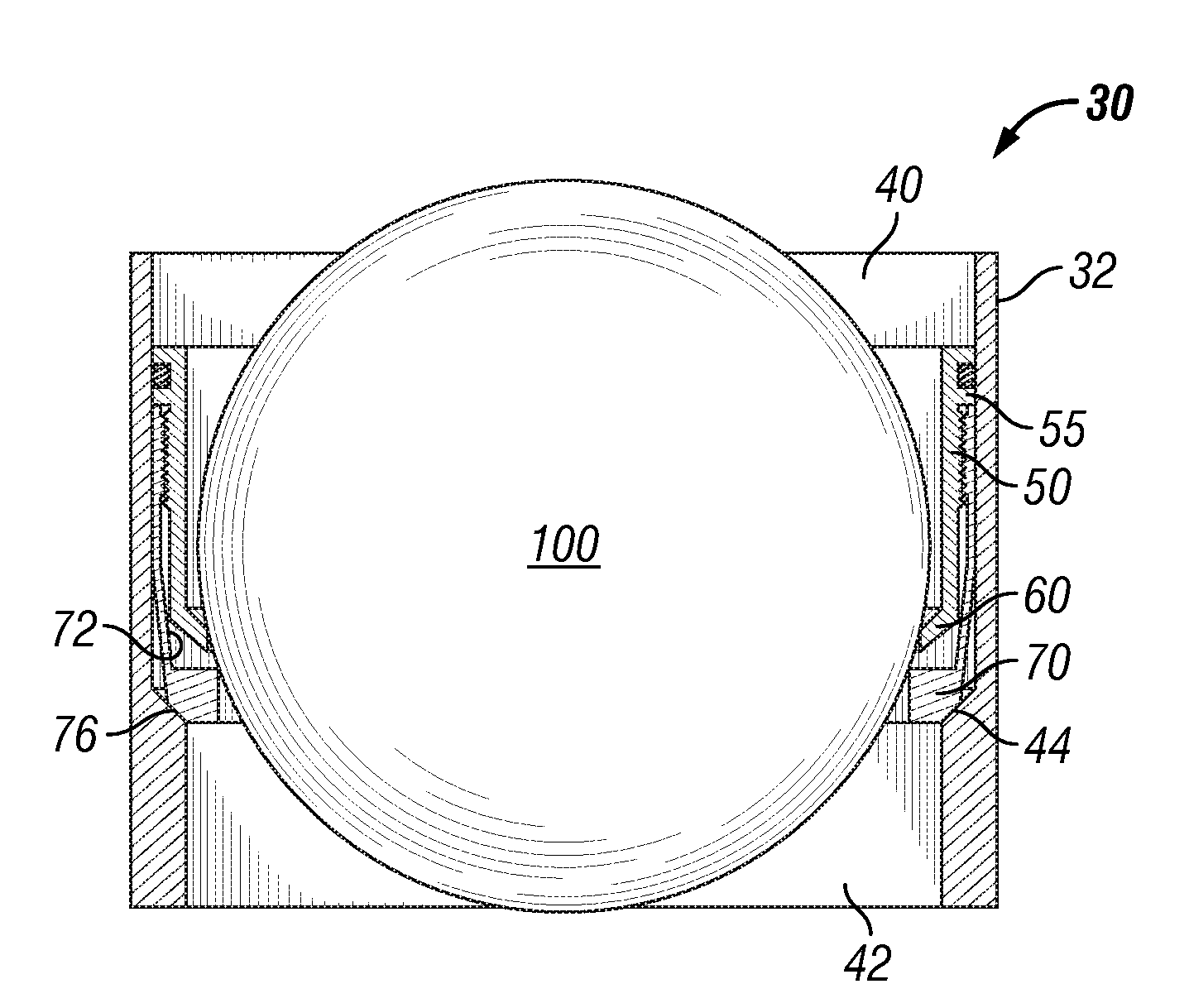

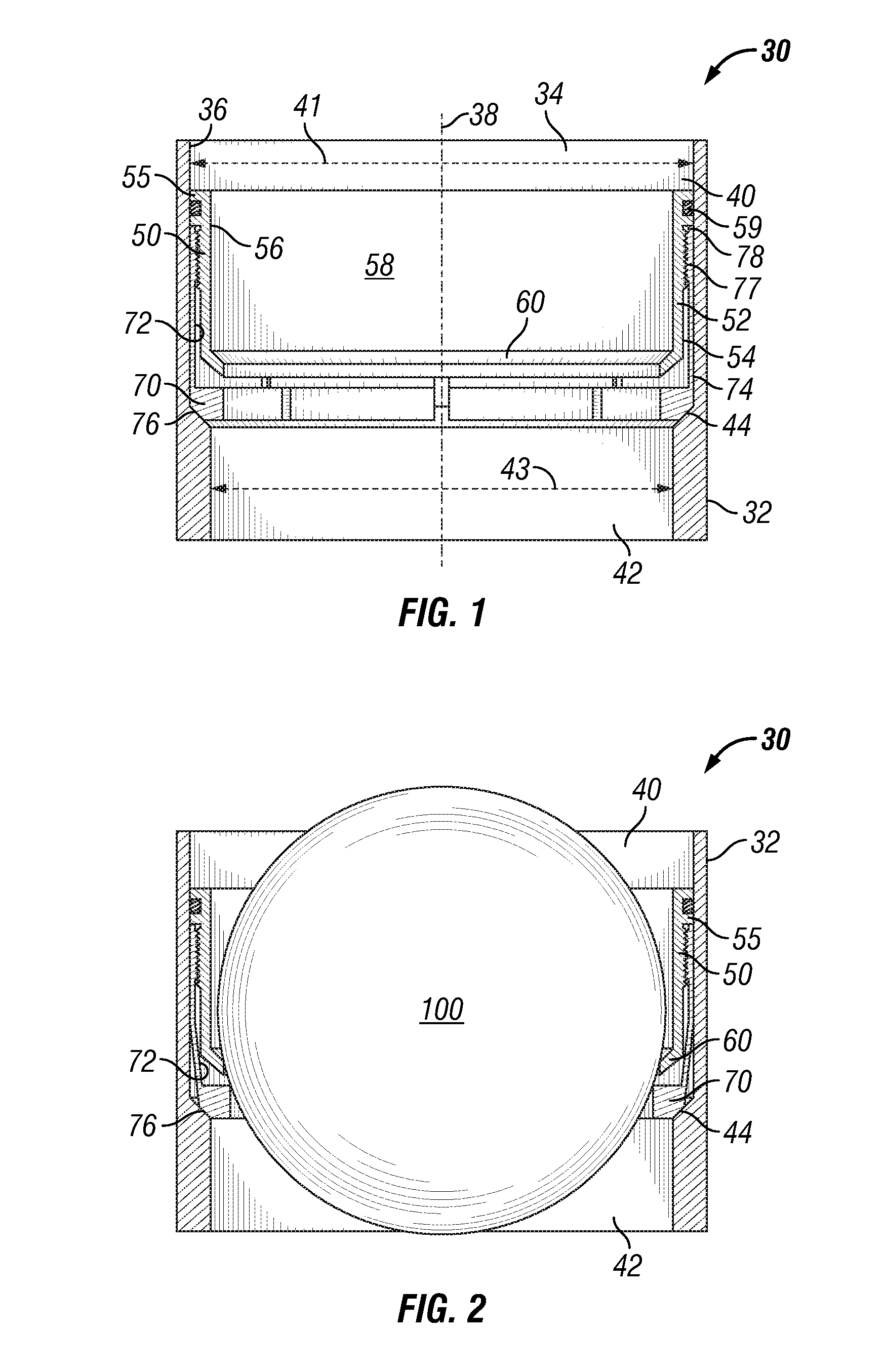

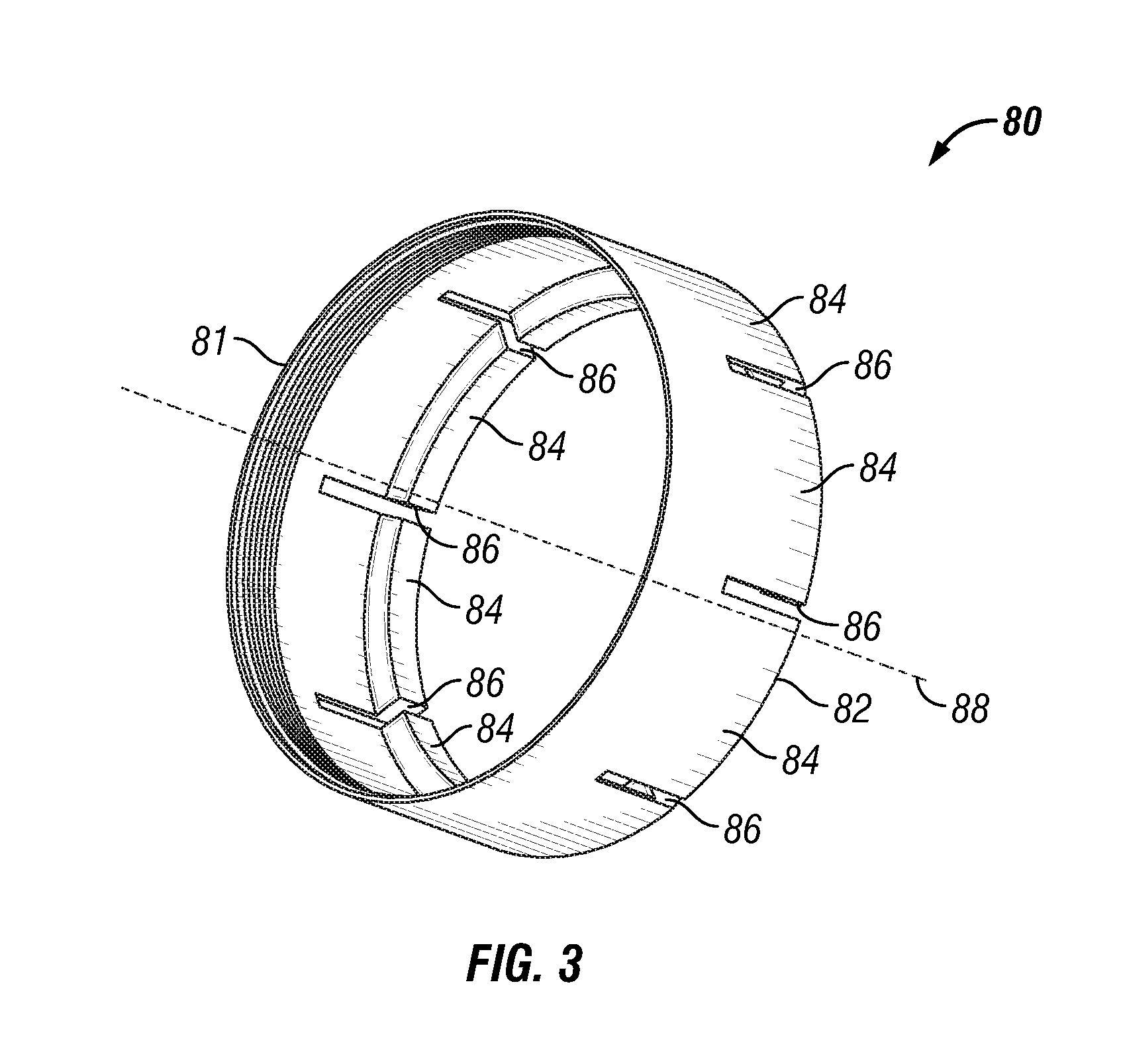

Reusable ball seat having ball support member

ActiveUS20090044955A1Reduce seat inner diameterIncrease pressureFluid removalWell/borehole valve arrangementsEngineeringGuide tube

Apparatuses for restricting fluid flow through a well conduit comprise a housing having a longitudinal bore and a reusable seat disposed within the bore. The seat comprises a slidable element, a fixed element, a plug element support member, a seat inner diameter, and a return member to urge the slidable element toward the run-in position. The plug element support member has a retracted position when the seat is in the run-in position and an extended position when the seat is in the set position. A plug element adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit is used to move the plug element support member from the retracted position to the extended position, thereby providing support to the plug element landed on the seat.

Owner:BAKER HUGHES INC

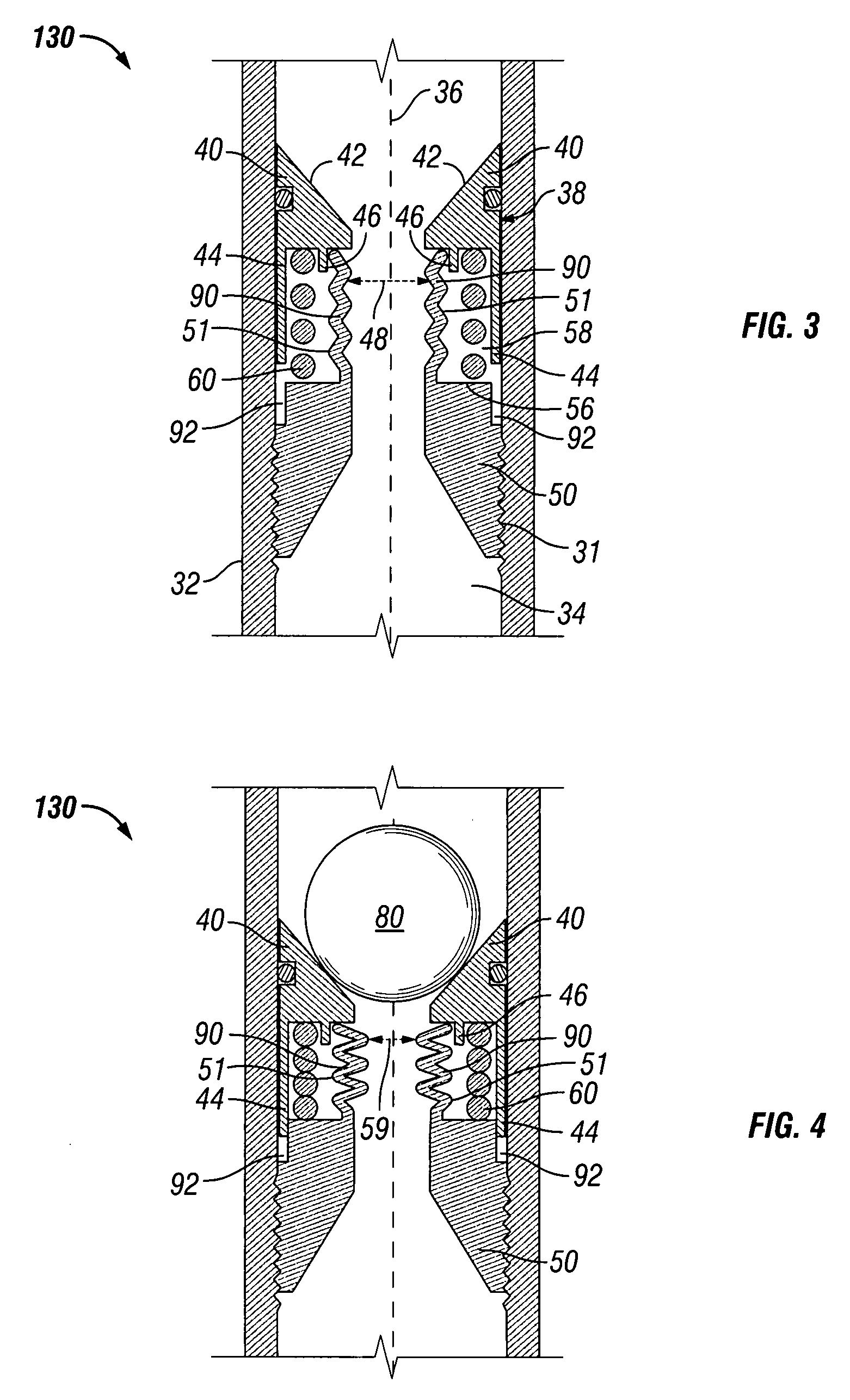

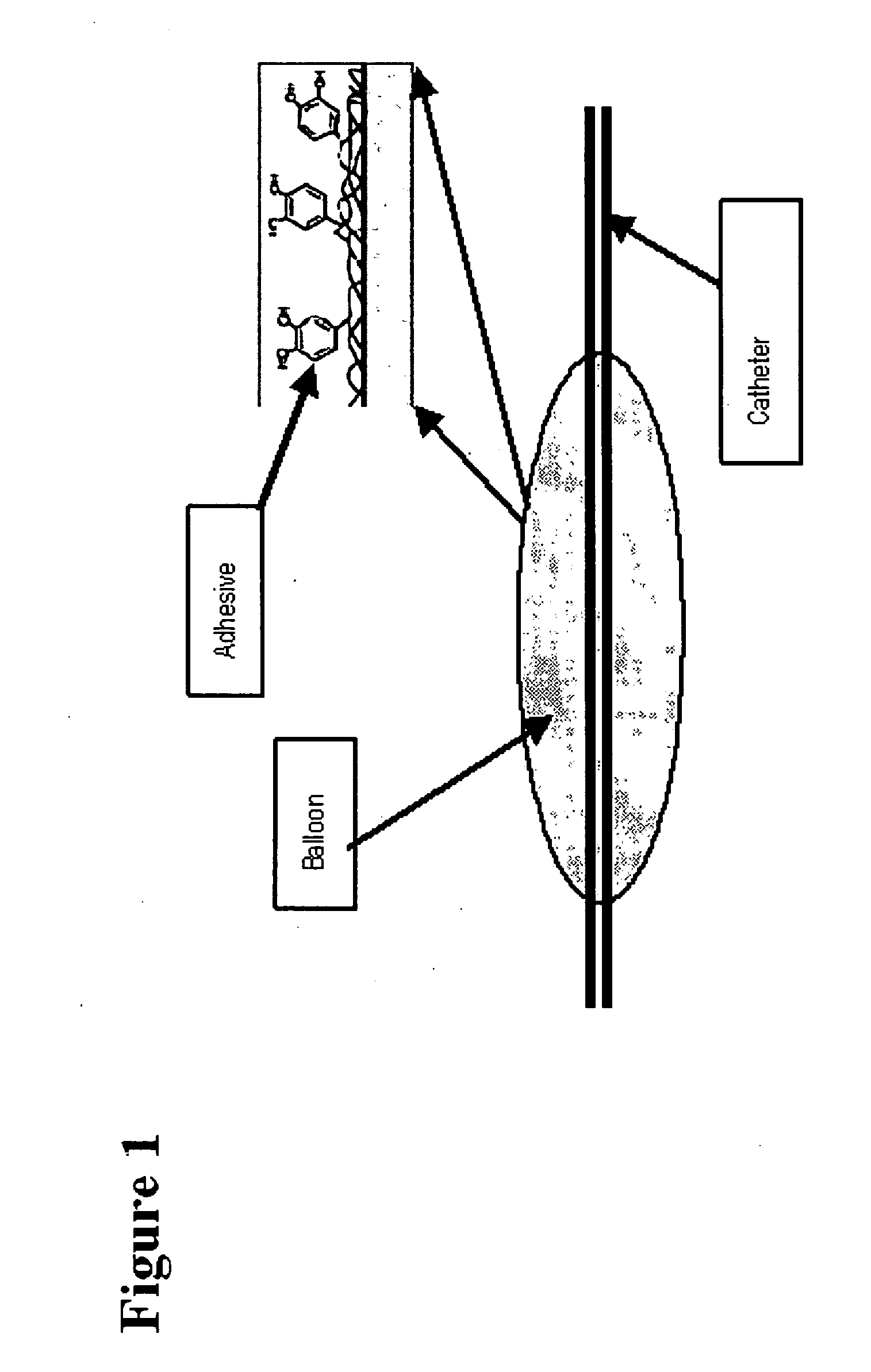

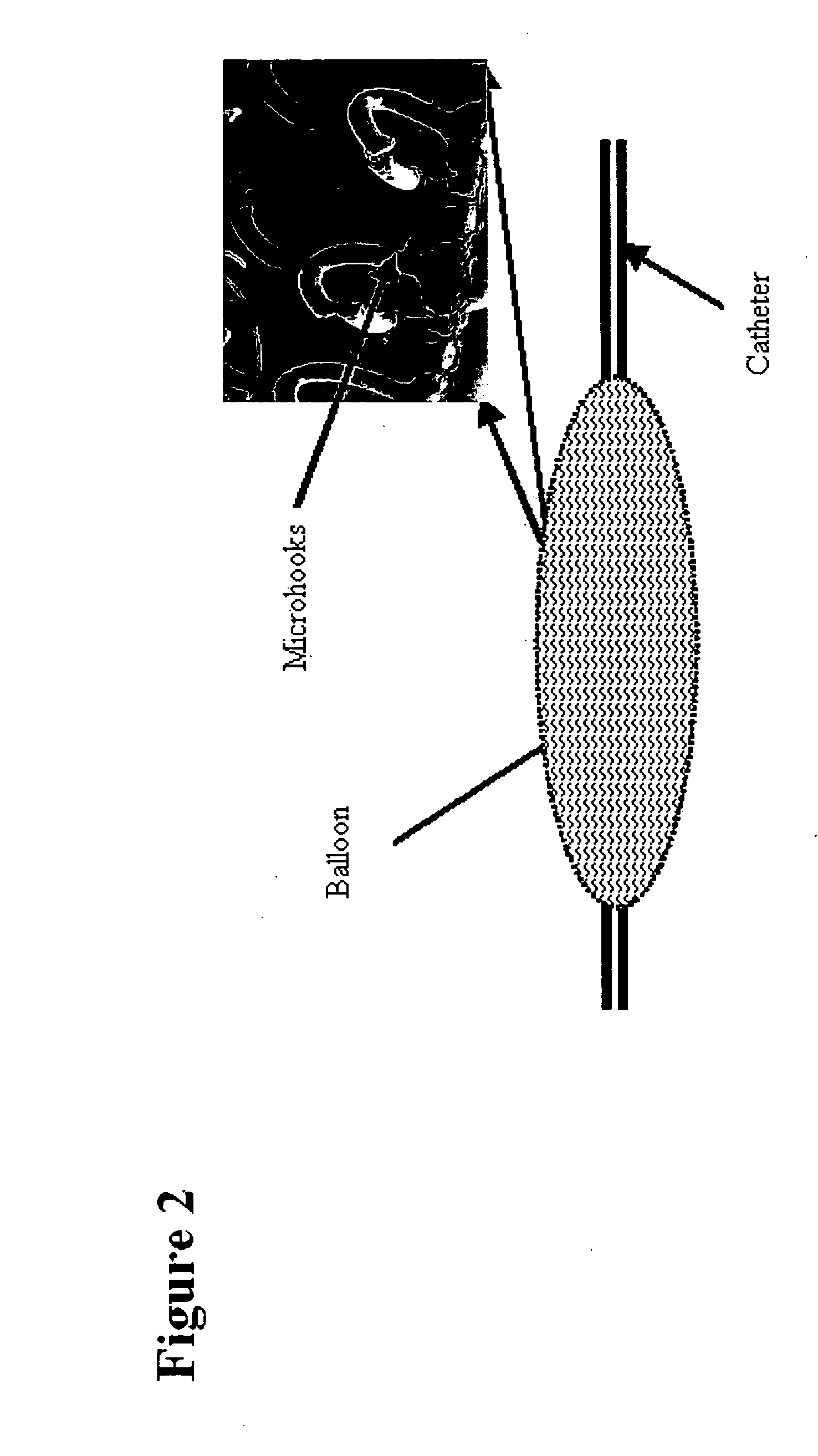

Sticky dilatation balloon and methods of using

The present invention involves an expandable element with an outer sticky surface. The expandable element may be in the form of a balloon with deflated and inflated configurations. The expandable element serves to both dilate a lumen in a blood vessel thereby opening it and to exert force upon the sticky surface in order to press it into apposition against a vessel wall. The outer sticky surface may be provided directly upon the expandable element or on a separate outer sheath that conforms to and follows the contours of the expandable element. The sticky surface may take the form of a biochemical composition and / or a mechanically abrasive structure such as microhooks, hairs, mesh netting, etc. Optionally, additional expandable elements may be provided proximal and distal to the main element to occlude blood flow on either side of a lesion in order to better trap emboli for collection.

Owner:SPECIALIZED VASCULAR TECH

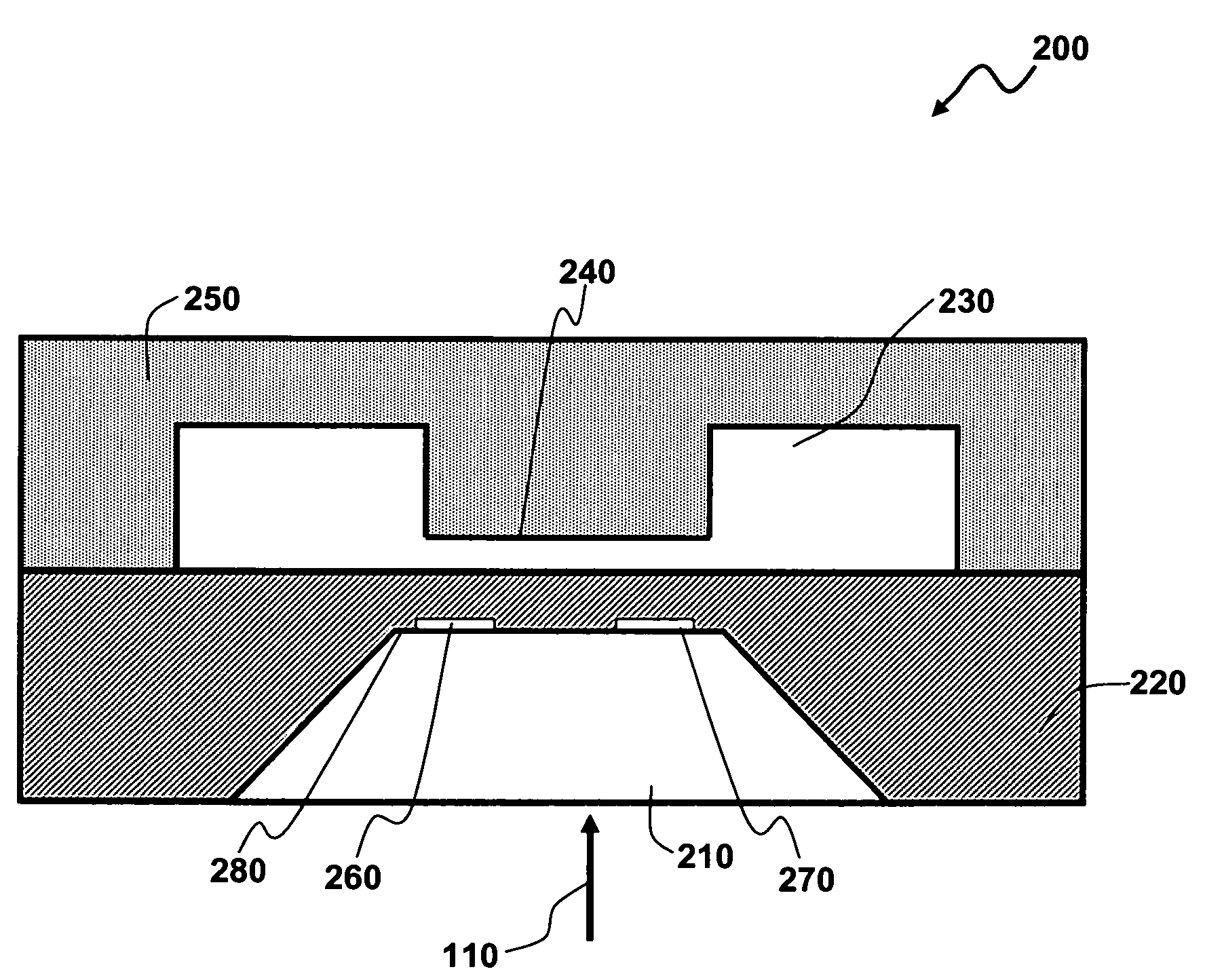

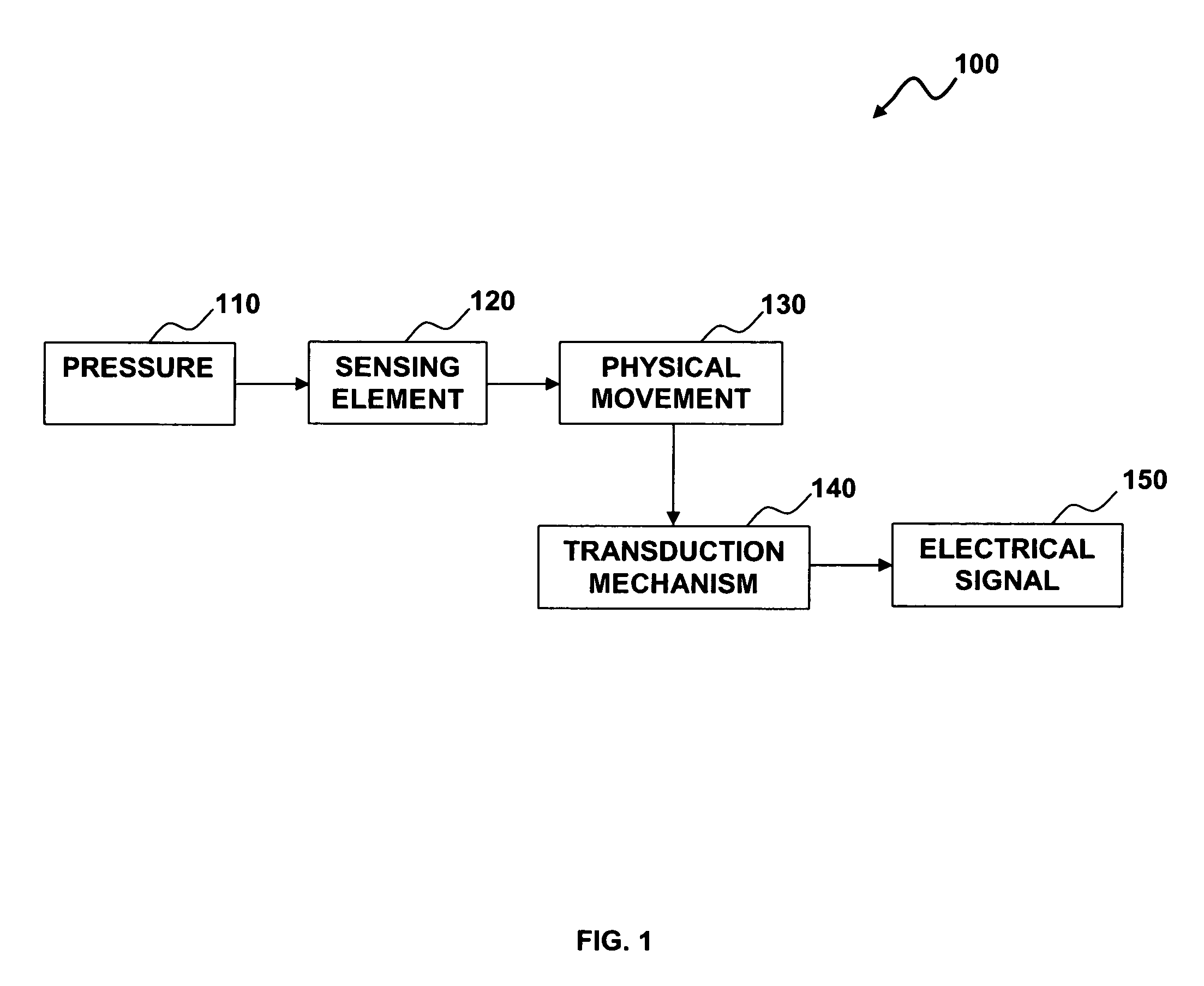

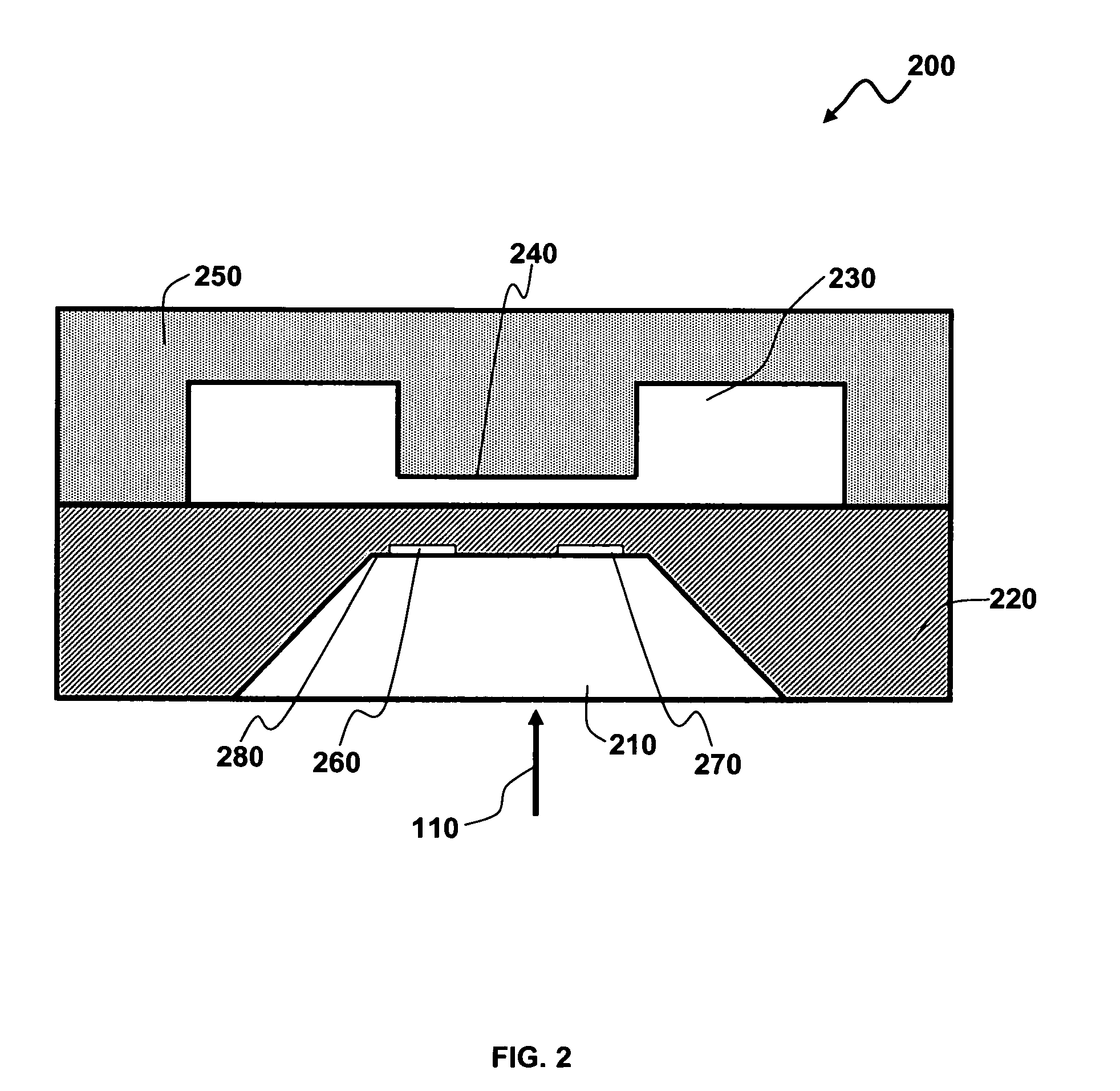

Dual span absolute pressure sense die

InactiveUS7503221B2Accurate measurementSmall voltageFluid pressure measurement using ohmic-resistance variationMultiple fluid pressure valves simultaneous measurementPressure senseHigh pressure

An absolute pressure sensor includes a sense die with a reference chamber on a top side thereof. The reference chamber comprises a precisely fabricated beam that limits the travel of a diaphragm. The beam can be positioned in a cap or cover member of the sense die, thereby allowing the sense die diaphragm to move freely for a particular distance. Over this distance, the sense die will have one sensitivity. When the sense die is pressurized to a certain point, the diaphragm moves until it contacts the beam member in the cap or cover. When the diaphragm hits the beam, the sensitivity of the sense die changes, thereby allowing a smaller voltage out for the greater pressure in. Such an arrangement permits the sensor to provide a function that accurately measures low pressure and measures a higher pressure without utilizing a linear scale.

Owner:HONEYWELL INT INC

Ball seat having segmented arcuate ball support member

ActiveUS7644772B2Increase pressureReduce the possibilityFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Owner:BAKER HUGHES HLDG LLC

Reusable ball seat having ball support member

ActiveUS7673677B2Reduce the overall diameterIncrease pressureFluid removalWell/borehole valve arrangementsEngineeringGuide tube

Apparatuses for restricting fluid flow through a well conduit comprise a housing having a longitudinal bore and a reusable seat disposed within the bore. The seat comprises a slidable element, a fixed element, a plug element support member, a seat inner diameter, and a return member to urge the slidable element toward the run-in position. The plug element support member has a retracted position when the seat is in the run-in position and an extended position when the seat is in the set position. A plug element adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit is used to move the plug element support member from the retracted position to the extended position, thereby providing support to the plug element landed on the seat.

Owner:BAKER HUGHES INC

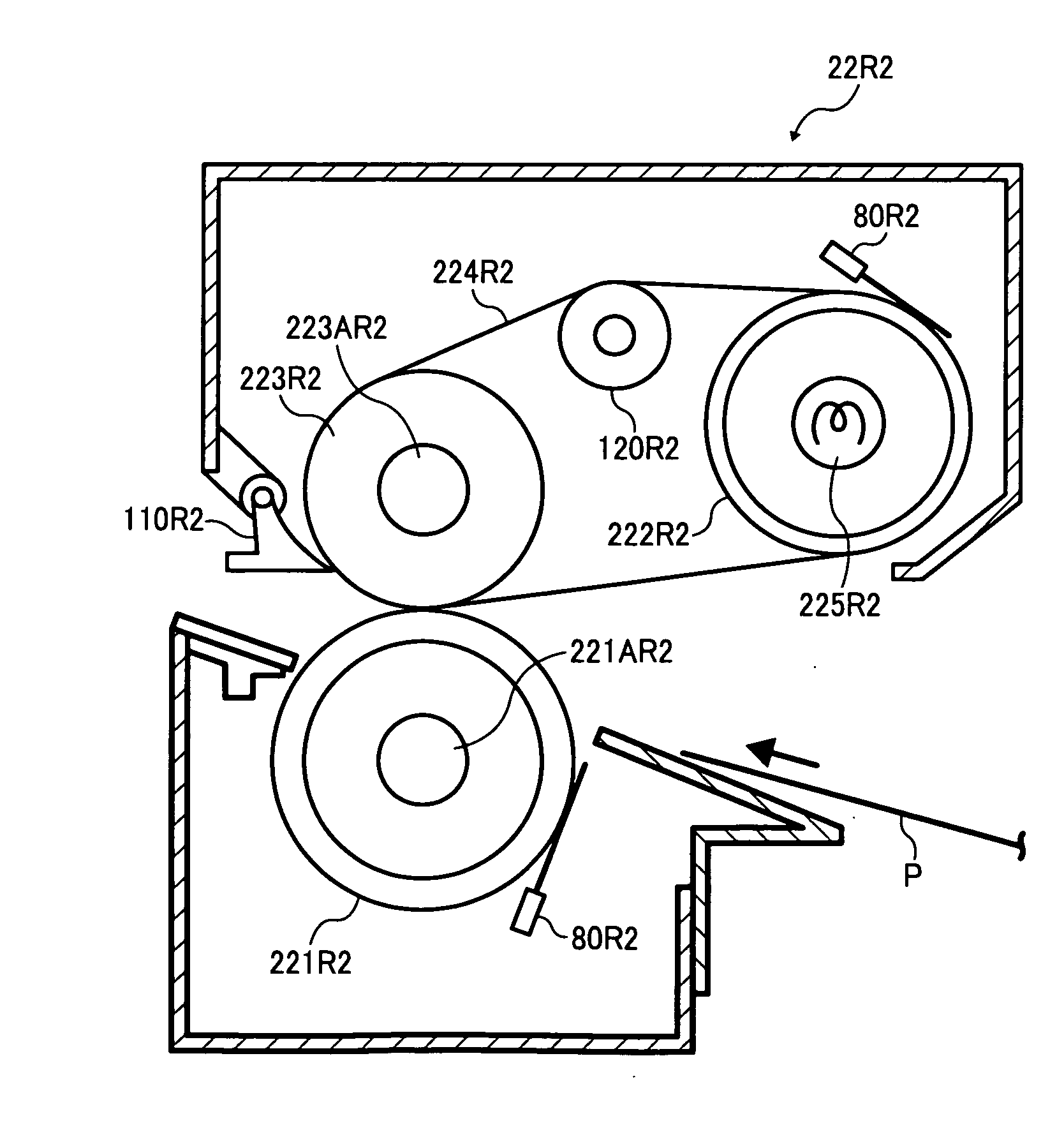

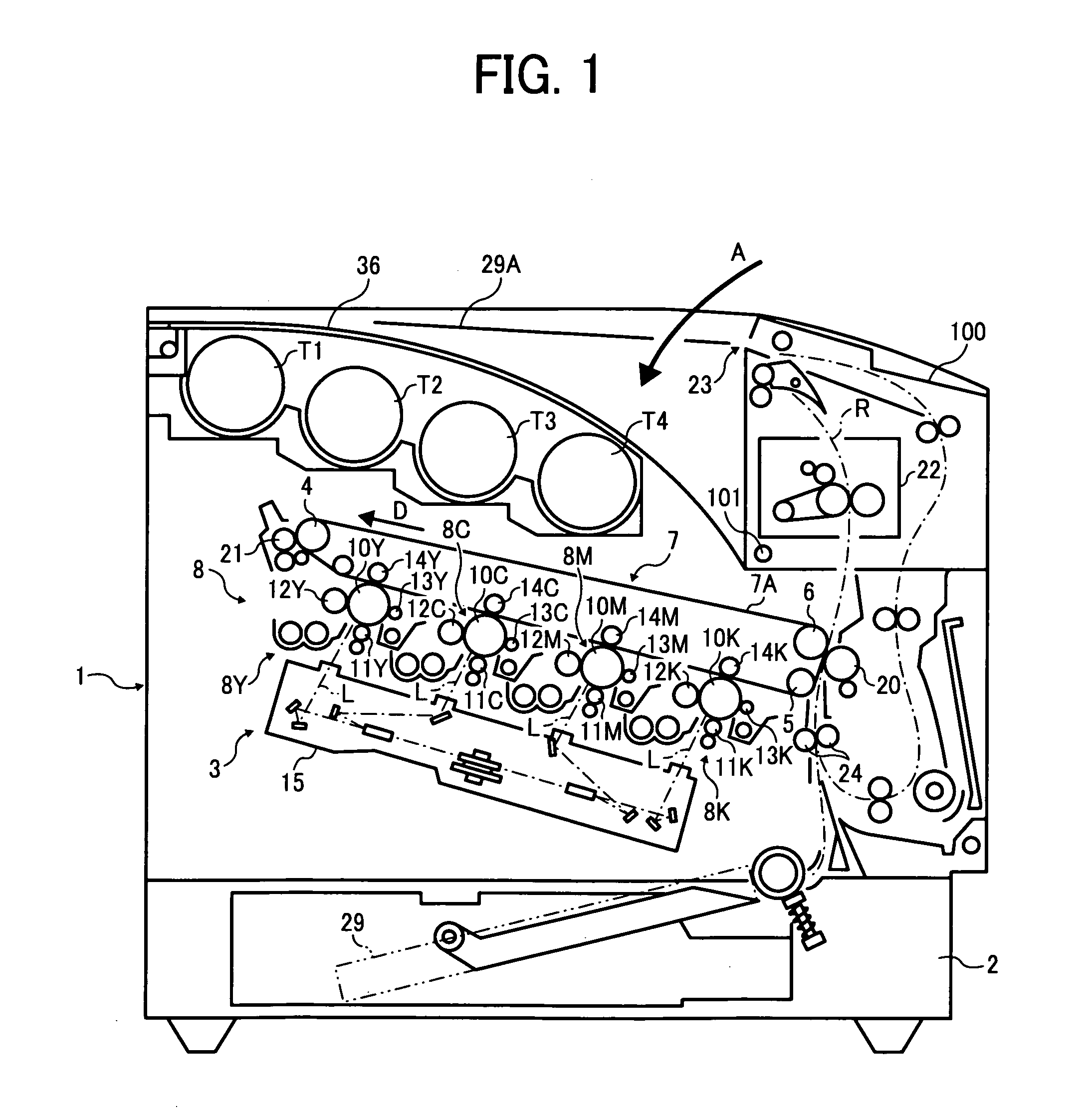

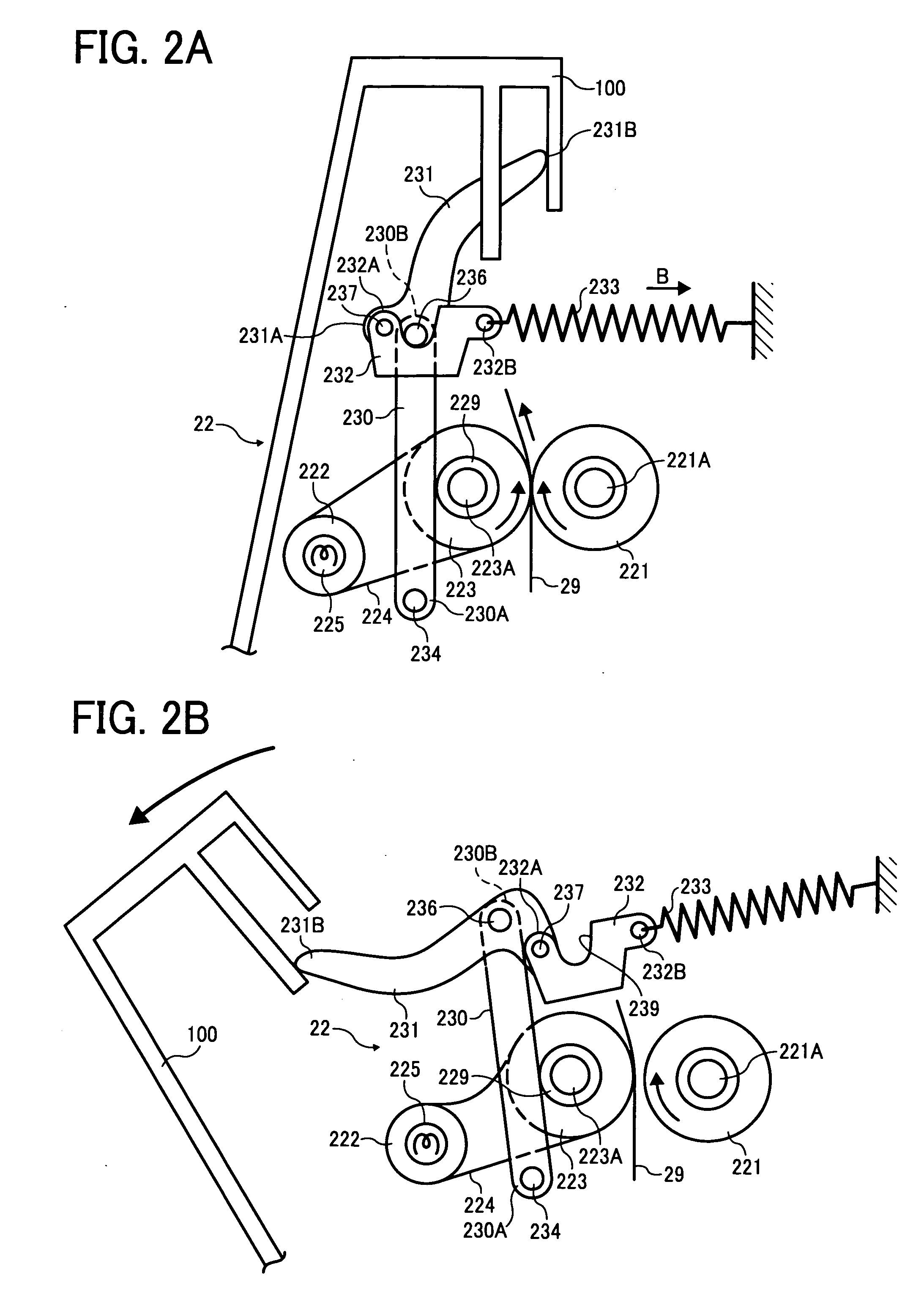

Fixing device, image forming apparatus, and method of manufacturing toner for image forming apparatus

ActiveUS20090067902A1High pressureIncrease speedElectrographic process apparatusImage formationRecording media

In a fixing device, a first fixing member and a second fixing member nip a recording medium so as to fix a toner image on the recording medium by applying heat and pressure to the recording medium. A pressure application lever presses the second fixing member toward the first fixing member. A pressure release lever supported by the pressure application lever supports a lock member. An elastic member pulls the lock member in a lock direction. The pressure release lever moves the lock member between a pressure application position, at which the lock member causes the pressure application lever to press the second fixing member toward the first fixing member so as to apply tension to the second fixing member, and a pressure release position, at which the second fixing member separates from the first fixing member so as to release tension applied to the second fixing member.

Owner:RICOH KK

Thrombectomy and tissue removal method

InactiveUS6926726B2Increase speedReduce local pressureCannulasSurgical instrument detailsThrombusHigh pressure

A method for removing thrombus or other material from a natural or synthetic body vessel or cavity without the need for direct surgical access. The method includes providing a device supplying high pressure fluid to at least one distal orifice, causing high pressure fluid to emanate from the orifice creating at least one fluid jet, and using the fluid jet to break up material in the vessel. The method further includes directing at least one fluid jet at the opening of an exhaust lumen or target incorporated into the device and using the jet to provide a localized negative pressure which entrains material into the jet for break-up. The method optionally includes using the jet to provide stagnation pressure which drives material along the exhaust lumen. The method optionally includes metering the exhaust to match the fluid input or to be greater or less than the input. A positive displacement pump operating at steady or pulsatile flow provides the high pressure saline to the distal end of the catheter.

Owner:MEDRAD INC.

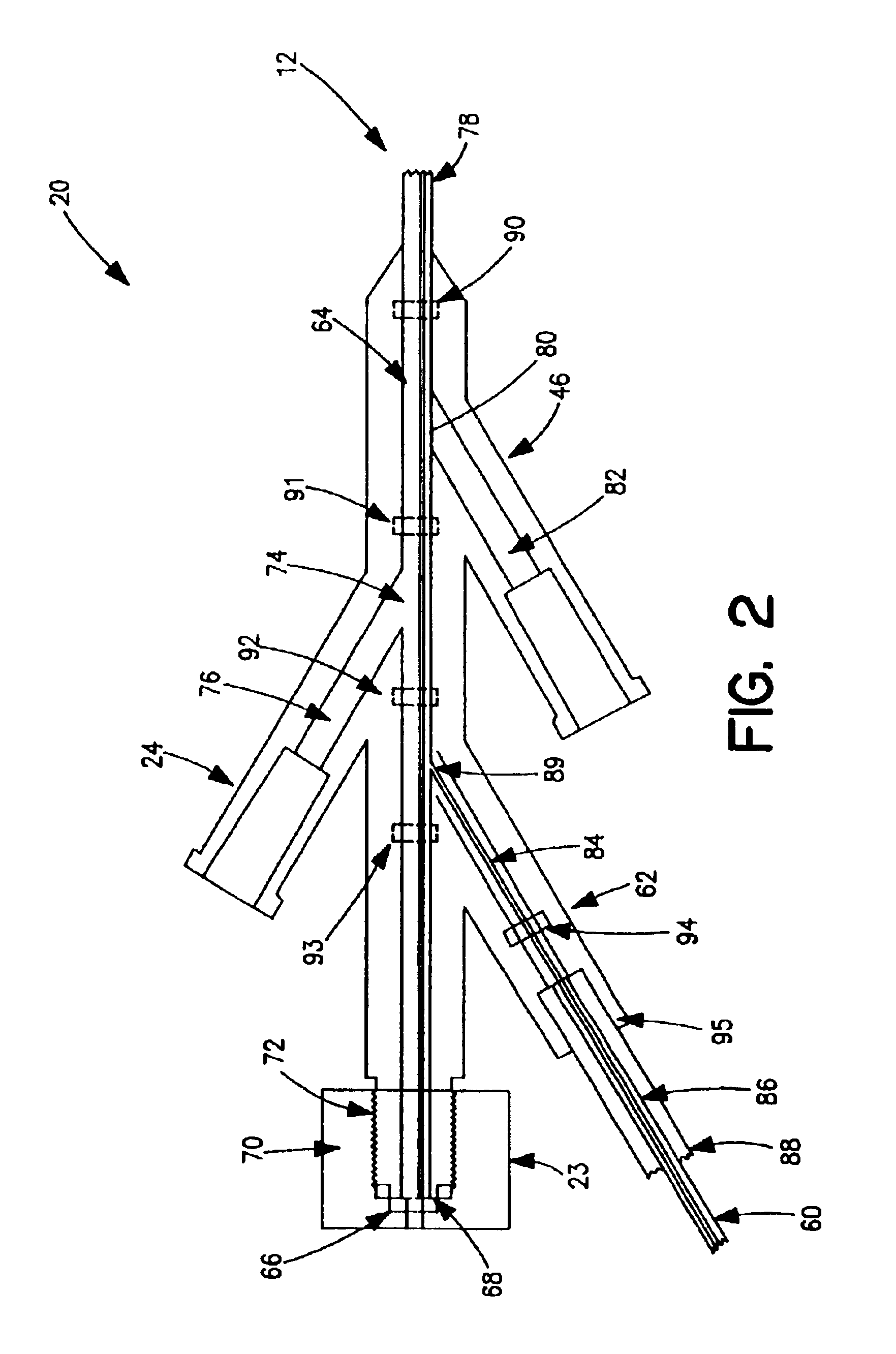

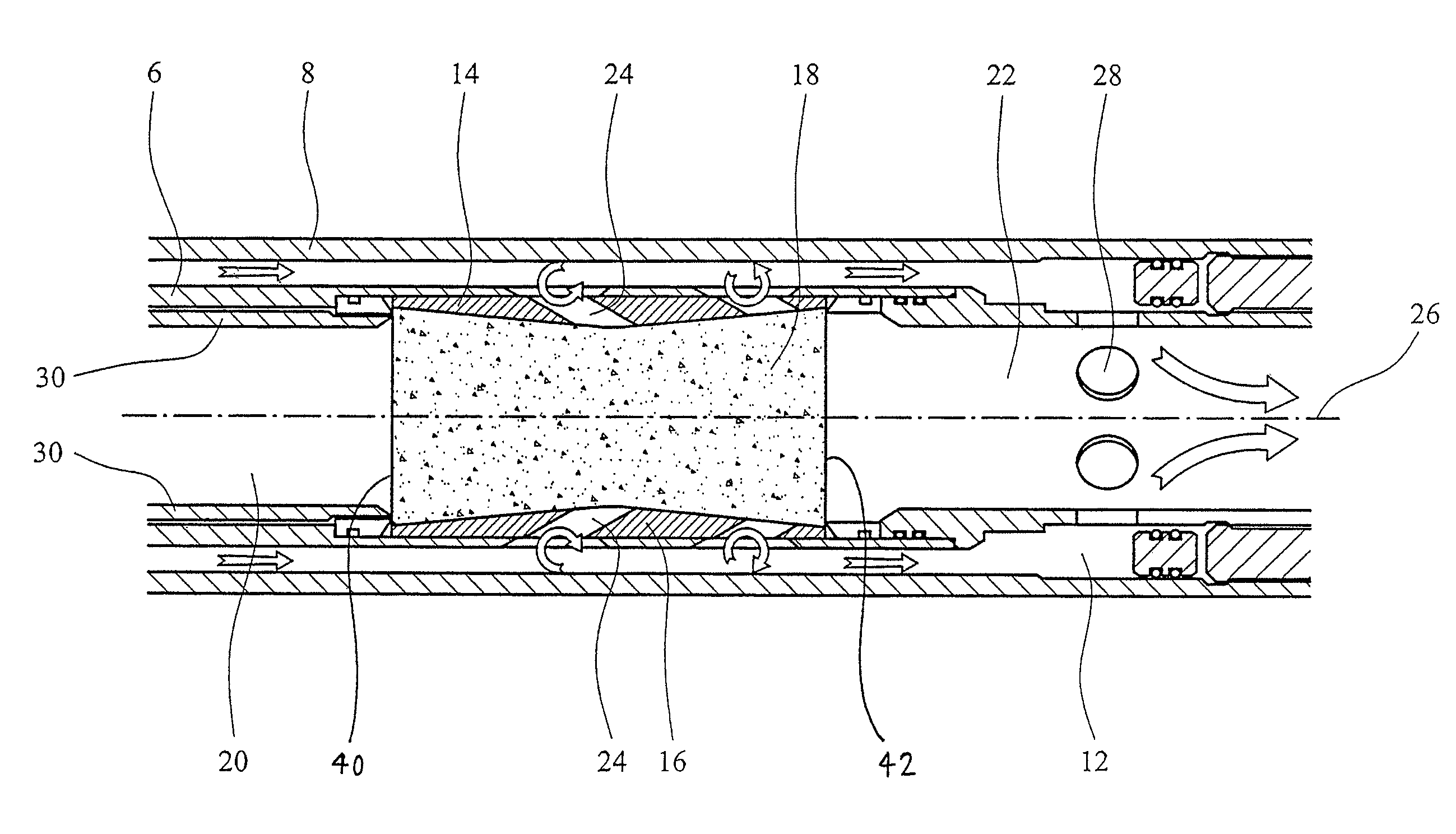

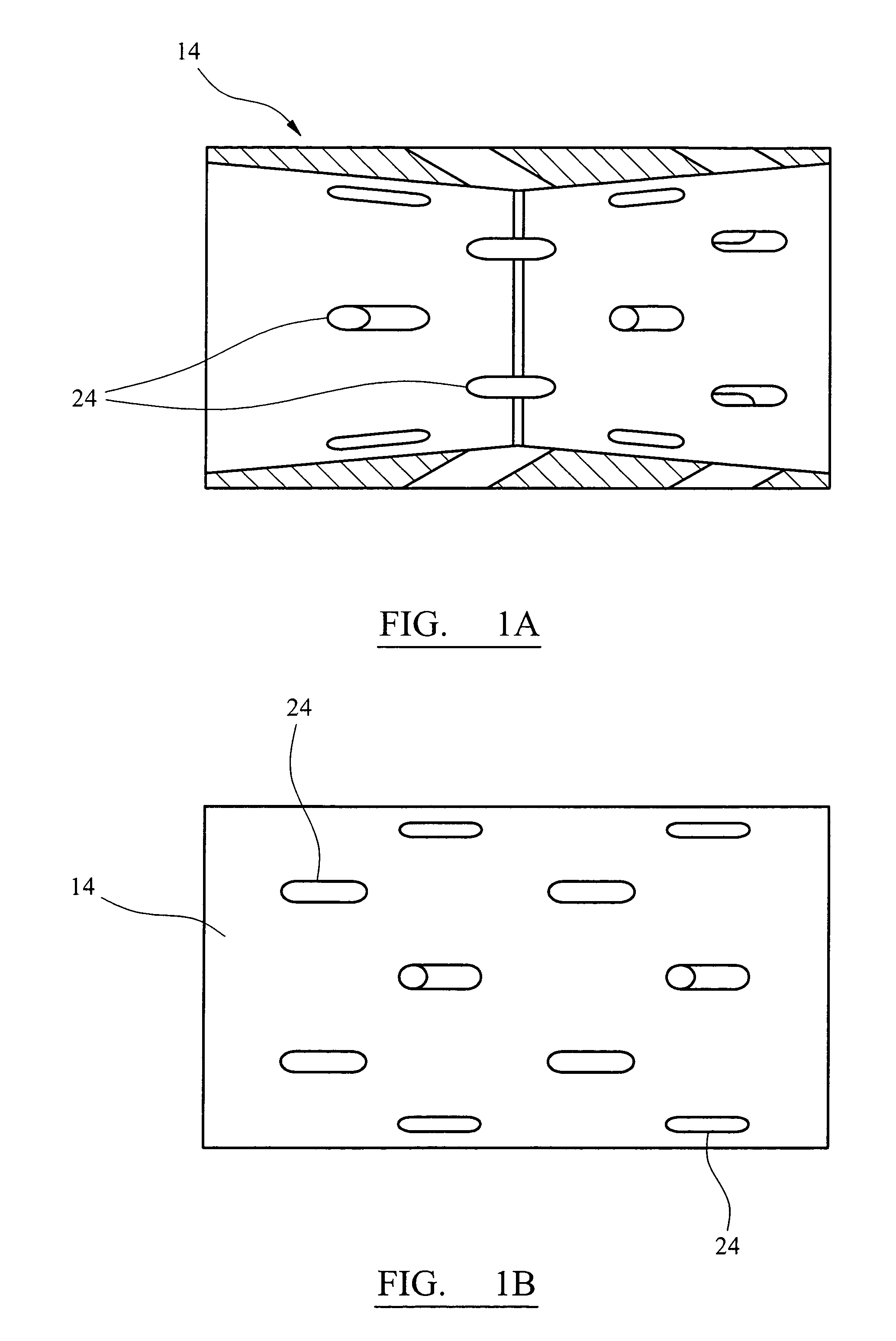

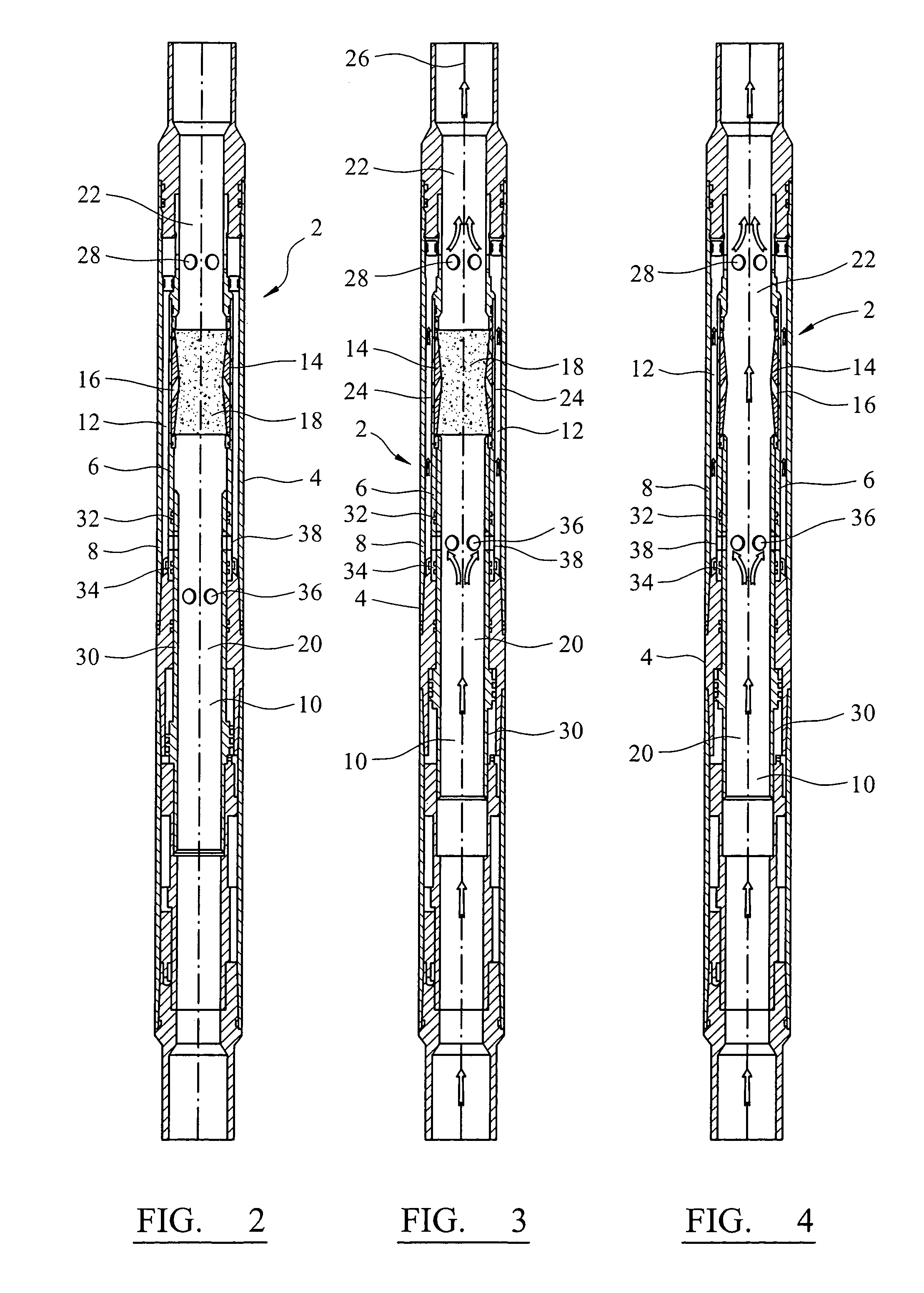

Pressure barrier apparatus

InactiveUS7703511B2Minimising risk of erosionReliable removalFluid removalWell/borehole valve arrangementsGuide tubeBiomedical engineering

A pressure barrier apparatus 2 for providing a removable pressure barrier in a borehole is described. The apparatus comprises a housing 6, 8 defining a central bore 10 having a first part 20 and a second part 22 separated by an erodeable pressure barrier member 18. The housing also defines a second fluid flow passage 12 for connecting the first part to the second part, and a plurality of conduits 24 for directing fluid onto the barrier member. A sleeve 30 has a first condition in which fluid communication between the first part 20 and the second fluid flow passage 12 is prevented, and a second condition in which fluid is permitted to flow from the first part to the second fluid flow passage to cause erosion of the barrier member.

Owner:OMEGA COMPLETION TECH

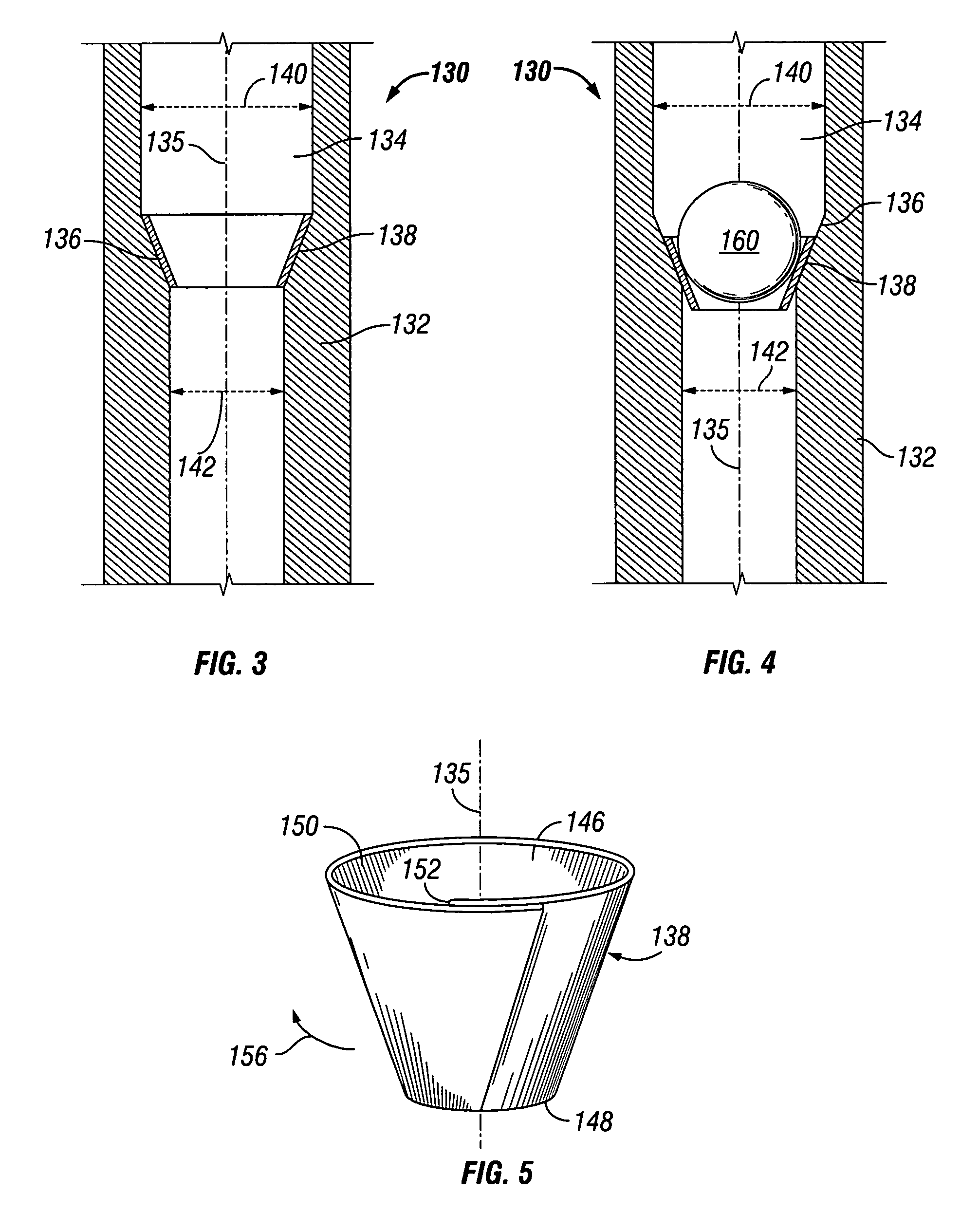

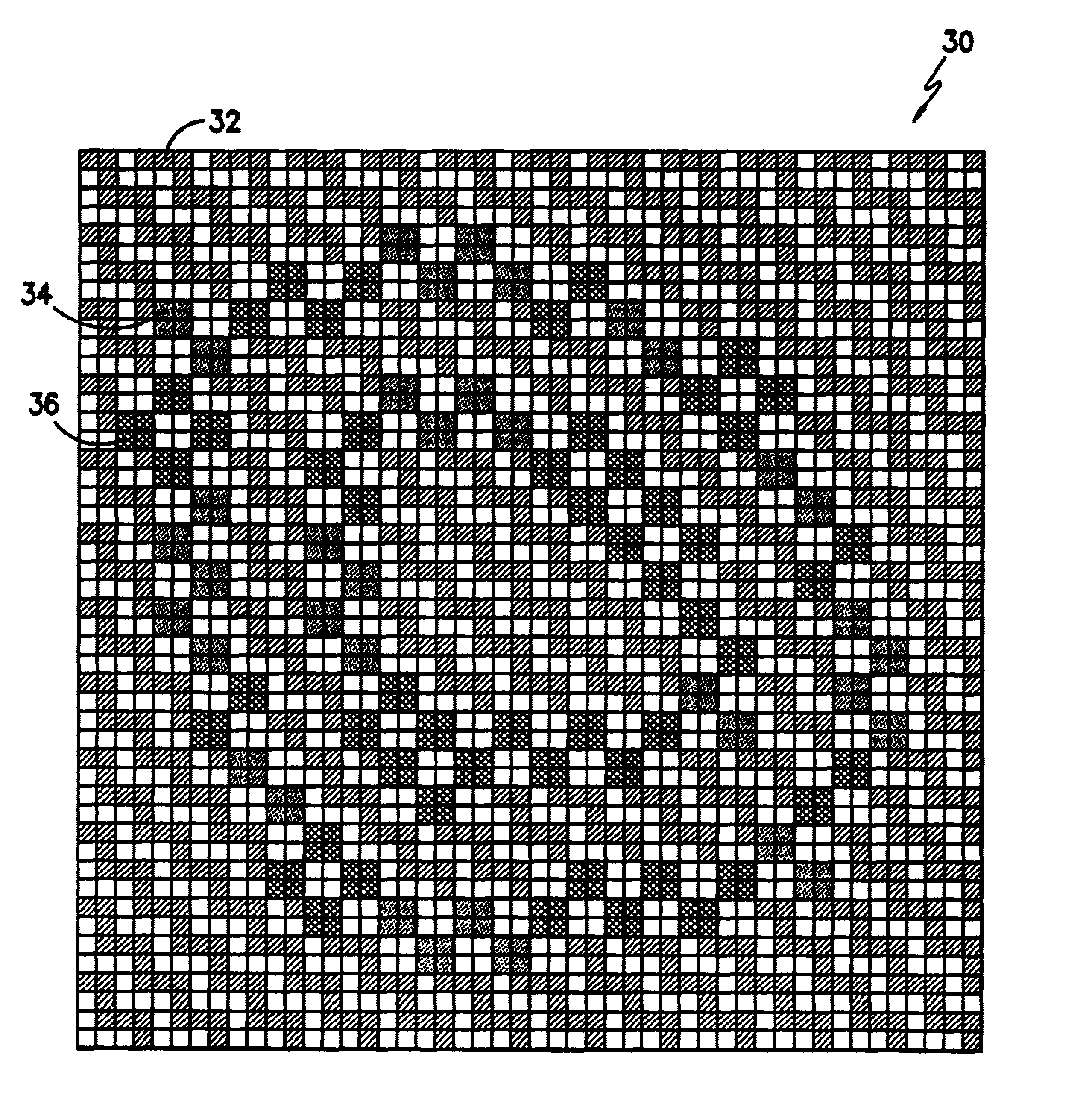

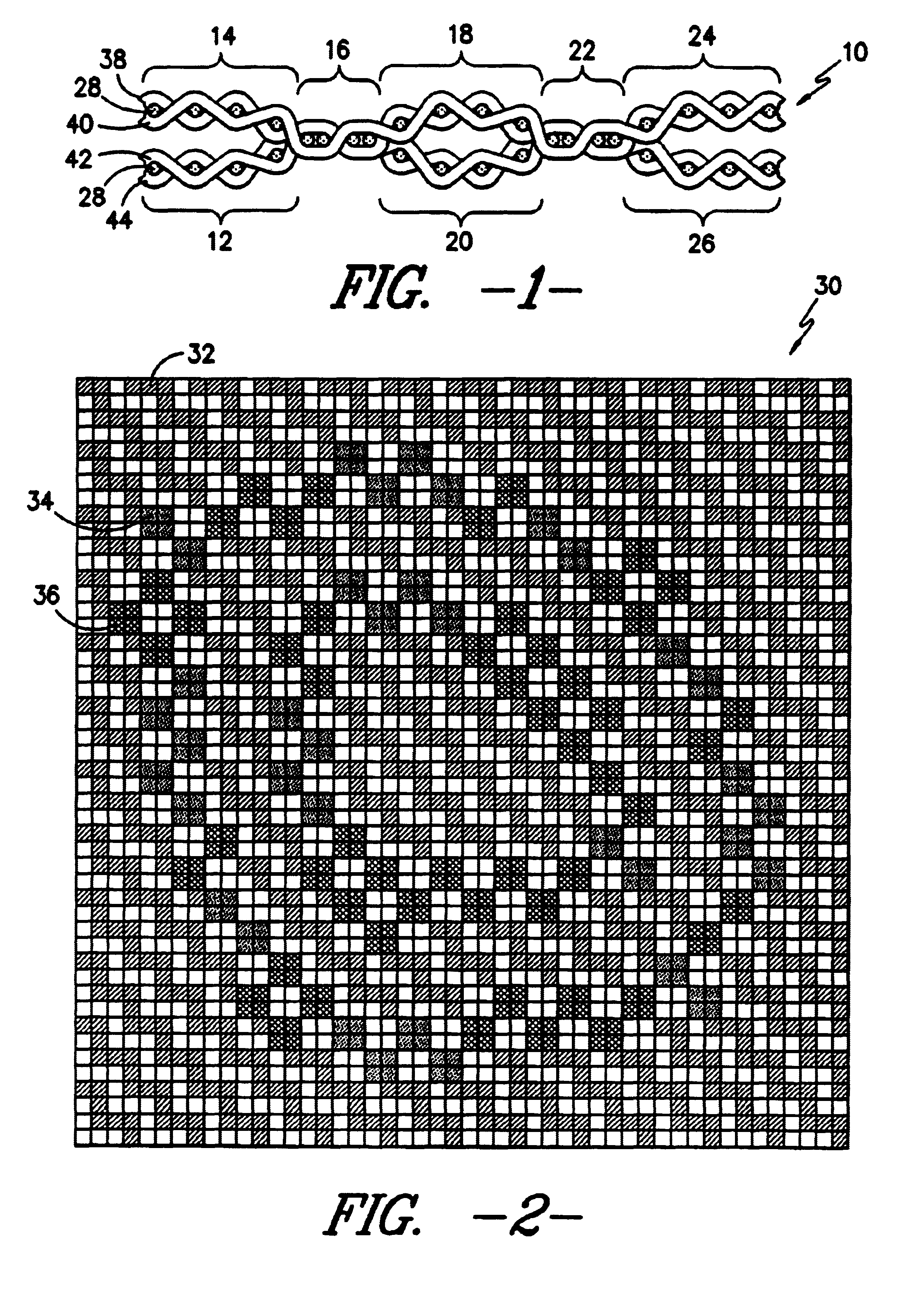

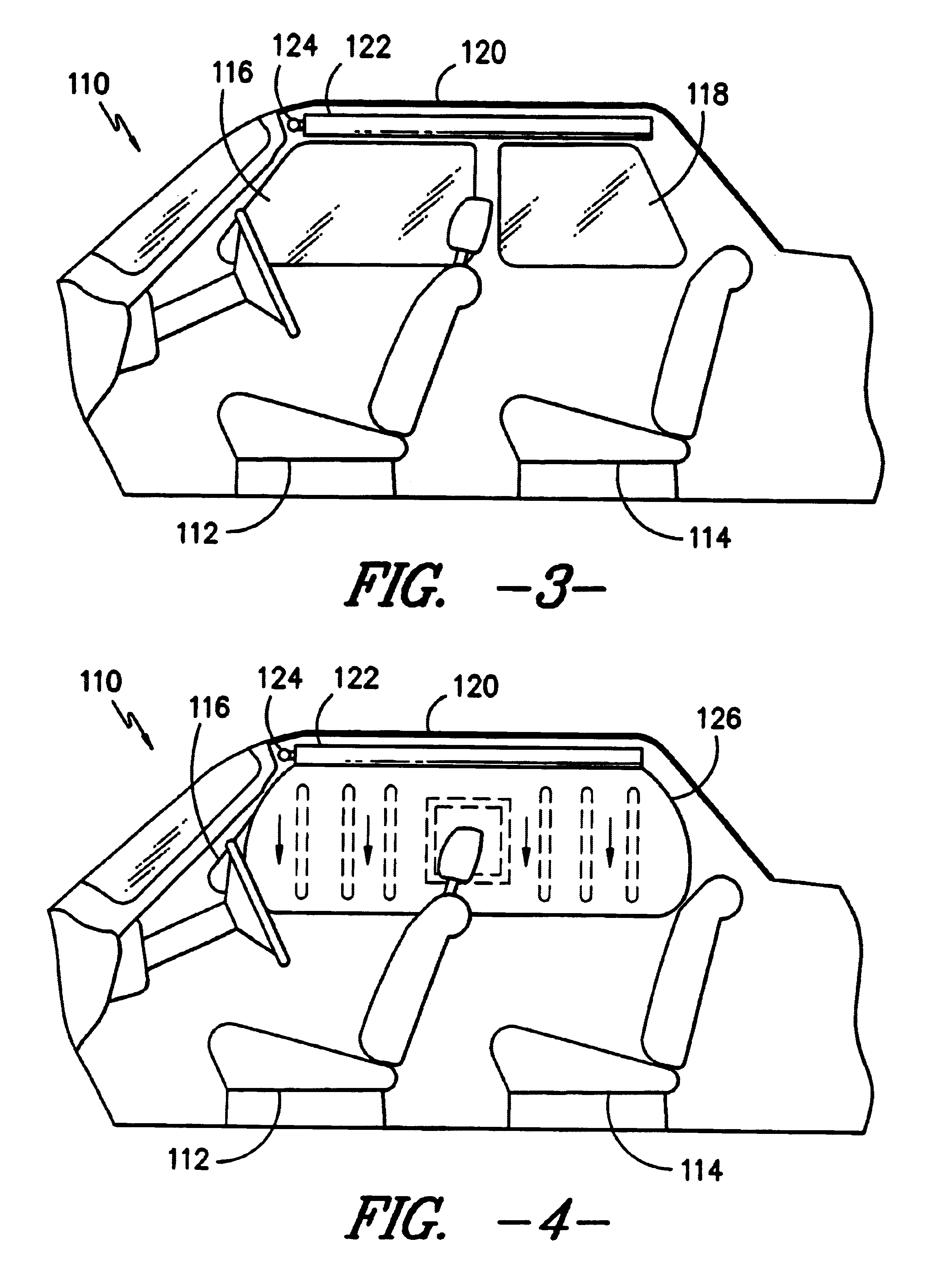

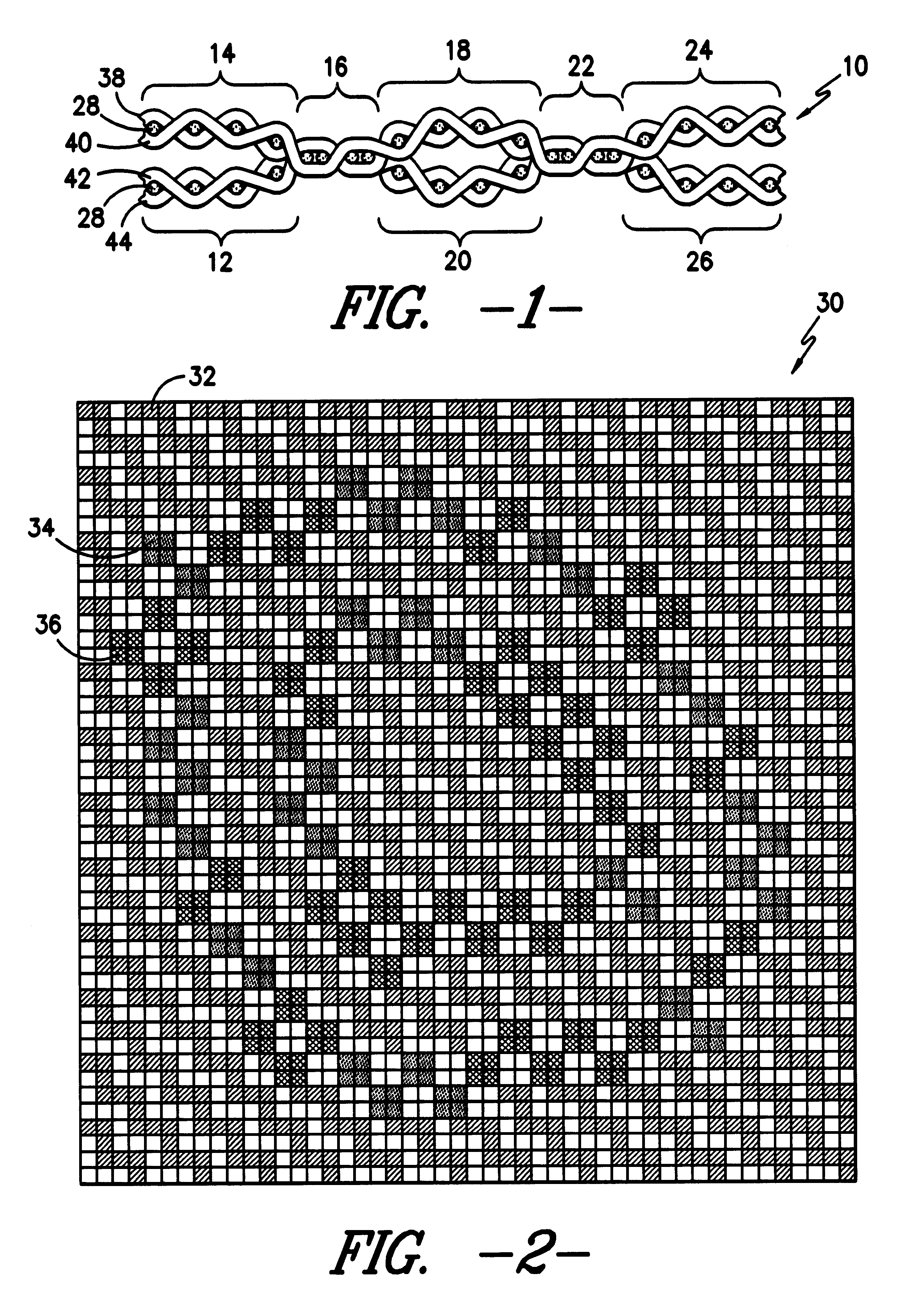

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6698458B1Beneficial and long-term low permeabilityExcellent long-term storage stabilityLeno shedding mechanismPreformed elementsNeopreneEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds wherein the film is present on the surface in an amount of at most 3.0 ounces per square yard of the fabric.

Owner:MILLIKEN & CO

Nasal respiratory devices for positive end-expiratory pressure

InactiveUS7806120B2Improve toleranceBreathe out easilyRespiratorsOperating means/releasing devices for valvesNosePositive pressure

Owner:THERAVENT

Ball seat having fluid activated ball support

ActiveUS7637323B2Reduce the possibilityReduce contact forceCheck valvesFluid removalEngineeringPiston

Apparatuses for closing a well conduit comprise a housing having a longitudinal bore and a seat disposed within the bore. A chamber is disposed within the housing and includes a plug element support member, such as ram or piston, operatively associated within the chamber. The plug element support member has a retracted position and an extended position. A passageway is in fluid communication with the bore and the chamber. A plug element such as a ball or drop plug, is adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit. Landing the plug element causes and allowing fluid pressure to build causes the plug element support member to move from the retracted position to the extended position to provide support to the plug element landed on the seat.

Owner:BAKER HUGHES INC

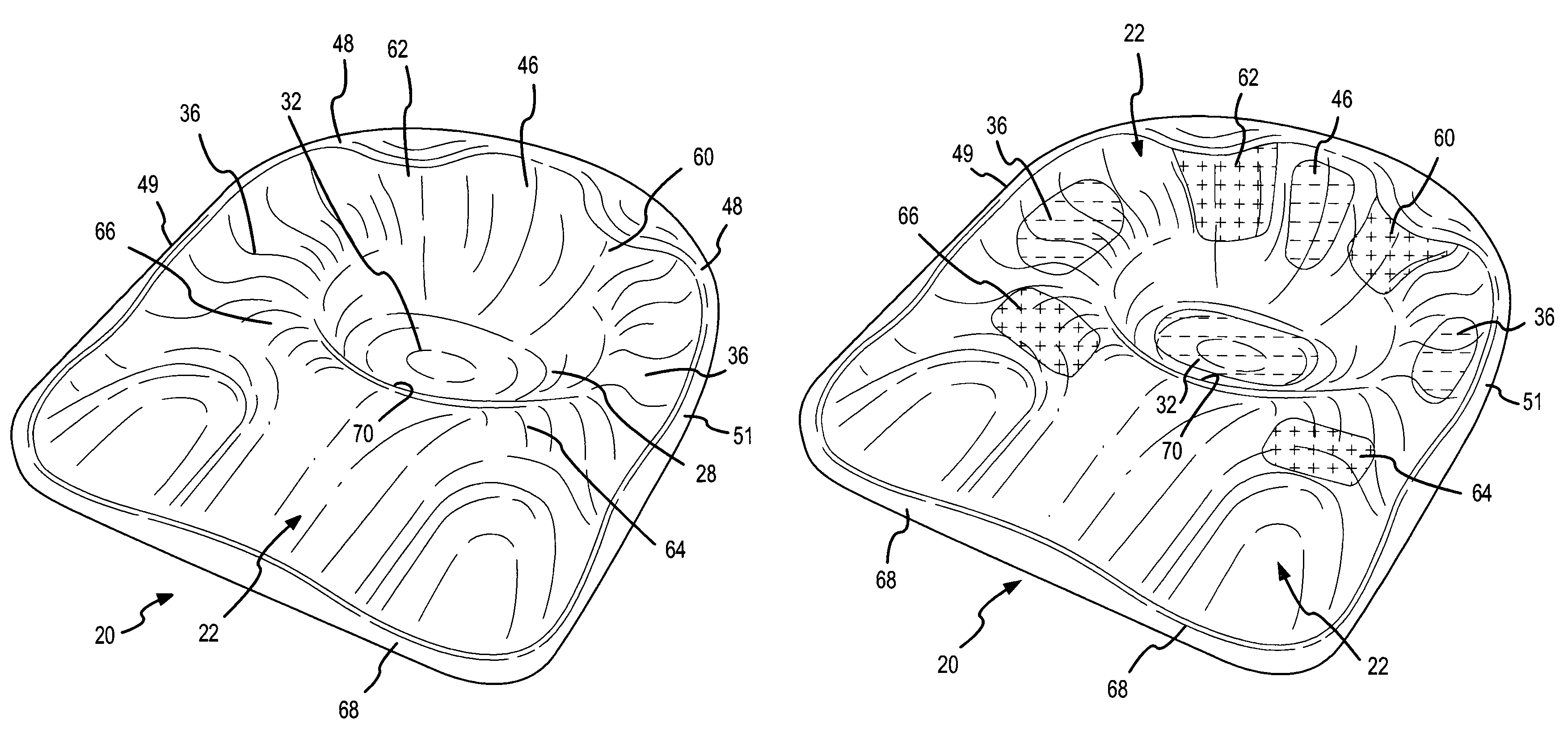

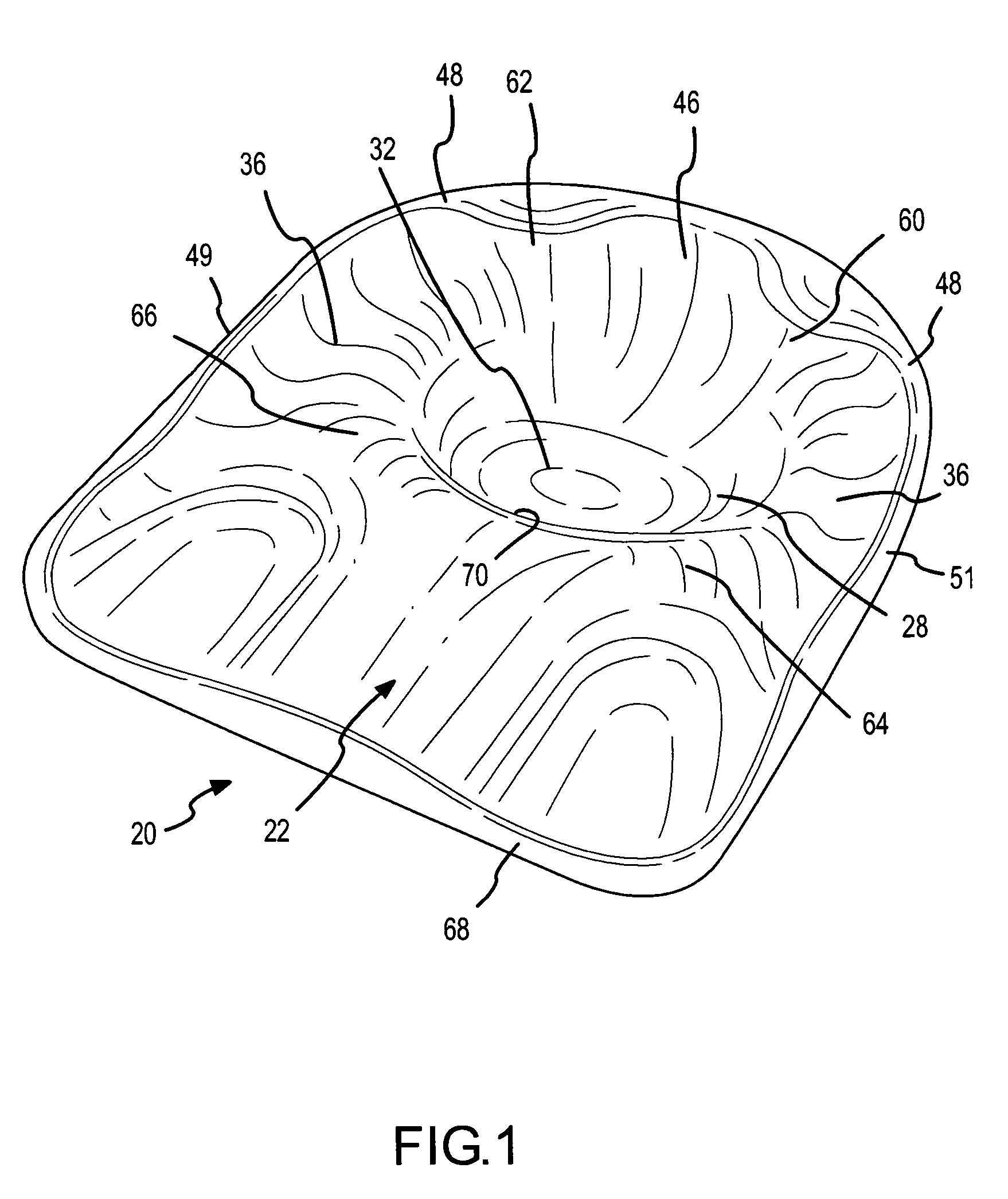

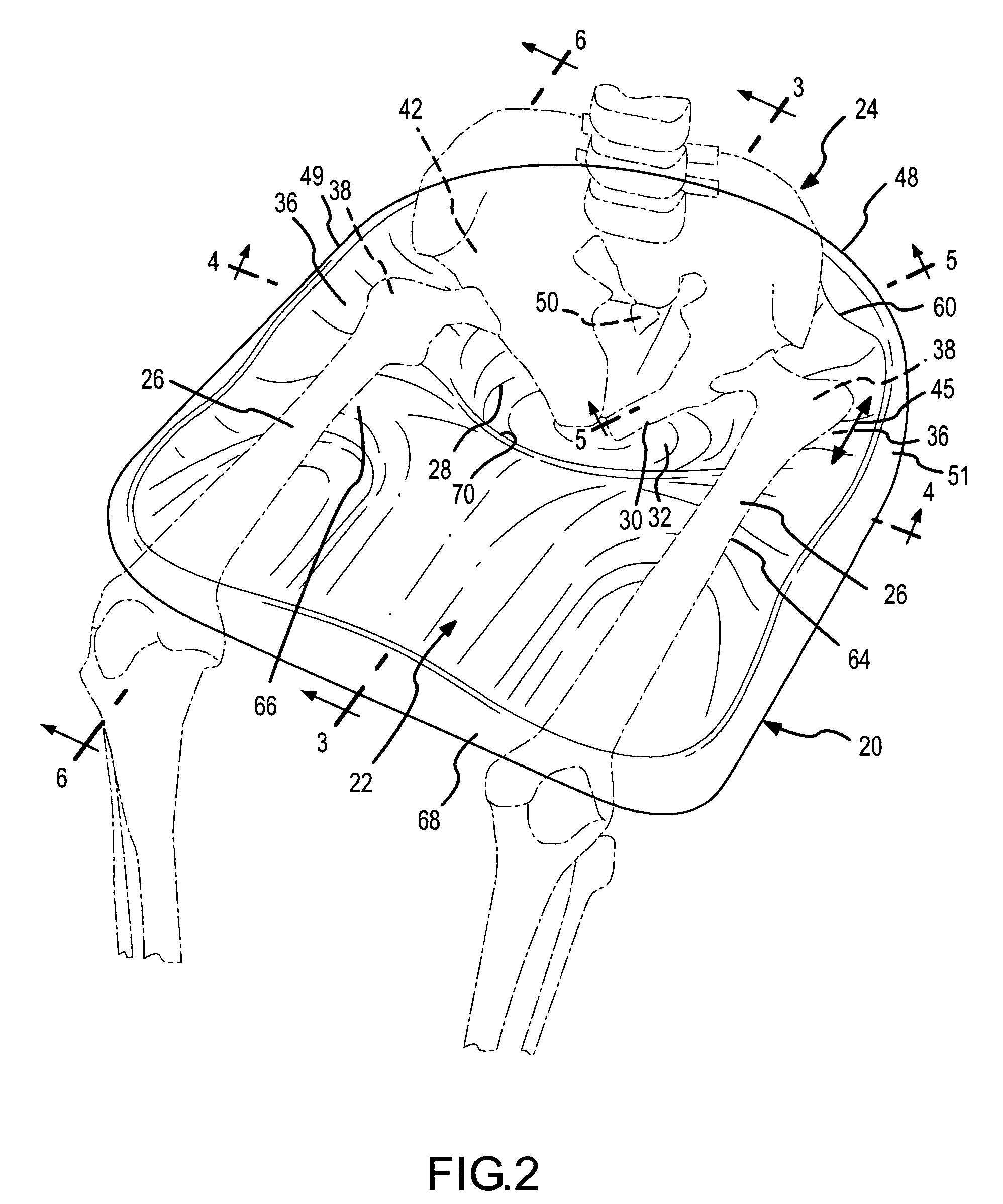

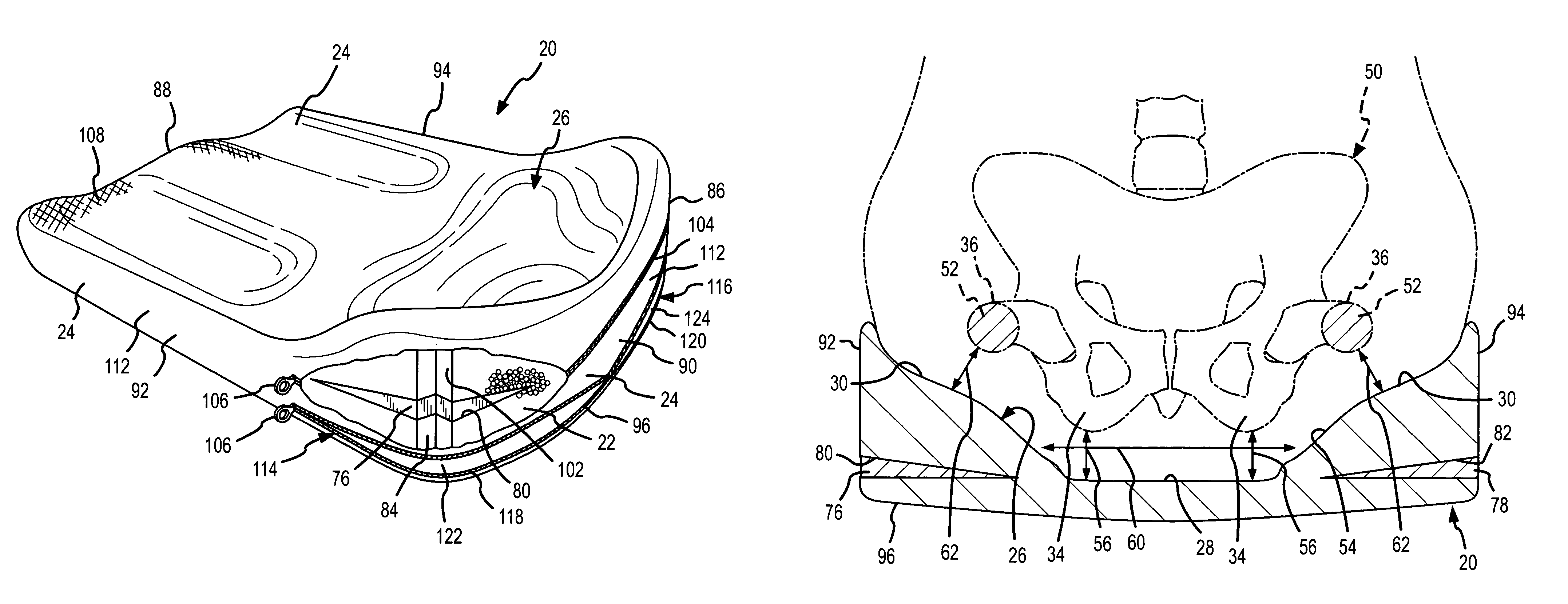

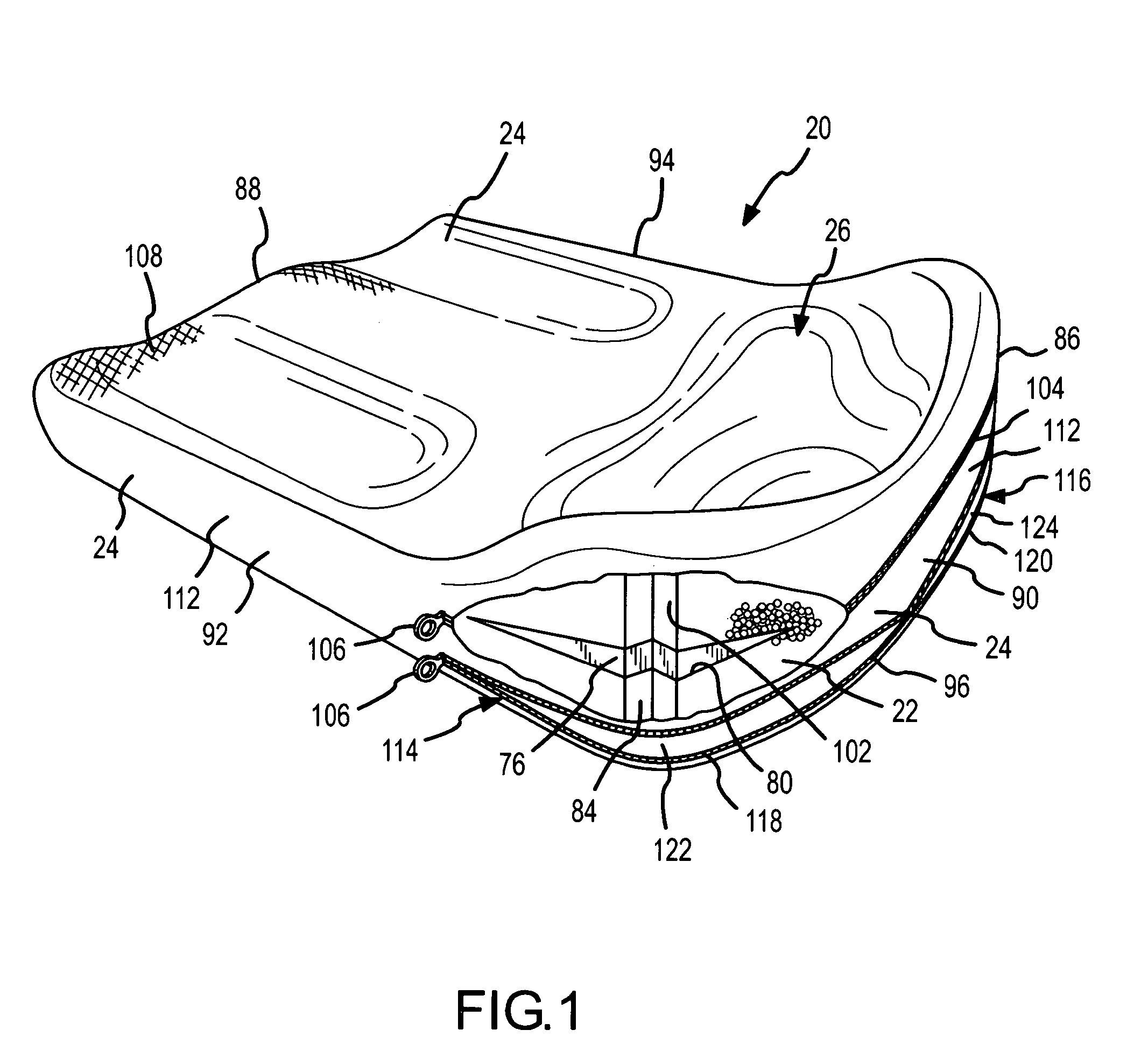

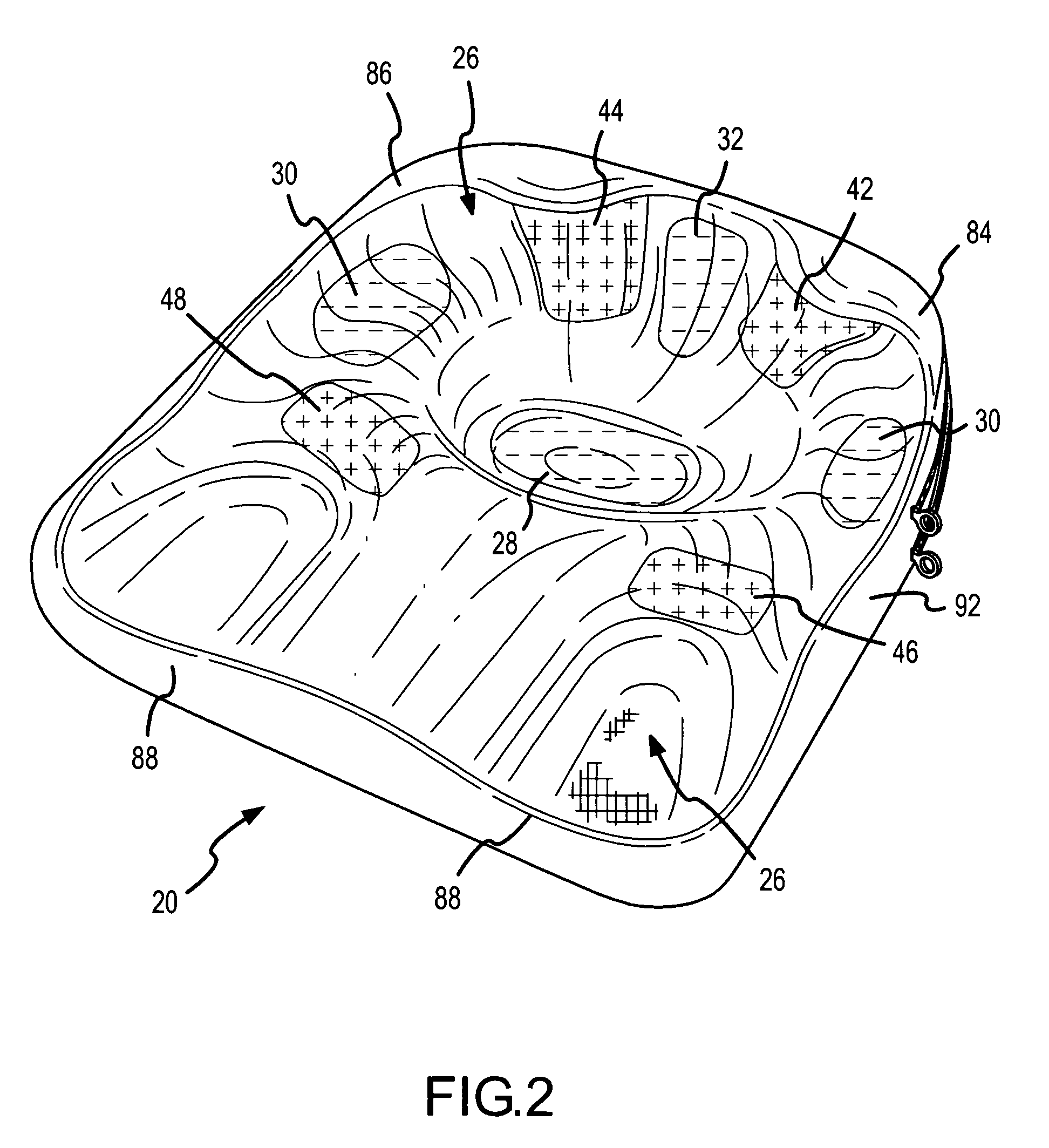

Contoured seat cushion and method for offloading pressure from skeletal bone prominences and encouraging proper postural alignment

InactiveUS7216388B2Reduce riskIncreased riskSofasWheelchairs/patient conveyanceSkin breakdownButtocks

A support contour of a cushion, such as a wheelchair cushion, defines relief areas at locations adjacent to skin covering the ischial tuberosities, the greater trochanters and the coccyx and sacrum of a person sitting on the support contour. Support areas of the support contour transfer force into the pelvic area adjacent to skin covering tissue masses on opposite lateral sides of the posterior buttocks and beneath the proximal thighs of the person. Greater clearance is also provided in the perineal area. Risks of pressure ulcers from pressure and shear forces on bony prominences is reduced while providing support at the broader areas without bony prominences in such a manner to encourage postural alignment. The risks of skin breakdown perineal are diminished.

Owner:ASPEN SEATING

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS20050084933A1Increased and enhanced sialic acid contentLow production costAnimal cellsCell receptors/surface-antigens/surface-determinantsBiotechnologyHigh cell

The present invention describes methods and processes for the production of proteins, particularly glycoproteins, by animal cell or mammalian cell culture, illustratively, but not limited to, fed-batch cell cultures. The methods comprise feeding the cells with D-galactose, preferably with feed medium containing D-galactose, preferably daily, to sustain a sialylation effective level of D-galactose in the culture for its duration, thus increasing sialylation of the produced proteins. The methods can also comprise at least two temperature shifts performed during the culturing period, in which the temperature is lower at the end of the culturing period than at the time of initial cell culture. The cell culture processes of the invention involving two or more temperature shifts sustain a high cell viability, and can allow for an extended protein production phase. The methods can also comprise the delayed addition of polyanionic compound at a time after innoculation. Supplementation of the cultures with D-galactose, preferably in a feed medium, to sustain galactose at sialylation effective levels in the cultures until the end of a culture run reverses a decline in sialylation that accompanies culture scale up, and is advantageous for large scale culturing processes.

Owner:BRISTOL MYERS SQUIBB CO

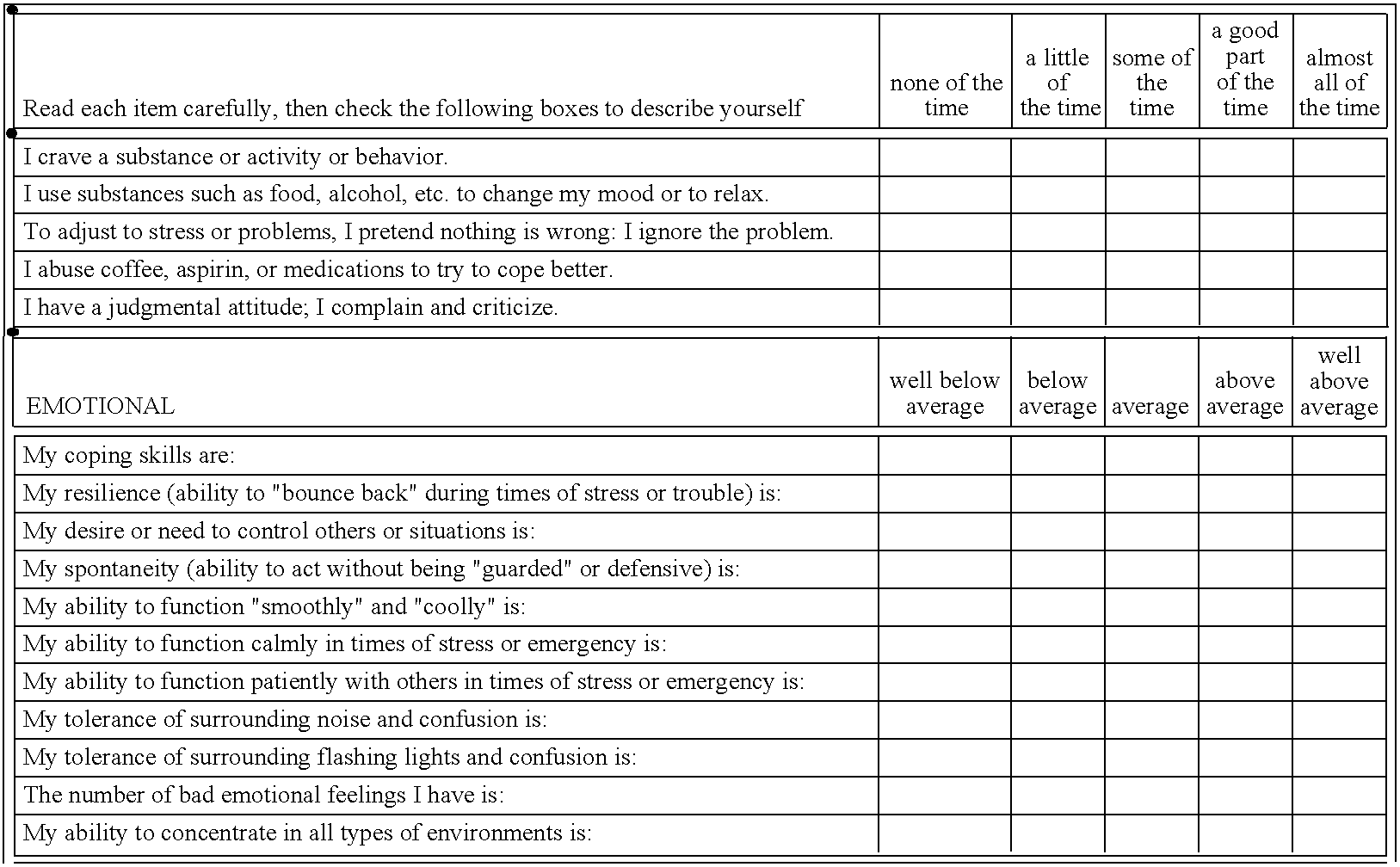

Diagnosis and treatment system for reward deficiency syndrome (RDS) and related behaviors

InactiveUS6955873B1Reduce the amount requiredLow caloric dietBiocideHydroxy compound active ingredientsNervous systemAllelotype Analysis

The present invention relates to a kit and an intervenously administrable preparation, both, with a signal transmitter precursor, an enhancer of precursor uptake, and an inhibitor of neurotransmitter reuptake or signal transmitter catabolism. The kit also contains an appropriate swab for obtaining oral cells suitable for allelic analysis. The intervenous formulation contains similar materials and, in some cases, ethanol. Either the kit composition or the intervenous formulation may be used as guided by a subjects allelic analysis. Collections of particular alleles, especially those relating to neural system are comprehensible in terms of likelihood of success in the administration of an interveinous formulation or ingestion of components of the subject kit.

Owner:SYNAPTAMINE INC

Ball seat having ball support member

ActiveUS20120261115A1Reduce the possibilityIncrease pressureFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Apparatuses for restricting fluid flow through a well conduit comprise a tubular member having an inner wall surface defining a bore and a seat in sliding engagement with the inner wall surface. Operatively associated with the seat is a plug element support member having an expanded position when the apparatus is in a run-in position and a contracted position when the apparatus is in a set position. A plug element adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit is used to move the seat which in turn moves the plug element support member from the expanded position to the contracted position, thereby providing support to the plug member landed on the seat.

Owner:BAKER HUGHES INC

Seat cushion with adjustable contour and method of adjusting the contour of a seat cushion

Owner:ASPEN SEATING

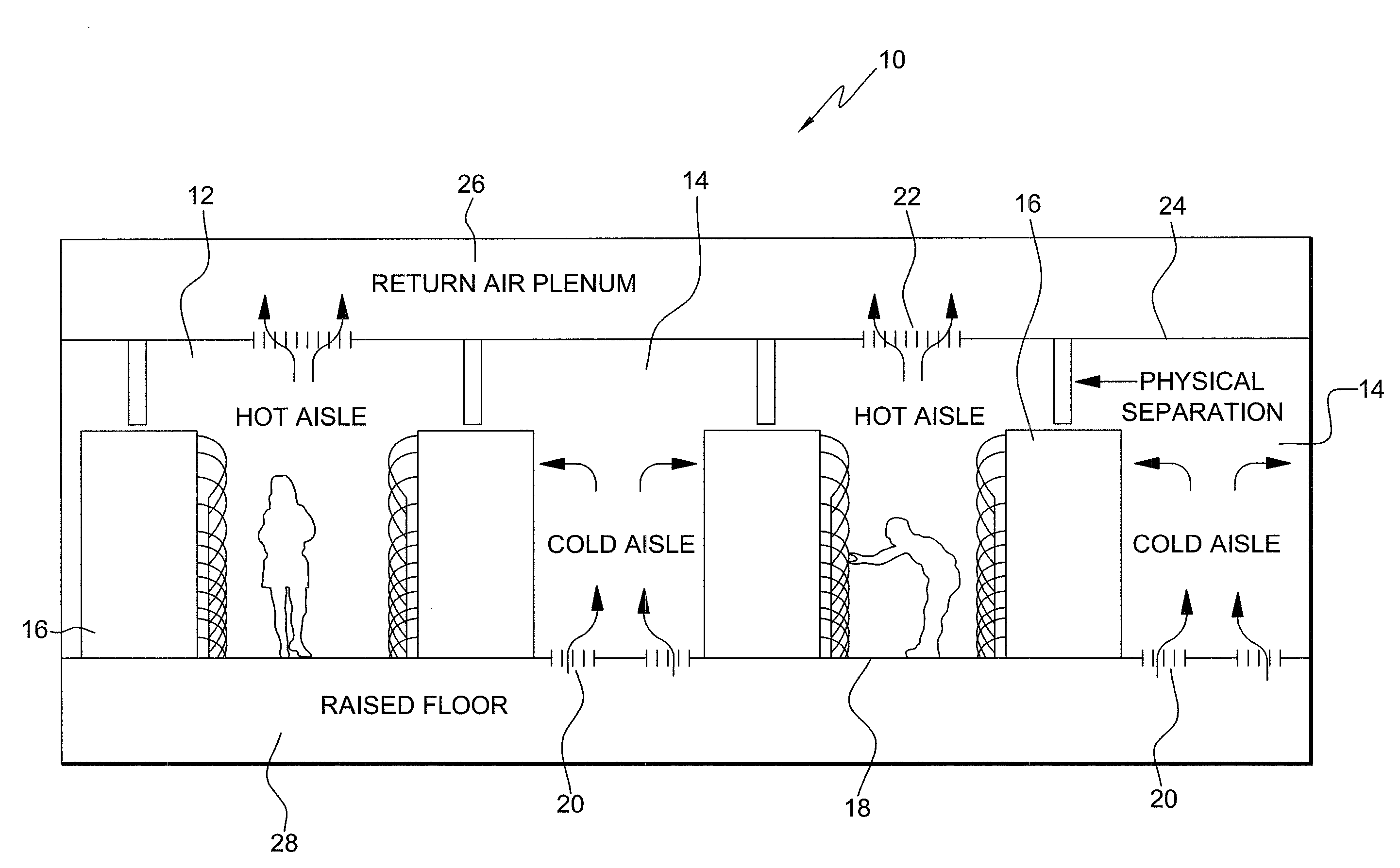

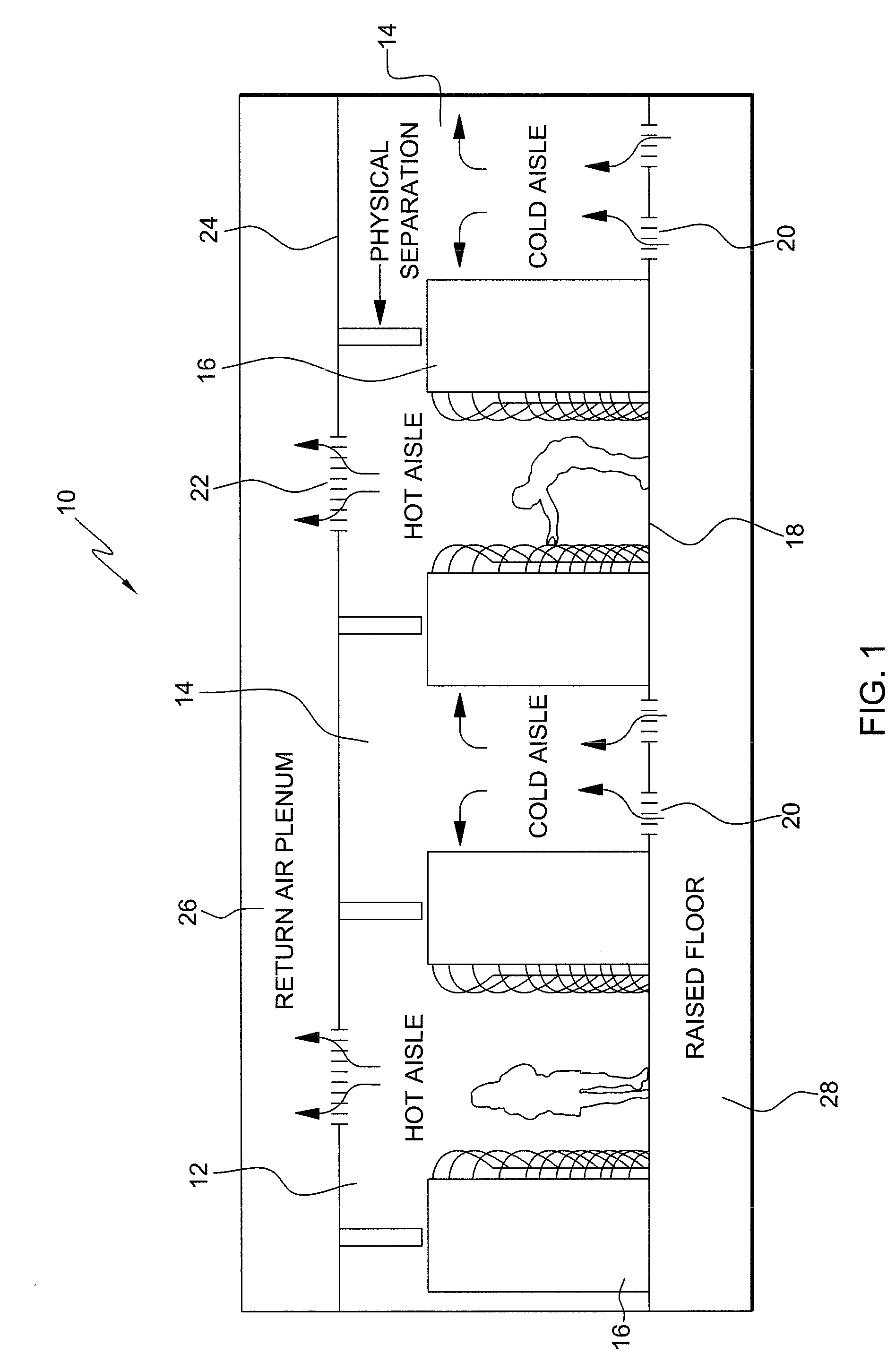

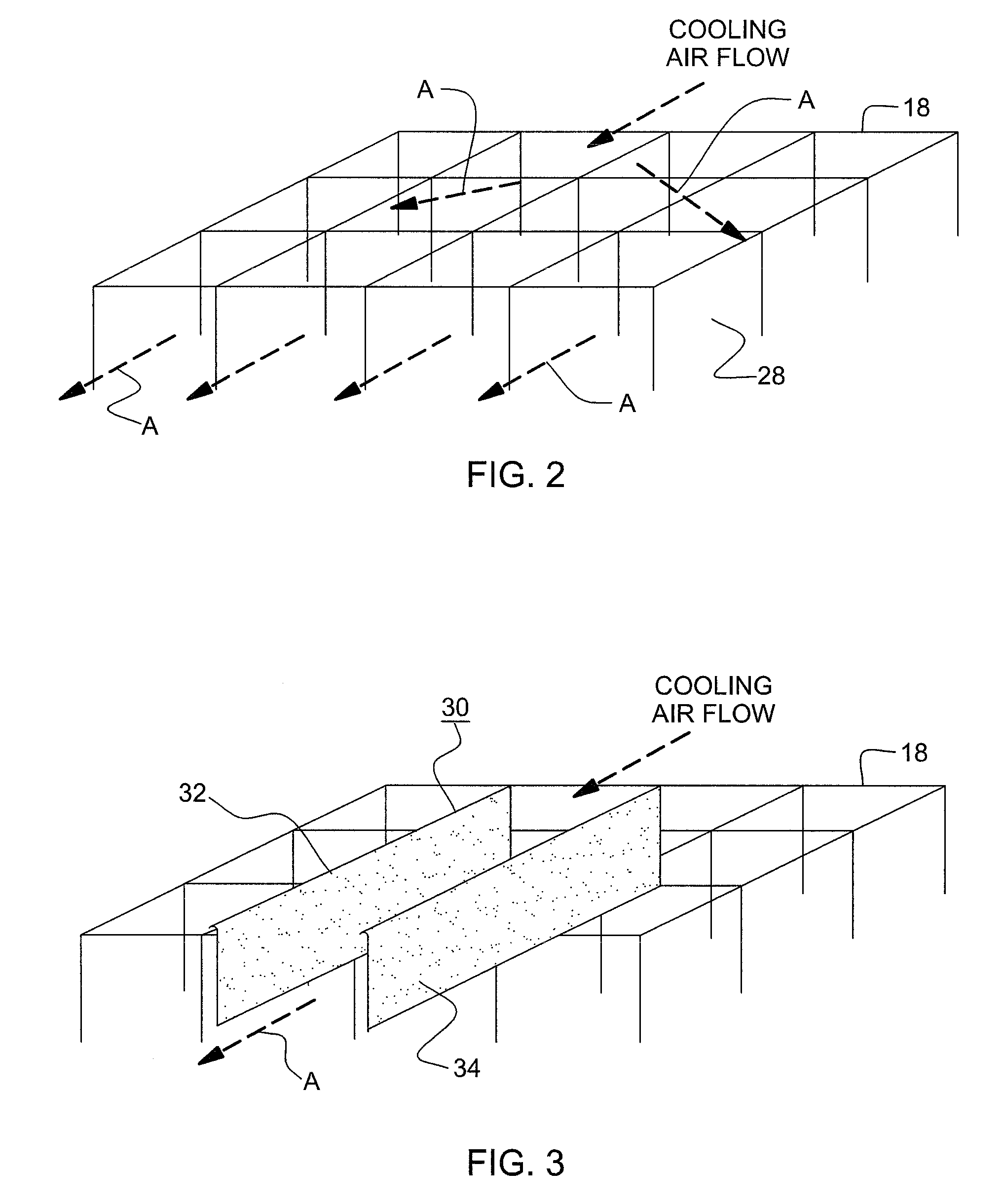

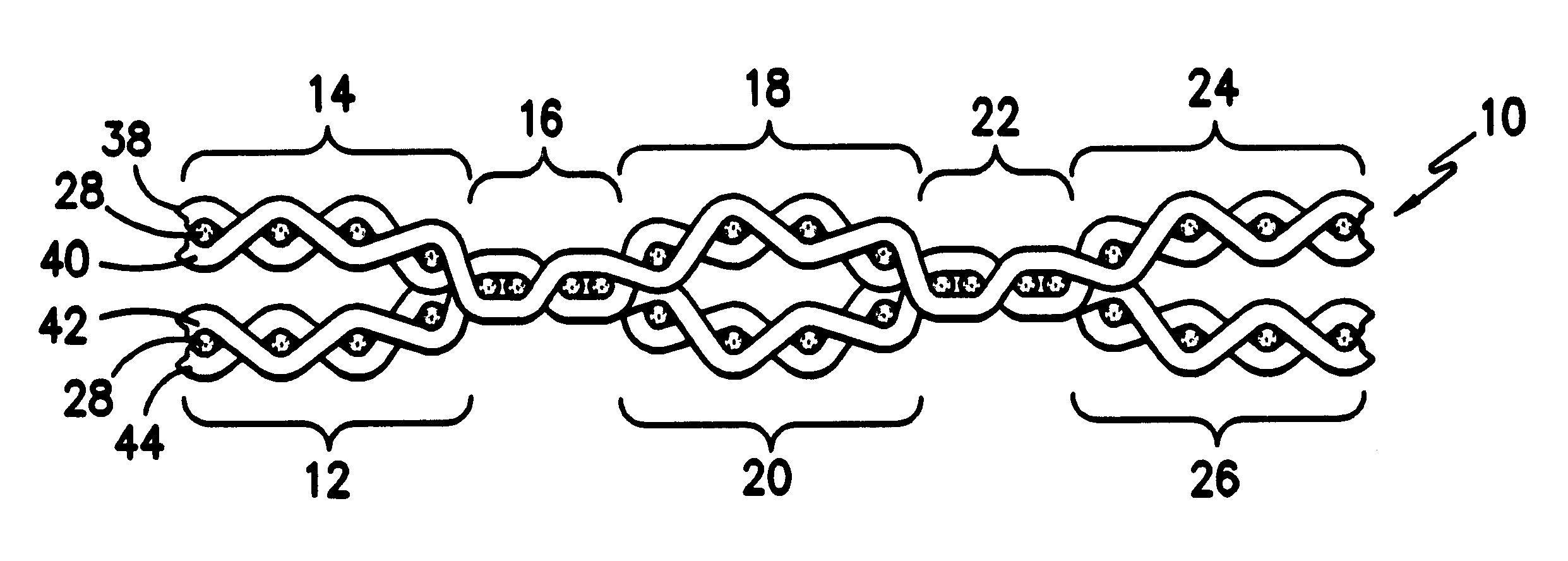

Air permeable material for data center cooling

InactiveUS20100190430A1Prevent any undue pressure buildMore and more conditionElectrical apparatus contructional detailsElectrical apparatus casings/cabinets/drawersData centerAir conditioning

An arrangement for the controllable cooling of a data center, and more particularly, pertains to an arrangement for the provision of an improved computer room air-conditioning system (CRACS), which utilizes the installation of equipment above a raised floor and enables cooling air to be controllably dispensed through ducting installed below the computer installations. Also provided is a method for the controllable cooling of data center installations.

Owner:IBM CORP

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6429155B1High leak-down timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementEngineeringNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds as well as a very low packing volume (for more efficient use of storage space within a vehicle) for the target side curtain airbag.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com