Surgical binding instrument binding mechanism

A stapler and surgical technology, applied in the field of medical devices, can solve problems such as failure of surgery, difficulty in withdrawing the nail anvil, increase the area of tissue being punched, etc., so as to facilitate rapid recovery, reduce the chance of damaging the anastomotic ring, and increase conditioning effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

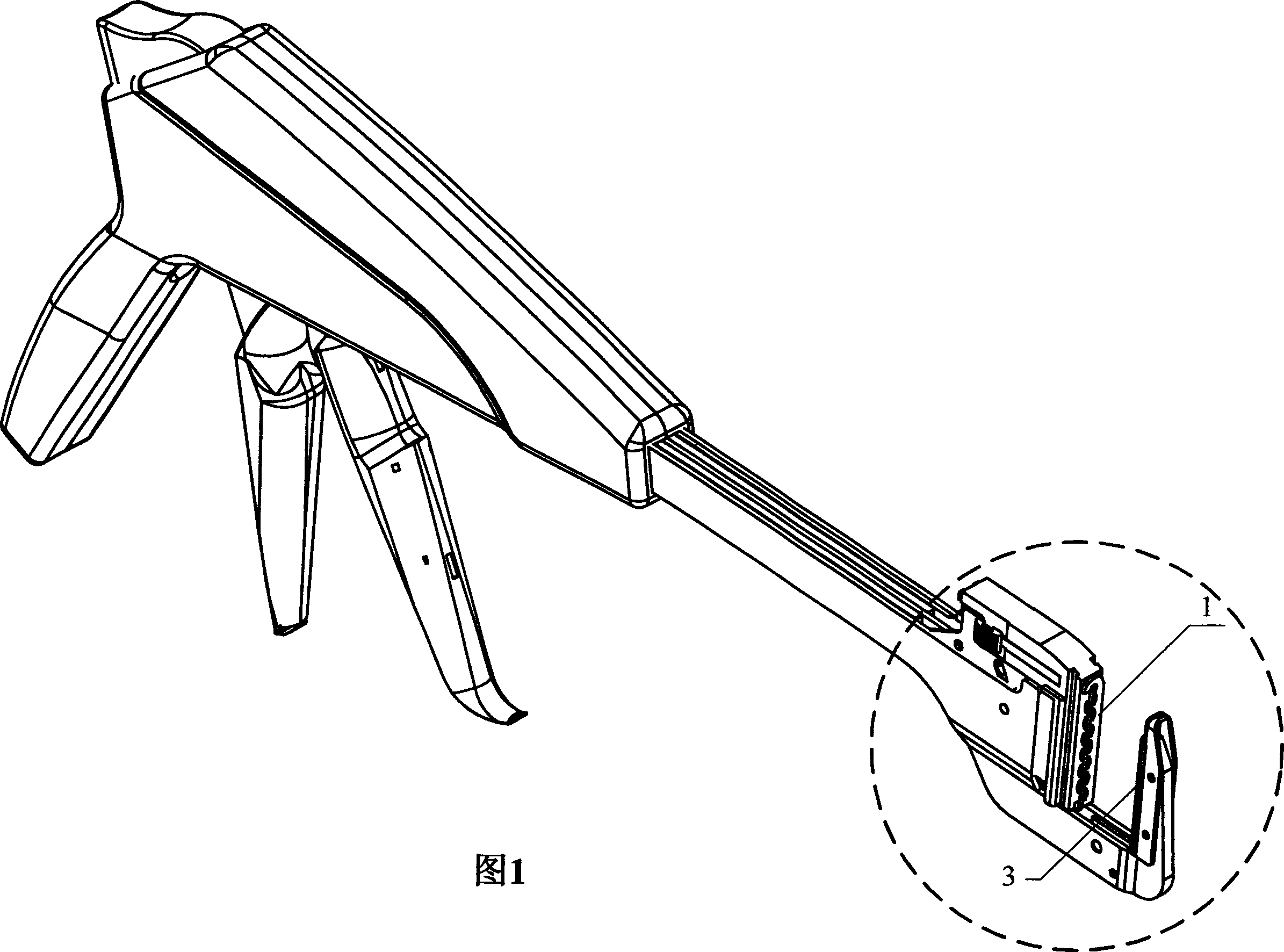

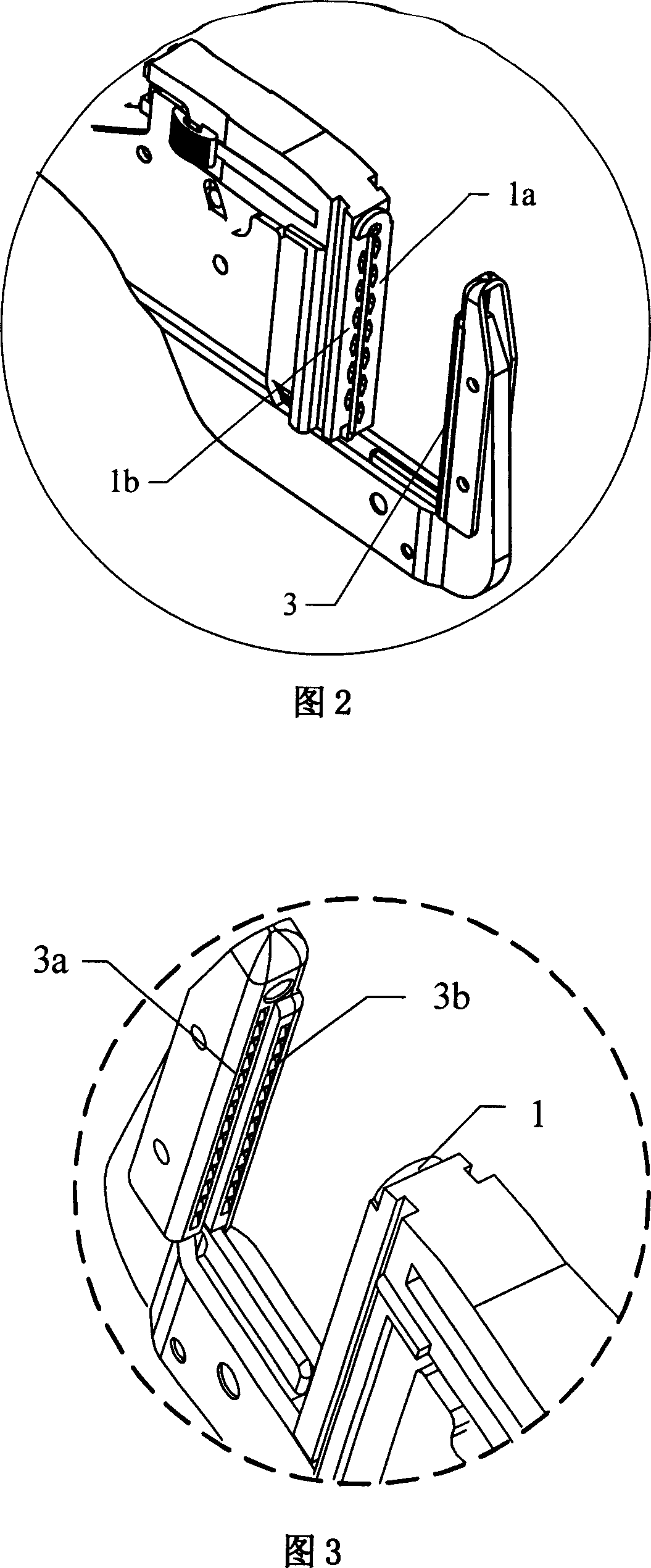

[0030] The stepped binding mechanism shown in Figures 1-3 includes a staple bin 1, a nail pusher 2 and an anvil 3, the nail pusher 2, and the staple bin 1 are installed in the body of the binding instrument, and the nail anvil 3 and the pusher The positions of the nail pieces 2 are corresponding, wherein: the working surfaces of the nail cartridge 1, the nail pushing piece 2 and the nail anvil 3 are not on the same horizontal plane, and at least present a step-like drop distribution structure, and the aforementioned steps are linear steps. That is to say, the staple cartridge 1, the nail pusher 2 and the nail anvil 3 are all linear, and more specifically, the distribution of the staple cartridge 1 and the nail pusher 2 is a linear step with a low inside and a high outside. The distribution of the corresponding nail anvil 3 is a linear step with a high inside and a low outside. It can be seen from Fig. 2 and Fig. 3 that the staple cartridge 1a is higher than the staple cartrid...

Embodiment 2

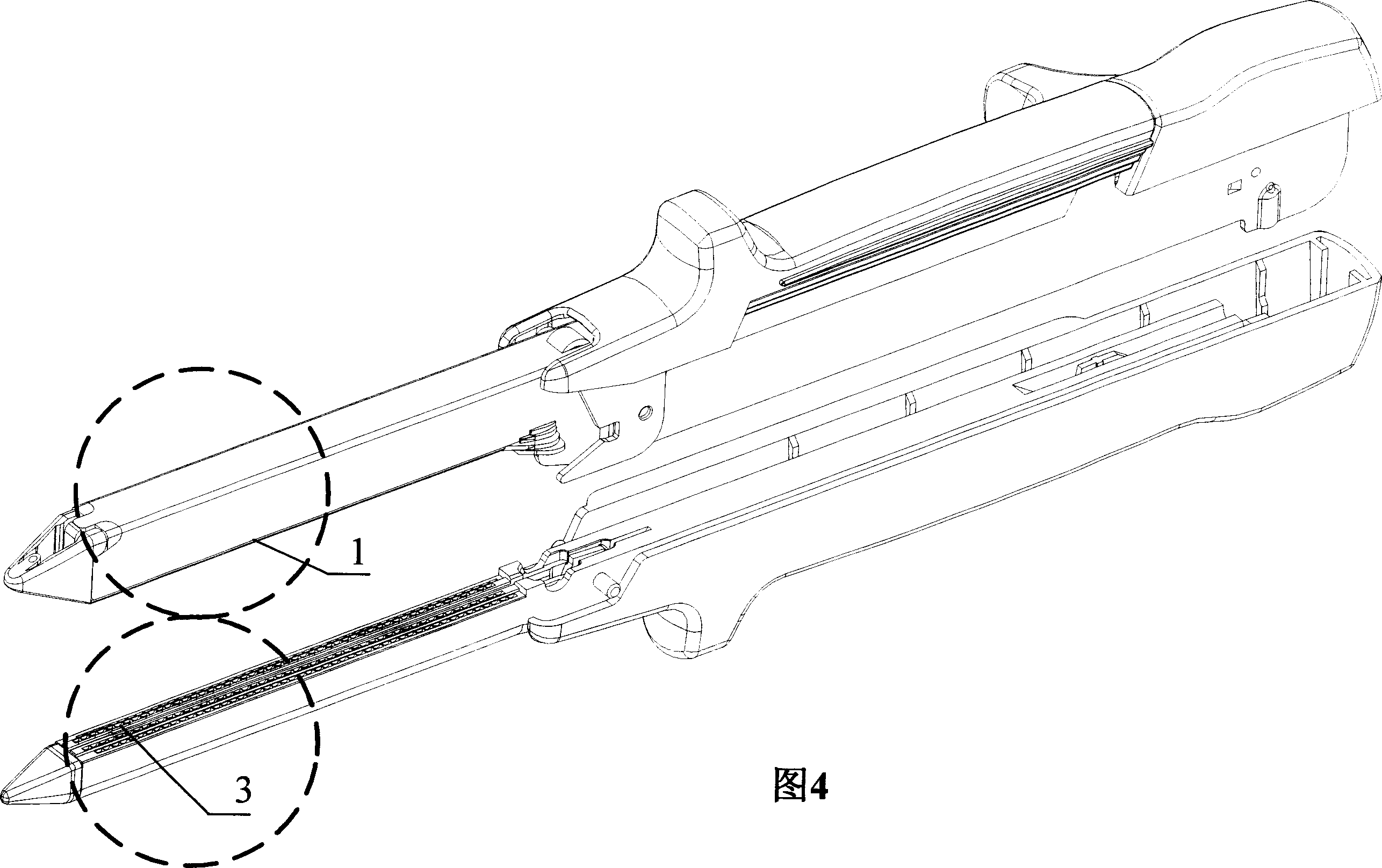

[0033] The stepped binding mechanism shown in Figures 4-6 includes a staple bin 1, a nail pusher 2 and an anvil 3, the nail pusher 2, and the staple bin 1 are installed in the body of the binding instrument, and the nail anvil 3 and the pusher The positions of the nail pieces 2 are corresponding, wherein: the working surfaces of the nail cartridge 1, the nail pushing piece 2 and the nail anvil 3 are not on the same horizontal plane, and at least present a step-like drop distribution structure, and the aforementioned steps are linear steps. That is to say, the staple cartridge 1, the staple pusher 2 and the staple anvil 3 are all linear and bilaterally symmetrical. More specifically, the distribution of the anvils 3 is that the middle two rows are higher than the two outer layers, as shown in Fig. 6, the anvils 3a, 3b are higher than the anvils 3c, 3d. The overall shape is "convex", which is opposite to the distribution of the corresponding staple cartridges 1 and pusher piece...

Embodiment 3

[0035] The stepped binding mechanism shown in Figures 7-10 includes a staple bin 1, a nail pusher 2 and an anvil 3, the nail pusher 2, and the staple bin 1 are installed in the body of the binding instrument, and the nail anvil 3 and the pusher The positions of the nail pieces 2 are corresponding, wherein: the working surfaces of the nail cartridge 1, the nail pushing piece 2 and the nail anvil 3 are not on the same level, and at least present a step-like drop distribution structure, and the aforementioned steps are circular arcs shaped steps, and finally formed into a closed circle. That is to say, the staple cartridge 1 presents a closed circle with stepped distribution, and the inner circle is lower than the outer circle, that is, the staple cartridge 1 a is lower than the staple cartridge 1 b as shown in FIG. 9 . Similarly, the pusher piece 2 also presents a closed circle with stepped distribution, and the inner ring is lower than the outer ring, that is, the pusher piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com