Method for preparing high carbon ferro-chrome by fusible chrome fine ore

A technology of high-carbon ferrochrome and chromium powder, which is applied in the field of high-carbon ferrochrome and its preparation, can solve the problems of insufficient submerged arc furnace load, unstable slag and iron discharge, poor gas permeability of the material layer, etc., and achieve cold strength Good, save power consumption, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

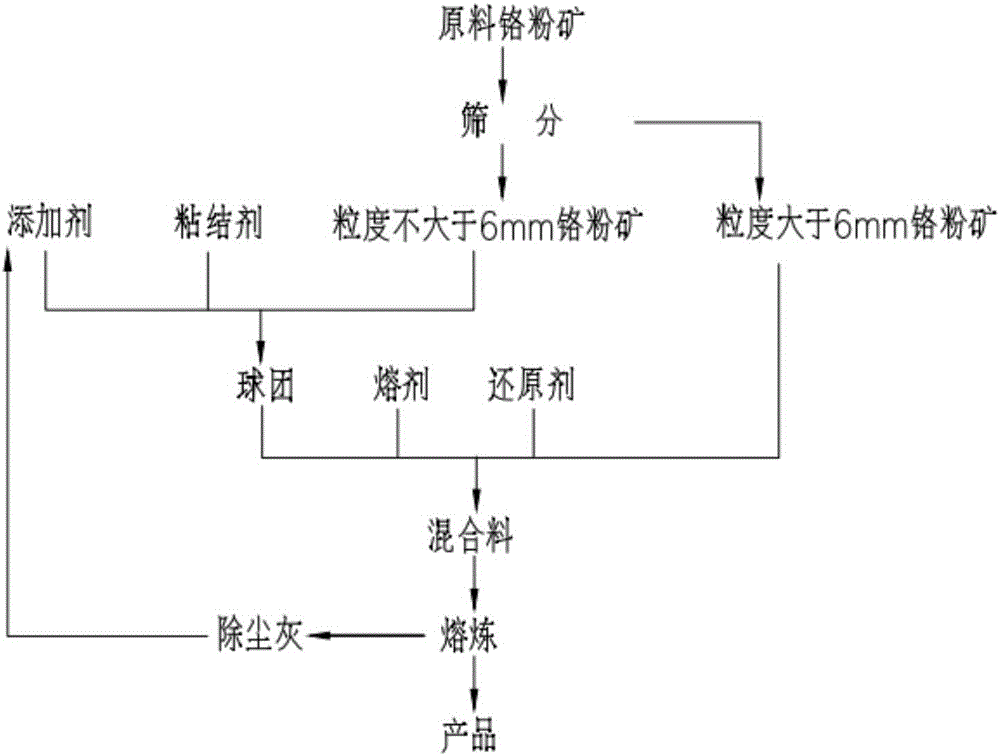

Method used

Image

Examples

Embodiment 1

[0052] (1) drying and sieving the fusible chrome powder ore to obtain no more than 6mm chrome powder ore and greater than 6mm chrome powder ore;

[0053] (2) Mix chromium powder no larger than 6mm, calcium oxide, and syrup in a ratio of 917:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0054] Mix chromium powder ore less than 6mm, dust ash, calcium oxide and syrup according to the ratio of 904:13:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0055] (3) The two types of pellets obtained in step (2) are mixed with the chrome powder ore larger than 6mm obtained in step (1), silica, magnesite, dolomite, and carbonaceous reducing agent according to a certain proportion and mixed. Table 1 shows the chemical composition and batching ratio of various types of ores put into the furnace (wherein, percentages are mass percentages, and batching ratios are weight ratios).

[0056] Table 1

[0057] Cr 2 o 3

FeO ...

Embodiment 2

[0061] (1) drying and sieving the fusible chrome powder ore to obtain no more than 6mm chrome powder ore and greater than 6mm chrome powder ore;

[0062] (2) Mix chromium powder no larger than 6mm, calcium oxide, and syrup in a ratio of 917:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0063] Mix chromium powder ore less than 6mm, dust ash, calcium oxide and syrup according to the ratio of 904:13:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0064] (3) The two types of pellets obtained in step (2) are mixed with the chrome powder ore larger than 6mm obtained in step (1), silica, magnesite, dolomite, and carbonaceous reducing agent according to a certain proportion and mixed. Table 2 shows the chemical composition and batching ratio of various types of ores put into the furnace (wherein, percentages are mass percentages, and batching ratios are weight ratios).

[0065] Table 2

[0066] Cr 2 o 3

FeO ...

Embodiment 3

[0070] (1) drying and sieving the fusible chrome powder ore to obtain no more than 6mm chrome powder ore and greater than 6mm chrome powder ore;

[0071] (2) Mix chromium powder no larger than 6mm, calcium oxide, and syrup in a ratio of 917:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0072] Mix chromium powder ore less than 6mm, dust ash, calcium oxide and syrup according to the ratio of 904:13:23:60, and press them into pellets. The pellet size was 75 x 40 x 23mm.

[0073] (3) The two types of pellets obtained in step (2) are mixed with the chrome powder ore larger than 6mm obtained in step (1), silica, magnesite, dolomite, and carbonaceous reducing agent according to a certain proportion and mixed. Table 3 shows the chemical composition and batching ratio of various types of ores put into the furnace (wherein, percentages are mass percentages, and batching ratios are weight ratios).

[0074] table 3

[0075] Cr 2 o 3

FeO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com