Patents

Literature

279results about How to "Reduce bring in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

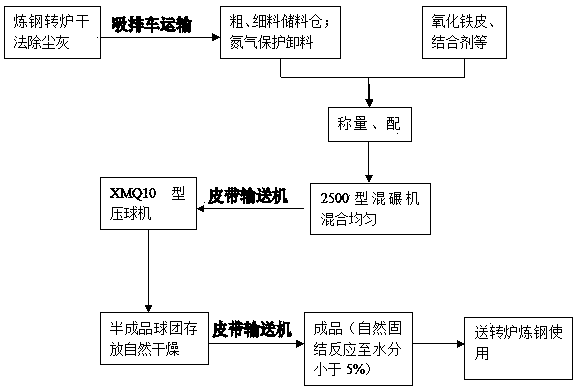

Technique for producing cold-bonded pellets from steel converter dust removal ash

The invention discloses a technique for producing cold-bonded pellets from steel converter dust removal ash, which comprises the following steps: separately collecting rough dust removal ash and fine dust removal ash of the steel converter, weighing iron scale, rough dust removal ash and fine dust removal ash in a mass ratio of (10-50):(20-80):(20-70), and uniformly mixing; adding the mixture into a magnesium chloride solution, and uniformly mixing, wherein the magnesium chloride solution accounts for 1-20 wt% of the total mass; and pelletizing with a pelletizer, stripping, and naturally solidifying to obtain the cold-bonded pellets. The dust removal ash does not need previous digestion treatment with water, thereby saving abundant water resources; the production technique is simple and feasible, and is implemented only by proportionally adding the inorganic weakly-alkaline binder into the iron scale, rough dust removal ash and fine dust removal, uniformly mixing and pelletizing; by using the inorganic weakly-alkaline binder, the finished cold-bonded pellets have the advantages of fewer impurities, low SiO2 content and high total iron content (not lower than 60%); and abundant cold-bonded pellets can be used in the steelmaking process, and the steelmaking process is not influenced by the addition amount.

Owner:CHONGQING ZHONGZHA METALLURGY RENEWABLE RESOURCESCO

Method for preparing titanium alloy cast ingot containing alloy component

The invention discloses a method for preparing titanium alloy ingots containing alloy components. The process of the method is: mixing alloy component powders with high melting point and high specific gravity and titanium powder in a certain proportion on a mixer for a certain period of time. After feeding, the evenly mixed bimetallic or polymetallic powder is prepared into an alloy bag, the alloy bag is added to the base material, the electrode block is pressed, the electrode is assembled and welded, and then smelted in a vacuum consumable electric arc furnace for 2 to 3 times. Finally, a homogeneous titanium alloy ingot is prepared. The invention has simple preparation process, low cost and convenient production organization, can greatly improve the efficiency of industrial production of this type of titanium alloy ingot, and is suitable for various binary system or multi-component titanium alloy ingots containing high melting point and high specificity recombinant elements. preparation.

Owner:西安稀有金属材料研究院有限公司

Method for preparing lithium manganate used as lithium ion battery anode material by using trimanganese tetroxide

ActiveCN102336441AReduce bring inUniform compositionCell electrodesManganates/permanganatesPhysical chemistryManganate

The invention discloses a method for preparing lithium manganate used as a lithium ion battery anode material by using trimanganese tetroxide, comprising the following steps of: firstly, preparing the trimanganese tetroxide and the lithium salt according to the molar ratio of lithium to manganese 0.5-0.6, uniformly mixing the trimanganese tetroxide and the lithium salt to get the precursor, and then, pre-sintering the precursor; executing ball milling and spray drying after pre-sintering, and then, executing secondary sintering; finally, executing isostatic cool pressing on the products of the secondary sintering process, and crashing and classifying the products to get the lithium manganate used as the lithium ion battery anode material. The method has the advantages of being simple and practical in technical steps, low in cost, easy to realize mass industrial production, excellent in product performance, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Preparation method of sulfadoxine

A preparation method of sulfadoxine belongs to the field of sulfanilamide antimicrobial drug preparation. Cyclization reaction comprises the following steps of: firstly pouring a sodium methoxide solution into a reactive pan, then successively adding methanamide and methyl ethyl methoxymalonate, keeping warm, recovering methanol, cooling for crystallization, drying by centrifugation, discharging,and drying to obtain 5-methoxy-4,6-disodium dihydroxypyrimidine; Chlorination reaction comprises the following steps of: firstly putting phosphorus oxychloride into a reaction vessel for heating, adding 5-methoxy-4,6-disodium dihydroxypyrimidine into the reaction vessel to react, decompressing and recovering phosphorus oxychloride until the material is dry, cooling, adding trichloro ethylene withuniformly stirring, putting into a hydrolysis pan for hydrolyzation, collecting a trichloro ethylene layer after standing and delaminating, followed by a neutralization reaction, controlling pH value, washing, removing a water layer, recovering trichloro ethylene, and releasing crystals to obtain 5-methoxy-4,6-dichloropyrimidine. The preparation method provided by the invention can be used to guarantee the product purity, prolong the service life of equipment, avoid the damage to the environment and human body, reduce emission, and save energy, and accords with foreign pharmacopoeia standard requirements.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

High-strength and high-toughness heat-treatment-free aluminum alloy material and preparation method thereof

PendingCN113755722AReasonably control the range of elementsGood mechanical propertiesMold fillingUltimate tensile strength

The invention discloses a high-strength and high-toughness heat-treatment-free aluminum alloy material and a preparation method, and belongs to the technical field of aluminum alloy casting. The high-strength and high-toughness heat-treatment-free aluminum alloy material comprises the following components in percentage by mass: 8.0-10.5% of Si, less than or equal to 0.15% of Fe, 0.05-0.3% of Mg, 0.05-0.3% of Zn, 0.3-0.6% of Mn, less than or equal to 0.1% of Cu, 0.05-0.15% of Ti, less than or equal to 0.005% of Ca, 0.005-0.030% of Sr, 0.1-0.3% of Zr, 0.01-0.1% of Mo, 0.01-0.3% of V, less than or equal to 0.02% of Cr, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.01% of Cd, less than or equal to 0.001% of Li, less than or equal to 0.0025% of B, less than or equal to 0.05% of Ga, and the balance Al and inevitable impurities. The alloy does not need to be subjected to heat treatment, and has excellent casting performance and mold filling capacity and good tensile strength, yield strength and toughness.

Owner:隆达铝业(顺平)有限公司 +2

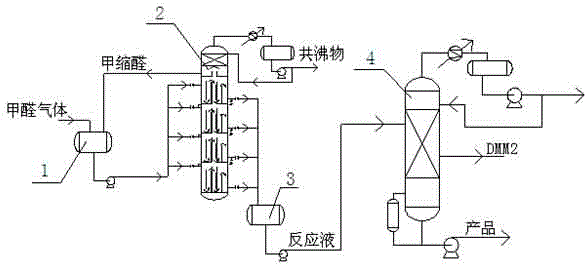

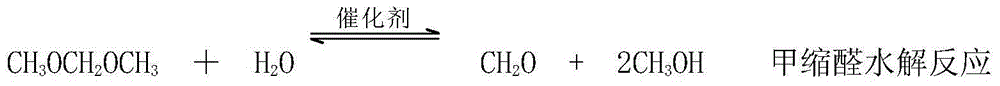

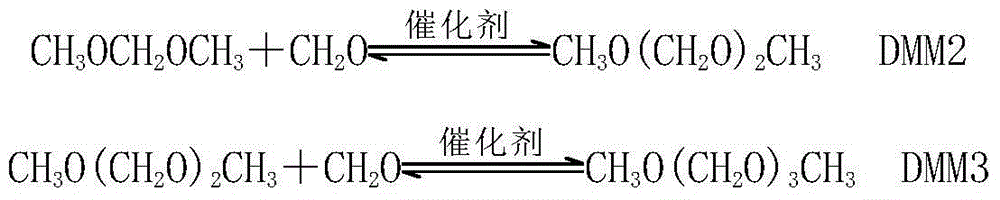

Dehydration technique and dehydration device for synthesizing poly-methoxy-dimethyl ether

InactiveCN104817437AReduce bring inRelieve pressureOrganic chemistryOrganic compound preparationHigh concentrationAcid catalysis

The invention discloses a dehydration technique and a dehydration device for synthesizing poly-methoxy-dimethyl ether. The dehydration technique comprises the following steps: selecting a formaldehyde gas of which the moisture content is within 0.1% and high-concentration dimethoxymethane to form a methylal solution of formaldehyde as a reactant; obtaining a poly-methoxy-dimethyl ether product under the acid catalysis condition; further carrying out hydrolysis reaction on high-concentration dimethoxymethane, and further consuming moisture, so as to control the reaction system in an anhydrous state. Therefore, the poly-methoxy-dimethyl ether yield is improved; furthermore, the reaction condition of the reaction system is also reduced; and the reaction energy consumption is reduced.

Owner:无锡智归科技有限公司

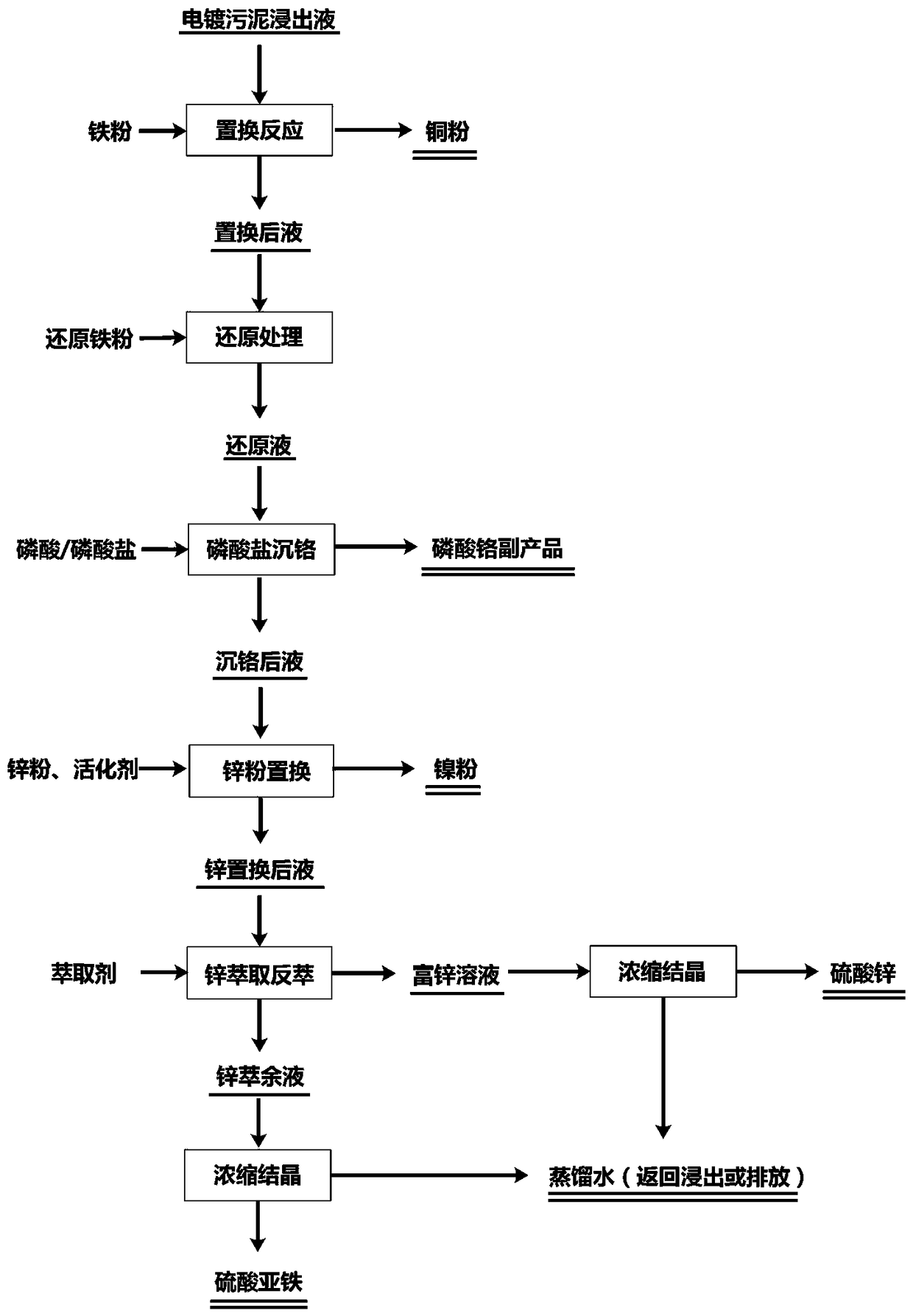

Method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate

The invention provides a method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate. The method comprises the following steps: (1) addingiron powder into the leachate to obtain a copper powder product and replaced liquid; 2) adding iron powder into the replaced liquid to obtain reduced liquid; (3) adding a chromium precipitating agentinto the reduced liquid, and carrying out filtering to obtain chromium-precipitated liquid and a chromium precipitate; (4) adding the activator antimony salt and zinc dust into the chromium-precipitated liquid, carrying out a reaction, and then carrying out filtering to obtain nickel powder and nickel-removed liquid; (5) adding an acidic phosphate extraction agent into the nickel-removed liquid to extract zinc, then carrying out reextraction by using dilute sulfuric acid, subjecting a zinc-rich solution to concentration and crystallization to prepare a zinc salt product, and subjecting zinc raffinate to subsequent treatment; and (6) subjecting the zinc raffinate to concentration and crystallization to prepare ferrous sulfate heptahydrate, and returning distilled water for leaching. The separation method of the invention has the advantages of short process and high efficiency, and can effectively solve the problem difficulties in separate separation of chromium, iron, nickel, copper and zinc metals in the high-iron high-chromium electroplating sludge leachate.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Method of preparing high-hematite self-fluxing pellets by adding limestone through usage of rotary kiln process

The invention relates to a method of preparing high-hematite self-fluxing pellet by adding limestone through usage of a rotary kiln process, and belongs to the technical field of metallurgy. The method specifically comprises the following steps of raw material pretreatment, high-pressure roller grinding, pelletizing, drying, preheating, roasting, cooling and screening; a proper amount of magnetiteis added, so that the problems that heat absorption is carried out when the limestone is decomposed, ring is easily caused due to a preheating roasting temperature of hematite pellet is high and coalash which mainly composed of silicon and aluminum brought by inner coal blending enters the interior of the pellet are solved, and the self-fluxing pellet which is less in harmful impurities, high incompressive strength, low in expansion index and good in reducibility is obtained.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

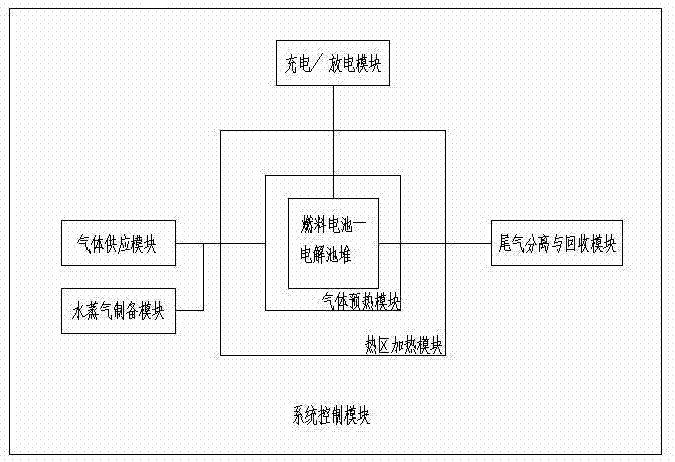

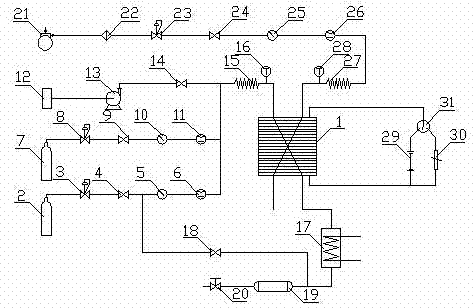

Test system for kilowatt-scale reversible solid oxide fuel cell-electrolysis cell

ActiveCN105449250AHighly integratedStrong visualizationFuel cell heat exchangeFuel cells groupingFuel cellsWater vapor

The invention provides a test system for a kilowatt-scale reversible solid oxide fuel cell-electrolysis cell. The test system comprises a solid oxide fuel cell-electrolysis cell stack, a gas supply module used for supplying gas to the cell-electrolysis cell stack, a vapor preparation module used for generating vapor that is supplied to the cell-electrolysis cell stack, a gas preheating module arranged in the same hot zone with the cell-electrolysis cell stack, a heat zone heating module used for heating the cell-electrolysis cell stack and the gas preheating module, a tail gas separation and recycling module used for separating and recycling tail gas generated by the cell-electrolysis cell stack, a fuel cell-electrolysis cell stack charge-discharge module used for performing charge-discharge test on the cell-electrolysis cell stack, and a system control module, wherein the system control module is configured to control the charge-discharge module to perform charge-discharge test on the fuel cell-electrolysis cell stack for realizing reversible switching operation of power generation or electrolysis of the cell-electrolysis cell stack.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method for white carbon black

The invention provides a preparation method for white carbon black. The preparation method comprises the following steps of: S1, removing impurities by sodium silicate: dissolving solid sodium silicate to obtain raw material crude liquid; adding the white carbon black into the raw material crude liquid; filtering mixture to obtain a qualified sodium silicate solution; S2, compounding the white carbon black: mixing the sodium silicate solution obtained in the step S1 with concentrated sulfuric acid; reacting the mixture obtain a white carbon black crude product; and S3, purifying the white carbon black: filter pressing, washing and pulping the white carbon black crude product obtained in the step S2, and drying the processed white carbon black crude product to obtain a white carbon black finished product. According to the preparation method for the white carbon black, the white carbon black is used for replacing diatomaceous earth to be used as a filter aid for removing the impurities by the sodium silicate; so that production cost is reduced and intake of other impurities and microelements can be reduced; load of a subsequent synthetic process is reduced, and quality of the white carbon black is improved.

Owner:ZHUZHOU XINGLONG CHEM IND

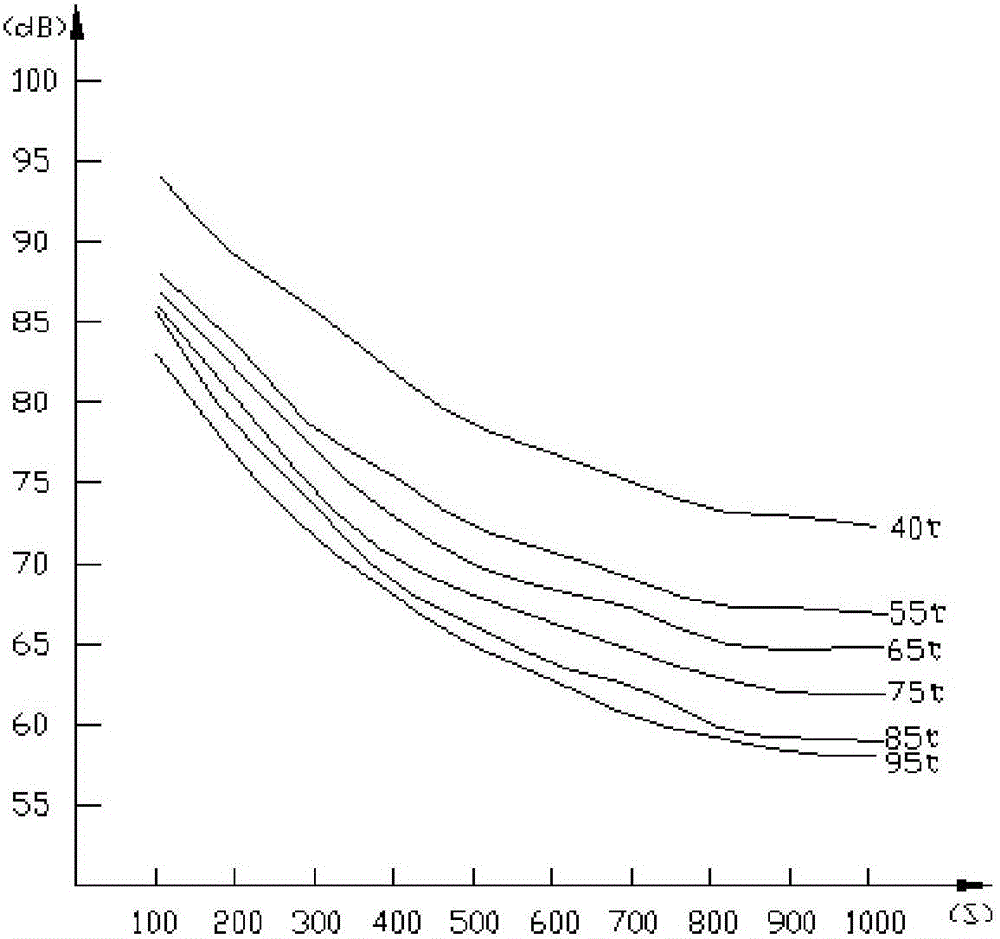

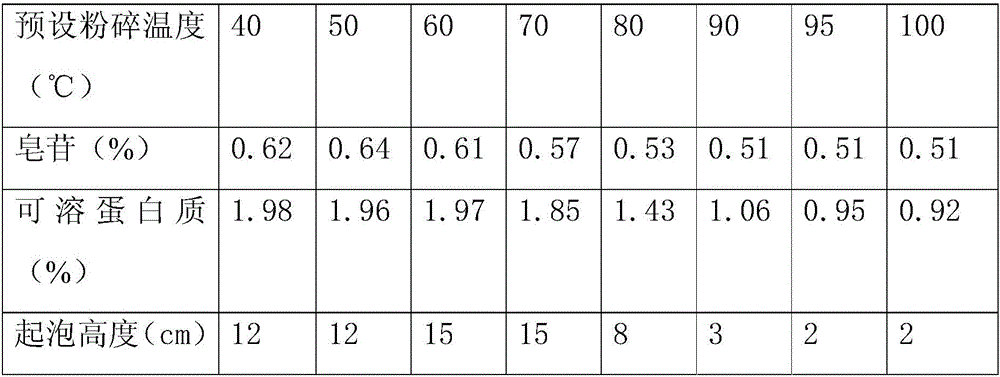

Low-noise milk-preparation method of soybean milk machine

InactiveCN105935247AReduce hardnessBad experienceBeverage vesselsDough shaping and cutting apparatusLow noiseElectricity

The invention relates to a low-noise milk-preparation method of soybean milk machine. A motor, a crushing cutter, a heating device and a cup body are provided. The control unit is electrically connected with the motor, and the heating device. The method at least comprises following phases: (1) a crushing stage: the motor drives the crushing cutter to rotate and crush water and material to milk and goes to the next phase; (2) a boiling phase: the heating device is used for heating milk till it is boiled. When the crushing phase begins, the temperature of liquid is larger than or equal to the pre-set crushing temperature. The pre-set crushing temperature is larger than or equal to 85 DEG C. Before the crushing phase, a heating pre-treatment phase is included. The heating pre-treatment phase lasts for 400 to 800 seconds. Therefore, noise can be effectively decreased and false boiling is avoided and reduced effectively.

Owner:JOYOUNG CO LTD

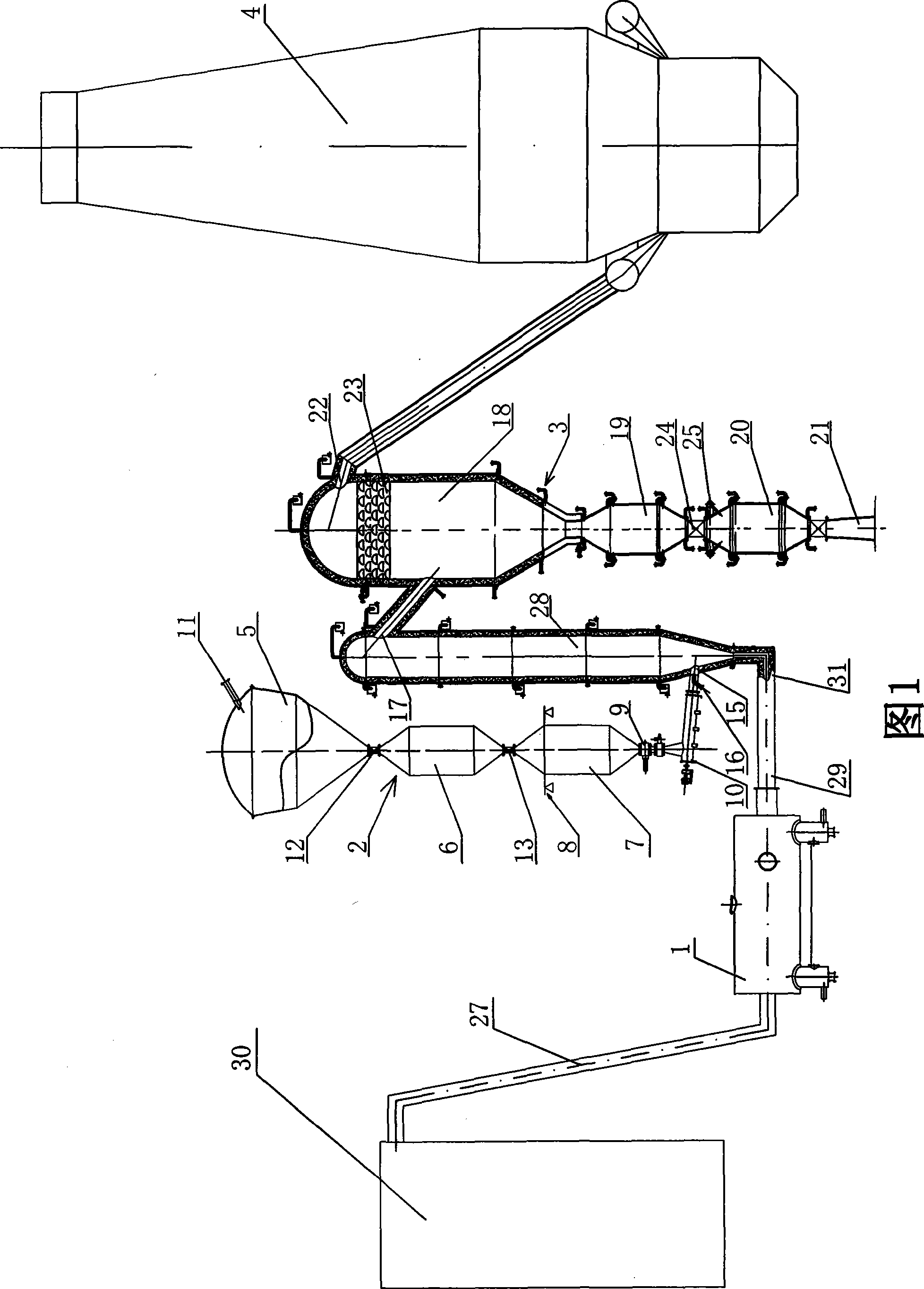

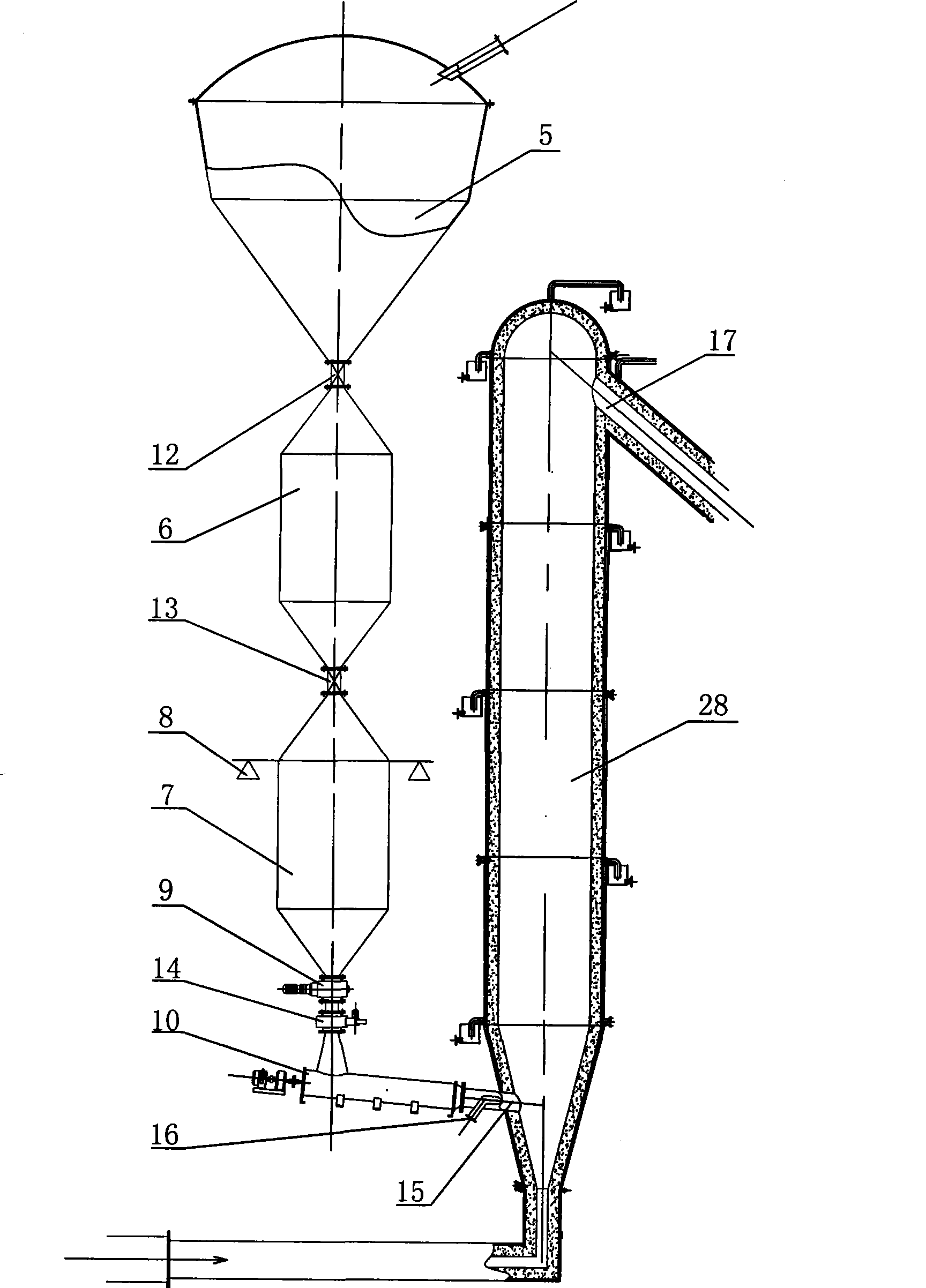

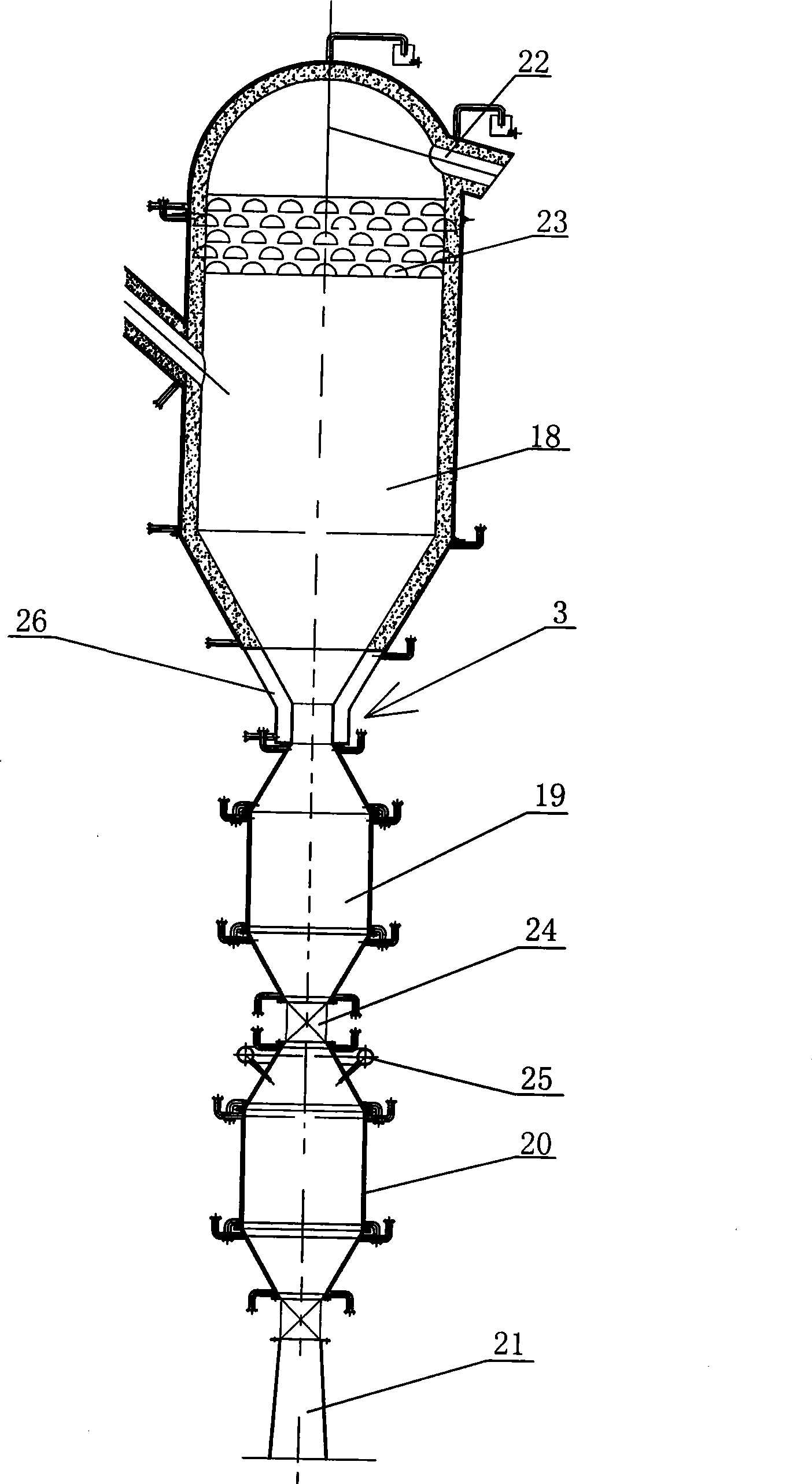

Coal powder pure oxygen blast furnace ironmaking process and equipment thereof

ActiveCN101413038AGood energy saving effectReduce coal injection costBlast furnace componentsBlast furnace detailsSlagMixed gas

The invention provides a pulverized coal pure oxygen blast furnace ironmaking technical method. The technical method is as follows: on the basis of the blast furnace spraying pulverized coal process, a mixed gas of oxygen enriched air or oxygen and vapor is preheated to the temperature of between 900 and 1500 DEG C by a regenerative hot blast furnace, the pulverized coal is sprayed in a high temperature gas generator or gas generator, at the same time, the mixed gas preheated at a high temperature is also sprayed into the high temperature gas generator or gas generator, the pulverized coal and the mixed gas undergo gasification reaction in the high temperature entrained flow gas generator or gas generator, 90 to 95 percent of dust in the high temperature coal gas is removed by a high temperature combined dust collector, the high temperature coal gas is directly sprayed into the lower part of a furnace body of the blast furnace to take part in the ironmaking reaction, blast furnace materials are mainly acid pellet, and properly part of high basicity sinter, for each ton of iron, 1200 to 1750m<3> of the high temperature coal gas and 80 to 120m<3> of oxygen is blown in the blast furnace. The method has the advanges of well saving energy, greatly lowering spraying coal cost, improving the unit volume capacity of the prior blast furance by more than 50 percent and making the utilization coefficient reach nearly 6T(M<3>day and night). Being capable of preparing low silicon good quality molten iron, the method greatly reduces the consumption of oxygen for steel-making, and contributes to the realization of a novel techique for making steel with little slag.

Owner:沈阳东方钢铁有限公司

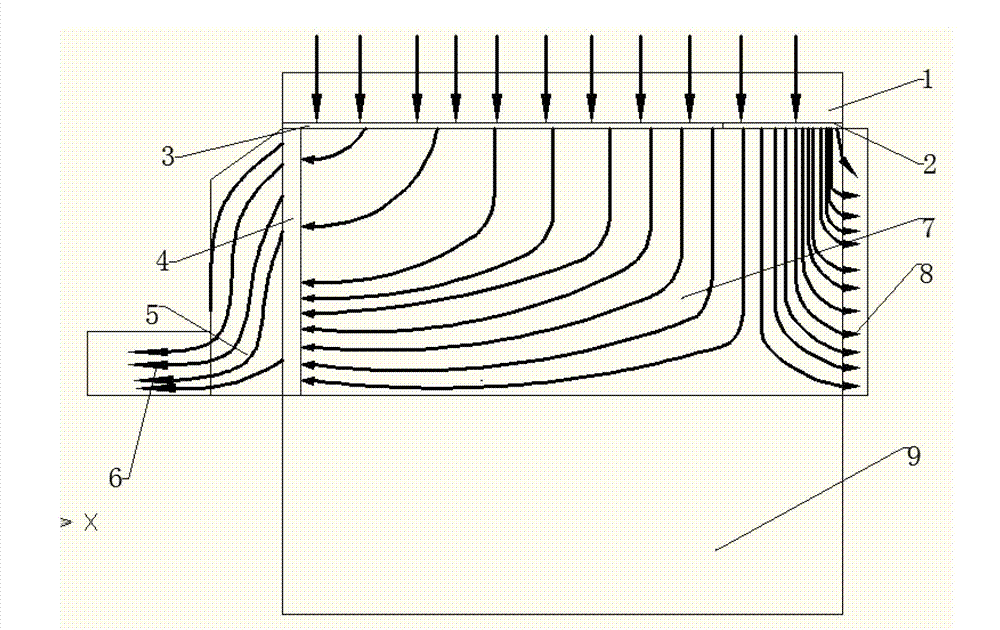

Double-layer-flow purification working table

InactiveCN103170376AEffective separationAvoid harmDust-free enclosuresWork benchesPositive pressureAtmospheric pressure

The invention relates to a double-layer-flow purification working table which comprises an air intake system and an air discharging system, wherein an air diffusion plate is arranged below the air intake system; a working chamber is arranged below the air diffusion plate; large holes are formed along the transverse direction on the front side of the air diffusion plate; small holes are formed along the transverse direction at other parts of the air diffusion plate; the air discharging system comprises an air collecting plate which is positioned inside the working chamber and is vertically arranged; the holes in the air collecting plate are increased gradually from top to bottom; an air collecting hood is installed on the outer side of the air collecting plate; the lower part of the air collecting hood is connected with an air discharging device through an air discharging tube; the air flow inside the working chamber is collected by the air collecting hood after horizontally passing through the air collecting plate and is discharged out by the air discharging device through the air discharging tube. By adopting a mutation hole mode, two positive pressure areas are formed at the working chamber, wherein the air pressure on one side close to working personnel is greater than the air pressure on the inner side; the air discharging system is put on the inner side of the working chamber; and by adopting a gradual change hole mode, the air flow inside the working chamber is collected by the air collecting hood after horizontally passing through the air connecting plate, and the phenomenon that the air flow rebounds below the working chamber is avoided.

Owner:NANTONG UNIVERSITY

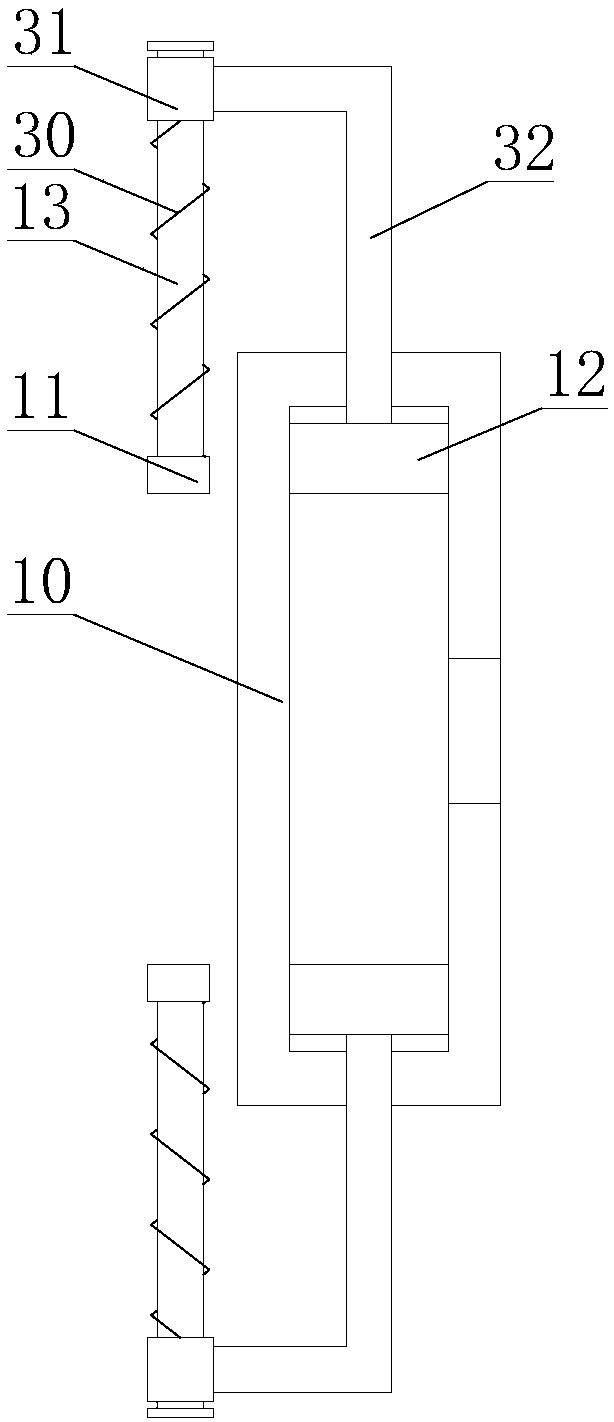

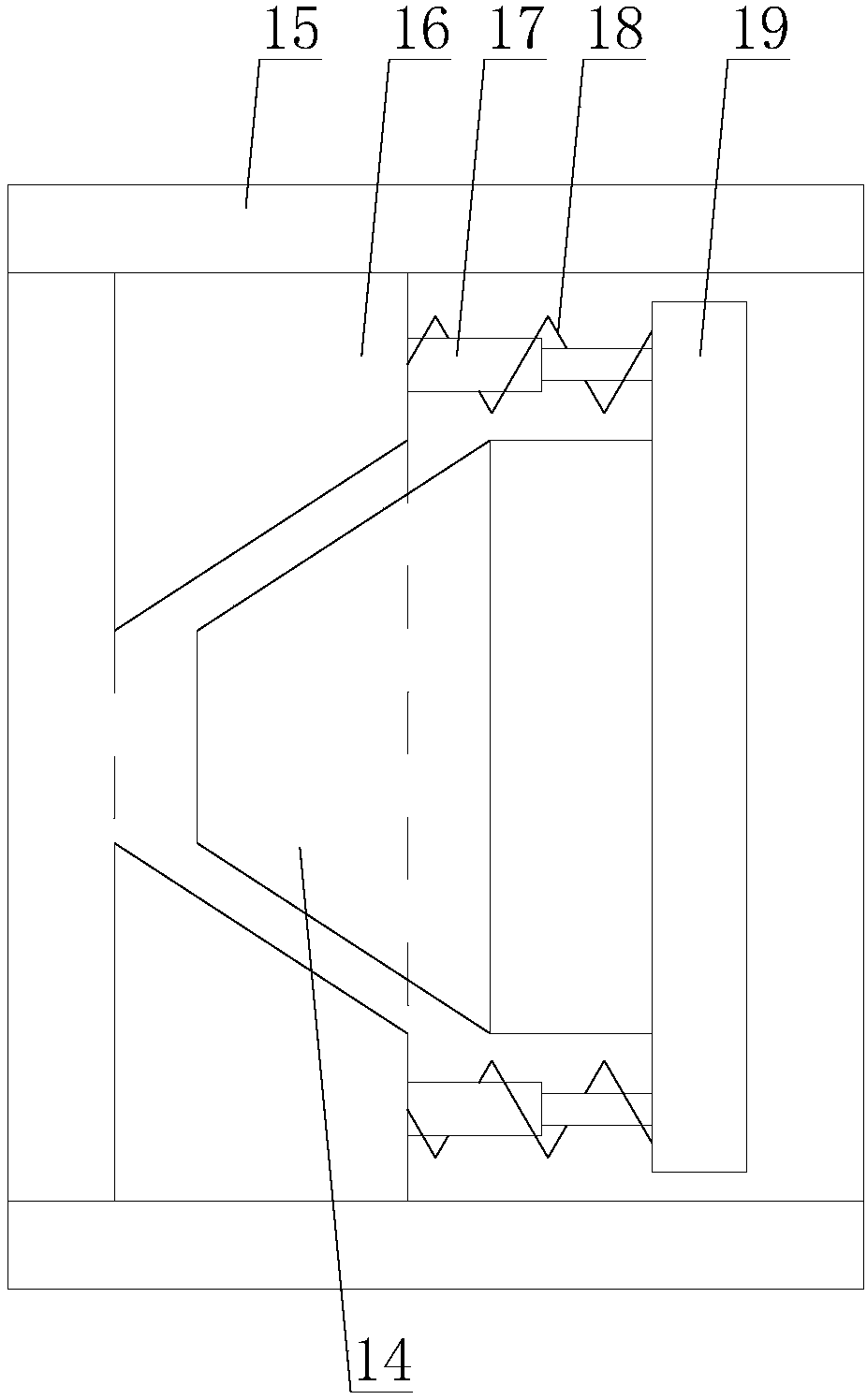

Dustproof type shock absorber with oil leakage detection function

ActiveCN108506406AReduce failureGuaranteed normal drivingSpringsCleaning using toolsPiston rodShock absorber

The invention relates to a dustproof type shock absorber with an oil leakage detection function. The dustproof type shock absorber comprises a connecting block, a piston rod, a first spring, an oil seal, a first piston, a stop valve, an oil storage chamber, an oil cylinder and at least two oil holes, and further comprises a detection mechanism and a dust removal mechanism, wherein the detection mechanism comprises a check assembly, an oil tank and two alarm assemblies, and the dust removal mechanism comprises two fixing rods, a second baffle, a first bearing seat, a cleaning brush, a first gear and a driving assembly. In the dustproof type shock absorber with the oil leakage detection function, oil leakage can be timely detected through the detection mechanism when slight oil leakage occurs in the shock absorber, and meanwhile, an alarm signal is sent to remind people, so that the probability of accidents caused by oil leakage of the shock absorber is reduced; and dust on the piston rod can be cleared away thoroughly through the dust removal mechanism, so that the probability of the dust being brought into the shock absorber by the piston rod is reduced, then the interior of the shock absorber can be kept clean, and the probability of faults of the shock absorber is reduced.

Owner:WENZHOU YIJIAN ELECTRONICS TECH CO LTD

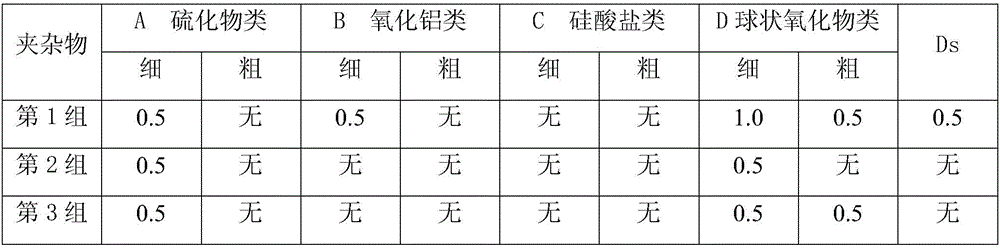

Production process for high-purity bearing steel

InactiveCN106591536ALow residual elementsReduce gas contentProcess efficiency improvementLow nitrogenSlag

The invention belongs to the technical field of steel preparation, and particularly relates to a production process for high-purity bearing steel. The production process comprises the following steps: firstly, adding blast-furnace molten iron and steel scrap in an electric converter and smelting; secondly, alloying a steel ladle by virtue of an alloy, an aluminium cake and a low-nitrogen carburant; thirdly, discharging molten steel into the steel ladle subjected to the alloying treatment after the smelting is completed, slagging and enabling the slagging result to meet the requirements of while slag in the earlier stage of refining, obtaining the while slag and then carrying out aluminium line feeding operation; fourthly, hoisting molten steel qualified after the refining into a vacuum tank and carrying out vacuum treatment; and finally carrying out continuous casting. Cancel of molten steel modification treatment is realized; and moreover, the molten steel is high in castability and meets the production requirements of high-standard bearing steel.

Owner:ZENITH STEEL GROUP CORP

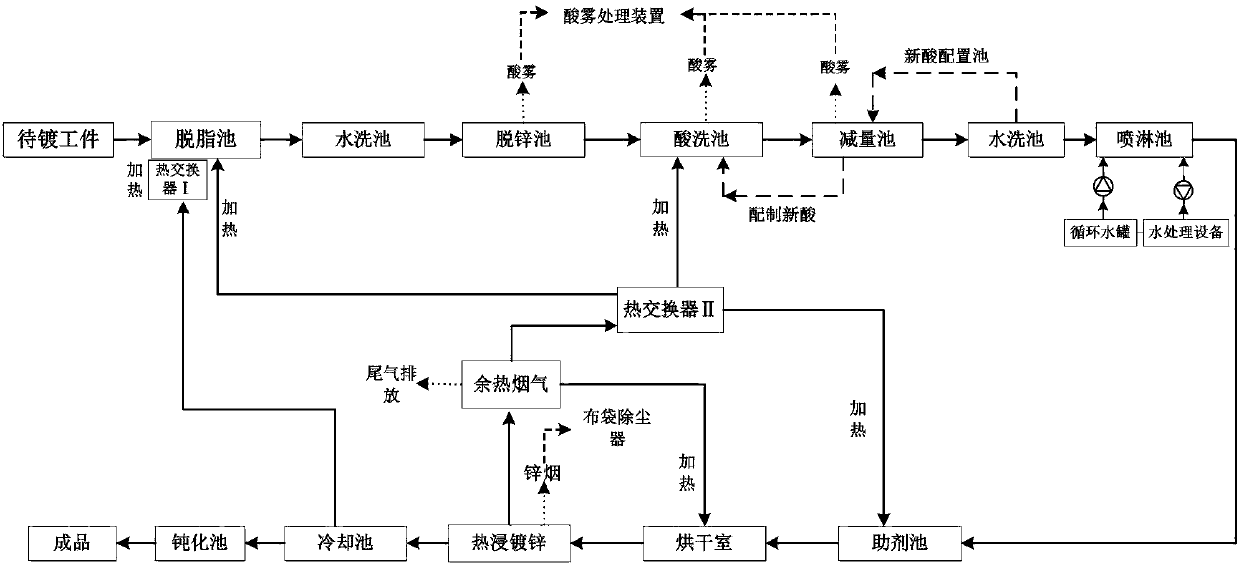

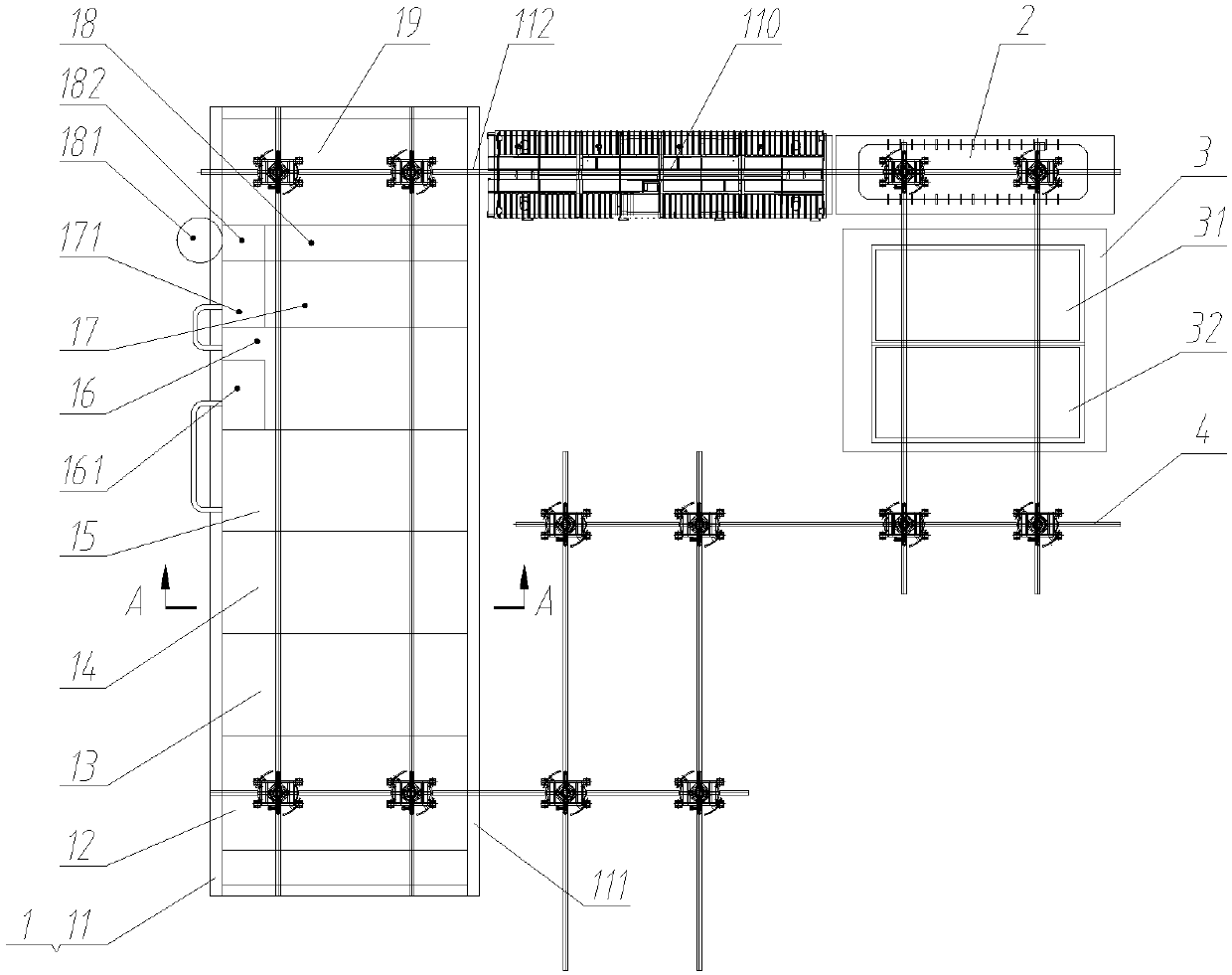

Closed-loop hot galvanizing production line and control method

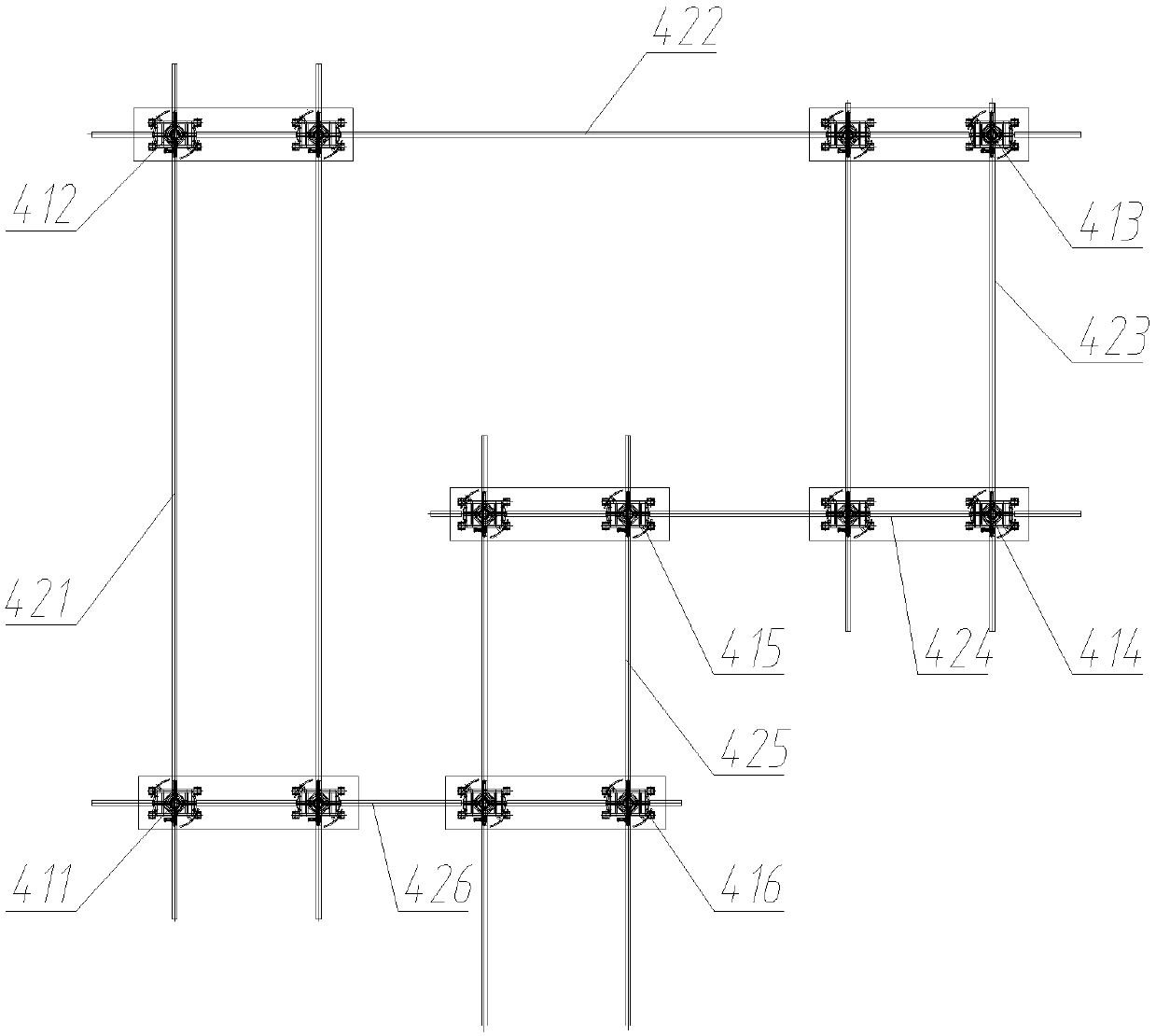

ActiveCN107557708ARealize secondary cleaningReduce surface quality defectsHot-dipping/immersion processesDirt cleaningProduction lineProcess engineering

The invention discloses a closed-loop hot galvanizing production line and a control method. The closed-loop hot galvanizing production line comprises a preplating device (1), a galvanizing device (2),a postplating device (3), a travelling rail unit and an electronic control unit. The device (1) used before galvanizing comprises a degreasing pool (12), a water washing pool I (13), a zinc removal pool (14), an acid cleaning pool (15), a reduction pool (16), a water washing pool II (17), a spraying pool (18), an addition agent pool (19) and a drying chamber (110), wherein the degreasing pool (12), the water washing pool I (13), the zinc removal pool (14), the acid cleaning pool (15), the reduction pool (16), the water washing pool II (17), the spraying pool (18), the addition agent pool (19)and the drying chamber (110) are connected with the interior of a chamber (11) used before galvanizing in sequence. The postplating device (3) and the galvanizing device (2) are perpendicularly arranged. The travelling rail unit comprises a travelling rail device (4) and a travelling rail electronic control circuit, wherein the travelling rail device (4) is located above the preplating device (1), the galvanizing device (2) and the postplating device (3). By the adoption of the closed-loop hot galvanizing production line and the control method, the content of iron entering the hot galvanizingworking procedure can be effectively reduced, the waste of liquid zinc is reduced, the frequency of treatment of dangerous waste iron mud is reduced, the purpose that the surface quality of a galvanized part is better is achieved, and the production efficiency is improved.

Owner:徐州瑞马智能技术有限公司

Technique for smelting mother liquor of stainless steel from electric furnace

InactiveCN1796586ALow cost of ingredientsAlleviate the tension of insufficient resourcesElectric arc furnaceFerrosilicon

This invention relates to an electric furnace smelting technique for crude stainless steel liquid with its process including: a) materials proportioning. Waste stainless steel shares 15~25% in total added metal. Chromium-iron alloy shares 15~25% in total added metal. Lime is added to an amount of 30~45 kg per ton of added metal. And dephosphorized molten iron shares 35~60% with its element content of 2.50~3.80% of C, less than 0.020% of phosphorus, less than 0.040% of sulfur. b) Smelting. Oxygen blowing amount is controlled at 5~10 cu m / t and blowing flux is controlled at 1500~2500N cu m / h. c) reduction. Ferrosilicon powders are spitted at 2.5~3.5kg / t and carbon powders at 1.5~2.5kg / t. Or ferrosilicon is added at 2.5~3.5kg / t and aluminium at 1.5~2.5kg / t. d) tapping, with ultimate temperature controlled at 1640~1660 deg.C. This invention employs dephosphorized molten iron, which reduces the raw materials proportioning cost and smelting time as well as the consumption of electricity power, electrodes and patching materials in electric furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

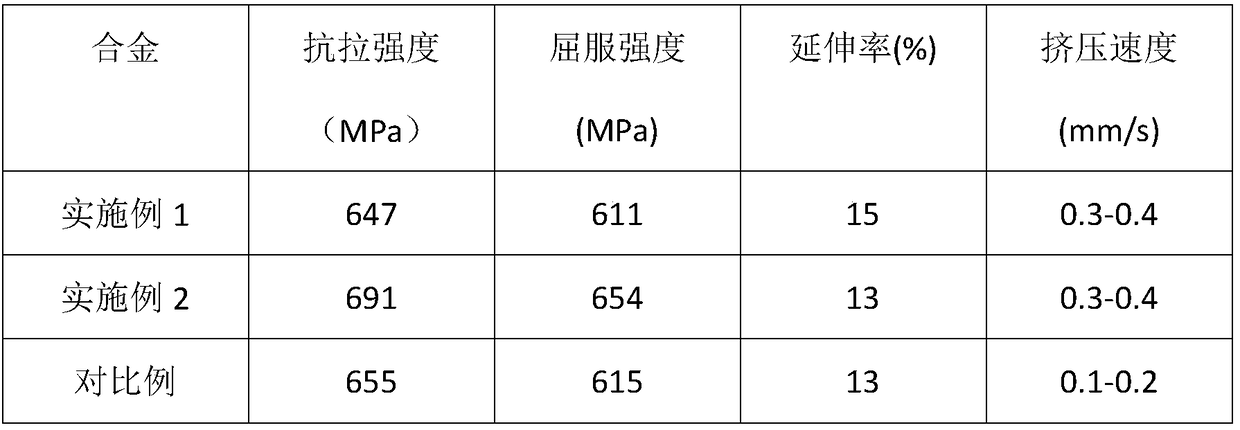

Ultra-strength, high-toughness and high-elongation 7XXX series aluminum alloy and preparation process thereof

The invention relates to an ultra-strength, high-toughness and high-elongation 7XXX series aluminum alloy and a preparation process thereof. The aluminum alloy comprises the following raw materials inpercentage by weight: 8.5-9.2% of Zn, 2.2-2.4%% of Mg, 1-1.6% of Cu, 0.1-0.2% of Zr, 0-0.05% of Ti, 0-0.1% of impurities and the balance of Al. In the invention, for the 7XXX series aluminum alloy, the strength is 640-700MPa, the elongation is 12-16%, and a problem that the high strength and the high elongation of existing aluminum alloy products are difficult to achieve simultaneously is solved.

Owner:CENT SOUTH UNIV

Method for synthesizing vanadium-containing steelmaking annexing agent through carbon thermal reduction and nitridation

The invention relates to a method for synthesizing a vanadium-containing steelmaking annexing agent through carbon thermal reduction and nitridation. A product is a low-iron-content vanadium nitrogen alloy, and main elements include 65%-78% of vanadium, 16%-20% of nitrogen and 0-15% of iron. The method is characterized in that vanadium oxide, iron oxide or iron simple substance, a binder and a carbon reducing agent are directly used as main raw materials to be evenly mixed to be subject to briquetting molding, then the raw materials are placed into a high temperature furnace (such as a pushed slab kiln, a tunnel kiln and the like) and sequentially pass through three zones including a prereduction zone, a high temperature carbon reduction nitridation zone and a cooling zone under the nitrogen atmosphere, and the final low-iron-content vanadium nitrogen alloy is obtained. The product synthesized by the process is good in compactness and even in nitrogen content. Compared with the vanadium nitrogen alloy, the content of impurities like carbon and oxygen is lower, and the density is higher. Compared with nitrided ferrovanadium, the product is lower in iron content and high in vanadium and nitrogen content; and in addition, the production process is short in process, and the process flow and cost can be greatly shortened.

Owner:UNIV OF SCI & TECH BEIJING

Tomato grafting culture planting method

InactiveCN103444445AImprove fruit setting rateGood quality fruitHorticultureTomato graftingFruit set

The invention relates to the technical field of agricultural planting, in particular to a tomato grafting culture planting method. The tomato grafting culture planting method specifically comprises the steps of culturing stocks, culturing and selecting scions, carrying out scion processing before grafting, selecting the stocks to carry out grafting, carrying out seedling management after grafting and carrying out field management. By reasonable technical processing, influence of diseases and insect pests can be reduced and cold resistance and drought resistance of tomato plants can be reinforced, so that the fruit setting rate is improved, fruit setting quality is promoted, planting cost is saved and incomes of farmers are increased.

Owner:普定县福海蔬菜种植场

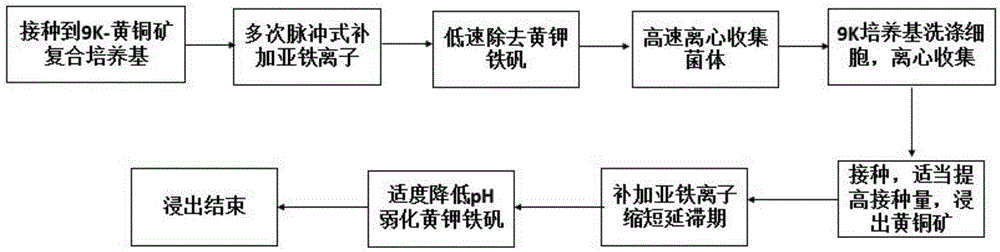

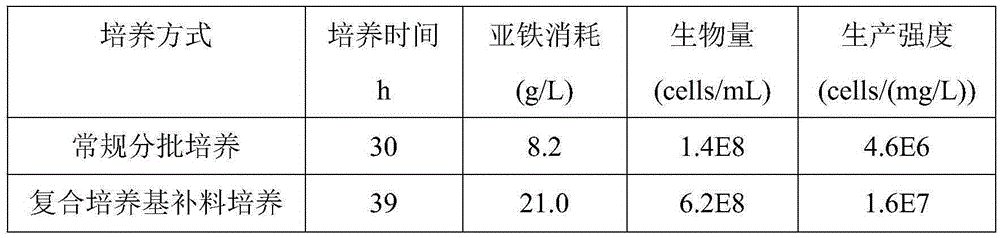

Method for leaching chalcopyrite through reinforced iron oxidized culture

ActiveCN105256133AIncrease cell concentrationImprove leaching efficiencyProcess efficiency improvementChalcopyriteHigh density

The invention discloses a method for leaching chalcopyrite through a reinforced iron oxidized culture and belongs to the technical field of bioleaching. The method includes the steps that on the basis of a 9K-chalcopyrite complex medium, a ferrous energy substrate is added through an impulse type supplementary material in the middle and later periods of cultivation, and ferric oxide thiobacillus is cultured at high density; centrifugal operation and suspended elution cells of the 9K medium are adopted for removing jarosite, the cells not containing jarosite are adopted for inoculation, the inoculation size is increased properly, and meanwhile ferrous ions are supplemented and included to shorten a lag phase; and the pH of lixivium is lowered level by level in the later leaching period, accumulation of the jarosite is reduced, and the leaching effect of the chalcopyrite is improved in the whole process. By the adoption of the method, the iron oxidized culture can be more efficiently cultured, the lag phase can be shortened, the passivation effect caused by accumulation of the jarosite can be weakened, the leaching process of the chalcopyrite is improved while iron metabolism is reinforced, operation is easy and feasible, and the method is suitable for being applied and popularized on a large scale.

Owner:JIANGNAN UNIV

Preparation method of high-content kasugamycin aqueous solution

ActiveCN106818752AReduce bring inReduce salt contentBiocideSugar derivativesHigh concentrationAqueous solution

The invention relates to a preparation method of a high-content kasugamycin aqueous solution. By the method, high-concentration kasugamycin aqueous solution with the content being 5 to 8 percent can be prepared, the salt concentration of a product is extremely low, the use effect is good, use convenience is achieved, the use requirement of plane prevention with high requirement on concentration can be met, and the storage and transportation cost is low.

Owner:陕西绿盾生物药业创新中心有限公司

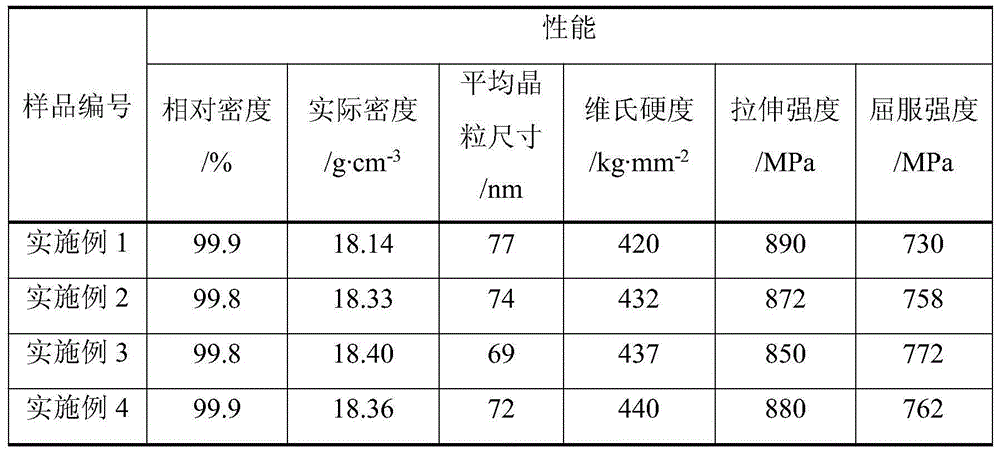

Preparation method of rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy

InactiveCN104651653AResolve the assigned stateOvercome the adverse effects of mechanical propertiesNitrateHigh density

The invention relates to a preparation method of a rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The preparation method comprises the following steps: firstly, preparing tungsten nitrate, nickel nitrate, copper nitrate, yttrium nitrate and water into a mixed solution according to a preset metering ratio, then preparing an alkali solution together with certain concentration of ammonia water solution, stirring the alkali solution, crystallizing, filtering, washing and drying to obtain precursor powder; placing the precursor powder into a reducing atmosphere furnace for dissociating and reducing, to obtain yttrium-containing tungsten-nickel-copper alloy powder; and grinding the alloy powder and mixing together with a forming agent and press-forming, dewaxing the formed blank and performing high-temperature sintering to finally obtain the rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The tungsten-nickel-copper alloy prepared by taking the rare earth microalloyed tungsten-nickel-copper alloy powder prepared by adopting a liquid / liquid doping method as a raw material through a proper powder metallurgy technology has the advantages that the density is more than or equal to 18.1g / cm<3>, the tensile strength is more than or equal to 850MPa, and the yielding strength is more than or equal to 690MPa.

Owner:SHAANXI UNIV OF TECH

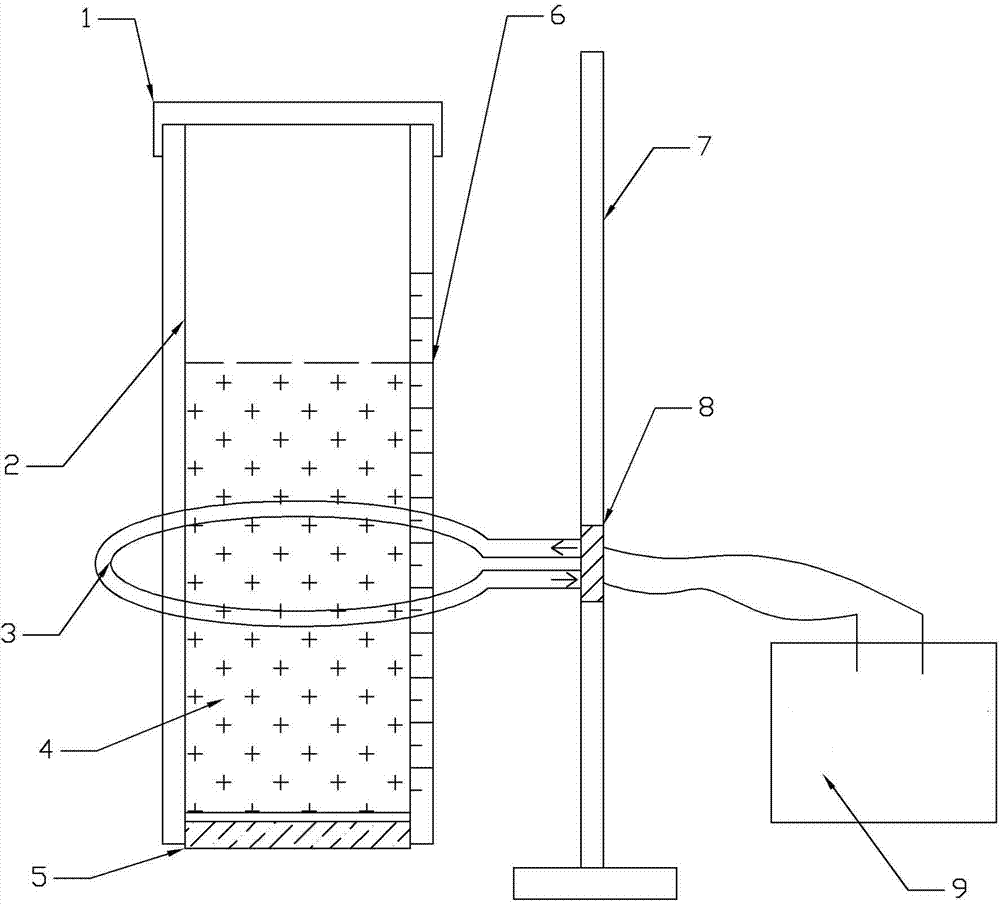

Method and apparatus for preparing high-purity gallium

ActiveCN104711438AEffective migrationStabilize the solid-liquid interface regionLiquid stateLiquid metal

The present invention discloses a method and an apparatus for preparing high-purity gallium. According to the method, liquid-state high-purity gallium is placed on the bottom portion of a container and is cooled as a seed crystal, the liquid-state metal gallium is poured into the cooling container to cool and crystallize, a thermal source coil is opened after complete crystallization, the temperature and the movement speed of the thermal source coil are controlled, the thermal source coil moves from bottom to top, the stable solid-liquid interface during the solidification process is ensured, the solidification interception ratio is 70-90%, and the metal gallium can be purified to achieve more than or equal to 6N. The apparatus comprises the cooling container, a constant temperature cold source, the thermal source coil and a control device, wherein the bottom portion of the cooling container is provided with the constant temperature cold source, the upper portion of the cooling container is provided with a dust preventing cover, the thermal source coil sleeves on the outer side of the cooling container, and the thermal source coil is connected with the control device through a conducting wire so as to make the temperature and the movement speed of the thermal source coil be controlled by the control device. According to the present invention, characteristics of simple apparatus mechanism, easy method operation, convenient specification quantifying, good product stability and the like are provided.

Owner:NORTHEASTERN UNIV

Method for producing steel for small square billet continuous casting high titanium alloy bonding wire

ActiveCN101457273AReduce consumptionEliminate blanking processManufacturing convertersProcess efficiency improvementSteelmakingSulfur

A method for producing steel used in a titanium master alloy bonding wire by small billet continuous casting belongs to the steelmaking technical field. The process route is as follows: low-sulfur molten iron and scrap steel, converter blowing, slag blocking and tapping, steel ladle deoxidation alloying, secondary refining, complete protection continuous casting by a small billet caster and casting blank inspection. The method is characterized by controlling technical parameters of critical process links, reducing the contents of aluminum and nitrogen in the molten steel, solving the problem of submerged nozzle clogging and crystallizer protecting slag floater easily occurring at the small billet continuous casting of high titanium steel variety, and realizing the smooth production of the steel used in the titanium master alloy bonding wire by the small billet continuous casting. The method has the advantages of being capable of replacing a production process for producing the steel used in the titanium master alloy bonding wire by continuous casting of die casting and large billets, achieving 0.08-0.17% titanium content of a product and fully meeting the use requirement of the steel used in the bonding wire.

Owner:SHOUGANG CORPORATION

Process for preparing sulfadoxine

A process for preparing sulfadoxine belongs to the preparation field of sulfonamides antibacterial agents. The process comprises a cyclization reaction and is characterized in that the cyclization reaction comprises the steps of adding a sodium methoxide solution into a reactor with a double helical ribbon stirrer; heating the solution while stirring; adding vaporific formamide and vaporific methyl ethyl methoxymalonate into the reactor at the same time in a spraying mode; controlling reaction temperatures; recovering solvents generated during reaction simultaneously; adding water for cooling and crystallizing after completing solvent recovery; centrifugally dripping; discharging; drying in vacuum; and obtaining 5-methoxy-4,6-dyhydroxy pyridine disodium. The process enables materials to diffuse, convect, cut, dislocate and radially move against one another, so that the effect of uniform mixing is achieved in a short time, reaction time is shortened, the reaction is completed, the purity of products are guaranteed, service lives of devices are prolonged, recycling time of solvents is shortened, resources are saved, and the high purity of the sulfadoxine which is the final product is guaranteed.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

Method for preparing sodium tanshinol

InactiveCN101289386AReduce the introduction of impurity metal ionsGuaranteed purityCarboxylic acid salt preparationPlant ingredientsSolventIon

The invention relates to a preparation method of sodium Danshensu with high purity which has simple steps and good purifying effect and which is suitable for industrialized production. The technical steps comprise: (1) extraction: the medicinal materials of salvia is heated and refluxed by a 0.5 mol / L aqueous hydrochloric solution; (2) multi-stage counter-current extraction: medical solution is infiltrated into a multi-stage counter-current extractor, multi-stage extraction is carried out by a n-hexane ethyl acetate (1:1-5) mixed solution; (3) refined salifying: the lower phase solution is taken and is added into alkaline anion exchange resin column to absorb, and uses an alkali solution containing sodium ions to elute, eluent is collected, concentrated and freezed, then sodium Danshensu is obtained after the crystallization is precipitated and separated. The preparation method of Danshensu sodium with high purity has the advantages of simple technology, high yield efficiency and good purity of products.

Owner:NANJING ZELANG MEDICAL TECH

Medical device monitoring method, medical device, server and medical system

InactiveCN101916157AEasy to operateSolve operational problemsDiagnosticsSurgeryMedical deviceComputer science

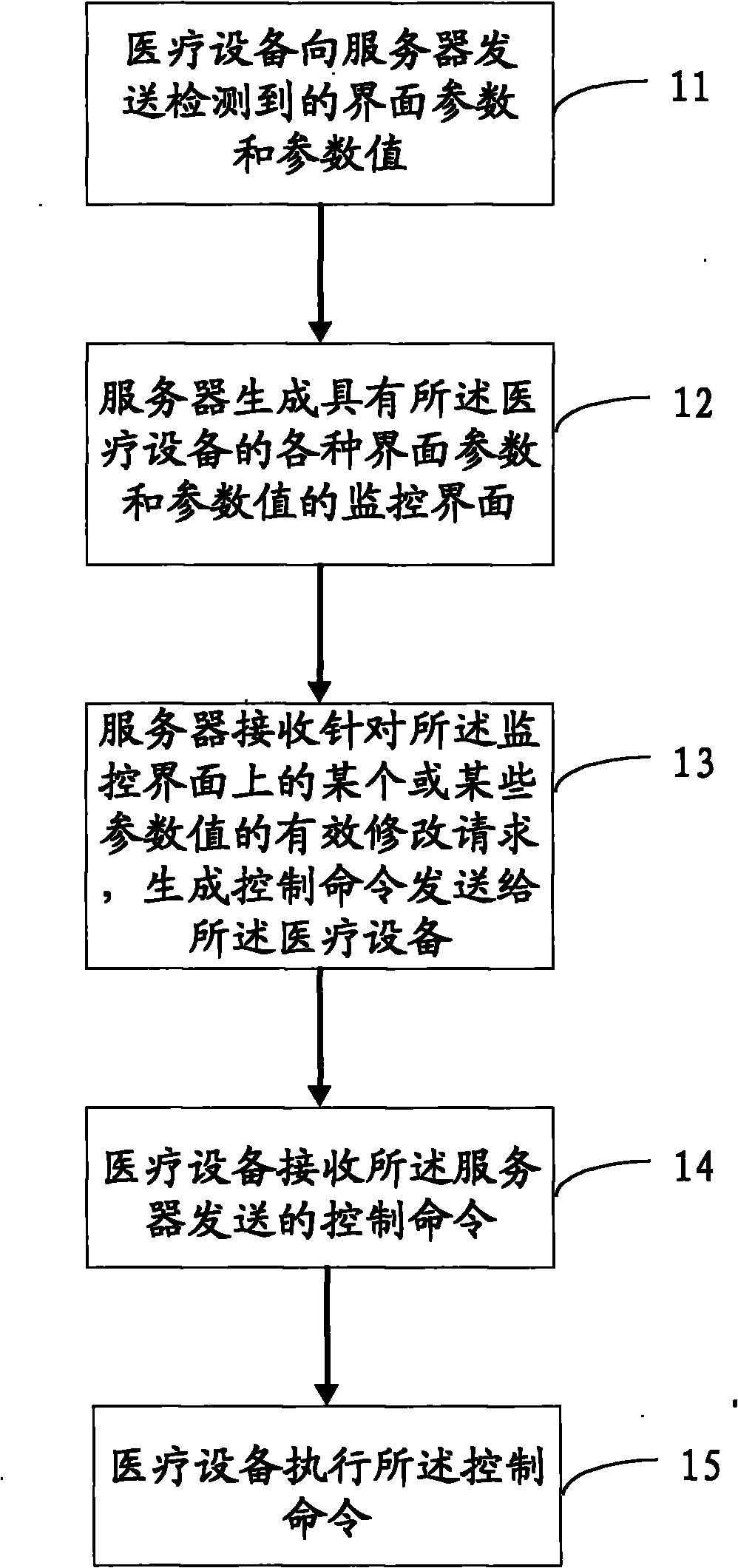

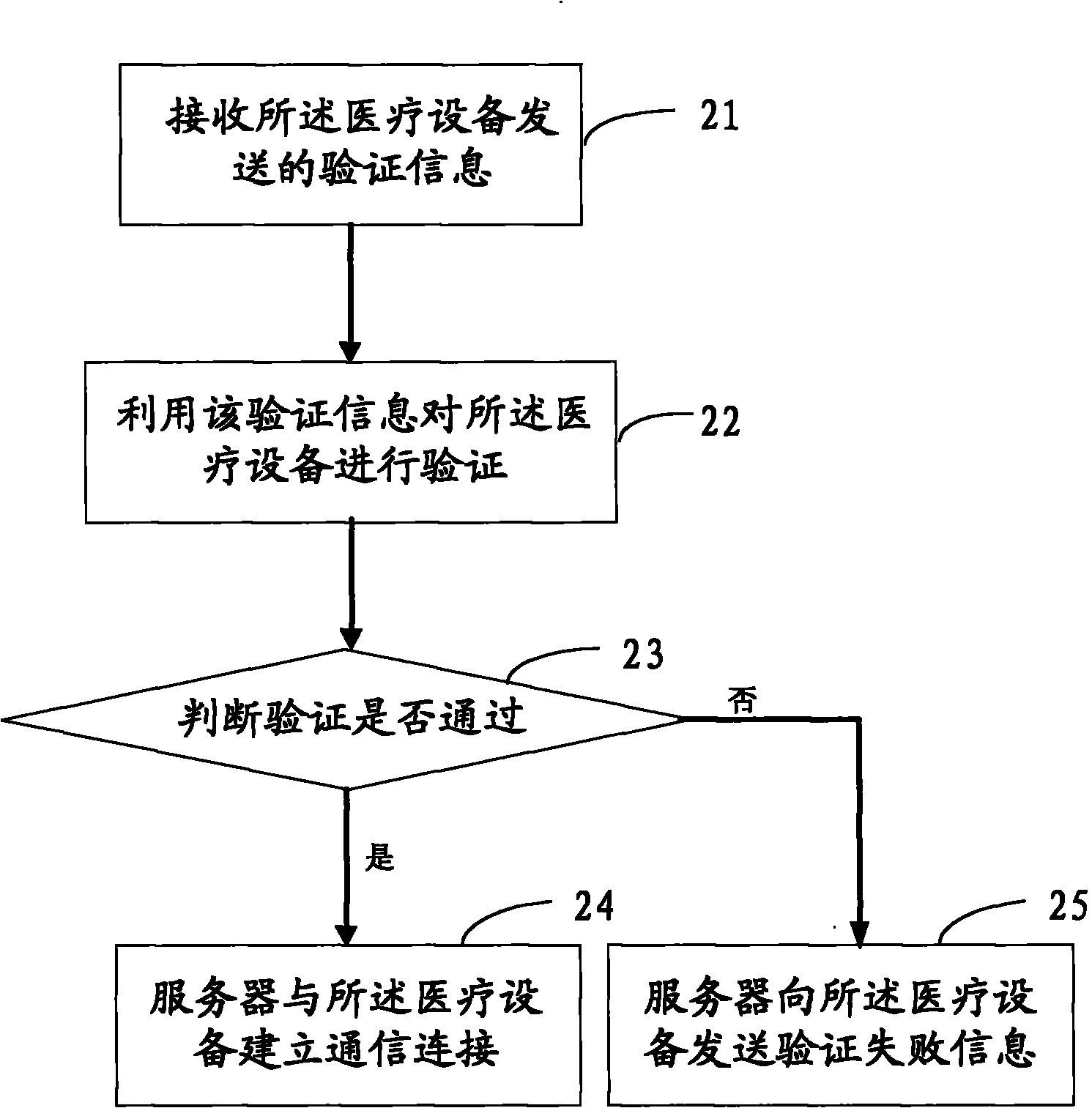

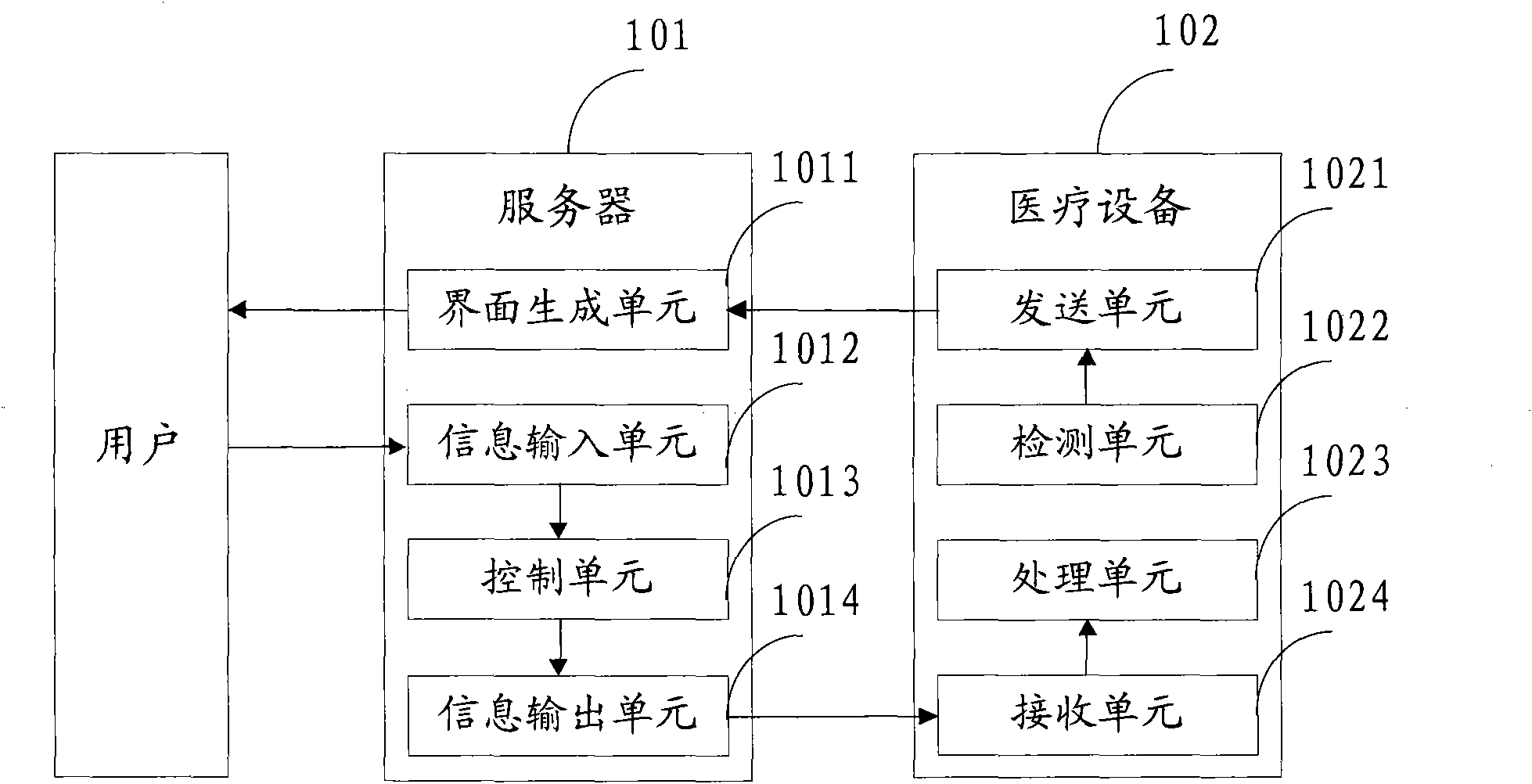

The invention discloses a medical device monitoring method, a medical device, a server and a medical system. The medical device monitoring method comprises that: the medical device sends the detected interface parameters and parameter values to the server; the server generates a monitoring interface with various interface parameters and parameter values of the medical device; the server receives an effective modification request for one or more parameter values on the monitoring interface to generate a control demand and send the control demand to the medical device; the medical device receives the control demand sent by the server; and the medical device executes the control demand. The medical device is subjected to concentrative integrated control, and workers can perform unified monitoring and operation on each medical device in an operating room; the method provided by the invention provides convenience for the workers to operate the medical device; and in the operation process, the workers do not need entering an operating room for adjusting the medical device, so the infection probability of the patient in the operation can be reduced.

Owner:ZHEJIANG SUPCON INFORMATION TECH CO LTD

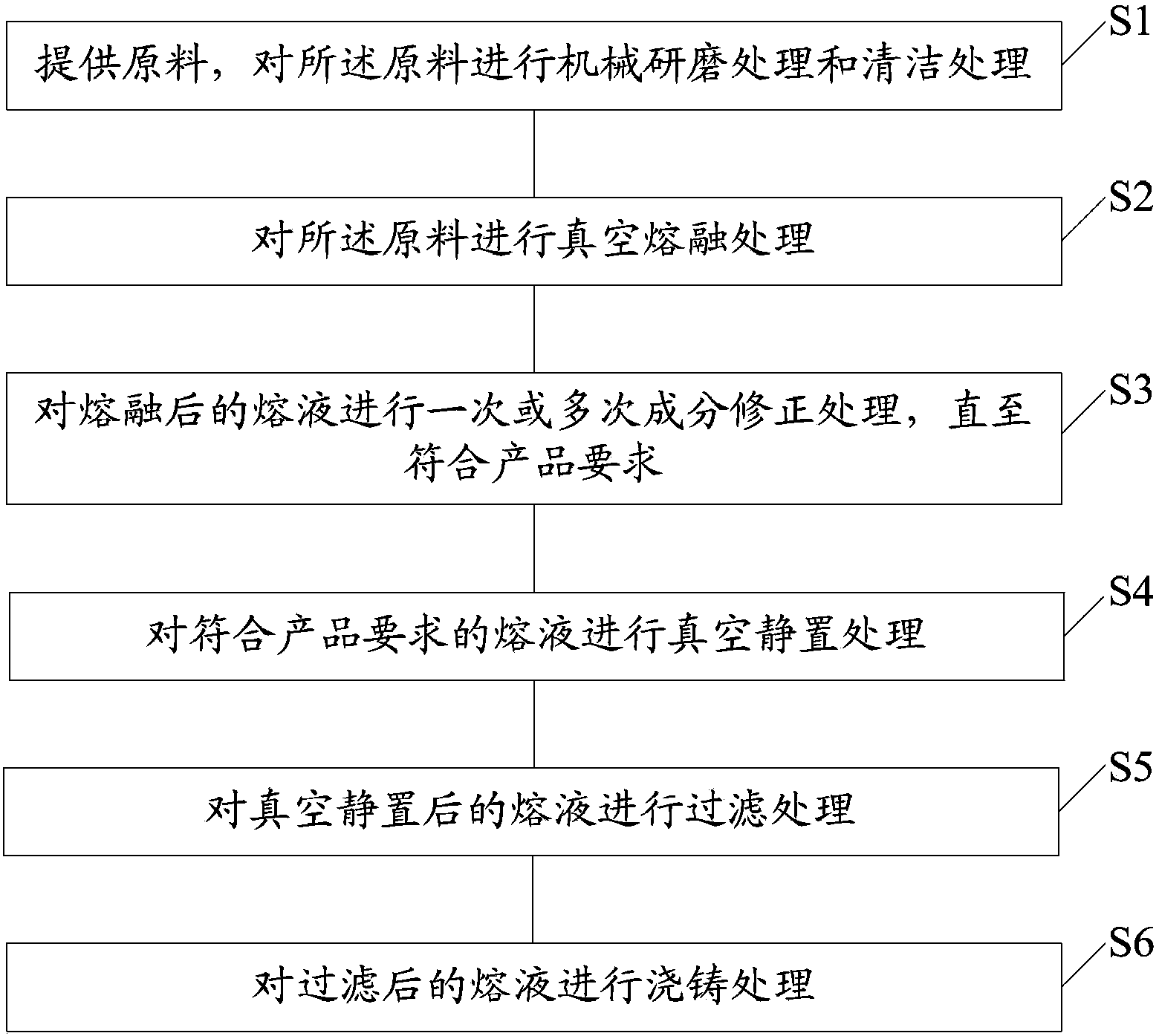

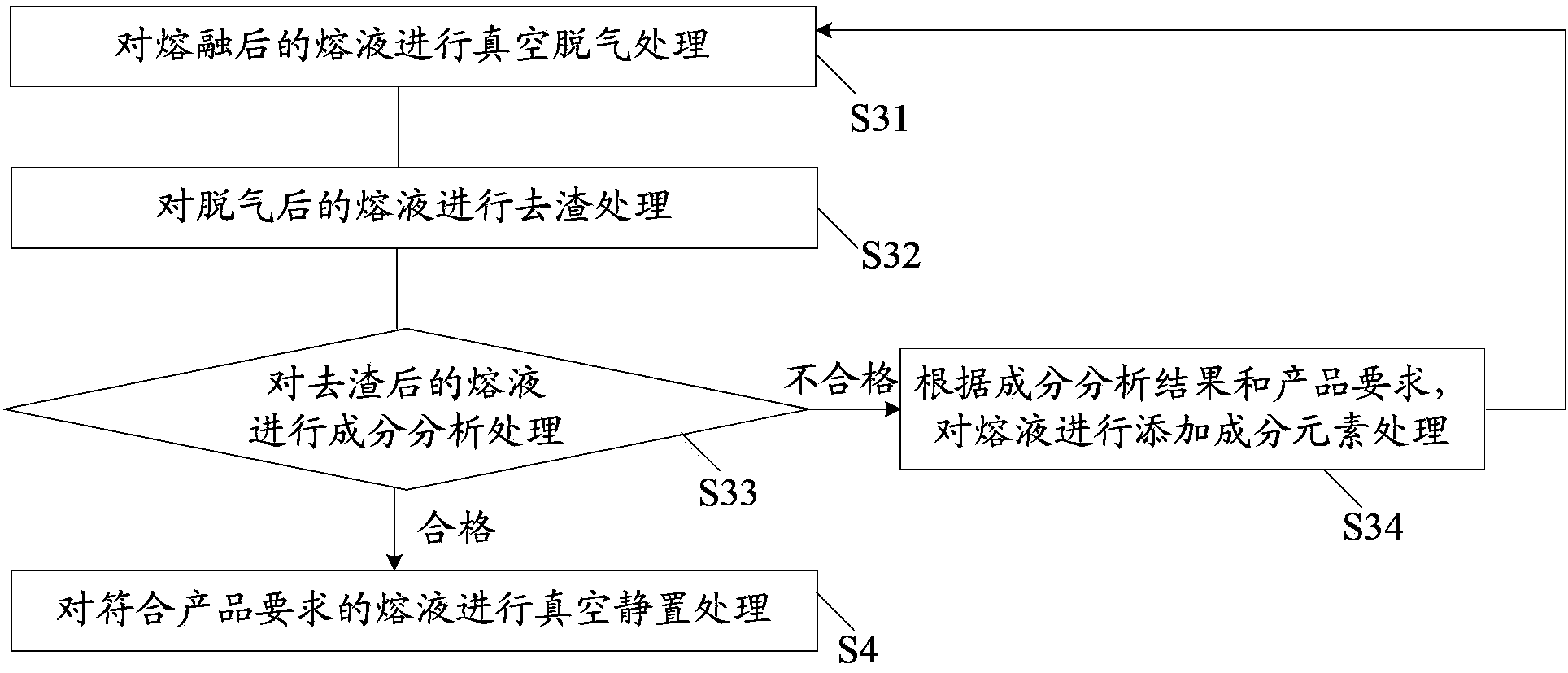

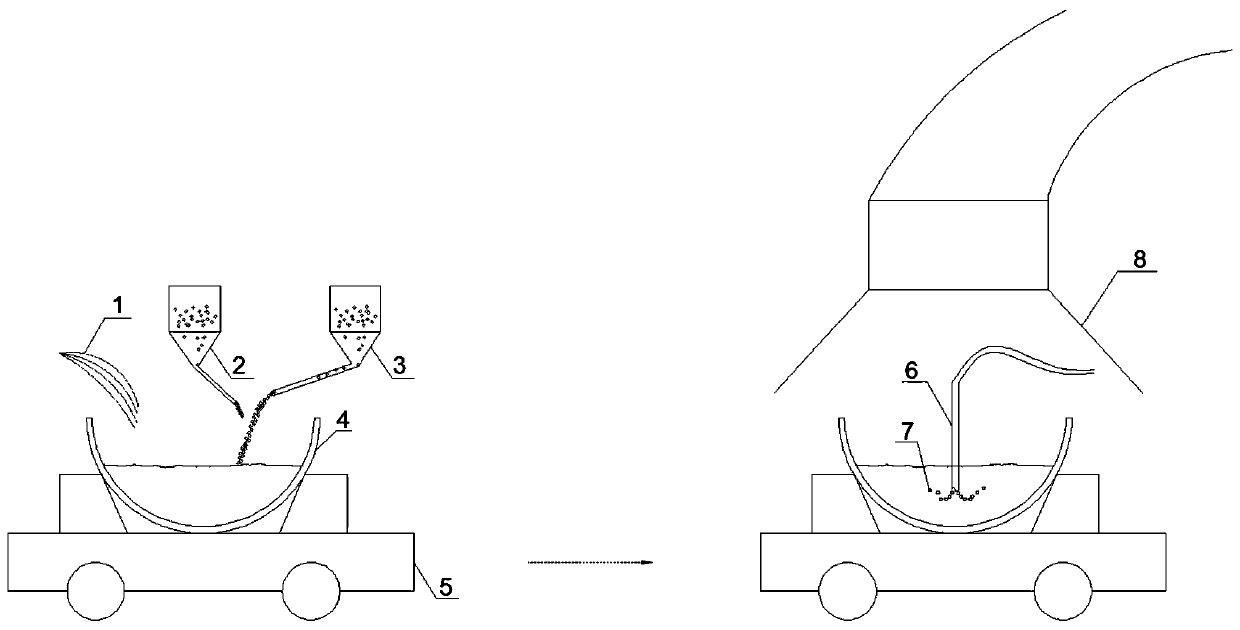

Aluminum alloy casting method

The invention discloses an aluminum alloy casting method. The aluminum alloy casting method comprises the following steps: raw materials are supplied; the vacuum melting treatment is performed for the raw materials; one or more times of component correction treatment is performed for the molten liquid until the product requirements are satisfied; the vacuum standing treatment is performed for the molten liquid satisfying the product requirements; and the filtering treatment and the casting treatment are performed for the molten liquid after the vacuum standing treatment. The aluminum alloy casting method can improve the aluminum alloy purity, and reduce the production cost.

Owner:宁波创润新材料有限公司

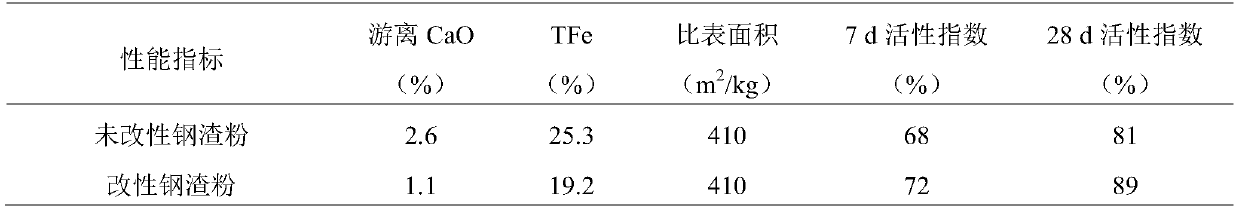

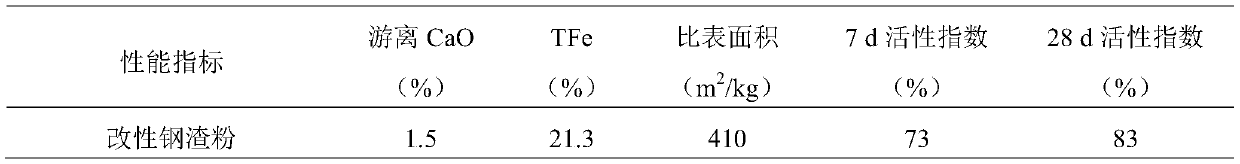

Novel high-temperature steel slag modifier and modification pretreatment process

ActiveCN110055370AAchieve high temperature modificationAchieve recyclingManufacturing convertersSlagNitrogen

The invention discloses a novel high-temperature steel slag modifier and a modification pretreatment process, and belongs to the technical field of steel slag modification. The novel high-temperaturesteel slag modifier comprises a substance containing elemental silicon and a substance containing elemental carbon, the content of the elemental silicon in the substance containing the elemental silicon is more than or equal to 60%, and the content of the elemental carbon in the substance containing the elemental carbon is more than or equal to 80%. The invention further discloses the novel high-temperature steel slag modification pretreatment process which comprises the following steps 1) adding the substance containing the elemental carbon and the substance containing the elemental silicon into a slag tank in advance; 2) when a converter is deslagging, adding the substance containing the elemental silicon into the slag tank at the same time; 3) blowing nitrogen into a material after deslagging, and collecting generated dust at the same time; and 4) carrying out hot stuffy treatment on steel slag subjected to nitrogen blowing treatment in the step 3). The novel high-temperature steelslag modifier and the modification pretreatment process can effectively improve the stability and grindability of the steel slag and improve the recovery rate of the slag and steel.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com