Preparation method of rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy

A micro-alloying and copper alloy technology, applied in the field of tungsten alloy materials, can solve the problems of restricting the microstructure and mechanical properties of tungsten-nickel-copper alloys, alloy powder segregation, and difficulty in particle size control, etc. High uniformity and composition control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the rare earth microalloyed high-density and high-strength tungsten-nickel-copper alloy according to the embodiment of the present invention, the specific steps are as follows:

[0025] (1) Weigh tungsten nitrate, nickel nitrate, copper nitrate, yttrium nitrate and water according to the molar ratio of 52~53.4: 1.5~4.8: 1.2~2.5: 0.11~0.34: 2500~3000, and make a mixed solution;

[0026] (2) under the condition of 25~40 DEG C, the ammonia solution mixed with the obtained mixed solution and the concentration of 14.56~15.12mol / L is made into an alkaline solution, and the volume ratio of the used ammonia solution to the mixed solution obtained in step (1) is 3:1, the obtained alkaline solution is stirred, crystallized, filtered, washed and dried to obtain the precursor powder;

[0027] (3) Putting the precursor powder into a reducing atmosphere furnace for dissociation and reduction treatment to obtain tungsten-nickel-copper alloy powder containing ...

Embodiment 1

[0038] First, weigh tungsten nitrate (WNO 3 2H 2 O), nickel nitrate (Ni(NO 3 )2·6H 2 O), copper nitrate (Cu(NO 3 )2·6H 2 O) and yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), the concrete consumption of the raw material that takes by weighing is: tungsten nitrate (WNO 3 2H 2 O) is 146.5g, nickel nitrate (Ni(NO3) 2 6H2O) is 12.8g, copper nitrate (Cu(NO3)2 6H2O) is 7.4g, yttrium nitrate (Y(NO 3 ) 3 ·6H 2 (2) is 0.42g, measures 450ml of distilled water with a graduated cylinder, adds the raw materials weighed and the distilled water measured into a beaker and stirs and dissolves to obtain a mixed solution. At 30°C, add ammonia solution with a concentration of 14.56mol / L to the mixed solution in a dropwise manner, the volume ratio of ammonia water / mixed solution is 3:1, and stir and crystallize at 59°C for 18 hours. Filtration and vacuum drying at 150°C to obtain precursor powder;

[0039] Take out the precursor powder, dissociate and reduce it in a carbon atmosphere rotary f...

Embodiment 2

[0043] First, weigh tungsten nitrate (WNO 3 2H 2 O), nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), copper nitrate (Cu(NO 3 ) 2 ·6H 2 O) and yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), the concrete consumption of the raw material that takes by weighing is: tungsten nitrate (WNO 3 2H 2 O) is 148.8g, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) is 7.86g, copper nitrate (Cu(NO 3 ) 2 ·6H 2 O) is 5.03g, yttrium nitrate (Y(NO 3 ) 3 ·6H 2 (2) is 0.84g, measures 500ml of distilled water with graduated cylinder, adds the raw material that takes by weighing and the distilled water that measures and stirs and dissolves in the beaker, obtains mixed solution. At 34°C, add the ammonia solution with a concentration of 14.88 mol / L to the mixed solution in a dropwise manner, the volume ratio of ammonia water / mixed solution is 3:1, and stir and crystallize at 62°C for 21 hours. Filtration and vacuum drying at 150°C to obtain precursor powder;

[0044] Take out the precursor powder, dissociate and...

PUM

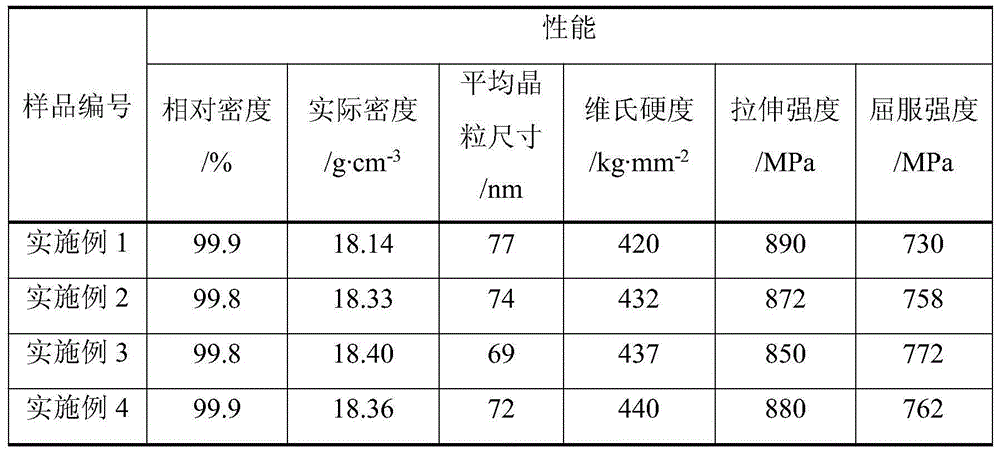

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com