Patents

Literature

67results about How to "Composition control with high precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy

InactiveCN104651653AResolve the assigned stateOvercome the adverse effects of mechanical propertiesNitrateHigh density

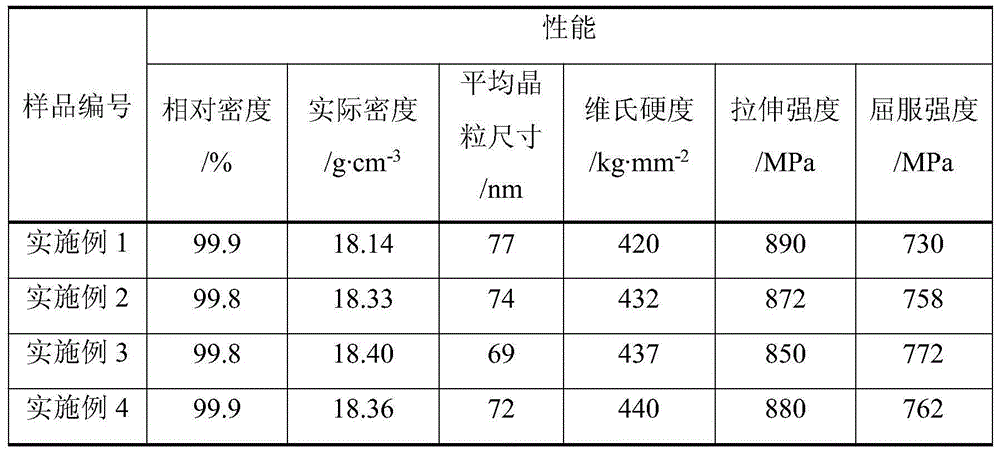

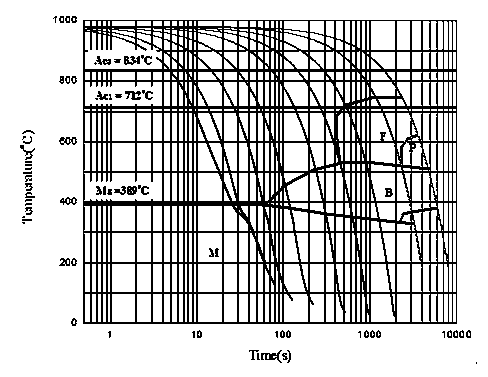

The invention relates to a preparation method of a rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The preparation method comprises the following steps: firstly, preparing tungsten nitrate, nickel nitrate, copper nitrate, yttrium nitrate and water into a mixed solution according to a preset metering ratio, then preparing an alkali solution together with certain concentration of ammonia water solution, stirring the alkali solution, crystallizing, filtering, washing and drying to obtain precursor powder; placing the precursor powder into a reducing atmosphere furnace for dissociating and reducing, to obtain yttrium-containing tungsten-nickel-copper alloy powder; and grinding the alloy powder and mixing together with a forming agent and press-forming, dewaxing the formed blank and performing high-temperature sintering to finally obtain the rare earth microalloyed high-density high-strength tungsten-nickel-copper alloy. The tungsten-nickel-copper alloy prepared by taking the rare earth microalloyed tungsten-nickel-copper alloy powder prepared by adopting a liquid / liquid doping method as a raw material through a proper powder metallurgy technology has the advantages that the density is more than or equal to 18.1g / cm<3>, the tensile strength is more than or equal to 850MPa, and the yielding strength is more than or equal to 690MPa.

Owner:SHAANXI UNIV OF TECH

Preparation method of cell structure gradient tungsten alloy material

The invention discloses a preparation method of a cell structure gradient tungsten alloy material. The preparation method comprises the following steps that high-tungsten base prealloy powder and low-tungsten base prealloy powder are obtained through prealloying treatment in advance, after the high-tungsten base prealloy powder is atomized and pelletized and is uniformly mixed with the low-tungsten base prealloy powder, compression forming is carried out in a cold isostatic pressing machine, two-step sintering is carried out in a high-temperature vacuum tube type furnace, and finally the cellstructure gradient tungsten alloy material is obtained.

Owner:SHAANXI SCI TECH UNIV

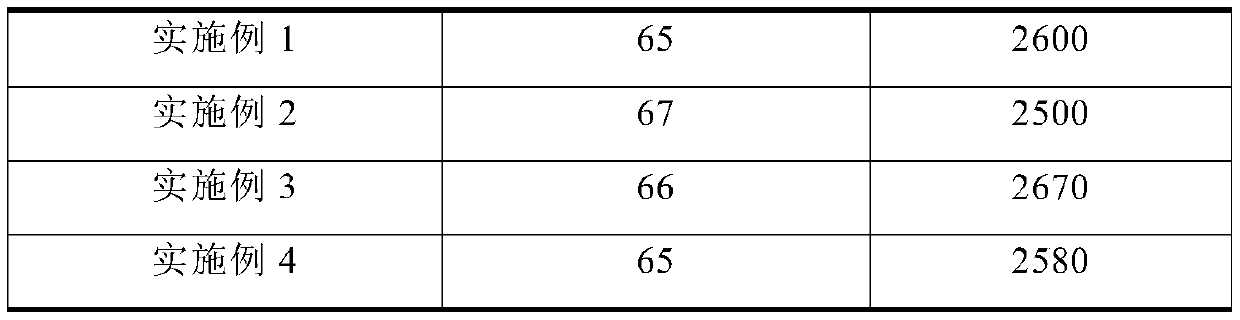

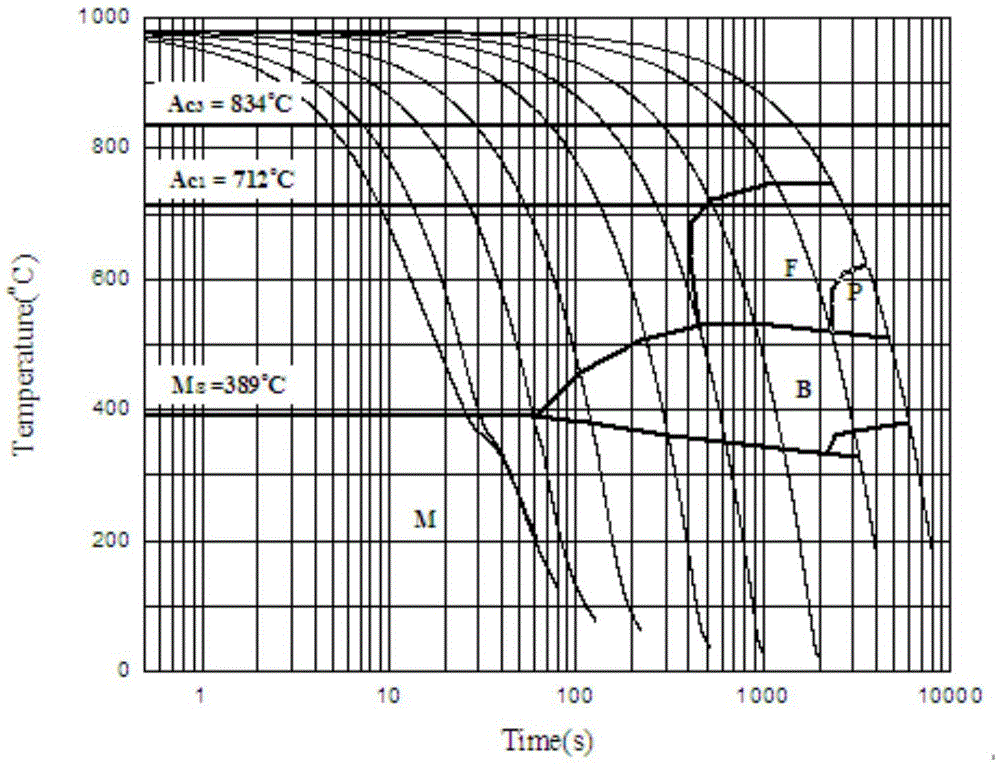

MnCr alloying thermal-forming steel and production method thereof

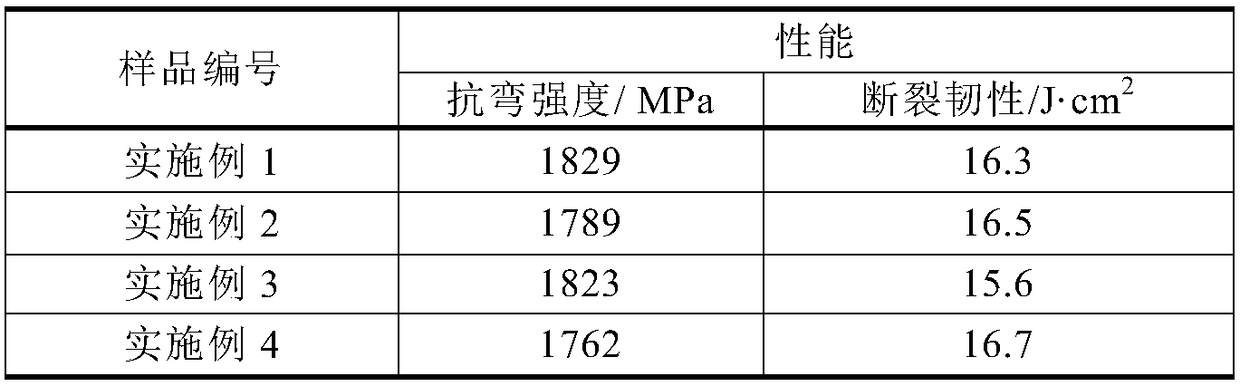

The invention provides MnCr alloying thermal-forming steel. The MnCr alloying thermal-forming steel is characterized by mainly containing the following chemical elements in percent by weight: 0.15%-0.25% of C, 0.10%-0.25% of Si, 1.5%-2.2% of Mn, and 2.0%-2.5% of Cr. Main process parameters in a production process of the MnCr alloying thermal-forming steel are controlled as follows: a casting blank tapping temperature is controlled to 1230 DEG C-1250 DEG C, a hot-rolling finishing temperature is controlled to 920 DEG C-950 DEG C, a hot-rolling coiling temperature is controlled to 630 DEG C-660 DEG C, and a stamping cooling rate is controlled to 18 DEG C / scond-22 DEG C / second. A thermal-forming product produced by the MnCr alloying thermal-forming steel disclosed by the invention has mechanical performances as follows: yield strength Rp is 1030 MPa, tensile strength Rm is 1510 MPa, and uniform elongation rate Agt is 5%. All thermally-formed microscopic structures are martensite.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

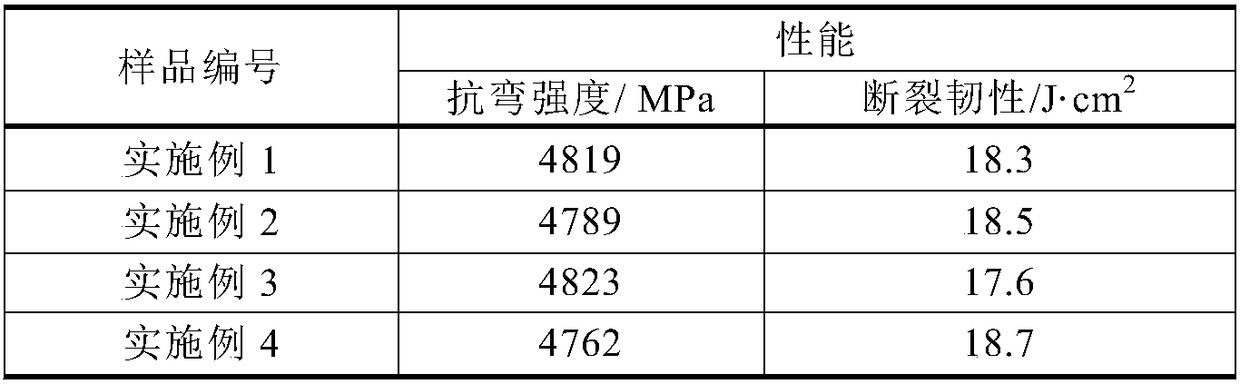

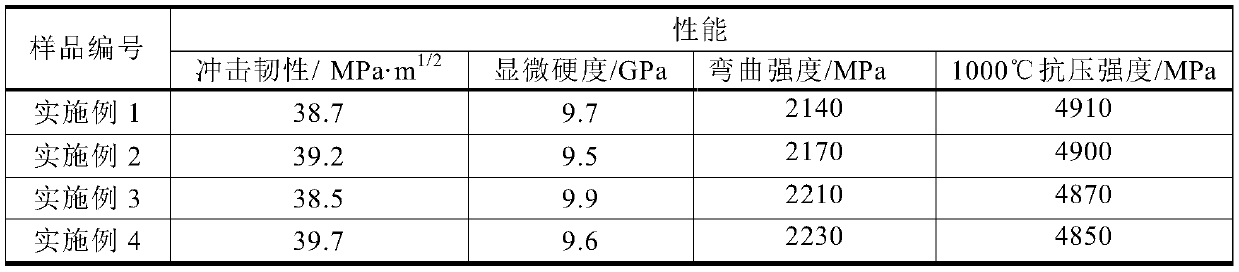

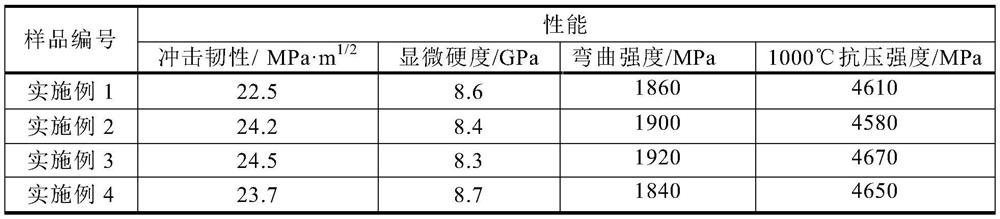

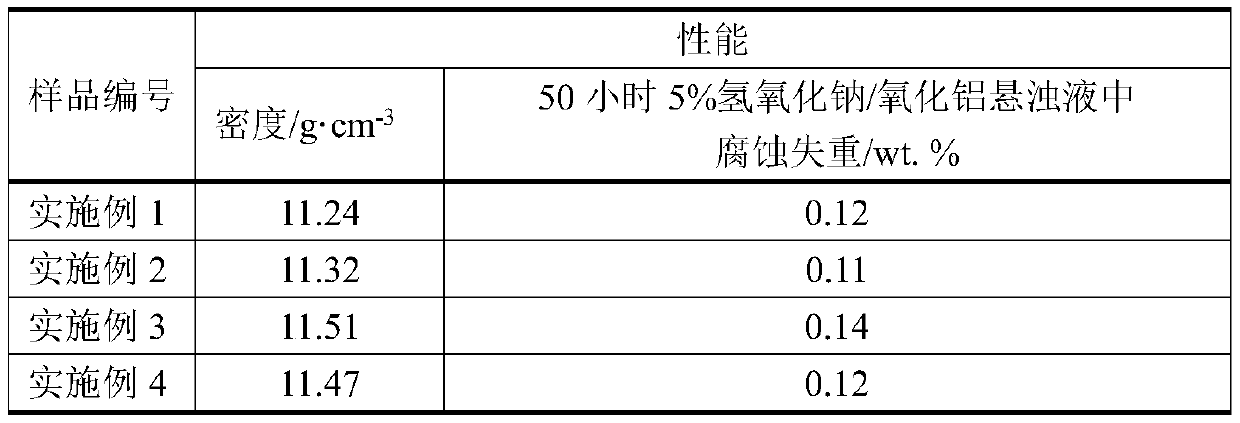

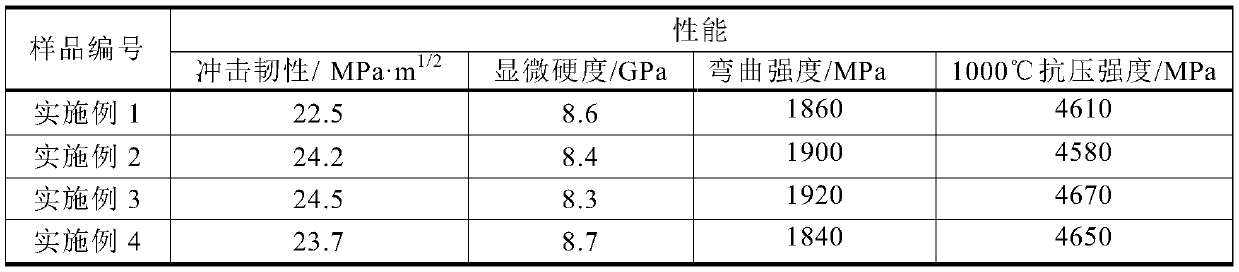

Method for preparing Ni-Fe-based high-temperature binder phase hard alloy

InactiveCN104593626AOvercome the adverse effects of high temperature mechanical propertiesComposition control with high precisionHigh energyFlexural strength

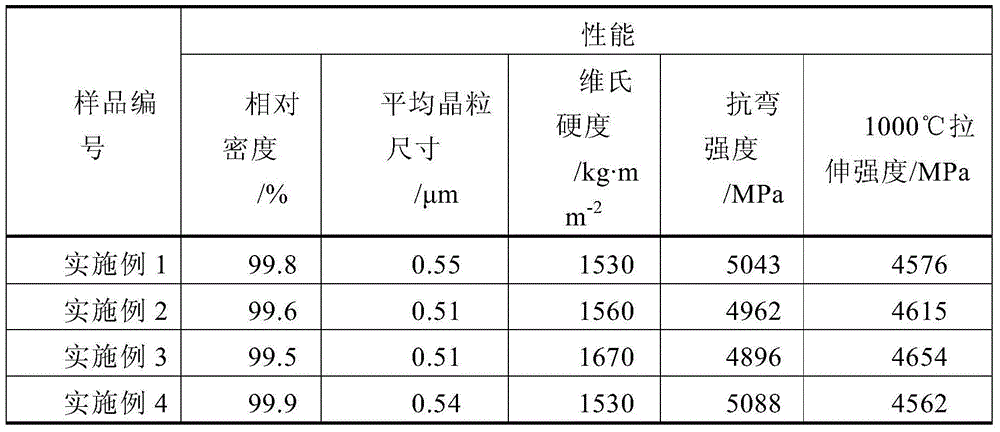

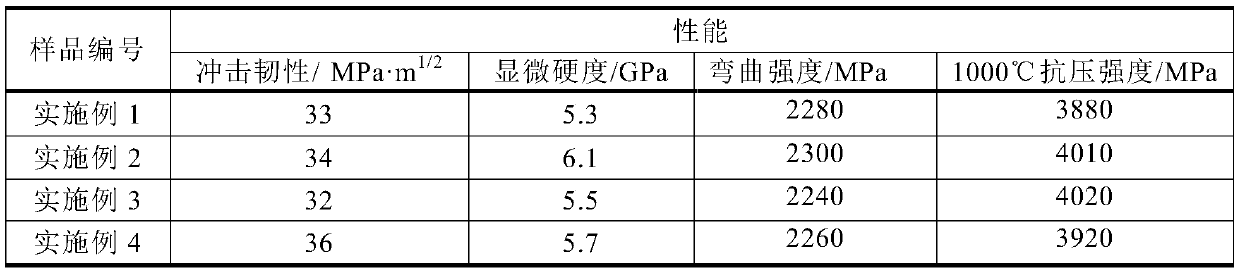

The invention discloses a method for preparing a Ni-Fe-based high-temperature binder phase hard alloy. The method comprises the following steps of firstly mixing nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder in a predetermined mass ratio and carrying out high-energy ball milling; carrying out ordinary ball milling on powder subjected to high-energy ball milling, tungsten carbide powder, titanium carbide powder and vanadium carbide powder to obtain a mixed powder; loading the prepared mixed powder into a mold and pressing by virtue of cold press to obtain a green body; carrying out sinter molding on the green body material under the protective atmosphere to finally obtain the Ni-Fe-based high-temperature binder phase hard alloy material. According to the method, Ni-Fe-based mechanical alloying powder instead of Co powder is used as a binder, and the prepared hard alloy has Vickers hardness equal to or greater than 1530 / kg.mm<-2>, flexural strength equal to or greater than 4880MPa and tensile strength equal to or greater than 4562MPa at 1000 DEG C.

Owner:SHAANXI UNIV OF TECH

Preparation method of W-Ni-Cu prealloyed powder

InactiveCN105268983AComposition control with high precisionImprove processing stabilityTube furnaceHydrogen atmosphere

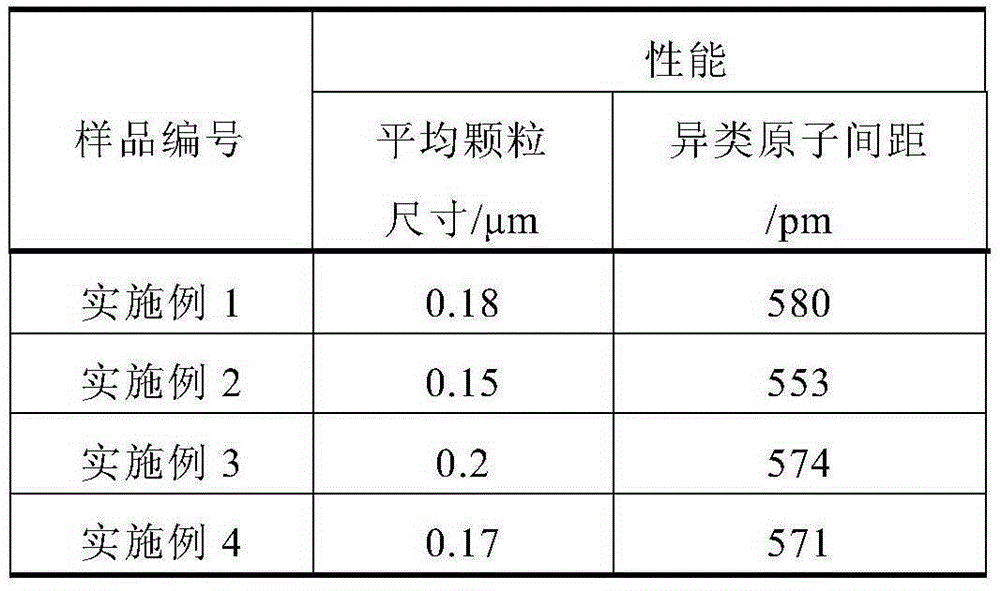

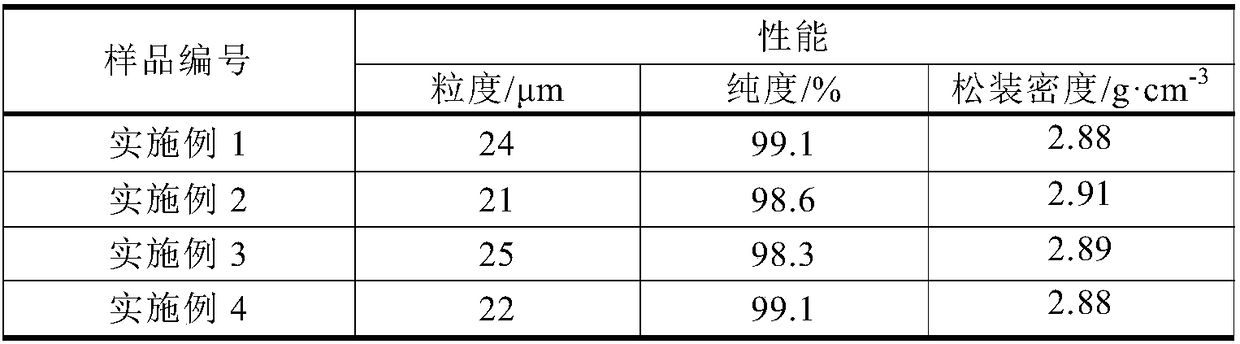

The invention discloses a preparation method of W-Ni-Cu prealloyed powder. The preparation method comprises the steps that NiCl2 6H2O, CuCl2 and deionized water are prepared into a solution, and then WO3 powder is added into the solution; a (NH4)2C2O4 solution is added into turbid liquid according to the volume ratio; the solution is filtered and dried in air, and precursor powder is obtained; dried powder is placed in a tube furnace to be reduced under the hydrogen atmosphere condition; and high energy ball milling is carried out on the reduced powder, and the W-Ni-Cu prealloyed powder is finally obtained. The average particle size of the W-Ni-Cu prealloyed powder prepared through the method is smaller than or equal to 0.2 micron, and the distance between dissimilar metal atoms is smaller than or equal to 580 pm.

Owner:SHAANXI UNIV OF TECH

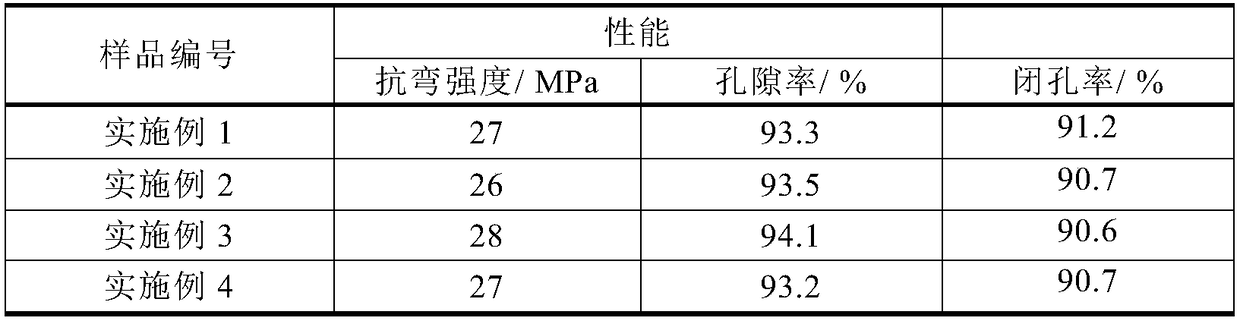

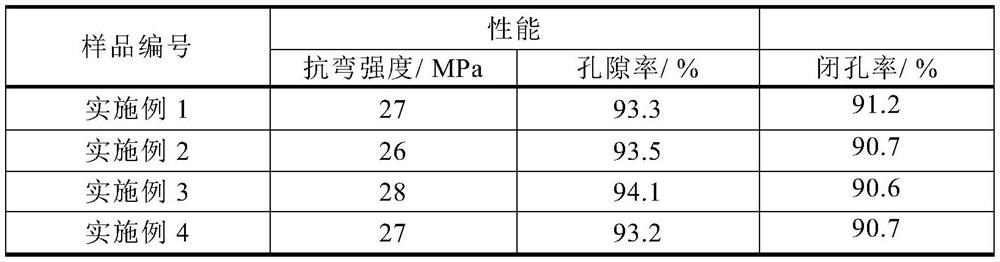

Method for preparing water-permeable bricks from vanadium-titanium magnetite tailings

InactiveCN109081705APromote rapid formationImprove water resistanceCeramic materials productionCeramicwareCompression moldingPorosity

The invention discloses a method for preparing water-permeable bricks from vanadium-titanium magnetite tailings. The method includes: performing roughening treatment to obtain activated vanadium-titanium magnetite tailings, subjecting to mixed ball milling along with strengthening materials, a foaming agent and an activating agent, adopting a low-pressure mould for compression molding, and finallysubjecting to foaming, sintering and subsequent treatment in a tunnel kiln to obtain a water-permeable brick material. By adoption of the vanadium-titanium magnetite tailings as a main material, high-water-permeability bricks are prepared according to a surface strengthening process through adding of the strengthening materials, the foaming agent and the activating agent, and water resistance ofpavement bricks is remarkably improved. The prepared water-permeable bricks have comprehensive strength larger than or equal to 12400MPa, porosity larger than or equal to 23.6% and through hole rate larger than or equal to 22.9%.

Owner:SHAANXI SCI TECH UNIV

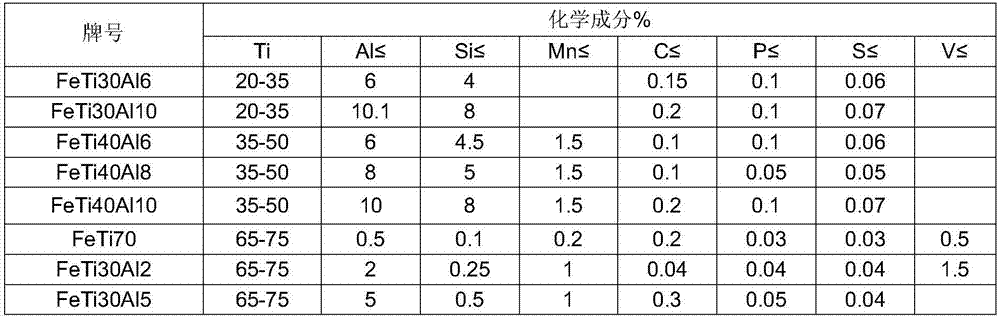

Method of preparing ferrotitanium alloy powder by adopting ferrovanadium slag and vanadium-titanium magnetite tailings

The invention discloses a method of preparing ferrotitanium alloy powder by adopting ferrovanadium slag and vanadium-titanium magnetite tailings. The method comprises the following steps: first, carrying out ball-milling treatment on mixed powder of ferrovanadium slag, graphite powder and calcium carbonate powder and then pre-sintering mixed powder of the vanadium-titanium magnetite tailings, sodium oxide and calcium chloride at a low temperature in a sintering furnace; granulating and degreasing the prepared two types of mixed powder; and finally, reductively sintering, crushing and screeningthe degreased powder to obtain the ferrotitanium alloy powder material finally. The method has the advantages of being high in component control precision, good in process stability and relatively high in repeatability, and high purity ferrotitanium alloy powder can be prepared.

Owner:SHAANXI SCI TECH UNIV

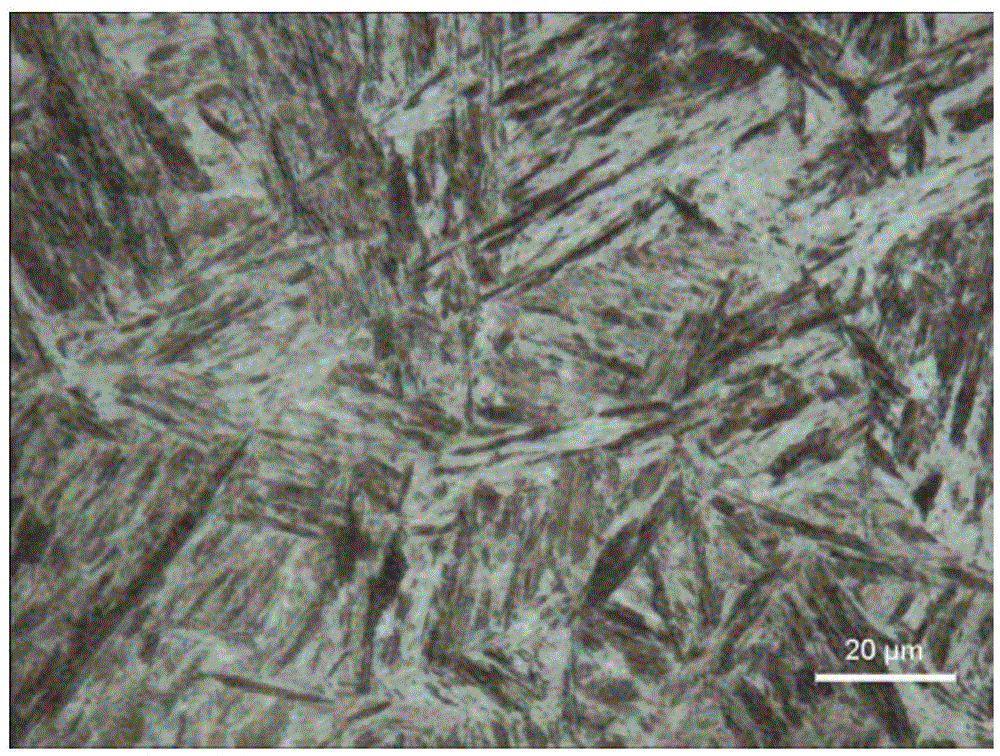

Preparation method of multilevel strip-shaped crystalline tungsten alloy material

ActiveCN110093544AIncrease the lengthImprove impact toughnessTransportation and packagingMetal-working apparatusContinuationRepeatability

The invention discloses a preparation method of a multilevel strip-shaped crystalline tungsten alloy material. The preparation method comprises the following steps of firstly, carrying out turning-over frequency vibration impact treatment on mixed powder of tungsten powder, titanium powder and yttrium powder in a certain proportion, adding a seaming agent into the obtained micron-sized layered tungsten-based composite powder to carry out biaxial micro-rolling continuation, degreasing, pressing, forming, and finally, placing the material in a normal-pressure inert atmosphere heat collection device for firing and molding to finally obtain the multilevel strip-shaped crystalline tungsten alloy material. The method has high component control precision, strong process stability and strong repeatability, and can realize strengthening and toughening and long service life of the tungsten alloy material.

Owner:SHAANXI SCI TECH UNIV

Method for preparing microcrystal foam glass from vanadium titano-magnetite tailings

ActiveCN109020243AIncrease profitLower melting temperatureGlass shaping apparatusFoaming agentSolvent

The invention discloses a method for preparing microcrystal foam glass from vanadium titano-magnetite tailings. Pickling is firstly carried out, so that activated vanadium titano-magnetite tailings are obtained, the activated vanadium titano-magnetite tailings, correcting material, a cosolvent and a foaming agent are mixed and ball-milled, the mixture is pressed to be shaped in a cold press, and is finally melted, crystallized and treated by heat in a sintering furnace, and ultimately, the microcrystal foam glass material is obtained. With vanadium titano-magnetite tailings as a main material,by adding the correcting material, the foaming agent and the cosolvent and adopting the crystallization process, the method can prepare the foam glass containing a small amount of microcrystals, thematerial cost is greatly reduced, and the toughness of the glass is increasedimproved. The method has the advantages of high component control precision and high process stability and repeatability, and can achieve higher industrial added value from vanadium titano-magnetite tailings.

Owner:SHAANXI SCI TECH UNIV

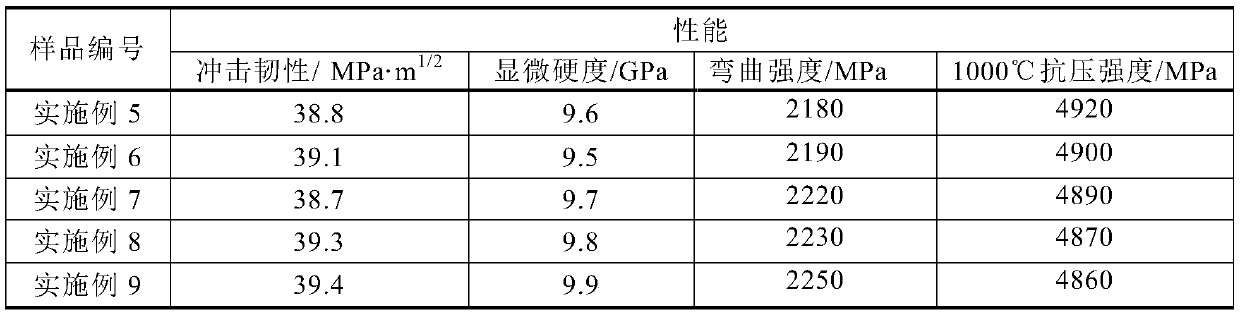

Preparation method of complex-phase co-strengthening hard alloy material

The invention discloses a preparation method of a complex-phase co-strengthening hard alloy material. According to the method, firstly, pre-alloying treatment is carried out to obtain tungsten carbidebase pre-alloying powder and titanium carbonitride base pre-allying powder, the two kinds of powder are mixed with cobalt powder uniformly, the powder is subjected to secondary atomizing, drying andpelletizing, then pressed and formed in a cold pressing machine, and finally sintered in a high-temperature vacuum pipe type furnace, and finally, the complex-phase co-strengthening hard alloy material is obtained.

Owner:SHAANXI SCI TECH UNIV +1

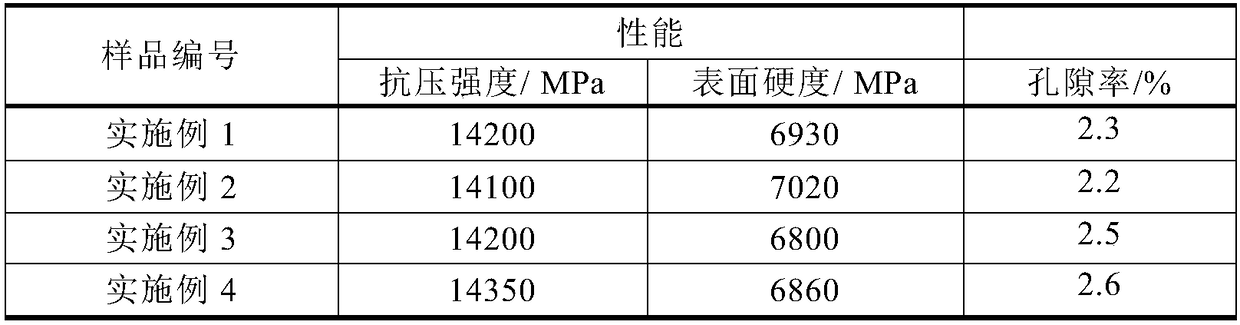

Method for preparing unglazed stair brick from vanadium-titanium magnet tailings

The invention discloses a method for preparing an unglazed stair brick from vanadium-titanium magnet tailings. The method comprises the following steps: firstly, performing refining treatment to obtain micron-sized active vanadium-titanium magnet tailings, mixing the micron-sized active vanadium-titanium magnet tailings with a correcting raw material, an oxidant and a cosolvent, mounding, finallysintering in a pushed slab kiln, and performing surface wear resisting treatment to finally obtain an unglazed stair brick material. By the method, with the vanadium-titanium magnet tailings as a mainraw material, through addition of the correcting raw material, the oxidant and the cosolvent and by a surface wear resisting technology, preparation of the unglazed stair brick is achieved, the costof the raw materials is greatly reduced and the wear resistance of the surface of the brick is improved. The unglazed stair brick prepared by the method provided by the invention has the compressive strength being higher than or equal to 14100 MPa, the surface hardness being higher than or equal to 6800 MPa and the porosity being lower than or equal to 2.6%.

Owner:SHAANXI SCI TECH UNIV

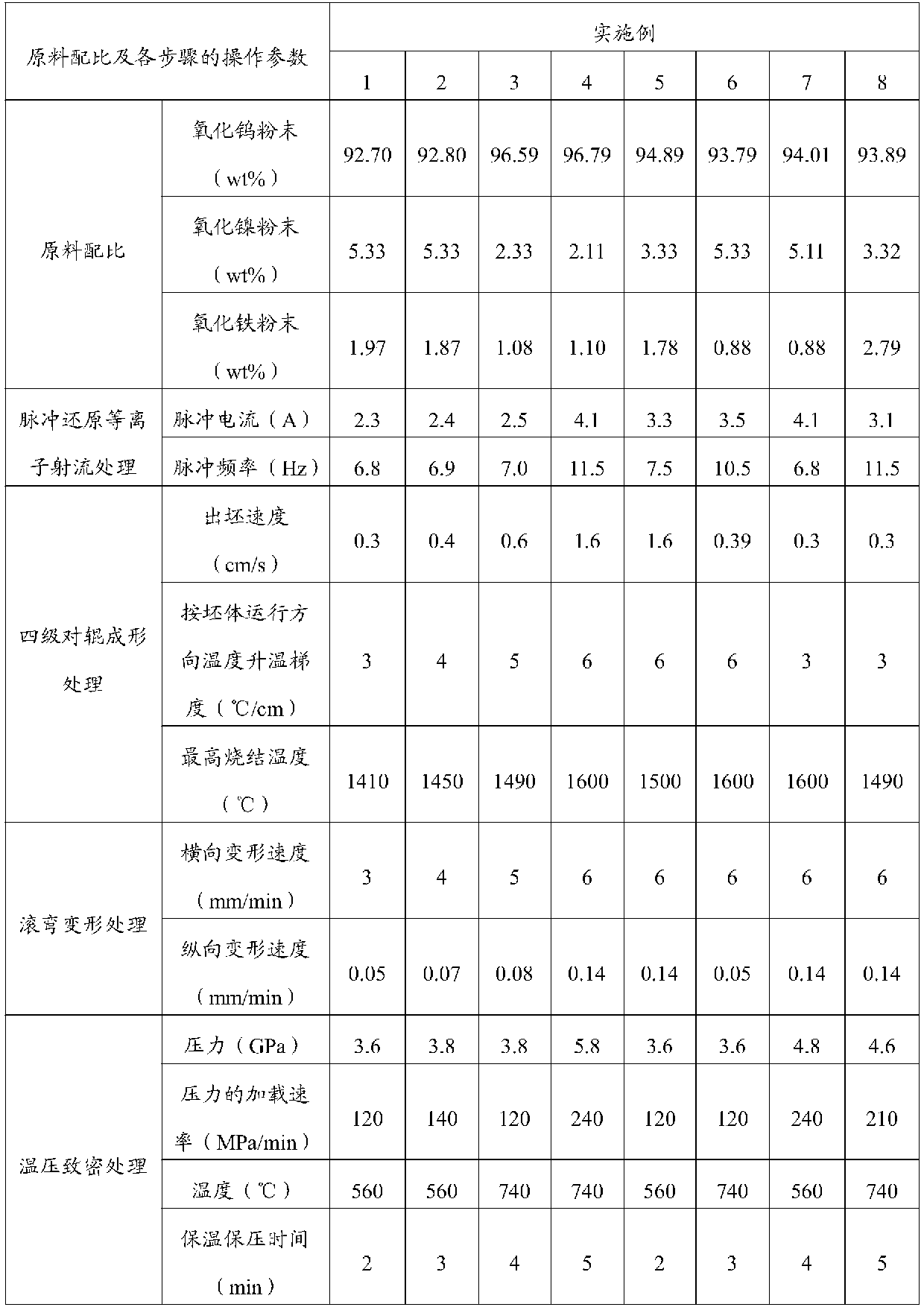

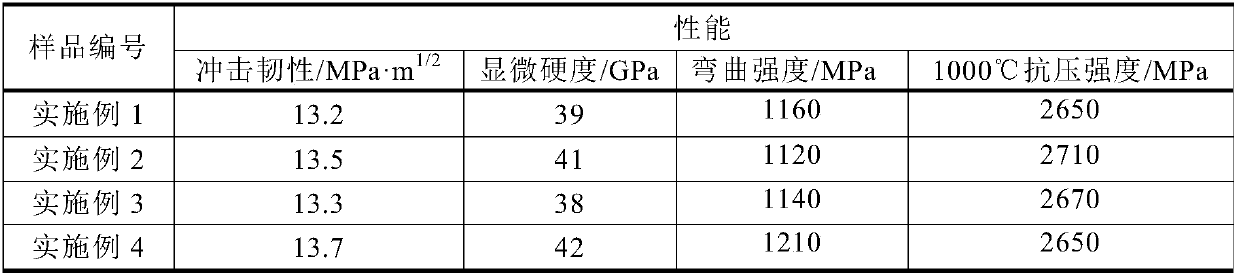

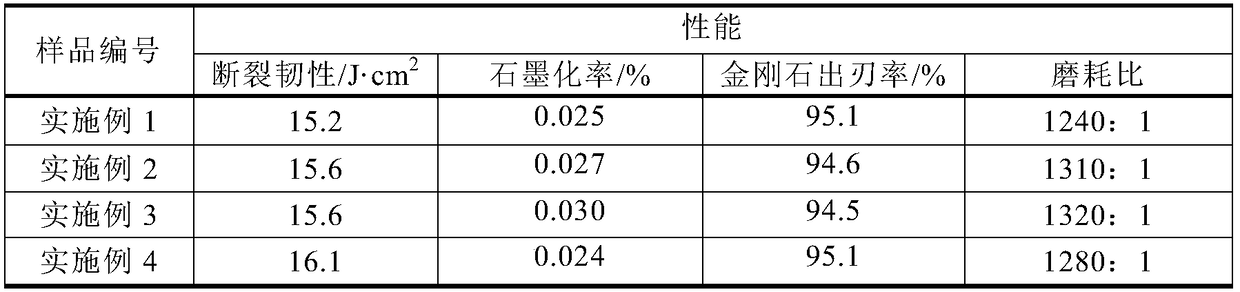

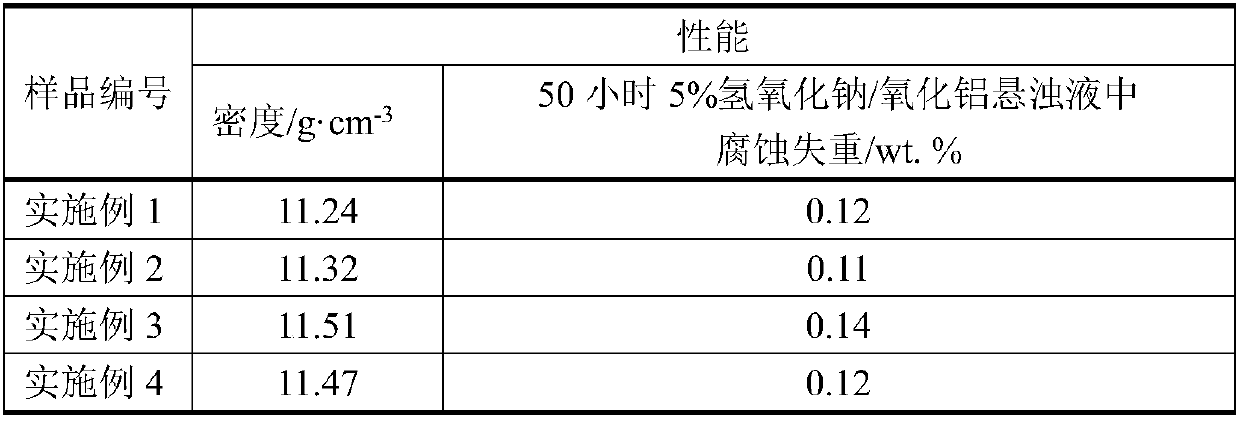

Stripped tungsten alloy material with self-sharpening structure, as well as preparation method and application thereof

ActiveCN111283212AGood adiabatic shear performanceInhibit growthIncreasing energy efficiencyPlasma jetUltimate tensile strength

The invention provides a stripped tungsten alloy material with a self-sharpening structure, as well as a preparation method and application thereof, and belongs to the technical field of tungsten alloy preparation. The preparation method comprises the steps of carrying out pulse reduction plasma jet treatment and cooling treatment on mixed powder obtained after mixing tungsten oxide powder, nickeloxide powder and ferric oxide powder, and obtaining tungsten-nickel-iron prealloyed powder; carrying out four-stage roll forming treatment on the tungsten-nickel-iron prealloyed powder, and obtaininga plate type tungsten-nickel-iron alloy; carrying out roll-bending deformation treatment on the plate type tungsten-nickel-iron alloy, and obtaining a deformed tungsten-nickel-iron alloy; and carrying out warm-pressing densification treatment on the deformed tungsten-nickel-iron alloy, and obtaining the stripped tungsten alloy material with the self-sharpening structure. According to the strippedtungsten alloy material with the self-sharpening structure, as well as the preparation method and the application thereof provided by the invention, through adopting a pulse reduction plasma jet technology, four-stage roll forming treatment, roll-bending deformation treatment and warm-pressing densification treatment, the technical advantages of chemical reduction and plastic deformation are fully played, so that the compatibility of the strength and the plasticity of the tungsten alloy material can be optimized, and the obtained stripped tungsten alloy material with the self-sharpening structure has a better adiabatic shear performance.

Owner:SHAANXI SCI TECH UNIV

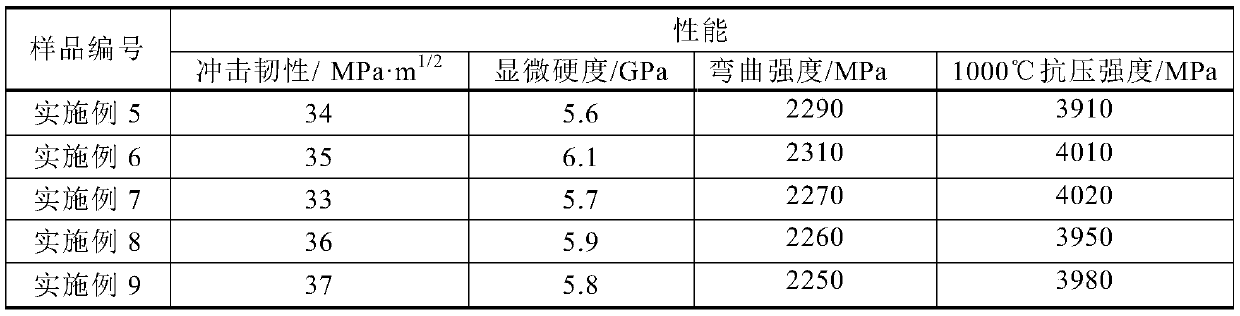

Preparation method of silicon nitride high-temperature ceramic material in multistage twin structure

The invention discloses a preparation method of a silicon nitride high-temperature ceramic material in a multistage twin structure. The method comprises processing monatomic silicon powder at high impulse, subjecting the processed monatomic silicon powder to reaction with nitrogen to obtain silicon nitride nanopowder, adding in gel for nodulizing and degreasing shaping to obtain a cold pressing blank, and sintering the shaped cold pressing blank at ultrahigh pressure and high temperature to obtain the silicon nitride high-temperature ceramic material in the multistage twin structure. The preparation method of the silicon nitride high-temperature ceramic material in the multistage twin structure is high in composition control precision, technical stability and repeatability and capable of achieving high-temperature toughening of silicon nitride ceramic materials.

Owner:SHAANXI SCI TECH UNIV

Preparation method of iron-based diamond tool material without graphitizing conversion

ActiveCN109234646AForm evenlyEliminate interface graphitizationDiamondIron powderAdditive ingredient

The invention discloses a preparation method of an iron-based diamond tool material without graphitizing conversion. The preparation method comprises the steps: firstly, homogenizing and surface ionizing iron powder, copper-tine alloy powder and silicon powder to prepare iron-based alloy powder; then obtaining polygonal diamond powder through diamond breaking treatment; evenly mixing the two kindsof powder and firing and shaping under the weak reduction atmosphere; finally, obtaining the iron-based diamond tool material without graphitizing conversion. The method has the advantages of high ingredient control accuracy, stronger technology stability and repeatability and ability in achieving toughness, stable interfaces without graphization and long service life of iron-based diamond cutters.

Owner:SHAANXI SCI TECH UNIV

Low-density anti-corrosion hard alloy material and preparation method thereof

The invention discloses a low-density anti-corrosion hard alloy material and a preparation method thereof. Tungsten carbide powder, cobalt powder and calcium carbonate powder are weighed according tomass percent and are put in a cold pressing machine to be made into cylindrical green bodies after being evenly mixed in a three-dimensional vortex material mixing machine; and the premade green bodies and nickel-based high-temperature brazing filler metal are put into a high-temperature electric conduction mould according to the mass ratio and are fired into the low-density anti-corrosion hard alloy material in a double-shaft high-pressure infiltration device.

Owner:株洲思瑞普硬质合金股份有限公司

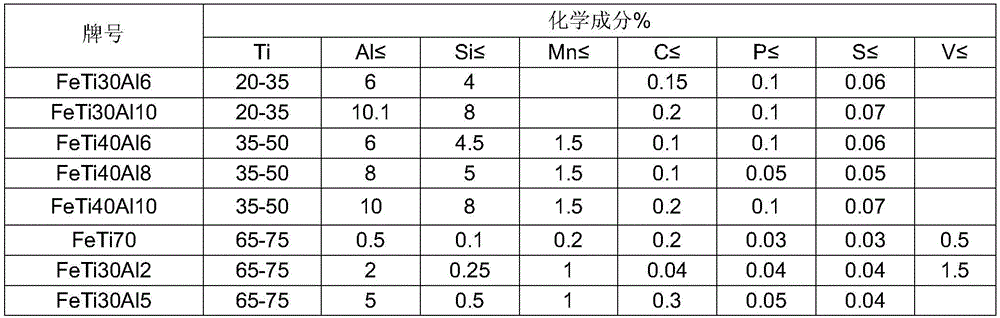

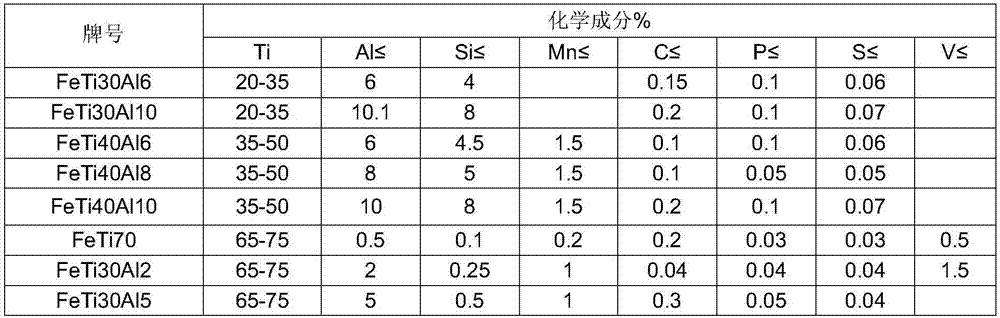

Production method of high-quality ferro-titanium

The invention relates to a production method of high-quality ferrotitanium, belongs to the technical field of ferroalloy smelting, and aims at providing a production method of high-quality ferrotitanium. In the invention, high-titanium and low-impurity content materials such as offgrade titanium sponge, titanium (alloy) scrap and titanium (alloy) shavings are adopted as titanium raw materials, and pure iron (powder, block and water) is used as an iron source; the titanium raw materials and iron source are separately molten in a vacuum or inert gas shielding condition and are heated to 1690 DEG C or over respectively; and the two molten metals are counter-mixed according to the required ferrotitanium grade, argon is blown from the bottom, and casting and cooling are performed to obtain the high-quality ferrotitanium. By adopting the method provided by the invention, ferrotitanium-series products with different requirements on titanium content can be produced; and moreover, the production method has the advantages of simplicity and easiness in implementation, high content control precision, low content of impurities and harmful elements and high quality of ferrotitanium products while the problems of great control difficulty and high impurity content of traditional ferrotitanium production technology are effectively solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for preparing microcrystalline foam glass from vanadium-titanium magnet tailings

ActiveCN109020243BIncrease profitLower melting temperatureGlass shaping apparatusFoaming agentPhysical chemistry

The invention discloses a method for preparing microcrystalline foam glass from vanadium-titanium magnet tailings. The activated vanadium-titanium magnet tailings are obtained by pickling first, mixed with calibration materials, co-solvents and foaming agents and ball-milled, then cold-pressed Compressed in the machine, finally melted and crystallized in the sintering furnace, and finally obtained the microcrystalline foam glass material. Using vanadium-titanium magnetite tailings as the main raw material, by adding correction raw materials, foaming agent, co-solvent and adopting crystallization process, the preparation of foam glass with a small amount of microcrystals can be realized, which greatly reduces the cost of raw materials and improves the toughness of glass. The method has high compositional control precision, strong process stability and repeatability, and can realize high industrial added value of vanadium-titanium magnet tailings.

Owner:SHAANXI SCI TECH UNIV

Preparation method of multi-scale spherical-grain hard alloy material

ActiveCN110125387AFast firingInhibit growthTransportation and packagingMetal-working apparatusLayer interfacePositive pressure

The invention discloses a preparation method of a multi-scale spherical-grain hard alloy material. The preparation method comprises the steps that tungsten carbide powder is reduced through positive-pressure shearing and micro-grinding treatment, then selective nano-cobalt plating is conducted, a gelling material is added into obtained polygonal tungsten carbide composite powder locally wrapped with a cobalt film for grinding and pelletizing, high-temperature steady-state re-crystallization is conducted after degreasing; and finally, the powder is placed in an over-pressure heat-collection vacuum device to be sintered and molded, so that a multi-scale multi-layer interface hard alloy material is obtained. The preparation method of the multi-scale spherical-grain hard alloy material has theadvantages that the component control precision is high, the process stability and repeatability are high, high strength and toughness of the hard alloy materials are achieved, and the long service life of the hard alloy material is also achieved.

Owner:SHAANXI SCI TECH UNIV

Method for preparing porous ceramic material from vanadium-titanium magnetite tailings

ActiveCN109987962AIncrease industrial added valueEvenly distributedCeramic materials productionCeramicwareTitaniumAdditional values

The invention discloses a method for preparing a porous ceramic material from vanadium-titanium magnetite tailings. The method comprises the following steps: firstly, treating the vanadium-titanium magnetite tailings by a polyacid leaching method, placing the treated vanadium-titanium magnetite tailings, aluminum oxide powder, calcium carbonate powder and glass powder into a backflow-type wheel-milling blowing device according to a certain ratio for refining, then putting the refined mixture into a slow-speed eccentric stirring device, adding water for pulping, carrying out water displacementtreatment, and finally carrying out foaming formation in a high-temperature blast heat-collection device to finally obtain the porous ceramic material. The method has the advantages that the componentcontrol precision is high, process stability and repeatability are relatively high, and high industrial additional values of the vanadium-titanium magnetite tailings can be realized.

Owner:SHAANXI SCI TECH UNIV

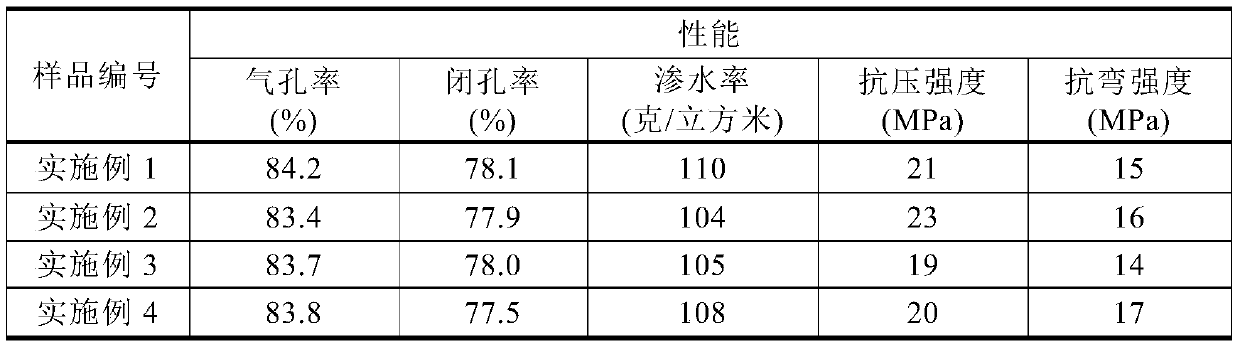

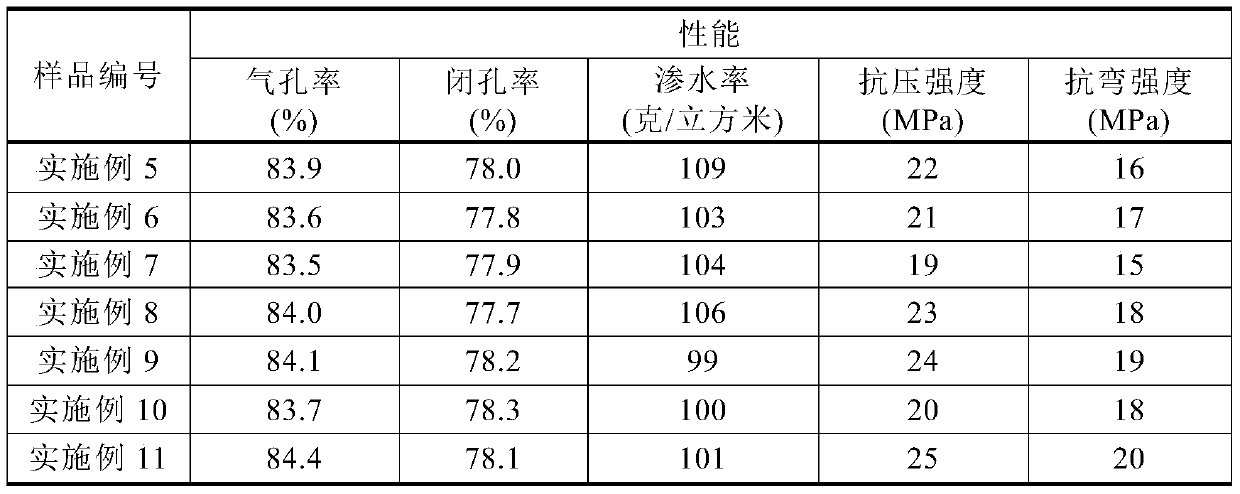

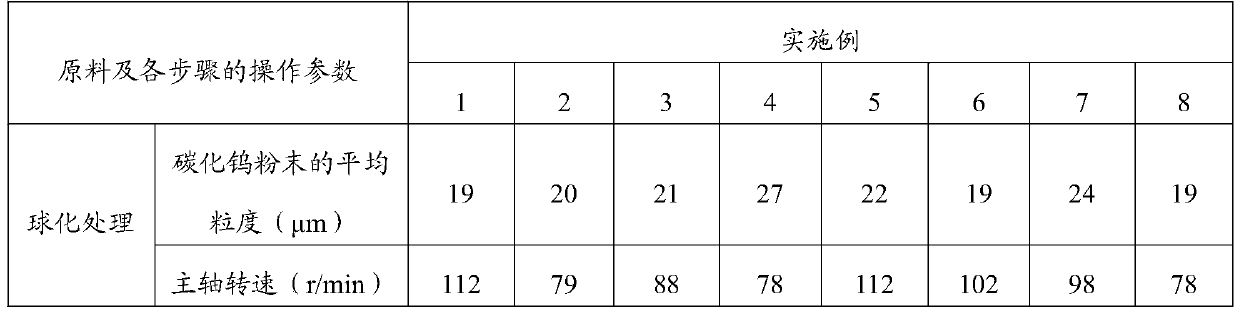

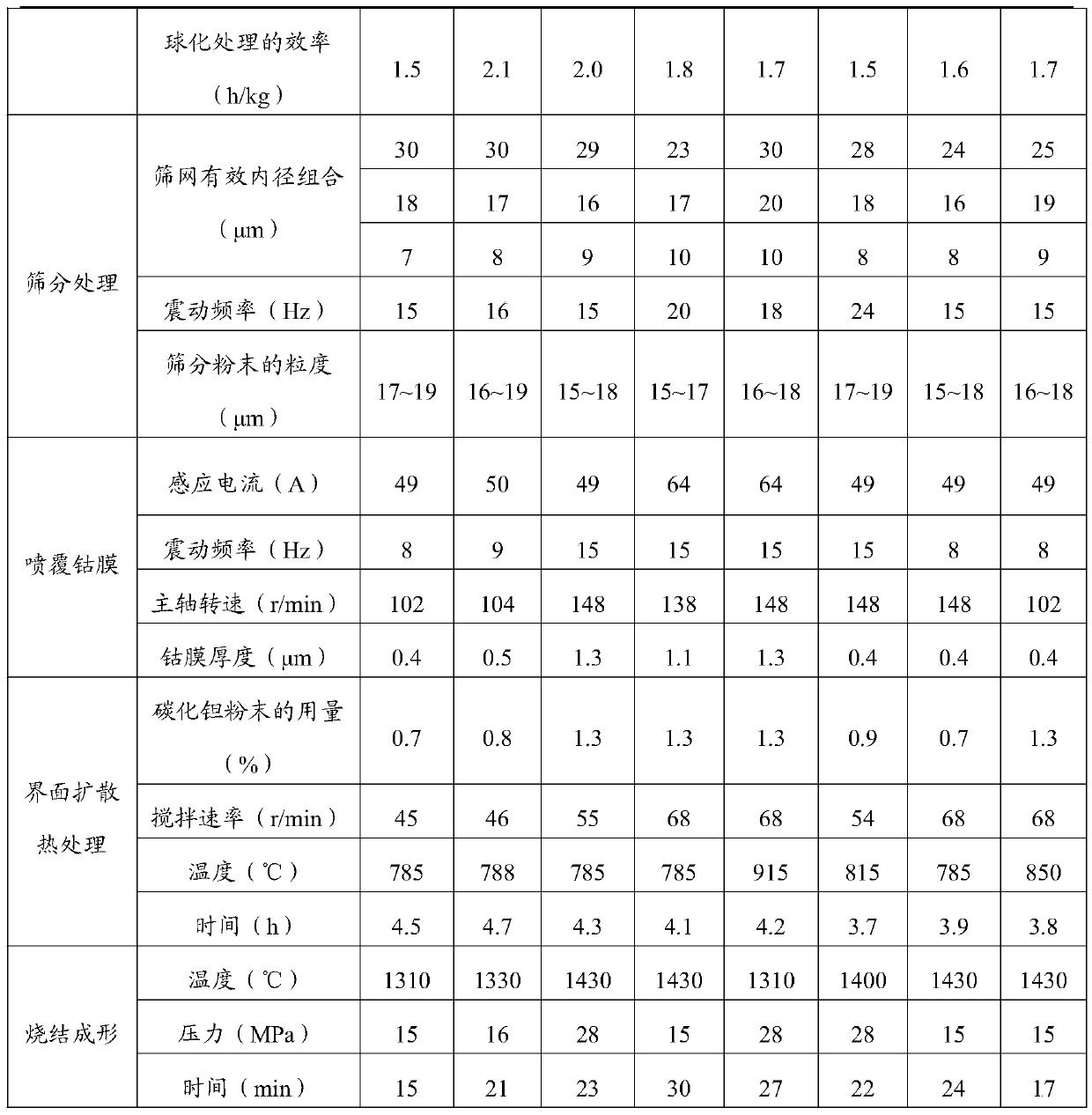

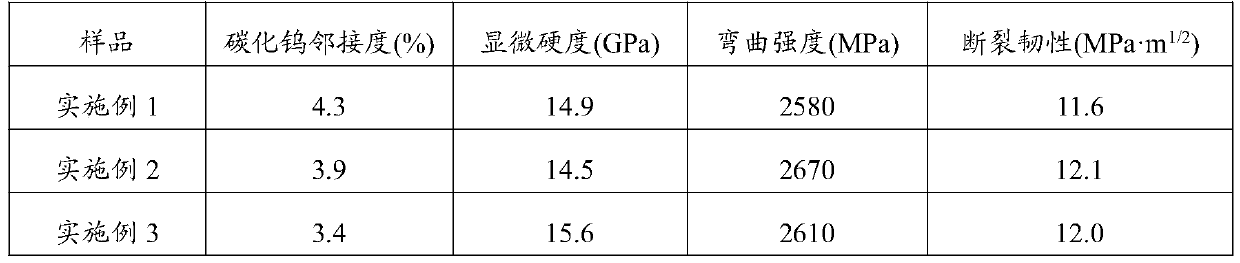

Low-tungsten-carbide-adjacency hard alloy and preparing method thereof

The invention provides a low-tungsten-carbide-adjacency hard alloy and a preparing method thereof, and belongs to the technical field of tungsten alloy preparation. The preparing method includes the following steps of sequentially performing balling treatment and screening treatment on tungsten carbide powder to obtain screened powder, spray-coating the surface of the screened powder with a cobaltfilm to obtain cobalt film and tungsten carbide composite powder, mixing the cobalt film and tungsten carbide composite powder with tantalum carbide powder, performing interface diffusion heat treatment under the stirring condition to obtain precursor powder, and performing selected laser sintering on the precursor powder to obtain the low-tungsten-carbide-adjacency hard alloy. The hard alloy prepared through the method has the low tungsten carbide adjacency, the excellent mechanical properties, the tungsten carbide adjacency of lower than or equal to 4.3%, the microhardness of higher than orequal to 14.5 GPa, the bending strength of higher than or equal to 2550 MPa and the breaking tenacity of higher than or equal to 11.3 MPa.m[1 / 2].

Owner:SHAANXI SCI TECH UNIV

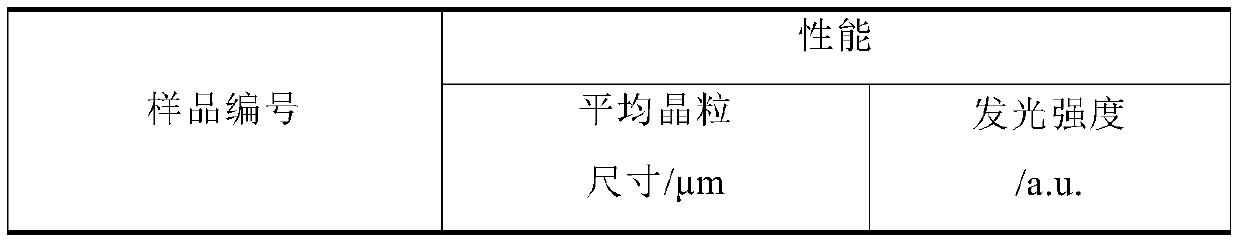

Preparation method of yttrium oxide photoexcited synergistically fine-grained high-alumina bronze indicator coating

The invention discloses a method for preparing a high-alumina bronze indicating coating through optical excitation in collaboration with fine grain strengthening of yttrium oxide. The surface of a 45# steel substrate is cleaned through ultrasonic waves, the spraying welding surface of the cleaned 45# steel substrate is subjected to roughening treatment through an acid spraying technique, and the treated substrate is placed into a heat treatment furnace to be preheated till the temperature is 260-300 DEG C; and high-alumina bronze powder and yttrium oxide powder are weighed according to the mass percent of (99.4-99.8):(0.2-0.6), and are subjected to mechanical alloying in a stirring ball mill, the powder is dried, is subjected to ball milling and is loaded into a welding gun, and the high-alumina bronze indicating coating is prepared on the preheated 45# steel substrate through a plasma spraying welding machine under the conditions that the transfer arc current is 165-175 A, the working voltage is 25.4-26 V, the powder feeding quantity is 17-21 g / min, and the distance of the welding gun and a workpiece is 8-11 mm.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Preparation method of multilevel twin structure silicon nitride high temperature ceramic material

ActiveCN109665851BImprove compactnessGive full play to the advantages of toughnessSilica fumeHigh heat

The invention discloses a preparation method of a silicon nitride high-temperature ceramic material in a multistage twin structure. The method comprises processing monatomic silicon powder at high impulse, subjecting the processed monatomic silicon powder to reaction with nitrogen to obtain silicon nitride nanopowder, adding in gel for nodulizing and degreasing shaping to obtain a cold pressing blank, and sintering the shaped cold pressing blank at ultrahigh pressure and high temperature to obtain the silicon nitride high-temperature ceramic material in the multistage twin structure. The preparation method of the silicon nitride high-temperature ceramic material in the multistage twin structure is high in composition control precision, technical stability and repeatability and capable of achieving high-temperature toughening of silicon nitride ceramic materials.

Owner:SHAANXI SCI TECH UNIV

Mncr alloyed hot forming steel and production method thereof

The invention provides MnCr alloying thermal-forming steel. The MnCr alloying thermal-forming steel is characterized by mainly containing the following chemical elements in percent by weight: 0.15%-0.25% of C, 0.10%-0.25% of Si, 1.5%-2.2% of Mn, and 2.0%-2.5% of Cr. Main process parameters in a production process of the MnCr alloying thermal-forming steel are controlled as follows: a casting blank tapping temperature is controlled to 1230 DEG C-1250 DEG C, a hot-rolling finishing temperature is controlled to 920 DEG C-950 DEG C, a hot-rolling coiling temperature is controlled to 630 DEG C-660 DEG C, and a stamping cooling rate is controlled to 18 DEG C / scond-22 DEG C / second. A thermal-forming product produced by the MnCr alloying thermal-forming steel disclosed by the invention has mechanical performances as follows: yield strength Rp is 1030 MPa, tensile strength Rm is 1510 MPa, and uniform elongation rate Agt is 5%. All thermally-formed microscopic structures are martensite.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Preparation method of multi-scale and multi-layer interface cemented carbide material

The invention discloses a preparation method of a multi-scale and multi-layer interface cemented carbide material. Firstly, the tungsten carbide powder is impact-treated, mixed with zirconia whiskers, then added with a spheroidizing agent to stir and granulate, and then mixed with cobalt powder after degreasing. , and finally put the mixed powder in a hydraulic fast heating device to sinter and shape, and finally obtain a multi-scale and multi-layer interface cemented carbide material. This method has the advantages of high precision of composition control, strong process stability and repeatability, and can realize the strengthening and toughness and long life of cemented carbide materials.

Owner:SHENZHEN QIANYAN MATERIAL TECH

Low-density wear-resistant hard alloy material and preparation method thereof

The invention discloses a low-density anti-corrosion hard alloy material and a preparation method thereof. Tungsten carbide powder, cobalt powder and calcium carbonate powder are weighed according tomass percent and are put in a cold pressing machine to be made into cylindrical green bodies after being evenly mixed in a three-dimensional vortex material mixing machine; and the premade green bodies and nickel-based high-temperature brazing filler metal are put into a high-temperature electric conduction mould according to the mass ratio and are fired into the low-density anti-corrosion hard alloy material in a double-shaft high-pressure infiltration device.

Owner:株洲思瑞普硬质合金股份有限公司

Remelting method for producing titanium iron

ActiveCN105838969ASimple production methodComposition control with high precisionIncreasing energy efficiencyTitaniumGas protection

The invention provides a remelting method for producing titanium iron, and belongs to the technical field of iron alloy smelting. The invention solves the technical problem of remelting method for producing titanium iron. The method uses ordinary iron as an iron source; molten iron smelting is carried out to control the impurities in the molten iron within 0.5%; the molten iron is heated to higher than 1700 DEG C, and hanged in vacuum or inert gas protection; and a titanium source is added in molten iron; constant bottom blowing of inert gas is carried out; and then casting cooling is carried out. The method of the invention can not only produce titanium iron series products with different titanium content requirements, and the production method is simple, has the advantages of high component control precision, low content of impurity and harmful elements; and the titanium iron product has high quality. The invention effectively solves the problems of difficult control and high content of impurities in a traditional titanium iron production process.

Owner:SICHUAN PAN YAN TECH

Method for preparing ceramic fritted glaze from vanadium titano-magnetite tailings

The invention discloses a method for preparing ceramic fritted glaze from vanadium titano-magnetite tailings. The method comprises the following steps: weighing the vanadium titano-magnetite tailings,a correction raw material and a decolorizing agent according to a certain ratio, performing ball-milling, putting the materials into a natural gas furnace, performing high-temperature melting, putting the obtained glaze high-temperature liquid into frit cutting and quick-cooling equipment, quickly cooling the liquid to prepare blocks, and finally grinding the blocks in a vertical mill to obtain the ceramic fritted glaze. The method has the advantages of being high in component control precision and high in process stability and repeatability, and fine application and a high utilization rate of the vanadium titano-magnetite tailings can be achieved.

Owner:SHAANXI SCI TECH UNIV

Method for producing ferro-titanium by remelting method

ActiveCN105838969BImprove qualitySimple production methodIncreasing energy efficiencyTitaniumIron alloys

Owner:SICHUAN PAN YAN TECH

Method of manufacturing seamless steel pipe for inhibiting hydrogen resulted abscission layer defect

The invention provides a seamless steel pipe manufacturing method for suppressing hydrogen-induced ionosphere defects, including converter smelting, LF furnace refining, square billet continuous casting, continuous rolling pipe billet and steel pipe rolling, which is characterized in that titanium is added after molten steel smelting alloy, and the final titanium content of the steel is controlled at 0.010% to 0.030% of the total. The titanium alloy can be added during the tapping process of the converter, or added in the LF furnace, or can be added for the first time during the tapping process of the converter, and then added again in the LF furnace. On the basis of the existing equipment and technology, the present invention adds seamless steel pipes produced by a simple micro-titanium treatment process, the yield of finished products is significantly improved, the product rejection rate is almost zero, and the operation is simple and the component control precision is high. Compared with the vacuum treatment or slow cooling process, it not only reduces the production process, reduces the cost, but also shortens the production cycle and improves the productivity.

Owner:ANGANG STEEL CO LTD

Multi-scale multi-layered interface cemented carbide material preparation method

The invention discloses a multi-scale multi-layered interface cemented carbide material preparation method. Firstly, impact treatment is conducted on tungsten carbide powder, the tungsten carbide powder is mixed with zirconium dioxide whiskers, then a spherical agent is added for stirring granulation, the obtained product is mixed with the cobalt powder after degreasing, finally, the mixed powderis placed in a hydraulic fast-heating device for burning molding to obtain a multi-scale multi-layered interface cemented carbide material finally. The method has high component control precision andhigh process stability and repeatability, and can realize the high toughness and long service life of the cemented carbide material.

Owner:SHAANXI SCI TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com