Preparation method of W-Ni-Cu prealloyed powder

A pre-alloyed powder, w-ni-cu technology, applied in the field of tungsten-based alloy powder preparation, can solve the problems of difficult particle size control, inclusions, and restrictions on the structure and performance of tungsten-nickel-copper alloys, and achieve high precision in composition control and process Strong stability and repeatability, the effect of overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

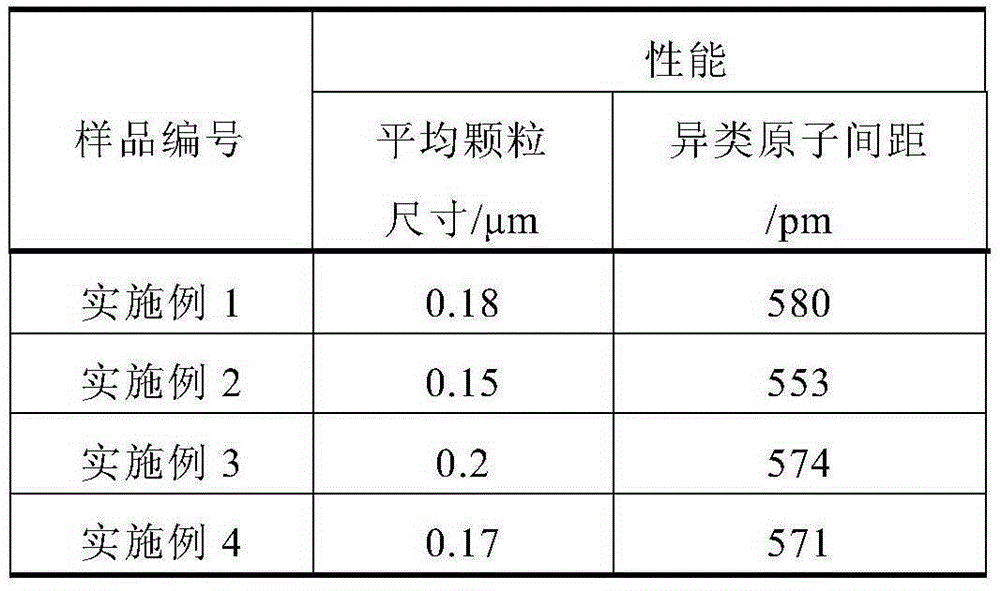

Examples

Embodiment 1

[0023] (1) In a vacuum glove box (vacuum degree 0.02MPa), take 83.8% WO by mass percentage 3 (tungsten trioxide), 8.89% NiCl 2 ·6H 2 O (nickel chloride hexahydrate) and 7.31% CuCl 2 (copper chloride) powder; NiCl was mixed with a magnetic stirrer 2 ·6H 2 O, CuCl 2 and deionized water to make a solution with a concentration of 0.34mol / L, and add WO to the solution 3 Powder, water bath temperature 50°C, stirring for 40min; add concentration of 0.358mol / L (NH 4 ) 2 C 2 o 4 (ammonium oxalate) solution, the temperature of the water bath is still 50°C at this time, and stirred for 1.5 hours.

[0024] (2) Filter the solution, and dry it in air at 120°C for 2.2 hours with a blast drying oven to obtain a precursor powder at a heating rate of 13°C / min; place the dry powder in a tube furnace (quartz tube, In a pipe diameter of 60mm), reduce at 510°C, with a heating rate of 5°C / min, a cooling rate of 10°C / min, and keep warm for 3 hours.

[0025] (3) The reduced powder was high-...

Embodiment 2

[0027] (1) Weigh 83.95% WO by mass percentage 3 , 8.56% NiCl 2 ·6H 2 O and 7.49% CuCl 2 powder; NiCl 2 ·6H 2 O, CuCl 2 and deionized water to make a solution with a concentration of 0.34mol / L, and add WO to the solution 3 powder, water bath temperature 50°C, stirred for 30min; add 0.364mol / L (NH 4 ) 2 C 2 o 4 The solution was stirred for 2 hours while the temperature of the water bath was still 50°C.

[0028] (2) Filter the solution and dry it in the air at 120°C for 2.5 hours in a blast drying oven to obtain the precursor powder at a heating rate of 13°C / min; place the dried powder in a tube furnace and reduce it at 530°C at a heating rate of 5°C / min, cooling rate 10°C / min, keep warm for 3.3 hours.

[0029] (3) The reduced powder was high-energy ball milled under the protection of argon for 14 hours, the speed of the ball mill was 340 rpm, the material: ball = 1:11, and finally W-Ni-Cu pre-alloyed powder was obtained.

Embodiment 3

[0031] (1) Weigh 83.45% WO by mass percentage 3 , 8.86% NiCl 2 ·6H 2 O and 7.69% CuCl 2 powder; NiCl 2 ·6H 2 O, CuCl 2 and deionized water to make a solution with a concentration of 0.34mol / L, and add WO to the solution 3 Powder, water bath temperature 50°C, stirred for 45min; add 0.374mol / L (NH 4 ) 2 C 2 o 4 (ammonium oxalate) solution, the temperature of the water bath is still 50° C. at this time, and stirred for 3 hours.

[0032] (2) Filter the solution and dry it in air at 120°C for 2.7 hours in a blast drying oven to obtain precursor powder with a heating rate of 13°C / min; place the dried powder in a tube furnace and reduce it at 520°C with a heating rate of 5°C / min, cooling rate 10°C / min, keep warm for 3.8 hours.

[0033] (3) The reduced powder was high-energy ball milled for 14 hours under the protection of argon, the speed of the ball mill was 330 rpm, and the material: ball = 1:12, and finally W-Ni-Cu pre-alloyed powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com