Multi-scale multi-layered interface cemented carbide material preparation method

A cemented carbide and multi-level technology, applied in the field of preparation of multi-scale and multi-level interface cemented carbide materials, can solve problems such as limited effects and achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A method for preparing a multi-scale and multi-level interface cemented carbide material of the present invention comprises the following steps:

[0019] 1) The tungsten carbide powder is subjected to high-impulse frequency conversion impact treatment by using a double-axis overturning ball mill. Zirconium whiskers are mixed, the mass percentage of tungsten carbide powder and zirconia whiskers is (99.88-99.95): (0.05-0.12), the mixing equipment is a low-speed mixer, the speed is 30-60 rpm, and the whiskers are wrapped and carbonized Tungsten composite powder;

[0020] 2) Stir and granulate the whisker-wrapped tungsten carbide composite powder with nodulizer. The nodulizer is 30mol / L polyvinyl alcohol aqueous solution, and the mass ratio of powder to glue is (86.6~94.6):(5.4~13.4). After degreasing Mix with cobalt powder, the degreasing temperature is 450°C, and the mass ratio of spheroidized powder to cobalt powder is (87.5-92.4): (7.6-12.5) to obtain mixed powder;

...

Embodiment 1

[0024] 1) The tungsten carbide powder is subjected to high-impulse frequency conversion impact treatment with a double-axis overturning ball mill, the spindle speed is 350 rpm, the turning time interval is 3 minutes, and the turning speed is 40 rpm, and then mixed with zirconia whiskers and carbonized The mass percentage of tungsten powder and zirconia whiskers is 99.88:0.12, and the mixing equipment is a low-speed mixer with a rotation speed of 30 rpm to obtain whisker-wrapped tungsten carbide composite powder;

[0025] 2) Stir and granulate the whisker-wrapped tungsten carbide composite powder with nodulizer. The nodulizer is 30mol / L polyvinyl alcohol aqueous solution, and the mass ratio of powder to glue is 86.6:13.4. After degreasing, it is mixed with cobalt powder. The degreasing temperature is At 450°C, the mass ratio of spheroidized powder to cobalt powder is 87.5:12.4 to obtain mixed powder;

[0026] 3) Put the mixed powder in a hydraulic rapid heating device for firin...

Embodiment 2

[0028] 1) The tungsten carbide powder is subjected to high-impulse frequency conversion impact treatment with a double-axis overturning ball mill. The spindle speed is 360 rpm, the turning time interval is 3 minutes, and the turning speed is 45 rpm. Then, it is mixed with zirconia whiskers and carbonized The mass percentage of tungsten powder and zirconia whiskers is 99.90:0.10, and the mixing equipment is a low-speed mixer with a rotation speed of 40 rpm to obtain whisker-wrapped tungsten carbide composite powder;

[0029] 2) Stir and granulate the whisker-wrapped tungsten carbide composite powder with nodulizer. The nodulizer is 30mol / L polyvinyl alcohol aqueous solution, and the mass ratio of powder to glue is 87:13. After degreasing, it is mixed with cobalt powder. The degreasing temperature is At 450°C, the mass ratio of spheroidized powder to cobalt powder is 88:12 to obtain mixed powder;

[0030] 3) Put the mixed powder in a hydraulic rapid heating device for firing mol...

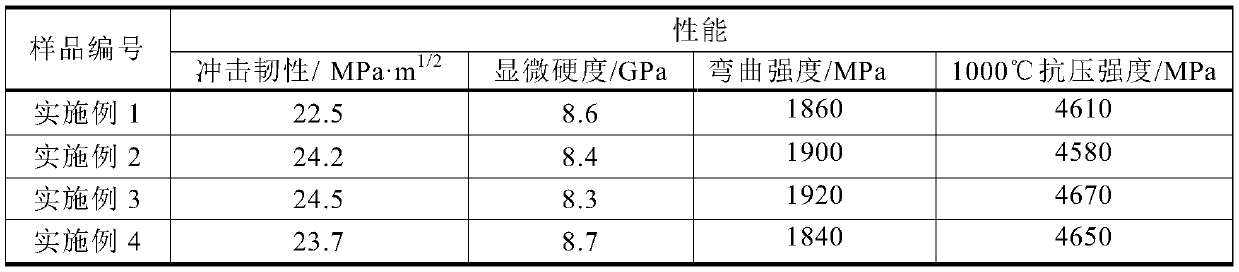

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com