Method for preparing ceramic fritted glaze from vanadium titano-magnetite tailings

A technology of vanadium-titanium magnetite and frit glaze, which is applied in the field of preparing ceramic frit glaze from vanadium-titanium magnetite tailings, can solve the problem that it is difficult to effectively improve the application value of vanadium-titanium magnetite tailings in the field of fine materials, etc. problems, to achieve the effects of strong process stability and repeatability, high precision application, and high precision of component control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh the vanadium-titanium magnetite tailings, silicon dioxide, calcium carbonate, sodium carbonate and ceria according to the mass percentage of 79.9:12.4:3.3:2.8:1.6, stir and ball mill them and put them into a natural gas furnace for high temperature melting, The spindle speed of the ball mill is 50 rpm, and the high-temperature melting temperature of the powder is 1510°C to obtain a glaze high-temperature liquid;

[0022] (2) Put the glaze high-temperature liquid in the frit cutting and fast cooling equipment to quickly cool the block. The cutting frequency of the cutting and fast cooling equipment is 2, the fast cooling speed is 89°C / min, and the cooling method is 0.5°C water cooling, and finally Grind in a vertical mill with a spindle speed of 30 rpm and a blast wind speed of 110 m / s to finally obtain a ceramic frit glaze.

Embodiment 2

[0024] (1) Weigh the vanadium-titanium magnetite tailings, silicon dioxide, calcium carbonate, sodium carbonate and ceria according to the mass percentage of 80.9:11.4:3.3:2.8:1.6, stir and ball mill them and put them into a natural gas furnace for high temperature melting. The spindle speed of the ball mill is 55 rpm, and the high-temperature melting temperature of the powder is 1520°C to obtain a glaze high-temperature liquid;

[0025] (2) Put the glaze high-temperature liquid in the frit cutting and fast cooling equipment to quickly cool the block. The cutting frequency of the cutting and fast cooling equipment is 2, the fast cooling speed is 90°C / min, and the cooling method is 0.5°C water cooling, and finally Grind in a vertical mill with a spindle speed of 32 rpm and a blast wind speed of 115 m / s to finally obtain a ceramic frit glaze.

Embodiment 3

[0027] (1) Weigh the vanadium-titanium magnetite tailings, silicon dioxide, calcium carbonate, sodium carbonate and ceria according to the mass percentage of 80.9:11.4:3.3:3.3:1.1, stir and ball mill them and put them into a natural gas furnace for high temperature melting. The spindle speed of the ball mill is 60 rpm, and the high-temperature melting temperature of the powder is 1530°C to obtain a glaze high-temperature liquid;

[0028] (2) Put the glaze high-temperature liquid in the frit cutting and fast cooling equipment to quickly cool the block. The cutting frequency of the cutting and fast cooling equipment is 2, the fast cooling speed is 90°C / min, and the cooling method is 0.5°C water cooling, and finally Grind in a vertical mill with a spindle speed of 34 rpm and a blast wind speed of 130 m / s to finally obtain a ceramic frit glaze.

PUM

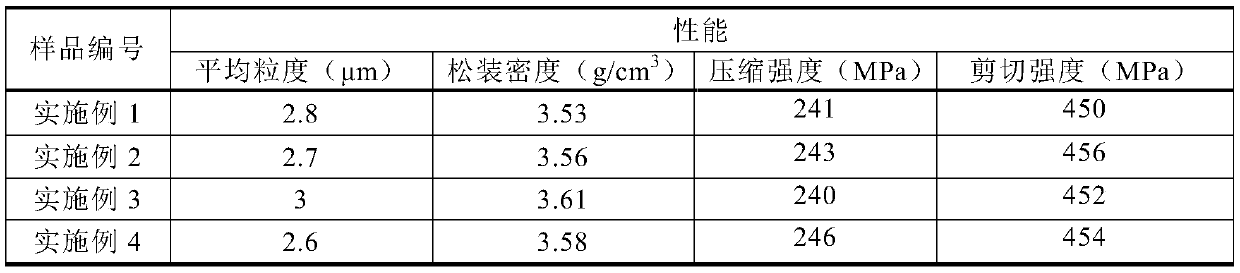

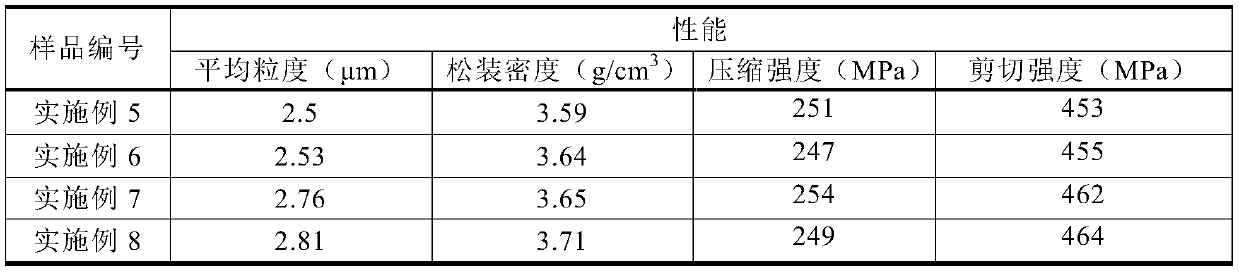

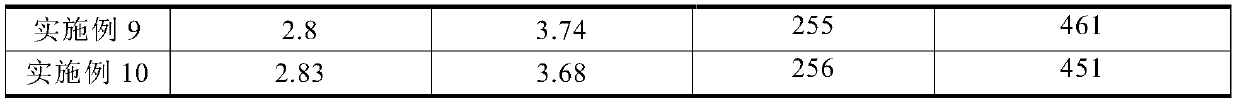

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com