Patents

Literature

2876results about How to "Simple production method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denier/superfine denier nylon master granule, preoriented yarn (POY) and draw textured yarn (DTY) stretch yarn and preparation method thereof

ActiveCN101724265AHigh tensile strengthImprove mixing performanceMelt spinning methodsMonocomponent polyamides artificial filamentYarnEngineering

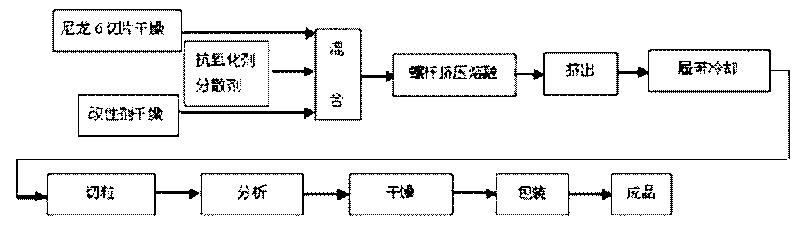

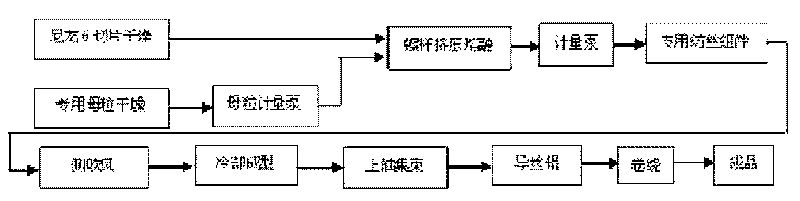

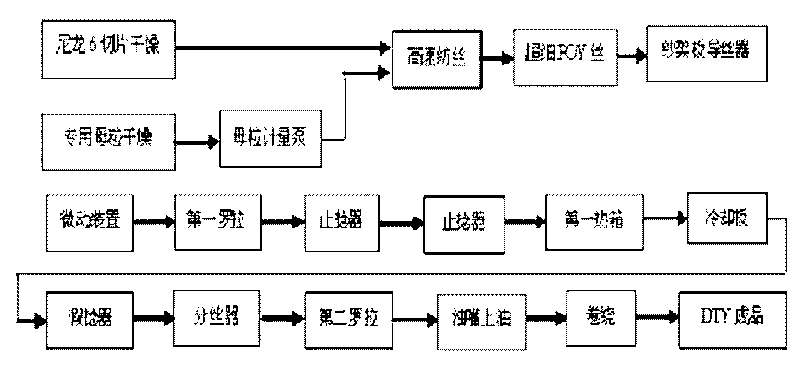

The invention belongs to the field of spinning materials. Firstly, the invention provides a fine denier / superfine denier nylon master granule prepared by proportionally adding a modifying agent, an antioxidant and a dispersant to nylon 6 sliced sheets according to the proportion, melting, mixing and extruding, and the modifying agent is a metallic salt which can take effect on nylon base; The fine denier / superfine denier nylon master granule and the nylon 6 sliced sheets are proportionally mixed, melted and spun, and the fine denier / superfine denier nylon POY is prepared by cooling, oiling, bundling and coiling; and the POY is textured to obtain the DTY. The invention provides the fine denier / superfine denier nylon POY of which the filament size is 0.3-0.8dtex, the filament size of the DTY is 0.25-0.70dtex, which fills the vacancy that the fine denier / superfine denier nylon POY and the DTY are produced by the conventional yarn-spinning process at home and abroad.

Owner:HANGZHOU NORMAL UNIVERSITY

Production method of concave convex stick ceramic grain filter

InactiveCN100423808CGood film-hanging performanceImprove stabilityFiltration separationClaywaresRough surfaceWater quality

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

Supported nano gold catalyst for clearing formaldehyde from indoor air and method for preparing the same

InactiveCN1698932ALow costHigh catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHoneycombRare earth

This invention relates to a supported nanometer gold catalyst which is used for cleaning formaldehyde of room air, in addition to its preparing method. The method comprises the following steps: a) using cordierite honeycomb ceramics as the carrier; b) coating a layer of rare earth oxide or composite rare earth oxide in the carrier surface evenly; c) depositing 3-10nm golden grain in the rare earth oxide or composite rare earth oxide, wherein the weight of gold is 1%-3% of the coating. Said catalyst can clean the formaldehyde of the air and the formaldehyde has a high conversion ratio. Meanwhile, the catalytic activity of said catalyst is larger by a magnitude order compared with Mn, Co oxide or rare earth composite oxide catalyst.

Owner:INNER MONGOLIA UNIVERSITY

Method for preparing insect repelling organic fertilizer

InactiveCN1872814AReduce pollutionGood qualityBio-organic fraction processingOrganic fertiliser preparationFecesNicotiana tabacum

This invention discloses a method for manufacturing an insecticidal organic fertilizer. The fertilizer is composed of human or animal excrement, straw powder, tree leaves, wine lees, drug residues, sawdust, edible fungi residues, furfural residues, lime powder, fermentation agent, phosphorus- and potassium-leaching bacteria, tobacco powder, Ricinus communis leaf powder, Zanthoxylum cake powder, Datura and Strychnos nuxvomica. The fertilizer has such advantages as wide raw material resources, low cost, convenient usage, abundant nutrition, low fertilizer application amount, high efficiency, no toxicity, no pollution and no residues.

Owner:白会新 +1

Valve element sealing lubricating agent composition

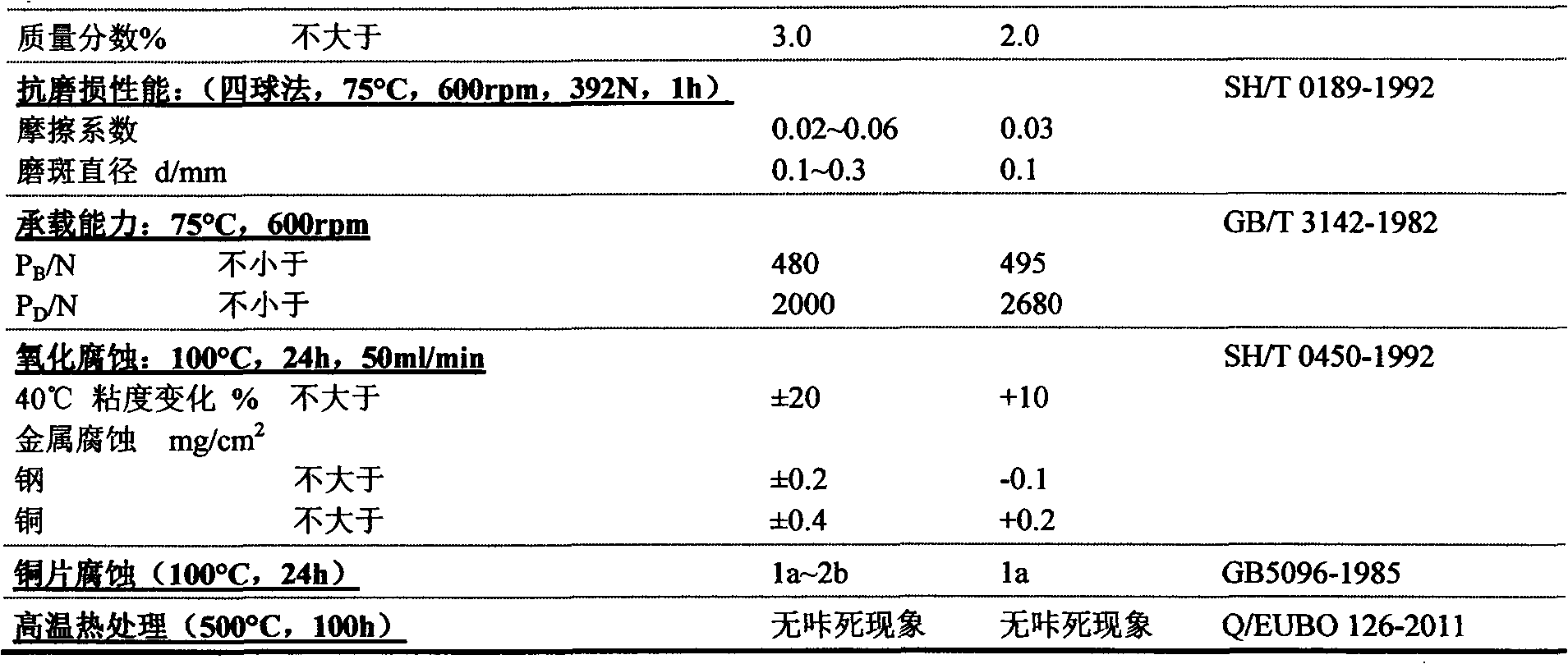

InactiveCN102433204ASimple production methodImprove high temperature resistanceLubricant compositionBase oilWear resistance

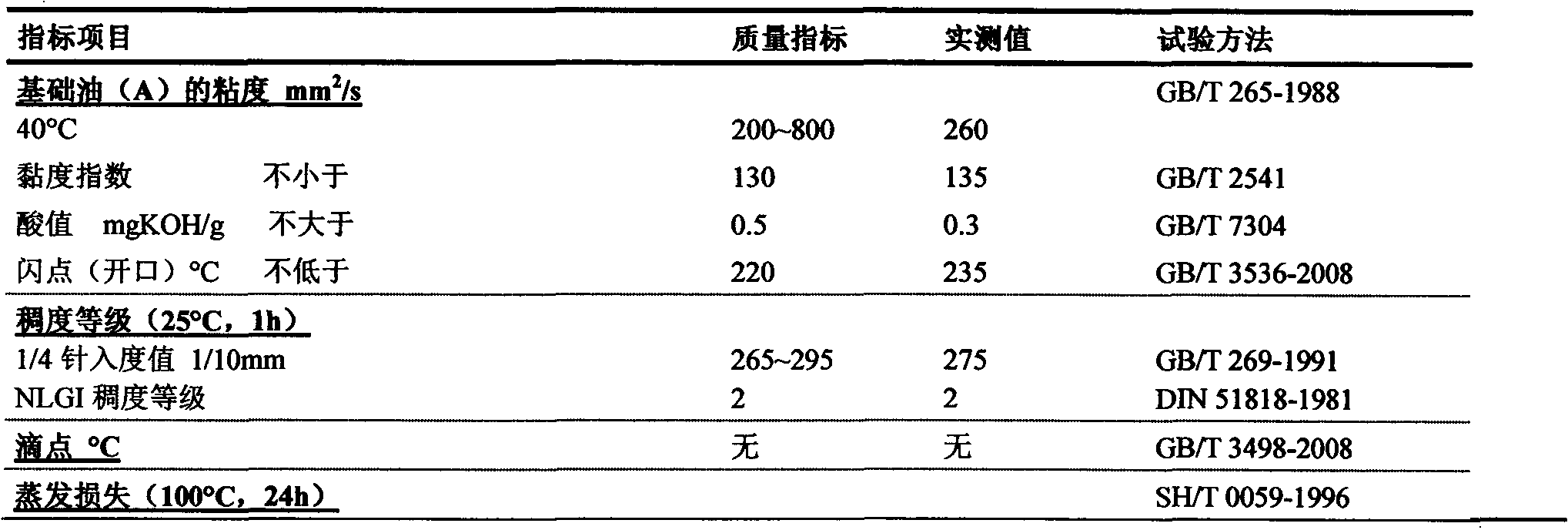

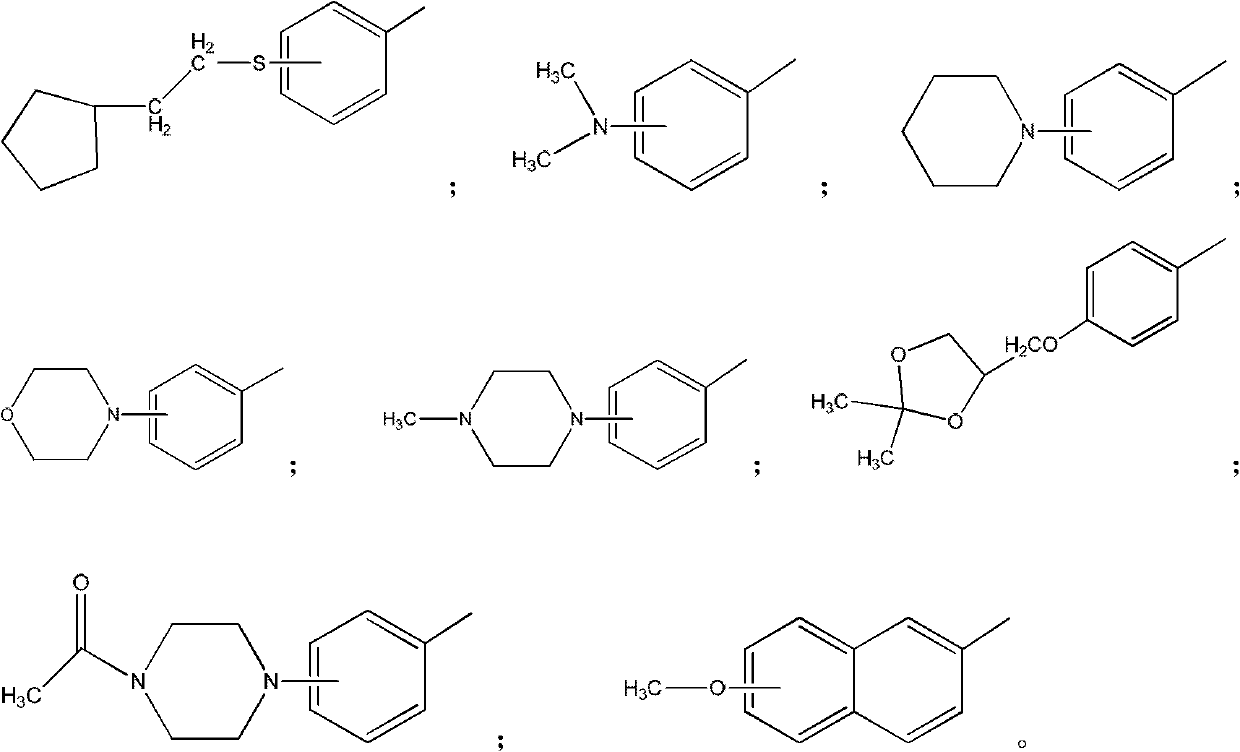

The invention relates to the field of lubricating materials, in particular to a valve core sealing lubricating agent composition, which comprises: (A) 100.0 weight parts of base oil; (B) 5.0 to 35.0 weight parts of thickening agent; (C) 3.0 to 55.0 weight parts of solid lubricating agent; (D) 0.1 to 3.0 weight parts of surfactant; (E) 0.1 to 2.5 weight parts of antioxygen; (F) 0.1 to 4.0 weight parts of extreme pressure antiwear agent; (G) 0.1 to 2.0 weight parts of metal passivating agent; and (H) 0.1 to 1.5 weight parts of antimicrobial agent. The finished lubricating agent prepared according to the mixing ratio has high high-temperature resistance, high antiwear and wear-resistance performance and high dead-locking-preventing performance. Meanwhile, the production and preparation method of the lubricating agent are simple, convenient and easy to implement and is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Anhydrous albany grease and preparation method thereof

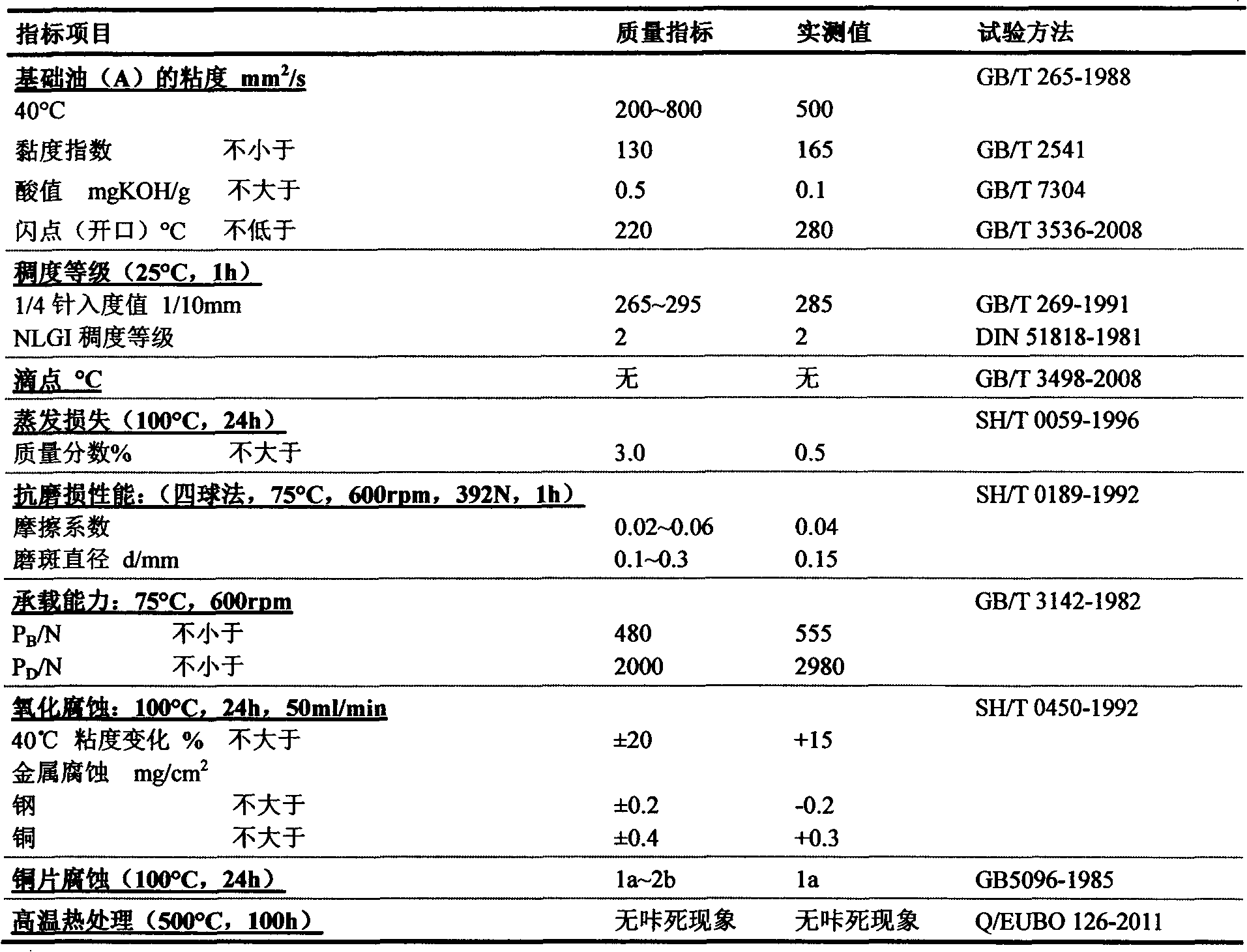

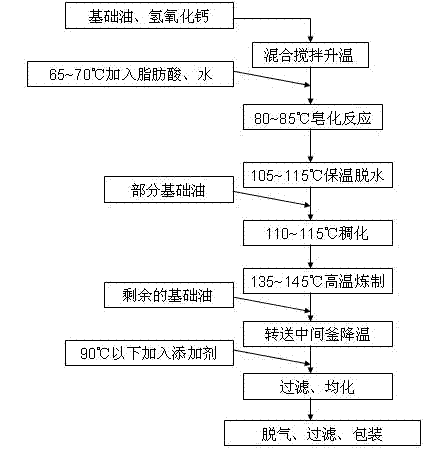

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

Functional resin tectorial membrane proppant and preparation method thereof

ActiveCN101531893AThrough highPrevent passageFluid removalDrilling compositionTectorial membraneSide chain

The invention relates to a functional resin tectorial membrane proppant and a preparation method thereof, and belongs to the technical field of oil-gas field development. The functional resin tectorial membrane proppant comprises aggregate and a resin film coated on the aggregate. Said resin film comprises organic silicon compounds of one or more active groups of amino, hydroxyl, carboxyl, alkoxyl and hydrosulphonyl. The side chain of the organic silicon compound is a hydrophobic group. The cured resin film has different wetting qualities for oil and water. The functional resin tectorial membrane proppant of the invention has a function of allowing the smooth permeation of oil gas and preventing water from penetrating through the proppant. Such a function improves the separation effect ofoil gas and water and reduces the oil production cost. The excellent hydrophobicity of the resin film facilitates the proppant to have excellent water resisting property and improves the crushing resistance of the proppant, so that the stream guidance effect is good for a long time.

Owner:围场满族蒙古族自治县津通铸造材料有限公司

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

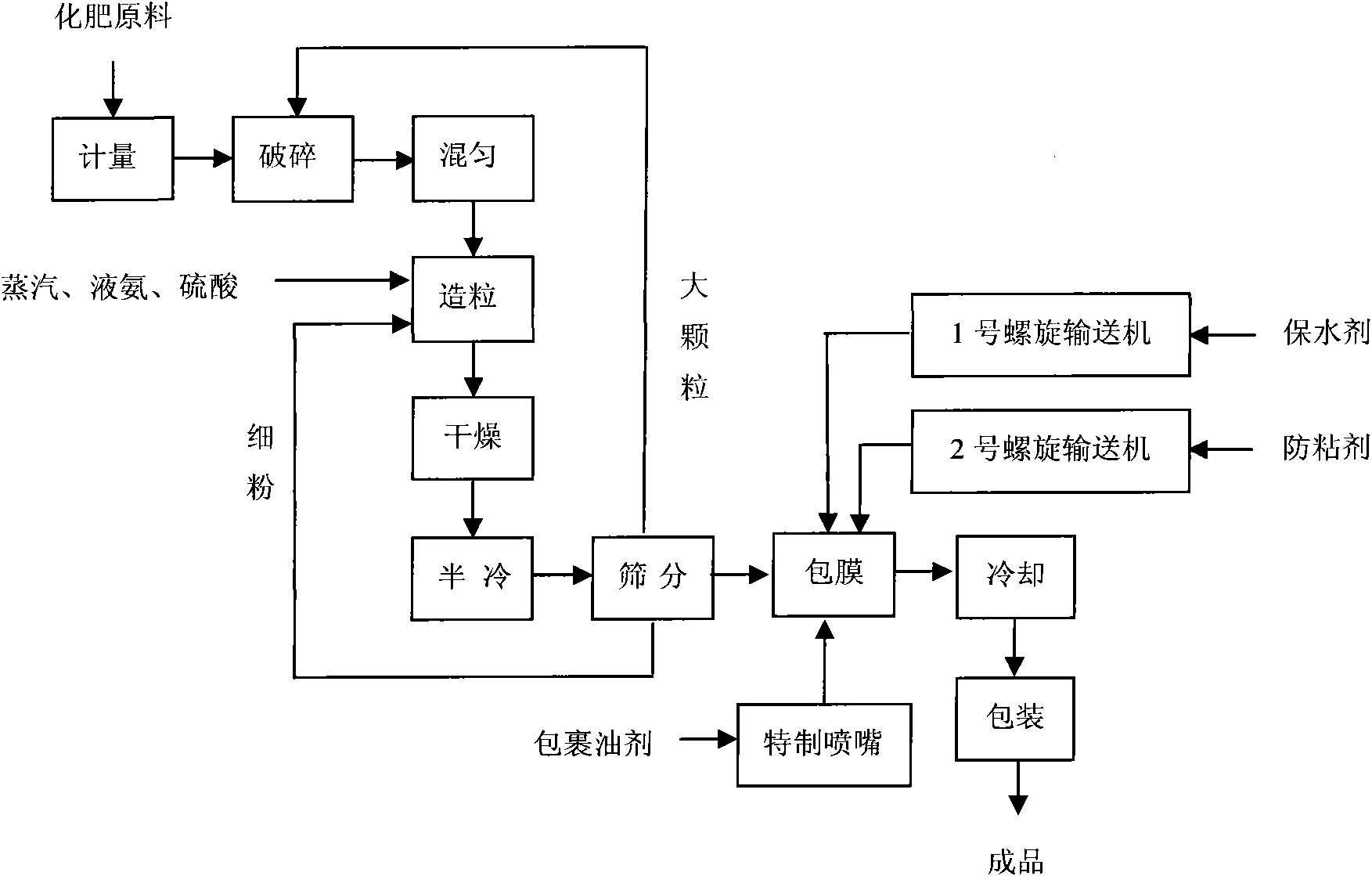

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

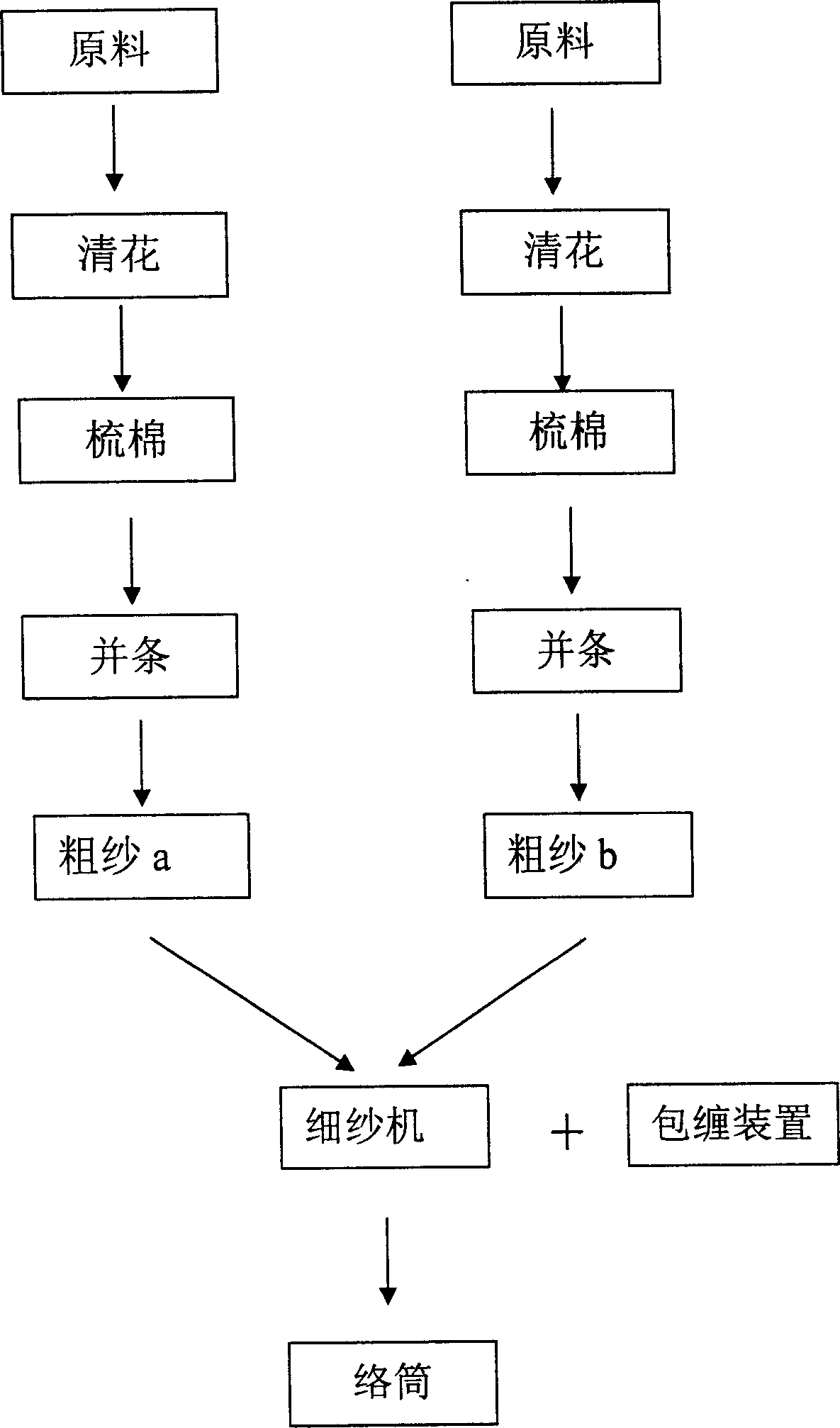

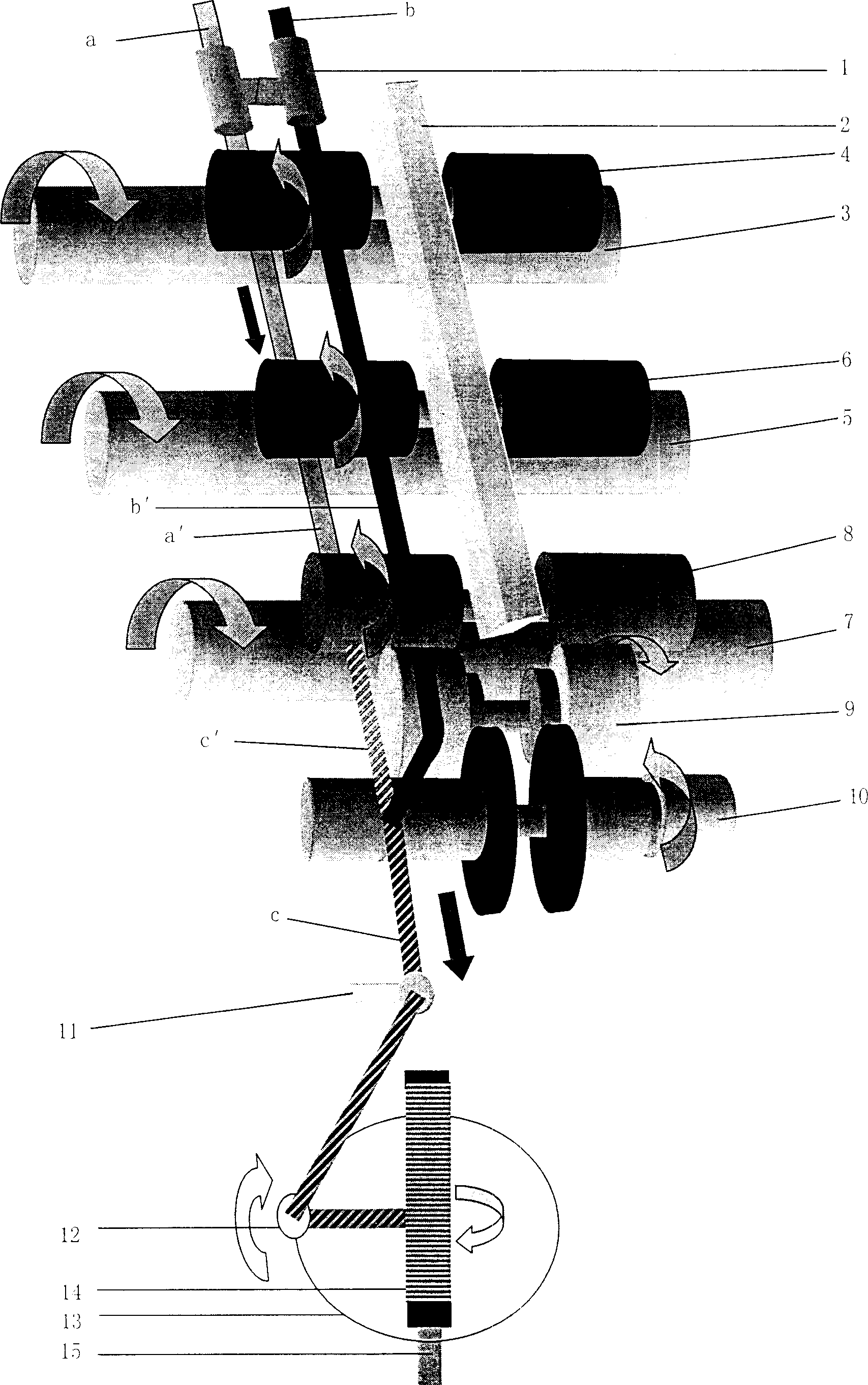

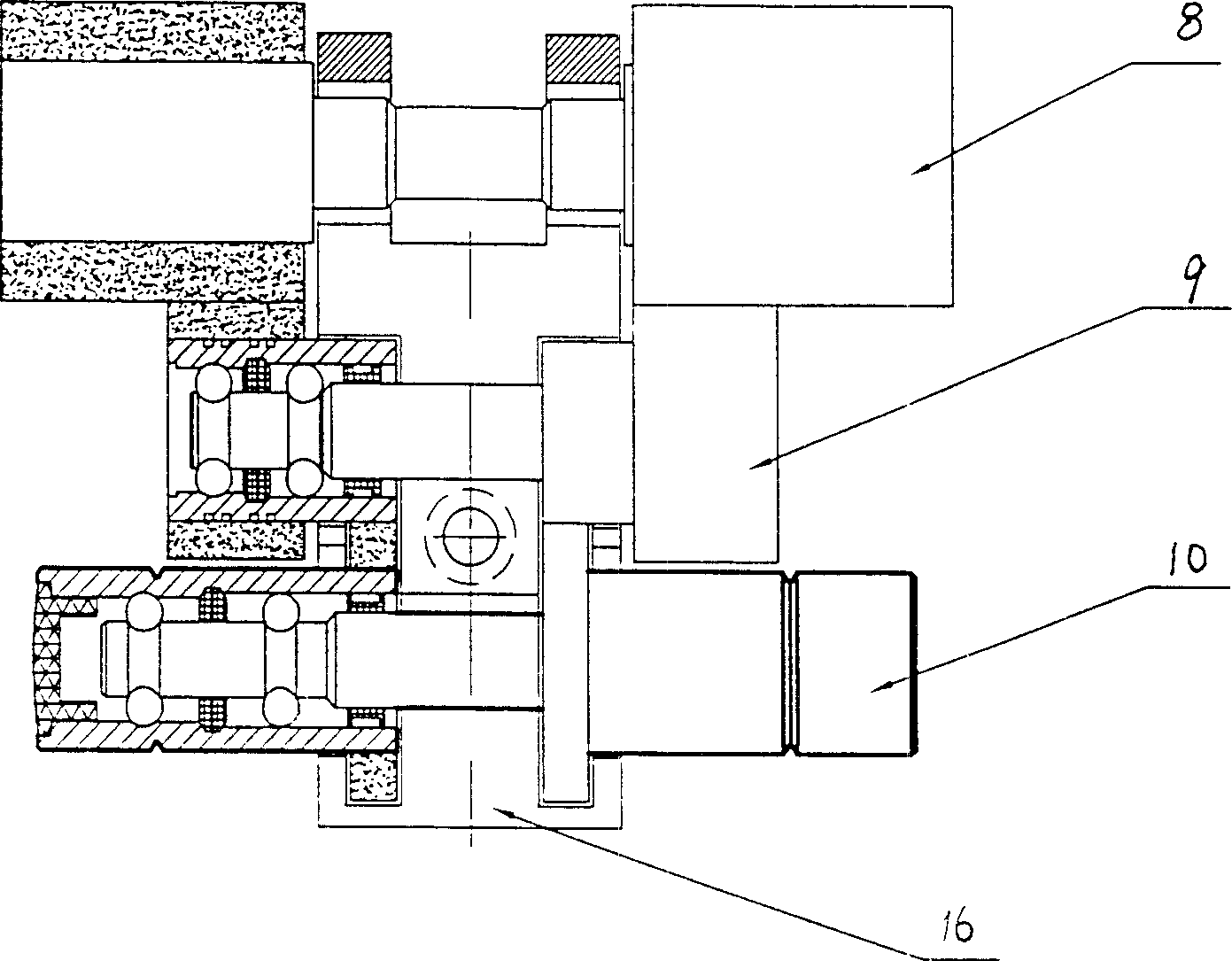

Production method of short staple enveloped composite yarn and its device

The present invention discloses a production method of short fibre wrapped composite yarn and its equipment. Said invention is implemented by using spinning frame and wrapping device, and its production method includes the following steps: raw material, scotching, carding, drawing, roving, spinning and doffing.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

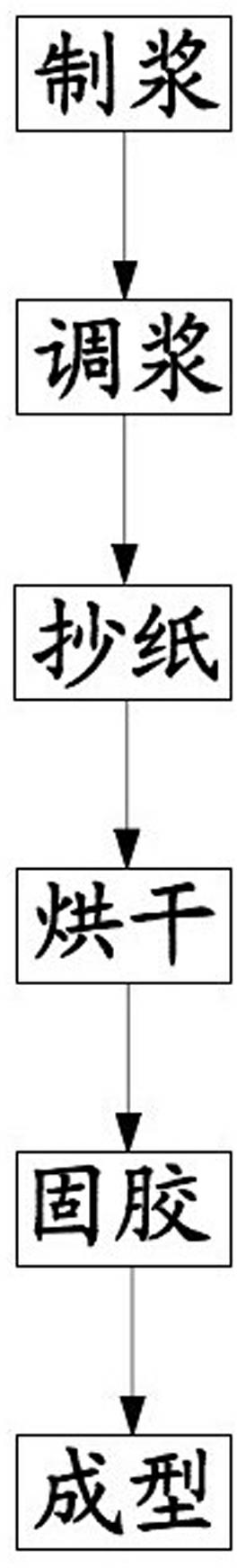

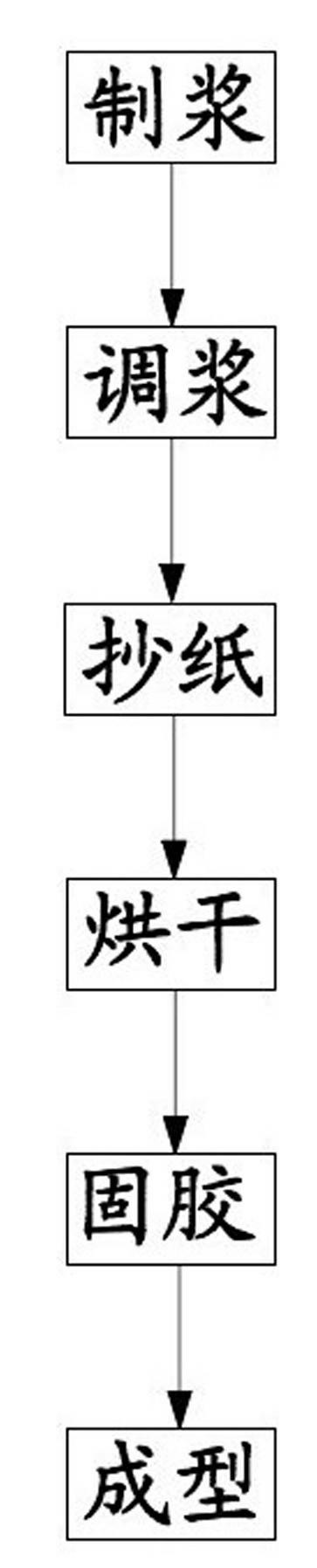

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

Method for producing ceramic tile by metallurgical steel slag

The invention discloses a method for producing a ceramic brick by metallurgical steel slag, which comprises the following steps: crushing waste slag after metallurgical steel-making; adding clay, talc, quartz and other materials to the waste slag according to the requirement of formulation property to mold a blank by a dry pressing method through ball milling by a wet method, and powdering by slurry spraying; drying and placing the molded blank into a roller kiln for maturing; and producing the matured product into a finished product through edging, polishing, grading and packaging. The invention can be widely applied in decoration, has the characteristics of environmental production, high strength, corrosion resistance, good decoration effect and so on. The method provided by the invention is simple and feasible, and is beneficial to industrial production.

Owner:GUANGXI OCEANO CERAMICS CO LTD

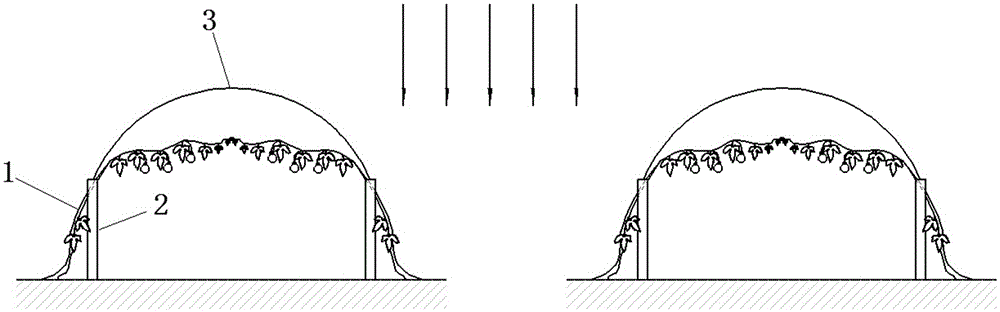

Method for planting organic passion fruit trees

ActiveCN105145253AHigh in sugarIncrease productionExcrement fertilisersBioloigcal waste fertilisersFruit juicePassion fruit

The invention discloses a method for planting organic passion fruit trees. The method includes the steps of variety selection, site selection, soil preparation, soil pH adjustment, establishment of a passion fruit tree foundation, field planting, reshaping and pruning, field management, blossoming, fruit yielding and the like. According to the method, organic fertilizer and a low-toxicity prevention method are adopted in fertilization and pest control, so that the pulp of produced passion fruits is full of yellow fruit juice, the content of sugar is high, the color is bright, the yield reaches up to 2 tons per mu each year, pollution is avoided, and five seasons of fruits can be harvested each year. The successful planting of the organic passion fruit trees provides a theoretical and practical basis for creating incomes of local farmers. According to the method, a leeward apricus flat ground is selected, and the place where a good source of water is obtained, the soil layer is thick, fertility of the soil is above the average and transportation is convenient is used as a planting foundation, so that it is guaranteed that the passion fruit trees can grow in a good environment, the roots of nursery-grown plants are planted in furrows and exposed to the sun, hence, the roots can better absorb sunshine, and fertilization and weeding are further facilitated.

Owner:广西优果百香农业发展有限公司

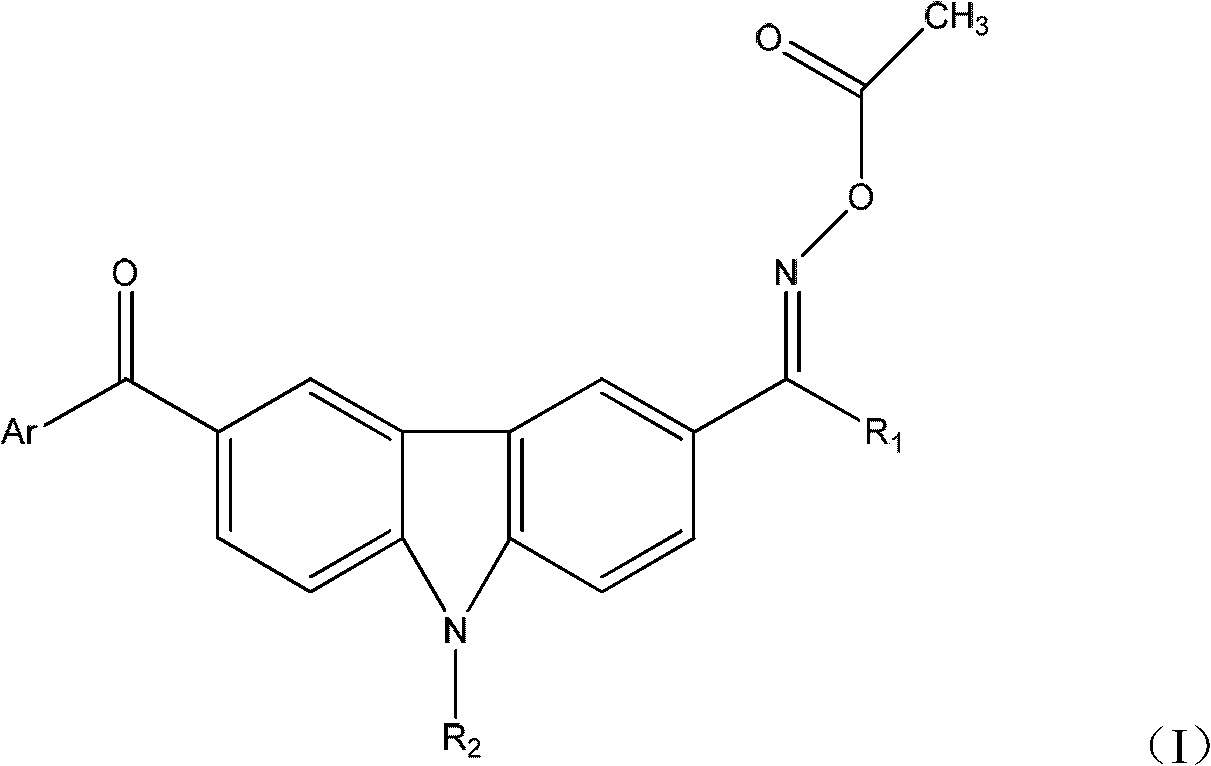

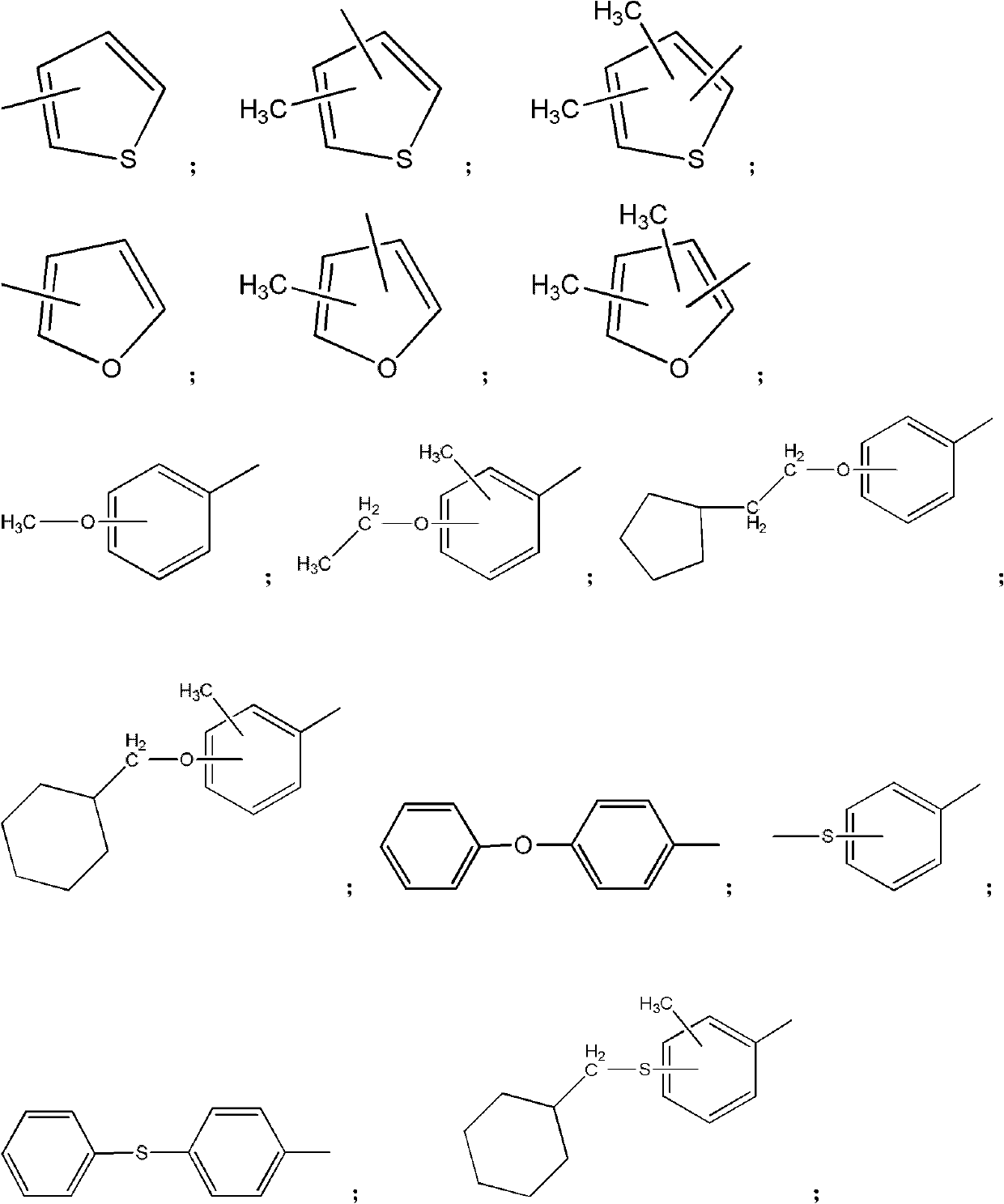

Pyrazole oxime ester photoinitiator with high photosensibility, preparation method and application thereof

ActiveCN102020727AImprove applicabilityHigh photosensitivityOrganic chemistryPhotosensitive materials for photomechanical apparatusColor gelPhotoinitiator

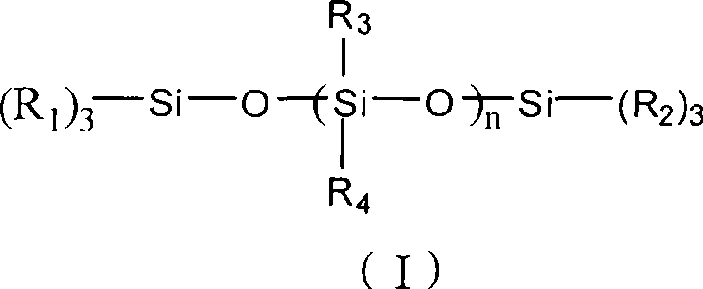

The invention relates to a pyrazole oxime ester photoinitiator with a chemical formula (I). The photoinitiator has excellent application performance and extremely high photographic performance, can greatly improve the photocuring performance when being applied to photosensitive compositions and remarkably improve the production efficiency of the photosensitive compositions in the application fields, such as the preparation of color filters, and the like. The invention also relates to a preparation method of the pyrazole oxime ester photoinitiator and the application of the pyrazole oxime ester photoinitiator to the photosensitive compositions.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD

Seed treatment in use for accelerating germination of seed

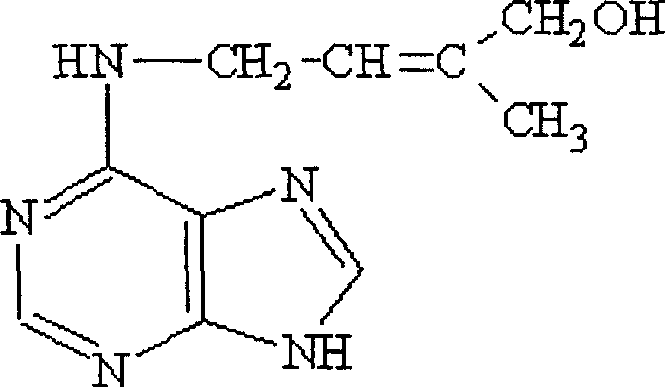

InactiveCN1915032AReduce seed usageIncrease vaccination rateBiocidePlant growth regulatorsCistancheCytokinin

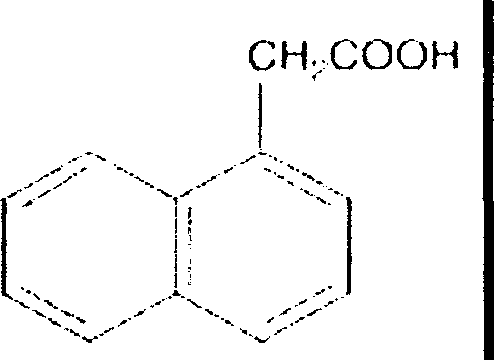

A seed treating agent for promoting the germination of plant seeds, especially the seeds of cistanche, contains gibberelline, naphthylacetic acid, cytokinin, carbendazim, and the optional one of the extracts of three plant roots (tamaisk root, vetchleaf sophora root, etc).

Owner:CHINA AGRI UNIV

Organic microorganism-containing ecological fertilizer and production method thereof

InactiveCN103553770AHigh activityThe amount added is stable and controllableFertiliser formsFertilizer mixturesContinuous croppingEcological environment

The invention discloses an organic microorganism-containing ecological fertilizer and a production method thereof. The ecological fertilizer consists of a three-layer structure, an inner layer is made of compound fertilizer granules, an urease inhibitor and nitrification inhibitor coating is used as a middle layer, an outer layer is made of an organic microorganism coating agent prepared by using an active bacteria packing method; and the production method comprises the steps of mixing and granulating, inhibitor coating, and organic microorganism coating. The production method disclosed by the invention is simple, and a prepared ecological fertilizer is complete in nutrients, ensures a high survival rate due to mixed bacterial manures, ensures long survival time of effective living bacteria, has sufficient inorganic nutrients, is convenient to apply, can avoid topdressing, and promotes the development of non-toxic and harmless fertilizers; and the ecological fertilizer has an obvious antagonism effect on continuous cropping pathogenic fungi, therefore, the proliferation of bacteria is effectively promoted, the micro-ecological environment of soil is significantly improved, and after the crops are harvested, the soil is fertile so that next-stubble crops can grow very well.

Owner:张喜梅

Waste rubber powder modified asphalt composition and its preparation method

ActiveCN1765998AUniform dispersion stabilityUniform storage stabilityBuilding insulationsWaste rubberDiluent

The invention provides a method to improve the storage stability for waste rubber powder modified asphalt. Wherein, the opposite compound comprises: 70~98.5% basic asphalt, 1~29.5% waste rubber, 0~10.0% diluent, and 0.1~5.0% coupling agent. The method comprises: adding the agents with given ratio into the waste rubber powder past 60-item screen to mix evenly; adding the treated rubber powder into asphalt to grinde for 30~190min by special device. As the alkoxy in coupling agent can form chemical bonding with inorganic filler to form organic active monomolecular layer between interfaces, this product can improve obviously the storage stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ceramic tile using polished waste material

The waste material collected from polish waste water and waste slag via deposition, press filtering and ageing is mixed with high temperature sand, kaolin and low temperature sand. The mixture is wet milled in a ball mill, 250-mesh sieved, iron eliminated and spray dried to form powdered material; the powdered material is dry formed into ceramic tile adobe in a ceramic press; and the ceramic tile adobe is baked in a roller hearth kiln at 1140-1200 deg.c in 40-75 min. The said method utilizes the waste reasonably and the product has excellent performance.

Owner:FOSHAN OCEANO CERAMICS

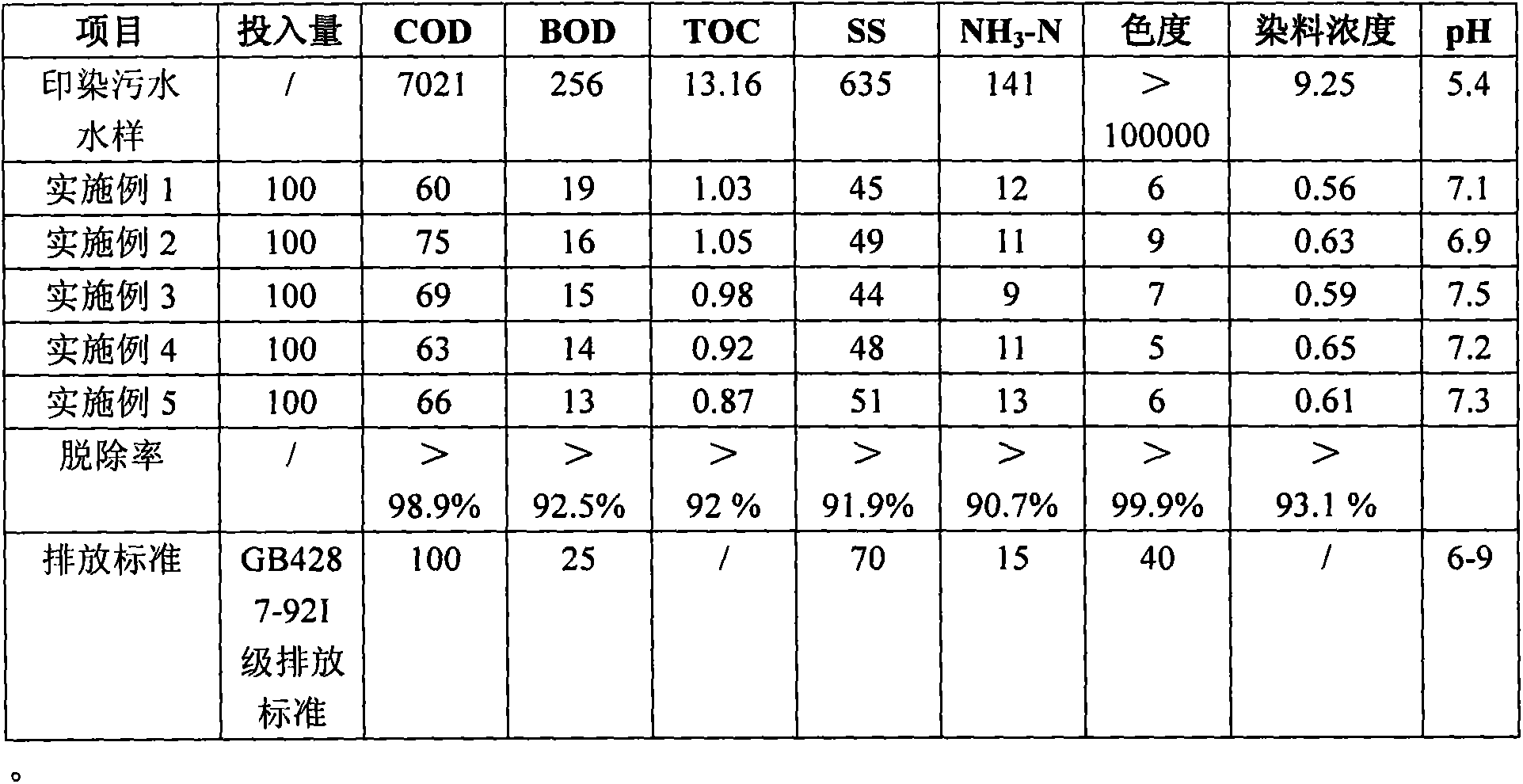

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

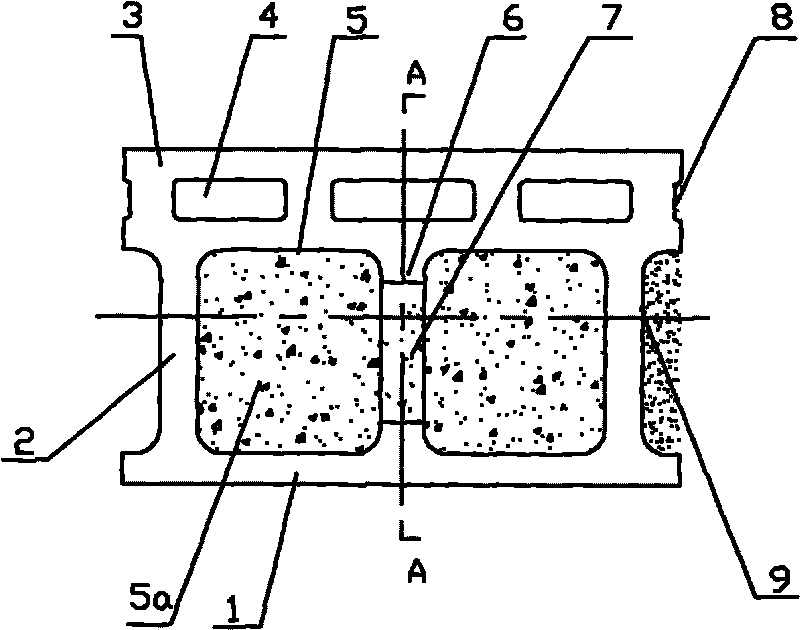

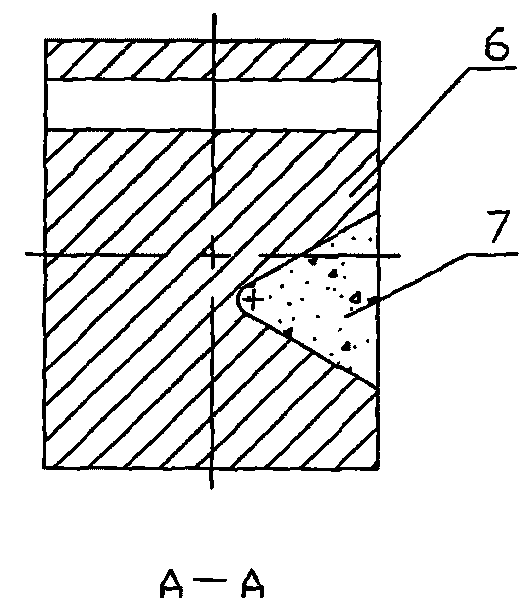

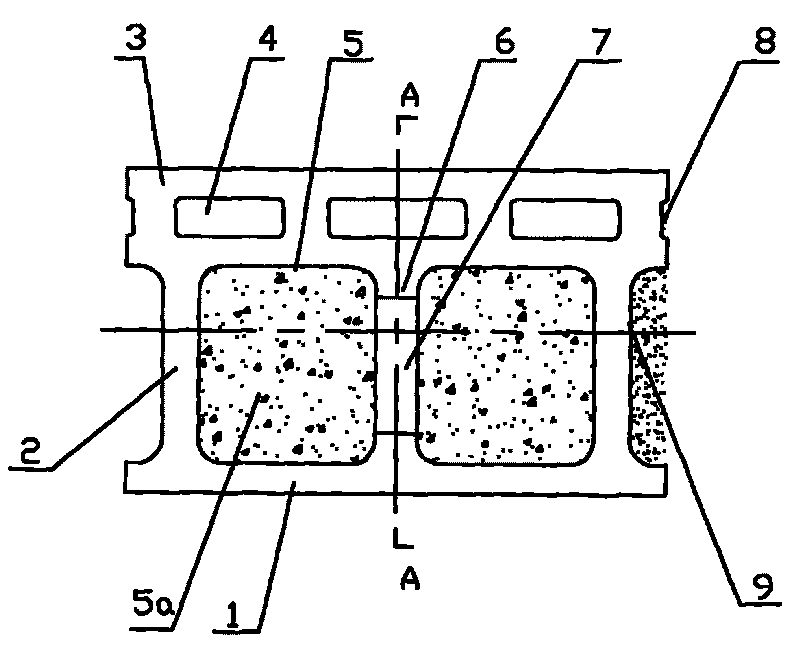

Non-homogeneous concrete composite automatic heat insulation building block

InactiveCN101694117AImprove insulation effectHigh void rateConstruction materialThermal engineeringBrick

The invention relates to a composite heat insulation building block which comprises a rectangular building block body, and is characterized in that one side of the rectangular building block body is provided with a group of parallel thermal insulation water-proof chamber (4); the middle part of the rectangular building block is provided with at least one heat insulation chamber (5) which is internally provided with heat insulation fillers (5a); the middle part of the rectangular building block is provided with two parallel heat insulation chambers (5); a leveling groove (7) used for leveling the heat insulation fillers are arranged on a rib plate (6) formed between the heat insulation chambers (5); and the connecting ends at two sides of the rectangular building block are respectively provided with an opening slit building groove (9) and an opening slit building groove (8). The composite heat insulation building block has the advantages of high void content (more than 60%), good heat insulation effect and high strength, and the produced composite heat insulation building brick has light weight, high strength, low water absorption rate, small air shrinkage rate, and good thermal engineering performance, and can meet the design requirement that building energy conservation rate can reach 65%.

Owner:金波

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

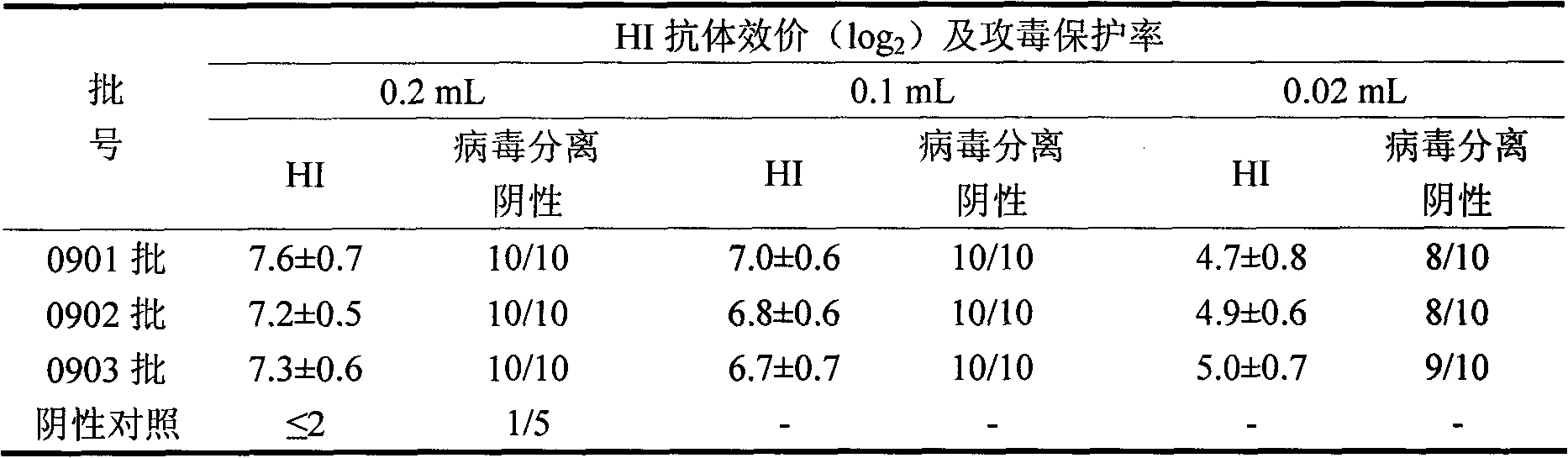

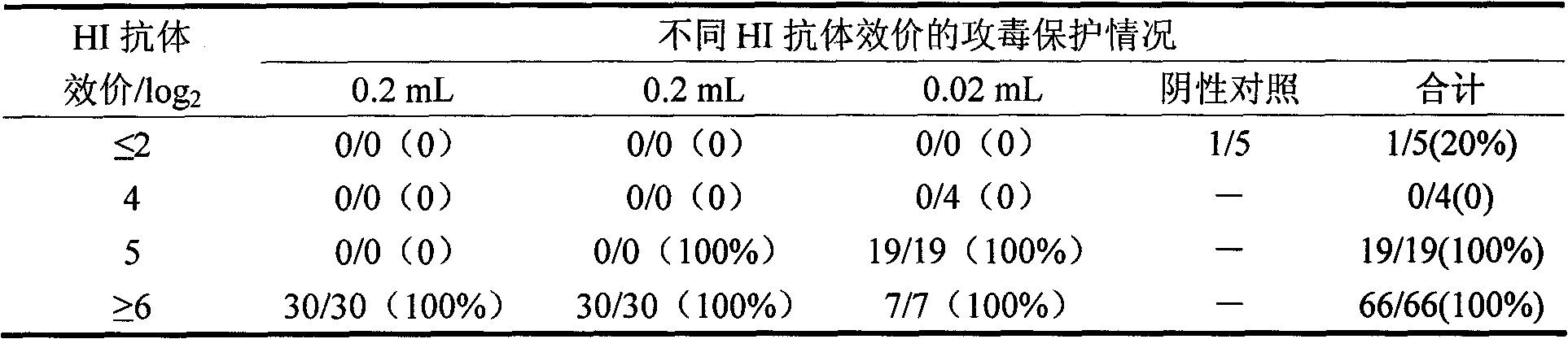

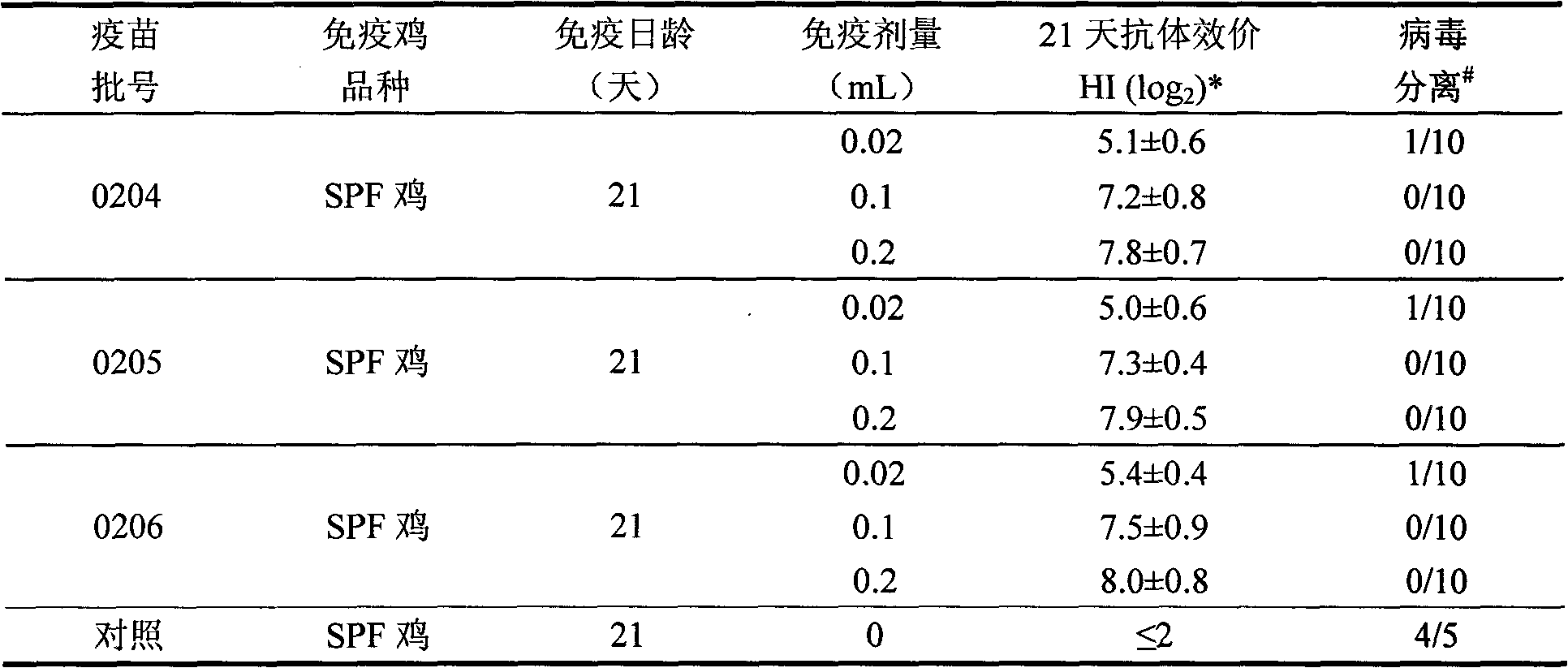

Preparation method and product of H9N2 subtype avian influenza inactivated vaccine

ActiveCN101816785AHigh titerSimple production methodAntiviralsAntibody medical ingredientsVirus multiplicationVaccine Production

The invention relates to a preparation method and a product of an H9N2 subtype avian influenza inactivated vaccine. The technical points of the invention mainly relate to the screening, the determination and the domestication of a virus-adapted cell line, the primary amplification cultivation and the continuous cultivation of a virus-adapted cell, the preparation of virus fluid by virus-inoculated culture and the preparation of final inactivated vaccine products. Firstly, the invention avoids the virus propagating method using a large amount of chick embryos in the avian influenza production at present, thereby avoiding the problem of biological potential safety hazards, and overcoming the problem that the mass production of vaccines is enslaved to the supply of the chick embryos; secondly, the invention provides a safe, continuous and closed cell culture virus production method, is used for the preparation of the H9N2 subtype avian influenza inactivated vaccine, enables the use of the cell culture method, and can simultaneously produce high-titer viruses to meet the requirements for the immunological production; and finally, the vaccine production method of the invention is simple and fast, thereby realizing the fast vaccine supply at the epidemic situation.

Owner:扬州优邦生物药品有限公司

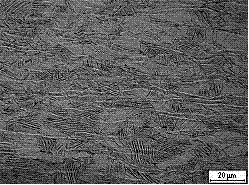

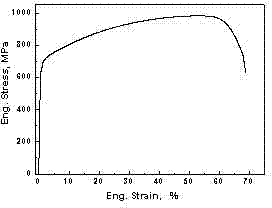

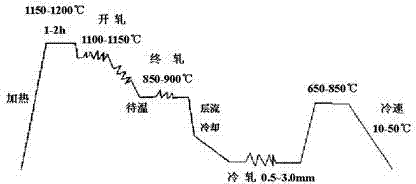

Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

ActiveCN102312158AExcellent overall performanceBroad application prospectsSteel platesManufacturing sector

The invention, belonging to the field of high-intensity alloy steel, relates to a preparation method of a Nb, Ti alloyed low-carbon high-intensity high-plasticity twinning induced plasticity (TWIP) steel. The steel comprises the following ingredients: 0.05-0.10 wt% C, 23.5-27 wt% of Mn, 0.01-0.03wt% of Si, at most 1.0 wt% of Al, at most 0.01 wt% of P, at most 0.02 wt% of S, 1.0-2.5 wt% of Nb, 0.5-1.25 wt% of Ti, 0.02 -0.08 wt% of N, and the balance consisting of Fe and inevitable impurities. The preparation method comprises the following steps: melting the ingredients and then casting into a casting blank, heating the casting blank and then carrying out hot rolling at the opening rolling temperature of 1100-1150 DEG C with multiple passes and small press quantity to obtain the accumulated deformation degree of more than 60 % at the temperature of more than 950 DEG C, processing the casting blank in a finishing rolling mode at the temperature of 850-900 DEG C, after the hot rolling, rapidly cooling to 400-550 DEG C for reeling, carrying out cold rolling on the steel plate processed by hot rolling with the thickness of 0.5-3.0 mm, preserving the steel plate processed by cold rolling at the temperature of 650-850 DEG C for 3-30 min, and then rapidly cooling to room temperature with the cooling rate of 10-50 DEG C / s. The material prepared by the method can be applied in automobile manufacturing industry. The material has the yield strength of more than 550 MPa and the elongation rate of no less than 60 %, thereby obviously improving the ability of anti-collision and impact of automobile for the first time and greatly increasing the crashworthiness indexes.

Owner:SHANGHAI JIAO TONG UNIV

Compound prepn of ornithine and asparagic acid for preventing and treating hepatosis and hepatic encephalopathy and its prepn process

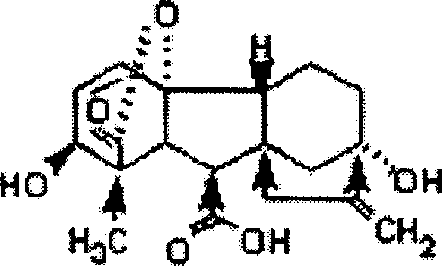

InactiveCN1383815ASimple production methodImprove product qualityPeptide/protein ingredientsDigestive systemOrnithine aspartateChronic liver disease

A compound preparation consists of ornithine or its salt and asparagic acid or its salt as well as proper amount of supplementary material; and is prepared into oral preparation or injection through mechanical mixing and other process. The said compound preparation is used for treating various acute hepatitis, chronic hepatosis and hepatic encephacopathy and has the obvious effects of protecting liver and strengthening physique. The preparation process is simple, short in production period and low in cost.

Owner:刘万忠

Giant salamander compound bait and production method thereof

InactiveCN102132775AReduce the cost of farmingReduce morbidityClimate change adaptationAnimal feeding stuffAnimal scienceShrimp

The invention discloses giant salamander compound bait and a production method thereof. The giant salamander compound bait includes bait for young salamanders and adult salamanders and bait for parent salamanders. The salamander compound bait takes fresh crucian carps, carps, grass carps, loaches and bull frogs as main materials and takes aggregates, mineral powder, micro amino acid and the like as auxiliary materials. After the main materials are mixed and minced, the auxiliary materials are added, and starch is then mixed. After being stirred and rubbed, the materials are filled by plastic casings in a sausage stuffer and dotted. Finally, sausages are sterilized at a temperature of 95-100 DEG C. The giant salamander compound bait can replace fresh fish and shrimp bait to feed giant salamanders. When the giant salamander compound bait is used for feeding, the plastic casings are stripped off, and the giant salamander compound bait is cut into strip materials suitable for the giant salamanders to swallow and thrown into a salamander pond. The giant salamander compound bait has good palatability. Practices prove that when the bait is used for feeding the giant salamanders, the breeding cost of the giant salamanders can be reduced by 30-50%, the growth rate of commercial salamanders can be increased by 10-30%, the salamander reproduction rate can be increased by 50-100%, and thedisease incidence rate of the giant salamanders is obviously reduced.

Owner:汉中天成生物工程有限公司

Coal dust depressor and preparation method thereof

InactiveCN101747866AEasy to operateSimple production methodOther chemical processesSulfonateCoal dust

The invention discloses a coal dust depressor and a preparation method thereof. The coal dust depressor of the invention is composed of 20-30% of sodium lignin sulfonate, 12-18% of crylic acid, 0.4-0.6% of hydrogen peroxide, 5% of calcium chloride, 0.5% of sodium tetraborate, 3% of methyl sodium silicate and 43-59% of water. The coal dust depressor of the invention has simple operation and simple and convenient production and preparation method, does not need special equipment for preparation and production, does not has toxicity, does not have corrosivity to equipment, has lower production cost, is convenient to operate and apply and conforms to environment protection requirements, and dust depression effect, especially water prevention effect is superior to that of the prior art.

Owner:NORTHWEST RES INST CO LTD OF C R E C

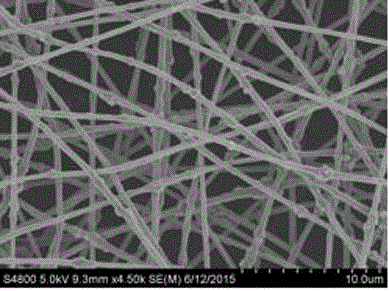

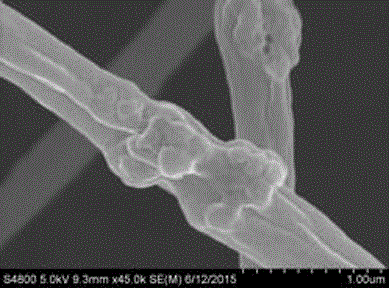

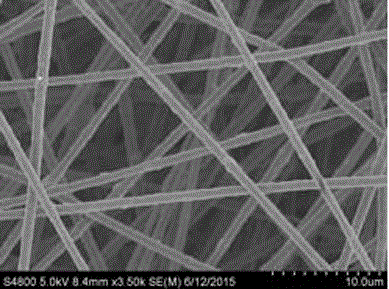

Filter membrane as well as preparation method and application

ActiveCN105536574AImprove filtering effectHEPASemi-permeable membranesDispersed particle filtrationPorosityFiltration membrane

The invention relates to a filter membrane, which is formed by a metal organic framework material and a polymer. The invention also provides a method for preparing the filter membrane which is formed by the metal organic framework material and the polymer. The method comprises the following steps: the metal organic framework material and the polymer are contacted, and the filter membrane is formed by spinning or dip-coating. The invention also relates to an application of the filter membrane to filtering of PM2.5 and volatile organic compounds. The filter membrane has the advantages of high specific surface area, abundant surface function groups, high amount of porosity, light transmission, ventilation, etc., and the filter membrane is used for realizing high-efficiency filtering of PM2.5 and volatile organic compounds.

Owner:理工清科(北京)科技有限公司

Water-soluble chitosan and shrimp antistaling agent prepared by ginger extract as well as using method

InactiveCN101496535AImprove sensory qualityStay hydratedMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAntioxidantPhytic acid

The invention provides a shrimp preservative prepared from water-soluble chitosan and ginger extract, and a using method thereof. The shrimp preservative is a composite preservative which is formed by taking water-soluble chitosan and ginger extract as main raw materials and compounding the main raw materials with antioxidant, phytic acid, sodium citrate and dextrin. Fresh shrimps or shrimp meat with no head and shell are soaked in seawater or clear water in which the shrimp preservative is dissolved at a temperature of between 0 and 10 DEG C, and then the aims of preventing decay, stopping shrimp heads from blackening, preventing fishy smell from increasing and the like can be achieved. The shrimp preservative has broad application prospects. As the shrimps subjected to freshness-keeping treatment seldom change color or decay in a processing course, are bright in body, pure in taste, strong and elastic in meat, the sensory quality of the shrimps is remarkably improved. The shrimp preservative has the advantages that the shrimp preservative is simple in production method, convenient to use, capable of applying to various types of food processing taking the shrimps as raw materials, remarkable in freshness-keeping effects and capable of keeping the moisture of the shrimps, raising product yield, improving product quality and increasing economic benefit.

Owner:GUANGDONG OCEAN UNIVERSITY

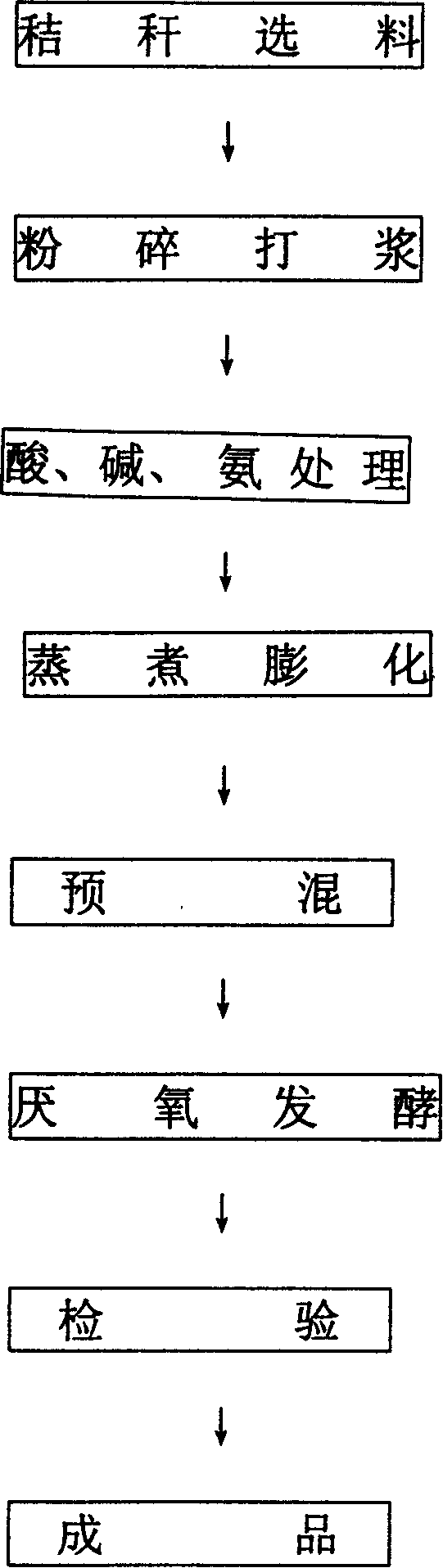

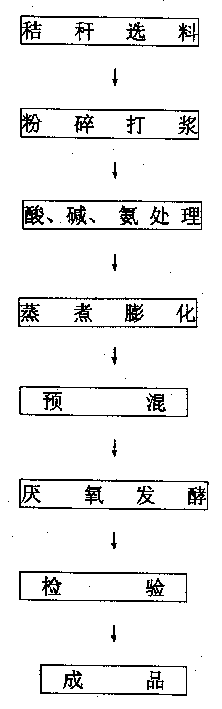

Method for producing stalk biochemical fodder

InactiveCN1473486ASolve full useQuality improvementFood processingAnimal feeding stuffBiotechnologyFodder

The present invention relates to the method of producing biochemical stalk fodder for farm animal and makes it possible to utilize crop stalk fully. The technological scheme is the production process including crushing stalk, pulping, chemical treating with acid, alkali and ammonia, puffing, steaming, mixing with wheat bran, corn powder, bean cake, fish meal, salt, water and grain enzyme and final anaerobic fermentation.

Owner:孙君坡 +1

Complex microorganism fungicide for treating animal manure and preparation method and application thereof

InactiveCN101775356ARaw materials are easy to getSimple production methodFungiBacteriaBiotechnologyFeces

The invention relates to a complex microorganism fungicide for treating animal manure and a preparation method and an application thereof. The adopted technical scheme is that the complex microorganism fungicide consists of saccharomyces cerevisiae, powdery pichia, bacillus subtilis, bacillus cereus, bacillus megaterium and lactobacillus plantarum. Microbial organic fertilizer can be prepared by treating the animal manure with the complex microorganism fungicide. The complex microorganism fungicide for treating the animal manure prepared by the invention has the advantages of easy obtainment of raw materials and simple manufacturing method. Preparing the microbial organic fertilizer by mixing the complex microorganism fungicide for treating the animal manure with the animal manure, organic materials and cornmeal not only can treat the animal manure, but also effectively utilizes rural wastes; and the prepared microbial organic fertilizer can not pollute crops and cultivated land because no chemical substance exists in the prepared microbial organic fertilizer.

Owner:YINGKOU HENGXIN BIOTECH DEV

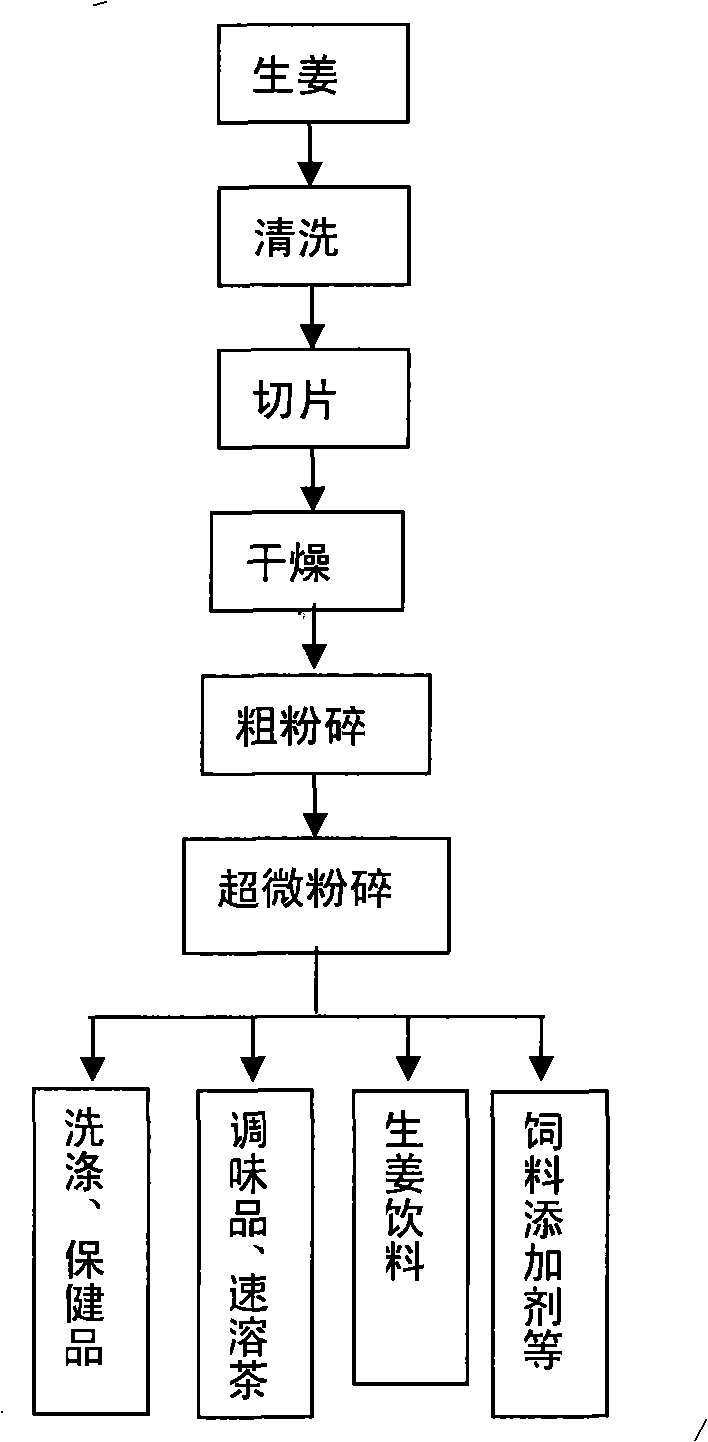

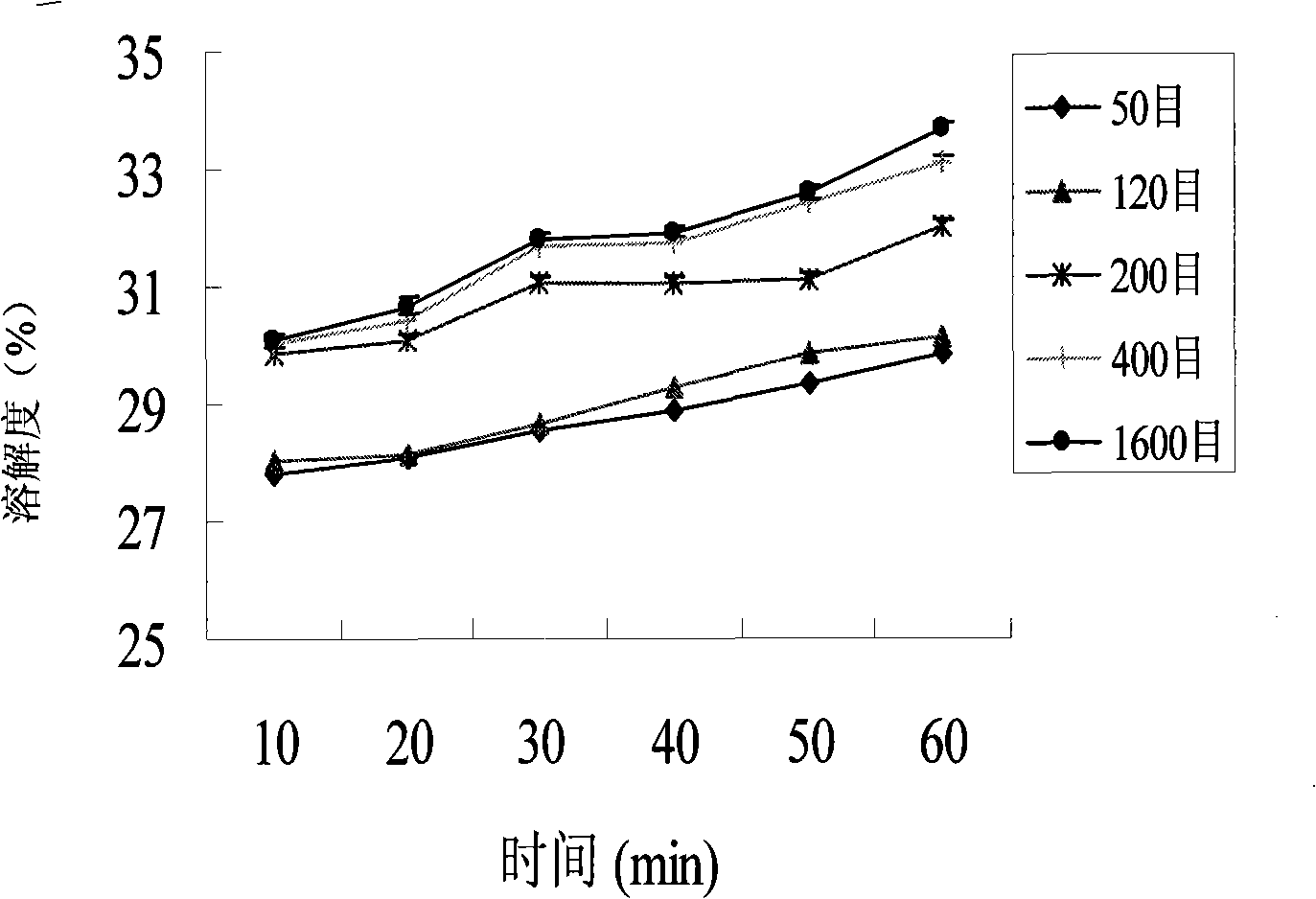

Ultramicro ginger powder and method for producing the same

InactiveCN101327016ASave resourcesChange structureCosmetic preparationsPowder deliveryProcess engineeringFood products

The invention discloses an ultramicro ginger powder processing method; the ultramicro ginger powder refers to the ginger powder with 700mesh to 2000mesh of grain size. The production method comprises the steps: raw material selection, slicing, drying, coarse grinding, ultramicro grinding, sterilization, packaging, etc. The method changes the traditional ginger grinding and processing technologies, injects the coarse ginger particles after coarse grinding into an air flow ultramicro grinding machine to prepare ultramicro powder by pressure or impulsion. The method solves the problems of the resource waste and poor solubility in the traditional ginger grinding processes; after the ultramicro grinding, the ginger powder has the advantages of high release speed of effective components, large release amount, convenient and fast use method, even distribution, etc., and is suitable to be promoted and applied in food, feed, cosmetics, health care and other industries.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com