Filter membrane as well as preparation method and application

A filter membrane and metal-organic framework technology, applied in the field of applied chemistry, can solve the problems of no technical methods and materials, and achieve the effect of simple and fast preparation process, high porosity, and rich surface functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Preparation of filter membrane

[0075] The contacting of the metal-organic framework material of the present invention with the polymer is carried out in a solvent.

[0076] The solvent includes at least one of water, methanol, ethanol, dimethylformamide, dimethylacetamide and diethylformamide. The inventors found that choosing dimethylformamide as a solvent can obtain a membrane with higher purity and better filtration effect.

[0077] With respect to 1 gram of the metal-organic framework material, the amount of the polymer used is 0.1-10 grams, more preferably 1-8 grams, and the amount of the solvent used is 10-100 milliliters, more preferably 15-80 milliliters.

[0078] The filter membrane of the present invention is prepared by a spinning method.

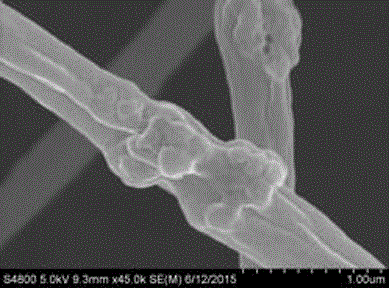

[0079] Metal-organic framework materials and polymers are spun onto non-woven fabrics, and the two interweave and grow together to obtain metal-organic framework / polymer filtration membranes. Specifically, first set t...

Embodiment 1

[0090] Disperse the metal-organic framework material (zirconium chloride as the metal source and 2-aminoterephthalic acid as the organic ligand) in the solvent dimethylformamide, then add polyacrylonitrile, and mix evenly to obtain a spinning solution. Wherein, relative to 1 gram of metal-organic framework material, the amount of polymer used is 5 grams, the amount of solvent used is 50 milliliters, the mixing temperature is room temperature, and the mixing time is 8 hours.

[0091] The above-mentioned spinning solution is spun, and the fiber is received by a non-woven fabric to obtain a filter membrane; wherein, the spinning parameters are a spinning feed rate of 3 milliliters per hour, a spinning voltage of 13 kilovolts, and a spinning distance of 20 centimeters. The spinning time is 10 minutes, and the needle type is 20G.

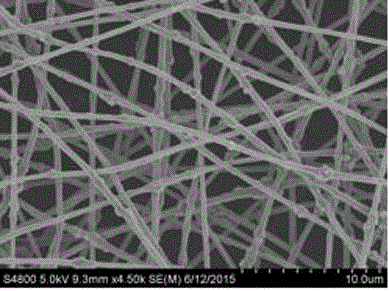

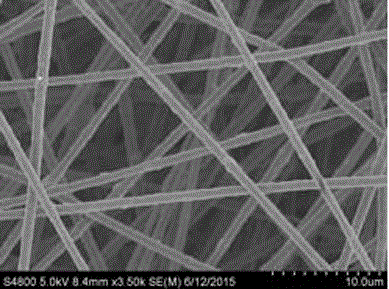

[0092] The filter membrane was analyzed by X-ray powder diffraction and scanning electron microscope. X-ray powder diffraction, model: BrukerD8Advance,...

Embodiment 2

[0095] The metal organic framework material (the metal source is copper acetate, and the organic ligand is trimesic acid) is dispersed in dimethylformamide, then polystyrene is added, and the spinning solution is obtained by mixing evenly. Wherein, relative to 1 gram of metal-organic framework material, the amount of polymer used is 8 grams, the amount of solvent used is 80 milliliters, the mixing temperature is room temperature, and the mixing time is 8 hours.

[0096] The above-mentioned spinning solution is spun, and the fiber is received by a non-woven fabric to obtain a filter membrane; wherein, the spinning parameters are a spinning feed rate of 5 milliliters per hour, a spinning voltage of 10 kV, and a spinning distance of 15 centimeters. The spinning time is 5 minutes, and the needle type is 20G.

[0097] The filter membrane was analyzed by X-ray powder diffraction and scanning electron microscope. The test method and test conditions were the same as in Example 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com