Anhydrous albany grease and preparation method thereof

A calcium-based grease and base oil technology, applied in the field of anhydrous calcium-based grease and its preparation, grease and its preparation, can solve the problem that the requirements for high temperature use cannot be met, the product performance cannot be known, and the preparation requires a lot of raw materials. and other problems, to achieve the effect of good water erosion resistance, good extreme pressure and anti-wear performance, and enhanced extreme pressure and anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

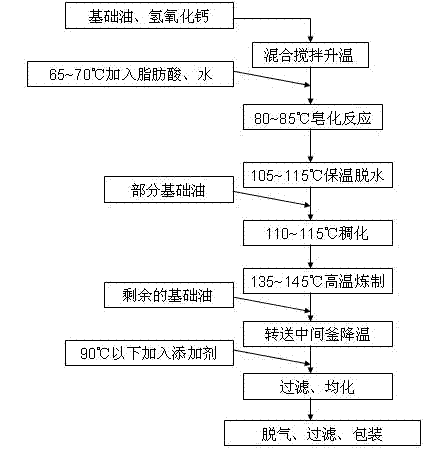

Method used

Image

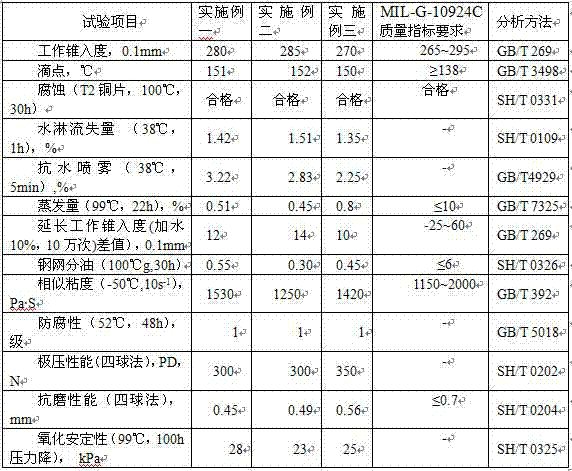

Examples

Embodiment 1

[0030] The present embodiment prepares anhydrous calcium base lubricating grease according to the following method:

[0031] Step 1. Paraffin base oil 500SN (kinematic viscosity at 40°C 115mm 2 / s) 1000kg and 36kg of calcium hydroxide were added to the open reaction kettle and stirred and mixed. After slowly heating up to 65°C, 54.8kg of stearic acid, 219.2kg of 12-hydroxystearic acid and 80kg of water were added in sequence, and the temperature was continued to rise to 85°C. saponification reaction;

[0032] Step 2. After the saponification reaction is completed, the temperature is raised to 110°C. After heat preservation and dehydration, divide into 2 times and add 500SN 900kg each time for thickening;

[0033] Step 3. Raise the temperature of the thickened reactant to 140°C for refining, transfer the reactant to an intermediate kettle, and add the remaining 500SN 700kg for cooling;

[0034] Step 4. When the reactant in step 3 is cooled to 80°C, add 15kg of di-tert-butyl p...

Embodiment 2

[0036] The present embodiment prepares anhydrous calcium base lubricating grease according to the following method:

[0037] Step 1, polyalpha-olefin oil PAO-12 (the kinematic viscosity of 40 ℃ 95mm 2 / s) 900kg and 38.1kg of calcium hydroxide are added to the open reaction kettle and stirred and mixed. After slowly heating up to 70°C, add 40.2kg of stearic acid, 267.7kg of 12-hydroxystearic acid and 95kg of water in sequence, and continue to heat up to 80°C Carry out saponification reaction;

[0038] Step 2. After the saponification reaction is completed, the temperature is raised to 105°C. After heat preservation and dehydration, add 1000kg of PAO-12 in 3 times for thickening;

[0039] Step 3. Raise the temperature of the thickened reactant to 135°C for refining, transfer the reactant to an intermediate kettle, and add the remaining 700kg of PAO-12 for cooling;

[0040] Step 4. When the reactant in step 3 is cooled to 85°C, add 9kg of phenyl-α-naphthylamine, 15kg of thiadia...

Embodiment 3

[0042] This embodiment prepares anhydrous calcium-based lubricating grease according to the following method (the kinematic viscosity at 40°C after mixing the two base oils selected in this embodiment is 245mm 2 / s):

[0043] Step 1. Add naphthenic oil YX-100 (the kinematic viscosity at 40°C is 97mm 2 / s) 950kg and 40.5kg of calcium hydroxide were added to the open reaction kettle and stirred and mixed. After slowly heating up to 65°C, 29.6kg of stearic acid, 295.9kg of 12-hydroxystearic acid and 120kg of water were added in sequence, and the temperature was continued to rise to 85°C Carry out saponification reaction;

[0044] Step 2. After the saponification reaction is completed, the temperature is raised to 110°C. After heat preservation and dehydration, add paraffin base oil 150BS in an average amount each time (the kinematic viscosity at 40°C is 460mm 2 / s) 1100kg for thickening;

[0045] Step 3, heat up the thickened reactant to 145°C for refining, transfer the reacta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com