Patents

Literature

688results about How to "Good extreme pressure and anti-wear properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

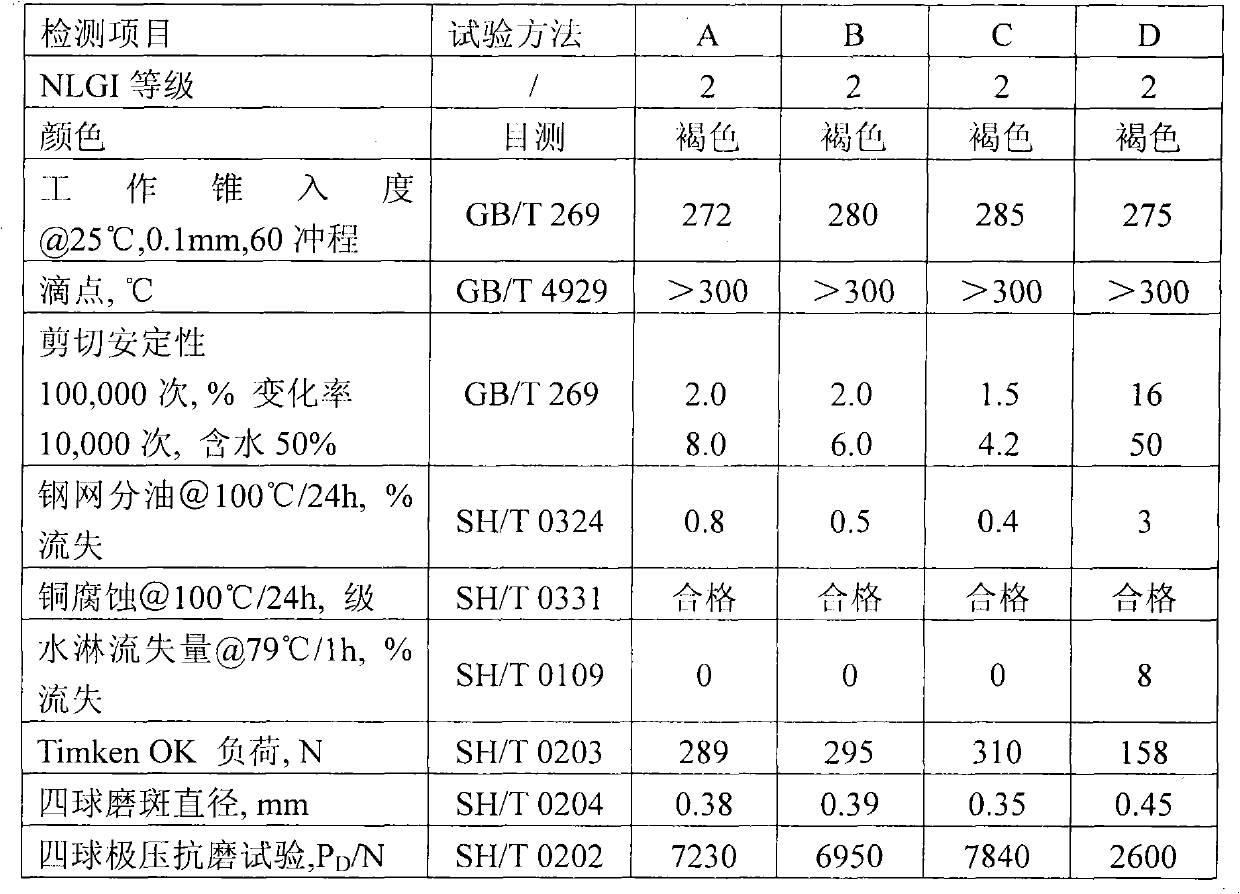

Polyurea grease composite

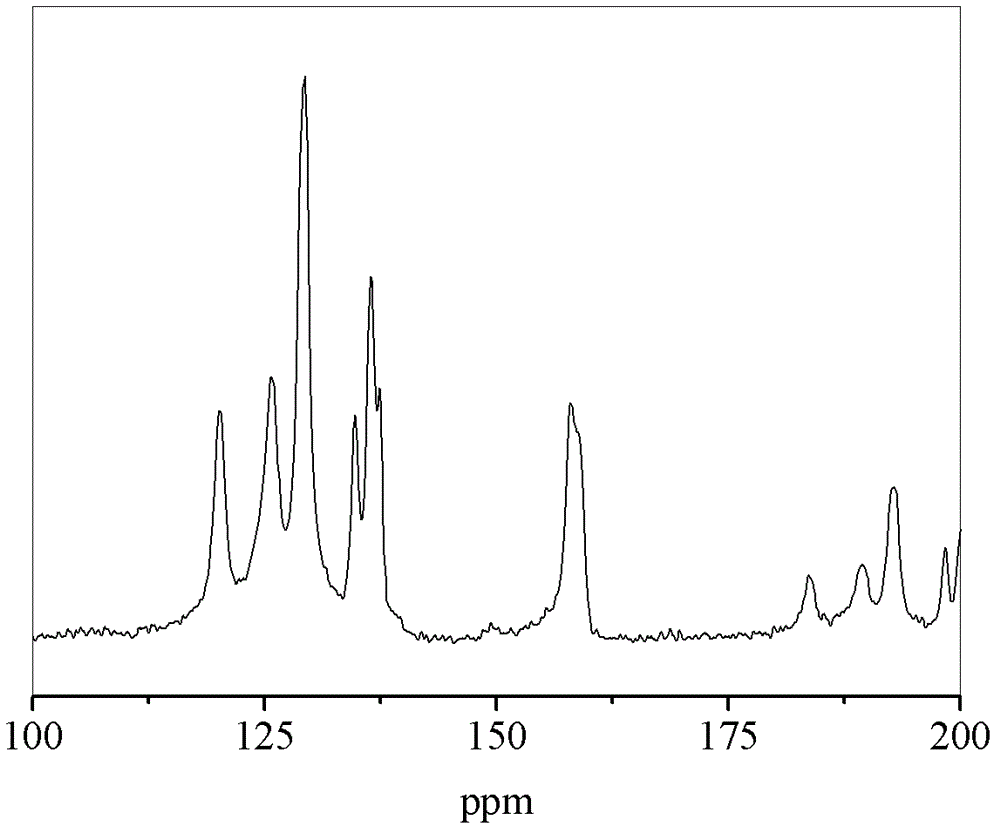

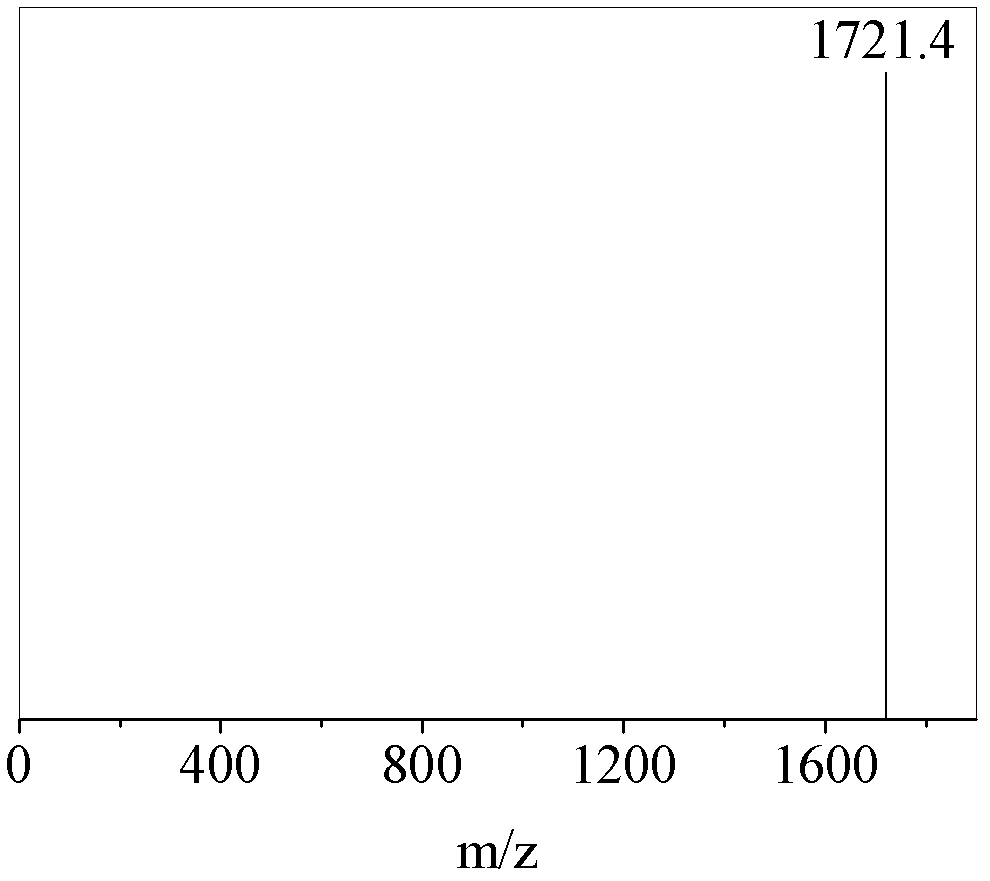

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

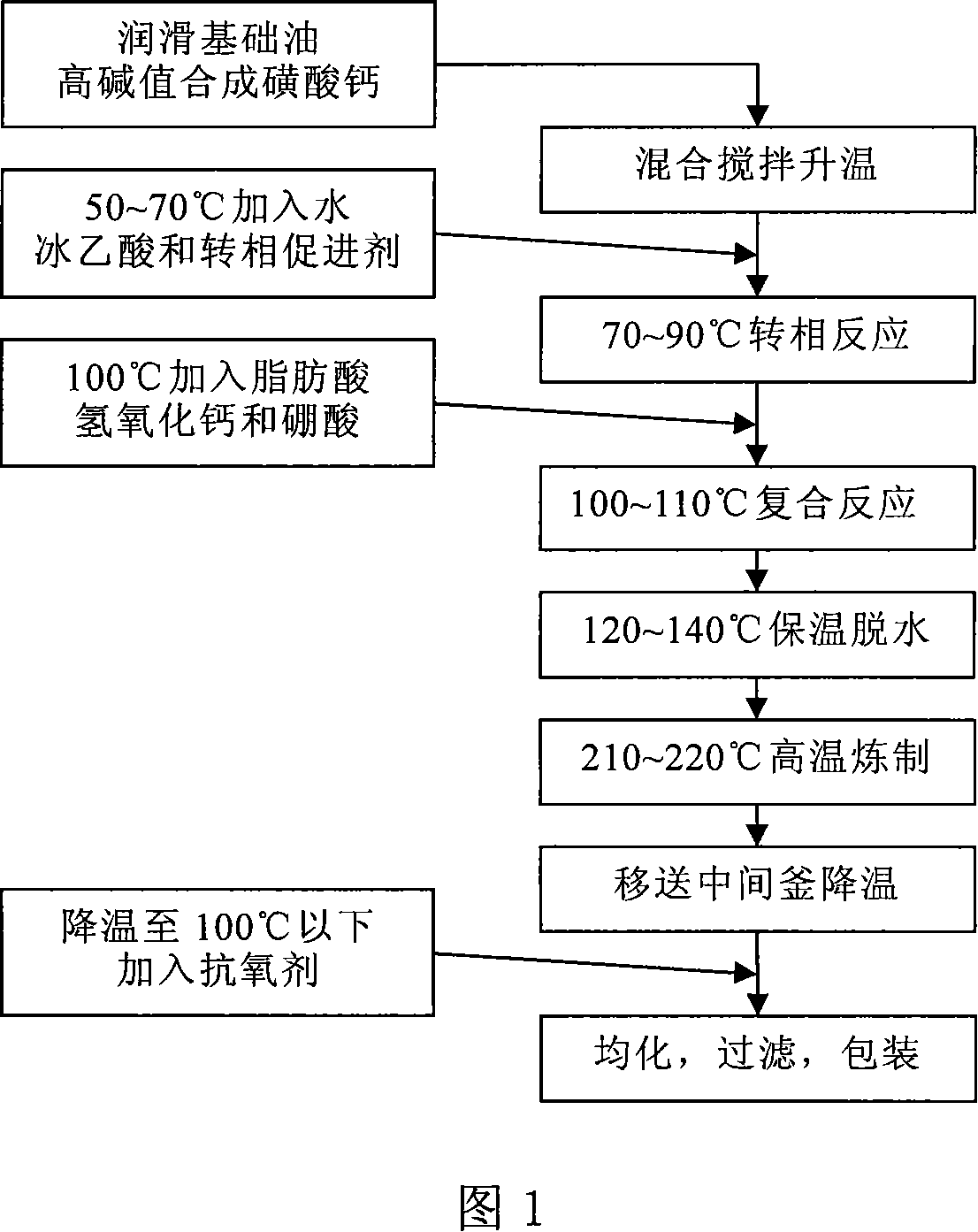

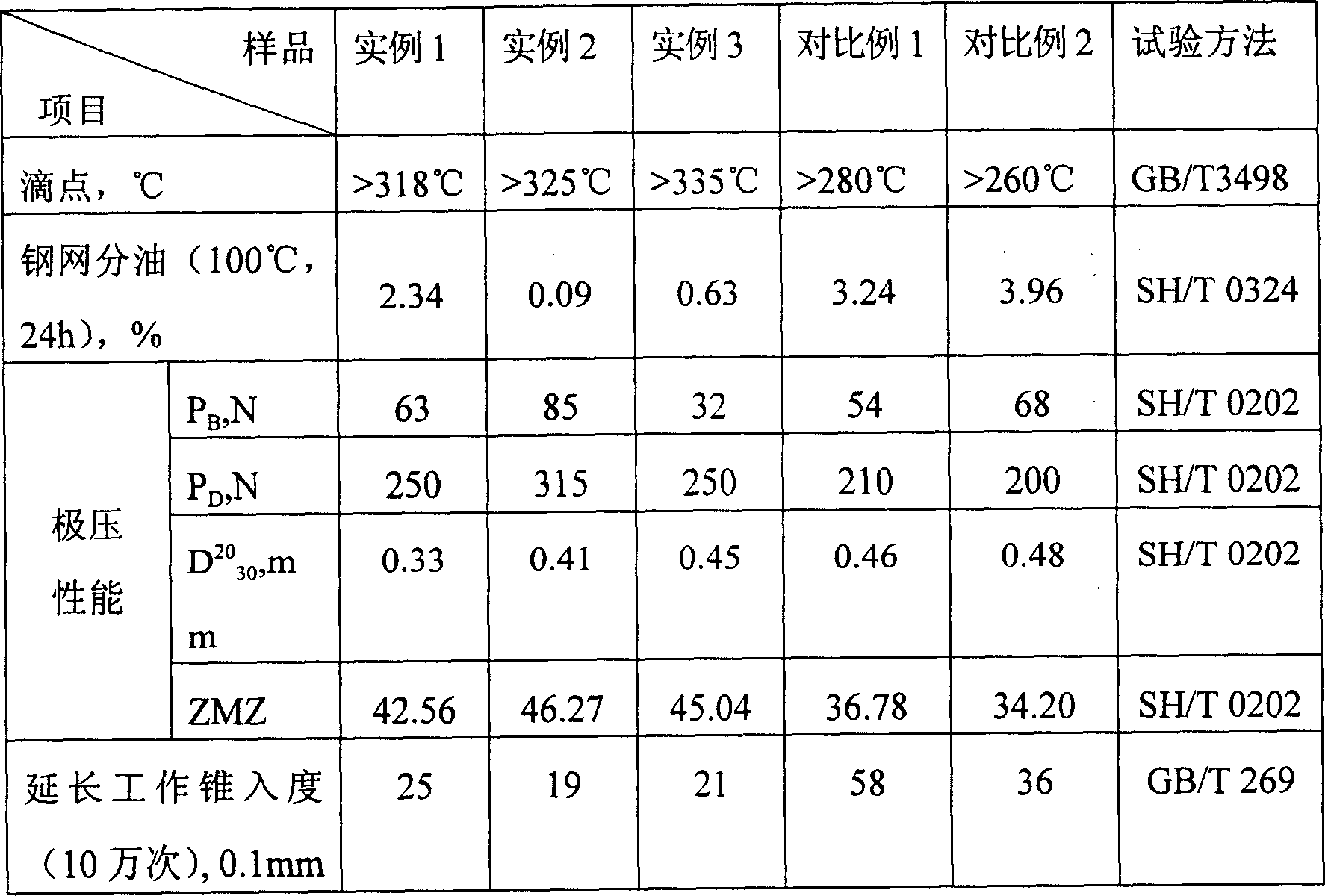

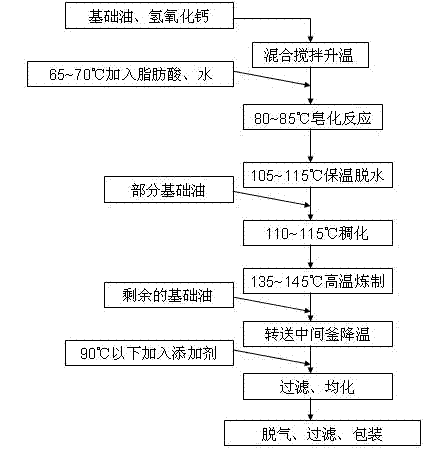

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

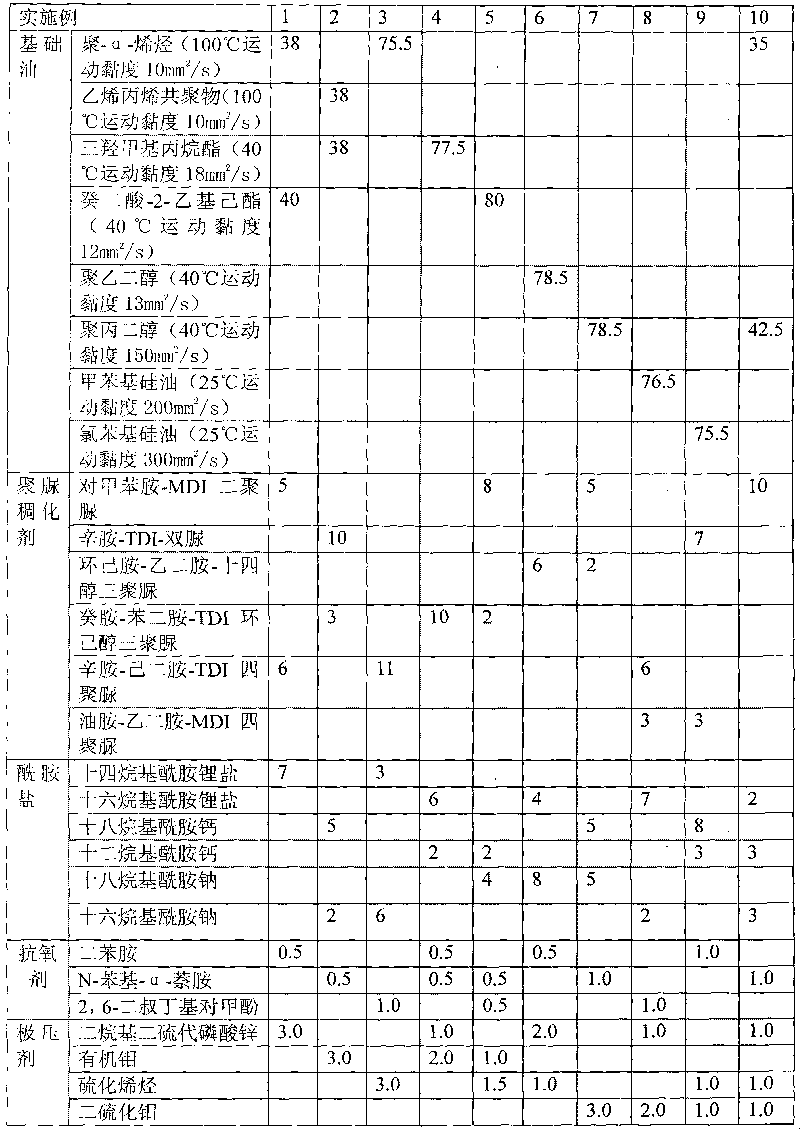

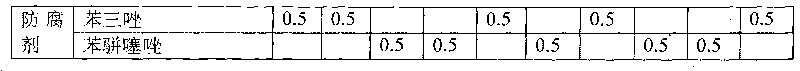

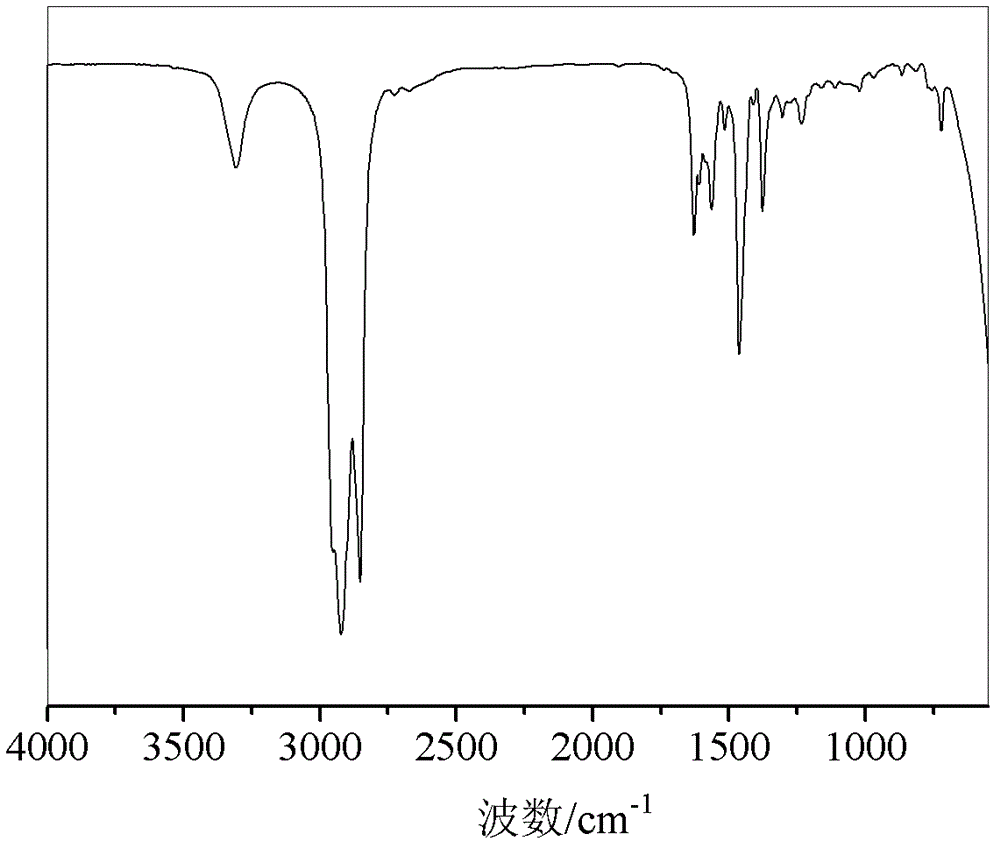

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of octapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the octapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyurea-composite calcium lubricating grease

InactiveCN1493673APrevent volatilizationImprove high temperature performanceAdditivesCalcium hydroxideOrganic acid

A lubricating polyureas-composite calcium grease is prepared through proportionally mixing basic oil, calcium hydroxide (oxide), water and C1-C20 organic acid together, heating to 30-100 deg.C, adding diisocyanate and organic amine, draining water, saponifying, heating to 210-230 deg.C, cooling and homogenizing. Its advantages are high refractory performance, stability and extreme-pressure antiwear nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anhydrous albany grease and preparation method thereof

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

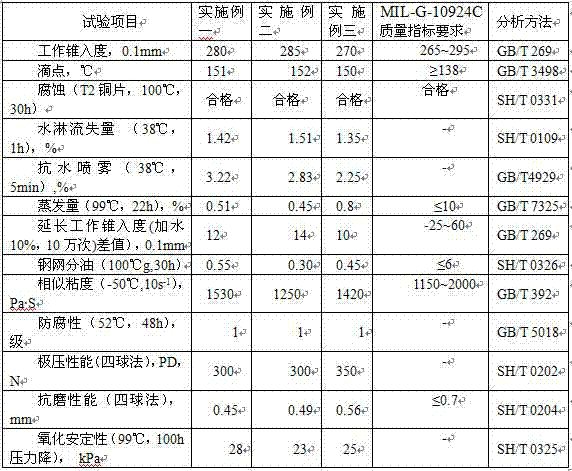

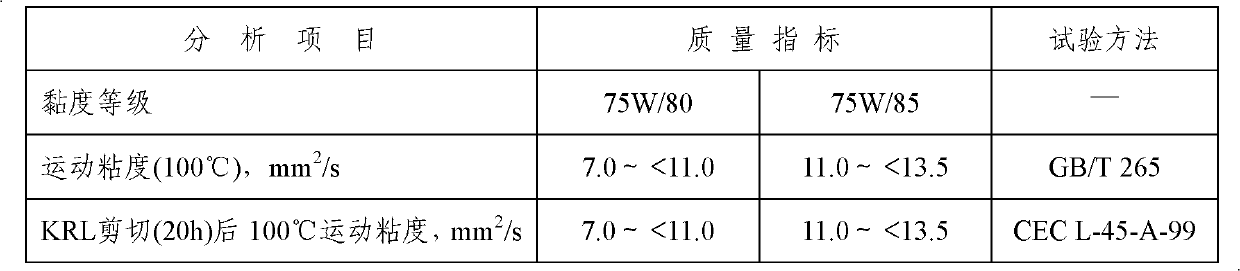

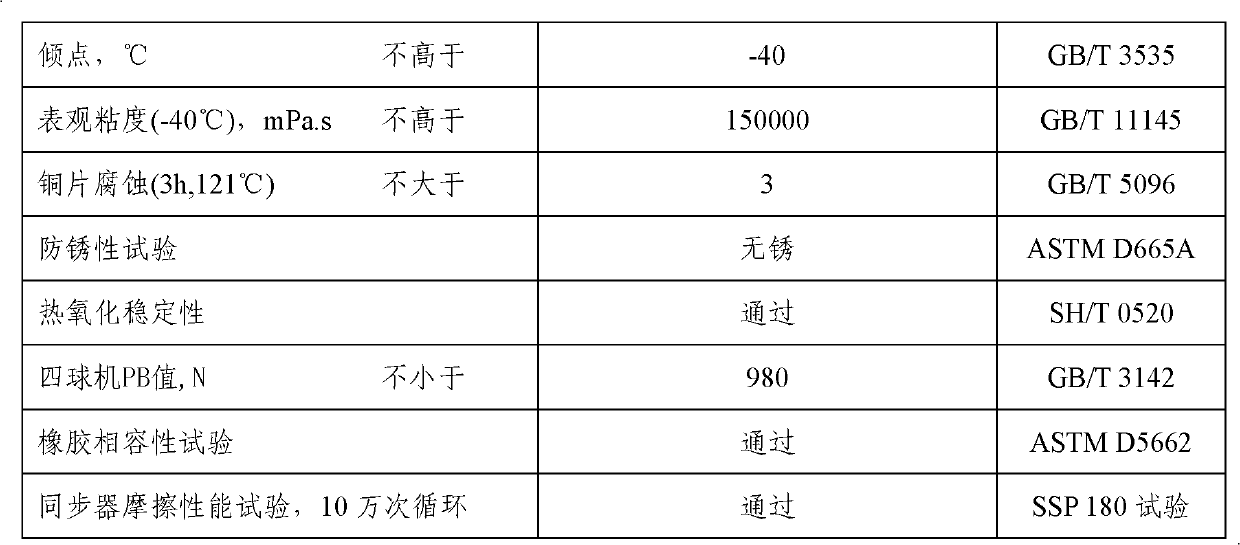

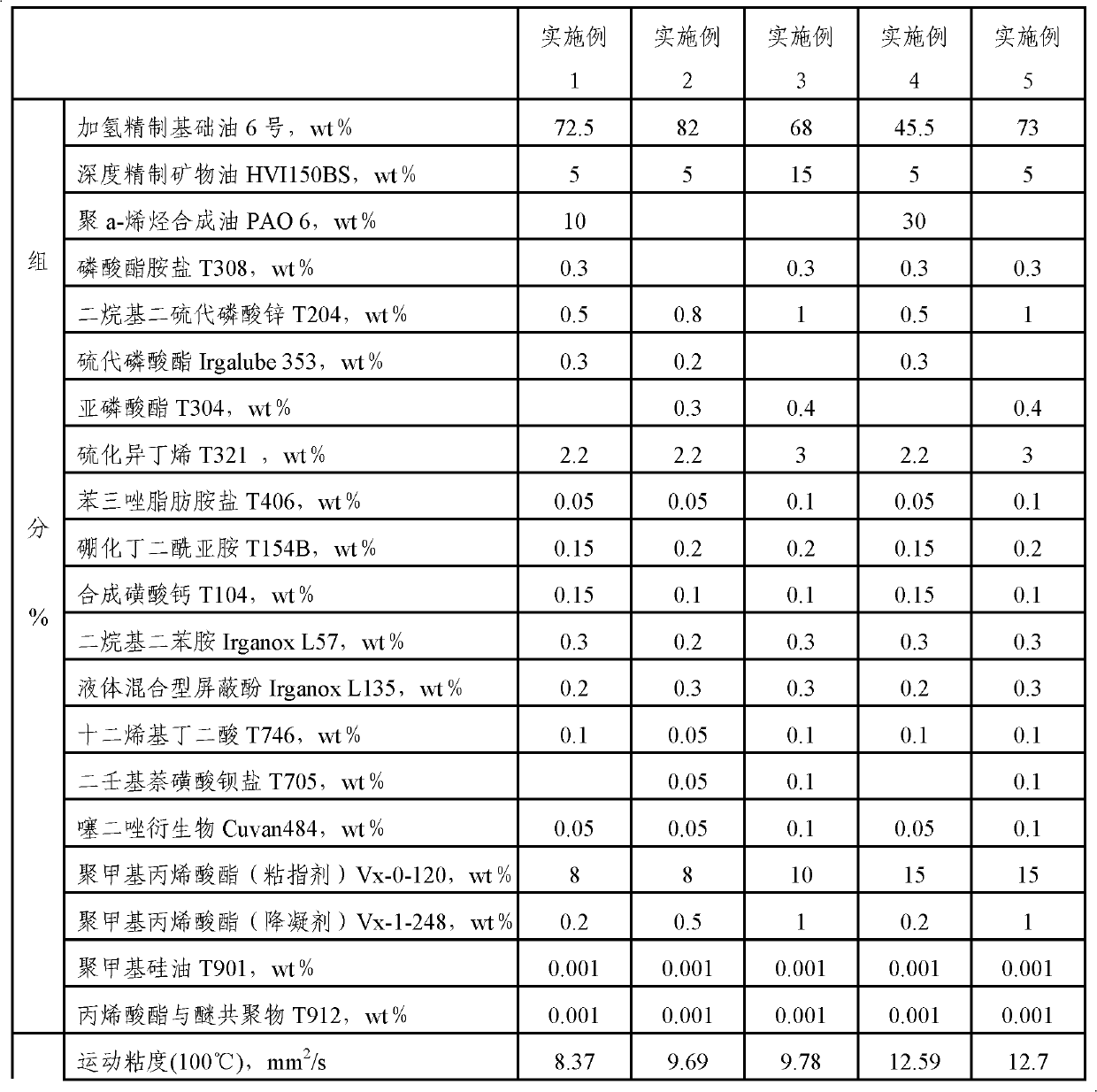

Manual transmission lubricating oil composition

ActiveCN103374452AGood high and low temperature performanceGood thermo-oxidative stabilityLubricant compositionManual transmissionViscosity index

The invention provides a manual transmission lubricating oil composition. The manual transmission lubricating oil composition comprises (a) at least one mineral oil and / or synthetic oil with high viscosity index, (b) at least one viscosity index improving agent, (c) at least one pour point depressant, (d) at least one phosphorus-containing antiwear agent, (e) at least one sulfur-containing extreme pressure agent, (f) at least one friction improving agent, (g) at least one clean dispersion agent, (h) at least one antioxidant, (i) at least one antirust agent, (j) at least one metal deactivator and (k) at least one anti-foaming agent. The manual transmission lubricating oil composition provided by the invention meets the vehicle gear oil viscosity level of 75W / 80 or 75W / 85, has excellent high-low temperature performances, anticorrosion performance, antirust performance and shearing-resistance performance, especially has excellent synchronizer friction performance, can be used for a manual transmission with a synchronizer, and can be completely suitable for the improvement of oil product performance requirement brought about by technique improvement of the manual transmission at present.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

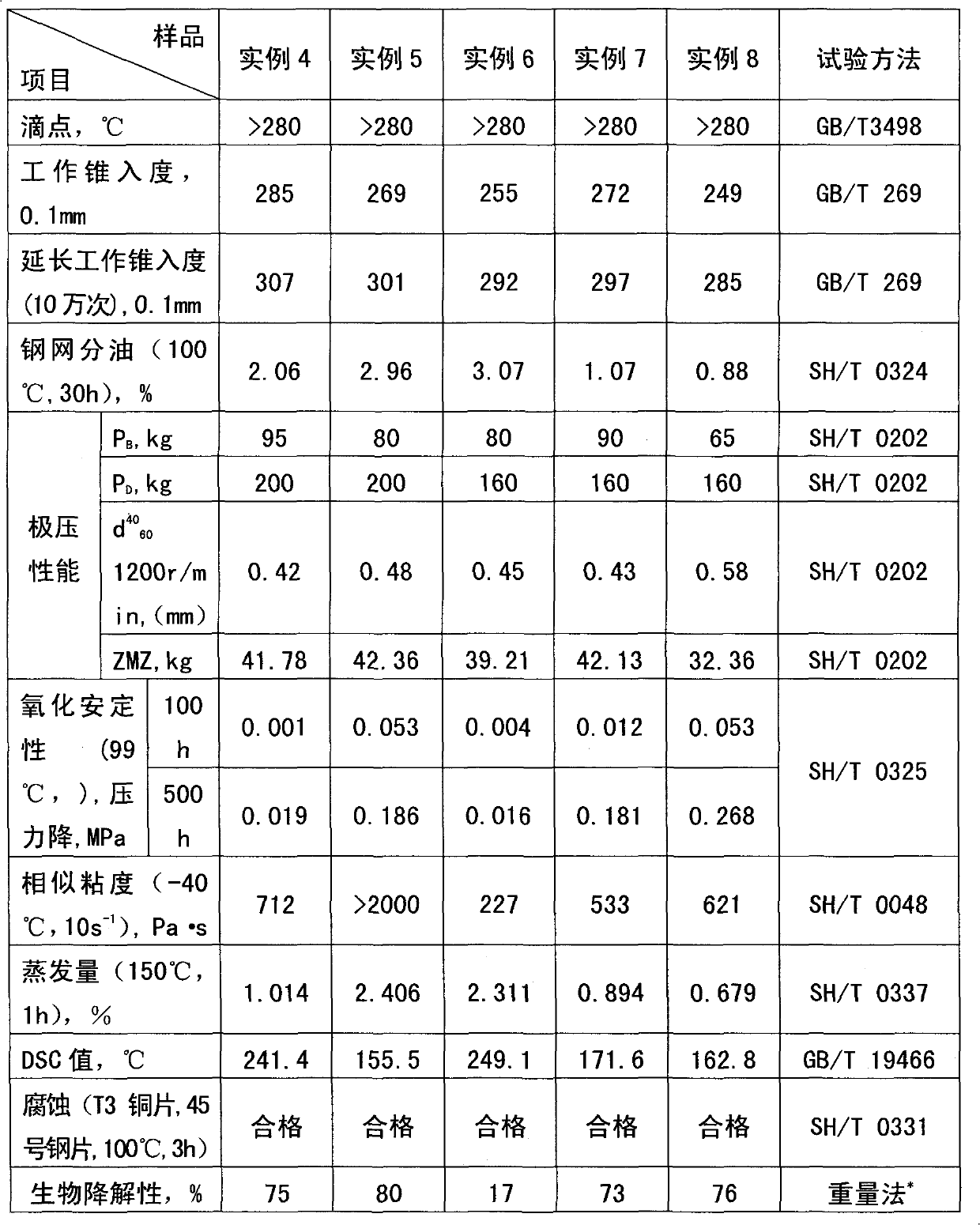

Environmentally friendly lubricating grease composition and preparation method thereof

InactiveCN104804842APromote degradationGood high and low temperature characteristicsLubricant compositionLithium soapAntioxidant

An environmentally friendly lubricating grease composition comprises base grease composed of base oil and a thickener, and an additive, wherein the base oil is selected form synthetic oil base oil, the thickener is a lithium soap or composite lithium soap thickener, and the additive at least contains an extreme pressure anti-wear agent selected from borate and a nanometer extreme pressure agent, an antioxidant and an antirust agent. The above lubricating grease has the advantages of good biodegradability, good high and low temperature characteristics, good extreme pressure anti-wear performances, and low starting torque and running torque, and is suitable for being used in railway switch machines.

Owner:CHINA PETROLEUM & CHEM CORP +1

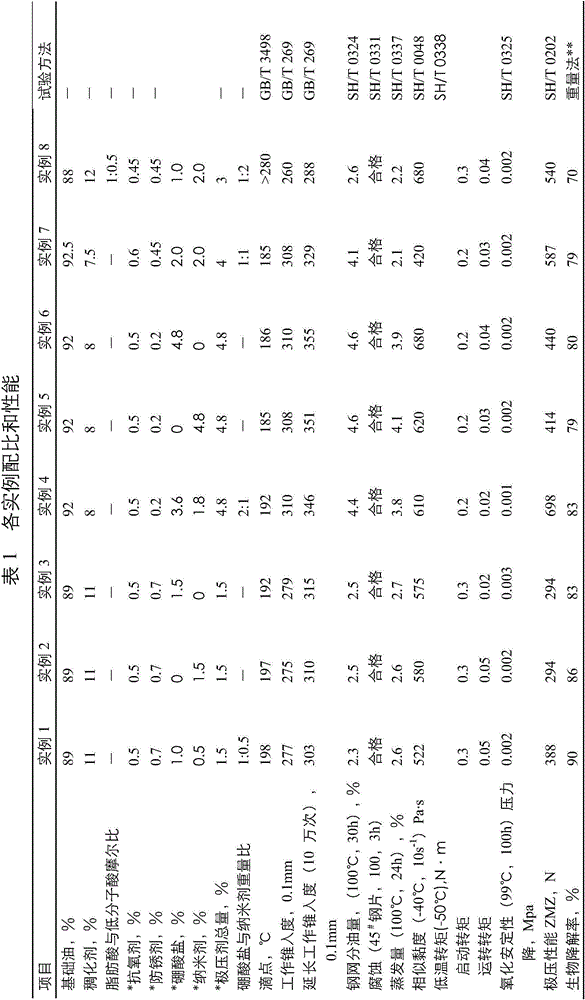

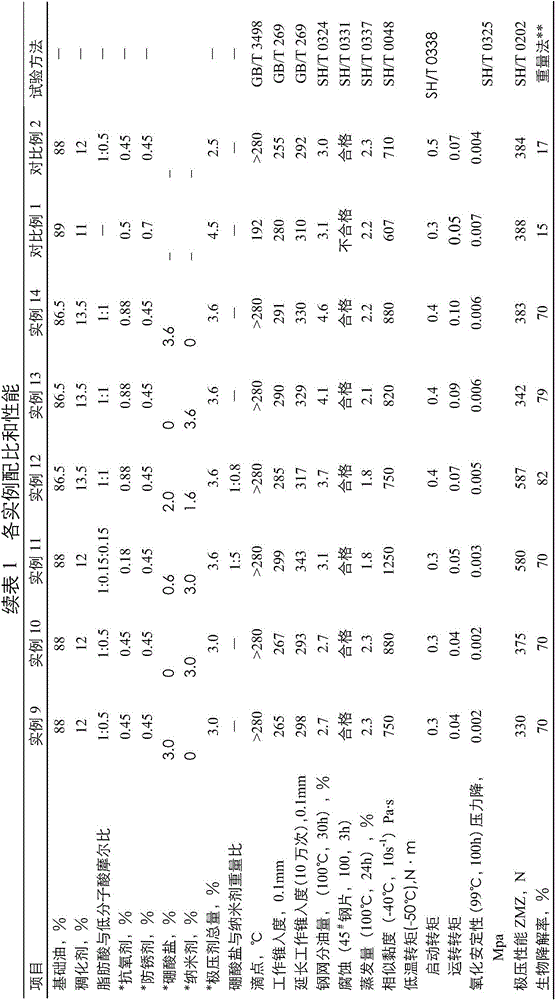

Composite calcium sulfonate lubricating grease composition and preparation method thereof

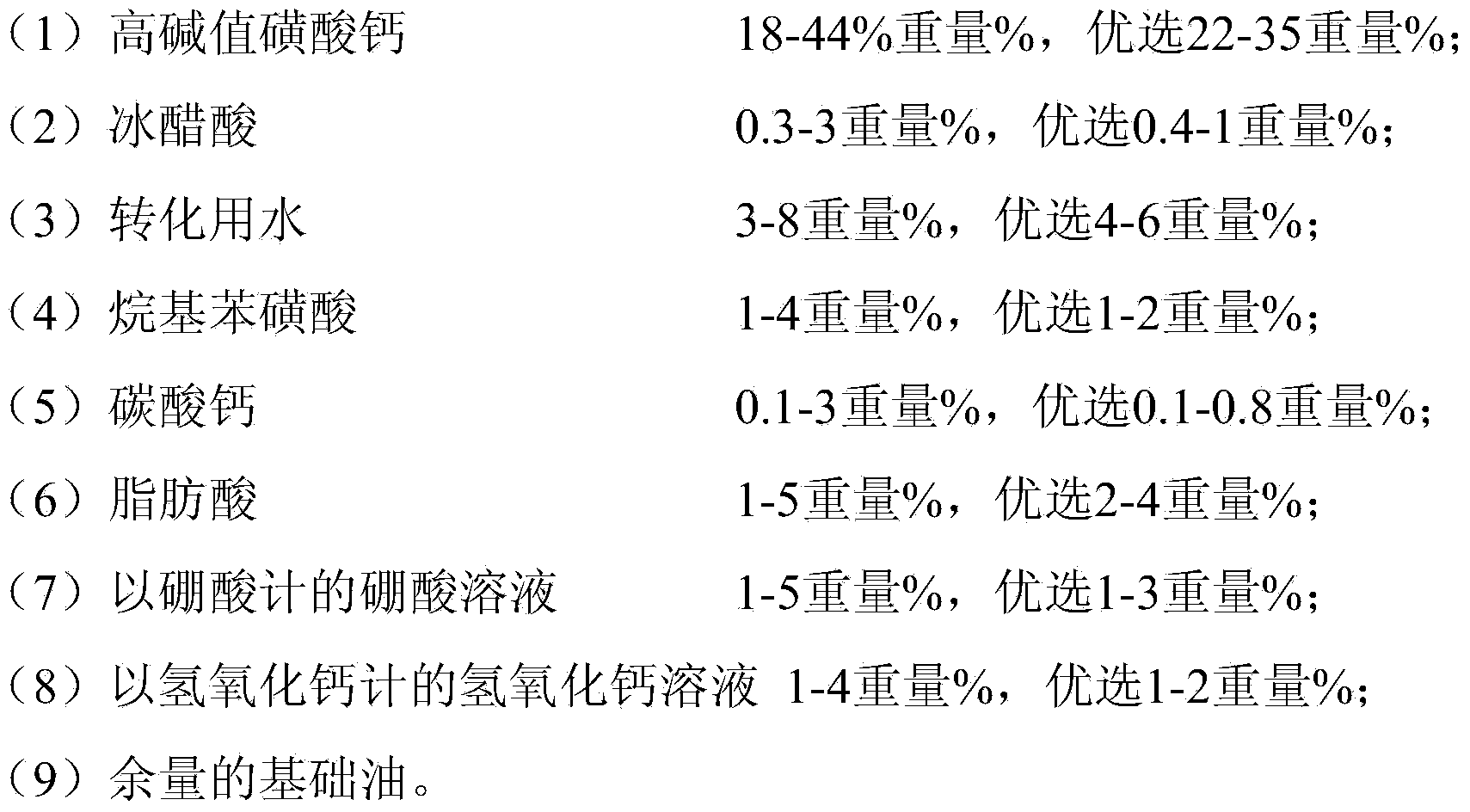

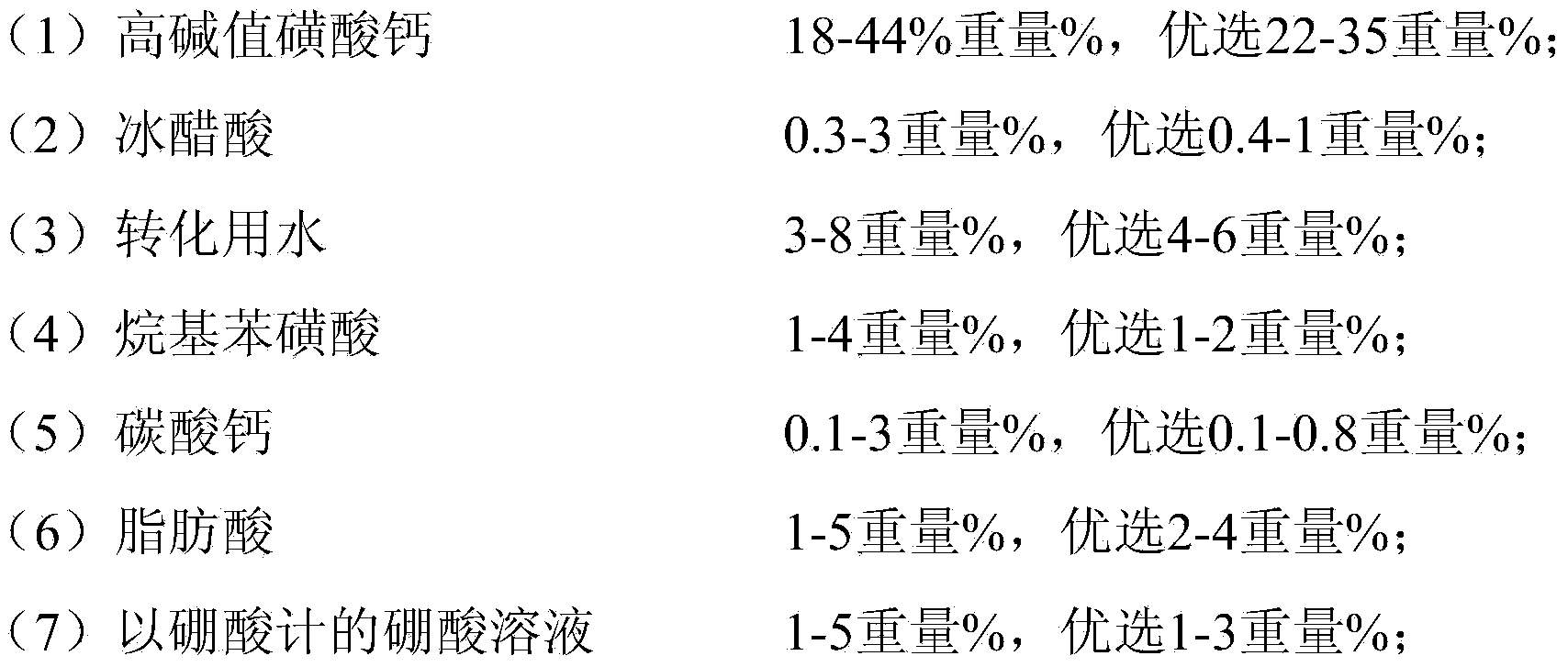

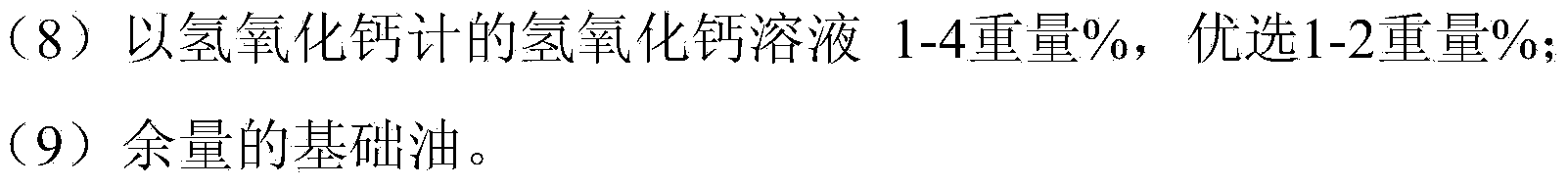

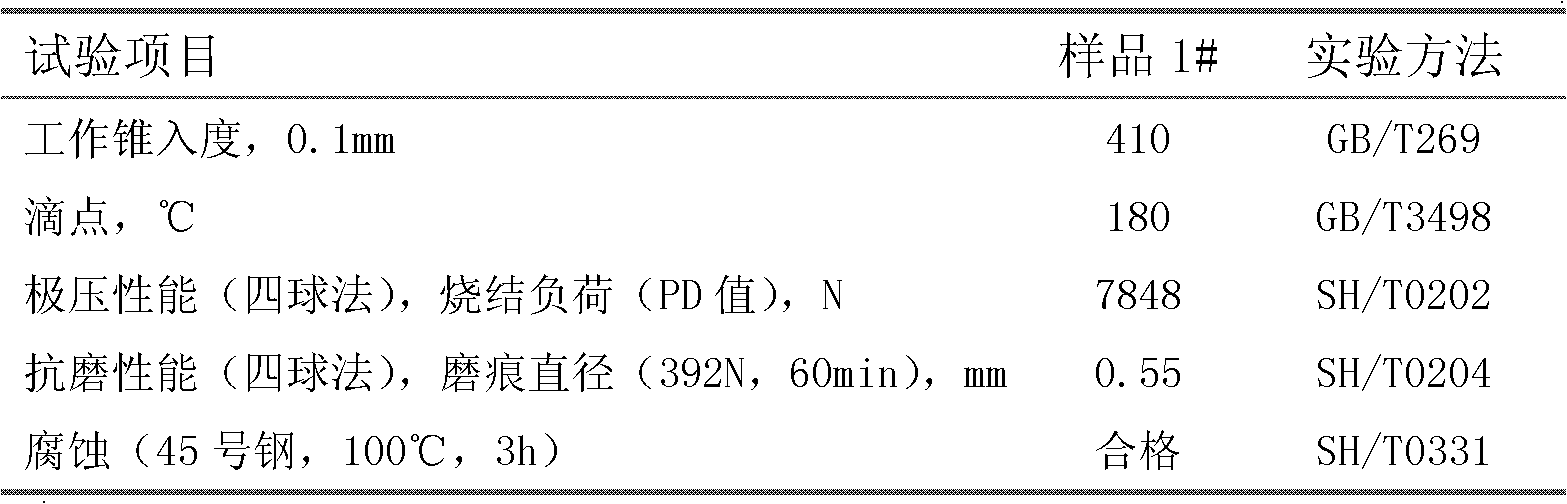

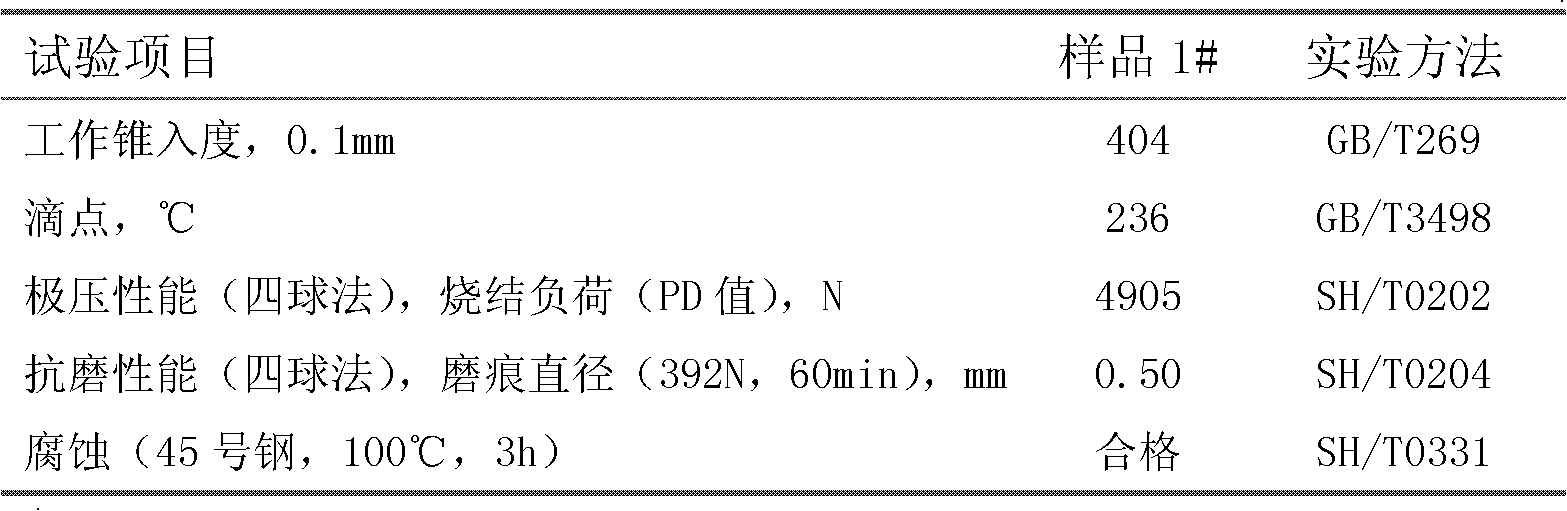

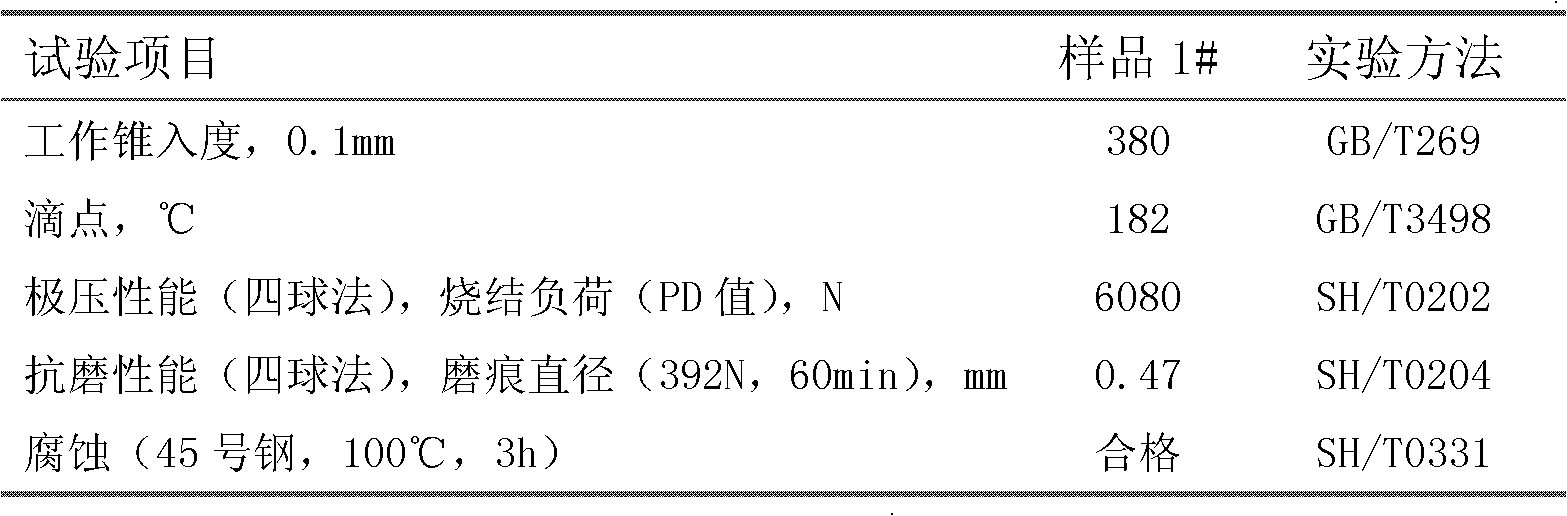

ActiveCN103740435ADrop point highGood extreme pressure and anti-wear propertiesThickenersChemistryBenzene

The invention relates to a composite calcium sulfonate lubricating grease composition and a preparation method thereof. The composite calcium sulfonate lubricating grease composition is prepared from the following raw materials in percentage by weight: 18 to 44 percent of high-base-number calcium sulfonate, 0.3 to 3 percent of glacial acetic acid, 3 to 8 percent of water for conversion, 1 to 4 percent of alkyl benzene sulfonic acid, 0.1 to 3 percent of calcium carbonate, 1 to 5 percent of fatty acid, 1 to 5 percent of a boric acid solution counted by using boric acid, 1 to 4 percent of a calcium hydroxide solution counted by using calcium hydroxide and the balance of base oil. The composite calcium sulfonate lubricating grease composition has the advantages of high dropping point, good extreme pressure antiwear property, excellent colloid stability and mechanical stability, and has a wide application range. The invention further relates to the preparation method for the composite calcium sulfonate lubricating grease composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Open gear lubricating grease composition

ActiveCN102433195AGood extreme pressure and anti-wear propertiesImprove the protective effectLubricant compositionVegetable oilPreservative

The invention relates to an open gear lubricating grease composition, which comprises the following components in percentage by weight: 15 to 25 percent of metallic soap, 40 to 50 percent of vegetable oil, 15 to 25 percent of ester-based oil and 10 to 20 percent of polyisobutene. Based on the 100-percent total weight of the base oil and a thickening agent, 2 to 5 percent of dialkyl dithiocarbamate, 0 to 4 percent of boric acid ester, 3 to 8 percent of borate, 1 to 3 percent of dialkyl dithiophosphate, 3 to 10 percent of sulfurized fat, 3 to 10 parts of graphite, 2 to 8 parts of molybdenum disulfide, 0.5 to 1 percent of antioxygen and 0 to 2 percent of preservative are added. The lubricating grease has the advantages that: a proper raw material mixing ratio is selected, so the extreme pressure wear-resistance performance, protective performance and adhesive performance are high; and as biodegradable raw materials are selected, environment friendliness is high.

Owner:CHINA PETROLEUM & CHEM CORP

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

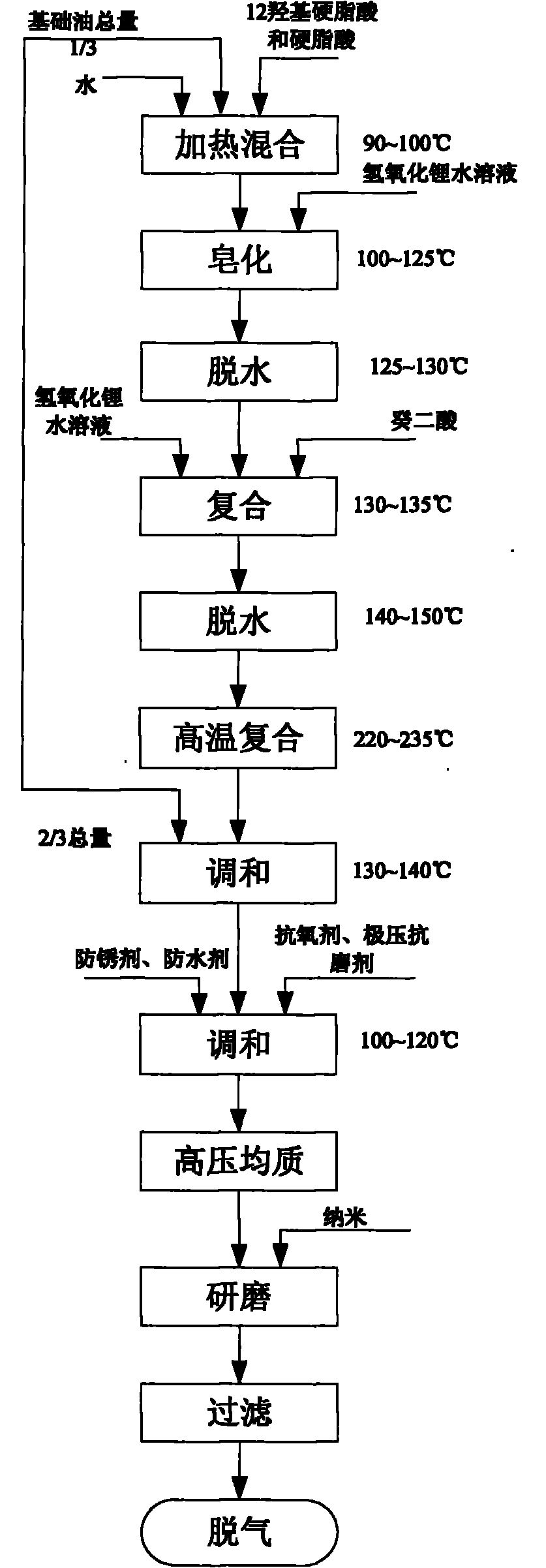

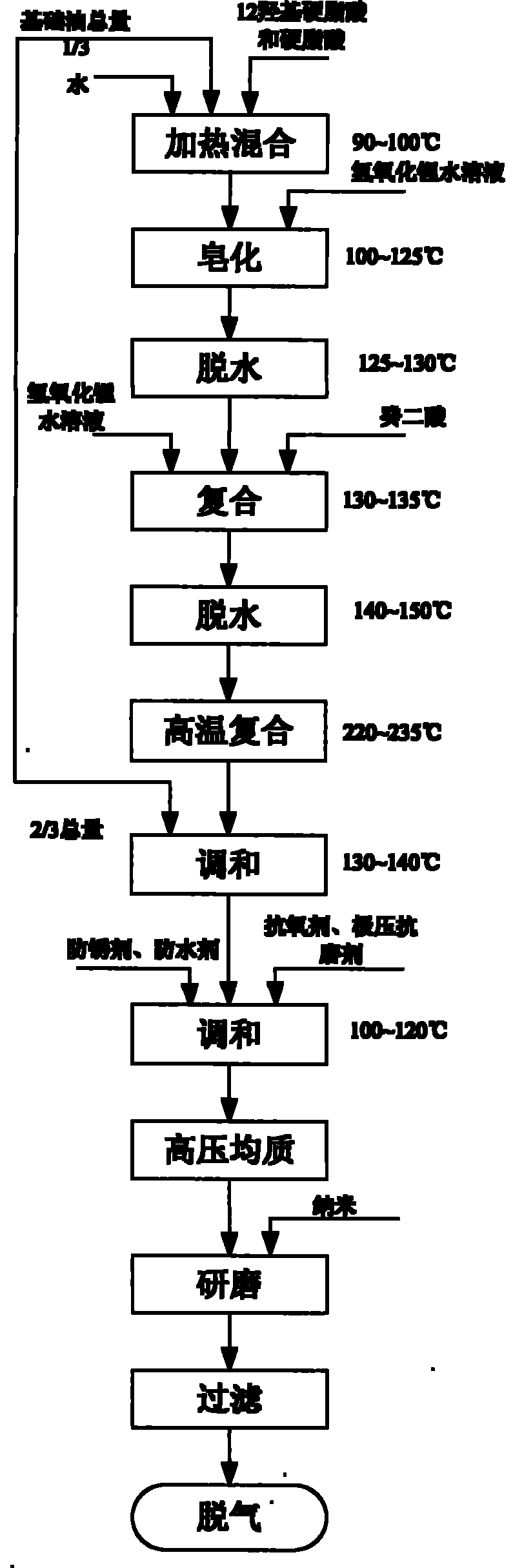

Hub bearing lubricating grease and preparation method thereof

InactiveCN102140382AGood extreme pressure and anti-wear propertiesImprove adhesionLubricant compositionLithium soapHigh resistance

The invention discloses a hub bearing lubricating grease and a preparation method thereof. In the lubricating grease, composite lithium soap is taken as a thickening agent, an antirusting agent, an antioxidant, an extreme-pressure anti-wear agent and a waterproofing agent are added, and a nanometer additive and the like are added according to different proportions. The lubricating grease is prepared by the processes including saponifying, dehydrating, blending, shearing, homogenizing, grinding, filtering, degassing and the like. A lubricating grease composition has the advantages of high dropping point, high wear resistance, high extreme pressure resistance, high high-low temperature performance and the like, has high water resistance and rust resistance, and is suitable for lubricating the automobile bush bearings under harsh working conditions.

Owner:SOUTH CHINA UNIV OF TECH

Lubricating anticorrosive oil and use thereof

ActiveCN101328445AExcellent anti-rustImprove the lubrication effectAdditivesPetroleum productOxidation resistant

The invention relates to lubricating rust preventive oil and application thereof, mainly aiming to solve the problems of the prior art that: a rustproof product has poor adhering property; and the prior art only lays stress on rustproof property and does not attach equal importance to the extreme pressure property, oxidation resistance and permeability of a petroleum product. The lubricating rust preventive oil solves the problems better through adopting the following technical proposal that: the compositions in percentage by weight of the lubricating rust preventive oil are: (a) 0.1 to 10 percent of extreme pressure antiwear agent, (b) 0.5 to 15 percent of rustproof agent, (c) 0.5 to 5 percent of oxidation and corrosion inhibitor, (d) 0.1 to 15 percent of viscidity temperature index improver, (e) 0.1 to 12 percent of friction improver and (f) the balance being base oil. The lubricating rust preventive oil can be used in fields such as harbor machinery, excavator, travelling crane, cargo winch and commercial elevator cable.

Owner:CHINA PETROLEUM & CHEM CORP

Composite lithium-calcium base lubricating grease and preparation method thereof

ActiveCN102977979AGood mechanical stabilityGood extreme pressure and anti-wear propertiesThickenersWater resistanceLithium

The invention relates to lubricating grease and a preparation method thereof, particularly relates to composite lubricating grease and a preparation method thereof, and belongs to the technical field of chemistry. According to the invention, base oil, thickener and additive are prepared into lithium-calcium base lubricating grease according to a proper ratio; the lithium-calcium base lubricating grease has the characteristics of favorable high temperature property, shear stability, extreme pressure wear resistance, water resistance and the like; and the invention is simple in preparation method, stable in product performance, low in product comprehensive cost and is suitable for large-scale industrial production.

Owner:JIANGSU LOPALTECH

Environmental protection type lubricating grease composition and method for preparing same

ActiveCN102199471AWide high and low temperature adaptabilityGood biodegradabilityLubricant compositionChemistryAntioxidant

The invention provides an environmental protection type lubricating grease composition. The composition comprises basic grease and an additive, wherein the basic grease comprises the following ingredients in percentage by weight: 60 to 95 percent of basic oil and 5 to 40 percent of composite lithium soap thickener; and the additive comprises the following ingredients based on the 100 weight percent of the basic oil: 0.05 to 2 percent of antioxidant, 0.5 to 10 percent of extreme pressure anti-wear agent and 0.1 to 2 percent of anti-rusting agent. The environmental protection type lubricating grease composition has high high-low temperature adaptability, high biodegradability, excellent an anti-oxidation, shear resistance and extreme pressure wear resistance and high anti-rusting property and corrosion inhibition, and is suitable to be used as the lubricating grease for bearings of electromotors of rail locomotives.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease for hubs of heavy trucks and preparation method for lubricating grease

ActiveCN102618368AStable structureImprove water resistanceLubricant compositionLithium soapHeat resistance

The invention discloses lubricating grease for hubs of heavy trucks. The lubricating grease consists of base oil, thickening agent and additive, the thickening agent is composite lithium soap thickener, and the additive consists of borate oiling agent, compound viscosity index improver, purification dispersant, amine-type antioxidant, sulfur-phosphorous-type antioxidant and sulfonate antirusting agent. The special lubricating grease for hubs of trucks which is obtained by means of circular shearing treatment is excellent in heat resistance, adhesion, mechanical stability, water resistance, extreme pressure abrasion resistance and the like, and can meet requirements on lubrication and protection for bearings of the hubs of the trucks under harsh conditions.

Owner:杭州得润宝油脂股份有限公司

Lubricating grease composition for heavy-loading roller press bearing and preparation method thereof

ActiveCN103275798AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionLithiumAntioxidant

The invention provides a lubricating grease composition for a heavy-loading roller press bearing and a preparation method thereof. The composition has prominent extreme-pressure anti-wear property, lubricating property and water resistance. The lubricating grease composition contains the following ingredients: (a) complex lithium and calcium-based lubricating grease, (b) a tackifier, (c) an oiliness additive, (d) an extreme-pressure anti-wear agent, (e) an antioxidant and (f) a graphite additive.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

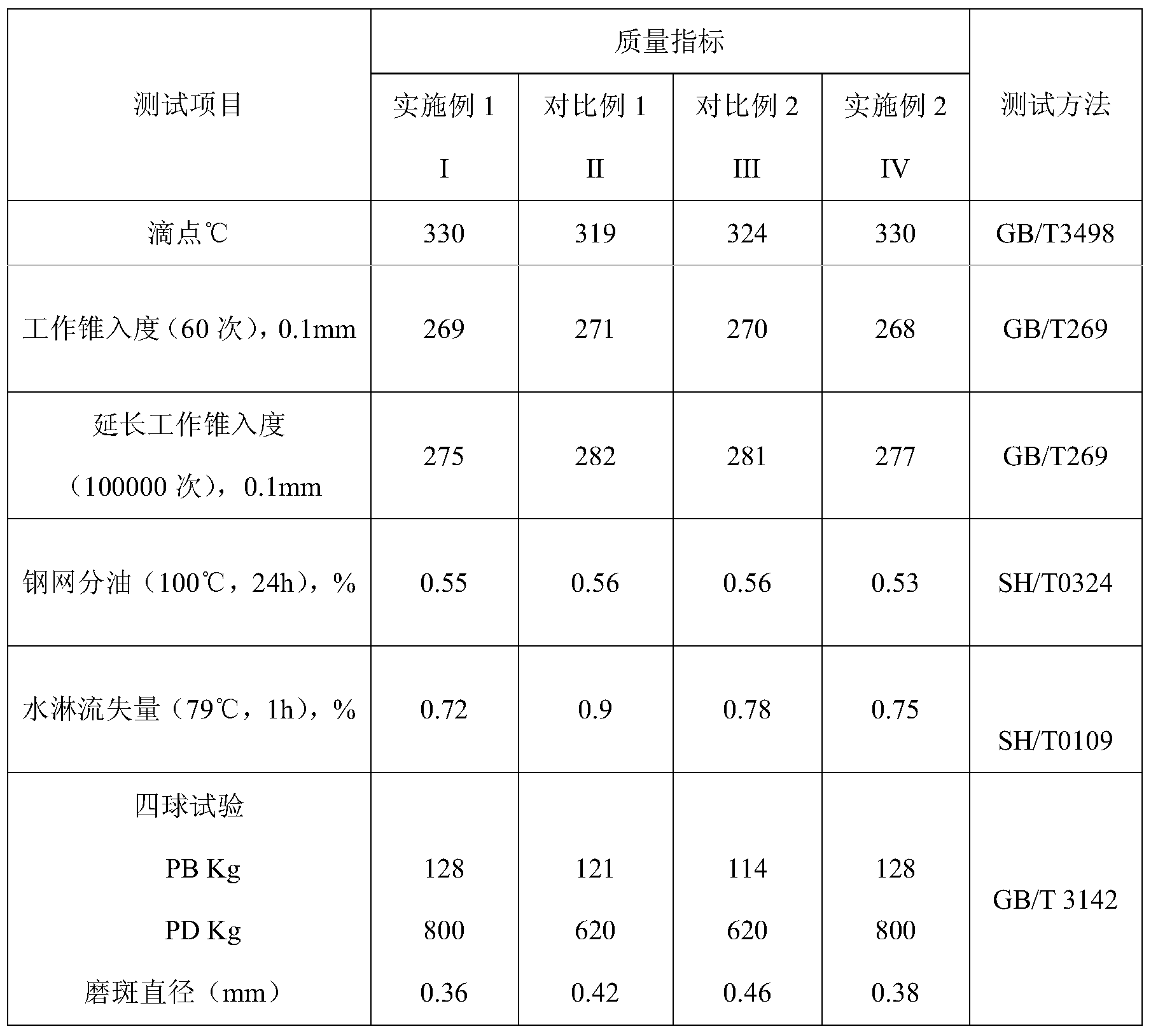

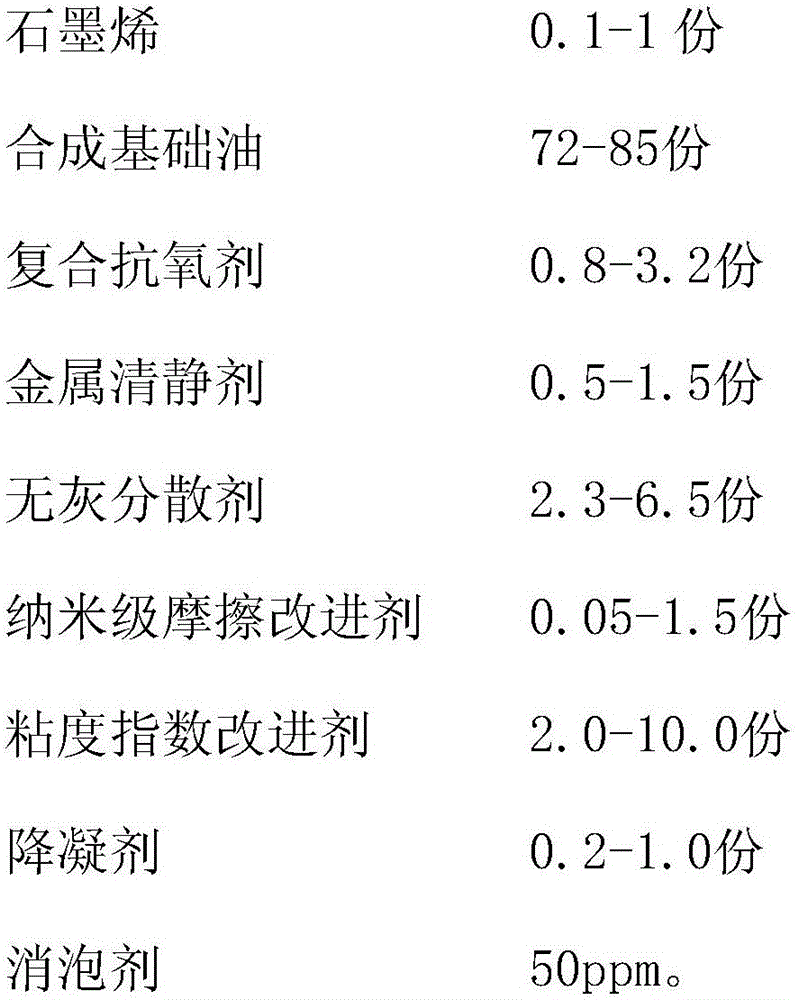

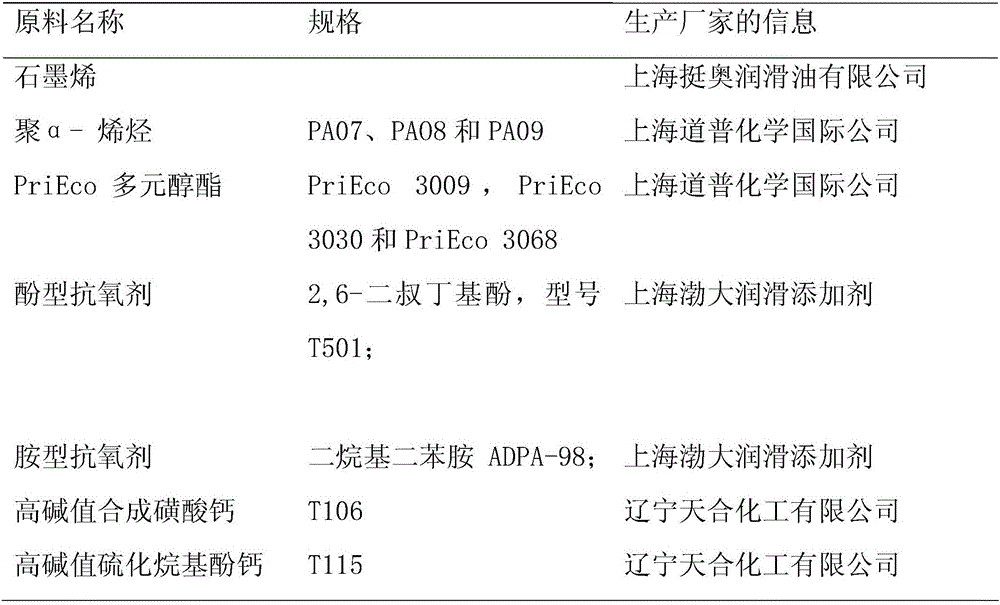

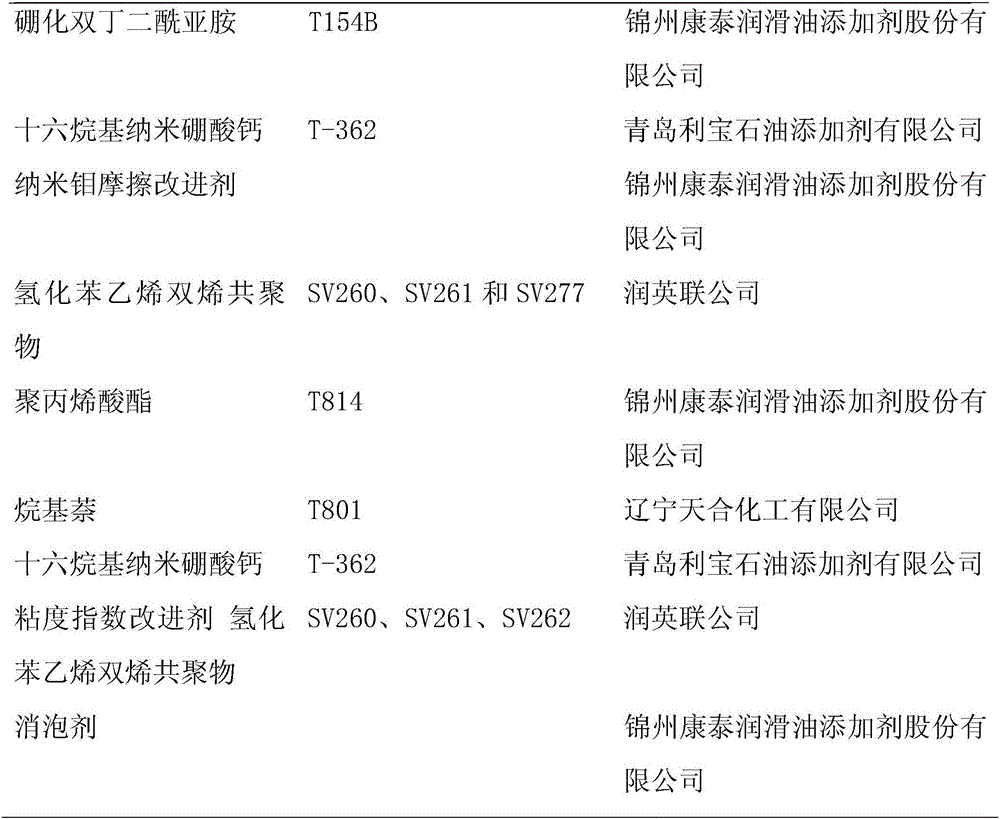

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

Lithium-calcium complex lubricating grease composition and preparation method

InactiveCN104449983AGood mechanical stabilityGood colloidal stabilityLubricant compositionLithium soapLong chain fatty acid

The invention relates to a lithium-calcium complex lubricating grease composition and a preparation method. The lubricating grease comprises the following components: (1) 60%-87% of base oil; (2) 10%-38% of a thickening agent; and (3) 1.5%-11% of an additive, wherein the thickening agent disclosed by the invention is a lithium-calcium complex thickening agent, comprises one or more long-chain fatty acid lithium soap and one or more micromolecular acid calcium soap, and is obtained from the reactants of acid and lithium hydroxide and calcium hydroxide. The lithium-calcium complex lubricating grease prepared by the method has good mechanical stability, colloid stability, water resistance and good extreme pressure antiwear property; and above all, the hardening phenomenon is not generated under room-temperature long-term storage and high-temperature (120 DEG C) conditions on the basis that excellent performances of the original lithium-calcium complex lubricating grease are reserved.

Owner:CHINA PETROLEUM & CHEM CORP

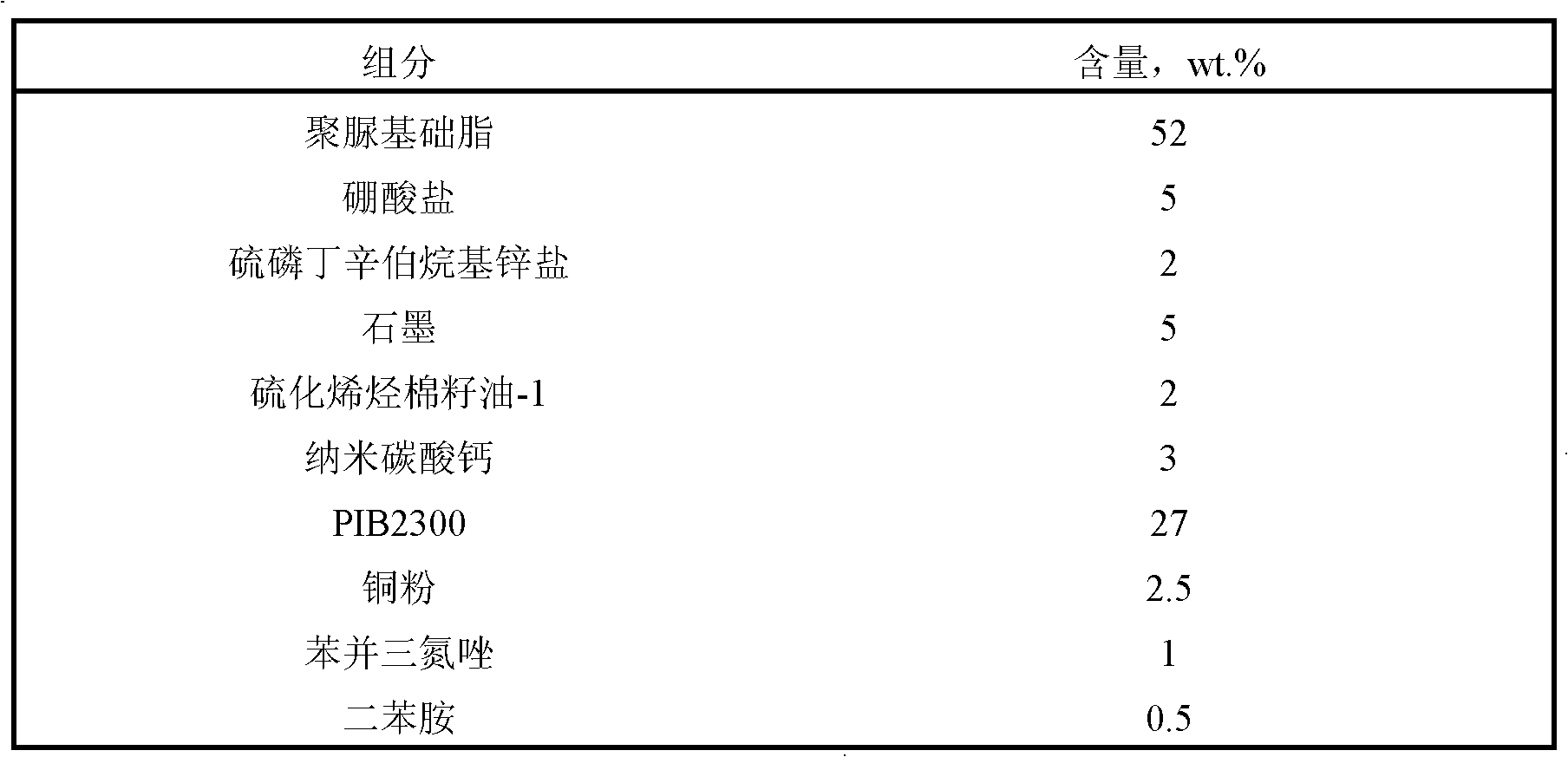

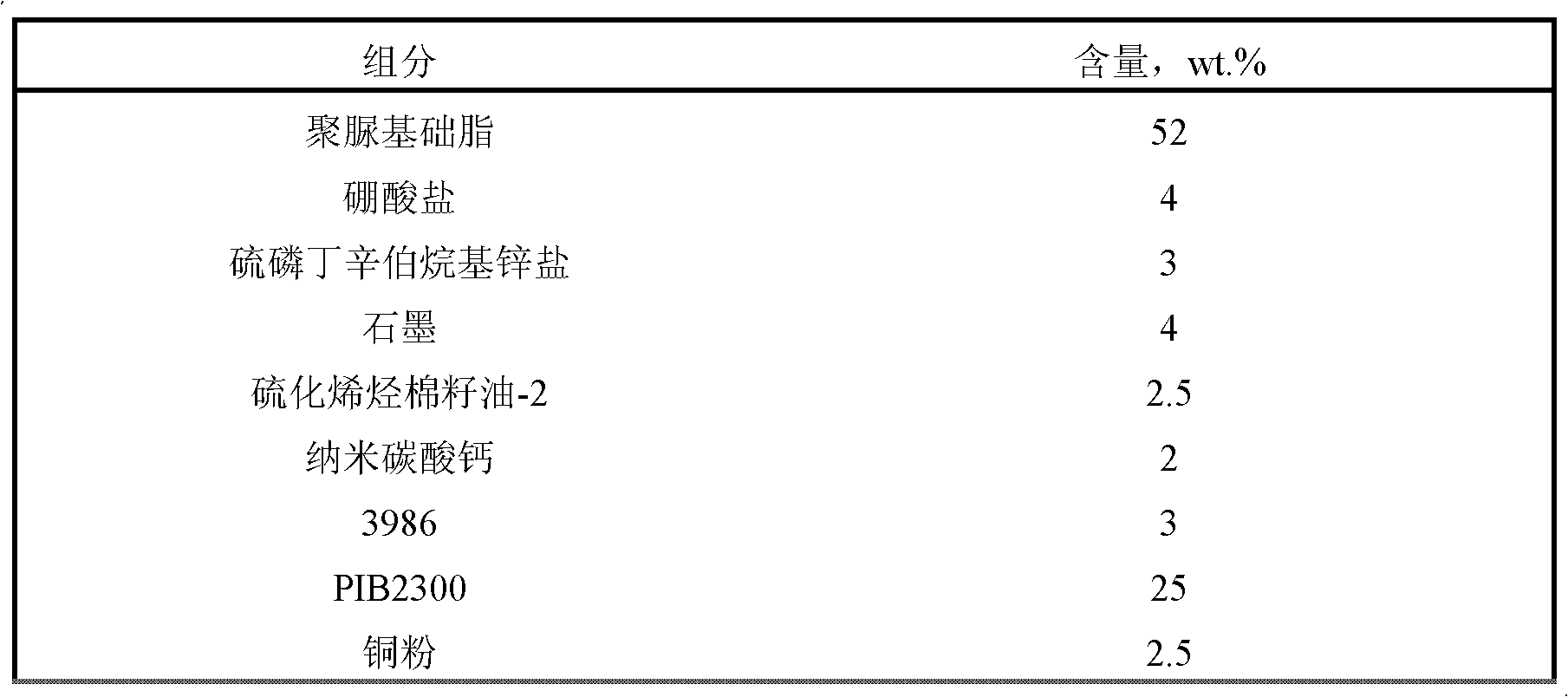

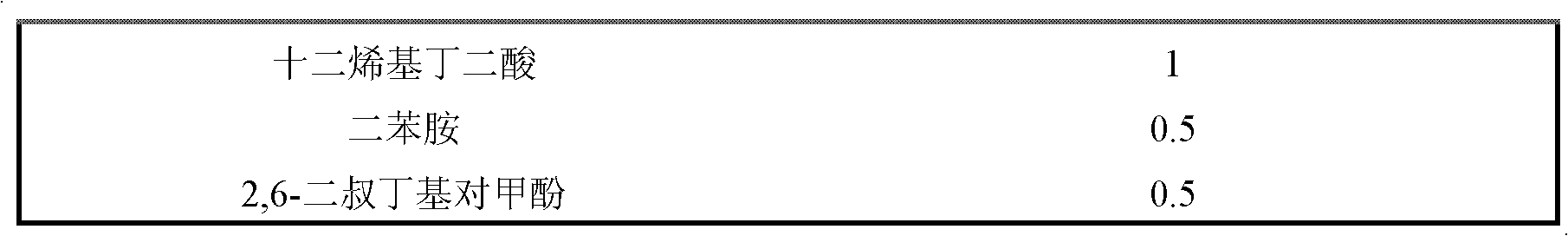

Heavy-duty self-repairing open gear grease

The invention discloses a clean-type heavy-duty open gear grease with self-repairing function. The product is composed of a lubricating grease base grease prepared from an organic compound thickening mineral oil containing carbamido in molecules or synthetic oil, and additives. A base grease thickener is composed of an MDI and organic amine in a molar ratio of 1:1-3; and the base oil is mineral oil or poly alpha olefin synthetic oil. The heavy-duty open gear grease comprises the following components, calculated by the weight of the base grease: 50-60wt% of base grease, 4-8wt% of a extreme pressure antiwear agent, 1-4wt% of an oily agent, 6-8wt% of a solid additive, 0.5-1.5wt% of an antirust agent, 25-35wt% of a tackifier, 2-4wt% of a self-repairing additive, and 0.3-1.0wt% of an antioxidant. The invention adopts borate as the extreme pressure antiwear agent added with an extreme pressure agent containing a small amount of sulfur phosphorus, so as to improve the extreme pressure anti-wear performance of the lubricating grease, as well as realize low toxicity, tastelessness and environment-friendliness of the grease. Besides, soft metal Cu nanoparticles employed by the invention endow good self-repairing performance on the grease. Compared with a traditional open gear lubricant product, the heavy-duty open gear grease provided by the invention has characteristics of excellent lubrication performance, self repairing, tastelessness and environment-friendliness, and can be widely used for lubricating of open gears.

Owner:PETROCHINA CO LTD

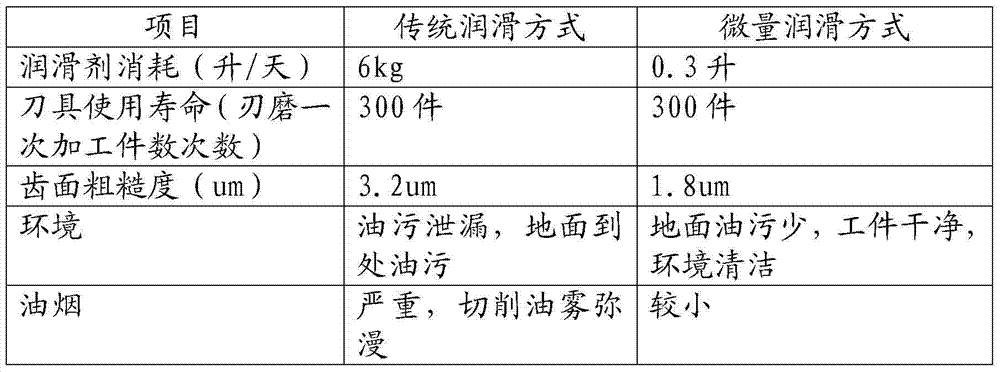

Special micro-lubricant for oil-water-gas-phase micro-lubricating system and preparation method of lubricant

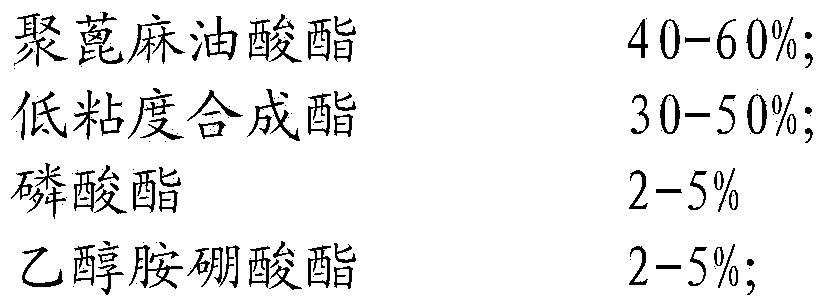

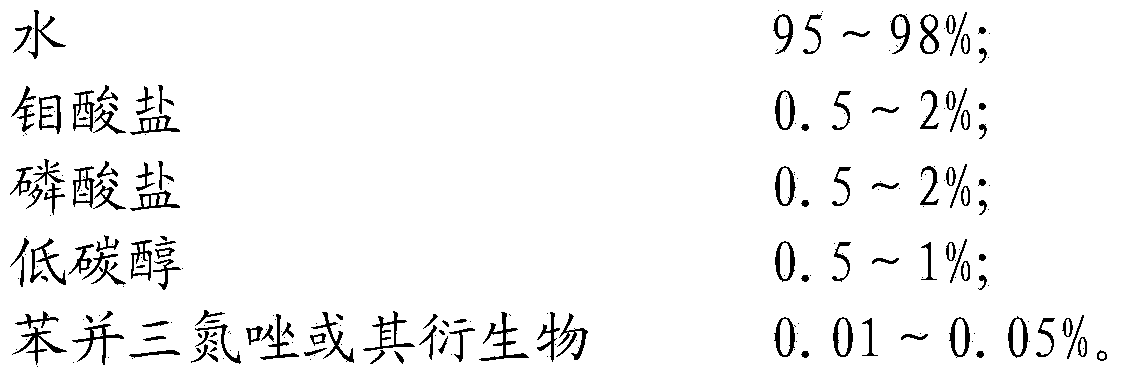

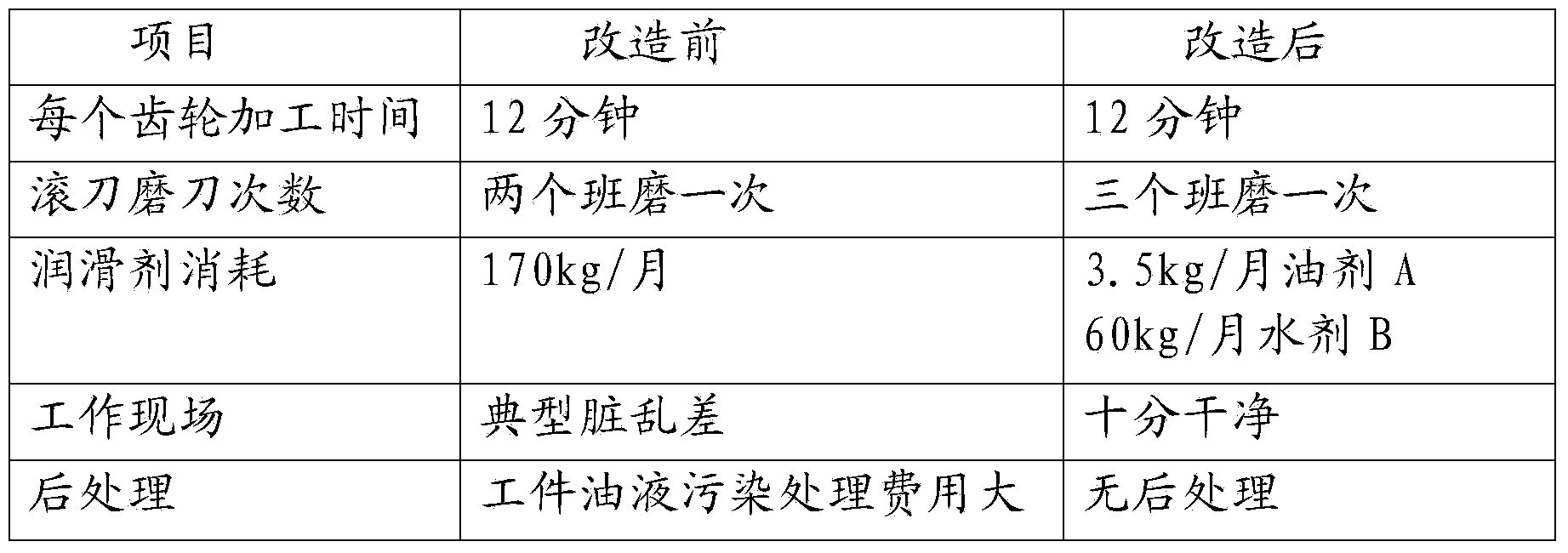

ActiveCN104031732AImprove cooling effectGood extreme pressure and anti-wear propertiesLubricant compositionAlcoholMolybdate

The invention relates to a special micro-lubricant for an oil-water-gas-phase micro-lubricating system. The lubricant is characterized by comprising an oiling agent A and water aqua B, wherein the oiling agent A is prepared from the following components in percentage by weight: 40-60% of polyricinoleate, 30-50% of low viscosity synthetic ester, 2-5% of phosphate and 2-5% of ethanolamine borate; the water aqua B is prepared from the following components in percentage by weight: 95-98% of water, 0.5-2% of molybdate, 0.5-2% of phosphate, 0.5-1% of lower alcohol and 0.01-0.05% of benzotriazole or derivatives. The special micro-lubricant for the oil-water-gas-phase micro-lubricating system, which is disclosed by the invention, is matched with a micro-lubricating device in use, so that the use level of a cutting liquid is saved by over 95%.

Owner:营口康如科技有限公司

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

High-temperature lubricating grease composition and preparation method

InactiveCN103525513AGood high temperature performanceImprove high temperature performanceLubricant compositionColloid millLubrication

The invention provides a high-temperature lubricating grease composition and a preparation method. The preparation method comprises the following steps of adding boron nitride and an anti-wear reagent at extreme pressure into base oil according to a certain proportion, mixing, heating to 60-160 DEG C, carrying out pre-dispersion by mechanical stirring with the pre-dispersion time being 0.5-1 hour; carrying out pre-dispersion again on pre-dispersed materials by a colloid mill, adjusting the dispersing effect by adjusting the fineness of the colloid mill, and when the penetration is proper, carrying out filling. The lubricating grease provided by the invention has the advantages that due to selection of a thickening agent with high-temperature performance and the base oil with high-temperature performance and addition of a solid lubricating agent with good high-temperature performance as the anti-wear reagent at extreme pressure, the lubricating grease has excellent high-temperature performance, anti-wear performance at extreme pressure and oxidation stability and obtains better technical effects. The high-temperature lubricating grease composition provided by the invention can be applied to lubrication and protection of high-temperature mechanical equipment in the industries of ceramic, metallurgy and machining and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Oil-air lubricating grease and production method thereof

The invention provides oil-air lubricating grease which comprises the following component in percentage by weight: 80-90% of ester oil, 2-6% of inorganic thickener, 2-3% of structure improver, 1-5% of solid lubricating material, 0.2-0.5% of antioxidant, 1-5% of extreme pressure antiwear additive and 0.3-0.8% of anticorrosive agent. Since the oil-air lubricating grease is produced by using the ester oil having good biodegradability and fine high and low temperature performance as the base oil to be mixed with the environment-friendly inorganic thickener and additives, the oil-air lubricating grease has favorable biodegradability, can not cause environmental pollution, has favorable high and low temperature performance and low temperature pumpability, and has favorable extreme pressure wear resistance, thereby meeting the requirements of railway industry for the development direction of the lubricating grease and being capable of bringing more economic benefits and social benefits to railway interests. With the development of railway interests in China, the oil-air lubricating grease has fine application prospects.

Owner:CHINA PETROLEUM & CHEM CORP

Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

InactiveCN102690716AStrong extreme pressureWear scar diameter is smallLubricant compositionAcetic acidCalcium hydroxide

The invention relates to superstrong extreme pressure antiwear lubricating grease and a preparation method thereof; particularly, a densifier is generated by calcium sulfonate with a high base number through a phase inversion reaction, and the lubricating grease is prepared by combining base oil with other functional additives, wherein the base oil is combined by base oil with high viscosity and medium viscosity. The method comprises the following steps: stirring and mixing the composite base oil and the calcium sulfonate in a reaction vessel, heating, adding a phase inversion promoter, glacial acetic acid, and water, heating and reacting at a constant temperature, adding calcium hydrate, aliphatic acid and boric acid after the phase inversion is completed, reacting at a constant temperature, heating and dehydrating, adding an anti-oxidant, refining, transferring the materials into a blending vessel, adding an eutectic rolling additive and an adhesion improver, dispersing and homogenizing the mixture, filtering, and degassing to obtain the finished product. The lubricating grease of the invention has excellent water sprinkling resistance, excellent high and low temperature performance, superstrong extreme pressure antiwear performance, excellent pumping performance, outstanding shearing stability, and antirust performance.

Owner:超美科技(深圳)有限公司

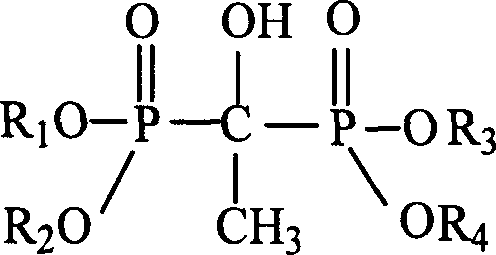

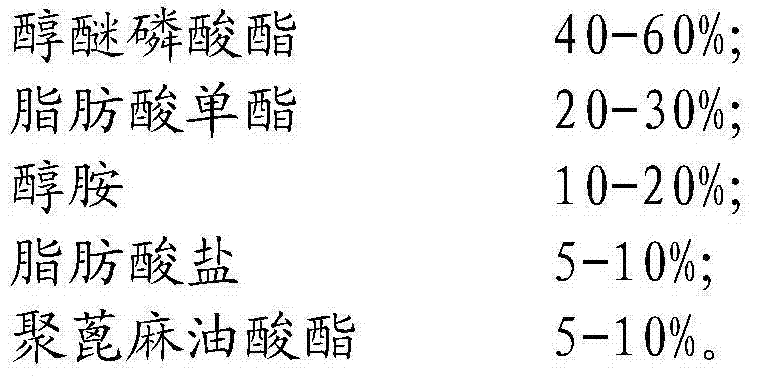

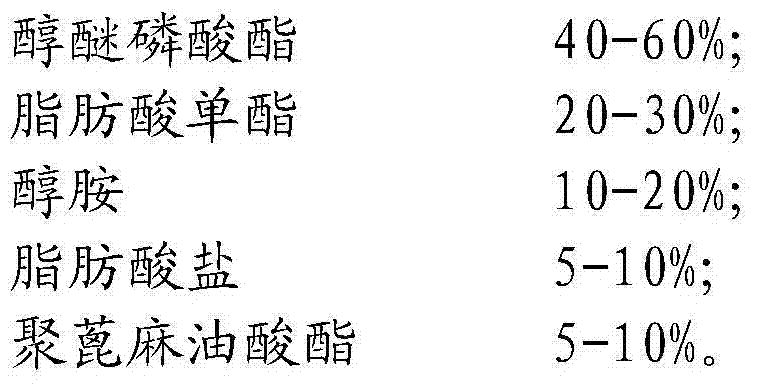

Alcohol ether phosphate and preparation method thereof and trace cutting fluid prepared by same

ActiveCN104710610AImprove the lubrication effectGood extreme pressure and anti-wear propertiesPhosphorus organic compoundsLubricant compositionPhosphoric Acid EstersPhosphate

The invention provides alcohol ether phosphate which is characterized by being prepared from the following substances: fatty alcohol, ethylene oxide, epoxypropane, and phosphorus pentoxide, wherein the molar ratio of fatty alcohol, ethylene oxide, epoxypropane and phosphorus pentoxide is 1:(5-10):(1-2):(0.3-1). The prepared alcohol ether phosphate has the advantages of excellent lubricity, extreme-pressure wear resistance, antirust performance, and relatively good water solubility, at the same time, also is an excellent surfactant, can totally or partly replace traditional extreme-pressure anti-wear agents containing chlorine, sulfur and phosphorus to be used in a trace cutting fluid; only a small amount of the trace cutting fluid can satisfy metal processing requirements of lubricating, cooling, extreme-pressure wear resistance and rust resistance; with cooperation of a trace lubrication device, the usage amount of the cutting fluid can be saved 90% or more, and the effects of energy saving, emission reduction and environmental protection are significant.

Owner:东莞市源源动力润滑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com