High-temperature lubricating grease composition and preparation method

A lubricating grease composition and composition technology, applied in the field of lubricating grease, can solve problems such as unpublished patents and achieve excellent high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

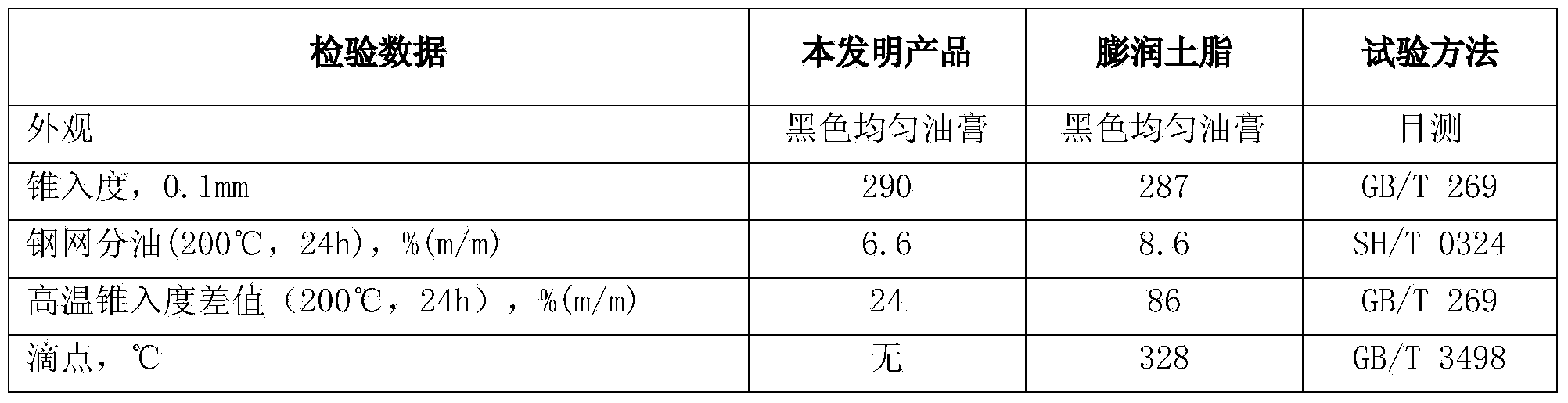

Embodiment 1

[0032] Add 60 grams of hexagonal boron nitride, 50 grams of F-1 micropowder graphite, and 150 grams of MCA to 740 grams and the viscosity is 100mm 2 / s PAO, heated to 100°C, and mechanically stirred for 1 hour to pre-disperse; the pre-dispersed material was dispersed again through a colloid mill to obtain the finished grease. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0033]

[0034] It can be seen from the above table that the high temperature performance, extreme pressure resistance performance and oxidation stability performance of the lubricating grease of the present invention are all very good.

[0035] The material ratio is described as follows:

[0036] The thickener accounts for 6% of the total grease,

[0037] Base oil accounts for 74% of the total grease,

[0038] F-1 micronized graphite accounts for 5% of the total grease,

[0039] MCA accounts for 15% of the total grease.

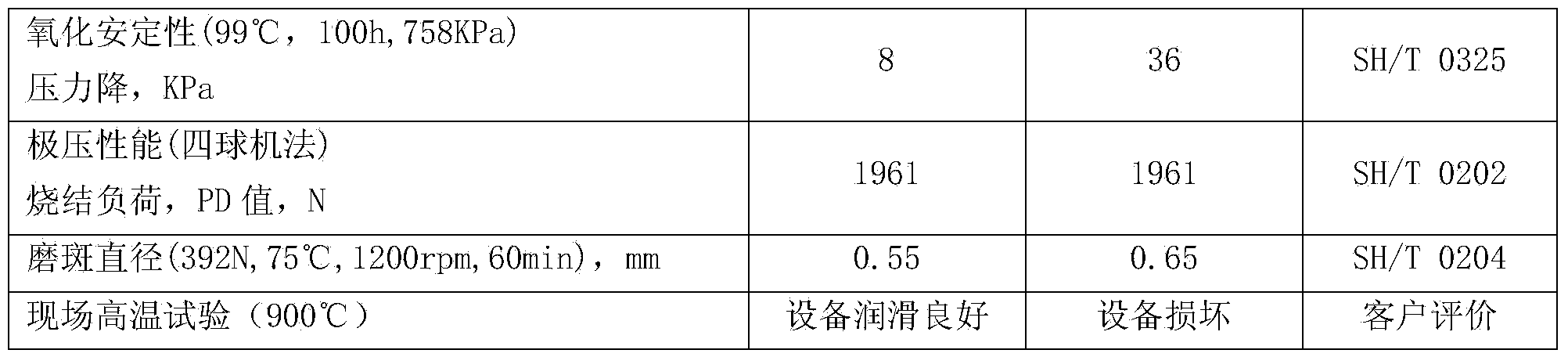

Embodiment 2

[0041] Add 160 grams of hexagonal boron nitride, 150 grams of F-1 micropowder graphite, and 20 grams of MCA to 670 grams and the viscosity is 40mm 2 / s PAO, heated to 90°C, and mechanically stirred for 1 hour to pre-disperse; the pre-dispersed material was dispersed again through a colloid mill to obtain the finished grease. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0042]

[0043] It can be seen from the above table that the high temperature performance, extreme pressure resistance performance and oxidation stability performance of the lubricating grease of the present invention are all very good.

[0044] The material ratio is described as follows:

[0045] Thickener accounts for 16% of the total amount of grease,

[0046] Base oil accounts for 67% of the total grease,

[0047] F-1 micropowder graphite accounts for 15% of the total amount of grease,

[0048] MCA accounts for 2% of the tot...

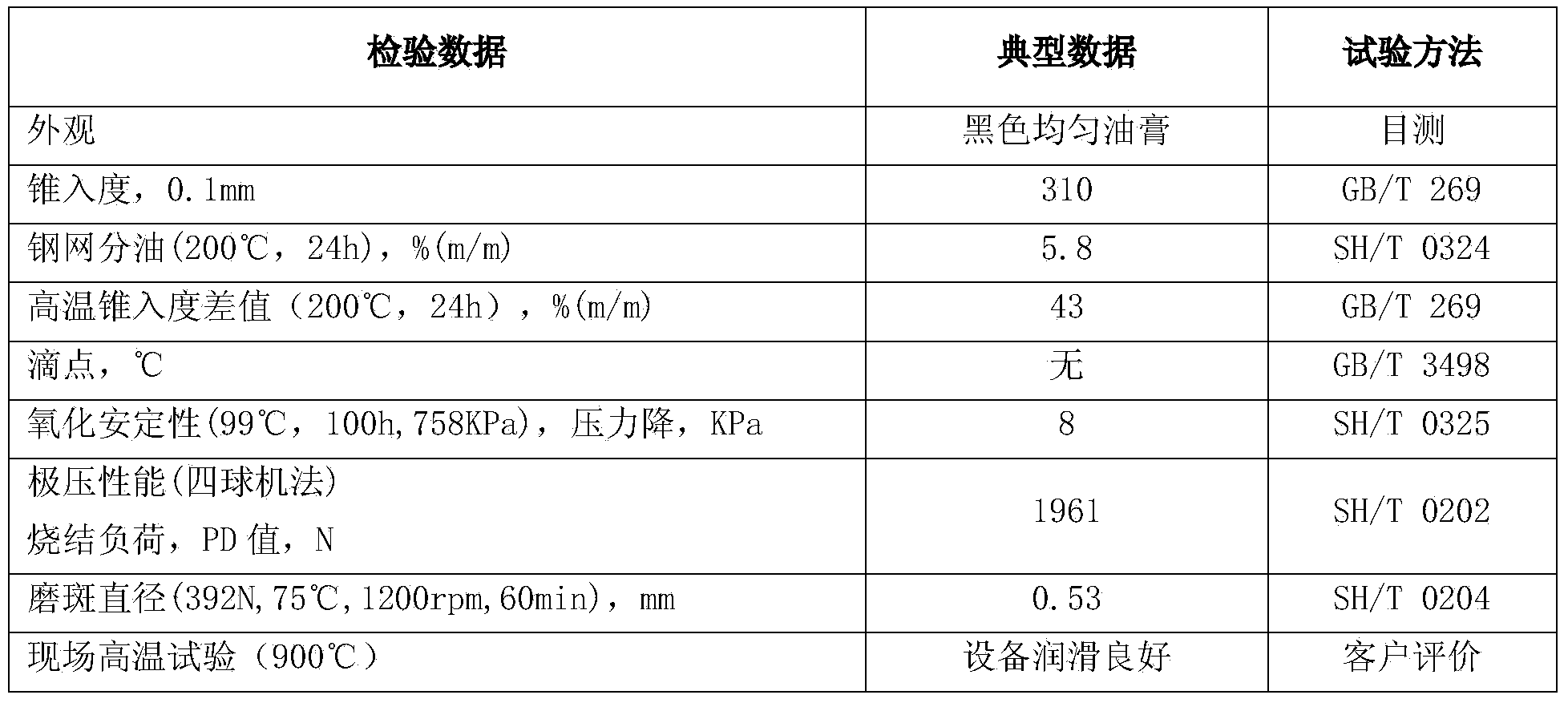

Embodiment 3

[0050] Add 150 grams of hexagonal boron nitride, 90 grams of F-1 fine powder graphite, and 50 grams of MCA to 710 grams and the viscosity is 2000mm 2 / s synthetic hydrocarbon base oil, heated to 100°C, and mechanically stirred for 1 hour to pre-disperse; the pre-dispersed material was dispersed again through a colloid mill to obtain the finished grease. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0051]

[0052] It can be seen from the above table that the high temperature performance, extreme pressure resistance performance and oxidation stability performance of the lubricating grease of the present invention are all very good.

[0053] The material ratio is described as follows:

[0054] The thickener accounts for 15% of the total grease,

[0055] Base oil accounts for 71% of the total grease,

[0056] F-1 micropowder graphite accounts for 9% of the total grease,

[0057] MCA accounts for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com