Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

An extreme pressure anti-wear and lubricating grease technology, which is applied in the field of multi-functional ultra-extreme pressure anti-wear grease and its preparation, can solve the problems of high cost and unfavorable enterprises to save costs, and achieve the effect of excellent extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

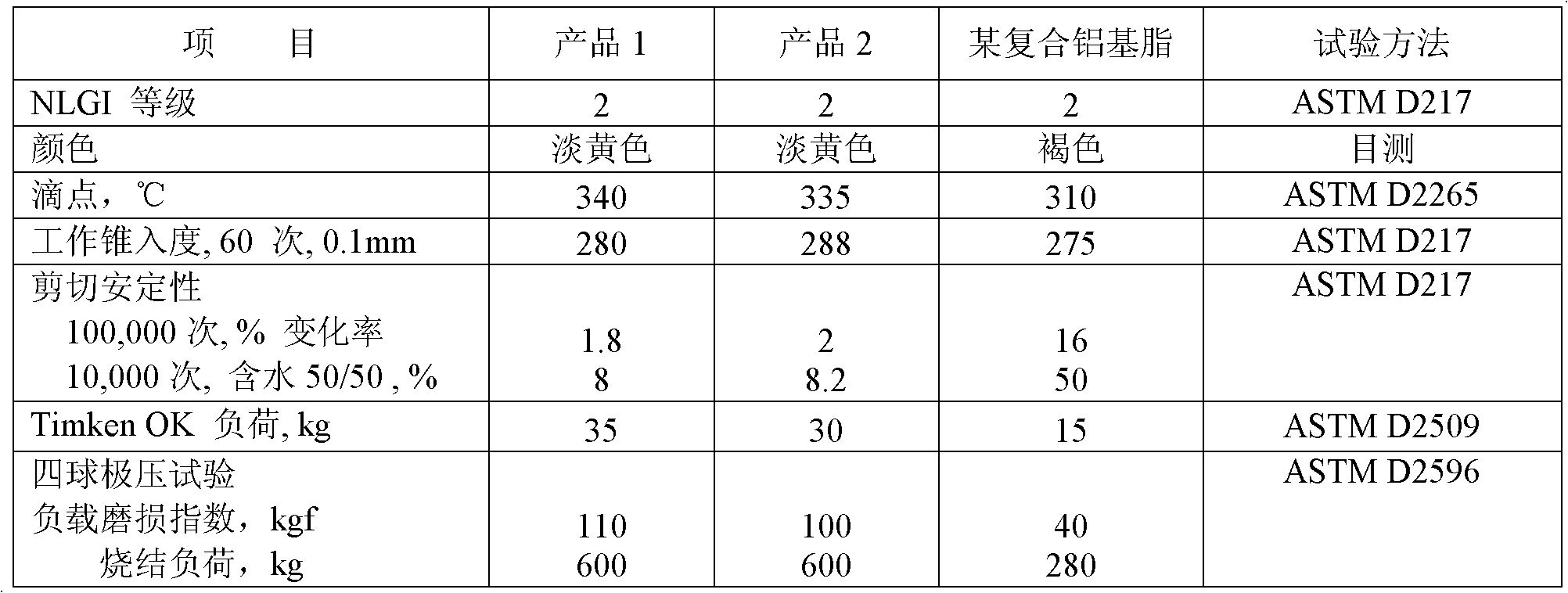

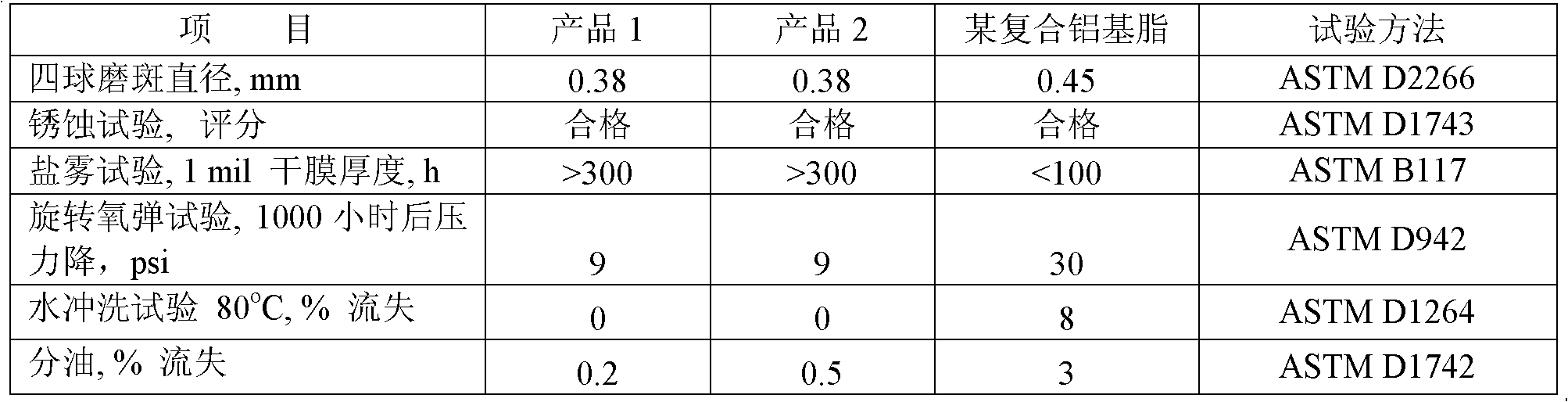

Examples

Embodiment 1

[0042] Multifunctional ultra-extreme pressure anti-wear grease, each component is calculated by mass fraction: composite base oil 40%; high alkali value calcium sulfonate (TBN 400) 35%; phase inversion accelerator 5%; glacial acetic acid 1%; water 5%; 12-hydroxystearic acid 7%; boric acid 0.5%; calcium hydroxide 1%; antioxidant T501 0.5%; eutectic rolling ball additive JPLUS-2000 3%; adhesion improver SV 251 2%. Wherein the composite base oil is blended by 150BS:500SN=5:1. The phase inversion accelerator is composed of 12-hydroxystearic acid:butanol=1:1.

[0043]Stir and mix the composite base oil and high alkali value calcium sulfonate, heat up to 60°C, add phase inversion accelerator, glacial acetic acid, water, stir evenly, raise the temperature to 85°C and keep the temperature for 90 minutes; after the phase inversion of the material is completed, heat up To 110°C, add calcium hydroxide (make cream with 2 times water), fatty acid, boric acid (dissolved with 3 times hot wa...

Embodiment 2

[0045] Multifunctional ultra-extreme pressure anti-wear grease, each component is calculated by mass fraction: composite base oil 47%; high alkali value calcium sulfonate (TBN 415) 28%; phase inversion accelerator 4%; glacial acetic acid 0.8%; water 4%; 12-hydroxystearic acid 7%; boric acid 0.2%; calcium hydroxide 1%; antioxidant T501 0.5%; eutectic rolling ball additive JPLUS-2000 4%; adhesion improver SV 251 3.5%. Wherein the composite base oil is blended by 150BS:500SN=3:1. The phase inversion accelerator is composed of 12-hydroxystearic acid:butanol=2:1.

[0046] Stir and mix the composite base oil and high alkali value calcium sulfonate, heat up to 60°C, add phase inversion accelerator, glacial acetic acid, water, stir evenly, raise the temperature to 85°C and keep the temperature for 80 minutes; after the phase inversion of the materials is completed, heat up To 110°C, add calcium hydroxide (make cream with 2 times water), fatty acid, boric acid (dissolved with 3 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com