Biodegradable grease composition for aerogenerator

A lubricating grease composition, biodegradable technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of fretting resistance and wear resistance, and achieve the effect of excellent biodegradability and low temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

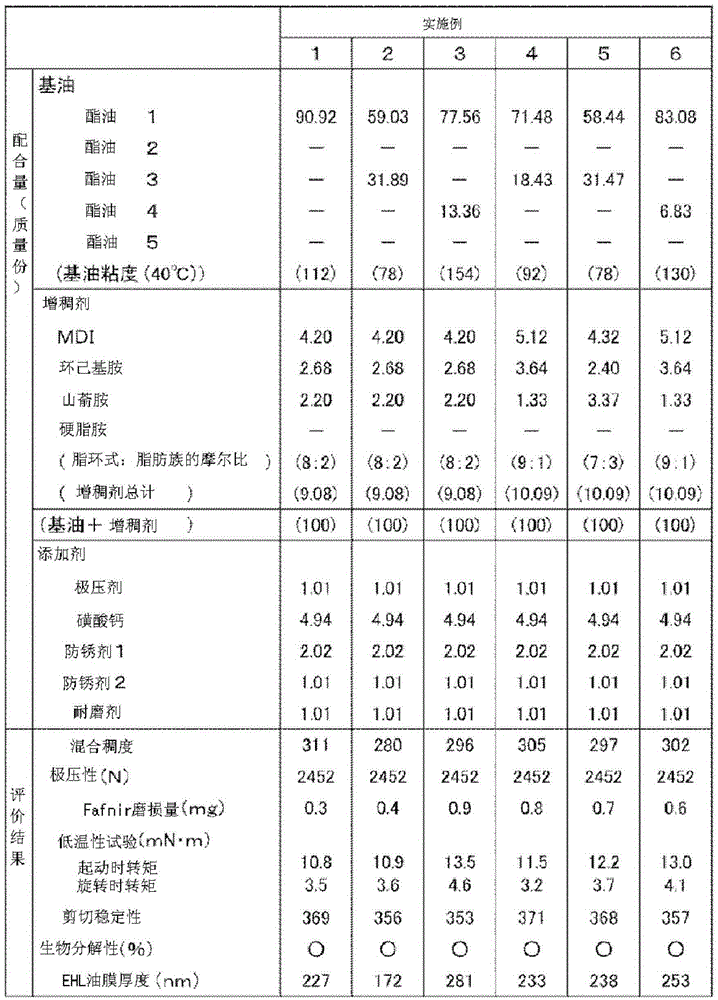

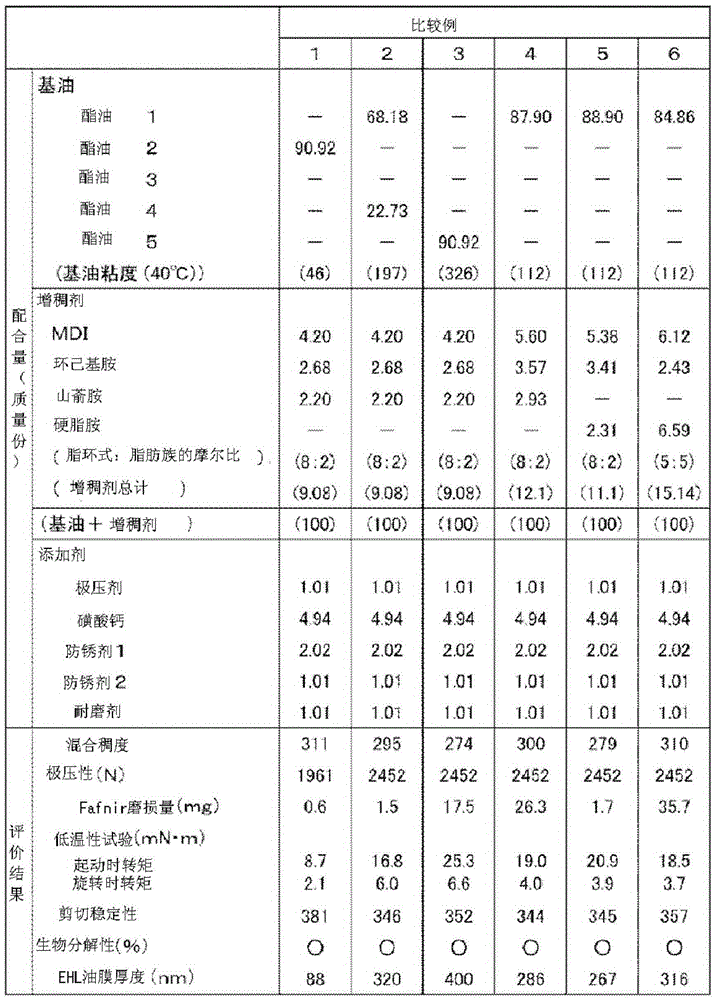

[0069] Each test grease composition was prepared according to the formula shown in Table 1. First, a part of calcium sulfonate (10% by mass of the thickener) and various amines are added to the base oil, and the temperature is maintained at 80 to 90°C. Further, a diisocyanate compound is added, heated to 160°C while stirring, and an extreme pressure agent is added. . Further, it was cooled while stirring, and homogenized by treatment with a homogenizer (at a pressure of about 300 bar) to obtain a base grease. Thereafter, the remaining calcium sulfonate and other additives were added to the base grease, and the grease compositions for each test were prepared by stirring and defoaming. The obtained test grease composition was evaluated as follows. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com