Polyurea thickening agent, lubricating grease prepared from polyurea thickening agent and preparation method of lubricating grease

A technology of polyurea thickener and polyurea grease, which is applied in the direction of thickener, lubricating composition, petroleum industry, etc., can solve the problems of polyurea grease lubricating performance and complex process, and achieve the reduction of types and usage, The effect of simple preparation process and good extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

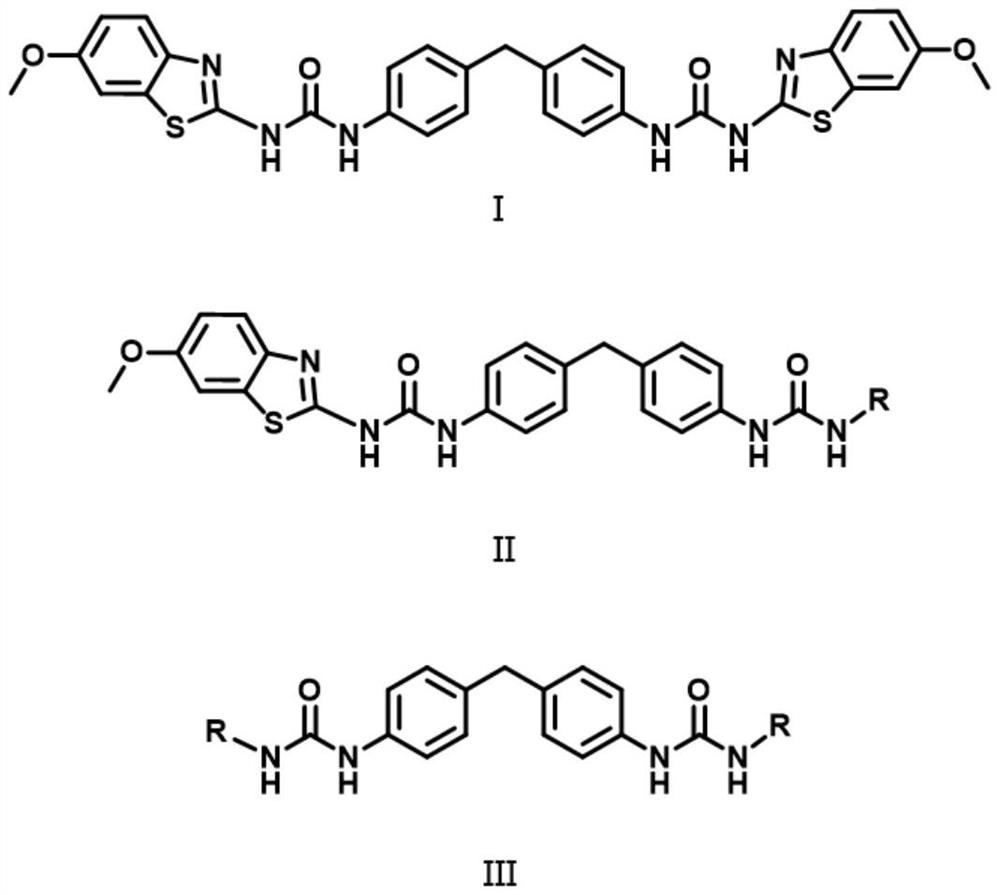

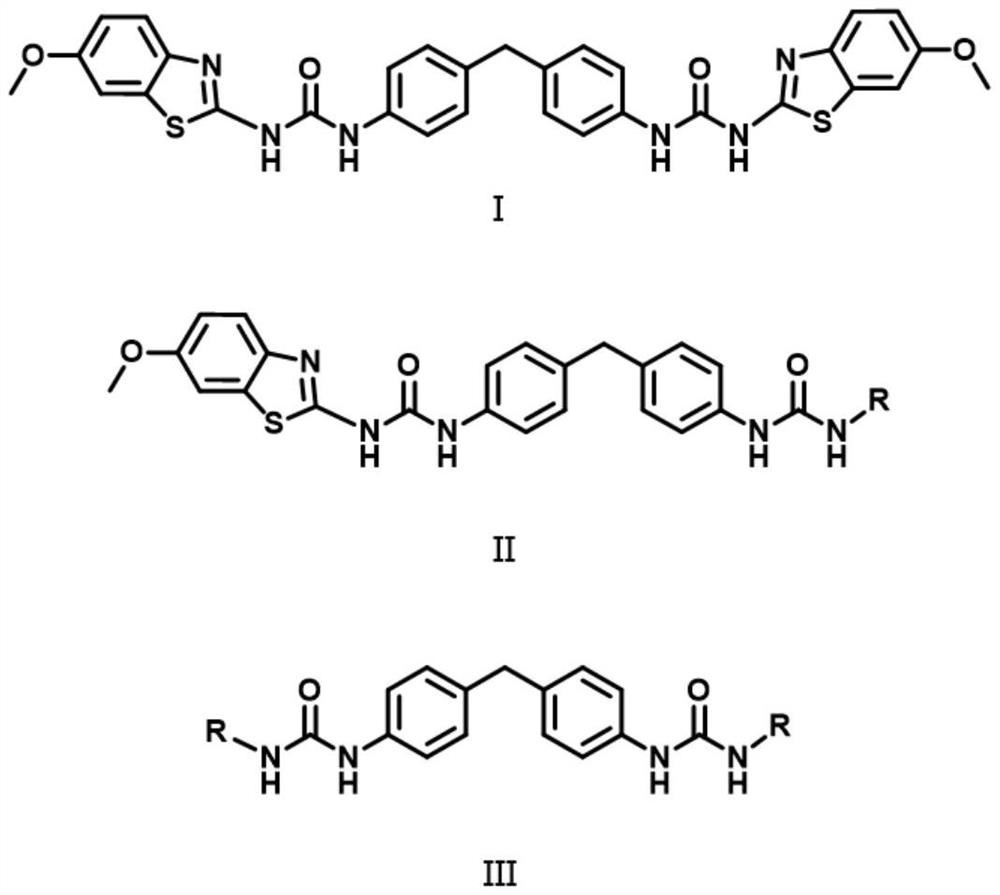

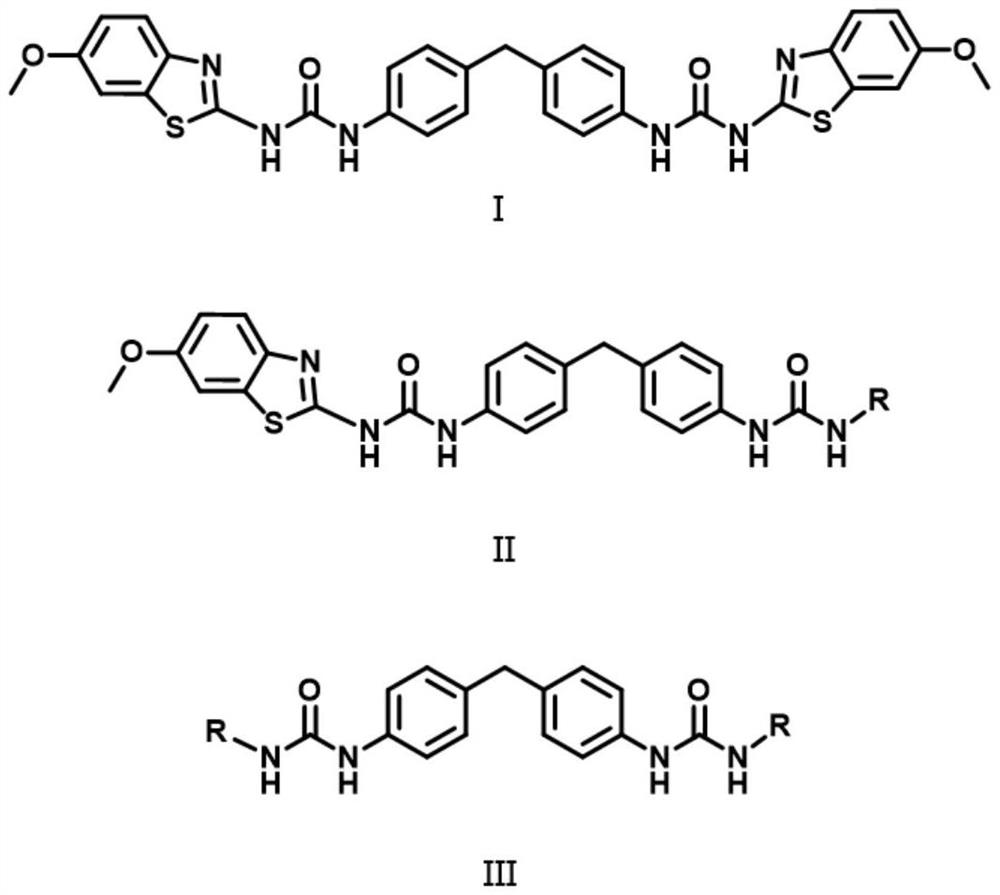

Image

Examples

Embodiment 1

[0023] Add 1490g of pentaerythritol ester oil and 301.02g of 2-amino-6-methoxybenzothiazole into a 5L reaction kettle, start stirring and raise the temperature to 95°C, keep stirring for 30min; add 1000g of pentaerythritol ester into a 5L dissolution kettle oil and 229.88 diphenylmethane-4,4'-diisocyanate, start stirring and heat up to 80°C, keep stirring for 30min; Then heat up to 160°C, refine for 120 minutes; cool down to 70°C, add 30g of antioxidant alkyl diphenylamine, 9g of antirust agent barium petroleum sulfonate, homogenize, filter, and degas to obtain about 3kg of the final product.

[0024] Wherein, the kinematic viscosity of the pentaerythritol ester oil at 40°C is 20-500mm 2 / s.

Embodiment 2

[0026] Add 894g pentaerythritol esters oil, 298g rapeseed oil and 298g alkylnaphthalene-15, 182.86g 2-amino-6-methoxybenzothiazole and 136.72g of octadecylamine in the reactor of 5L, start stirring and Heat up to 100°C, keep warm and stir for 30 minutes; add 600g of pentaerythritol ester ester oil, 200g of rapeseed oil, 200g of alkylnaphthalene-15 and 209.74g of diphenylmethane-4,4'-diisocyanate into a 5L dissolution kettle, Start stirring and heat up to 80°C, keep stirring for 30 minutes; then add the mixture in the dissolution kettle to the reaction kettle, raise the temperature to 110°C, keep the temperature for 60 minutes, then raise the temperature to 170°C, and refine for 100 minutes; cool down to 70°C, add Antioxidant N-phenyl α-naphthylamine 45g, rust inhibitor barium dinonyl naphthalene sulfonate 15g, after homogenizing, filtering and degassing, about 3kg of the final product was obtained.

[0027] Wherein, the kinematic viscosity of the pentaerythritol ester oil, rap...

Embodiment 3

[0029] Add 1043g pentaerythritol ester oil, 298g base oil MVI500 and 149g polyalphaolefin (PAO10), 235.60g 2-amino-6-methoxybenzothiazole and 56.31g octylamine in a 5L reactor, start stirring And heat up to 100°C, keep stirring for 30min; add 700g of pentaerythritol ester ester oil, 200g of base oil MVI500, 100g of polyalphaolefin (PAO10) and 239.90g of diphenylmethane-4,4'- For diisocyanate, start stirring and heat up to 80°C, keep stirring for 30 minutes; then add the mixture in the dissolution tank to the reaction kettle, raise the temperature to 115°C, keep the temperature for 50 minutes, then raise the temperature to 210°C, refine for 30 minutes; cool down to 70 ℃, add antioxidant dioctyl diphenylamine 25g and N-phenyl α-naphthylamine 20g, rust inhibitor 9g and benzotriazole, homogenize, filter and degas to obtain about 3kg of final product.

[0030] Wherein, the kinematic viscosity of the pentaerythritol ester oil, base oil MVI500 and PAO1040°C is 20-500mm 2 / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com