Lubricating oil containing oleic acid-modified superparamagnetic nanometer hollow beads and preparation method thereof

A technology of hollow microspheres and superparamagnetism, applied in the field of lubricating oil, can solve the problems of not being able to effectively improve the tribological properties of lubricating oil, affecting the effect of mechanical lubrication and the life of lubricating oil, difficult to recycle nano-materials, etc., and achieve easy magnetic Separation and recovery, good anti-wear performance and load-bearing performance, and self-repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

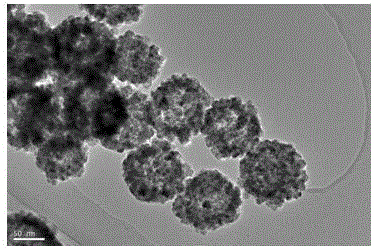

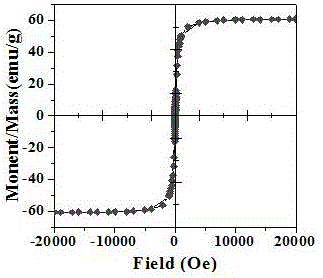

[0020] A kind of lubricating oil containing oleic acid-modified superparamagnetic nano hollow microspheres described in this specific embodiment and its preparation method, its lubricating oil composition is: 1, the superparamagnetic nano Fe of grafting oleic acid functional group 3 o 4 The weight ratio of hollow microspheres is 0.1%-2%; 2. The weight ratio of the three types of base oils is 98%-99.9%; its preparation method is: 1. Apply solvothermal synthesis method to synthesize superparamagnetic nano-Fe in one step 3 o 4 cenospheres, while superparamagnetic nano-Fe 3 o 4 The surface of the hollow microspheres is grafted with oleic acid functional groups; 2. Fe that will be grafted with o...

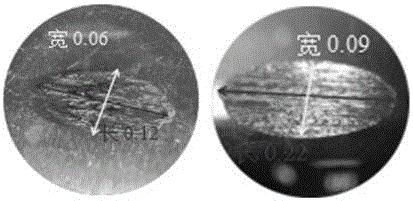

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com