Layered zirconium phosphate and molybdenum disulfide compound extreme pressure grease and preparation method thereof

A molybdenum disulfide, extreme pressure lubrication technology, used in lubricating compositions, petroleum industry, additives, etc., can solve the problems of poor bearing capacity and anti-wear performance of base grease, and achieve excellent anti-wear performance, long extreme pressure performance, The effect of improving the bearing capacity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

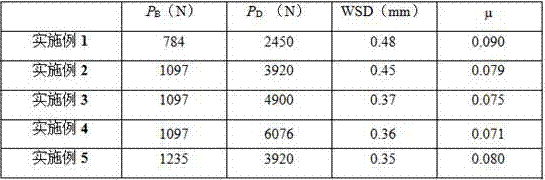

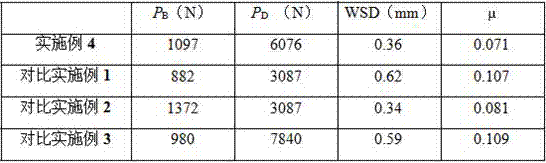

Examples

Embodiment 1

[0027] The preparation method of α-layered zirconium phosphate material: 0.294 g (7.0 mmol) sodium fluoride (NaF, Aladdin reagent (Shanghai) Co., Ltd.), 22.5 g (68.4 mmol) zirconium oxychloride octahydrate (ZrOCl 2 •8H 2 O, Sinopharm Chemical Reagent Co., Ltd.) and 24.95 mL of distilled water were added to a 150 mL polytetrafluoroethylene-lined reaction kettle in sequence, and after fully stirring to completely dissolve the solid reactants, 15.81 g (161.3 mmol) of phosphoric acid (H 3 PO 4 , Aladdin Reagent (Shanghai) Co., Ltd.) after stirring evenly, put the reaction kettle into 180 o C oven was reacted for 36 h. After the reaction, the solid product was filtered and washed with distilled water to neutrality, and the α-ZrP sample was obtained after natural air drying.

[0028] α-ZrP and MoS 2 The preparation method of the mixed powder: 8.0 g α-ZrP and 4.0 g molybdenum disulfide (MoS 2 , Aladdin Reagent (Shanghai) Co., Ltd.) were mixed in an agate jar, and 12.0 g of petrol...

Embodiment 2

[0033] α-ZrP preparation method is the same as embodiment 1;

[0034] The base lithium grease is the same as in Example 1, the difference is that 150 g of naphthenic mineral oil (viscosity at 100°C is 10.4mm 2 / s) was replaced with 150 g of polyalphaolefin PAO8 base lubricating oil (viscosity of 8.1 mm at 100 °C 2 / s);

[0035] α-ZrP and MoS 2 The preparation method of the mixed powder is the same as in Example 1, except that 8.0 g α-ZrP and 4.0 g molybdenum disulfide (MoS 2 , Aladdin Reagent (Shanghai) Co., Ltd.) was replaced with 10.0 g α-ZrP and 4.0 g molybdenum disulfide (MoS 2 , Aladdin Reagent (Shanghai) Co., Ltd.), adding 14.0 g petroleum ether (boiling range 60 - 90 o C, Tianjin Kemiou Reagent Co., Ltd.);

[0036] Add 3.0 g α-ZrP and MoS directly to 94.0 g base lithium grease 2 Mixed powder, 2.0 g extreme pressure agent (a mixture of 1.0 g thiophosphoric acid complex ester amine salt and 1.0 g sulfurized isobutylene, Shenyang Zhongda Jiusheng Chemical Technology ...

Embodiment 3

[0039] α-ZrP preparation method is the same as embodiment 1;

[0040] The base lithium grease is the same as in Example 1, the difference is that 150 g of naphthenic mineral oil (viscosity at 100°C is 10.4mm 2 / s) replaced with 150 g polyol ester base lubricating oil (viscosity 18.0 mm at 100 °C 2 / s);

[0041] α-ZrP and MoS 2 The preparation method of the mixed powder is the same as in Example 1, except that 8.0 g α-ZrP and 4.0 g molybdenum disulfide (MoS 2 , Aladdin Reagent (Shanghai) Co., Ltd.) was replaced with 12.0 g α-ZrP and 4.0 g molybdenum disulfide (MoS 2 , Aladdin Reagent (Shanghai) Co., Ltd.), adding 16.0 g petroleum ether (boiling range 60 - 90 o C, Tianjin Kemiou Reagent Co., Ltd.);

[0042] Add 3.0 g α-ZrP and MoS directly to 94.0 g base lithium grease 2 Mixed powder, 2.0 g extreme pressure agent (a mixture of 1.0 g thiophosphoric acid complex ester amine salt and 1.0 g sulfurized isobutylene, Shenyang Zhongda Jiusheng Chemical Technology Co., Ltd.) and 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com