Urea-based lubricating grease composition for electric hammer cylinder and preparation method thereof

A lubricating grease composition and electric hammer technology, applied in the field of lubricating grease, can solve the problems of not being able to better meet the lubrication conditions of the electric hammer cylinder, and the high-temperature performance of the lubricating grease needs to be improved, so as to achieve good anti-corrosion protection effect and anti-oxidation performance Good, the effect of improving shear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

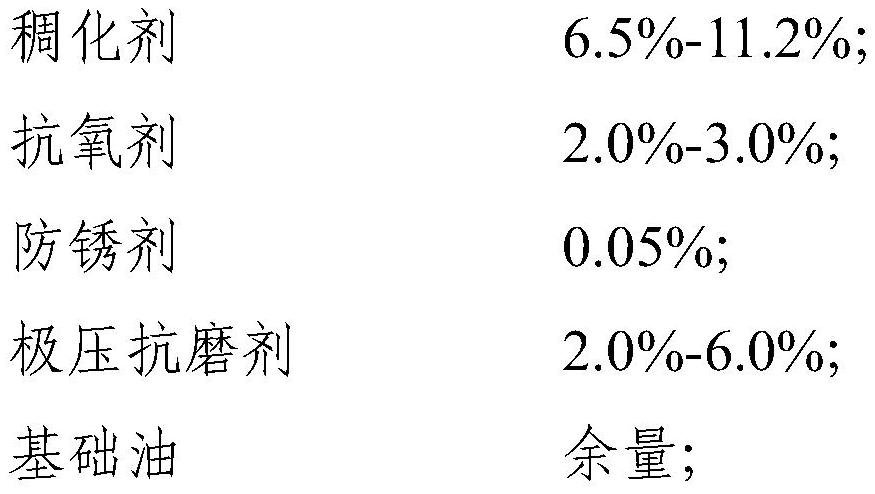

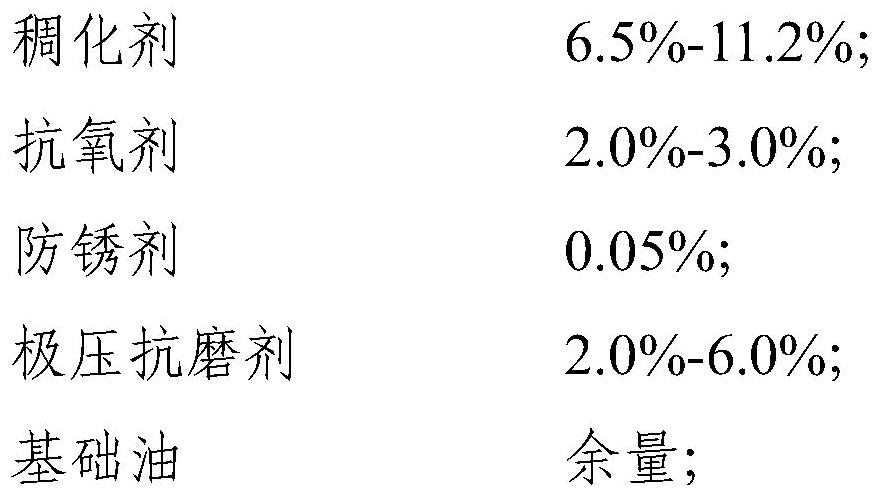

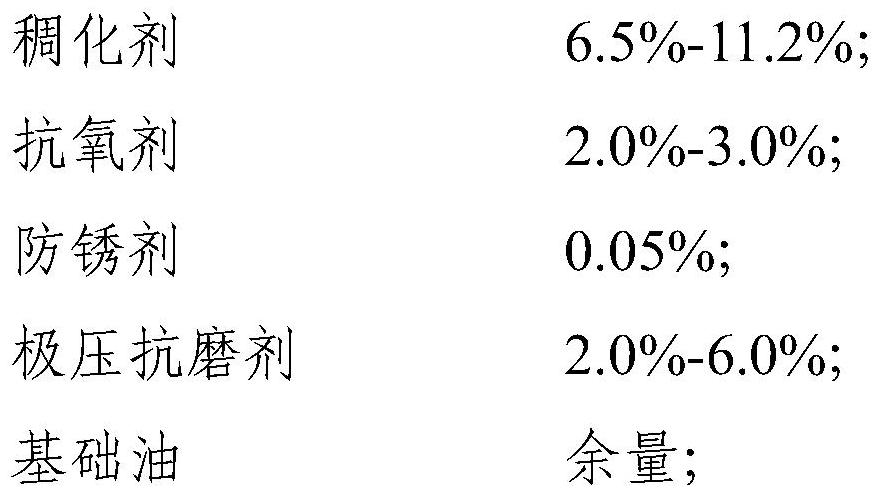

Method used

Image

Examples

Embodiment 1

[0024] Including the following steps: 890g PAO20 (40 ℃ viscosity 168mm 2 / s) into the reaction kettle, heat up to 62°C, add 91.2g of diphenylmethane diisocyanate, stir rapidly at constant temperature for 10min; at the same time, use 628g of PAO20 to dissolve 75.3g of octylamine and 13.6g of aniline, and heat up to 65°C; The final octylamine / aniline solution was slowly and uniformly added to the reactor, and then the temperature was raised to 100°C to start a constant temperature reaction, and the reaction time was 60 minutes; then the temperature in the kettle was raised to 190°C, kept at a constant temperature for 10 minutes, and then the kettle was poured to cool down; the temperature dropped to 100 Below ℃, use the remaining 300g base oil to adjust the grease consistency; when the temperature drops to 70℃, add 40g zinc dialkyl dithiophosphate, 30g Vanlube 855, 50g tert-butyl / octyl diphenylamine, 1g benzotri Azole and 20g molybdenum dialkyldithiocarbamate are ground by a thr...

Embodiment 2

[0026] Blend 890g of blended oil (150BS and HVIⅡ10 hydrogenated base oil at a weight ratio of 47:53, with a viscosity of 178mm at 40°C 2 / s) into the reaction kettle, heat up to 62°C, add 91.2g of diphenylmethane diisocyanate, stir rapidly at constant temperature for 10min; at the same time, dissolve 75.3g of octylamine and 13.6g of aniline with 628g of blending oil, and heat up to 65°C; The dissolved octylamine / aniline solution is slowly and uniformly added to the reactor, and then the temperature is raised to 100°C to start a constant temperature reaction, and the reaction time is 60 minutes; then the temperature in the kettle is raised to 190°C, kept at a constant temperature for 10 minutes, and then the kettle is cooled down; the temperature drops to Below 100°C, use the remaining 300g base oil to adjust the grease consistency; when the temperature drops to 70°C, add 40g zinc dialkyl dithiophosphate, 30g Vanlube 855, 50g tert-butyl / octyl diphenylamine, 1g benzo Triazole an...

Embodiment 3

[0028] Blend 890g of blended oil (150BS and PAO10 base oil at a weight ratio of 60:40, with a viscosity of 180mm at 40°C 2 / s) into the reaction kettle, heat up to 62°C, add 91.2g of diphenylmethane diisocyanate, stir rapidly at constant temperature for 10min; at the same time, dissolve 75.3g of octylamine and 13.6g of aniline with 628g of blending oil, and heat up to 65°C; The dissolved octylamine / aniline solution is slowly and uniformly added to the reactor, and then the temperature is raised to 100°C to start a constant temperature reaction, and the reaction time is 60 minutes; then the temperature in the kettle is raised to 190°C, kept at a constant temperature for 10 minutes, and then the kettle is cooled down; the temperature drops to Below 100°C, use the remaining 300g blending oil to adjust the grease consistency; when the temperature drops to 70°C, add 40g zinc dialkyldithiophosphate, 30g Vanlube 855, 50g tert-butyl / octyl diphenylamine, 1g benzo Triazole and 20g molyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com