Patents

Literature

158 results about "Sodium aluminosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium aluminosilicate refers to compounds which contain sodium, aluminium, silicon and oxygen, and which may also contain water. These include synthetic amorphous sodium aluminosilicate, a few naturally occurring minerals and synthetic zeolites. Synthetic amorphous sodium aluminosilicate is widely used as a food additive, E 554.

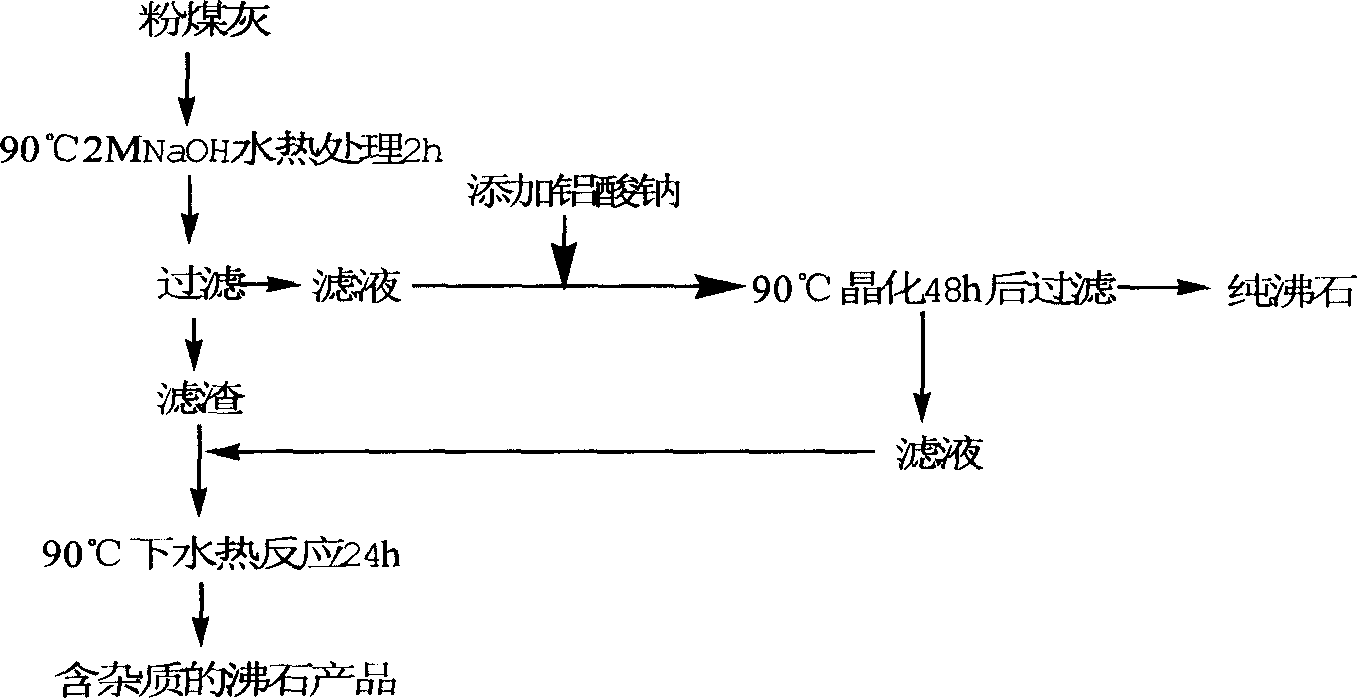

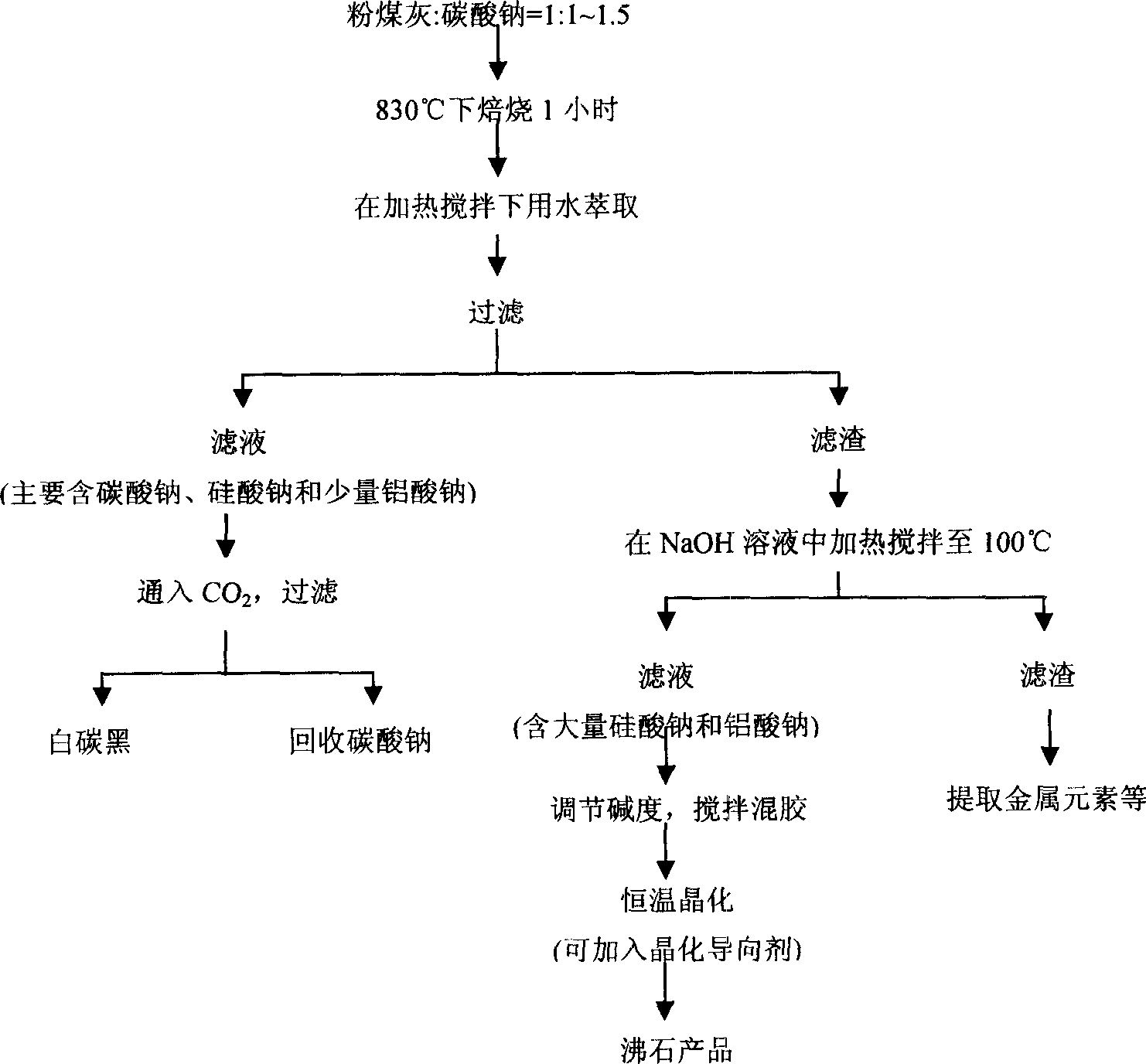

Method for preparing white carbon black and pure zeolite molecular sieve using flyash

InactiveCN1911800AAccelerate emissionsSilicon oxidesCrystalline aluminosilicate zeolitesSolubilityMetallic materials

The process of preparing white carbon black and pure zeolite molecular sieve with fly ash material belongs to the field of inorganic non-metal material preparing technology. The preparation process includes the following steps: roasting the mixture of high silicon fly ash with SiO2 content of 30-65 % and sodium carbonate in the weight ratio of 1 to 1-1.5 at 830 deg.c for 1 hr to obtain roasted product with sodium silicate and sodium aluminosilicate as main components; soaking the roasted product in water in 5 times to leach out sodium silicate with high water solubility, filtering to obtain sodium silicate solution, introducing CO2 to the solution and depositing to obtain white carbon black product; and further leaching desilicated fly ash with alkali solution, heating and stirring to obtain solution of sodium aluminosilicate, which is soluble in strong alkali solution, filtering, regulating pH value and crystallizing to obtain pure zeolite molecular sieve.

Owner:UNIV OF SCI & TECH BEIJING

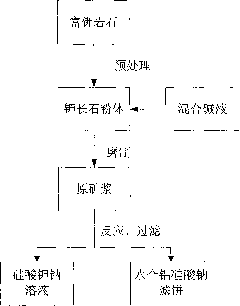

Process for preparing sodium potassium silicate solution by predesiliconizing potassium-rich rock

InactiveCN101798095ARaise the ratioReduce consumptionAluminium silicatesAlkali metal silicatesWater insolubleSlag

The invention discloses a process for preparing a sodium potassium silicate solution by predesiliconizing potassium-rich rock. The process comprises the following steps of: crushing and homogenizing potassium-rich rock to prepare potash feldspar powder; grinding the potash feldspar powder and an alkali solution together to prepare original ore pulp; carrying out a constant temperature reaction of the original ore pulp in a reaction at 180-250 DEG C for 1-4h to obtain reaction slurry; and diluting, filtering and reversely washing the reaction slurry to prepare a sodium potassium silicate solution and an Al-rich hydrated sodium aluminum filter cake. The sodium potassium silicate solution can be used as a raw material for preparing inorganic silicon compounds and sylvite products, and the Al-rich hydrated sodium aluminum filter cake is further processed to extract alumina therein. The process solves the problems of great silicon-calcium slag castoff emission and scaled production restriction existing in the potassium-extracting process from water-insoluble potassium ore.

Owner:昊青薪材(北京)技术有限公司

Pulverized coal combustion improver for thermal power plant

InactiveCN102559331ALow ignition pointImprove combustion effectSolid fuelsCombustionEconomic benefits

The invention discloses a pulverized coal combustion improver for a thermal power plant. The pulverized coal combustion improver comprises components with weight percentages as follows: 50 to 80 percent of manganese ore, 10 to 40 percent of chemical activator, 5 to 15 percent of clinker sintering agents and smaller than 2 percent of water, wherein the chemical activator is sodium aluminosilicate or potassium aluminum silicate. Raw materials of the chemical activator in the pulverized coal combustion improver are easy to obtain and an effect of saving more than 13 percent of coal can be achieved, so that the pulverized coal combustion improver has great economic benefits and is worthy of popularization.

Owner:洛阳大泽节能环保科技有限公司

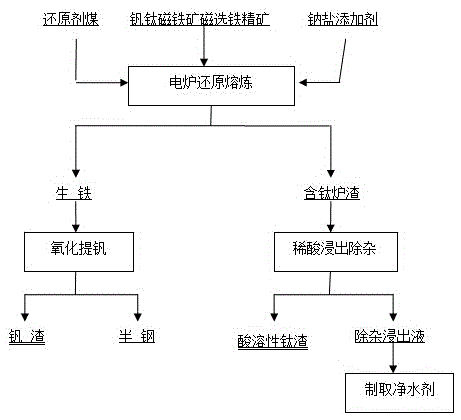

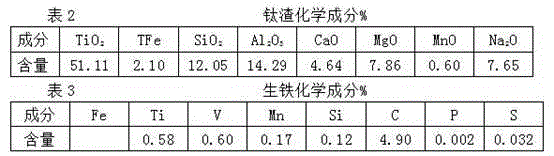

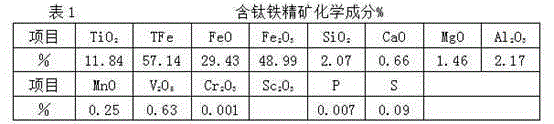

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

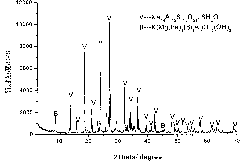

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

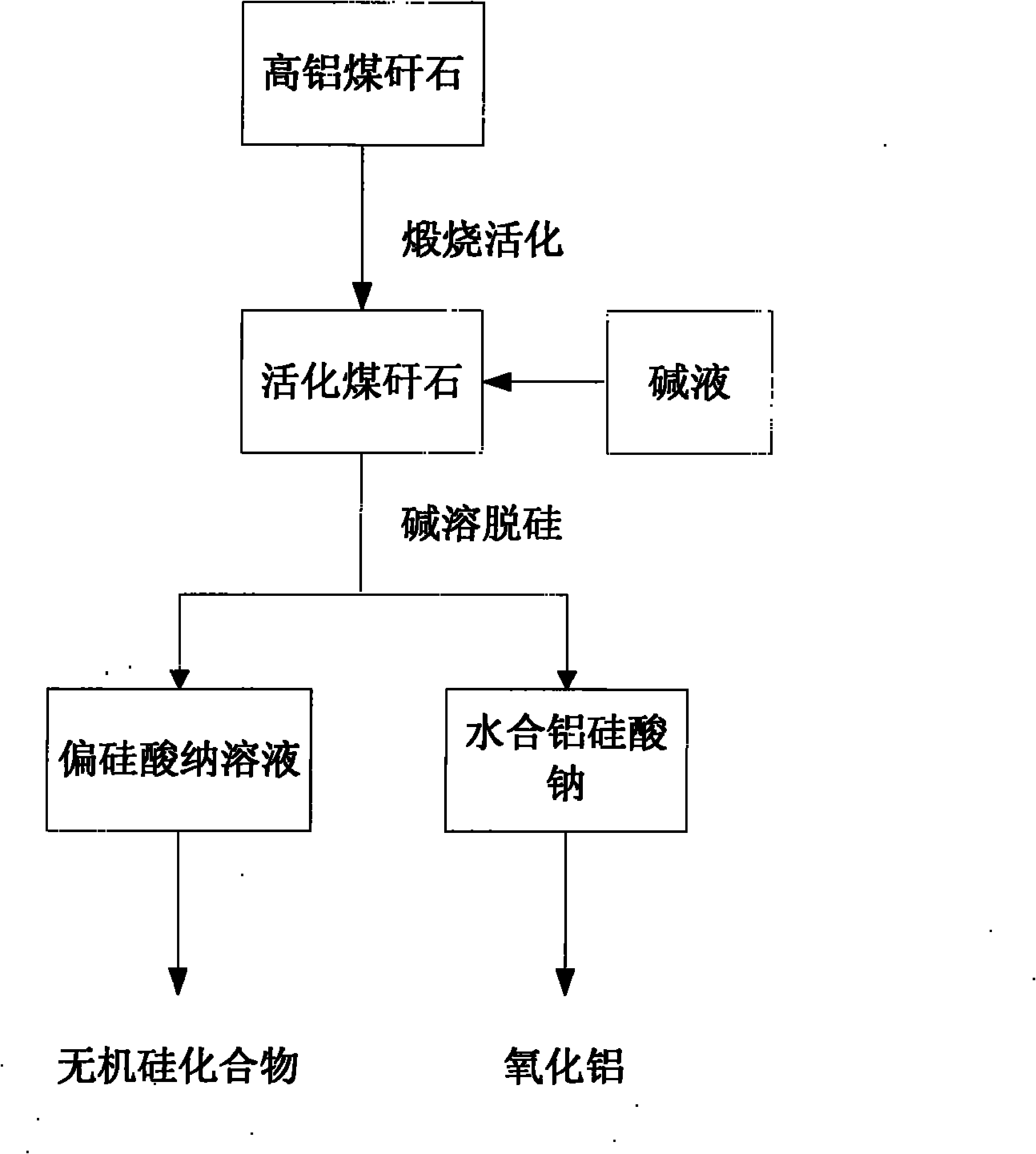

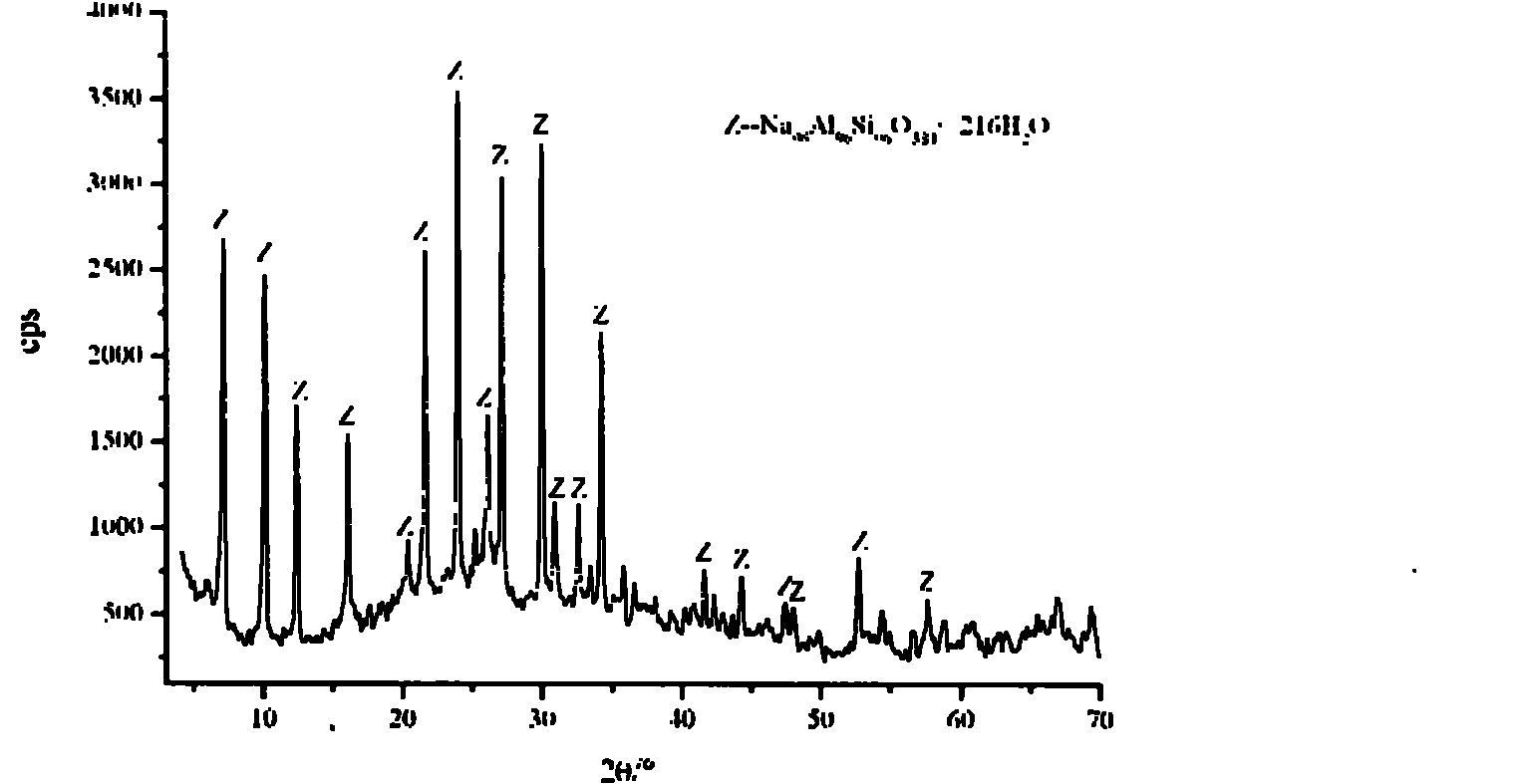

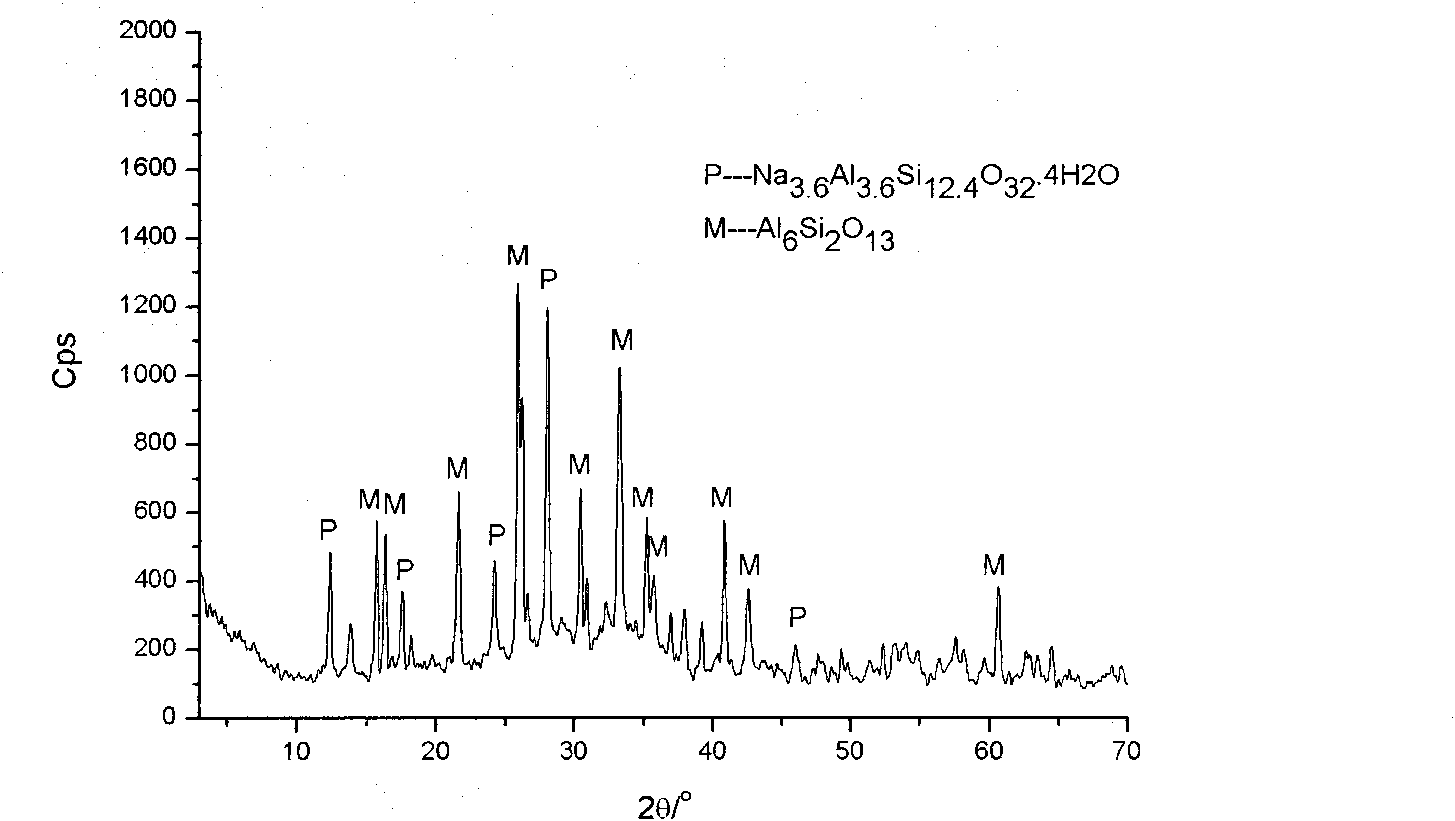

Technology for preparing hydrated sodium aluminosilicate by utilizing high-alumina coal gangue and fly ash alkali soluble desiliconization

InactiveCN102167338AIncrease Al-Si RatioEmission reductionAluminium silicatesSODIUM SILICATE SOLNSodium aluminosilicate

The invention discloses a technology for preparing hydrated sodium aluminosilicate by utilizing high-alumina coal gangue and fly ash alkali soluble desiliconization, and the technology provided by the invention comprises a high-alumina coal gangue alkali soluble desiliconization technology and a high-alumina fly ash alkali soluble desiliconization technology. The high-alumina coal gangue is activated in a roasting way and is leached by alkali liquor, solid-liquid separation is carried out, and the filter liquor is sodium silicate solution which can be used for preparing an inorganic silicon compound; and a filter cake is a hydrated sodium aluminosilicate material which can be used as a raw material for producing aluminum oxide. The high-alumina fly ash can be formed at a high temperature,the activating working procedure in a roasting way can be omitted, and the alkali soluble desiliconization can be directly performed. The technology is characterized in that the technical process is simple, the obtained hydrated sodium aluminosilicate material is taken as the raw material for producing the aluminum oxide, the hydrated sodium aluminosilicate is higher in aluminum-silicon mass ratio and higher in sodium oxide mass fraction, the alkali matching quantity and the silicon-calcium tailings discharging quantity of the process for preparing the aluminum oxide by utilizing the high-alumina coal gangue or the high-alumina fly ash can be obviously reduced, and the economic benefit of the technical process for preparing the aluminum oxide by utilizing the high-alumina coal gangue or the high-alumina fly ash can be improved.

Owner:昊青薪材(北京)技术有限公司

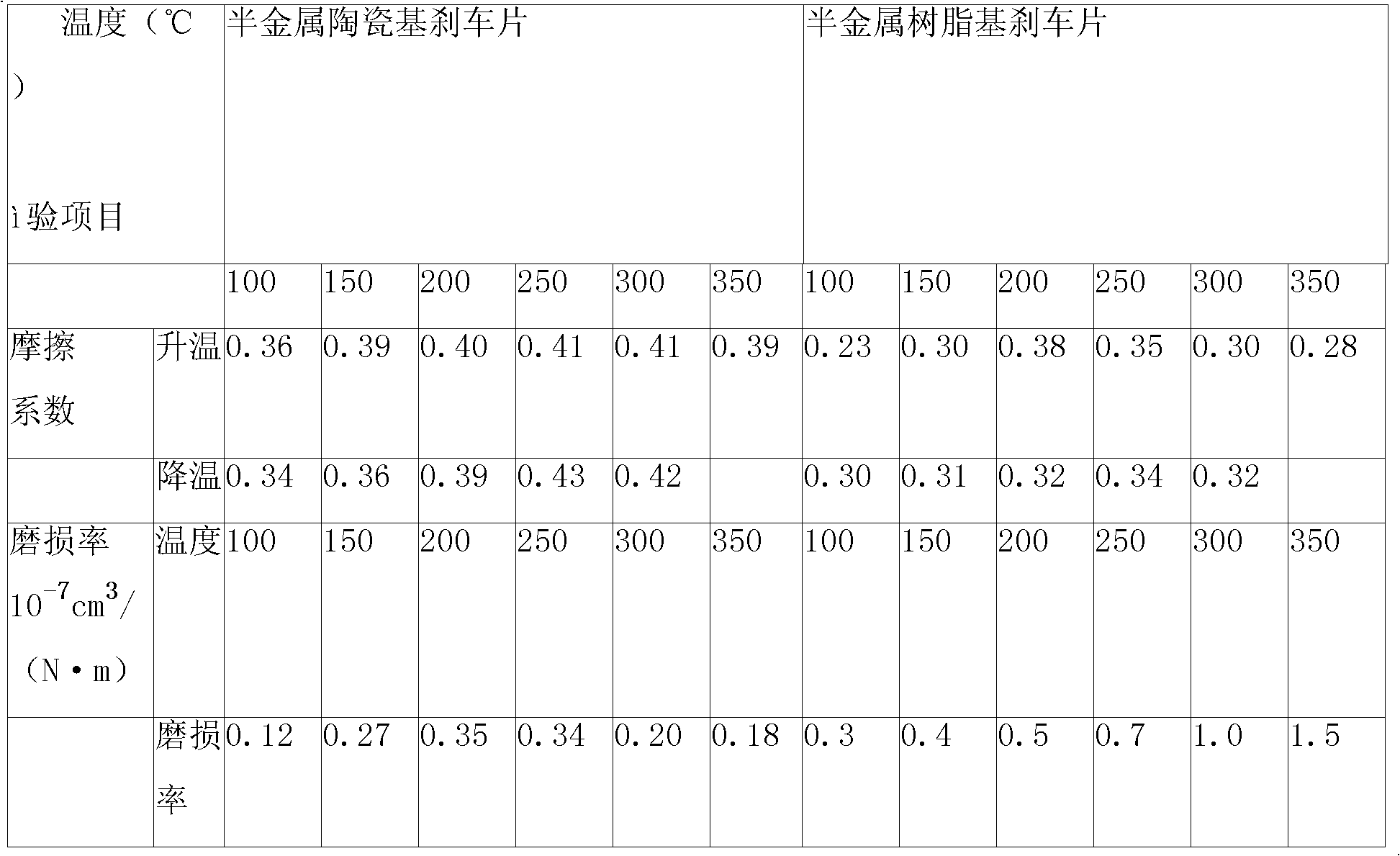

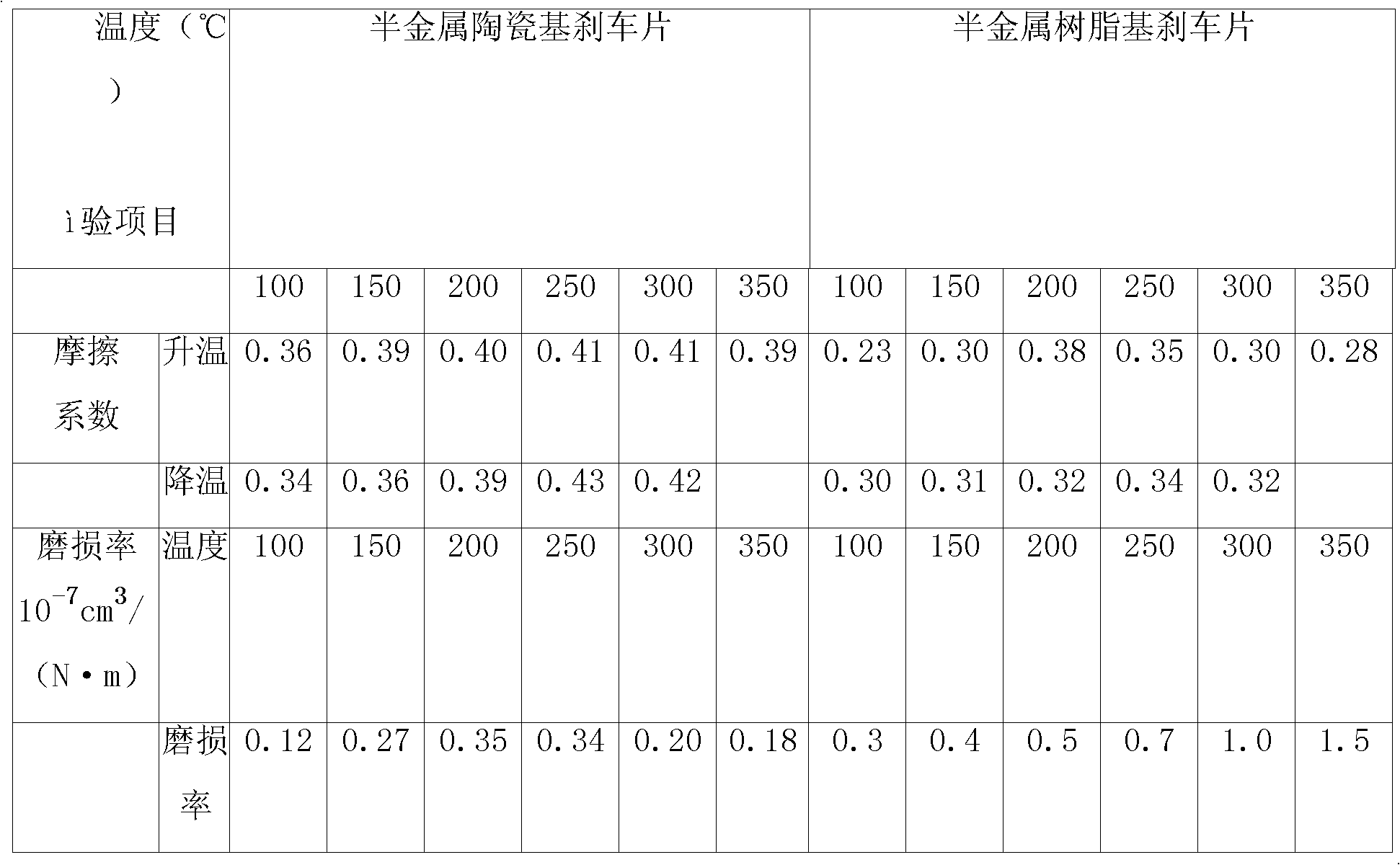

Semimetal ceramic base automobile brake pad and preparation method thereof

The invention discloses a semimetal ceramic base automobile brake pad, and a material formula of the semimetal ceramic base automobile brake pad is calculated in percentage by weight: 15 to 30 percent of bonding substrate, 25 to 50 percent of reinforcing fibre, 10 to 20 percent of friction performance adjusting agent, and 10 to 30 percent of filler, wherein the bonding substrate mainly takes modified sodium aluminosilicate as an inorganic high temperature adhesive, and less phenolic resin and rubber as organic middle-low temperature auxiliary adhesives; the weight ratio of inorganic ceramic adhesive to the organic adhesive is 5:1; the reinforcing fibre mainly takes steel fibre, copper fibre, ceramic or mineral fibre as auxiliary reinforcing fibres, and the weight ratio of the steel fibre to the auxiliary reinforcing fibres is 10:1; the friction performance adjusting agent comprises chromite, graphite and friction dust; and the filler is oil coke and barite. The automobile brake pad is a semimetal ceramic base automobile brake pad with high safety and reliability, and a preparation method is simple and reliable.

Owner:CENT SOUTH UNIV +1

Method for extracting aluminum oxide from fluidized bed coal ash

InactiveCN102602969AReduced leach flowEasy to industrializeSolid waste disposalAluminium oxides/hydroxidesEnvironmental resistanceAluminium hydroxide

The invention discloses a method for extracting aluminum oxide from fluidized bed coal ash, comprising the following steps: 1, mixing the fluidized bed coal ash and sodium hydroxide aqueous solution and carrying out ball milling to obtain slurry; 2, carrying out pre-desilicication reaction on the slurry, and filtering; 3, adding calcium oxide, sodium hydroxide and water in a filter cake, carrying out hydrothermal reaction by utilizing a high-pressure water chemical method, vacuum filtering; 4, adding hydration sodium aluminosilicate in the filtrate to carry out the first-stage desilicication reaction, and adding hydration calcium aluminate to carry out the second-stage desilicication reaction; 5, evaporating and crystallizing the reaction liquid to obtain hydration sodium aluminate, and crystallizing; 6, dissolving and crystallizing, introducing carbon dioxide and filtering to obtain aluminum hydroxide solid; and 7, washing and calcining to obtain aluminum oxide. By utilizing high activity of the fluidized bed coal ash, the amount of the subsequent aluminum oxide extract is greatly reduced through pre-desilicication reaction so as to ensure industrialization; and the silicon oxide and aluminum oxide in the coal ash are separated by adding alkaline substances and utilizing the high-pressure water chemical method so as to save energy and protect the environment.

Owner:CHANGAN UNIV

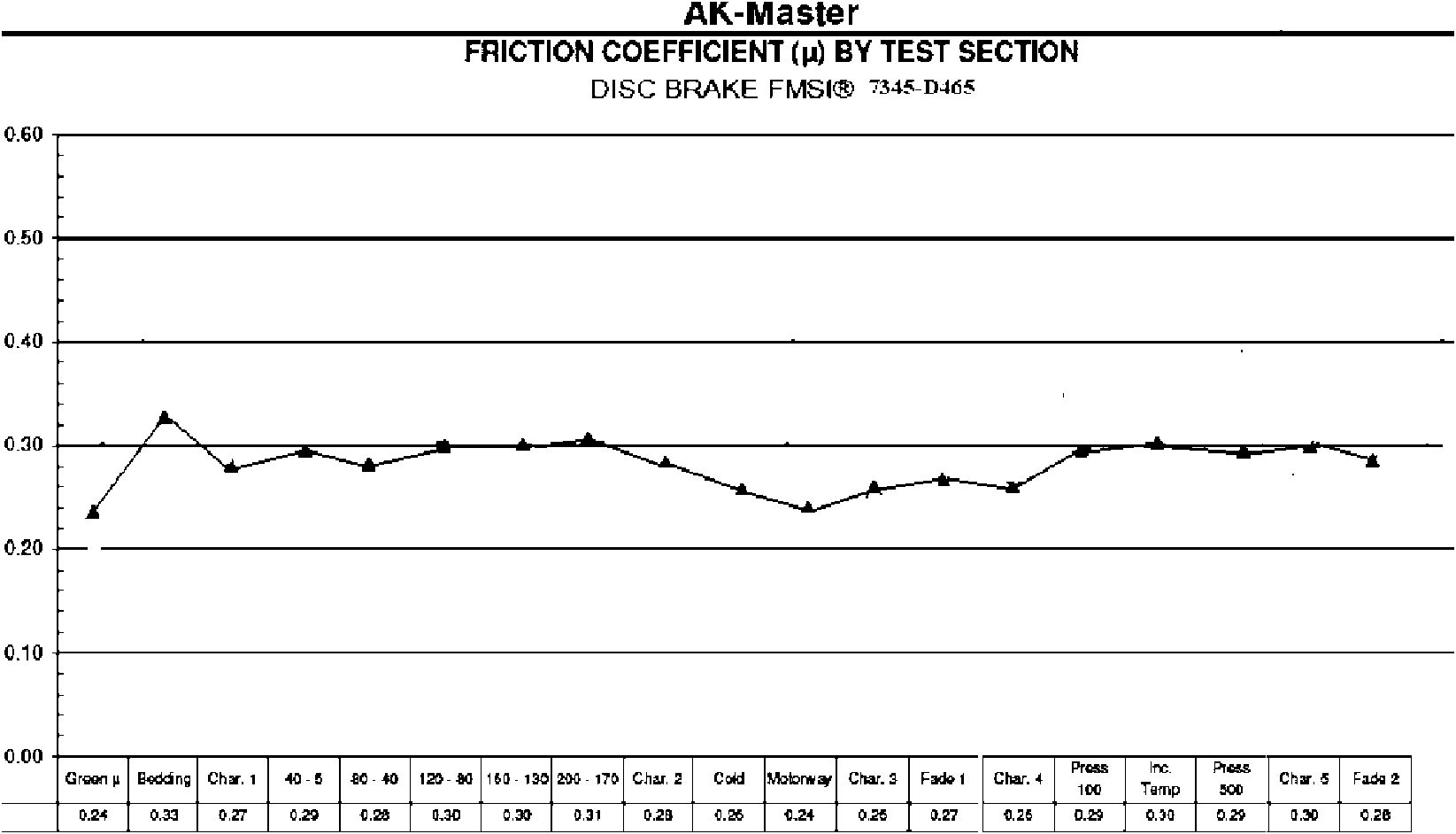

Low ceramet group automobile brake block and preparation method thereof

The present invention discloses a low ceramet group automobile brake block, comprising by weight percentage 15-30 of cementing matrix, 25-50 of fortifying fiber, 10-20 of frictional property regulating agent, 5-10 of elastic toughening agent, and 10-30 of filling material. The cementing matrix principally employs a modified sodium aluminosilicate as an inorganic high temperature binder, a little phenol aldehyde resin and rubber as an organic middle / low-temperature auxiliary binder, wherein the weight ratio of the inorganic ceramic binder and the organic binder is 5:1; the fortifying fiber is principally the steel fiber, the copper fiber, mineral fiber and organic fiber are used as the auxiliary fortifying fiber, the weight ratio of the steel fiber and the auxiliary fortifying fiber is 1:1; the frictional property regulating agent principally includes chromic iron, graphite and friction powder; the elastic toughening agent principally includes acrylonitrile butadiene, and organic friction powder; and the filling material is principally petroleum coke and barite. The low ceramet group automobile brake block has a long service life and a superior braking performance, and the preparation method is simple and feasible.

Owner:CENT SOUTH UNIV +1

Process for enhancing yield of sodium aluminosilicate molecular sieves during synthesis

InactiveUS20050158237A1Increase productionReduce loadAluminium compoundsFaujasite aluminosilicate zeoliteMolecular sieveSodium silicoaluminate

The present invention relates to a process for enhancing the yield of molecular sieve zeolite during the synthesis from a sodium aluminosilicate reaction mixture, said process comprising the step of adding at an intermediate stage of crystallization a source of aluminum to the sodium aluminosilicate reaction mixture and allowing the mixture to crystallize.

Owner:INDIAN OIL CORPORATION

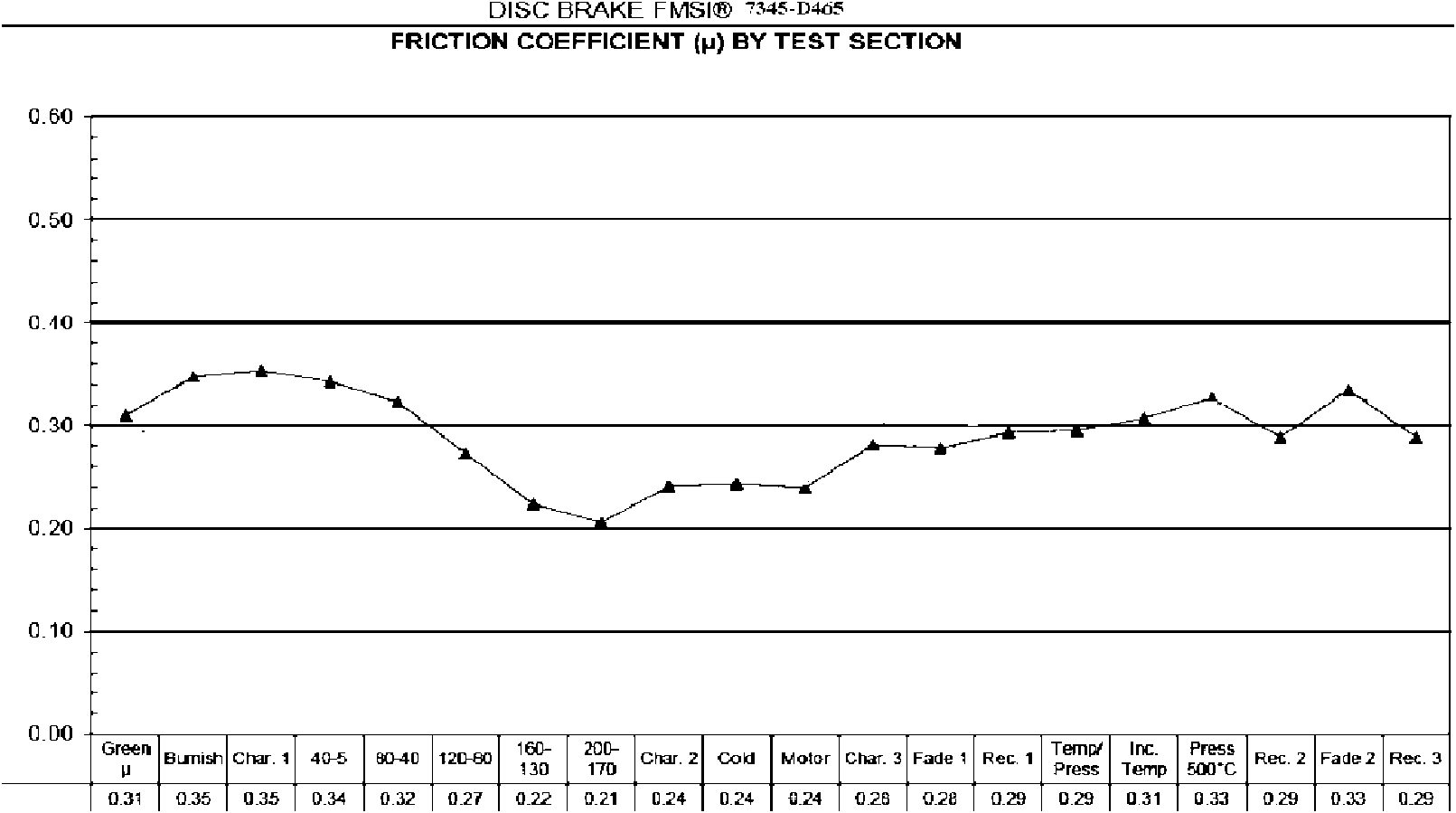

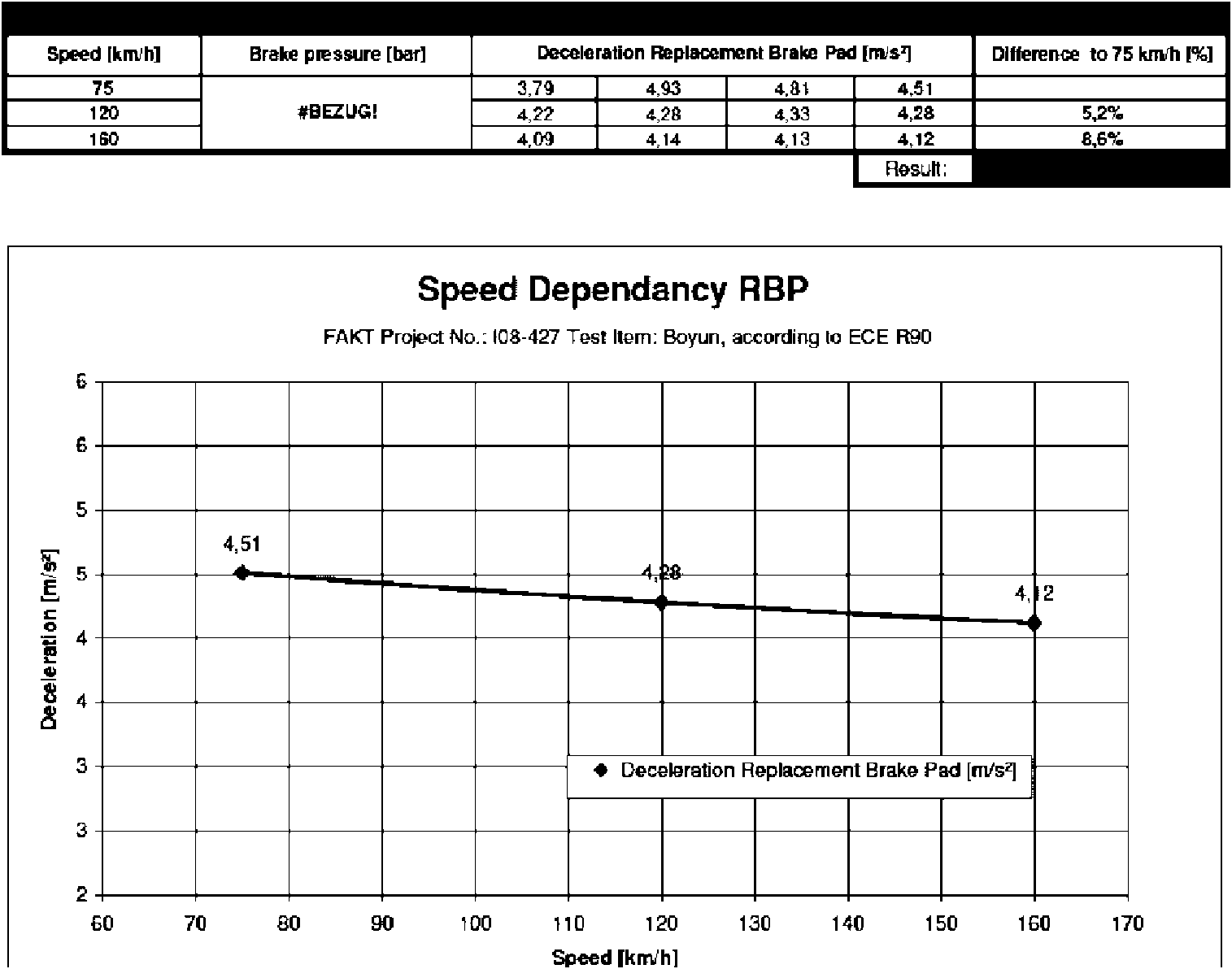

Semimetal ceramic matrix brake pad and manufacturing method thereof

InactiveCN101571174AImproved speed/pressure correlationHigh speedFurnace typesFriction liningAdhesiveFilling materials

The invention discloses a semimetal ceramic matrix brake pad, the material formulation of which is as follows by weight percentage: 15-30 parts of bonding matrices, 25-50 parts of reinforcing fibers, 10-20 parts of regulators with frictional properties, and 10-30 parts of filling materials; wherein, the bonding matrix mainly takes modified sodium aluminosilicate as inorganic HTAs (high temperature adhesives) and a little of phenolic resin and rubber as organic low-and-medium temperature accessorial adhesives, and the weight ratio of an inorganic ceramic adhesive to an organic adhesive is equal to 5:1; the reinforcing fiber mainly takes steel fiber, cooper fiber, ceramics or mineral fiber as an accessorial reinforcing fiber, and the weight ratio of the steel fiber to the accessorial reinforcing fiber is 10:1; the regulators with frictional properties comprise chromite, graphite and friction dust; the filling materials comprise oil coke and baria. The semimetal ceramic matrix brake pad prepared in the invention is safe and reliable, and the manufacturing method is simple and reliable.

Owner:CENT SOUTH UNIV +1

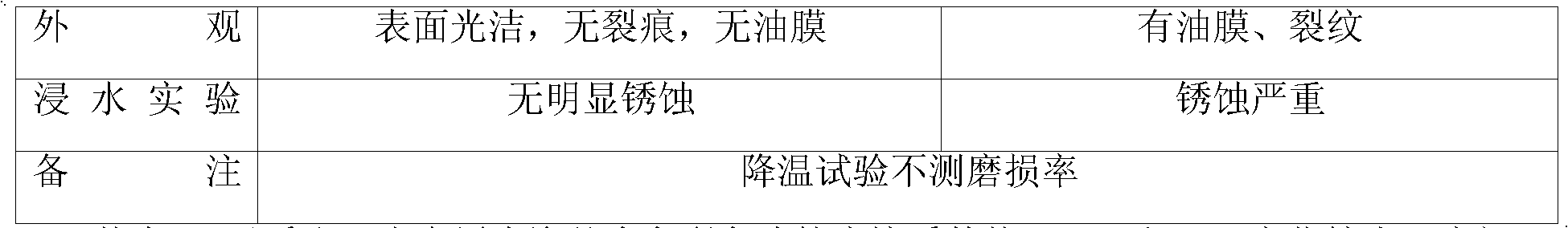

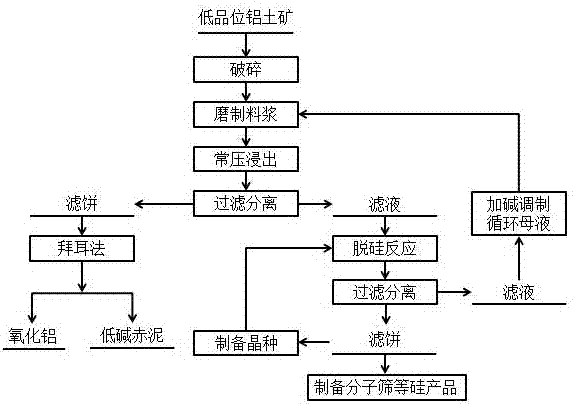

Method for producing aluminium oxide and by-product silicon by low-temperature alkali digestion of low-grade bauxite

InactiveCN107235501AAluminium silicatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagRed mud

The invention relates to a method for producing aluminium oxide and a by-product silicon by low-temperature alkali digestion of low-grade bauxite, and belongs to the technical field of aluminium oxide production. The method comprises the following steps: firstly, smashed low-grade diasporic bauxite and a circulating mother liquid are grinded to form a mineral slurry; secondly, a digestion reaction is performed enable kaolinite in the mineral to be dissolved, react and enter a solution, filtration residues are high-grade bauxite concentrate, and the high-grade bauxite concentrate is processed for produce aluminium oxide and low-alkali red mud by adopting a Bayer process; sodium aluminosilicate in a filtrate is subjected to desilication reaction, so that sodium-silicon residues, and a filtrate containing aluminium oxide, silicon oxide and sodium oxide are obtained; and finally, the filtrate is supplemented by sodium hydroxide, and the supplemented filtrate is used as the circulating mother liquid to return for preparation of the mineral slurry through grinding, and part of the sodium-silicon residues are used as a seed crystal to return to a desilication process, and the other part of the sodium-silicon residues are used to prepare silicon products such as molecular sieves. The method is a whole-procedure wet treatment process, aluminium and silicone are fully extracted from the bauxite for preparing the corresponding products, also alkali consumption in the red mud during the Bayer process is substantially reduced, the alkali content in the red mud is reduced, and recycle value of the red mud is improved.

Owner:NORTHEASTERN UNIV

Deep desilication method for adding composite desiliconization agent to middle and high concentration sodium aluminosilicate solution

InactiveCN101423237ASimple production processHigh silicon content indexAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHigh concentrationSodium aluminosilicate

A composite desiliconization agent is added in sodium aluminosilicate solution with medium and high concentration for deep desiliconization, the invention relates to a chemical process method for carrying out the desiliconization of the sodium aluminosilicate solution with medium and high concentration by adopting the composite desiliconization agent under atmospheric pressure, the silicon content index of the solution after the desiliconization can be more than 7000, and the desiliconization method comprises the following steps: composition containing the sodium aluminosilicate solution is prepared, 80-90ml of the solution is taken and put in a reaction kettle, a calcium oxide and calcium sulfate composite desiliconization agent is added, the reaction kettle is put in a heat collection type constant temperature heating magnetic stirrer, supernatant liquor is taken after the solution is cooled, the concentration of Al2O3 is measured by using the complexometric titration, and the content of SiO2 is measured by using a spectrophotometer. The chemical process method is applicable to the secondary desiliconization of the sodium aluminosilicate solution with medium and high concentration. The economic benefits of using the sodium aluminosilicate solution with medium and high concentration are much higher than those of using the sodium aluminosilicate solution with low concentration under the situation of the same energy consumption, thereby being beneficial to reducing the energy consumption and promoting the sustainable development of the production of aluminum oxide.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Process for enhancing yield of sodium aluminosilicate molecular sieves during synthesis

InactiveUS20070059238A1Increase productionReduce loadAluminium compoundsFaujasite aluminosilicate zeoliteMolecular sieveSodium silicoaluminate

The present invention relates to a process for enhancing the yield of molecular sieve zeolite during the synthesis from a sodium aluminosilicate reaction mixture, said process comprising the step of adding at an intermediate stage of crystallization a source of aluminum to the sodium aluminosilicate reaction mixture and allowing the mixture to crystallize.

Owner:INDIAN OIL LIMITED A

Method for producing aluminum hydroxide by roasting bauxite at low temperature

InactiveCN109279633AReduce trafficReduce sintering energy consumptionAluminium silicatesProcess efficiency improvementAluminium hydroxideRed mud

The invention belongs to the technical field of aluminum industries, and specifically discloses a method for producing aluminum hydroxide by roasting bauxite at a low temperature. The method includesmixing crushed bauxite with a caustic solution to obtain raw slurry; roasting the raw slurry with 160-890 DEG C to obtain clinkers; performing dissolution reaction on the clinkers to obtain digestionliquor, and performing solid-liquid separating on the digestion liquor, wherein a solid phase is a pug whose iron content is larger than or equal to 40%, the pug can be sold as an iron concentrate rawmaterial after washing, a liquid phase is crude liquid, and a desilication solid phase is a sodium aluminosilicate product after the desiliconization of the crude liquid; and adding aluminum hydroxide seeds into the liquid phase to perform decomposition reaction, and performing solid-liquid separating on decomposition liquid, wherein the obtain liquid phase is seeded precipitation spent liquor, and the solid phase is an aluminum hydroxide product. The method enhances decomposition rate and cyclic efficiency, and reduces energy consumption; and compared with traditional sintering methods, theroasting temperature can be obviously reduced, the method does not generate red mud, more than 70% of silicon dioxide in the bauxite is made into the sodium aluminosilicate products, and the standardof the quality of the prepared aluminum hydroxide is better than that of the aluminum hydroxide produced by the traditional sintering methods and Bayer process.

Owner:陈湘清

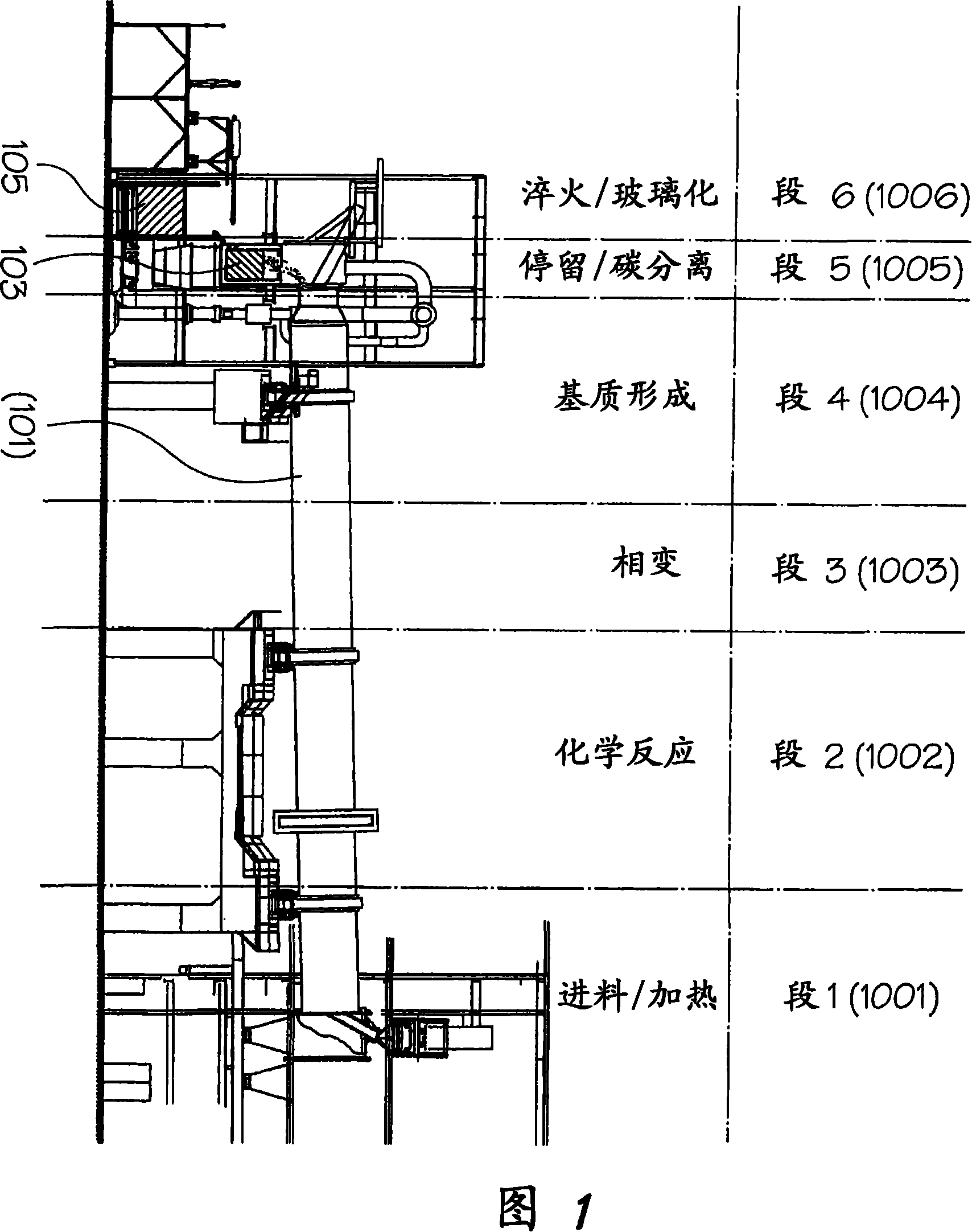

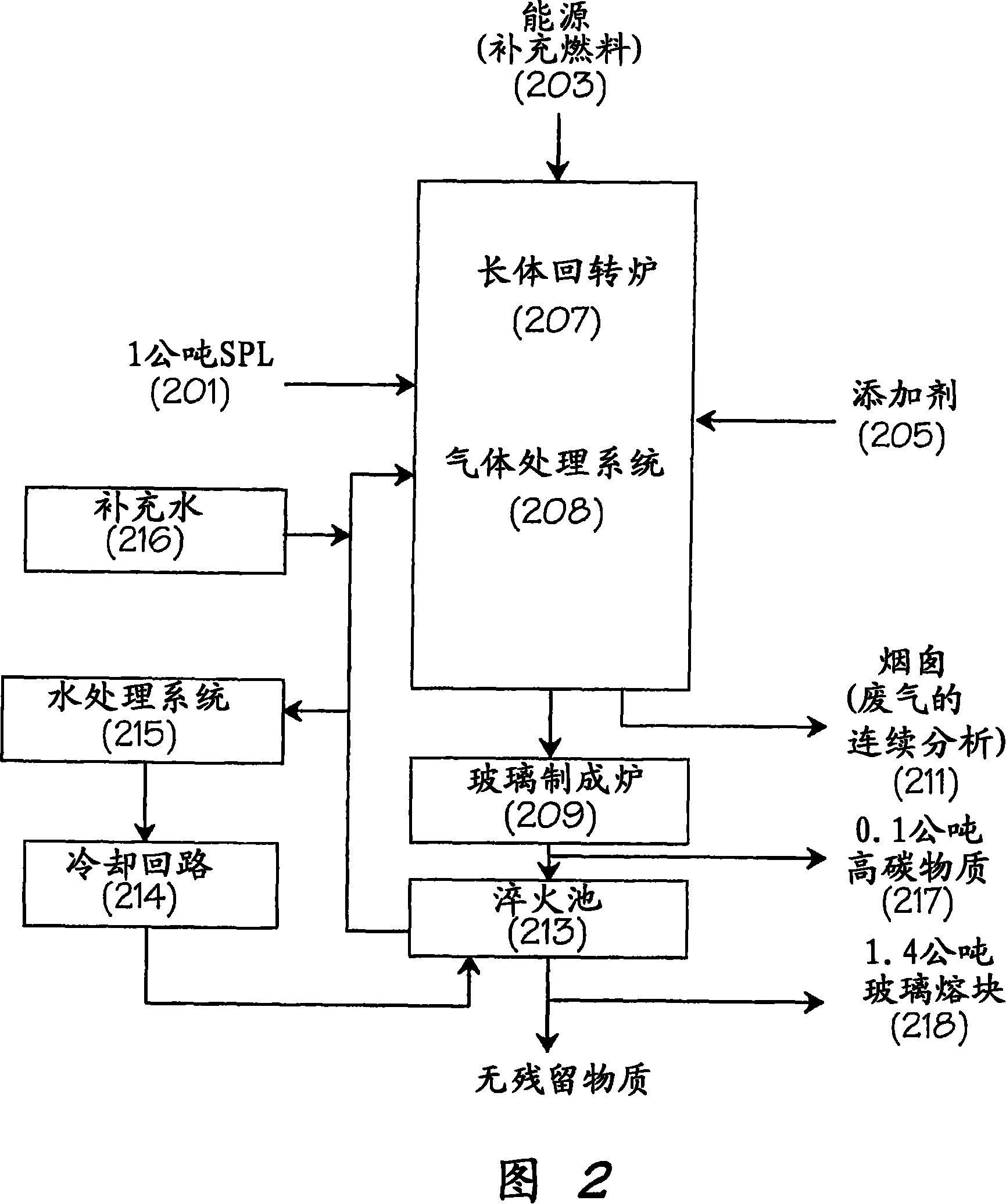

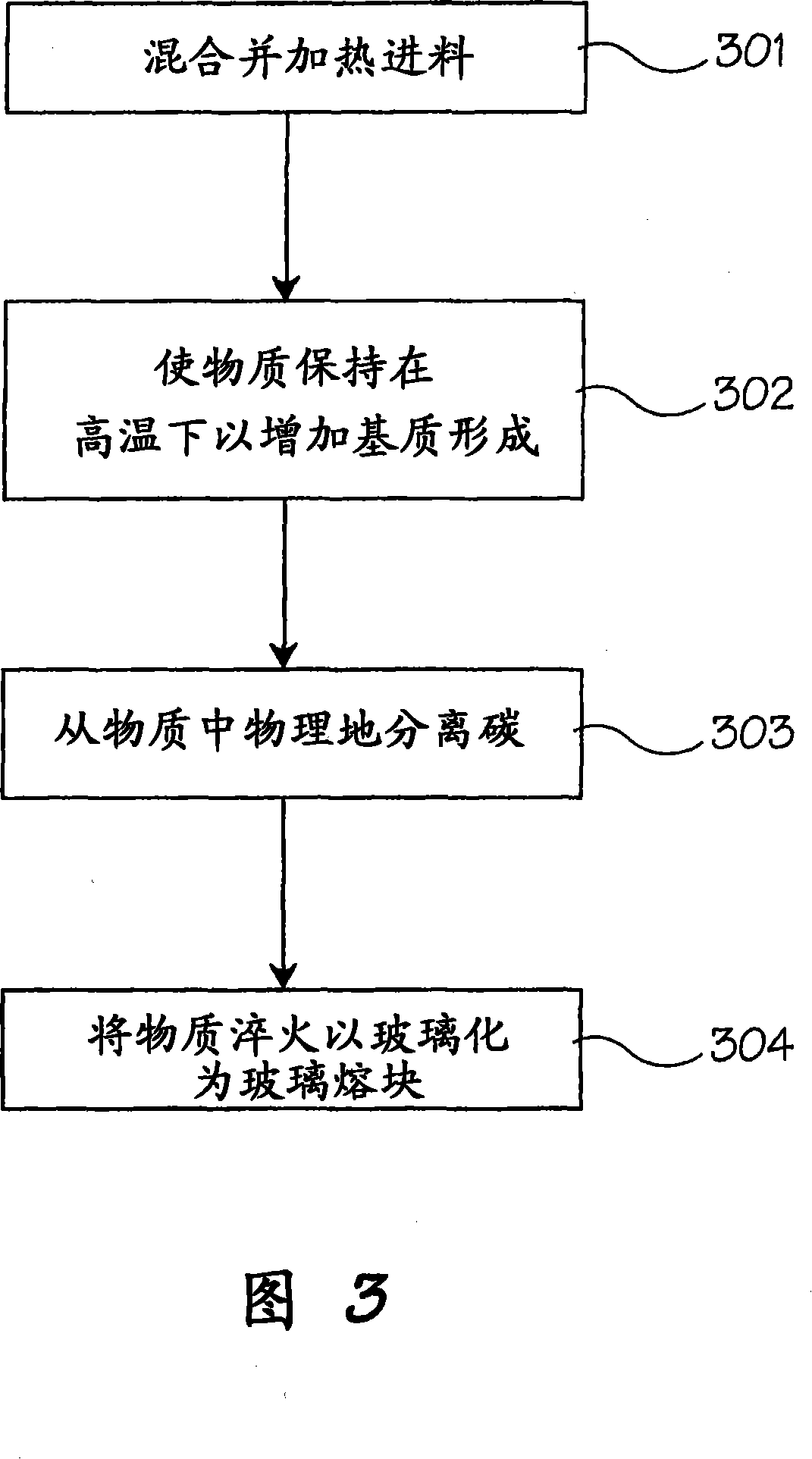

Process and apparatus for converting spent potliners into a glass frit, and resulting products

The present invention relates to a fire metallurgy method for converting the waste slot liner or other harmful material from the aluminum production industry to the glass clinker clew of amorphous fluorine-bearing sodium aluminosilicate and amorphous fluorine-bearing aluminum calcium silicate and converting to the high-carbon material and the device. The raw materials of waste slot liner, silicon dioxide or siliceous material and calcium oxide are added to the non-burner end of the counterflow rotary burner. The material is heated to destroy the cyanide, the salt fluoride is converted to calcium fluoride and forms a homogeneous liquid material. Then the carbon is physically separated from the material. Afterwards the material is glassed to generate the valuable glass clinker clew and high-carbon material.

Owner:NUOVOFORD INT

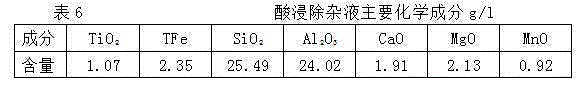

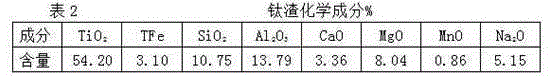

Preparing method for titaniferous inorganic flocculant

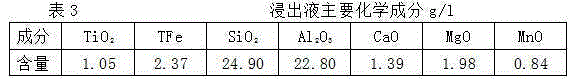

InactiveCN105217755AImprove the solution and leaching rateSolve the key technical problems of rich titanium and impurity reductionWater/sewage treatment by flocculation/precipitationAluminateHydrometallurgy

The invention discloses a preparing method for titaniferous inorganic flocculant and relates to the technical field of preparing methods for the titaniferous inorganic flocculant in the technical field of chemistry. Vanadium titano-magnetite serves as a basic material, a sodium or sylvine additive is added in iron ore concentrate obtained through magnetic separation in the reduction smelting process in an electric furnace, and molten iron and titaniferous slag are obtained, wherein vanadium and iron are reduced to enter the molten iron while silicon and aluminum impurities and the sodium or sylvine additive form sodium aluminosilicate capable of dissolved in diluted acid under the high-temperature smelting condition, and the sodium aluminosilicate and titanium and calcium and magnesium impurities are left in the titaniferous slag; then silicon, aluminum and iron in the titaniferous slag are extracted by adopting a hydrometallurgy method on the titaniferous slag and serve as raw materials for preparing the inorganic polymer flocculant. According to the preparing method for the titaniferous inorganic flocculant, the sodium salt additive is added in the smelting process of the iron ore concentrate in the electric furnace, the acidolysis leaching rate of silicon and aluminum in the smelting slag is greatly increased, the raw materials are provided for preparing the inorganic flocculant, and the key technical purpose of impurity reduction of rich titanium of the titaniferous slag is achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Preparation method for low-smell ABS engineering plastic

The invention provides low-odor ABS engineering plastic, which is characterized in that the ABS engineering plastic contains, by weight percentage, 60 to 94.5 percent of ABS resin, 5 to 37.5 percent of modifier, 0.1 to 0.5 percent of antioxidant, 0.1 to 0.5 percent of lubricant, 0.15 to 0.5 percent of sodium aluminosilicate, and 0.15 to 1.0 percent of castor oil zinc salt. The method for preparing the low-odor ABS engineering plastic comprises the following steps: weighing above materials according to a certain ratio, mixing uniformly in a high-speed mixer, and extruding and granulating in a double-screw extruder. The method can reduce the odor of general plastic and at the same time keep the original properties of the ABS engineering plastic.

Owner:SHANGHAI KINGFA SCI & TECH +1

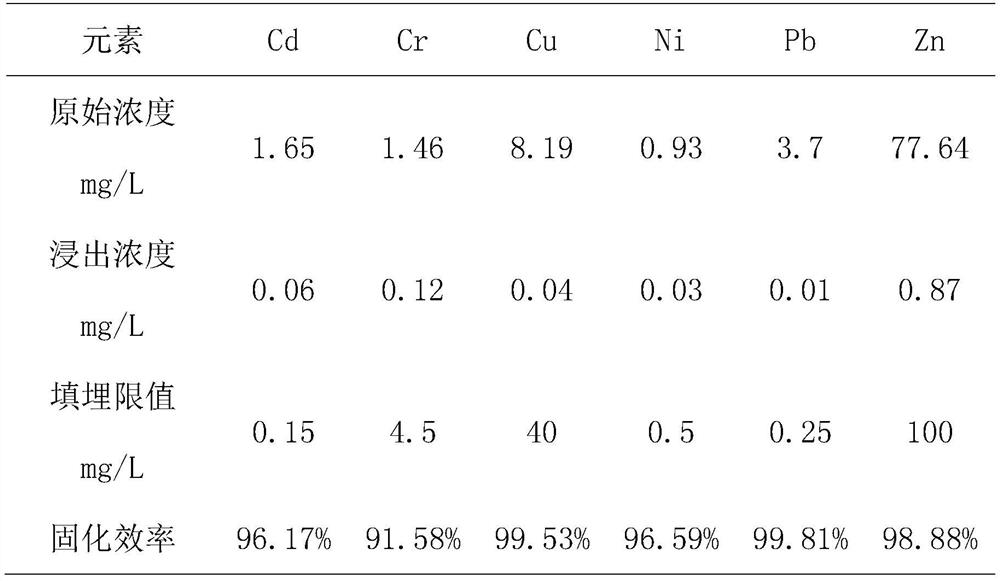

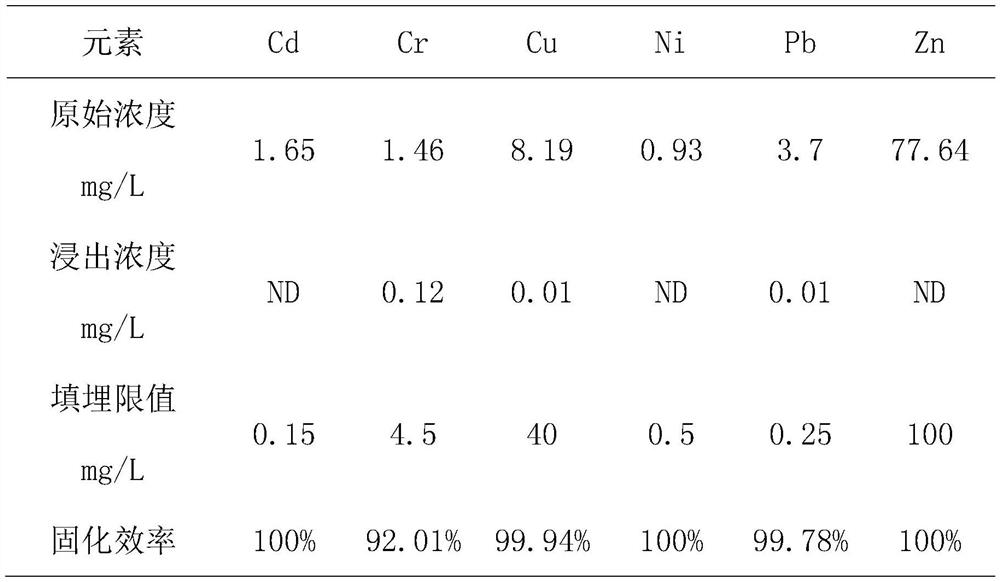

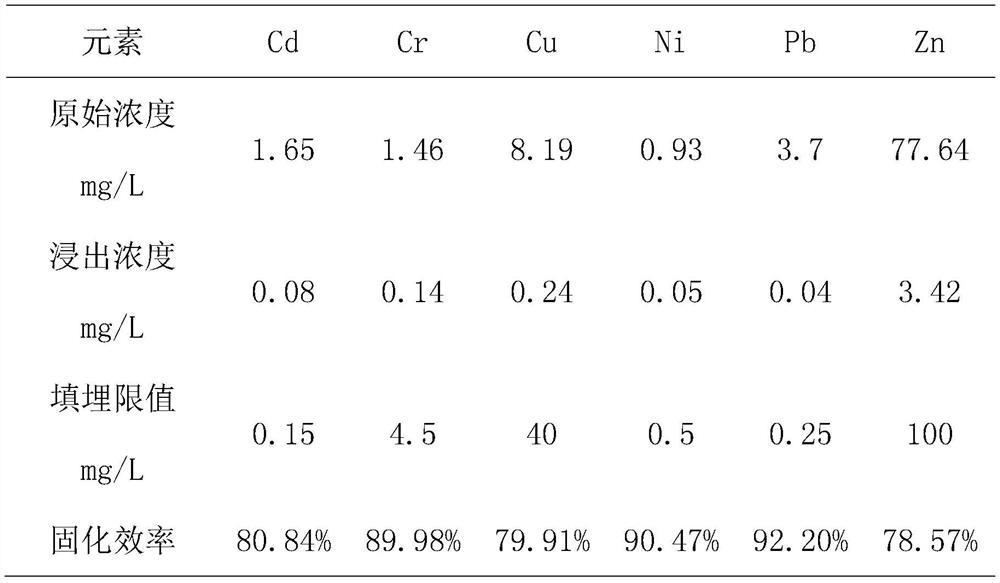

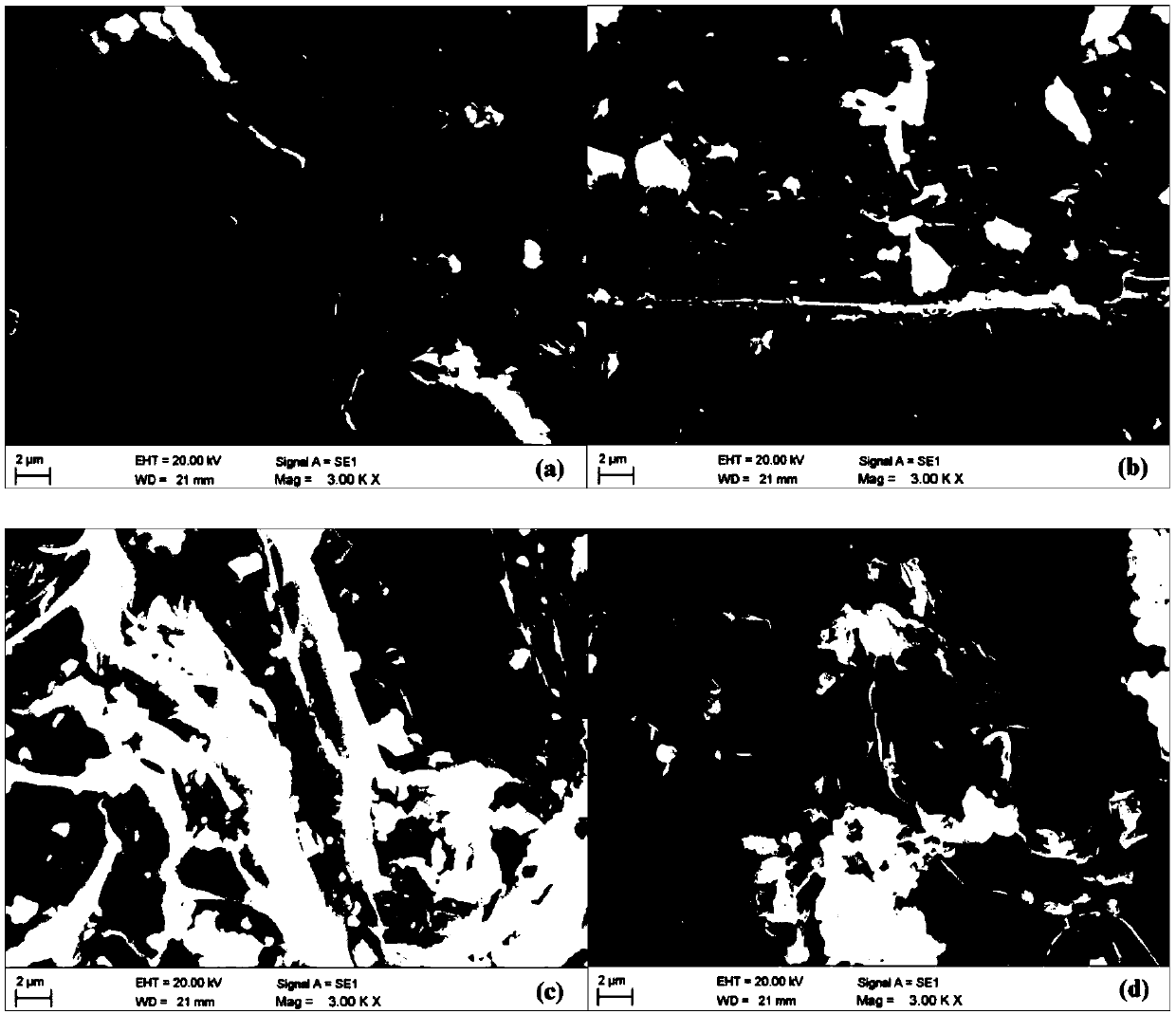

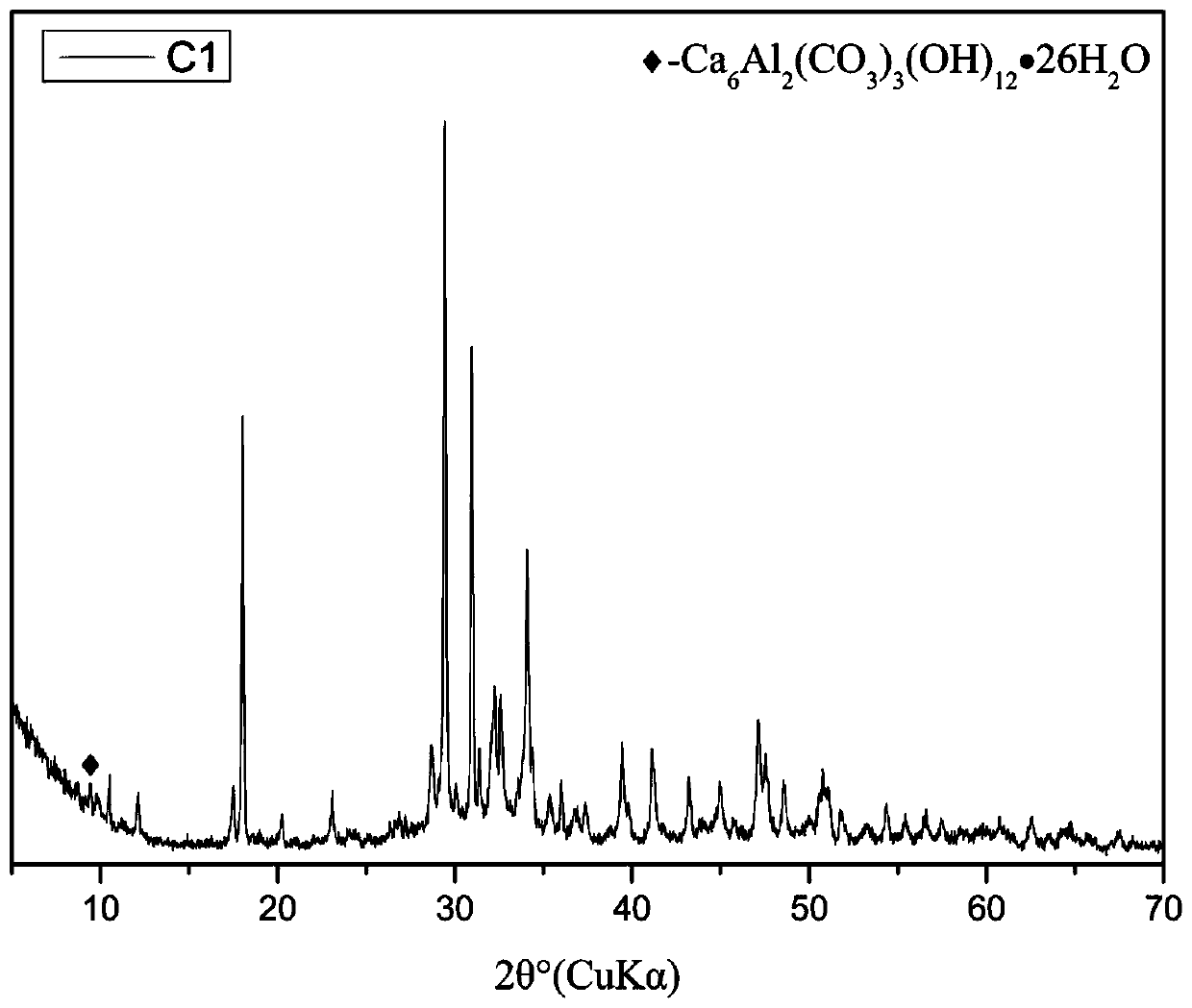

Method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide

ActiveCN113441526ASave stacking costLow raw material costSolid waste disposalCement productionCalcium silicateIon exchange

The invention discloses a method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide, and belongs to the field of household waste incineration fly ash treatment. Coal gangue and amorphous SiO2 and Al2O3 in household waste incineration fly ash are subjected to a geological polymerization reaction under the condition of an alkali activator, an inorganic polymer of a three-dimensional net structure is formed, meanwhile, calcium oxide is added, a large quantity of hydrated calcium silicate, hydrated calcium aluminosilicate and hydrated sodium aluminosilicate gel are formed in a cured body during maintenance and react with the heavy metals in manners of physical encapsulation, physical adsorption and ion exchange, so that the heavy metals in the fly ash are harmlessly treated, and it is guaranteed that the heavy metal leaching concentration of the fly ash-coal gangue-calcium oxide polymerization cured body meets the landfill safety standard. The heavy metals in the waste incineration fly ash are stabilized and produced though combination of coal gangue and calcium oxide, the curing efficiency of the heavy metals in the fly ash is further improved, the curing cost is reduced, and the environment-friendly concept of treating wastes with wastes is met.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

Calcium and magnesium additive for improving coal slagging performance and application

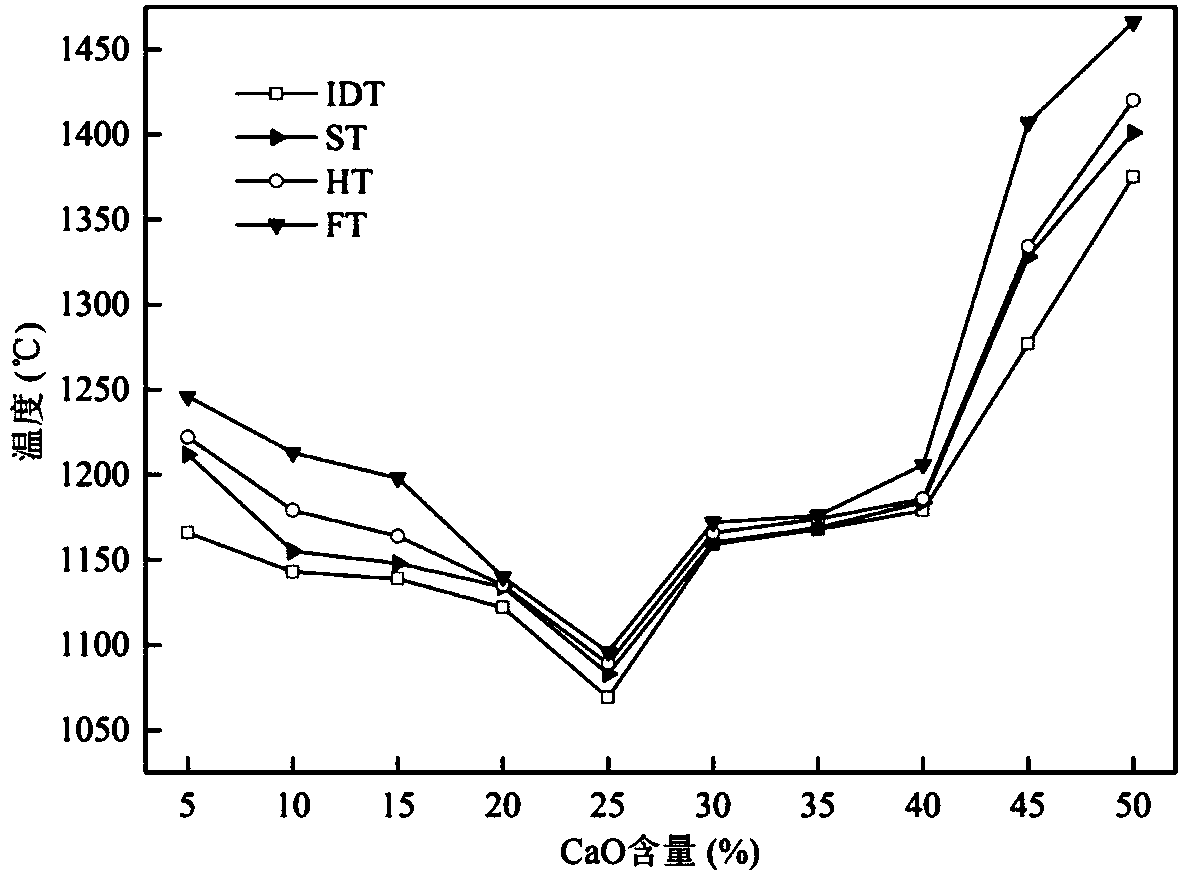

PendingCN108676601AHigh melting pointImprove slagging characteristicsSolid fuelsFuel additivesSlagToxic industrial waste

The invention discloses a calcium and magnesium additive for improving the coal slagging performance and application, and belongs to the technical field of coal chemical industry. The calcium and magnesium additive is a mixture of carbide slag and magnesium-containing waste slag; when the addition amount of the calcium and magnesium additive is within a suitable range, the ash melting point can beincreased by 100-150 DEG C, and calcium oxide in the carbide slag is produced into calcium-containing aluminosilicate having a melting point higher than that of sodium aluminosilicate through a competitive reaction so as to increase the ash melting point and solve the slagging problem; meanwhile, calcium carbide in the carbide slag reacts with water in air to produce acetylene gas, so that a combustion-supporting effect is achieved and flameout of a hearth is avoided; magnesium oxide in the magnesium-containing waste slag reduces the viscosity and avoids large slag formation in a boiler through prevention of aggregation of a polymer; the used carbide slag and the used magnesium-containing waste slag are industrial wastes, and the purchase cost thereof is much lower than that of kaolin, diatomite and bauxite, so that low-cost improvement on the slagging performance can be achieved, and thus the operating cost of a power plant is greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Composite cement

The invention discloses composite cement, which relates to a building material and is made from the following raw materials in weight proportions: red mud 10-70 parts, cement clinker 10-15 parts and sulfate 15-40 parts. The sulfate may be the mixture of more than one selected from phosphogypsum, coal ash, silica slag and sodium silicoaluminate. The weight proportions of components of the sulfate mixture are as follows: phosphogypsum 2-10 parts, coal ash 5-20 parts, silica slag 5-15 parts and sodium silicoaluminate 3-10 parts. The invention is used for cement production.

Owner:周士合

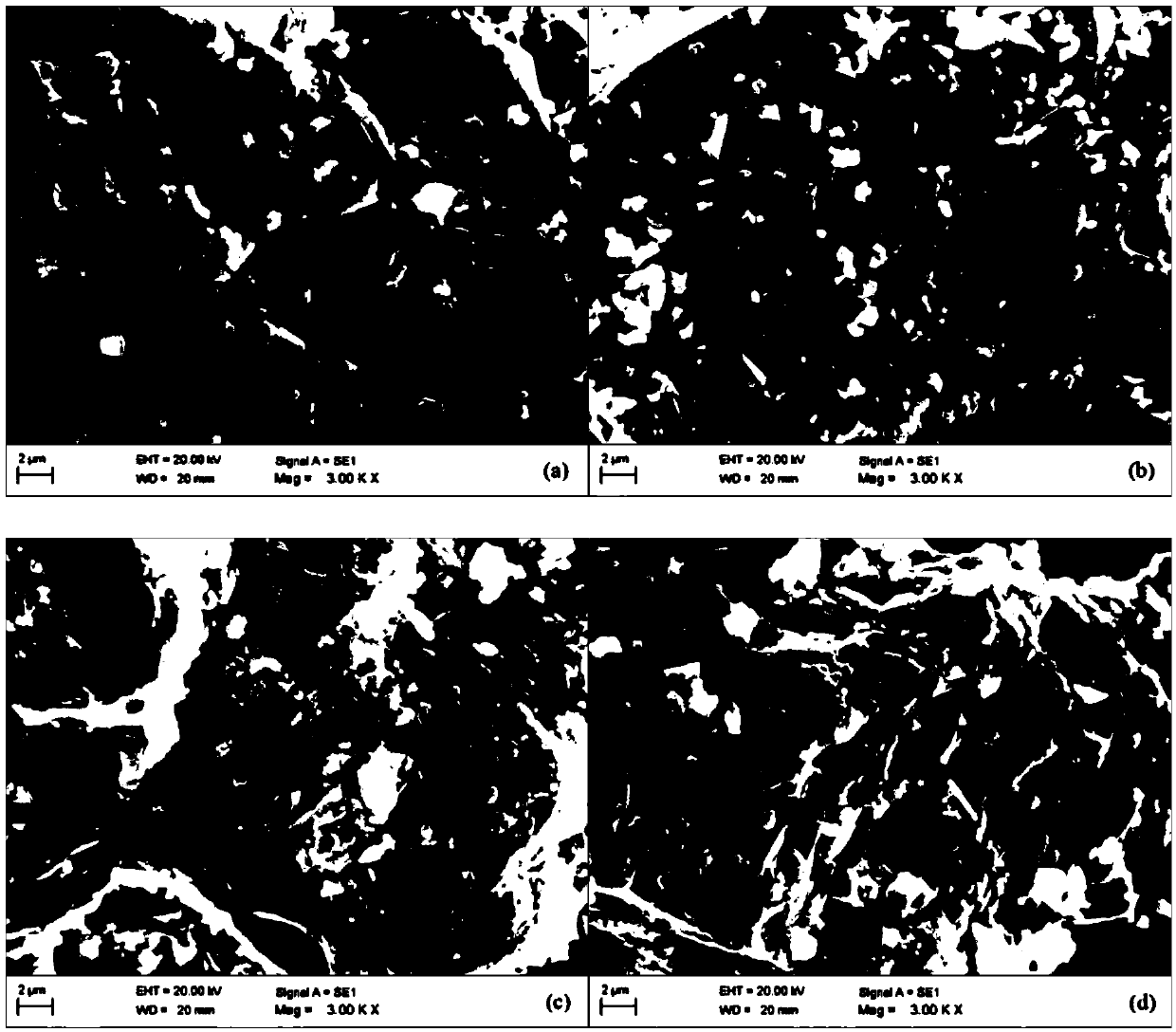

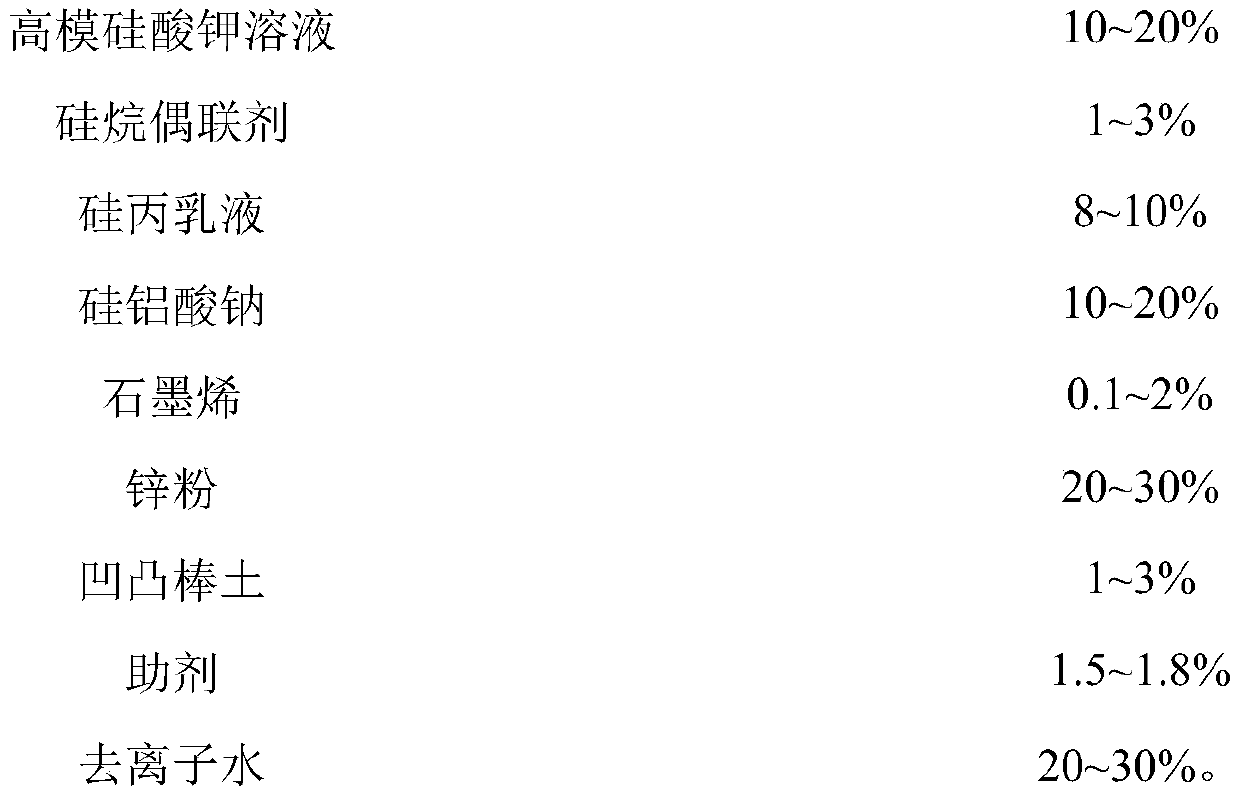

Graphene modified inorganic potassium silicate coating and preparation method thereof

InactiveCN111378305AImprove toughnessImprove adhesionAlkali metal silicate coatingsAnti-corrosive paintsSilicic acidSodium aluminate

The invention discloses a graphene modified inorganic potassium silicate coating. The coating is prepared from the following components in percentage by weight: 10 to 20 percent of a high-modulus potassium silicate solution, 1 to 3 percent of a silane coupling agent, 8 to 10 percent of a silicone acrylic emulsion, 10 to 20 percent of sodium aluminosilicate, 0.1 to 2 percent of graphene, 15 to 20 percent of zinc powder, 1 to 3 percent of attapulgite, 1.5 to 1.8 percent of aid and 20 to 30 percent of deionized water. The invention further discloses a corresponding preparation method. The preparation method comprises the following steps: preparing the high-modulus potassium silicate solution, the silicone acrylic emulsion, a graphene dispersion solution and the like. The coating prepared fromthe graphene-modified inorganic potassium silicate coating has good toughness, adhesion and hardness, the overall corrosion resistance of the coating is improved, metal surface erosion is effectivelyprevented, and the graphene-modified inorganic potassium silicate coating has extremely wide application in preparation of metal anticorrosive coatings.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

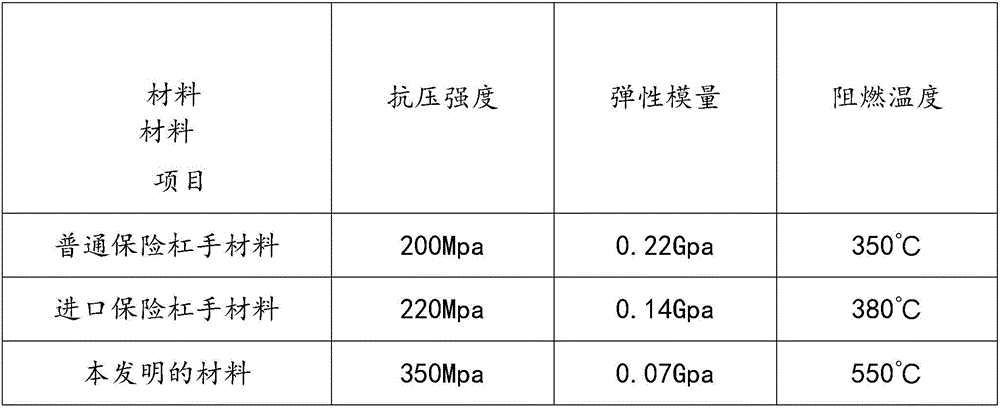

Mold material for injection molding of automobile bumper and preparation method of mold material

InactiveCN106633692AStable structureHas a cushioning effectPolyethylene terephthalate glycolInjection molding machine

The invention discloses a mold material for injection molding of an automobile bumper. The mold material is prepared from the following materials in parts by weight: 25 to 30 parts of polycarbonate, 35 to 40 parts of polyethylene terephthalate, 16 to 20 parts of polyurethane, 7 to 11 parts of polyacrylonitrile-based carbon fiber, 5 to 10 parts of nano aluminum oxide, 14 to 18 parts of silicon carbide, 3 to 8 parts of calcium stearate, 6 to 9 parts of pentaerythritol, 2 to 5 parts of trioctyl ester, 7 to 11 parts of molybdenum dioxide, 16 to 18 parts of montmorillonoid, 12 to 14 parts of sodium aluminosilicate, 3 to 8 parts of silicon rubber, 14 to 18 parts of polyvinyl acetate emulsion, 12 to 15 parts of titanium dioxide, 20 to 22 parts of a titanate coupling agent, 12 to 15 parts of an ethylene-vinyl acetate copolymer, 6 to 10 parts of glyceride and 4 to 7 parts of dibasic lead stearate. The mold material for the injection molding of the automobile bumper, disclosed by the invention, has a buffering effect, a firm structure and a good flame-retarding effect.

Owner:芜湖天鸿汽车零部件有限公司

ABS engineering plastic

The invention discloses an ABS engineering plastic. The ABS engineering plastic is composed of 93-96wt% of an ABS resin, 0.2-0.8wt% of a stabilizer, 0.2-0.6wt% of an ultraviolet ray absorber, 0.3-0.8wt% of a dispersant, 0.15-0.5wt% of sodium aluminosilicate, 0.4-0.9wt% of an adhesive, and the balance color master batch. The engineering plastic has the advantages of difficult color fading, good ageing resistance, realization of the color fading of below 0.2DEG after continuous direct light under 500w strong light, long service life reaching above 3 years, and substantial reduction of the offensive odors of plastics.

Owner:SHANGHAI BAILI PROPERTY MANAGEMENT

Active admixture, preparation method and application for active admixture, and concrete

The invention discloses an active admixture, a preparation method and an application for the active admixture, and concrete, belonging to the technical field of building materials. The active admixture comprises the following components in parts by weight: 10-30 parts of Bayer process red mud, 5-15 parts of quicklime powder and 80-120 parts of limestone powder, wherein the water content of the Bayer process red mud is 15%-35%, and the mass content of aluminum oxide in the Bayer process red mud is 20%-40%. According to the invention, the Bayer process red mud and the limestone powder are used as main raw materials; the problem of difficult dehydration for the Bayer process red mud is solved by utilizing the principle of a violent reaction of quick lime and water; hydrated sodium aluminosilicate with high content and relatively good water solubility in the Bayer process red mud is utilized to react with the limestone powder to produce hydrated aluminosilicate; thus, the hydration activity of the active admixture can be improved; and the active admixture can completely replace fly ash to reduce the production cost of the building materials like the concrete.

Owner:XUZHOU ZHONGLIAN CONCRETE CO LTD

Evenly dispersed aluminum section production lubricant

The present invention discloses an evenly dispersed aluminum section production lubricant, and the evenly dispersed aluminum section production lubricant is obtained from the following parts by weight of raw materials: 2-4 parts of molybdenum disulfide, 1-2 parts of sodium molybdate, 0.5-0.9 part of alkyl phenol polyoxyethylene ether, 3-7 parts of rapeseed oil, 1-2 parts of choline, 3.5-5.5 parts of industrial white oil, 20-30 parts of modified graphite powder, 4-6 parts of colloidal graphite, 1-2 parts of aluminum dihydrogen phosphate, 8-16 parts of paraffin oil and 1-2 parts of sodium aluminosilicate. The evenly dispersed aluminum section production lubricant has good homogeneity and cohesion, can be repeatedly removable without damaging of a lubricating film, can work at high and low temperature environment, and ensures that lubricating parts in working conditions are lubricant, zero-resistant, anti-corrosion, scuffing, and the like, and the evenly dispersed aluminum section production lubricant can be applied to aluminum section extrusion machine lubrication, and can also be used on lubrication of parts of other fields.

Owner:DANGTU WEISIGONGCHUANG IND PROD DESIGN CO LTD

Wear-resistant, heat insulation and waterproof building coating and preparation method thereof

The invention discloses a wear-resistant, heat insulation and waterproof building coating. The wear-resistant, heat insulation and waterproof building coating is characterized by being prepared from the following raw materials in parts by weight: 33-36 parts of water-soluble alkyd resin, 33-36 parts of an organic silicone resin emulsion, 1-2 parts of 1, 2-benzisothiazolin-3-one, 0.4-0.8 part of hydroxyethyl cellulose, 1-2 parts of sodium aluminosilicate, 1-3 parts of tert-butyl methacrylate, 0.5-1.0 part of fumed silica powder, 2-3 parts of silicon carbide powder, 1-3 parts of clay, 1-2 parts of dibutyl phthalate, 0.3-0.4 part of an organic silicon defoamer, 0.3-0.6 part of polyoxyethylene lauryl ether, 2-3 parts of diatomite, 2-4 parts of propanediol butyl ether, 7-9 parts of heat insulation slurry and 13-18 parts of deionized water. The coating disclosed by the invention is fast in drying, high in hardness of a paint film after curing, smooth, good in color and luster, very high in adhesion and good in wear resistance; the deionized water is adopted as a thinner, thereby having low cost and low toxicity and being green and environment-friendly; the added heat insulation slurry has an excellent heat insulation effect; and furthermore, the coating has excellent corrosion resistance, aging resistance and water resistance, is convenient to construct and is harmless to human bodies.

Owner:ANHUI LENCAQI BUILDING MATERIAL

ABS engineering plastic with anion release function and preparation method of ABS engineering plastic

InactiveCN102875951AGood for healthIn line with green environmental protectionAntioxidantEngineering plastic

The invention relates to an acrylonitrile-butadiene-styrene ABS engineering plastic with an anion release function, which is characterized by comprising the following components in percentage by weight: 60-90% of ABS resin, 5-30% of modifier, 0.1-0.5% of antioxidant, 0.1-0.5% of lubricating agent, 10-20% of anion powder, 0.15-0.5% of sodium aluminosilicate and 0.15-1.0% of castor oil zinc salt. The invention further relates to a preparation method of the ABS engineering plastic with the anion release function. The original properties of the ABS engineering plastic can be maintained, the smell of common plastics is reduced, and released anions are beneficial to human bodies and environments.

Owner:薛申生

High-adsorbability composite material for sewage treatment as well as preparation method thereof

InactiveCN107930604AImprove adsorption capacityHigh selectivityOther chemical processesWater contaminantsSophocarpidinePolyacrylamide Hydrogel

The invention discloses a high-adsorbability composite material for sewage treatment. The high-adsorbability composite material comprises the following raw materials in parts by weight: 18 to 30 partsof polyacrylamide hydrogel, 6 to 12 parts of hirudin, 5 to 17 parts of glucomannan glue, 6 to 17 parts of sodium aluminosilicate, 4 to 10 parts of Curdlan powder, 2 to 5 parts of calcium phosphate, 1to 3 parts of L-lysine, 2 to 7 parts of lotus root powder, 1 to 5 parts of sophocarpidine, 3 to 6 parts of polymethylacrylic acid, 3 to 5 parts of modified waste water purifier activated carbon filter element powder and 60 to 90 parts of deionized water. The high-adsorbability composite material for sewage treatment has the advantages of high adsorption capacity, high selectivity and high efficiency, can capture various metal ions in a water body, has high removal rate on various metal ions in the heavy metal water and has treatment efficiency; furthermore, the treatment method is simple, andthe high-adsorbability composite material only needs to be thrown into the water during use.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Cleaning agent for residual oil storage tank

InactiveCN105754734AEasy to cleanProduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPetrochemicalCleansing Agents

The invention discloses a cleaning agent for a residual oil storage tank and relates to the technical field of the petrochemical industry. The cleaning agent is prepared from raw materials in parts by weight as follows: 20-25 parts of palm oil, 10-15 parts of attapulgite, 10-15 parts of charcoal powder, 8-12 parts of polymerization ferric chloride, 6-11 parts of activated aluminum oxide, 5-8 parts of polyoxyethylene rosin ester, 5-8 parts of cetearyl alcohol, 4-6 parts of wollastonite powder, 4-6 parts of polyoxyethylene lauryl ether, 3-4 parts of an anti-rust auxiliary agent, 2-3 parts of asbestos wool, 2-3 parts of bamboo vinegar, 1-2 parts of sodium aluminosilicate, 40-50 parts of acetone and 150-200 parts of ethanol. The cleaning agent has a great cleaning effect on the residual oil storage tank, can completely remove residual oil and dirt attached to the inner wall of the storage tank, cannot corrode the storage tank and has an excellent anti-rust effect.

Owner:ANHUI HAIDE PETROCHEM

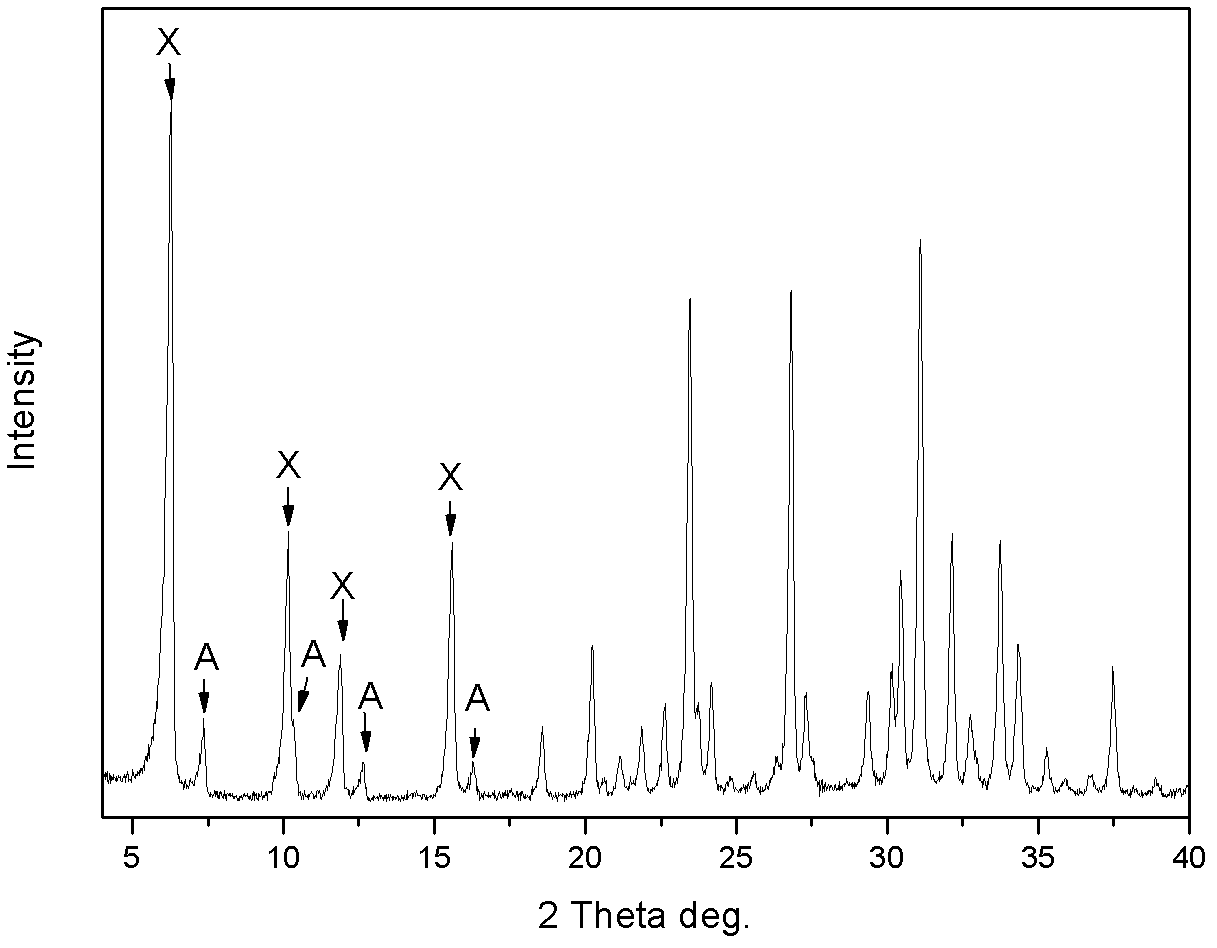

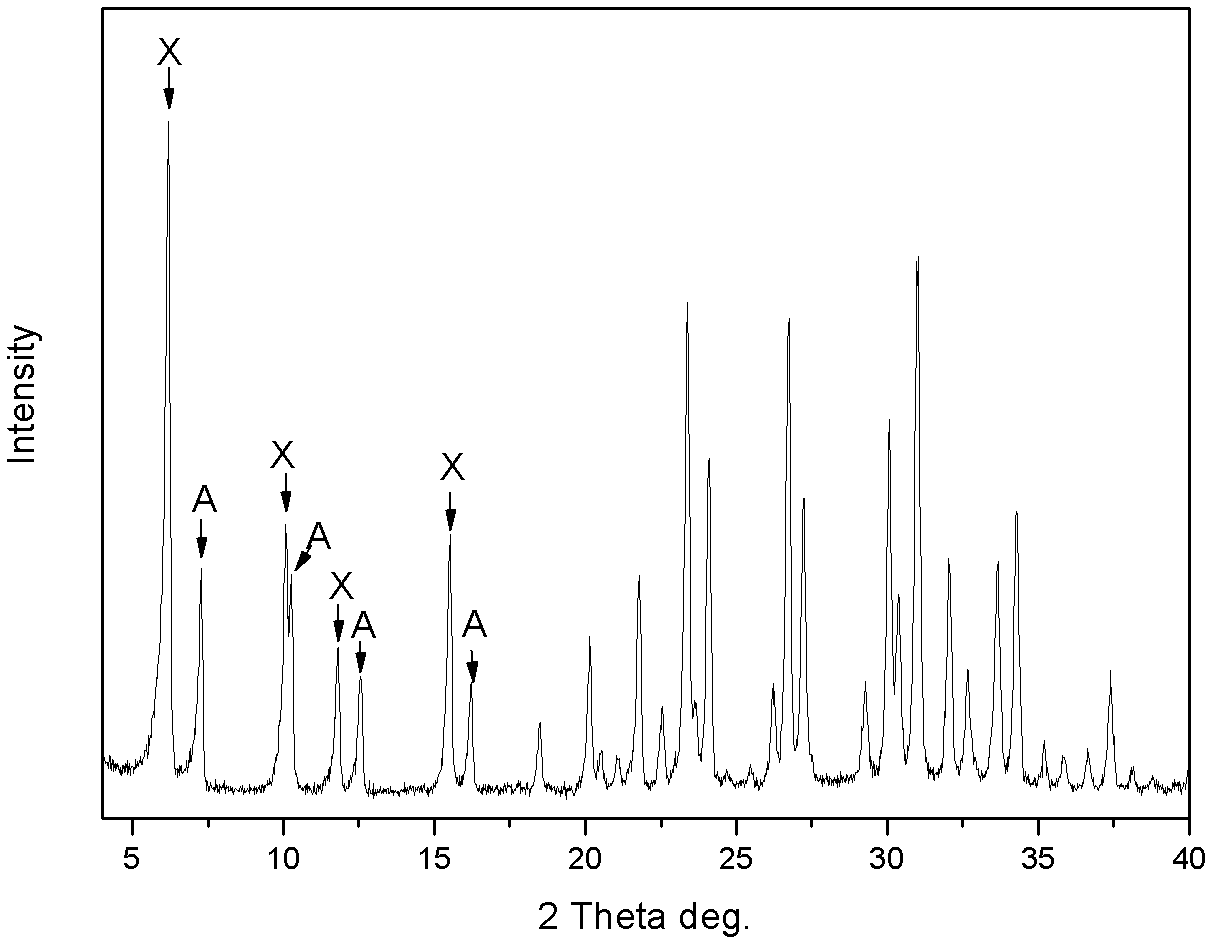

Method for preparing low-silicon Na-A/X cocrystallization zeolite in pure sodium aluminosilicate system

InactiveCN102557067AFulfil requirementsFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveIon exchange

The invention belongs to the technical field of zeolite molecular sieve synthesis and particularly relates to a method for preparing a low-silicon Na-A / X cocrystallization zeolite molecular sieve in a pure sodium aluminosilicate system. The method comprises the following two steps: preparing an activated silica source and synthesizing low-silicon Na-A / X cocrystallization zeolite. The method is characterized in that a potassium raw material is not used, and Na-A / X cocrystallization zeolite with low silicon and aluminum ratio is synthesized in the pure sodium aluminosilicate system. As the potassium raw material is not used, not only is the production cost is reduced, but also the bad effect of potassium ions left in the zeolite on the ion exchange performance is avoided. The silicon and aluminum ratio (SiO2 / Al2O3) of the Na-A / X cocrystallization zeolite synthesized by the method is 2.0-2.2 and is lower than that of the reported A / X cocrystallization zeolite. With the adoption of the method, the proportion of zeolite A to zeolite X in the Na-A / X cocrystallization zeolite can be adjusted and changed through changing the synthesis conditions to adapt to the softening demands of hard water with different Ca2+ and Mg2+ contents in different areas.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com