Patents

Literature

69 results about "Calcium aluminosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium aluminosilicate, an aluminosilicate compound with calcium cations, most typically has formula CaAl₂Si₂O₈. In minerals, as a feldspar, it can be found as anorthite, an end-member of the plagioclase series.

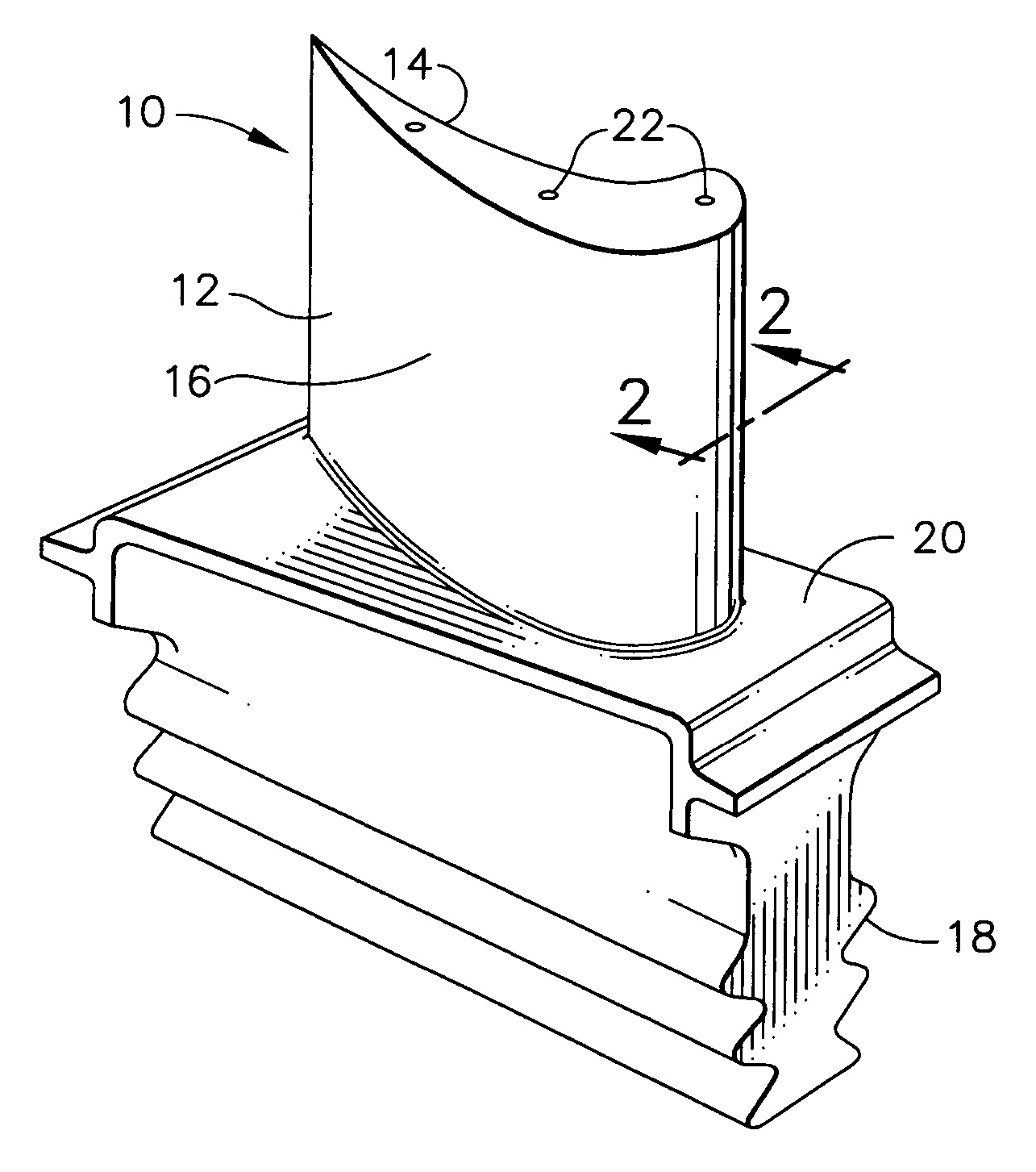

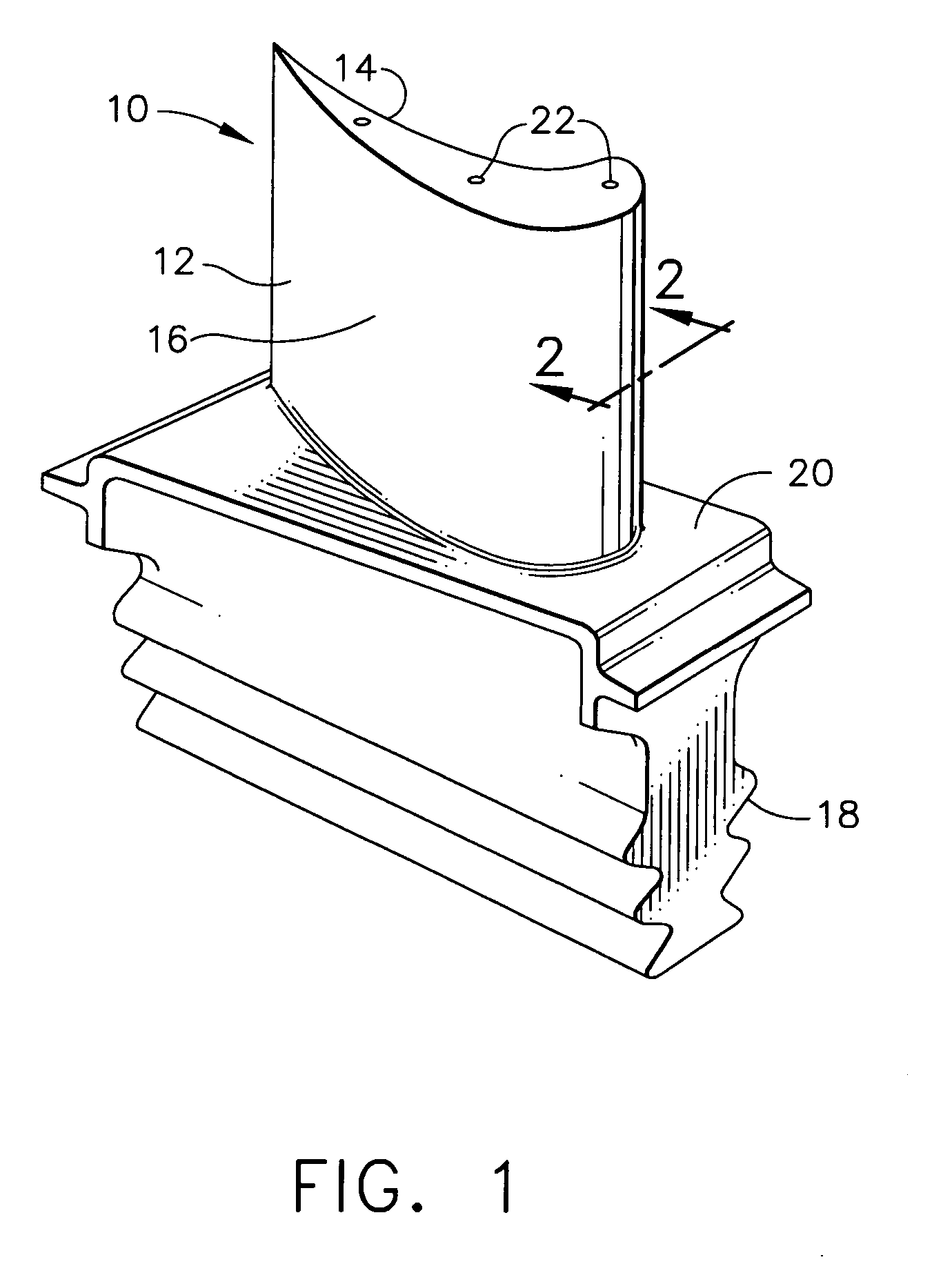

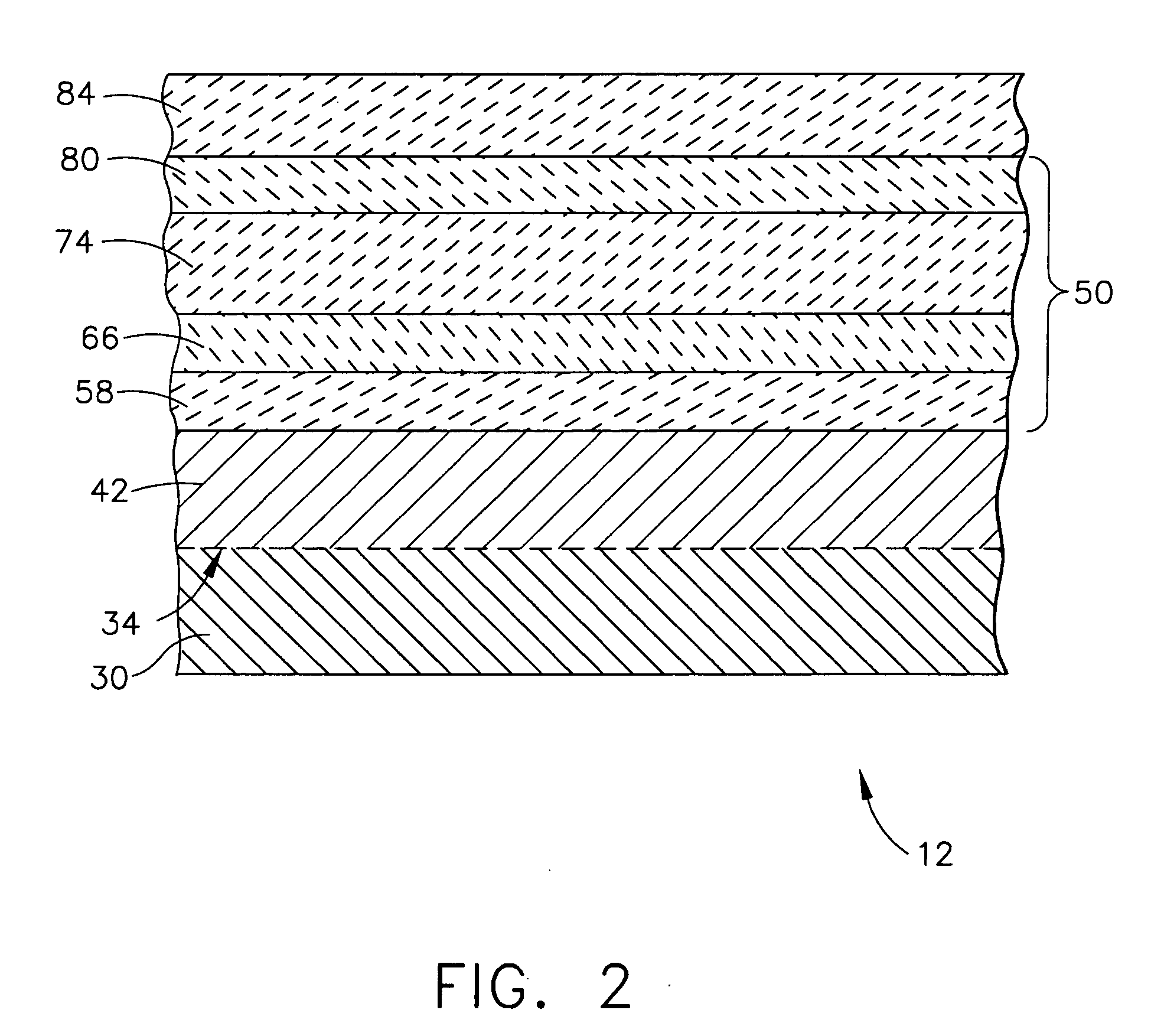

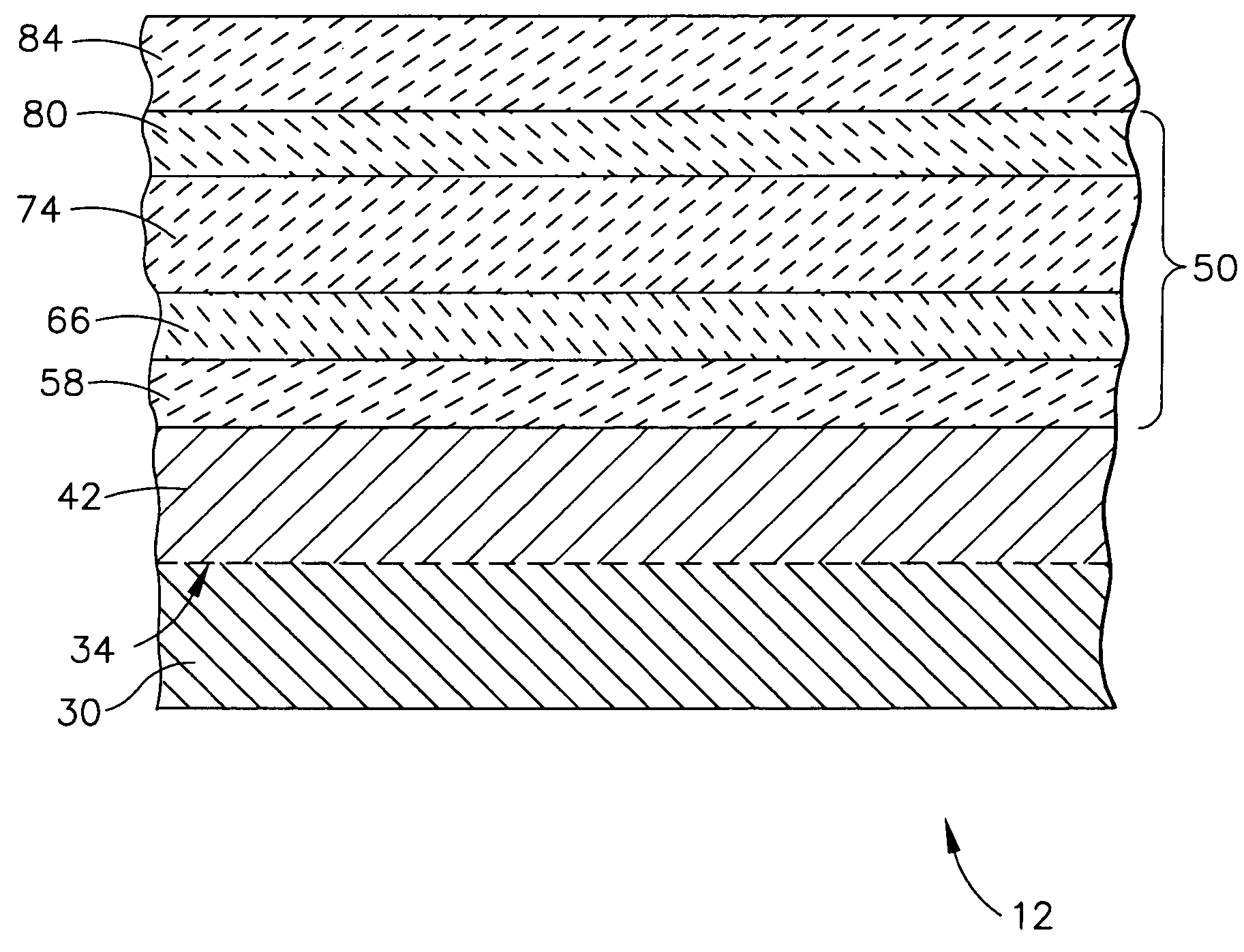

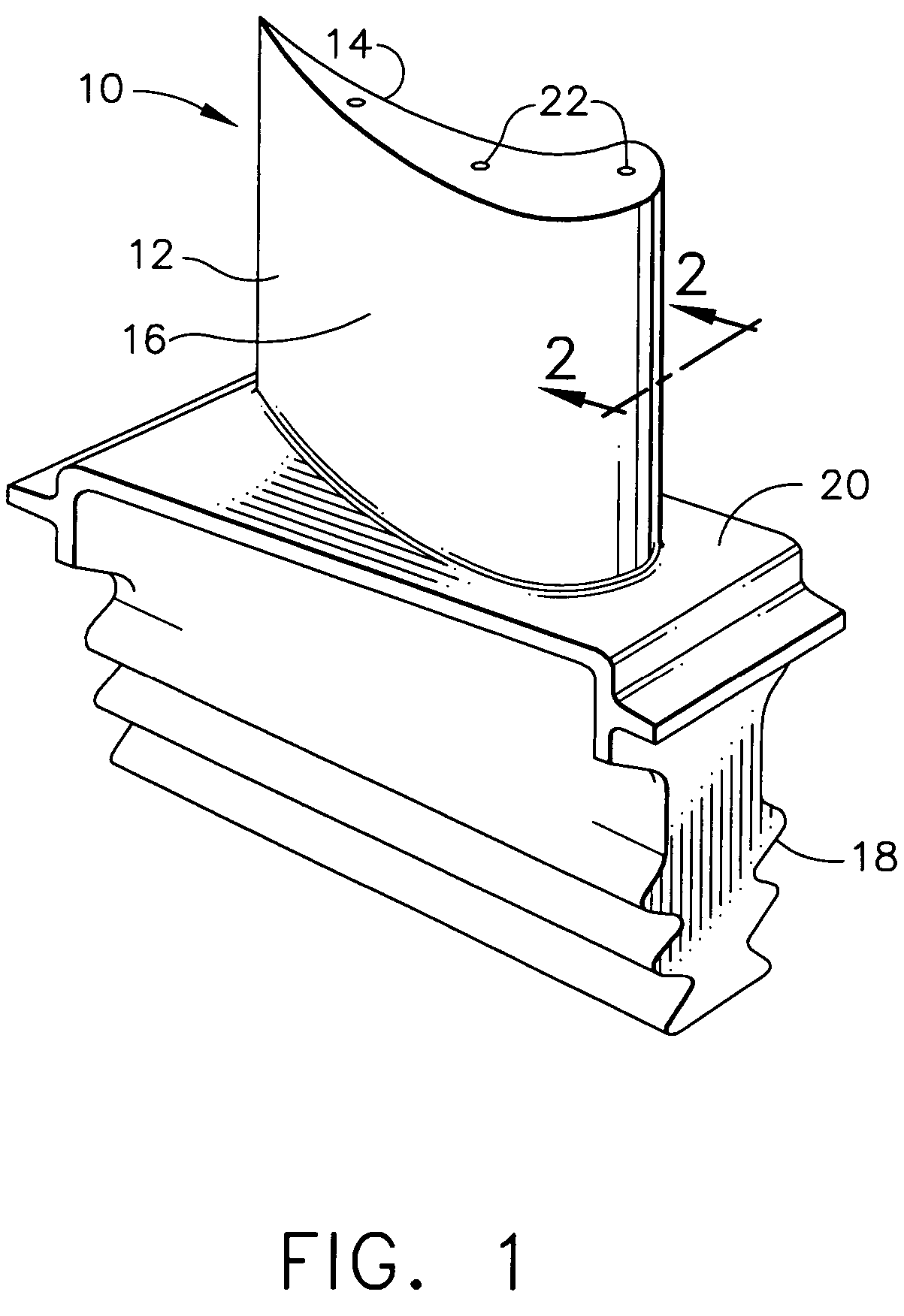

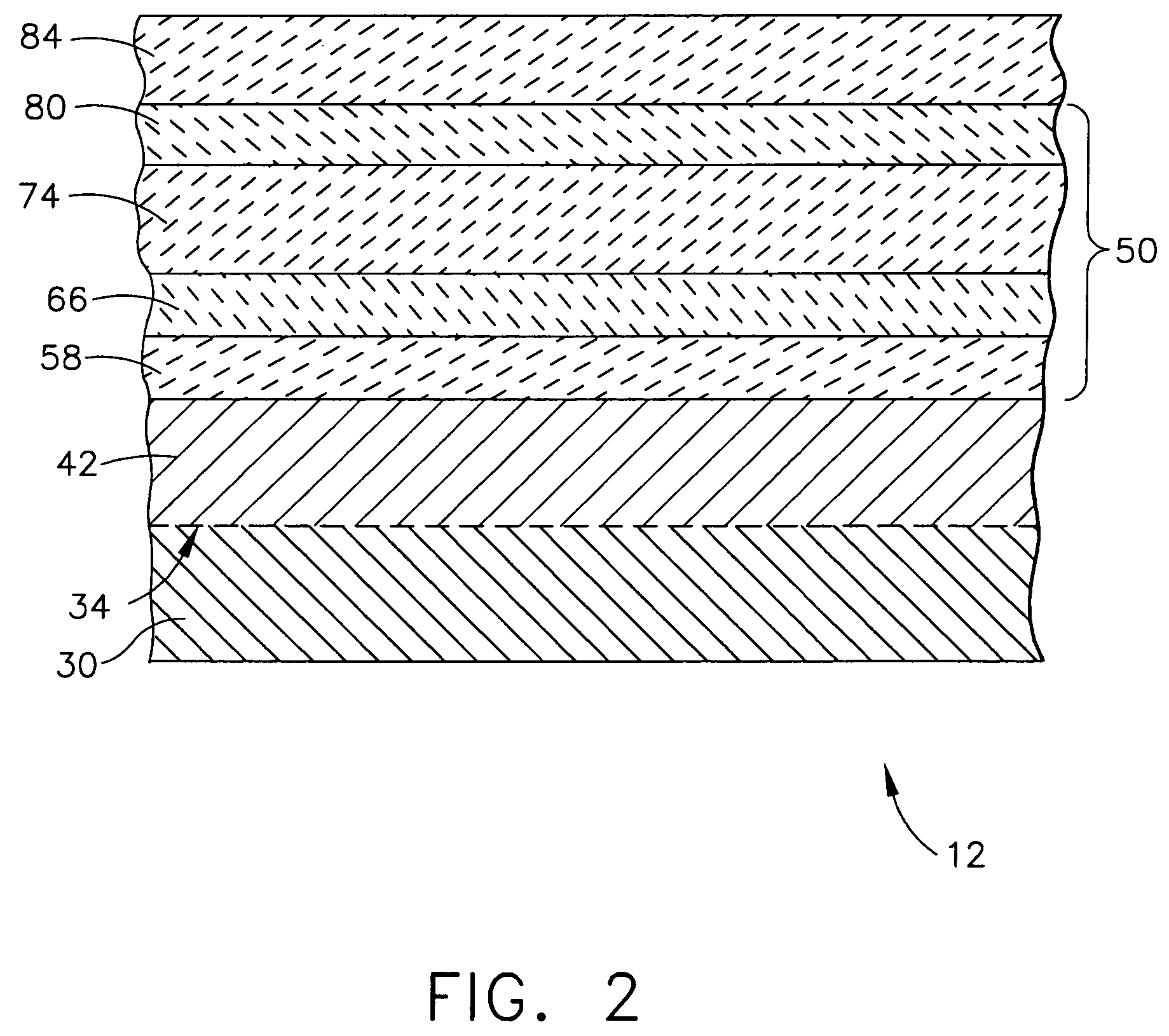

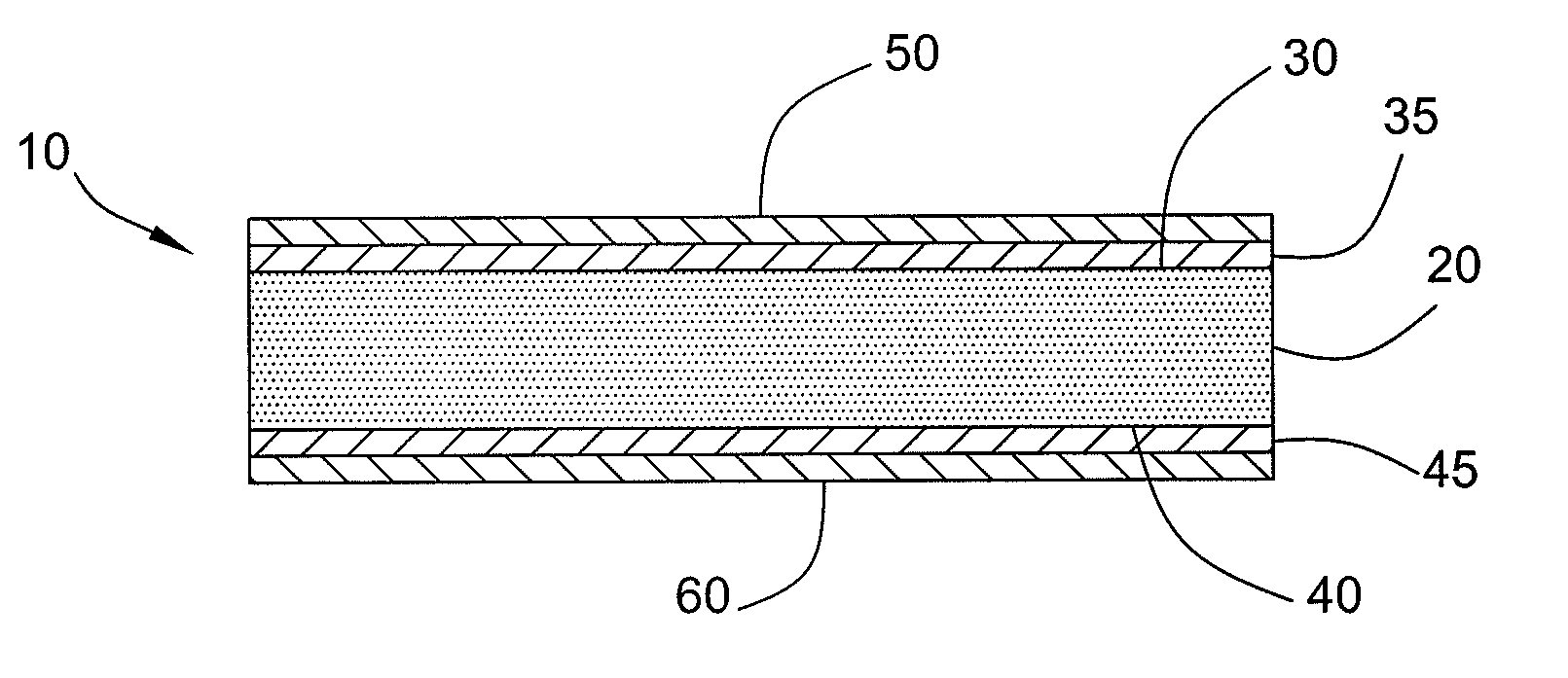

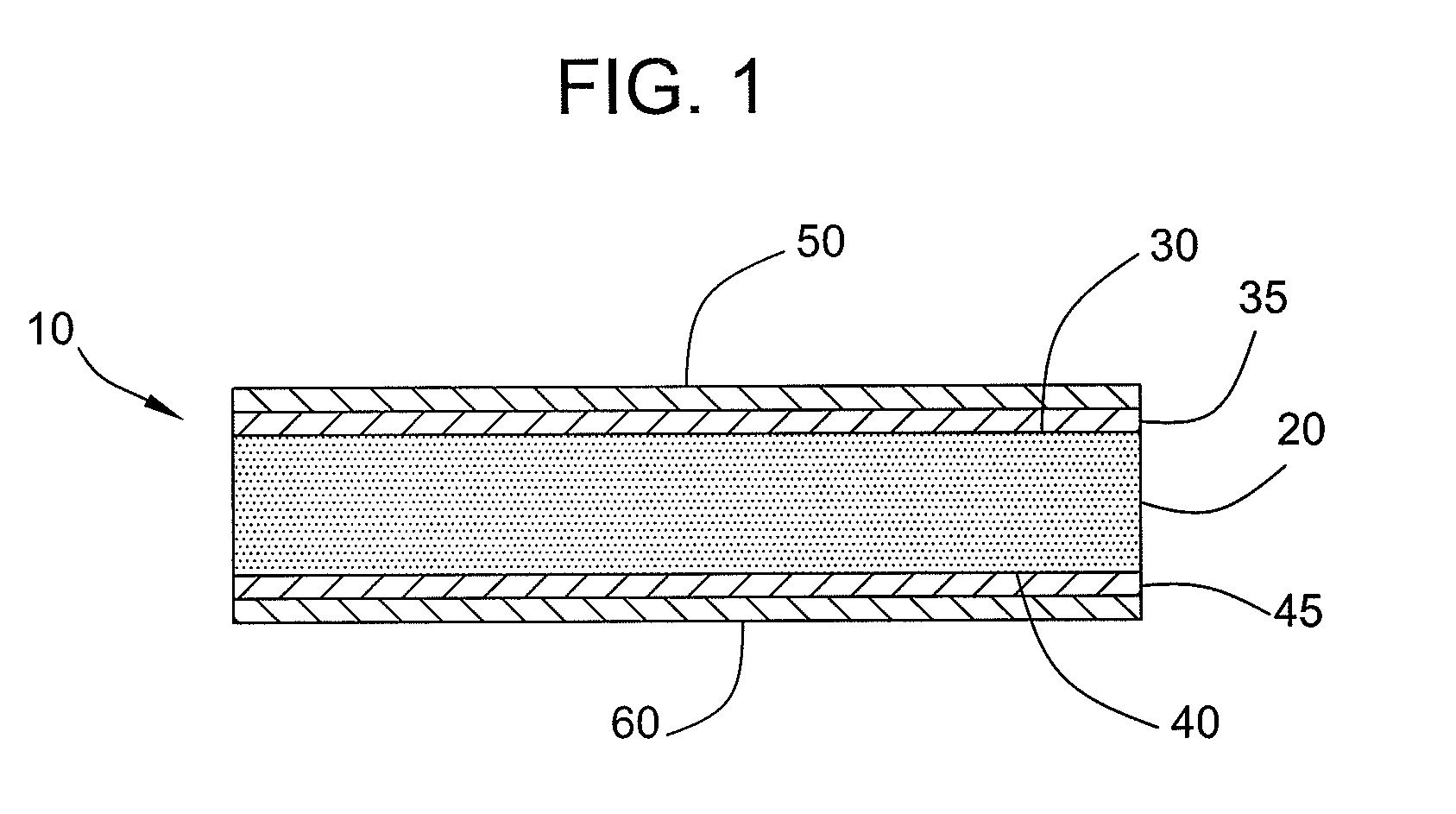

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS20060280953A1Improve adhesionHigh melting pointLiquid surface applicatorsMolten spray coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS7442444B2Improve adhesionHigh melting pointMolten spray coatingVacuum evaporation coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

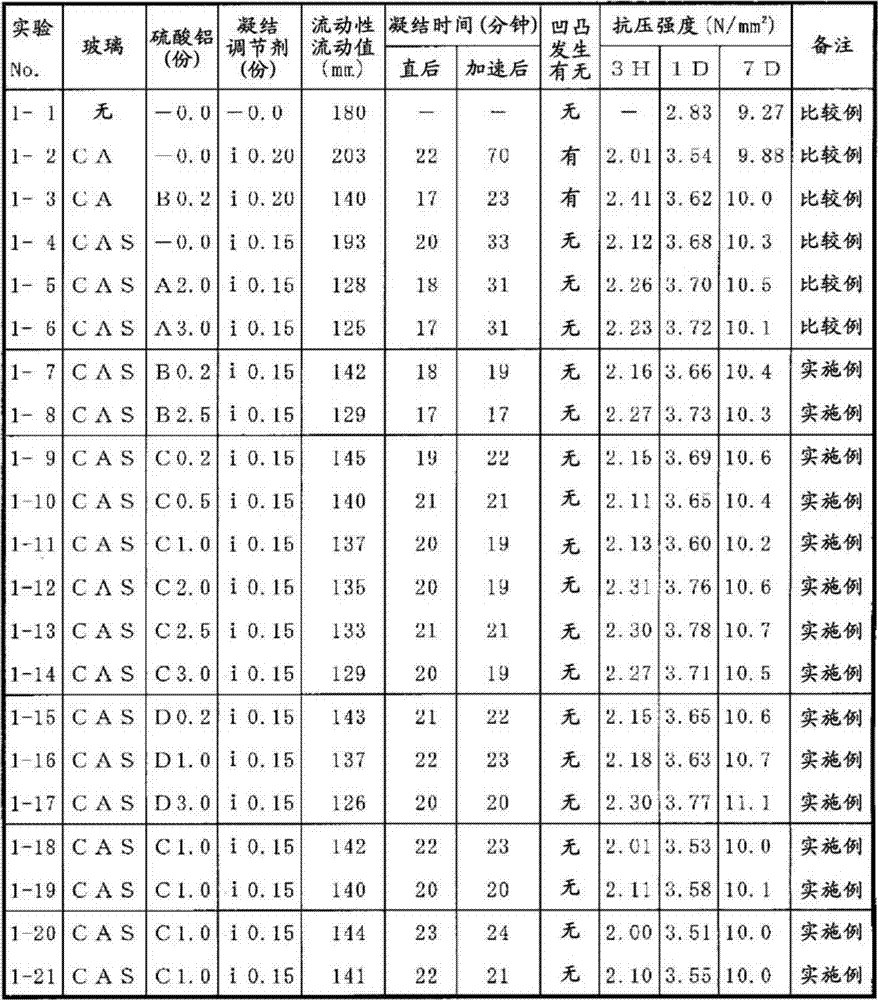

Spraying material and spray technique employing the same

To provide a spraying material having an excellent quick-setting property and excellent adherability, a small alkali amount and excellent initial strength development, and a spraying method using it.The spraying material comprises a liquid quick-setting admixture containing an aluminum source, a sulfur source and a fluorine source, one or more quick-setting aids selected from the group consisting of calcium aluminate, calcium sulfoaluminate, calcium aluminosilicate, an alkali metal-containing substance, calcium hydroxide and aluminum hydroxide, and a cement concrete, and the method is to spray this spraying material.

Owner:DENKA CO LTD

Spraying material and spray technique employing the same

ActiveUS20070054059A1Excellent initial strength developmentSmall amountLiquid surface applicatorsCoatingsAluminium hydroxideAlkali metal

To provide a spraying material having an excellent quick-setting property and excellent adherability, a small alkali amount and excellent initial strength development, and a spraying method using it. The spraying material comprises a liquid quick-setting admixture containing an aluminum source, a sulfur source and a fluorine source, one or more quick-setting aids selected from the group consisting of calcium aluminate, calcium sulfoaluminate, calcium aluminosilicate, an alkali metal-containing substance, calcium hydroxide and aluminum hydroxide, and a cement concrete, and the method is to spray this spraying material.

Owner:DENKA CO LTD

Calcium aluminosilicate glasses for use as information recording medium substrates

InactiveUS20080130171A1Low densityHigh modulusDifferent record carrier formsRecord information storageCalcium silicateAlkali metal oxide

A glass substrate, and a information recording medium comprised of a glass substrate, comprising an a alkali-containing calcium aluminosilicate glass comprising SiO2, Al2O3, CaO, and alkali oxides (Li2O+Na2O+K2O) as essential components, specifically comprising the following components, expressed in terms of mole percent (mol %): 55-70% SiO2, 4-15% Al2O3, 0-8% B2O3, 8-20% CaO, 3-12% Na2O+K2O+Li2O, 0-5% MgO, up to 5% BaO and 13-35% MgO+CaO+BaO.

Owner:CORNING INC

Method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag

InactiveCN101973709AIncreased crystallization tendencyImprove mechanical propertiesSlagSilicon oxide

The invention provides a method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag. The method comprises the following steps: 1) classifying, grinding and screening natrium silica calcium glass waste slag to prepare glass powder; 2) adding silicon dioxide, calcium oxide, aluminum oxide, boron oxide, TiO2 / P2O5 composite nucleating agent and rare-earth oxide to ensure that component requirement of the calcium aluminosilicate (CAS) microcrystal glass can be fulfilled; 3) filling the uniformly mixed glass materials into a high-alumina crucible, and pouring into a die to press and mold; and 4) putting the pressed glass plate in a muffle furnace for heat treatment, cooling to room temperature with the furnace after heat treatment to obtain the CAS nanometer microcrystal glass. The method has the advantages that: (1) the mechanical performance of the microcrystal glass is greatly improved; and (2) the additive dosage is adjusted according to the component composition of the glass residues to ensure that the glass achieves the regulated formula proportion. The method is suitable for the conventional various civil natrium silica calcium glass waste slag.

Owner:NANCHANG HANGKONG UNIVERSITY

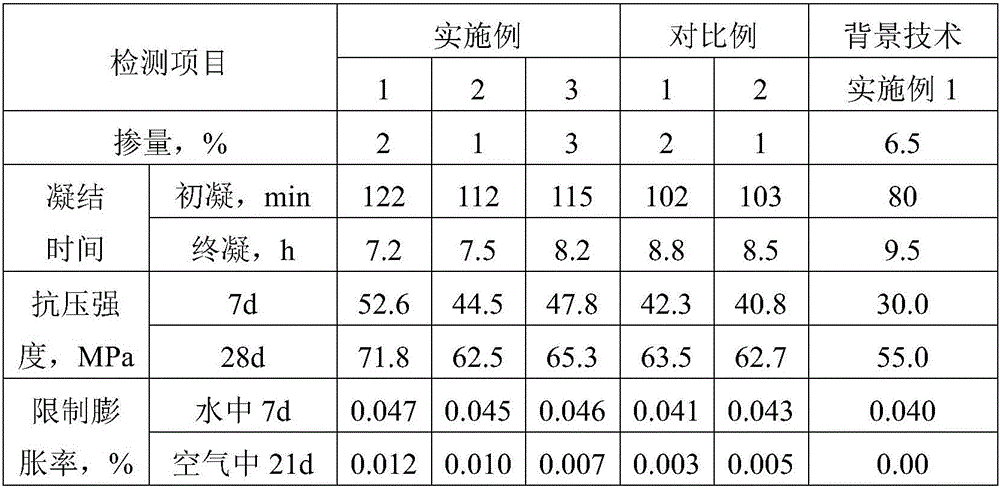

Compound concrete expanding agent

The invention discloses a compound concrete expanding agent. The compound concrete expanding agent is prepared by using the following components in parts by weight: 15 to 20 parts of calcium aluminosilicate, 25 to 30 parts of calcium sulphoaluminate, 20 to 30 parts of sulfur fixation waste residue, 10 to 20 parts of red mud, 10 to 15 parts of lithium slag, 4 to 8 parts of modified calcium oxide, 3 to 6 parts of magnesium oxide, 5 to 8 parts of methyl sodium silicate, 0.1 to 0.3 part of azodicarbonamide, 0.4 to 0.7 part of sodium tripolyphosphate, 2 to 4 parts of lauryl sodium sulfate, 0.3 to 0.6 part of ethylene-acrylic acid copolymer, 0.7 to 0.9 part of polycarboxylate superplasticizer and 0.5 to 0.7 part of nano calcium carbonate. The compound concrete expanding agent has the advantages of high strength, good compensation capability, calcium oxide reaction regulation and the like, and is a concrete additive which has a great development prospect.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

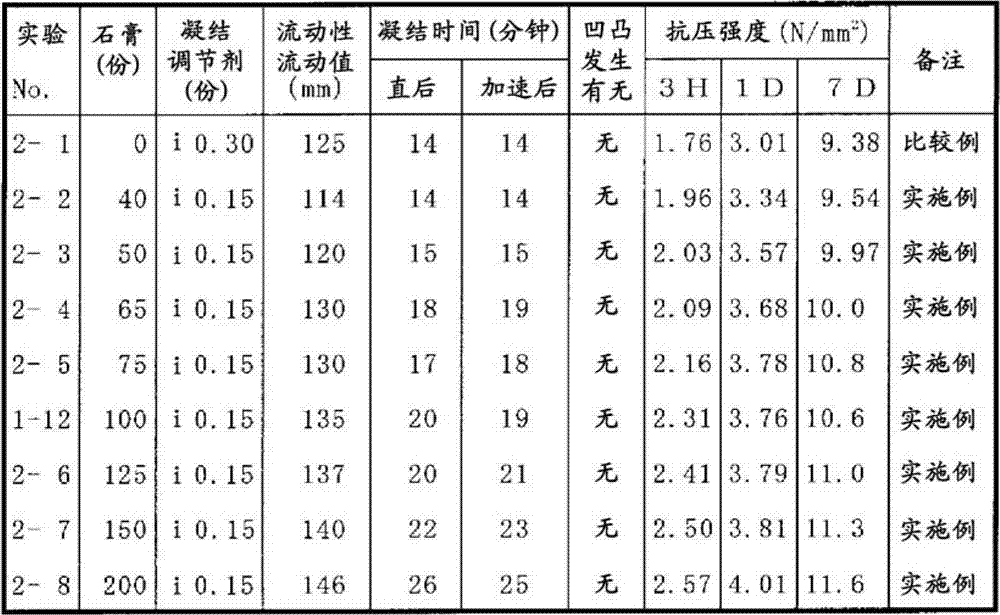

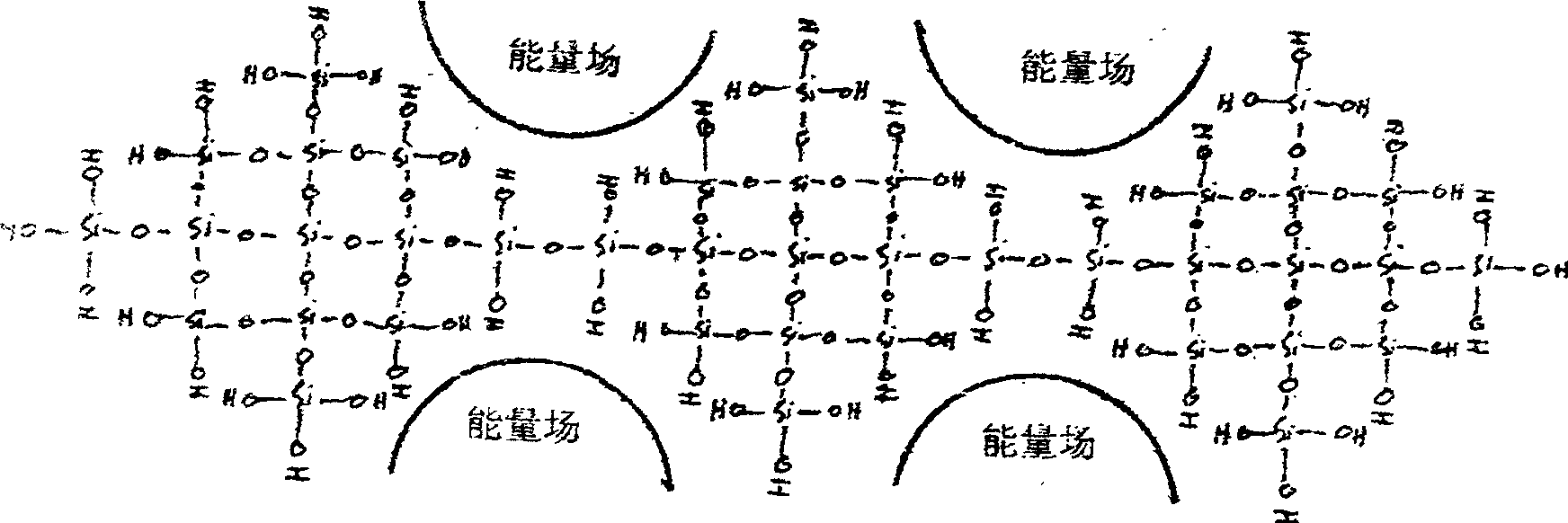

Cement mortar composition for grout and grout mortar obtained from the same

A cement mortar composition for grouts which retains satisfactory flowability, is free from bleeding and material separation, has an anti-cracking ability due to high strength, high durability, and reduction in dry shrinkage, and is for use in applications such as foundations for machines; and a grout mortar obtained from the composition. The cement mortar composition for grouts comprises a binder, a setting retarder, a water-reducing agent, and a fine aggregate. It is characterized in that the binder comprises a quick hardening material comprising a cement, calcium aluminosilicate glass, and plaster and a fine pozzolan powder, the water-reducing agent comprises at least a polycarboxylate-type water-reducing agent, and the fine aggregate is a heavy aggregate having a density of 3.0 g / cm<3> or higher. The grout mortar is obtained by kneading the cement mortar composition together with water.

Owner:DENKA CO LTD

Formaldehyde free coatings for panels

The invention, provides a curable, formaldehyde free coating composition comprising a composition comprising a polyacid copolymer crosslinked with a hydroxyl group-containing compound and calcium aluminosilicate powder, panels coated with the coating composition, and a method of coating a panel with the coating composition.

Owner:USG INTERIORS INC

Formaldehyde free coatings for panels

The invention, provides a curable, formaldehyde free coating composition comprising a composition comprising a polyacid copolymer crosslinked with a hydroxyl group-containing compound and calcium aluminosilicate powder, panels coated with the coating composition, and a method of coating a panel with the coating composition.

Owner:USG INTERIORS INC

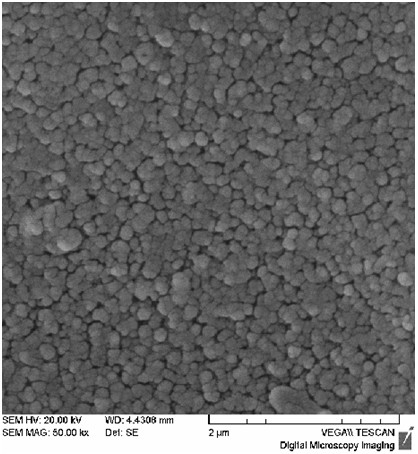

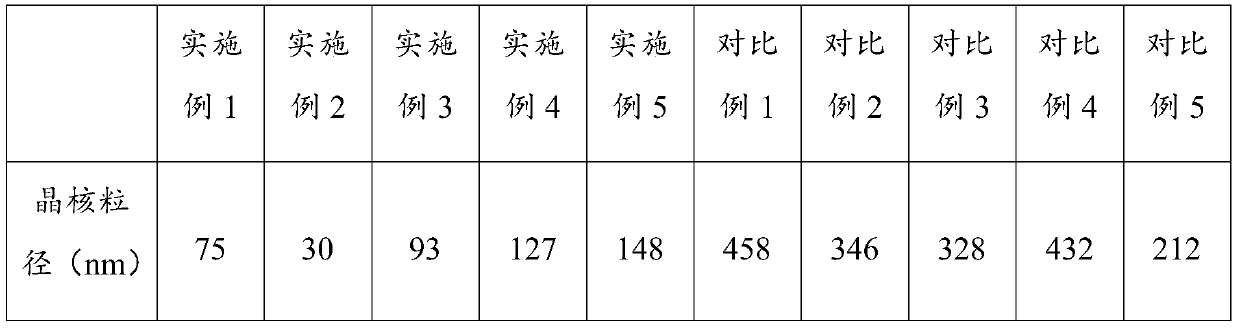

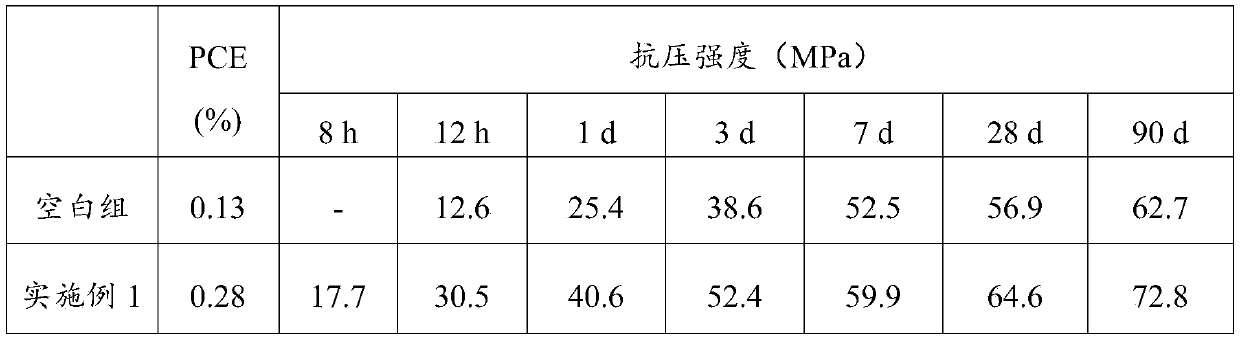

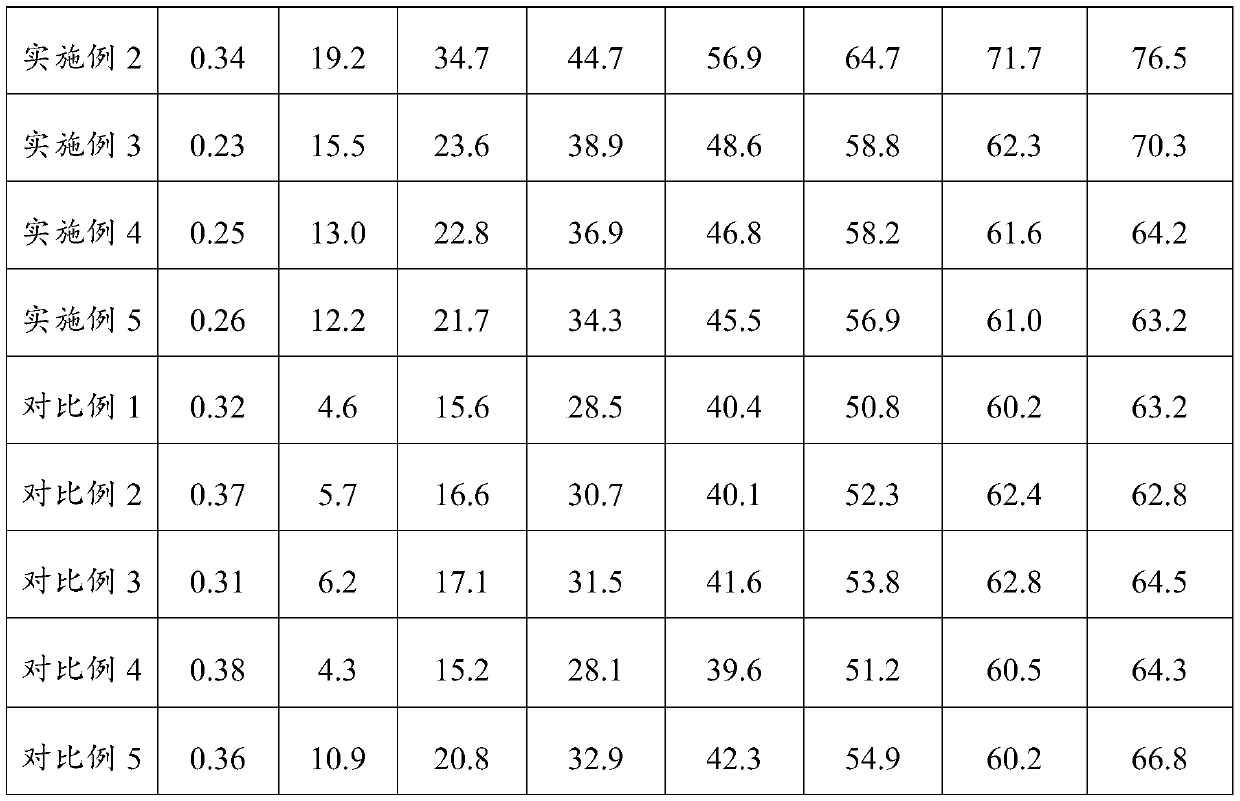

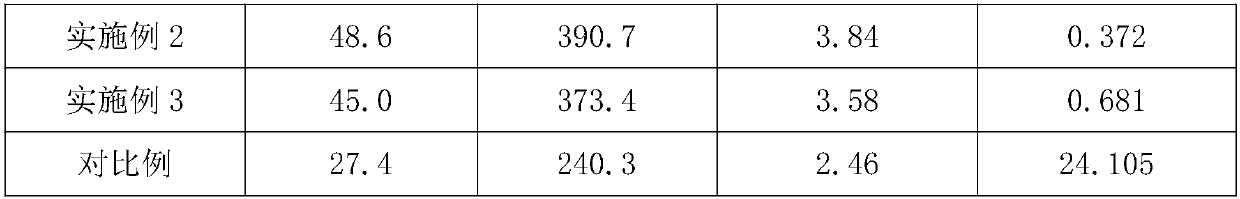

Hydrated calcium aluminosilicate nano crystalline nucleus early strength agent and preparation method thereof

ActiveCN111470794AImproves early hydrationImprove mechanical propertiesAluminium silicatesCalcium silicateCarboxylic acid

The invention discloses a hydrated calcium aluminosilicate nano crystalline nucleus early strength agent and a preparation method thereof. The preparation method comprises the following steps: dropwise adding an aqueous solution of a calcium source, an aqueous solution of a silicon source and an aqueous solution of an aluminum source into a polycarboxylate water reducer dispersion liquid, adjusting the pH value to 10.0-13.5, and carrying out reactions under stirring to obtain the hydrated calcium aluminosilicate nano crystalline nucleus early strength agent. The hydrated calcium aluminosilicate nano crystalline nucleus early strength agent is small in particle size and good in dispersion stability, can greatly improve early hydration and mechanical behaviors of a cement-based material, andhas a good application prospect. The preparation method of the hydrated calcium aluminosilicate nano crystalline nucleus early strength agent comprises the following steps: mixing an aqueous solutionof a calcium source, an aqueous solution of a silicon source and an aqueous solution of an aluminum source with a polycarboxylate water reducer according to a specific molar ratio under specific temperature and pH conditions and carrying out reactions under stirring. The preparation process is simple, subsequent processes such as washing, drying and ultrasonic dispersion are not needed, and the preparation method is suitable for large-scale production.

Owner:WUHAN UNIV OF TECH

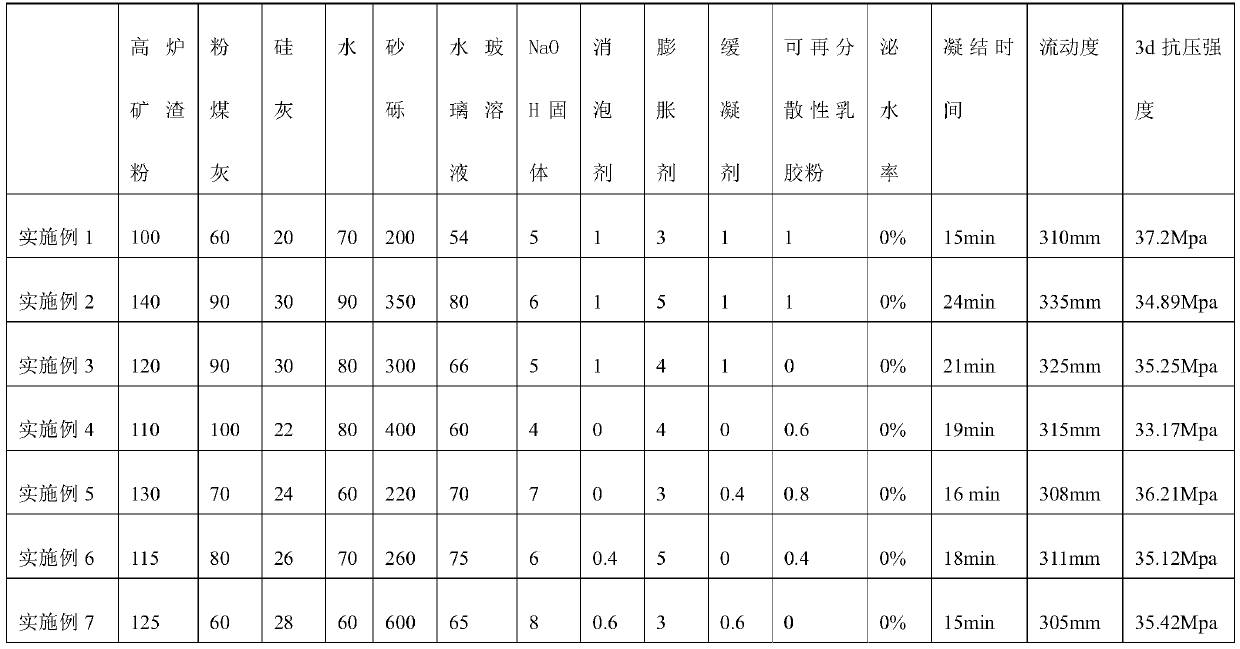

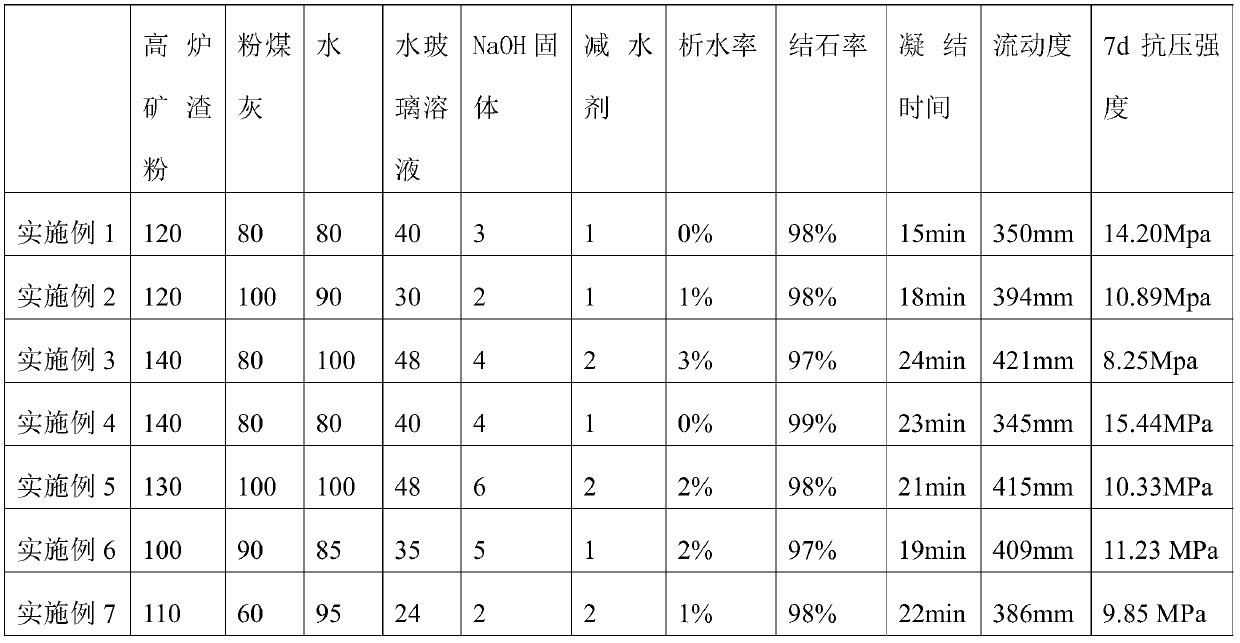

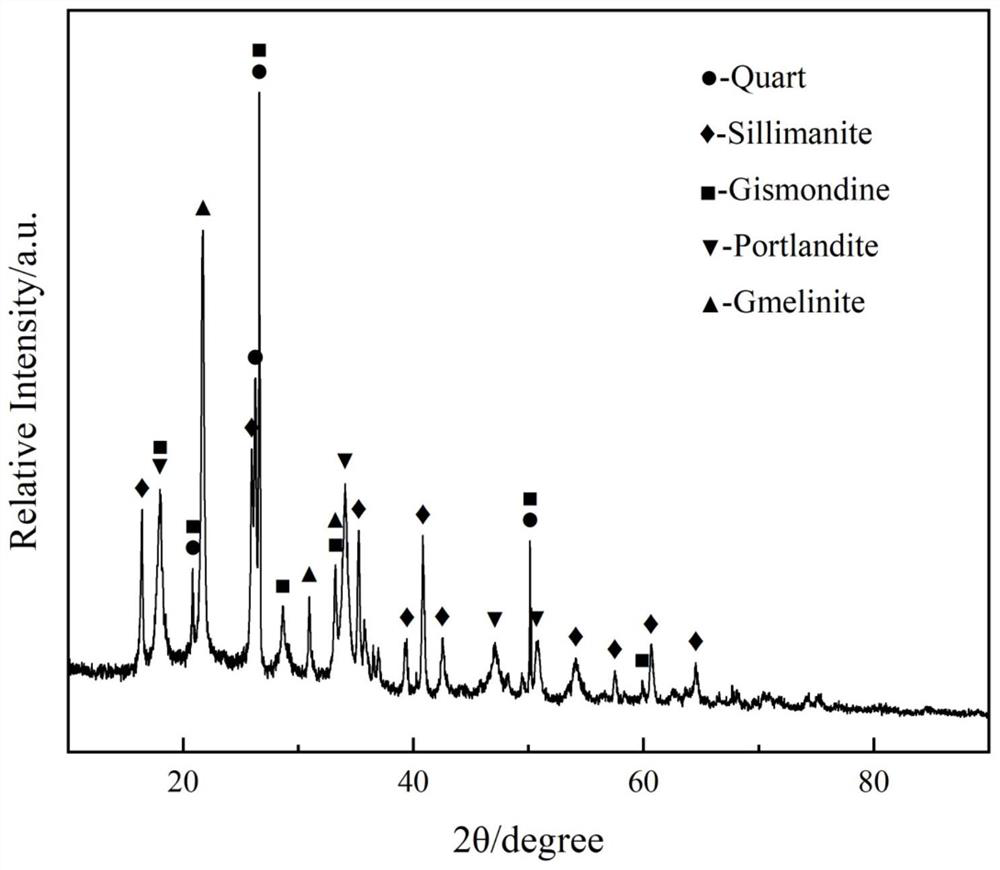

Uncemented geopolymer grouting material and preparation method thereof

he invention discloses an uncemented geopolymer grouting material and a preparation method thereof. Gravel is used as a supporting material to improve the overall strength of the material, blast furnace slag powder, fly ash and silica fume are added, and the silica ash mainly composed of SiO2 can optimize the pore structure and reduce the porosity of the system; a water glass solution and NaOH are used to dissolve and rejoin active silicon, aluminum and calcium substances in the fly ash and slag powder in order to form hydration products which are C-S-H hydrated calcium silicate and C-S-A-Hhydrated calcium aluminosilicate, and a solution composed of the water glass solution and NaOH is used to firstly react the fly ash with alumina in the slag powder in order to ensure the increase of the reinforcing material after the calcium oxide removal, so the utilization rates of the blast furnace slag powder and the fly ash are effectively improved, and the working performances of the grouting material are improved. The grouting material prepared in the invention has the advantages of good fluidity, low bleeding ratio, high concretion rate, effectiveness in utilization of the industrial wastes which are slag powder and fly ash, and realization of the purpose of changing industrial wastes into valuables.

Owner:CHANGAN UNIV

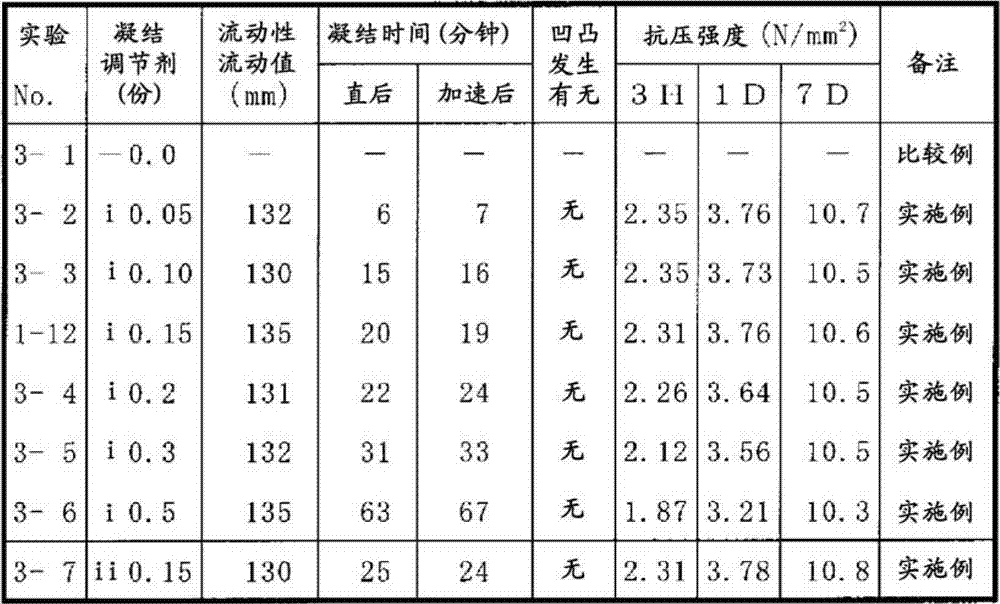

Oxygen storage capacity substance and method of oxygen storage capacity in three-way catalyst for purifying automotive exhaust gas

InactiveUS20090148369A1Low priceLarge capacityOxygen/ozone/oxide/hydroxideNitrogen compoundsSilicon dioxideTetrahedron

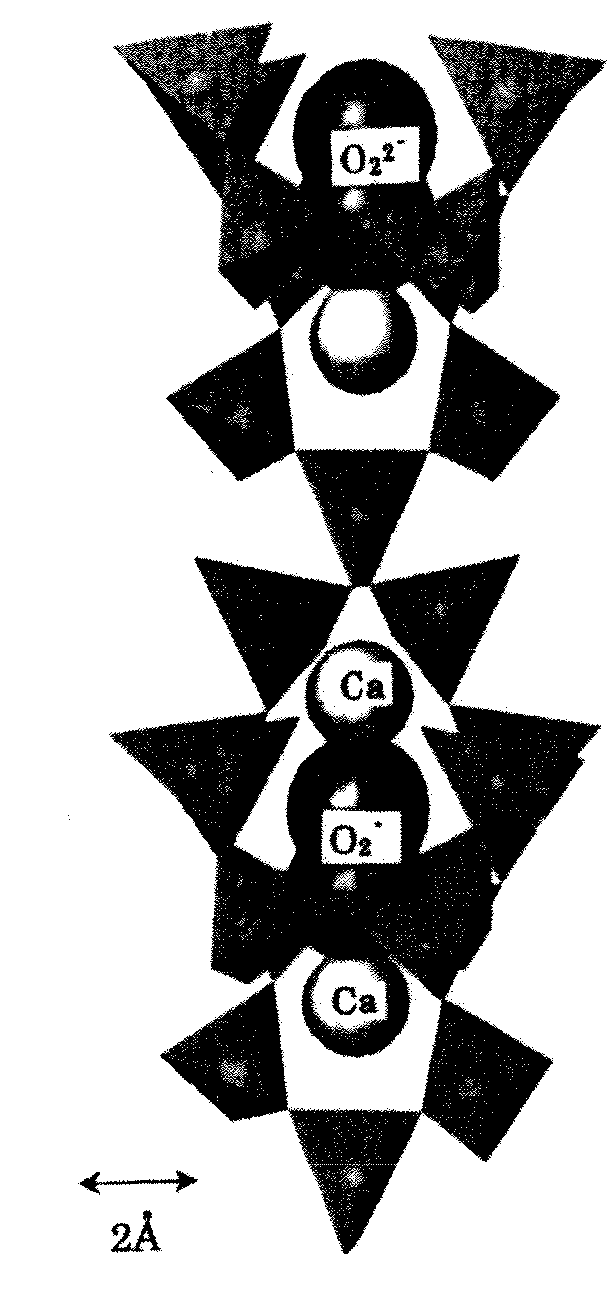

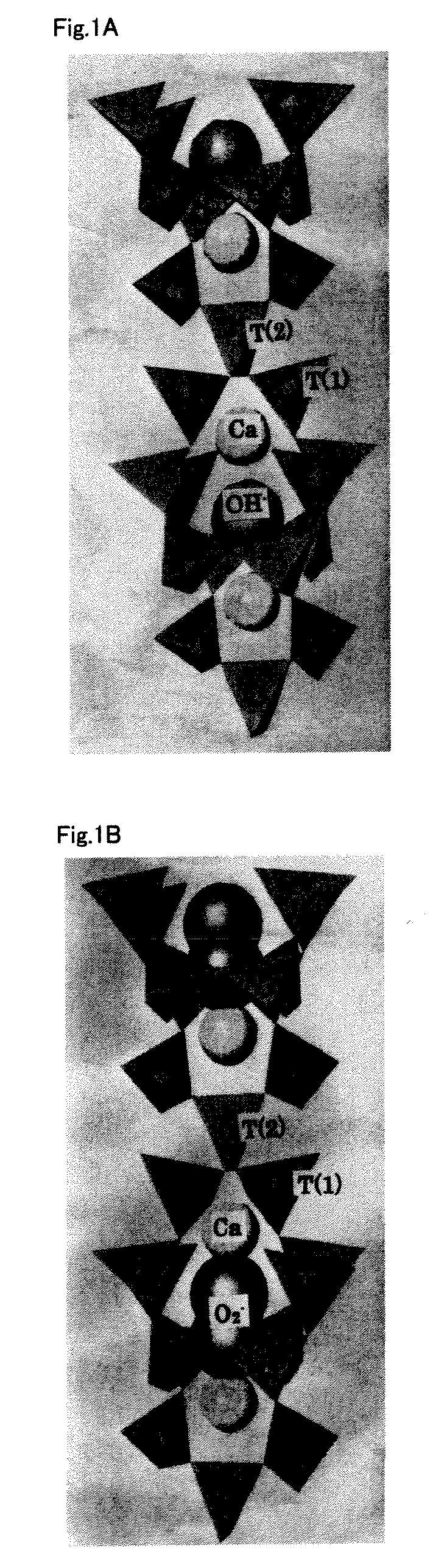

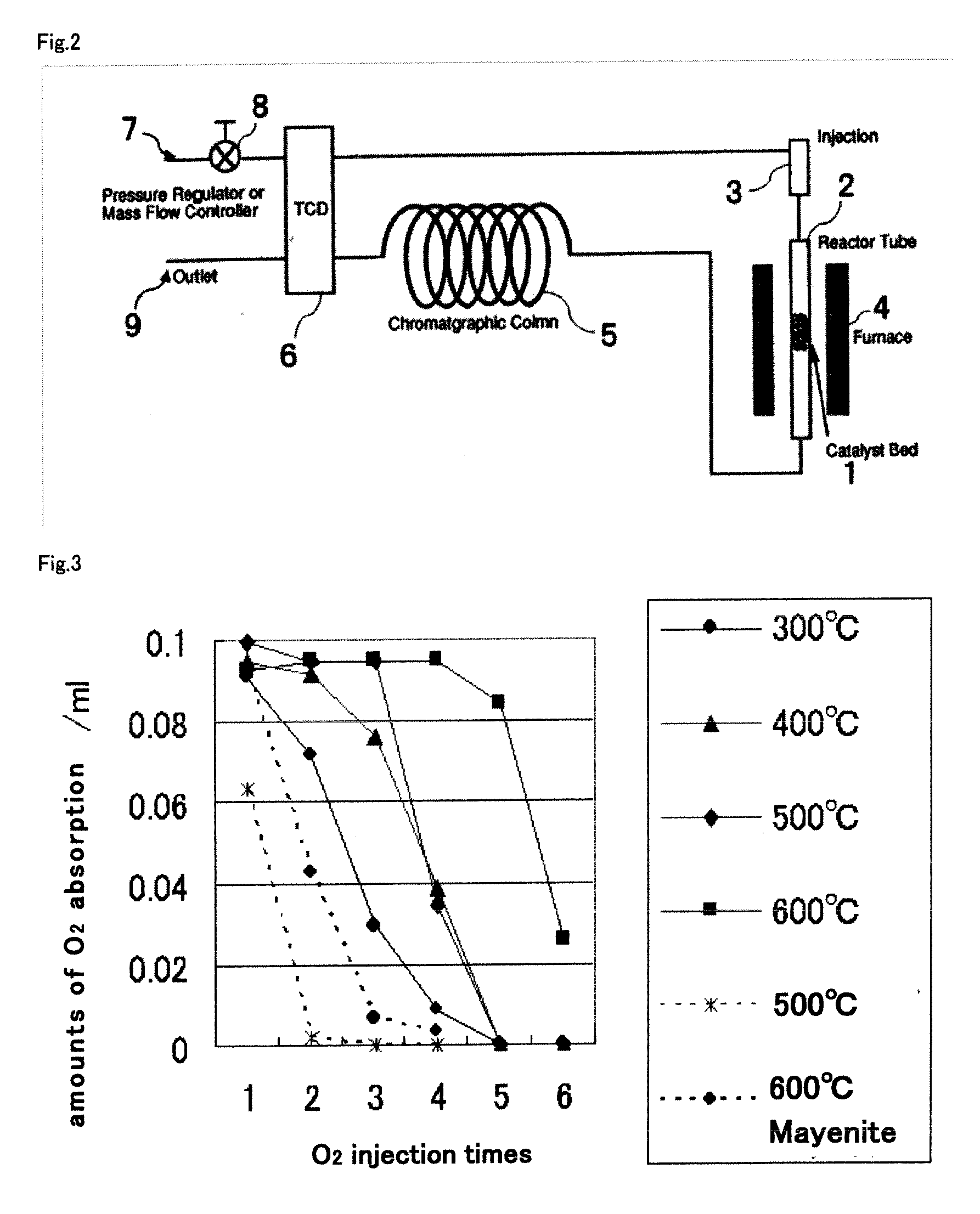

[PROBLEMS] To provide an oxygen storage substance which has higher oxygen storage capacity than conventional substances and is inexpensive. [MEANS FOR SOLVING PROBLEMS] The oxygen storage substance is a calcium aluminosilicate (mayenite), i.e., a substance of a crystal structure which is synthesized by hydrothermally treating a mixture of calcium oxide, alumina (sol), and amorphous silica, has a three-dimensional network composed of AlO4 tetrahedrons and (Al,Si)O4 tetrahedrons in which part of the aluminum atoms have been replaced with silicon atoms, with vertex oxygen atoms being shared, and has oxide ions (O2−) occluded in microspaces in the structure. Part of the calcium atoms may be replaced with atoms of a transition metal, e.g., copper.

Owner:HIROSAKI UNIVERSITY

Calcium treatment method under special steelmaking process

ActiveCN103614513AReduce in quantityImprove purityProcess efficiency improvementSteelmakingAluminate

The invention relates to a calcium treatment method implemented under a special steelmaking process. The calcium treatment method is characterized by comprising the following steps: carrying out desulfurization in a molten iron pretreatment process, namely, blowing CaO+Mg powder to desulfurize the molten iron until the sulfur content is 0.0018 to 0.0022 percent, and slagging off after the desulfurization; controlling the oxygen content at an end point of a converter within 650ppm in an converter process; ensuring the vacuum degree to be less than or equal to 300Pa in the RH (Ruhrstahl Heraeus) process, and maintaining the vacuum degree for 10 to 30 minutes; and secondarily returning the molten iron subjected to RH treatment to an LF (Ladle Furnace), adjusting the temperature, slagging after the RH treatment is completed, then conducting the calcium treatment, ensuring the feeding speed of a calcium line to be 180 to 200m / min, ensuring the feeding quantity of steel to be 1.4m / t, and controlling the bottom-blowing flow rate at 50 to 100 NL / min. By adopting the method, the impurities can be gradually converted from primary silicon manganate to calcium aluminosilicate, so that the quantity of the impurities per unit area of a steel plate can be remarkably reduced and is reduced from 87 to 100 / mm<2> to 12 to 25 / mm<2>. After the RH vacuum and calcium treatment, the type of the impurities is changed, and a product is deviated to the side of CaO-CaS; the size of the impurities in a tundish is relatively small, the impurities with the size being less than 10 micrometers account for 99.61 percent, and the impurity with the size being more than 30 micrometers is not found. By adopting the method, the molten steel purity and the steel plate flaw detection qualification rate can be improved, the calcium yield is stabilized at 20 percent or more, and the economic benefit is obvious.

Owner:NANJING IRON & STEEL CO LTD

Cement admixture for repair, cement composition for repair using same, and cement mortar material for repair

Disclosed is a cement mortar which exhibits good workability free from recesses and projections, while having excellent storage stability. Specifically disclosed are: a cement admixture for repair, which contains calcium aluminosilicate glass, gypsum, aluminum sulfate hydrate and a setting regulating agent; the cement admixture for repair, which additionally contains a water reducing agent; a cement composition for repair, which contains the cement admixture for repair and cement; a cement mortar material for repair, which contains the cement composition for repair and fine aggregate; the cement mortar material for repair, wherein the maximum particle diameter of the fine aggregate is 0.3 mm or less; a cement mortar for repair, which contains the cement mortar material for repair and water; and a construction method wherein a cement mortar for repair, which contains cement, calcium aluminosilicate glass, gypsum, aluminum sulfate hydrate, a setting regulating agent, fine aggregate and water, is applied to a floor surface.

Owner:DENKA CO LTD

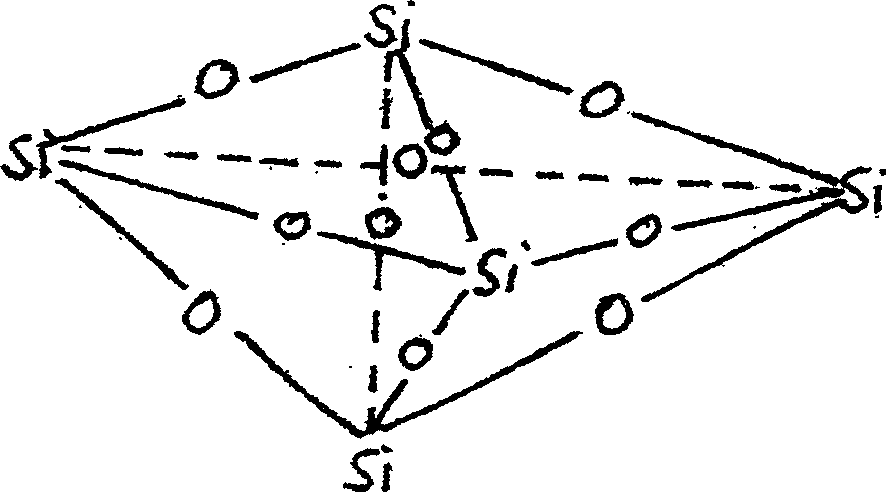

Water-proof nanometer cement and production thereof

A nano waterproof cement and its production are disclosed. The water-proof cement consists of nanometer SiO-xA380 2-3%, Al(OH)3 1-2%, CaO 5-6%, S(COOH)3F3 5-6%, polycrystalline Si granule 0.05-0.1%, Al powder 0.05-0.1%, pure Ca granule 0.1-0..5%, Na2S2O8 0.6-1.7% and cement 80-85%. The process is carried out by using SiO-xA380, Al(OH)3, CaO and S(COOH)3F3 to prepare active calcium aluminosilicate base metal, using polycrystalline Si, Al powder and pure Ca to prepare calcium aluminosilicate reductive powder and oxidation reacting from Na2S2O8 to obtain nanometer water-proof cement. It can be used for waterproof coating, concrete and water reducer.

Owner:王镇生 +1

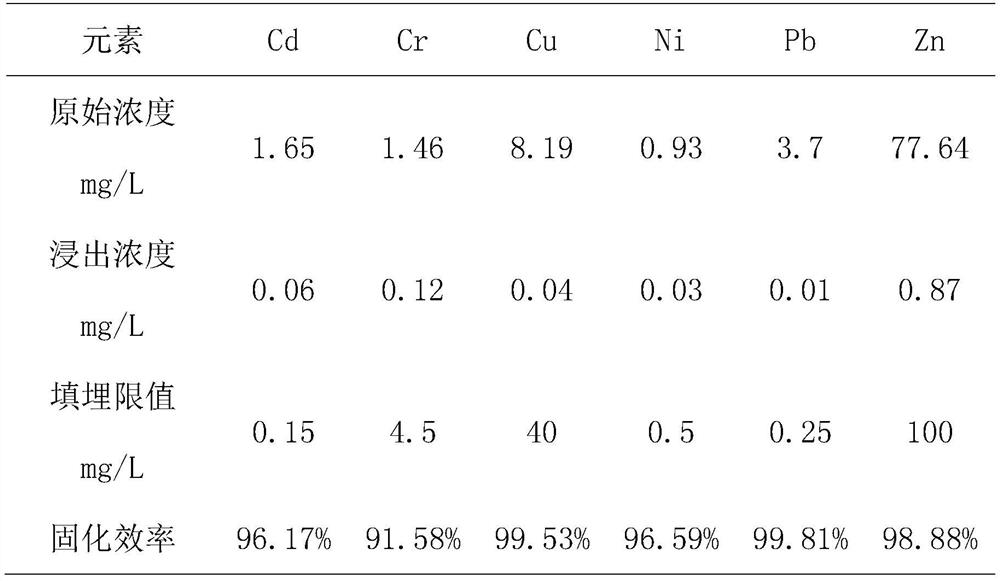

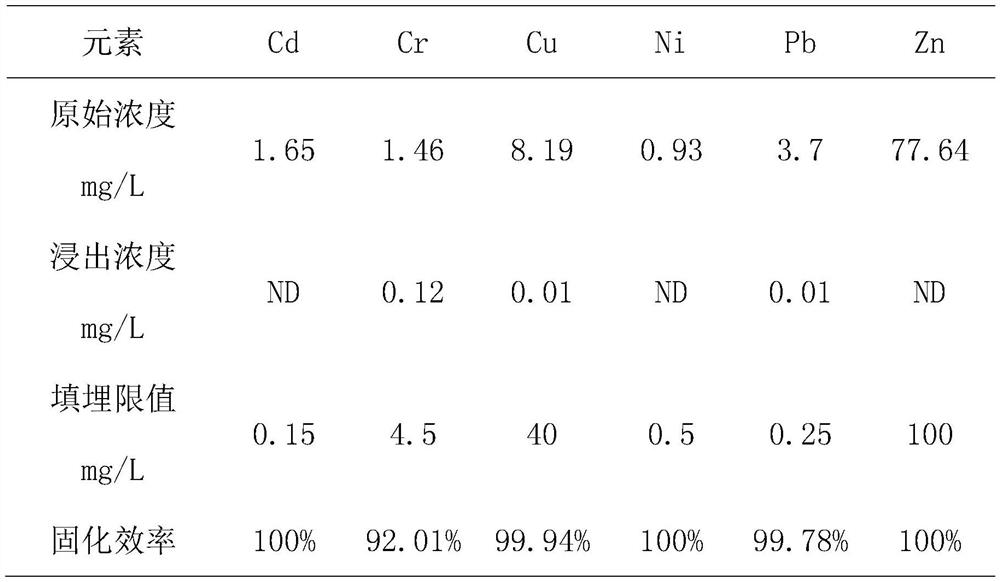

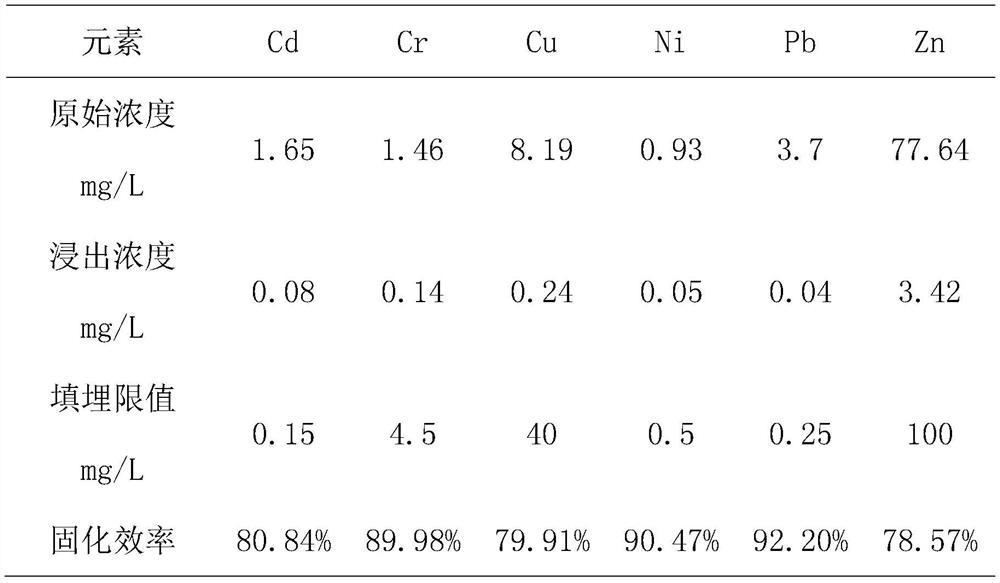

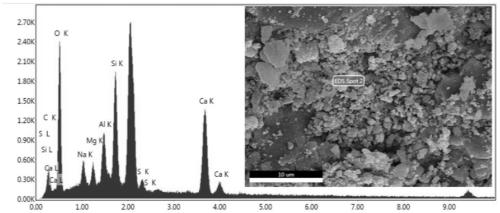

Method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide

ActiveCN113441526ASave stacking costLow raw material costSolid waste disposalCement productionCalcium silicateIon exchange

The invention discloses a method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide, and belongs to the field of household waste incineration fly ash treatment. Coal gangue and amorphous SiO2 and Al2O3 in household waste incineration fly ash are subjected to a geological polymerization reaction under the condition of an alkali activator, an inorganic polymer of a three-dimensional net structure is formed, meanwhile, calcium oxide is added, a large quantity of hydrated calcium silicate, hydrated calcium aluminosilicate and hydrated sodium aluminosilicate gel are formed in a cured body during maintenance and react with the heavy metals in manners of physical encapsulation, physical adsorption and ion exchange, so that the heavy metals in the fly ash are harmlessly treated, and it is guaranteed that the heavy metal leaching concentration of the fly ash-coal gangue-calcium oxide polymerization cured body meets the landfill safety standard. The heavy metals in the waste incineration fly ash are stabilized and produced though combination of coal gangue and calcium oxide, the curing efficiency of the heavy metals in the fly ash is further improved, the curing cost is reduced, and the environment-friendly concept of treating wastes with wastes is met.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

Polymeric calcium aluminosilicate coagulant prepared from gold tailings

InactiveCN101979332AHigh reuse rateImprove protectionWater/sewage treatment by flocculation/precipitationBULK ACTIVE INGREDIENTRenewable resource

The invention belongs to the technical field of environmental protection, and relates to an environment-friendly polymeric coagulant. The polymeric calcium aluminosilicate coagulant comprises the following raw materials in percentage by mass: 50 to 60 percent of filtrate of gold tailings processed by mixed acid, 30 to 45 percent of filtrate of the gold tailings processed by sodium hydroxide and 5 to 10 percent of oxidizing agent. Because the calcium aluminosilicate coagulant is prepared from the gold tailings serving as a main raw material, the repeated utilization factor of the nonrenewable resource can be improved, the tailings can be changed into things of value, and the active ingredients of the gold tailings are fully utilized. Meanwhile, the preparation process of the coagulant accords with the nationally advocated pollution-free production idea, secondary pollution is not produced while the waste resource is effectively utilized, and the coagulant is favorable for environmental protection and meets the policy of national energy conservation and emission reduction.

Owner:UNIV OF JINAN

Preparation method of weakly-alkaline activated carbide slag-high-calcium ash composite cementing material

The invention provides a preparation method of a weakly-alkaline activated carbide slag-high-calcium ash composite cementing material. The preparation method comprises the following steps: adding 0.1-0.15 part by mass of triisopropanolamine, 0.1-0.15 part by mass of triethanolamine and 0.5-0.75 part by mass of powdery naphthalene water reducer into high-calcium ash according to the water-materialratio of 0.5: 1, and carrying out wet grinding to obtain high-calcium mortar with the median particle size of 1-5 mu m; mixing and stirring 405-473 parts of high-calcium mortar, 135-180 parts of carbide slag, 23-27 parts of sodium carbonate or 31-36 parts of sodium sulfate and 23-45 parts of water to be uniform, and preparing the weakly-alkaline activated carbide slag-high-calcium ash composite cementing material. Calcium-silicon-aluminum solid waste carbide slag and high-calcium ash are used as raw materials, and the carbide slag can react with fly ash to generate hydrated calcium silicate and hydrated calcium aluminosilicate. Sodium carbonate or sodium sulfate is doped as an excitant to excite the activity of the cementing material, the preparation operation process is simple, and the application prospect is good.

Owner:HUBEI UNIV OF TECH

Rapid purifying agent for urban black and odorous water body

InactiveCN107162135AWith slow-release oxygenation functionSettling fastWater/sewage treatment by substance additionWater/sewage treatment by flocculation/precipitationCalcium silicateAluminum silicate

The invention belongs to the technical field of water environment treatment and relates to a sewage purifying agent. An urban sewage rapid purifying agent is composed of 0.1-25 parts of boron-iron-aluminum polysilicate, 2-10 parts of calcium peroxide, 1-10 parts of magnesium peroxide, 1-15 parts of aluminum ferric polysilicate, 1-10 parts of polyacrylamide, 1-10 parts of ployferric sulfate, 1-15 parts of calcium nitrate, 1-3 parts of sodium silicate and 1-2 parts of polyferric chloride. The agent provided by the invention has the advantages that pH after hydration can be controlled to be 7.5-9.5, and tight composite mineralized sediments which are provided with sustained release oxygen and are mainly calcium silicate, magnesium silicate, aluminum silicate, calcium aluminosilicate and aluminosilicic acid can be gradually formed. Therefore, suspending particular matters and various kinds of harmful impurities in sewage can be rapidly settled, sustained release and oxygenation functions on mud at the water bottom can be realized, bottom mud with a tight structure also can be formed after settlement, and the sewage purifying agent can be applied to treatment of printing and dyeing wastewater, urban polluted landscape water and urban inland river black and odorous water.

Owner:GUANGDONG RUIJIE ENVIRONMENTAL PROTECTION ENG CO LTD

Subgrade reinforcing quick-setting grouting material and preparation method thereof

The invention discloses a subgrade reinforcing quick-setting grouting material and a preparation method thereof. The preparation method comprises the following steps: mixing blast furnace slag powderwith fly ash according to a specific mass fraction, enabling the mixed surface of the blast furnace slag powder and the fly ash to be fully contacted, utilizing silica and alumina contained in the flyash and calcium oxide and silica contained in the slag powder, then mixing water, a water glass solution, a NaOH solid and a water reducer to form a reflection solution, dissolving active silicon, aluminum and calcium substances in the fly ash and the slag powder by using the water glass solution and NaOH and then performing reagglomeration to form C-S-H hydrated calcium silicate and C-S-A-H hydrated calcium aluminosilicate hydration products. According to the preparation method, alumina in the fly ash and the slag powder is firstly reacted by using a solution comprising the water glass solution and NaOH, so that excessively fast condensation caused by excessive fly ash can be prevented, the post removal of calcium oxide can be ensured to reflect the growth of reinforcing materials, the utilization rate of the blast furnace slag powder and the fly ash can be effectively improved, and the working performance of the grouting material can be improved at the same time.

Owner:CHANGAN UNIV +1

Process for producing high-alumina cement by utilizing aluminum ash and fly ash generated after waste incineration

InactiveCN113943116AStable curing and low leaching rateCalcium/strontium/barium chloridesChemical industryFlue gasDust control

The invention discloses a process for producing high-alumina cement by using aluminum ash and fly ash generated after waste incineration. The process comprises the following steps of: mixing and homogenizing the aluminum ash and the fly ash generated after waste incineration according to the weight ratio of (6-7): (3-4); heating the material to 1400-1700 DEG C by a high-temperature smelting furnace; heating and preserving heat for 2-3 hours; and performing cooling, and then performing crushing and grinding to obtain the high-alumina cement. According to the process, the aluminum ash and the fly ash obtained after waste incineration are mixed, homogenized and fused at high temperature, the high-alumina cement with calcium aluminate and calcium aluminosilicate as main components is prepared, and the high-alumina cement can reach the CA-60 cement grade. After a large amount of heavy metal salts in the fly ash are molten, the leaching rate is very low after the heavy metal salts are stably solidified, dioxin can be degraded and harmlessly treated at about 1400 DEG C; and after treatment, toxic leaching meets the environmental protection requirement and national standard. After chlorate in the aluminum ash is volatilized at the high temperature of 1400-1700 DEG C, calcium chloride is collected through a flue gas pipeline rapid cooling dust collection bag, and a harmless calcium chloride byproduct is formed.

Owner:霍林郭勒市锦正物资再生利用有限公司

Environment-friendly preparation technology of baking-free brick

The invention discloses an environment-friendly preparation technology of a baking-free brick. The preparation technology takes iron tailings as a major raw material, has important significance to environmental protection and complies with novel wall material development requirements and the energy conservation and emission reduction policy of China at the present stage; emery is modified by pulverized fuel ash; the surface of the modified emery absorbs much pulverized fuel ash; the pulverized fuel ash can react with free Ca(OH)2 in cement slurry to generate cementitious substances such as calcium aluminosilicate; the compatibility of the emery with a brick body matrix is improved; at the same time, the technology has a positive effect on later strength of the baking-free brick; and the compressive strength of the baking-free brick is greatly improved due to the addition of the modified emery.

Owner:界首市静峰新型建材有限公司

Preparation method of anorthite-based porous lightweight refractory material

InactiveCN114014695AReduce contentHigh strengthCeramicwareTetramethylammonium hydroxidePolyvinyl alcohol

The invention belongs to the technical field of porous lightweight refractory materials, and particularly relates to a preparation method of an anorthite-based porous lightweight refractory material, the preparation method comprises the following steps: taking a tetramethylammonium hydroxide aqueous solution in which a foam stabilizer polyvinyl alcohol is dissolved as an alkaline activator; taking a mixture of metakaolin, calcium oxide and silicon dioxide which are proportioned according to the chemical components of the calcium aluminosilicate as raw material powder, fully stirring and reacting an alkaline exciting agent and the raw material powder, and then stirring at a high speed by taking sodium dodecyl benzene sulfonate as a foaming agent / initiator to prepare a porous calcium aluminosilicate-based geopolymer blank; and finally, firing the dried green body at high temperature to obtain the anorthite-based porous lightweight refractory material. According to the preparation method, metakaolin is taken as a main raw material source, the raw material source is wide, the whole preparation process is pollution-free and waste-free, the cost is relatively low, and the industrial popularization value is relatively high.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

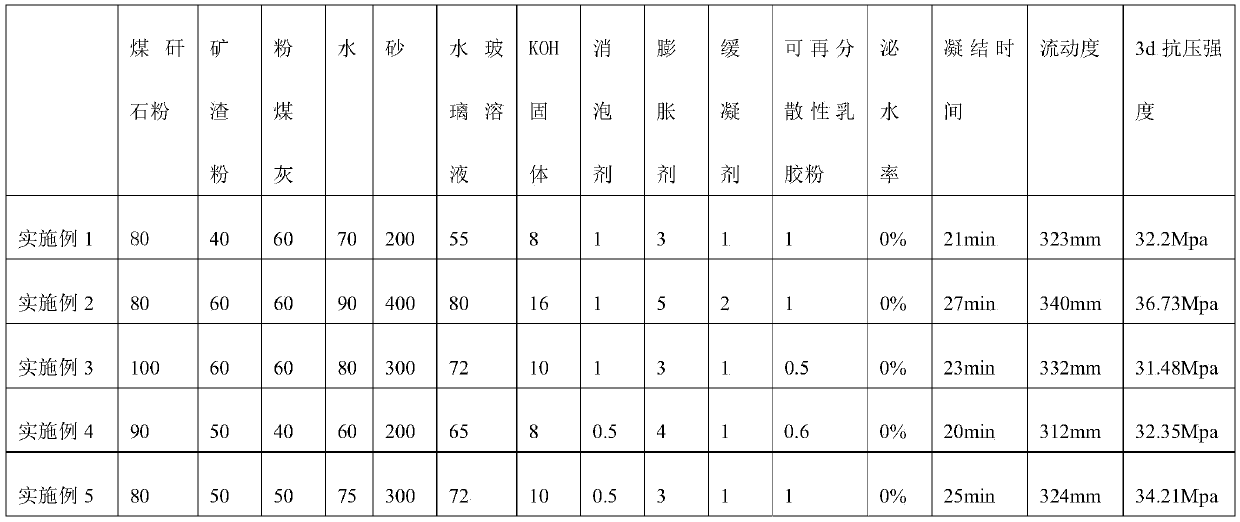

Coal gangue powder-based grouting material for pavement voids and preparation method of coal gangue powder-based grouting material

InactiveCN111039604AIncrease usageImprove the utilization rate while improving the working performance of the grouting materialSolid waste managementCalcium silicateSlag

The invention discloses a coal gangue powder-based grouting material for pavement voids and a preparation method of the coal gangue powder-based grouting material. Gravel is used as a supporting material to improve the overall strength of the grouting material, coal gangue powder, slag powder and coal ash are added, and an alkaline activator is used for activation of the above materials so as to prepare a material with gelling capacity; the gravel is used as a filling material to support a void area of a pavement, and the coal gangue powder and other powder can permeate into fine pores of thegravel, so the grouting material and a pavement structure are bonded into a whole through the permeation of fine materials; and a solution prepared from a sodium silicate solution and a NaOH solid isadopted, active silicon, aluminum and calcium substances in the coal gangue powder, the slag powder and the coal ash are dissolved by using the sodium silicate solution and KOH and then re-aggregatedto form a solution composed of C-S-H hydrated calcium silicate, a C-S-A-H hydrated calcium aluminosilicate hydration product, the sodium silicate solution and KOH, and the formed solution enables thecoal gangue powder and aluminum oxide in the slag powder to react firstly, can prevent too fast coagulation caused by too much coal ash, and the working performance of the grouting material is improved.

Owner:CHANGAN UNIV

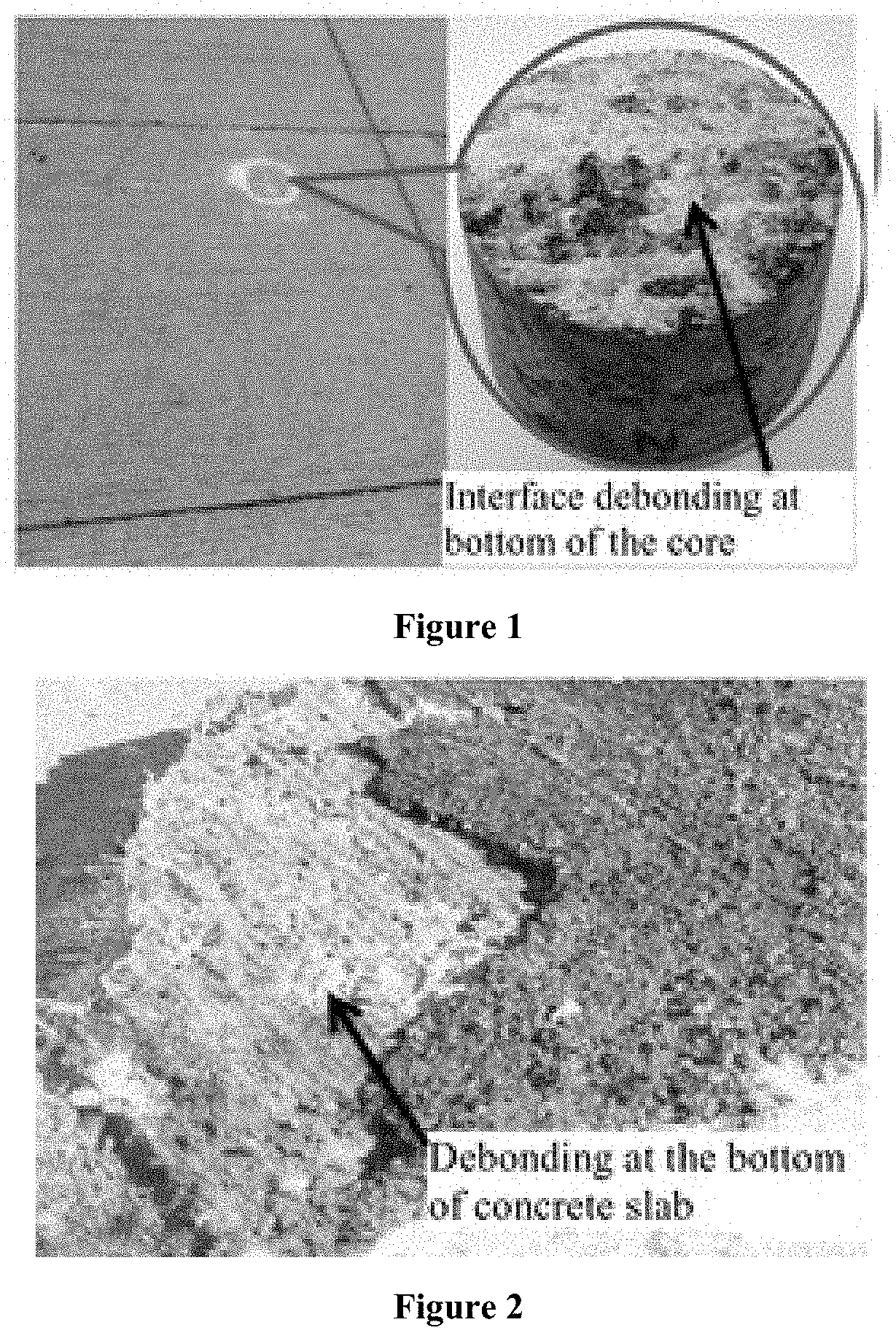

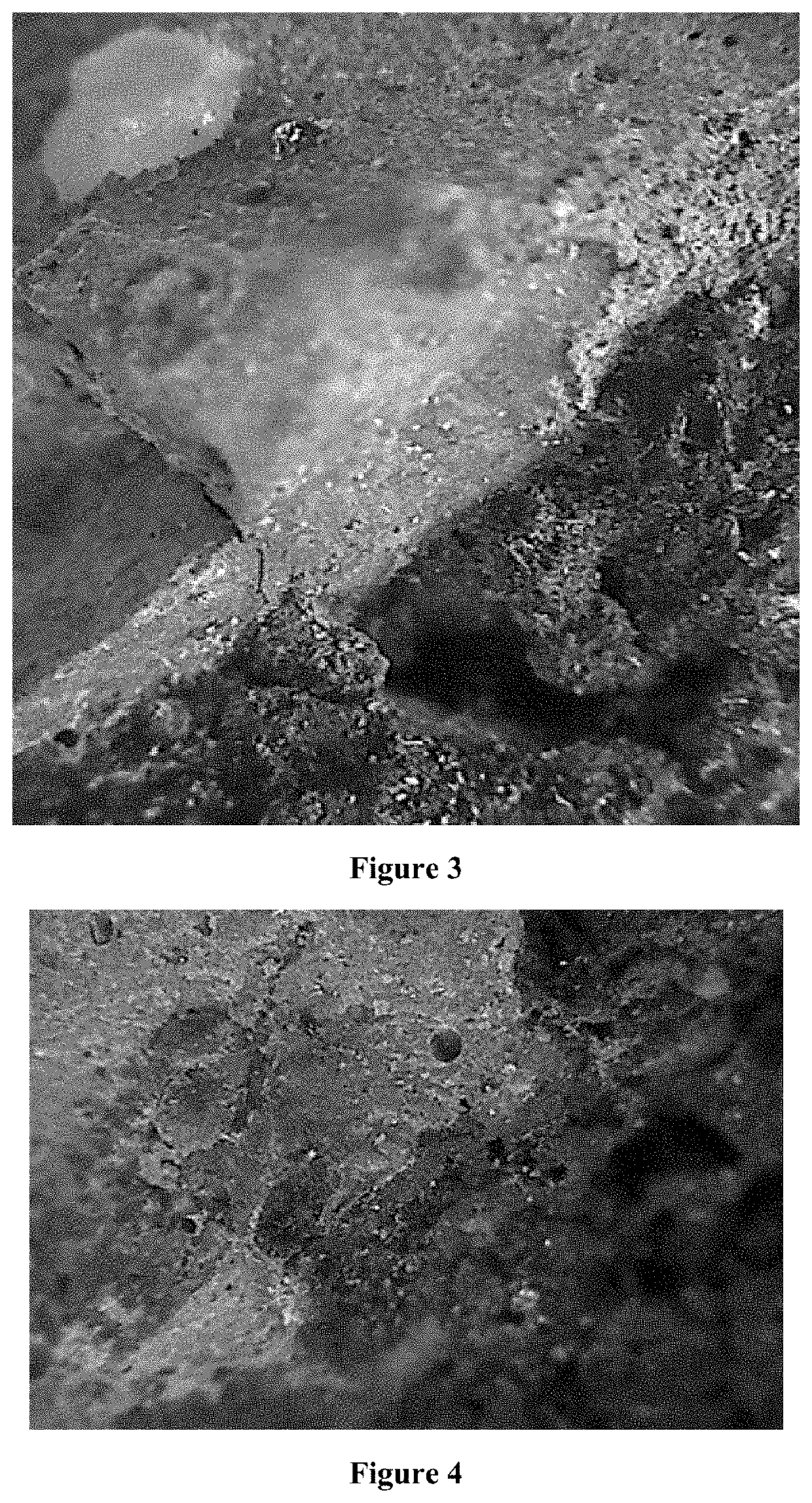

Cementitious Composition With High Bond Strength To Both Asphalt And Cement Based Materials

ActiveUS20200407276A1Potential environmental damageSolid waste managementCalcium silicateHydration reaction

A hydratable cement composition which will bond to both asphalt and cementitious substrates is supplied for the repair of various surfaces. The composition comprises of a combination of Portland cement, calcium sulfoaluminate cement or calcium aluminosilicate, and an alkali metal salt activated pozzolonic powder, wherein the Portland cement content of the hydratable portion of the composition is greater than 20%. The composition is free from latex bonding agents and calcium aluminate. The composition is mixed with water to form a typical cement, mortar, or concrete consistency, placed and allowed to cure. The result is a self-adhering patch to damaged surfaces. The hydratable cement composition may also be used to fabricate items of original construction by casting into molds or forms.

Owner:SAMPSON PAUL

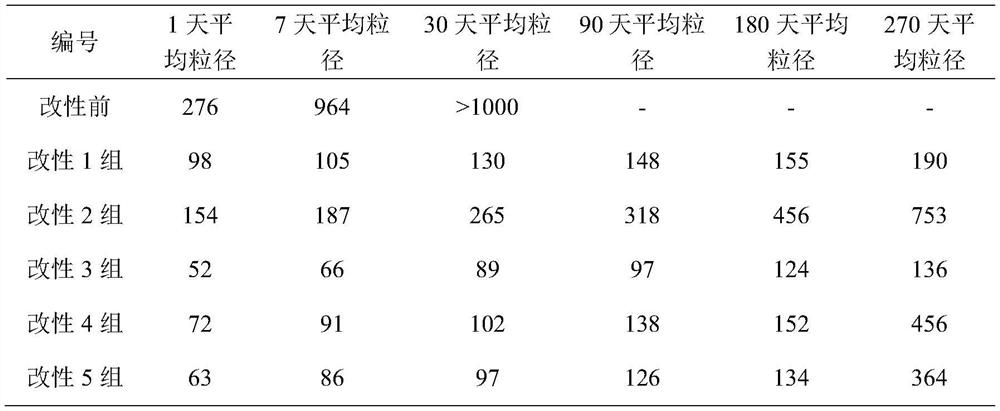

Polysaccharide-modified hydrated calcium aluminosilicate nano crystalline nucleus suspension and preparation method thereof

The invention discloses polysaccharide modified hydrated calcium aluminosilicate nano crystalline nucleus suspension, which comprises hydrated calcium aluminosilicate nano crystalline nucleus suspension and dispersion stabilizing liquid, the hydrated calcium aluminosilicate nano crystalline nucleus suspension is prepared from a reaction stock solution and a reaction base solution, and the mass ratio of the reaction stock solution to the reaction base solution is 1.57-5.24: 1; wherein the reaction stock solution comprises soluble calcium salt, soluble silicate and soluble aluminum salt, and themolar ratio of the soluble calcium salt to the soluble silicate to the soluble aluminum salt is (0.2-1.8): 1: (0.01-0.5); the reaction base solution comprises a polycarboxylate superplasticizer; thedispersion stabilizing liquid comprises soluble polysaccharide; the mass ratio of the hydrated calcium aluminosilicate nano crystalline nucleus suspension to the soluble polysaccharide is (100-10000):1. The invention solves the problem of long-acting dispersion stability of the hydrated calcium silicate nano crystalline nucleus suspension in the prior art. The invention also provides a preparation method of the polysaccharide modified hydrated calcium aluminosilicate nano crystalline nucleus suspension.

Owner:WUHAN UNIV OF TECH

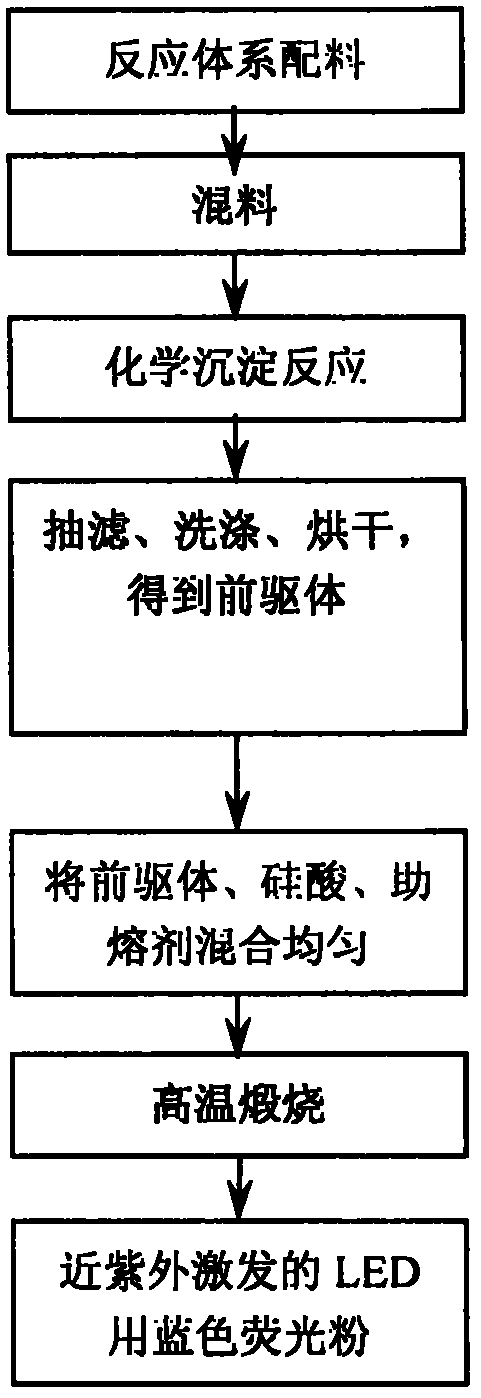

Preparation method of calcium aluminosilicate blue phosphor powder for near-ultraviolet excited LED (Light Emitting Diode)

InactiveCN103215040AWide excitation spectrumEffective stimulationGas discharge lamp usageLuminescent compositionsLuminous intensitySilicic acid

The invention discloses a preparation method of calcium aluminosilicate blue phosphor powder for a near-ultraviolet excited white LED (Light Emitting Diode) and belongs to the preparation technology of rare earth phosphor powder. The chemical formula of the calcium aluminosilicate blue phosphor powder disclosed by the invention is as follows: Ca(1-x)Al2Si2O8:xEU2+, wherein x is greater than 0 and less than or equal to 0.12. The preparation method disclosed by the invention comprises the following specific steps of: respectively weighing required calcium salt, aluminium salt, silicic acid and europium nitrate according to a chemical general formula of Ca1-xAl2Si2O8; then respectively weighting a surfactant and a fluxing agent accounting for 0.1-1.5wt% of the total mass of the above medicines; weighing a sufficient quantity of a precipitant to prepare as a solution; preparing the calcium salt, the aluminium salt, nitrate and the surfactant as a solution, uniformly mixing and slowly dropping into the precipitant solution, simultaneously and continuously stirring till a precipitin reaction is completely processed; washing, filtering and drying precipitate to acquire a precursor; uniformly mixing the precursor, the fluxing agent and the silicic acid, and calcining for 2-4 hours at temperature of 1150-1400 DEG C to acquire a target product. The phosphor powder prepared by the method disclosed by the invention is wide excitation wavelength, high in luminous intensity and good in crystallinity, and is suitably used as the blue phosphor powder for the white LED.

Owner:JIANGSU FUXIN ELECTRONICS LIGHTING TECH

Method for preparing composite deoxidant silicon aluminium barium calcium manganese iron ally used for steel making

InactiveCN1284868CImprove solubilityLow steam pressureBlast furnace componentsBlast furnace detailsSteelmakingSilicon alloy

The invention relates to a composite deoxidizer for steelmaking-silicon-aluminum-barium-calcium-manganese-ferroalloy and a preparation method thereof, belonging to the technical field of steelmaking. The chemical composition (% by weight) of the composite deoxidizer for steelmaking is: 10-35% of Si, 5-15% of Al, 4-14% of Ba, 4-14% of Ca, 2-10% of Mn, and the balance For Fe and unavoidable impurities. The preparation method is as follows: use an intermediate frequency furnace or a power frequency furnace, take a certain proportion of scrap steel and 3 / 2 aluminum ingots and put them into the bottom of the furnace, then add silicon-barium alloy, silicon-calcium alloy, medium-carbon ferromanganese, and ferrosilicon alloy. Add the rest of the aluminum ingots after all the melting, fully stir and melt, and then get out of the furnace to obtain the composite deoxidizer for steelmaking with the required chemical composition—silicon-aluminum-barium-calcium-manganese-ferroalloy. The deoxidizer has specific gravity (3.5~4.5g / cm 3 ), low melting point (1050-1200°C), fine and hard crystallization, especially when using this composite deoxidizer when smelting low-alloy structural steel and carbon steel, it can effectively improve the comprehensive performance of steel.

Owner:陈恩泽

High-strength glass-ceramic and preparation method thereof

InactiveCN108017284AImprove practicalityHigh flexural and compressive strengthGlass rolling apparatusPorosityFiber

The invention discloses high-strength glass-ceramic and a preparation method thereof and relates to the technical field of glass products. The glass-ceramic is prepared from crushed glass, modified quartz powder, tremolite, mordenite, nano-silica, brucite fibers, sodium borosilicate, sodium metasilicate pentahydrate, calcium aluminosilicate, boron oxide, ammonium nitrate, antimony dioxide and calcium fluoride. The preparation method comprises raw material melting, stirring melting, standing clarification, pressing molding and uniform annealing. The high-strength glass-ceramic has low surface porosity, high mechanical strength, good toughness, a long service life and a wide application range.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com