Patents

Literature

140results about How to "Reduce disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

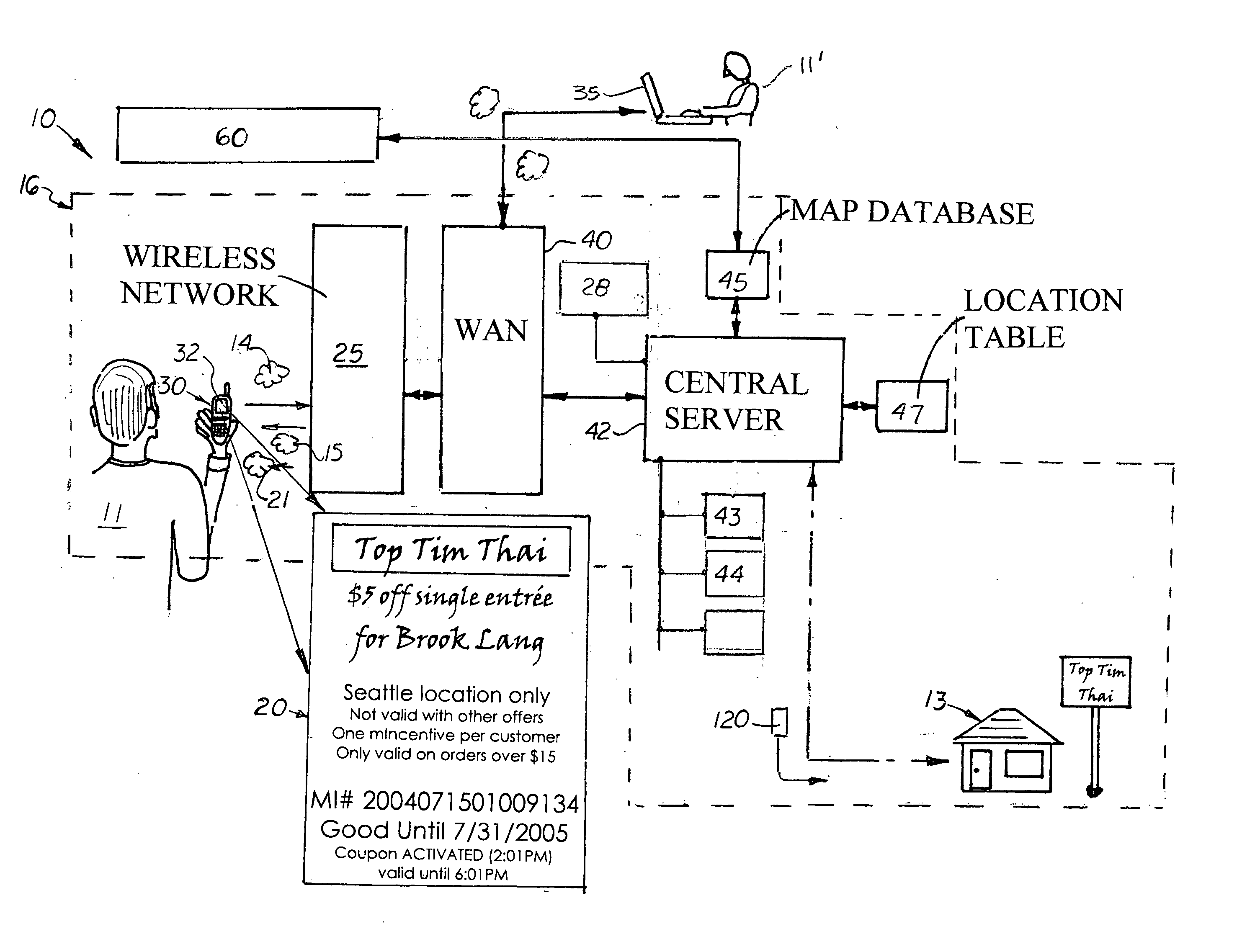

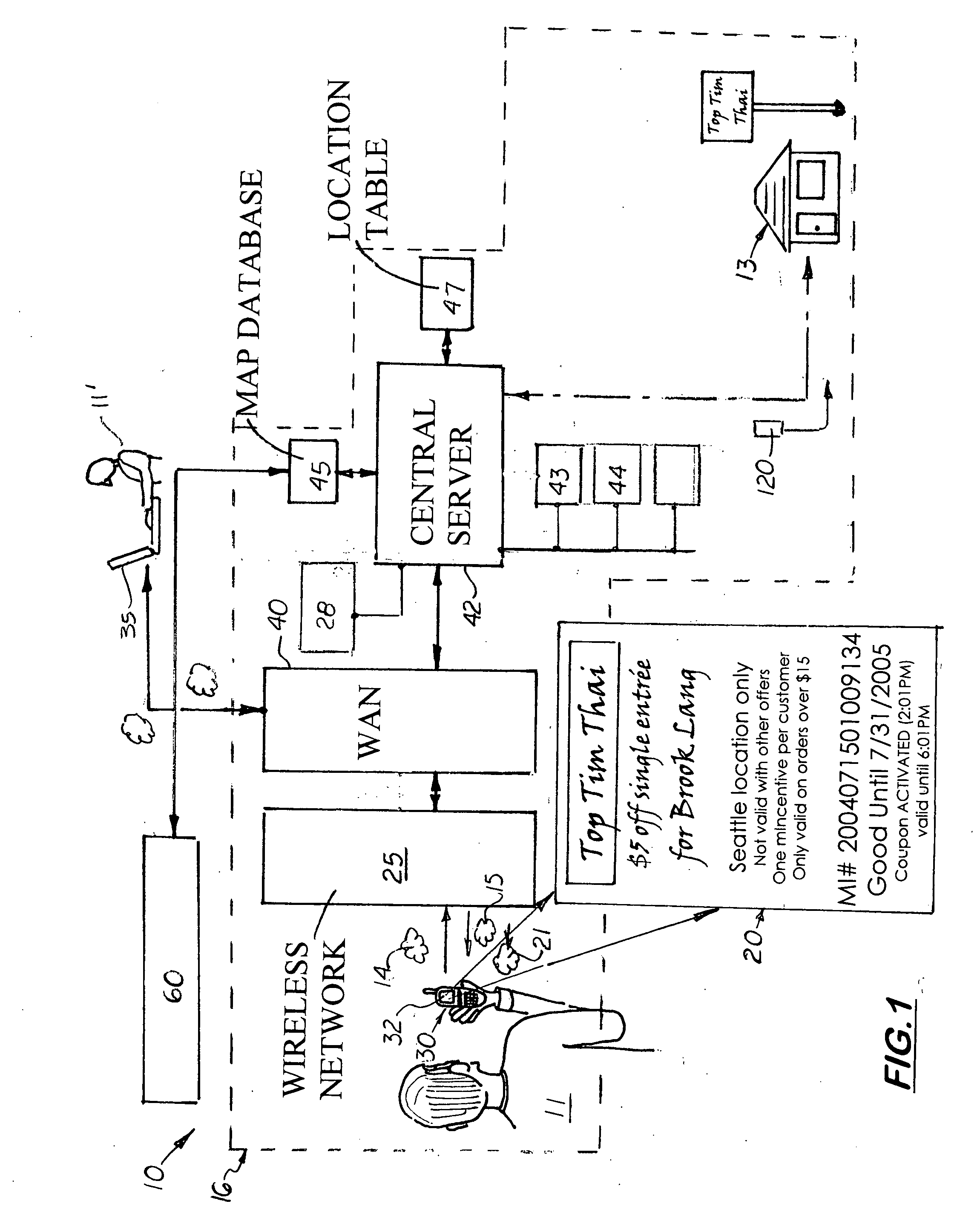

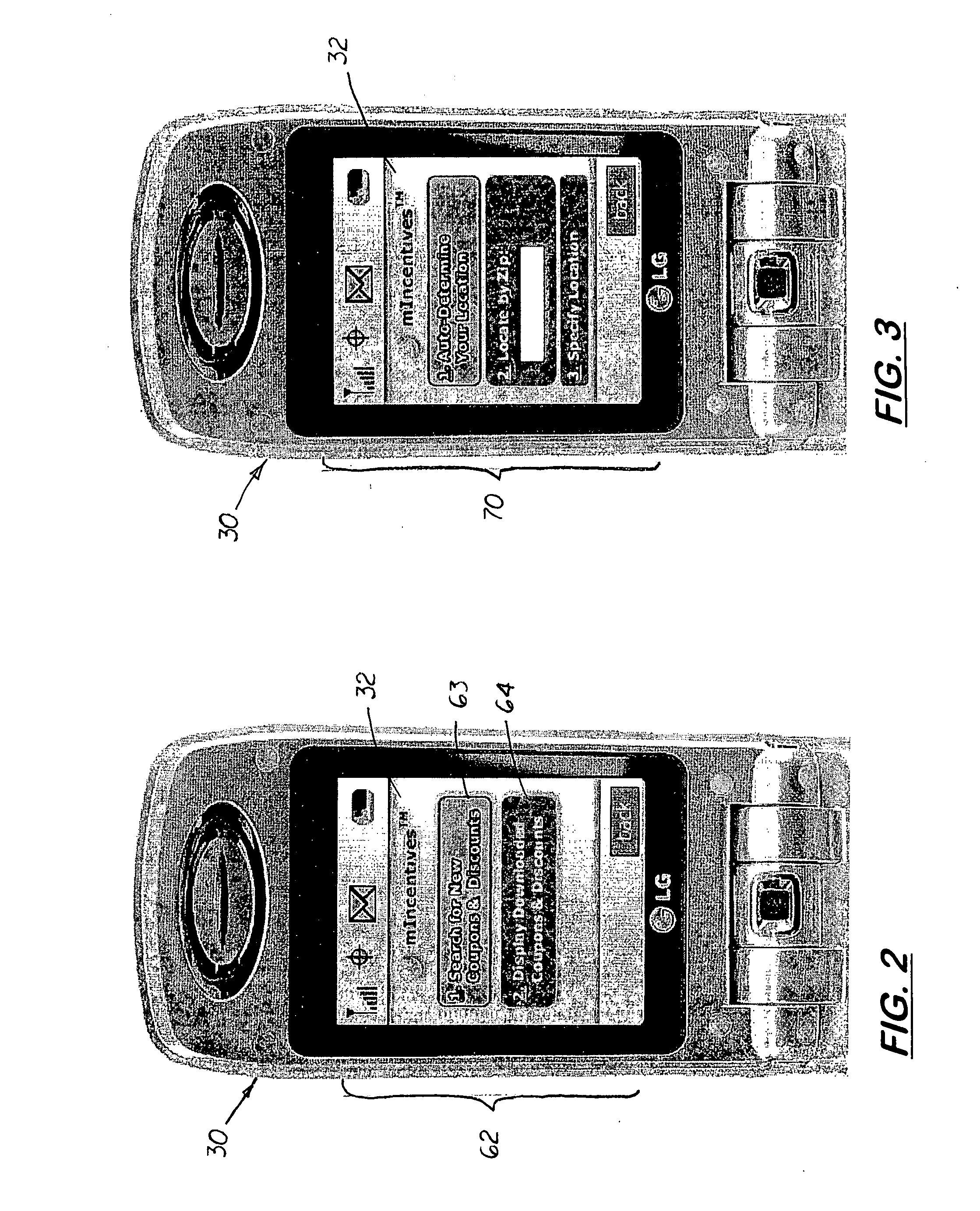

Method and distribution system for location based wireless presentation of electronic coupons

A method and system for distributing electronic coupons offered by businesses via the wireless devices operated by potential customers in a region. The invention includes a wireless communication device and a central server capable of communicating via a wireless communication network The central server is connected to a search engine, a business database containing the names and locations of businesses located in the region offering discounted coupons for goods and services to its potential customers. Connected to the central server is a discount coupon database and a map database that contains coupon information, a graphic file of the coupon, and the businesses location information. When the potential customer desires a discount coupon for a particular service or goods in the region, the potential customer contacts the central server, which instructs the search engine to conduct a search based on the criteria submitted by the potential customer. The search engine produces a list of businesses currently offering discount coupons that is then transmitted to the potential customer.

Owner:LANG BROOK W

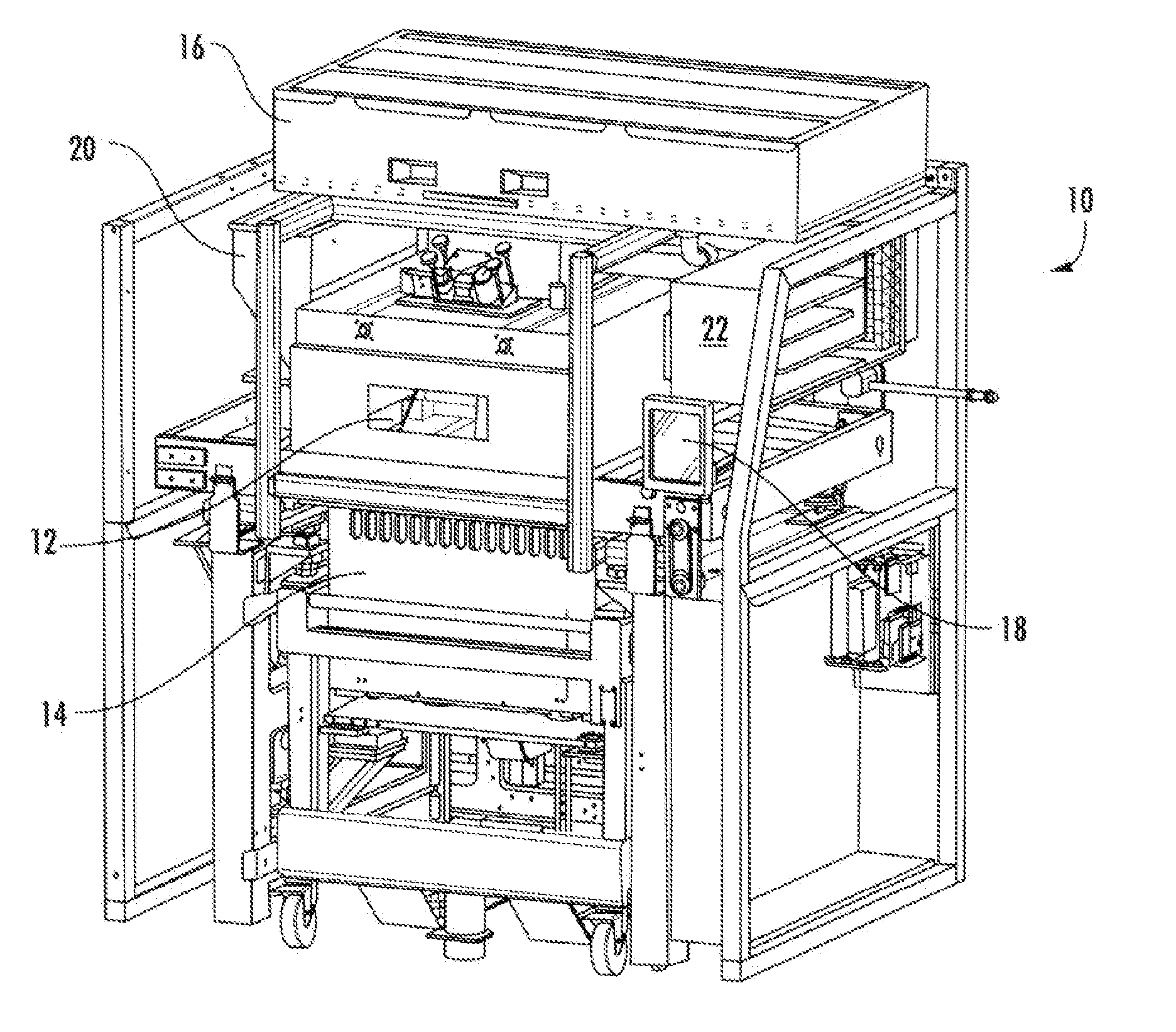

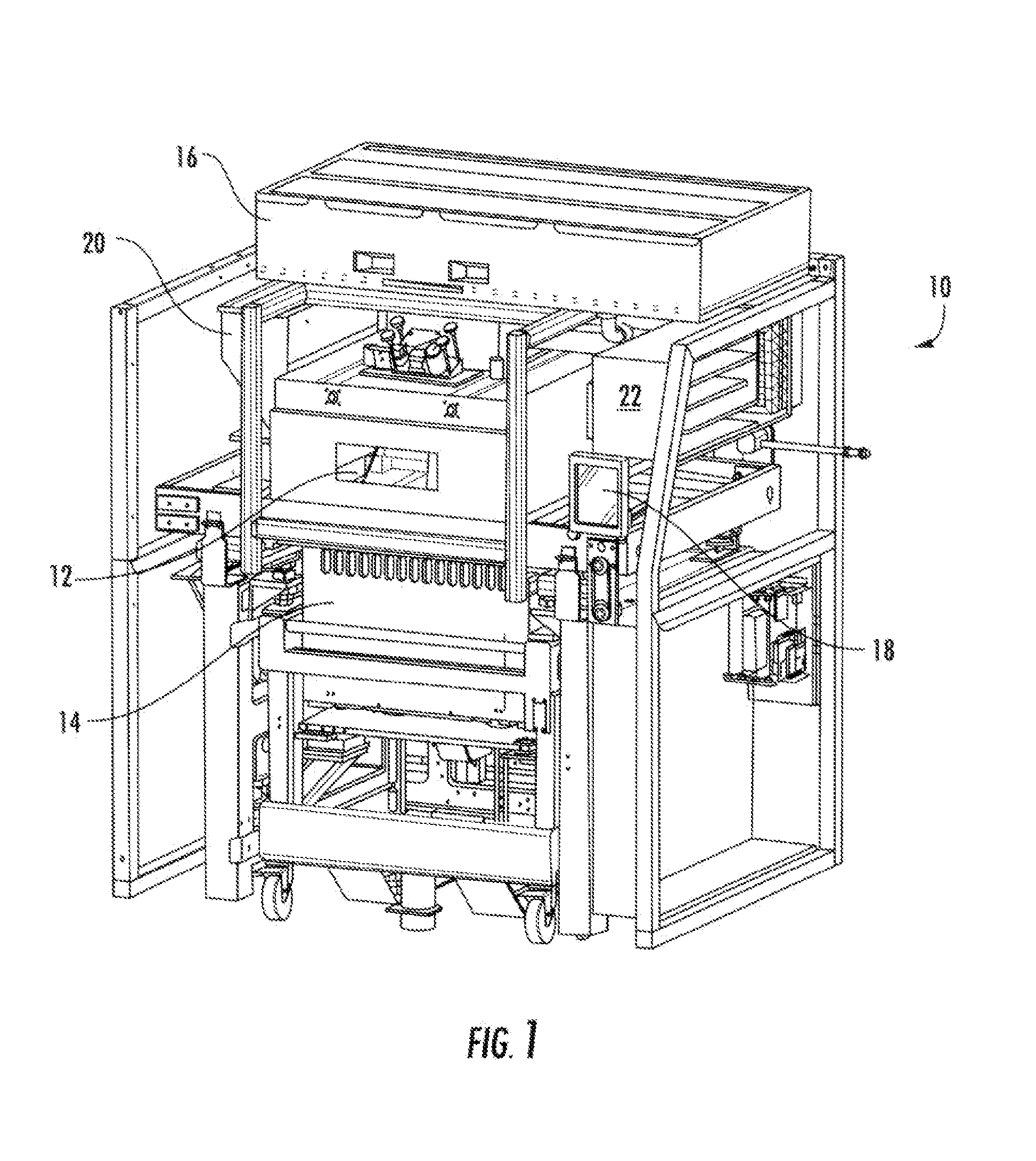

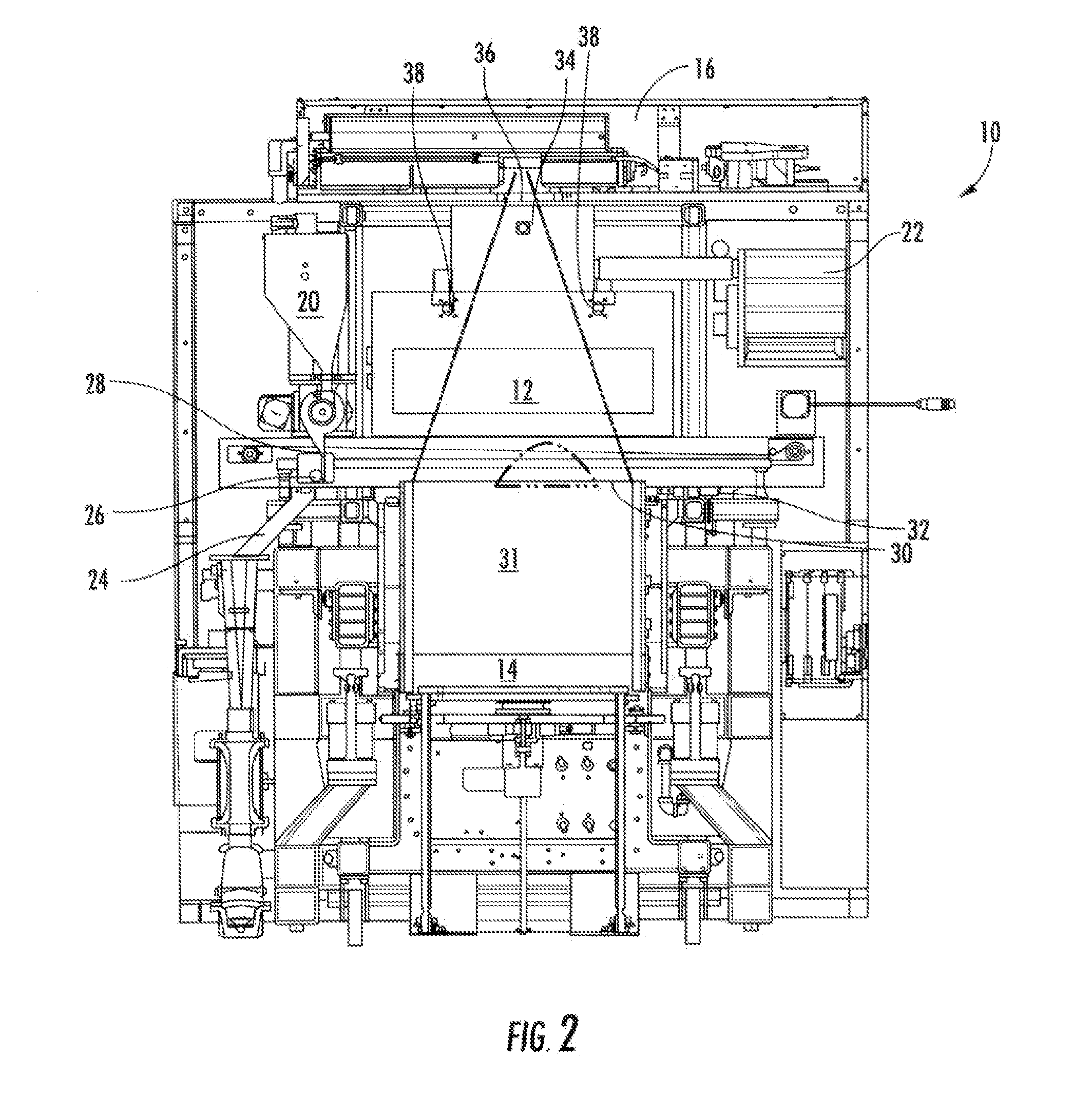

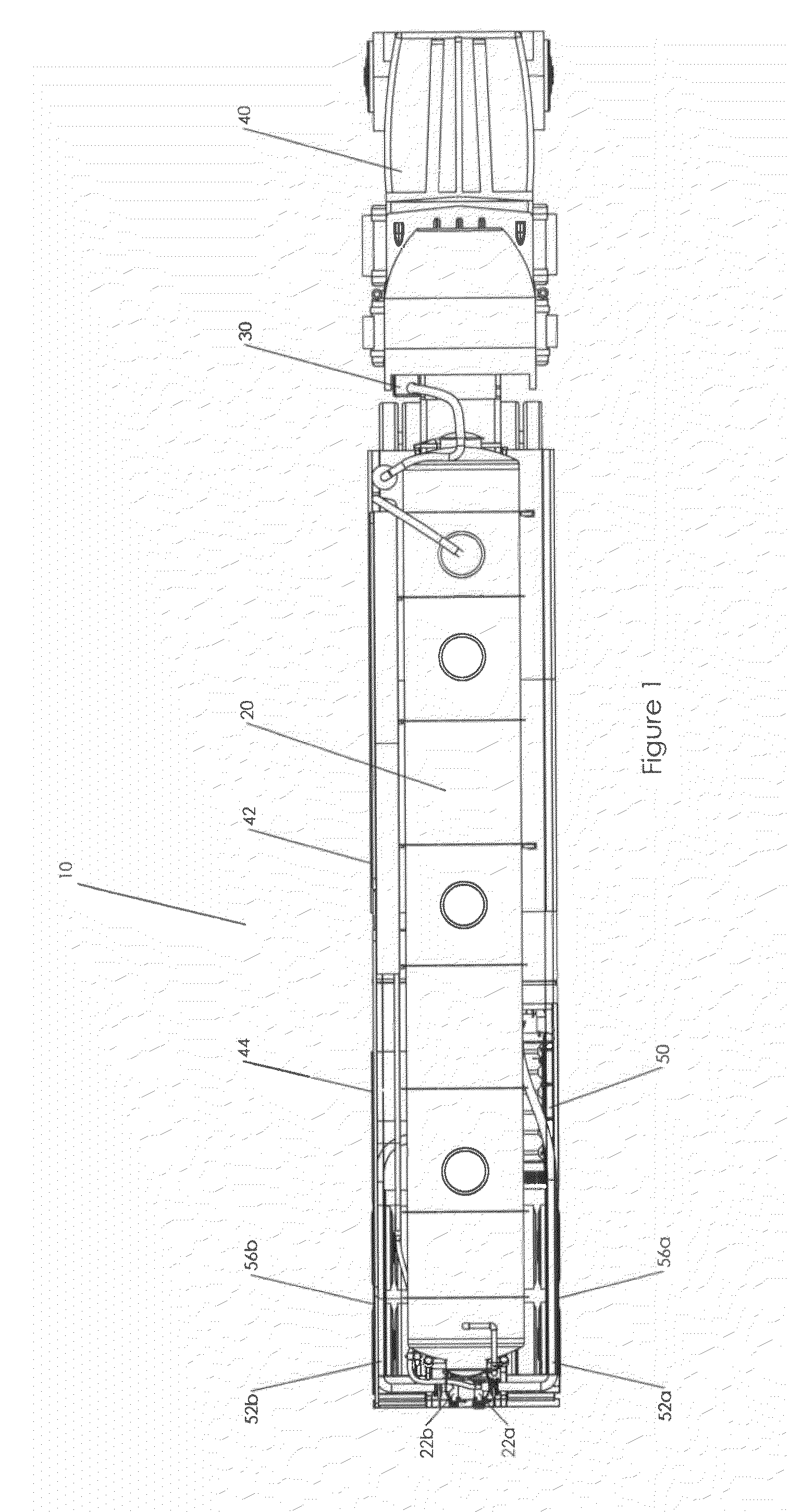

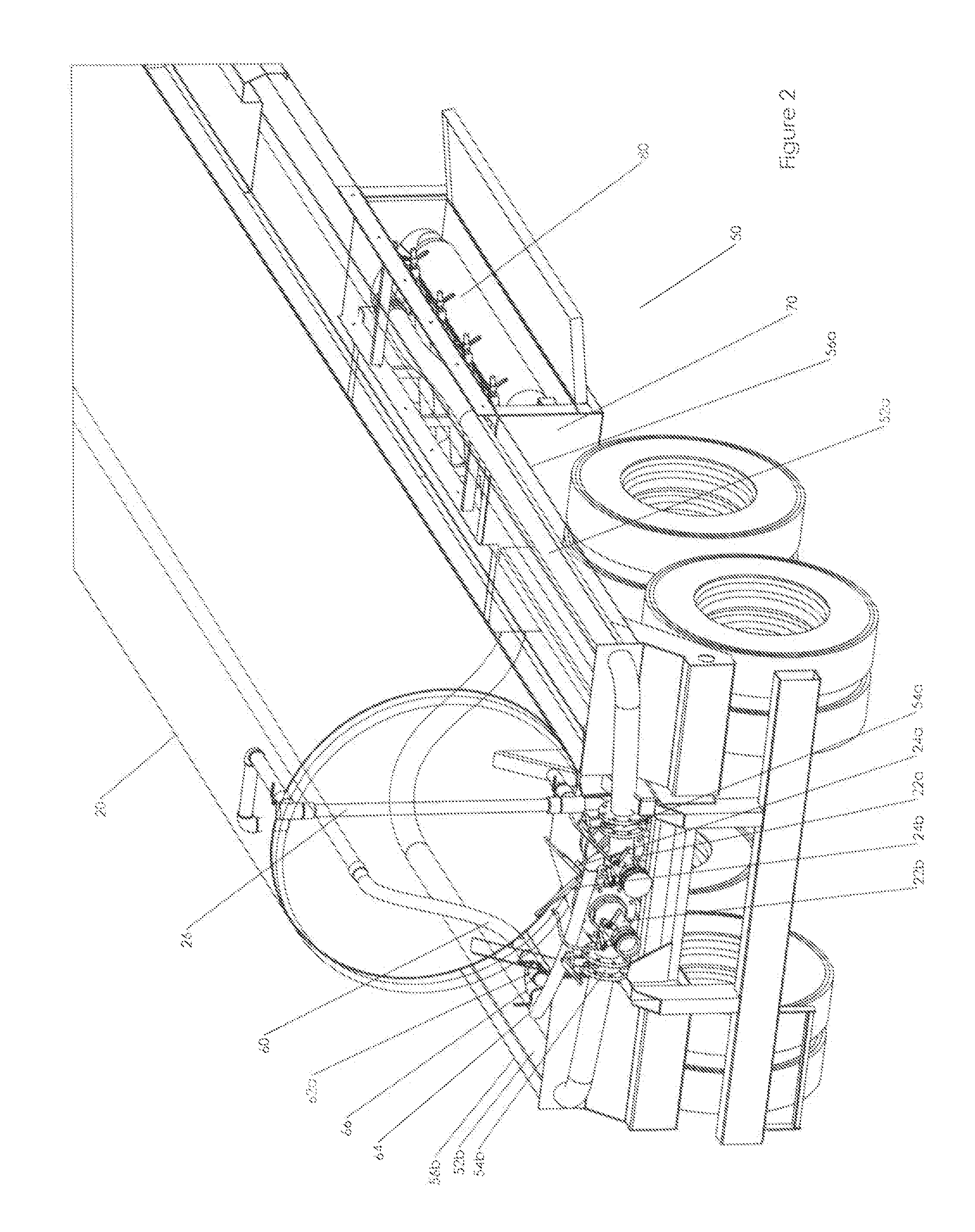

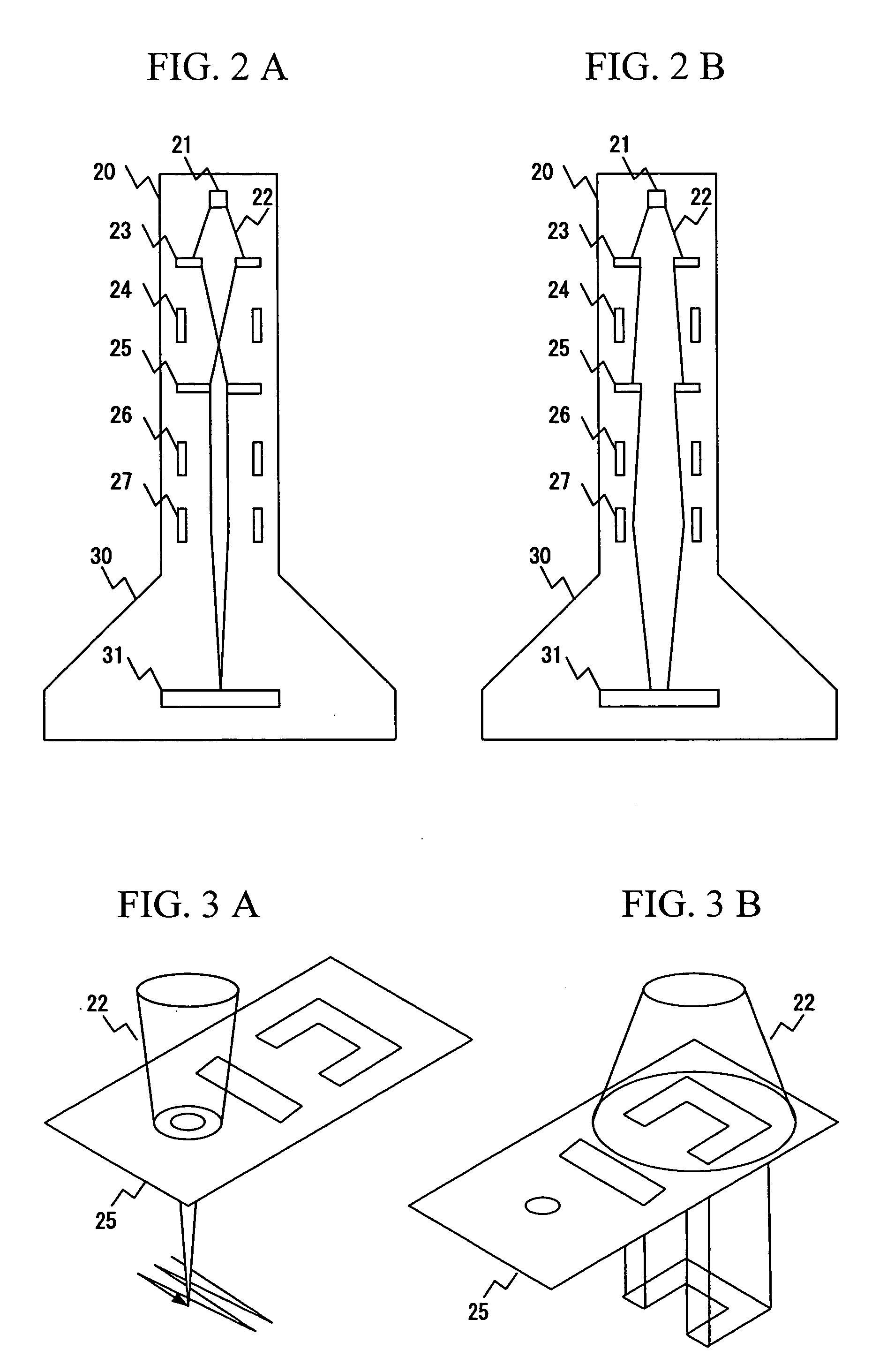

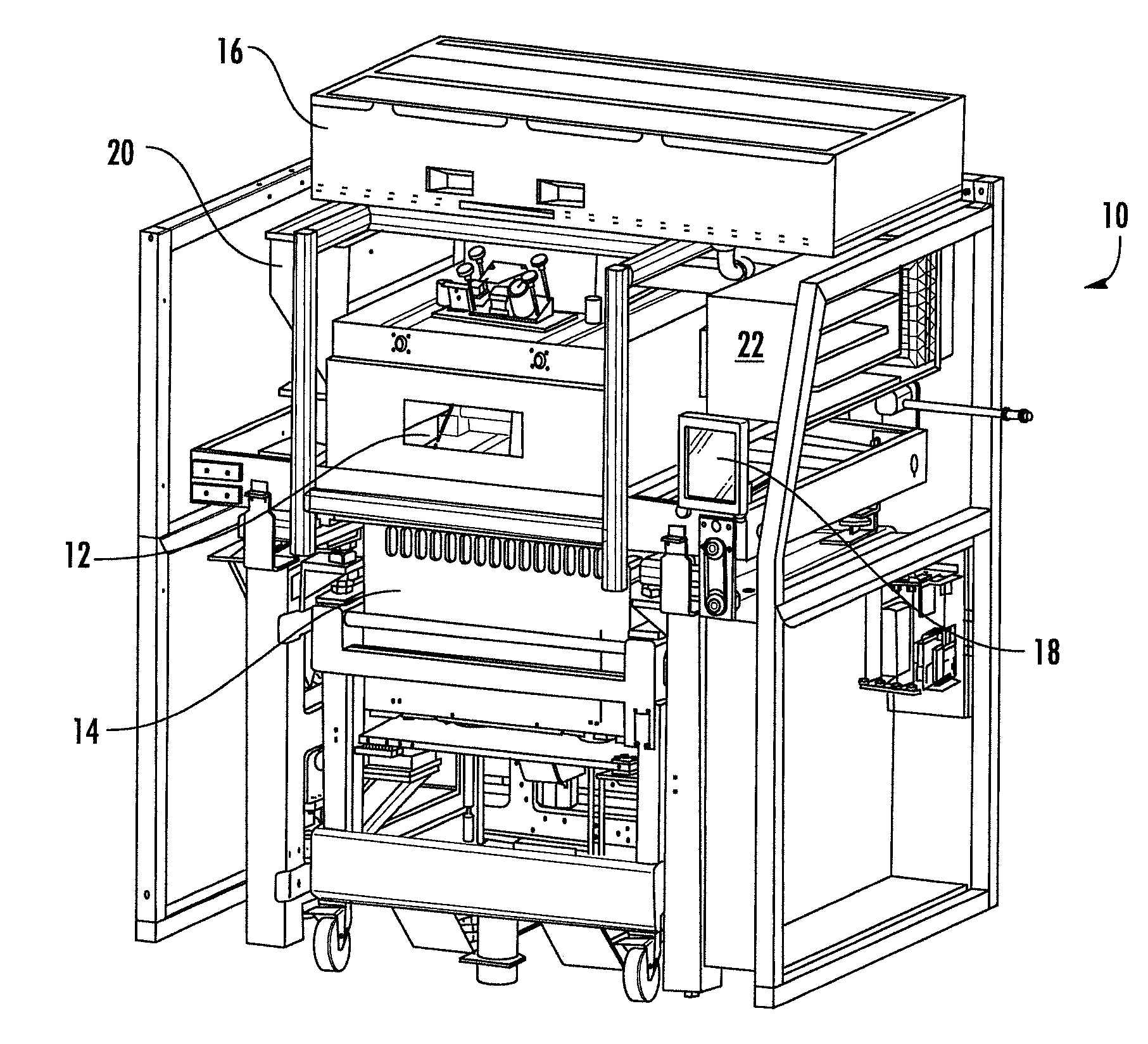

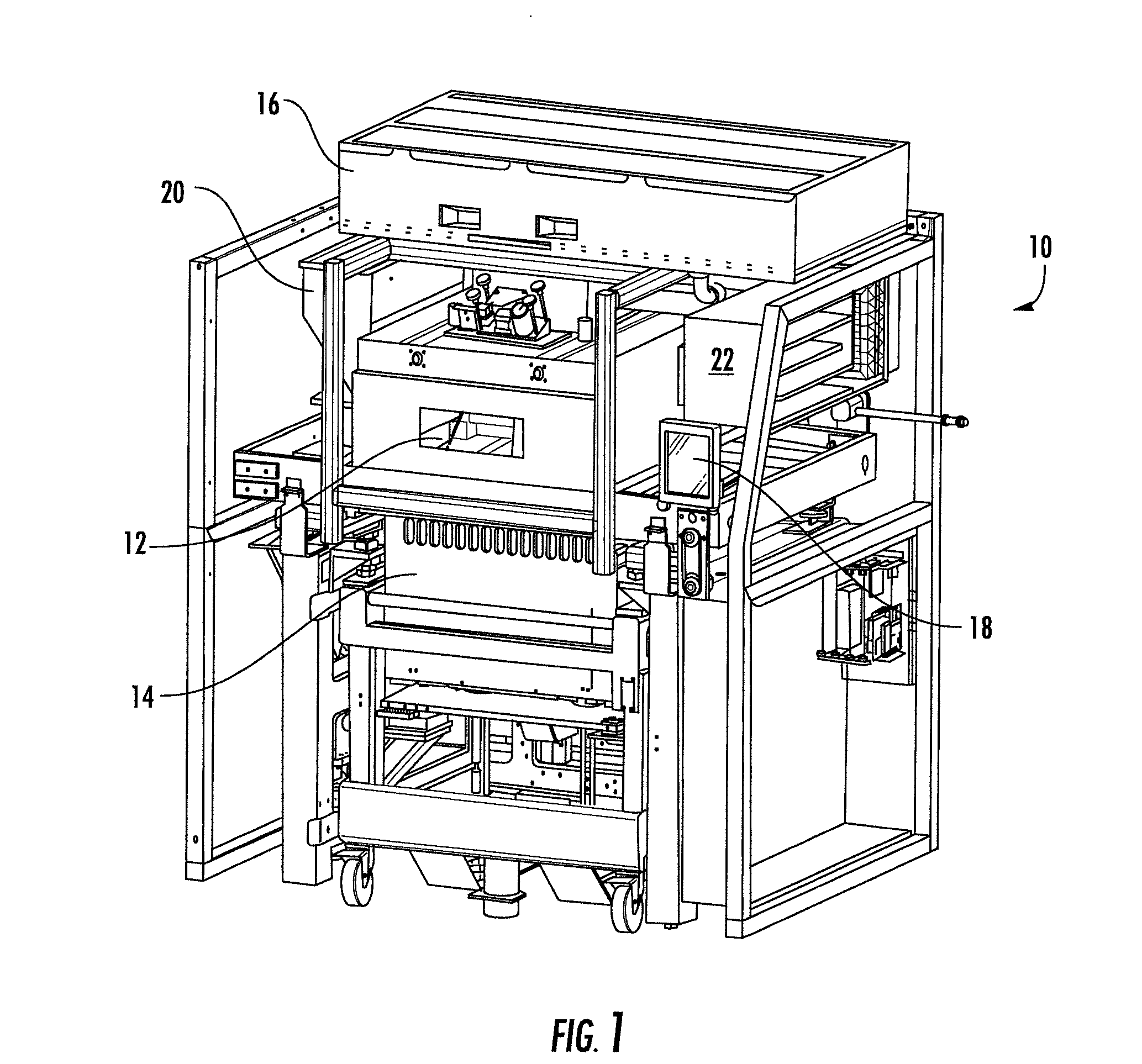

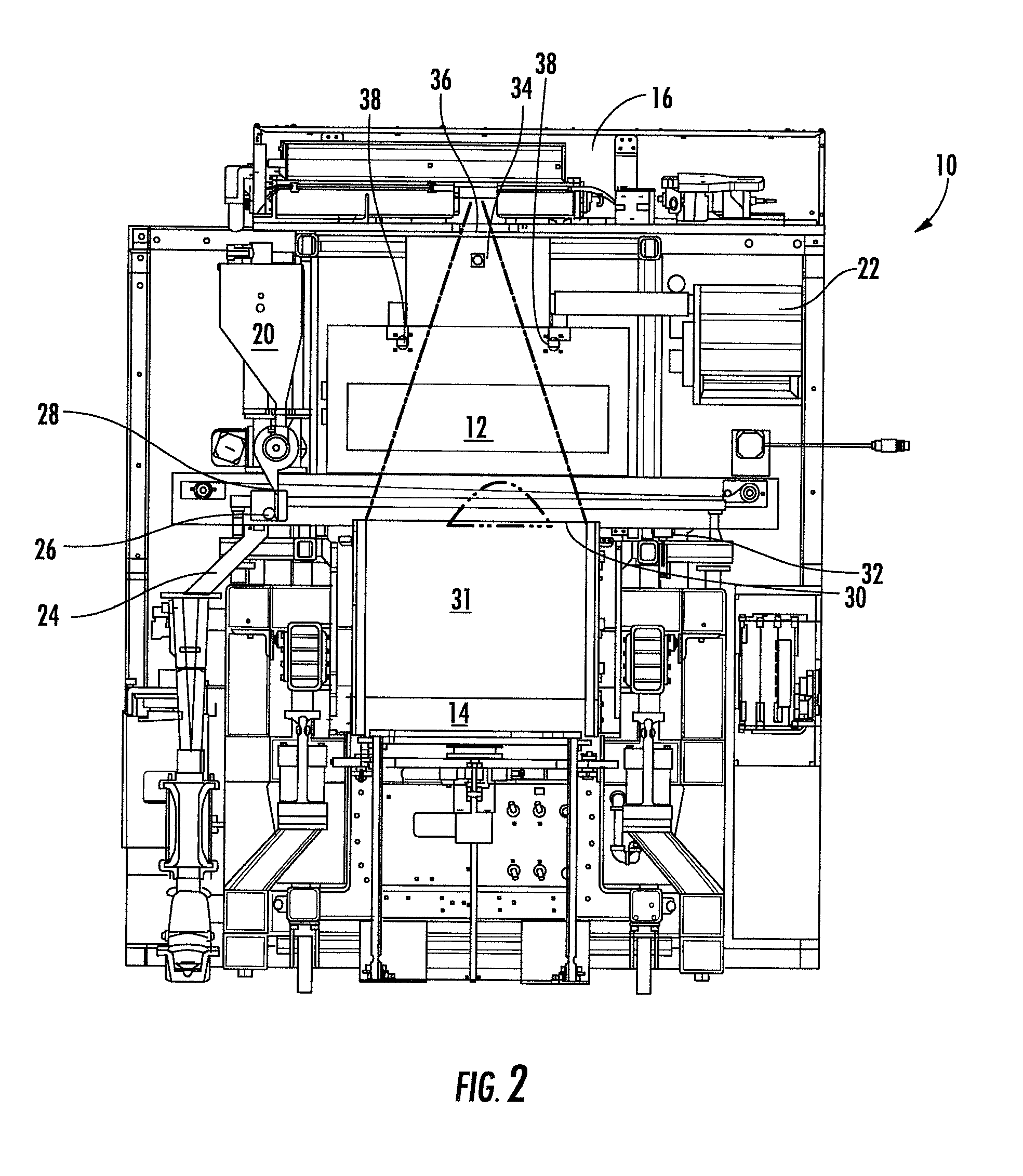

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

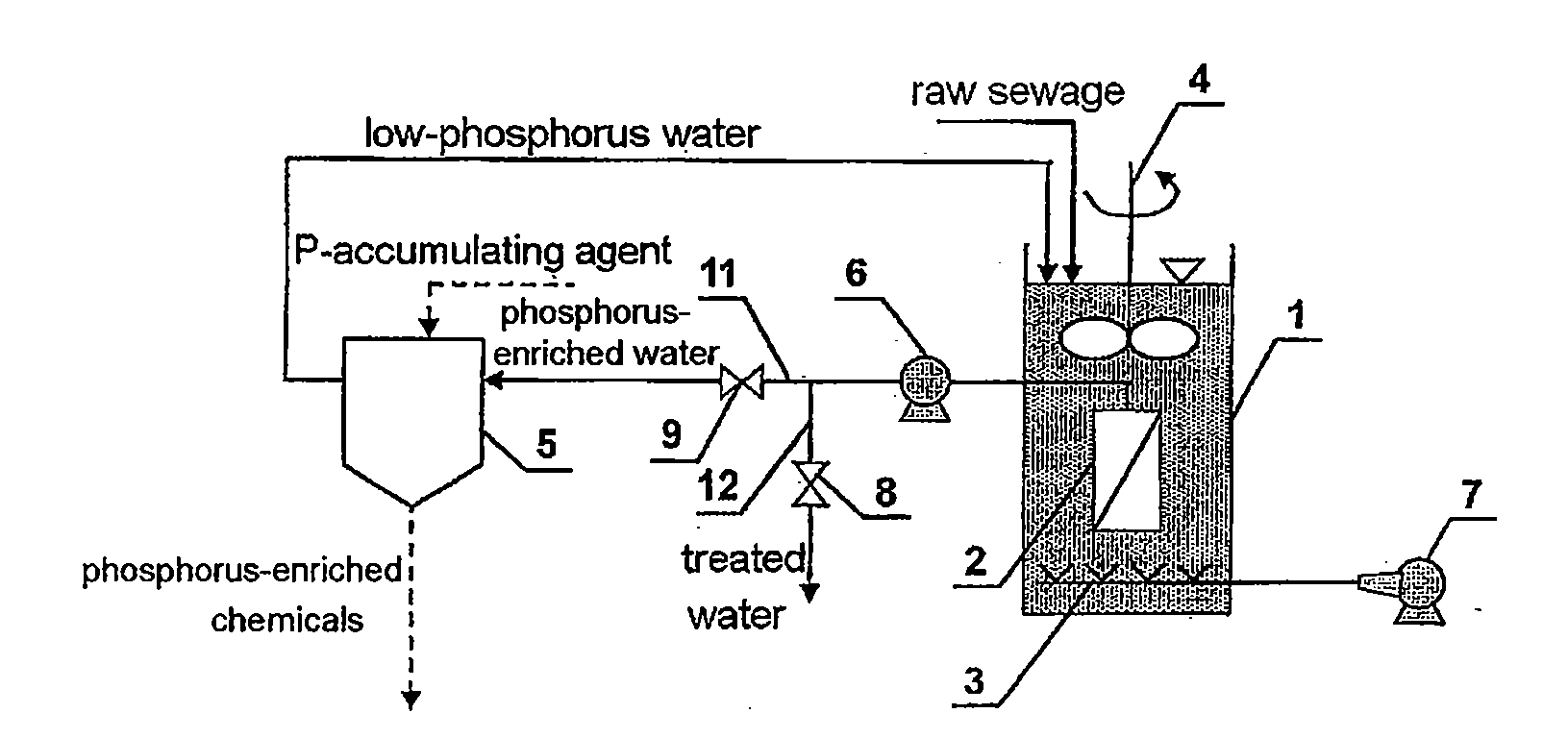

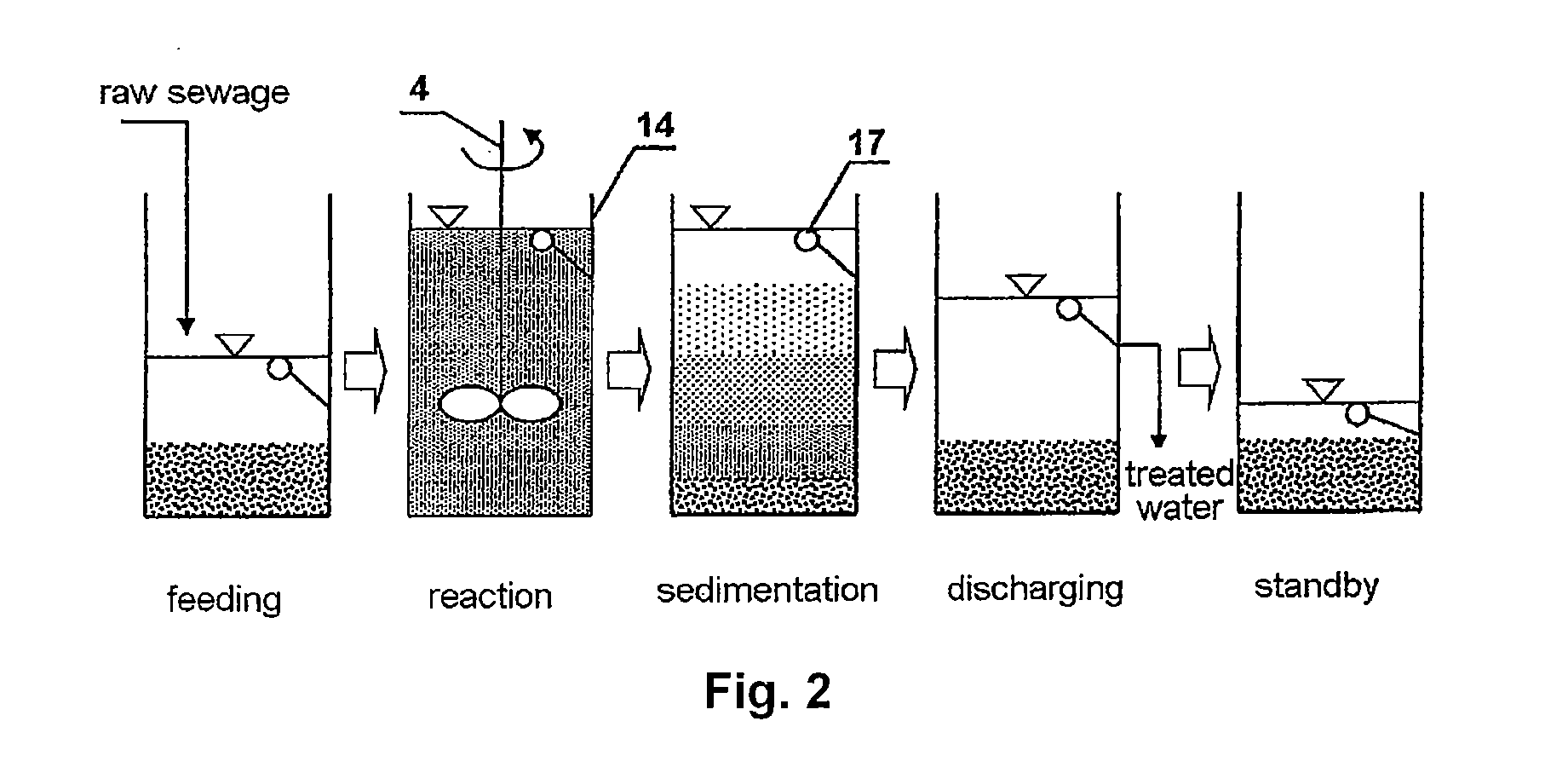

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

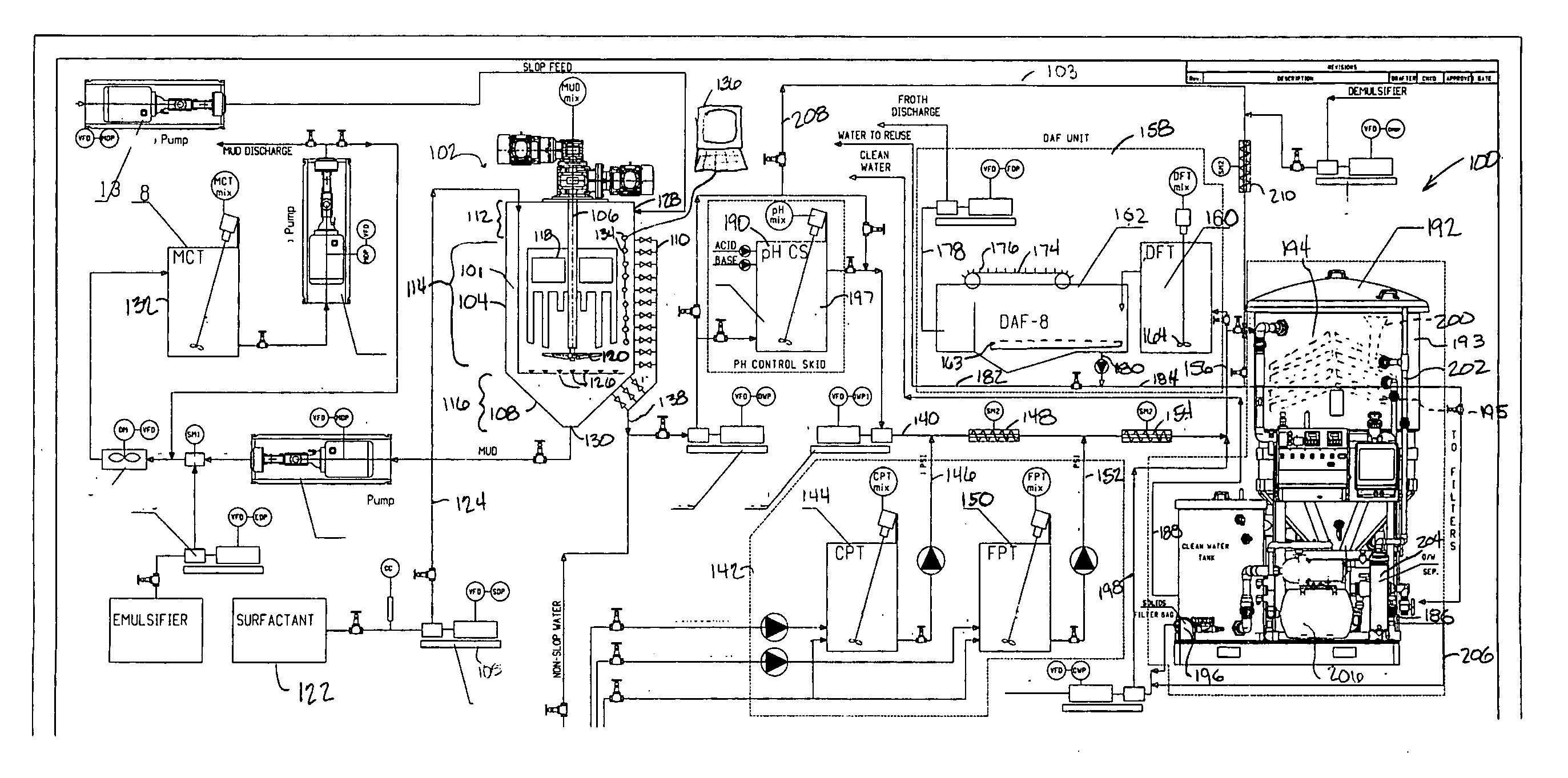

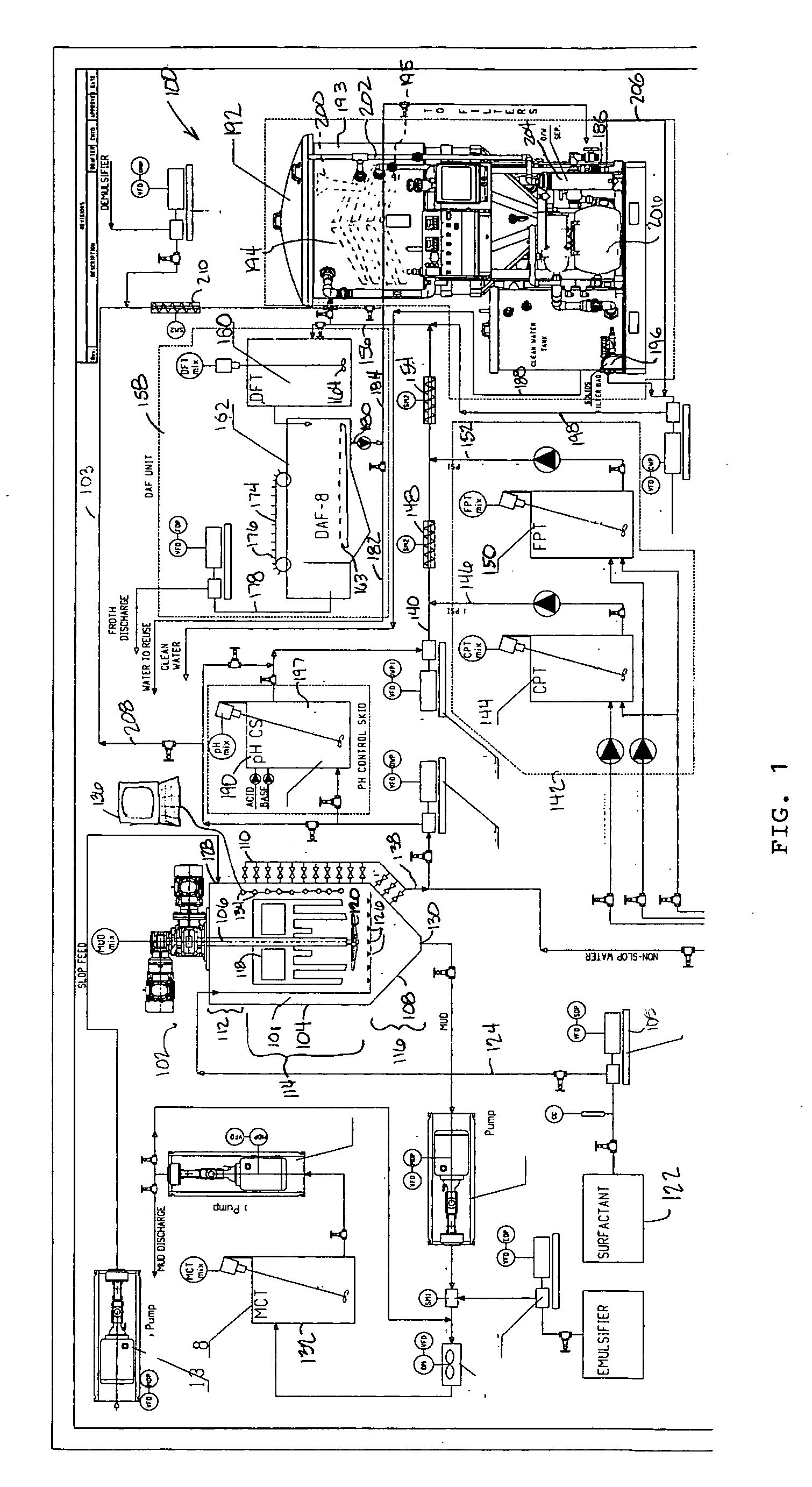

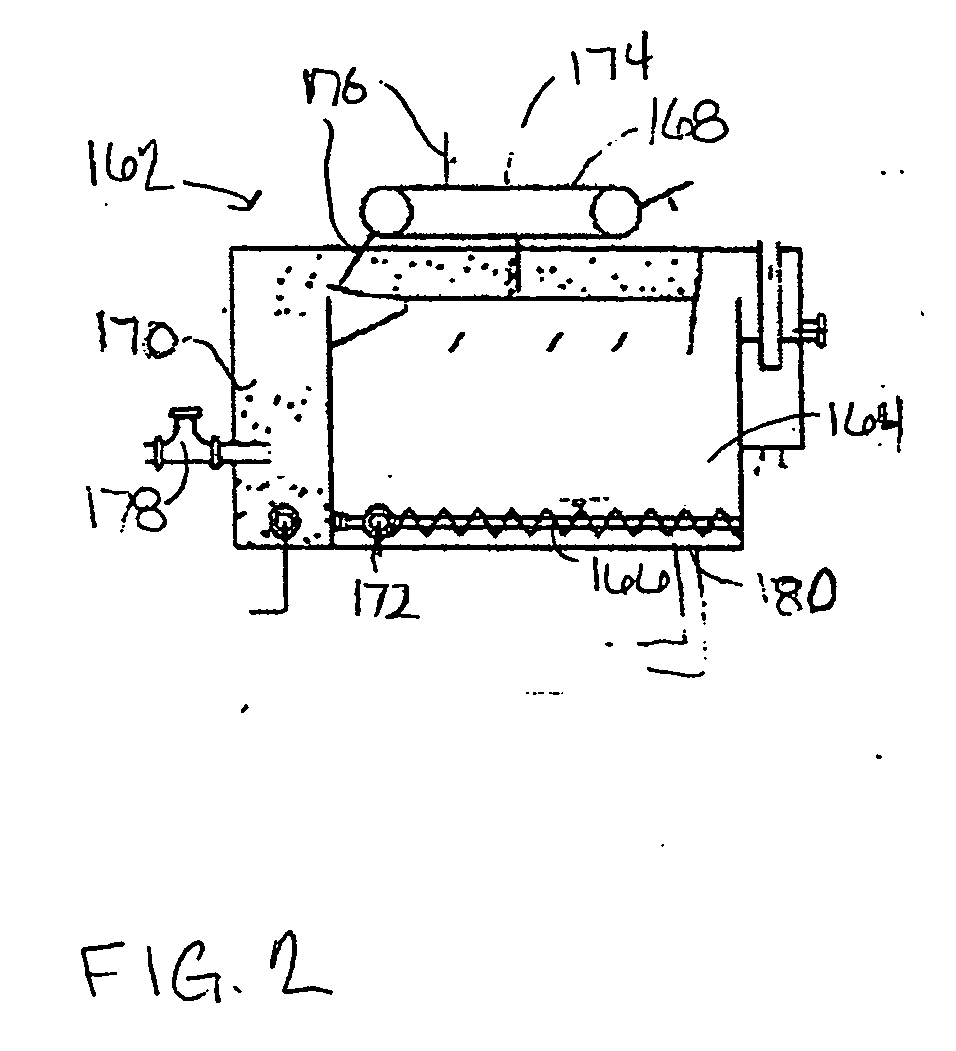

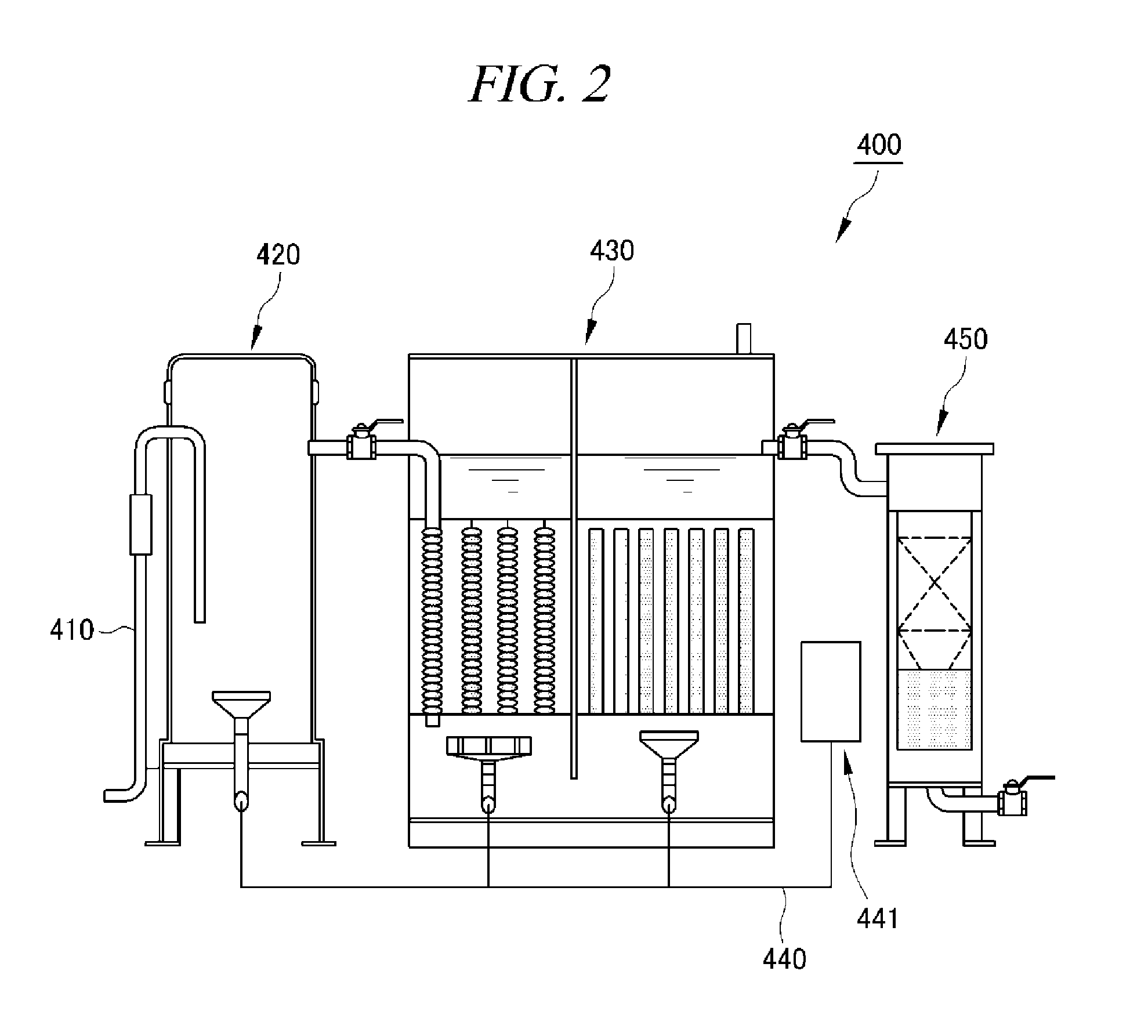

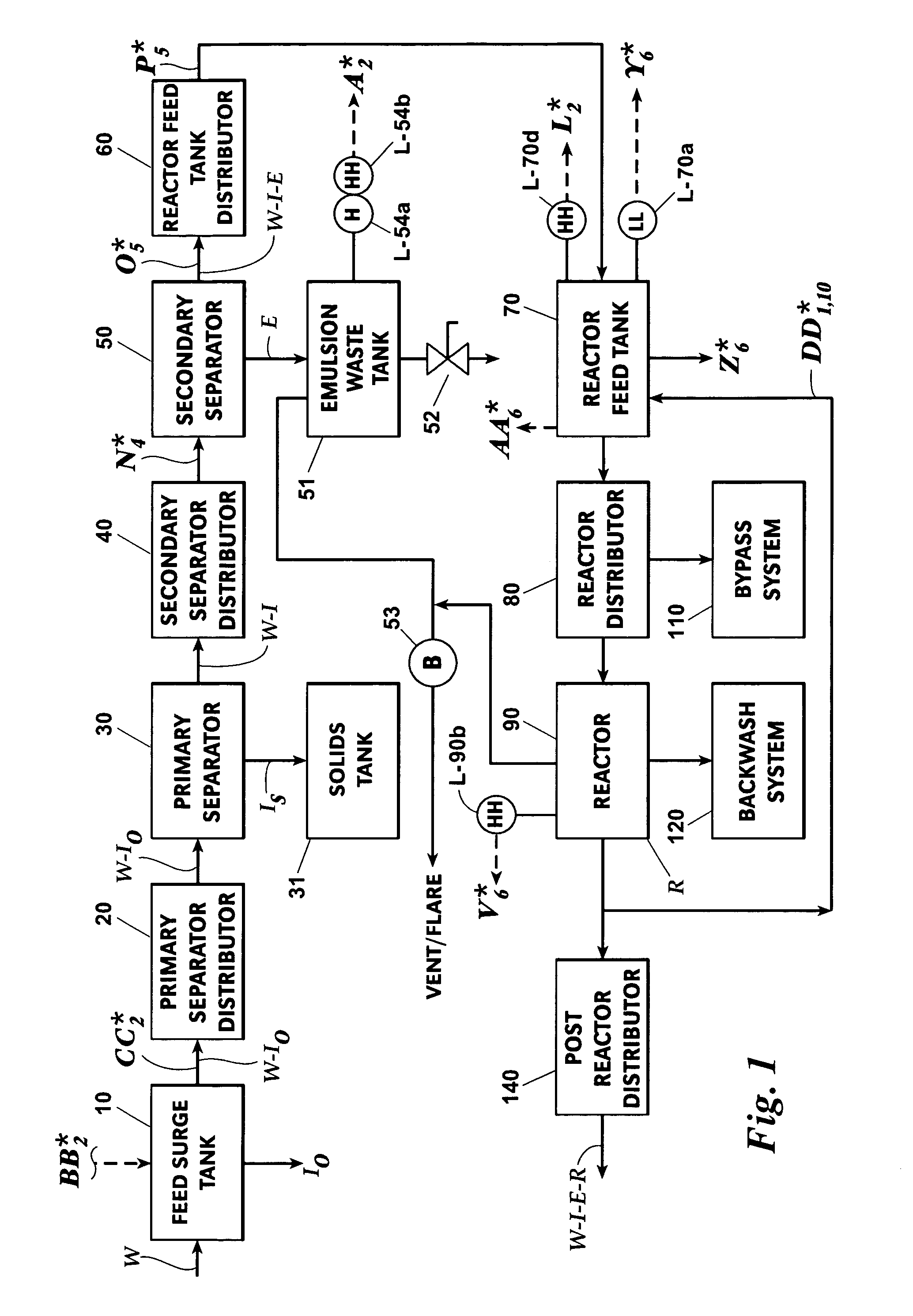

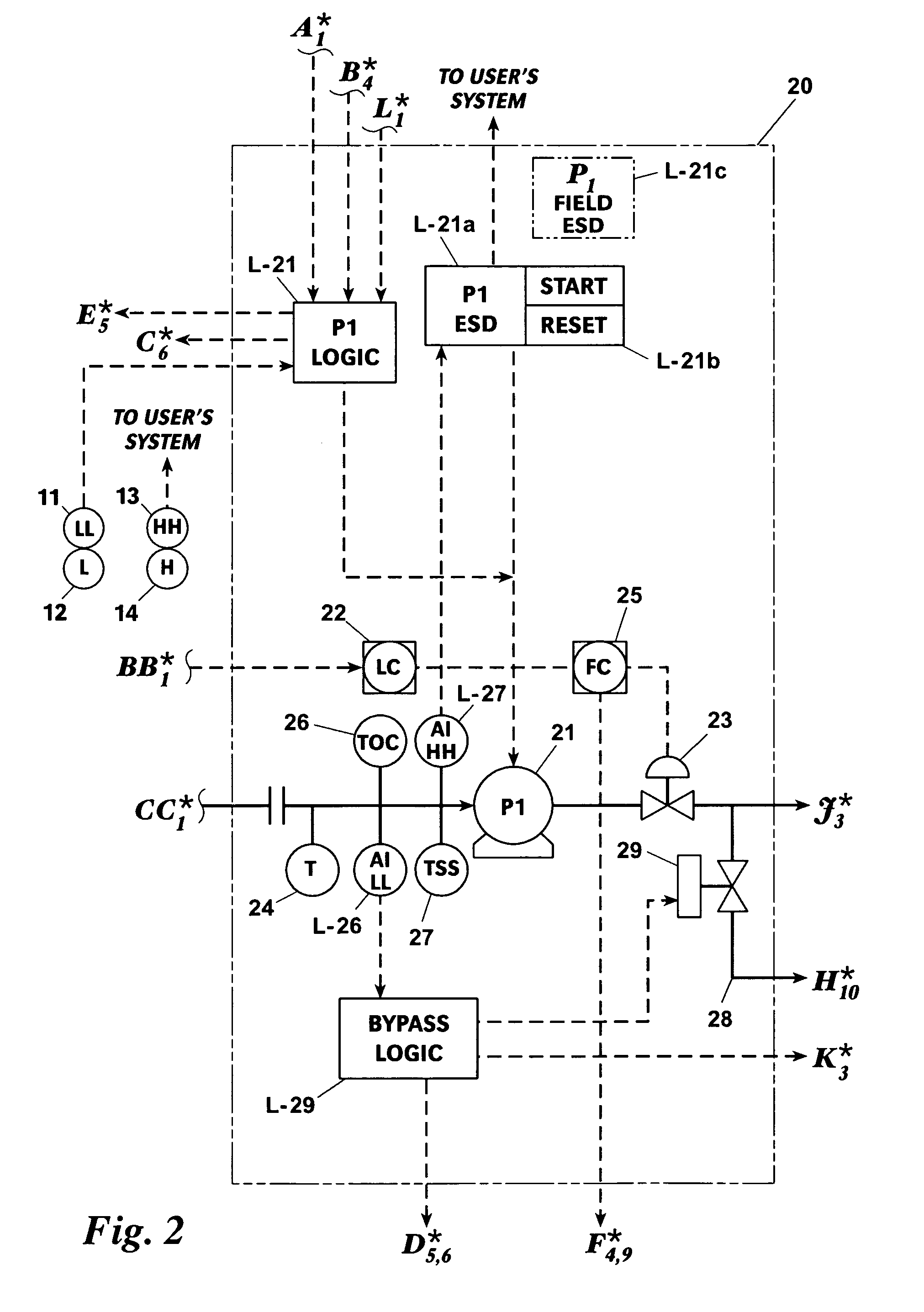

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

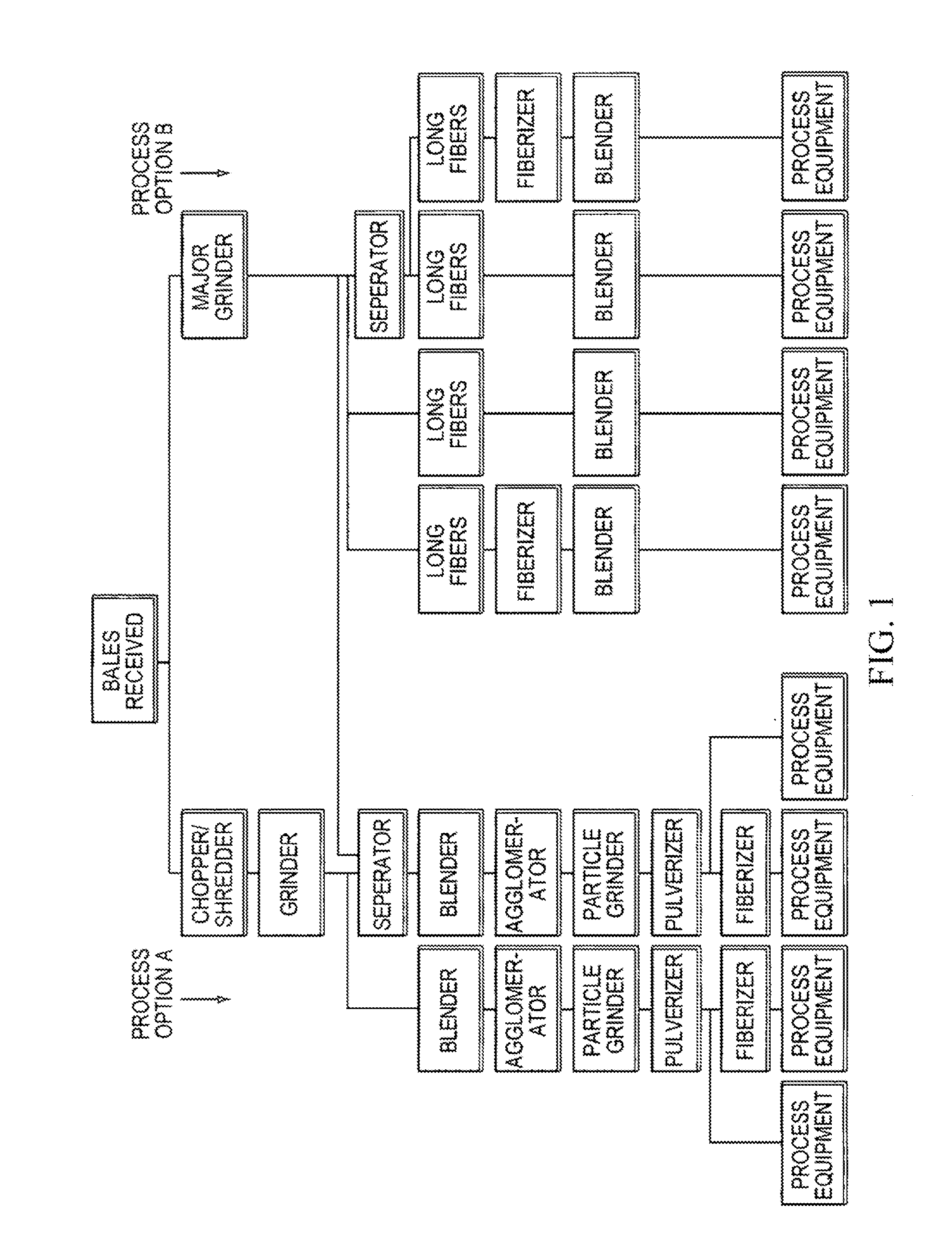

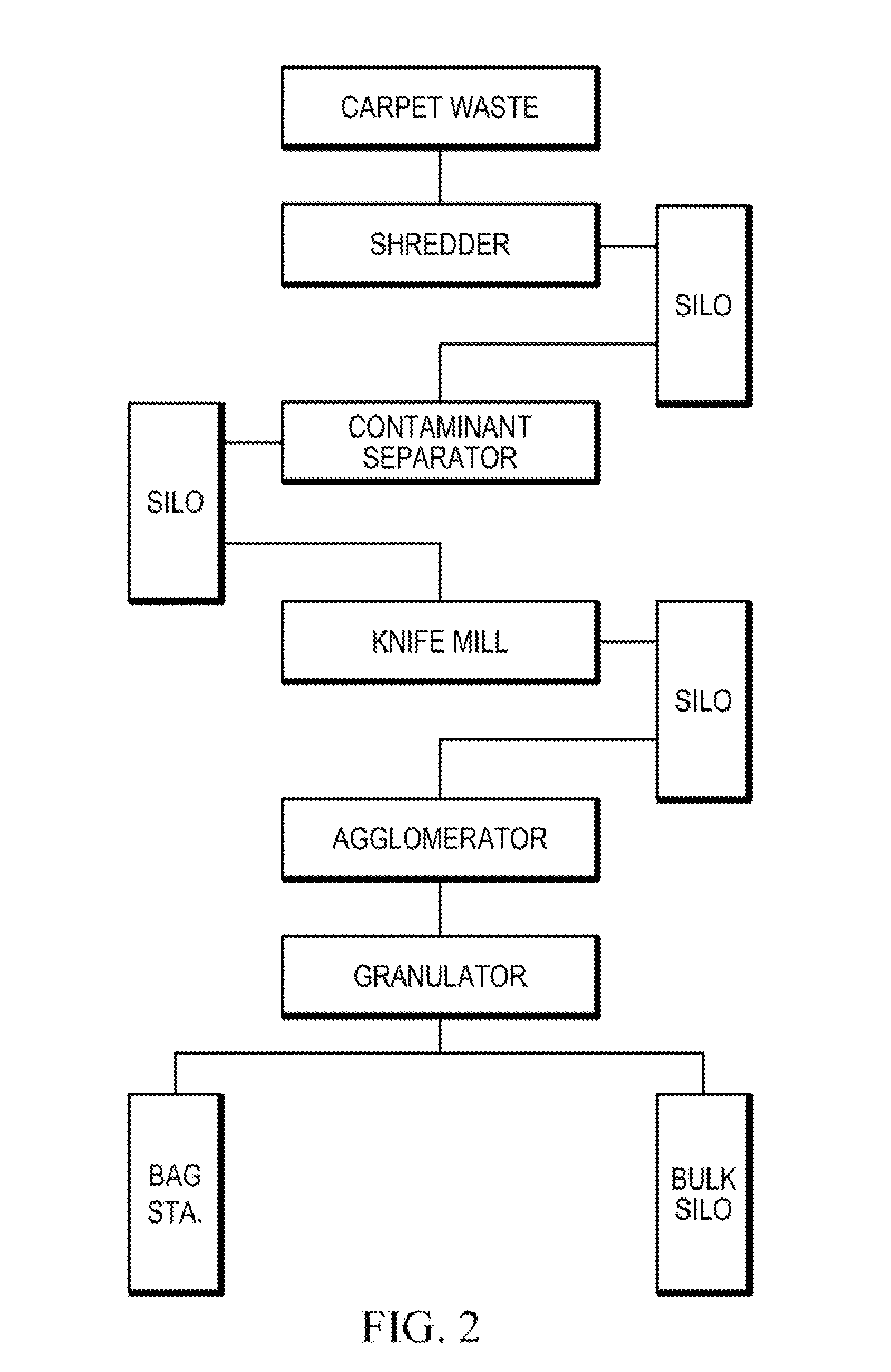

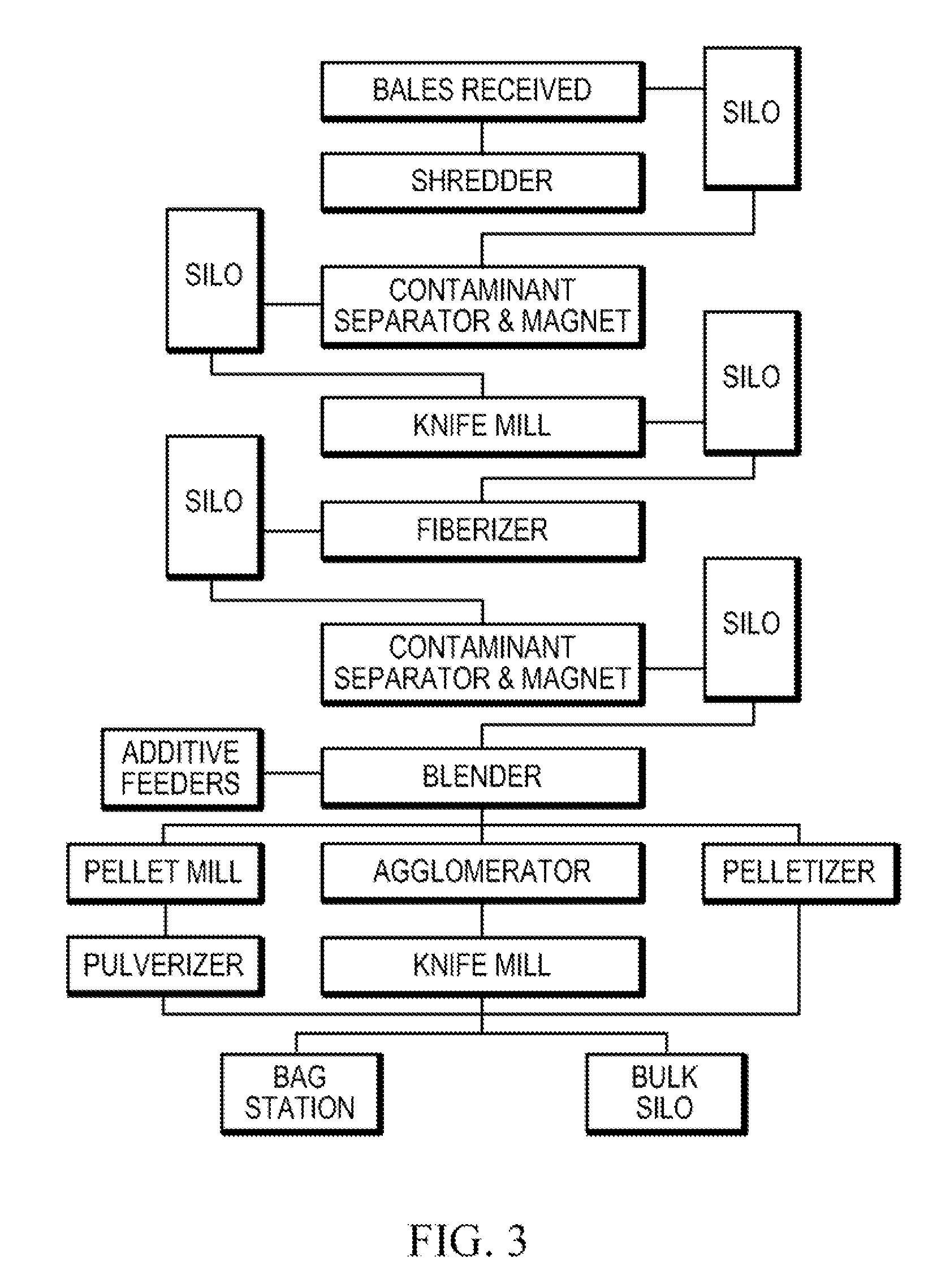

Composite Building Materials and Methods of Manufacture

InactiveUS20120077890A1Reduce manufacturing costImproved resistance to moisture degradation and mildewPlastic recyclingPharmaceutical non-active ingredientsWaxFiber

A composite building material includes carpet waste having carpet fibers and adhesive, and an inorganic filler that includes fly ash. The composite building material may be produced by providing the carpet waste, mixing the carpet waste with the inorganic filler to produce a homogeneous blend, and forming the homogeneous blend into the composite building material. The composite building material may optionally include a base polymer, slack wax, and / or calcium carbonate.

Owner:MATERIAL INNOVATIONS LLC

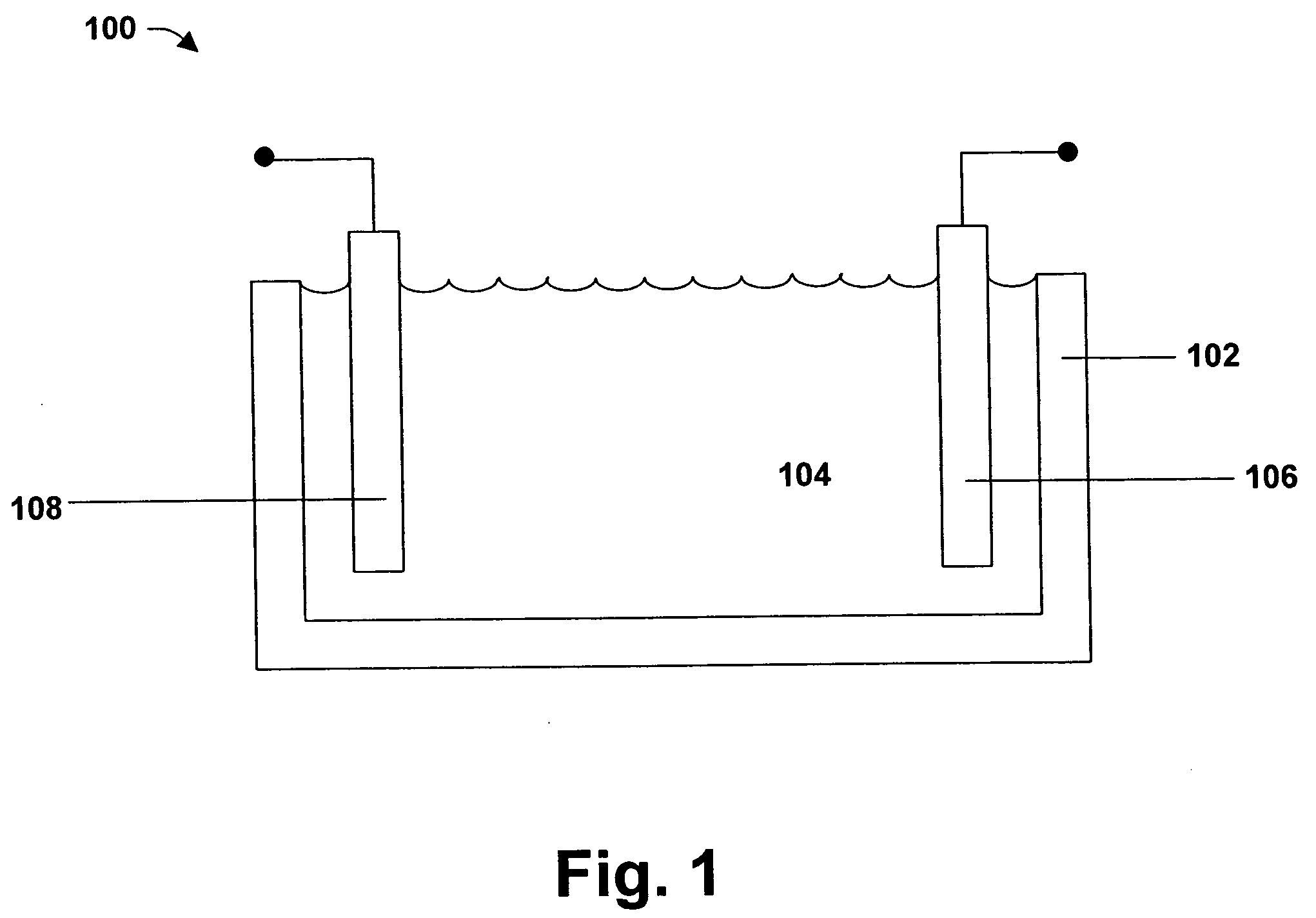

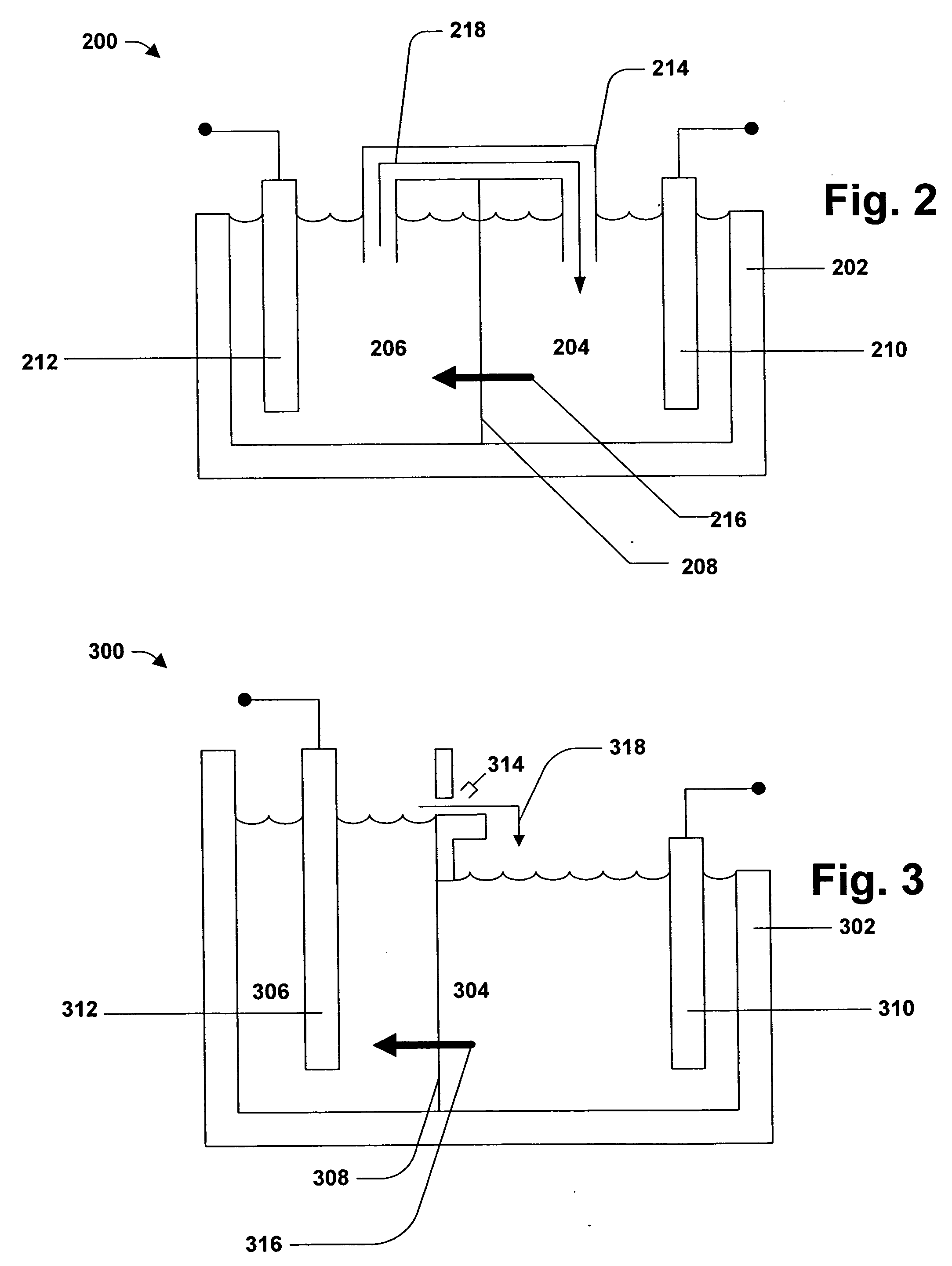

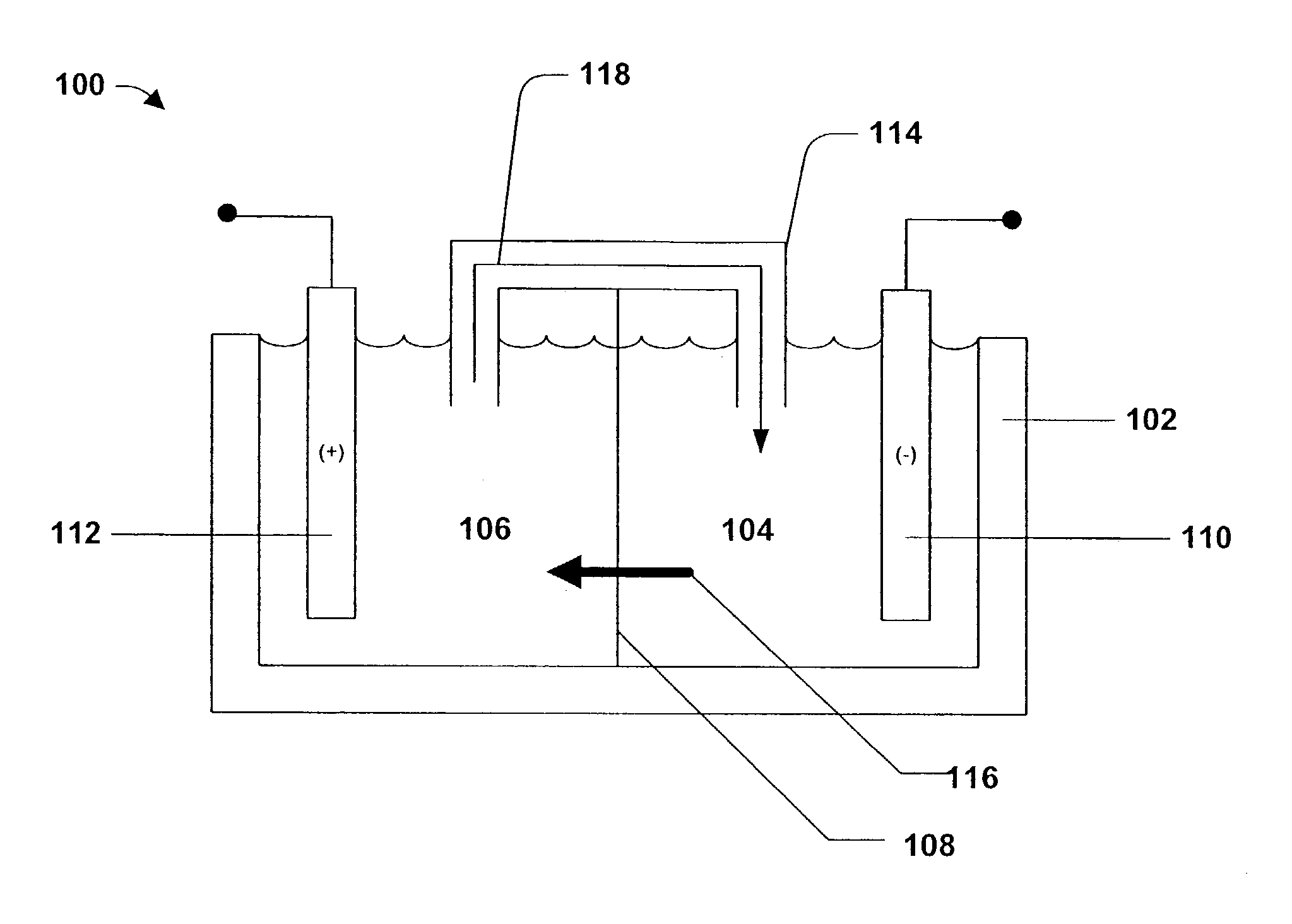

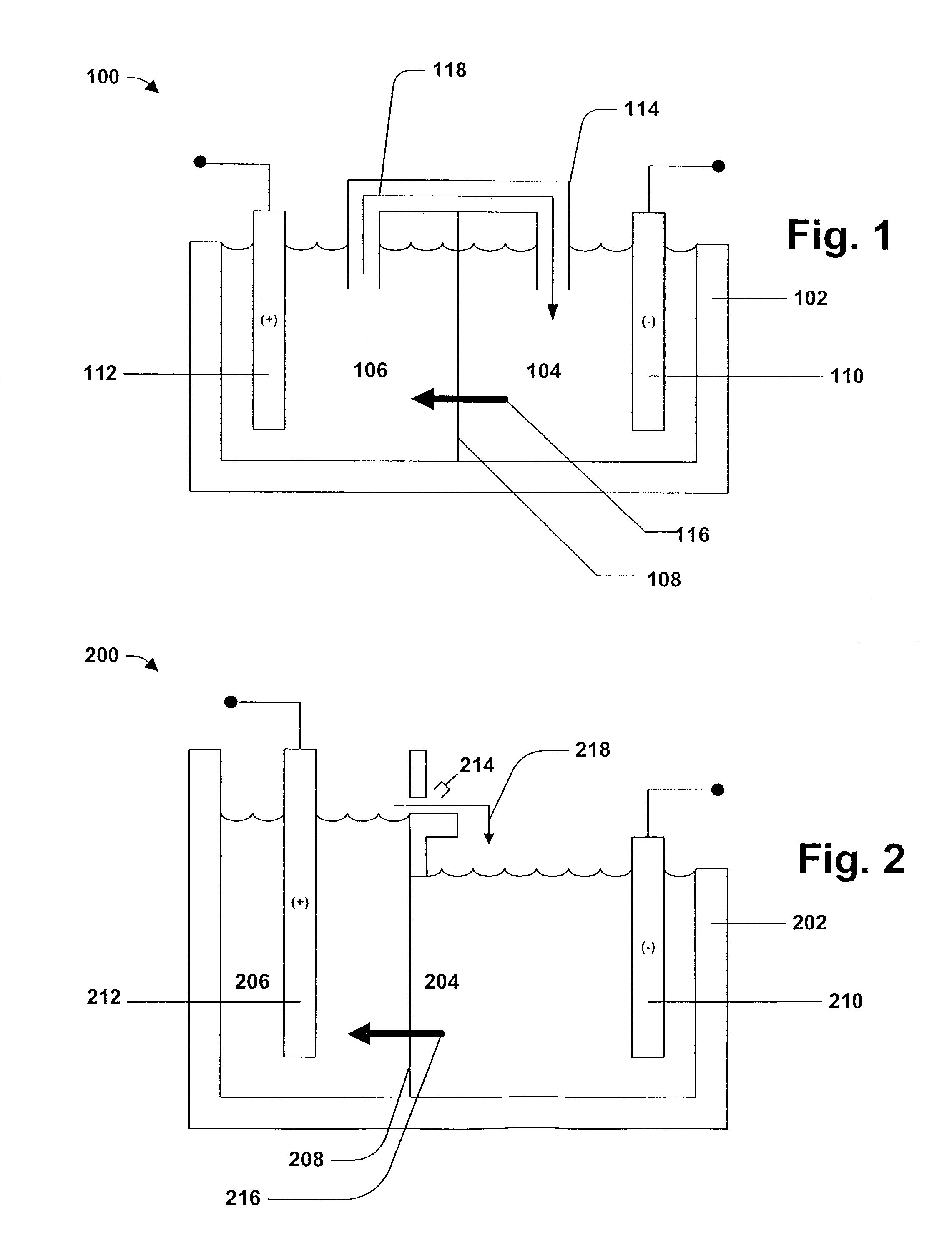

Tin alloy electroplating system

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. The system for plating a tin alloy contains an electrochemical cell containing an anode, the cathode, and an electroplating bath. The electroplating bath contains water, an acid, at least one nitrogen-containing heterocyclic complexing agent, an ionic alloy metal, and ionic tin. The methods involve applying a current to the electroplating bath whereby a tin alloy forms on the cathode.

Owner:TASKEM

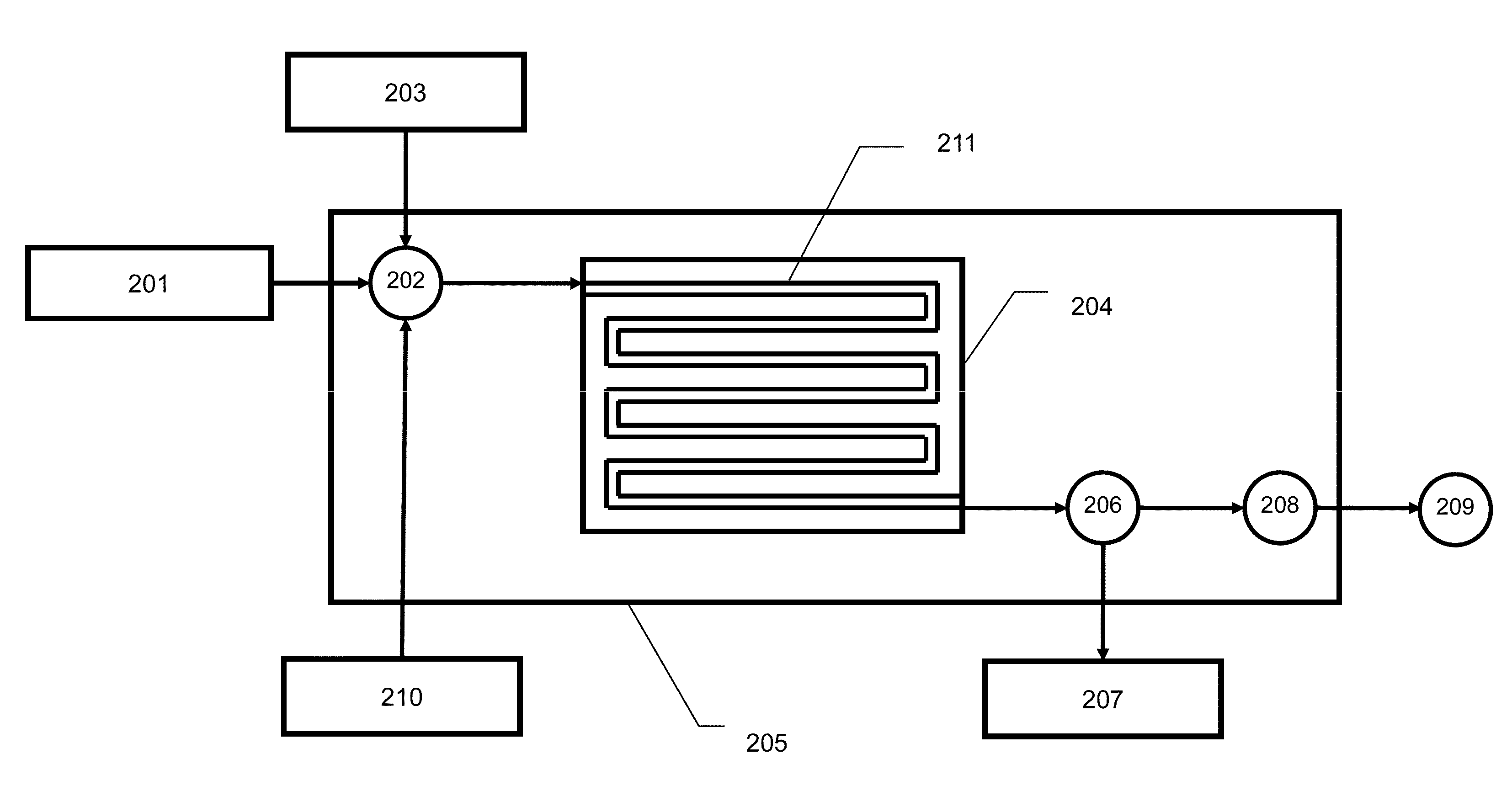

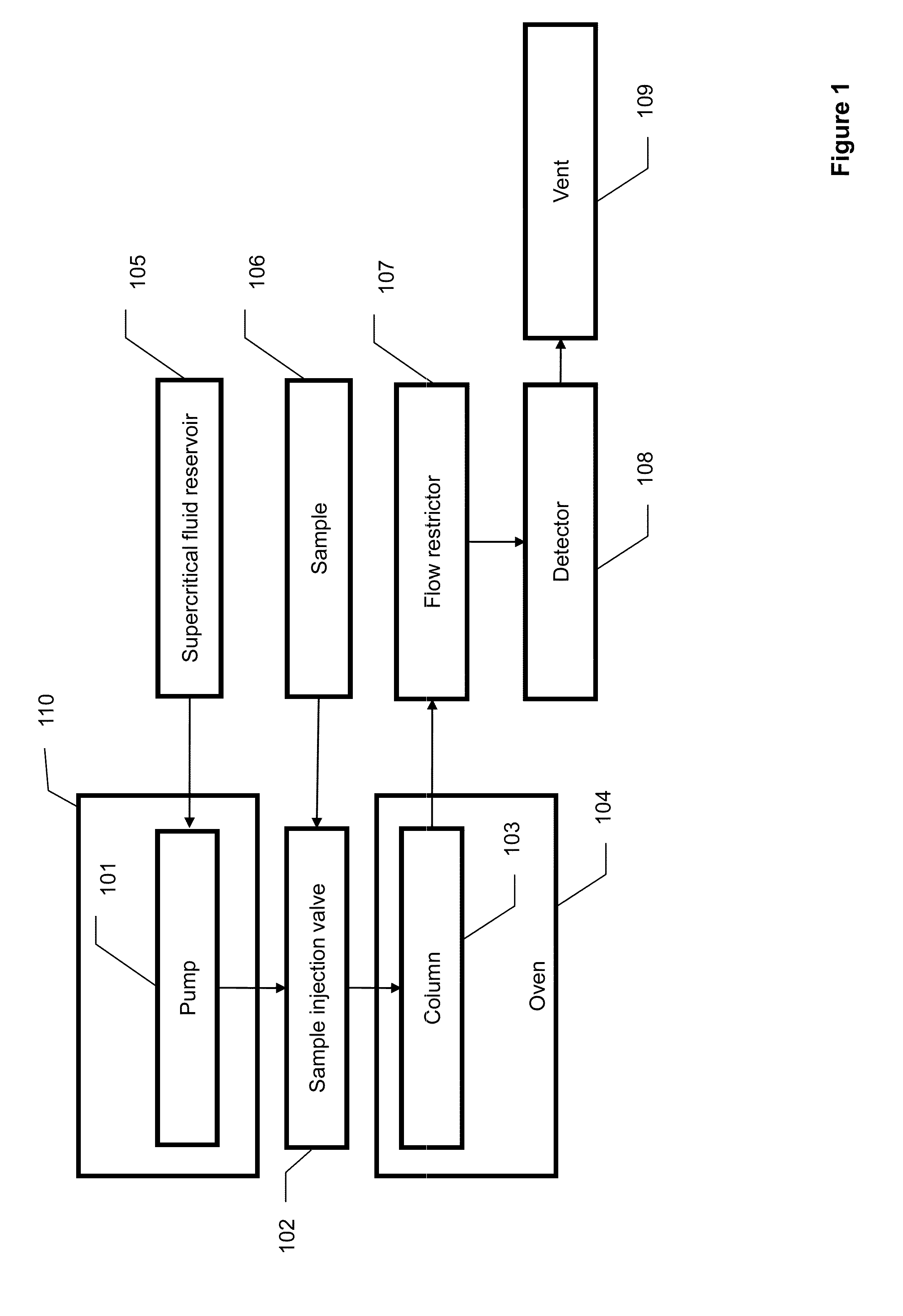

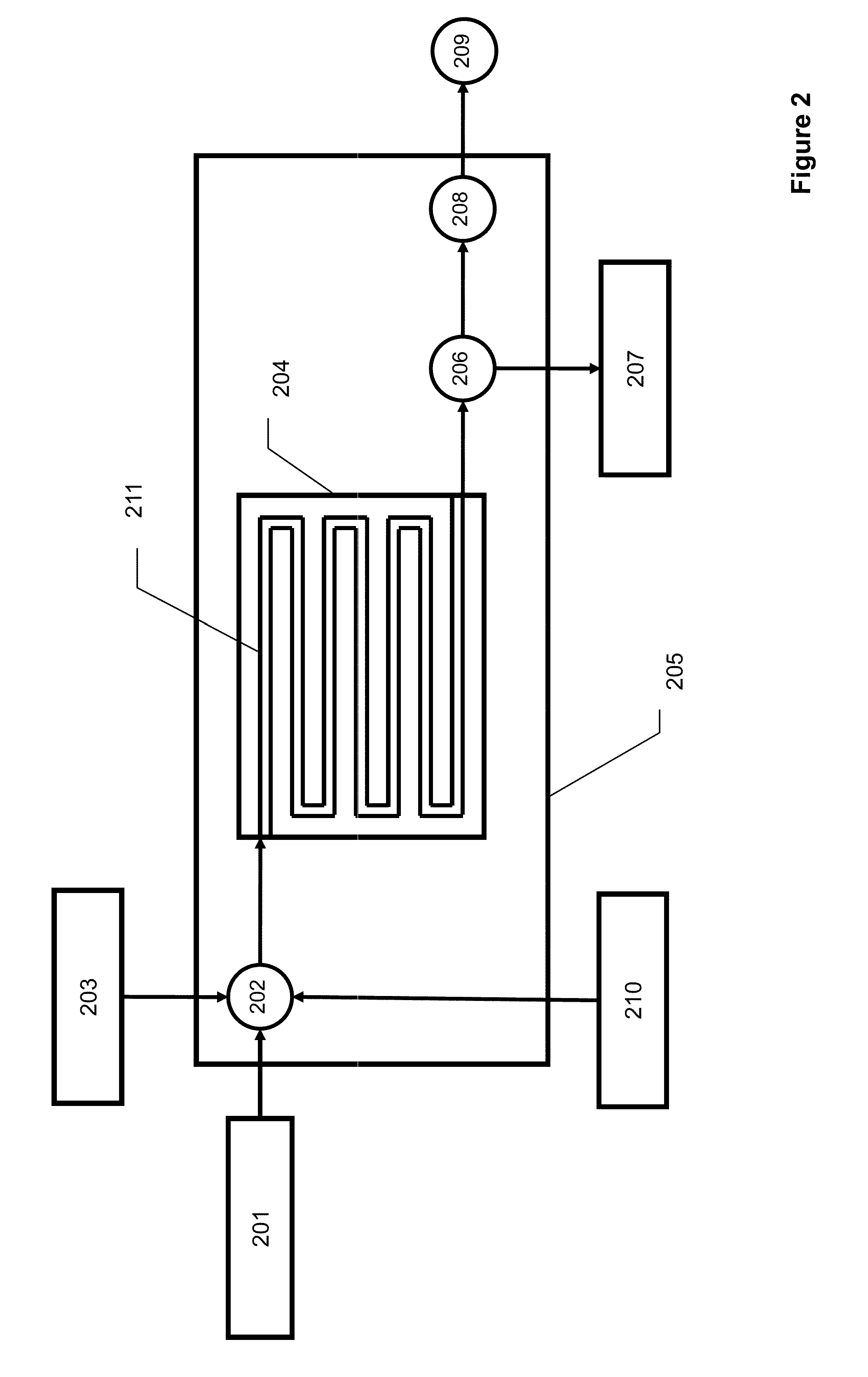

Microengineered Supercritical Fluid Chromatography System

InactiveUS20110113866A1Use littleUse no solventOptical radiation measurementParticle separator tubesTemperature cyclingChromatography column

This invention describes a microengineered SFC system for rapidly and efficiently separating the constituents of a complex mixture. The SFC system includes a microchannel that is microfabricated from a suitable substrate so that it forms a chromatographic column for separation of chemicals. The surface area of the microchannel of the column is sufficiently small as to permit use of miniature and relatively inexpensive pumps, and the thermal mass of the microengineered column is sufficiently low as to permit rapid temperature cycling using a miniature, low power and inexpensive heating element. At least a portion of this microchannel is packed with suitable sorbent materials or includes surfaces which are suitably coated with sorbent, or both, so as to retain and elute analyte under certain conditions. As a result analyte passing within this microchannel undergoes chromatographic separation.

Owner:FINLAY ALAN

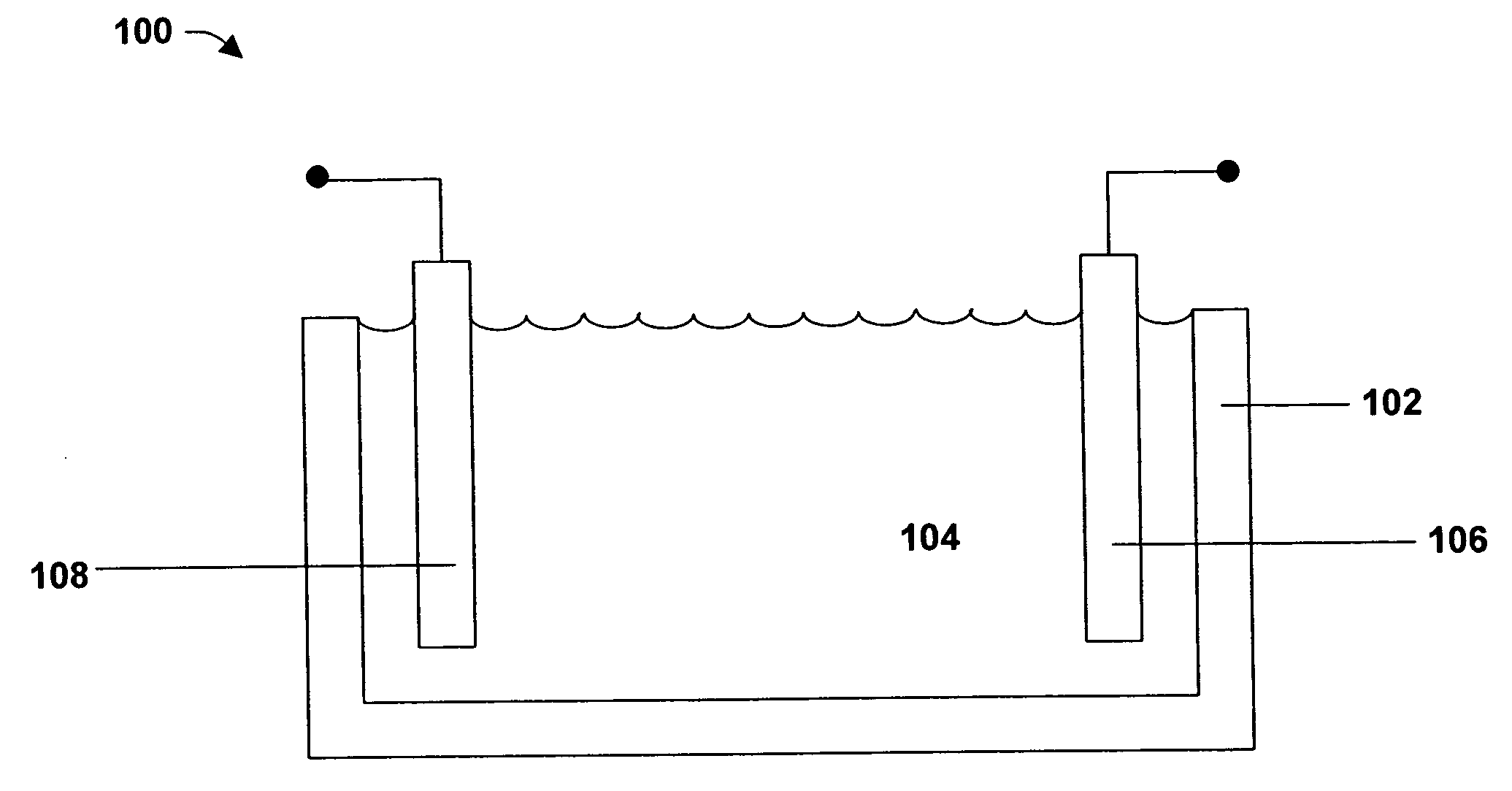

Tin alloy electroplating system

ActiveUS7195702B2Minimizing and eliminating latent whiskeringReduce disposalCellsAlloyElectrochemical cell

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. An electrochemical cell containing an anolyte compartment and a catholyte compartment separated by a selective membrane is employed. The selective membrane prevents ionic metals from migrating from the catholyte compartment to the anolyte compartment. A conduit may be employed in the electrochemical cell to permit one way flow of anolyte to the catholyte compartment thereby replenishing tin to the catholyte compartment.

Owner:COVENTYA INC

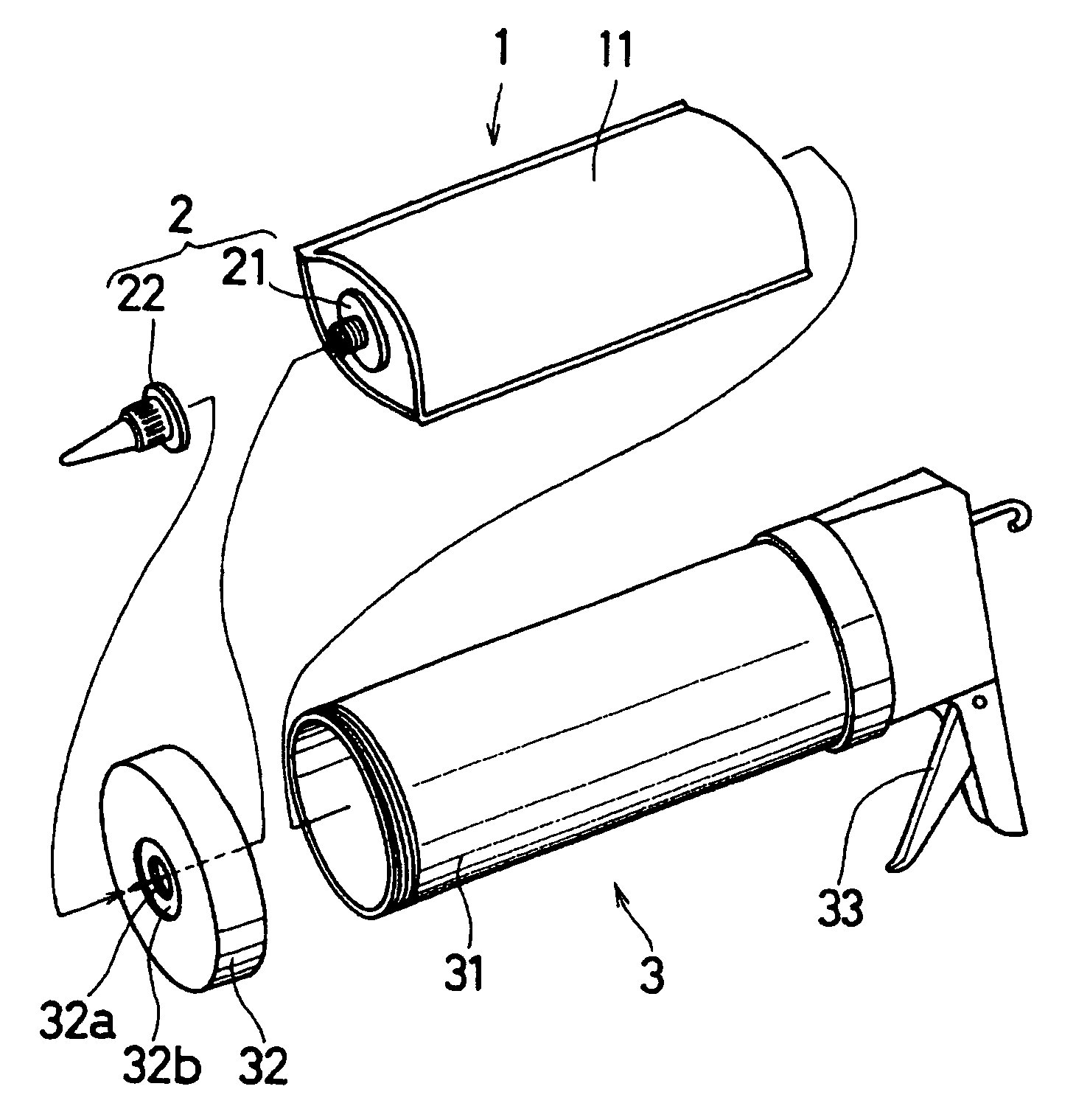

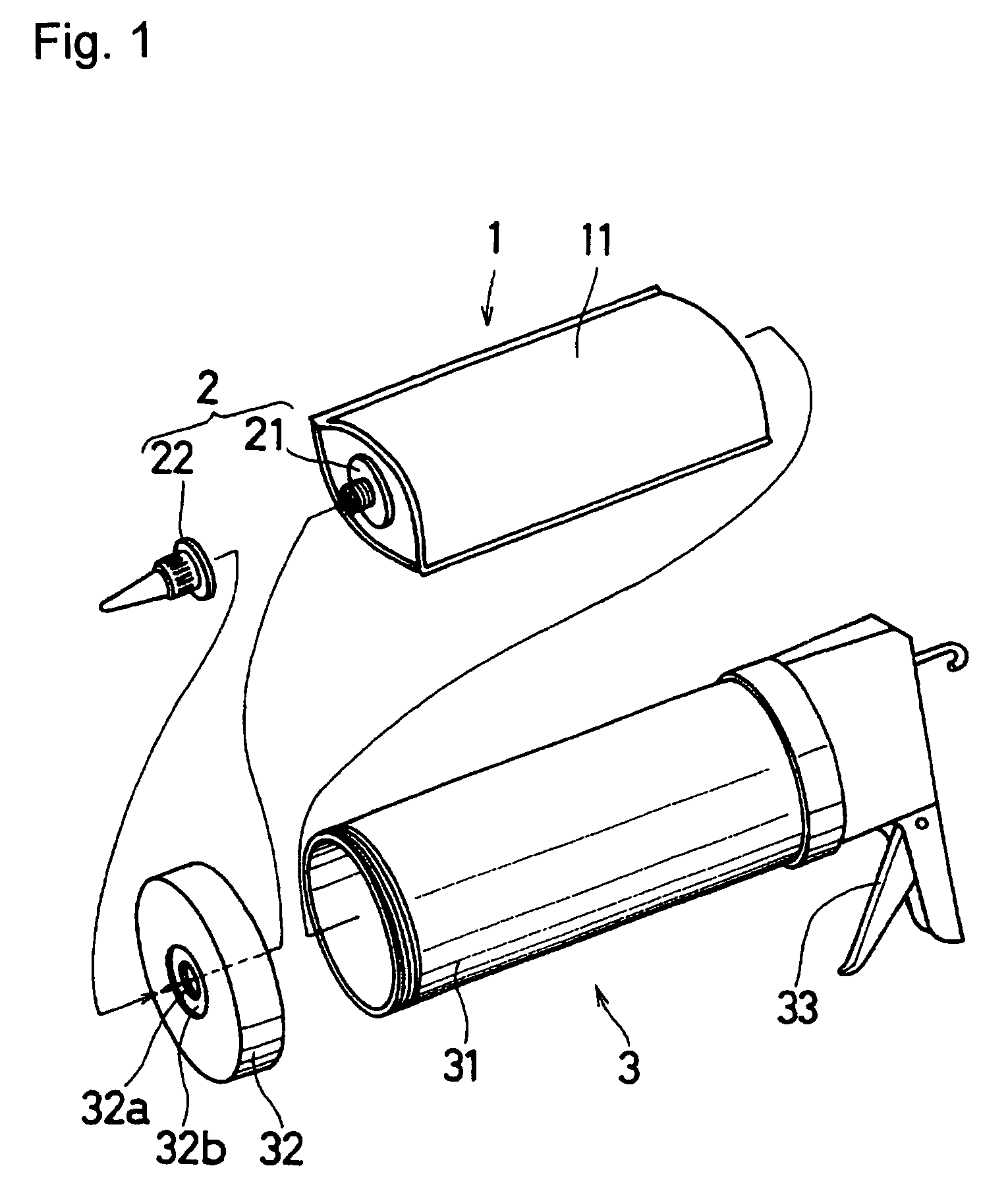

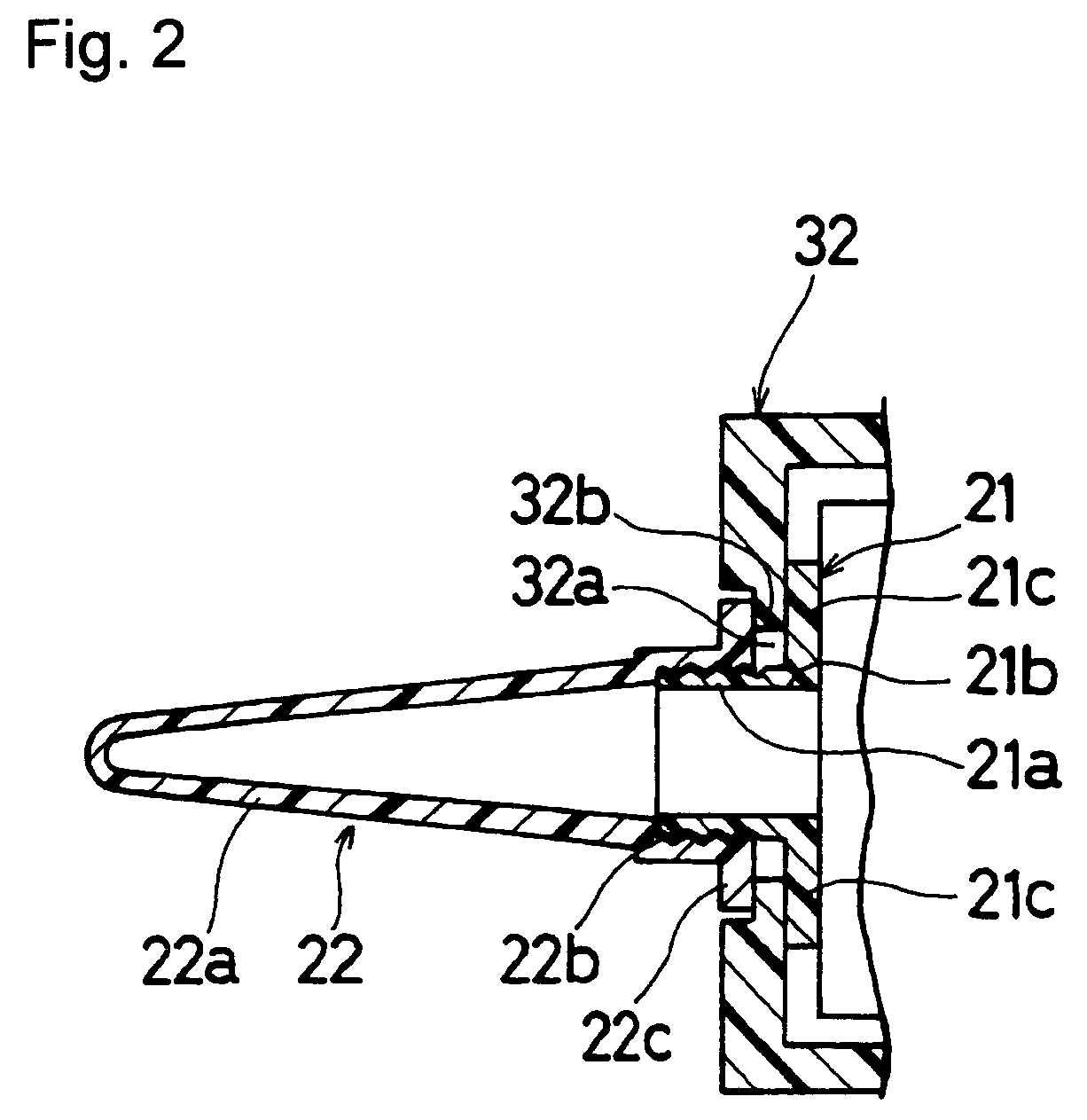

Container and pusiier

InactiveUS7445135B2Low costExtrusion process is simpleLiquid surface applicatorsBagsEngineeringSealant

A container, which houses a liquid such as a sealant in a flexible pouch 11 in a sealed state, is provided with a spout 2 that is constituted by an extrusion nozzle 22 and a spout base member 21 and formed on one end thereof so that the extrusion nozzle 22 is fixed by sandwiching the vicinity of a hole 32a formed on one end face of an extruder 3 by a flange portion 21c of the spout base member 21 and a flange portion 22c of the extrusion nozzle 22, and an extruder 3a is arranged so that an adjusting member 322b, which controls the tilt of the nozzle 22, is allowed to protrude outward from a hole 322a of the extruder 3a.

Owner:SHARP KAGAKU INDS

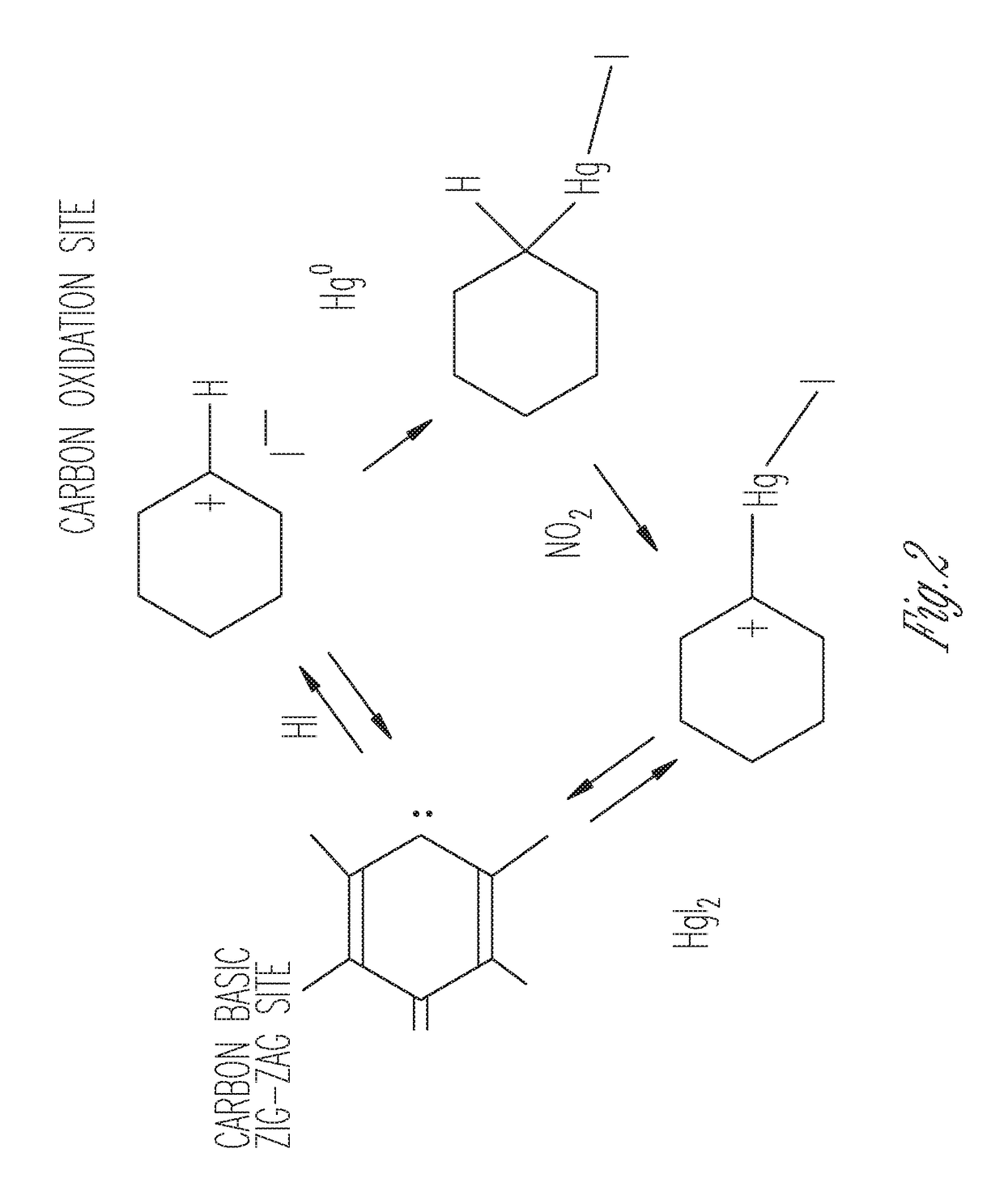

Activated carbon sorbent including nitrogen and methods of using the same

ActiveUS20140255279A1Reduce disposalLow costOxygen/ozone/oxide/hydroxideGas treatmentActivated carbonHalogen

The present invention relates to activated carbon sorbents including nitrogen. In various embodiments, the present invention provides an activated carbon sorbent including a halogen- or halide-promoted activated carbon, the activated carbon sorbent particles including nitrogen in a surface layer of the sorbent particles. In various embodiments, the present invention provides a method of reducing the pollutant content in a pollutant-containing gas using the activated carbon sorbent. In various embodiments, the activated carbon sorbent can remove mercury from a mercury-containing gas that includes sulfur(VI) such as SO3 more efficiently than other sorbents.

Owner:MIDWEST ENERGY EMISSIONS CORP

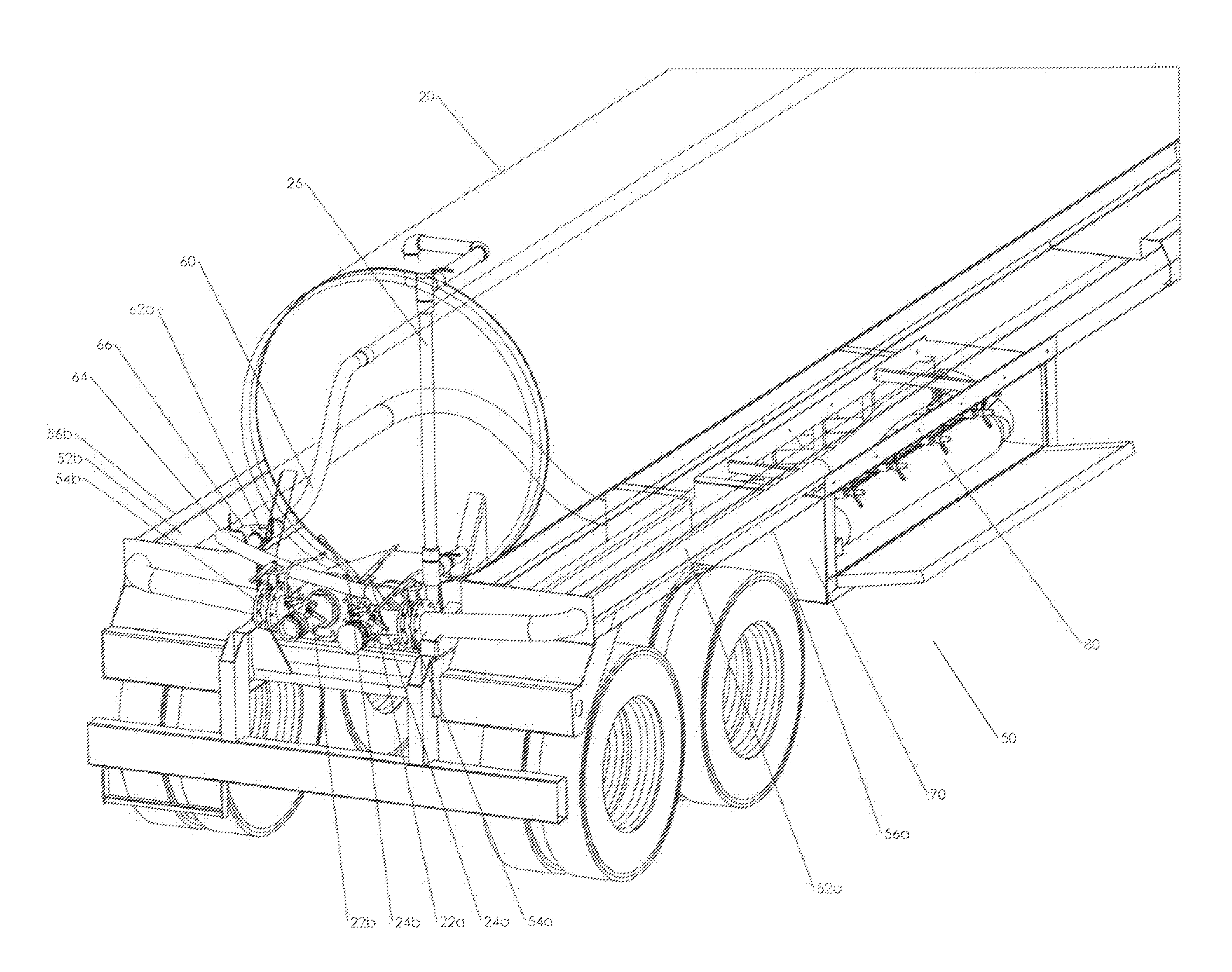

Mobile water treatment

ActiveUS20110089123A1Reduces water procurementReduce transportationWaste water treatment from quariesWatering devicesFiltrationWater treatment

A mobile water treatment apparatus to on-load a dirty fluid into a storage container attached to a motor vehicle and transport the fluid in the storage container from a first location and to a second location where the fluid is filtered by a filtration system attached to the motor vehicle. The filtered fluid is discharged from the mobile water treatment apparatus at the second location.

Owner:IBEX

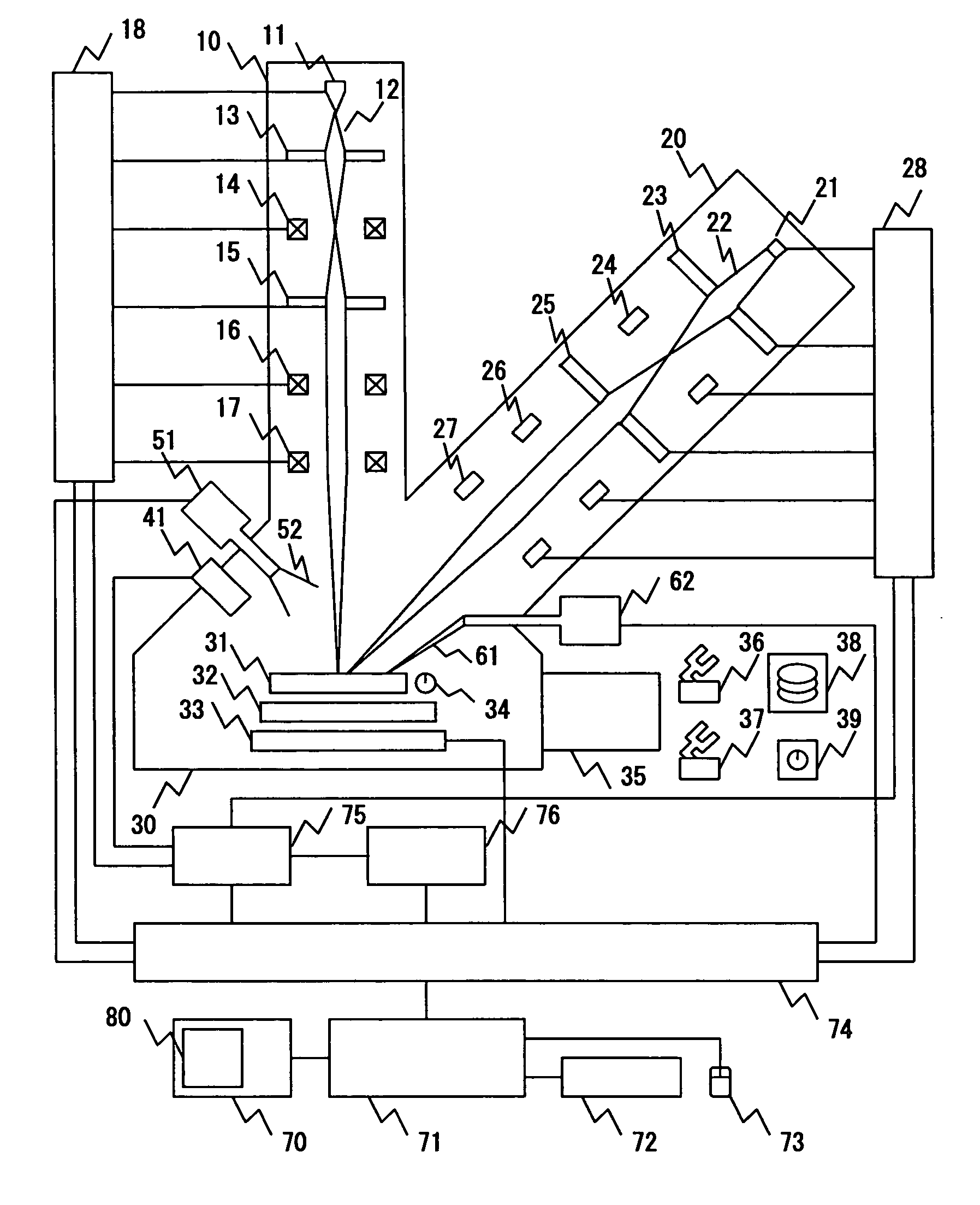

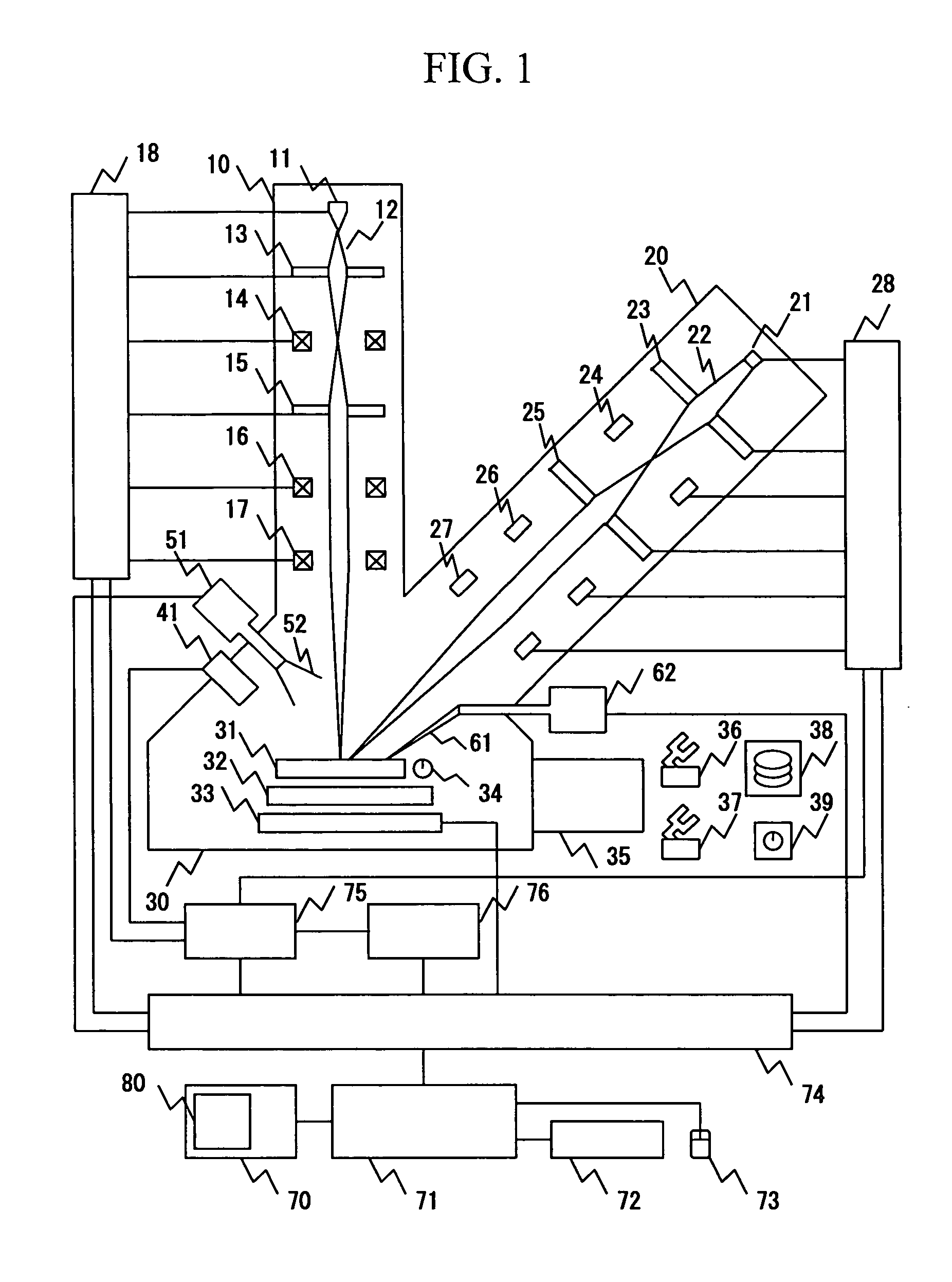

Charged particle beam system, semiconductor inspection system, and method of machining sample

InactiveUS20070158560A1Accurately taken outReduce disposalMaterial analysis using wave/particle radiationElectric discharge tubesIon sourceSemiconductor

Provided is a technique for accurately taking out a defect detected by an electron beam, and for analyzing the defect. In this technique, a defective portion in a wafer is detected by the irradiation of the electron beam. A mark made of a deposition layer is formed by irradiating the electron beam onto the defective portion while supplying a deposition gas thereto. On the basis of this mark, the defective portion is machined into a sample piece by using a projection ion beam generated from a gas ion source, and thereby the defective portion is taken out.

Owner:HITACHI HIGH-TECH CORP

Activated carbon sorbent including nitrogen and methods of using the same

The present invention relates to activated carbon sorbents including nitrogen. In various embodiments, the present invention provides an activated carbon sorbent including a halogen- or halide-promoted activated carbon, the activated carbon sorbent particles including nitrogen in a surface layer of the sorbent particles. In various embodiments, the present invention provides a method of reducing the pollutant content in a pollutant-containing gas using the activated carbon sorbent. In various embodiments, the activated carbon sorbent can remove mercury from a mercury-containing gas that includes sulfur(VI) such as SO3 more efficiently than other sorbents.

Owner:MIDWEST ENERGY EMISSIONS CORP

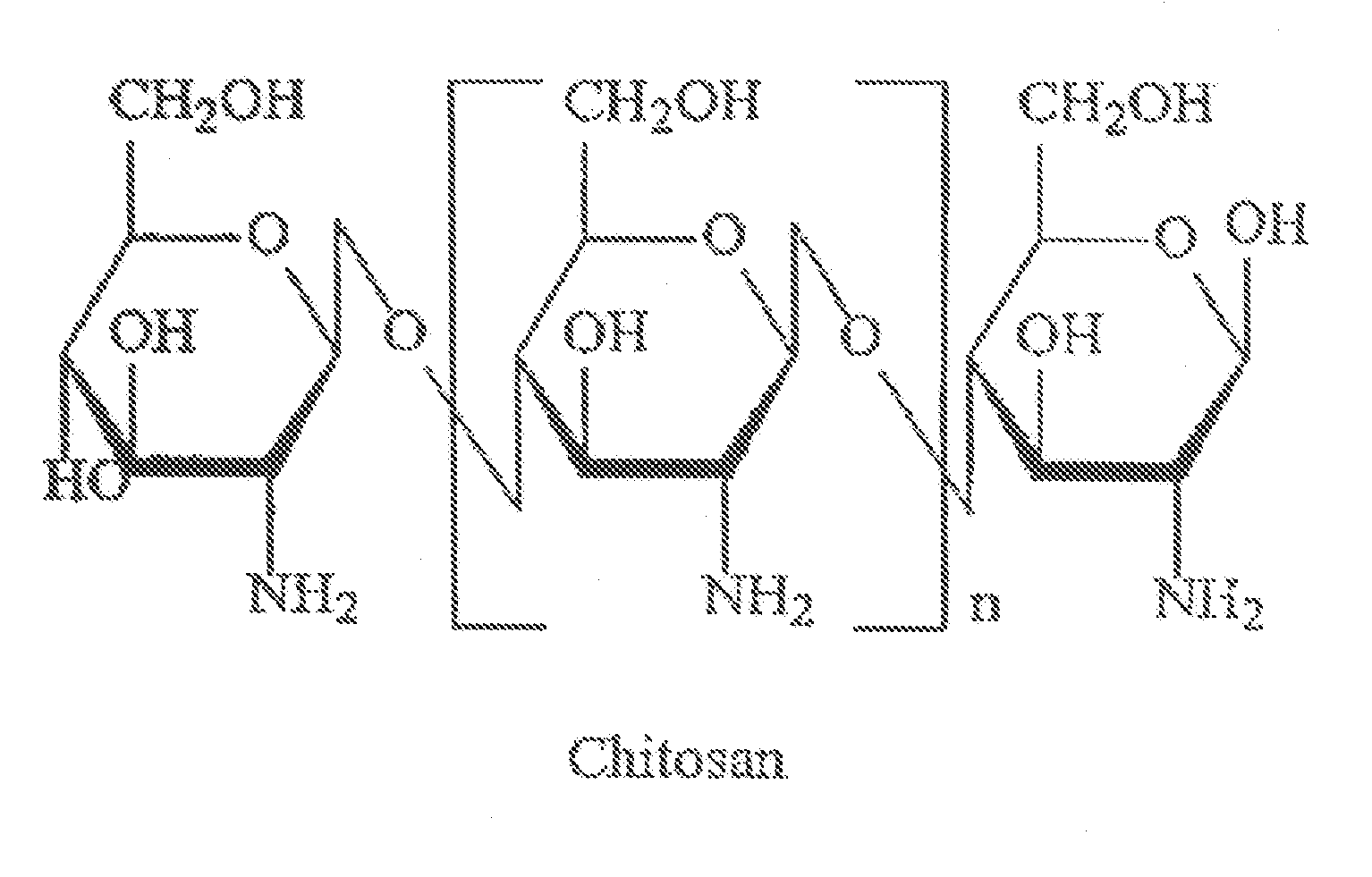

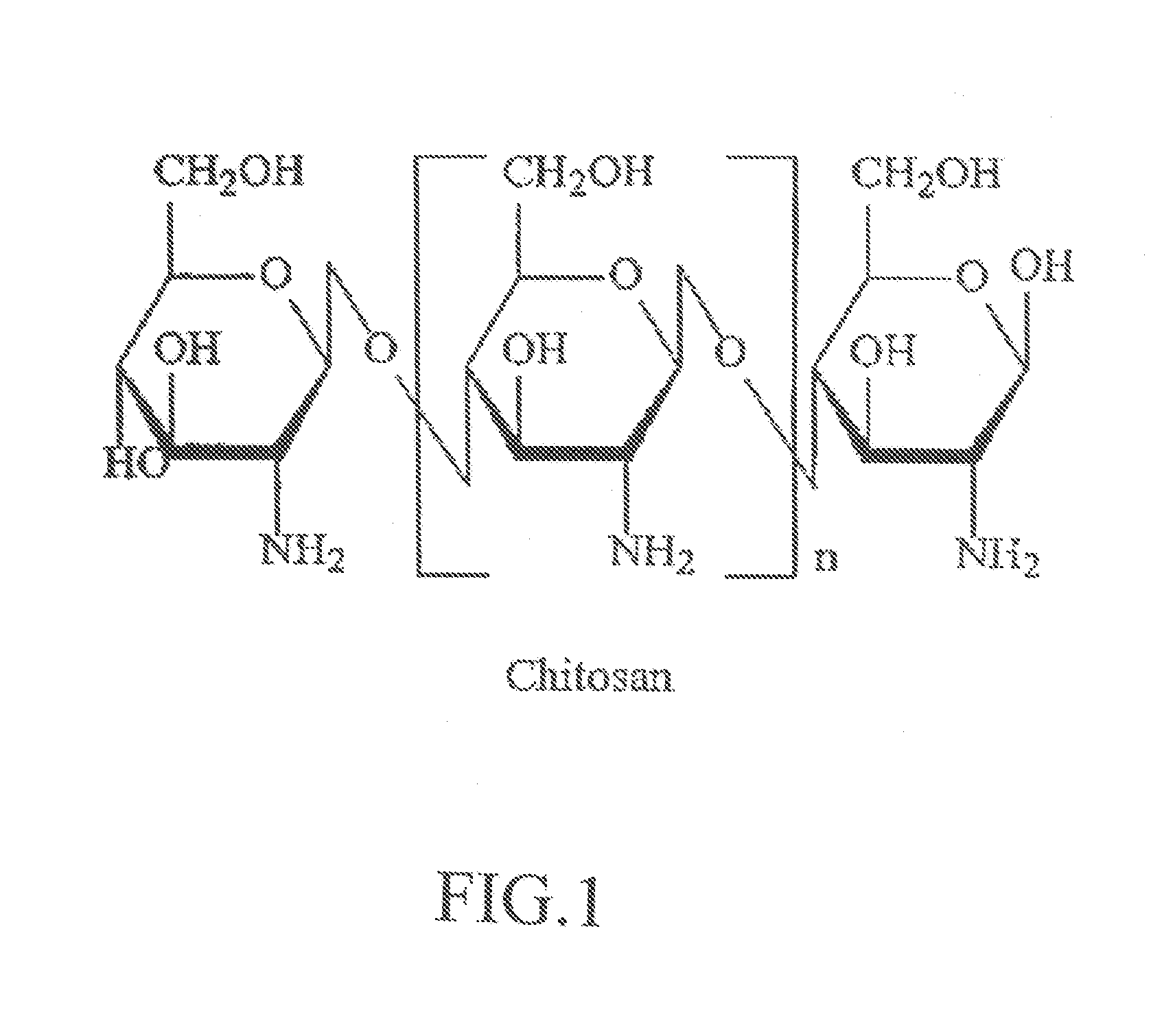

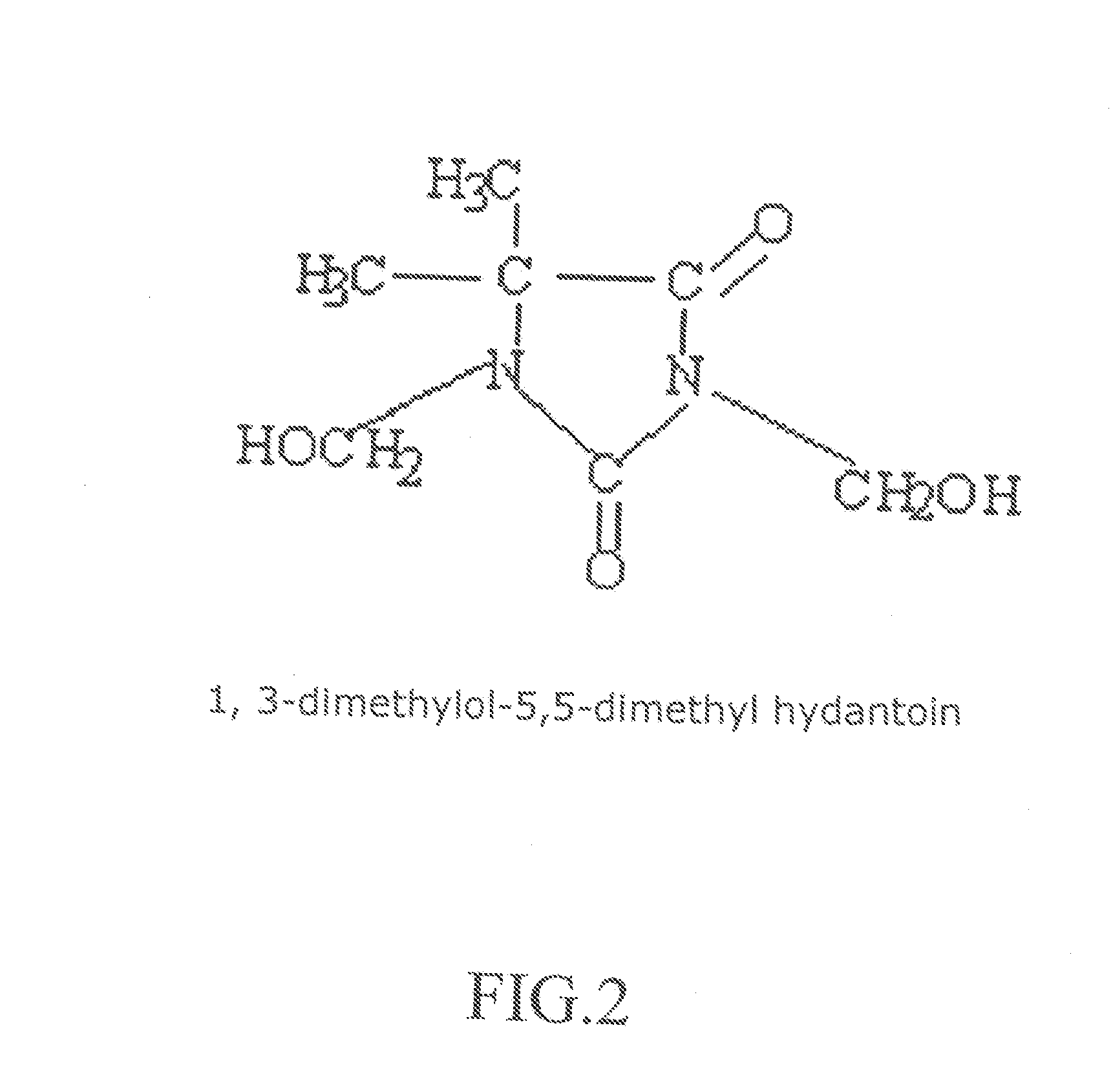

Process for Anti-microbial textiles treatment

InactiveUS20080102217A1Easy to prepareBroad spectrum of biocide activityBiocideBiochemical fibre treatmentCellulosePathogenic microorganism

A process for anti-microbal textile treatment which provides durable and anti-microbial textiles and methods for preparing same. Such textiles can be readily prepared using a wet curing process to covalently attach a Complex Formula Compounds to a cellulose based material or other polymeric material. Once prepared, the textiles of the present invention have a broad spectrum of biocide activity against pathogenic microorganisms, and durability and efficacy of the antimicrobial properties.

Owner:LIN YU TE

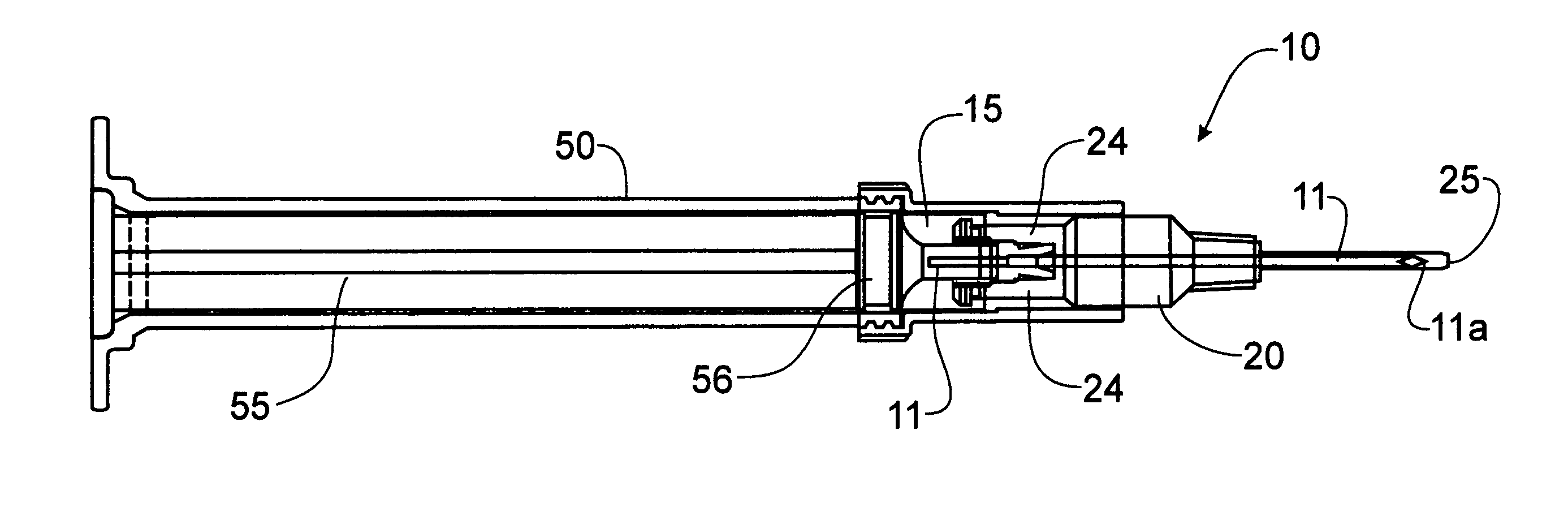

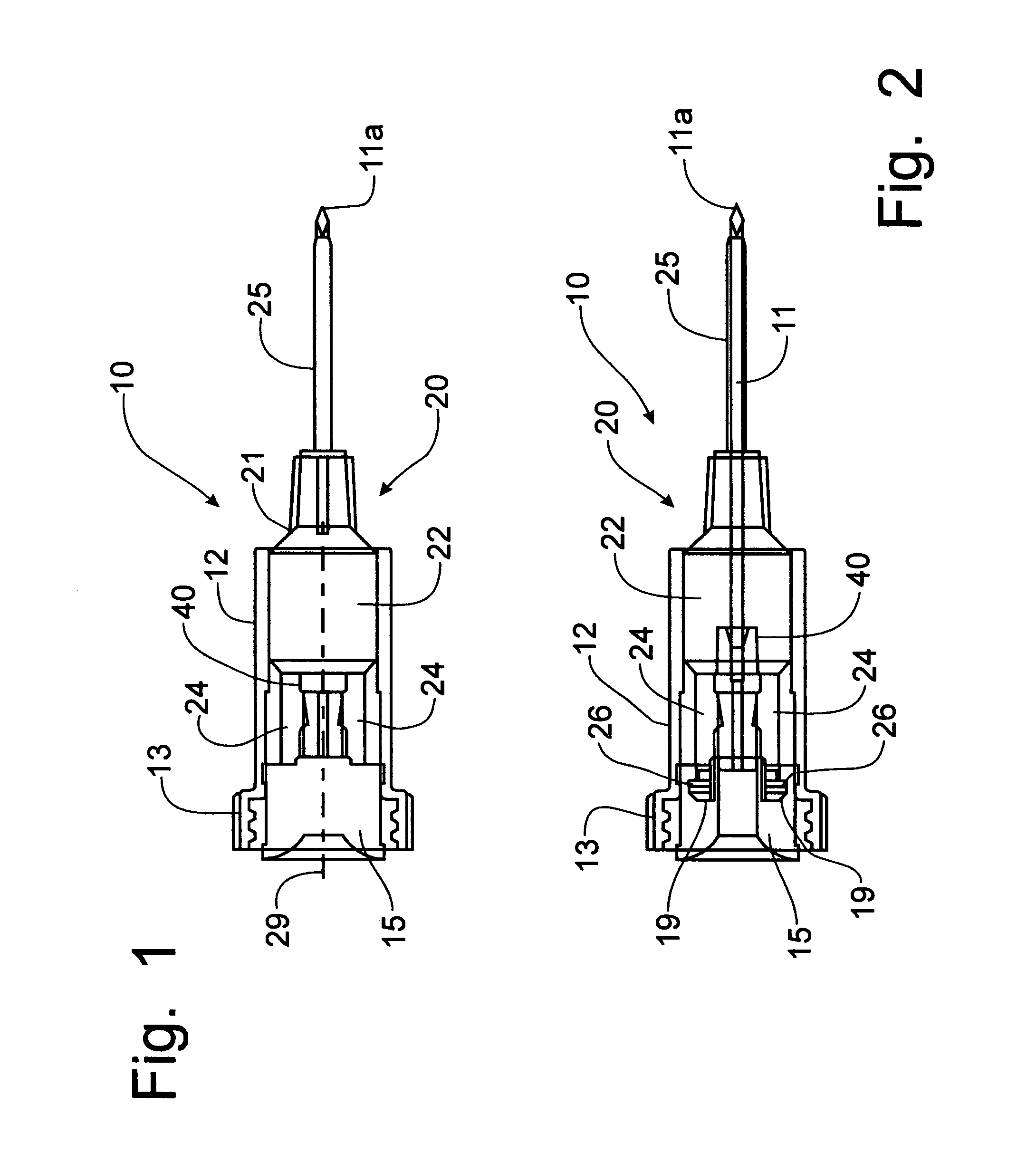

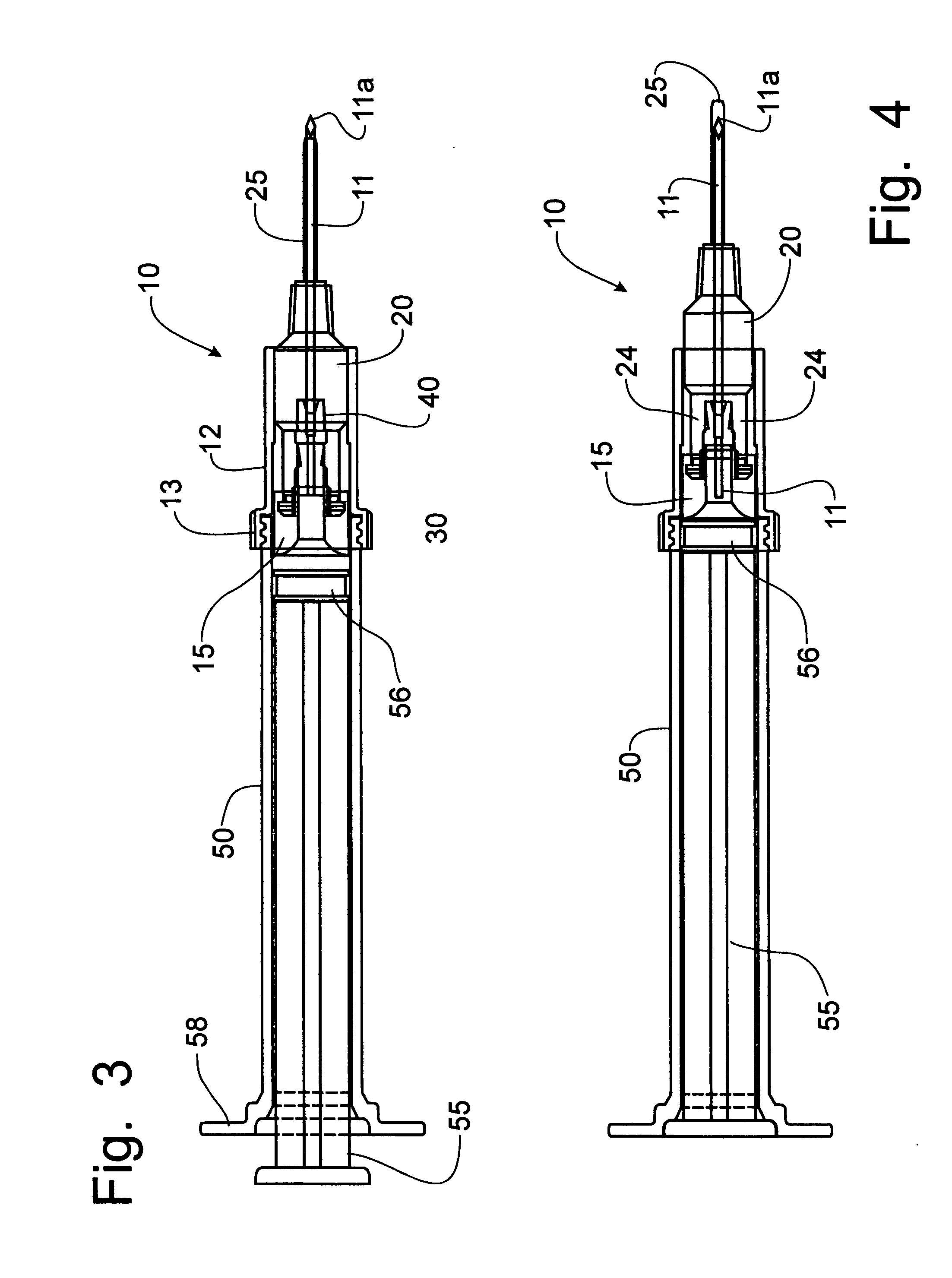

Needle assembly for multiple syringe barrels

InactiveUS20070016145A1Great flexibilityDurable in constructionInfusion syringesInfusion needlesSyringeBiomedical engineering

A safety needle assembly having a rigid housing that encloses a locking mechanism, an actuator that is operable to slide a sheath over the tip of the needle to prevent accidental sticks after the needle has been used, and an actuator that is operable in response to the final end movement of the syringe plunger to effect movement of the actuator over the needle tip. The housing is made in a standard size that is mountable on a connection port formed on a syringe barrel that can have a much greater diameter than the connection port. An adapter is provided for mounting a standard needle having a Luer lock to enable a health care professional the flexibility to use conventional needles to load medicine into the syringe barrel then replacing with a safety needle assembly for injection of the medicine.

Owner:DEVON SAFETY PRODS

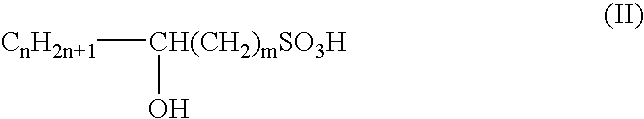

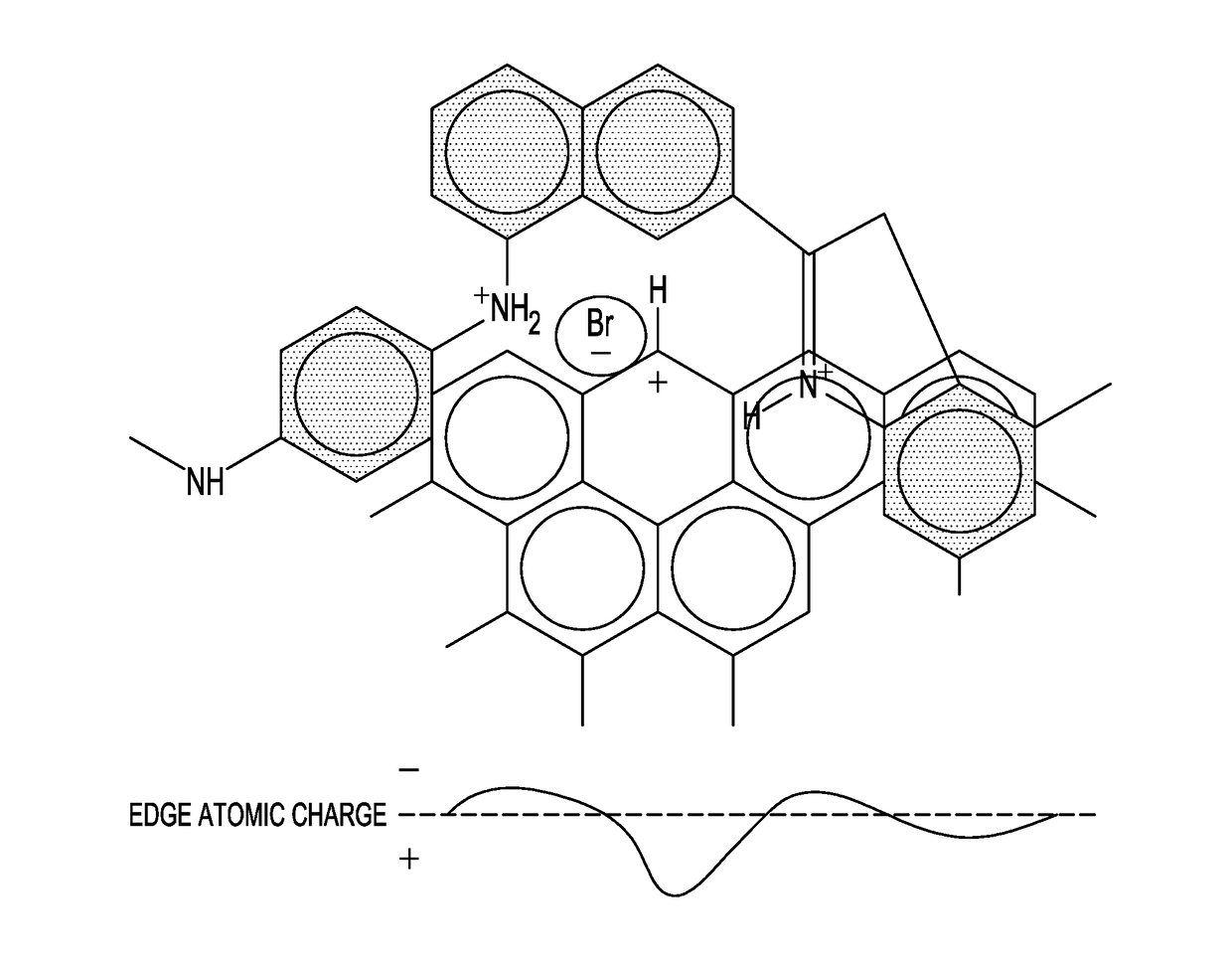

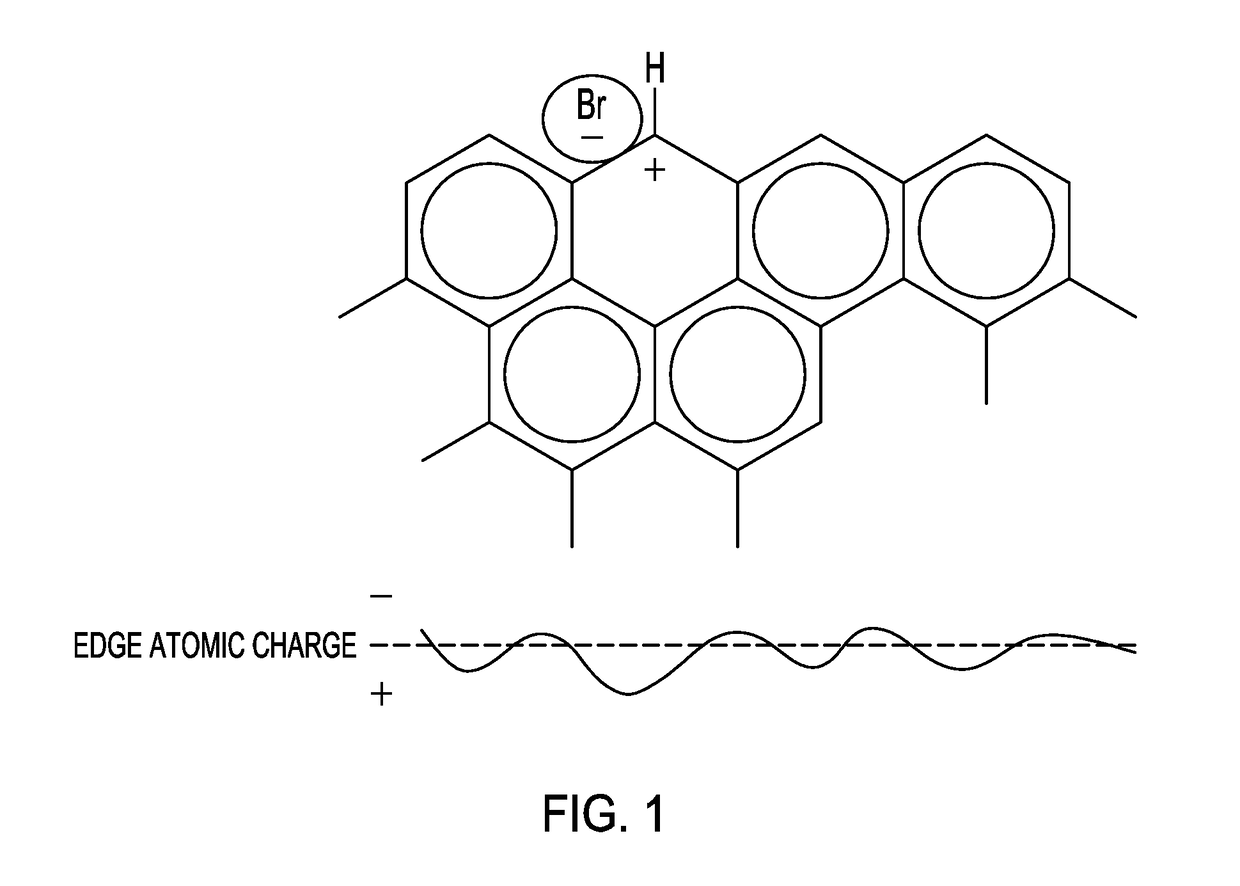

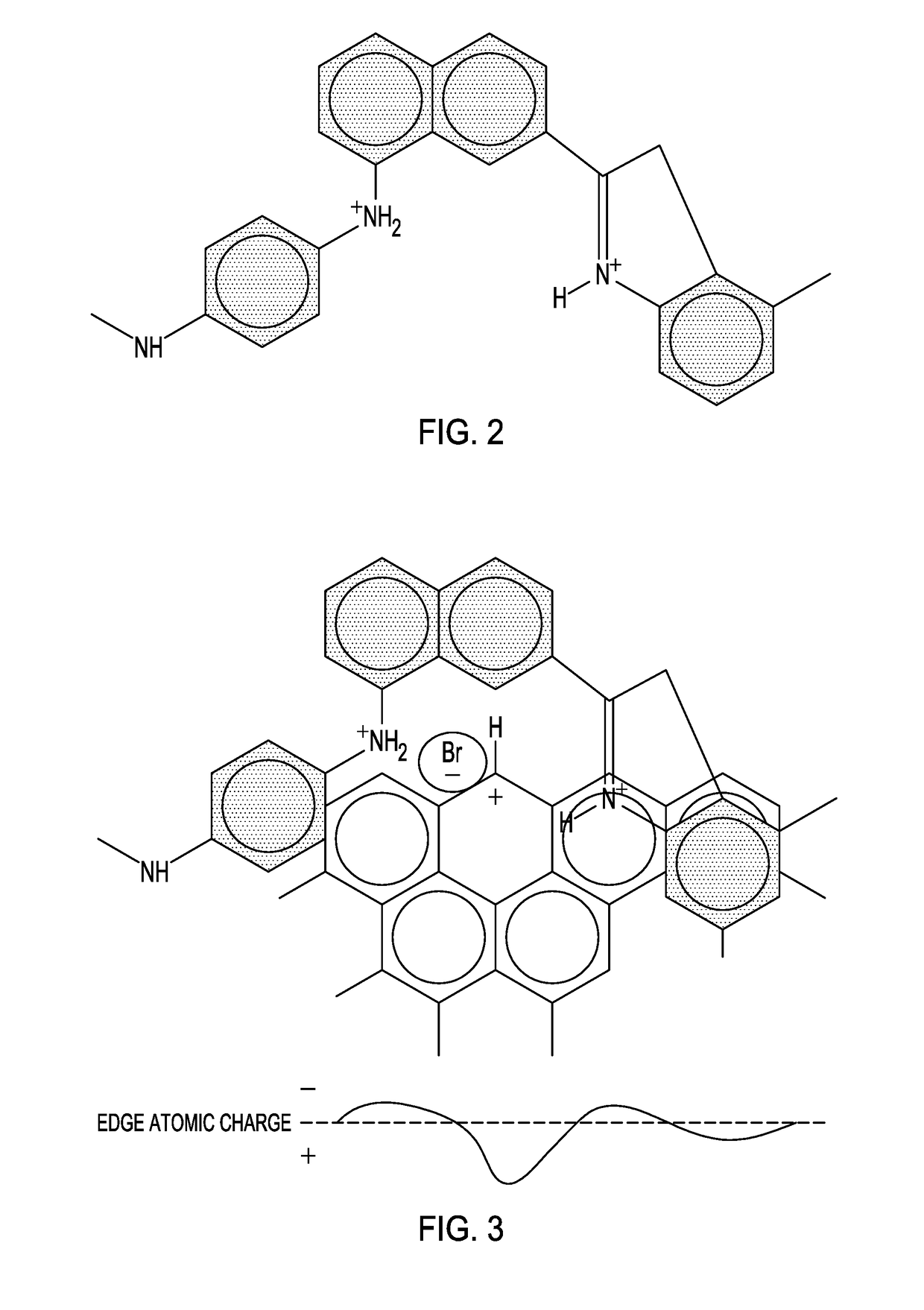

Sorbent comprising carbon and nitrogen and methods of using the same

ActiveUS20170173557A1Reduce disposalLow costGas treatmentCarbon compoundsNitrogen atomEnvironmental chemistry

The present invention relates to sorbents including carbon and nitrogen. In various embodiments, the sorbent can remove mercury from a mercury-containing gas that includes sulfur(VI) such as SO3 more efficiently than other sorbents. The sorbent can include a graphene edge comprising an active site for mercury oxidation and a nitrogen layer structure including cationic nitrogen atoms, neutral nitrogen atoms, or a combination thereof proximate the active site.

Owner:MIDWEST ENERGY EMISSIONS CORP

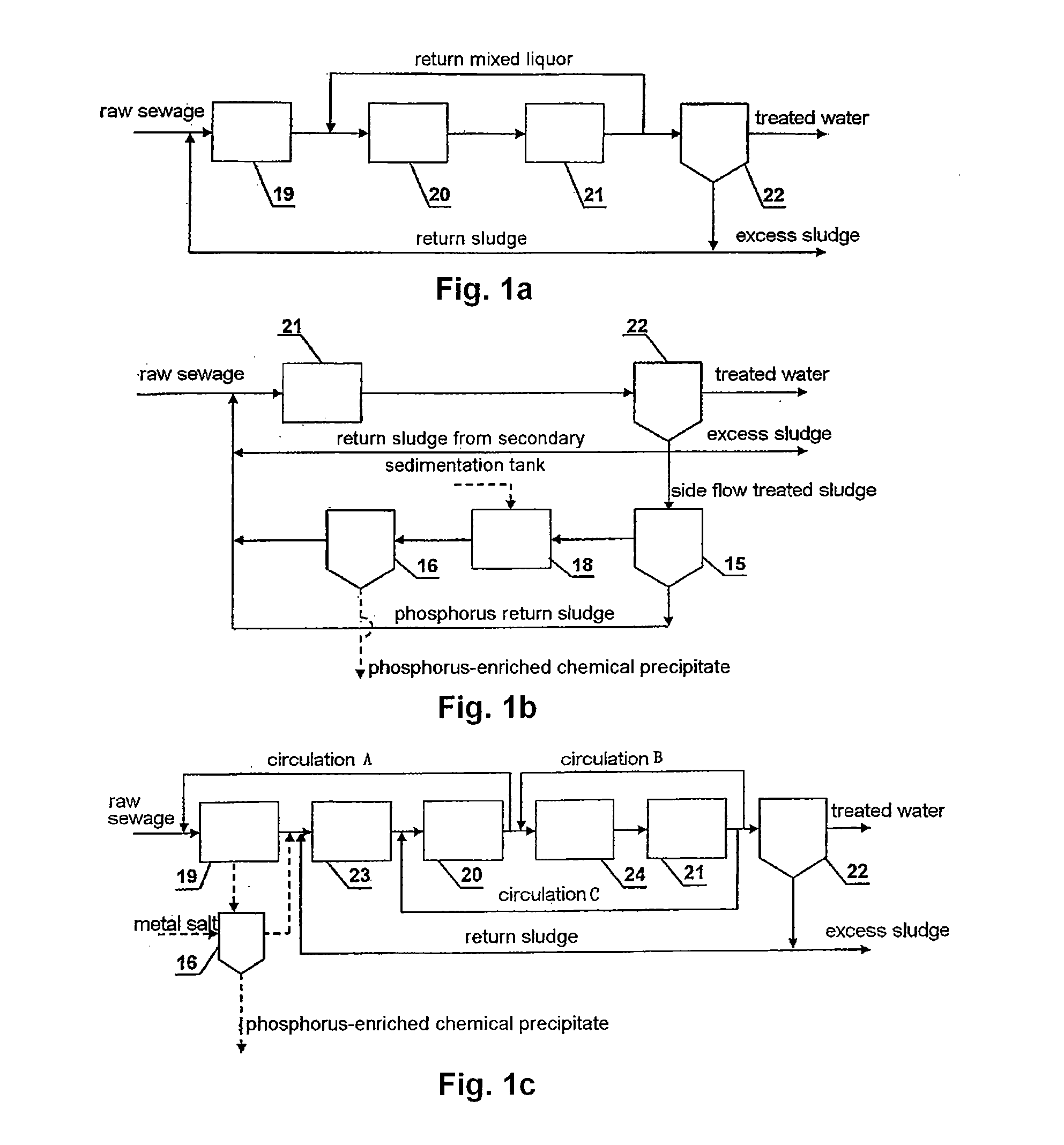

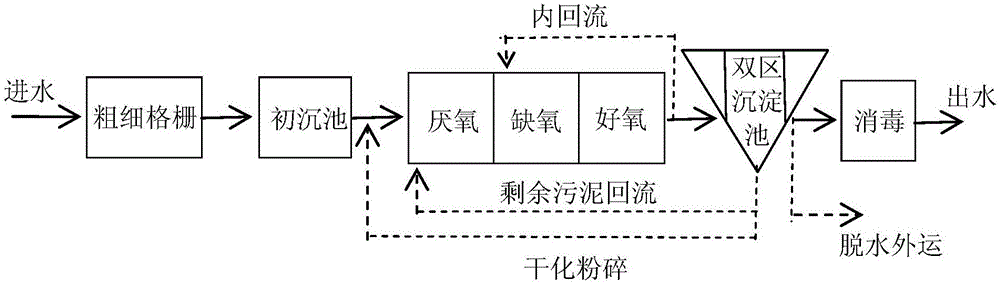

AAO continuous-flow aerobic granular sludge nitrogen and phosphorus removal process and system

ActiveCN106167340AQuality improvementFine grainSpecific water treatment objectivesMultistage water/sewage treatmentNitrogen removalSludge

The invention relates to an AAO continuous-flow aerobic granular sludge nitrogen and phosphorus removal process. Intake water enters a biochemical tank after passing coarse and fine screens and a primary settling tank, the biochemical tank comprises an anaerobic tank, an anoxic tank and an aerobic tank, part of effluent of the biochemical tank flows back to the front end of the anoxic tank, the other part enters a secondary sedimentation tank for mud-water separation, the secondary sedimentation tank is a dual-region sedimentation tank, light sludge is collected prior to direct concentrating, drying and outward transportation for disposal, heavy sludge is collected, then part of the heavy sludge serves as excess sludge flowing back to the front end of the anaerobic tank, the other part is dried and crushed to be put to the front end of the biochemical tank, and effluent of the secondary sedimentation tank passes a disinfection apparatus prior to up-to-standard discharge. The invention further relates to an AAO continuous-flow aerobic granular sludge nitrogen and phosphorus removal system. Granulation of aerobic sludge is promoted, carbon sources are supplemented to denitrification for promoting nitrogen removal, and biological phosphorus removal is enhanced.

Owner:ZHEJIANG UNIV OF TECH

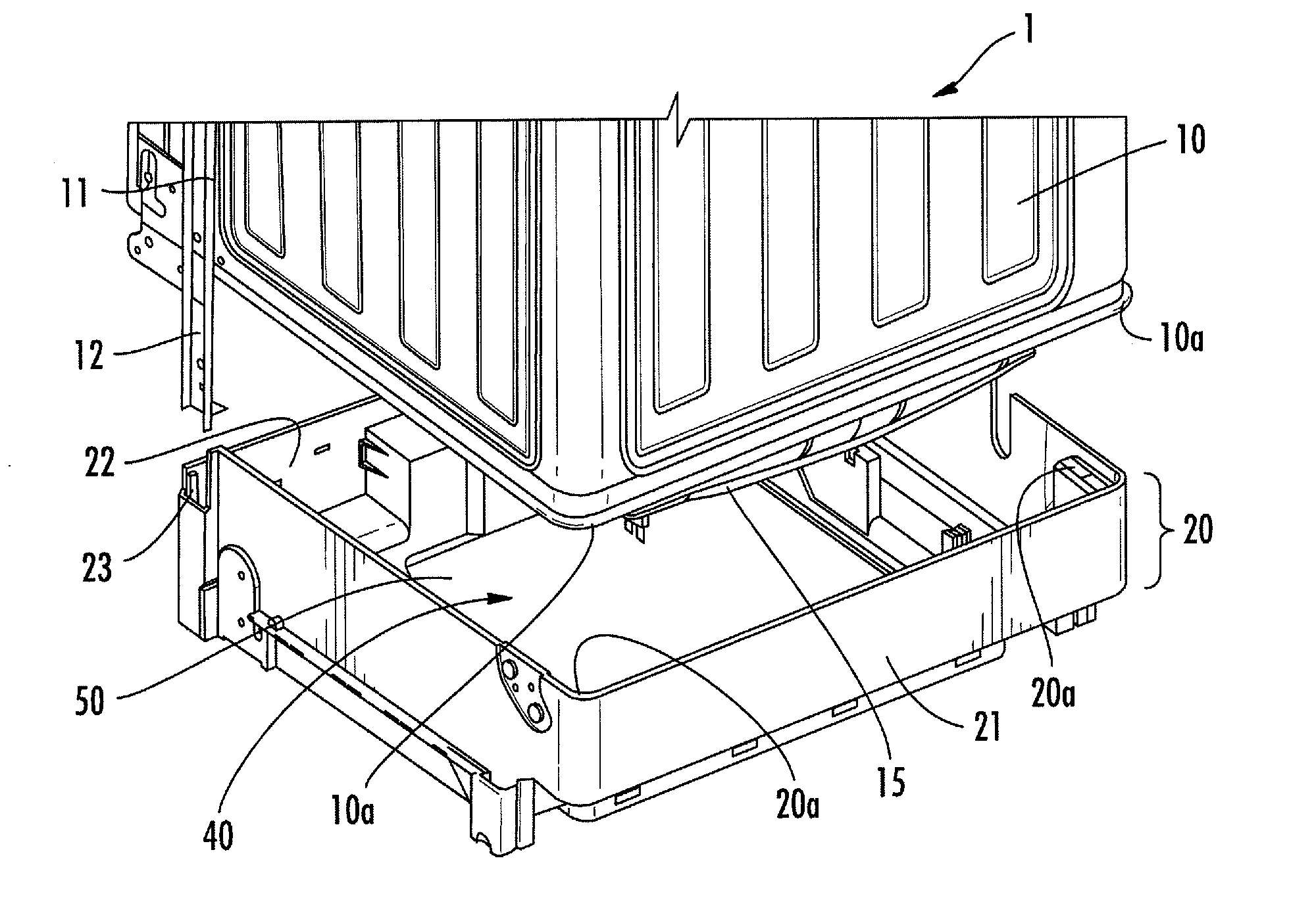

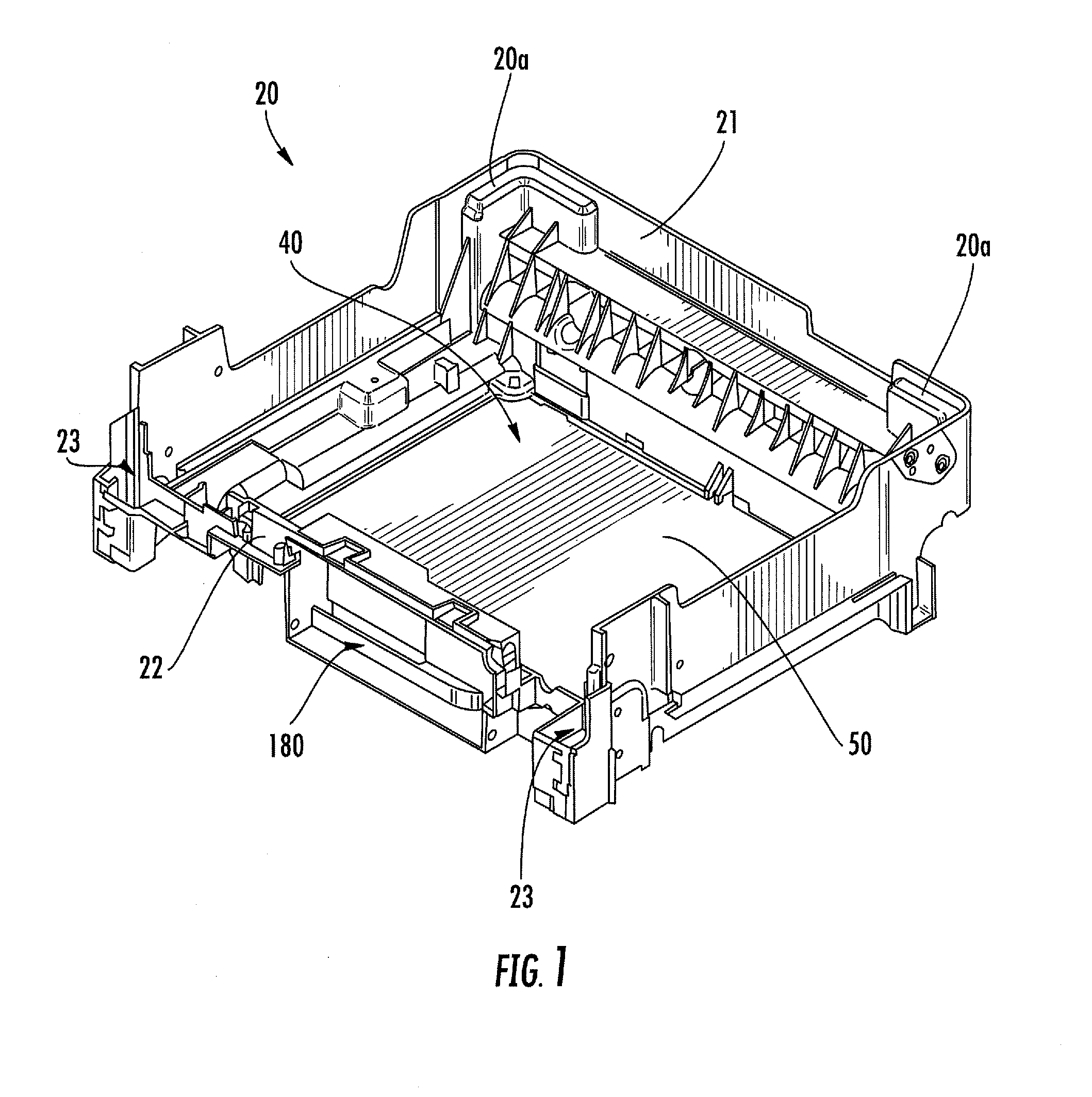

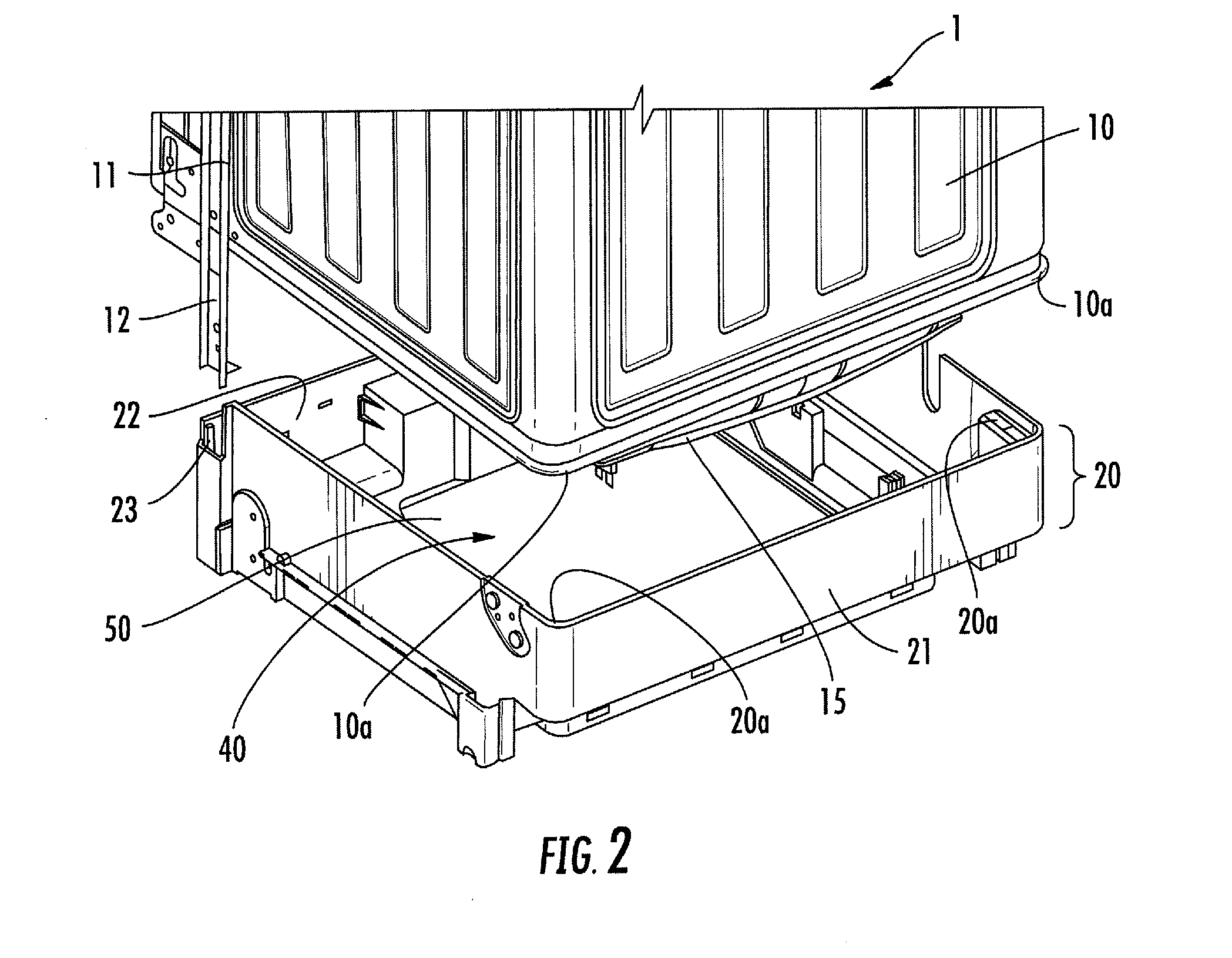

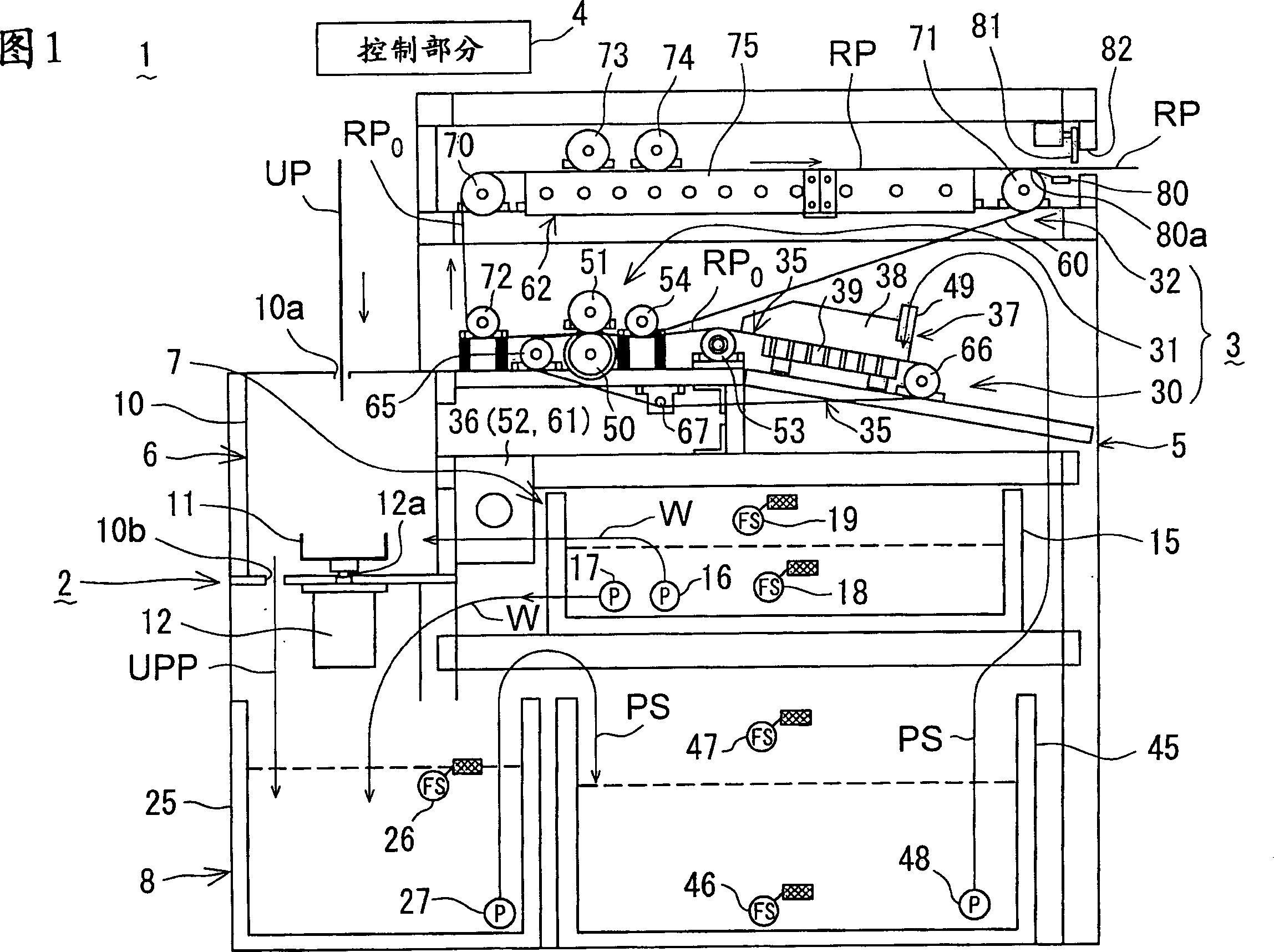

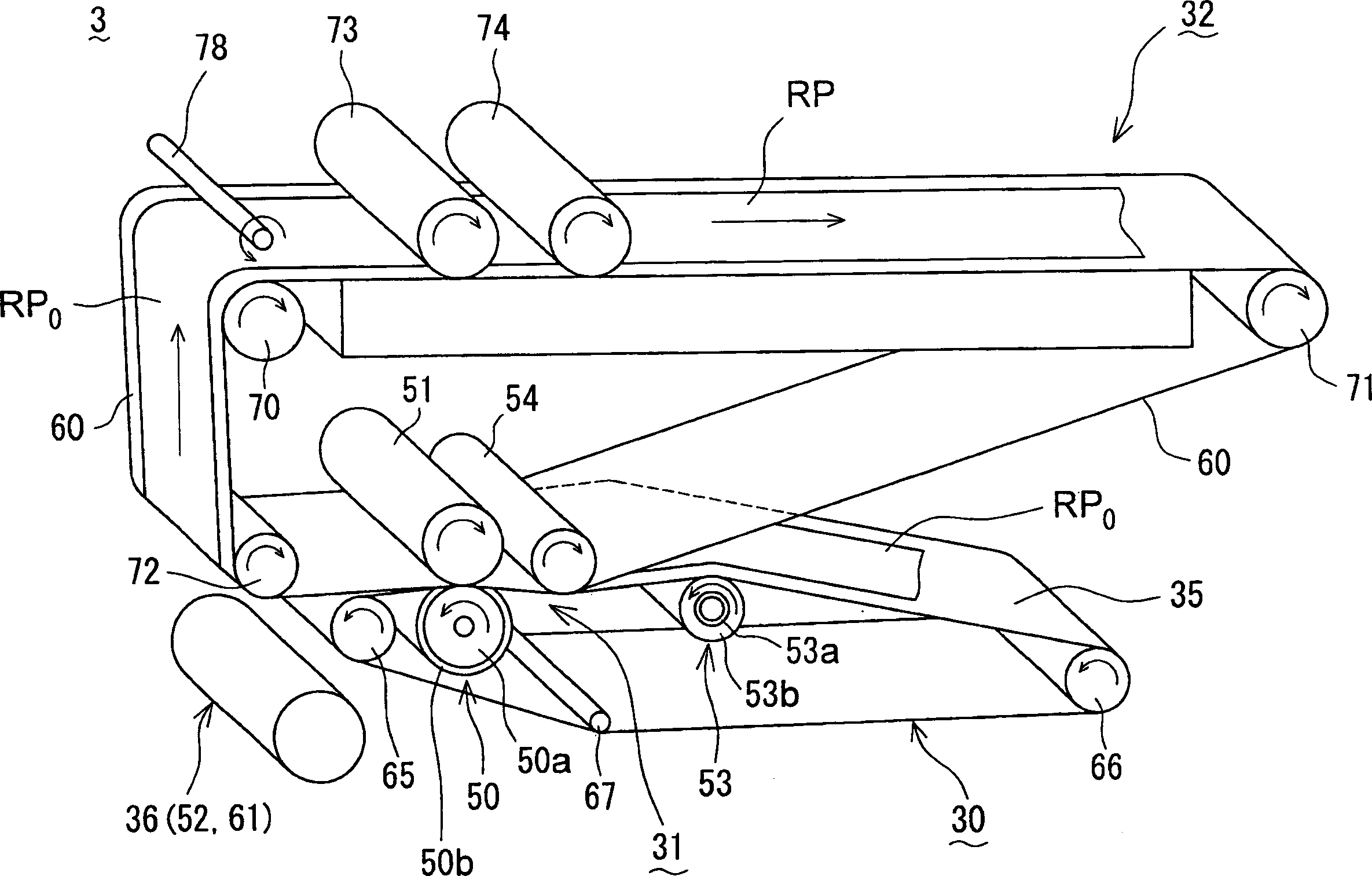

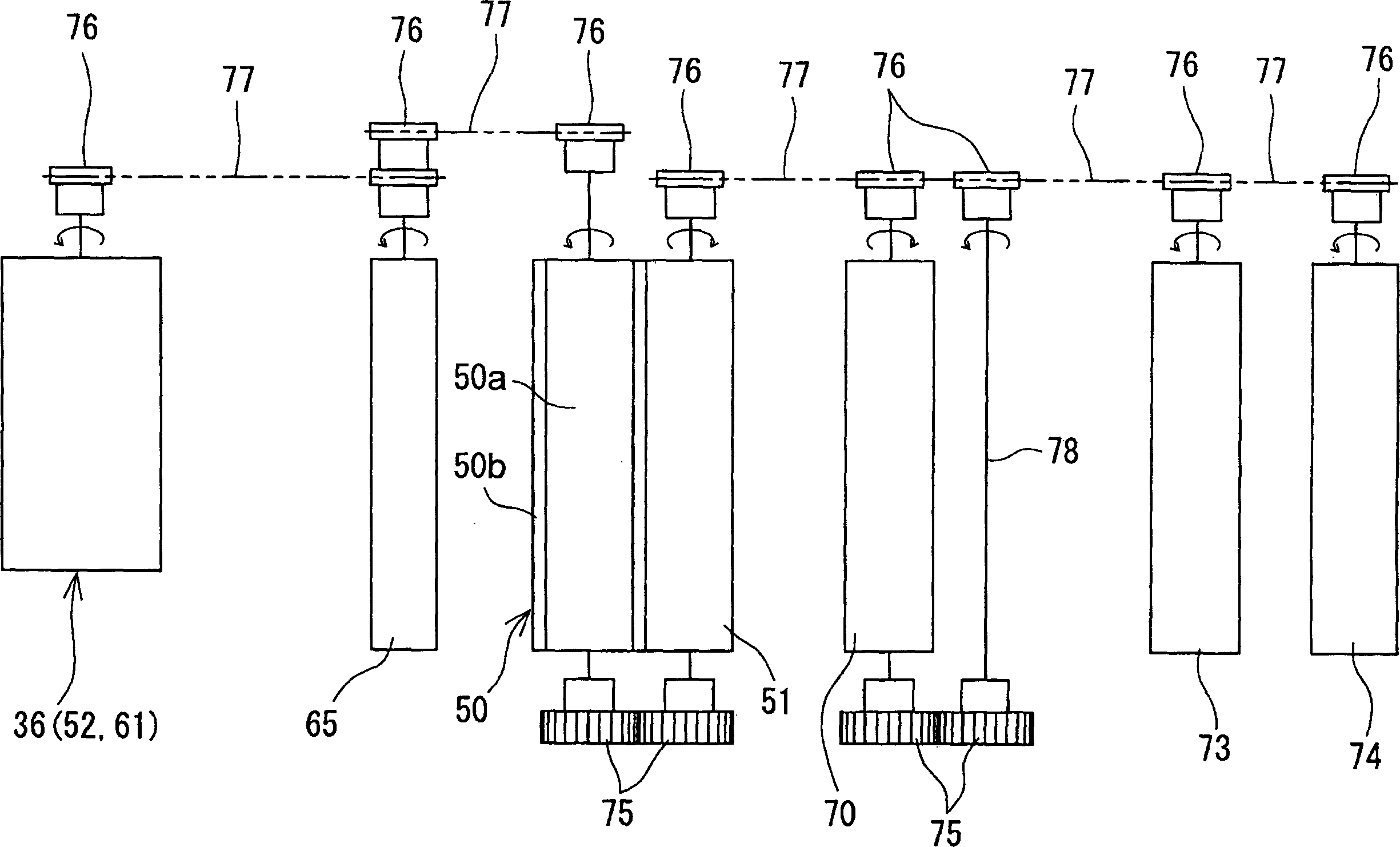

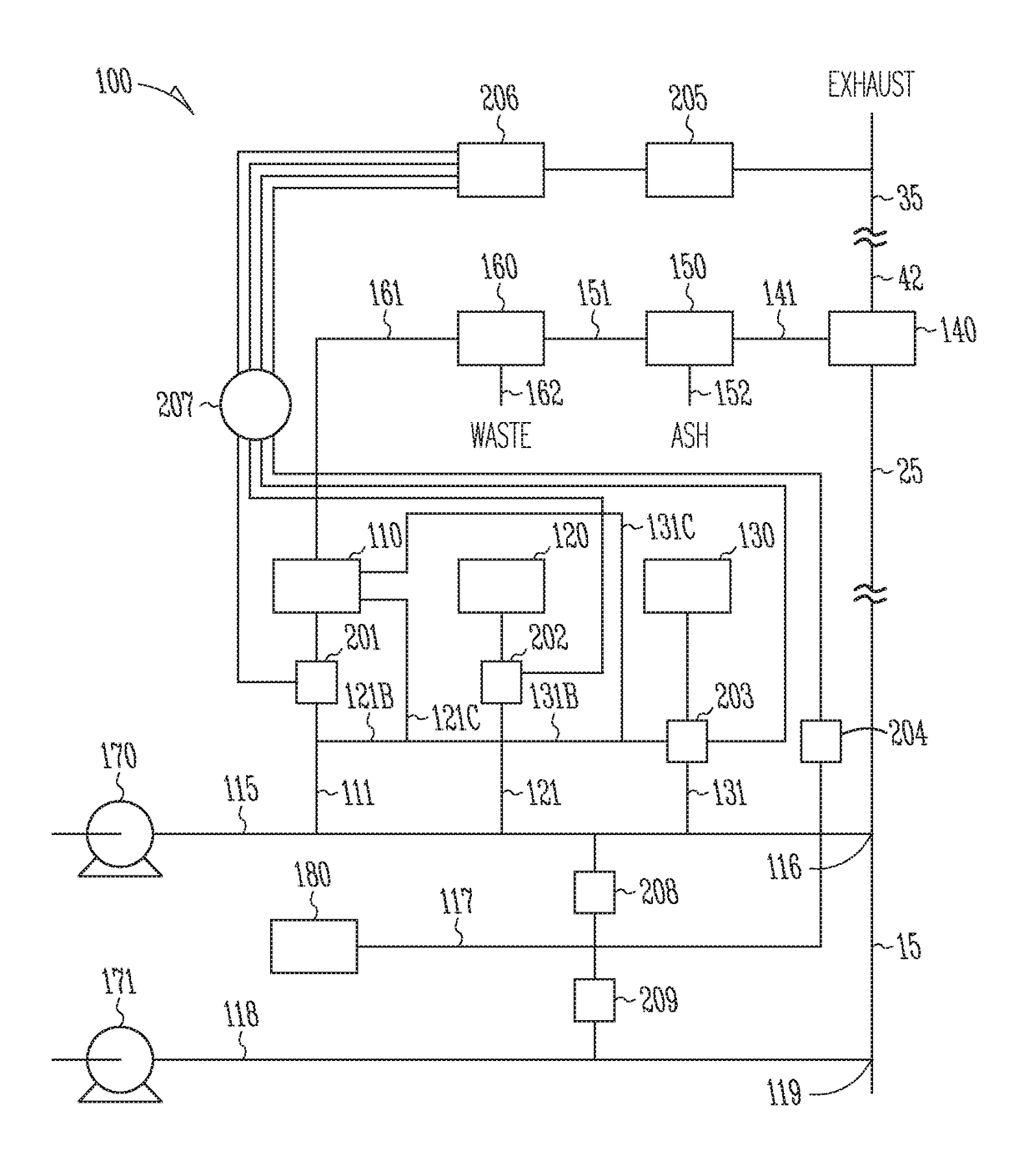

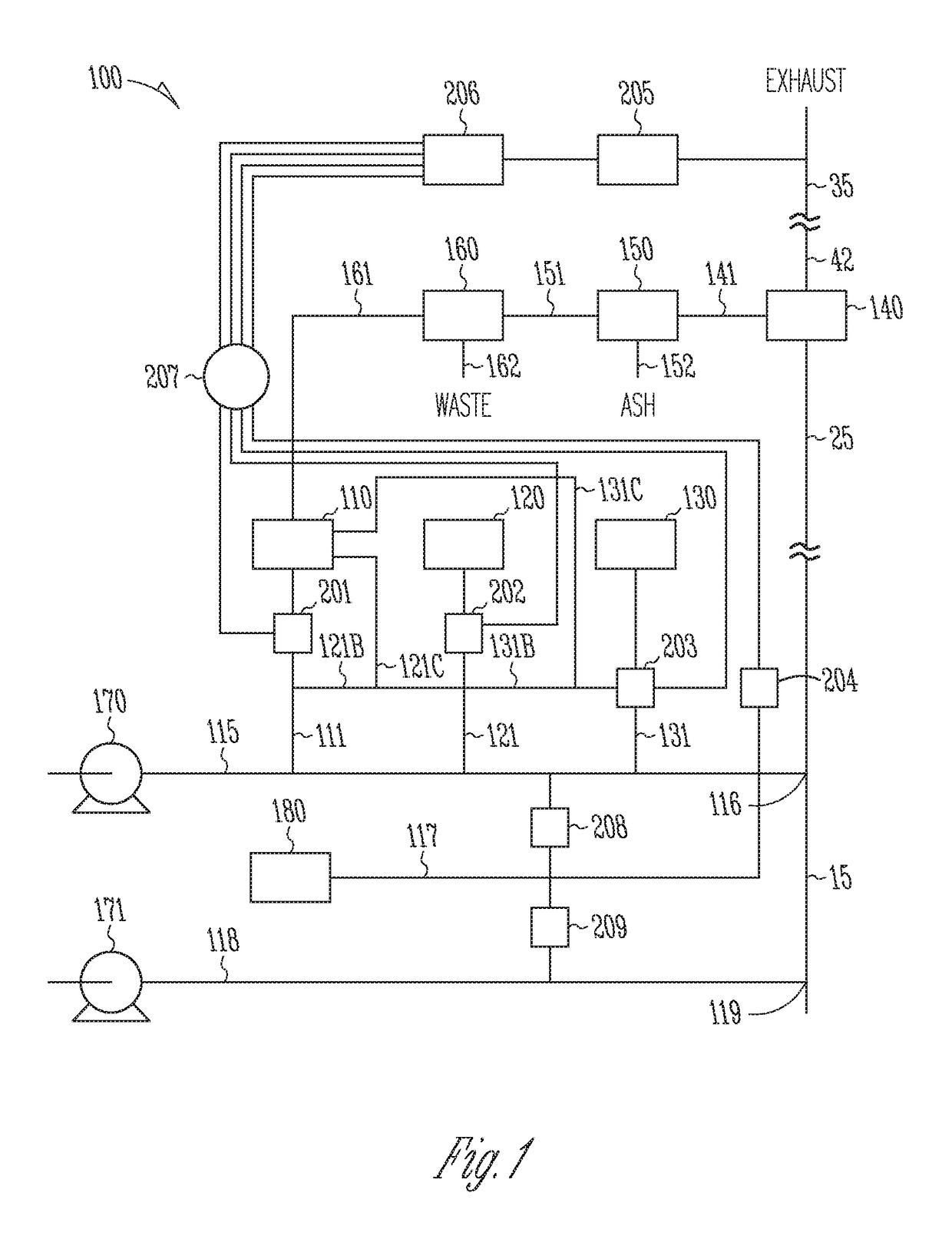

Powder Distribution for Laser Sintering Systems

ActiveUS20170008234A1Reduce the possibilityHigh densityManufacturing heating elementsCeramic shaping apparatusRadiant heaterMetallurgy

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

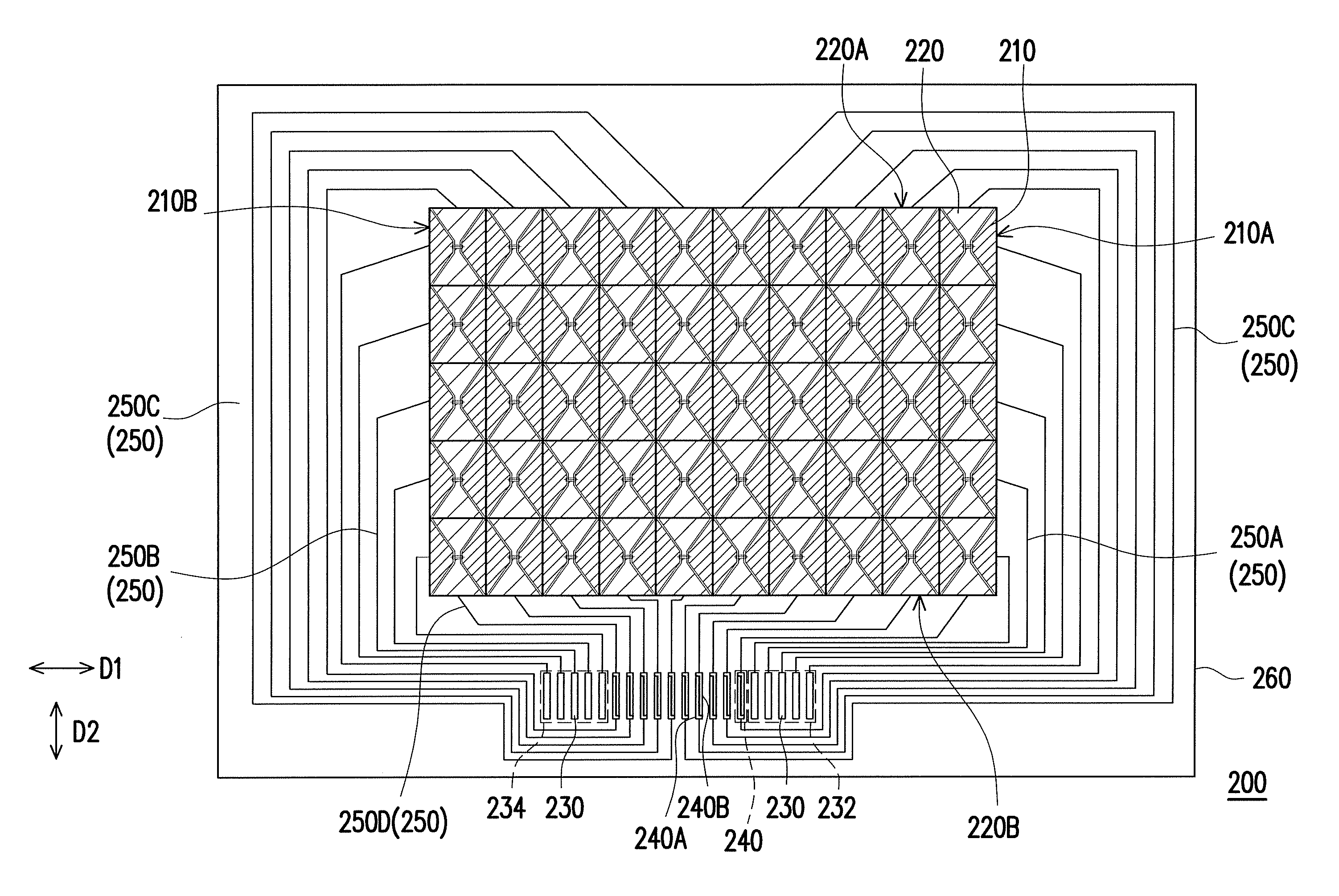

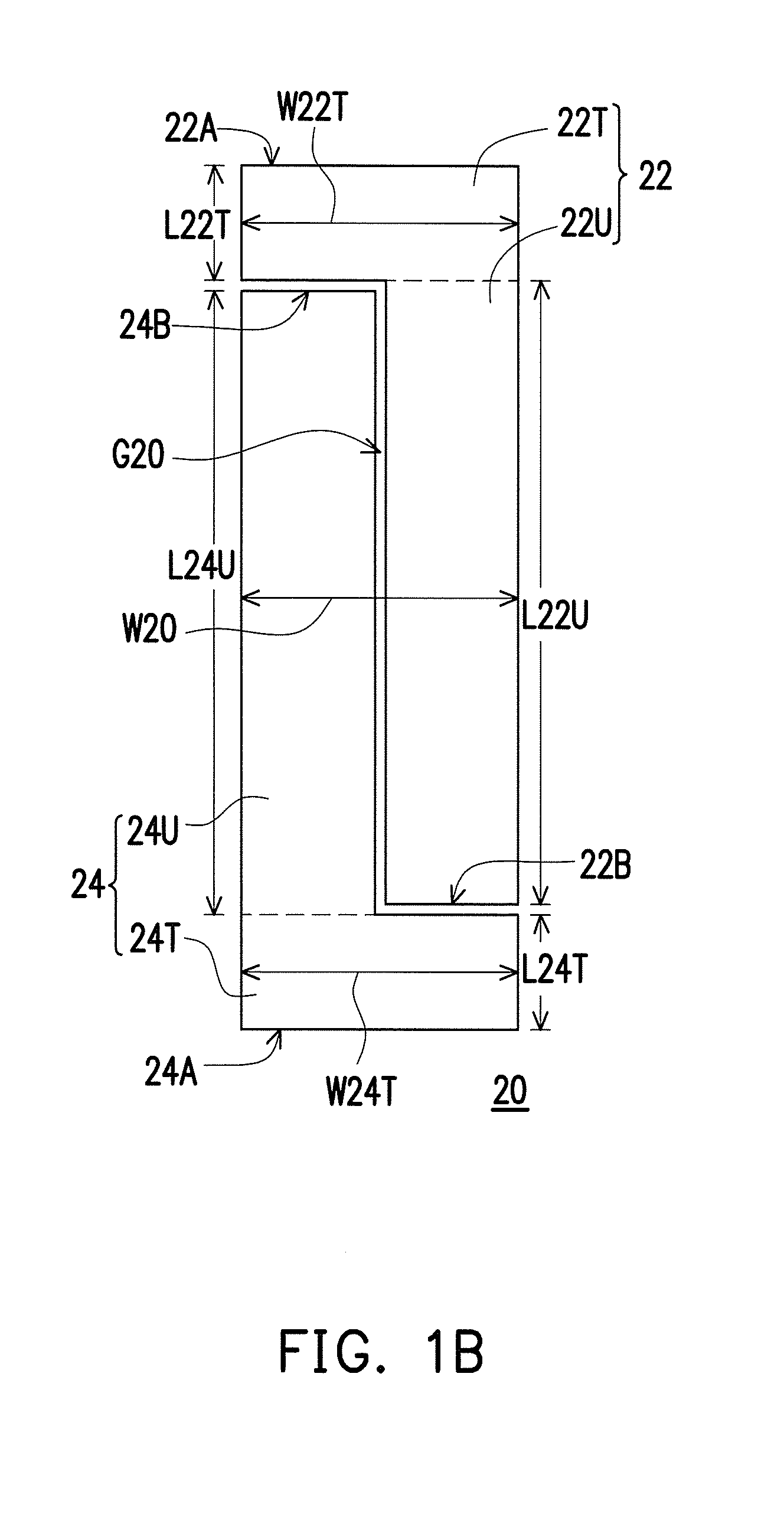

Bonding pad structure and touch panel

InactiveUS20150253897A1Easy to testReduce areaNon-insulated conductorsDigital data processing detailsEngineeringTouch panel

A bonding pad structure including a first sub-bonding pad and a second sub-bonding pad and a touch panel are provided. The first sub-bonding pad has a first connection terminal at an opposite side of a first end terminal. A width of the first connection terminal is greater than a width of the first end terminal. The first sub-bonding pad has a second connection terminal at an opposite side of a second end terminal. A width of the second connection terminal is greater than a width of the second end terminal. The first connection terminal is close to the second end terminal and the second connection terminal is close to the first end terminal. A first outline of the first sub-bonding pad and a second outline of the second sub-bonding pad are formed as a pair in a complementary manner to construct a configuration of the bonding pad structure.

Owner:WISTRON CORP

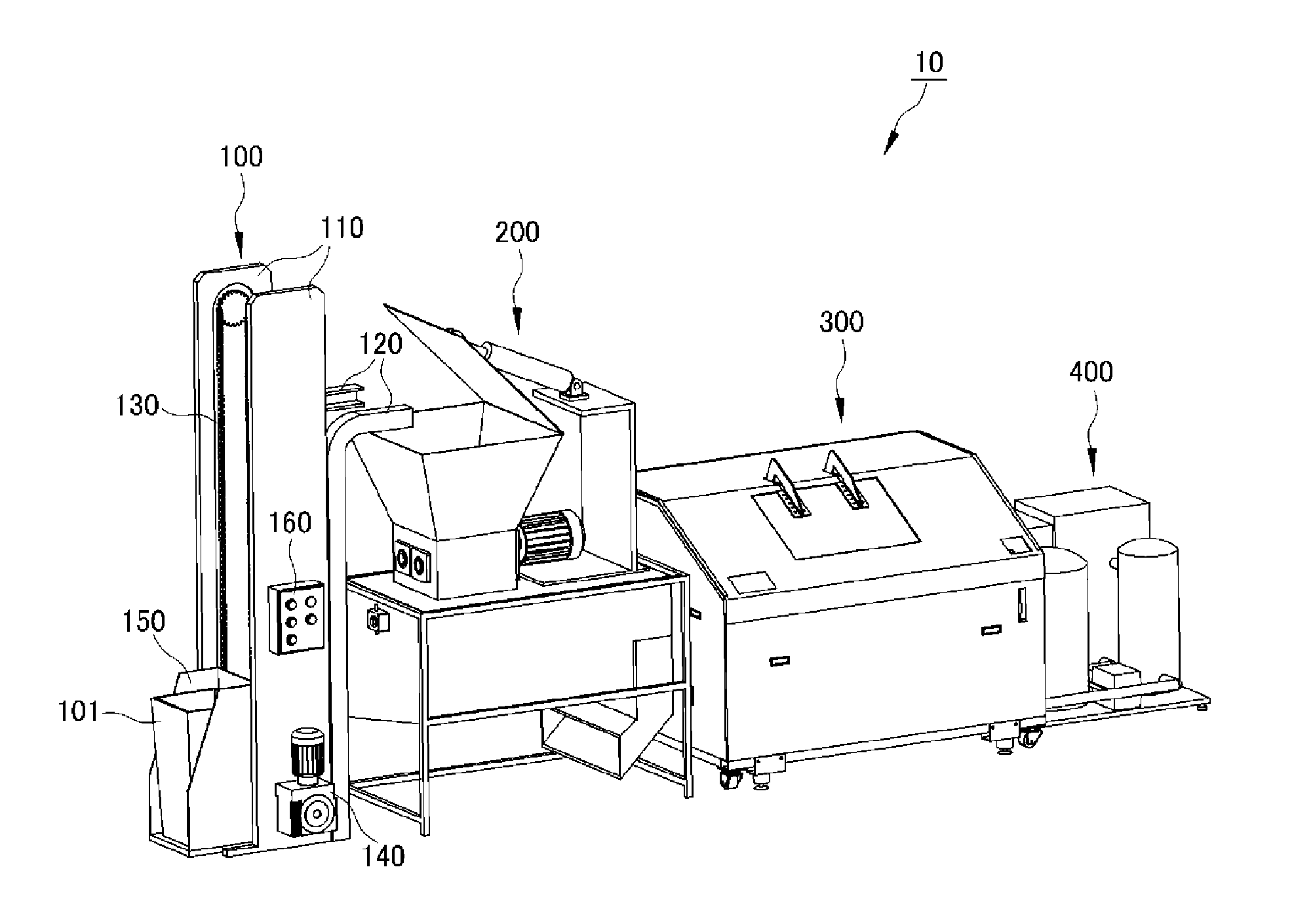

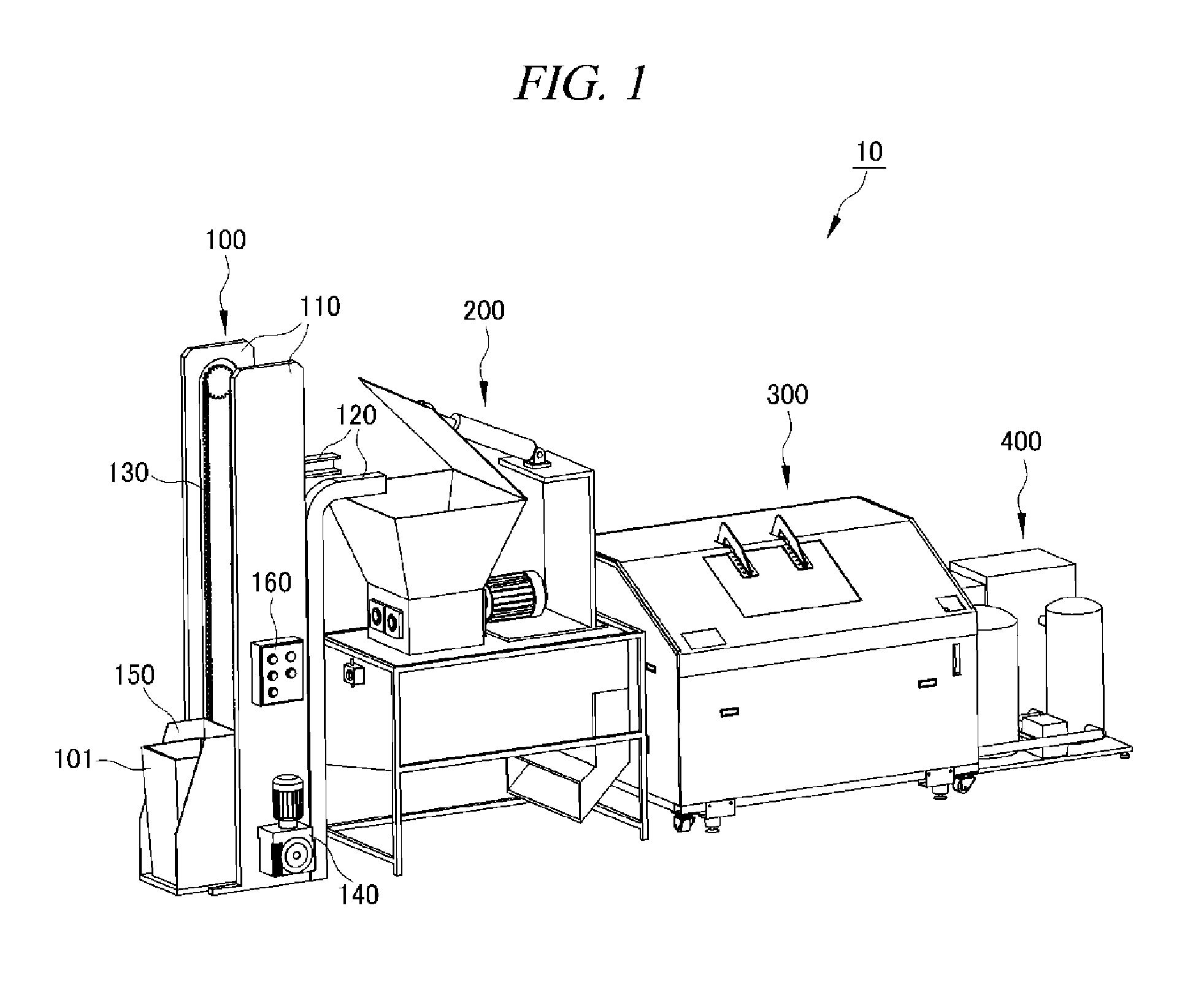

Garbage separating apparatus and food waste disposal system including the same

ActiveUS20130171725A1Reduce burdenReduce processing timeBioreactor/fermenter combinationsSludge treatmentFood wasteLitter

There is provided a garbage separating apparatus including an input unit having an inlet opening through which garbage is input, a crushing unit configured to crush garbage input through the inlet opening, a filtering chamber having an outlet opening and a perforation member provided with a plurality of holes for allowing separation of the garbage crushed by the crushing unit, a food waste collection chamber for accommodating, among the crushed garbage, food waste having passed through the perforation member, and a sweeper device configured to move, among the crushed garbage, impurity garbage remaining on the perforation member to the outlet opening.

Owner:KOH CHUN IL

Washing appliance and associated method

InactiveUS20090205378A1Reduce disposalReduce noiseOther washing machinesTableware washing/rinsing machinesFlangeEngineering

A washing appliance and associated method are provided. The appliance includes a tub having a bottom wall member with forward and rearward edges. A door member has a lower edge pivotably engaged with the forward edge. A base member supports the tub and extends from about the rearward edge of the bottom wall member toward the forward edge. The base member has a forward end disposed opposite the forward edge from the lower edge of the door member, to form a toe kick recess between the lower edge and the forward end. A cover member engages the forward end of the base member, and has a flange portion extending to the forward edge of the bottom wall member, for covering the forward end of the base member and the bottom wall member about the toe kick recess, while allowing the door member to pivot to provide access to the tub.

Owner:ELECTROLUX HOME PROD CORP NV

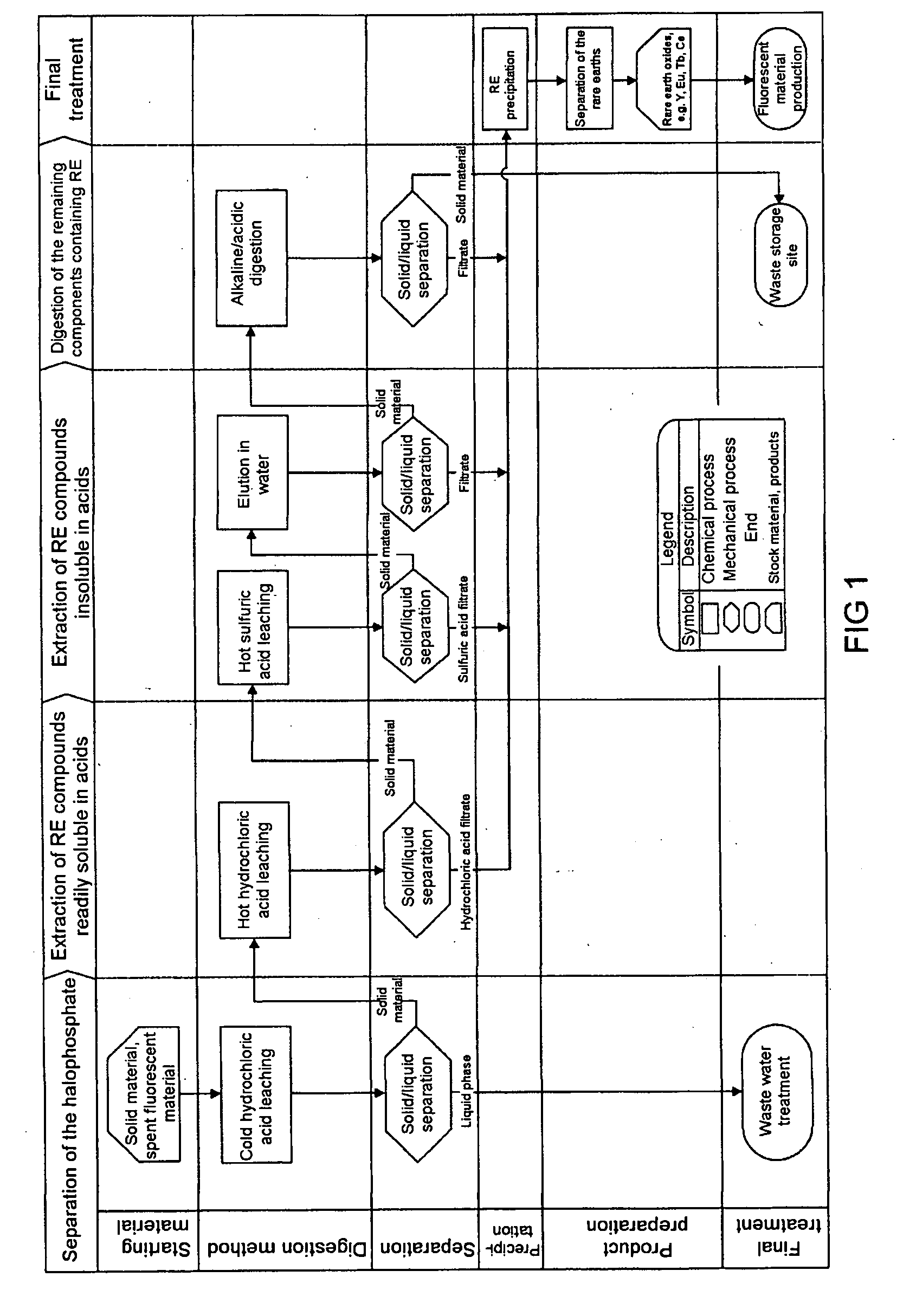

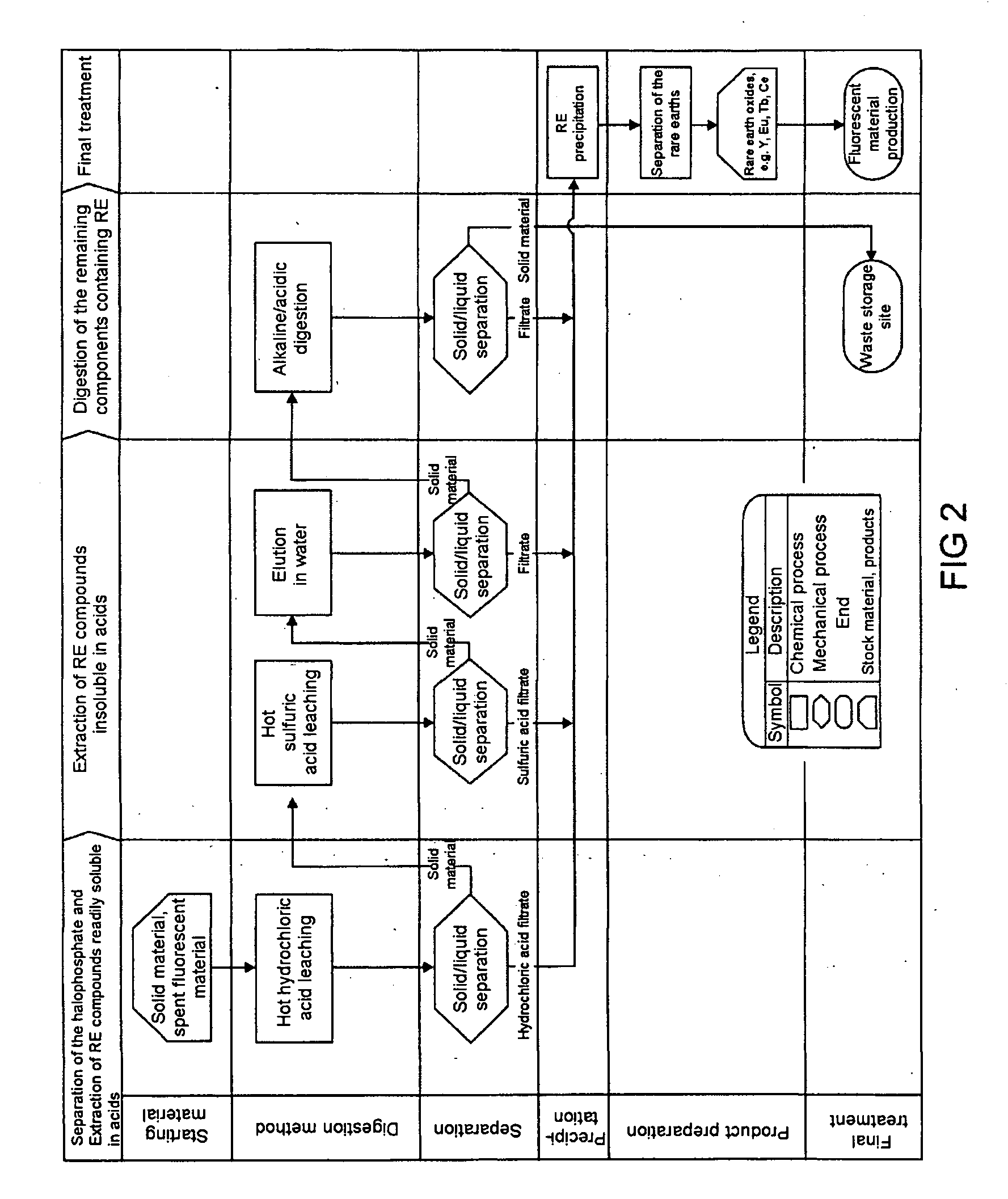

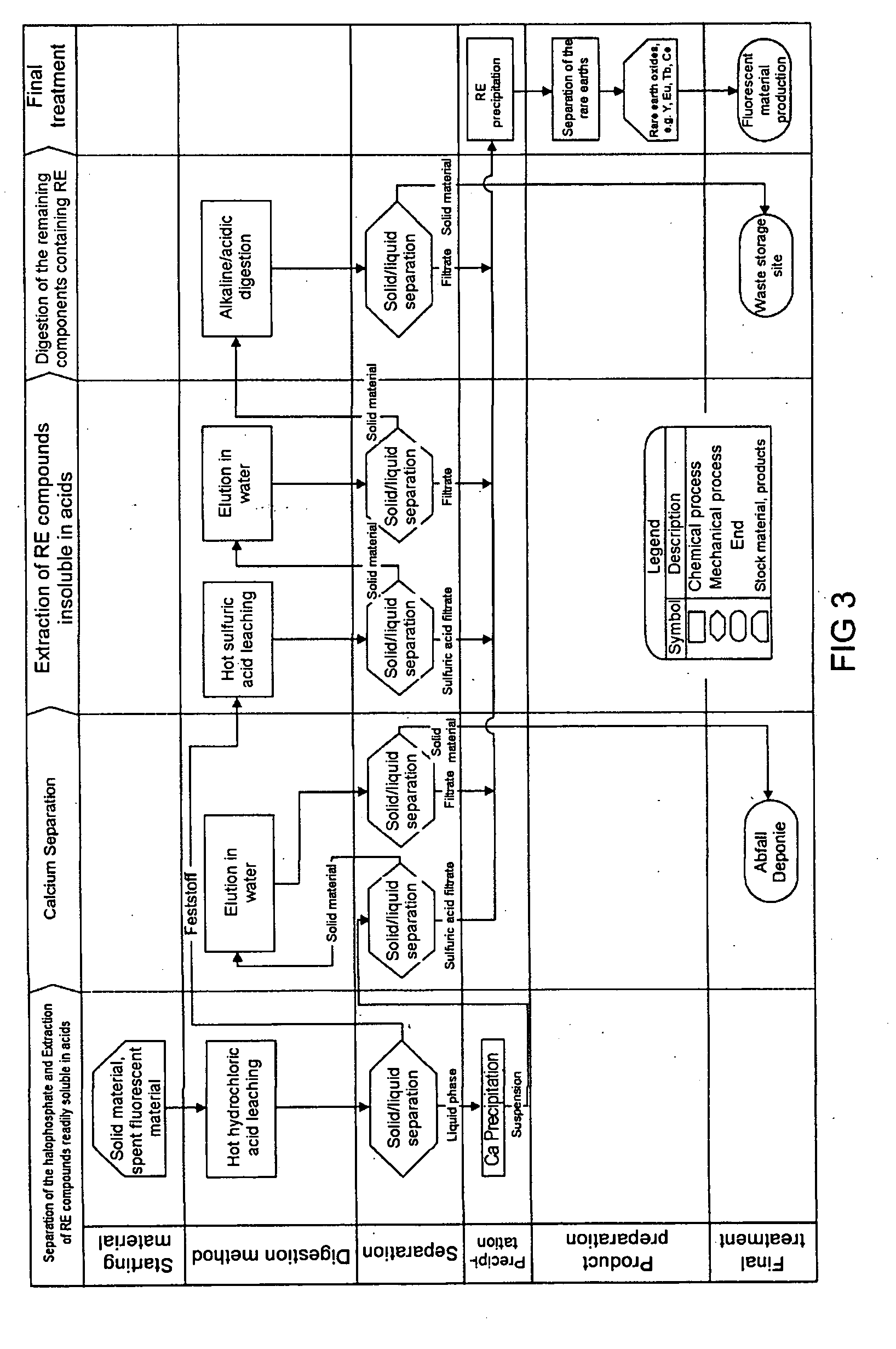

Method for Recovery of Rare Earths from Fluorescent Lamps

InactiveUS20090162267A1Reduce overall mass and volumeReduce disposalRare earth metal compoundsLuminescent compositionsAluminateRare-earth element

Method for recovery of rare earths from fluorescent lamps. The method comprises six steps. The individual process steps are: Mechanical separation of coarse components. Separation of the halophosphate. Extraction in acids of easily soluble rare-earth fluorescent substances (mainly Y, Eu-oxide) Extraction in acids of rare-earth fluorescent substances which dissolve with difficulty (for example rare-earth phosphates) Breakdown of the remaining components which contain rare earths (for example rare-earth-aluminates) Final treatment.

Owner:OSRAM GMBH

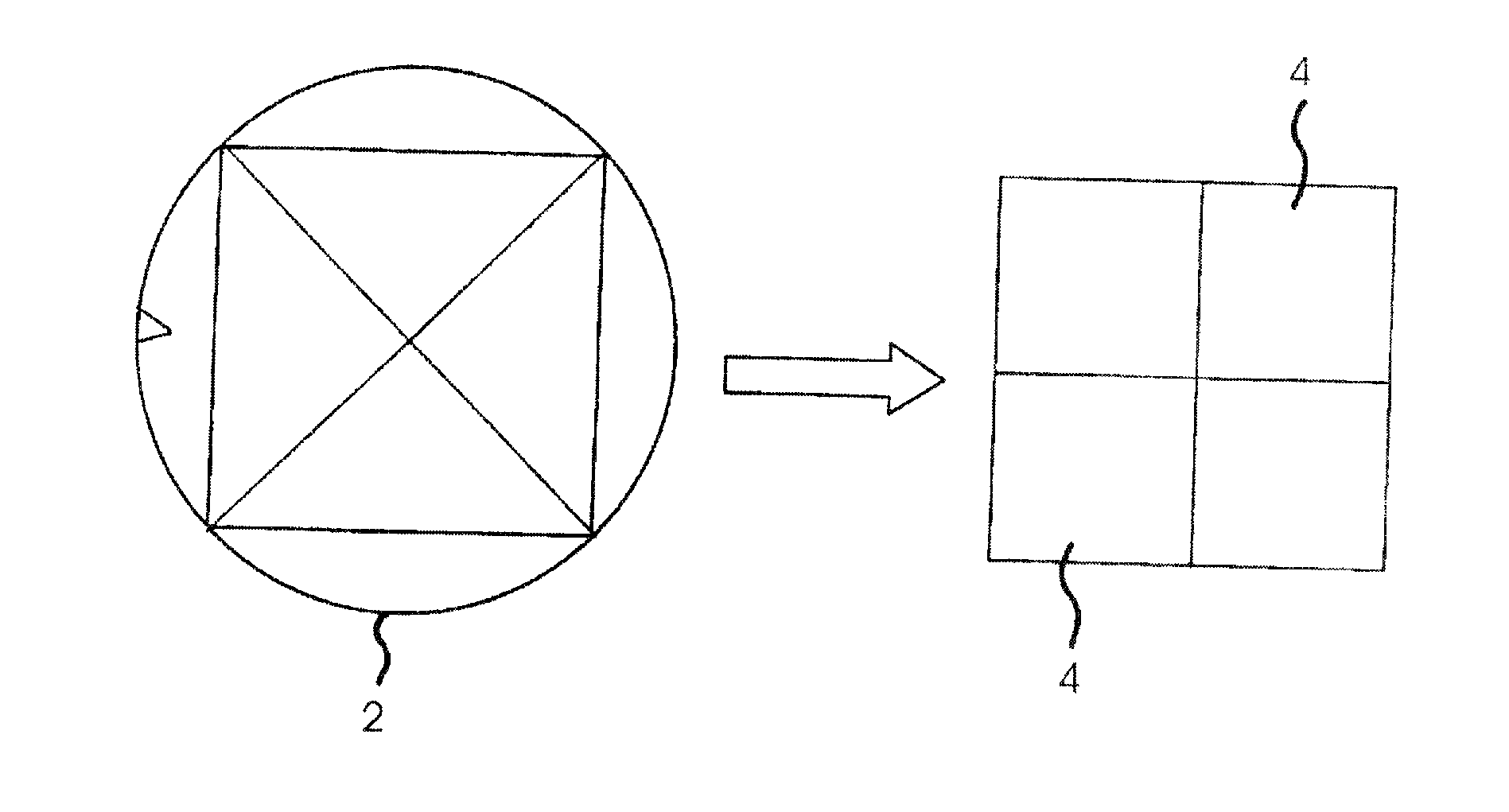

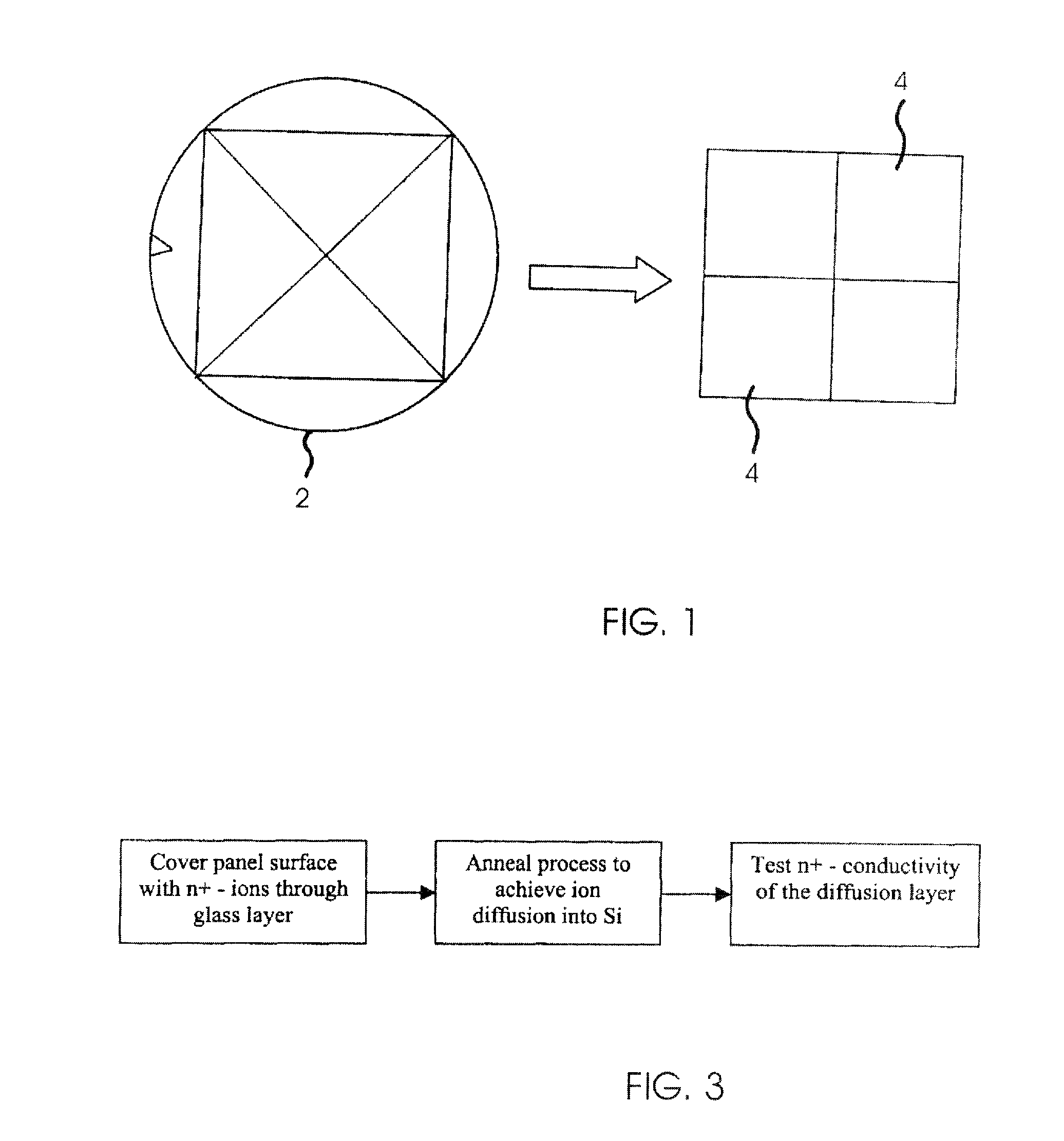

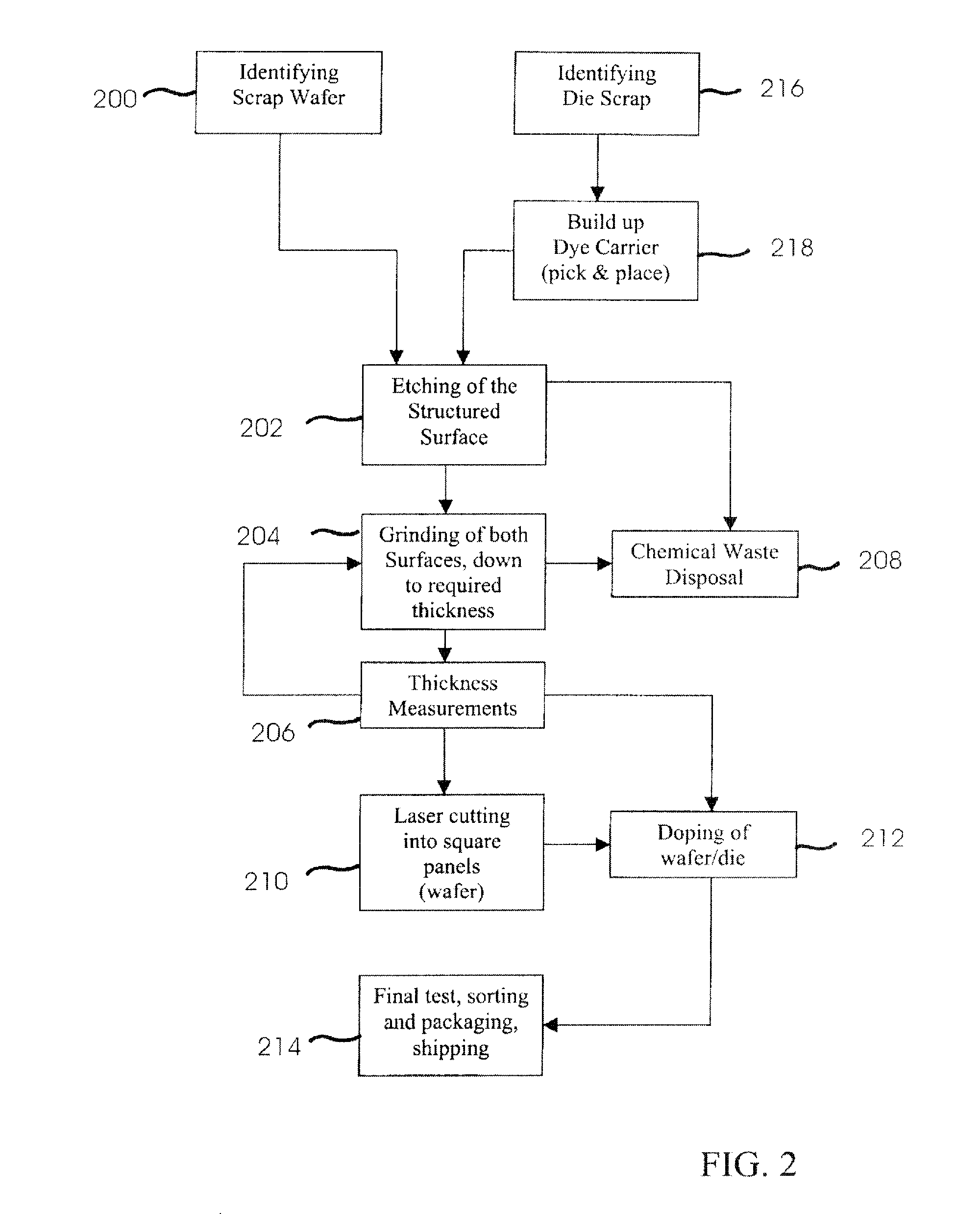

Method for the manufacture of solar panels and special transport carrier

InactiveUS20080014661A1DisposalReduce disposalSiliconSemiconductor/solid-state device manufacturingSurface cleaningEngineering

A method for the manufacture of solar panels from scrapped wafers and / or scrapped dies is provided, including the following steps: identifying scrap wafers and / or scrap dies; cleaning and removing remaining structures from the surface of the wafers / dies; grinding both surfaces of the wafers / dies down to a required thickness; doping the wafers / dies; and further processing the wafers / dies using a solar panel manufacturing method.

Owner:IBM CORP

Used paper processing apparatus

InactiveCN1900416APrevent leakageLow running costDryer sectionPaper recyclingPulp and paper industry

Owner:SEED RUBBER CO LTD

Sorbents for the oxidation and removal of mercury

ActiveUS20180133646A1Efficient use ofEasy to controlGas treatmentOther chemical processesSorbentProduct gas

Various embodiments disclosed relate to sorbents for the oxidation and removal of mercury. The present invention includes removing mercury from a mercury-containing gas using a halide-promoted and optionally ammonium-protected sorbent that can include carbon sorbent, non-carbon sorbent, or a combination thereof.

Owner:MIDWEST ENERGY EMISSIONS CORP

Activated carbon sorbent including nitrogen and methods of using the same

The present invention relates to activated carbon sorbents including nitrogen. In various embodiments, the present invention provides an activated carbon sorbent including a halogen- or halide-promoted activated carbon, the activated carbon sorbent particles including nitrogen in a surface layer of the sorbent particles. In various embodiments, the present invention provides a method of reducing the pollutant content in a pollutant-containing gas using the activated carbon sorbent. In various embodiments, the activated carbon sorbent can remove mercury from a mercury-containing gas that includes sulfur(VI) such as SO3 more efficiently than other sorbents.

Owner:MIDWEST ENERGY EMISSIONS CORP

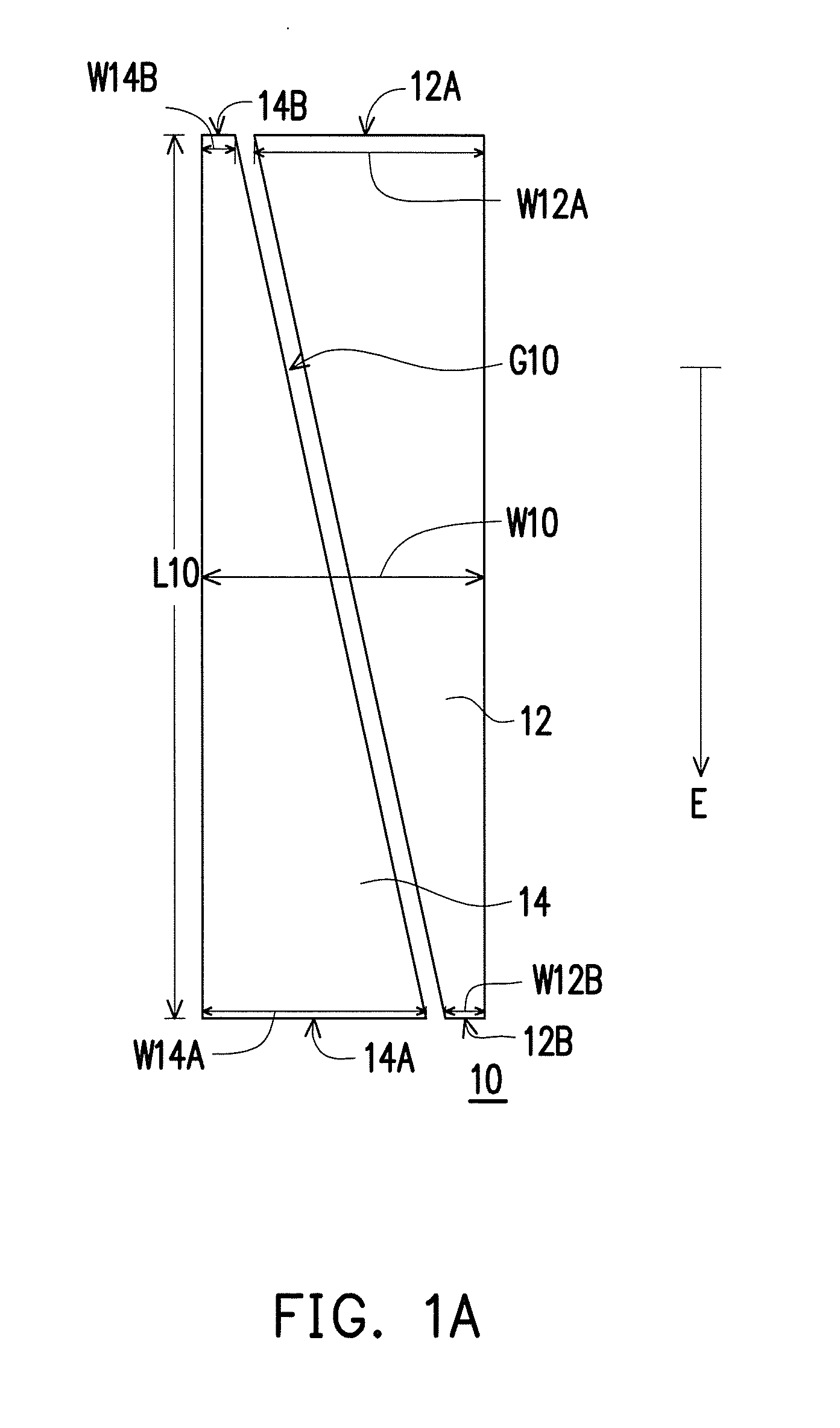

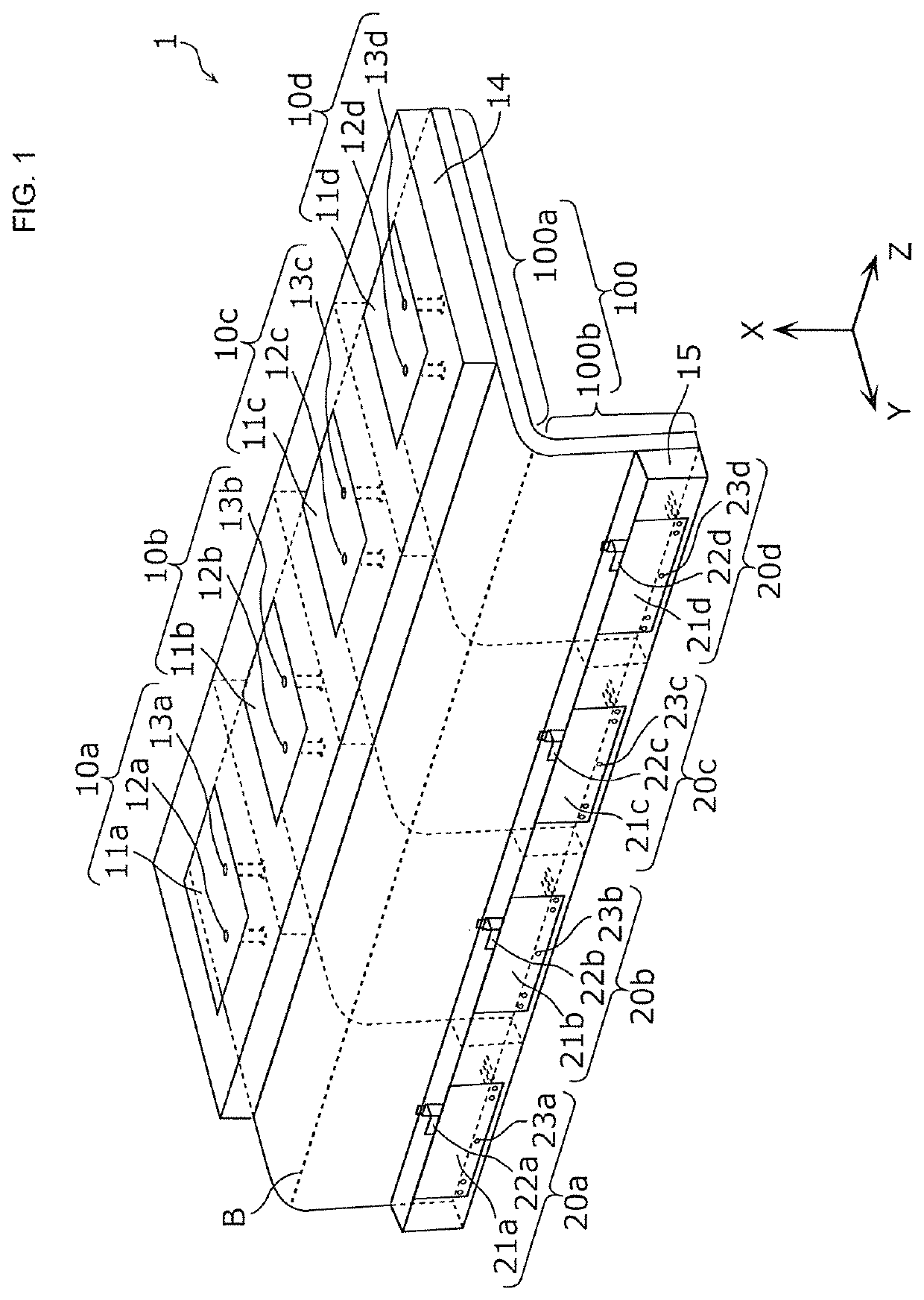

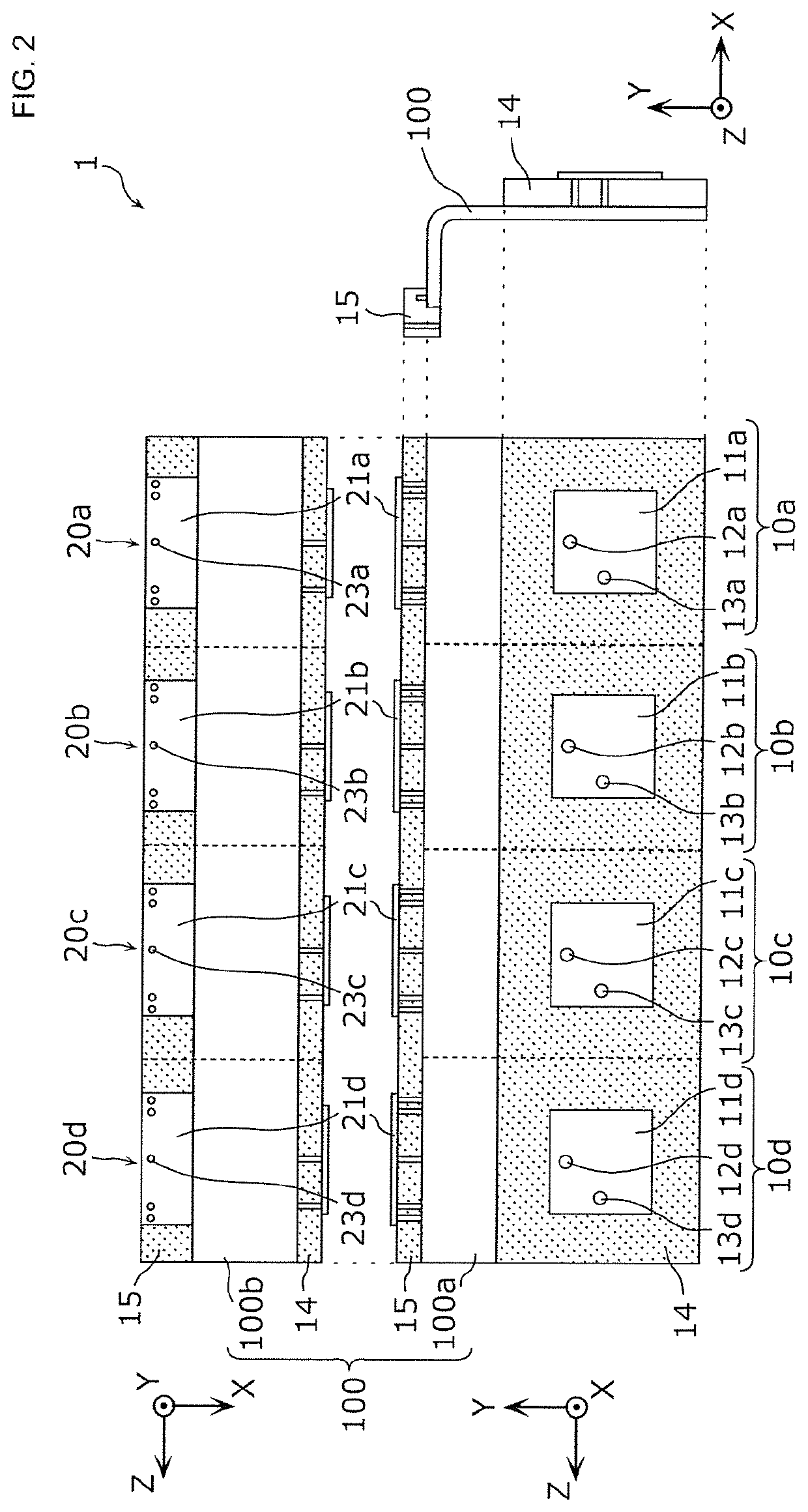

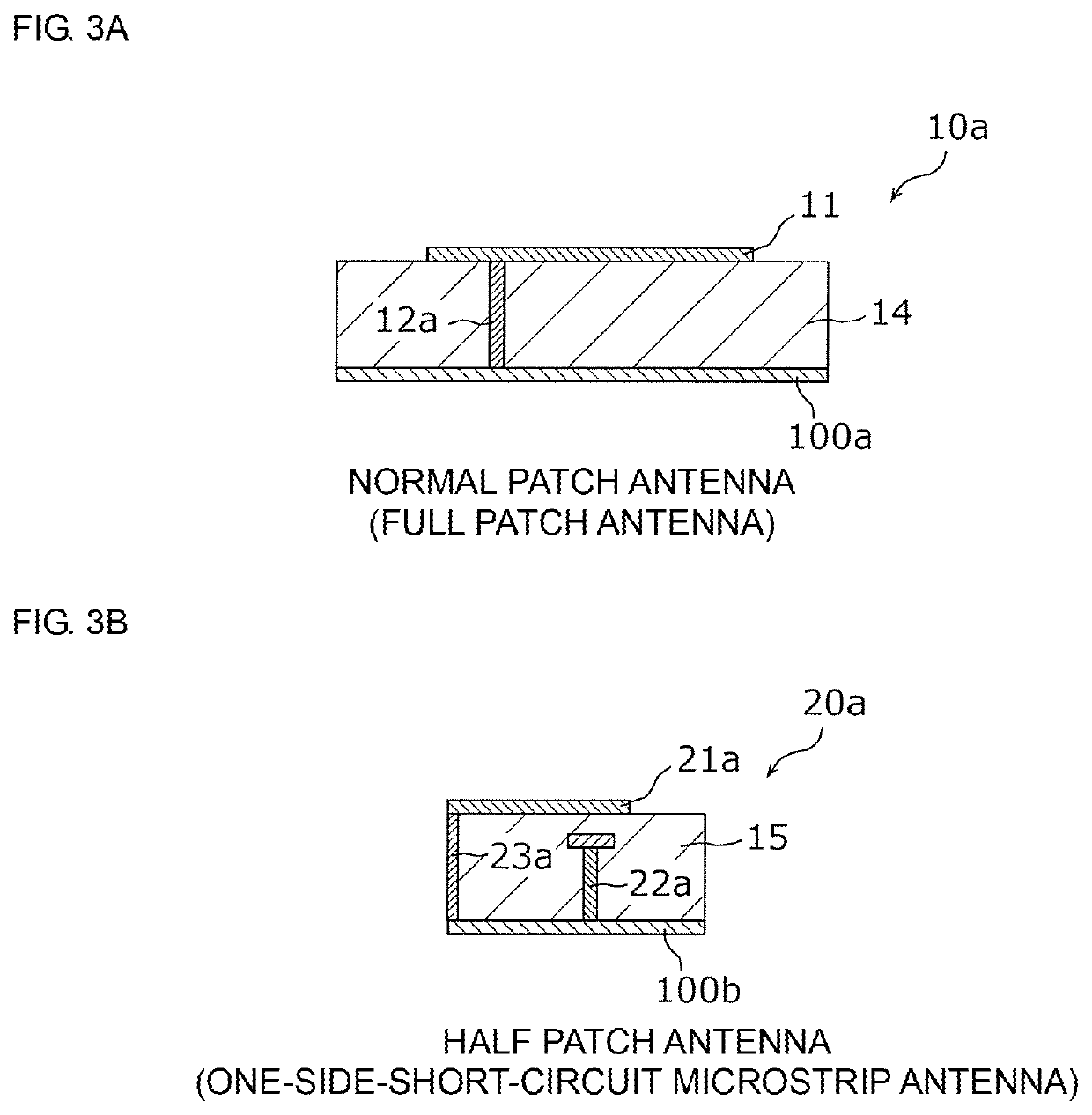

Antenna module and communication device

ActiveUS20200119453A1Improve featuresReduce thicknessIndividually energised antenna arraysModular arraysMechanical engineeringCommunication device

An antenna module (1) includes a substrate (100) including a first flat plate portion (100a) and a second flat plate portion (100b) that have respective normals intersecting with each other and that are continuous, first patch antennas (10a to 10d) that are formed on the first flat plate portion (100a) and second patch antennas (20a to 20d) that are formed on the second flat plate portion (100b). The first patch antennas (10a to 10d) are arranged in at least a column in a column direction parallel to a boundary line (B) between the first flat plate portion (100a) and the second flat plate portion (100b). The second patch antennas (20a to 20d) are arranged in at least a column in the column direction.

Owner:MURATA MFG CO LTD

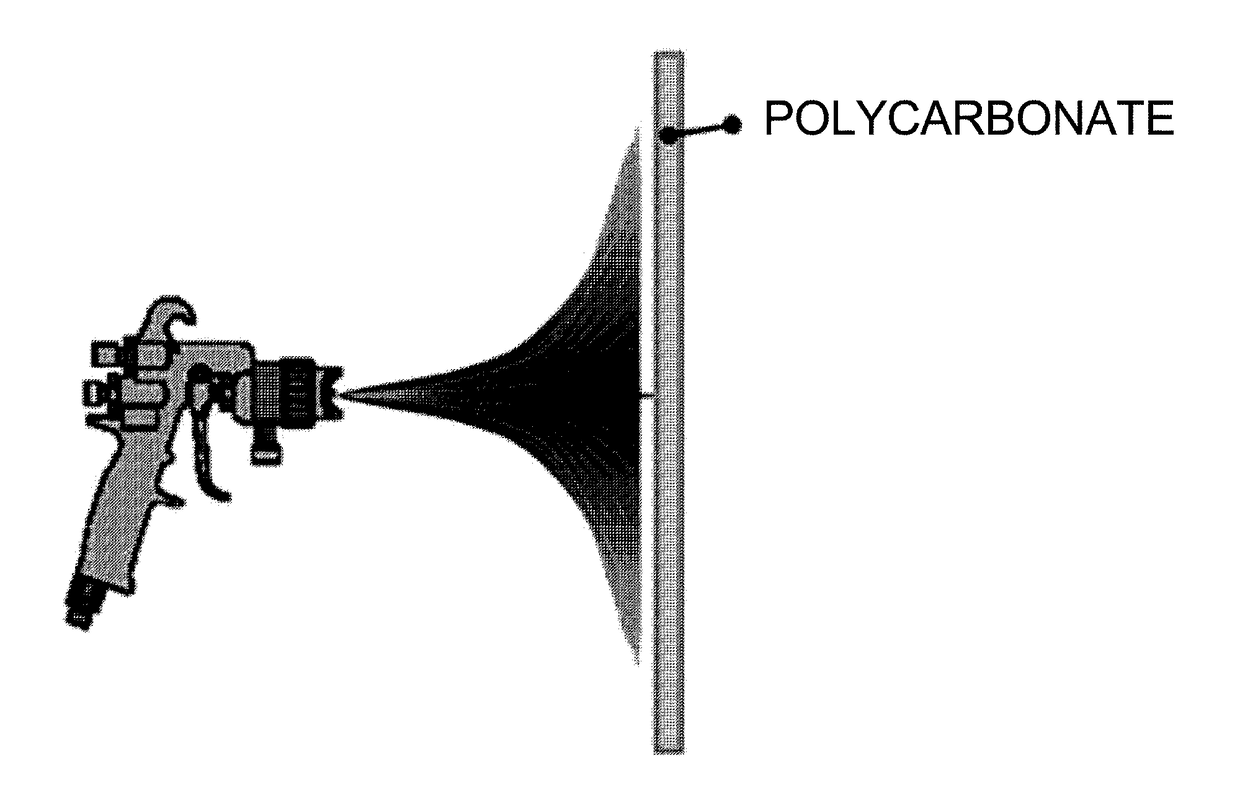

UV-curable hard coating composition and coated article using the same

ActiveUS10227501B2Increase resistanceImprove production yieldPolyurea/polyurethane coatingsWeather resistanceInorganic particle

A UV-curable hard coating composition and a coated article coated with the coating composition are provided herein. The UV-curable hard coating composition can be coated on a plastic material such as polycarbonate to form a coated film having excellent material adhesion, abrasion resistance, and weather resistance. The coating composition may be coated by a general coating method. In some instances, inorganic particles as a coating component are not included in the coating composition. Few foreign substances are generated during spray-coating using the composition. The coating composition can be easily stored. Also, the coated article can be polished or recoated with the UV-curable hard coating composition if needed.

Owner:HYUNDAI MOTOR CO LTD +1

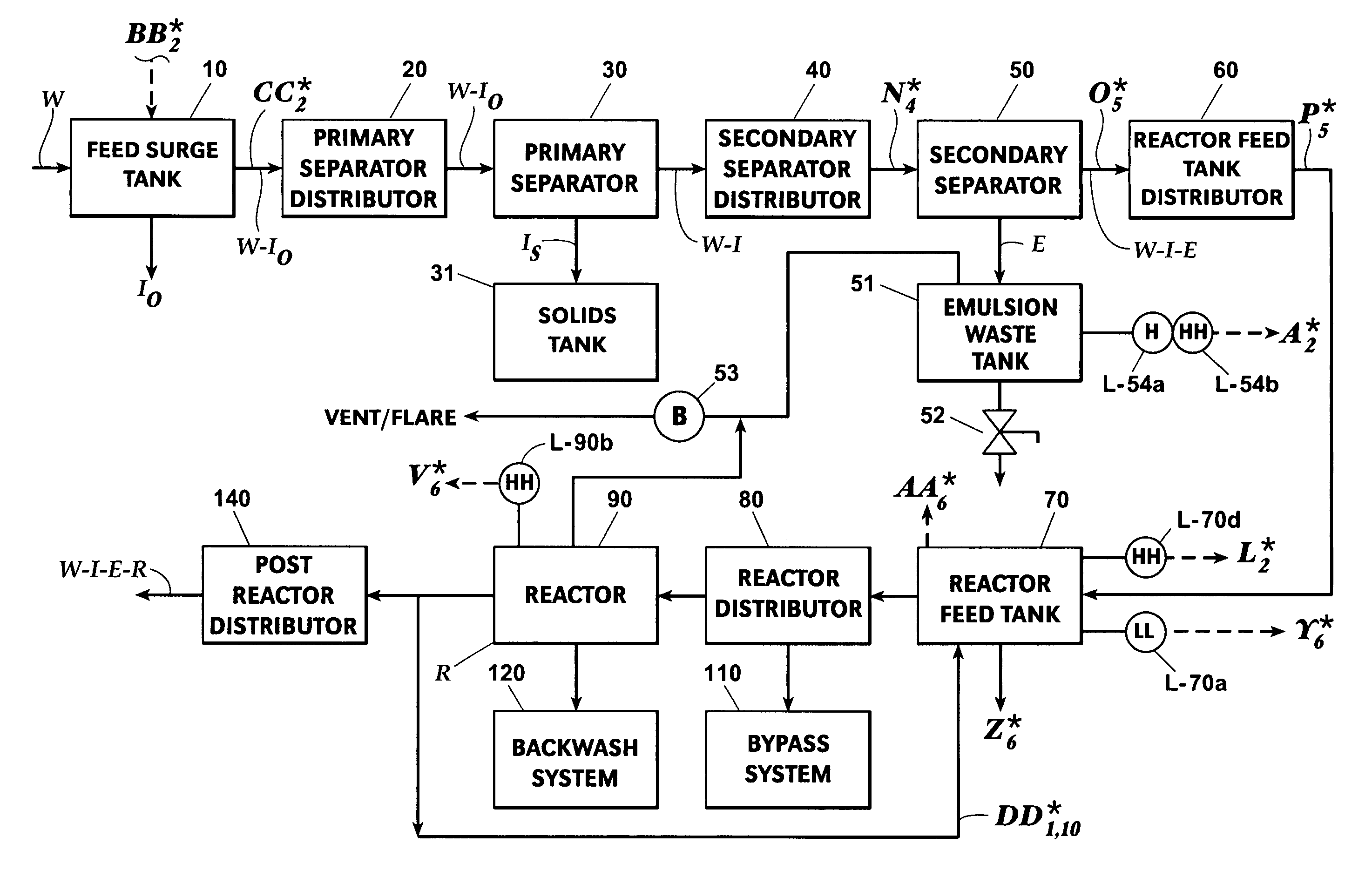

Process for treating industrial effluent water with activated media

ActiveUS7491336B2Reduce disposalWater treatment parameter controlFatty/oily/floating substances removal devicesIndustrial effluentSludge

In a process for treating effluent water, a stream of effluent water is fed to a porous ceramic media filled reactor. Organic and inorganic impurities are absorbed and / or oxidized from the effluent water into the media and / or off-gases. The remainder of the effluent water stream is dispensed from the reactor in an outlet stream suitable for direct discharge to the sea or for recycling without incurring the disadvantages of generating a solid sludge. The reactor includes a chamber containing activated media, such as pellets of porous ceramic material. The pellets are stored in a vertical stacks of sub chambers defined by horizontal perforated trays and / or in a horizontal chains of sub chambers defined by vertical perforated baffles.

Owner:AGUA DULCE TREATMENT SYST LLC

Method of making organohalosilanes

Owner:DOW SILICONES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com