AAO continuous-flow aerobic granular sludge nitrogen and phosphorus removal process and system

An aerobic granular sludge, nitrogen and phosphorus removal technology, applied in water/sludge/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., to promote the improvement of sludge quality and improve the effect of mud-water separation , Conducive to the effect of biological nitrogen and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

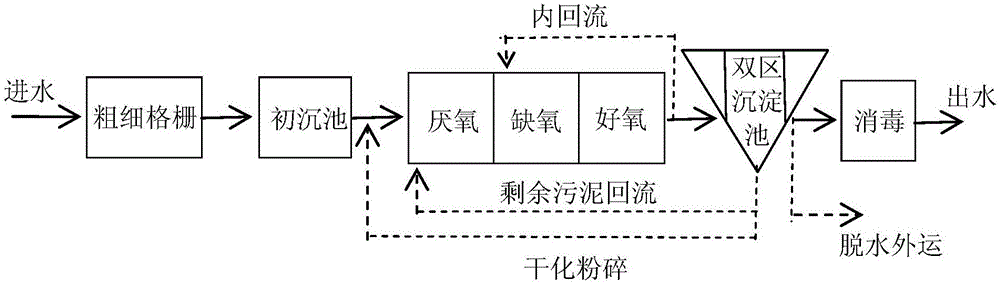

[0018] Example 1: An AAO continuous flow aerobic granular sludge nitrogen and phosphorus removal process, the sludge from the aeration tank of the sewage treatment plant was inoculated into the reactor at 1000mg / L, the inoculated sludge was in the form of floc, and the SVI was 80ml / g, using sodium acetate, ammonia oxide, potassium dihydrogen phosphate to make COD 1000mg / L, NH 4 + - Sewage with a N concentration of 60mg / L and a TP concentration of 10mg / L, continuous water inflow operation, the reflux ratio in the sludge is set to 2Q (Q is the inflow flow rate), and the light sludge in the dual-zone secondary sedimentation tank is directly discharged. Part of the sludge is refluxed, and the other part is dried and crushed to 100-800 mesh and put into the front end of the biochemical tank. After 25 days of continuous operation of the reactor, the aerobic sludge is granulated, and the sedimentation rate is 20-30m / h, SVI<50ml / g, the removal rate of COD is about 95%, the removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com