Patents

Literature

76results about How to "Disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

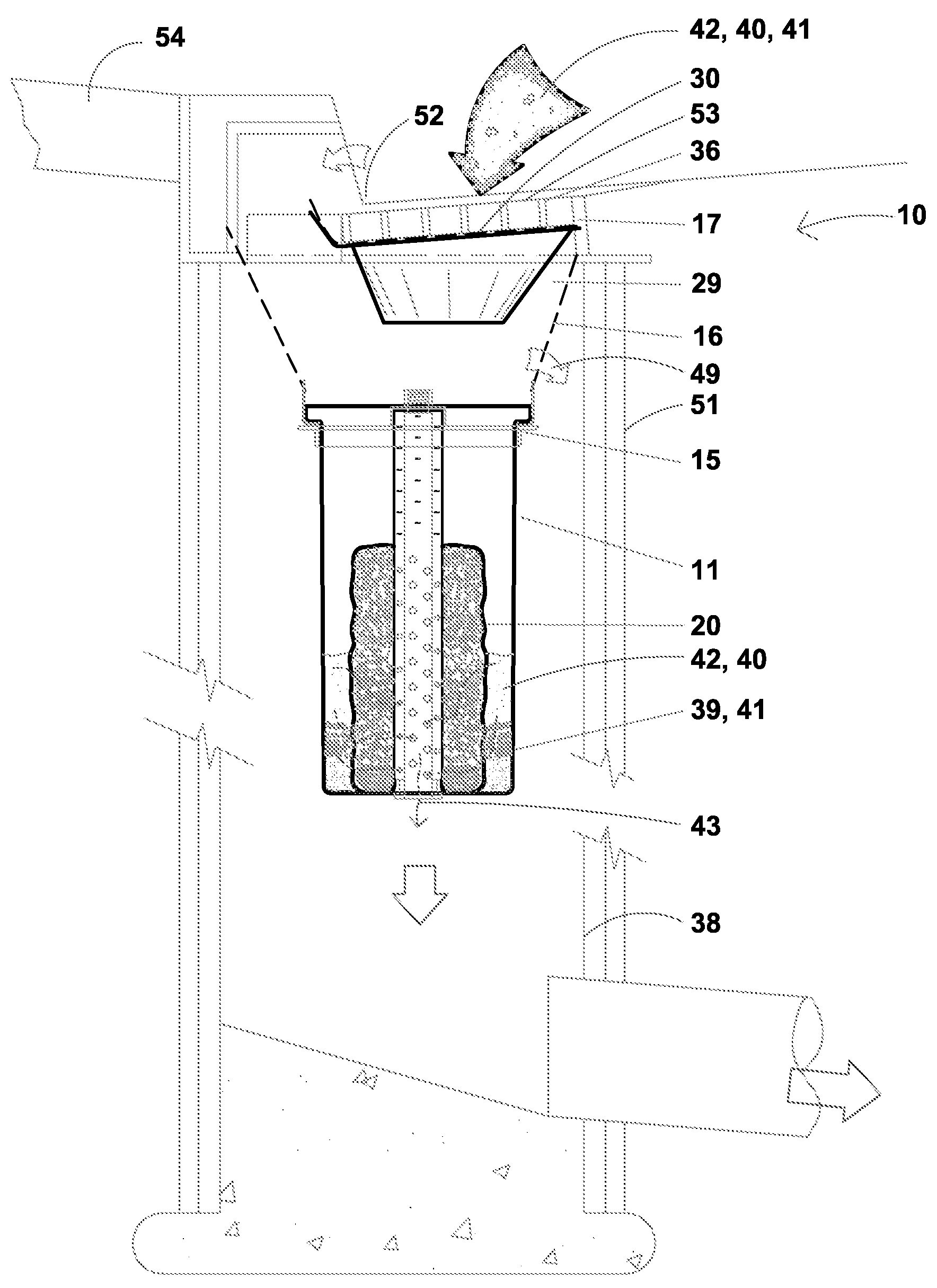

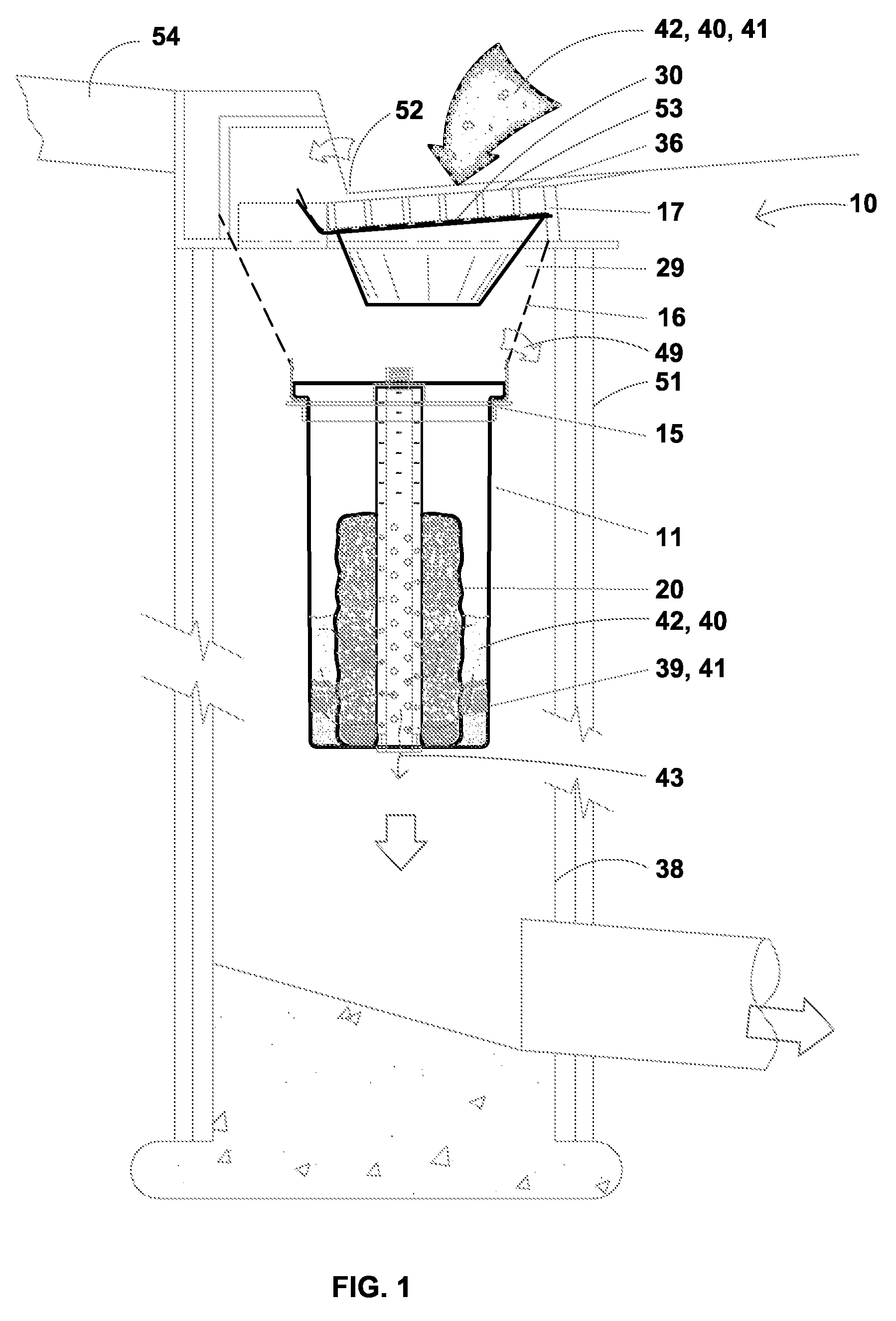

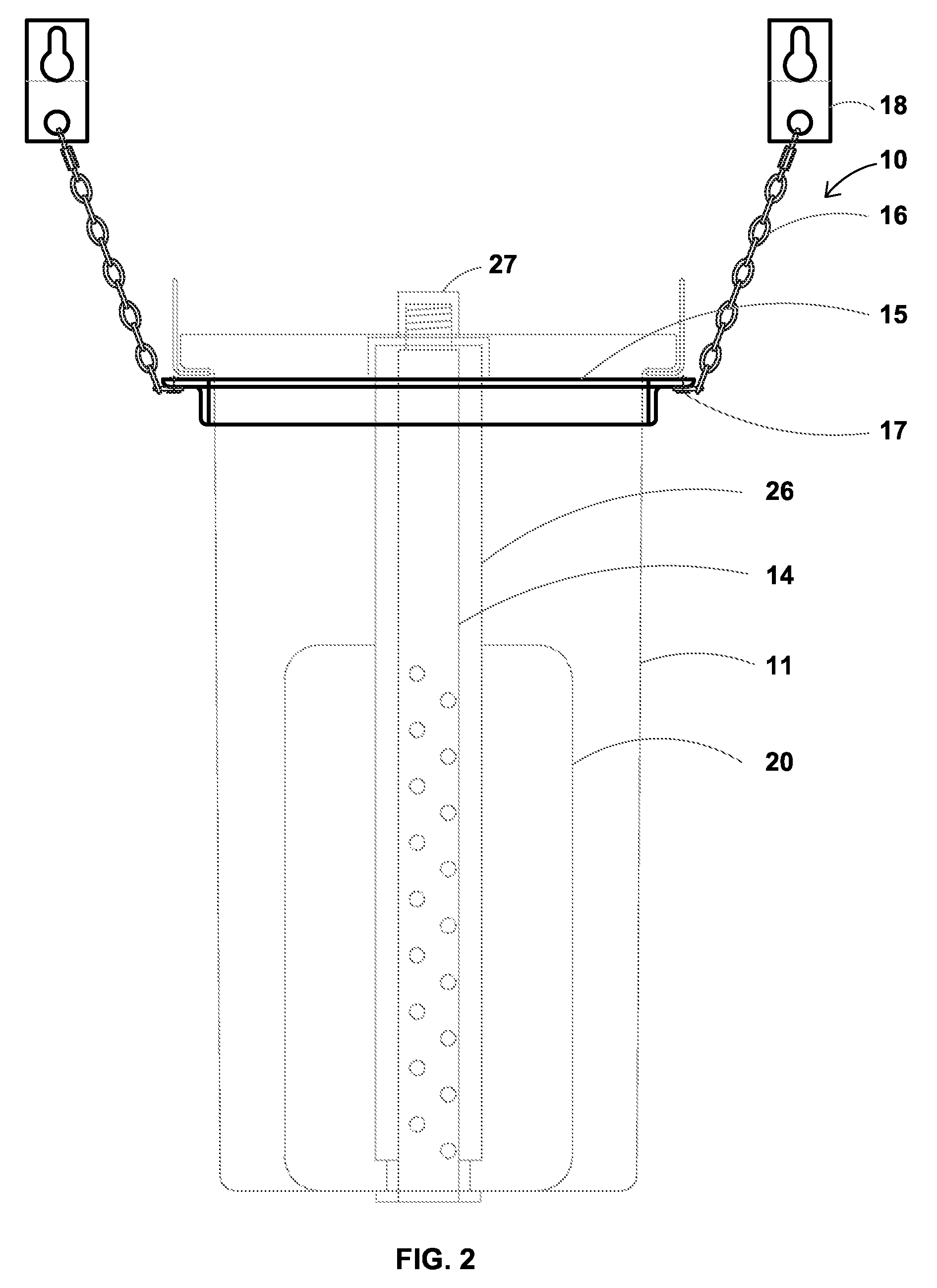

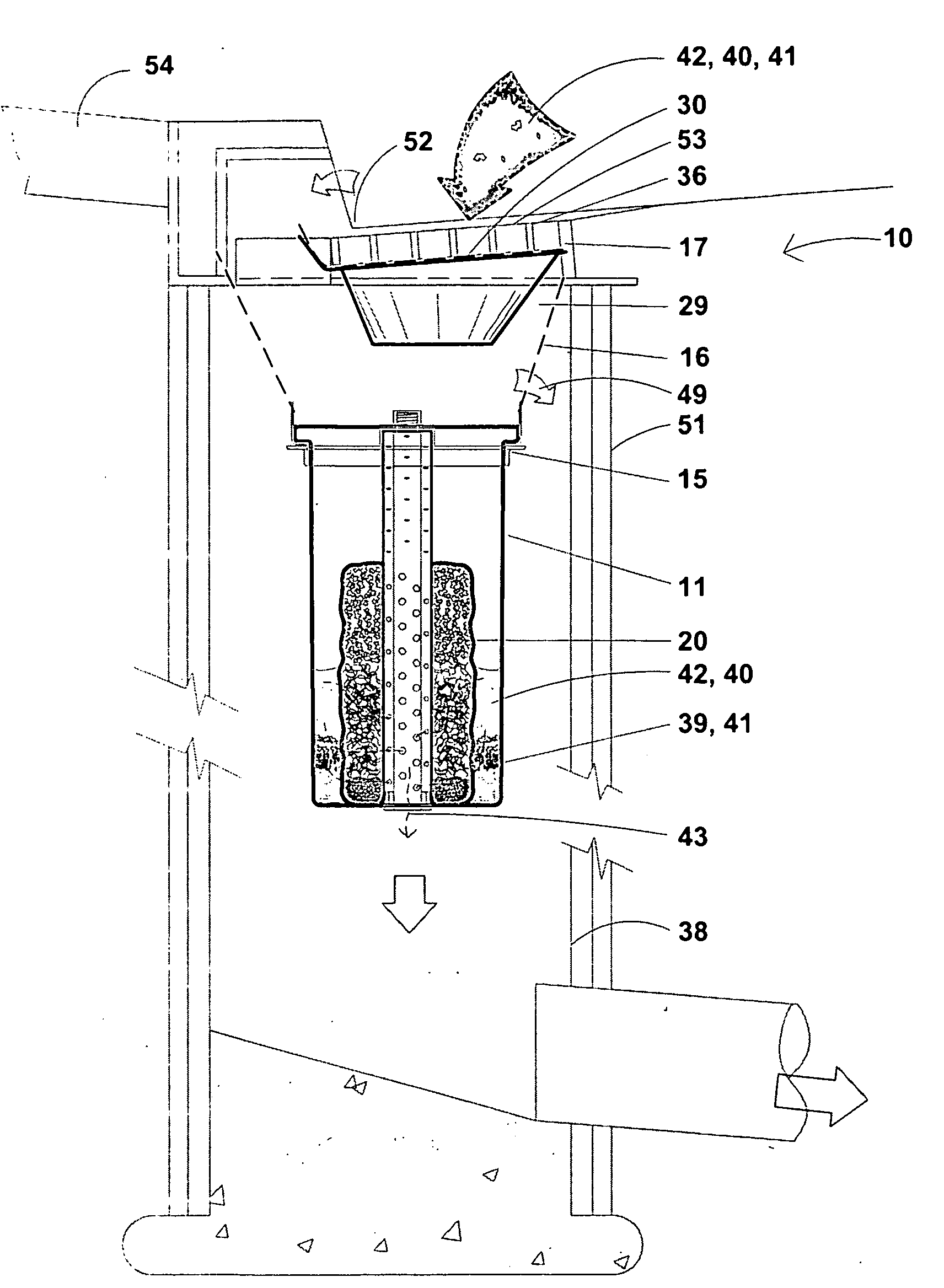

Catch basin filter absorber apparatus and method for water decontamination

ActiveUS20080073277A1Great emphasisEasy to installFatty/oily/floating substances removal devicesGround-workActivated carbonStormwater treatment

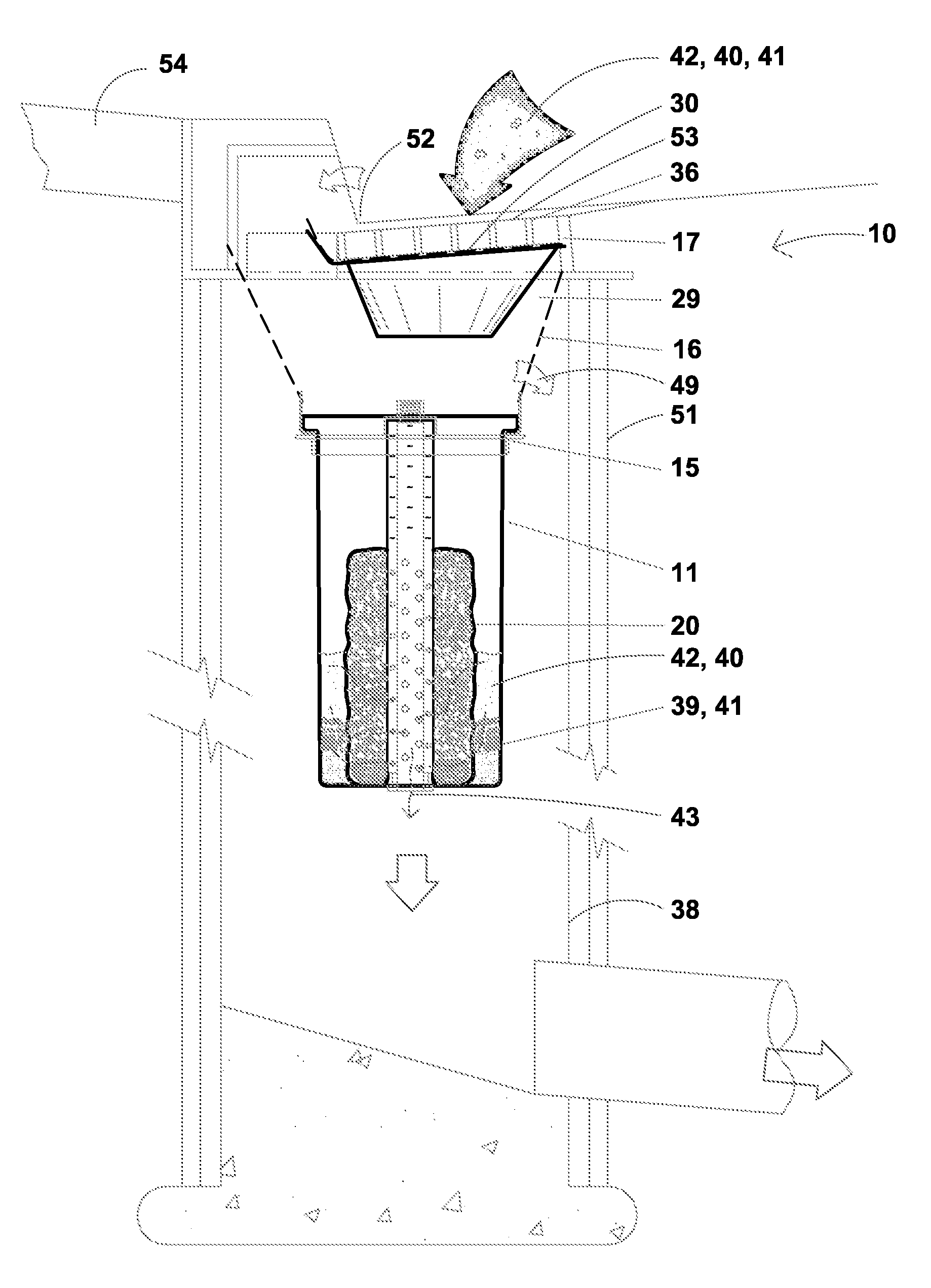

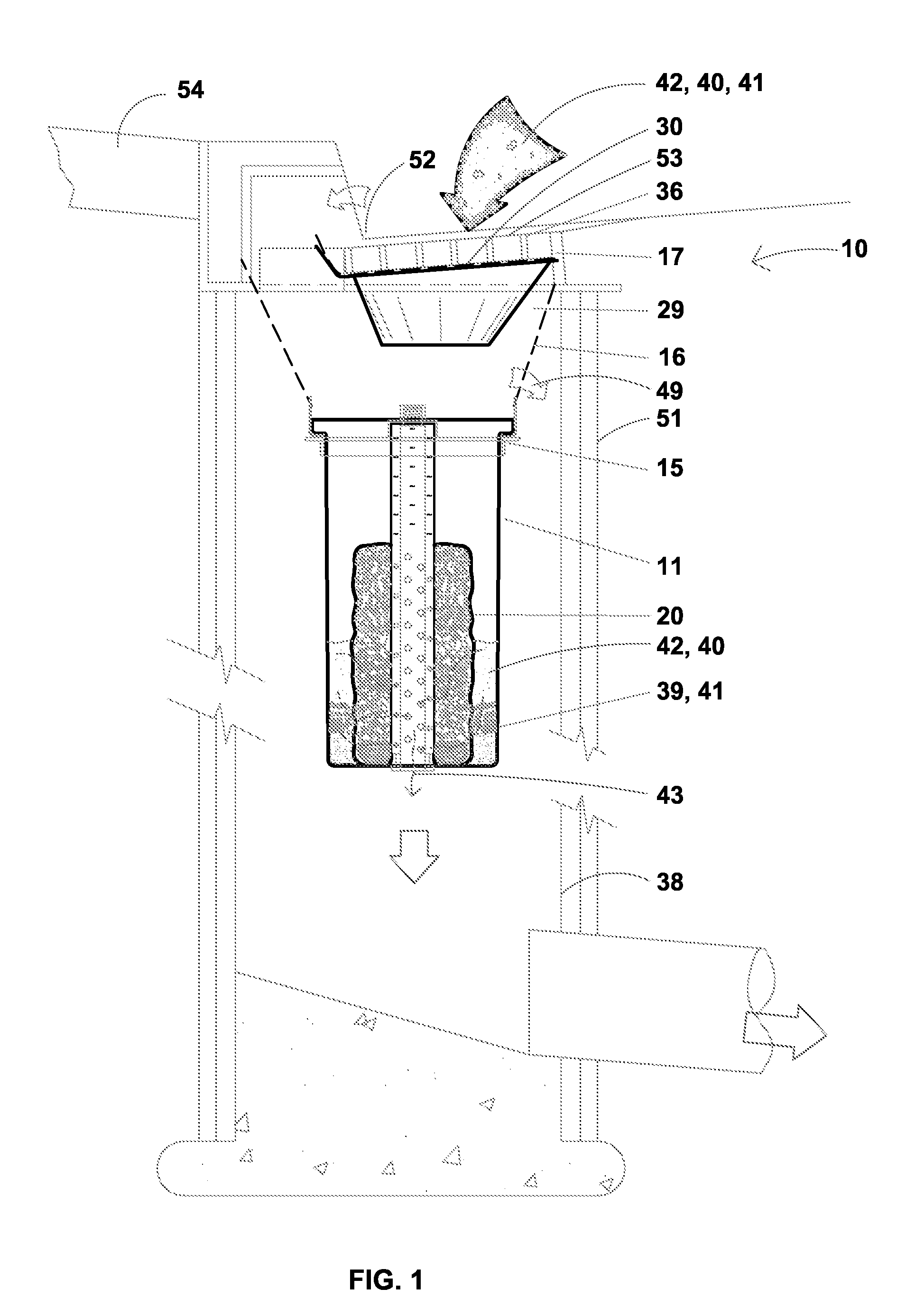

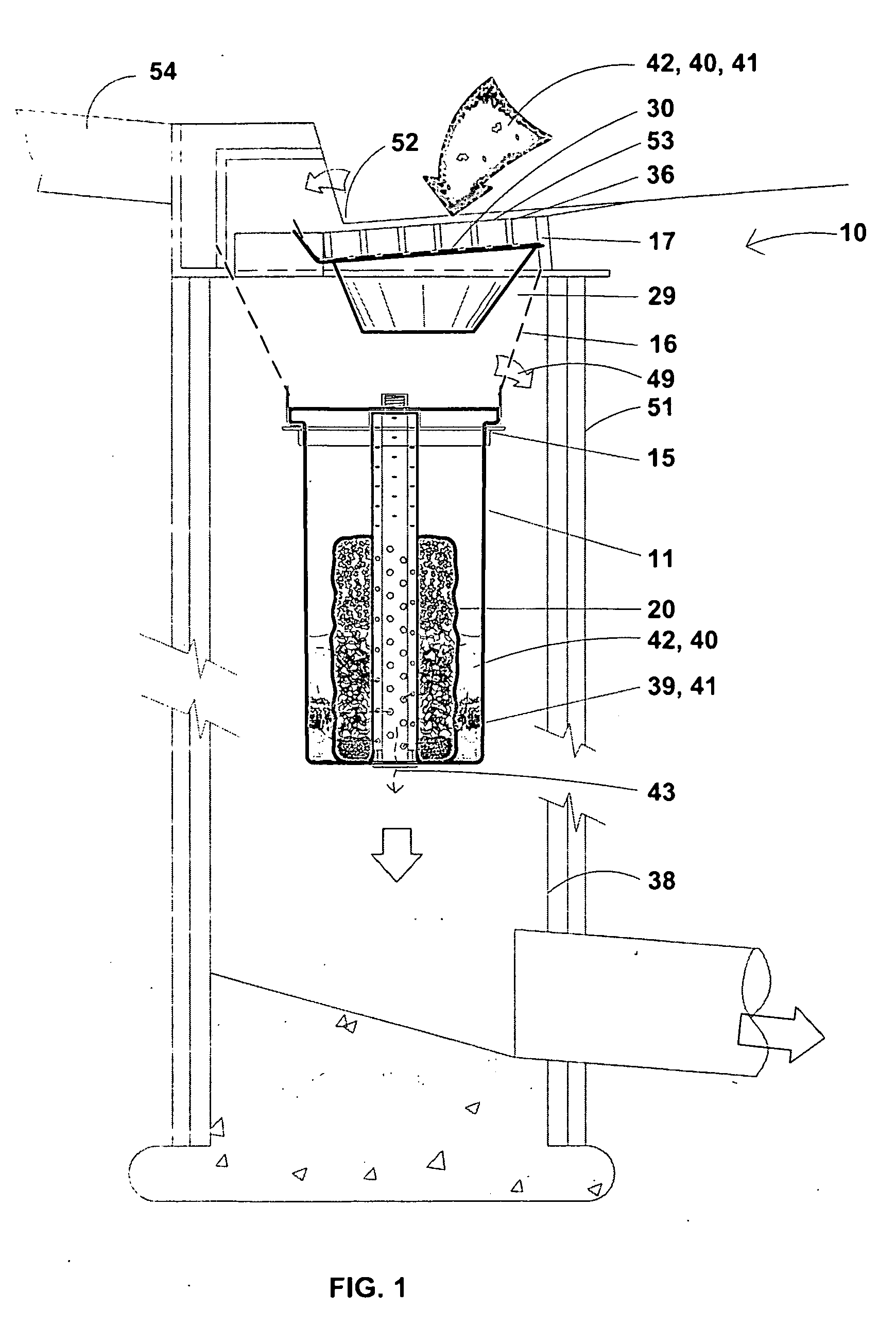

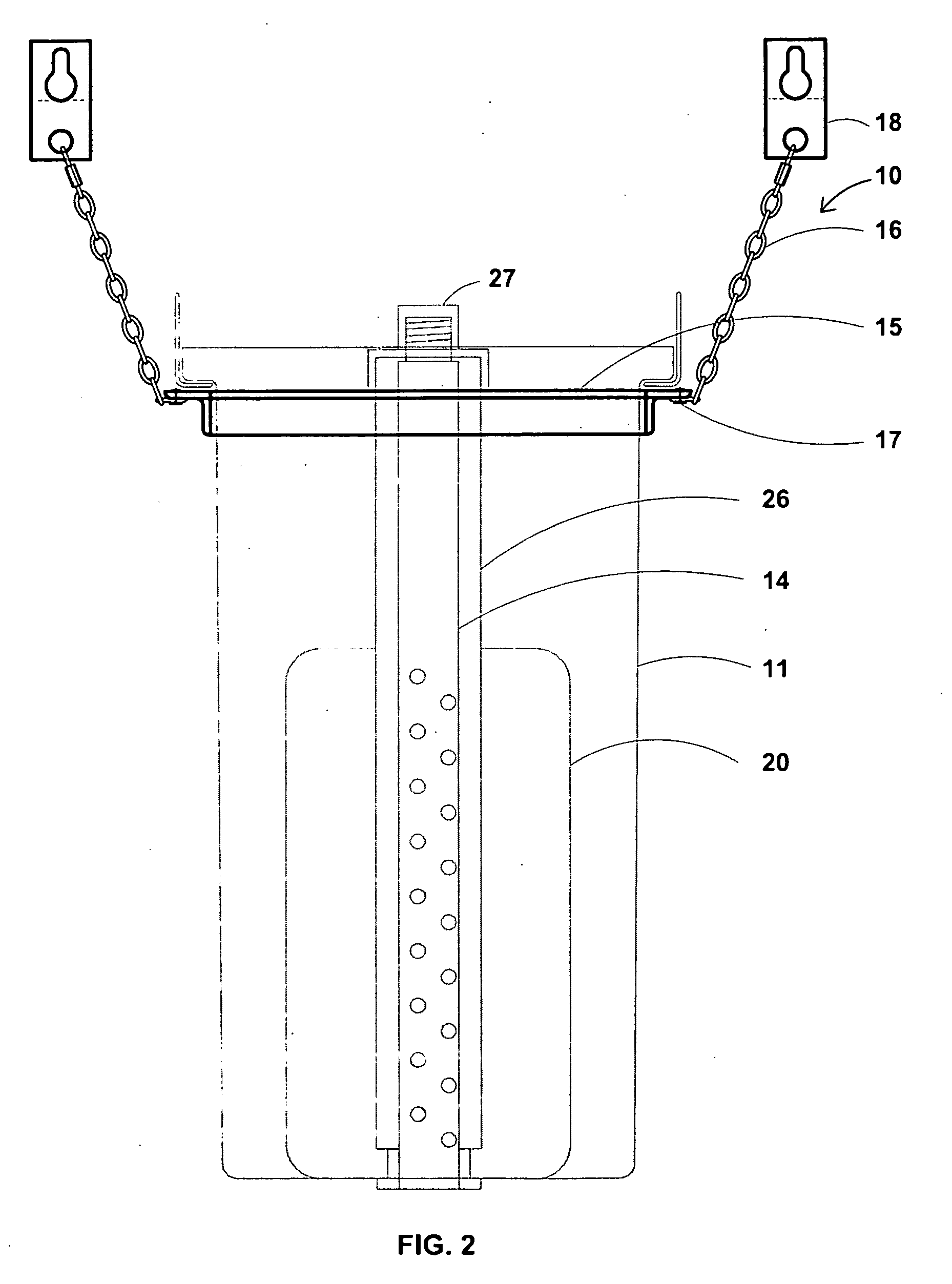

A storm water treatment device that is installed under the grate of new or existing catch basins, and more commonly referred to as an insert. The catch basin decontamination apparatus has a universal housing and support ring that allows one design to fit most applications. Adjustable chains allow for proper position below grate and a semi-flexible molded or rigid deflector directs incoming drain water to the housing. A slip-on filter / absorber cartridge fits over a perforated drain tube, in the center of the housing, allowing the drain water to first pass through the filter / absorber media before exiting through the drain tube and out the bottom of the housing. The filter / absorber cartridge includes a variety of absorber materials that absorb oil and repel water. Activated carbon, microbes and other site specific absorbents can be used in the replaceable slip-on cartridge. A leaf pre-strainer helps prevent leaves and debris from entering the housing. A clean in place suction tube and clod buster form of the apparatus aids in cleaning the housing.

Owner:INVENTIVE RESOURCES

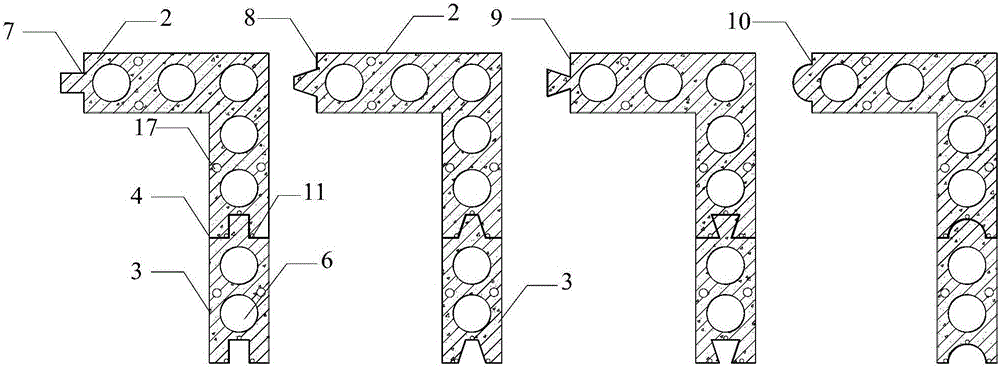

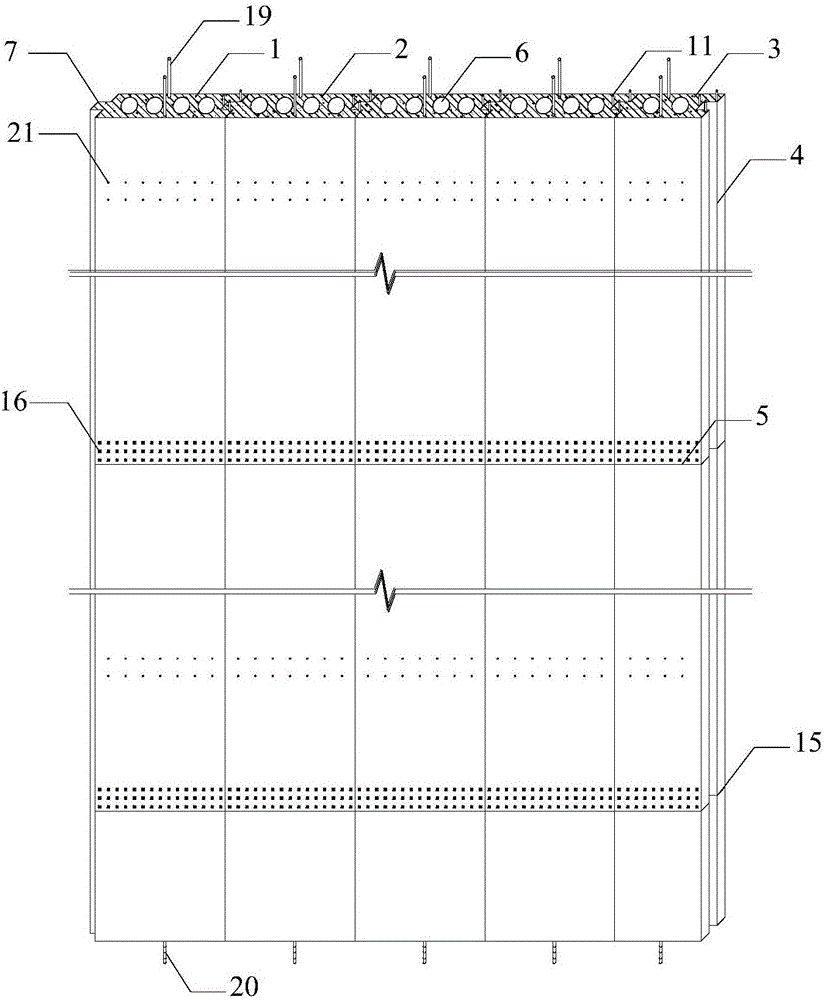

Assembled type underground diaphragm wall and construction method thereof

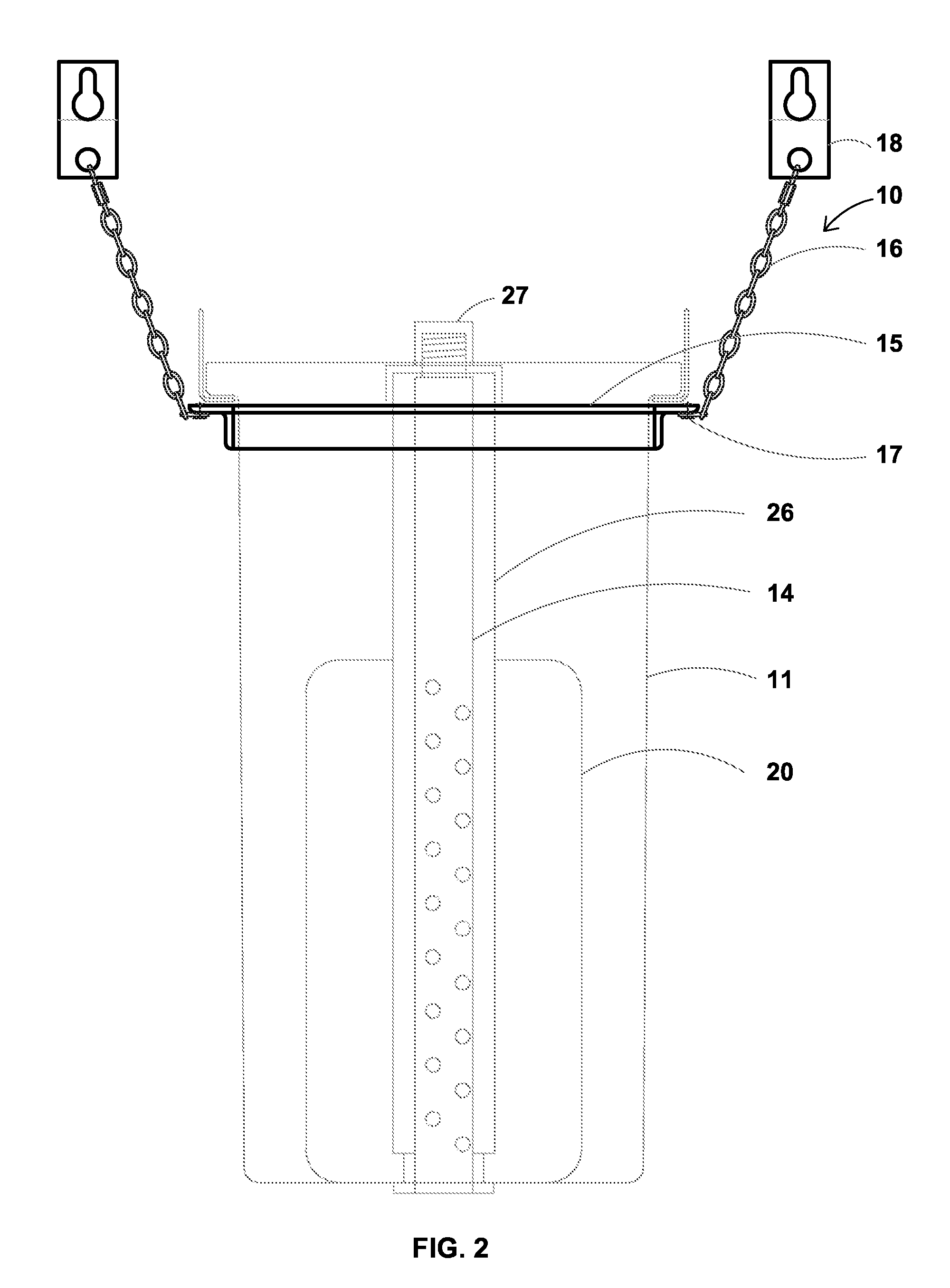

The invention discloses an assembled type underground diaphragm wall. Diagram wall members are of cavity structures, and are prefabricated in a factory or at the construction site; the members are continuously spliced and connected in pre-dug trench sections; joints comprise transverse joints and vertical joints; the vertical joints are connected through tenons, and the transverse joints are connected through bolts in a staggering or tenoning manner; buried connection pieces are arranged on the side surfaces of the members; compact grouting pipes are arranged at the vertical joints of the members; grouting pipes are arranged in the members; hardcore beds for reinforcement are arranged at the bottoms of the members. According to the construction method, the prefabricated underground diagram wall members are assembled in the trench sections at the construction site, to form the underground diaphragm wall structure with both overall structure rigidity and anti-seepage performance according to vertical joint grouting, compact grouting at the bottom of the wall and gravel reinforcement. The construction method is high in construction controllability, high in quality, high in efficiency, short in period, low in engineering manufacturing cost and good in construction implementation effect, and materials can be saved.

Owner:SHANGHAI STRONG FOUND ENG +1

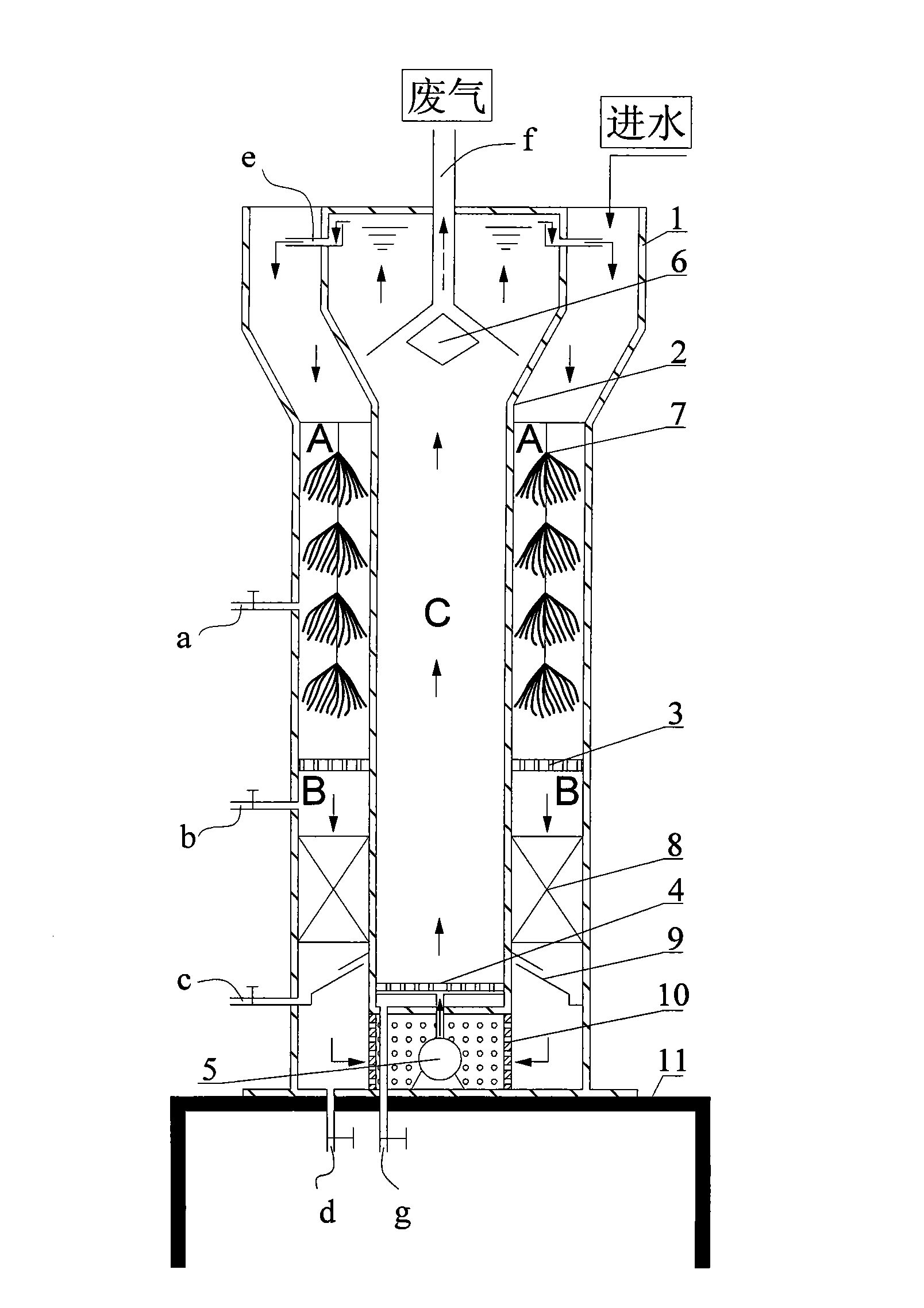

Sequencing batch internal circulation biological denitrification process and device thereof

InactiveCN101514064AHigh volume loadLow toxicityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTherapeutic effectOxidative treatment

The invention discloses a sequencing batch internal circulation biological denitrification process. The process mainly comprises four steps of water feeding, biological denitrification reaction, precipitation and water and mud discharge. The biological denitrification reaction comprises an internal circulation reaction from short-cut nitrificaition treatment to deoxidation treatment, anaerobic ammoxidation treatment and to the short-cut nitrificaition treatment, and the short-cut nitrificaition treatment, the deoxidation treatment and the anaerobic ammoxidation treatment are carried out in three intercommunicated different reaction areas of one reactor. The invention further discloses a biological denitrification device. The device is separated into three intercommunicated reaction areas, that is, a short-cut nitrificaition treatment reaction area, a deoxidation treatment reaction area and an anaerobic ammoxidation treatment reaction area. The device is further equipped with an aerating device, an internal circulation pump, a water distributor and the like. The process has the advantages of convenient operation management, low energy consumption, high denitrification efficiency and stable treatment effect, and the device matching the process has the advantages of compact structure, convenient use, low cost and the like.

Owner:HUNAN UNIV

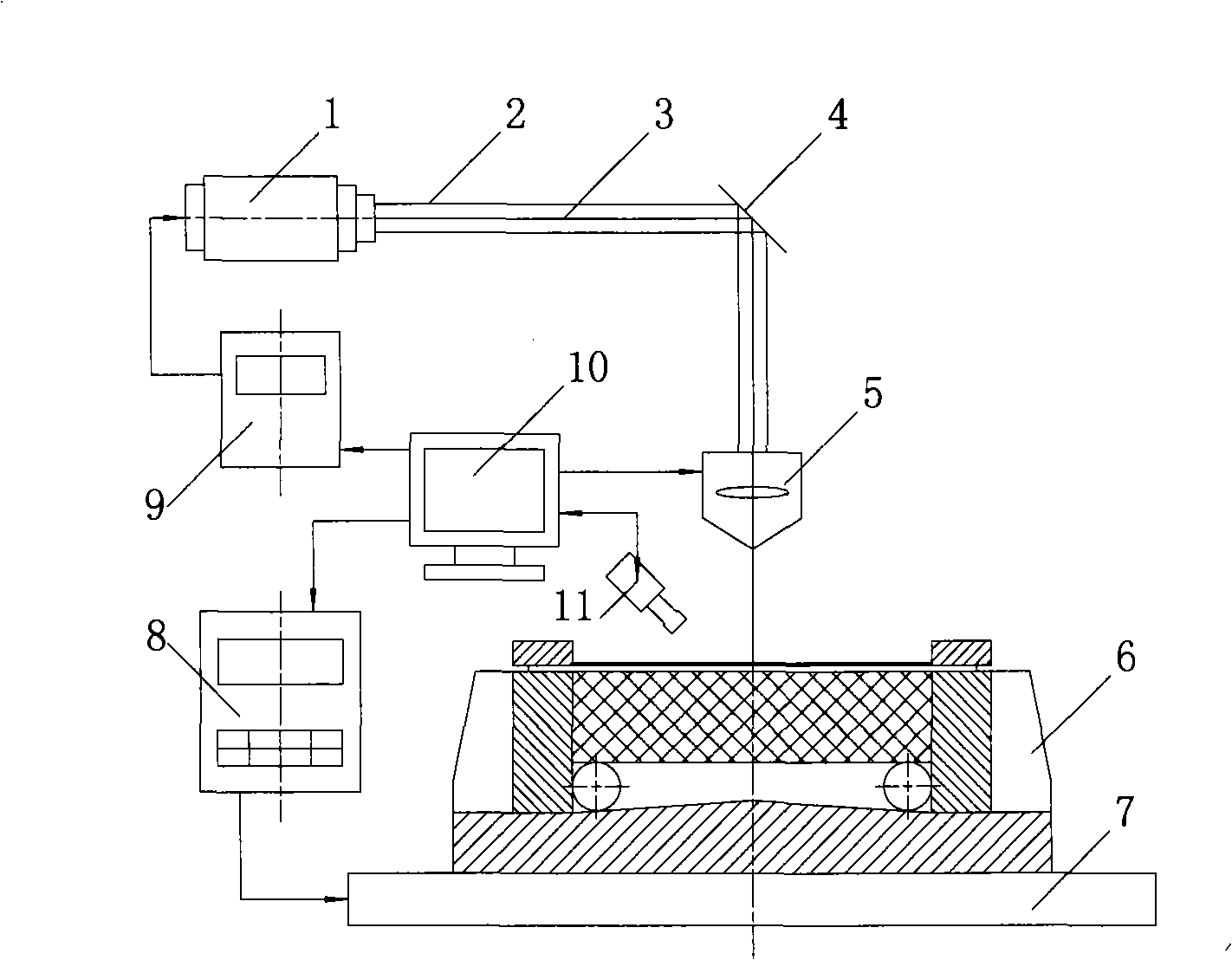

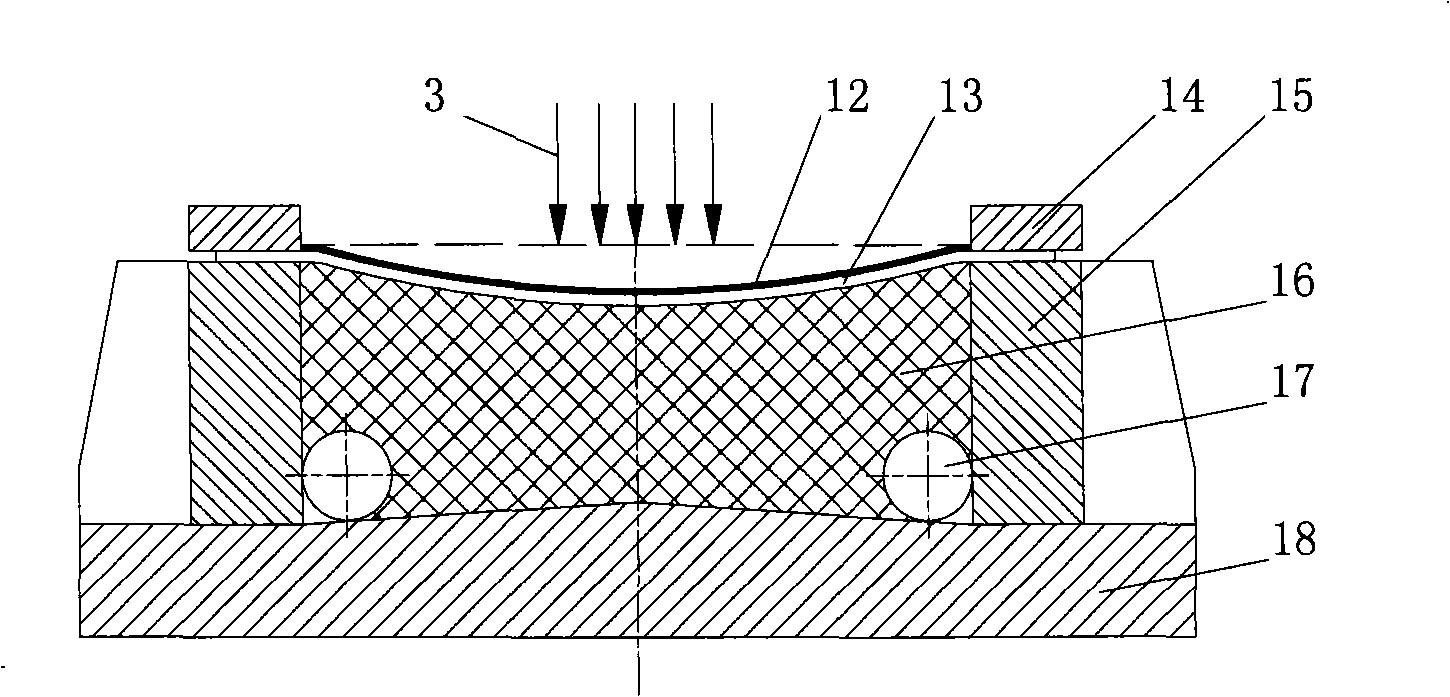

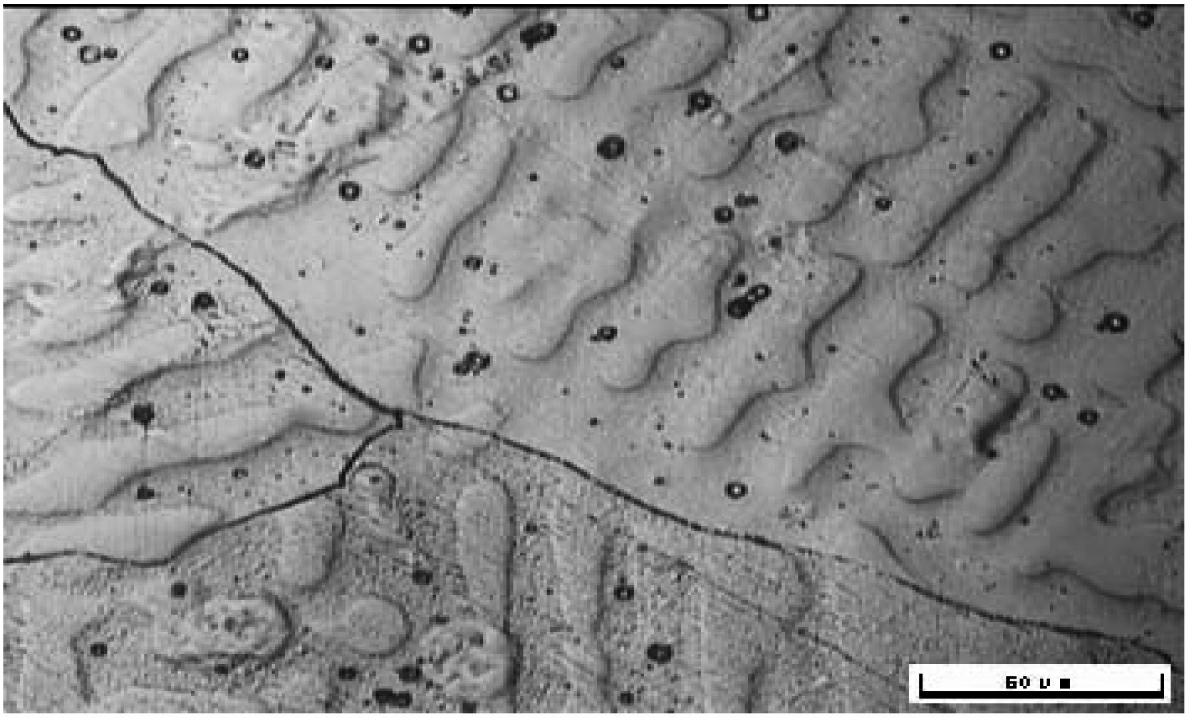

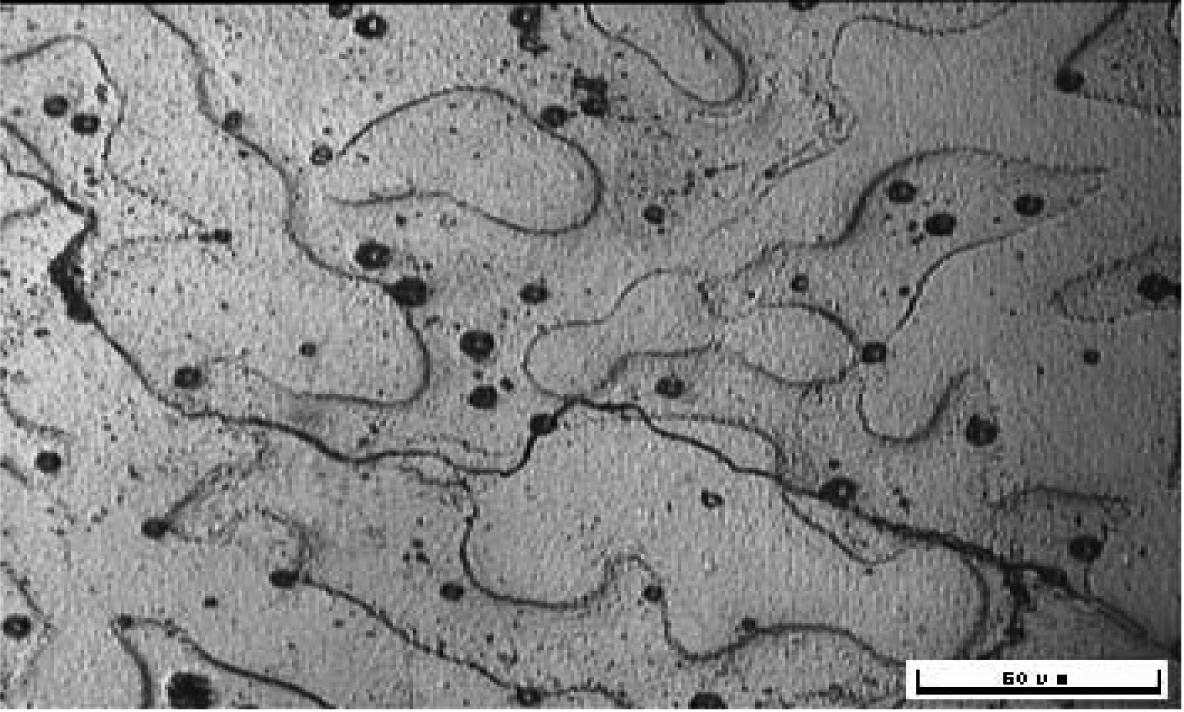

Method and device for laser shock forming on the basis of polyurethane rubber film

ActiveCN101524784APrecise large area impact formingPrecise and flexible levelingLaser beam welding apparatusShock waveStress conditions

The invention relates to a method and a device for laser shock forming on the basis of a polyurethane rubber film. The method is characterized in that shock waves induced by laser are used as a power source for forming; the polyurethane rubber film is used as a concave film for the laser shock forming; and the stress condition of a plate under the action of the shock waves is changed to achieve the shock forming of a complicated curved surface. The device comprises a laser generating device, a light guide system, a laser shock head, a polyurethane rubber film system and a control system and is also provided with a detection feedback system with a displacement measuring device. According to the requirement of the curved surface shape and forming rules of a plate, laser shock process parameters are optimized, the polyurethane rubber of proper hardness and thickness are selected, and the plate is deformed under the associative action of the shock waves and the polyurethane rubber. The device not only can achieve the complicated and precise forming of the plate, but also can carry out the flexible leveling of the plate, and also can be applied to the surface shock strengthening treatment of materials.

Owner:JIANGSU UNIV

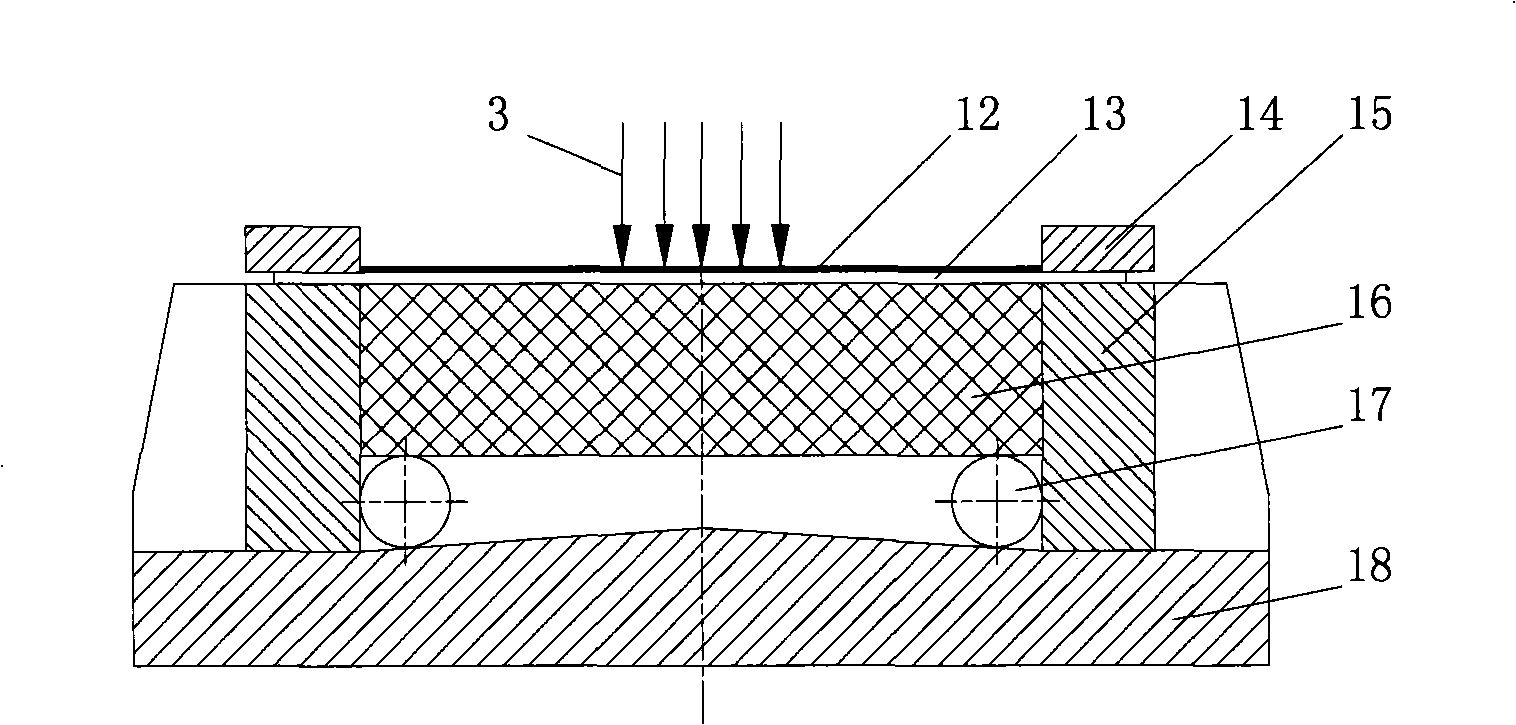

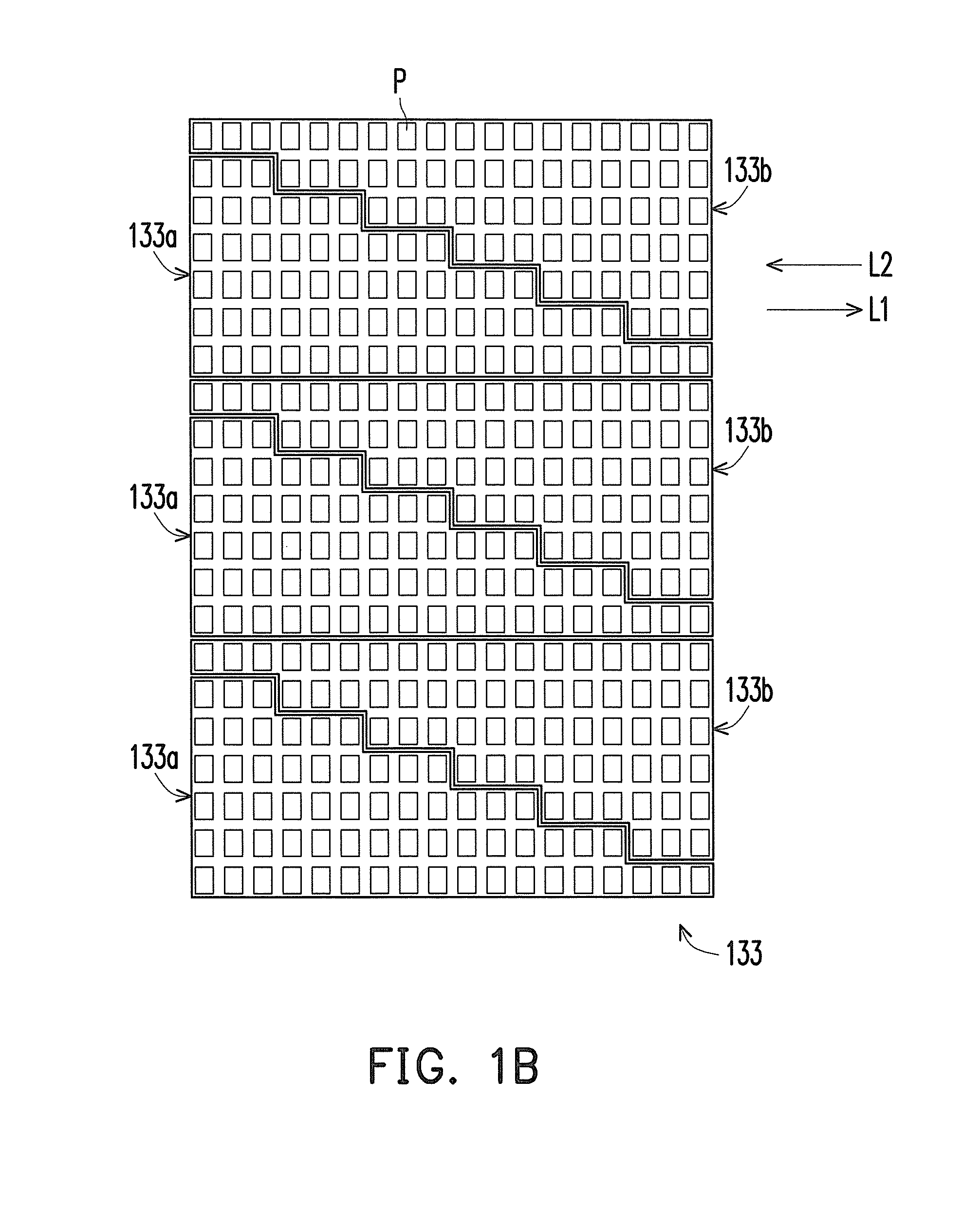

Touch display panel

InactiveUS20130306946A1Increasing the thicknessReduce thickness and weightSolid-state devicesSemiconductor/solid-state device manufacturingTouch SensesSealant

A touch display panel including a array substrate, an opposite substrate, an organic light emitting diode (OLED) structure, a plurality of conductive spacers and a sealant is provided. The OLED structure is disposed on the opposite substrate and located between the array substrate and the opposite substrate. The OLED structure includes a first electrode layer, an organic light emitting layer and a second electrode layer which are sequentially disposed. The first electrode layer is located on the opposite substrate and includes a plurality of touch sensing electrode. The second electrode layer is electrically connected to the array substrate via the conductive spacers. The sealant is sealed the OLED structure and the conductive spacers between the array substrate and the opposite substrate.

Owner:WINTEK CORP

Catch basin filter absorber apparatus for water decontamination

ActiveUS7479221B2Easy to installLow costFatty/oily/floating substances removal devicesGround-workActivated carbonAbsorbent material

Owner:INVENTIVE RESOURCES

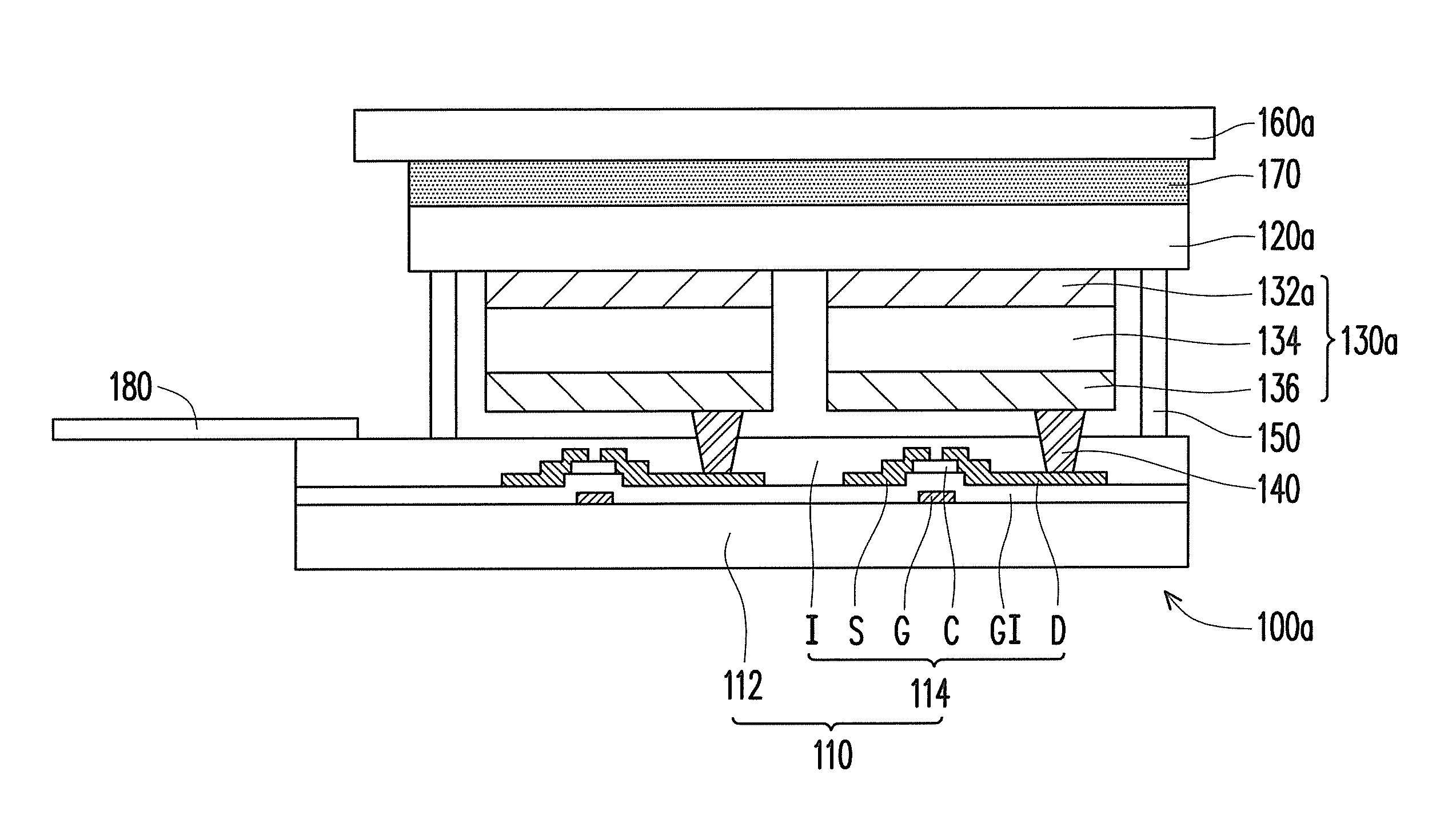

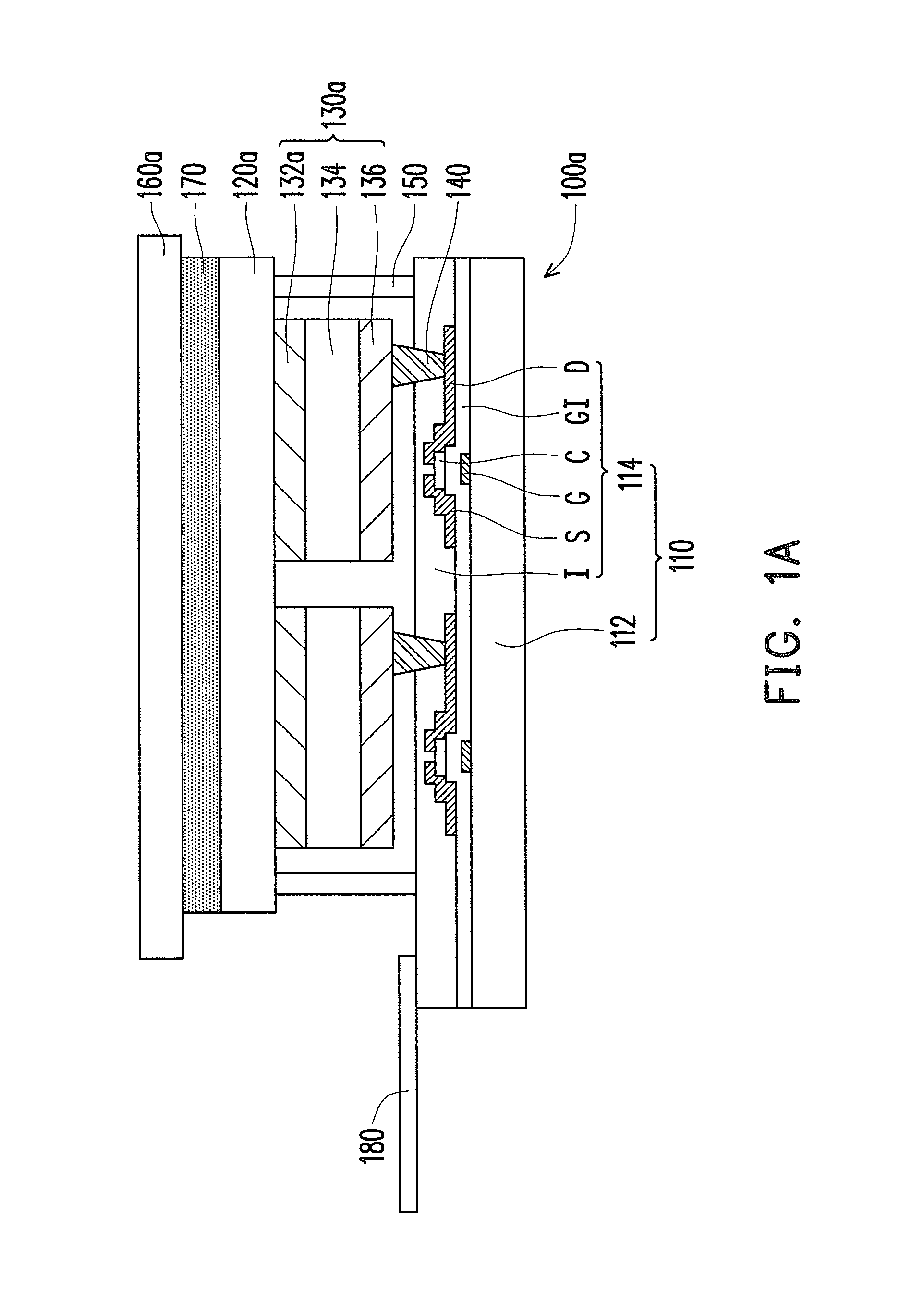

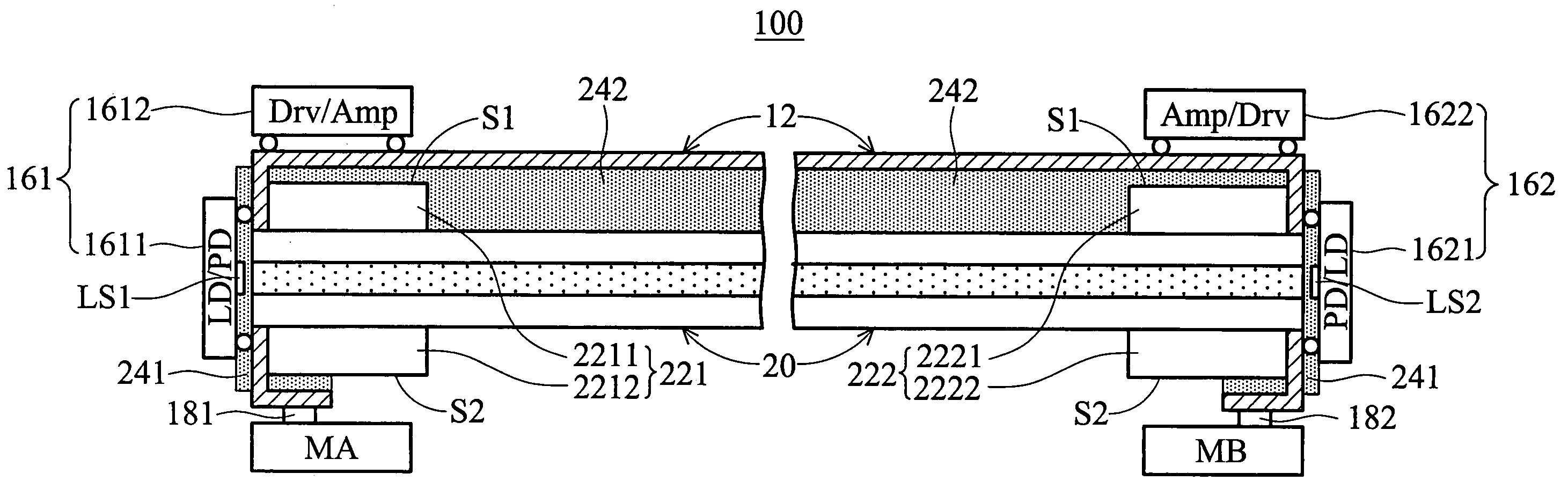

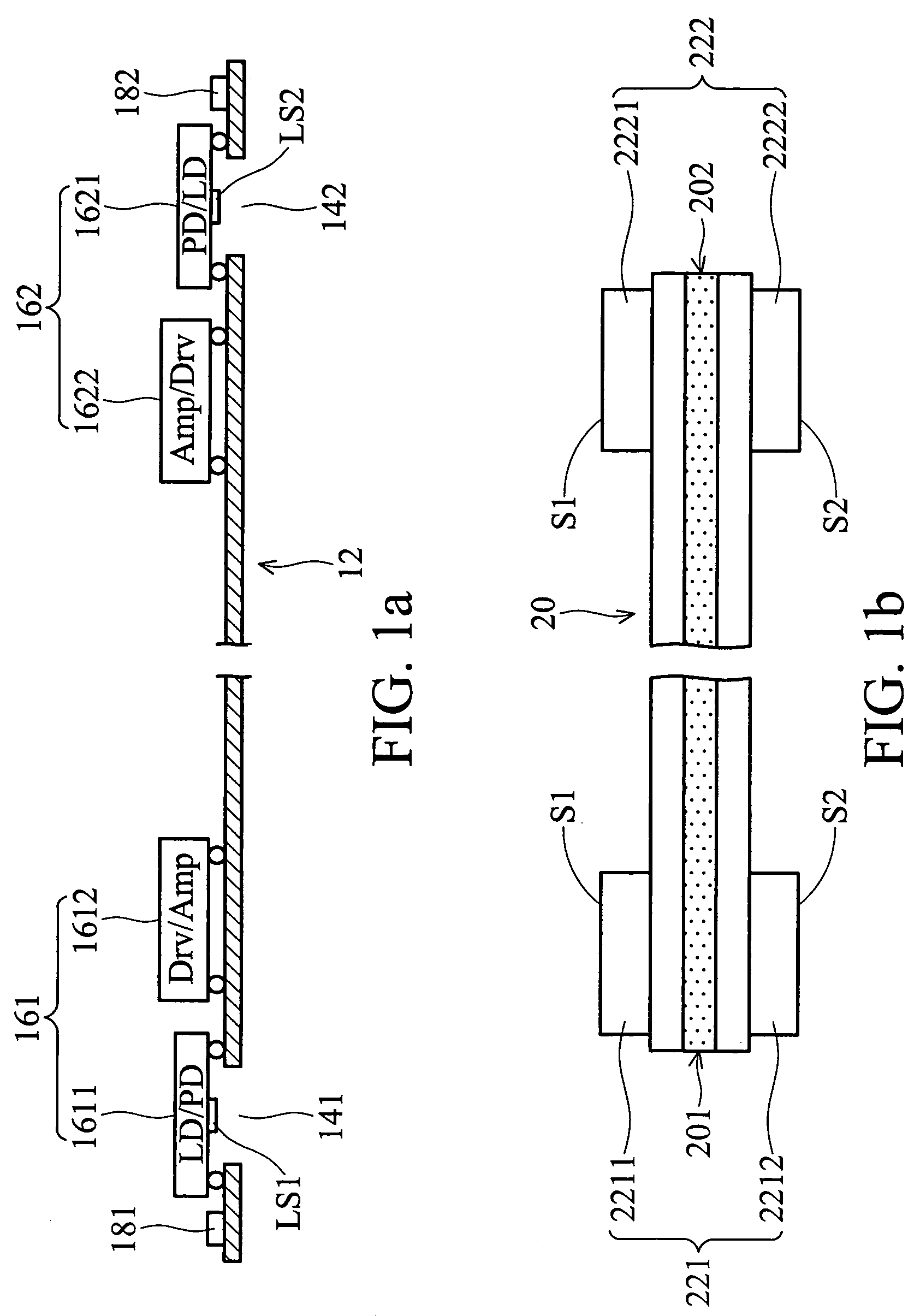

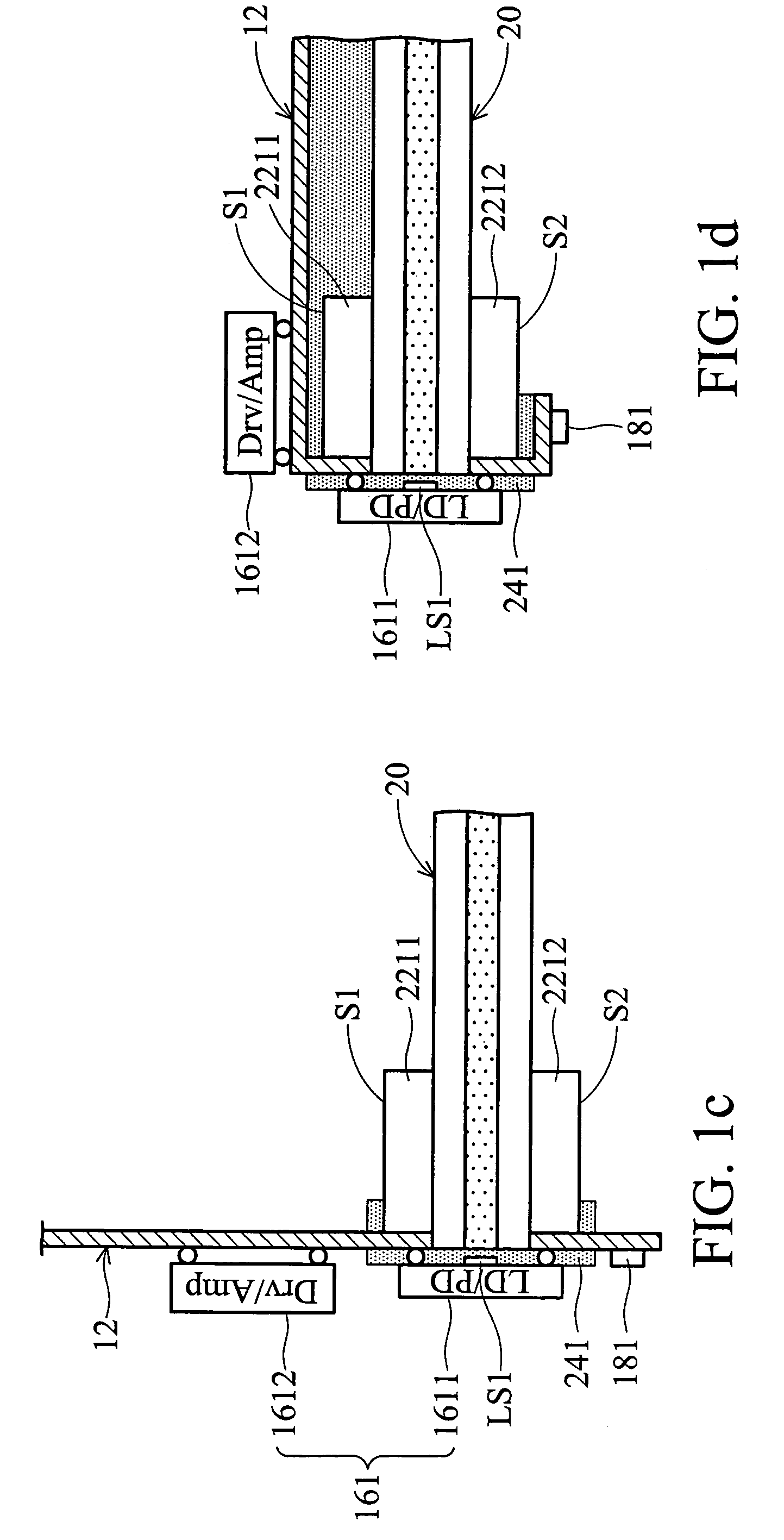

Optoelectronic transmission module and fabrication method thereof

ActiveUS7046871B2DisposalSimple opticalCoupling light guidesFibre mechanical structuresElectricityTransducer

An optoelectronic transmission module. In the optoelectronic transmission module, a light transmissive element has first and second ends and top and bottom surfaces, a circuit board transmits electrical signals and has first and second openings. The circuit board is conformably extended from the top surface of the light transmissive element to the bottom surface such that the first and second openings are aligned with the first and second ends respectively. Two light transducers, each having a light transmitter / detector optically aligned with one of the first and second ends of the light transmissive element, wherein the light transducers transmit / receive light signals through the light transmissive element and the light transmitter / detector thereof. Two electrical interconnections are disposed on the circuit board and neighbored with the two ends of the light transmissive element respectively to interconnect the electrical signals.

Owner:IND TECH RES INST

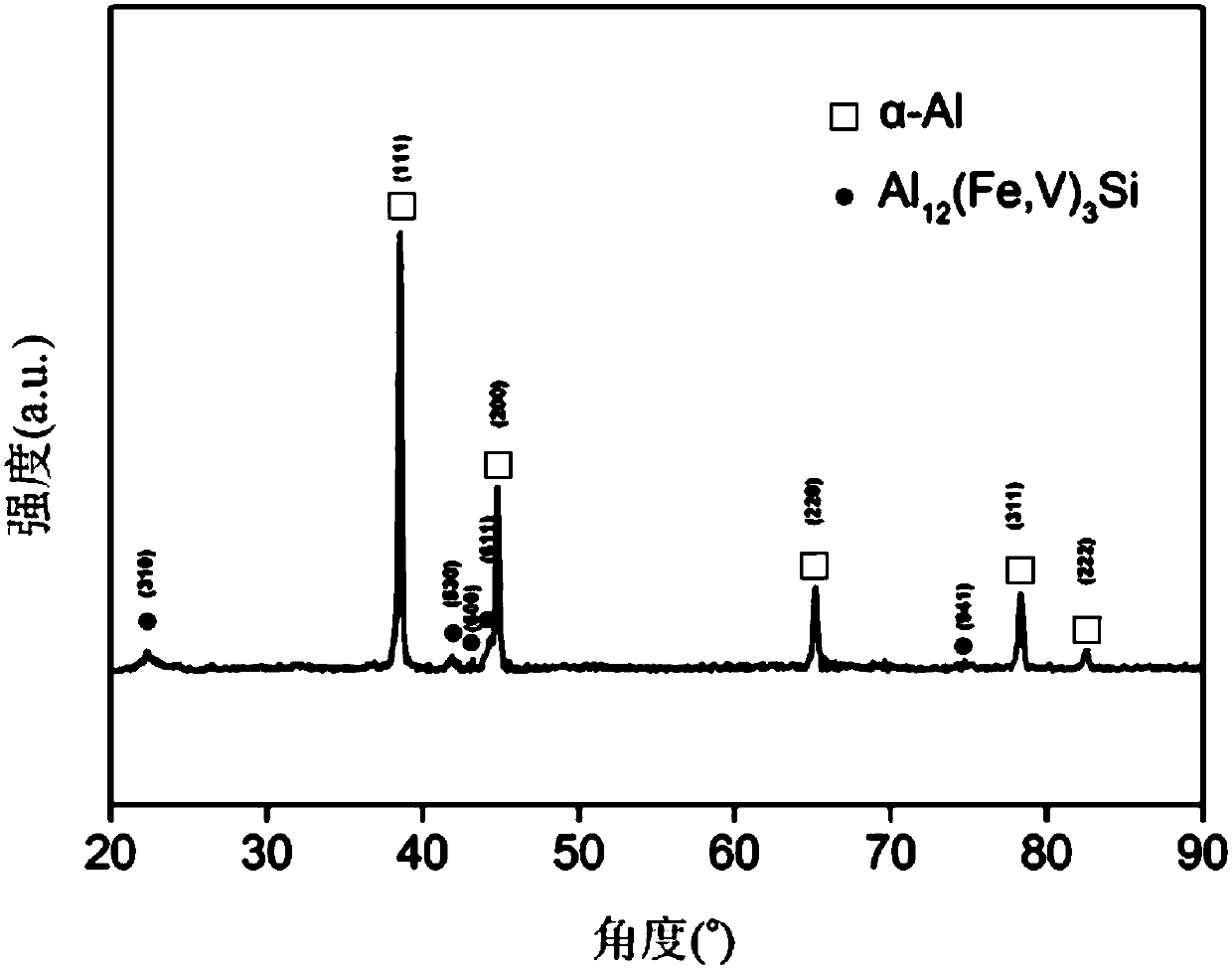

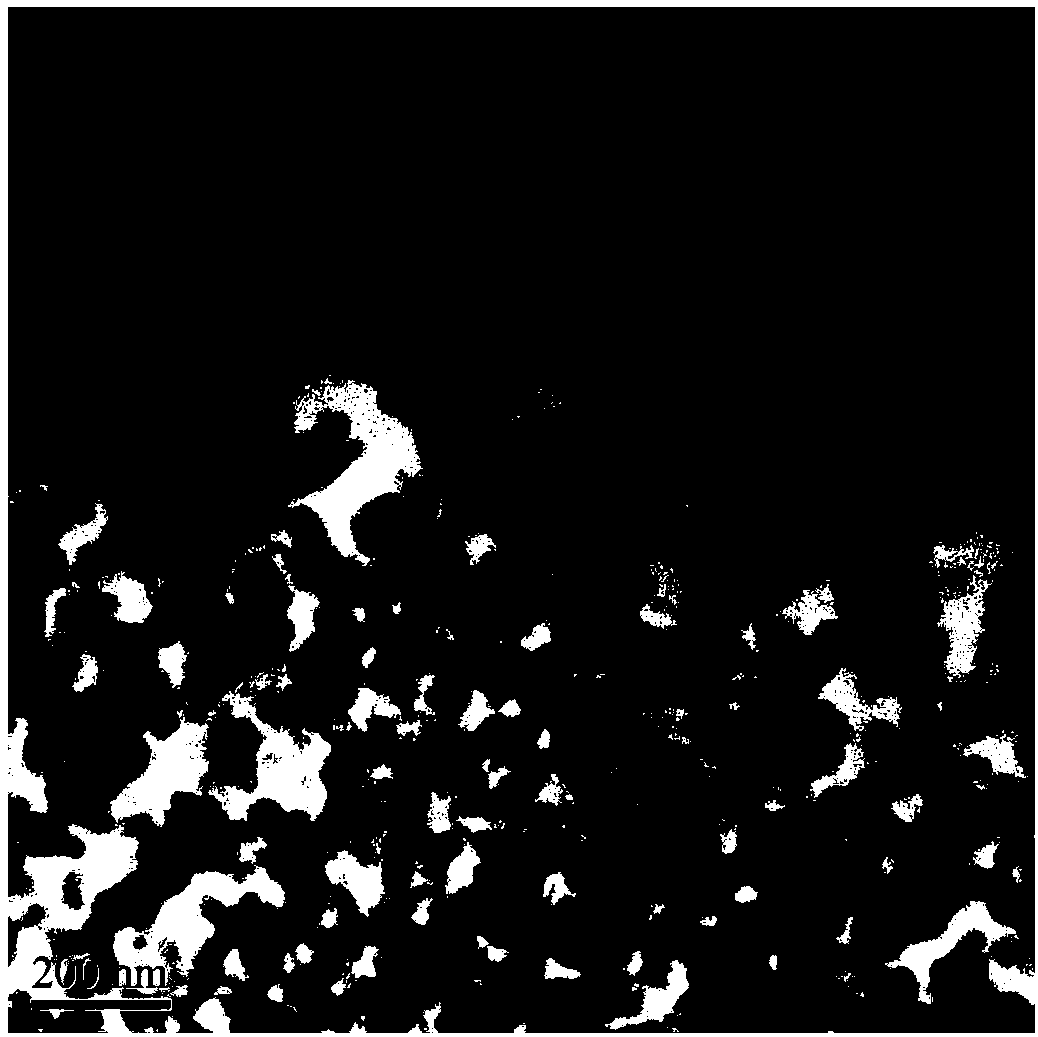

Method for preparing heat-resisting aluminum alloy

InactiveCN107649681ASave R&D cycleSave manufacturing cycleAdditive manufacturing apparatusIncreasing energy efficiencySlice thicknessControl table

The invention discloses a method for preparing a heat-resisting aluminum alloy, and belongs to the field of metal manufacturing. The method comprises the steps that according to the shape of an Al-Fe-V-Si alloy part to be processed, a three-dimensional model is established; layered slice cutting processing is conducted on the three-dimensional model, so that the preset slice thickness in the height direction is formed; a scanning path of each slice is determined according to the cross section profile information of each slice of the three-dimensional model; a layer of pre-alloy powder is laidin accordance with the slice thickness to form a powder layer; the current powder layer is scanned by using a laser beam according to the scanning path, thus a deposition layer corresponding to a slice of the three-dimensional model is made; a control table is controlled to be dropped to the distance of the thickness of a slice, and a layer of pre-alloy powder is laid on the deposition layer againof a formed substrate plate through a powder paving mechanism according to the slice thickness to form a powder layer; and repeating is conducted until processing is finished. The alloy part preparedby the method is high in surface forming precision and good in quality, the research and manufacture cycle can be effectively shortened, the production efficiency is improved, and the production costis reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

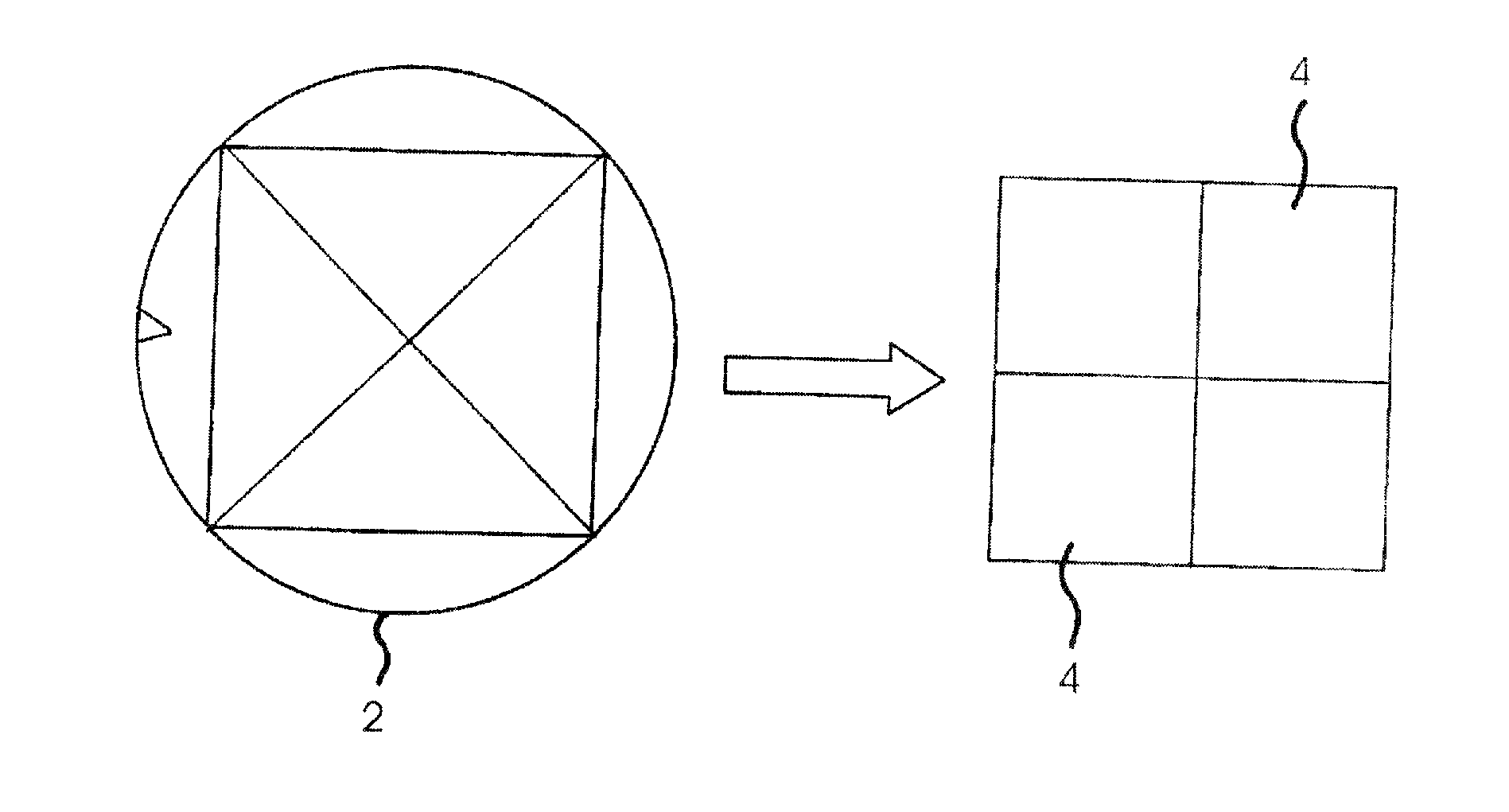

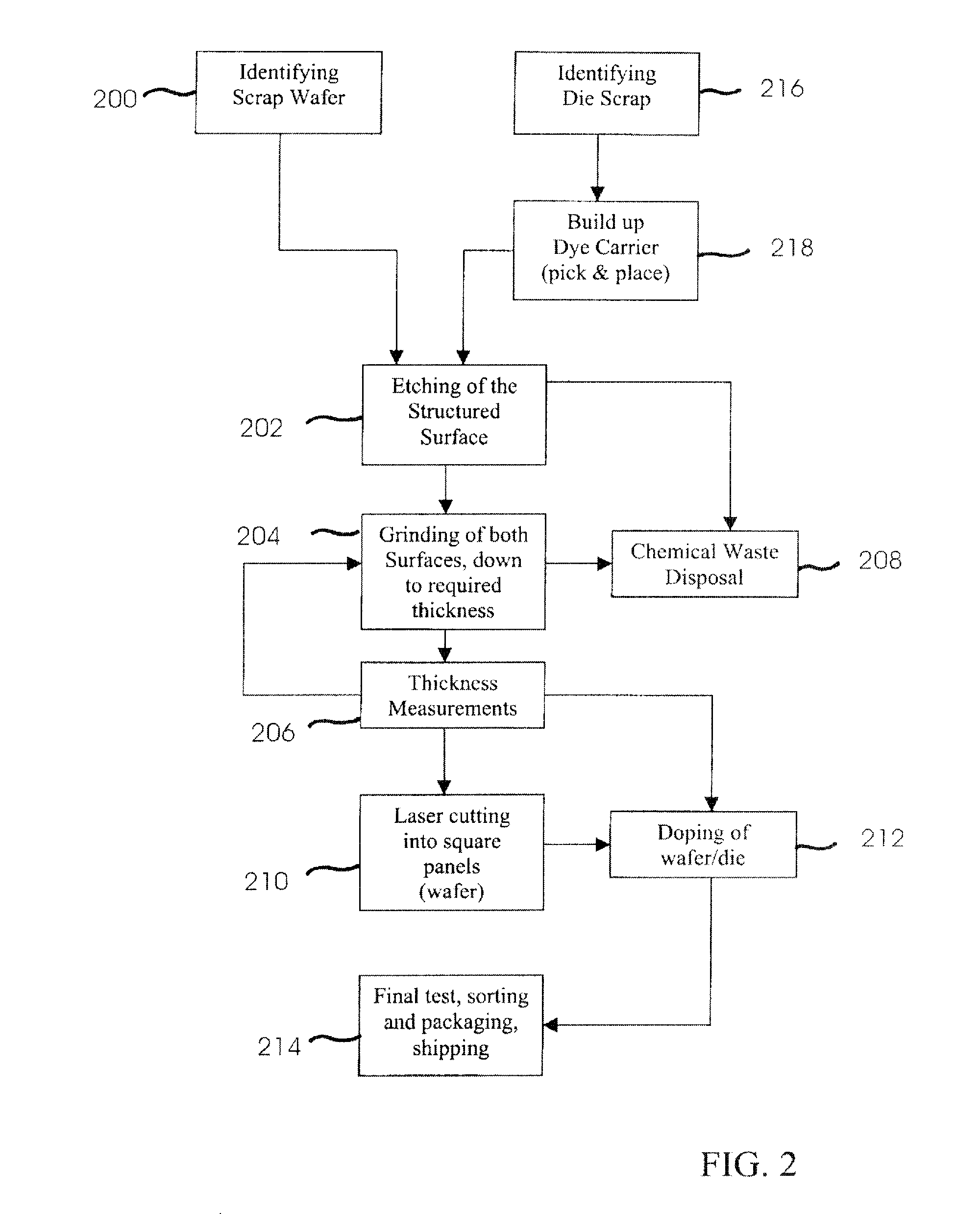

Method for the manufacture of solar panels and special transport carrier

InactiveUS20080014661A1DisposalReduce disposalSiliconSemiconductor/solid-state device manufacturingSurface cleaningEngineering

A method for the manufacture of solar panels from scrapped wafers and / or scrapped dies is provided, including the following steps: identifying scrap wafers and / or scrap dies; cleaning and removing remaining structures from the surface of the wafers / dies; grinding both surfaces of the wafers / dies down to a required thickness; doping the wafers / dies; and further processing the wafers / dies using a solar panel manufacturing method.

Owner:IBM CORP

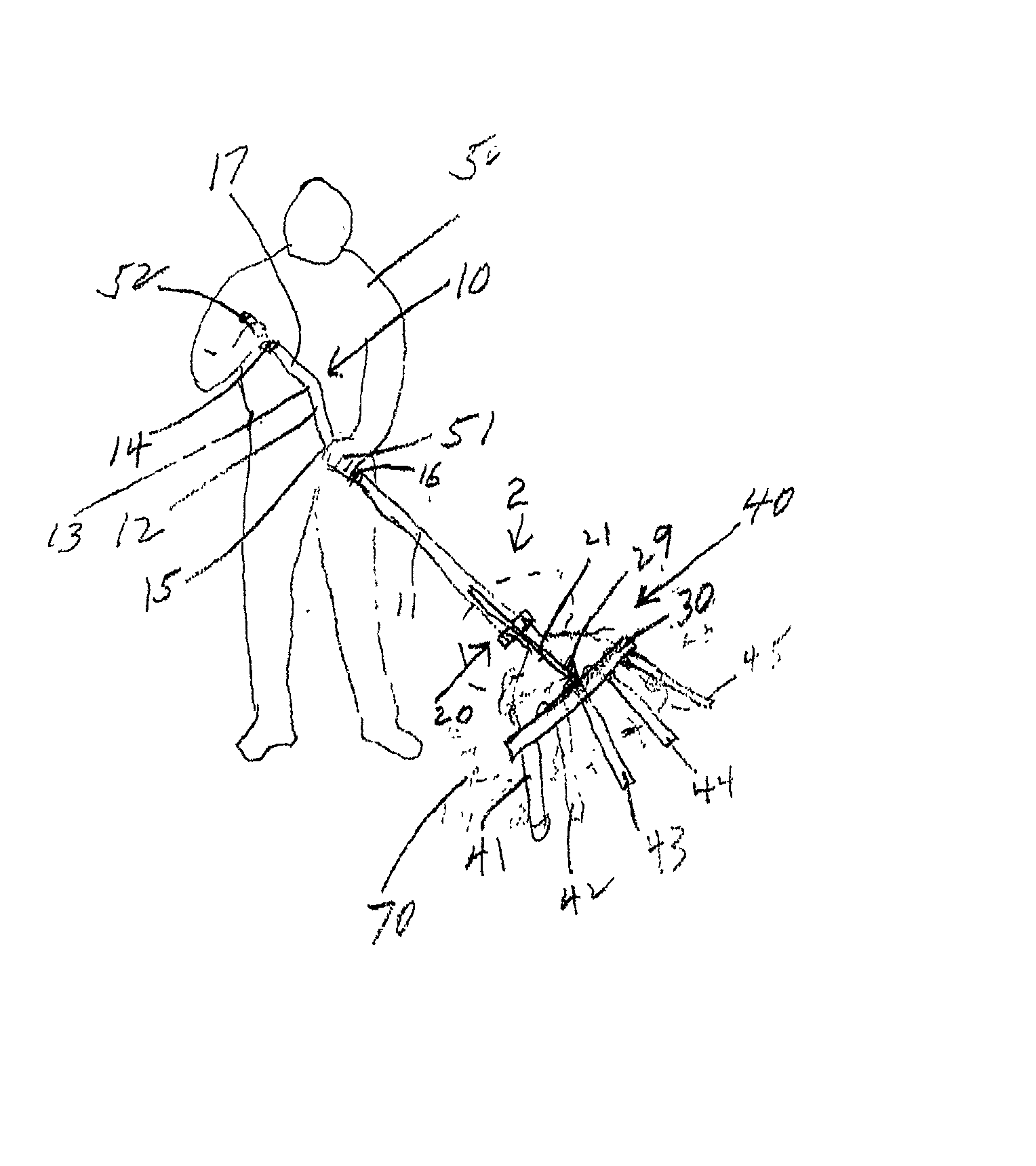

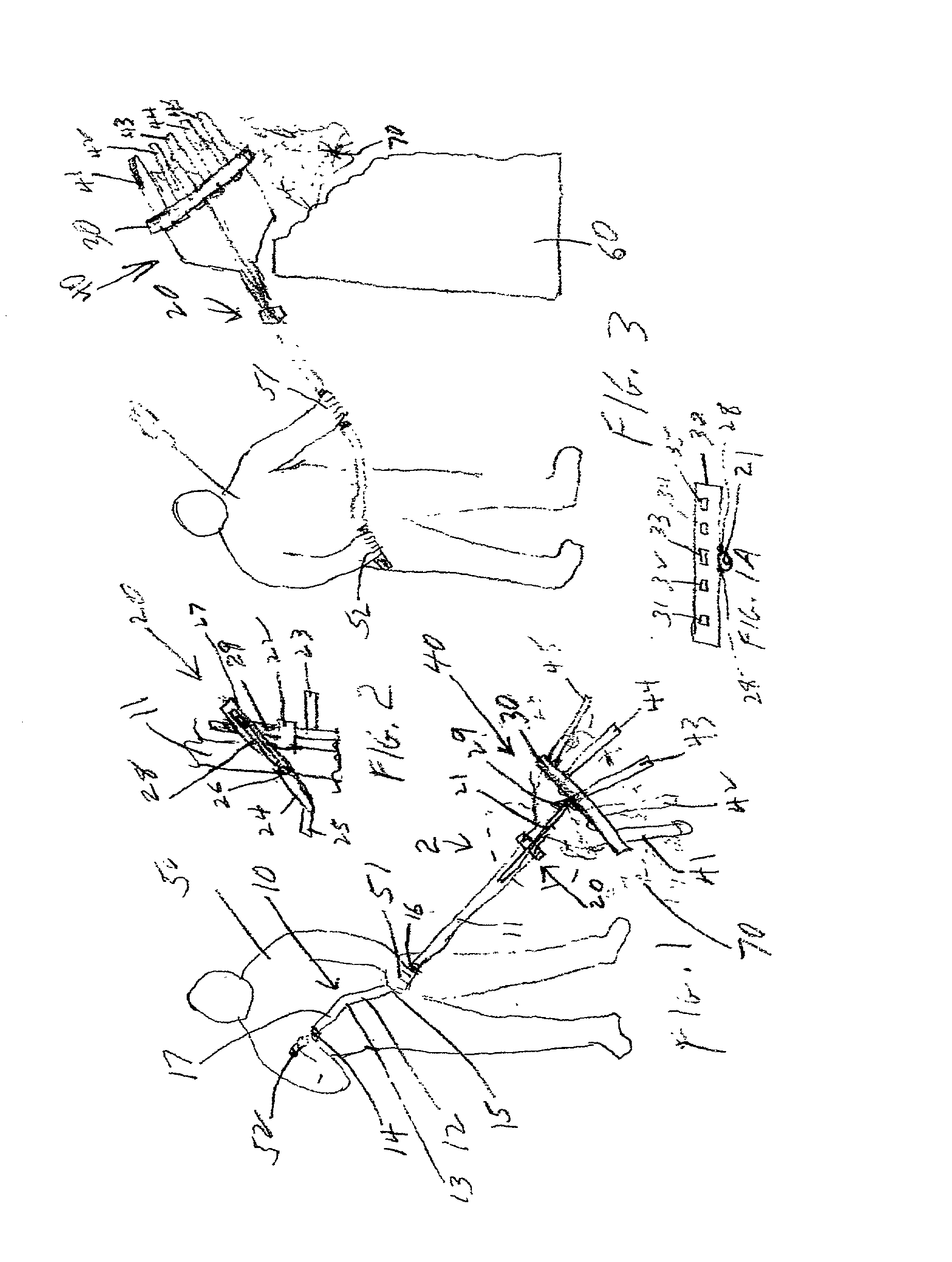

Ergonomic garden implement

This is a new rake incorporating the principles of spreading and compressing the rake tines by foot actuated lineal movement of a tine space adjustment member with the principles of an ergonomic mop handle which allows for quick conversion from a wide rake to a shovel-like member for easy conversion from raking to shoveling debris.

Owner:BIGGS BLYTH S

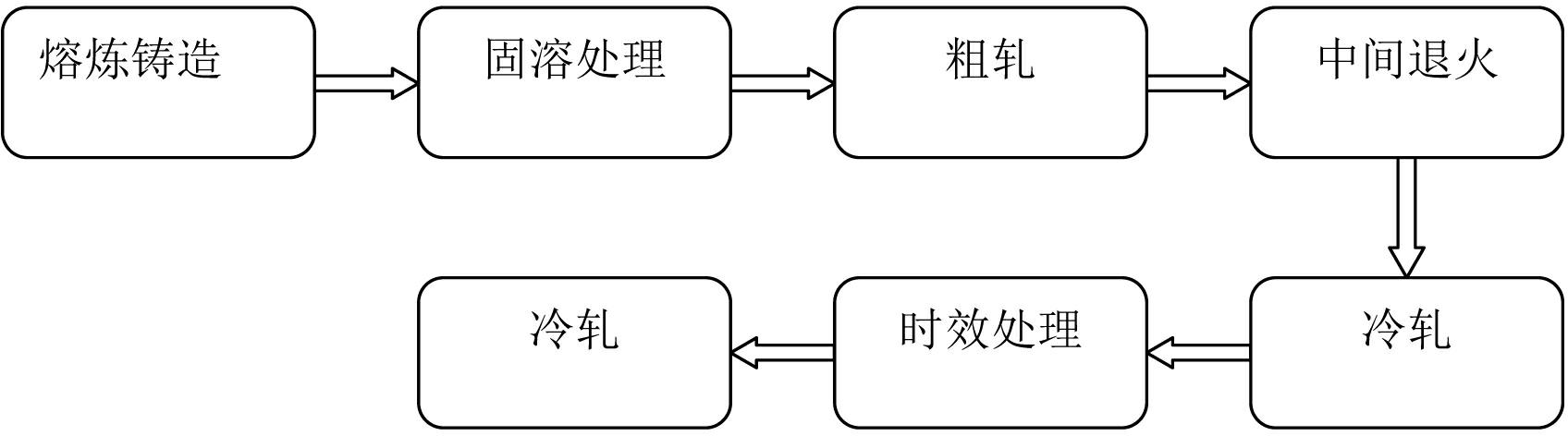

A kind of preparation method of copper-nickel-tin alloy

The invention discloses a method for preparing a copper-nickel-tin alloy. The preparation method is composed of smelting and casting, solid solution, rough rolling, annealing, cold rolling, aging treatment, cold rolling and other processes. The preparation method of the copper-nickel-tin alloy of the present invention does not require homogenization treatment between smelting and rough rolling, and can directly dissolve the Sn-rich phase in the alloy into the copper matrix after a short-term solution heat treatment at high temperature, eliminating the The brittle phase NixSny produced in the casting process makes the alloy obtain good plastic workability, which is beneficial to subsequent processing. In addition, direct rough rolling after solution treatment saves the homogenization treatment and hot rolling process in the existing preparation method, thereby saving energy, shortening the process flow, improving production efficiency and reducing production cost.

Owner:JIANGXI UNIV OF SCI & TECH

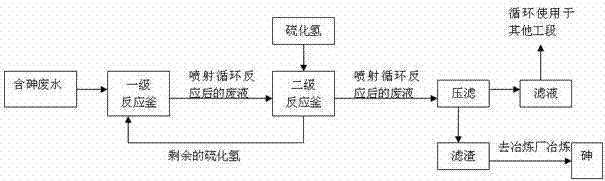

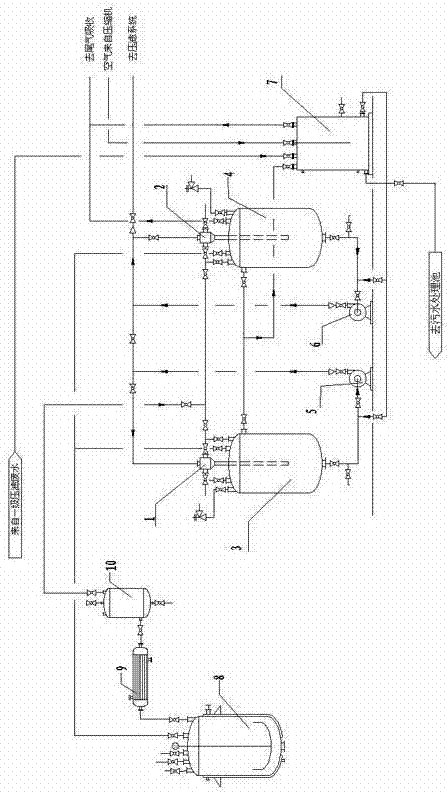

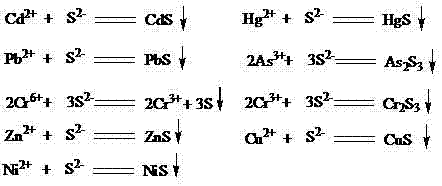

Double-circulation spraying type arsenic removal method and equipment for sulfuric acid industry

InactiveCN102897885AControl the amount added at any timeThe amount added is notWater/sewage treatment by flocculation/precipitationLiquid wasteSlag

The invention provides a double-circulation spraying type arsenic removal method and equipment for sulfuric acid plants. Vulcanizing agents are placed in a hydrogen sulfide generator, generated hydrogen sulfide enters a reaction kettle (3) through a pipeline, and a circulation pump (5) is opened so that materials in the reaction kettle (3) carry out internal circulation; and meanwhile, the rest hydrogen sulfide of the reaction kettle (3) enters a reaction kettle (4), and a circulation pump (6) is opened so that the materials in the reaction kettle (4) carry out internal circulation. After the reaction is carried out for 60 to 90 minutes, liquid after reaction in the reaction kettle (3) is placed in a storage tank through a pipeline, the still standing is carried out for 30 to 60 minutes, the liquid is subjected to filter pressing, the obtained filter slag can be conveyed to a smelting plant for heavy metal recovery, the filter liquid is directly discharged, and waste liquid of the reaction kettle (4) is left to be used as the subsequent reaction liquid of the reaction kettle (3). The method and the equipment have the advantages that the arsenic removal rate can reach higher than 99 percent, the arsenic content of the filter slag is high, and the deep processing is favorably realized.

Owner:GUANGXI NANNING DHXY ENTECH

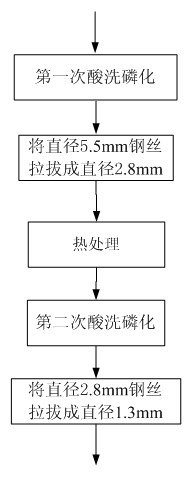

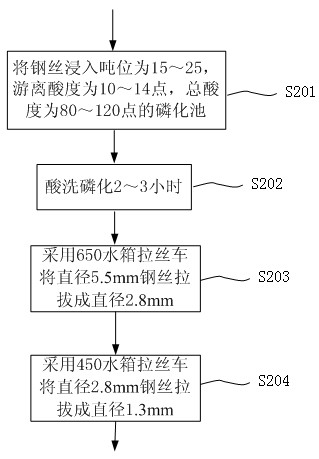

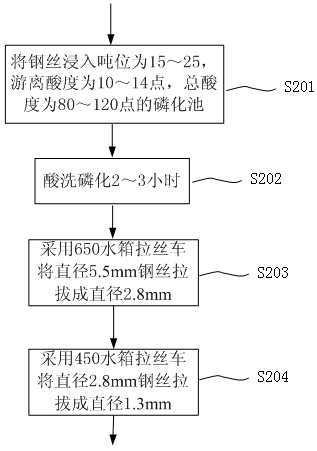

Method for drawing steel wire

The invention discloses a method for drawing a steel wire. The method comprises the following steps in turn: a) immersing the steel wire into a phosphating tank which has tonnage of between 15 and 25, free acidity of between 10 and 14 and total acidity of between 80 and 120; b) performing acid-washing and phosphating for 2 to 3 hours; c) primarily drawing the steel wire with diameter of 5.5mm to be 2.8mm by using a water tank drawing vehicle with roller diameter of 650mm; and finally d) secondarily drawing the steel wire to be 1.3mm by using the water tank drawing vehicle with roller diameter of 450mm. In the method for drawing the steel wire of the invention, by adjusting the size of the phosphating tank and the concentration of phosphoric acid, the steel wire with diameter of 5.5mm is drawn to be the steel wire with diameter of 1.3mm by using the water tank drawing vehicles with different sizes, so that the thermal treatment and second acid washing are saved, the process is simplified, and the cost is reduced.

Owner:JIANGSU TAILI STEEL ROPES

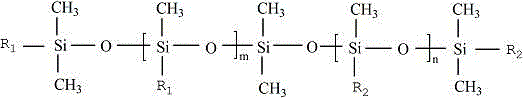

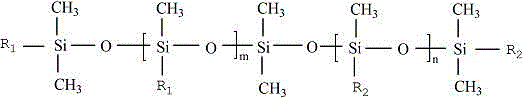

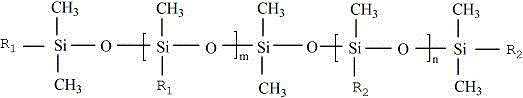

Organic silicon rubber composite tackifier and preparation method thereof

The invention discloses an addition-type organic silicon rubber composite tackifier and a preparation method thereof. The addition-type organic silicon rubber composite tackifier is prepared in a way of grafting two types of polar groups (epoxy and acryloyl) to a Si-O chain of common organic silicon rubber. After being mixed, the addition-type organic silicon rubber composite tackifier and addition-type organic silicon rubber can be cured at 100-120 DEG C together with a base material so as to ensure that the adhesive strength of addition-type organic silicon rubber to an aluminum product can reach 2.6-2.8MPa, the adhesive strength of addition-type organic silicon rubber to copper can reach 1.6-1.8 MPa, the adhesive strength of addition-type organic silicon rubber to PC plastic can reach 1.6-1.8 MPa, and the adhesive strength of addition-type organic silicon rubber to a nylon base material can reach 1.8-2.0 MPa. The adhesive strength of the addition-type organic silicon rubber composite tackifier containing two types of polar groups (epoxy and acryloyl) is obviously higher than that of a tackifier containing a single polar group.

Owner:SHENZHEN FLOURISH ORGANOSILICONE MATERIAL CO LTD

Catch basin filter absorber method for water decontamination

ActiveUS20090095682A1Easy to installLow costSewerage structuresSolid sorbent liquid separationActivated carbonAbsorbent material

A storm water treatment device that is installed under the grate of new or existing catch basins, and more commonly referred to as an insert. The catch basin decontamination apparatus has a universal housing and support ring that allows one design to fit most applications. Adjustable chains allow for proper position below grate and a semi-flexible molded or rigid deflector directs incoming drain water to the housing. A slip-on filter / absorber cartridge fits over a perforated drain tube, in the center of the housing, allowing the drain water to first pass through the filter / absorber media before exiting through the drain tube and out the bottom of the housing. The filter / absorber cartridge includes a variety of absorber materials that absorb oil and repel water. Activated carbon, microbes and other site specific absorbents can be used in the replaceable slip-on cartridge. A leaf pre-strainer helps prevent leaves and debris from entering the housing. A clean in place suction tube and clod buster form of the apparatus aids in cleaning the housing.

Owner:INVENTIVE RESOURCES

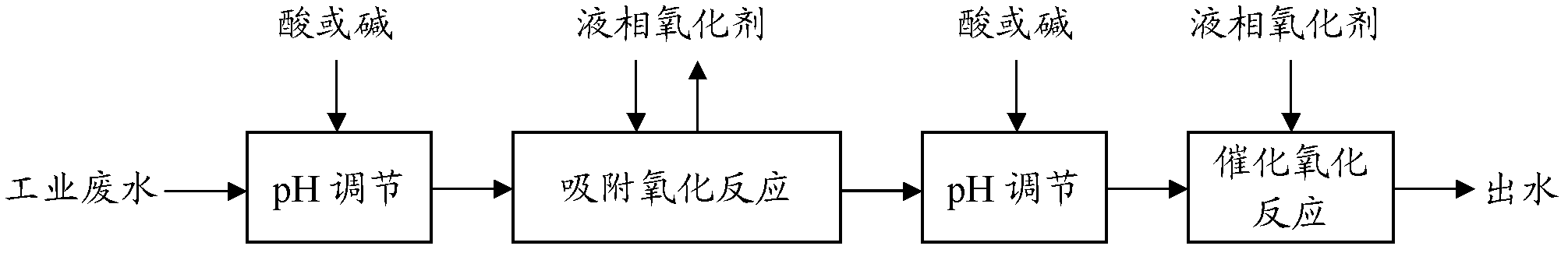

Industrial wastewater decoloring treatment process

ActiveCN102276084AExtend your lifeLower activation energyMultistage water/sewage treatmentIndustrial effluentCatalytic oxidation

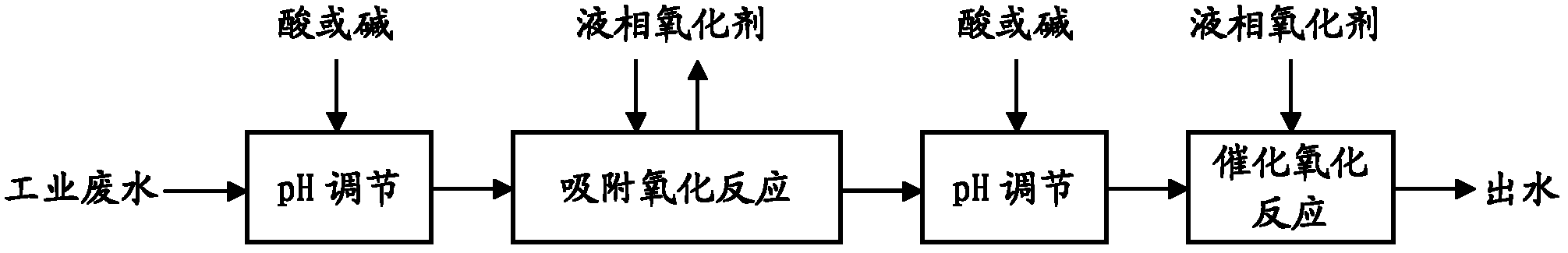

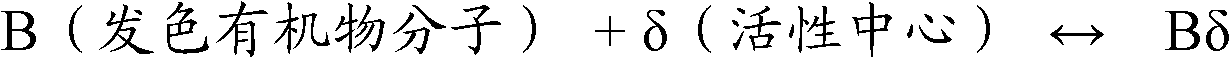

The invention discloses an industrial wastewater decoloring treatment process. The process comprises the following steps: the pH value of wastewater is adjusted, an adsorption and oxidation reactor filled with adsorption resin is introduced, a lot of chormophoric organics are adsorbed in the resin, when the chroma removal rate is less than 60%, drainage is performed, a liquid-phase oxidant is added in the adsorption resin to perform oxidative decoloration, the resin is activated and regenerated; and after the pH value of the discharged water of the adsorption and oxidation reactor is adjusted, the discharged water enters a catalytic oxidation reactor, the adsorption resin loaded with a transition metal catalyst is filled in the reactor, and the liquid-phase oxidant is added to perform heterogeneous catalytic oxidation decoloration and remove the small molecules and nonpolar chormophoric organics which are difficult to be adsorbed by the adsorption and oxidation unit. By adopting the method, the polar and nonpolar chormophoric organics with wide molecular weight range can be removed and the effects of efficient decoloring and wide applications can be achieved.

Owner:杭州浙大易泰环境科技有限公司

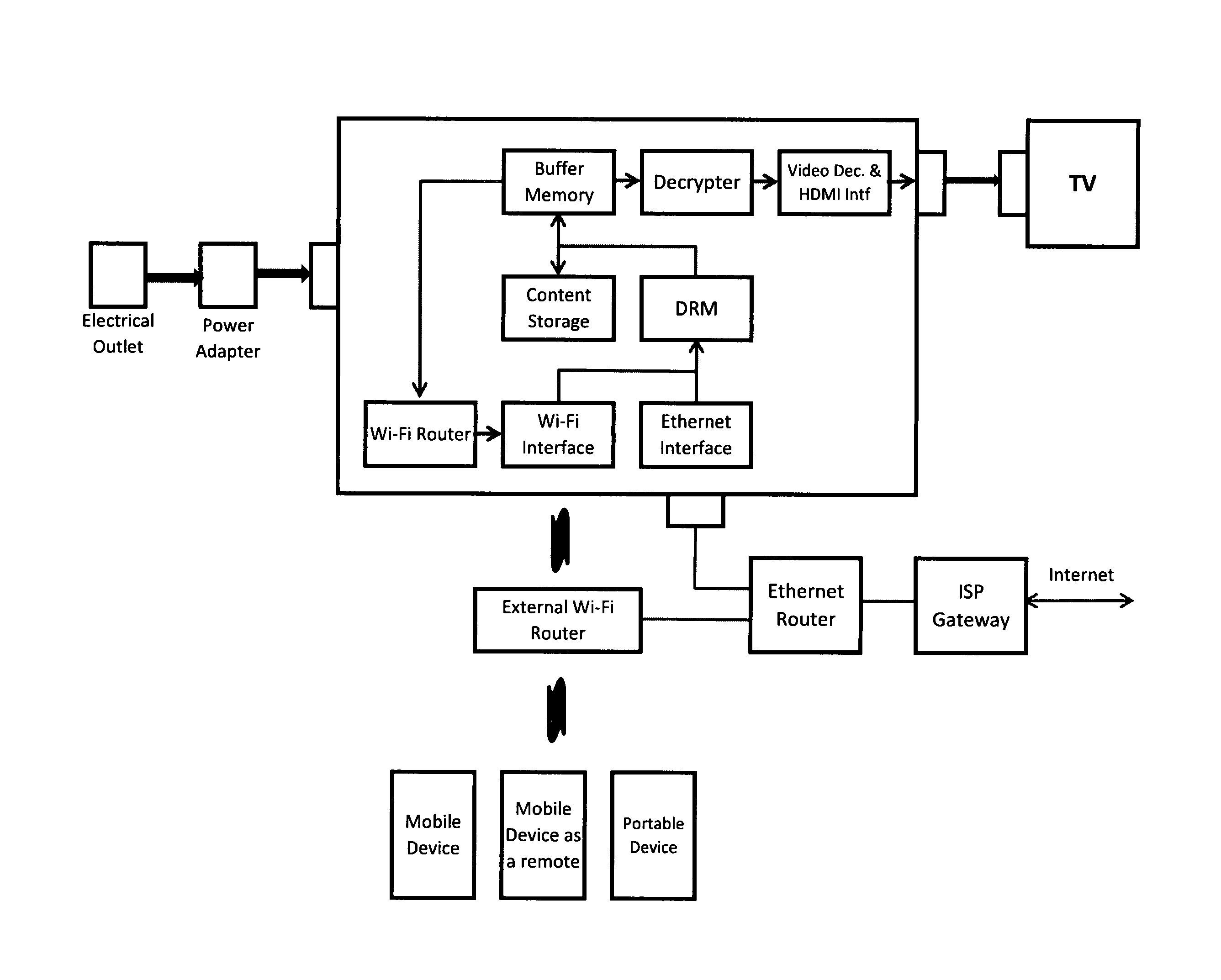

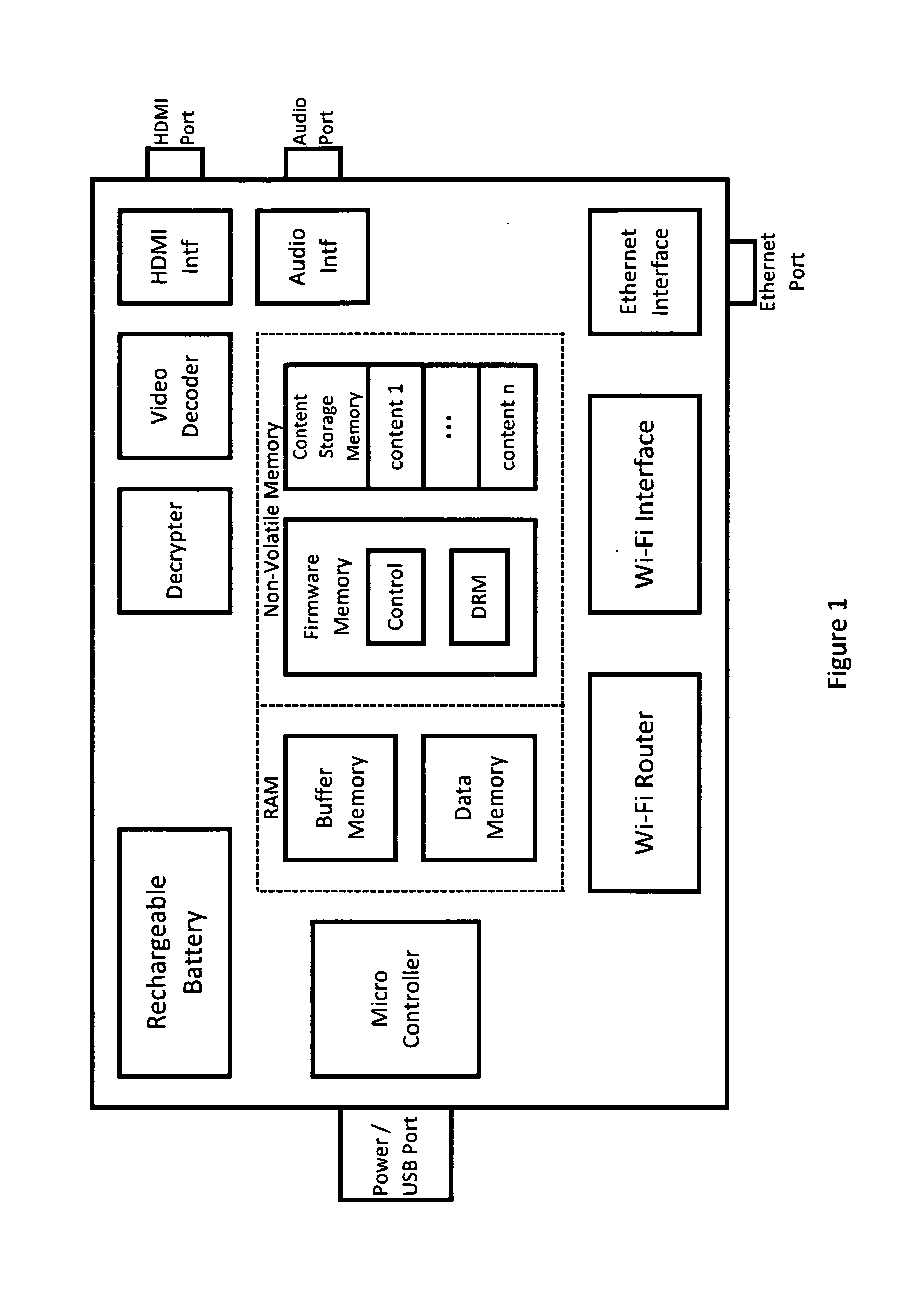

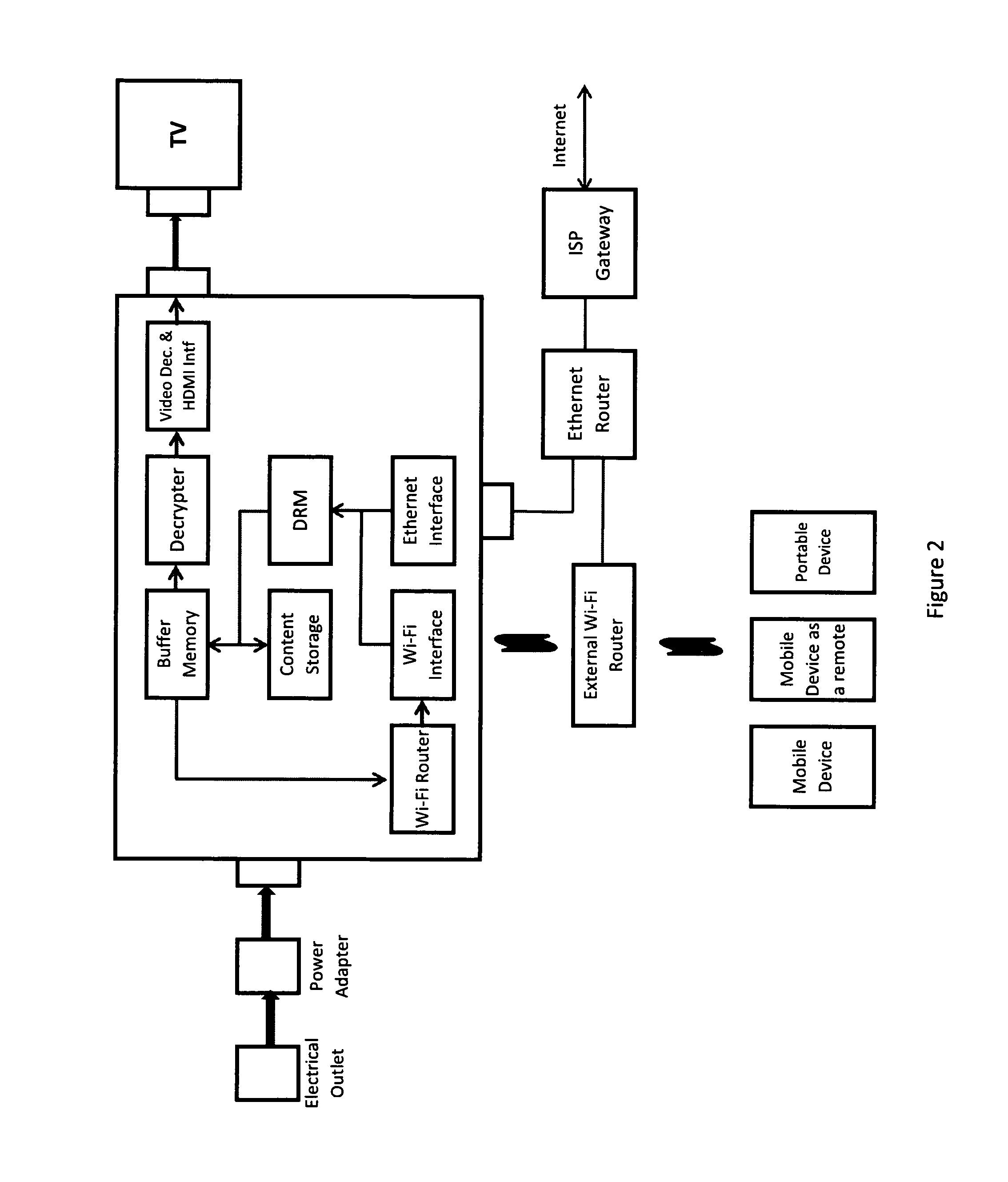

Portable, multi-channel, multi-user, online streaming and recording and offline streaming and playback device

InactiveUS20150156538A1DisposalEliminate needClosed circuit television systemsSelective content distributionService provisionThe Internet

The current invention pertains to a device comprising a connection to the internet, a storage memory for storing one or more audiovisual contents downloaded from one or more service providers, wherein the one or more audiovisual contents are stored in a manner accessible only by the architecture of the device and wherein the device transmits the stored one or more audiovisual contents only to the one or more authorized audiovisual devices, and one or more connections for transmitting the one or more audiovisual contents to the one or more authorized audiovisual devices. The device of the current invention is capable of streaming and / or downloading one or more audiovisual contents and simultaneously transmitting the one or more audiovisual contents to the one or more authorized audiovisual devices as data packets over a local area network (LAN) or as uncompressed audiovisual signal over a multimedia interface.

Owner:GODBOLE VISHWAS

Method for detecting gene chips of SS2 (streptococcus suis serotype 2) and application method thereof

InactiveCN103014144ADisposalEliminate the prehybridization stepMicrobiological testing/measurementFluorescence/phosphorescenceGenomic DNAStreptococcus suis serotype 2

The invention relates to a method for detecting gene chips of SS2 (streptococcus suis serotype 2) and an application method thereof, which can effectively solve the problems that the existing detection equipment and method are long in time consumption and large in investment. The technical scheme of the invention is as follows: a method for detecting gene chips of SS2 is implemented through designing and synthesizing a primer and a probe, dissolving the synthesized probe by using sterilized water, and carrying out contact sample application on an aldehydized substrate by using a gene chip sample application instrument according to a preset program. The application method comprises the following steps of: extracting the genomic DNA (deoxyribonucleic acid) of SS2 to be detected; preparing a PCR (polymerase chain reaction) product for hybridization by using an asymmetric PCR, and hybridizing the prepared PCR product with a prepared gene chip; and after the obtained product is washed and dried, placing the chip on a laser confocal scanner to scan the chip, and synthesizing results. The methods disclosed by the invention are simple and easy to operate; steps of carrying out hydration treatment and pre-hybridization on chips subjected to sample application are omitted, and the hybridization is implemented just through half an hour, thereby greatly saving the time; and the signal strength can be achieved by using a probe concentration of 5mu m / L, therefore, the detection cost is low, and the methods can be used for large-scale detection.

Owner:ZHENGZHOU COLLEGE OF ANIMAL HUSBANDRY ENG

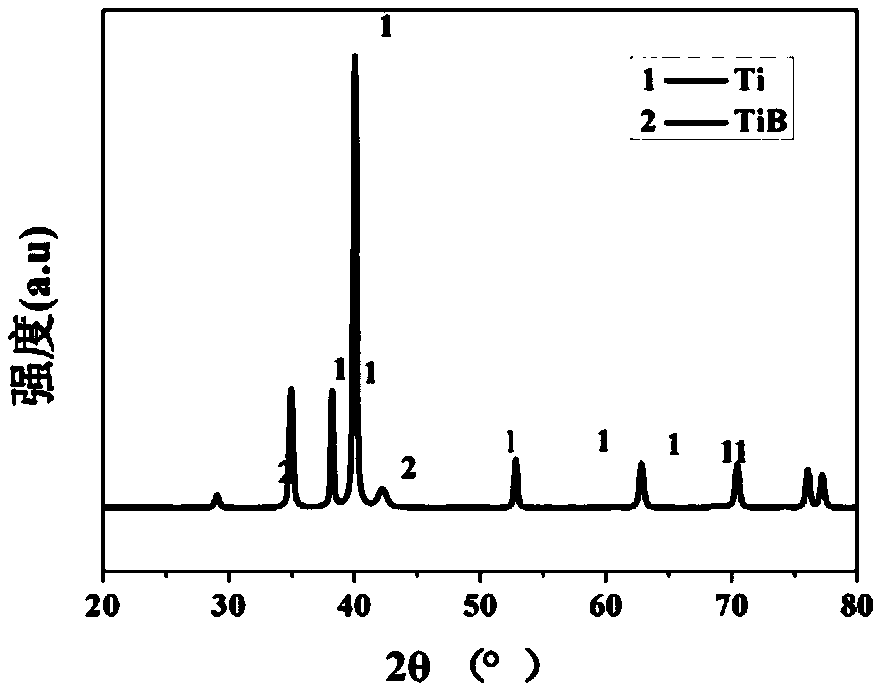

3D printing high-compactness titanium-titanium boride composite material and preparation method thereof

InactiveCN108620586AAbundant resourcesLow priceAdditive manufacturing apparatusIncreasing energy efficiencySand blastingLaser scanning

The invention relates to a 3D printing high-compactness titanium-titanium boride composite material and a preparation method thereof. 45-84 wt% of titanium powder and 16-55 wt% of titanium diboride powder are mixed to obtain raw material powder; and titanium and titanium diboride powder is obtained through burdening and mixing according to a mass ratio of the raw material powder to agate balls of1: (1-5). The titanium and titanium diboride powder is manually paved on a substrate of 3D printing equipment according to each-layer powder paving thickness; the manual powder pavement and the manualcontrol of laser scanning of 3-5 layers are firstly performed; and then, the each-layer automatic powder pavement and the each-layer automatic laser scanning are performed until targets are printed to obtain the titanium-titanium boride composite material. The 3D printing high-compactness titanium-titanium boride composite material is obtained through polishing by a sand blasting machine, surfaceimpurity removal, drying and heat treatment. The process is simple, and needs no mold, no high-temperature and high-pressure preparation condition and no subsequent material reducing treatment; and the prepared product is high in purity, compactness and size precision and excellent in mechanical performance.

Owner:WUHAN UNIV OF SCI & TECH

Method for processing half-dried sea bass conditioning food

The invention discloses a method for processing half-dried sea bass conditioning food. The method comprises the following steps: (1) pretreating; (2) slightly pickling; (3) preparing a seasoning liquid; (4) conditioning the taste; and (5) drying and packaging. The half-dried sea bass conditioning food processed by using the method is good in taste, compact in meat structure, free of fishy smell, rich in tea fragrance flavor and can be preserved for more than half a year at a low temperature.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation process of neopentyl polyol oleate

InactiveCN104945247ATake advantage ofReduce high energy consumptionOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePolyol

The invention relates to a preparation process of neopentyl polyol oleate. The preparation process comprises the following steps: by aiming at different batches of purchased neopentyl polyol and oleic acid, firstly determining a theoretical molar ratio required by a complete esterification reaction between neopentyl polyol and oleic acid according to the number of hydroxide radicals in molecules of utilized neopentyl polyol or mixed neopentyl polyol, or carrying out multiple small experiments according to a previous experience molar ratio of neopentyl polyol or mixed neopentyl polyol to oleic acid, ending the experiment when the acid value of a small experiment sample is less than or equal to 1.5mgKOH / g and synthetic liquid and water is well separated, and producing by taking the raw material batch and raw material ratio of the last small experiment as the raw material ratio for large-scale production. The preparation process has the advantages that the raw materials can be adequately utilized, and troubles in after-treatment of products are reduced.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

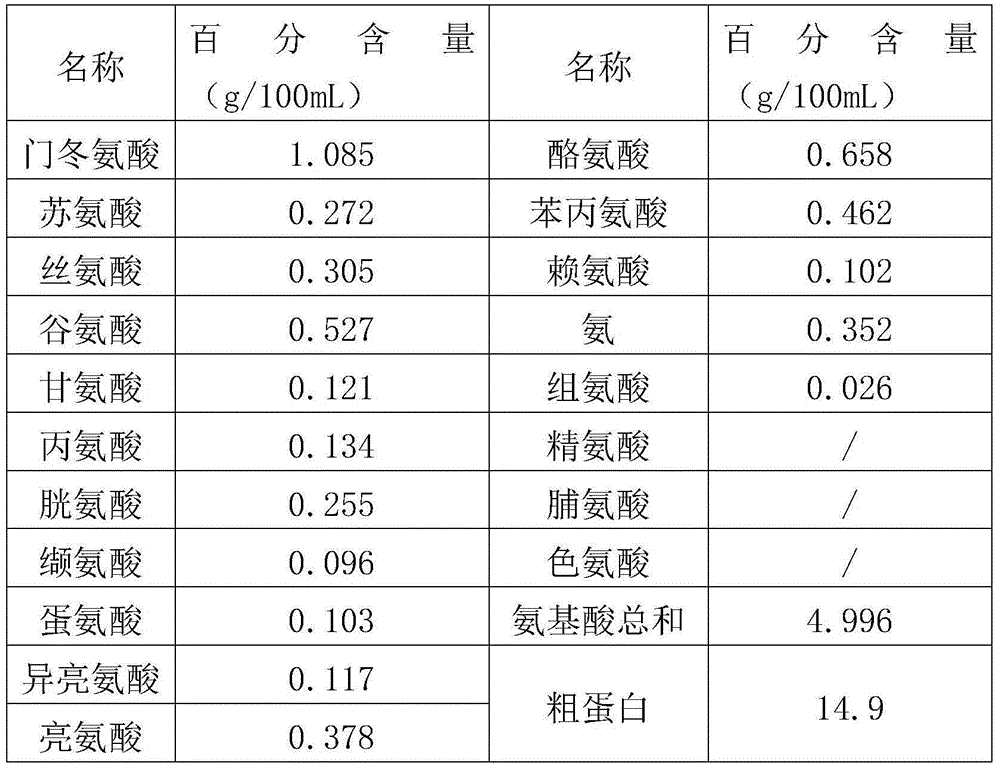

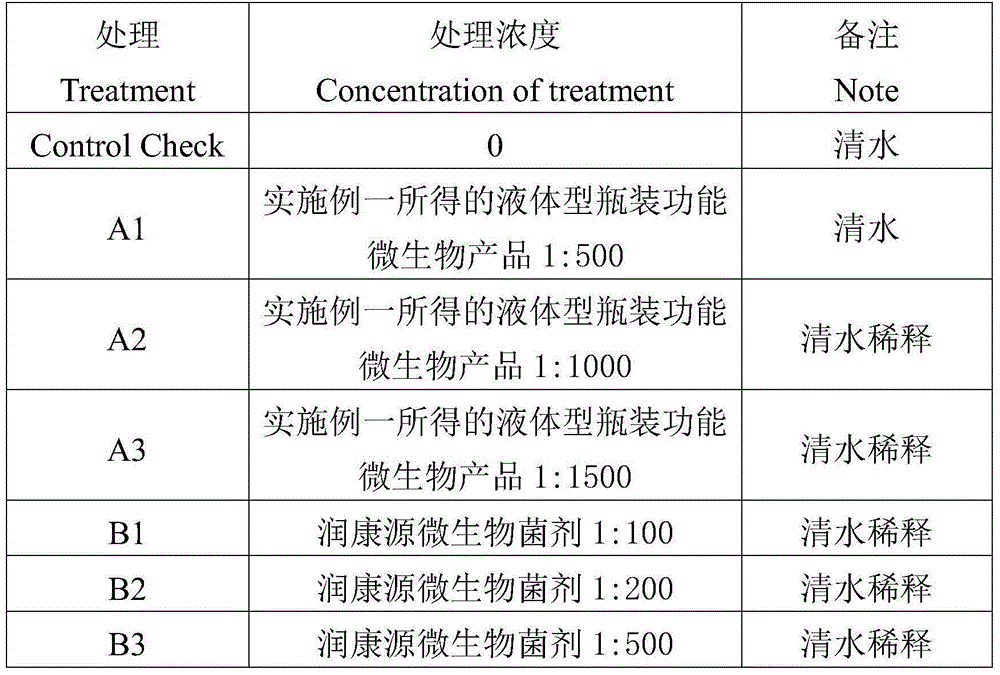

Method for producing functional microbes with glutathione waste liquid

The invention discloses a method for producing functional microbes with glutathione waste liquid and belongs to the field of microbes. The method includes: a, respectively subjecting bacillus licheniformis seed solution, candida utilis seed solution, lactobacillus acidophilus seed solution, lactobacillus acidophilus seed solution and bacillus subtilis seed solution to seeding tank culture by taking the glutathione waste liquid as an effective ingredient of a seed culture medium; b, performing fermentation in a fermentation tank by taking the glutathione waste liquid as an effective ingredient of a fermentation tank culture medium to obtain functional fermentation broth. Compared with the prior art, the method has the advantages that the functional microbes are produced with the glutathione waste liquid, and the method is low in cost, diversified in product, high in economic value, high in waste recycling rate and the like and has extensive application value.

Owner:山东君德生物科技有限公司

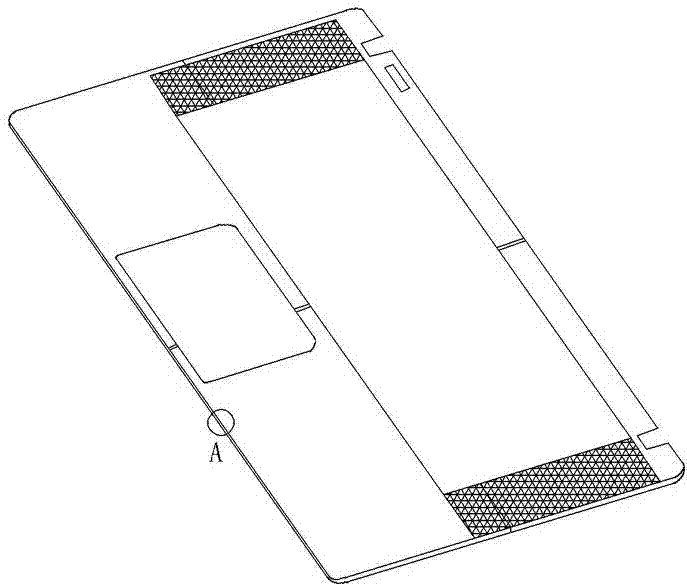

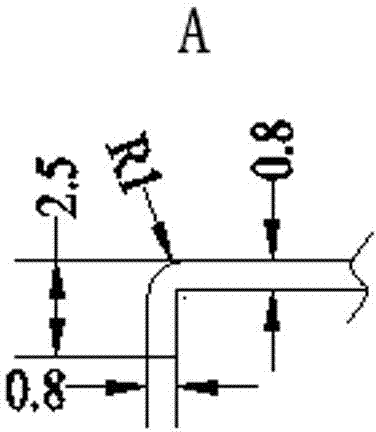

Right angle extrusion processing method and right angle extrusion processing mould

The invention discloses a right angle extrusion processing method and a right angle extrusion processing mould. The method comprises the following steps: a) stamping a metal sheet through the mould, and processing a semi-finished product workpiece of which the edge is provided with downwards annular bending edge and the outer corners are round corners; b) performing more than two times of extrusion processing on the semi-finished product workpiece through the mould to make the outer corners extrude into right angles. When the mould is closed, the upper part of an extrusion male mould is positioned in an upper concave part of an upper template; a stamping gap is formed between the upper surface of the extrusion male mould and the upper template; a bending gap is formed between the side face of the upper part of the extrusion male module and the upper template; the middle of an outer stripping plate is also provided an extrusion punch for upwards squeezing the workpiece bending edge; and the extrusion punch corresponds to the bending gap and is arranged on the side face of the extrusion male mould. According to the method and the mould, electronic product parts of which the outer corners between metal sheet bodies and the bending edges are right angles can be processed; the workpiece is not damaged by pressing or scratching during processing, and the sequential processing procedures of grinding and polishing are saved.

Owner:ZHUCHANG PRECISION STAMPINGSHANGHAICO

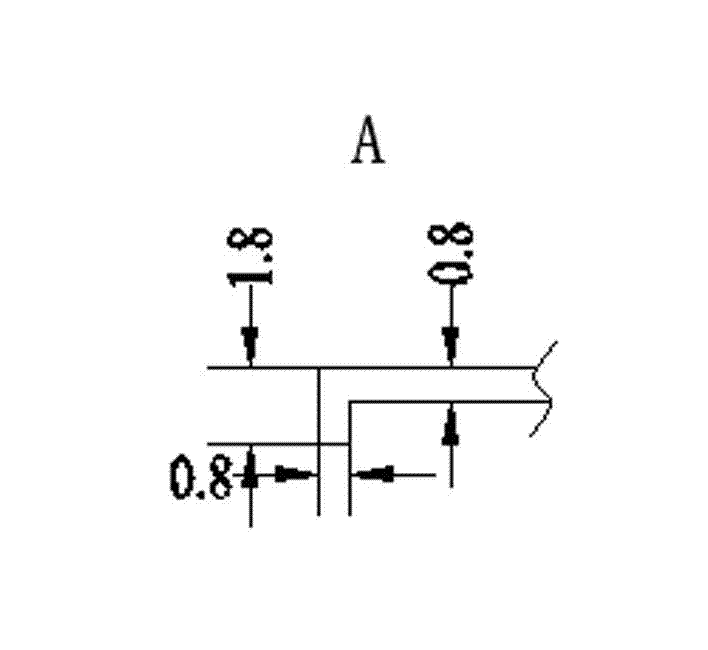

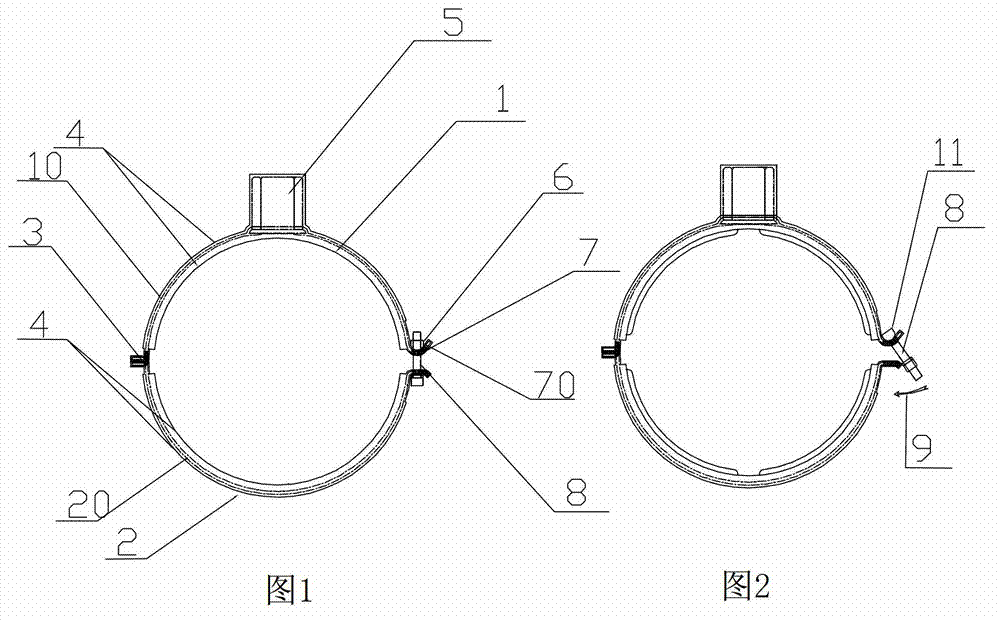

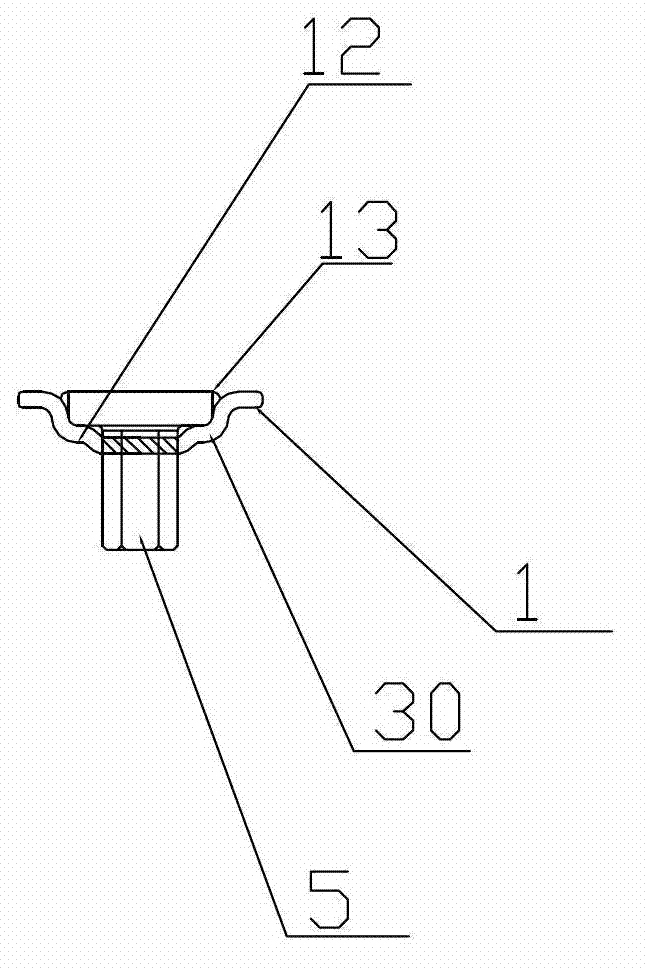

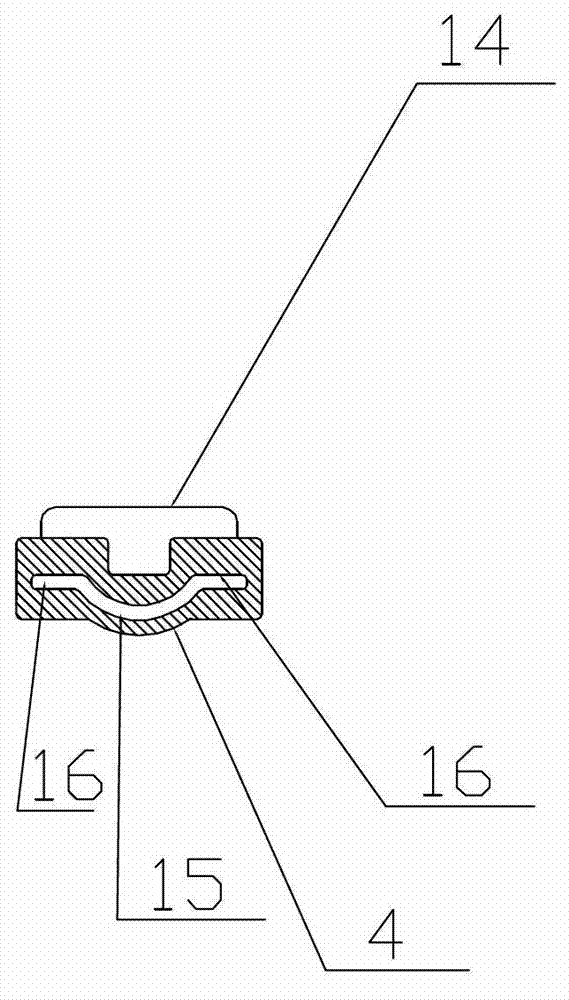

Multifunctional safety pipe hoop

The invention provides a multifunctional safety pipe hoop which comprises a first metal hoop ring and a second metal hoop ring. The first metal hoop ring and the second metal hoop ring are combined to enclose a pipe. One ends of the first metal hoop ring and the second metal hoop ring are connected in a movable mode, and the other ends of the first metal hoop ring and the second metal hoop ring are fastened by a connecting component. Anti-skidding anti-corrosion layers are arranged on the metal hoop rings. Connecting nuts or connecting screws are arranged on the metal hoop rings. The hoop rings have various safety functions, such as shockproof function, reliable load-bearing function and anti-corrosion function. Besides, the hoop rings are simple in structure and low in cost. The multifunctional safety pipe hoop is long in service life, and technologies which produce pollution, such as acid treatment and electrofacing are eliminated. The multifunctional safety pipe hoop is particularly suitable for public places and undergrounds which has anti-corrosion requirements. Besides, pipes in complex pipelines are enabled not to generate static electricity and conduct electricity. Furthermore, the anti-skidding anti-corrosion layers are made of fire-proof materials, the problem that the pipes fall down to block a road due to metal creep in a fire is solved, and opportunities are created for escaping and firefighting.

Owner:斯泰科技(杭州)有限公司 +2

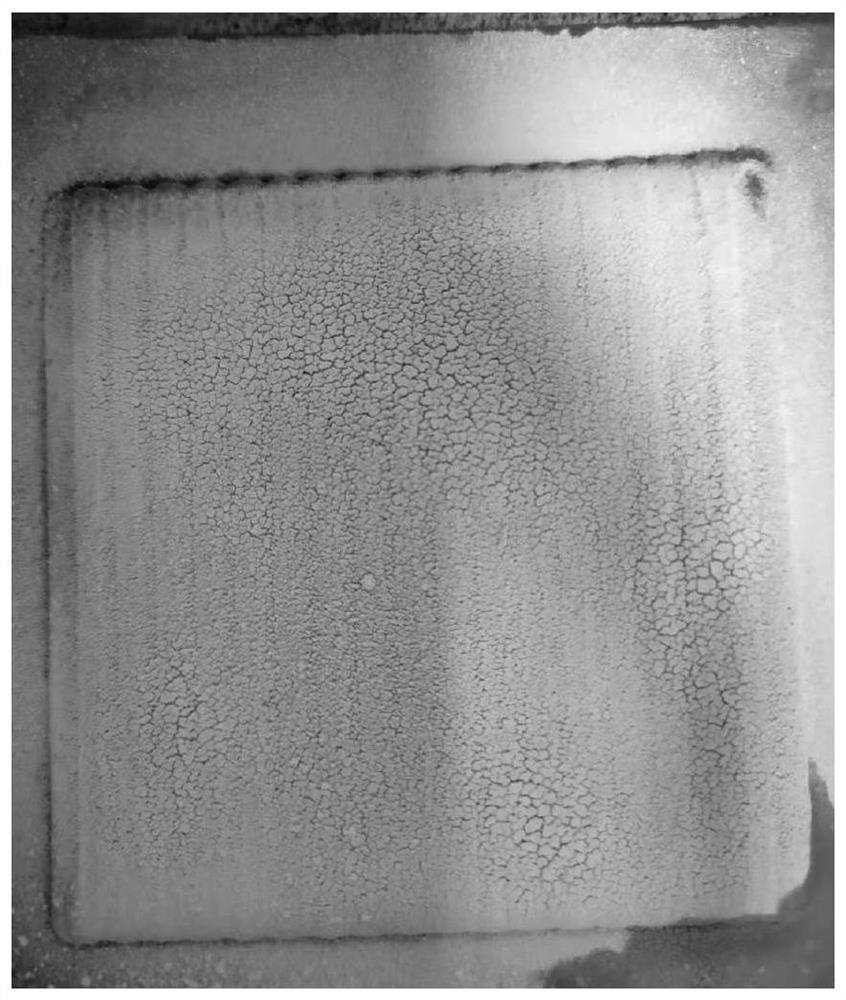

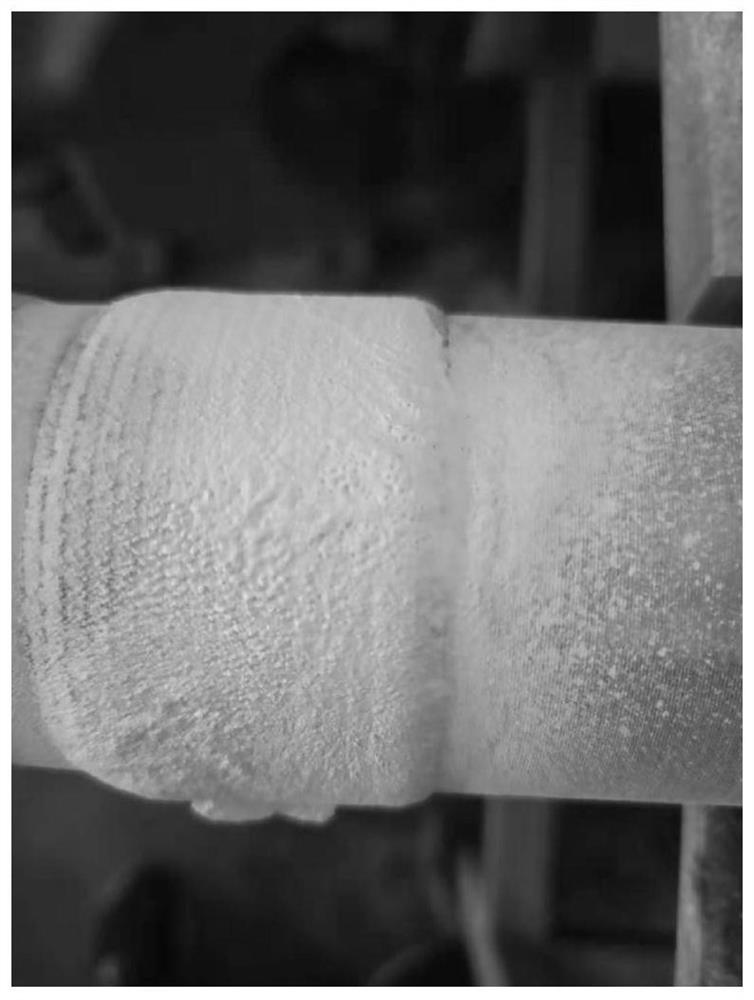

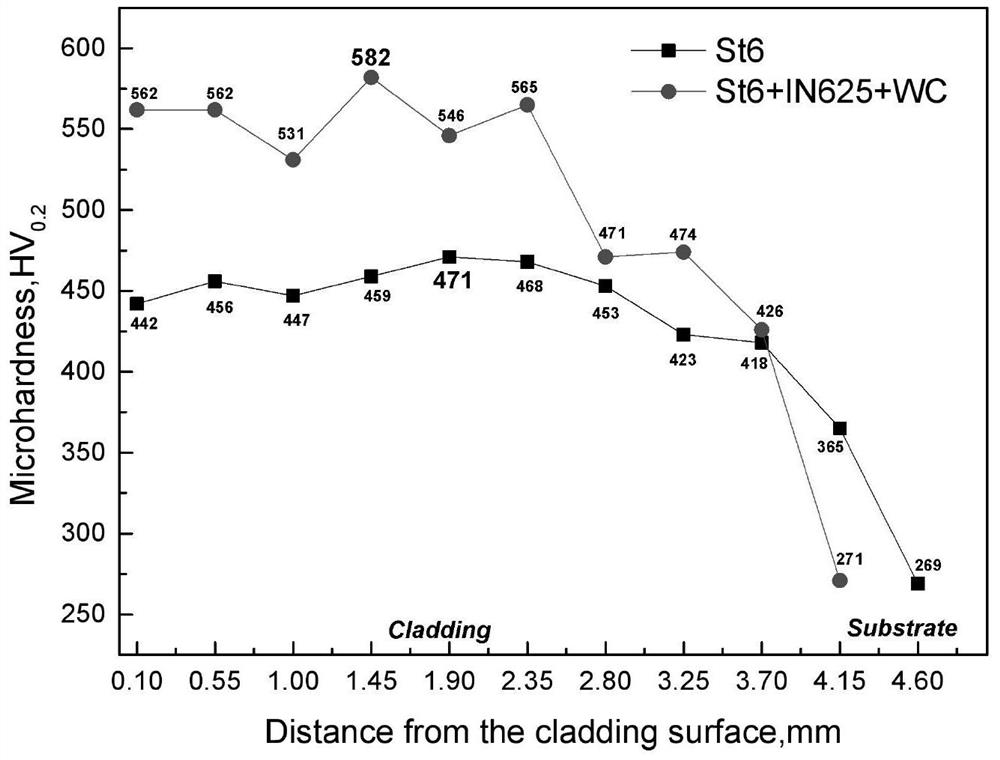

Preparation method of cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance

ActiveCN112647076AHigh hardnessImprove wear resistanceIncreasing energy efficiencyMetallic material coating processesSS - Stainless steelStellite

The invention discloses a preparation method of a cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance. The preparation method comprises the following steps that (1) oxide skin and oil stain on the surface of a duplex stainless steel base material are removed; (2) three kinds of material powder, namely Stellite 6, Inconel 625 and WC ceramic particles are weighed; (3) the three kinds of powder are uniformly mixed and dried; (4) technological parameters are set, and laser cladding is conducted on the surface of the duplex stainless steel base material; (5) finish machining is conducted. The Stellite 6 widely applied to cobalt-based alloy is selected as a powder main body, the high-hardness WC ceramic particles are added as an enhancer, the nickel-based alloy Inconel 625 powder with excellent welding performance is added, and the coating is prepared by changing the proportion of composite powder and adjusting laser cladding process parameters. The preparation process is simple, the traditional procedures of base material preheating treatment and workpiece post-treatment can be omitted, the powder preparation cost can be reduced, and the problem that the cobalt-based ceramic particle composite powder cracks in large-area cladding in actual engineering application is solved.

Owner:浙江翰德圣智能再制造技术有限公司

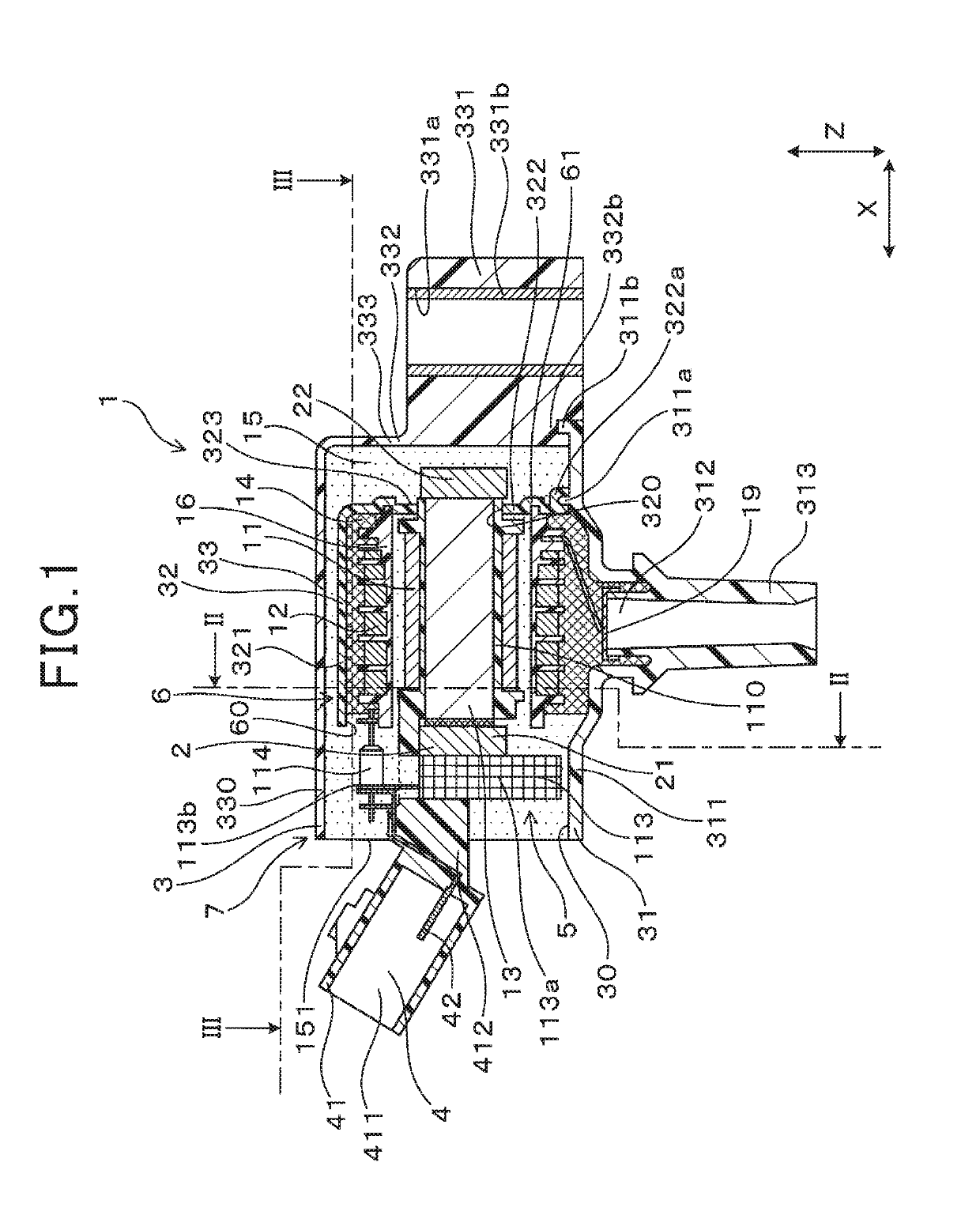

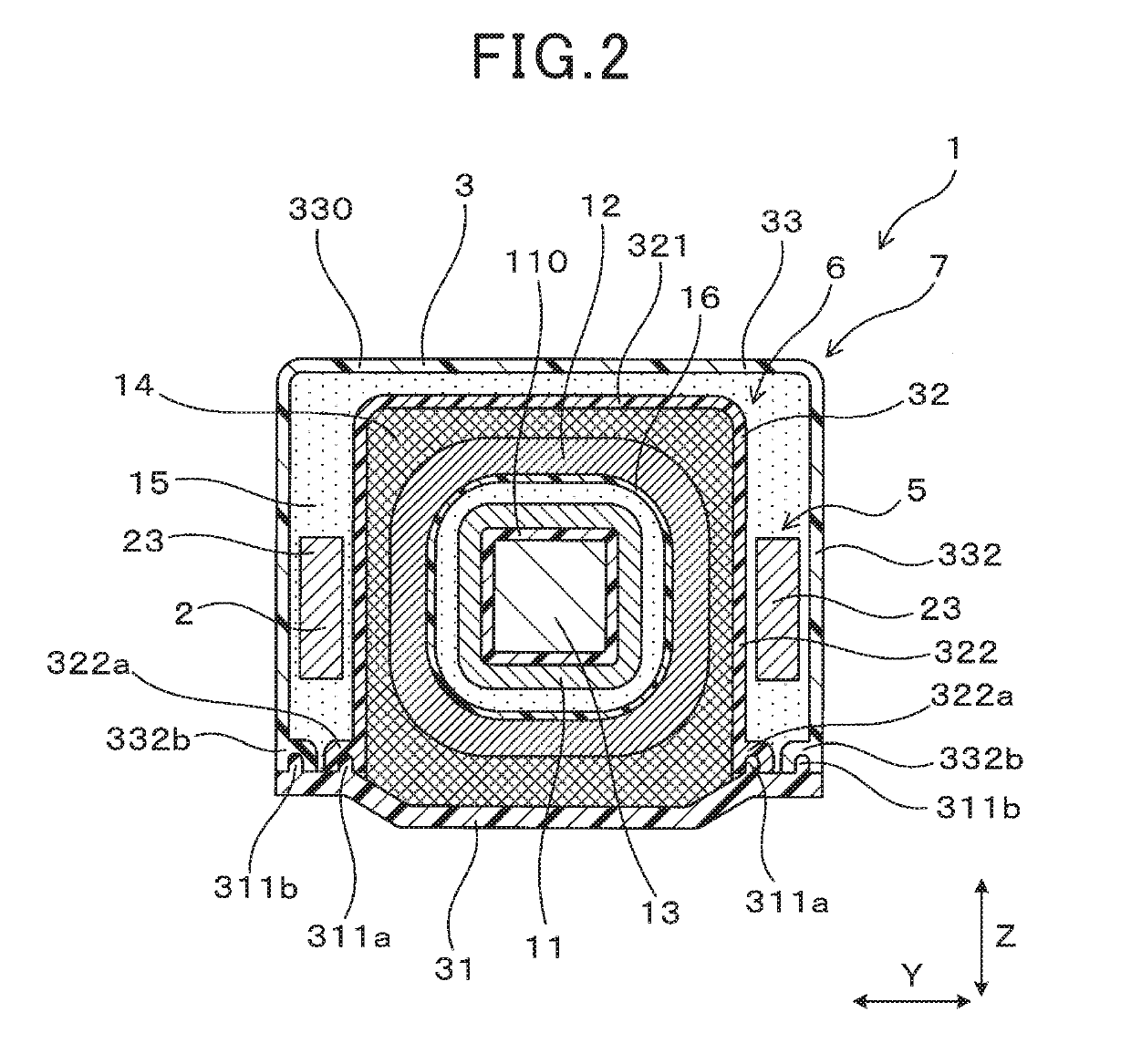

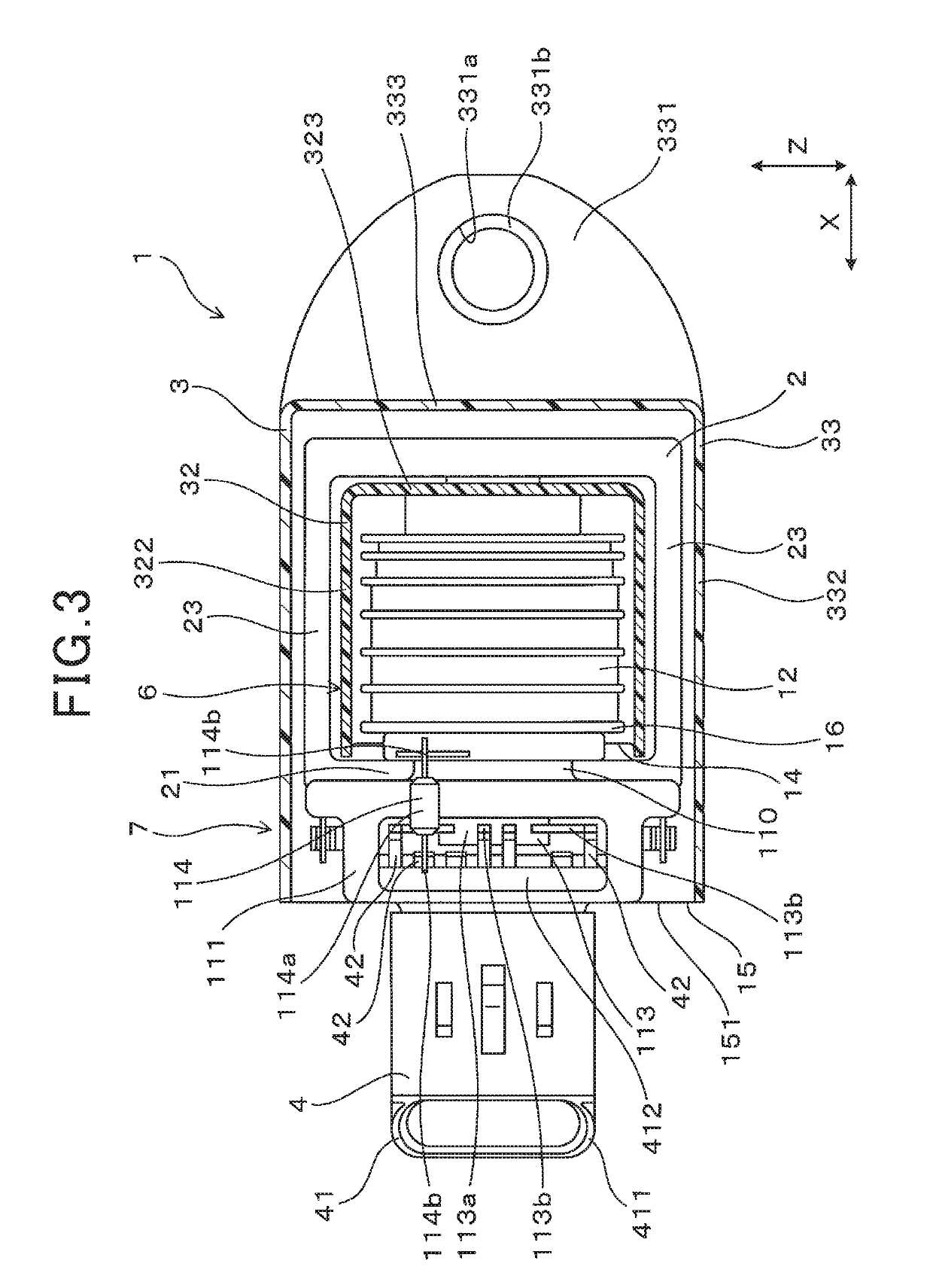

Ignition coil for internal combustion engine and manufacturing method thereof

ActiveUS20190189341A1Improve insulation performanceIncrease flexibilityTransformersTransformers/inductances casingsIgnition coilExternal combustion engine

A first filler resin is disposed to cover at least an outer peripheral side of a secondary spool and a secondary coil. The second filler resin is filled inside a case and seals a cover sealant which includes a primary coil, secondary spool, a secondary coil, a center core, an outer core and the first filler resin. The connector protrudes to an outside of the case. The case has a fixing portion. The second filler resin has a lower elasticity than the first filler resin. The ignition coil is manufactured by filling the first resin inside the case, and filling the second resin after the first resin is cured.

Owner:DENSO CORP

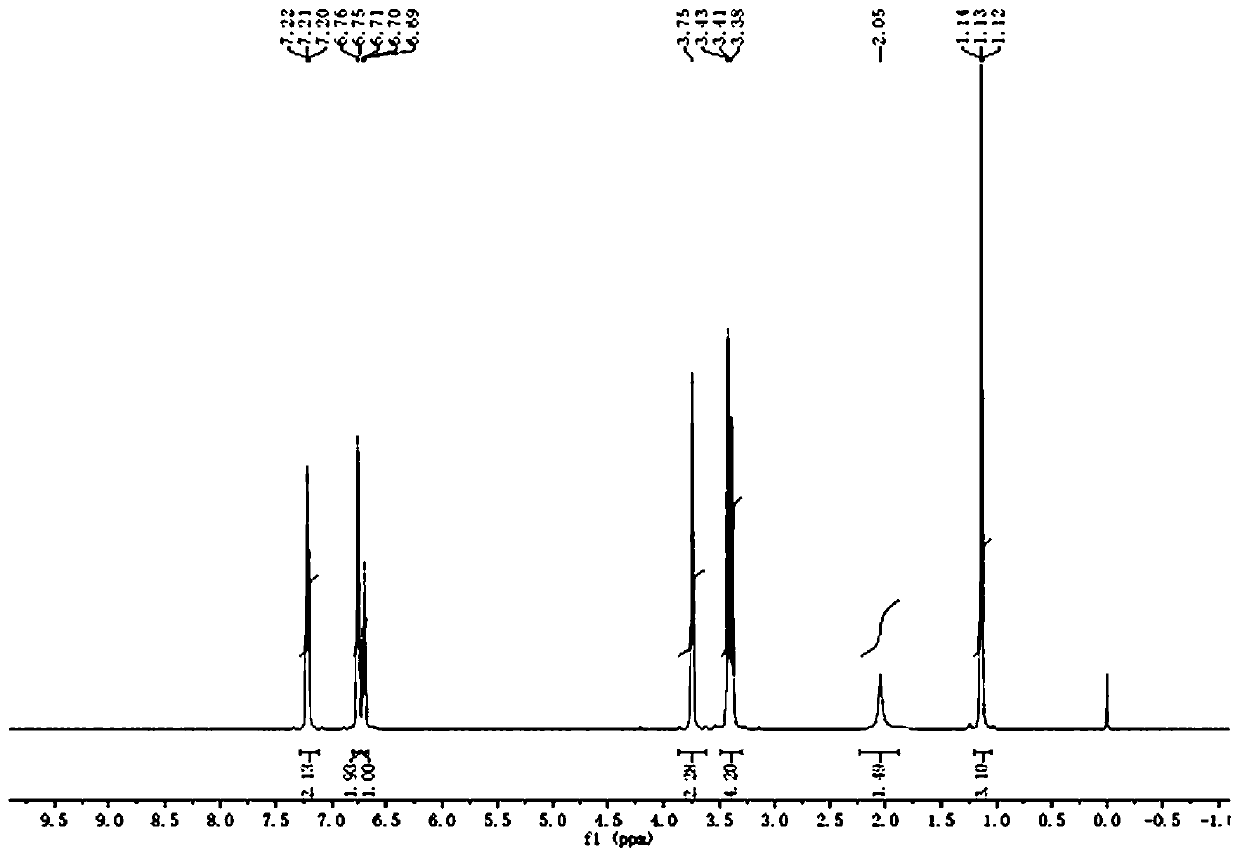

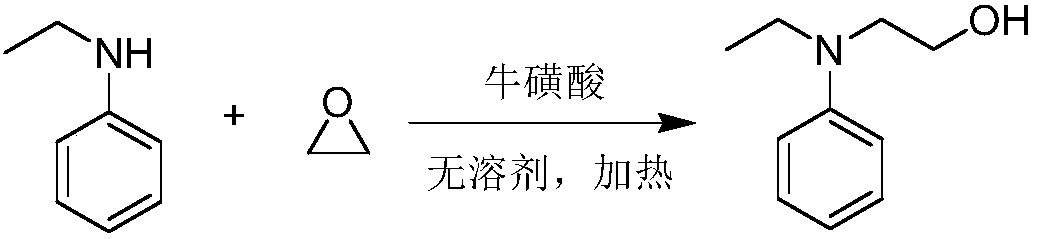

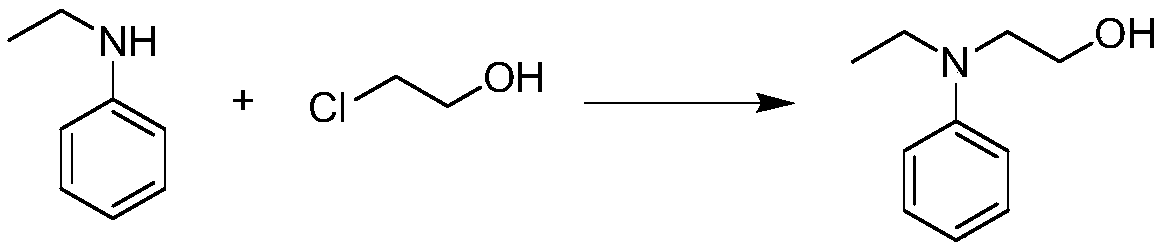

Method for preparing N-ethyl-N-hydroxyethylaniline

InactiveCN108117492AReduce dosageImprove catalytic performanceOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideSolvent

The invention discloses a method for preparing N-ethyl-N-hydroxyethylaniline. The method comprises the following steps: by taking N-ethylaniline and ethylene oxide as raw materials, in the absence ofa solvent, under catalysis of taurine, performing programmed heating, directly synthesizing N-ethyl-N-hydroxyethylaniline, cooling, and discharging, thereby obtaining a finished product. The method iseasy in raw material obtaining, good in atom economy, gentle in reaction condition, green and environment-friendly, simple and efficient and applicable to industrial production.

Owner:JIANGSU YUANDA XIANLE PHARMA

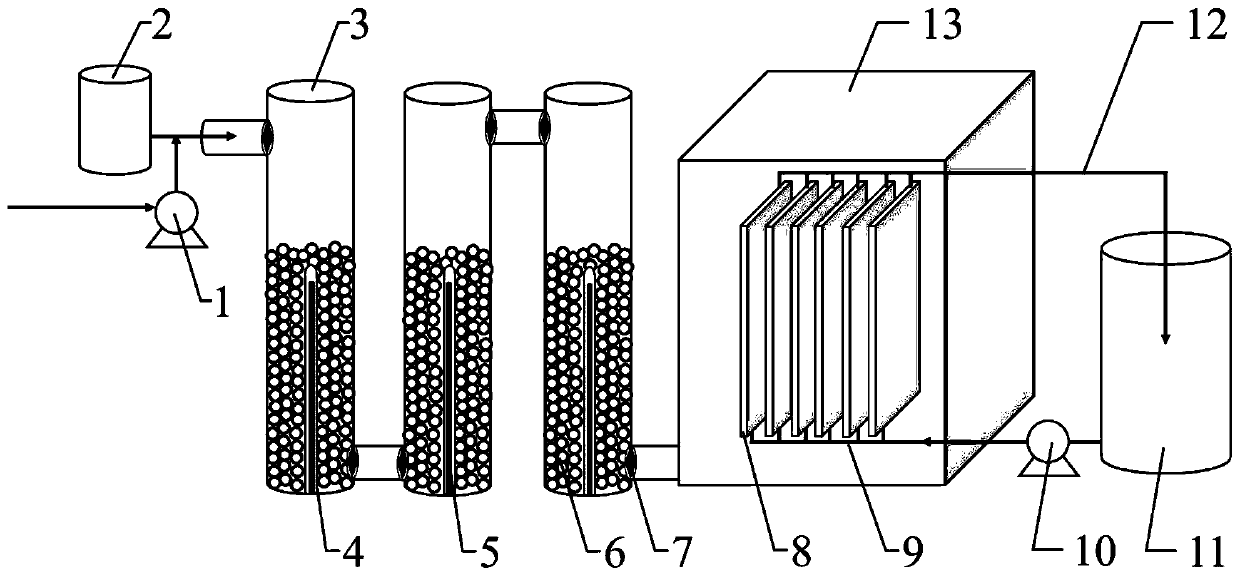

Photo-Fenton-positive permeation integrated device for treating organic wastewater difficult to biodegrade and using method of device

InactiveCN110204031AReduce the risk of contaminationEfficient removalWater/sewage treatment by irradiationWater treatment compoundsTherapeutic effectCirculating pump

The invention relates to a photo-Fenton-positive permeation integrated device for treating organic wastewater difficult to biodegrade and a using method of the device. The device comprises a photo-Fenton unit and an immersed positive permeation unit. The method for treating the water by using the device comprises the photo-Fenton process and the positive permeation process, and while organic pollutants are effectively degraded or converted by using the photo-Fenton unit, the organic pollutants which are not completely degraded or converted in the photo-Fenton process are permselectively intercepted by using a positive permeation membrane. The immersed positive permeation unit adopts an immersed positive permeation structure, a water inlet end circulating pump or an inlet water tank is notneeded, the overall structure is compact, the energy consumption is low, and the photo-Fenton-positive permeation integrated device is easily combined with other technologies or devices. Active substances generated by the photo-Fenton unit are used up in the pollutant degradation and converting process and in the positive permeation unit migration process, the strong oxidizing property of the photo-Fenton unit cannot affect the stability of the membrane, the wastewater treatment efficiency is high, the wastewater treatment effect is good, and the device is suitable for application and popularization.

Owner:CHANGCHUN UNIV OF SCI & TECH

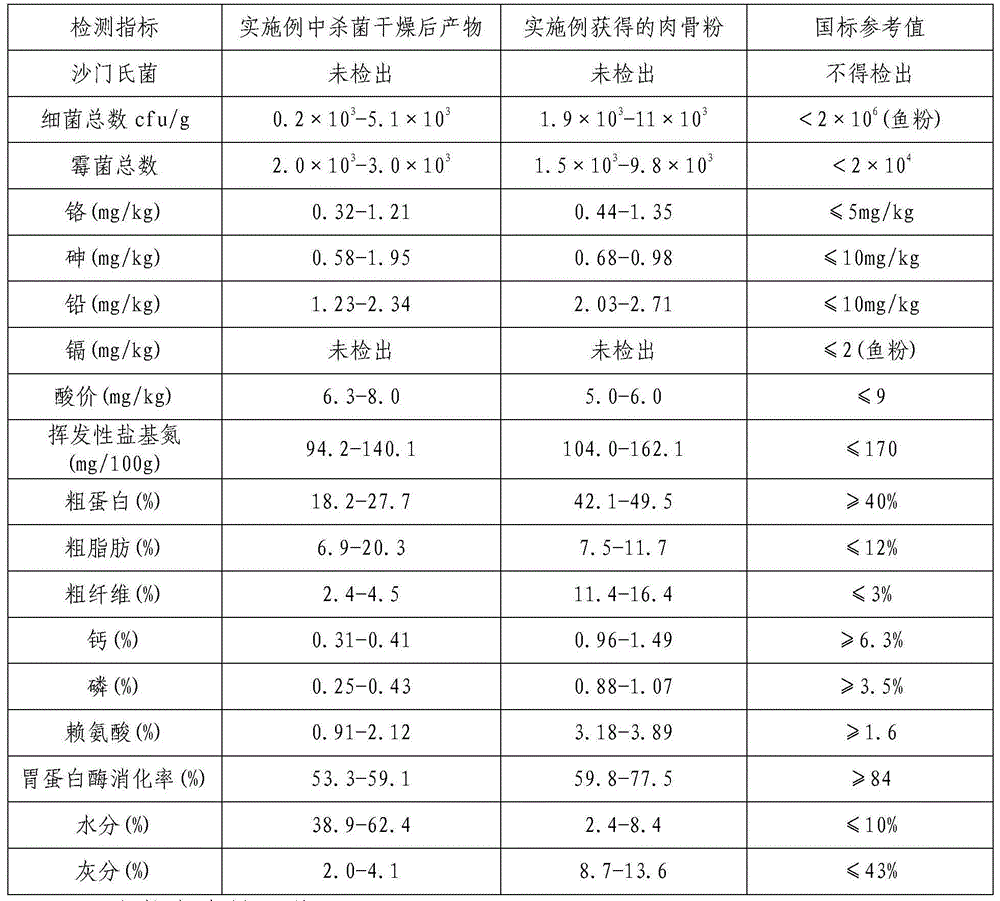

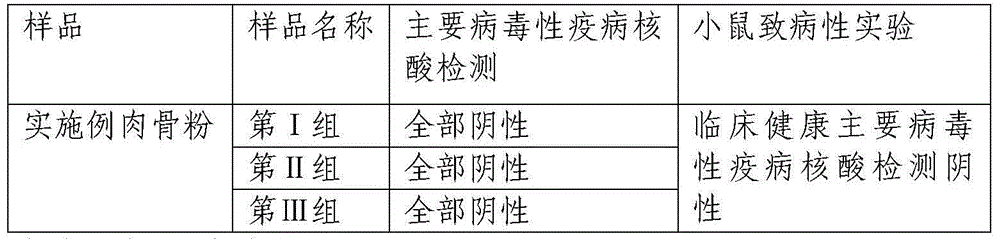

Feed raw material, and preparation method and application thereof

ActiveCN104782888AReduce security risksReduce the chance of animal disease transmission and spreadFood processingAnimal feeding stuffDyeingDisease

The invention relates to reprocessing of livestock and poultry dying of diseases, and concretely relates to a feed raw material (meat and bone meal), and a preparation method and an application thereof. The meat and bone meal is obtained through the steps of biodegradation bacterium treatment on livestock and poultry dyeing of diseases, and reprocessing. The method is adopted to carry out harmless treatment, so the livestock and poultry dying of diseases can be timely collected and processed in a standardized manner, so the food safety and public health safety risk is reduced; the propagation and spreading probability of animal epidemic diseases is effectively reduced, the health level of animals is improved, and the healthy and stable development of the animal husbandry is guaranteed; environment pollution can be reduced, and the rural settlement environment is improved; and additionally, the livestock and poultry dying of diseases contains abundant proteins and oils, so resource recycling and changing of wastes into valuables can be realized.

Owner:刘敬先

Technique for fabricating axes material in stainless steel

InactiveCN1626685ALow heating temperatureLow costFurnace typesHeat treatment furnacesSlow coolingHeat treated

A technology for manufacturing the shaft made of stainless steel includes rolling 2Cr13 stainless steel, cooling in air, slow cooling in pit, and tempering at 600-700 deg.C instead of annealing at 800-900 deg.C. Its advantages are saving energy and short period.

Owner:SHANGHAI LIANCHENG(GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com