Right angle extrusion processing method and right angle extrusion processing mould

A processing method and right-angle technology, applied in the direction of metal extrusion dies, etc., can solve the problems of scratches, complex metal sheet forming structure, crushing and other problems, and achieve the effect of eliminating grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

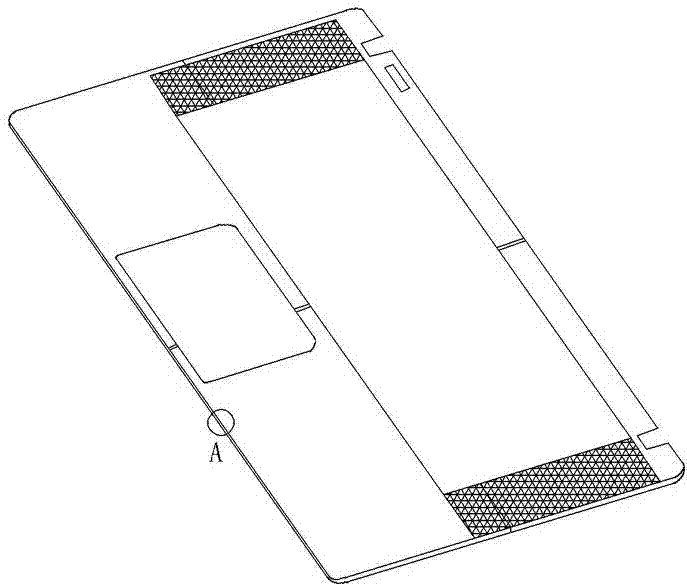

[0017] Through the method of the present invention, it is possible to process figure 1 electronics parts shown. The electronic product part is an aluminum thin plate device, the edge of the aluminum thin plate main body has a downward circular bending edge, and the outer corner between the aluminum thin plate main body and the bending edge is a right angle.

[0018] The right-angled outer corners of the peripheral edges of the aluminum sheet main body are the focus of the processing of the present invention. Below to figure 1 The outer corner of the part A is an example to describe the method of the present invention in detail.

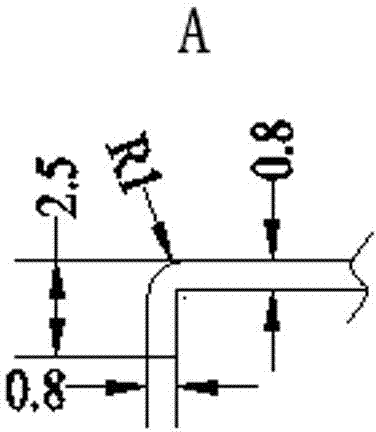

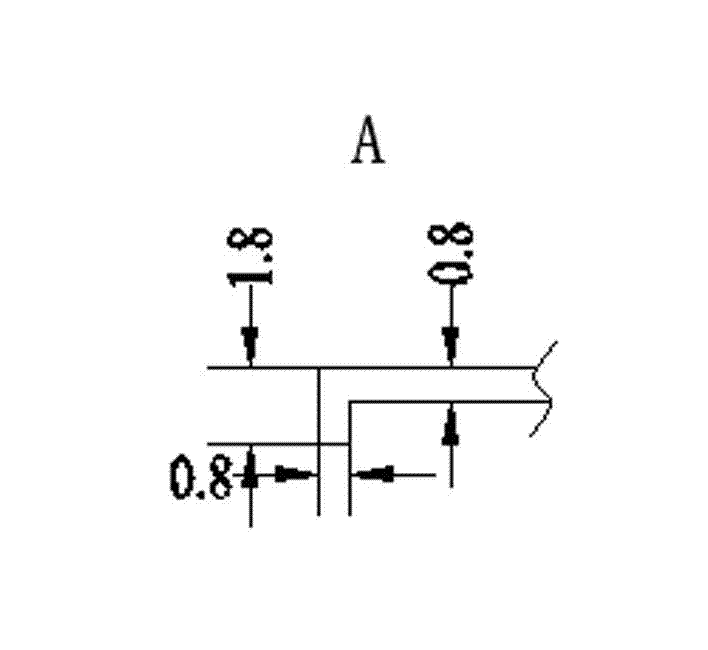

[0019] In the process of processing, firstly, the metal sheet is punched through the mold, and the semi-finished workpiece with a downward circular bending edge is processed. The outer corner between the metal sheet body and the bending e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com