Method for machining linear saddle groove of main cable saddle of suspension bridge

A processing method, the technology of the main cable saddle, which is applied in the processing field of mechanical parts, can solve the problems of low efficiency, undercutting of the step surface of the saddle groove, etc., and achieve the effects of good interchangeability, saving on grinding, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with description of drawings and specific embodiments:

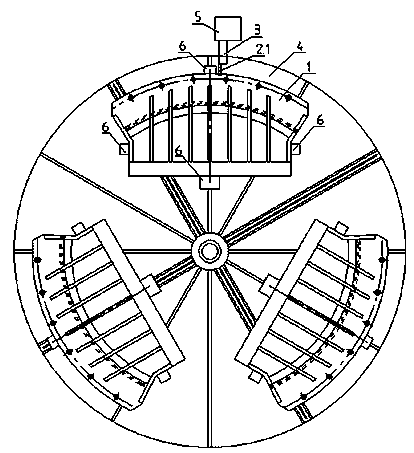

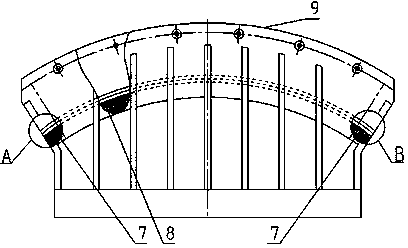

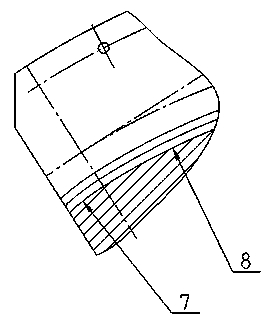

[0048] see figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 11 , Figure 12 , a method for processing a linear saddle groove of a main cable saddle of a suspension bridge, comprising the following steps:

[0049] A. CNC boring and milling machine processing

[0050] A1. Align according to the machining allowance, clamp the main cable saddle 1 on the CNC boring and milling machine, and process a bottom surface and a side surface;

[0051]A2. Install the bottom of the main cable saddle 1 on the CNC boring and milling machine workbench, align the main cable saddle 1 based on the processed bottom and side surfaces of the main cable saddle 1, and process the arc of the top surface of the saddle groove Surface 9 is exposed to light and is concentric with the main curve 8 of the theoretical arc of the saddle groove.

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com