Patents

Literature

37results about How to "Consistent machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

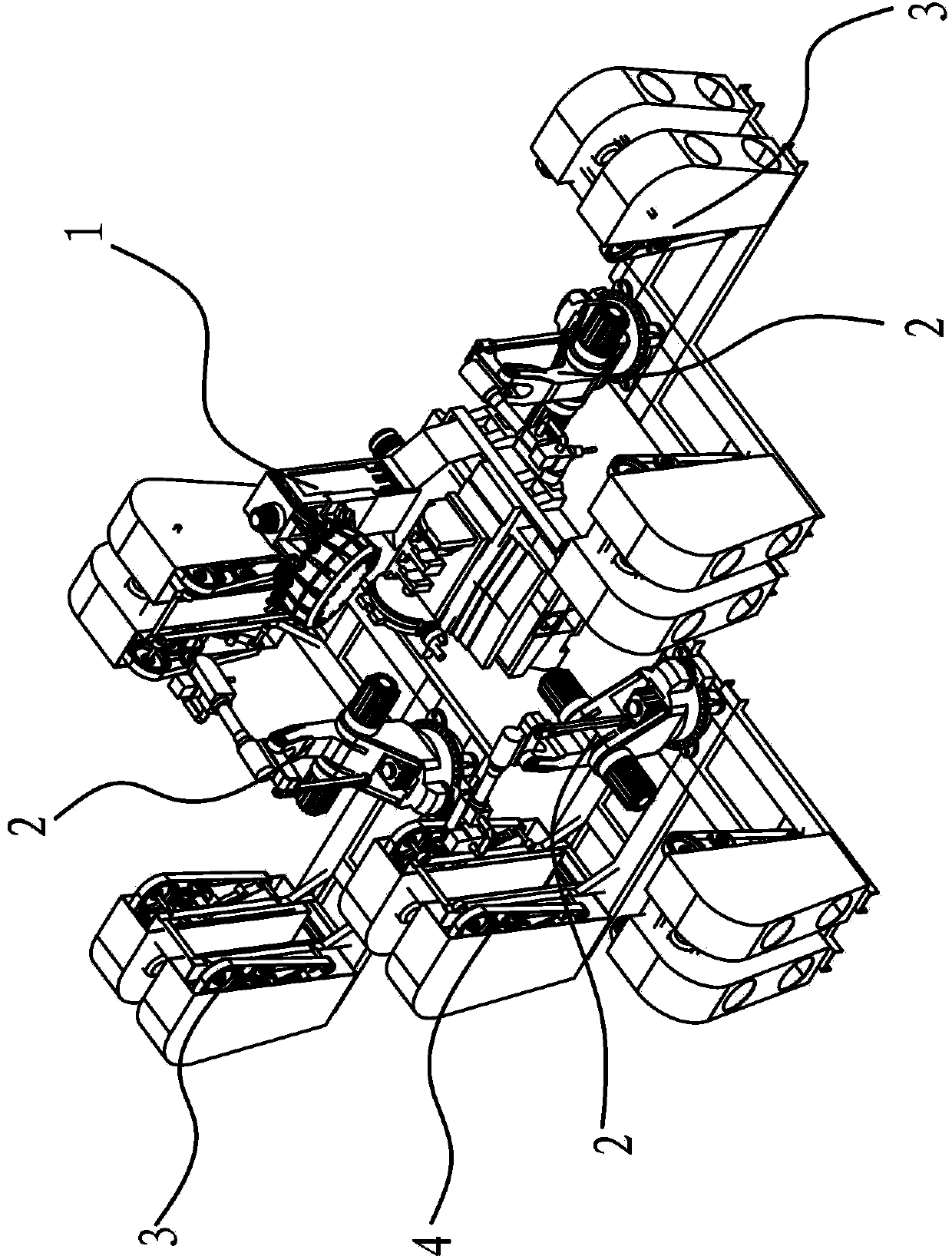

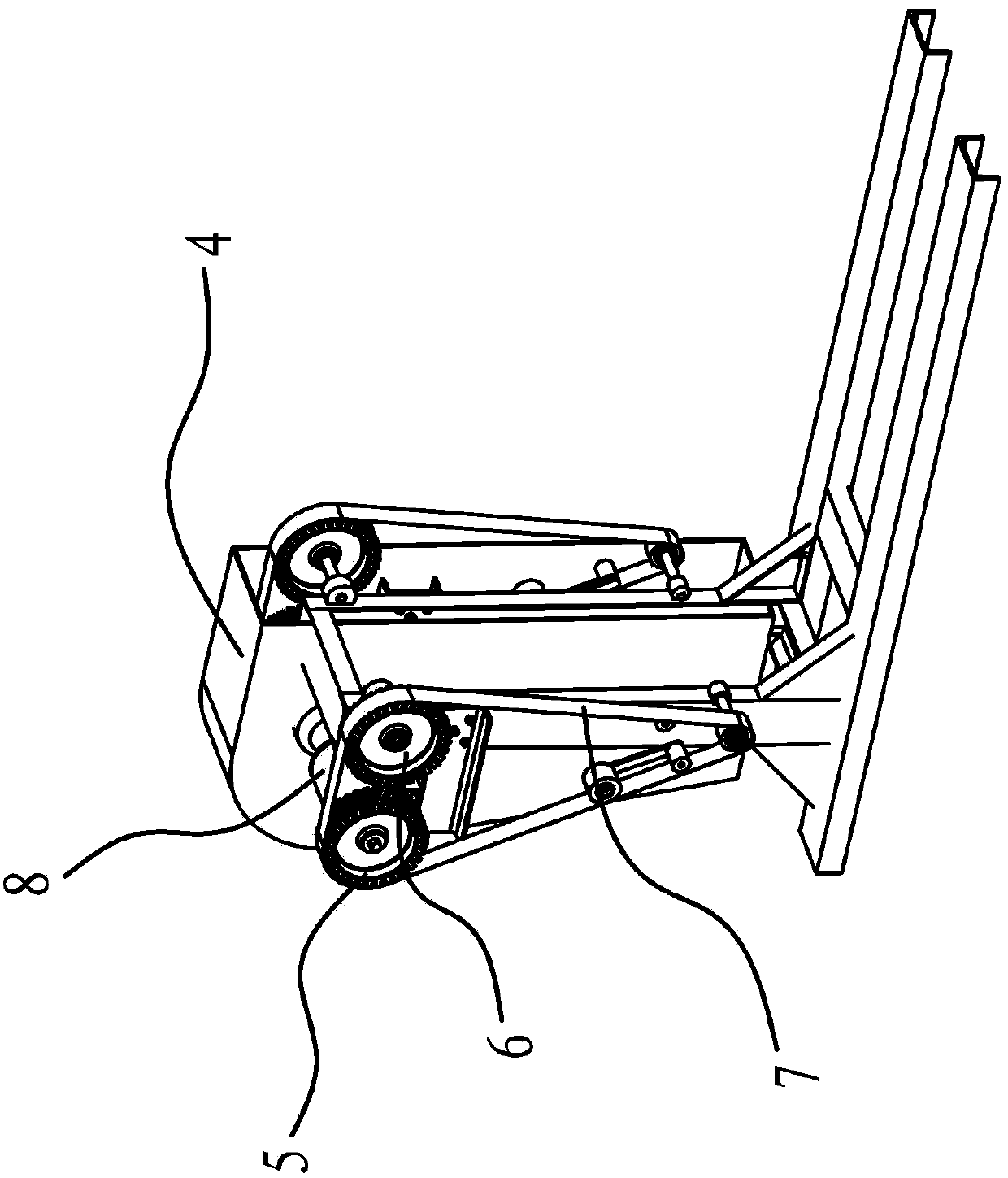

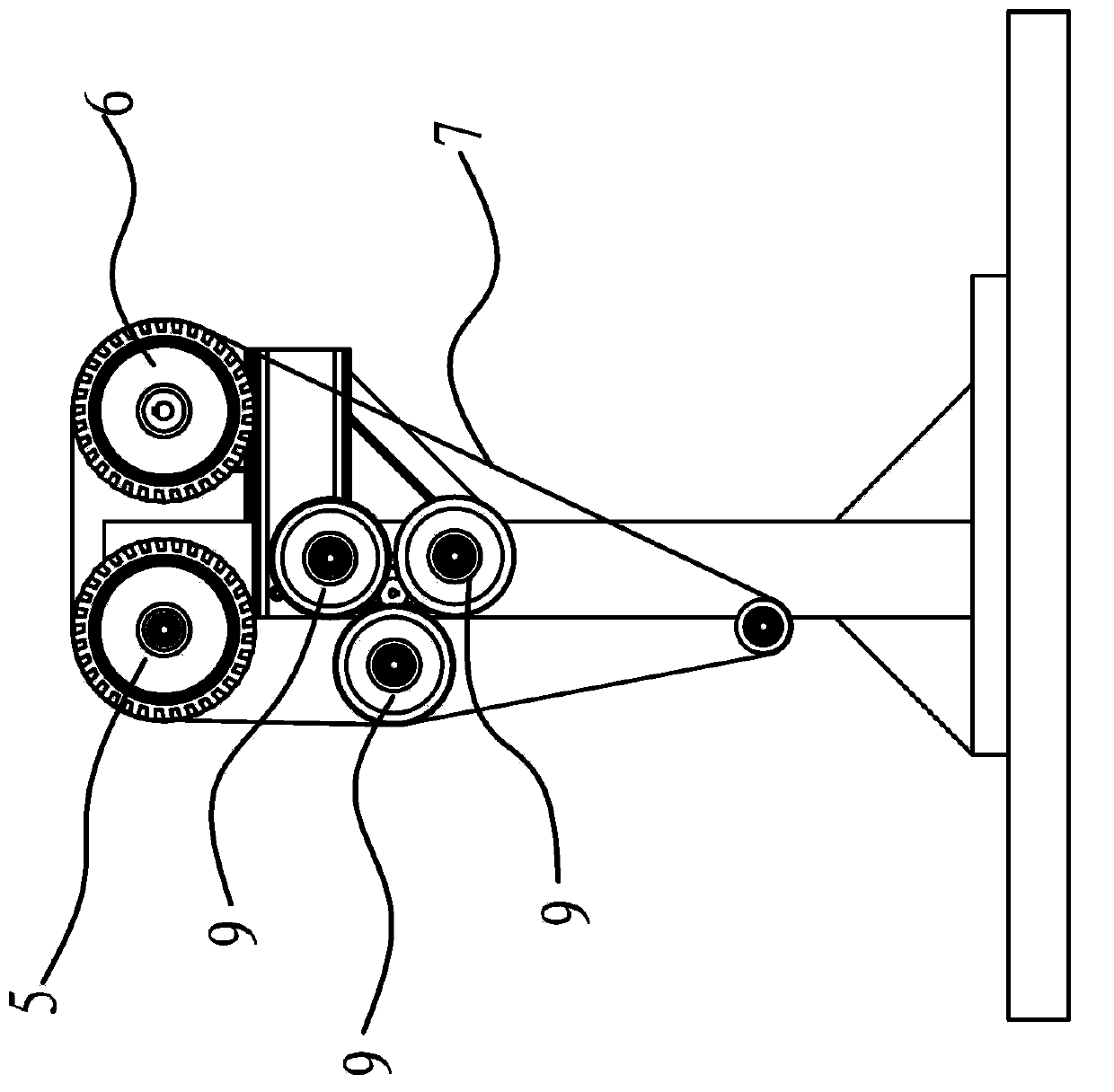

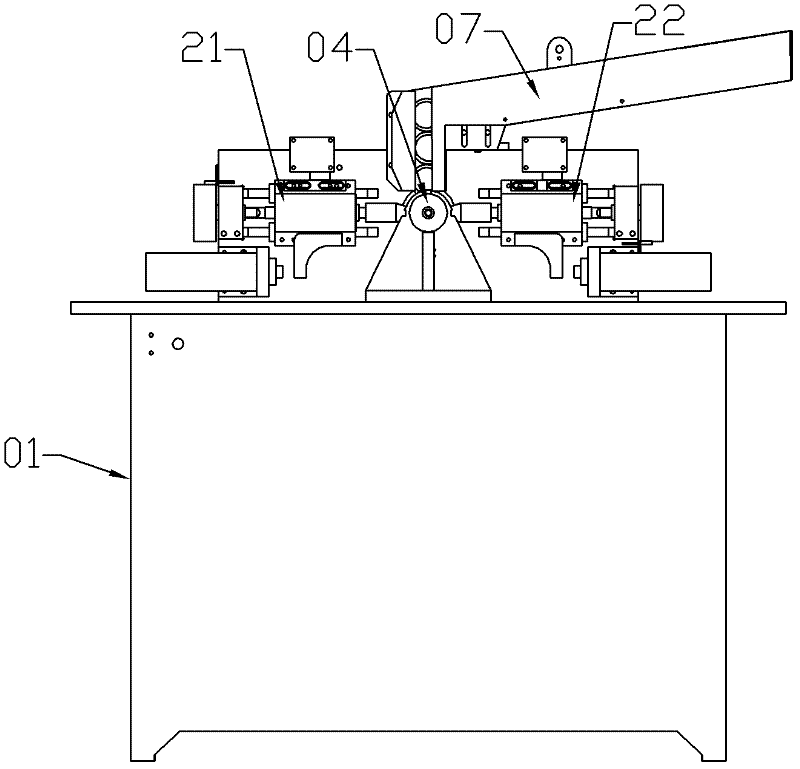

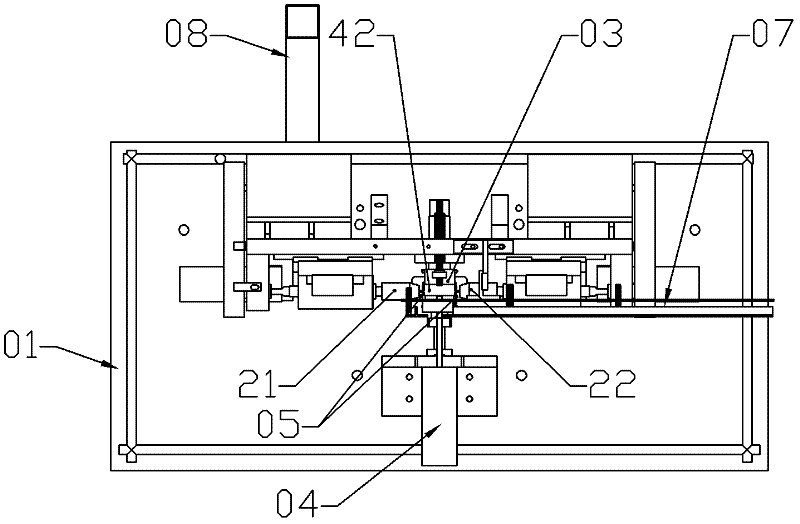

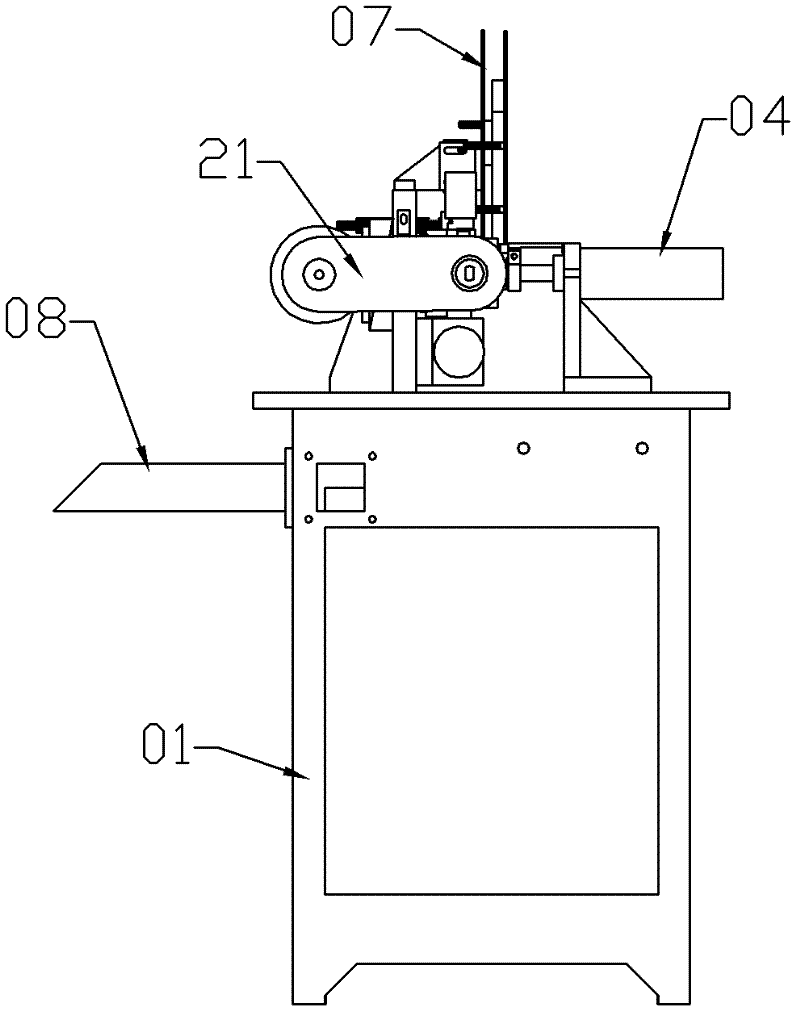

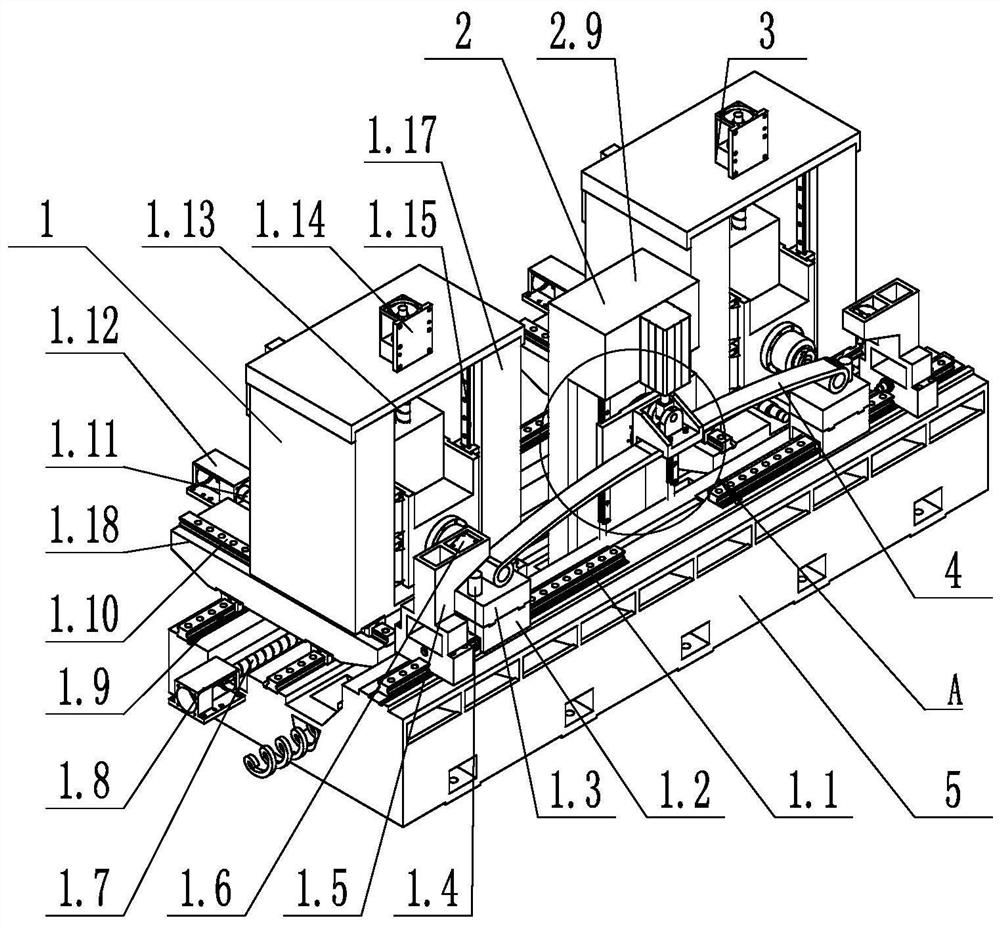

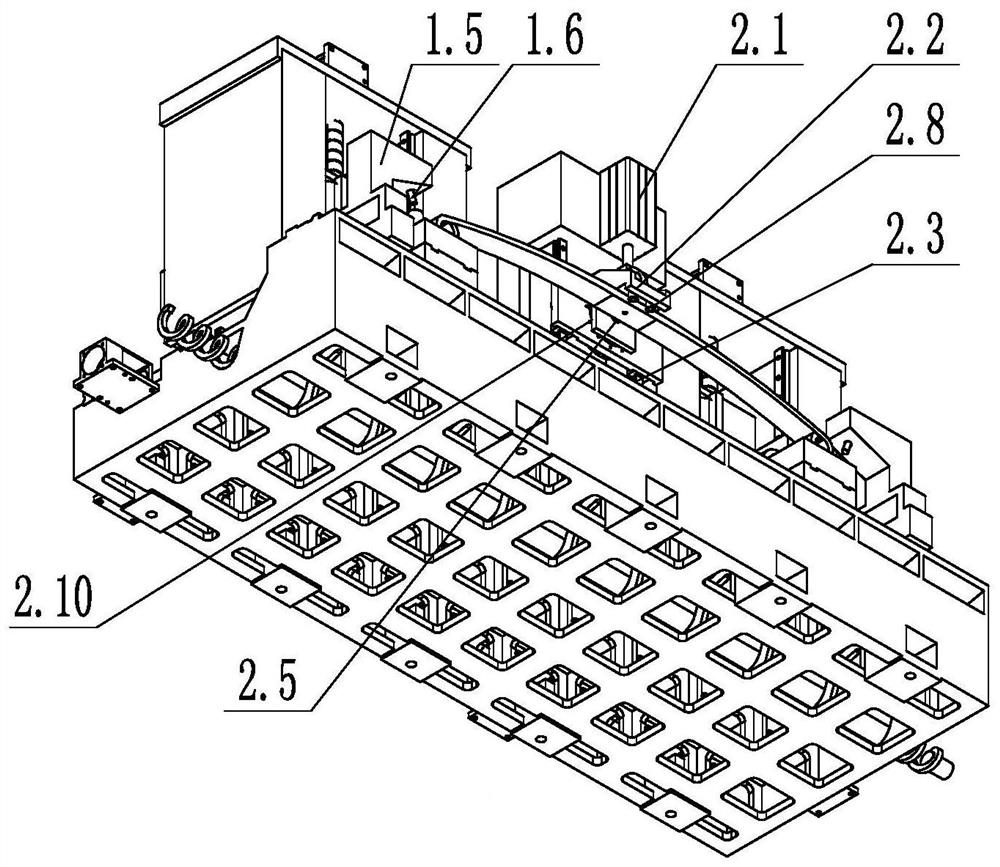

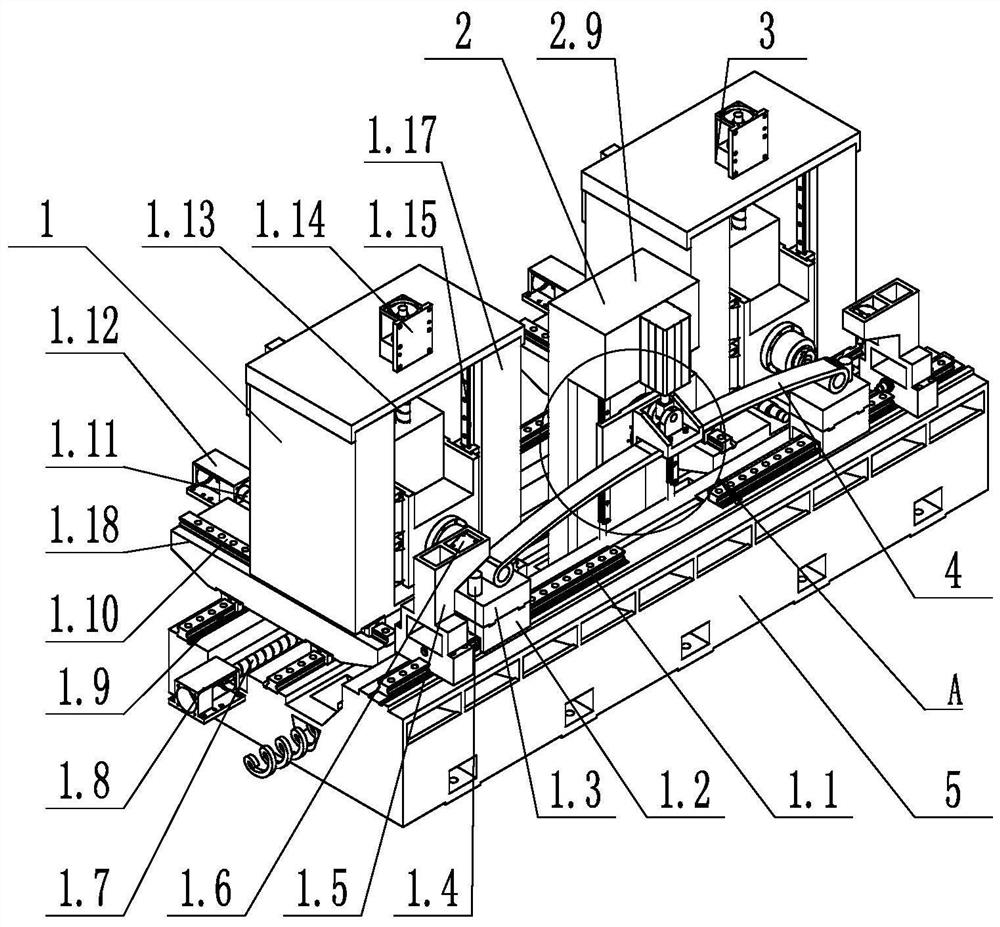

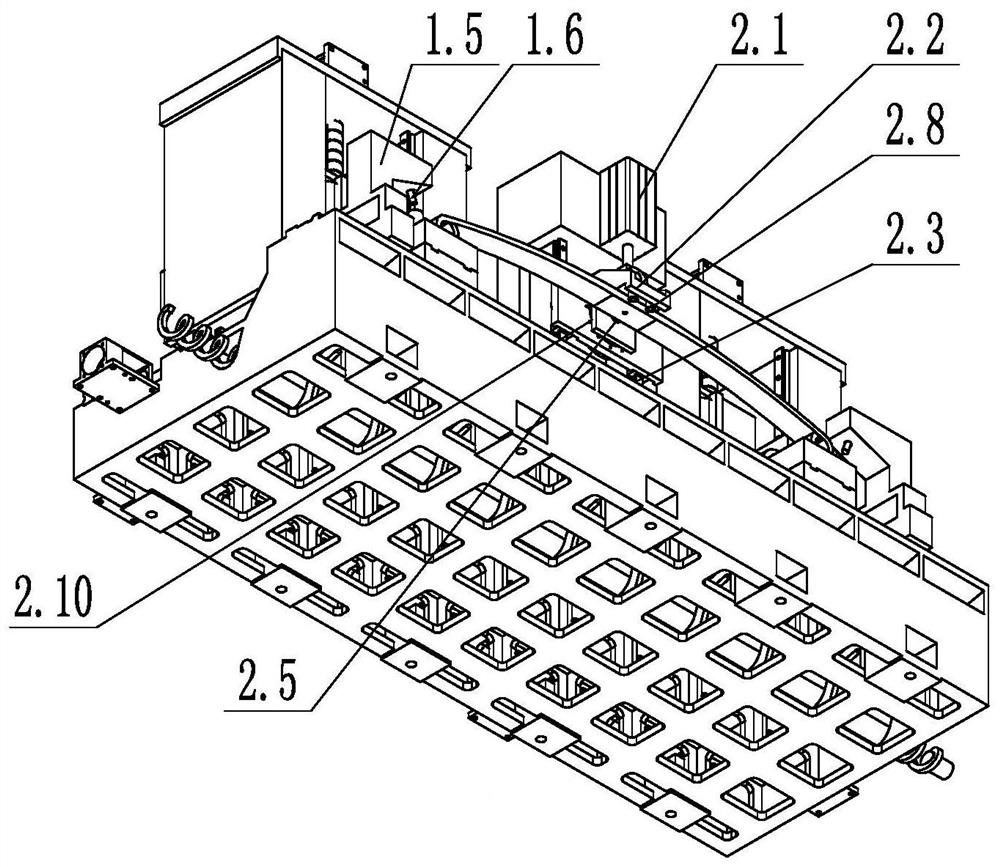

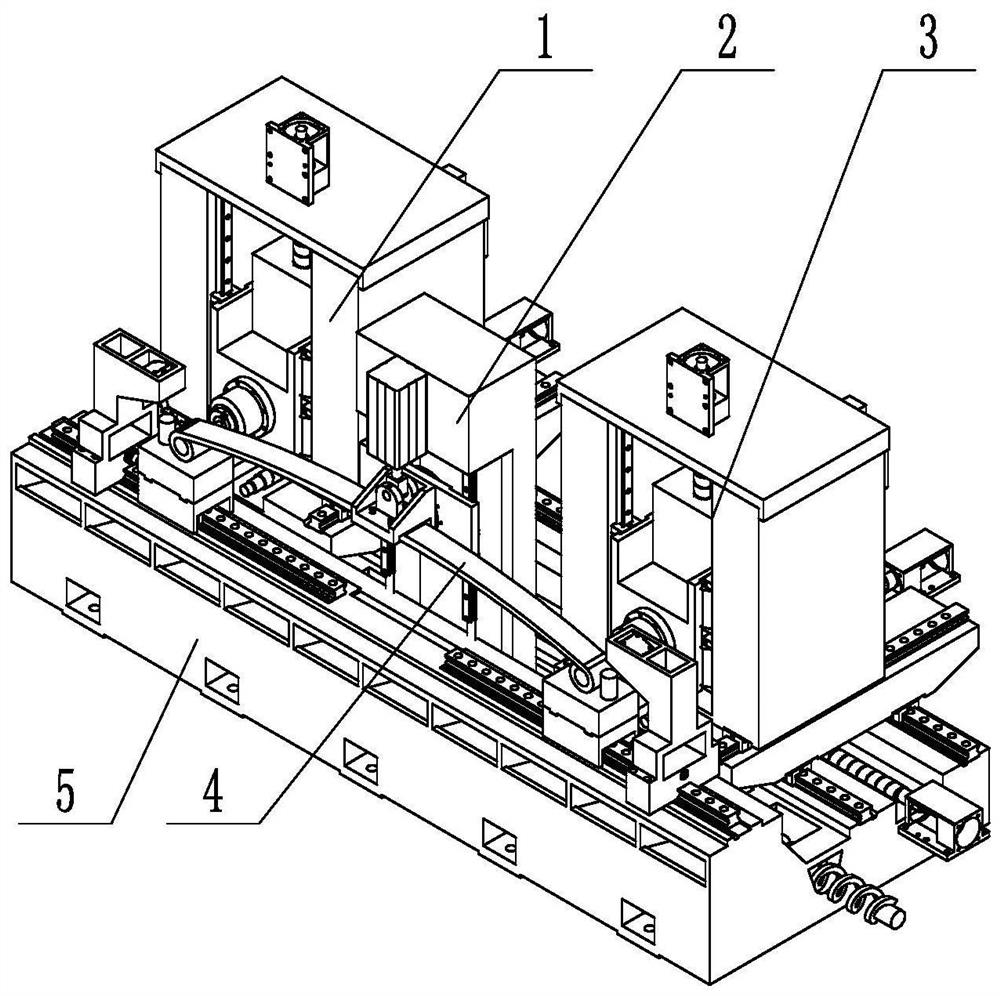

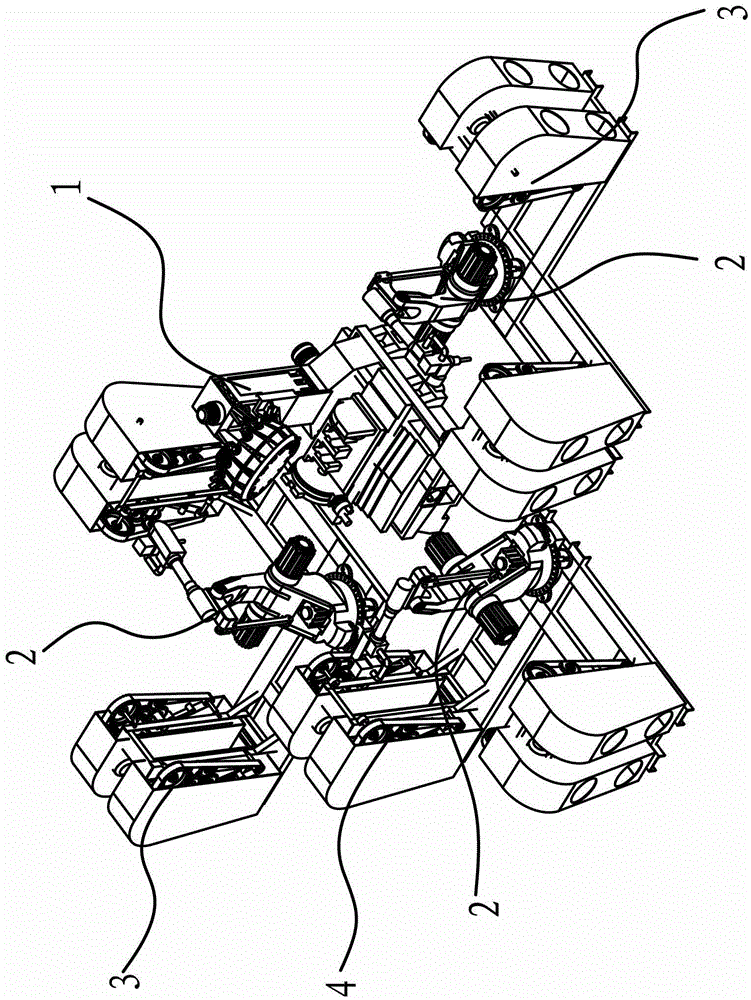

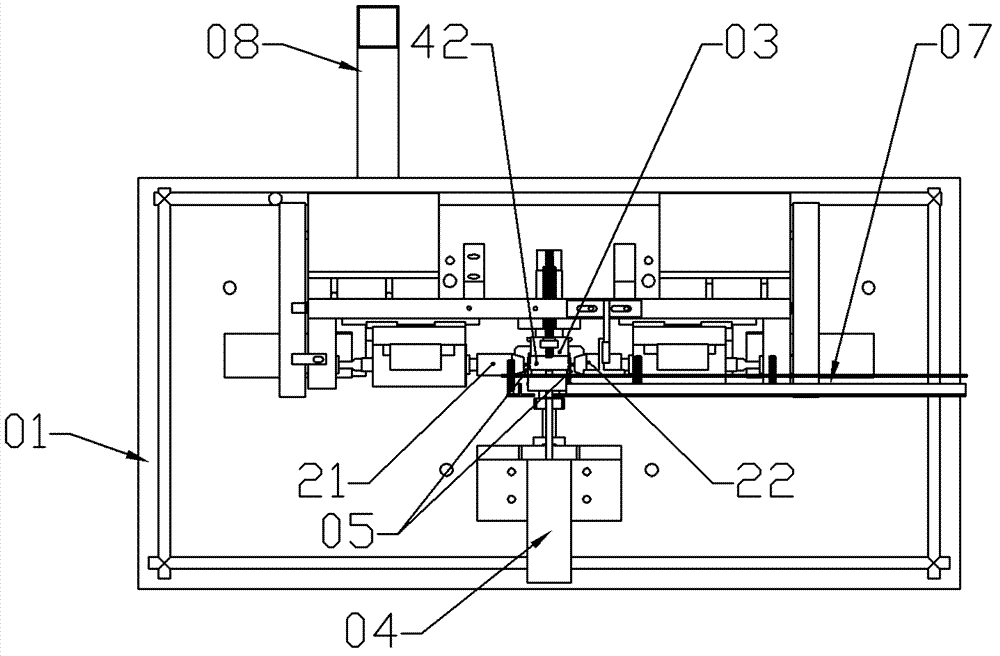

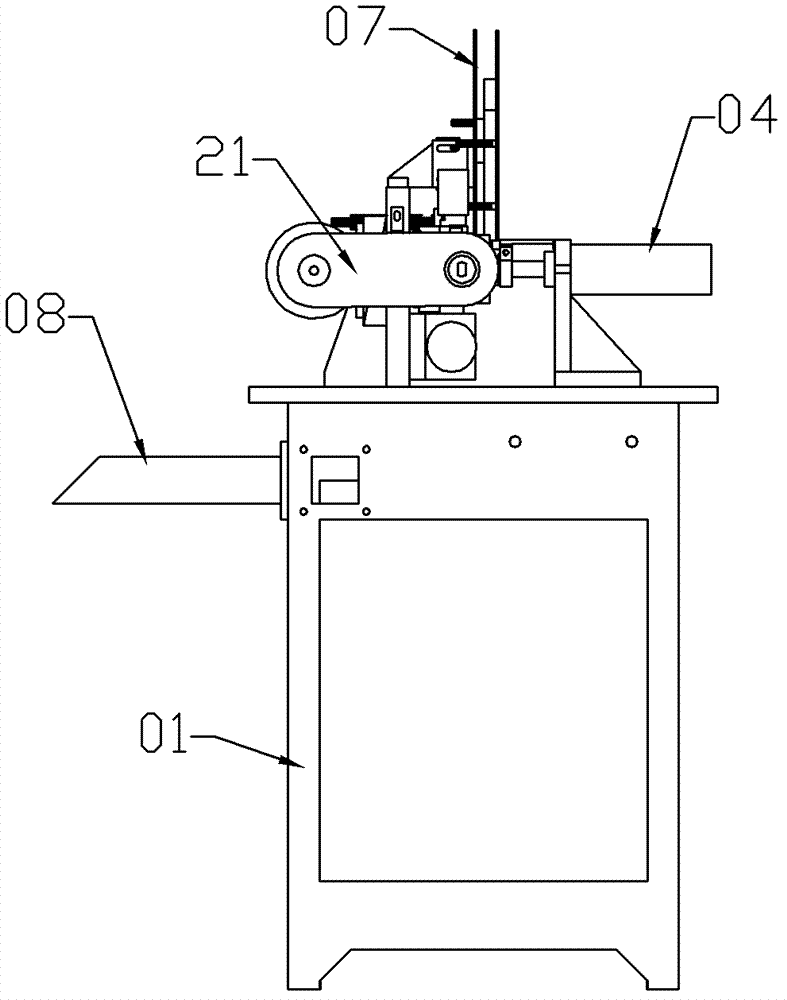

Workpiece automatic machining system and grinding method of surface of workpiece

ActiveCN103419111AHigh precisionImprove integrityBelt grinding machinesMechanical engineeringEngineering

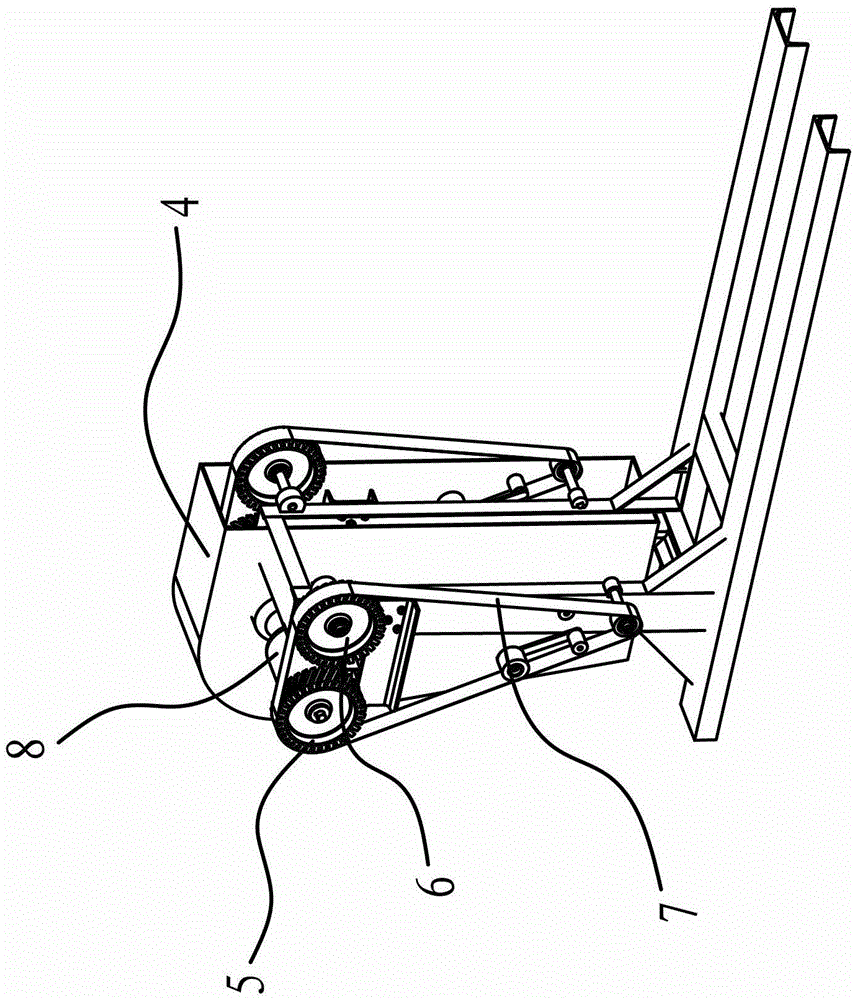

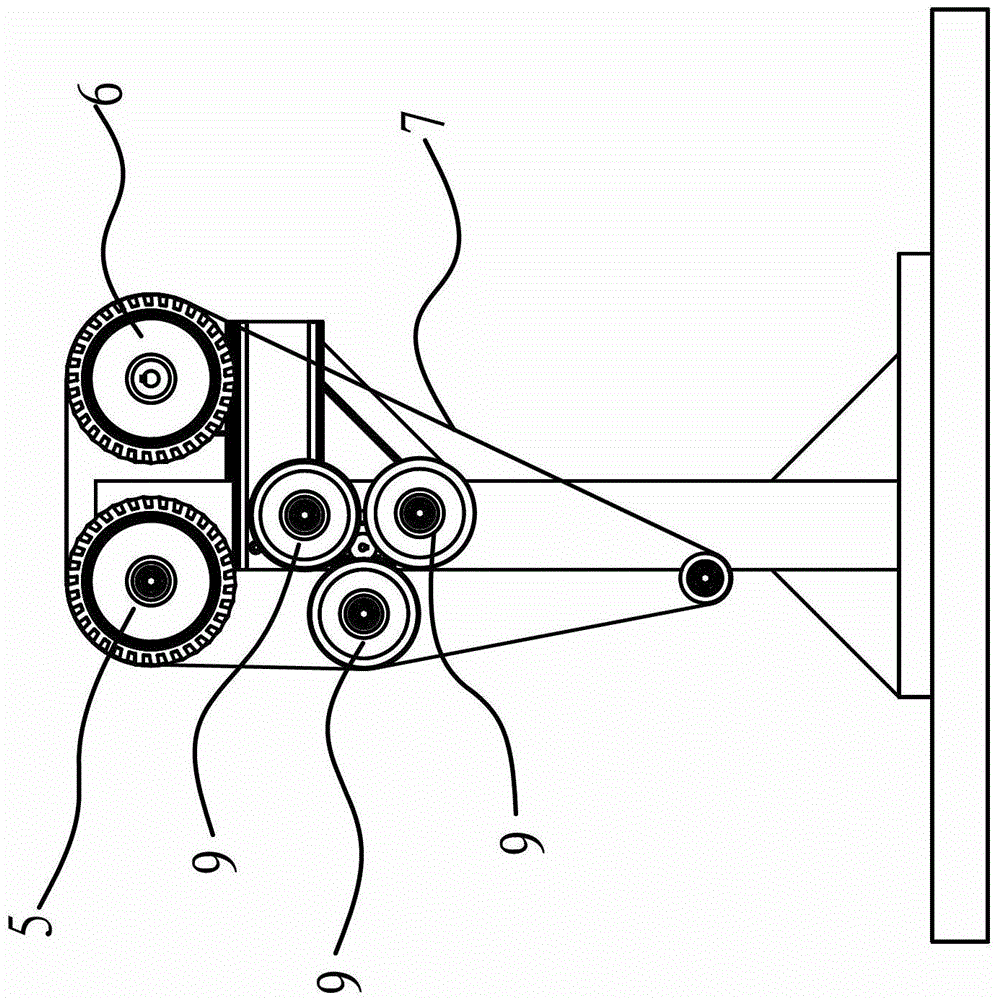

The invention provides a workpiece automatic machining system and a grinding method of the surface of a workpiece, and belongs to the technical field of machines. The problems that an existing grinding polishing machine is not unified in machining precision and not uniform in workpiece forming are solved. The workpiece automatic machining system comprises a machining center which conducts machining work on the workpiece, and further comprises a grinding unit which is adjacent to the machining center. The grinding unit is provided with a mechanical arm and a plurality of grinding machines, and the mechanical arm can clamp and convey the workpiece which has been machined at the machining center to the grinding machines to be ground. The workpiece automatic machining system and the grinding method of the surface of the workpiece have the advantages of being high in automatic degree, good in uniformity of workpiece forming, high in grinding precision and the like.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

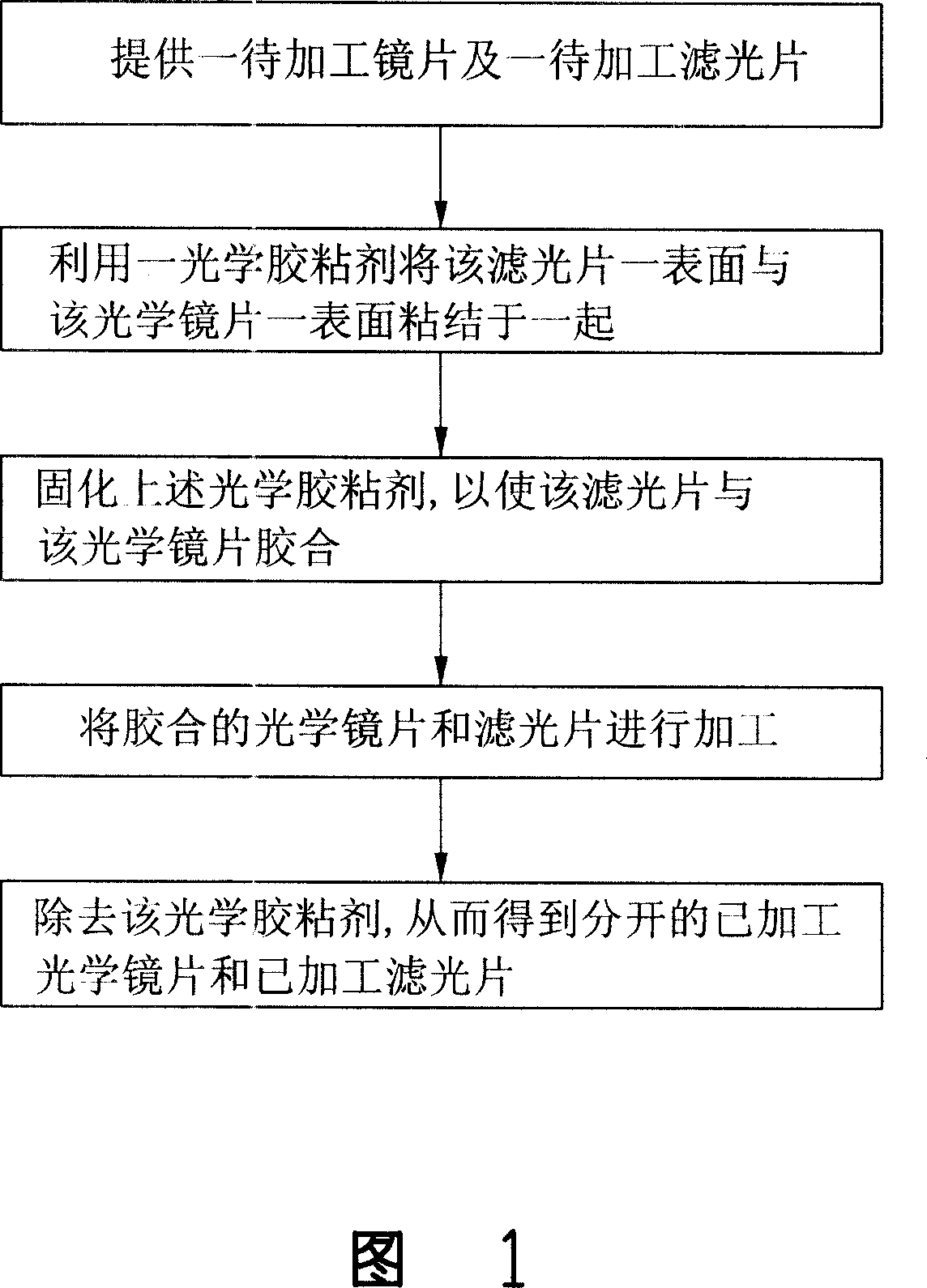

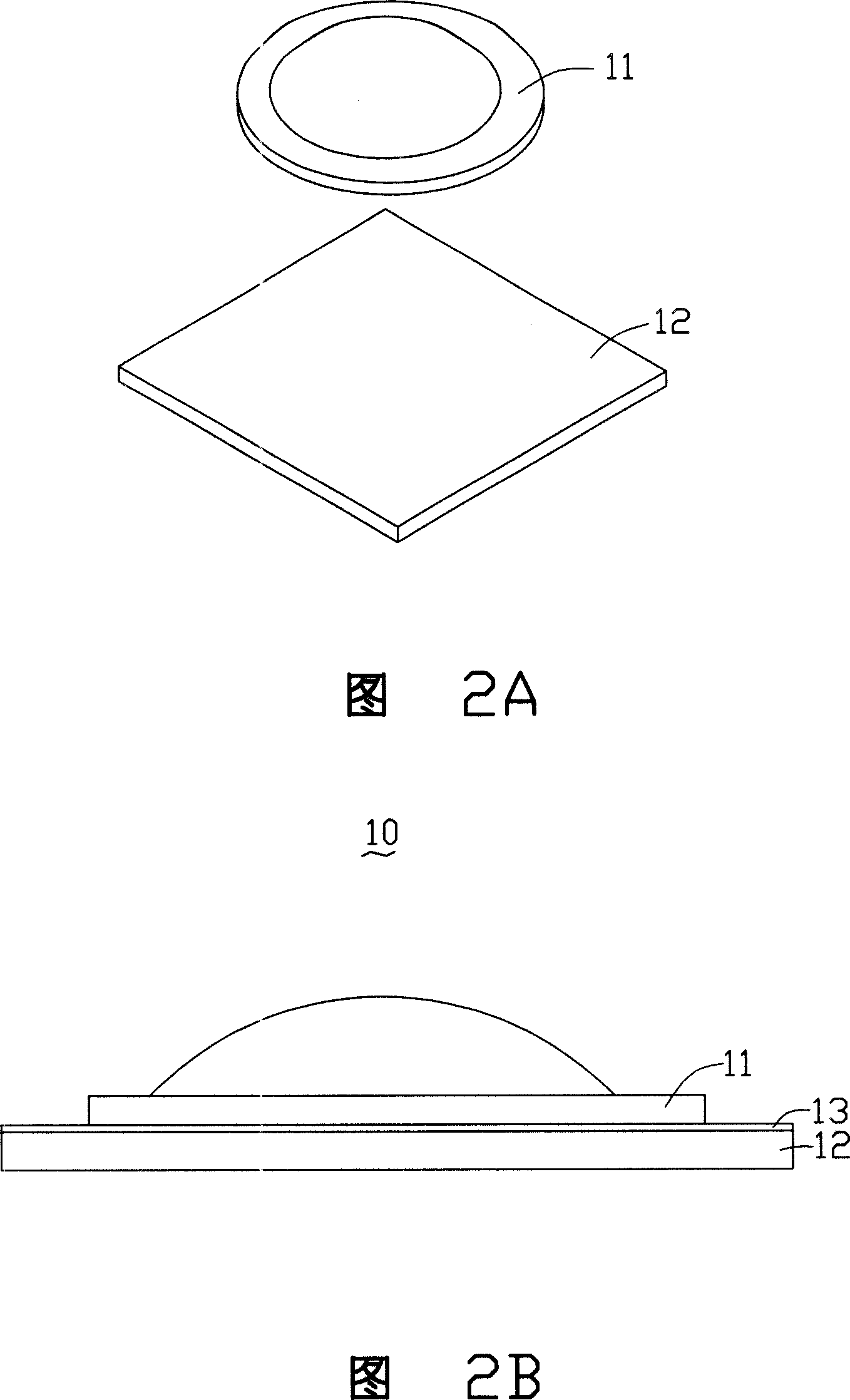

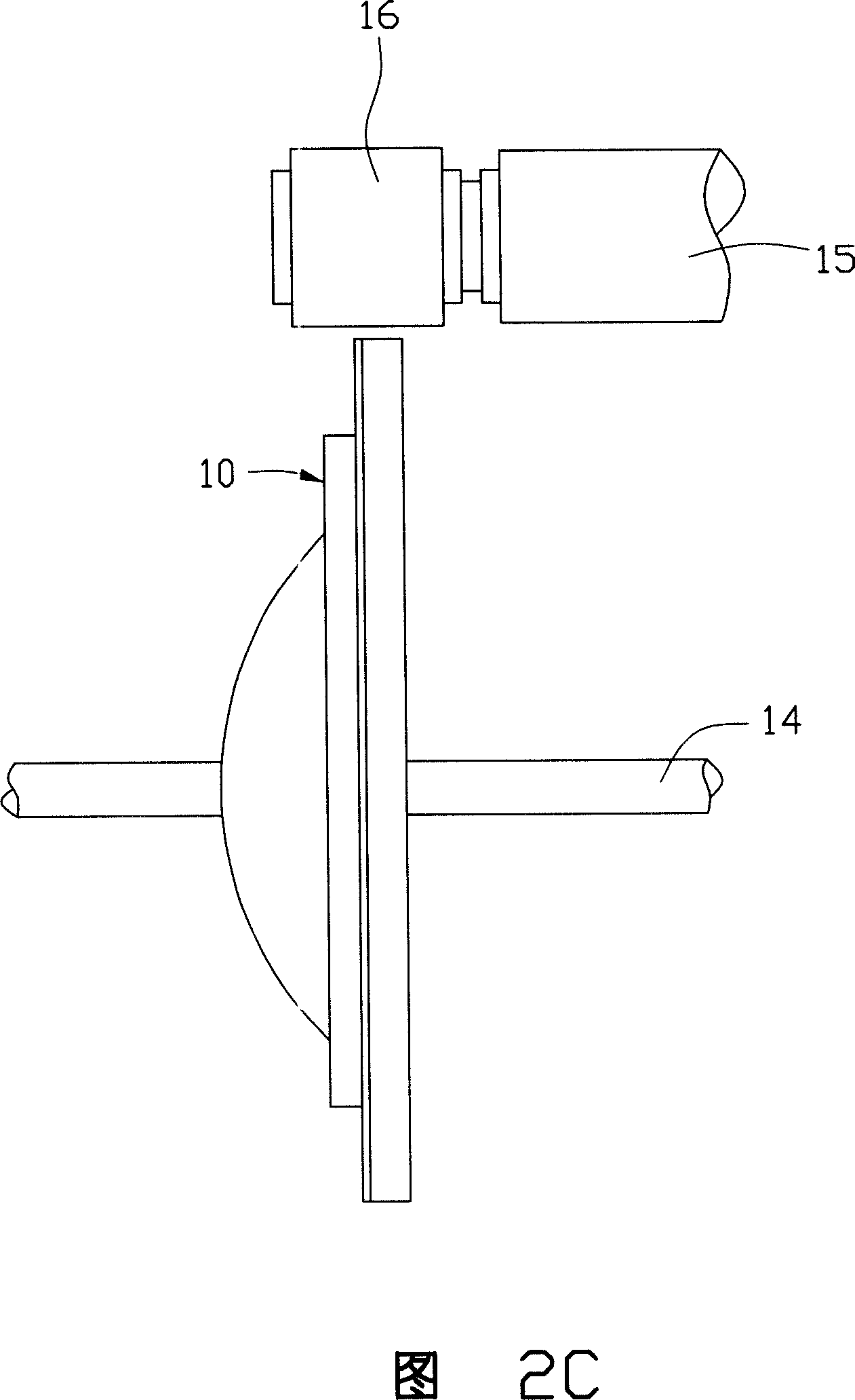

Method for manufacturing optical element

InactiveCN101144879AConsistent machining accuracyImprove assembly accuracyEdge grinding machinesGlass severing apparatusLight filterLens plate

The present invention provides an optical component processing method, and includes the following procedures: providing an optical lens needing to be processed and a light filtering piece needing to be processed, using an optical adhesive to bond a surface of the light filtering piece and a surface of the optical lens together; solidifying the above optical adhesive to bond the light filtering piece and the optical lens together; processing the bonded optical lens and the light filtering piece; removing the optical adhesive and then obtaining the processed optical lens and the processed light filtering piece which are separated. In the technical proposal, the processing precisions of the optical lens and the light filtering piece are essentially consistent, that can facilitate to improve the assembly precision, to reduce the production time, and to improve the yield.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

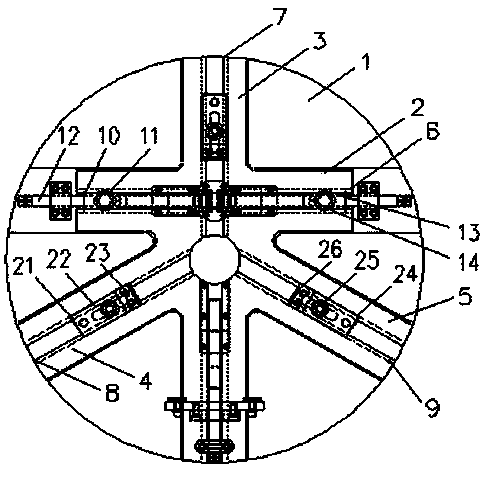

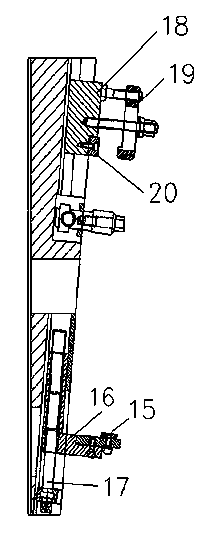

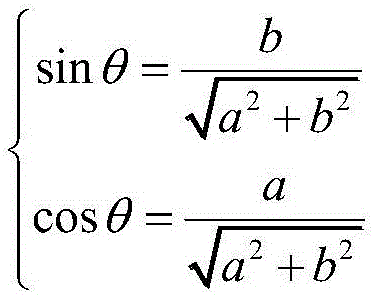

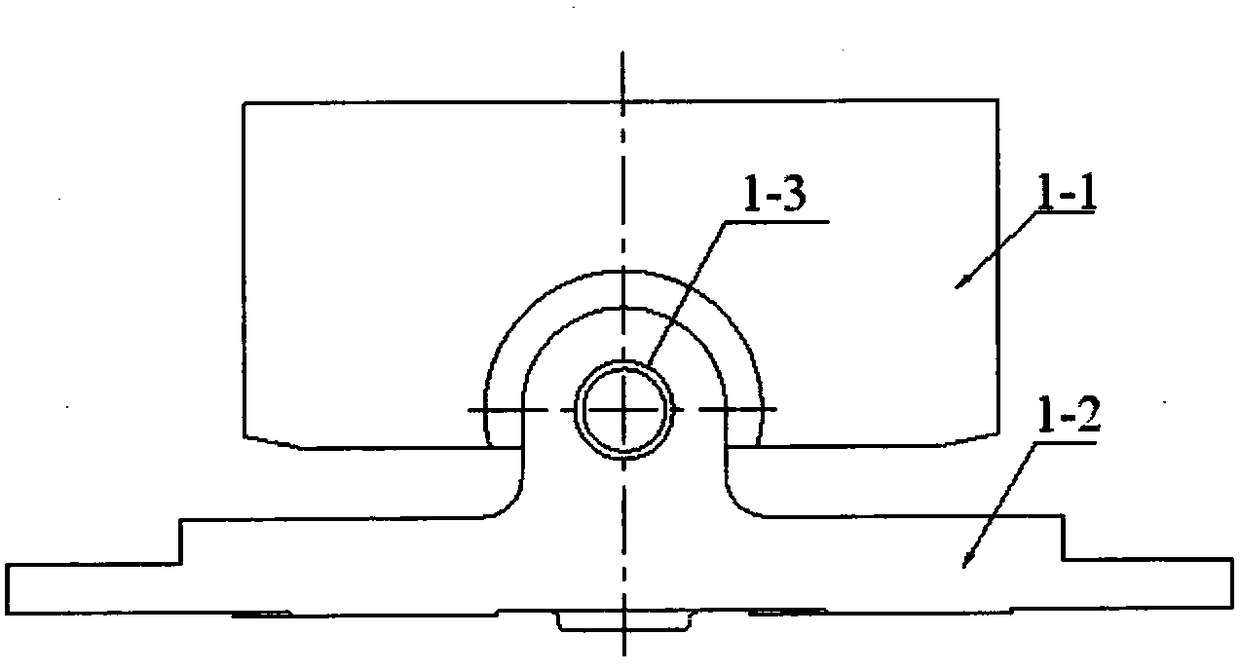

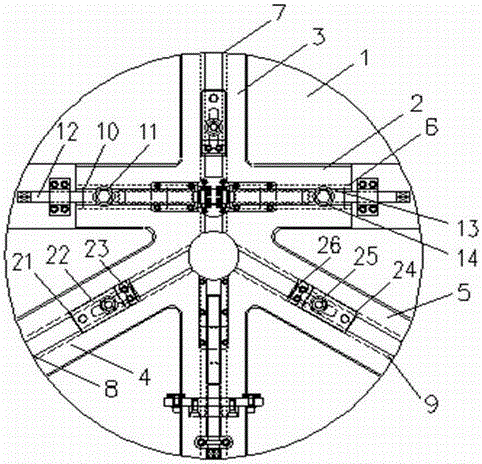

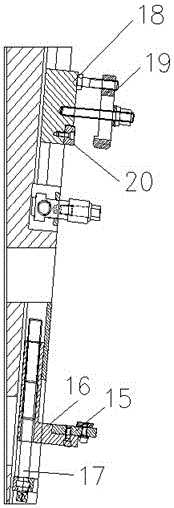

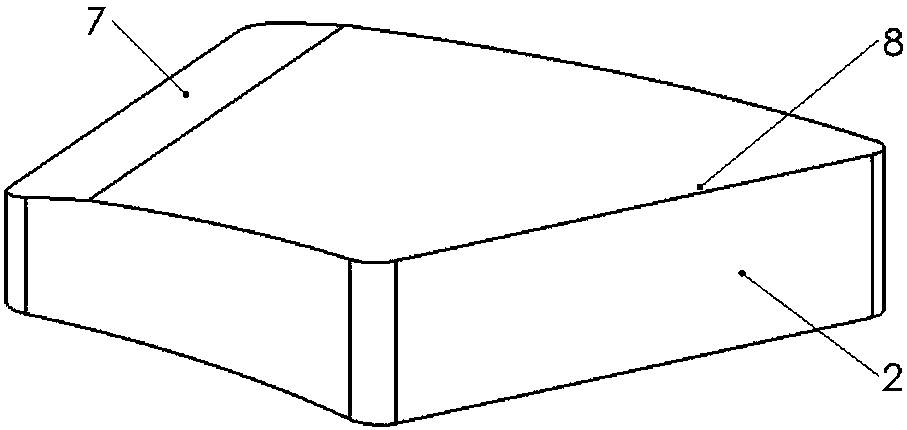

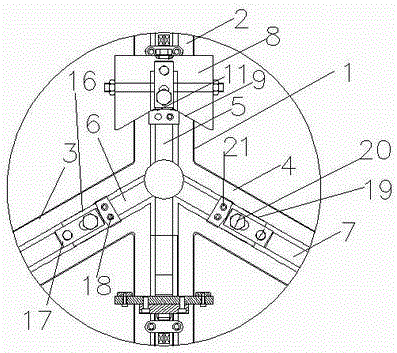

Universal fixture for sealing surface of valve body for vertical lathe and clamping method thereof

ActiveCN104209776AImprove versatilityExact symmetryWork clamping meansPositioning apparatusEngineeringSymmetric structure

The invention provides a universal fixture for a sealing surface of a valve body for a vertical lathe and a clamping method thereof. The universal fixture comprises a fixture body, wherein the included angle between the upper surface of the fixture body and the horizontal direction is 5 degrees, so that the consistency and accuracy of the angles of the processed sealing surfaces of the valve bodies of wedge gate valves or swing check valves are effectively ensured. The fixture body is of an axially symmetric structure, and such a structure can be used for overcoming the defects that fixtures in the prior art generally have poor universality for valve bodies of wedge gate valves or swing check valves which are different in size, specification and model, accurate symmetry of positions of two opposite valve body sealing surfaces is difficult to ensure, the consistency and accuracy of angles of the valve body sealing surfaces are difficult to ensure and the assembly and disassembly of the valve body of the wedge gate valve or the swing check valve is inconvenient.

Owner:NANTONG HIGH & HIGH PRESSURE VALVE CO LTD

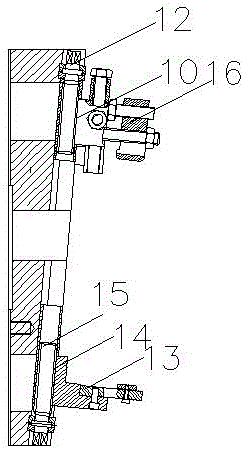

Universal valve body sealing surface clamp for horizontal machine tool and clamping method of universal valve body sealing surface clamp

ActiveCN104259907AImprove versatilityExact symmetryWork clamping meansPositioning apparatusEngineeringCheck valve

The invention relates to a universal valve body sealing surface clamp for a horizontal machine tool and a clamping method of the universal valve body sealing surface clamp. The universal valve body sealing surface clamp for the horizontal machine tool comprises a clamp body adopting an axisymmetric structure, and is connected with the spindle of the horizontal machine tool; and a 5-degree included angle is formed between the universal valve body sealing surface clamp and the vertical direction. Such a structure avoids the defect that a clamp in the prior art generally has poor universality for the valve bodies of wedge gate valves or swing check valves of various sizes, specifications and models, can hardly ensure accurate symmetry of the positions of two opposite valve body sealing surfaces and the consistency and accuracy of the angles of the valve body sealing surfaces, and cannot load and unload the valve bodies of wedge gate valves or swing check valves conveniently.

Owner:NANTONG HIGH & HIGH PRESSURE VALVE CO LTD

Ferrule perforation method

ActiveCN102335774AImprove efficiencyReduce defective productsAutomatic control devicesFeeding apparatusElectrical controlProcessing accuracy

The invention discloses a ferrule perforation method, belonging to a machining method. The traditional operation of perforating a ferrule is finished manually, which has the disadvantages of low efficiency, more inferior-quality products and inconsistent machining precision. The ferrule perforation method is characterized in that a feed channel conveys a ferrule to a material supporting rack; an electrical control system controls a clamping device to move to a backer, the electrical control system and the backer oppositely clamp two end surfaces of the ferrule on the material supporting rack so as to clamp the ferrule on a perforation workstation; electrical control system controls a perforation device to feed to radially perforate the ferrule on the punching workstation; and after the operation of perforation is finished, the electrical control system controls the perforation device to retract, the clamping device is reset, and a charging ram pushes down processed ferrule from the material supporting rack. With the ferrule perforation method, equipment replaces manpower to machine the ferrule, the electrical control system control equipment to work, efficiency is improved, inferior-quality products are reduced, and machining precision is guaranteed to be consistent.

Owner:XINCHANG JINCHENG PML PRECISIION MECHANISM CO LTD

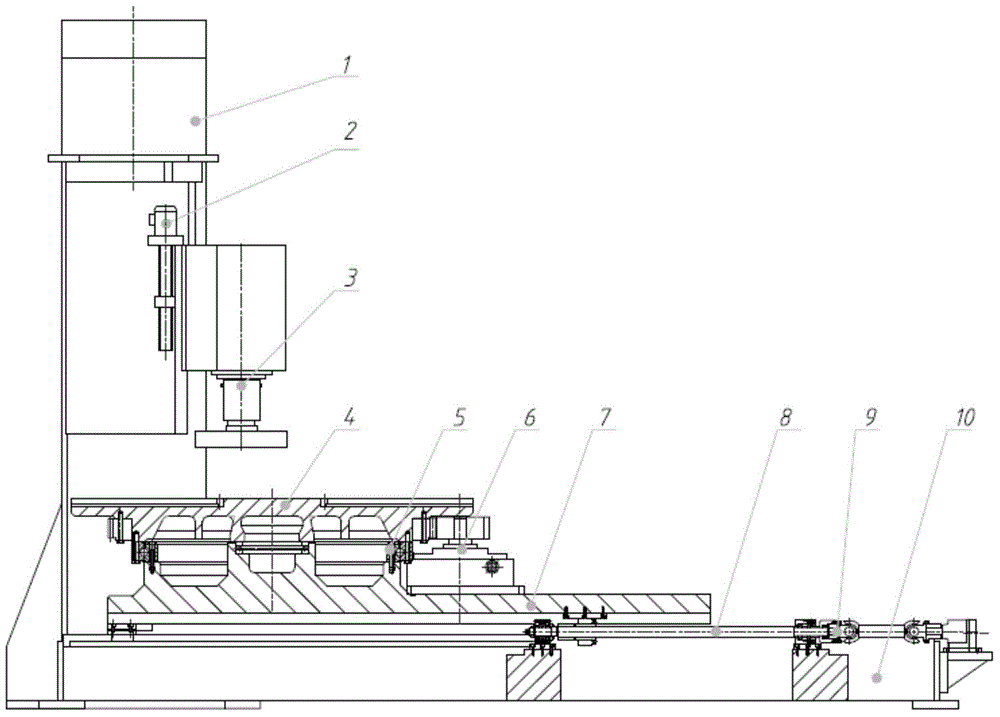

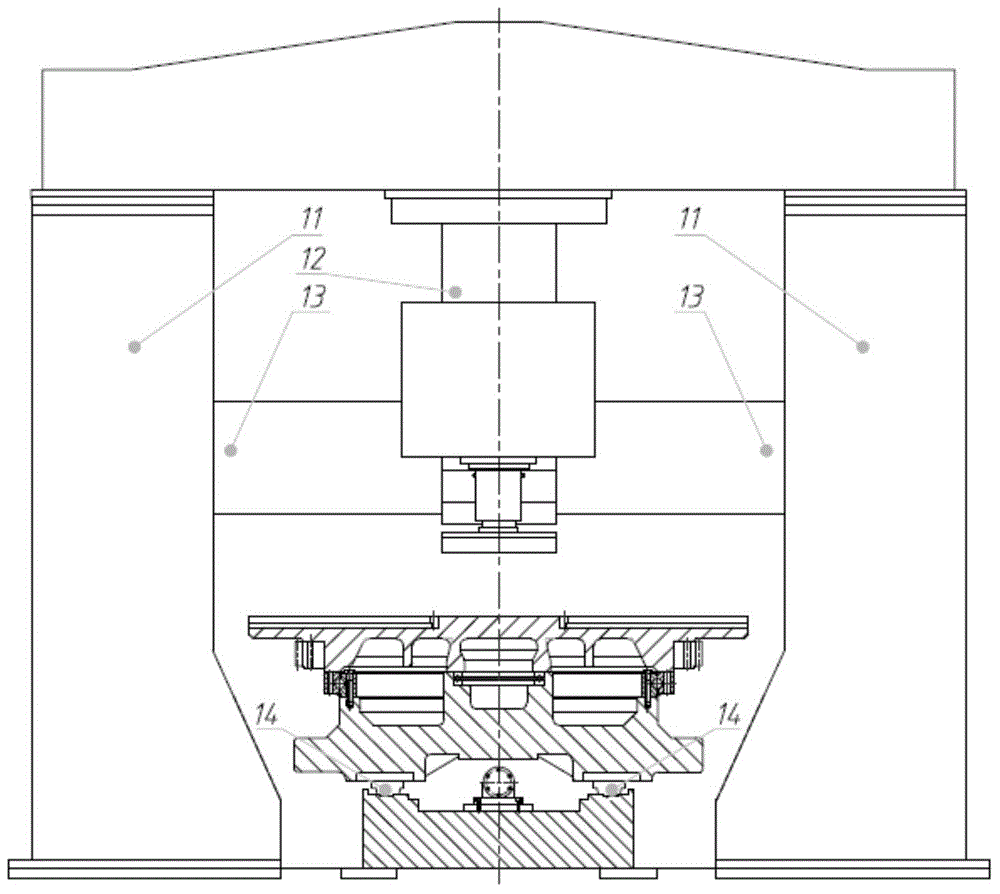

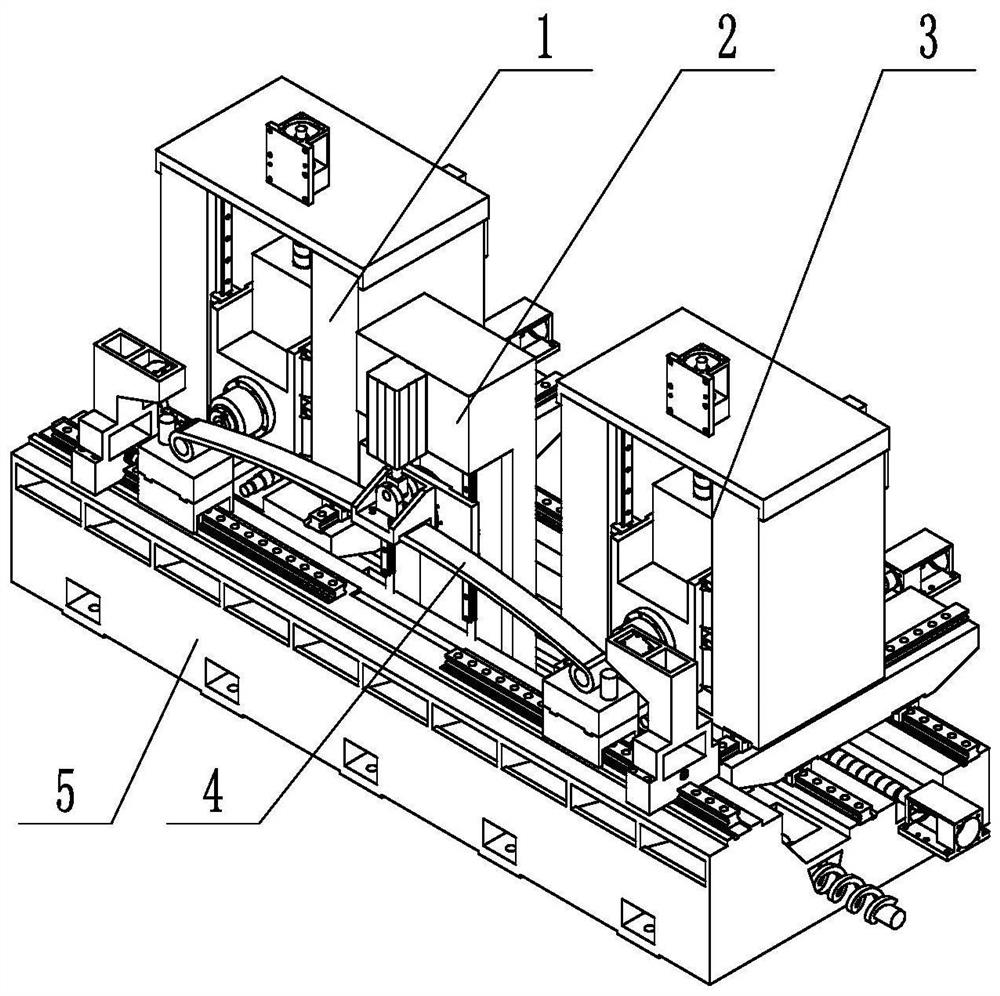

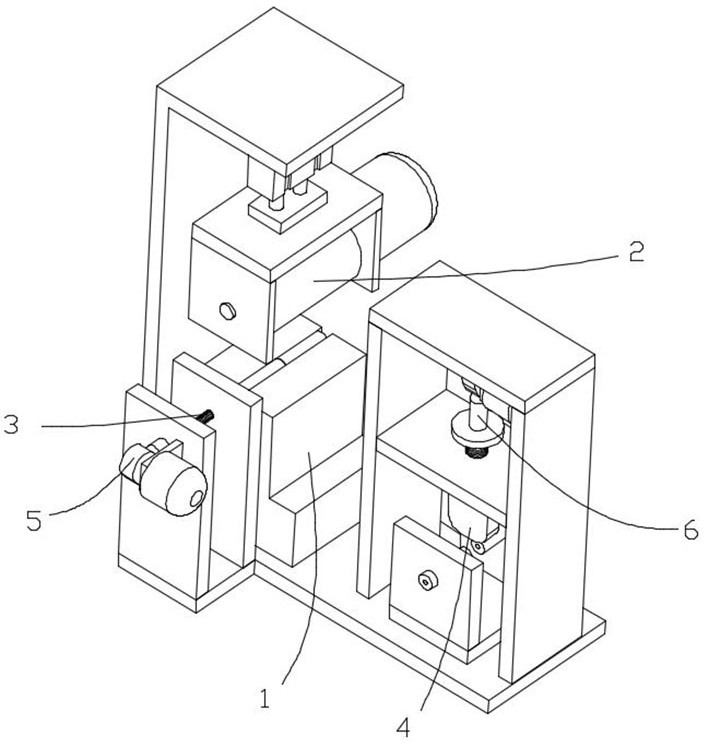

Constant linear velocity gantry vertical-spindle grinding machine with round table

InactiveCN105215814AImprove stabilityExpand the range of grinding operationsGrinding drivesGrinding machinesConstant linear velocityRound table

The invention relates to a constant linear velocity gantry vertical-spindle grinding machine with a round table. The constant linear velocity gantry vertical-spindle grinding machine with the round table comprises a gantry transverse beam (1), a Z-axis servo feed system (2), a grinding head (3), a rotary working table (4), a rotary support (5), a rotary table servo power system (6), a sliding way table (7), ball screws (8), an X-axis servo feed power system (9), a base (10), gantry stand columns (11), an upright sliding way (12), reinforcing ribs (13) and a linear guideway (14). According to the constant linear velocity gantry vertical-spindle grinding machine with the round table, a gantry structure is adopted, the stability of the vertical-spindle grinding machine with the round table is improved, and the abrasive machining range of the grinding machine with the round table is enlarged. Besides, the constant linear velocity gantry vertical-spindle grinding machine with the round table can achieve constant linear velocity grinding, and machining accuracy and ground patterns of the machined surface of a rotary workpiece can maintain consistent.

Owner:YANTAI SHANGWAY MACHINE TOOL MFG CO LTD

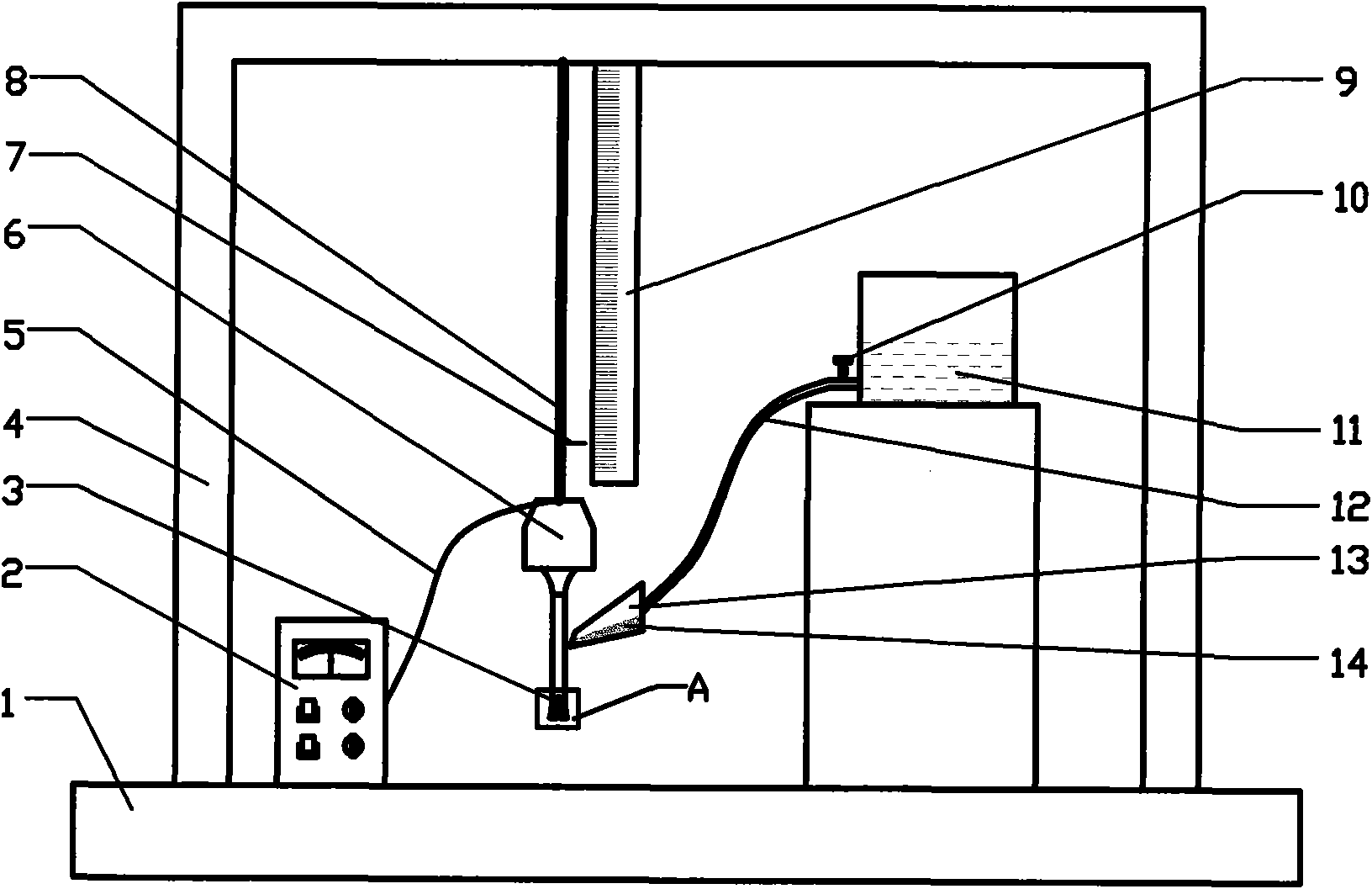

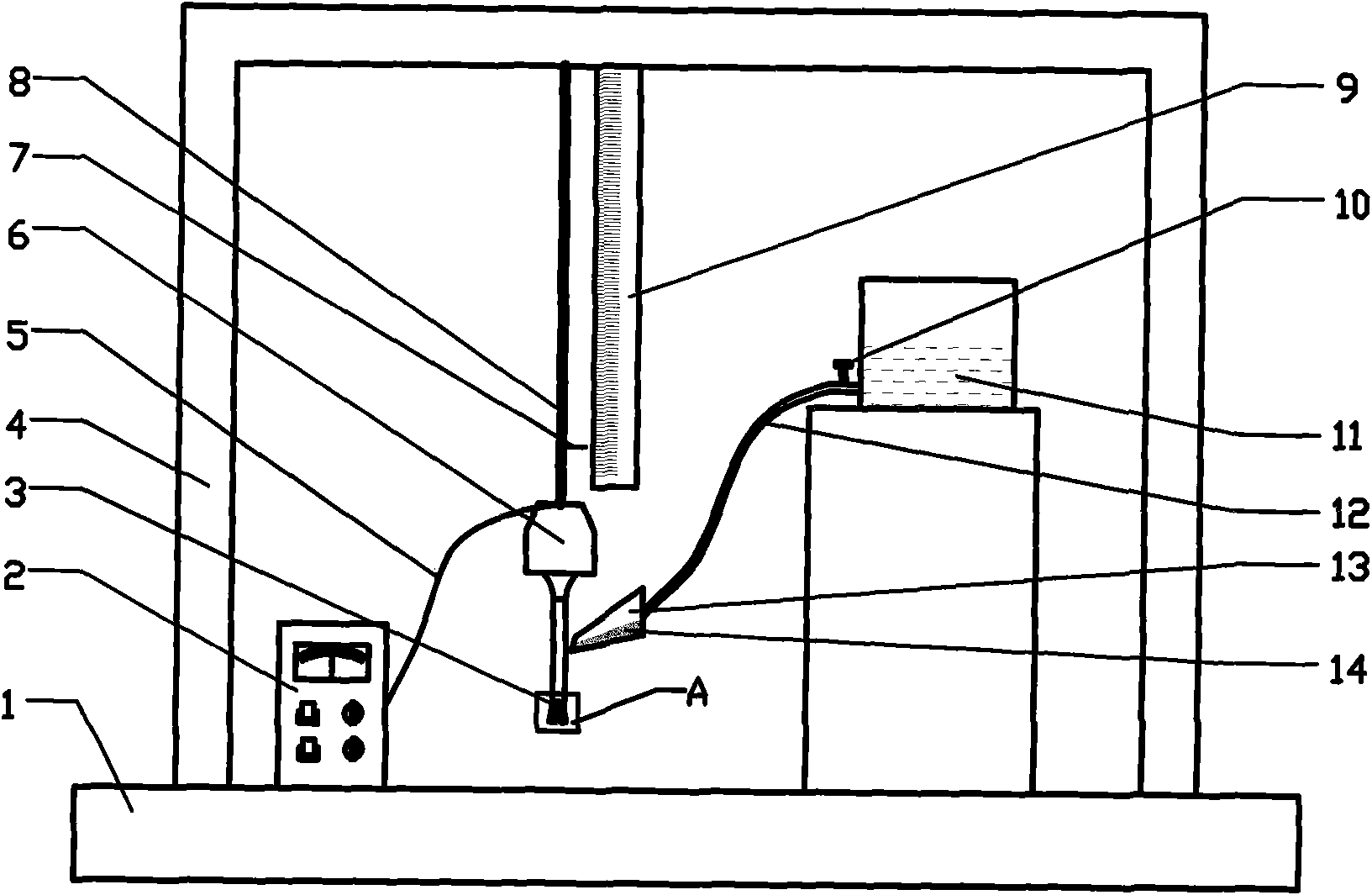

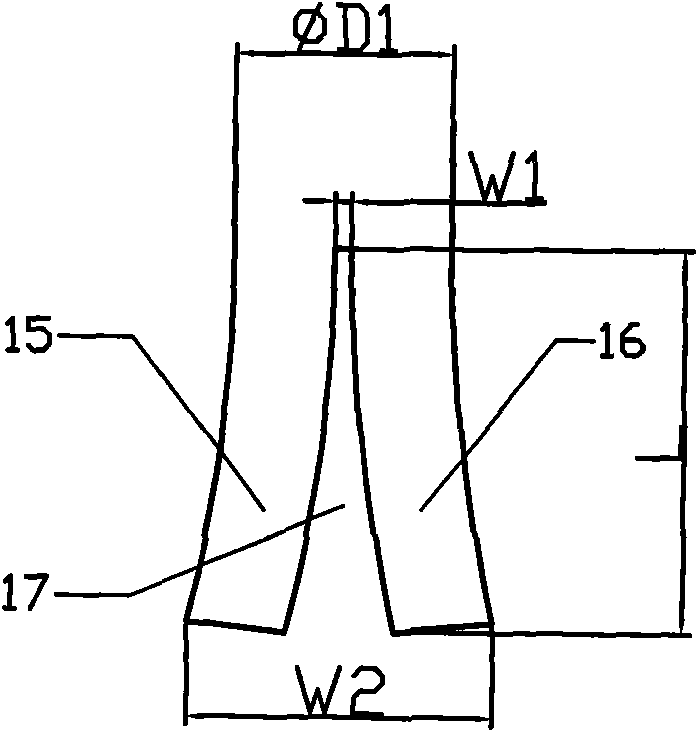

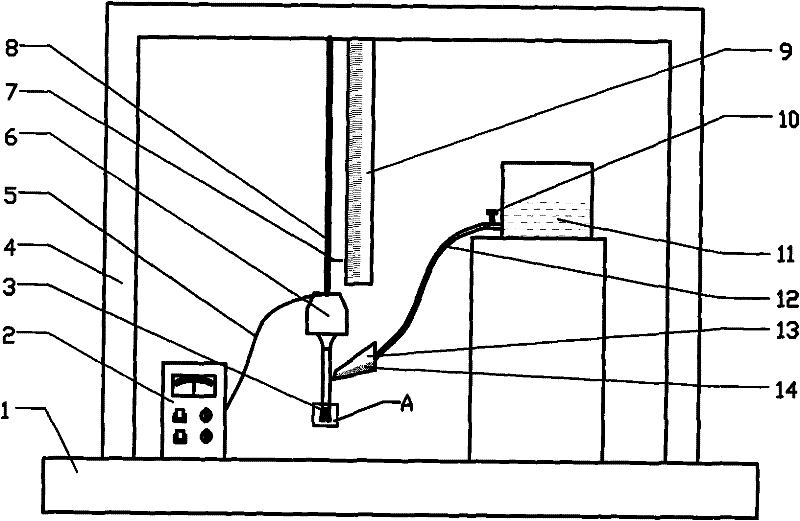

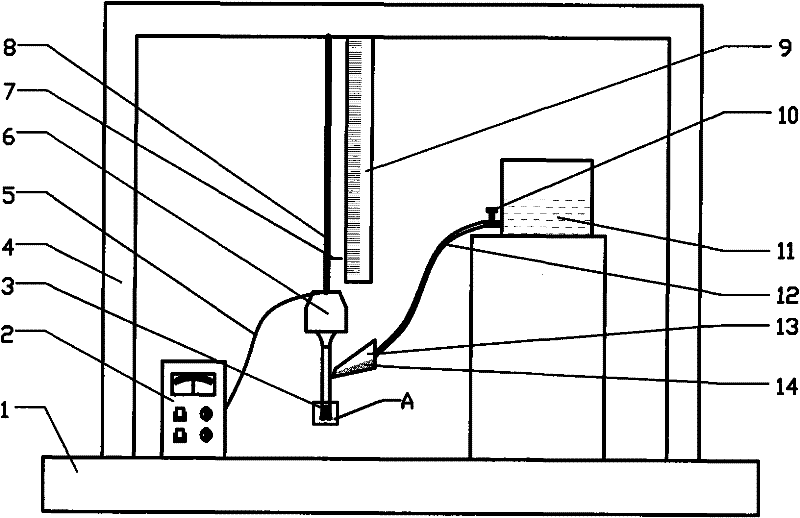

Small-size hand-hold deep small hole composite deburring device

InactiveCN101811279AImprove surface qualityEliminate processing marksEdge grinding machinesRevolution surface grinding machinesHand heldMiniaturization

The invention relates to a small-size hand-hold deep small hole composite deburring device used for complicated case parts, which belongs to a mechanical processing tool. The deburring device comprises a work table, a fixed support frame, a vibration generator and a vibration converter provided with a deburring tool, wherein the fixed support frame and the vibration generator are arranged on the work table, the vibration converter with the deburring tool is arranged on the fixed support frame through strip steel, he vibration converter with the deburring tool is connected with the vibration generator, a micro powder grinding container is arranged on the work table, a water container is higher than the micro powder grinding container and is arranged on the work table, the deburring tool is connected with the vibration converter, the deburring tool is a cylindrical slender metal rod, the center of the front end of the metal rod is provided with a penetrated open rectangular groove with the width between 0.25 mm and 0.3 mm, and the depth of the rectangular groove is 3 to 5 times of the diameters of the metal rod. The invention is applicable to the deburring of deep small holes with the length-to-diameter ratio greater than 40 and the diameter phi smaller than 3 mm, and the processing efficiency is improved by more than 50 to 70 percent.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

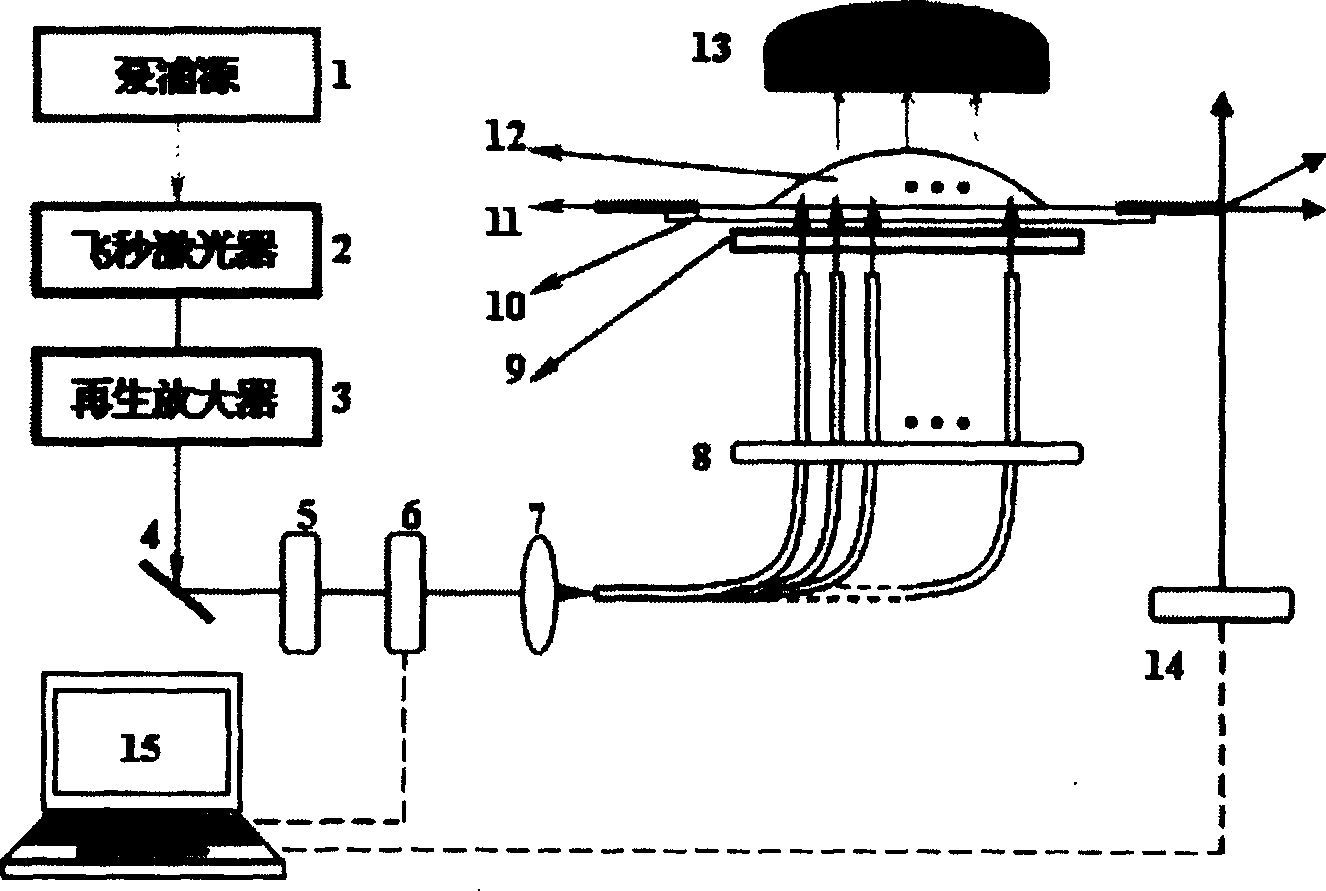

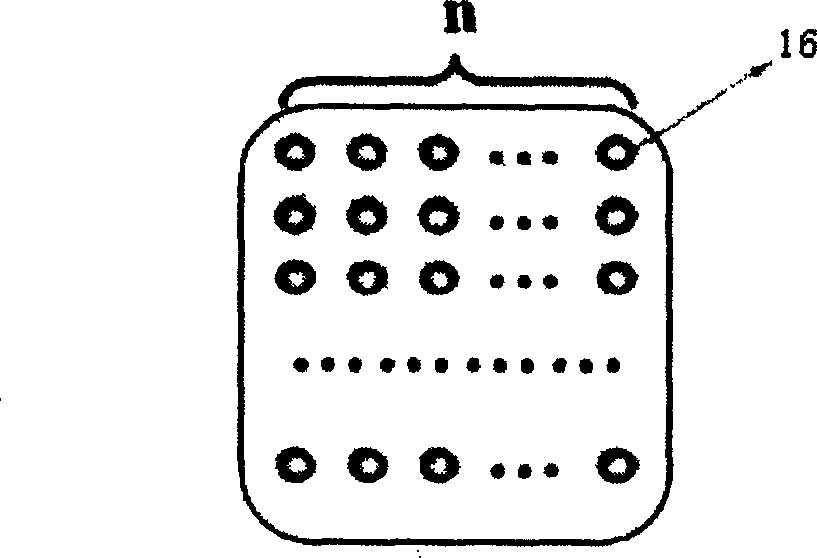

Parallel Fs laser double photon photopolymerization micro-nano processing method and apparatus thereof

InactiveCN100392514CMass productionHigh processing resolutionNon-linear opticsFemto second laserFiber array

The present invention relates to a parallel femtosecond laser two-photon photopolymerization micron nano processing method and its equipment. Said equipment includes the following several portions: pump laser, femtosecond laser, resonant cavity, amplifier, reflecting mirror, attenuator, optical gate, fibre-optic coupler, microlens array, three-dimensional scanning platform and its driven and computer control system. Said invention also provides the concrete steps of its processing method.

Owner:JIANGSU UNIV

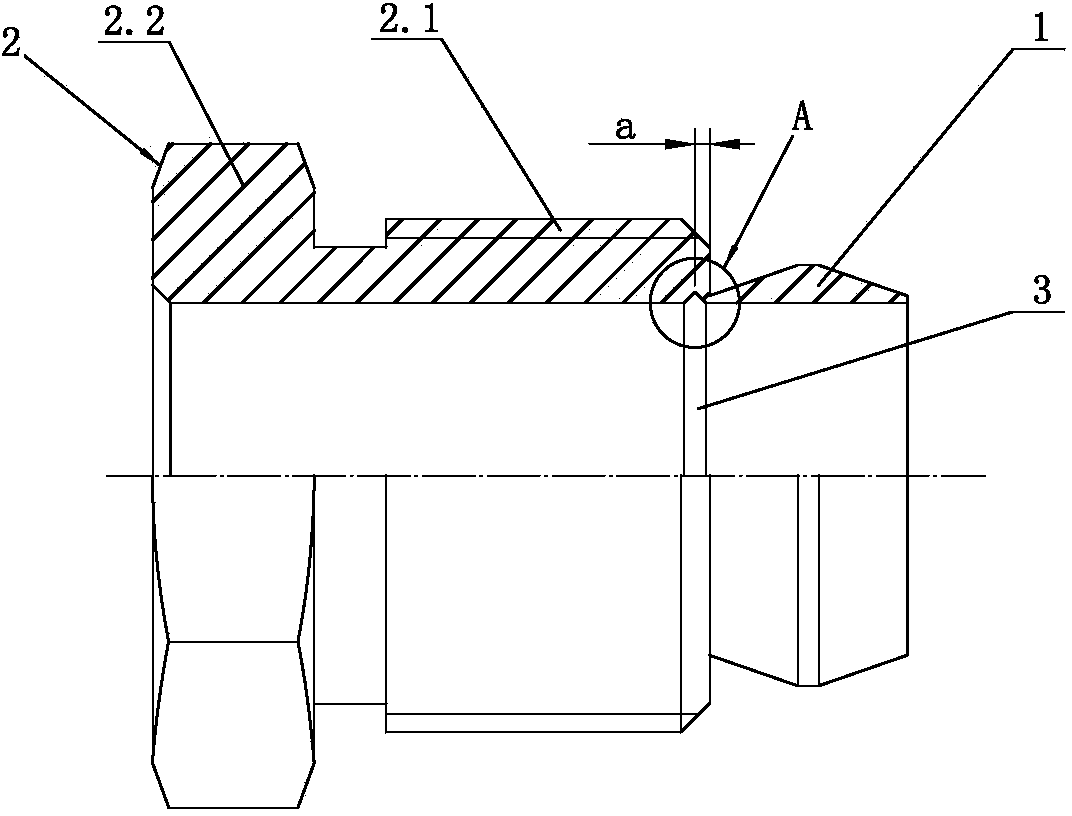

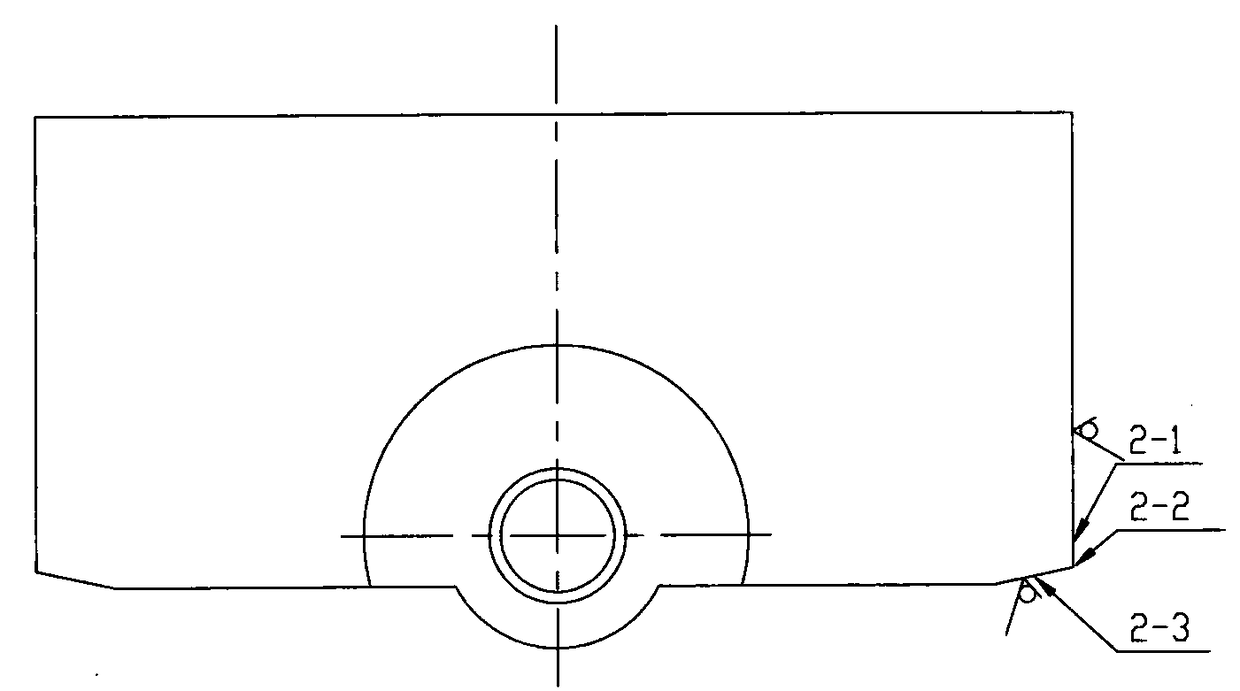

Integral ferrule joint

InactiveCN104075053ALess prone to lossImprove reliabilityScrew threaded jointsEngineeringBiomedical engineering

The invention discloses an integral ferrule joint. The integral ferrule joint comprises a ferrule (1) and a pressing cap (2), wherein the pressing cap (2) is partitioned into a threaded portion (2.1) and a spanner clamping portion (2.2); the ferrule (1) is connected to the threaded portion (2.1) and far away from the end of the spanner clamping portion (2.2); the axis of the ferrule (1) and the axis of the threaded portion (2.1) are on the same straight line, and the ferrule (1) is integrated with the threaded portion (2.1); the cross section of the ferrule (1) has a trapezoidal structure, and the inner surface of the ferrule (1) corresponds to the lower side of the trapezoidal structure. Compared with the prior art, the integral ferrule joint has the characteristics of prevention of losing since the pressing cap and the ferrule can be placed and carried as an integral structure, high mounting efficiency, high connecting reliability and prevention of leakage.

Owner:NINGBO WANAN

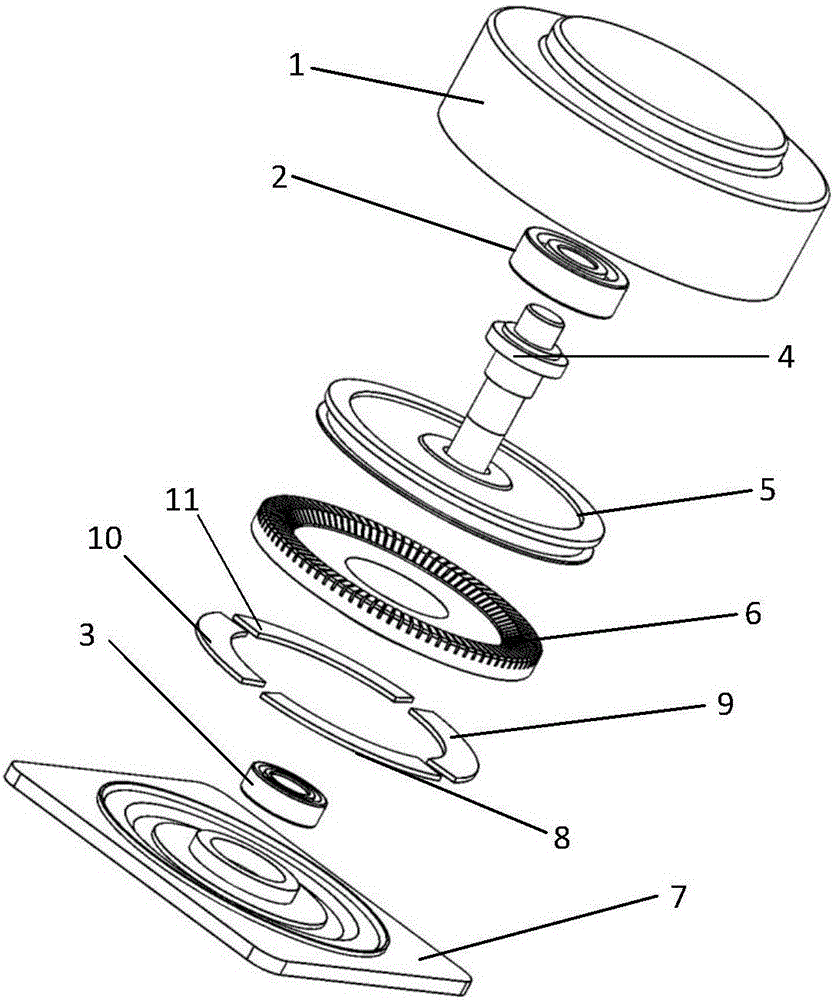

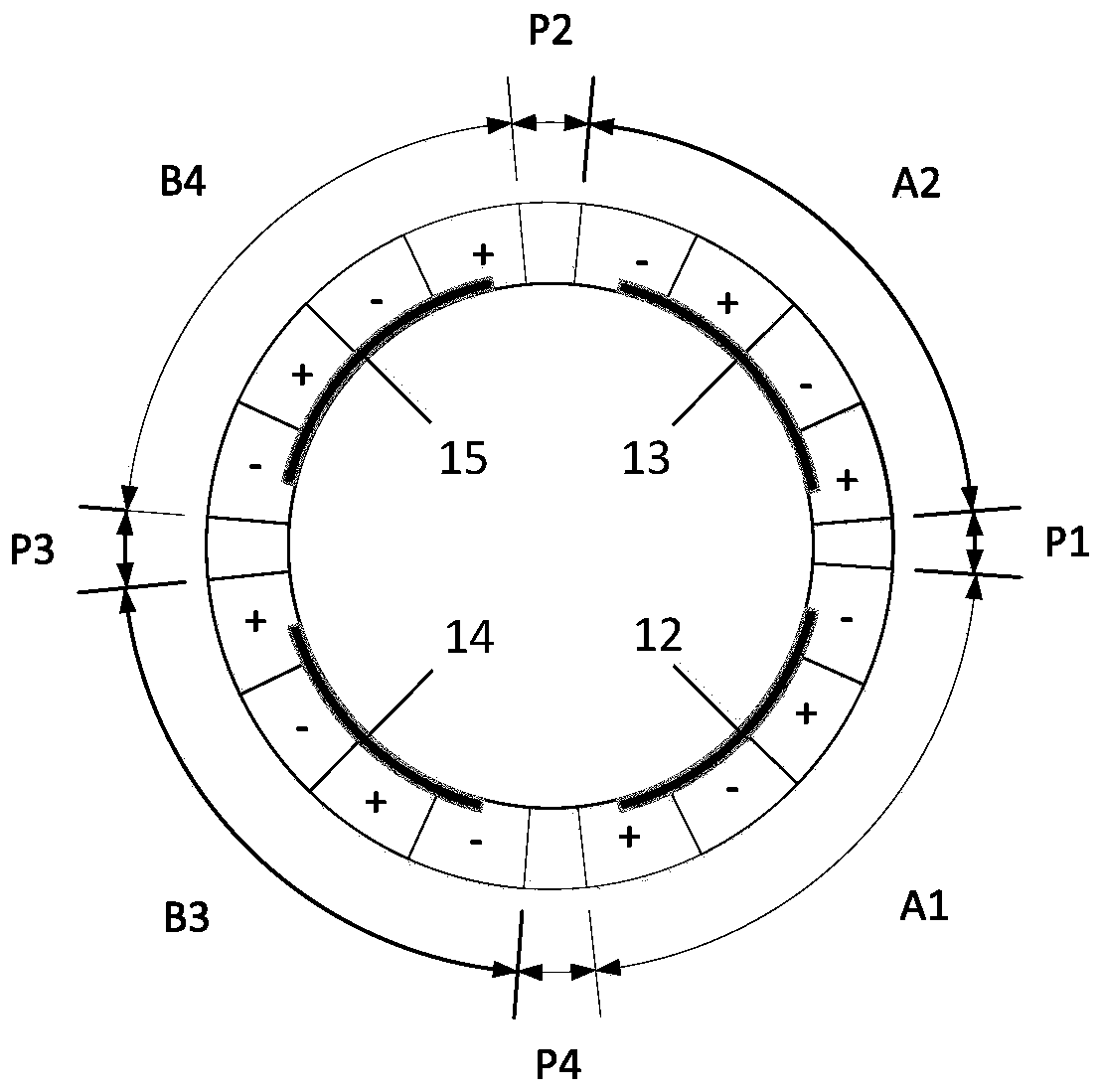

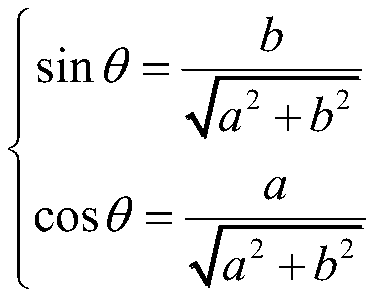

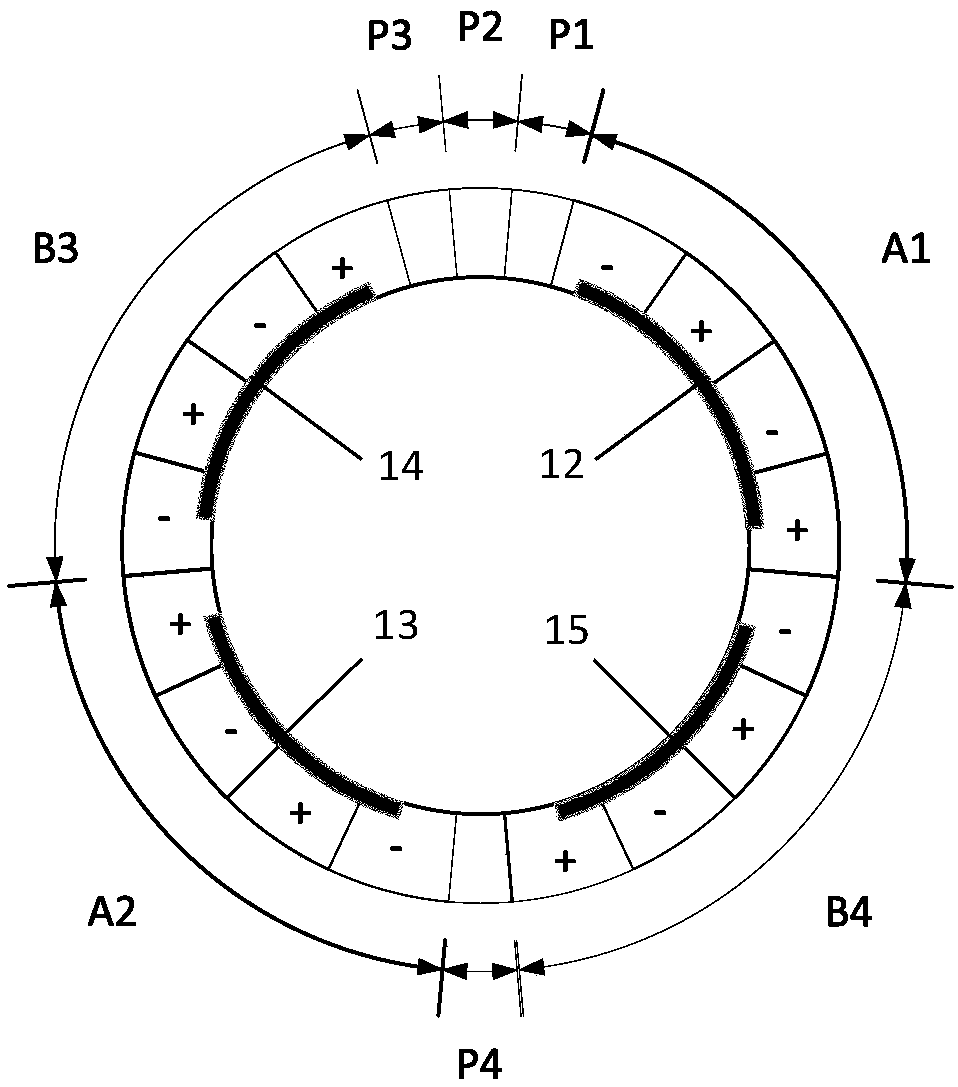

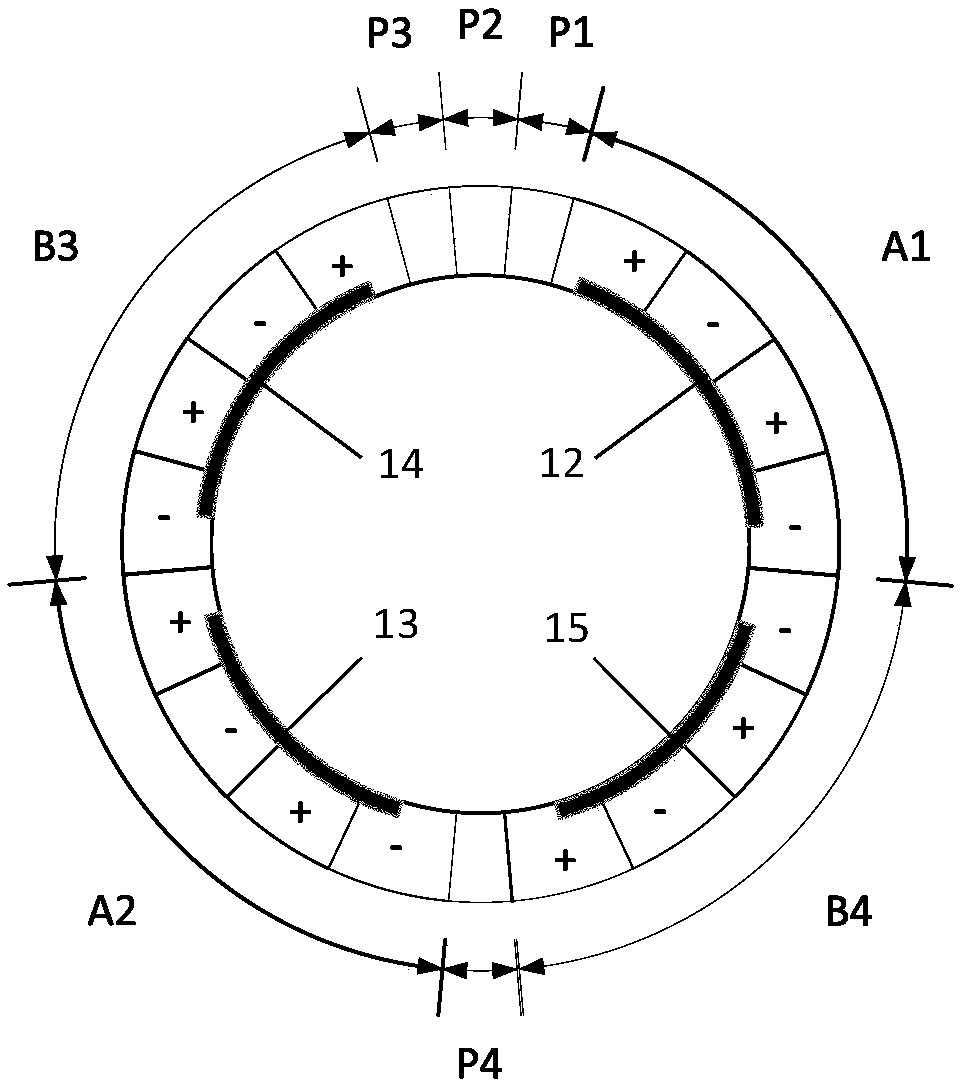

Space phase modulation toroidal traveling wave ultrasonic motor with symmetrical ceramic partitions and control method thereof

ActiveCN106533255AEasy wiringConsistent Ceramic Machining AccuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityLength wave

The invention provides a space phase modulation toroidal traveling wave ultrasonic motor with symmetrical ceramic partitions and a control method thereof. Piezoelectric ceramic comprises A1-area piezoelectric ceramic, A2-area piezoelectric ceramic, B3-area piezoelectric ceramic and B4-area piezoelectric ceramic. The ceramic partitions are successively arranged along the circumference in the space according to A1-area, A2-area, B4-area and B3-area piezoelectric ceramic. The ceramic partitions are spaced by quarter wavelength from each other. The ceramic in each area occupies two wavelengths in the space. The width of each polarization partition of the piezoelectric ceramic is half wavelength. In the counterclockwise direction, the polarization directions of the polarization partitions of the piezoelectric ceramic of any three areas are arranged in the order of +, -, + and -. The polarization directions of the polarization partitions of the piezoelectric ceramic of another area are arranged in the order of -, +, - and +. According to the invention, the motor has all functions and advantages of a space phase modulation toroidal traveling wave ultrasonic motor with a traditional subdivision ceramic structure; each polarization partition of the piezoelectric ceramic is wider; all polarization partitions of the piezoelectric ceramic in each area are spatially continuous; and the processing and production are more convenient and accurate.

Owner:NANJING INST OF TECH

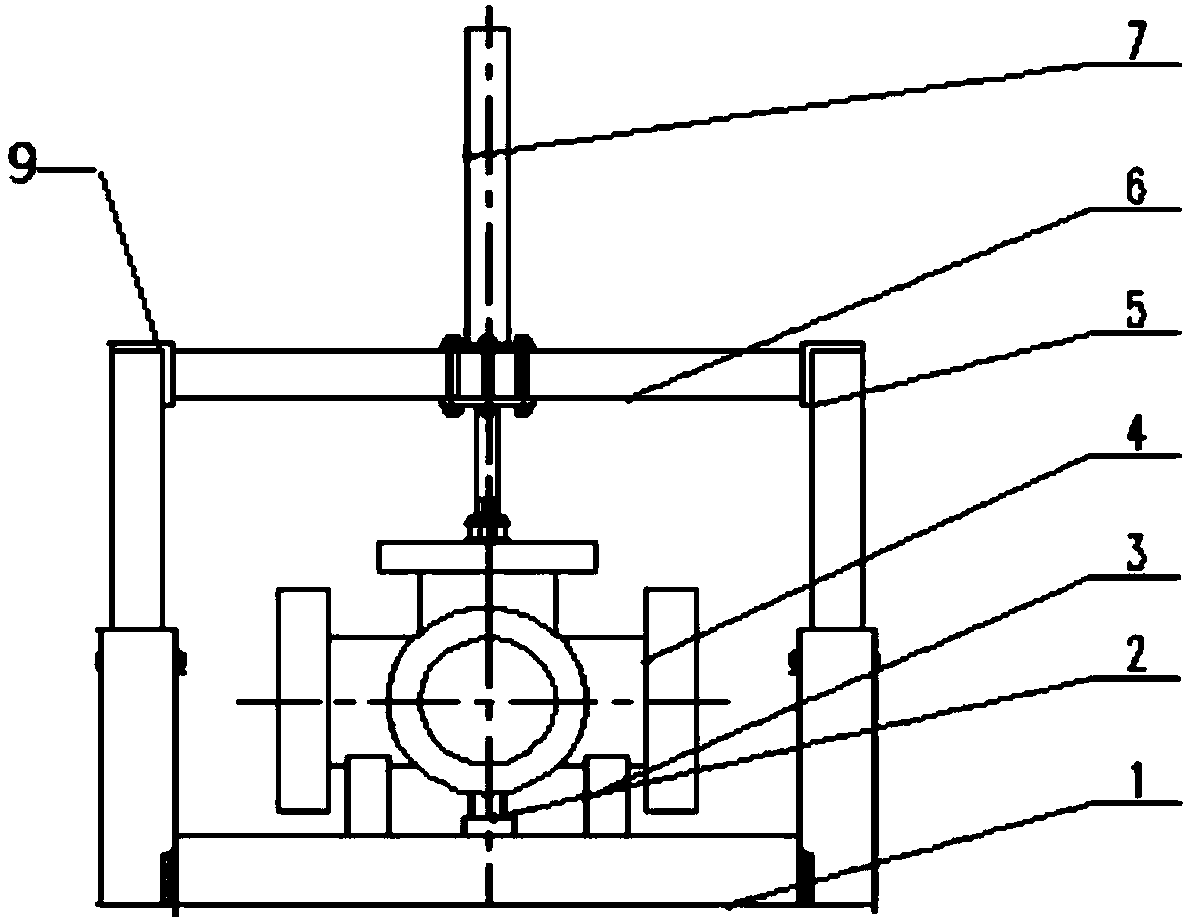

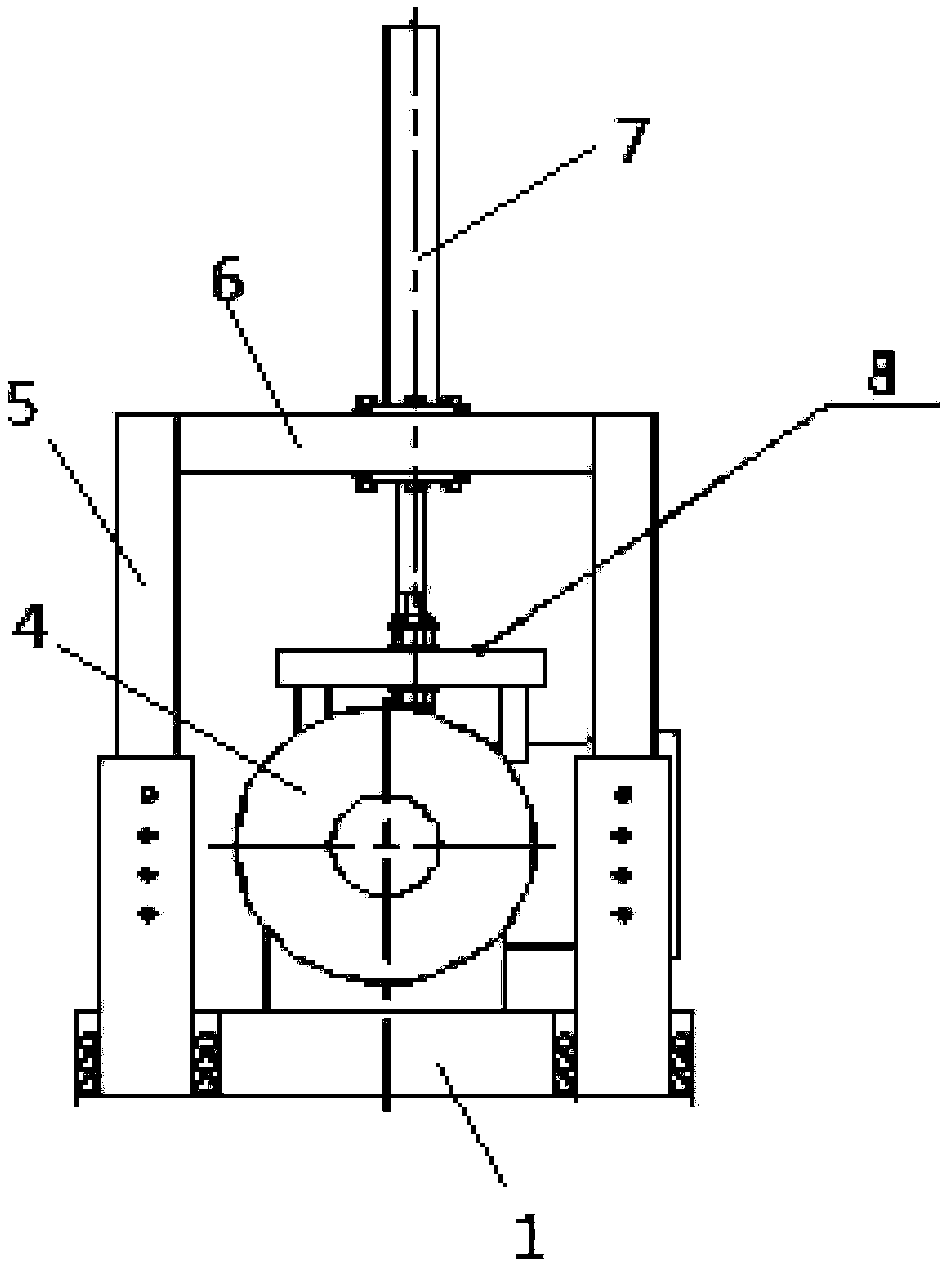

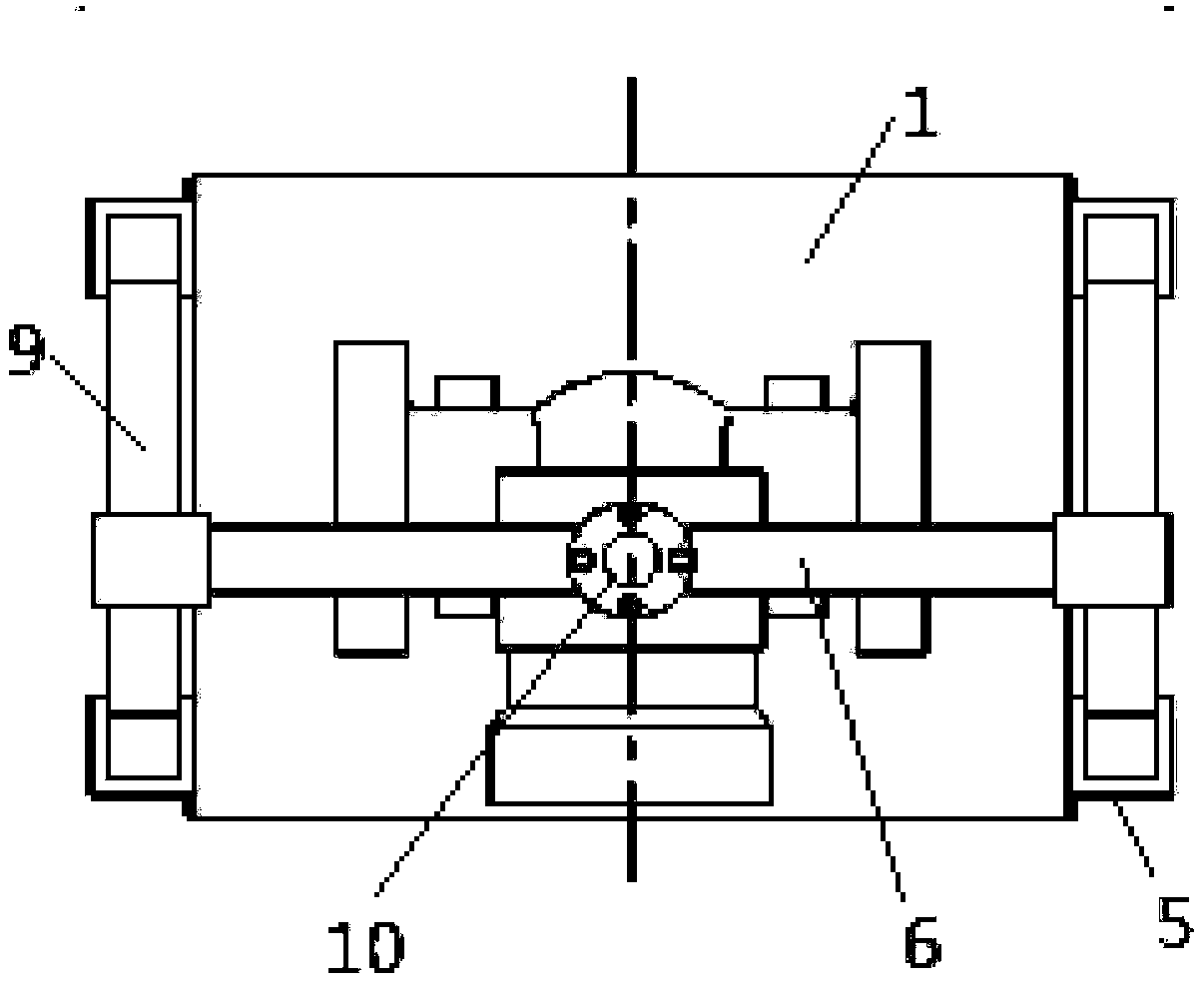

Fast clamping device for valve machining

PendingCN107685238AGuaranteed machining accuracyGuaranteed positioning accuracyLarge fixed membersPositioning apparatusHydraulic cylinderEngineering

The invention discloses a fast clamping device for valve machining. The device comprises a machine tool table, a jack is fixedly connected to the middle portion of the upper side of the machine tool table, a first V-shaped iron part is fixedly connected to the top of the jack, and a machined valve is placed on the first V-shaped iron part; vertical square steel bars are fixedly connected to the periphery of the machine tool table, guiding rails are arranged between the front and rear vertical square steel bars respectively, a horizontal square steel bar is arranged between the two guiding rails, a hydraulic oil cylinder is fixedly connected to the middle portion of the horizontal square steel bar, and a second V-shaped iron part is fixedly connected to the lower end of the hydraulic oil cylinder. The device has the advantages that 1, the machining precision of the valve can be stably guaranteed, by means of the fast clamping device, the valve is clamped, the position precision of the valve relative to a tool and a machine tool is guaranteed by a clamp, and the machining precision of the same valve or a same batch of valves is basically the same; 2, the working efficiency is improved, and fast and convenient clamping can be conducted by the fast clamping device, so that clamping labor-hour of the valve is significantly reduced.

Owner:LANZHOU HIGH PRESSURE VALVE

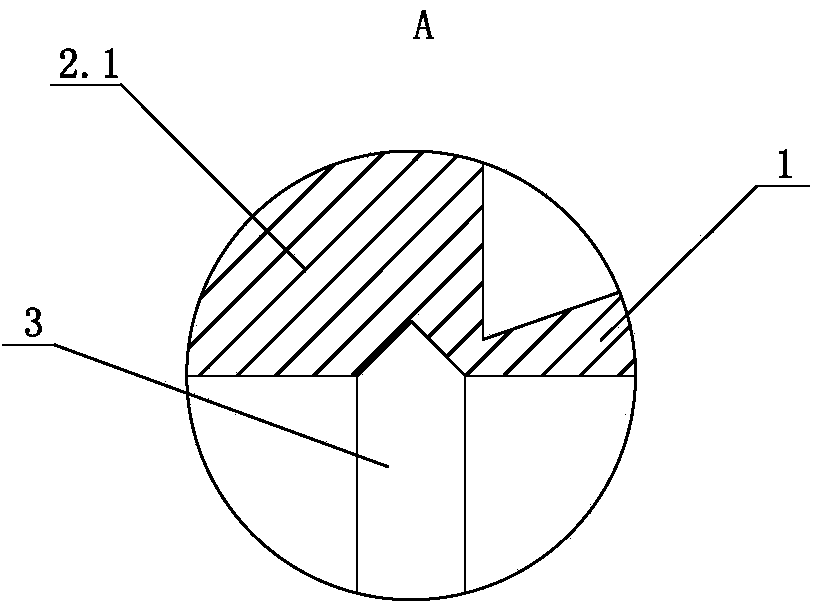

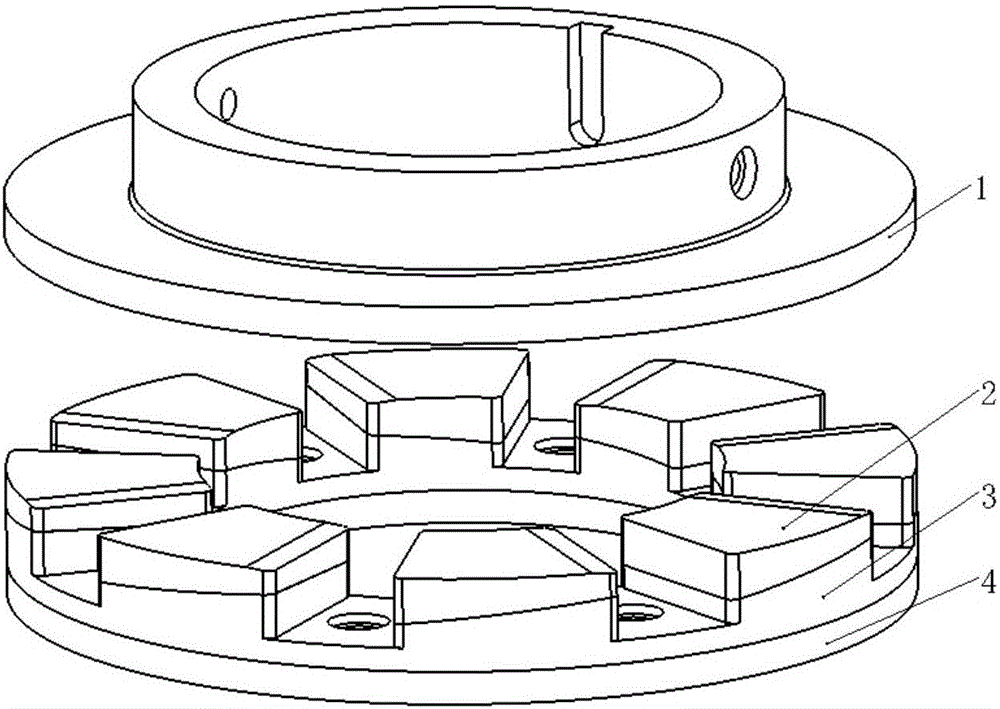

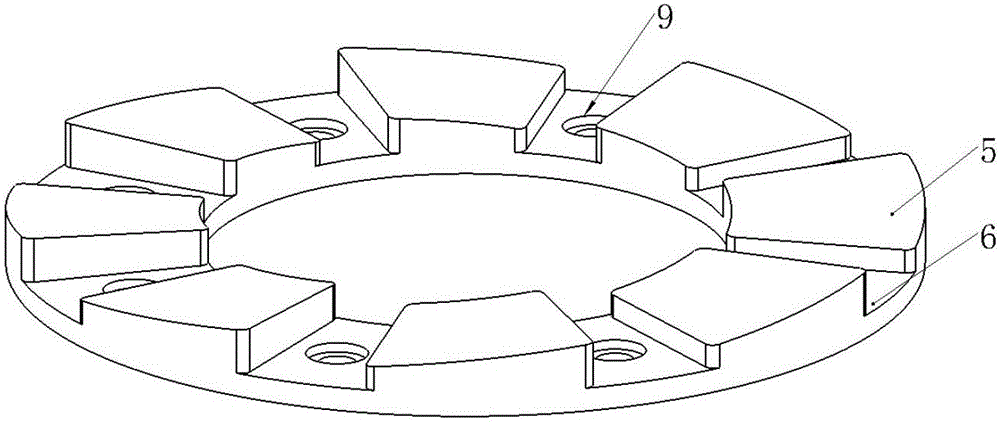

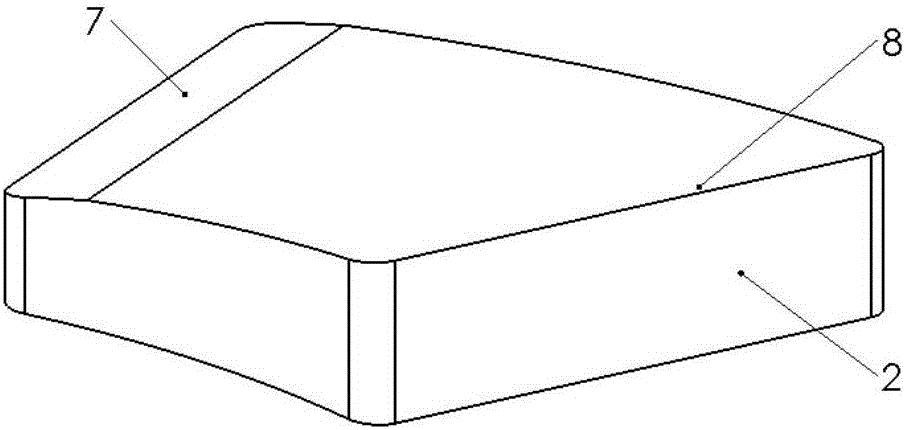

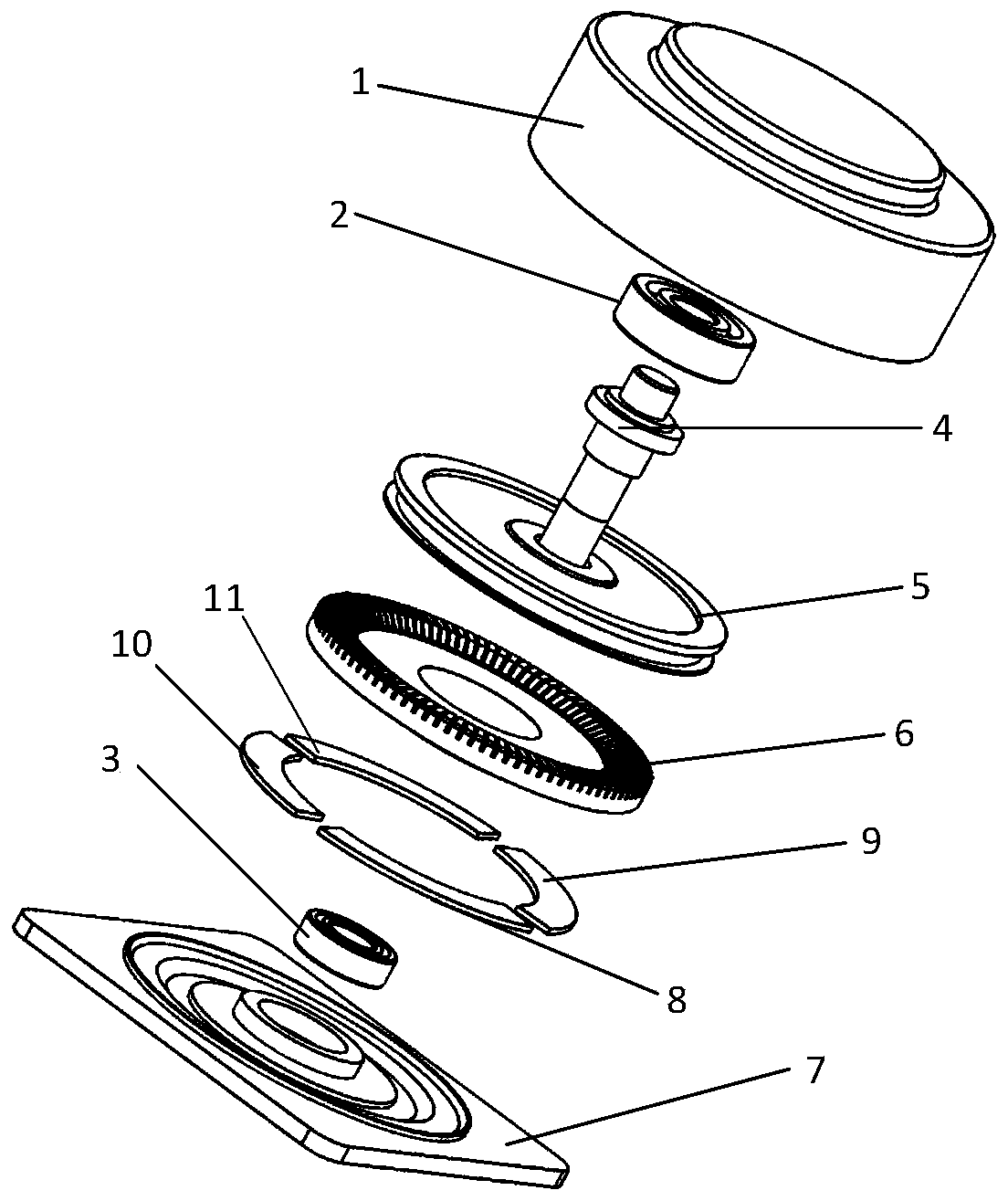

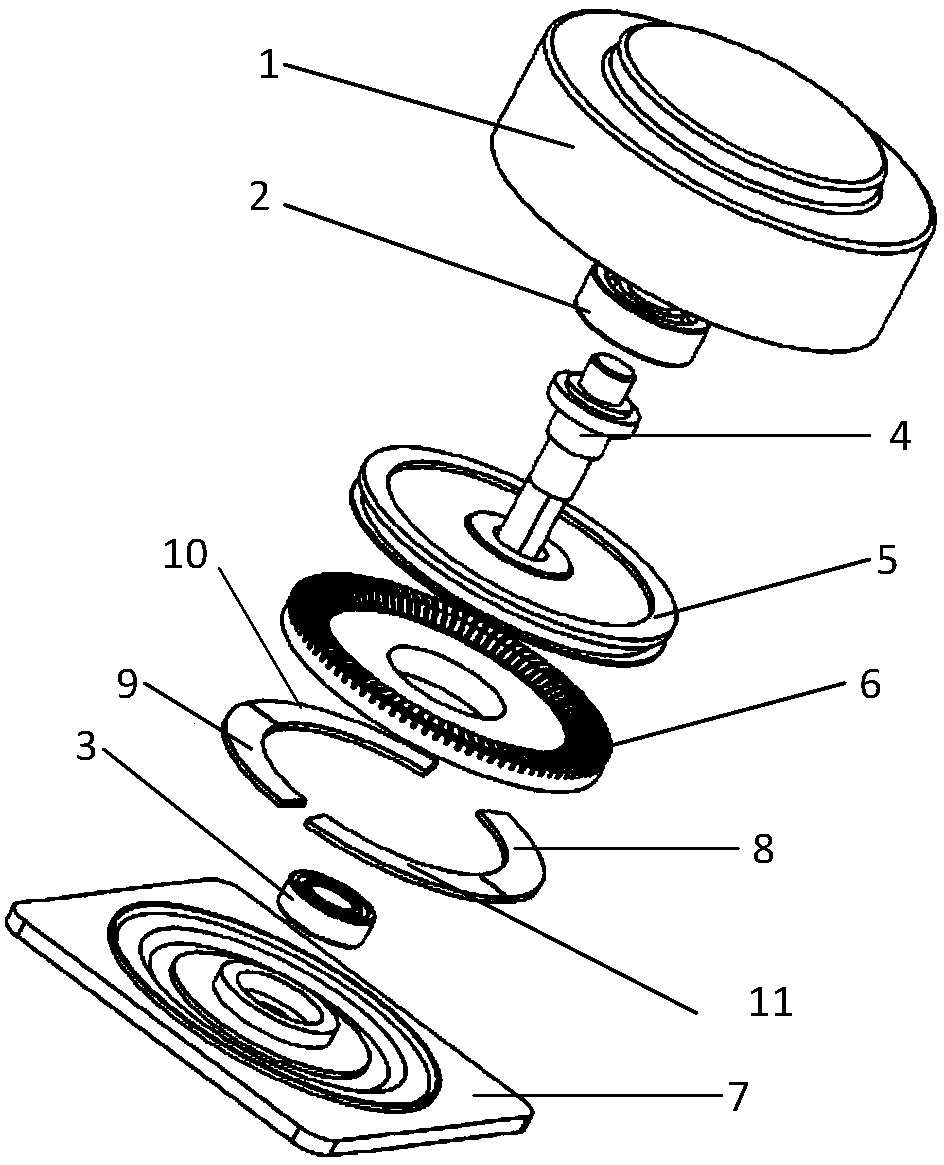

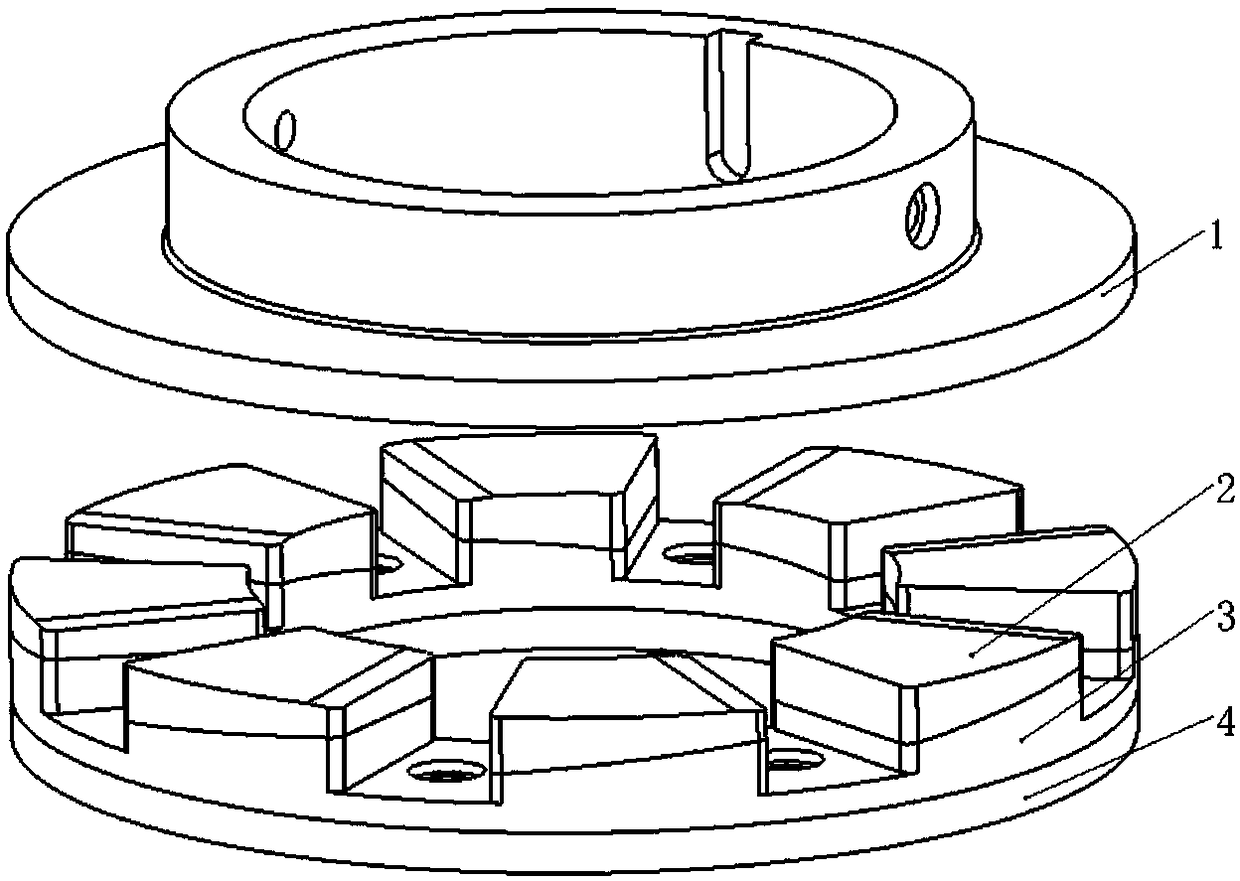

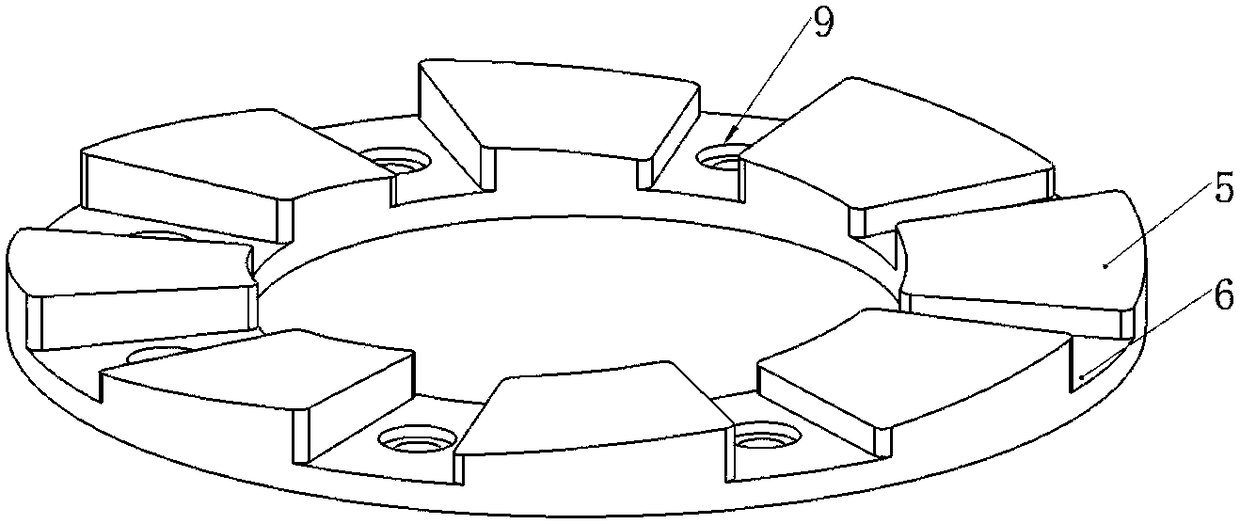

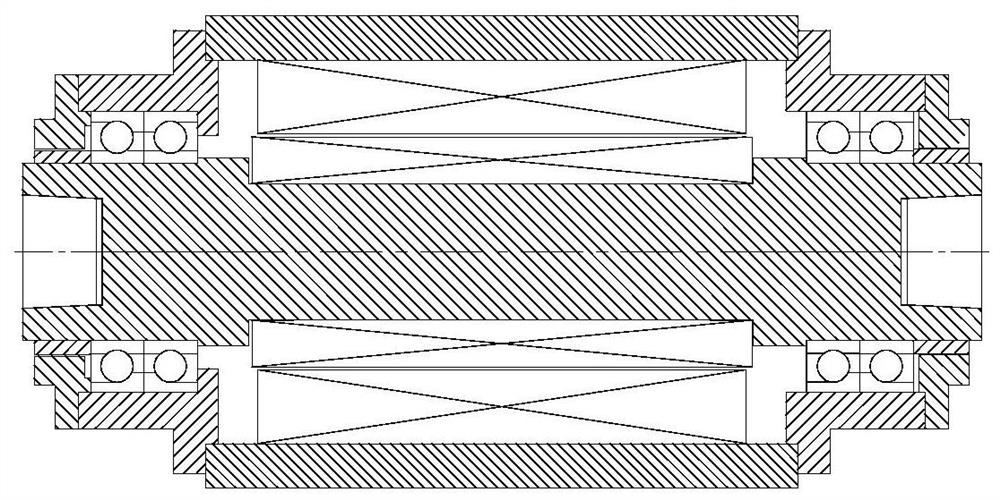

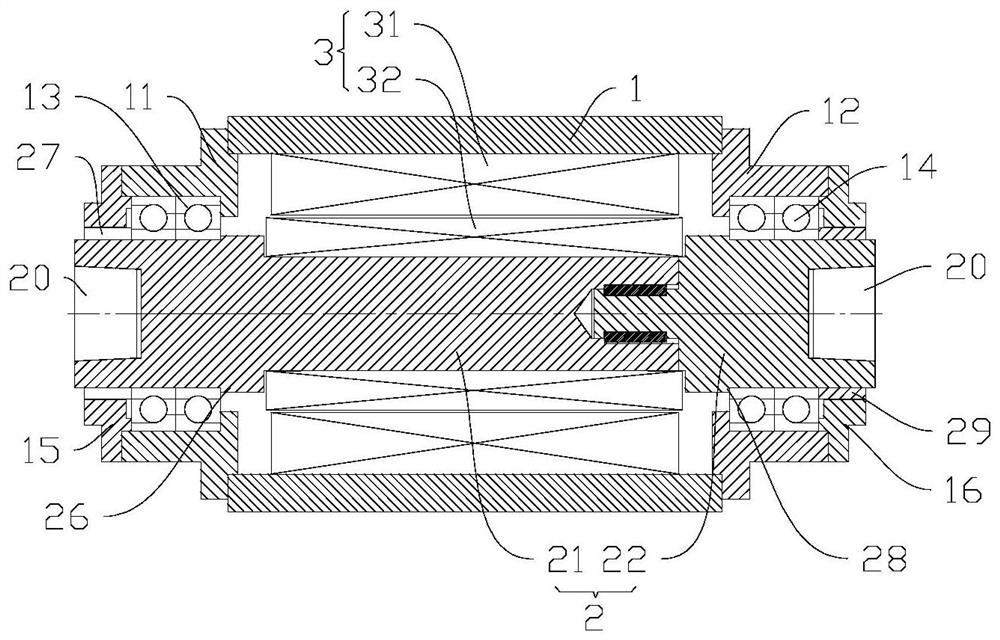

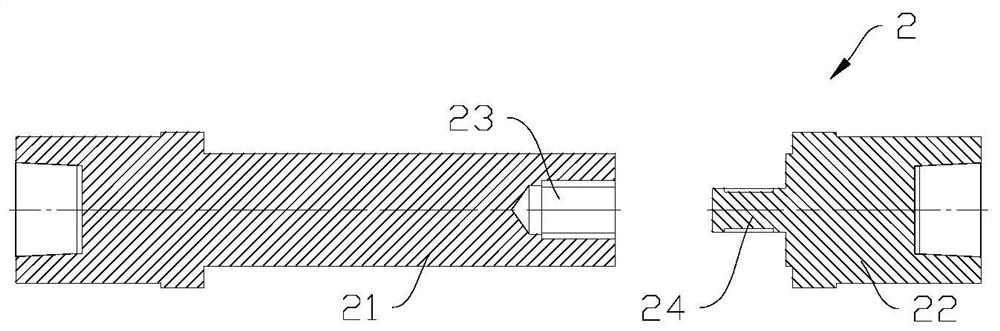

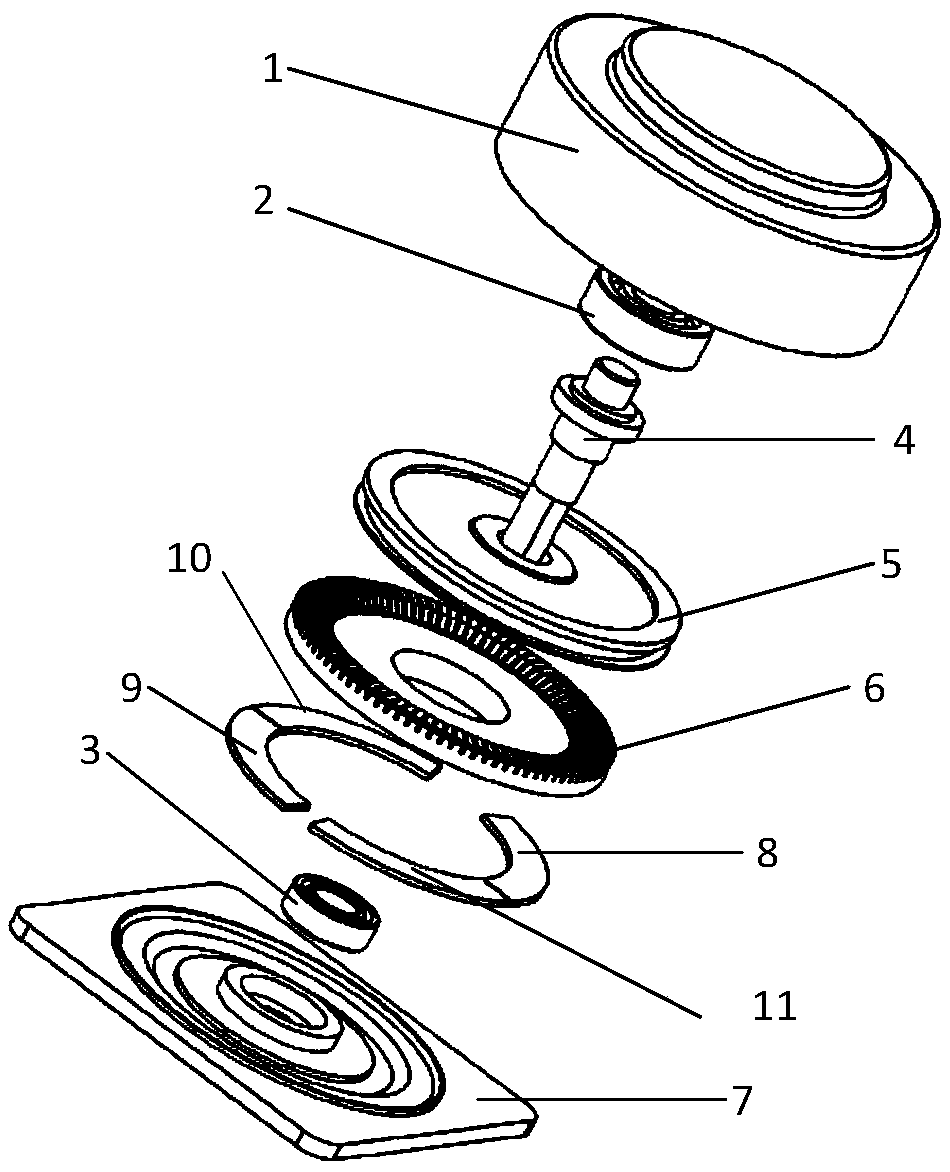

Tilting-pad thrust bearing supported through elastic disc

ActiveCN106438675ASimple structureFew partsBearing componentsSliding contact bearingsThrust bearingAxial thrust

The invention discloses a tilting-pad thrust bearing supported through an elastic disc. The tilting-pad thrust bearing is mainly composed of a thrust disc (1), a tilting material layer (2), the elastic disc (3) and a copper ring (4). The copper ring (4) is bonded to the lower surface of the elastic disc (3) and has the functions of supporting the elastic disc (3) and improving the strength of the elastic disc (3). The tilting material layer (2) is bonded to bosses (5) of the elastic disc and used for bearing axial thrust from the thrust disc (1). The tilting-pad thrust bearing has the beneficial effects of being simple in structure, convenient to machine and the like; the integral machining manner is adopted in the elastic disc, and it can be guaranteed that tiles have high planeness; and according to the thrust bearing, the character of deformation coordination of elastic materials is ingeniously utilized, and the thrust bearing has outstanding performance in the aspects of vibration reducing, noise lowering, tile load equalizing, lubricating and the like.

Owner:WUHAN UNIV OF TECH

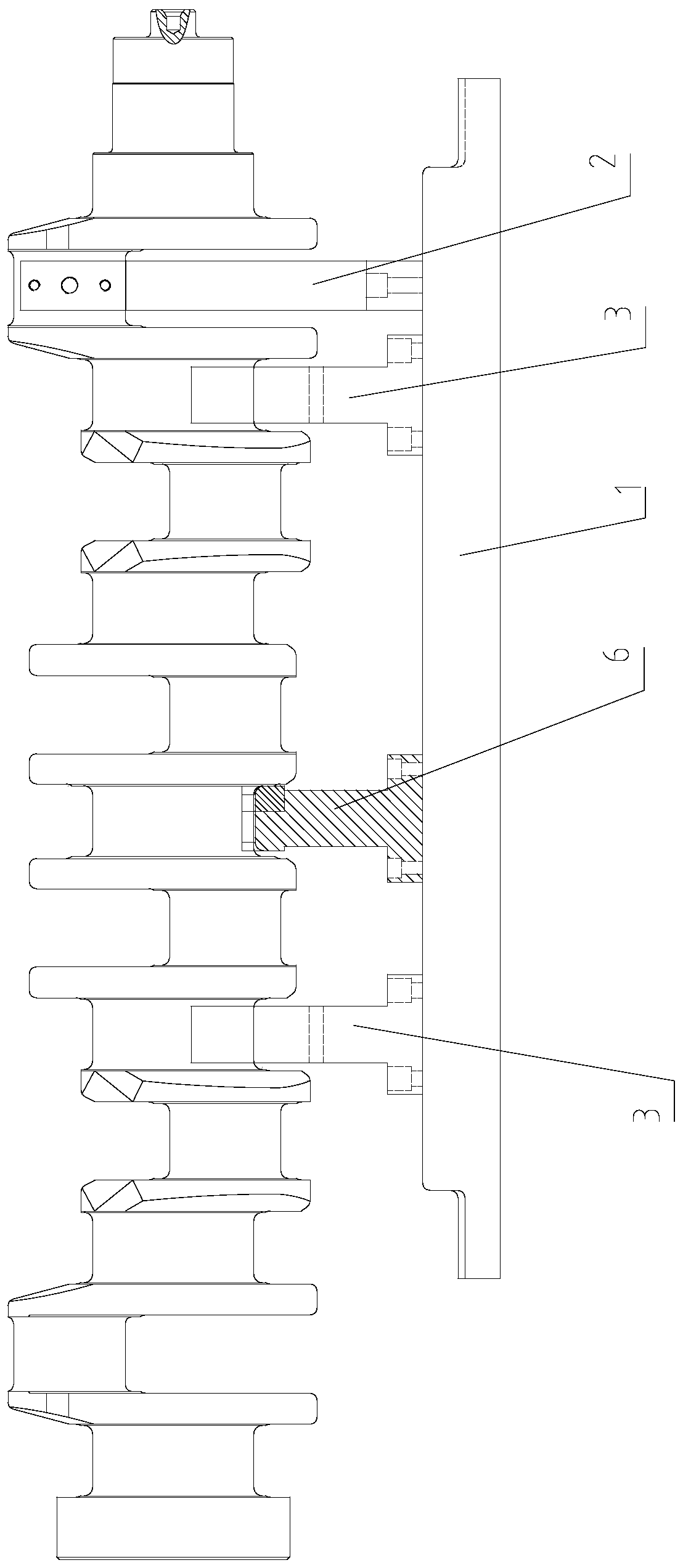

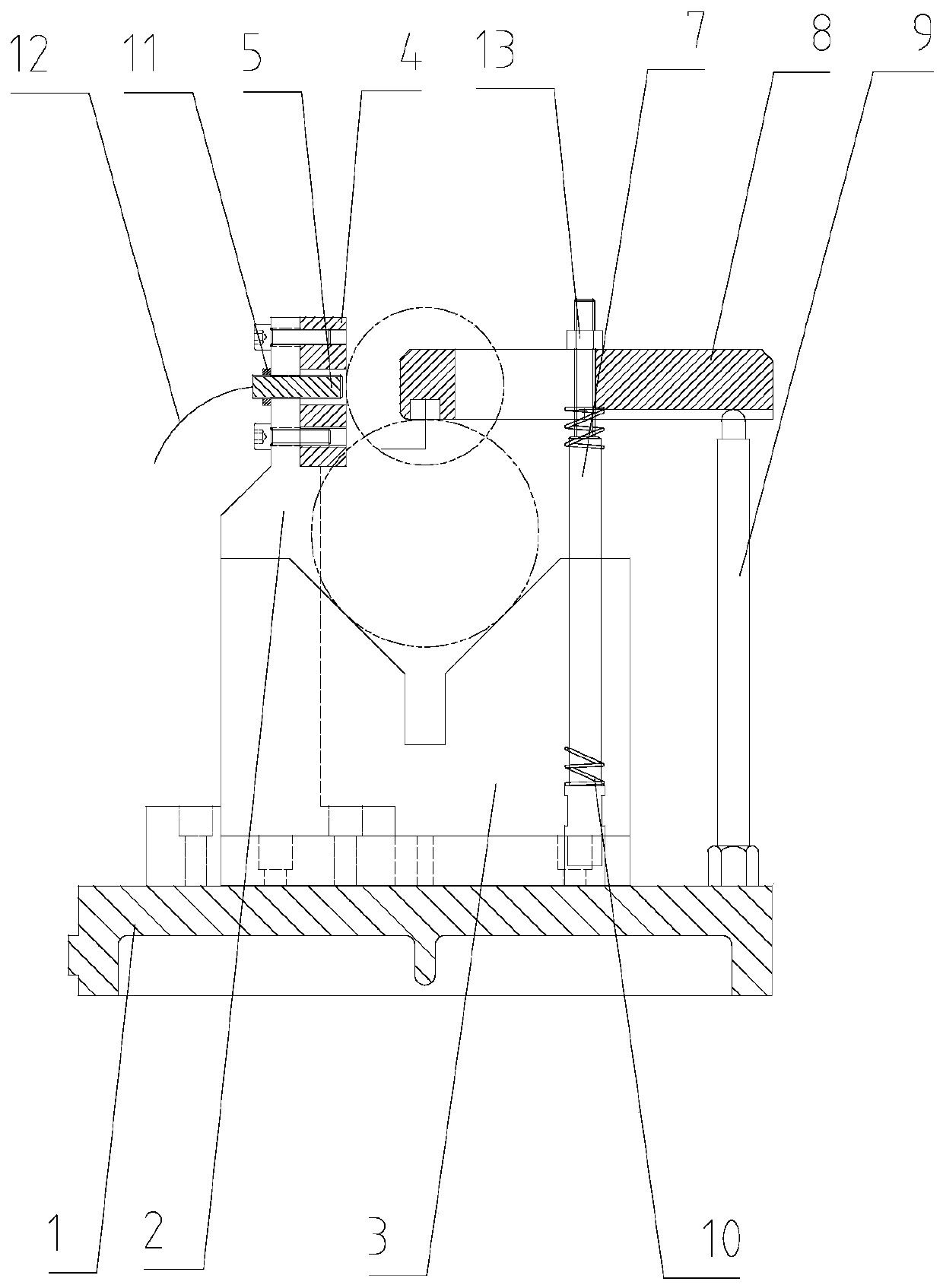

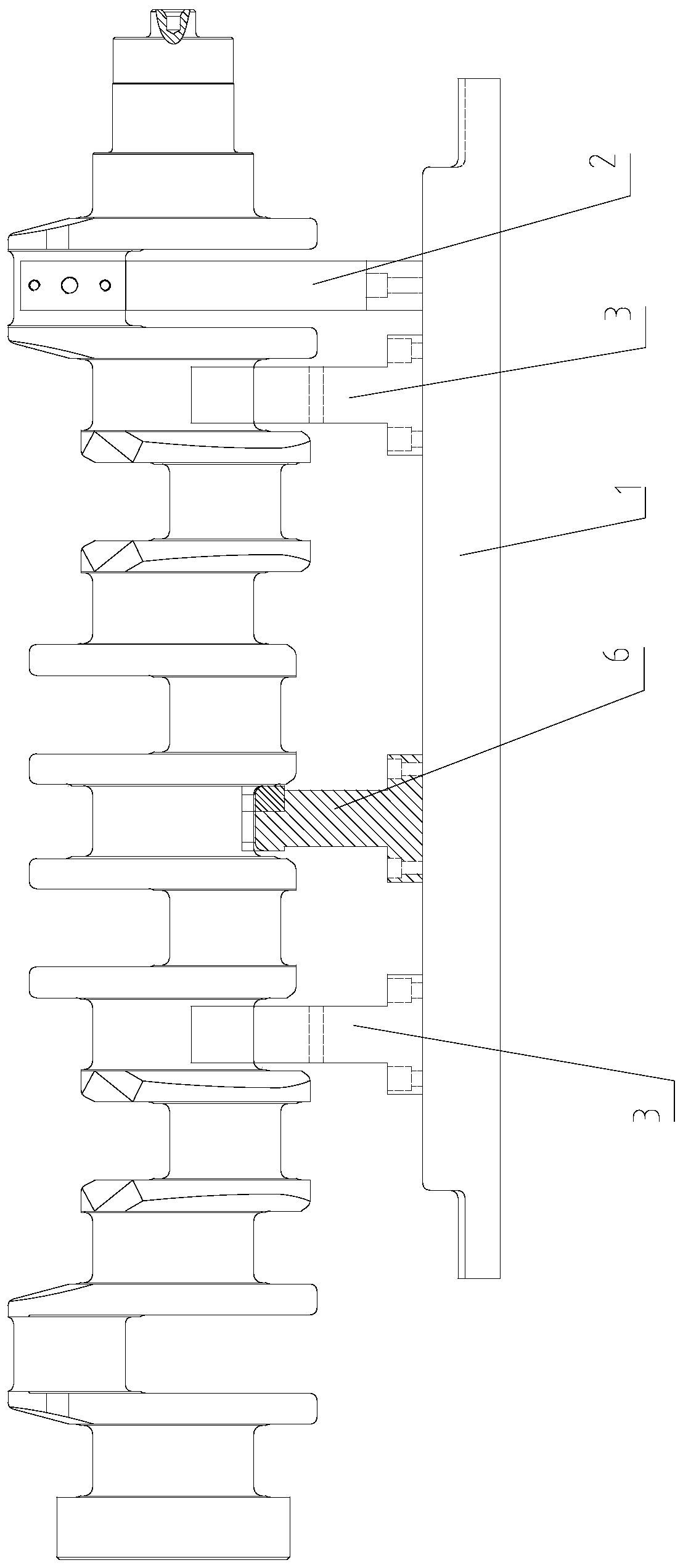

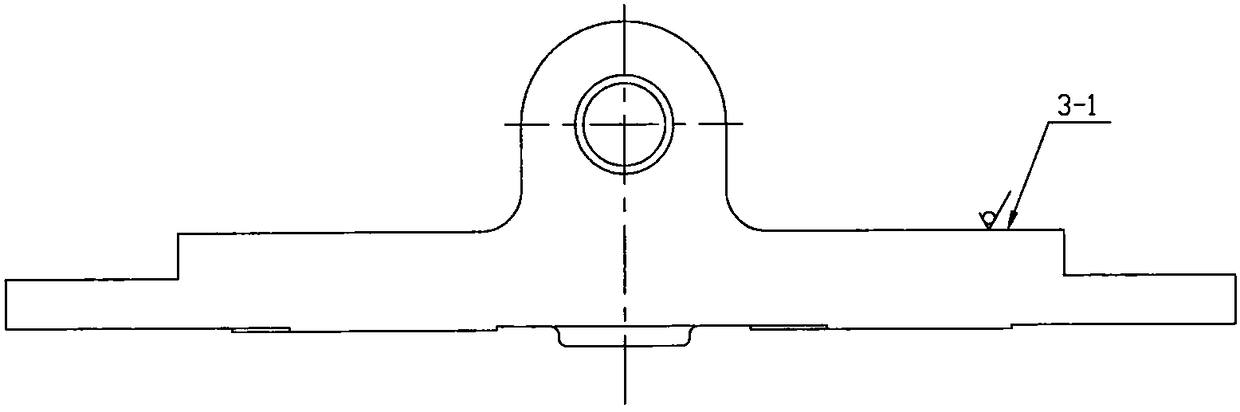

Crankshaft keyseat mistake-proofing positioning device

PendingCN111136481AConsistent machining accuracyStable processingWork clamping meansMeasurement/indication equipmentsNumerical controlControl system

The invention provides a crankshaft keyseat mistake-proofing positioning device, and solves the technical problem that an existing crankshaft keyseat positioning device is inaccurate in positioning, so that the symmetry degree of a keyseat is out of tolerance. The crankshaft keyseat mistake-proofing positioning device is provided with a clamp body, the clamp body is provided with an axial positioning column and a crankshaft support, the axial positioning column and the crankshaft support are fixedly installed on the clamp body, the clamp body is further provided with a pressing plate supporting column and a pressing stud, the pressing stud is provided with a pressing plate, the clamp body is further fixedly provided with an angular positioning column, the angular positioning column is fixedly provided with a positioning cushion block, a proximity switch sensor is mounted on the angular positioning column, a data line is arranged on the proximity switch sensor and connected with a machine tool control system, and a through hole allowing the proximity switch sensor to penetrate is formed in the positioning cushion block. The crankshaft keyseat mistake-proofing positioning device canbe widely applied to numerical control machine tool equipment.

Owner:SHANDONG UNIV OF TECH +1

External spiral rollaway nest forming technology

InactiveCN101569914AImprove efficiencyFast processingExtrusion diesScrew-threads articlesMachine pressAxial pressure

The invention relates to an external spiral rollaway nest forming technology comprising a press, a centre, a male die, a rotation female die, a roll thrust bearing, a sliding bearing, and the like. A preprocessed work piece is put in an inlet of the female die, the centre supports a center hole of the work piece so as to position the work piece, and when extrusion starts, axial pressure enables the female die to generate circumferential tangential component force, and the work piece can establish a rotation extrusion mechanism when running down; a stock is extruded into a reshaping area from an extrusion area, the female die and the rough stock do relative joggle movement according to the requirement of a spiral angle under the control of the spiral angel in the reshaping area to enable rollaway nest tooth forms to form on the surface of the work piece. The invention has chip-free forming, adopts a one-time extrusion forming technology, is particular suitable for power transmission with high cooperation requirement, has quick process speed, high efficiency, consistent process accuracy and low cost and greatly enhances the economic benefic.

Owner:孙乙钦

Miniaturized handheld deep and small hole compound deburring device

InactiveCN101811279BImprove surface qualityEliminate processing marksEdge grinding machinesRevolution surface grinding machinesHand heldEngineering

The invention belongs to mechanical processing tools, and relates to a hand-held deep and small hole composite deburring device for miniaturization of complex shell parts. The deburring device includes a worktable, a fixed support frame, a vibration generator, and a vibration converter equipped with a deburring tool. The fixed support frame and the vibration generator are placed on the workbench, and the vibration converter equipped with a deburring tool passes through the steel belt. Installed on a fixed support bracket, the vibration converter of the deburring tool is connected with the vibration generator, the grinding powder container is installed on the workbench, the water container is higher than the grinding powder container and placed on the workbench; the deburring tool is connected with the vibration converter , The deburring tool is a cylindrical slender metal rod, and the center of the front end of the metal rod has a transparent opening rectangular groove with a width of 0.25 mm to 0.3 mm, and the depth of the rectangular groove is 3 to 5 times the diameter of the metal rod. The invention is suitable for deburring deep and small holes with a length-to-diameter ratio greater than 40 and a diameter less than Ф3 mm, and the processing efficiency is increased by more than 50% to 70%.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

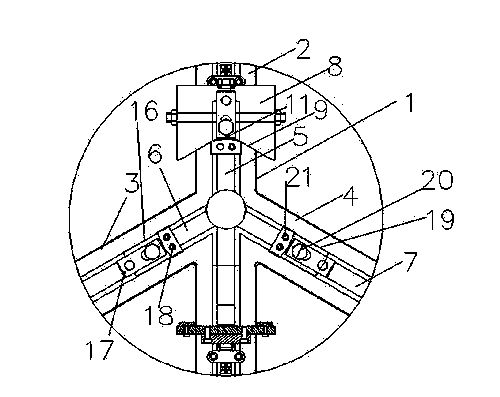

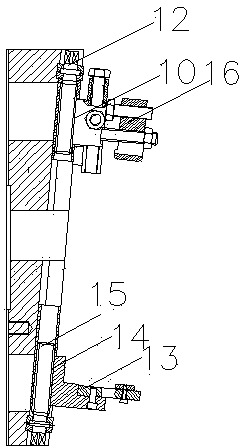

Double-head lifting lug boring equipment capable of realizing automatic centering of plate spring

ActiveCN112517970AConsistent machining accuracyHigh positioning accuracyPositioning apparatusBoring/drilling componentsPiston rodMachining

The invention relates to double-head lifting lug boring equipment capable of realizing automatic centering of a plate spring, and belongs to the technical field of mechanical plate spring boring machining. The equipment comprises a workbench; a clamping assembly is arranged in the middle of the workbench; head boring assemblies are arranged on the two sides of the clamping assembly; each head boring assembly comprises a boring cutter assembly, the boring cutter assembly is connected with a Z-axis adjusting mechanism, a Y-axis adjusting mechanism is arranged on one side of the Z-axis adjustingmechanism, the Y-axis adjusting mechanism is arranged on an X-axis adjusting mechanism, and the X-axis adjusting mechanism is arranged on the workbench; a positioning assembly is arranged at the frontend of each boring cutter and is used for positioning and fixing a reed; the clamping assembly comprises a pressing air cylinder, the pressing air cylinder is arranged on the clamping support, a piston rod of the pressing air cylinder is connected with a pressing seat, a positioning roller is arranged on the outer side of the pressing seat, a clamping air cylinder is arranged on the inner side ofthe pressing seat, and the clamping air cylinder and the positioning roller are arranged in a matched mode. The positioning precision is high, the center points of lifting lugs at the two ends of themachined reed are located on the same axis, and the product precision is high.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

Spatially phase-modulated annular traveling wave ultrasonic motor with symmetrical ceramic partitions and its control method

ActiveCN106452172BEasy wiringConsistent Ceramic Machining AccuracyPiezoelectric/electrostriction/magnetostriction machinesAll ceramicLength wave

The invention provides a spatial phase modulation round traveling wave ultrasonic motor with symmetrical ceramic zones and a control method of the ultrasonic motor. The ultrasonic motor comprises piezoelectric ceramics. The piezoelectric ceramics comprise A1-zone piezoelectric ceramics, A2-zone piezoelectric ceramics, B3-zone piezoelectric ceramics and B4-zone piezoelectric ceramics. All ceramic zones are arrayed according to the A1-zone piezoelectric ceramics, the A2-zone piezoelectric ceramics, the B4-zone piezoelectric ceramics and the B3-zone piezoelectric ceramics along the circumference in space and are separated from one another by a quarter of wavelength, and each ceramic zone takes up two wavelengths in space. The width of each polarized zone of the piezoelectric ceramics is one-half wavelength. According to the counter-clockwise direction, the polarized directions of all polarized zones of the piezoelectric ceramics are sequentially arrayed according to a positive and negative alternating sequence. The motor and the control method thereof have all the functions and advantages of a traditional spatial phase modulation round traveling wave ultrasonic motor with a subdivided ceramic structure, moreover, each polarized zone of the piezoelectric ceramics is wider, all polarized zones of each zone of piezoelectric ceramics keep continuous in space, and processing and manufacture are more convenient and accurate.

Owner:NANJING INST OF TECH

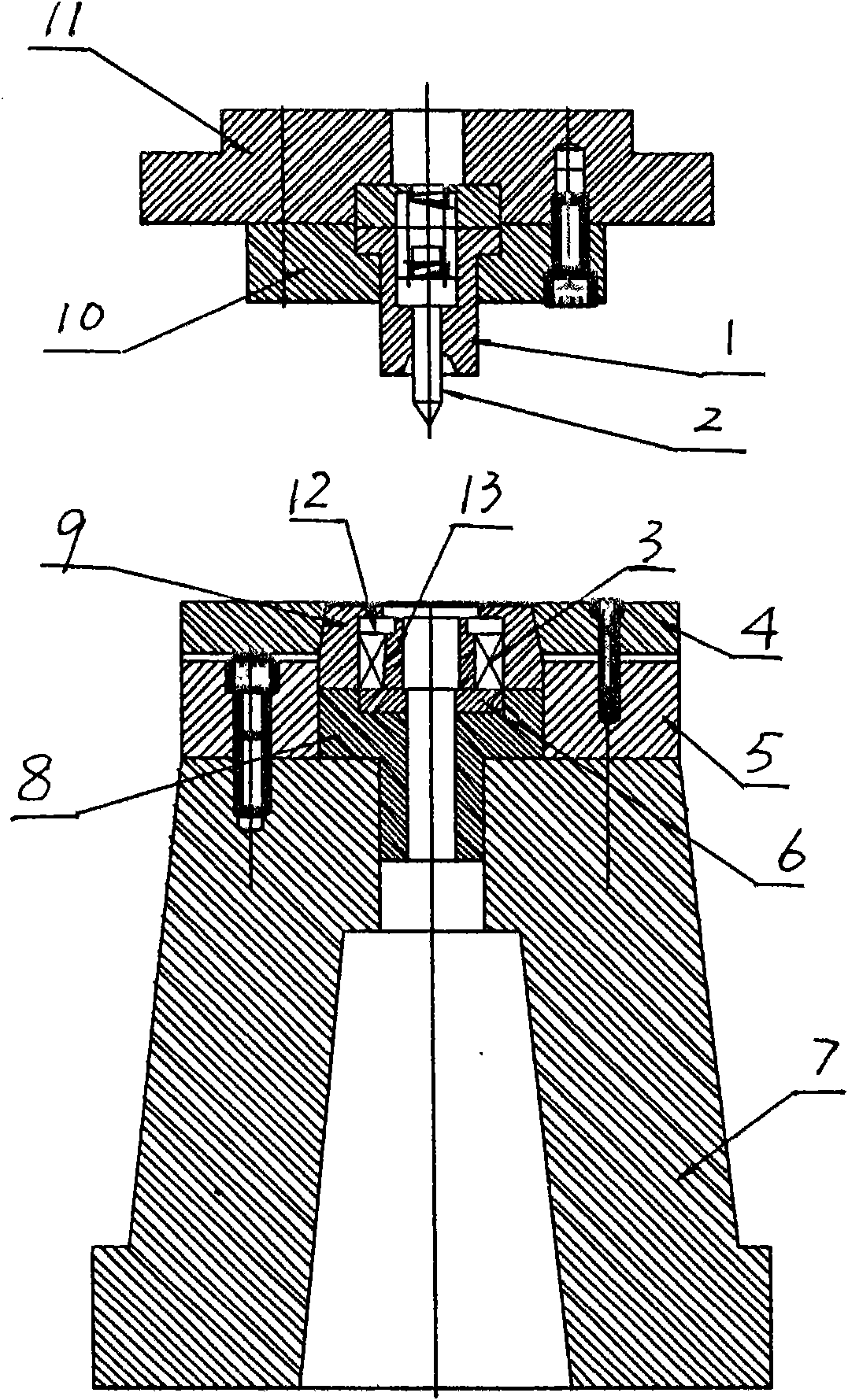

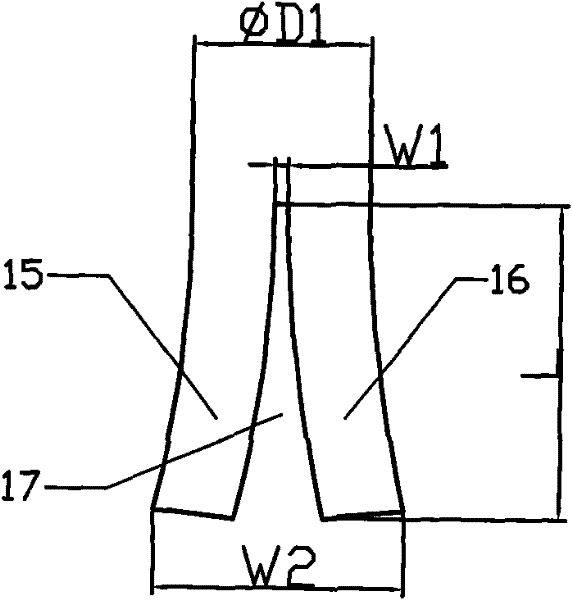

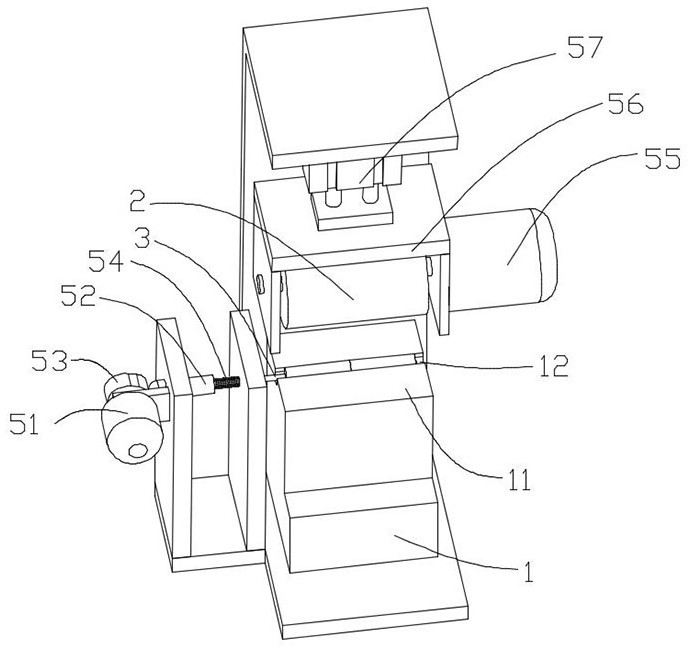

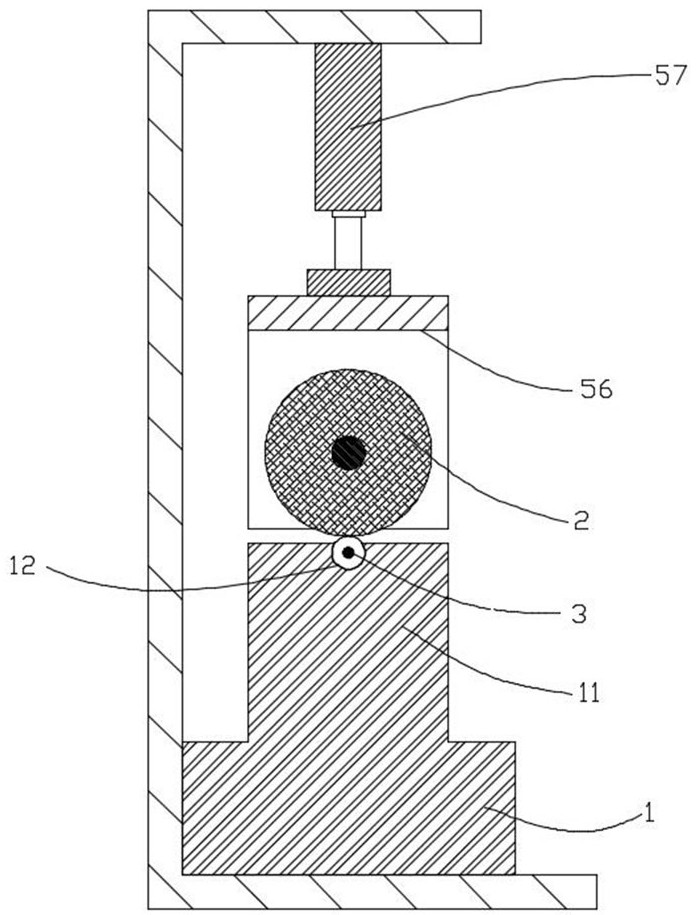

Processing technology and processing device of ceramic ferrules

PendingCN114083431AConsistent processing sizeConsistent machining accuracyGrinding drivesLapping machinesMedical diagnosisGrinding wheel

The invention relates to the technical field of medical diagnosis, and in particular, relates to a processing technology and processing device for ceramic ferrules, wherein the processing device comprises a grinding seat, a grinding wheel, a grinding rod and a grinding plate. A grinding groove can contain the two ceramic ferrules which are axially arranged, and the length of the grinding rod is larger than two times of the length of the ceramic ferrules. When the ceramic ferrules are ground, the two ceramic ferrules which are in butt joint with each other serve as a group, and the ceramic ferrules are ground at the same time. The grinding wheel and the grinding groove are matched to grind the outer contours of the two ceramic ferrules at the same time, and grind insertion holes of the two ceramic ferrules at the same time through the grinding rod, and grind the ends of the two ceramic ferrules at the same time through the grinding plate, and it can be effectively guaranteed that the processing sizes and the processing precision of the ceramic ferrules in butt joint are consistent. The two ceramic ferrules in butt joint form a group and are ground simultaneously, so that the consistency of the processing sizes and the processing precision of the ceramic ferrules in butt joint can be effectively ensured, the operation is simple, the process steps are few, and the production efficiency is high.

Owner:深圳市源国科技有限公司

Spatial Phase Modulation Annular Traveling Wave Ultrasonic Motor with Asymmetric Ceramic Partition and Its Control Method

ActiveCN106452171BEasy wiringConsistent Ceramic Machining AccuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityLength wave

The invention provides a space phase modulation based ring-type traveling-wave ultrasonic motor with asymmetric ceramic subareas and a control method of the space phase modulation based ring-type traveling-wave ultrasonic motor with the asymmetric ceramic subareas. Piezoelectric ceramics comprise area-A1 piezoelectric ceramics, area-A2 piezoelectric ceramics, area-B3 piezoelectric ceramics and area-B4 piezoelectric ceramics, wherein the ceramics in every area occupy two wavelengths in space, the area-A1 piezoelectric ceramics and the area-B4 piezoelectric ceramics have the same space phases, the area-A2 piezoelectric ceramics and the area-B3 piezoelectric ceramics have the same space phases, the area-A1 piezoelectric ceramics and the area-A2 piezoelectric ceramics have a difference in one quarter wavelength in space, the area-B3 piezoelectric ceramics and the area-B4 piezoelectric ceramics have a difference in one quarter wavelength in space, and polarization directions of polarization subareas of the piezoelectric ceramics in all the areas are arranged according to '+-+-' sequentially. The space phase modulation based ring-type traveling-wave ultrasonic motor with the asymmetric ceramic subareas has all the advantages and functions of traditional space phase modulation based ring-type traveling-wave ultrasonic motors with subdivided ceramic structures, every polarization subarea of the piezoelectric ceramics is wider, all the polarization subareas of the piezoelectric ceramics in every area can keep continuous in space, and accordingly processing and manufacturing are facilitated and processing and manufacturing precision is improved.

Owner:NANJING INST OF TECH

A rotating assembly that effectively reduces the staggering amount of the pedal valve

ActiveCN105937651BUniform roughnessConsistent machining accuracyOperating means/releasing devices for valvesEngineeringMachine tool

The invention provides a rotating assembly capable of effectively decreasing stagger amount of a foot operated valve. The rotating assembly comprises a connecting plate, wherein left and right rotating seats are arranged on the connecting plate; the rotating seats are connected with the connecting plate through hinge pins; the bottom ends of the two side surfaces of the rotating seats are concave inwards to form end faces; the two ends of the bottom surfaces of the rotating seats are oblique upwards to form upper oblique surfaces; the bottoms of the end faces and the tops of the upper oblique surfaces intersect with each other to form limiting parts; and grooves are formed in the parts, corresponding to the limiting parts of the two rotating seats, on the connecting plate. According to the rotating assembly, through utilizing a surface processing method, the parts where the rotating seats and the connecting plate are in mutual contact are formed through processing of a machine tool, the processing accuracy is uniform, the dimensional tolerances of horizontal distances and vertical distances from the limiting parts in the rotating seats to the centers of the hinge pins, and the dimensional tolerance of horizontal distances from the upper plane of the connecting plate to the centers of the hinge pins are decreased, and the deflection angle difference of the two rotating seats does not exceed the design requirement; and the device is simple in structure, the stagger amount of the two rotating seats of the foot operated valve is effectively decreased, and the ex factory pass rate of the foot operated valve is increased.

Owner:龙工(上海)精工液压有限公司

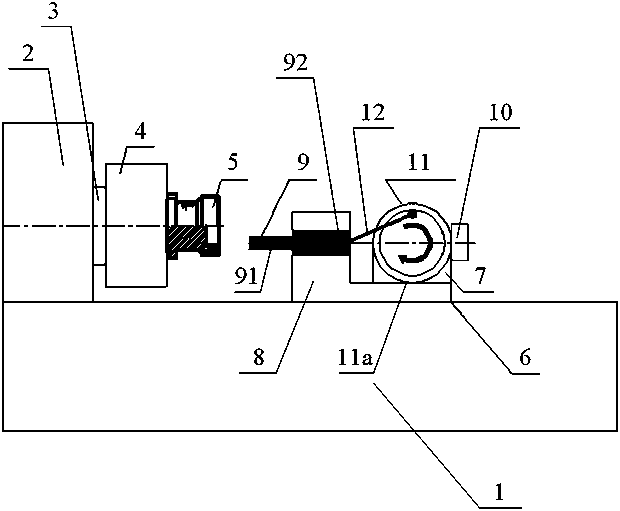

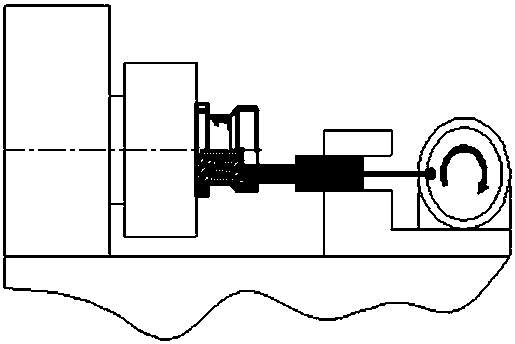

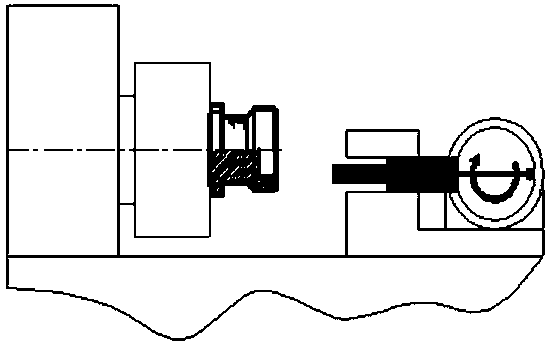

Special-shaped key groove high-speed machining platform and machining method thereof

PendingCN110076383AShorten the timeGuaranteed machining accuracyPlaning/slotting machinesElectric machineDrive shaft

The invention relates to a special-shaped key groove high-speed machining platform and a machining method. The special-shaped key groove high-speed machining platform is characterized by comprising amachine tool (1), a machine tool support (2), a rotary driving shaft (3), a machine tool chuck (4), a to-be-machined workpiece (5), a machine tool moving guide rail (6), an eccentric wheel mounting frame (7), a tool bearing table (8), a machining tool (9), a driving motor (10), a rotary eccentric wheel (11) and an eccentric wheel connecting rod (12). An eccentric wheel guide rail reciprocating method is adopted, the limitation on the moving speed of a machine tool screw rod is avoided, the speed is completely dependent on the running speed of the driving motor, and the rotating speed of 6000 revolutions or higher can be achieved; and, while ensuring the machining accuracy, machining a key groove can be realized only by reciprocating the machining tool back and forth, so that the machiningtime of the key groove is shortened.

Owner:ZHENJIANG ZHENGKAI ELECTRONICS

A clamping method for a universal clamp for the sealing surface of a valve body used in a vertical machine tool

ActiveCN104209776BImprove versatilityExact symmetryPositioning apparatusMetal-working holdersCheck valveSymmetric structure

A universal clamp for the sealing surface of a valve body used in a vertical machine tool and a clamping method thereof, including a clamp body, the upper surface of the clamp body forms an included angle of 5 degrees with the horizontal direction, effectively ensuring that the processed wedge The consistency and accuracy of the angle of the sealing surface of the valve body of the gate valve or the sealing surface of the valve body of the swing check valve. The clamp body has an axisymmetric structure, which avoids the poor versatility of the clamps in the prior art for valve bodies of wedge gate valves of various sizes and models or valve bodies of swing check valves. , It is difficult to ensure the exact symmetry of the positions of the two relative valve body sealing surfaces, it is difficult to ensure the consistency and accuracy of the valve body sealing surface angle, and the valve body of the wedge gate valve or the valve body of the swing check valve is loaded and unloaded Inconvenient downside.

Owner:NANTONG HIGH & HIGH PRESSURE VALVE CO LTD

A tilting pad thrust bearing supported by an elastic disc

ActiveCN106438675BSimple structureFew partsBearing componentsSliding contact bearingsThrust bearingAxial thrust

The invention discloses a tilting-pad thrust bearing supported through an elastic disc. The tilting-pad thrust bearing is mainly composed of a thrust disc (1), a tilting material layer (2), the elastic disc (3) and a copper ring (4). The copper ring (4) is bonded to the lower surface of the elastic disc (3) and has the functions of supporting the elastic disc (3) and improving the strength of the elastic disc (3). The tilting material layer (2) is bonded to bosses (5) of the elastic disc and used for bearing axial thrust from the thrust disc (1). The tilting-pad thrust bearing has the beneficial effects of being simple in structure, convenient to machine and the like; the integral machining manner is adopted in the elastic disc, and it can be guaranteed that tiles have high planeness; and according to the thrust bearing, the character of deformation coordination of elastic materials is ingeniously utilized, and the thrust bearing has outstanding performance in the aspects of vibration reducing, noise lowering, tile load equalizing, lubricating and the like.

Owner:WUHAN UNIV OF TECH

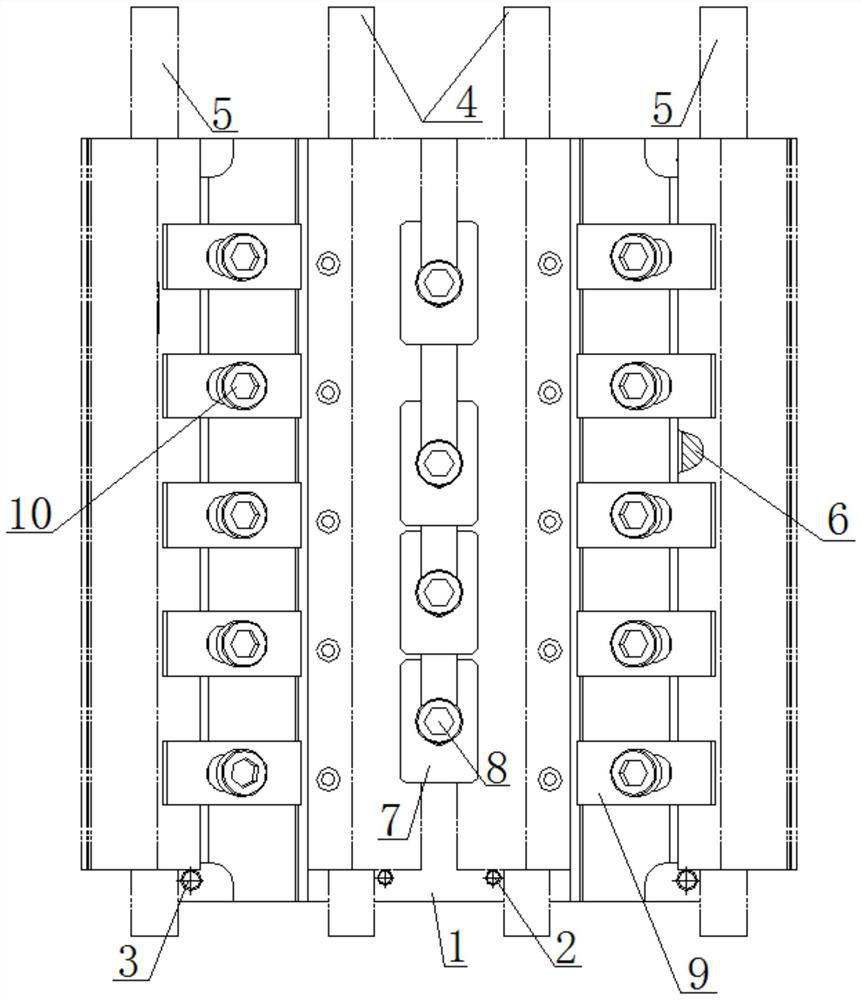

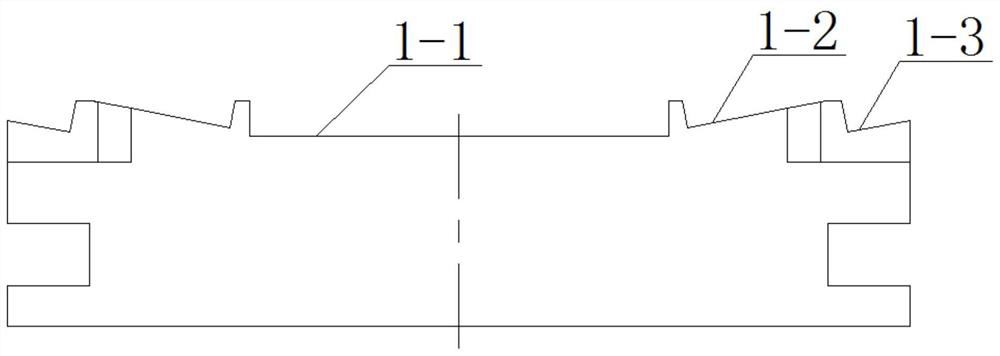

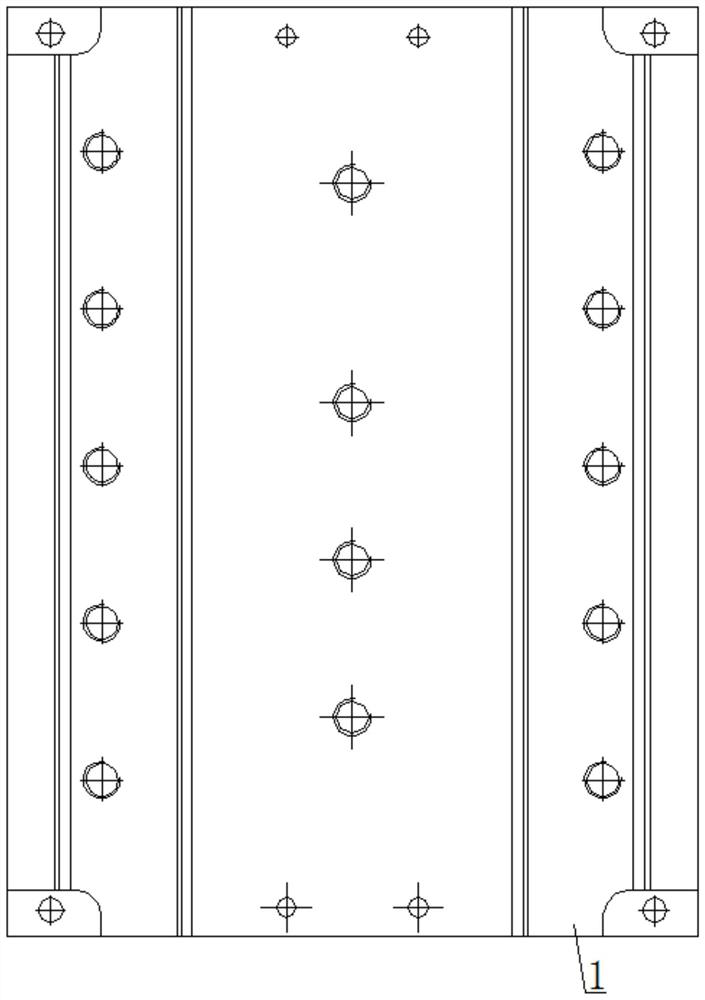

Multi-process, multi-workpiece and double-station fixture for rudder shaft

ActiveCN112207592AThe workpiece position is accurateReduce labor intensityPositioning apparatusMetal-working holdersStructural engineeringManufacturing engineering

The invention discloses a multi-process, multi-workpiece and double-station fixture for a rudder shaft, relates to a fixture, and aims to solve the problems that an existing rudder shaft workpiece isstrict in dimensional tolerance requirement, high in surface roughness requirement and high in machining difficulty, and is prone to generate unqualified products, products often need to be repaired,and the machining time is long. At present, no fixture for simultaneously performing multiple procedures of workpieces on three-axis equipment exists. The fixture comprises a fixture body, a first locating hinge pin, a second locating hinge pin, an inner groove plug block, a U-shaped pressing plate, a first pressing plate connecting piece, a step pressing plate and a second pressing plate connecting piece. A first stepped slope and a second stepped slope are sequentially machined on the two side walls of a through groove, and two first hinge pin locating holes are symmetrically machined in thetwo ends of the bottom of the through groove separately; and each rudder shaft slope workpiece to be machined is arranged on the surface of the second stepped slope in the length direction of the fixture body. and a plurality of stepped pressing plates are arranged on each rudder shaft slope workpiece to be machined. The fixture is applied to the field of multi-workpiece machining.

Owner:HARBIN JIANCHENG GRP

Leaf spring automatic centering double-head lifting lug boring equipment

ActiveCN112517970BConsistent machining accuracyHigh positioning accuracyPositioning apparatusBoring/drilling componentsPiston rodIndustrial engineering

The invention relates to a flat spring automatic centering double-head lifting lug boring device, which belongs to the technical field of mechanical flat spring boring processing. Including the workbench, there is a clamping assembly in the middle of the worktable, and a boring head assembly is installed on both sides of the clamping assembly; the boring head assembly includes a boring tool assembly, which is connected to the Z-axis adjustment mechanism, and the Z-axis adjustment mechanism One side is equipped with a Y-axis adjustment mechanism, the Y-axis adjustment structure is set on the X-axis adjustment mechanism, and the X-axis adjustment mechanism is set on the workbench; the front end of the boring tool is equipped with a positioning component, which is used to position and fix the reed; the clip The clamping assembly includes a clamping cylinder, which is set on the clamping bracket, the piston rod of the clamping cylinder is connected to the clamping seat, the positioning roller is arranged on the outside of the clamping seat, the clamping cylinder is arranged on the inside of the clamping seat, and the clamping cylinder Set in conjunction with the positioning roller. The positioning accuracy of the invention is high, the center points of the lifting lugs at both ends of the processed reed are on the same axis, and the product accuracy is high.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

A workpiece automatic processing system and workpiece surface grinding method

ActiveCN103419111BPrecision grindingConsistent machining accuracyBelt grinding machinesEngineeringMachining system

The invention provides a workpiece automatic machining system and a grinding method of the surface of a workpiece, and belongs to the technical field of machines. The problems that an existing grinding polishing machine is not unified in machining precision and not uniform in workpiece forming are solved. The workpiece automatic machining system comprises a machining center which conducts machining work on the workpiece, and further comprises a grinding unit which is adjacent to the machining center. The grinding unit is provided with a mechanical arm and a plurality of grinding machines, and the mechanical arm can clamp and convey the workpiece which has been machined at the machining center to the grinding machines to be ground. The workpiece automatic machining system and the grinding method of the surface of the workpiece have the advantages of being high in automatic degree, good in uniformity of workpiece forming, high in grinding precision and the like.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

A clamping method for a universal clamp for the sealing surface of a valve body used in a horizontal machine tool

ActiveCN104259907BImprove versatilityExact symmetryWork clamping meansPositioning apparatusEngineeringSymmetric structure

The invention relates to a universal valve body sealing surface clamp for a horizontal machine tool and a clamping method of the universal valve body sealing surface clamp. The universal valve body sealing surface clamp for the horizontal machine tool comprises a clamp body adopting an axisymmetric structure, and is connected with the spindle of the horizontal machine tool; and a 5-degree included angle is formed between the universal valve body sealing surface clamp and the vertical direction. Such a structure avoids the defect that a clamp in the prior art generally has poor universality for the valve bodies of wedge gate valves or swing check valves of various sizes, specifications and models, can hardly ensure accurate symmetry of the positions of two opposite valve body sealing surfaces and the consistency and accuracy of the angles of the valve body sealing surfaces, and cannot load and unload the valve bodies of wedge gate valves or swing check valves conveniently.

Owner:NANTONG HIGH & HIGH PRESSURE VALVE CO LTD

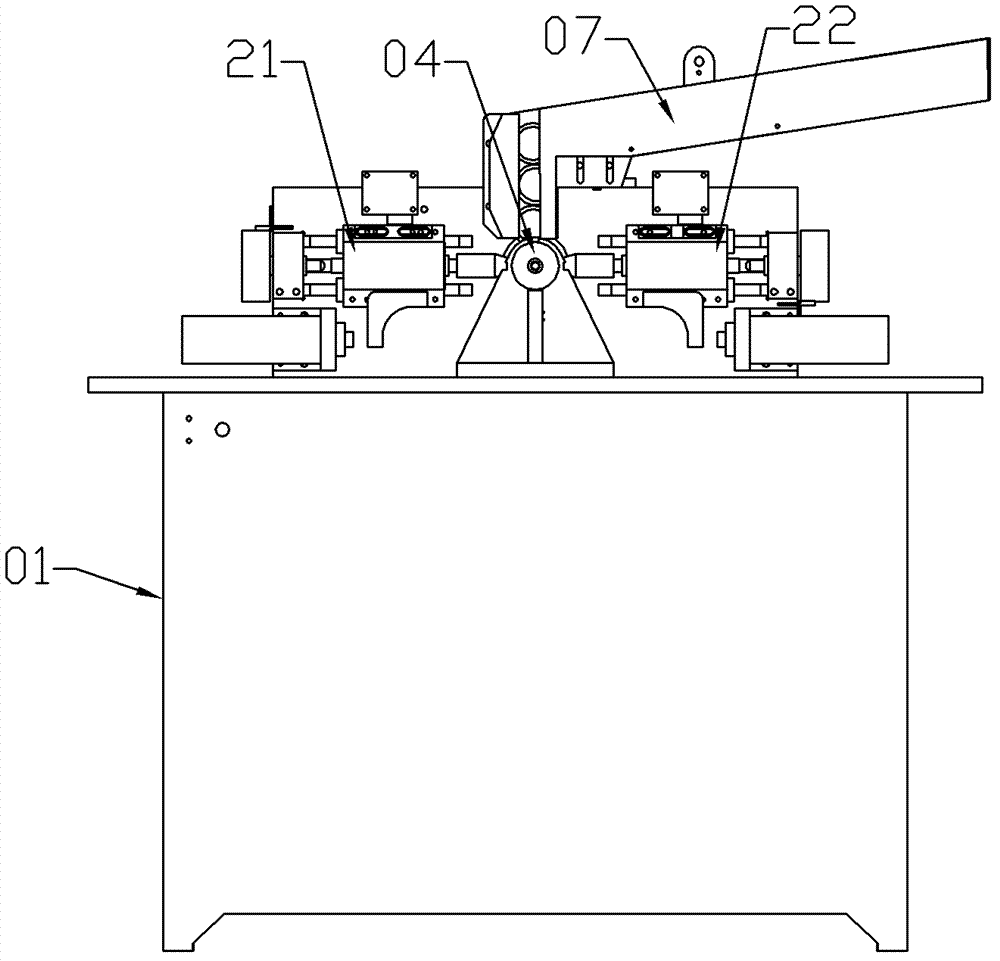

Electric main shaft and machine tool

PendingCN114082998AEliminate elongationStable processing performanceGrinding machine componentsLarge fixed membersPhysicsEngineering

The invention discloses an electric main shaft and a machine tool. The electric main shaft comprises a machine body, a shaft core assembly and a motor; the shaft core assembly comprises a first shaft core and a second shaft core; the first shaft core and the second shaft core are coaxially connected to form the shaft core assembly capable of synchronously rotating together; the first shaft core and the second shaft core can float in the axial direction at the joint so as to absorb the elongation generated when the shaft core assembly is heated; the shaft core assembly penetrates through an inner cavity of the machine body; the first shaft core is supported on a first bearing seat through a first bearing, the outer ring of the first bearing is locked on the first bearing seat in the axial direction, and the inner ring of the first bearing is locked on the first shaft core in the axial direction; the second shaft core is supported on a second bearing seat through a second bearing, the outer ring of the second bearing is locked on the second bearing seat in the axial direction, and the inner ring of the second bearing is locked on the second shaft core in the axial direction; and the motor comprises a stator and a rotor. The elongation in the shaft cores is eliminated, so that the elongation at the two ends of each shaft core is kept stable, and finally, the machining performance of the two ends of the main shaft is consistent and stable.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Ferrule perforation method

ActiveCN102335774BImprove efficiencyConsistent machining accuracyAutomatic control devicesFeeding apparatusPunchingControl system

The invention discloses a ferrule perforation method, belonging to a machining method. The traditional operation of perforating a ferrule is finished manually, which has the disadvantages of low efficiency, more inferior-quality products and inconsistent machining precision. The ferrule perforation method is characterized in that a feed channel conveys a ferrule to a material supporting rack; an electrical control system controls a clamping device to move to a backer, the electrical control system and the backer oppositely clamp two end surfaces of the ferrule on the material supporting rack so as to clamp the ferrule on a perforation workstation; electrical control system controls a perforation device to feed to radially perforate the ferrule on the punching workstation; and after the operation of perforation is finished, the electrical control system controls the perforation device to retract, the clamping device is reset, and a charging ram pushes down processed ferrule from the material supporting rack. With the ferrule perforation method, equipment replaces manpower to machine the ferrule, the electrical control system control equipment to work, efficiency is improved, inferior-quality products are reduced, and machining precision is guaranteed to be consistent.

Owner:XINCHANG JINCHENG PML PRECISIION MECHANISM CO LTD

Spatial Phase Modulation Annular Traveling Wave Ultrasonic Motor with Asymmetric Ceramic Partition and Its Control Method

ActiveCN107070301BEasy wiringConsistent Ceramic Machining AccuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityLength wave

The invention provides a space phase modulation-based ring-type traveling wave ultrasonic motor with asymmetric ceramic subareas and a control method thereof. Piezoelectric ceramics comprise area-A1 piezoelectric ceramics, area-A2 piezoelectric ceramics, area-B3 piezoelectric ceramics and area-B4 piezoelectric ceramics, wherein the ceramics in every area occupy two wavelengths in space, the area-A1 piezoelectric ceramics and the area-B4 piezoelectric ceramics have the same space phases, the area-A2 piezoelectric ceramics and the area-B3 piezoelectric ceramics have the same space phases, the width of each polarization subarea of the piezoelectric ceramic is a 1 / 2 wavelength, polarization directions of any three piezoelectric ceramic subareas are arranged according to '+-+-' sequentially in an anticlockwise direction, and the polarization directions of the other piezoelectric ceramic subarea arranged according to '-+-+' sequentially. The motor and the control method thereof have all the advantages and functions of traditional space phase modulation-based ring-type traveling-wave ultrasonic motors with subdivided ceramic structures, every polarization subarea of the piezoelectric ceramics is wider, all the polarization subareas of the piezoelectric ceramics in every area can keep continuous in space, and processing and manufacturing are facilitated and processing and manufacturing precision is improved.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com