Spatially phase-modulated annular traveling wave ultrasonic motor with symmetrical ceramic partitions and its control method

A ceramic and space technology, which is applied in the field of space phase modulation annular traveling wave ultrasonic motor and its control, can solve the problems of reduced silver-coated area, complicated motor wiring, difficult ceramic processing, etc., and achieves the effect of simplified wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

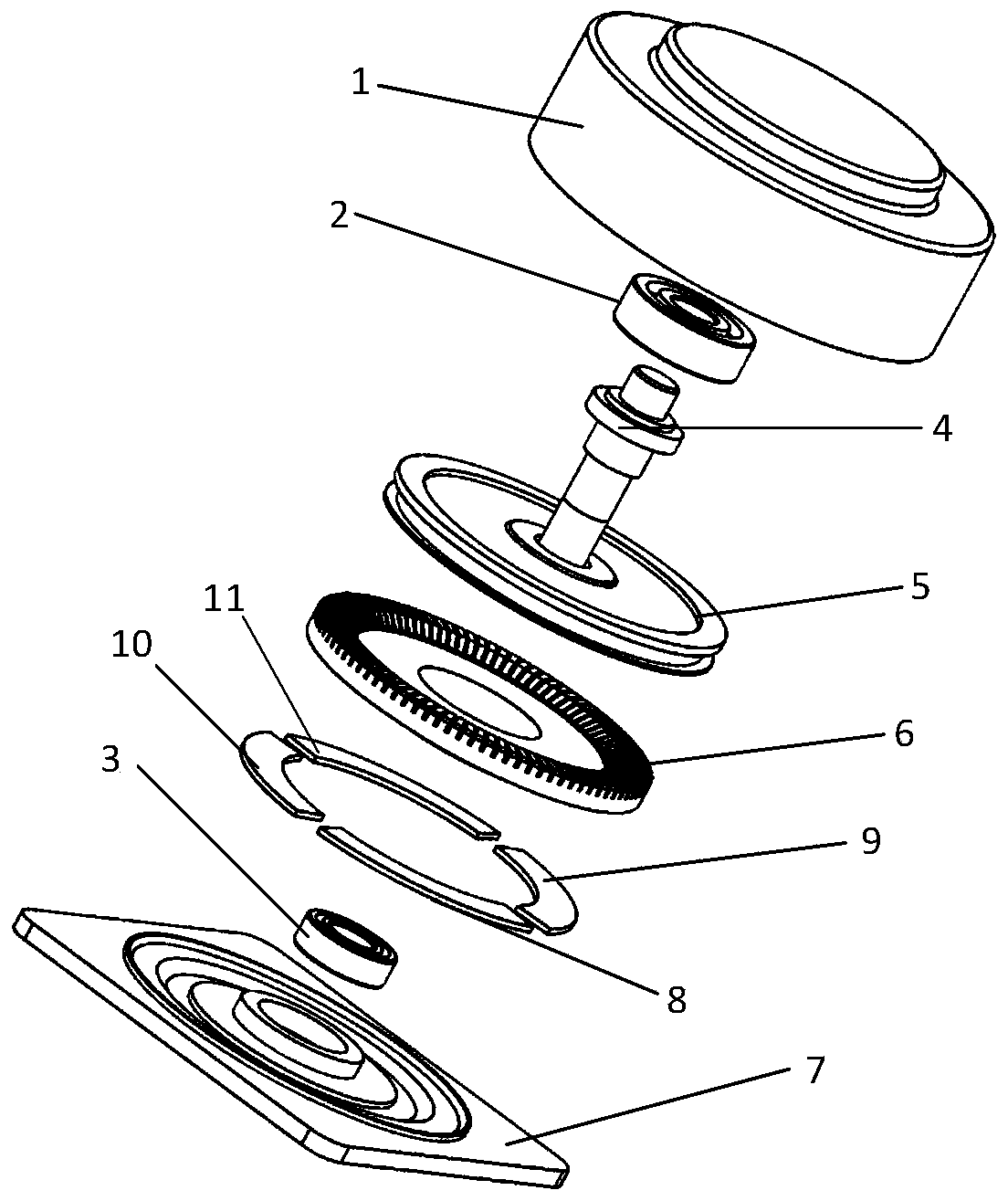

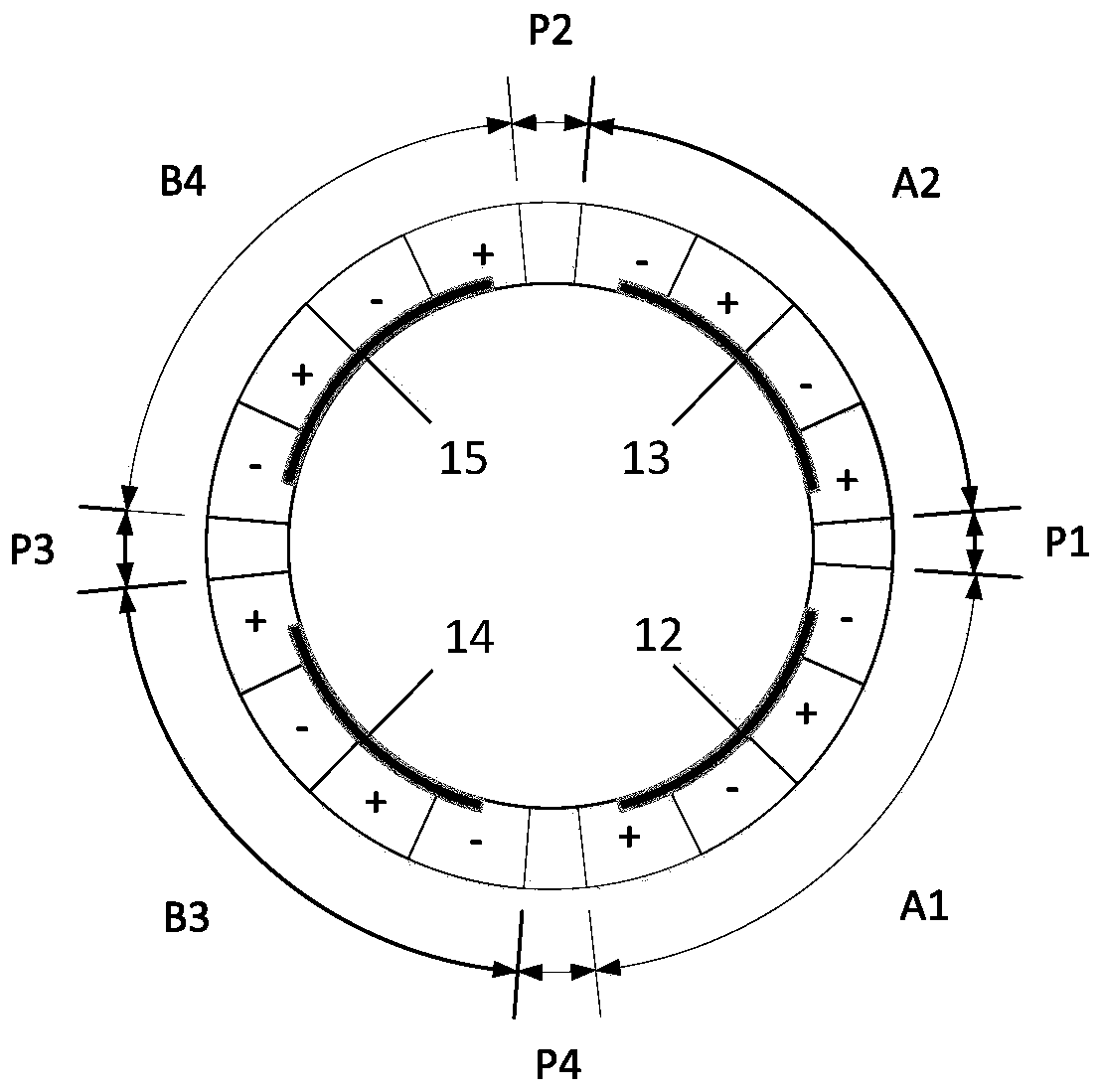

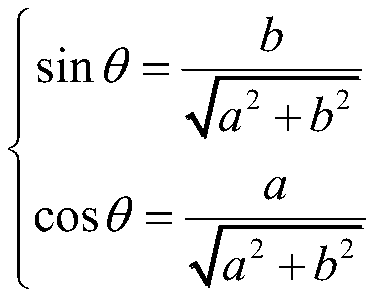

[0020] Such as figure 1 As shown, a spatial phase-modulated annular traveling wave ultrasonic motor with symmetrical ceramic partitions includes an end cover 1, a bearing 1 2, a bearing 2 3, a rotating shaft 4, a rotor 5, a stator 6, a base 7 and piezoelectric ceramics. Except for the zoning and polarization zoning methods of piezoelectric ceramics, the other structures, materials and assembly schemes of the motor are completely consistent with the traditional annular traveling wave ultrasonic motor. The piezoelectric ceramics of the spatially modulated annular traveling wave ultrasonic motor with symmetrical ceramic partitions in the embodiment are divided into piezoelectric ceramics 8 in A1 area, piezoelectric ceramics 9 in A2 area, piezoelectric ceramics 10 in area B3 and piezoelectric ceramics 11 in area B4. Such as figure 2 As shown, when the motor is working, space traveling waves with nine wavelengths are distributed on the circumference of the stator. If each traveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com