Patents

Literature

146 results about "Wave motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wave motors were machines designed and built in the late 19th and early 20th century to harness the power of wave or tidal energy. Many experiments were planned or built in California employing various methods. The earliest wave motors were not intended for the creation of electricity. Prior to 1880, wave motors were designed to operate non-electrically to power vehicles or mills.

Wave energy conversion device for desalination, ETC

InactiveUS7023104B2Improve efficiencyEasy to operateWind motor controlGeneral water supply conservationWater qualityEngineering

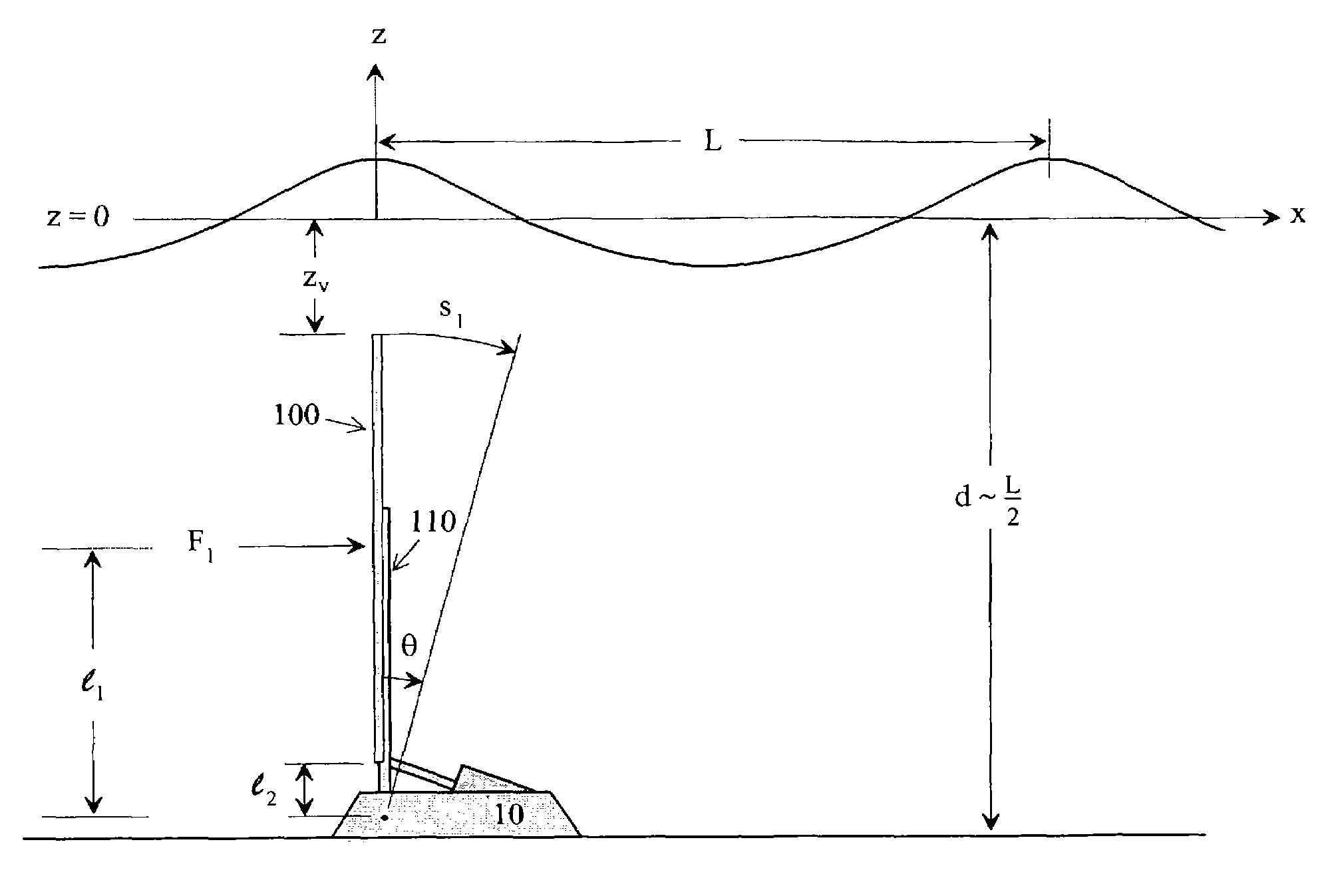

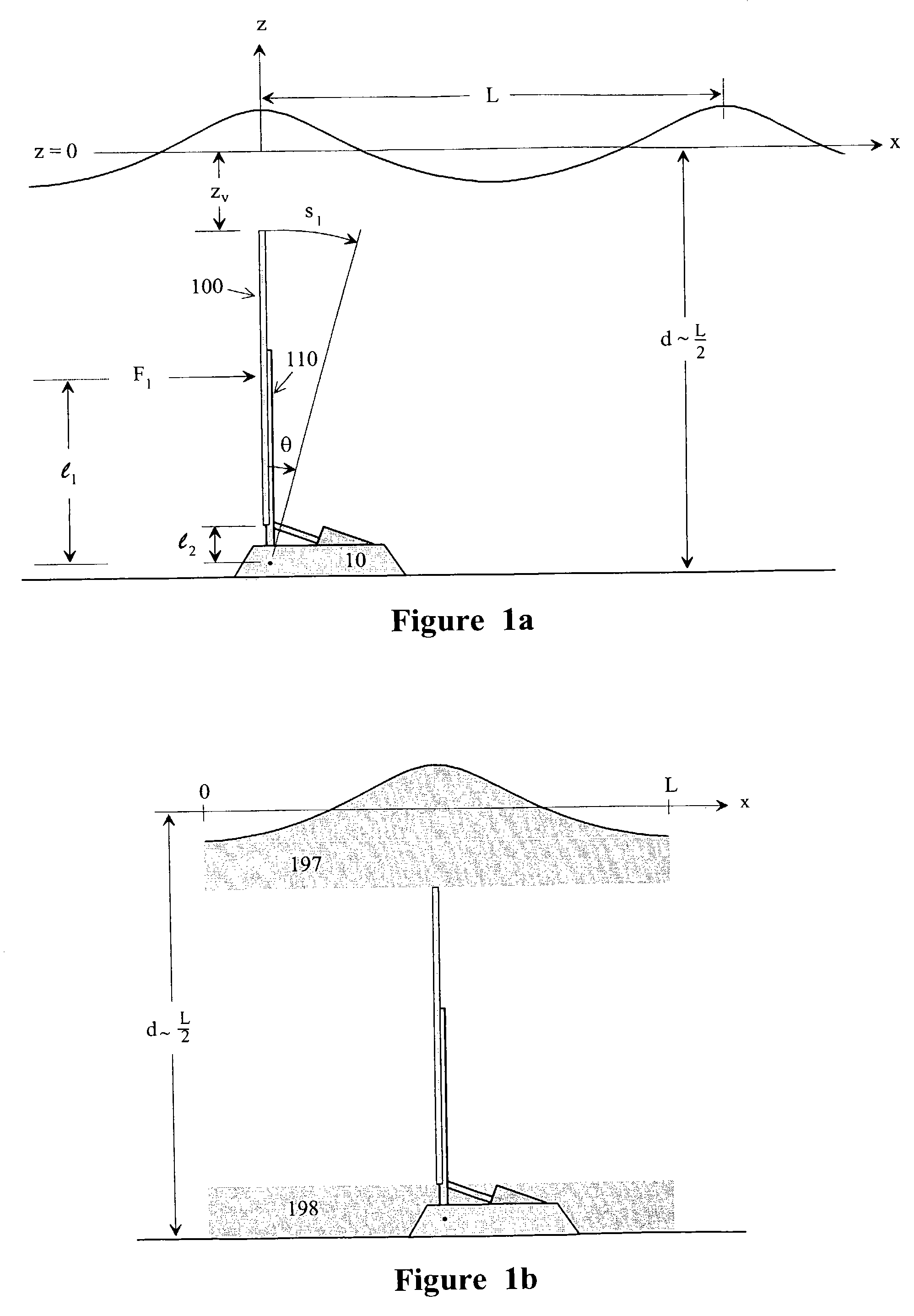

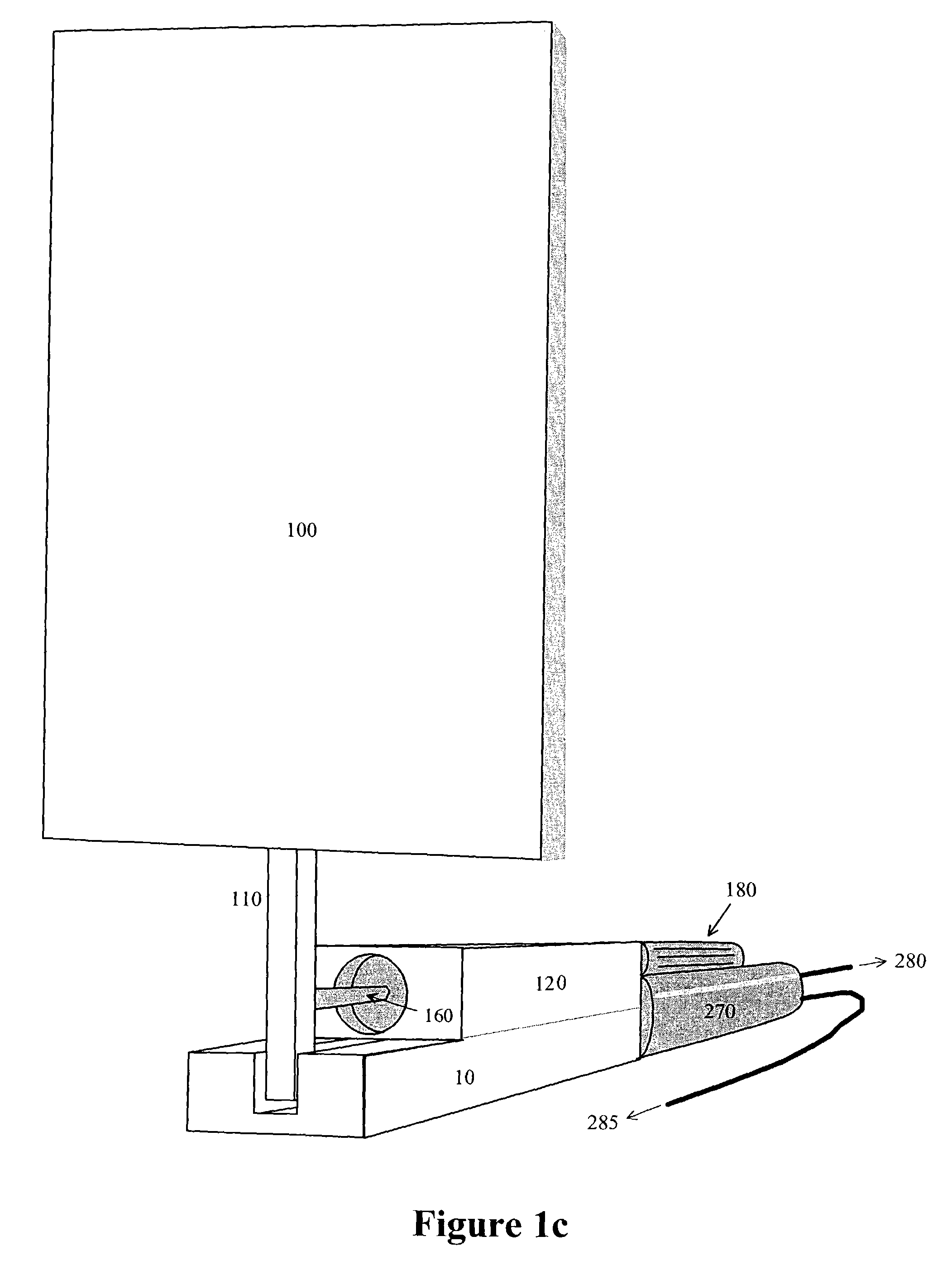

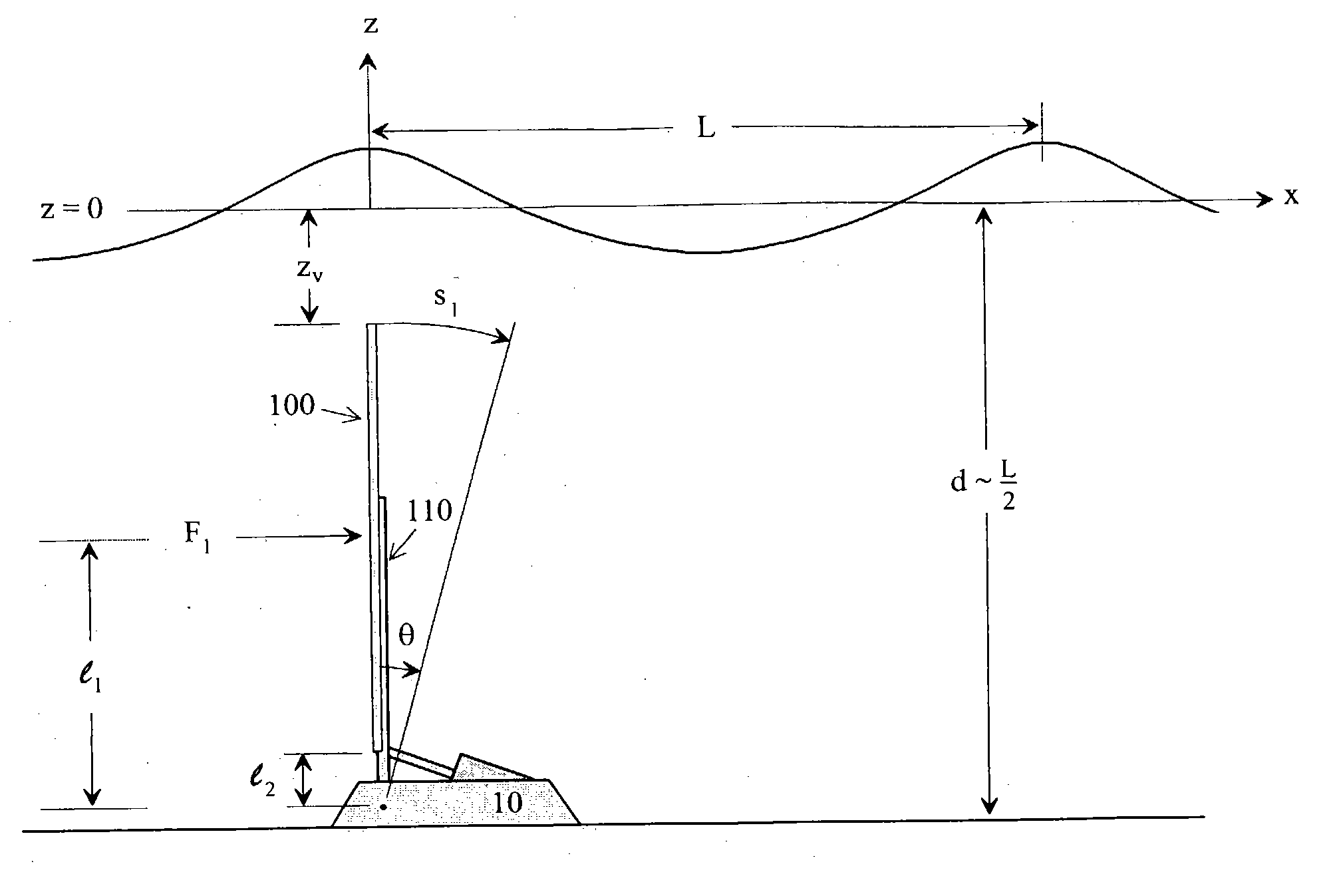

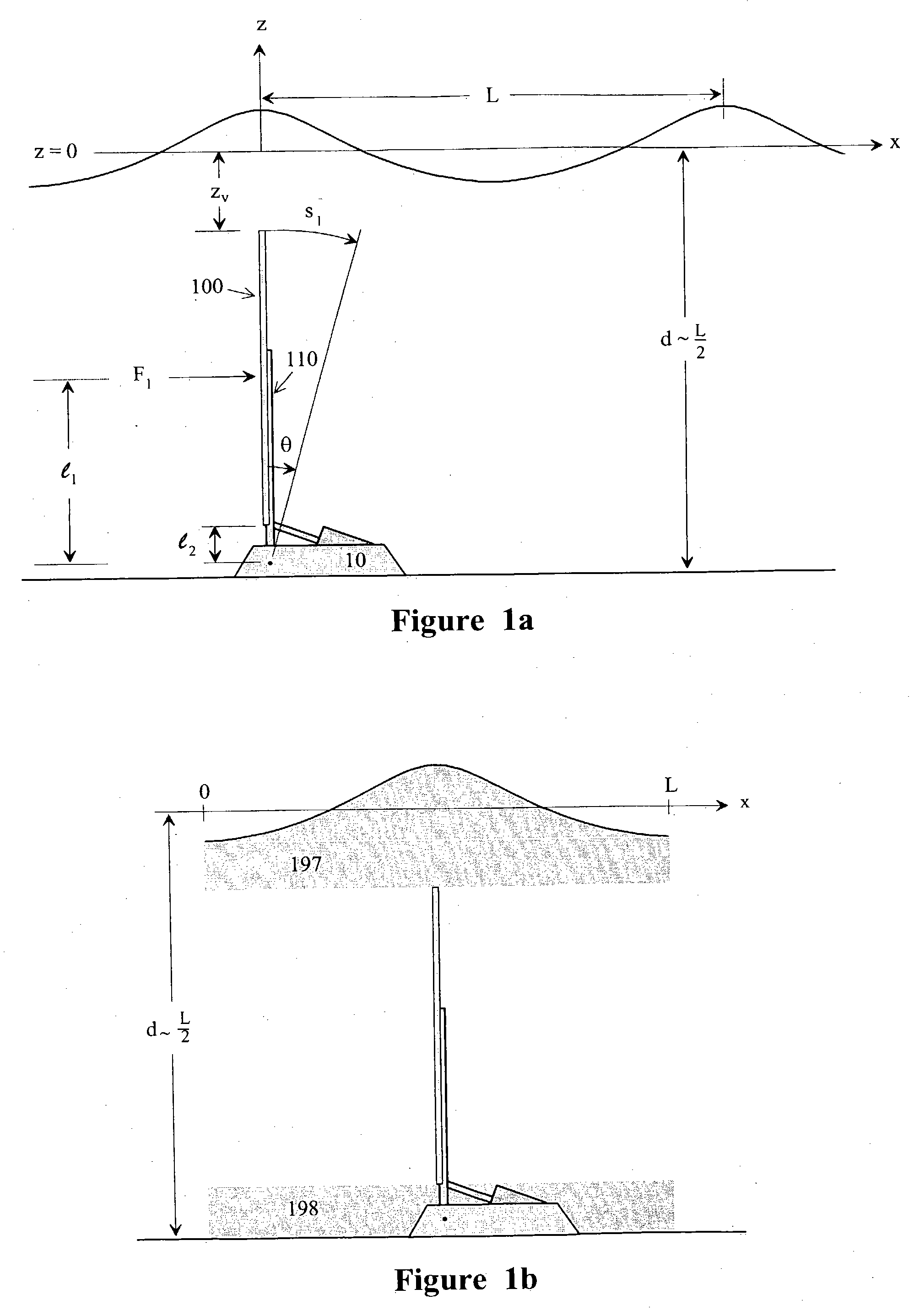

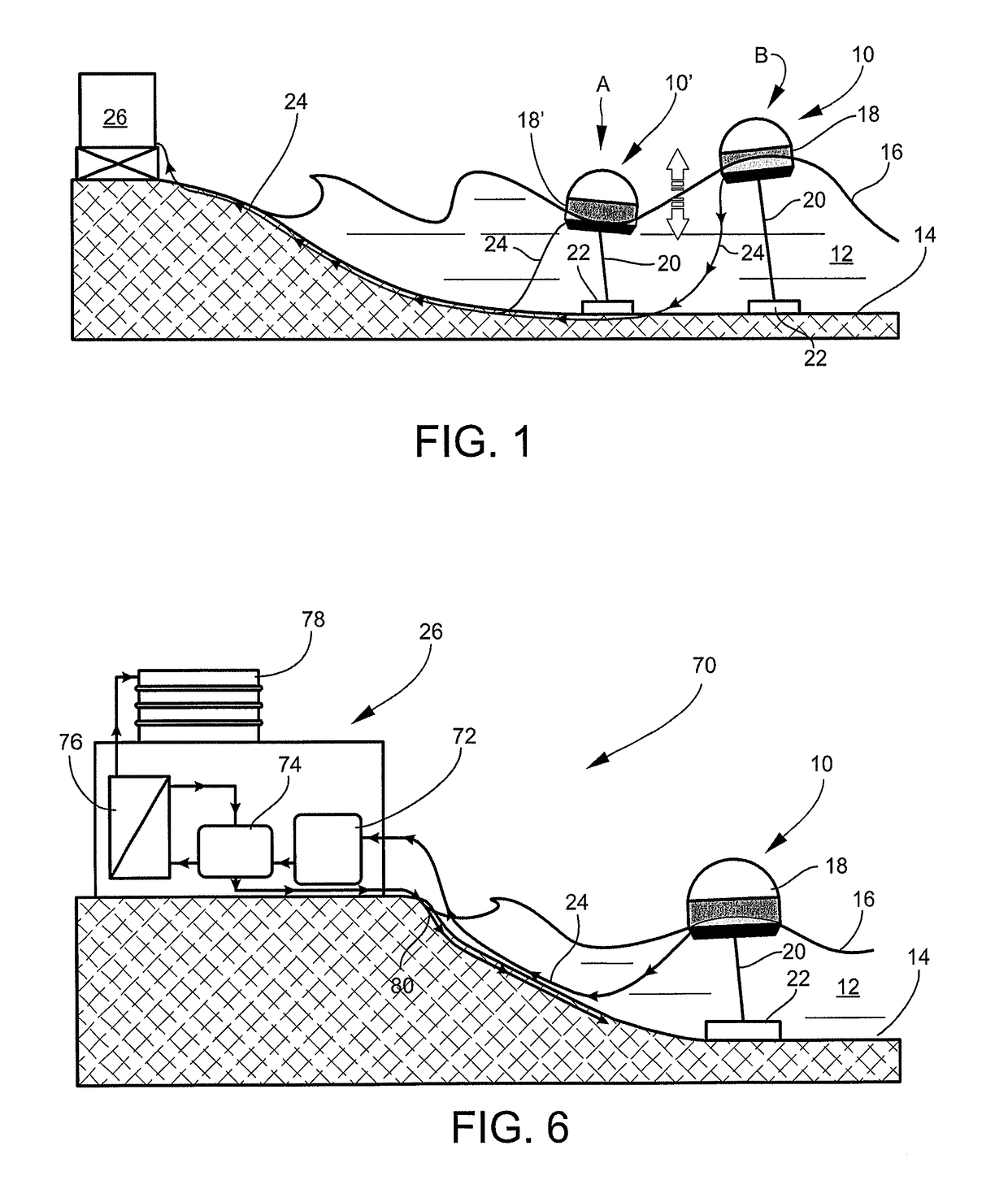

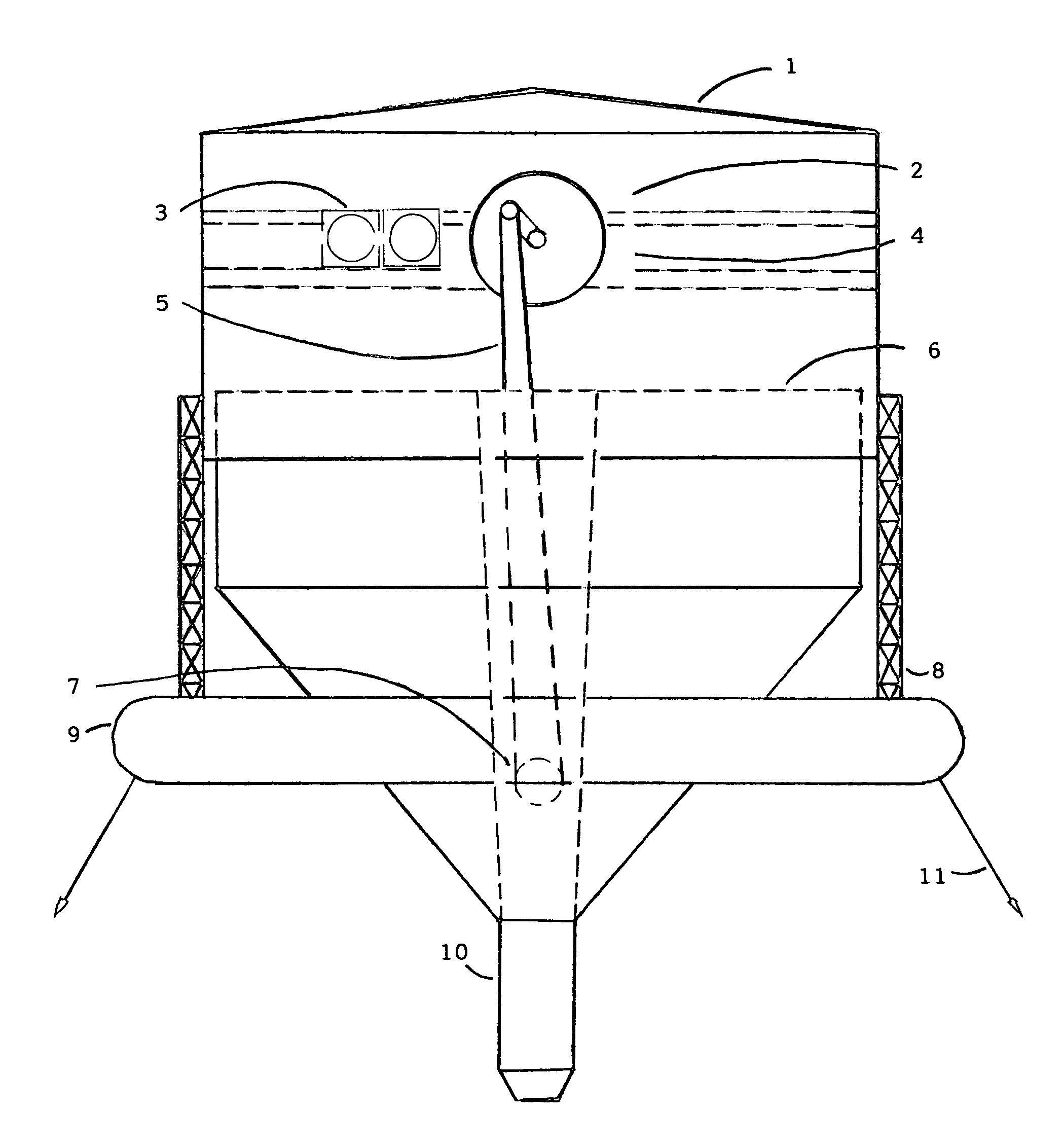

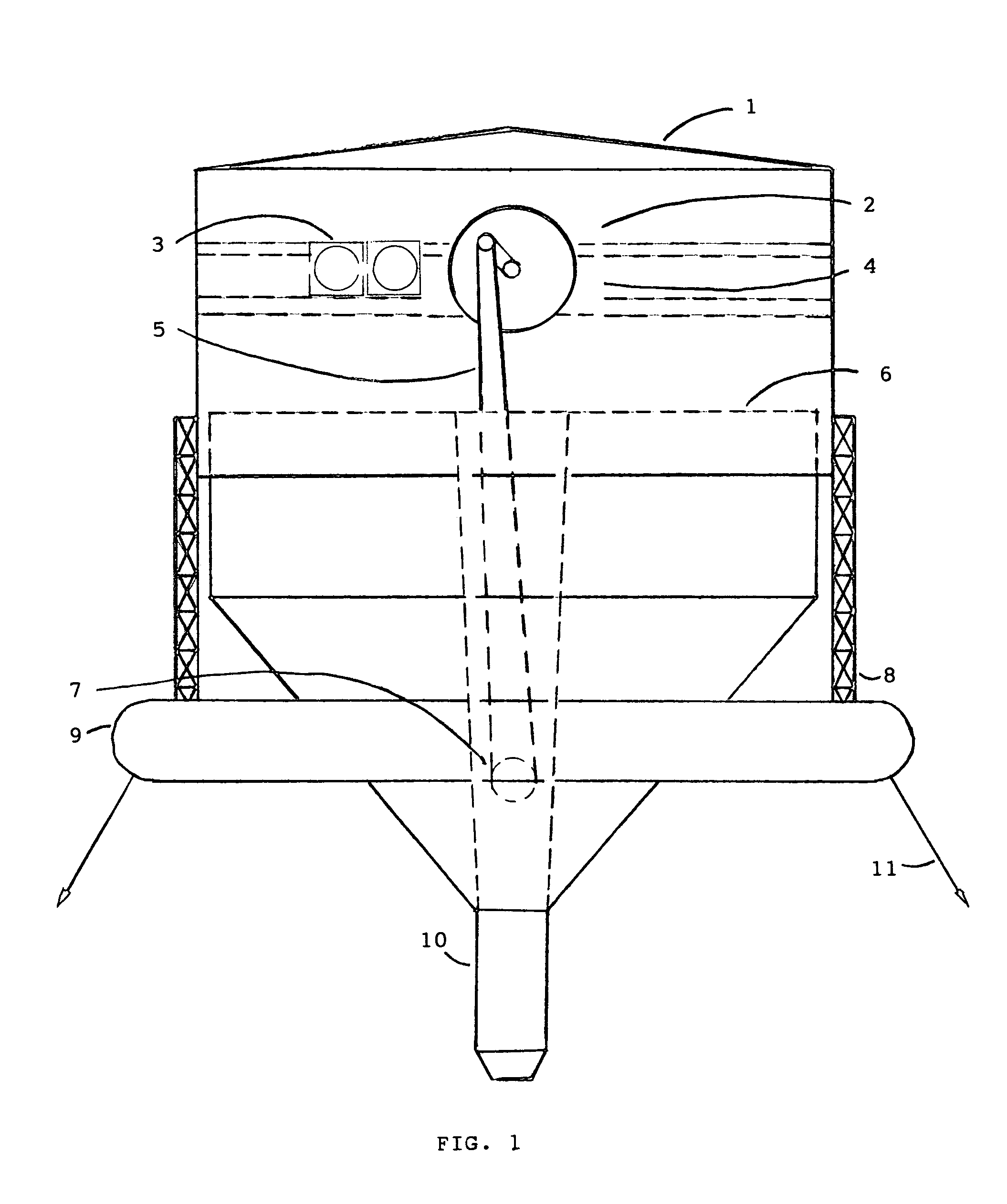

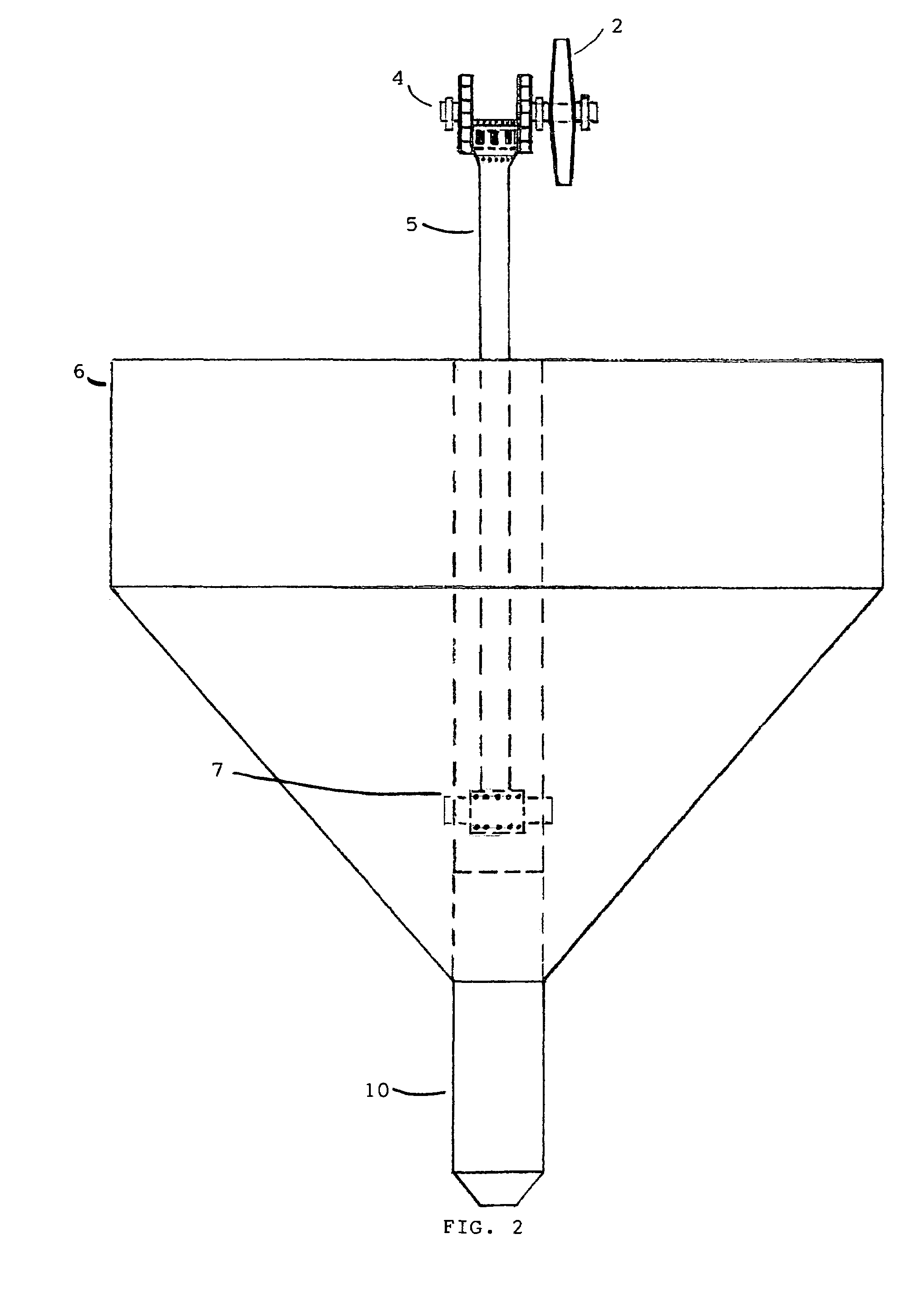

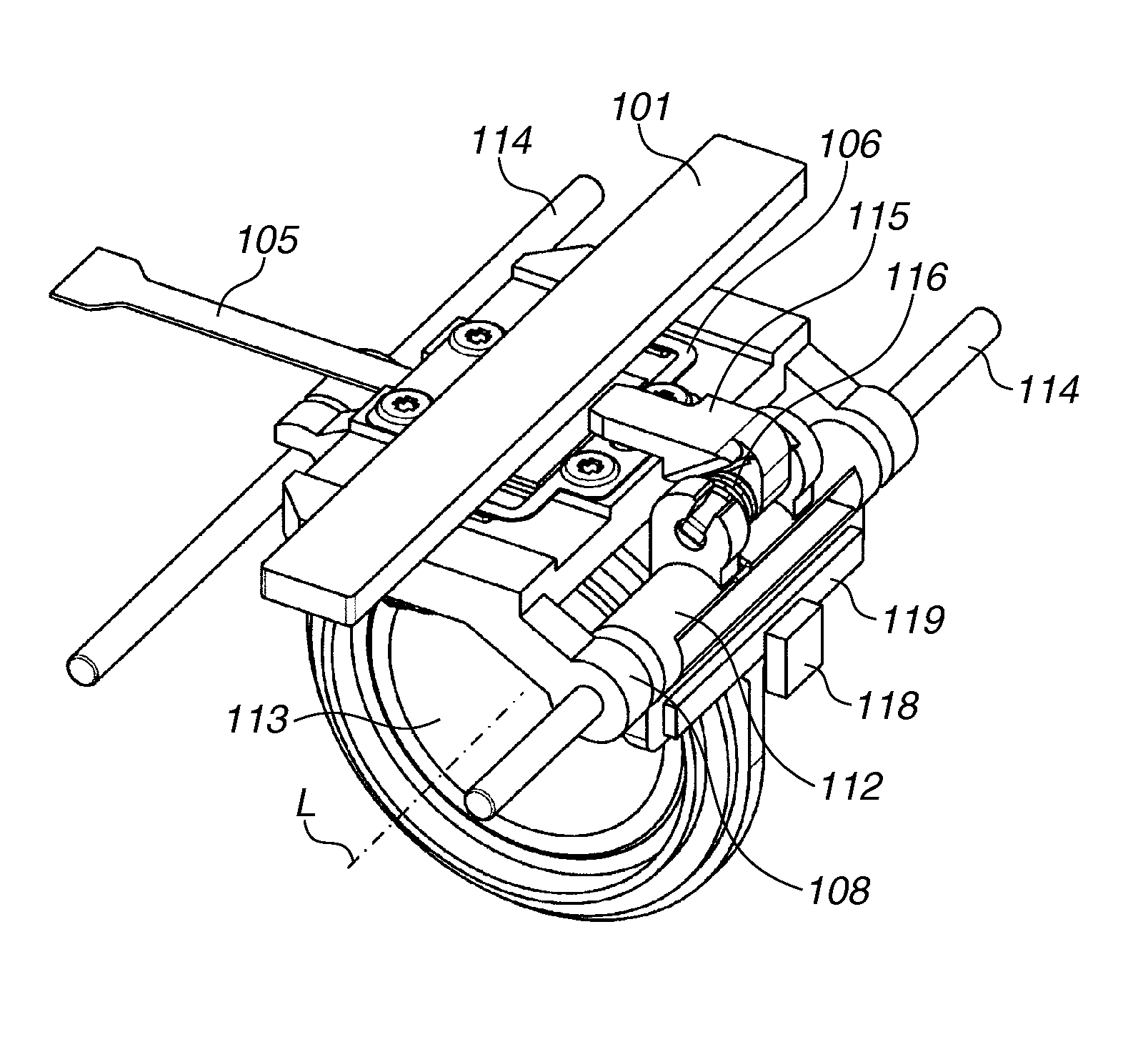

An impulse-type “wave motor” employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

Wave energy conversion device for desalination, ETC

InactiveUS20040007881A1Minimize exposureLow profileWind motor controlGeneral water supply conservationWater qualityWave motor

An impulse-type "wave motor" employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

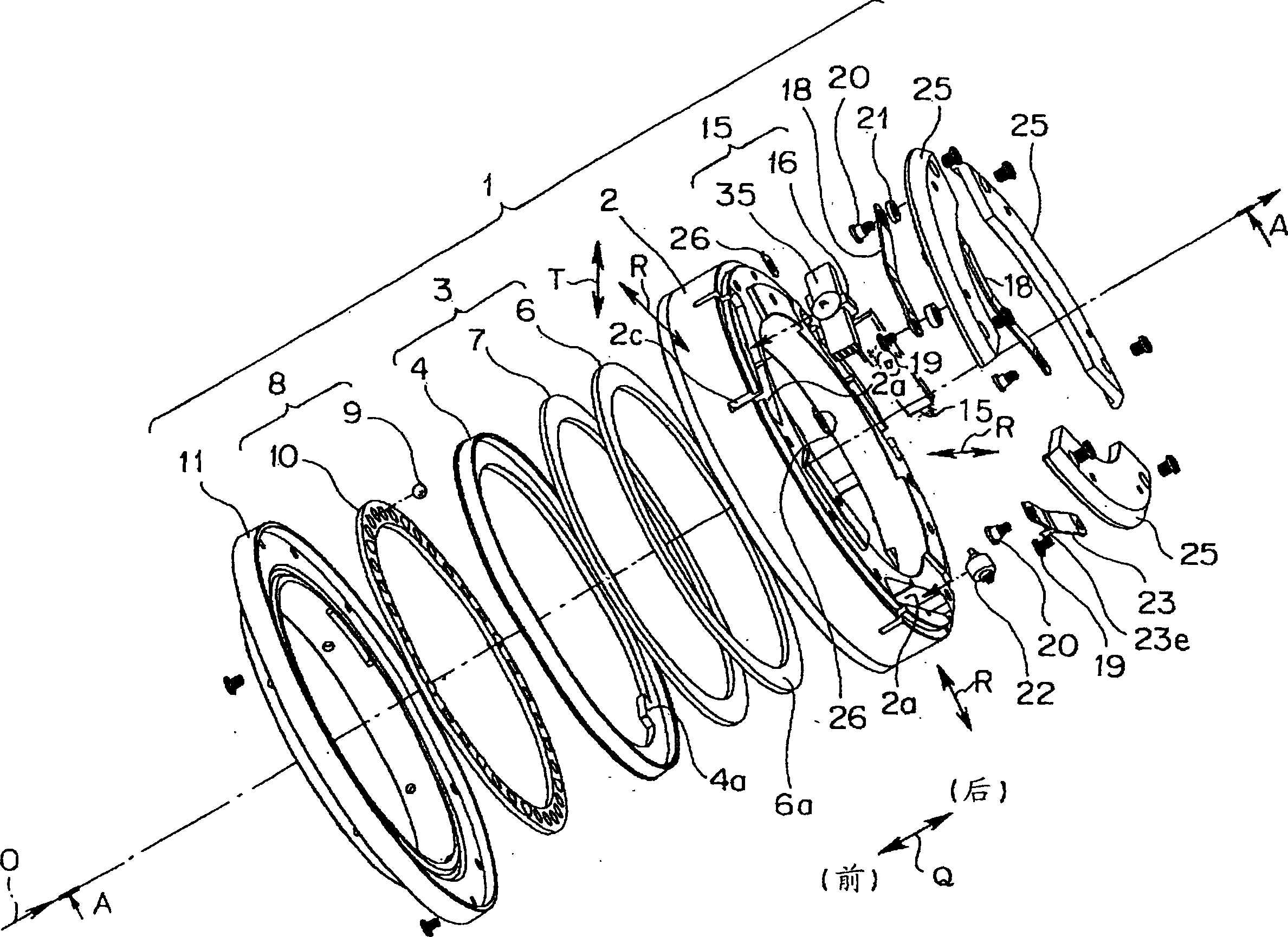

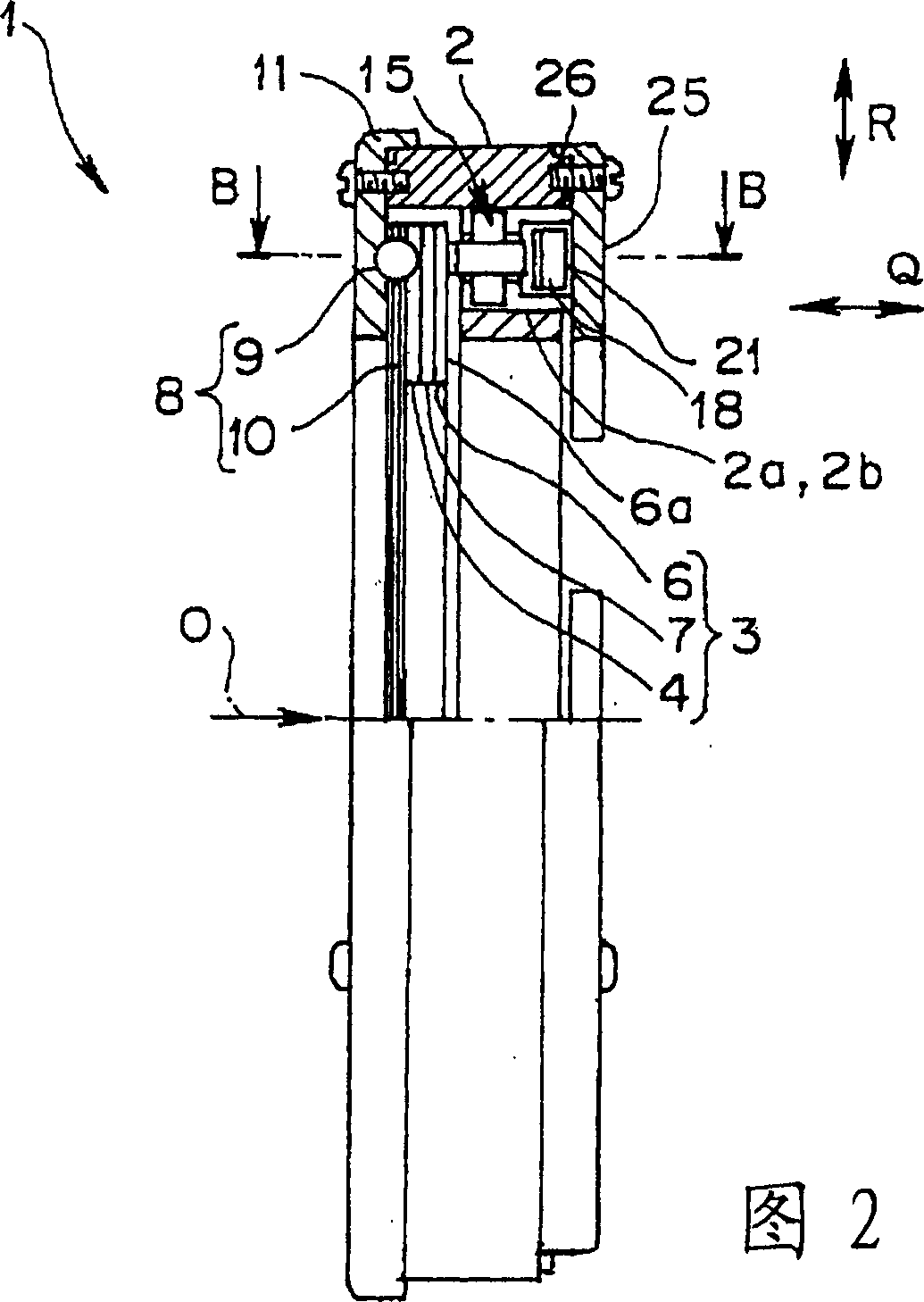

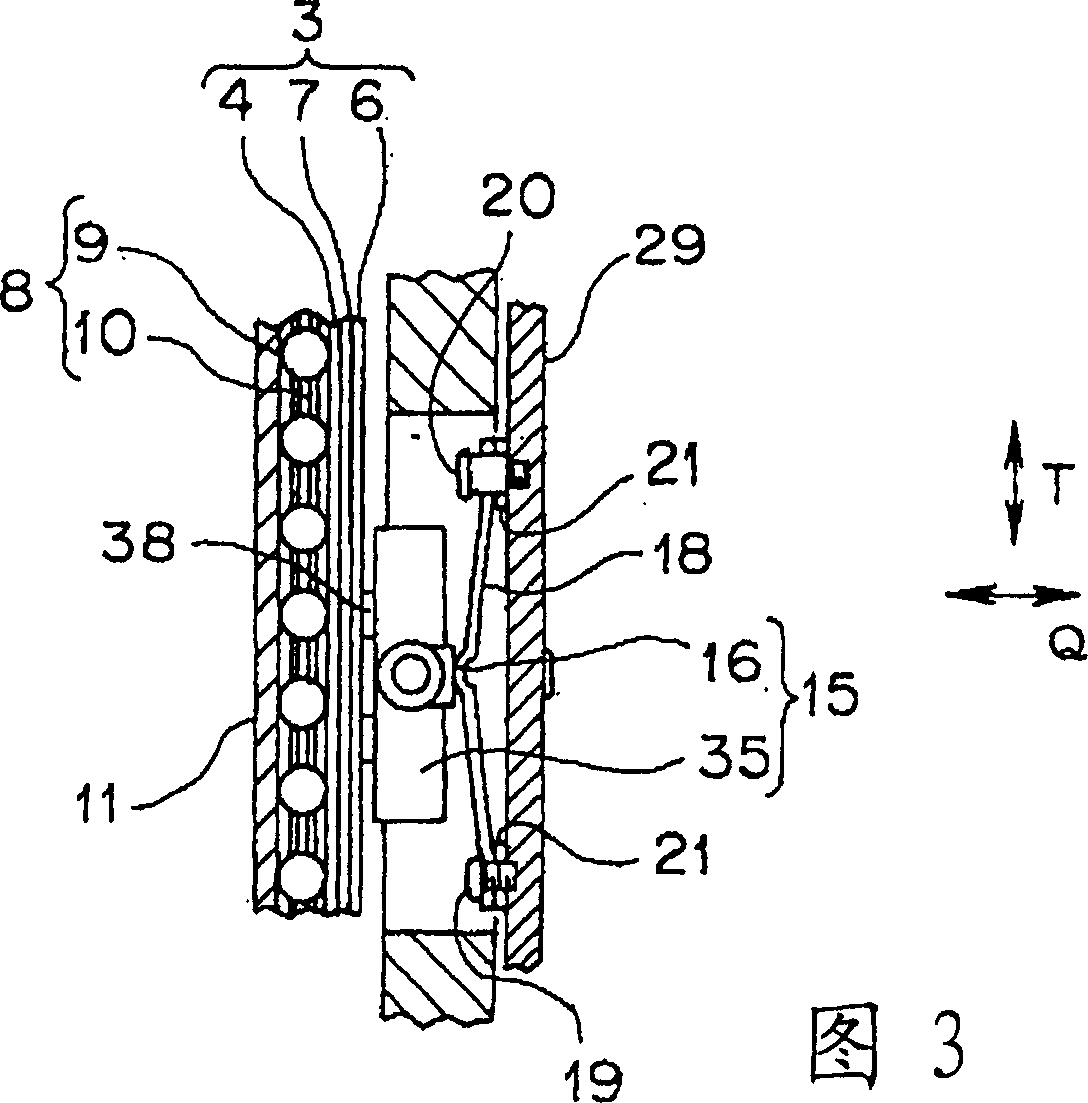

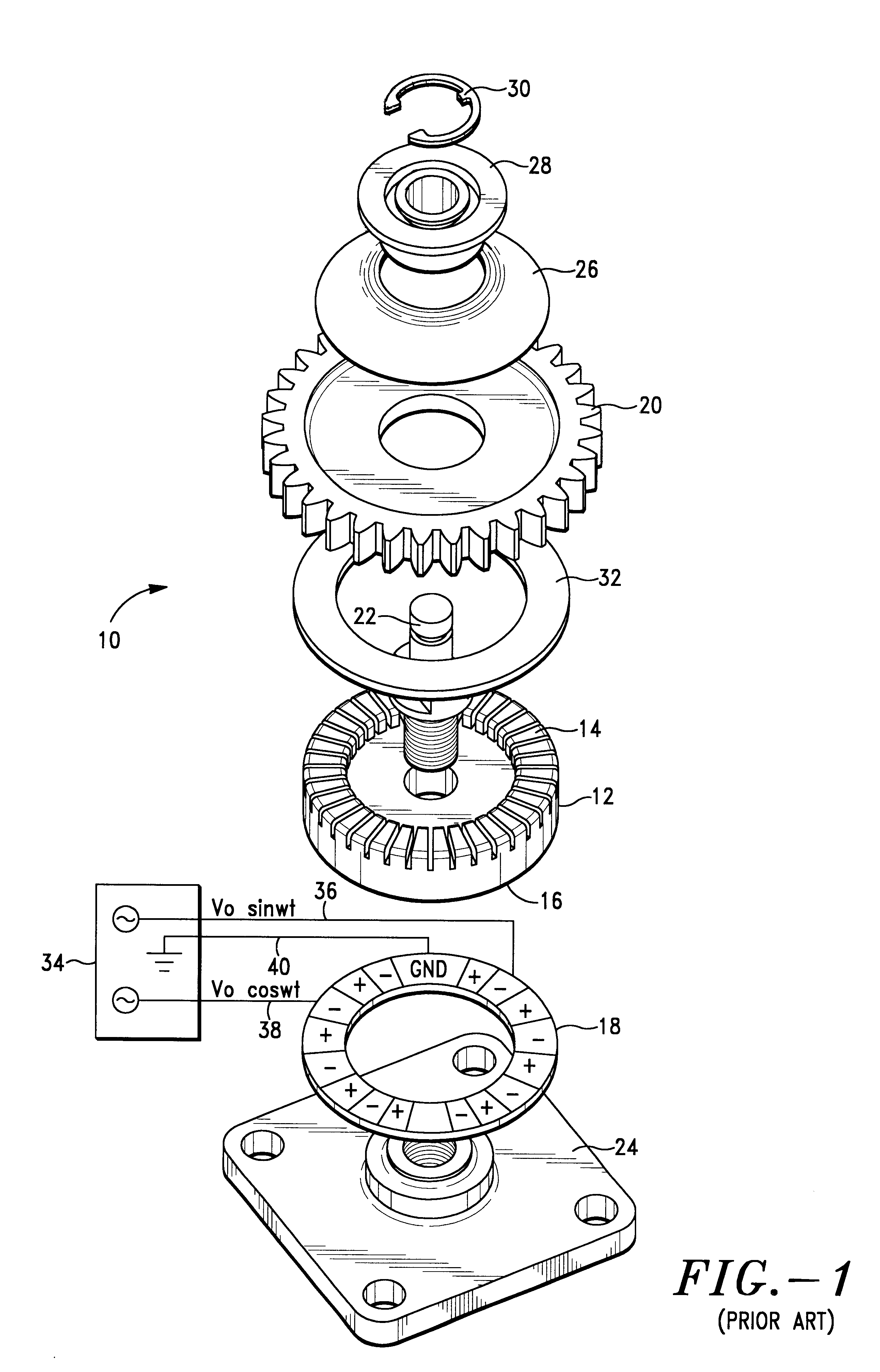

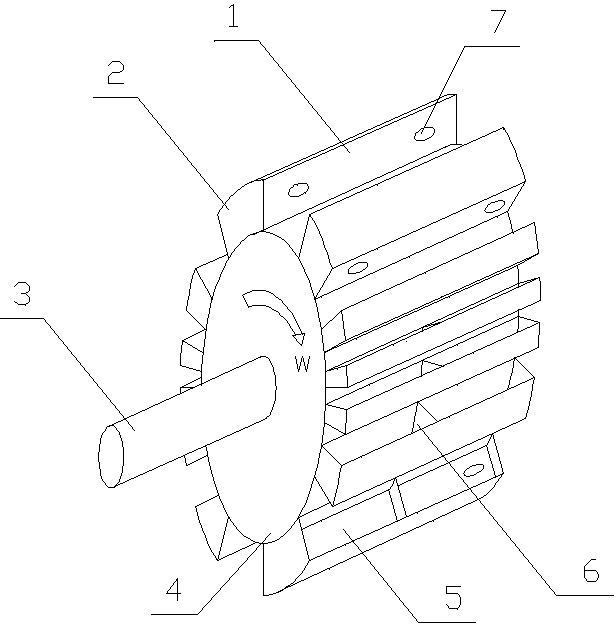

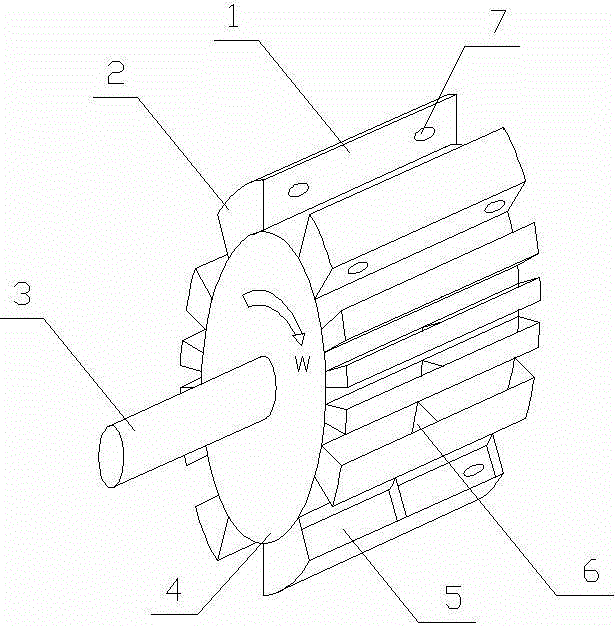

Bidirectional rotary motion-converter, wave motors, and various other applications thereof

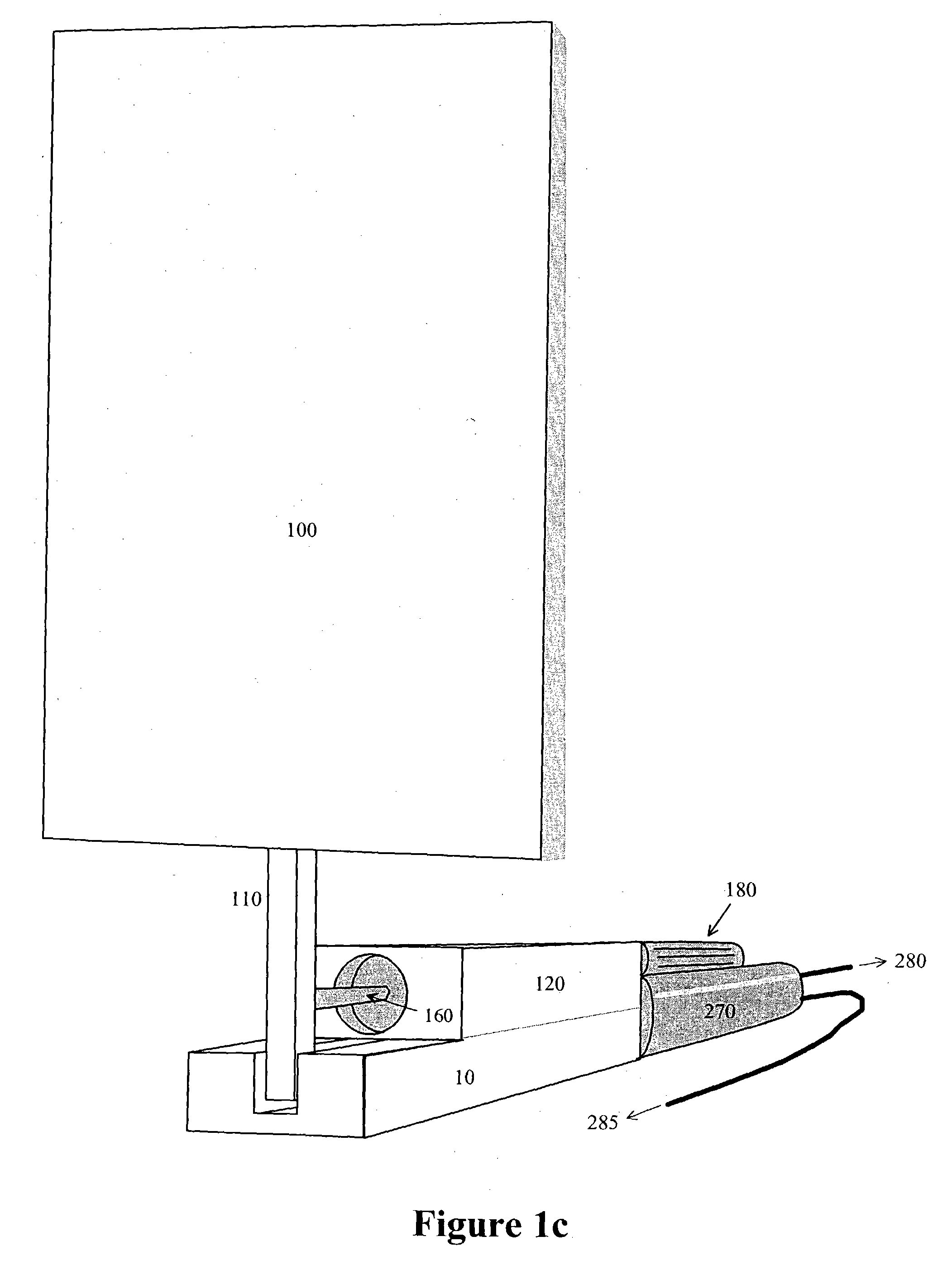

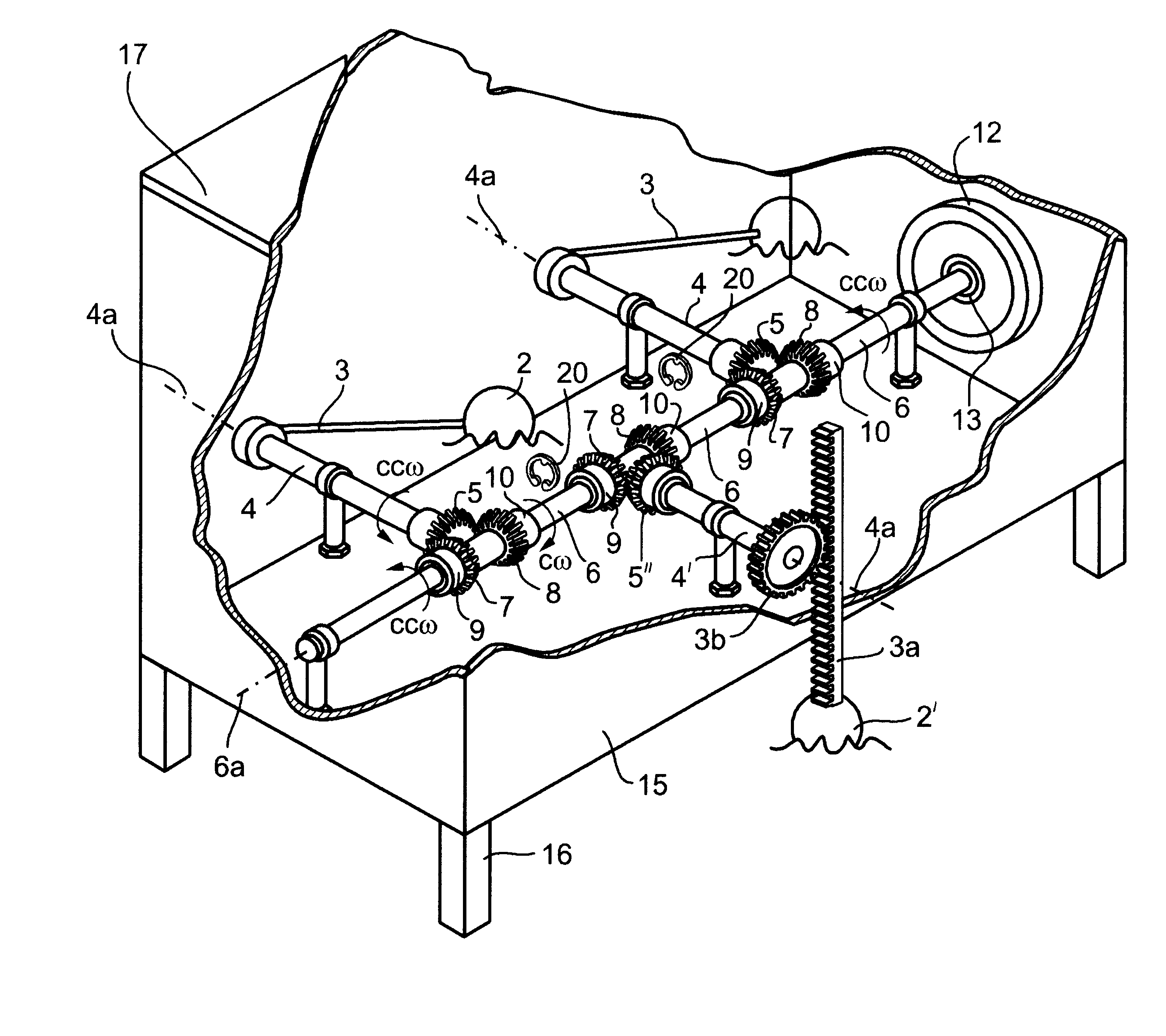

Motion-converter apparatus for converting bidirectional rotary movements to unidirectional rotary movements includes: an input shaft for inputting the bidirectional rotary movements; an output shaft for outputting the unidirectional rotary movements, the output shaft having a longitudinal axis perpendicular to the longitudinal axis of the input shaft; a drive bevel gear coaxial with, and driven bidirectionally by, the input shaft; a pair of driven bevel gears coaxial with the output shaft and meshing with the drive bevel gear on opposite sides of the axis of the drive bevel gear so as to be driven bidirectionally thereby but in opposite directions with respect to the output shaft; and a pair of one-way clutches coupling the driven bevel gears to the output shaft such that both one-way clutches are effective to drive the output shaft only in one direction. Various applications of such apparatus are also described, including wave and tide motors, wind turbines and bidirectional-movement measuring devices.

Owner:WORLDWIDE SOLUTIONS

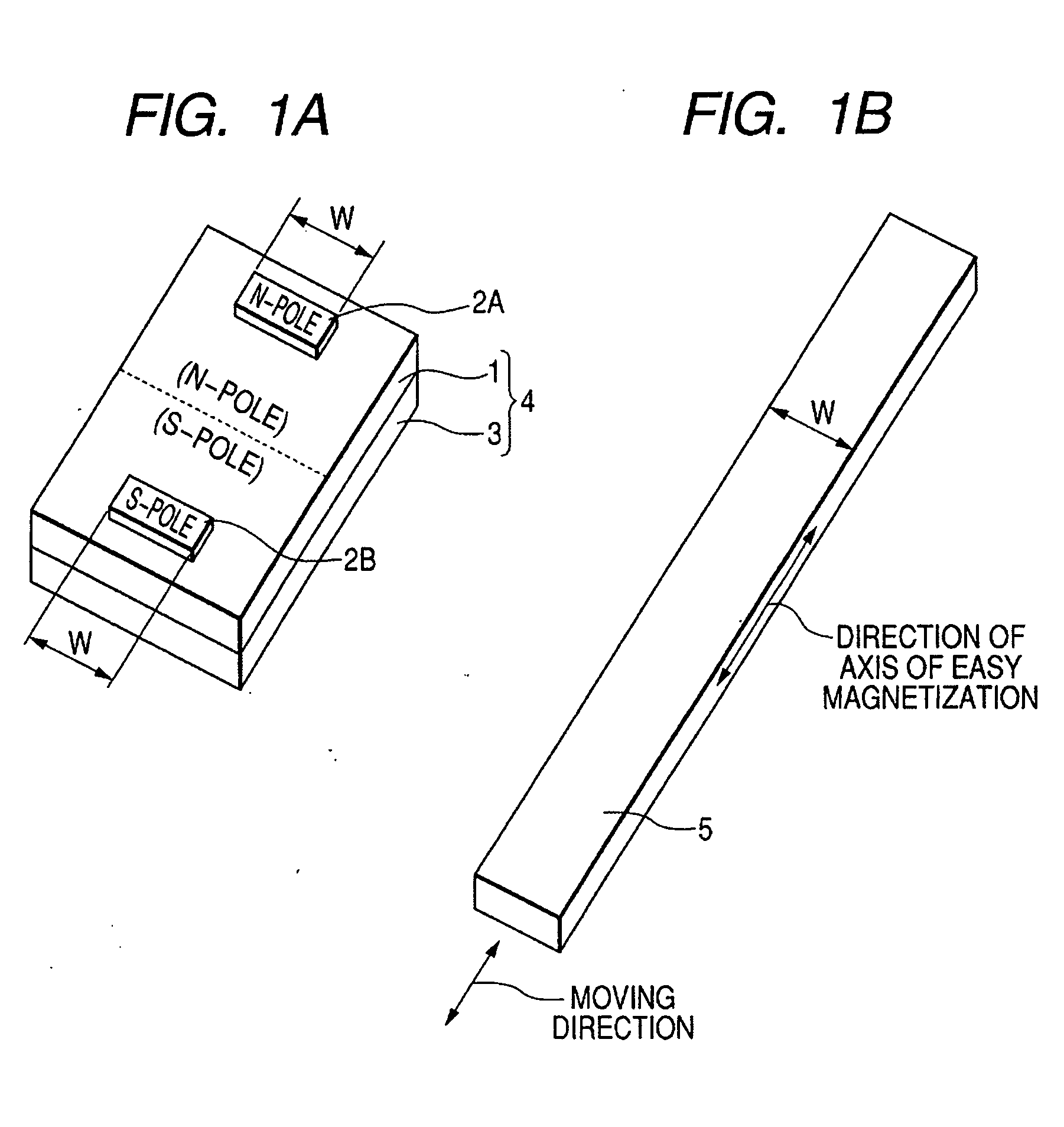

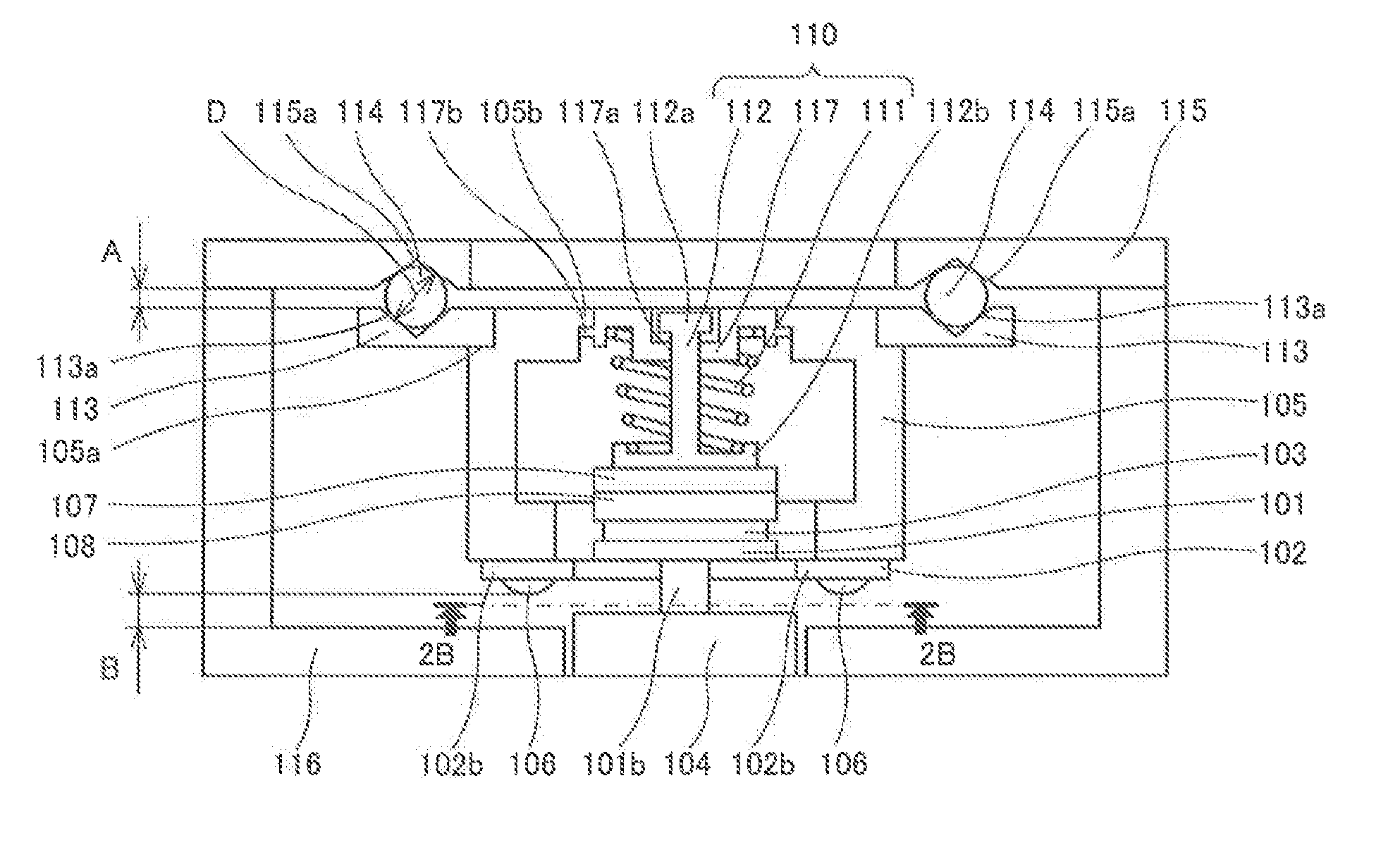

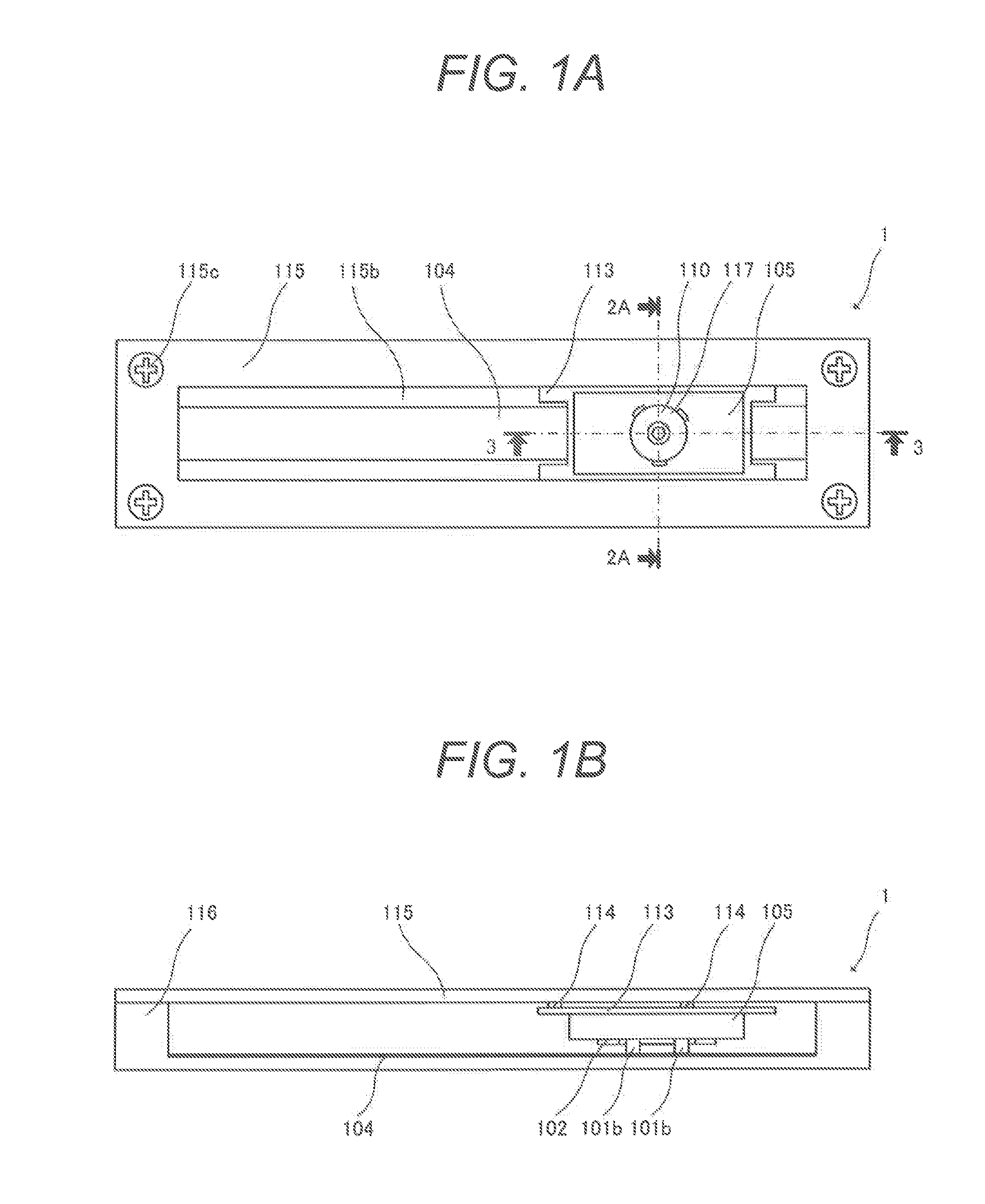

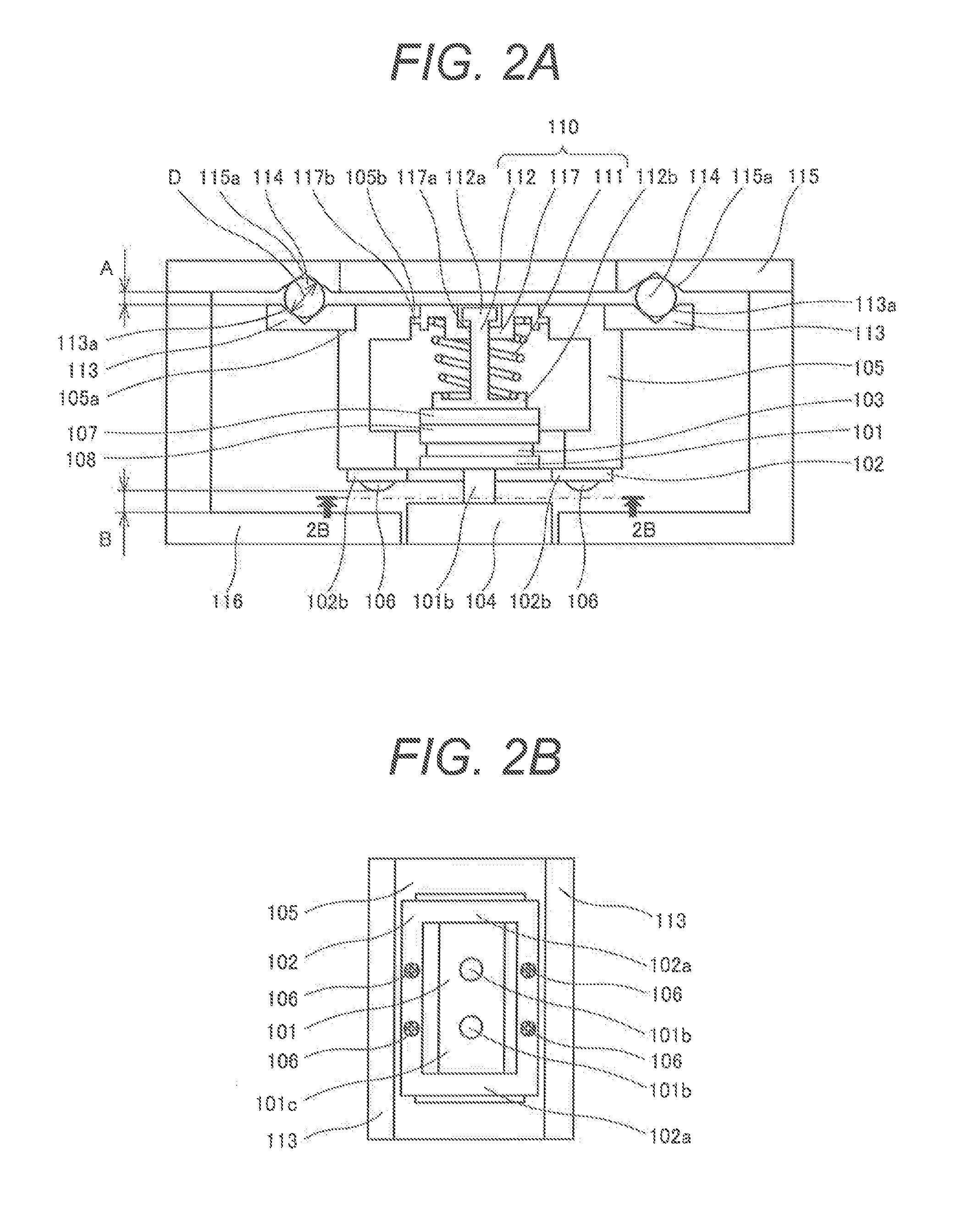

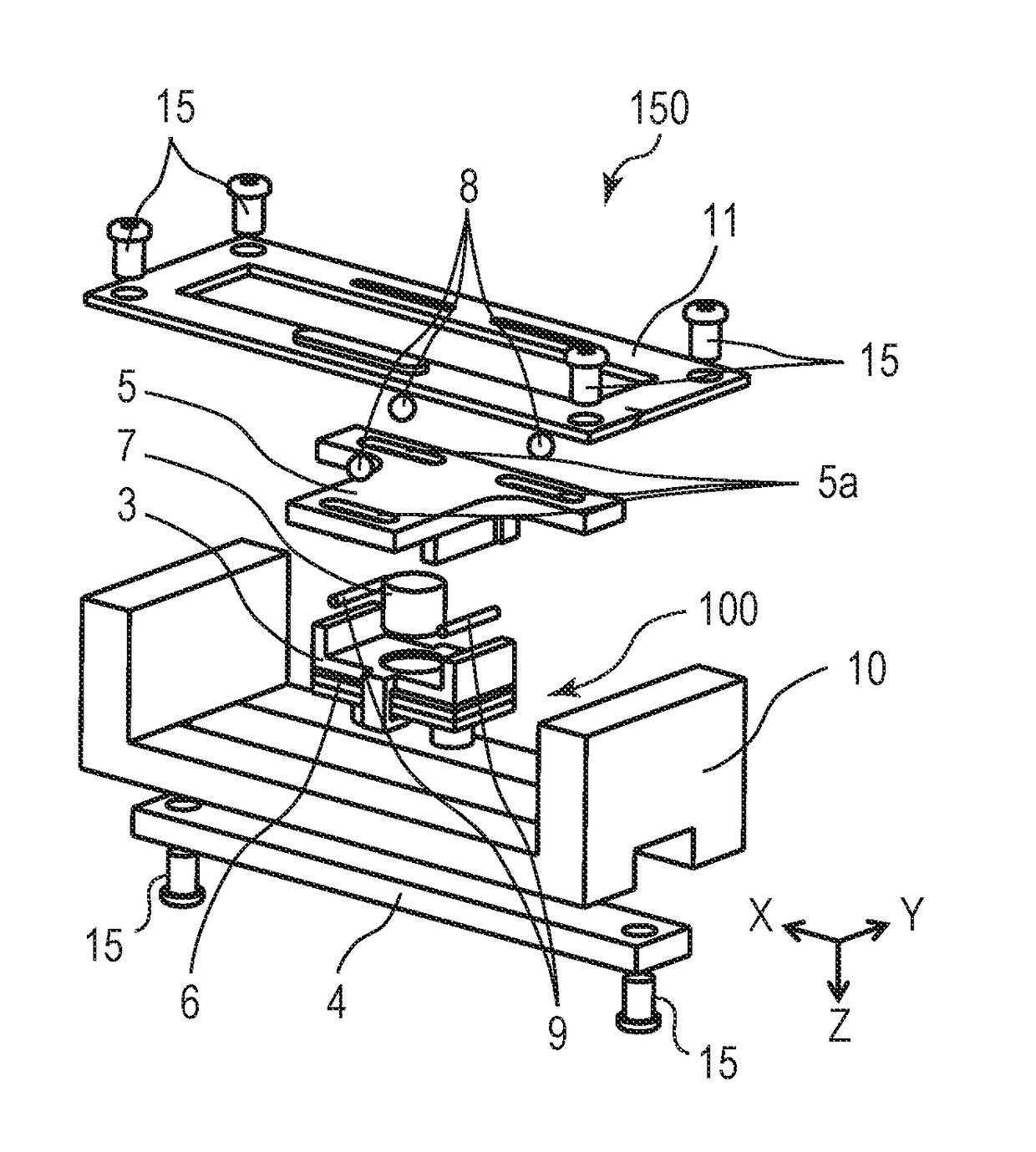

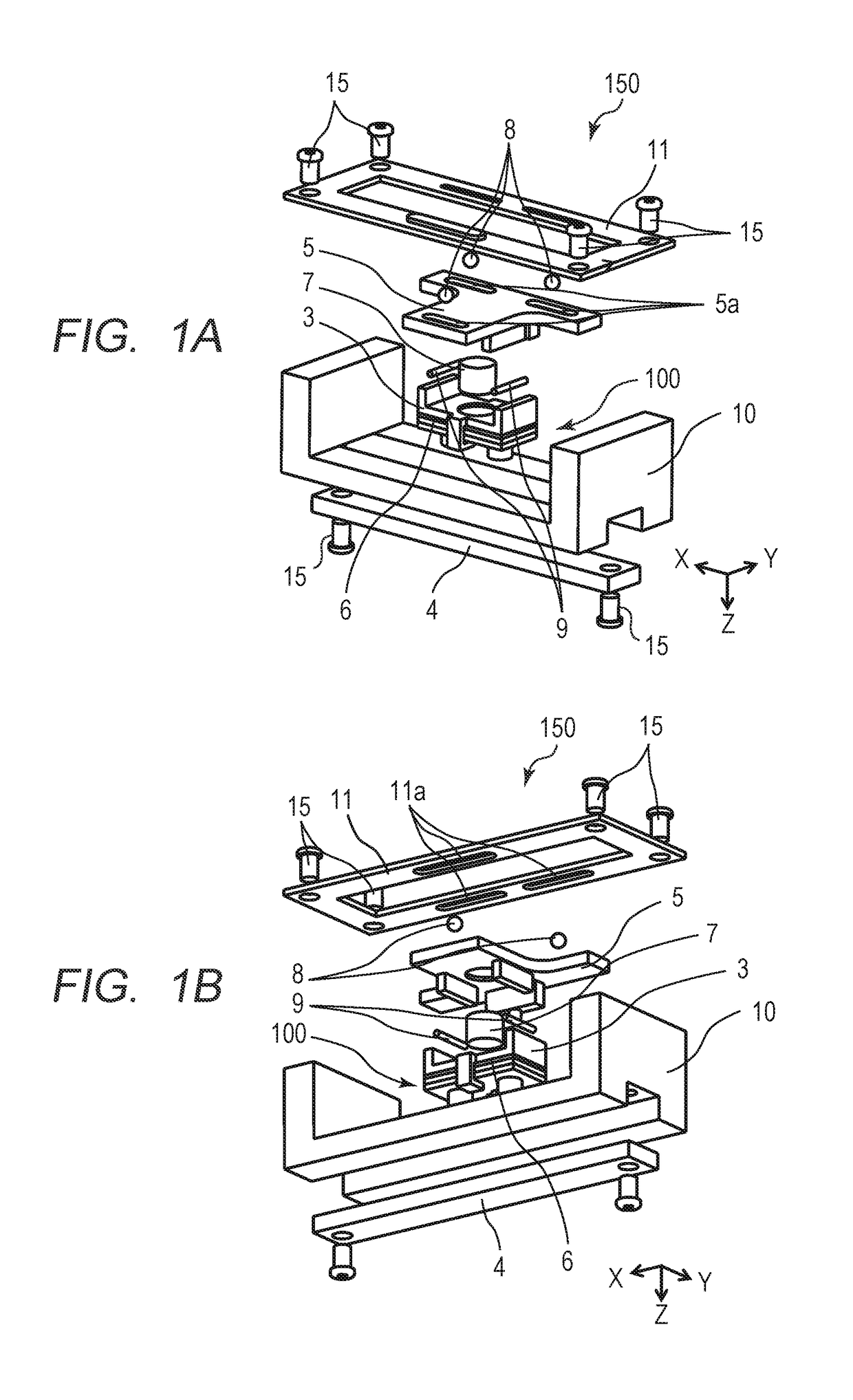

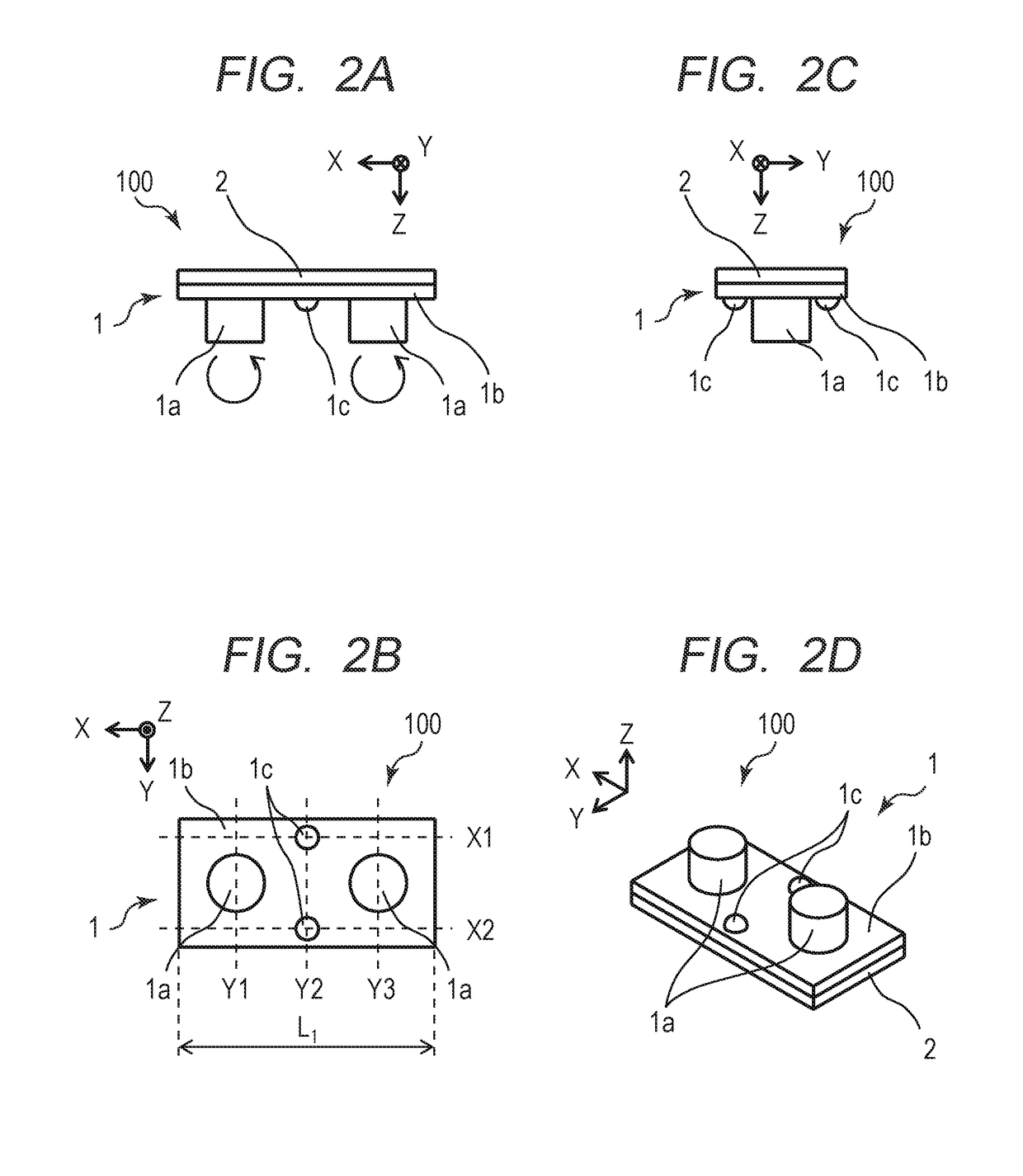

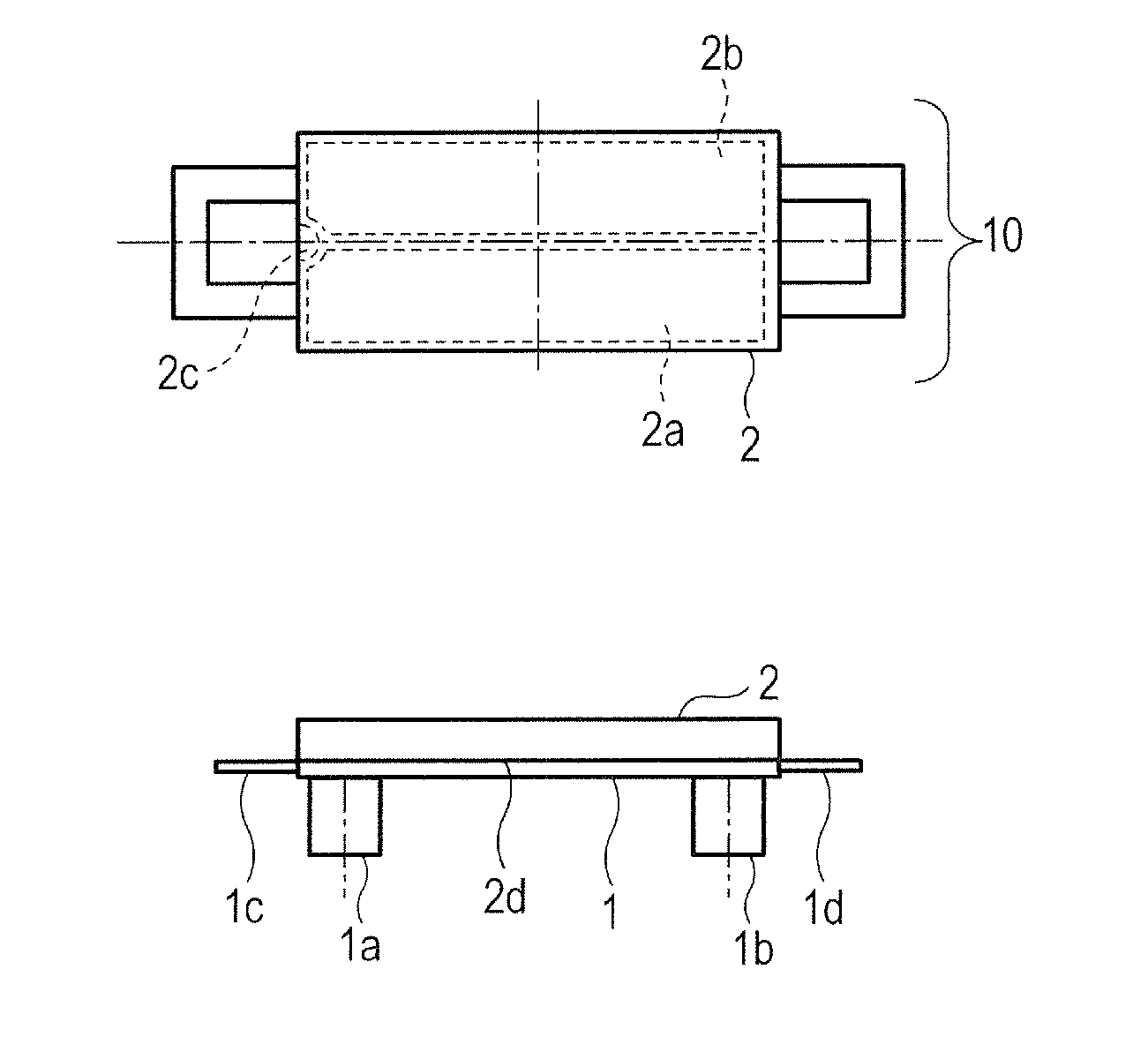

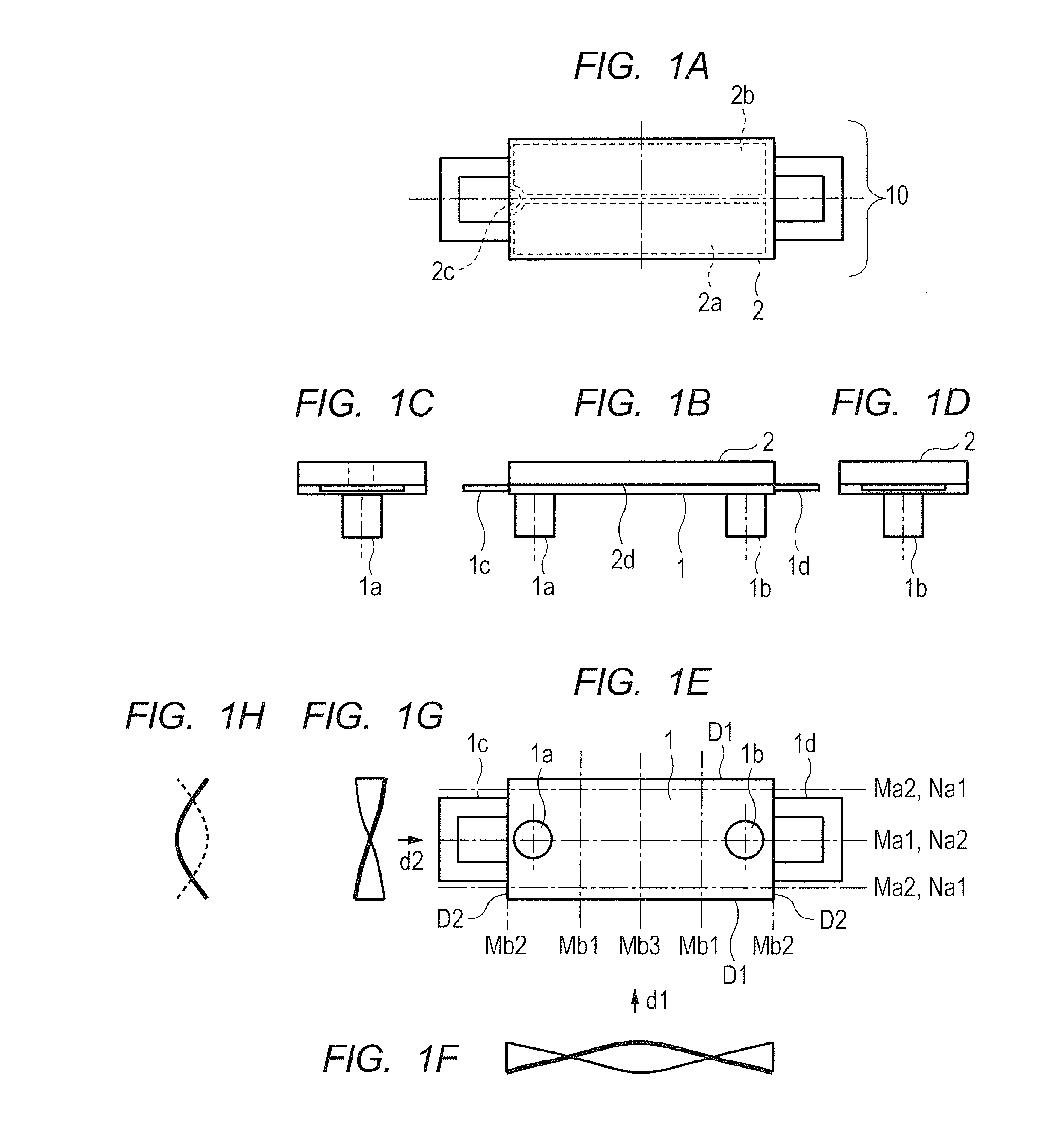

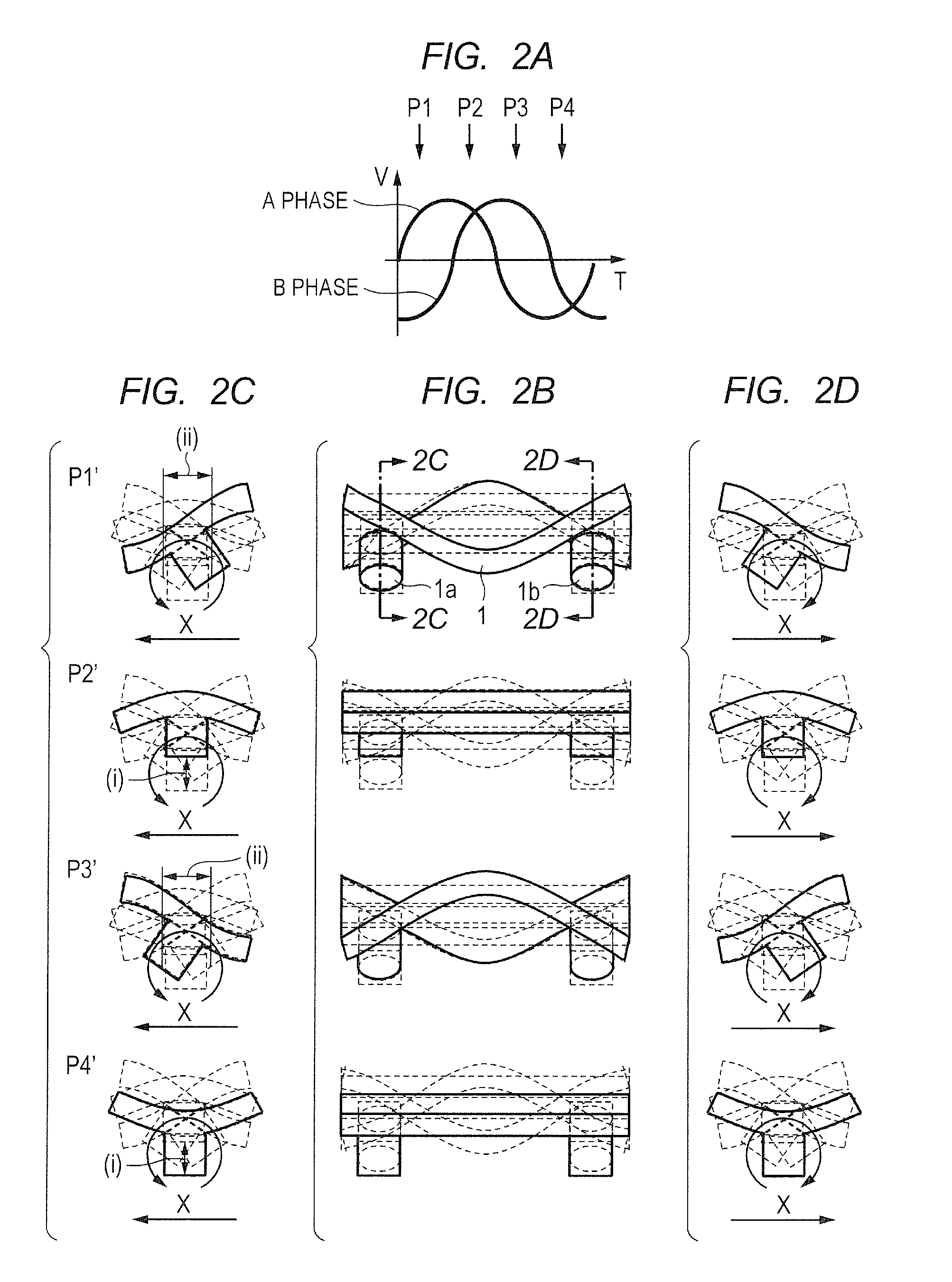

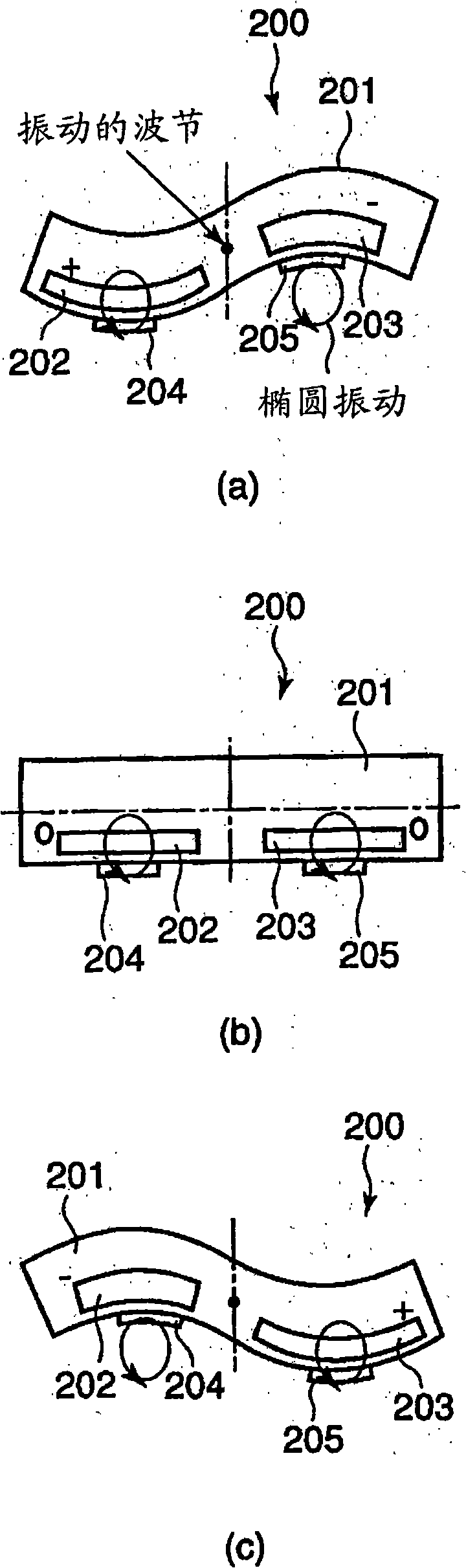

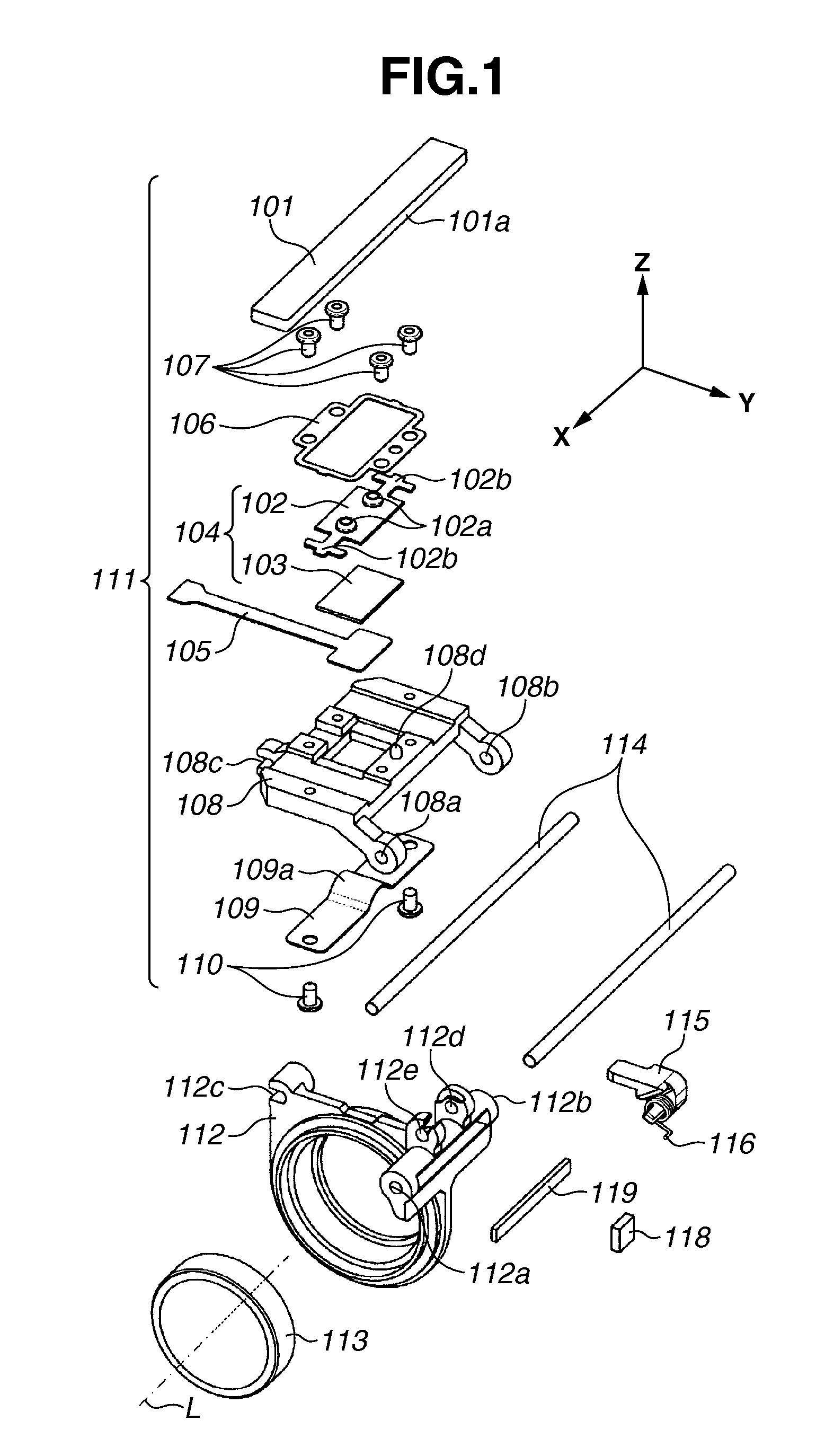

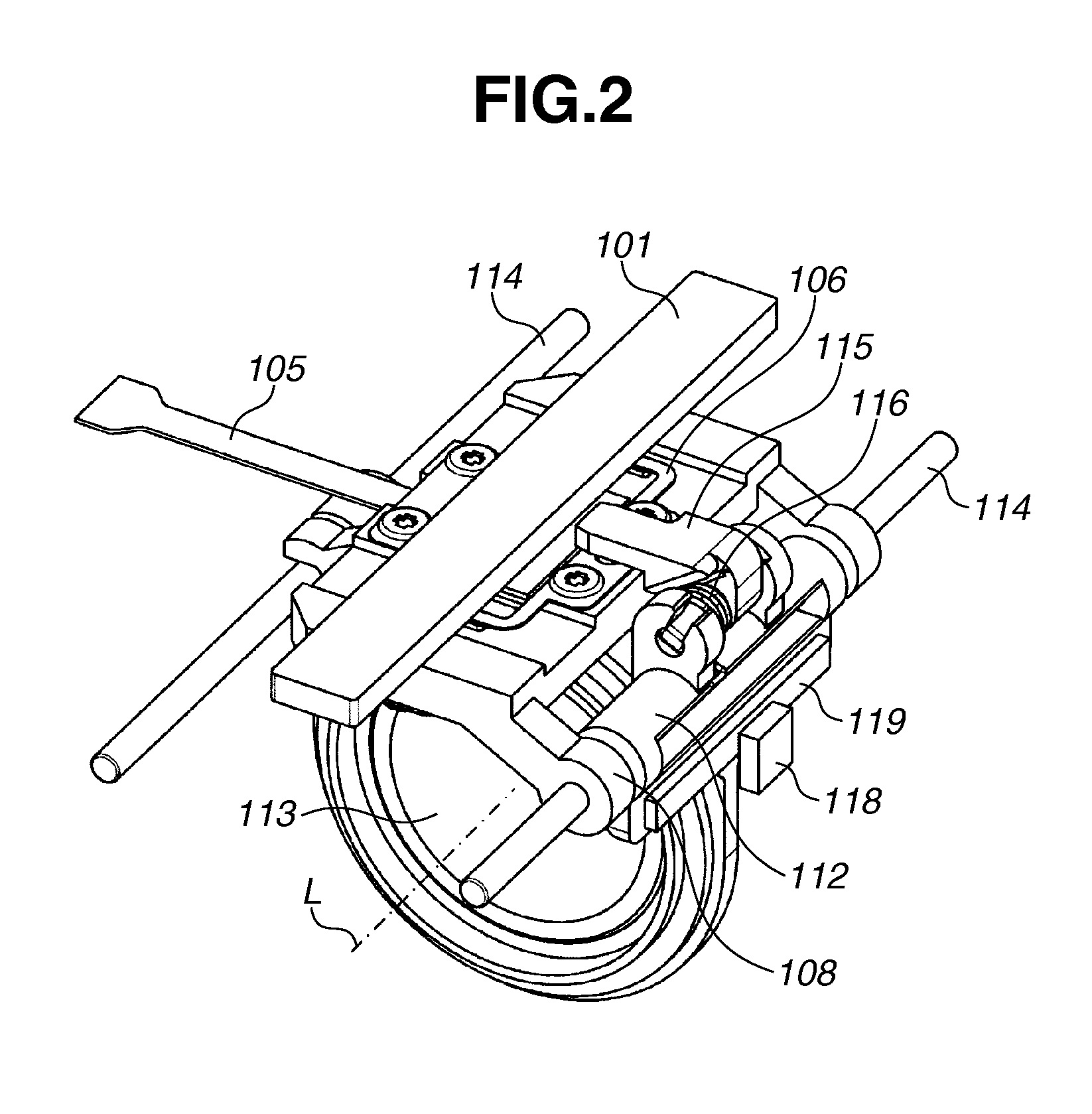

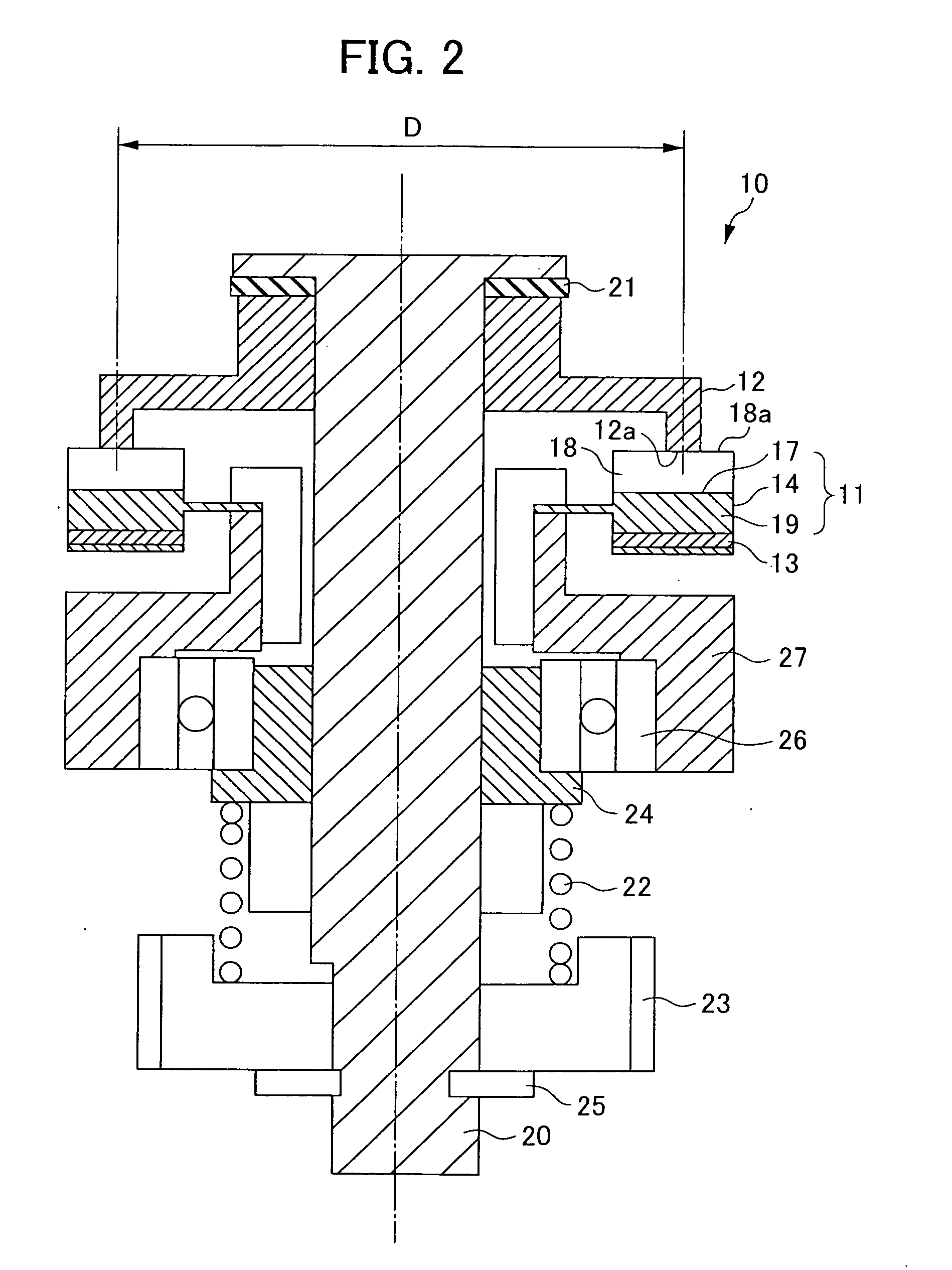

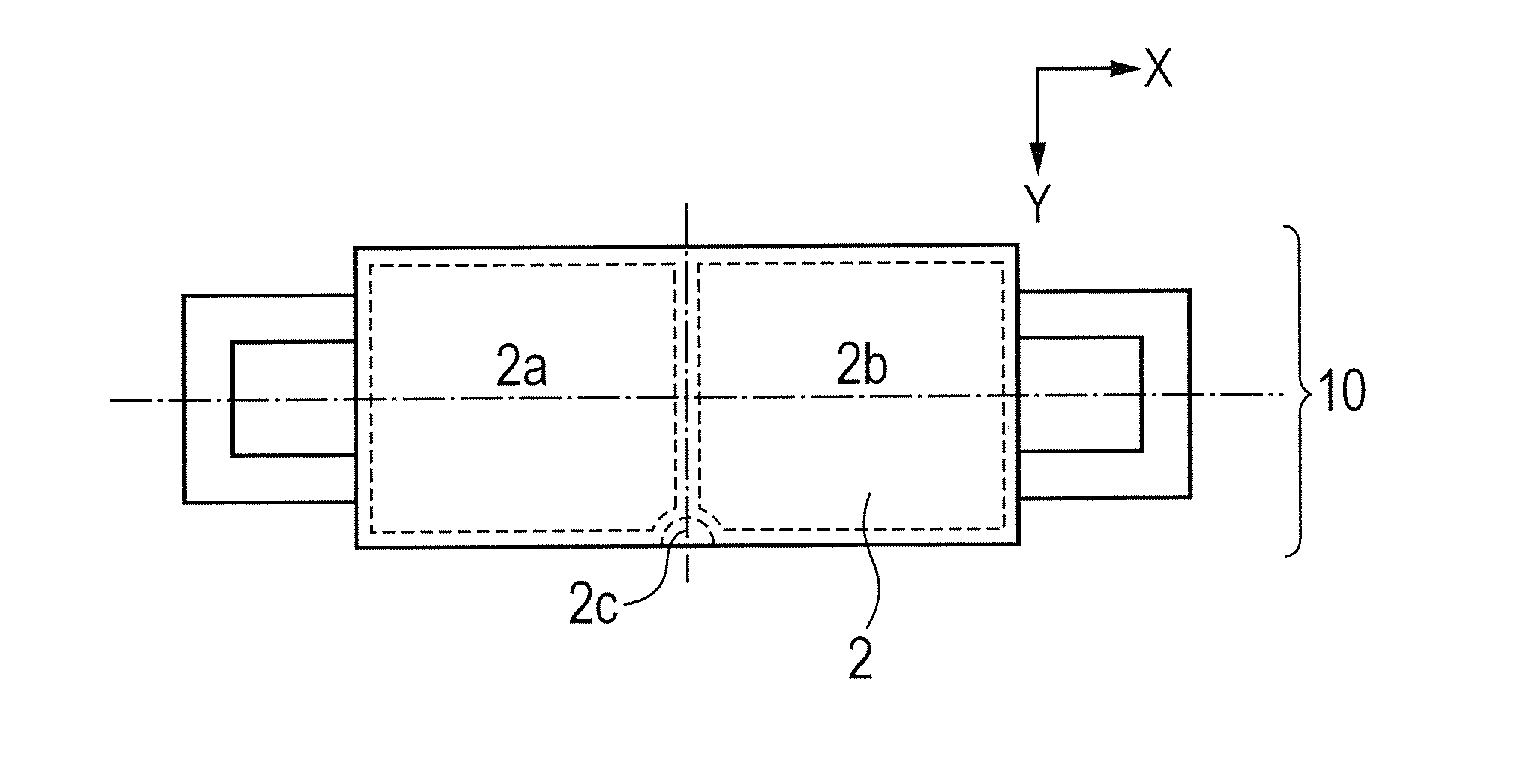

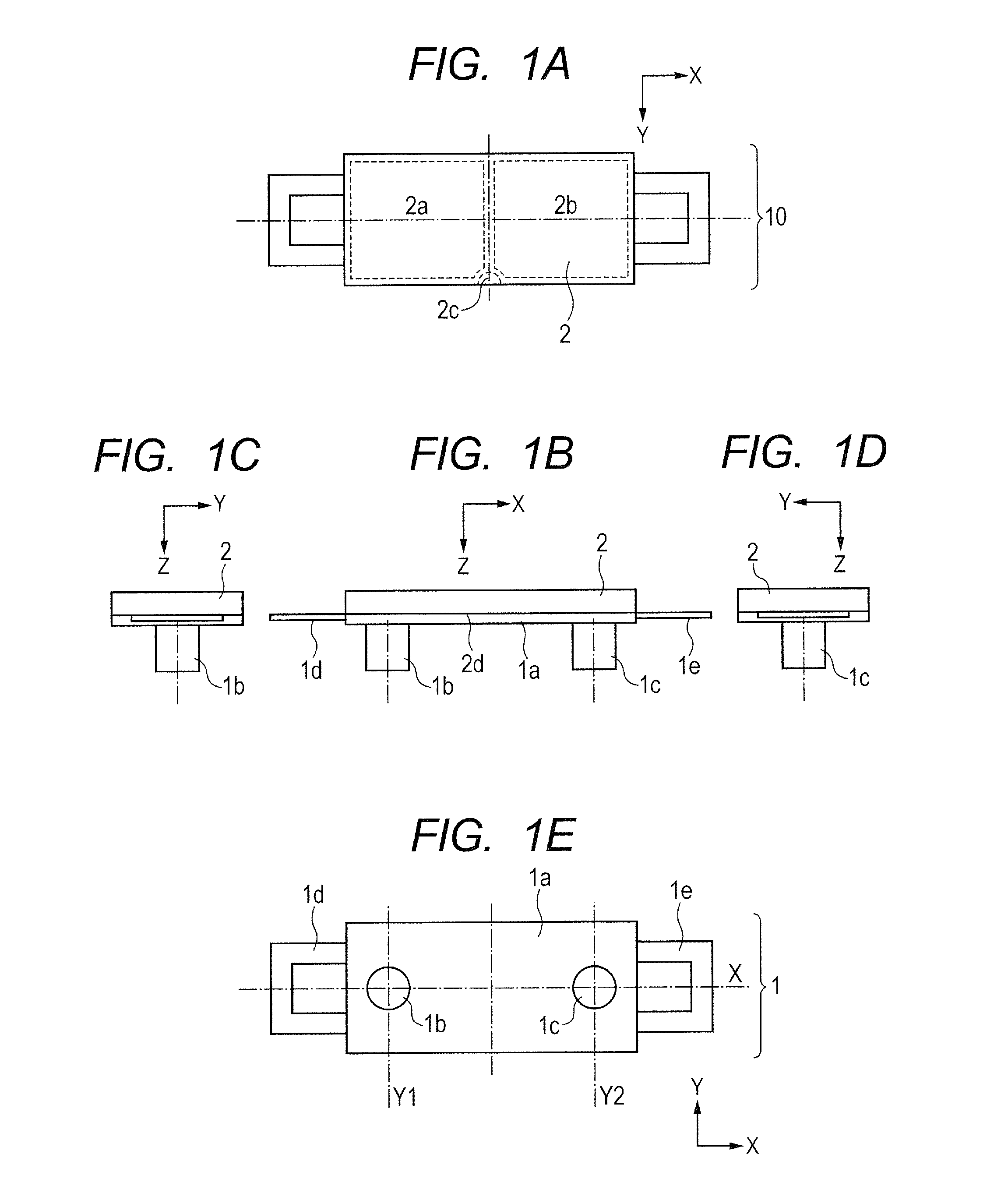

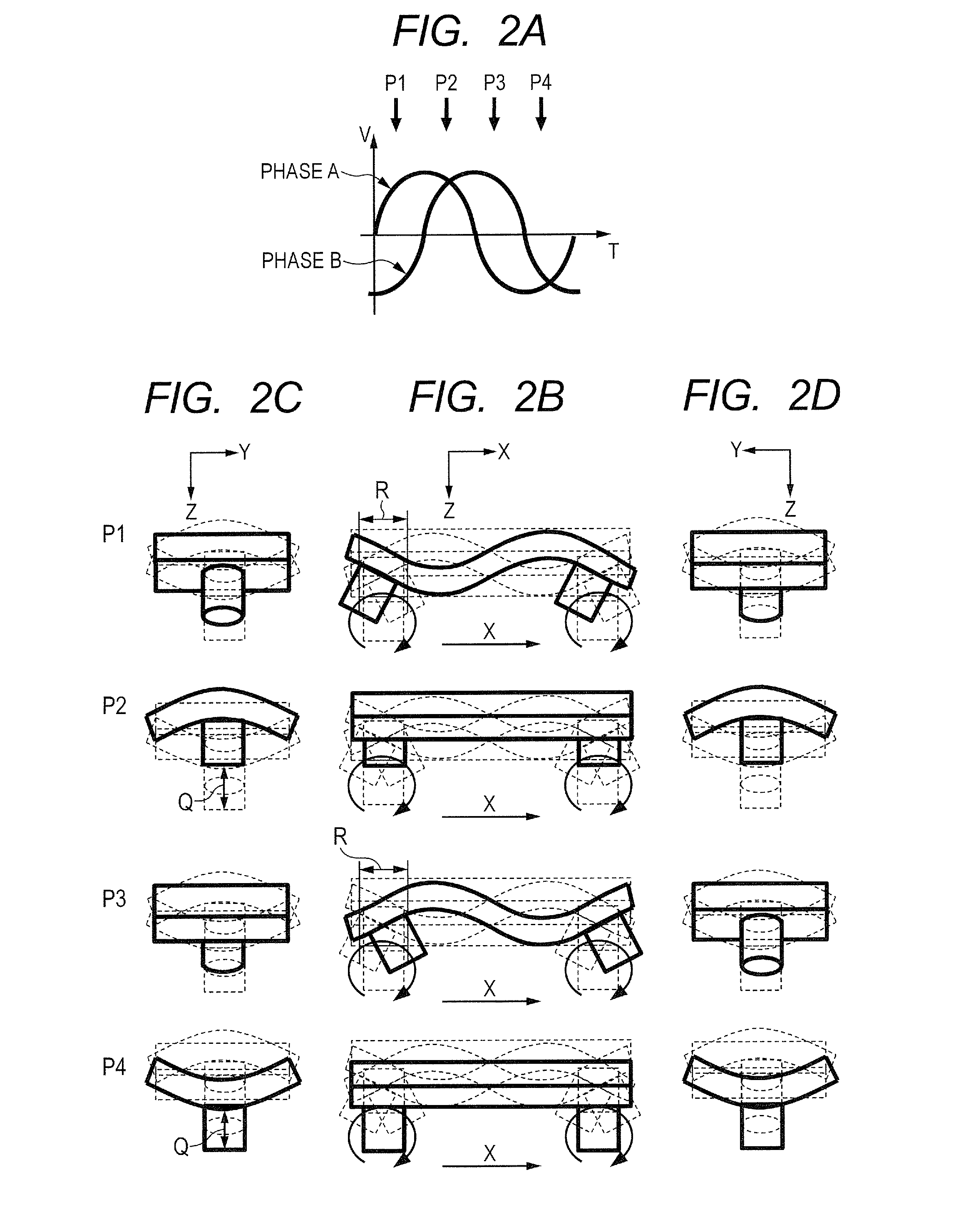

Vibration wave motor and driving apparatus using the vibration wave motor

InactiveUS10171008B2Downsizing of a driving apparatusSmall sizePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesWave motorTorsional vibration

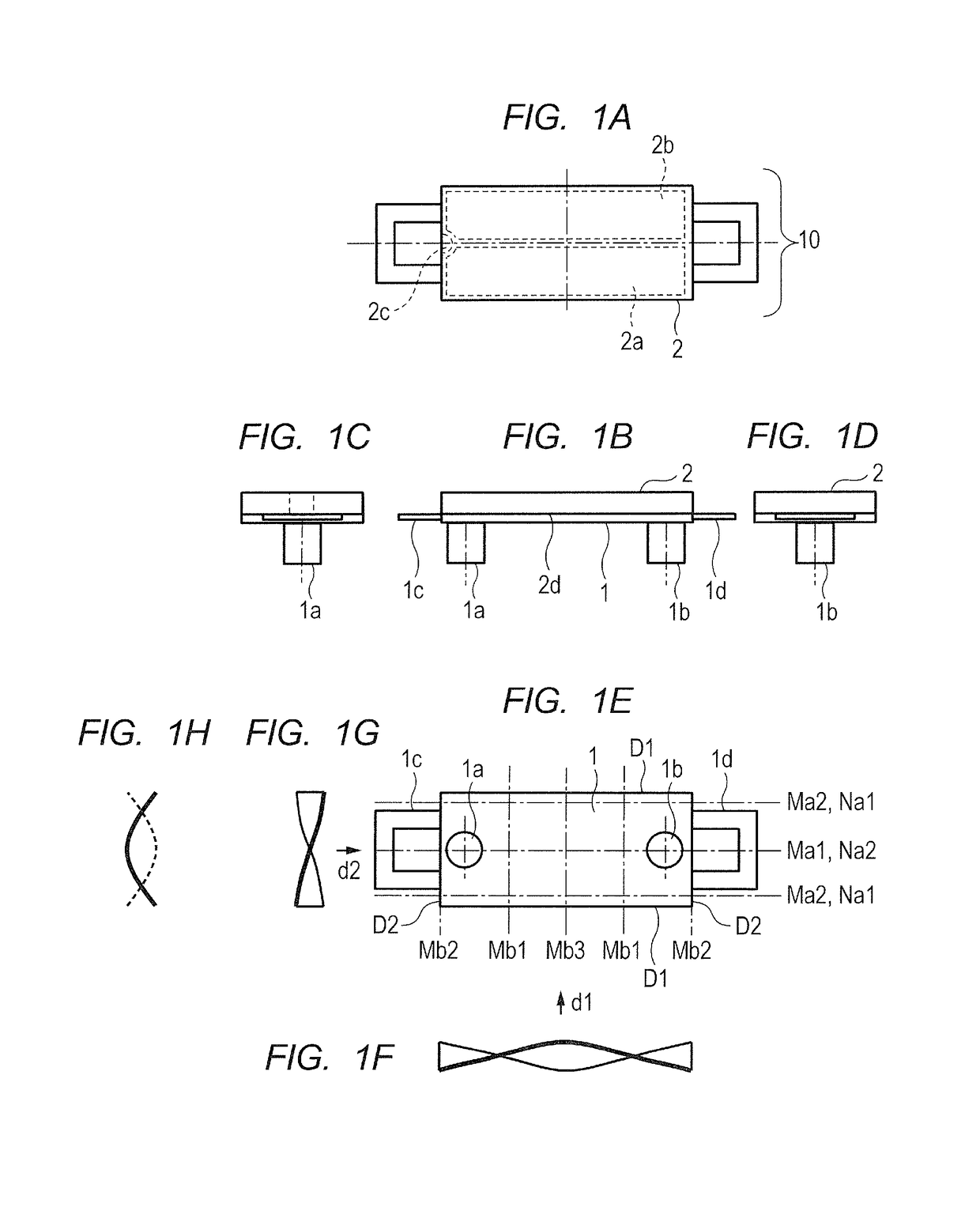

A vibration wave motor includes a vibrating plate having a rectangular surface; a piezoelectric device bonded to the vibrating plate, and configured to vibrate at high frequency; and a projection provided on the vibrating plate or the piezoelectric device. In the vibration wave motor, a natural vibration mode, which has a resonant frequency equal to or adjacent to a resonant frequency of torsional vibration in a natural vibration mode under a state in which the vibrating plate, the piezoelectric device, and the projection are integrated, is a natural vibration mode of bending vibration in a direction parallel to or orthogonal to a torsion center axis of the torsional vibration in the natural vibration mode. The projection is provided at a position closer to an antinode than to a node, which are in the direction orthogonal to the torsion center axis of the torsional vibration in the natural vibration mode.

Owner:CANON KK

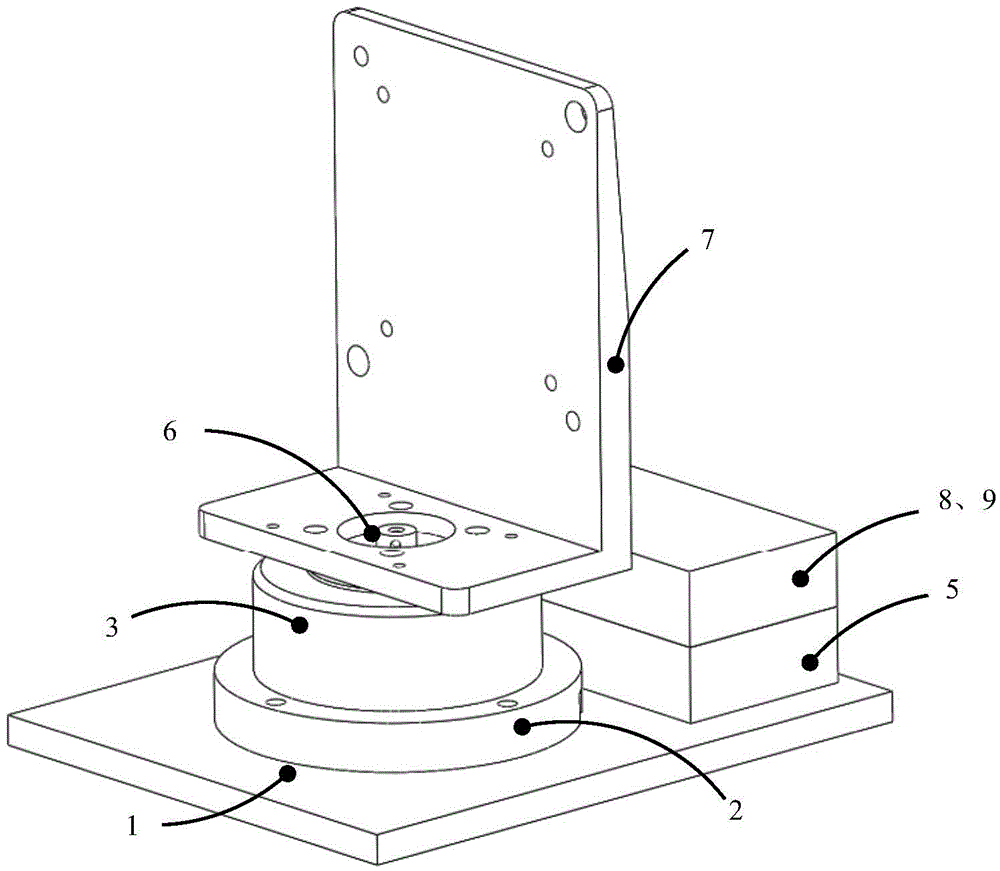

Ultrasonic wave motor transient characteristic testing device and control system thereof

InactiveCN103513181AImprove accuracyOvercoming nonlinearityDynamo-electric machine testingWave motorFlywheel

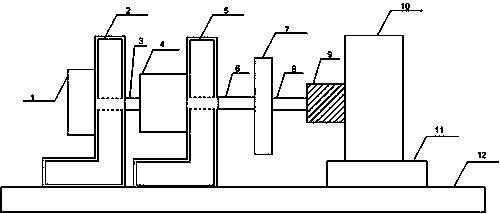

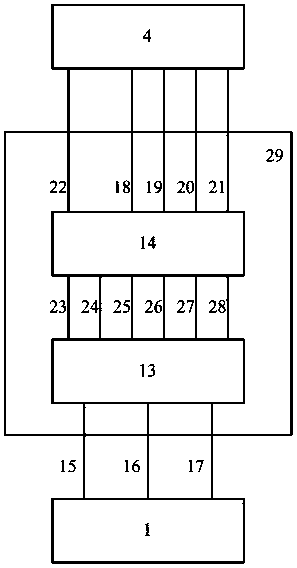

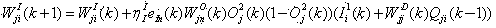

The invention relates to an ultrasonic wave motor transient characteristic testing device and a control system of the device. The device comprises a base and an ultrasonic wave motor arranged on the base, wherein an output shaft on one side of the ultrasonic wave motor is connected with an optical-electricity encoder, an output shaft on the other side of the ultrasonic wave motor is connected with a flywheel inertia load, an output shaft of the flywheel inertia load is connected with a torque sensor through a coupler, the signal output end of the optical-electricity encoder and the signal output end of the torque sensor are respectively connected to the control system, and the control system is composed of an RNNI and an RNNC. The RNNI completes the identification of the input characteristics and the output characteristics of the ultrasonic wave motor under the different control variables and different flywheel inertia loads, and the RNNC achieves the speed / position / torque control output of the ultrasonic wave motor according to the identified result so as to determine the control dynamic characteristic under the different loads and the different control variables. The device and the control system are high in testing accuracy, simple and compact in structure and good in using effect.

Owner:MINJIANG UNIV

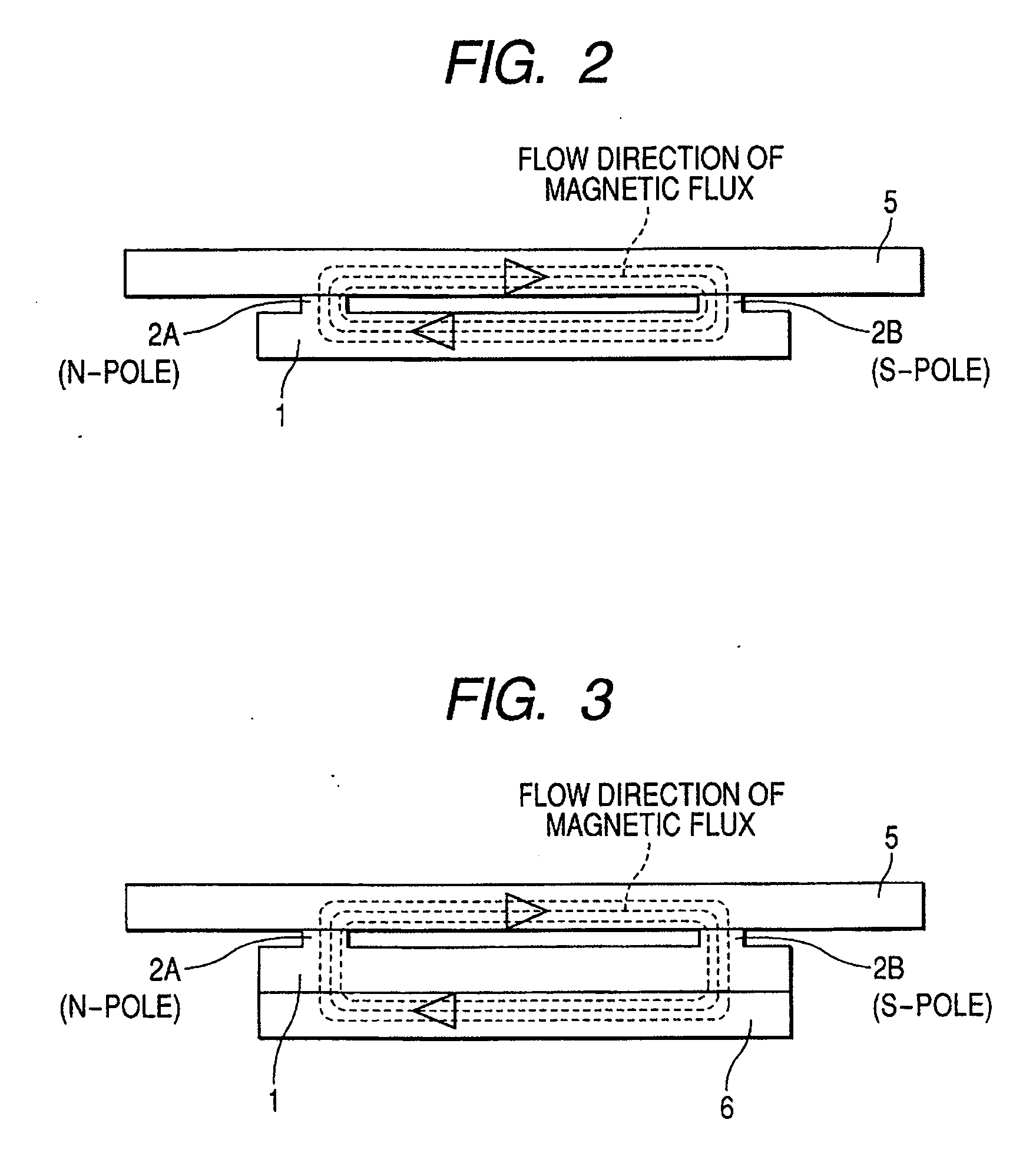

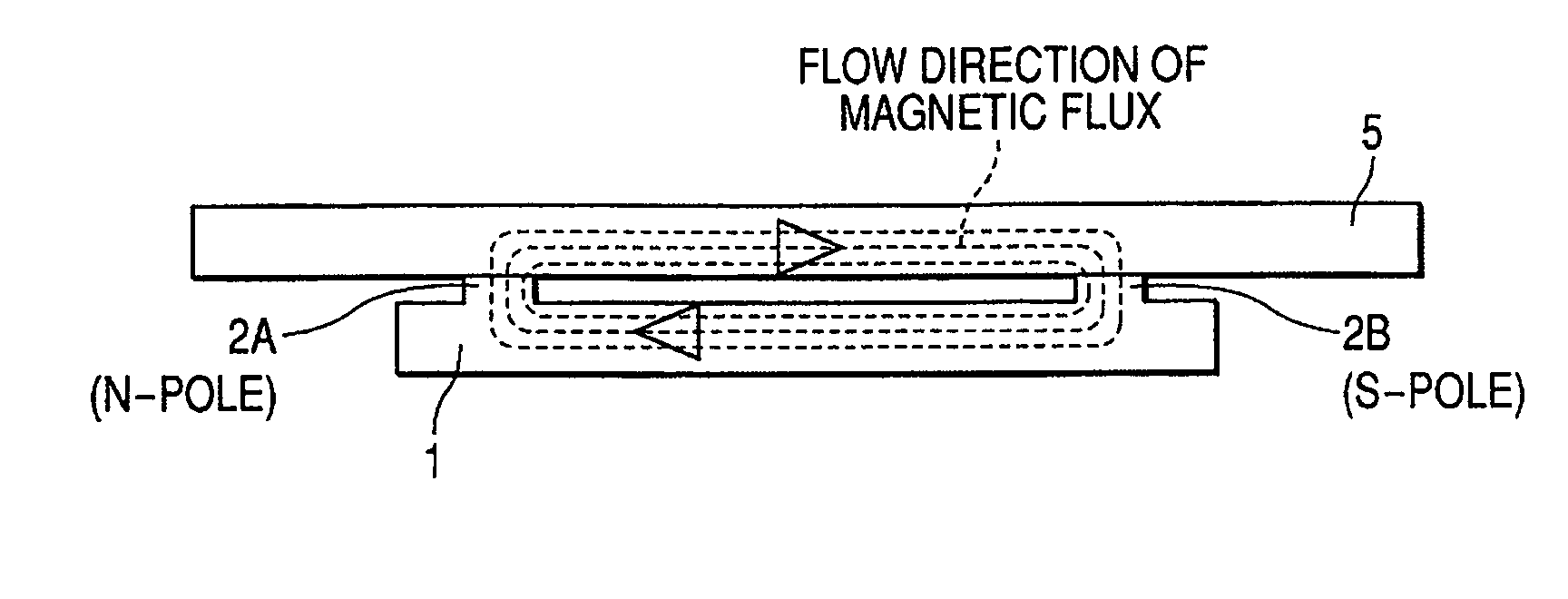

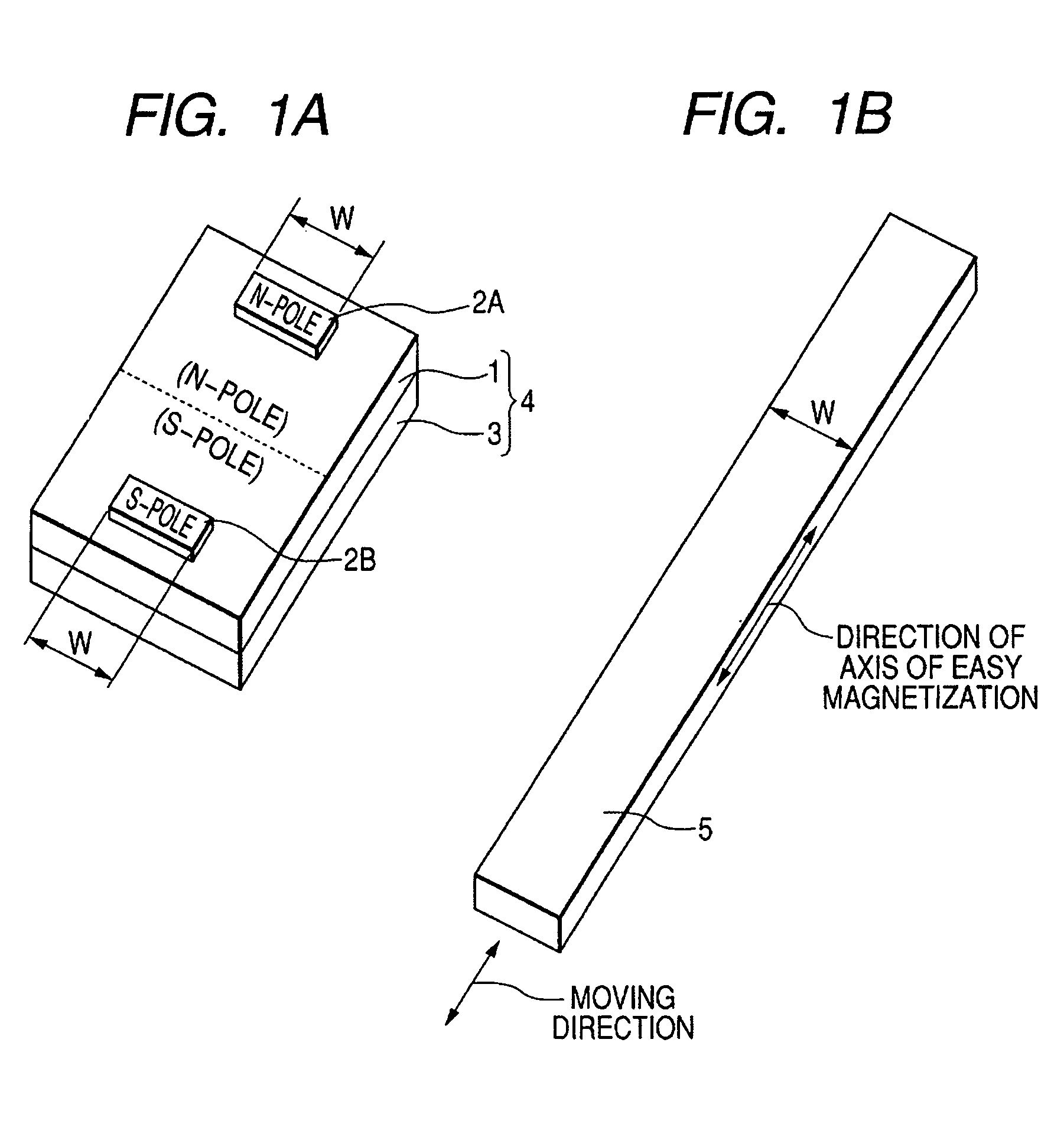

Vibration wave motor

InactiveUS20060267416A1Piezoelectric/electrostriction/magnetostriction machinesMachines/enginesElastic vibrationEngineering

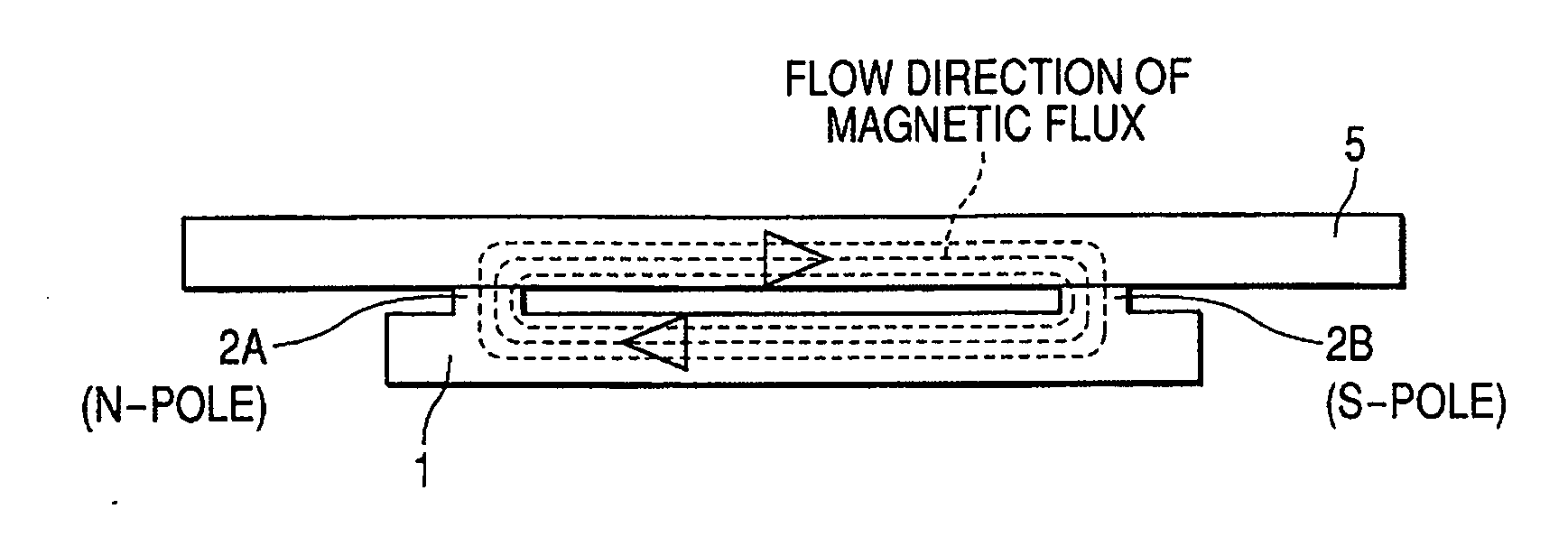

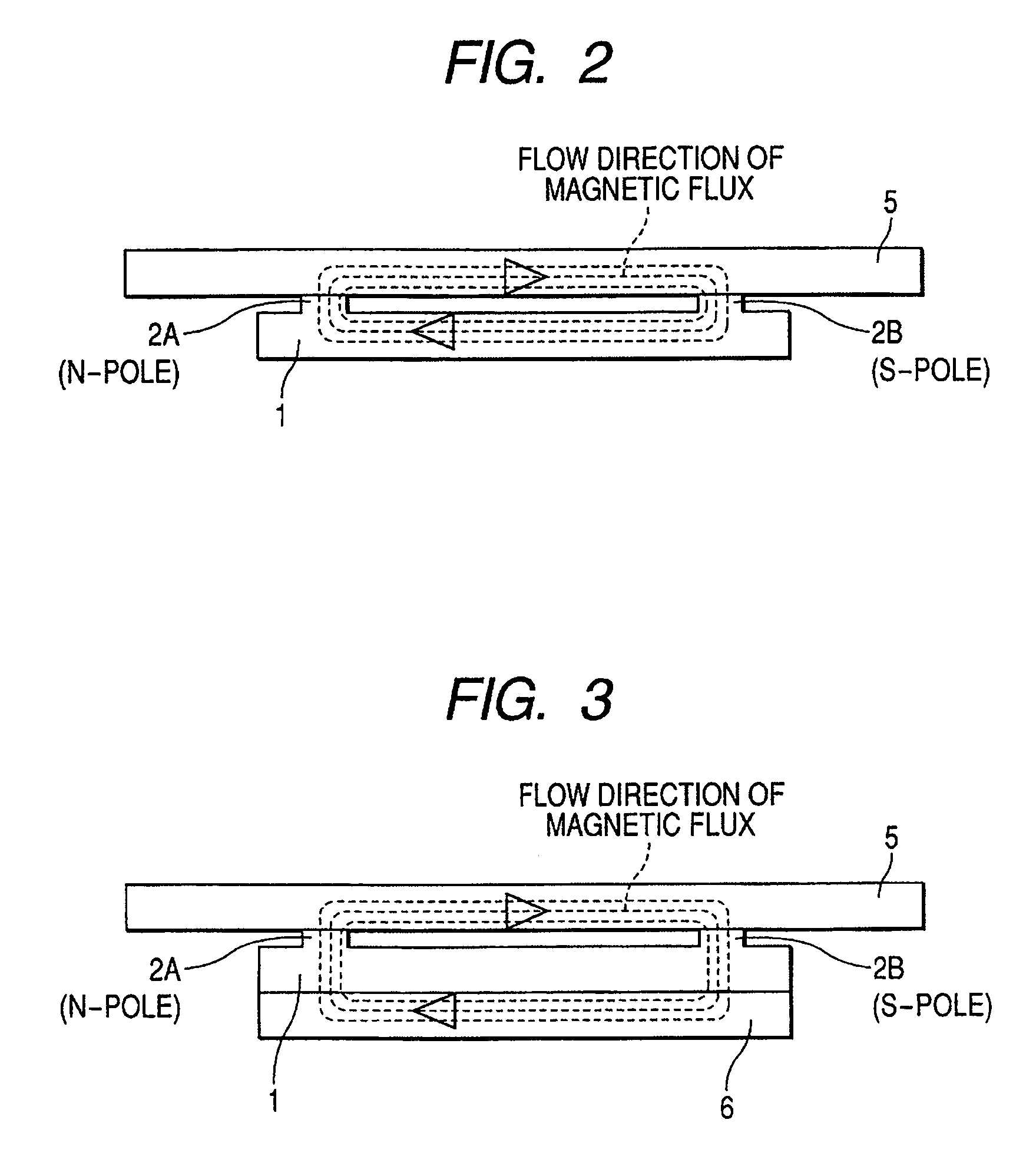

Provided is a vibration wave motor including a pressurizing mechanism and a guide mechanism which are used for a moving member and can be thinned. The influence of a restoring force can be eliminated. The vibration wave motor includes an elastic vibration member which is composed of a permanent magnet and a piezoelectric element which are fixed to each other, a plurality of motion extraction portions provided on the permanent magnet, and a moving member which is pressurized to be in contact with the plurality of motion extraction portions. A closed magnetic circuit of a magnetic flux is formed to connect between the elastic vibration member and the moving member through the plurality of motion extraction portions. A flow direction of the magnetic flux passing through the moving member is aligned with a moving direction of the moving member.

Owner:CANON KK

Vibration wave motor

InactiveUS7425770B2Piezoelectric/electrostriction/magnetostriction machinesMachines/enginesElastic vibrationEngineering

Provided is a vibration wave motor including a pressurizing mechanism and a guide mechanism which are used for a moving member and can be thinned. The influence of a restoring force can be eliminated. The vibration wave motor includes an elastic vibration member which is composed of a permanent magnet and a piezoelectric element which are fixed to each other, a plurality of motion extraction portions provided on the permanent magnet, and a moving member which is pressurized to be in contact with the plurality of motion extraction portions. A closed magnetic circuit of a magnetic flux is formed to connect between the elastic vibration member and the moving member through the plurality of motion extraction portions. A flow direction of the magnetic flux passing through the moving member is aligned with a moving direction of the moving member.

Owner:CANON KK

Motor driving method, program therefor, and motor driving apparatus

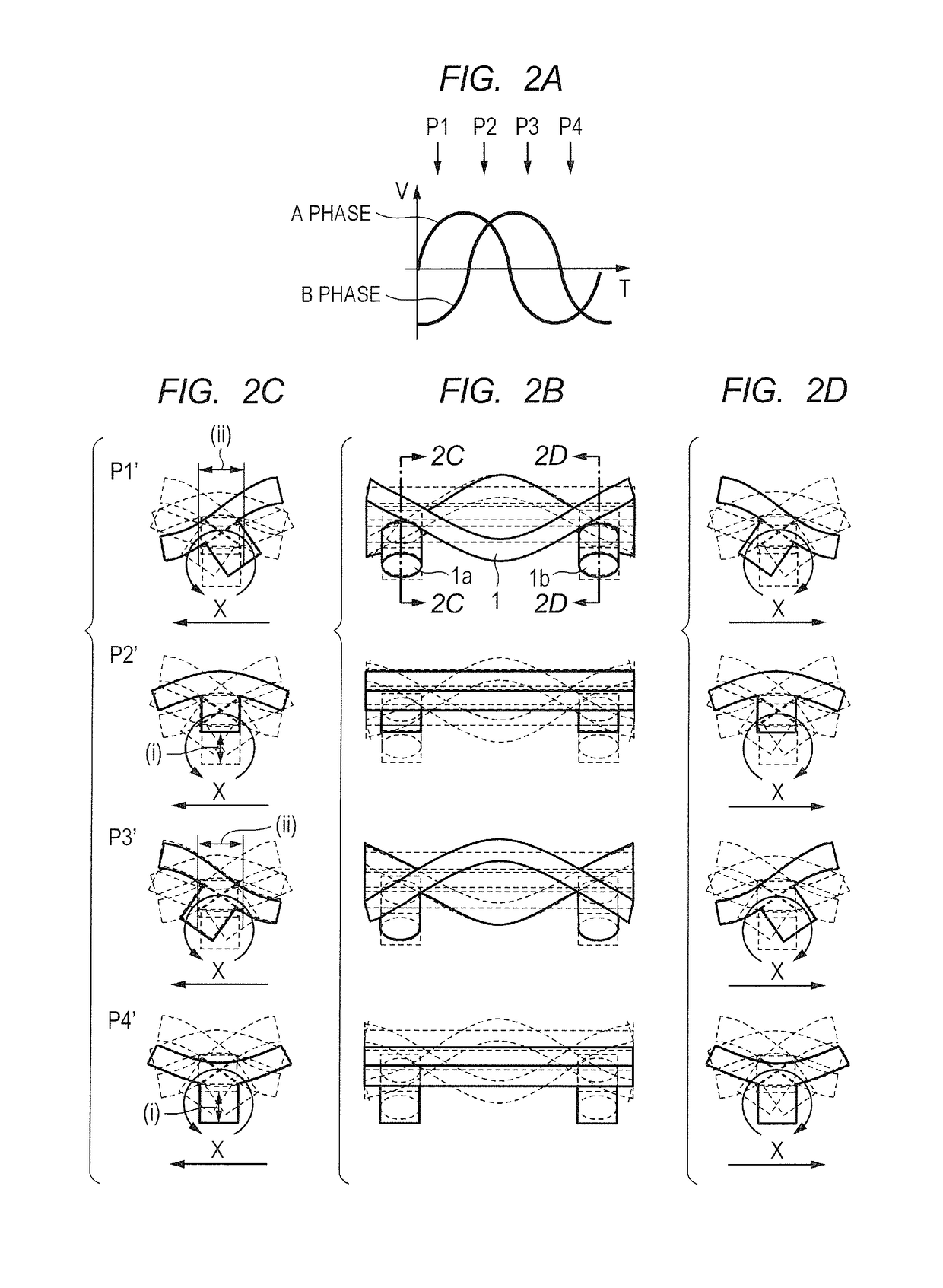

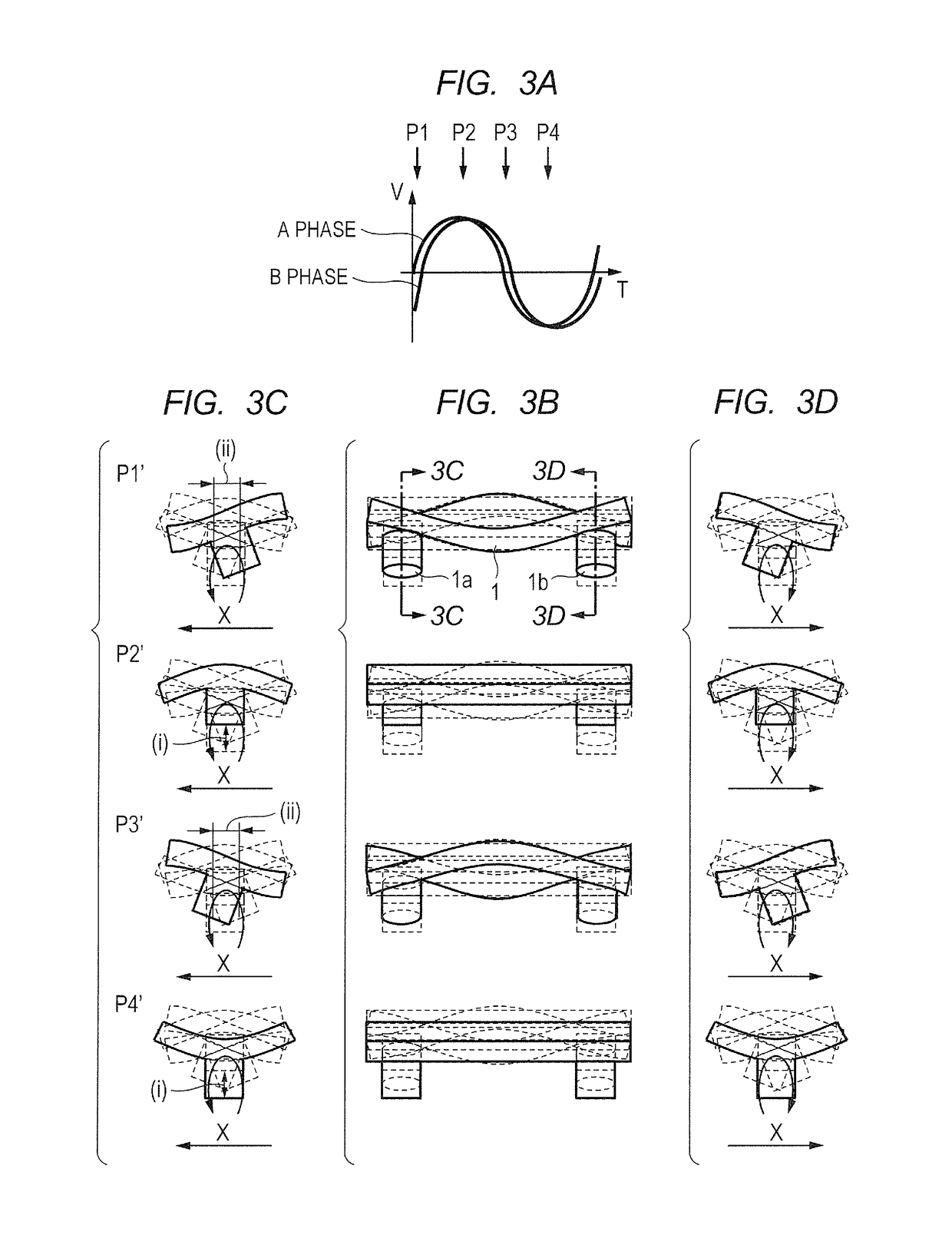

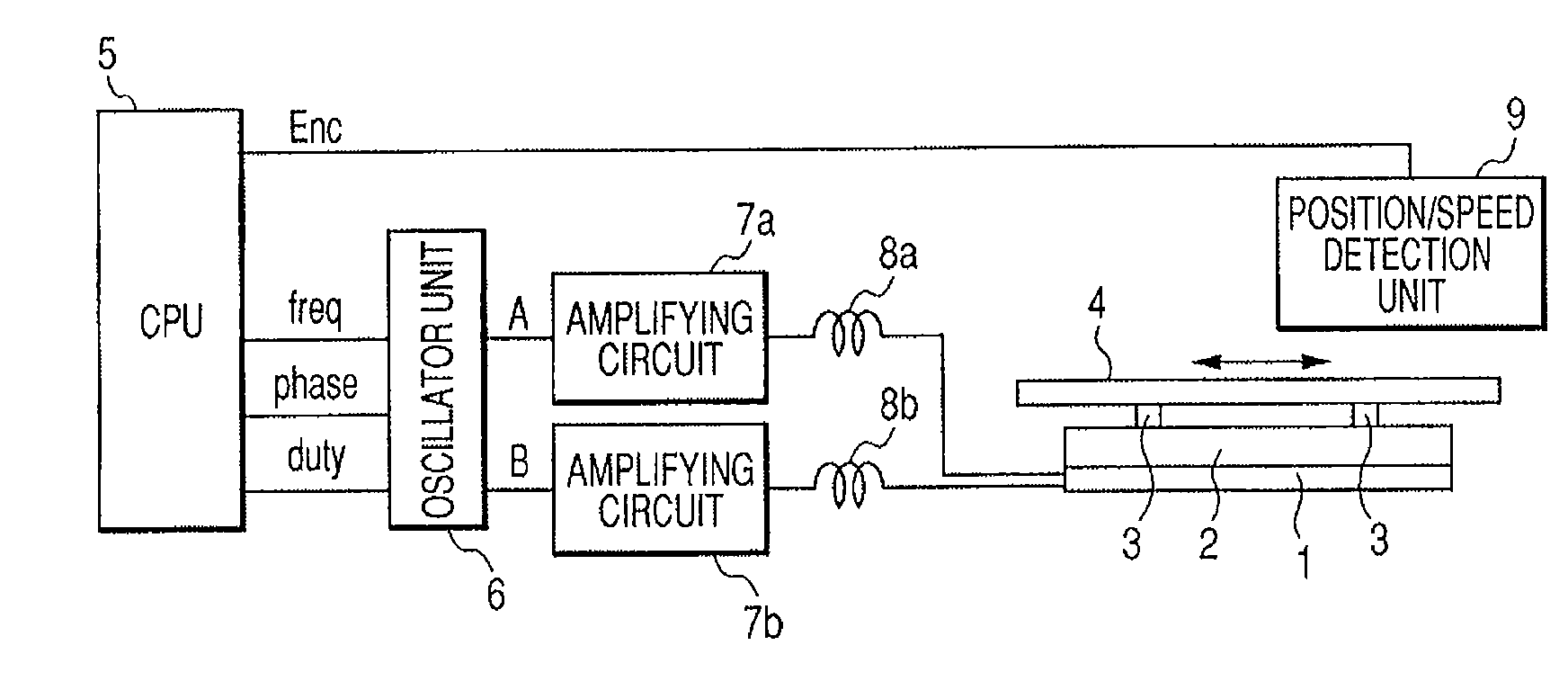

InactiveUS7701116B2Shorten vibration timeStable controlPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStart timeMotor drive

Provided are a motor driving method, a program therefor, and a motor driving apparatus which can shorten starting time of a vibration wave motor. A driving circuit of the vibration wave motor includes a control unit. The control unit controls two-phase driving voltages applied to an electro-mechanical energy conversion element of the vibration wave motor. The control unit controls a phase difference between the two-phase driving voltages to drive a driven member at a predetermined speed in a fixed state of frequencies of the two-phase driving voltages. In this case, when the phase difference is set outside a predetermined range, the control unit changes the frequencies of the two-phase driving voltages.

Owner:CANON KK

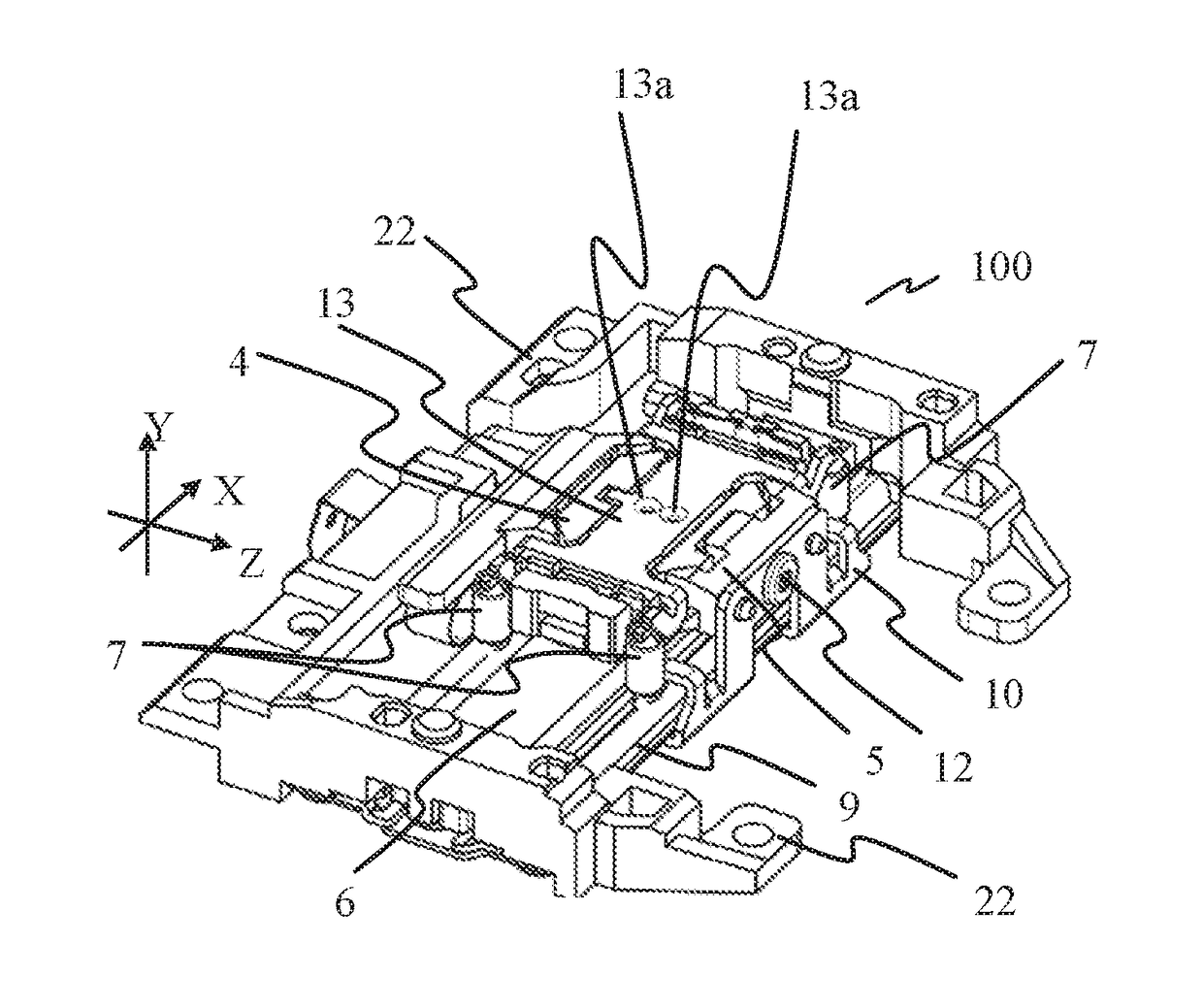

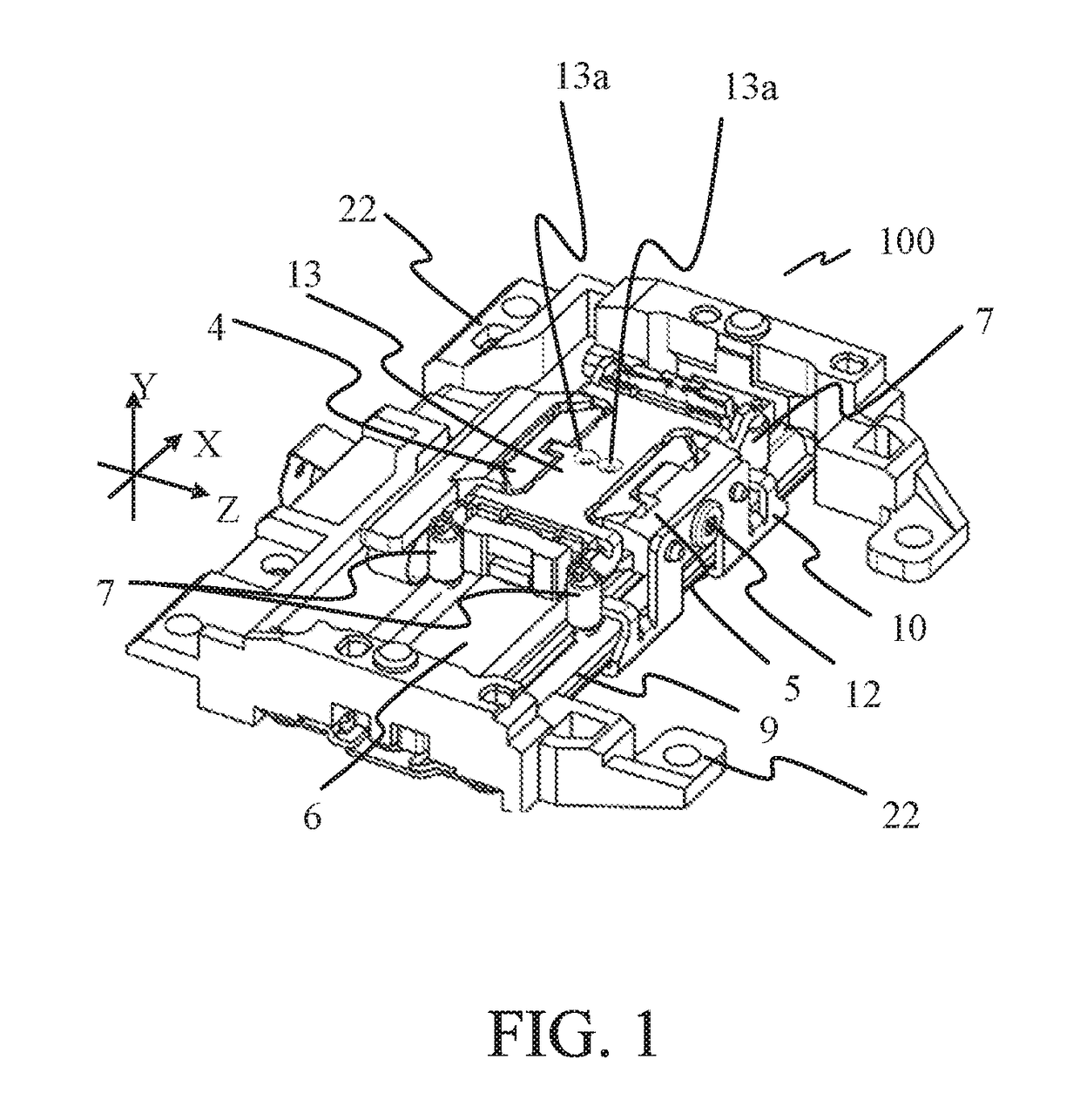

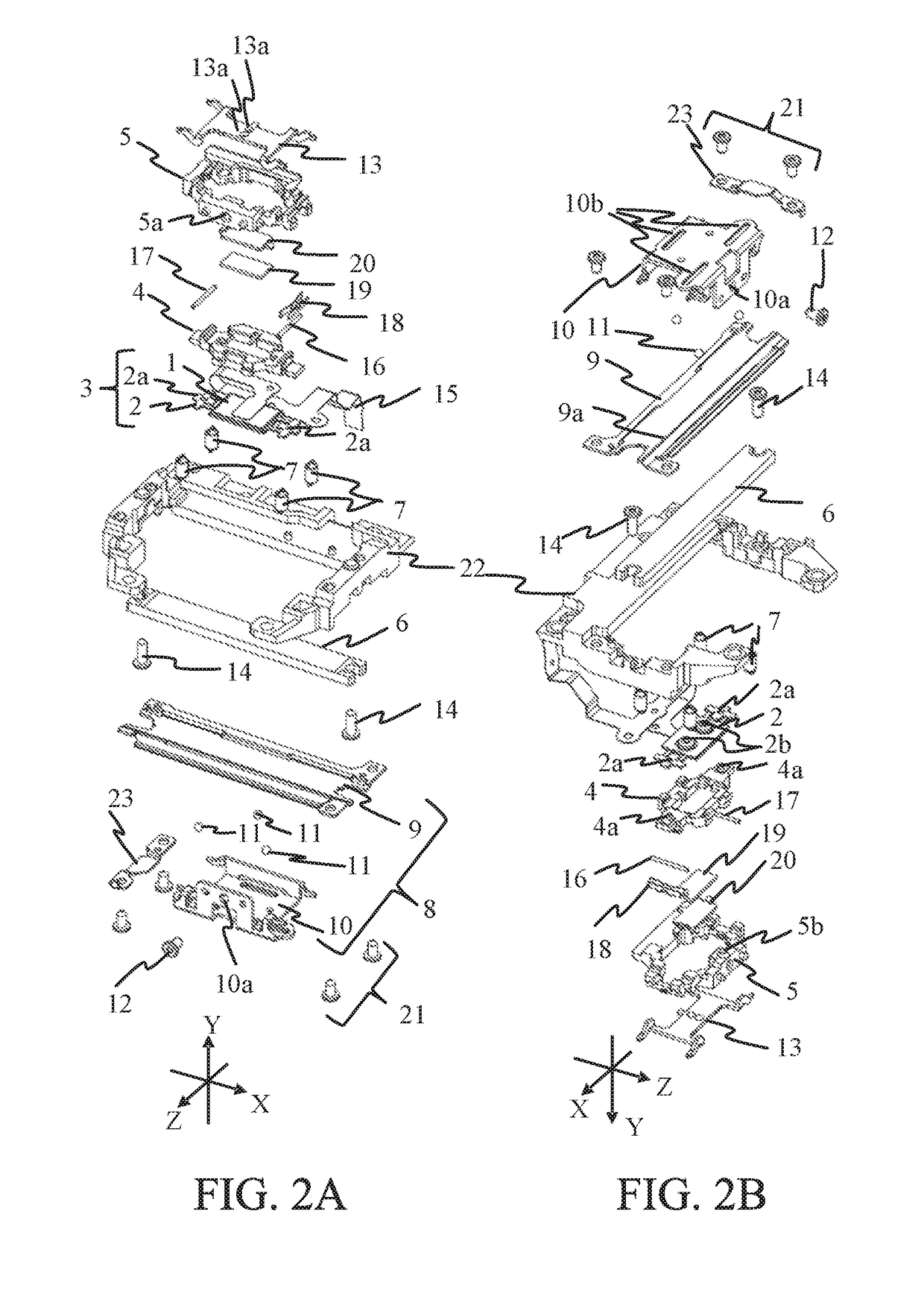

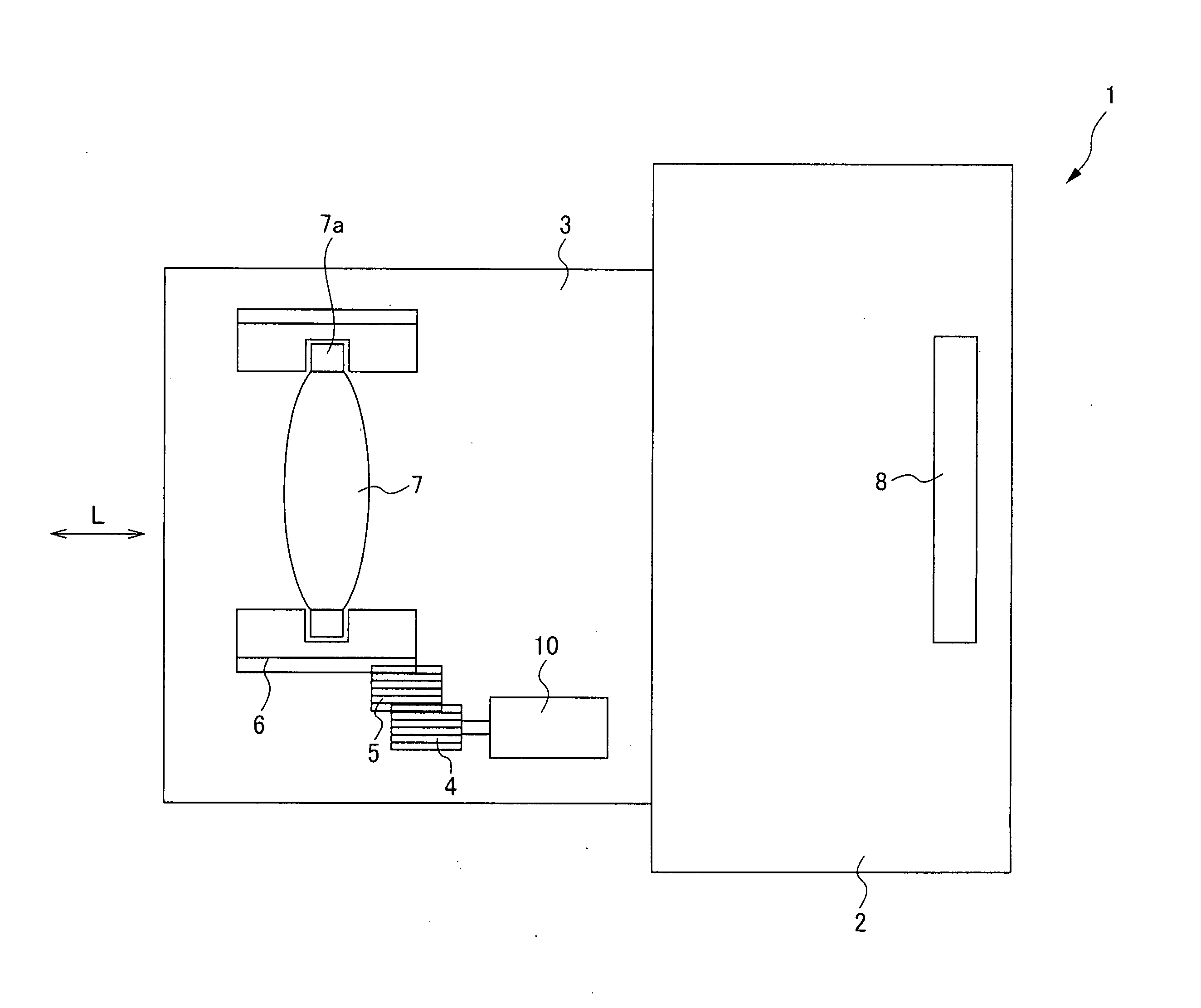

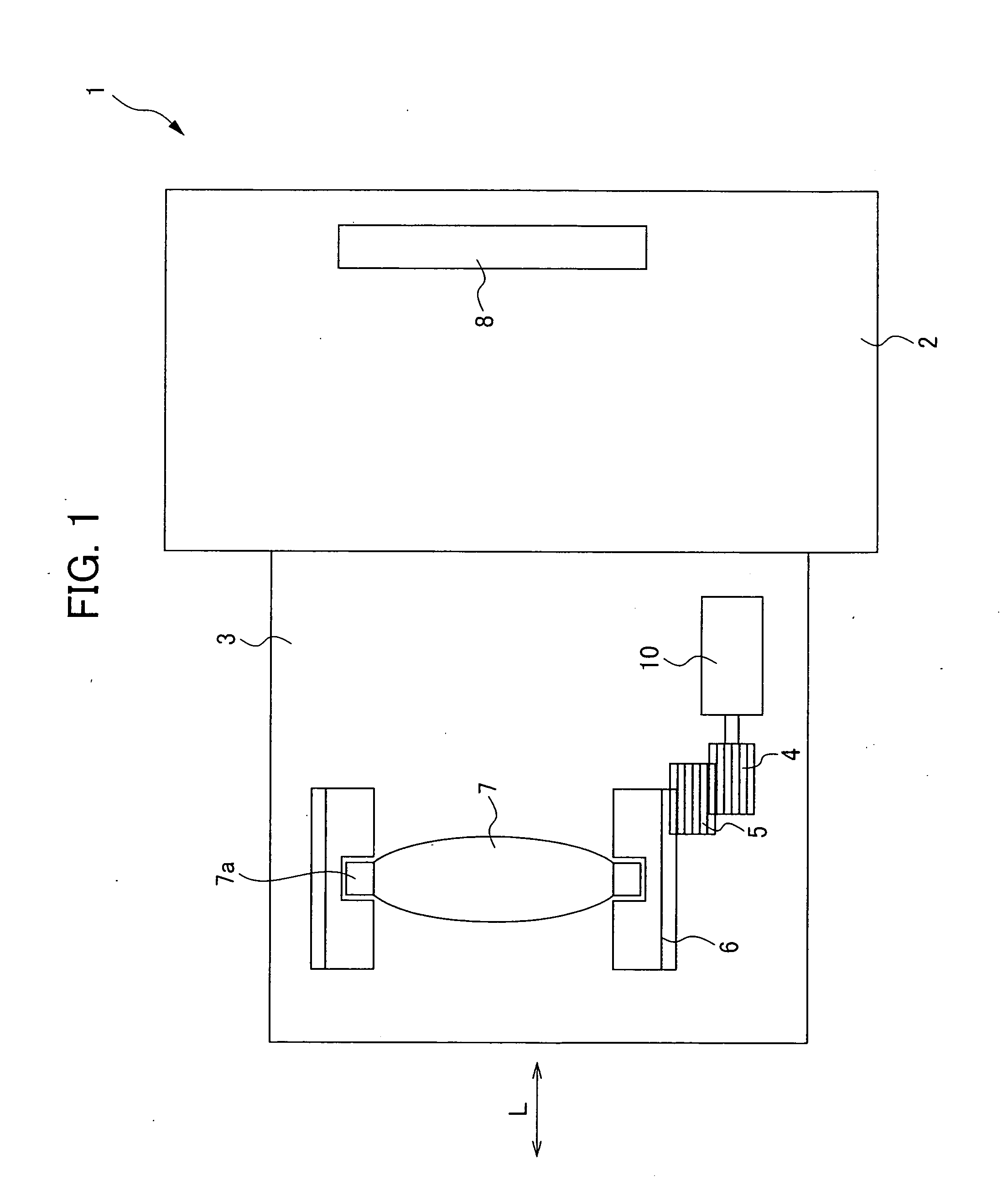

Linear vibration-wave motor

ActiveUS20150200611A1Guaranteed performancePiezoelectric/electrostriction/magnetostriction machinesMountingsWave motorEngineering

A linear vibration-wave motor being configured to apply a driving force to a lens barrel of an optical device includes a vibrator being operable to excite a vibration, a member to be contacted contacting the vibrator, the vibrator being arranged to move in a direction of the driving force with respect to the member to be contacted upon exciting the vibration, a vibrator support being fixed to the lens barrel and configured to support the vibrator, a pressurization member being operable to press the vibrator against the member to be contacted, a unit cover member including an opening extending in the direction of the driving force, and a unit base member having fixed thereto the member to be contacted and the unit cover member. The pressurization member is detachable from the vibrator support via the opening.

Owner:CANON KK

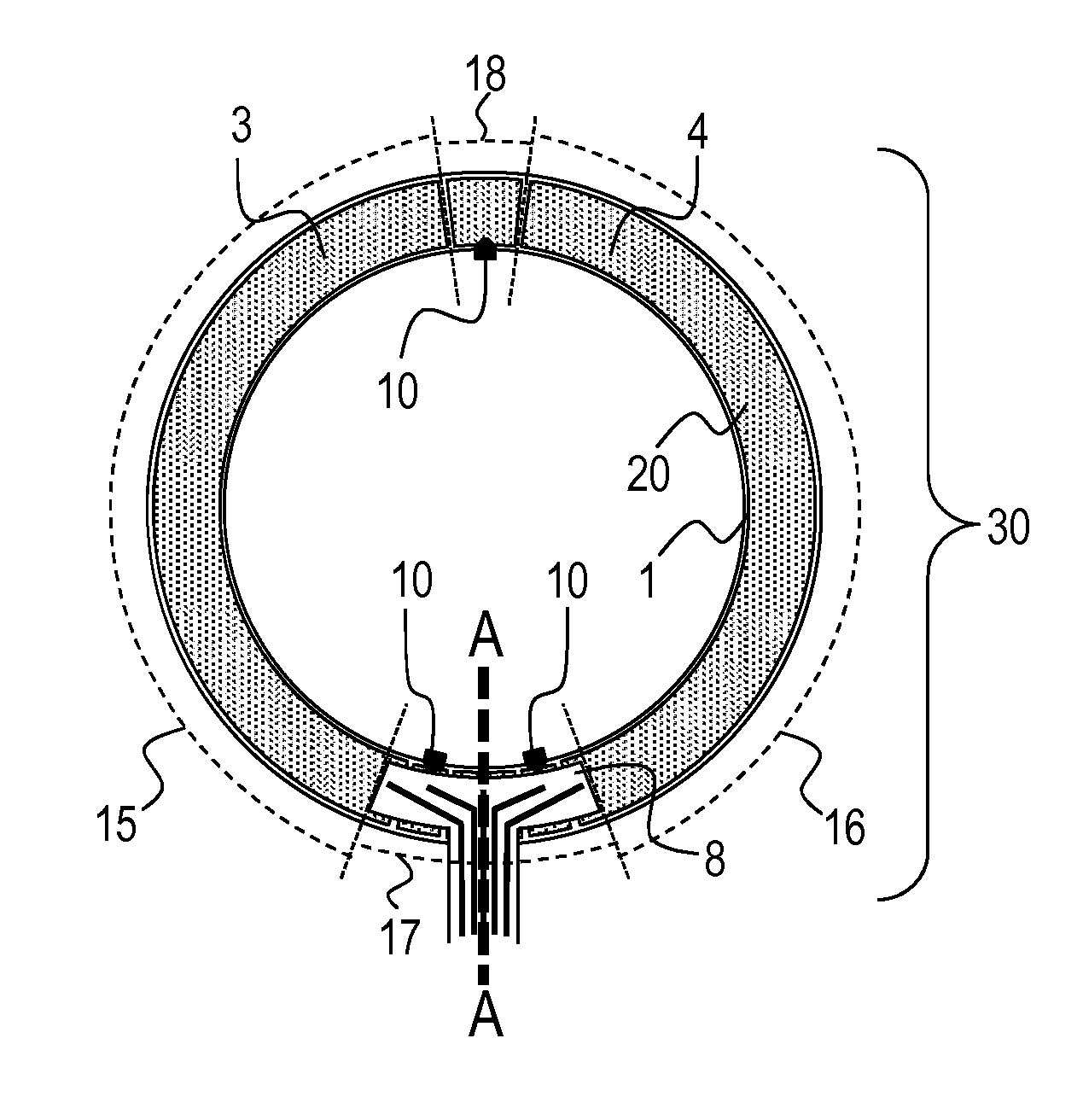

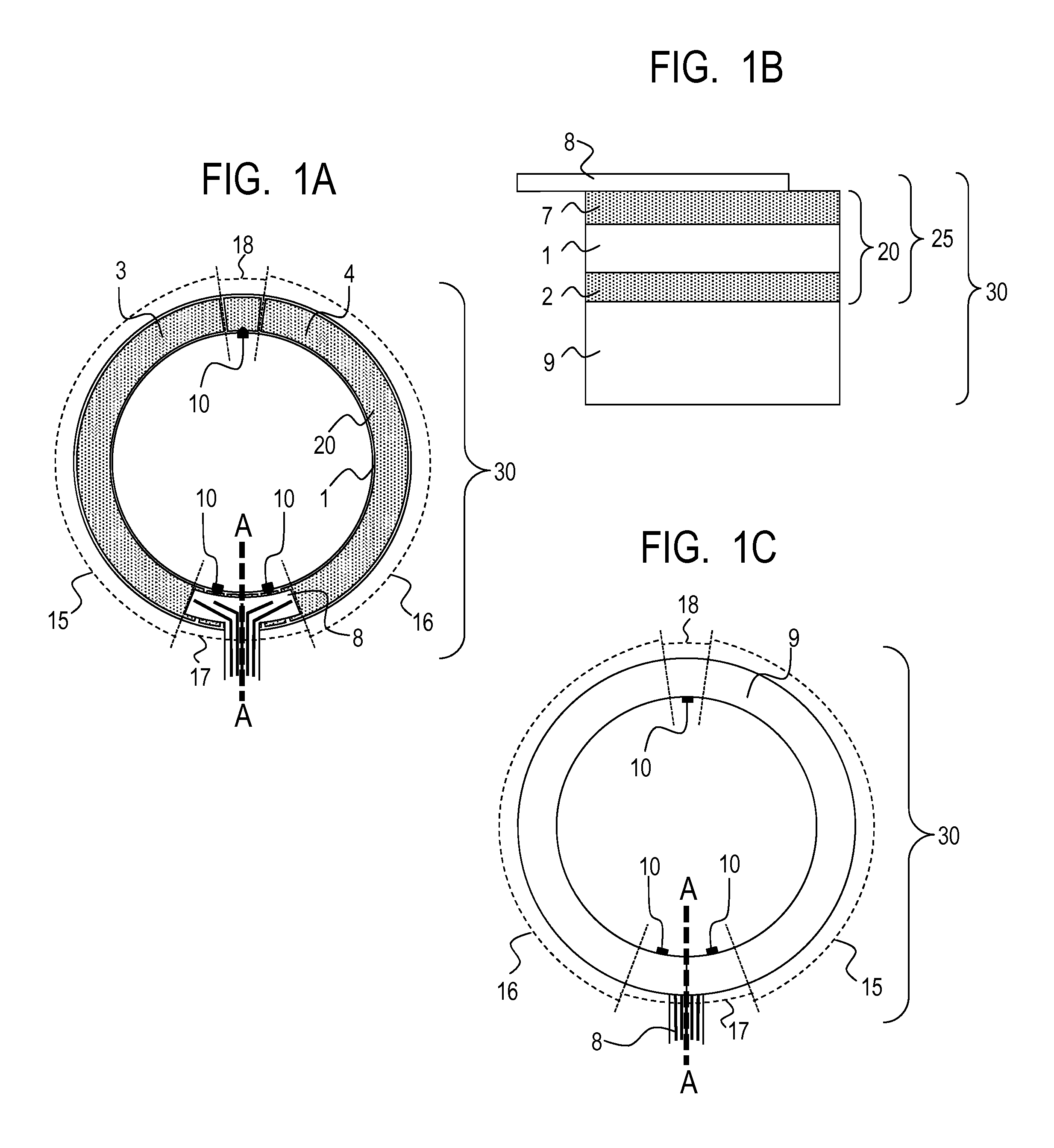

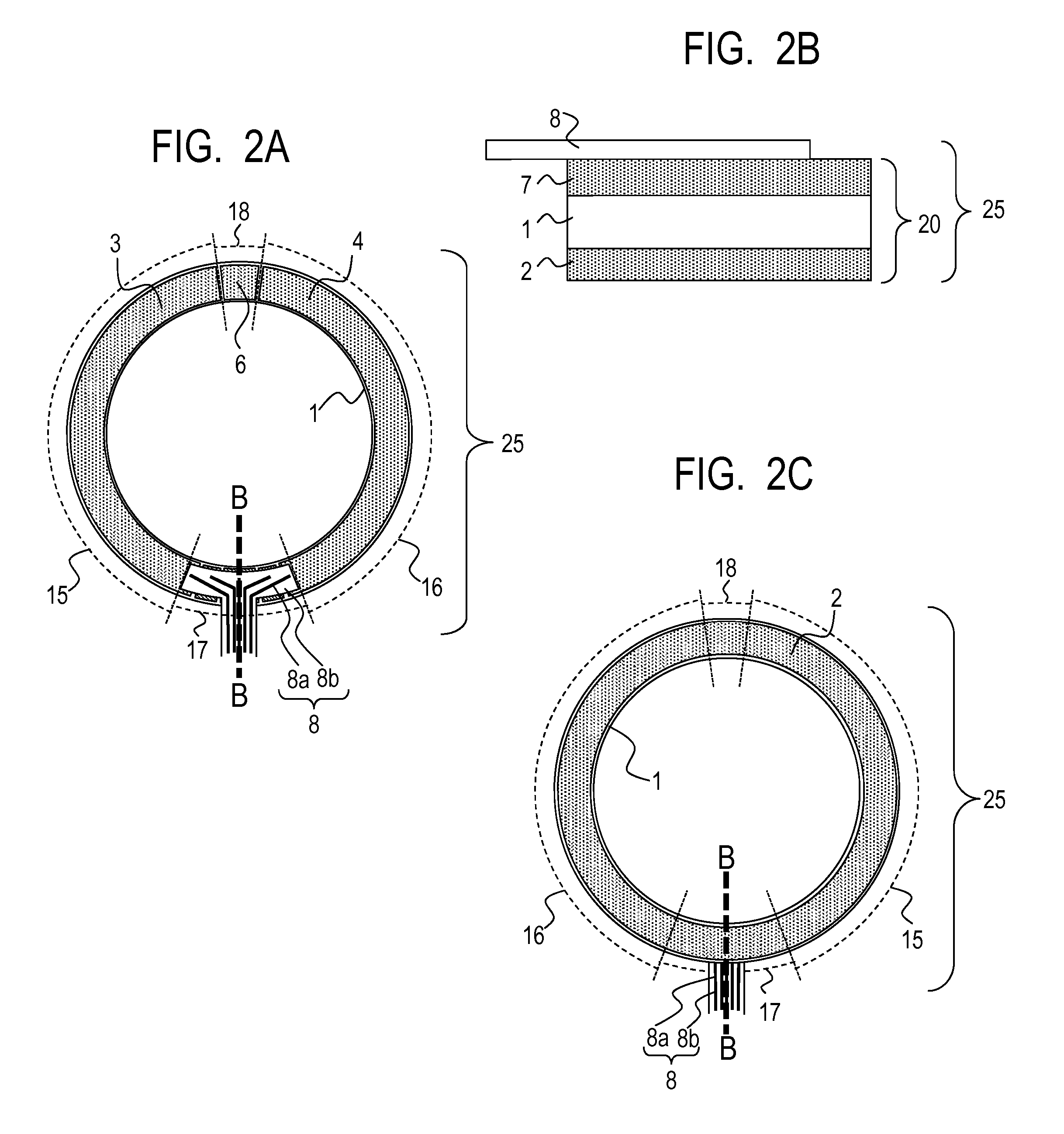

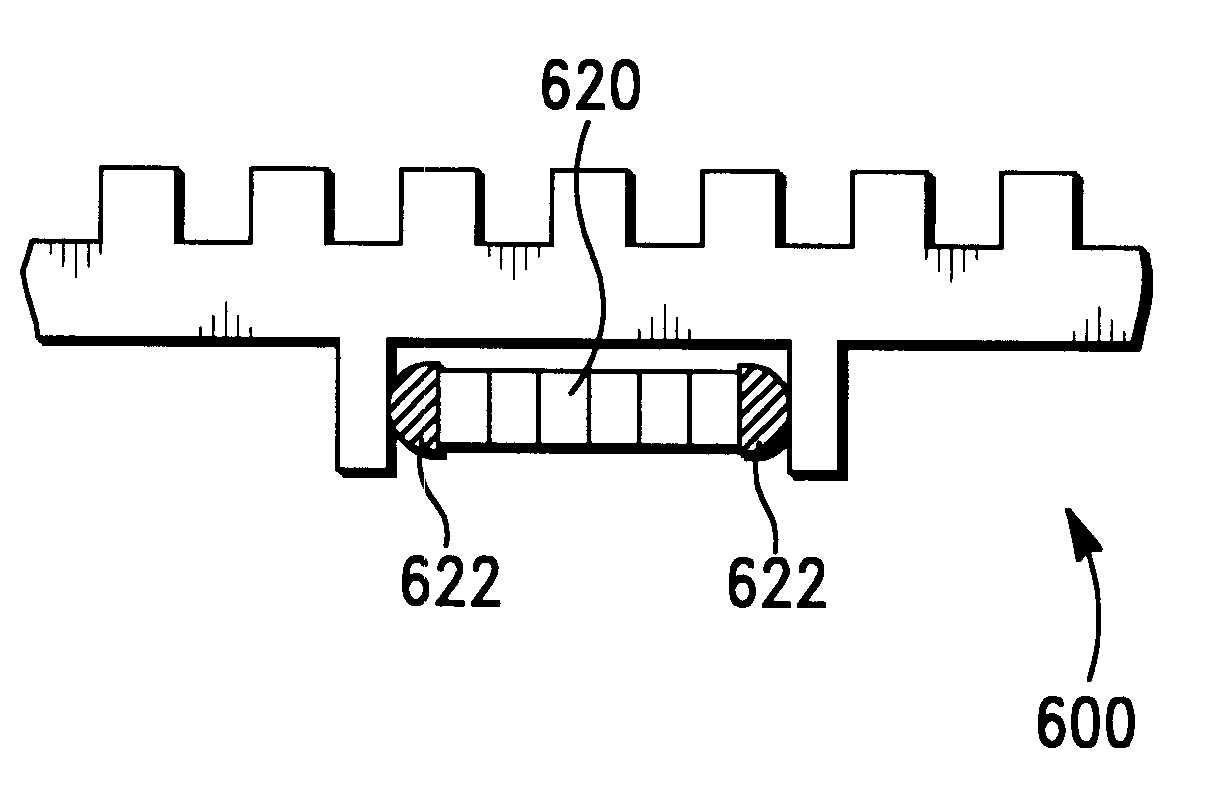

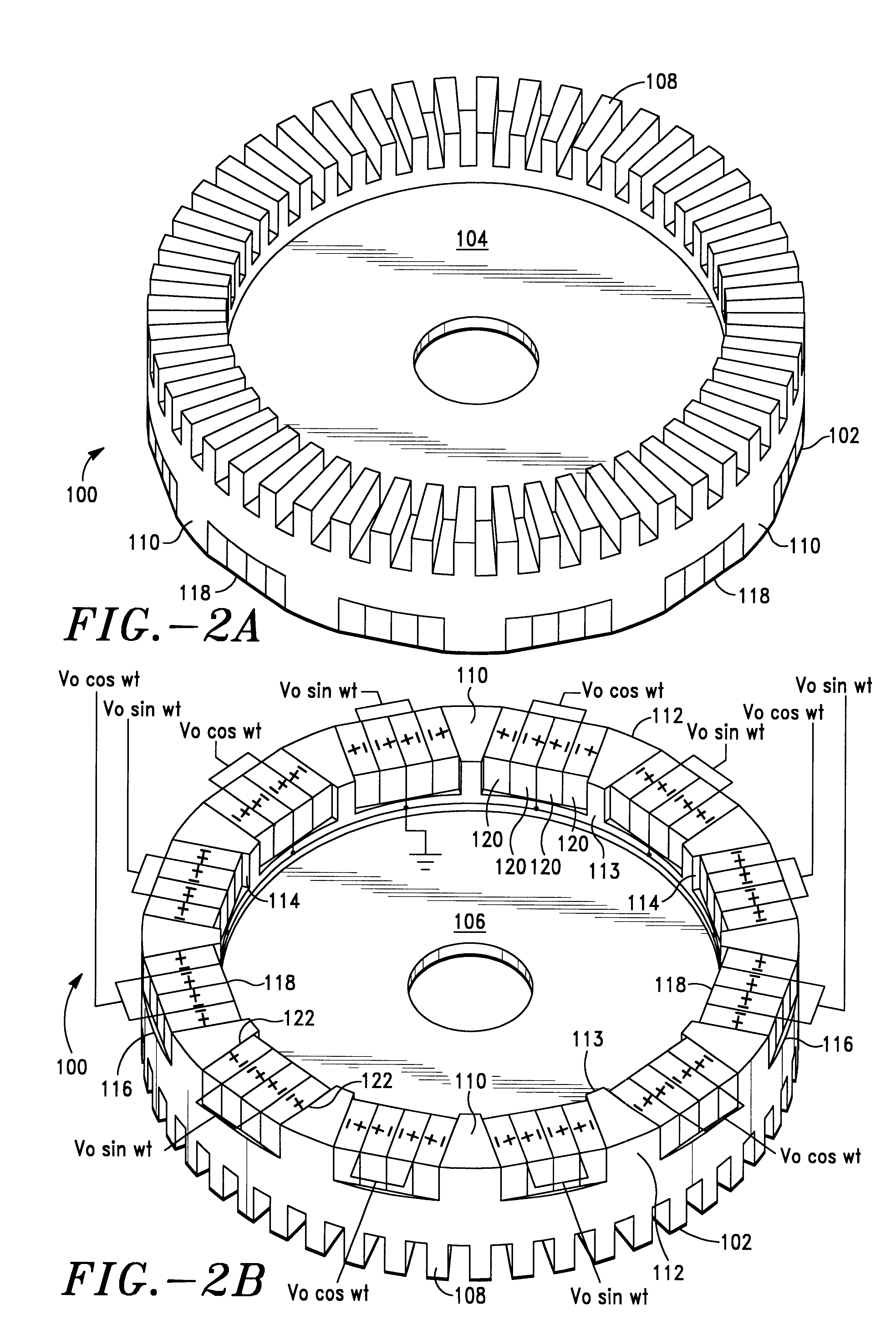

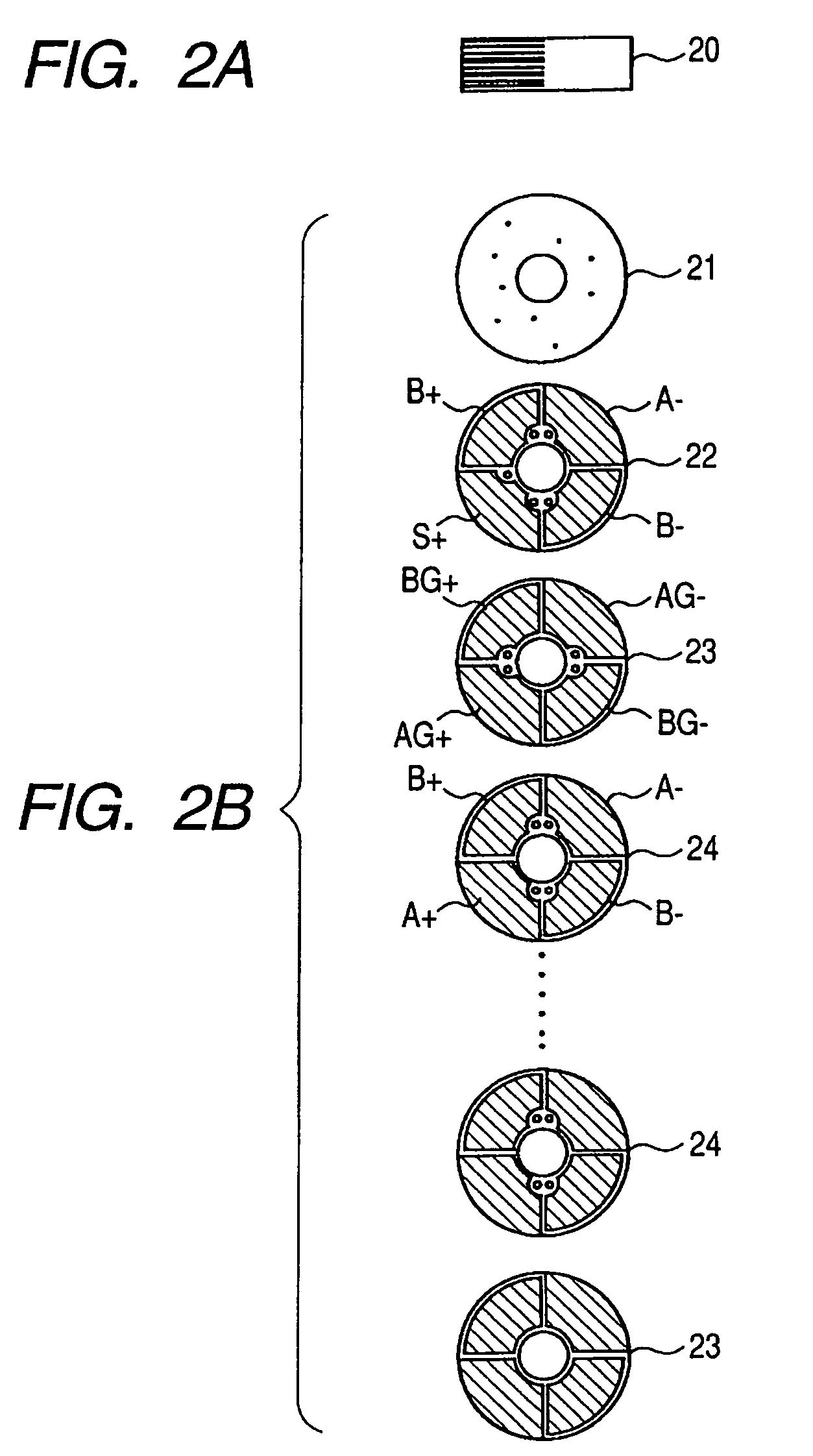

Vibration wave drive device, stator for a vibration wave motor, vibration wave motor, driving control system, optical apparatus, and manufacturing method of a vibration wave driving device

ActiveUS20160118914A1Improve performanceLow costPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesControl systemWave motor

A vibration wave drive device (25) includes an annular piezoelectric element (20) including a piezoelectric material (1) and multiple electrodes provided sandwiching the piezoelectric material (1), the annular piezoelectric element being configured to vibrate by a traveling wave of a wavelength λ; and a power feeding member (8) including at least electric wire (8a) for supplying electric power to the element (20), the feeding member (8) being provided to a first surface of the element (20). The element (20) includes at least two driving regions (15, 16), and a non-driving region (17) arranged between two of the at least two driving regions and has an average annular length of nλ / 4, n being an odd number. At least one electrode provided on the first surface is arranged across the region (15, 16) and the region (17), and is electrically connected to the feeding member (8) only in the region (17).

Owner:CANON KK

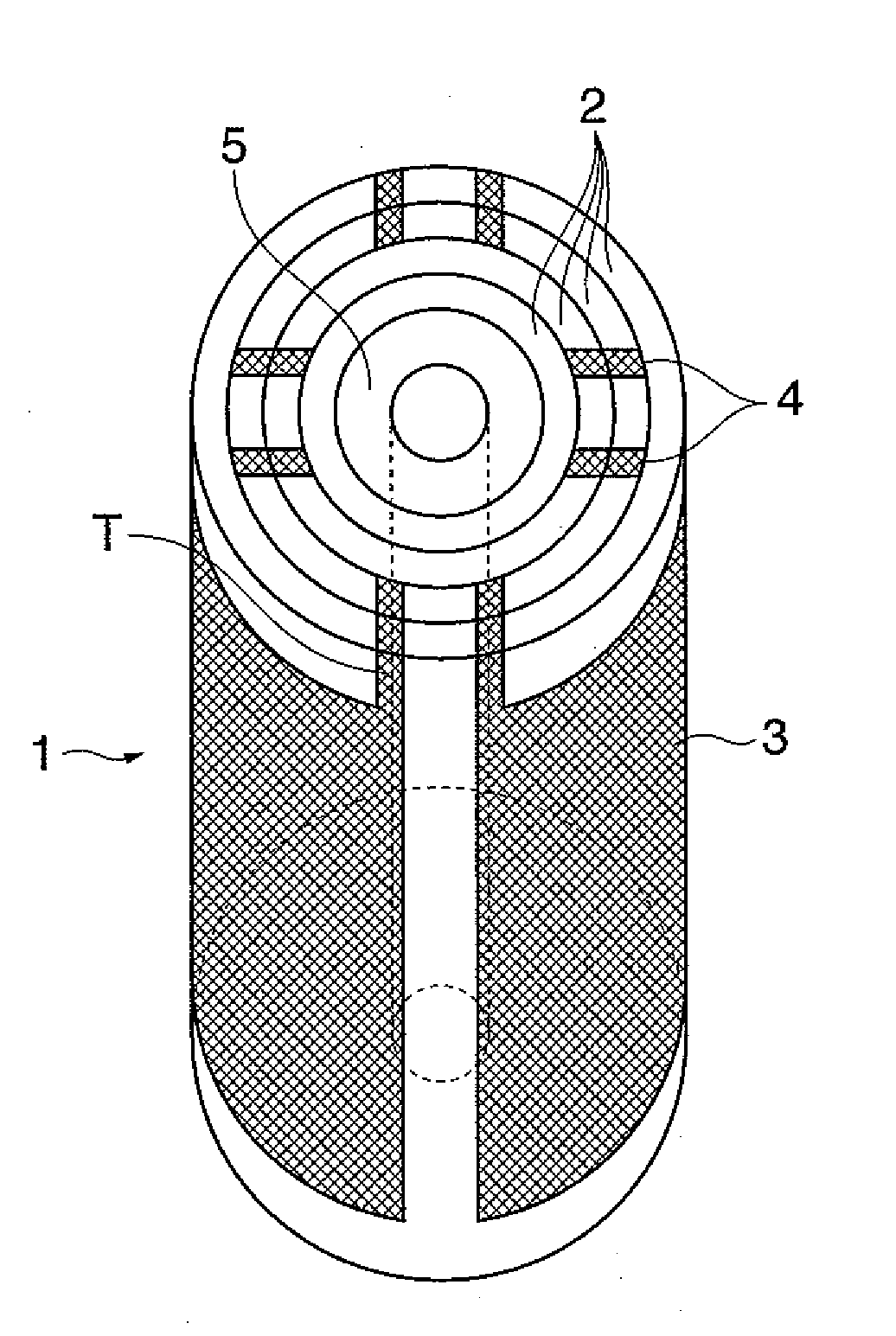

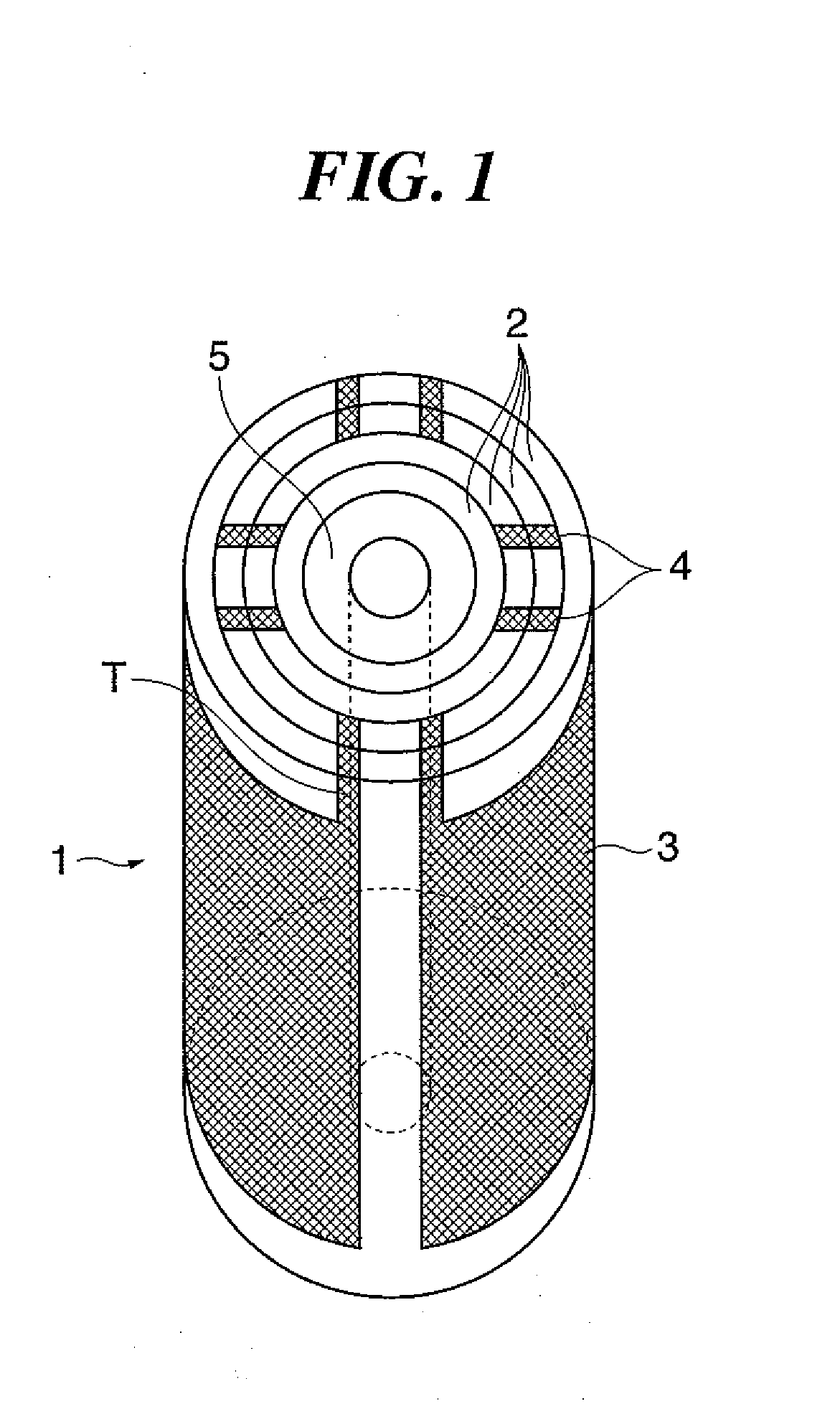

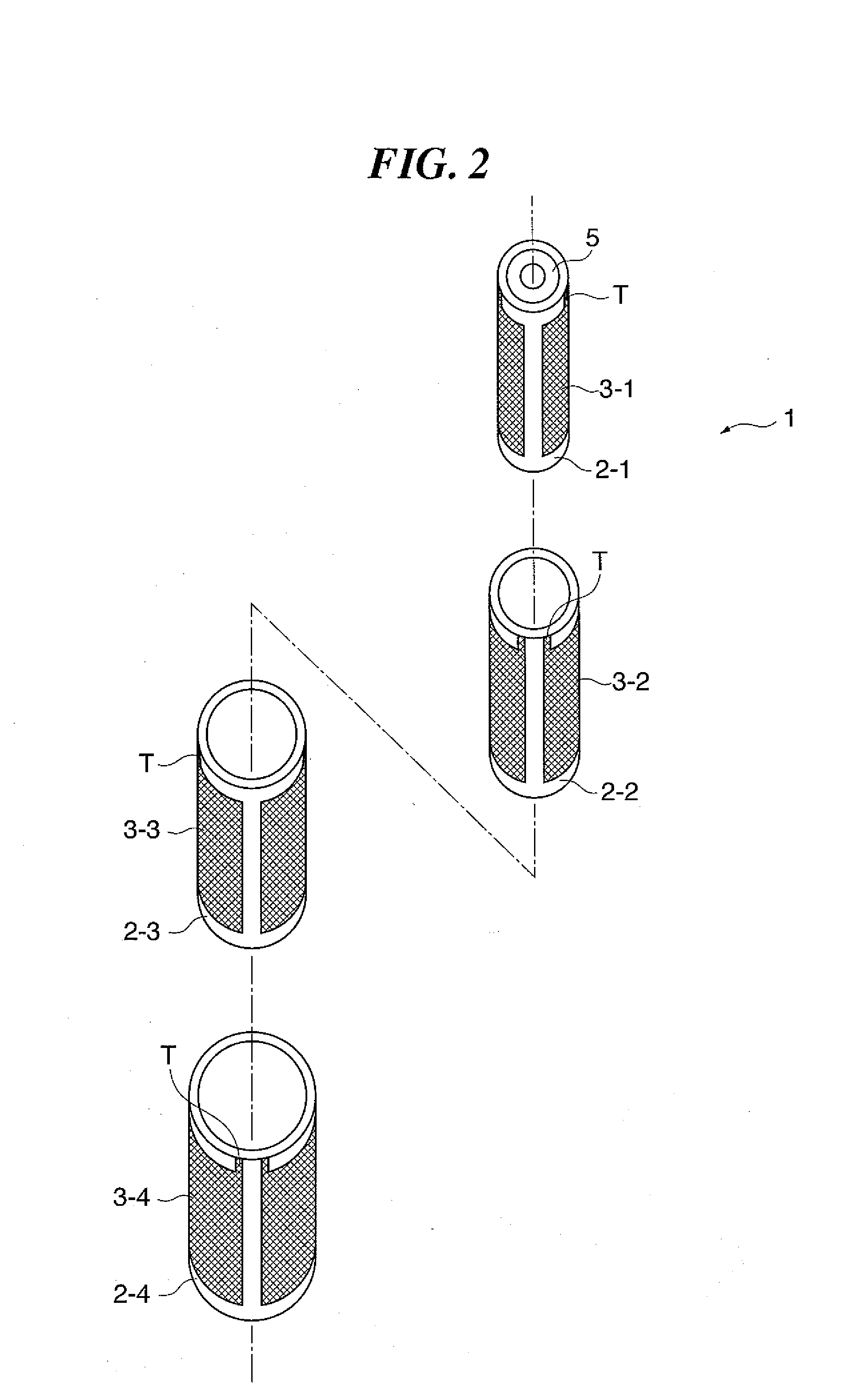

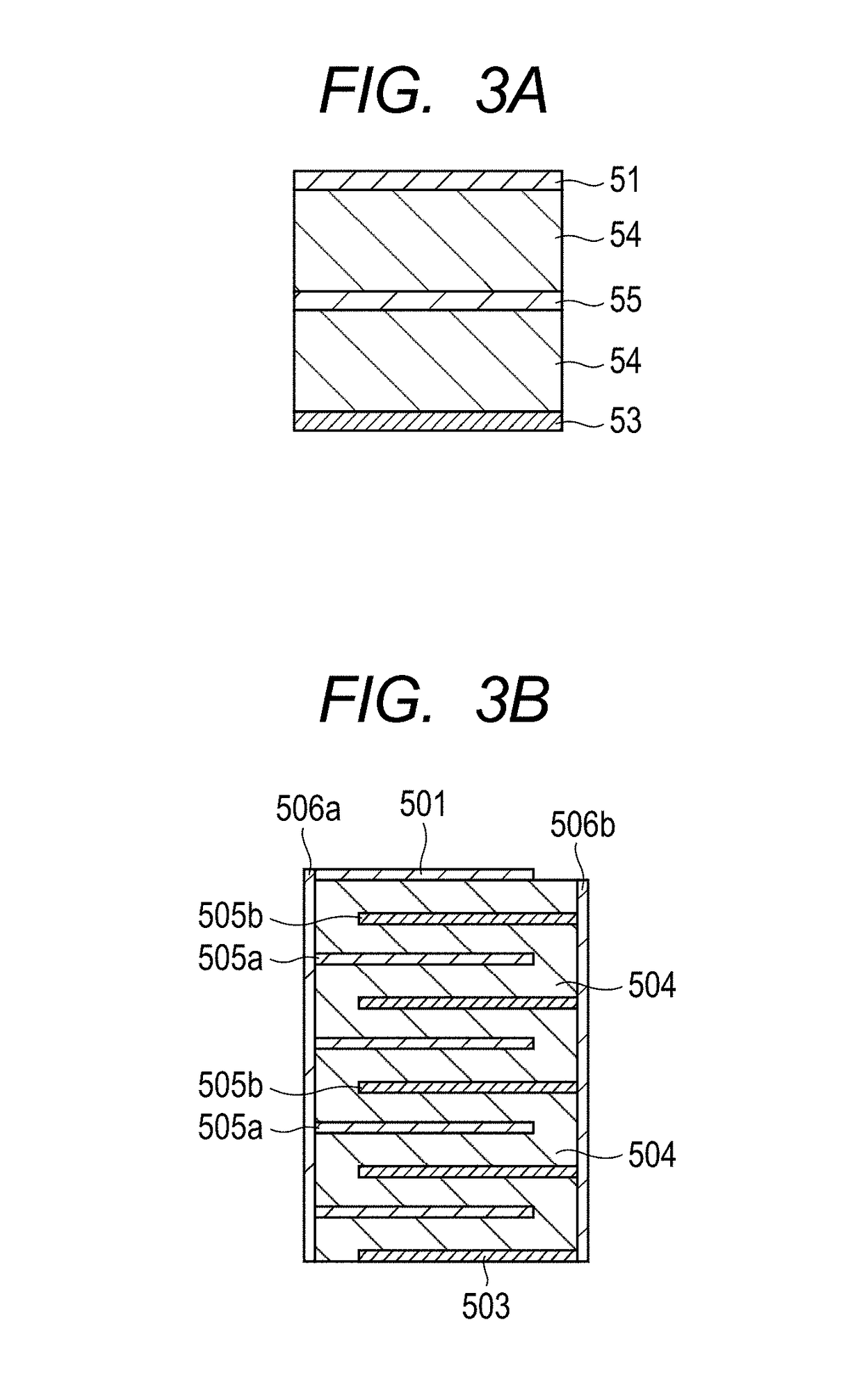

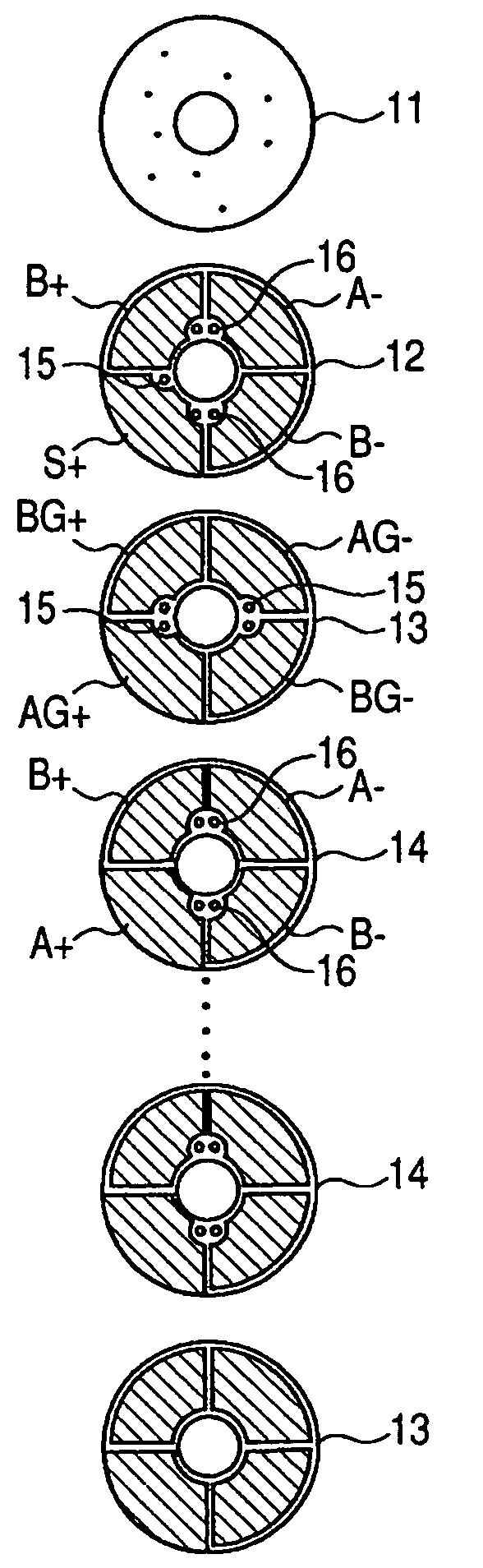

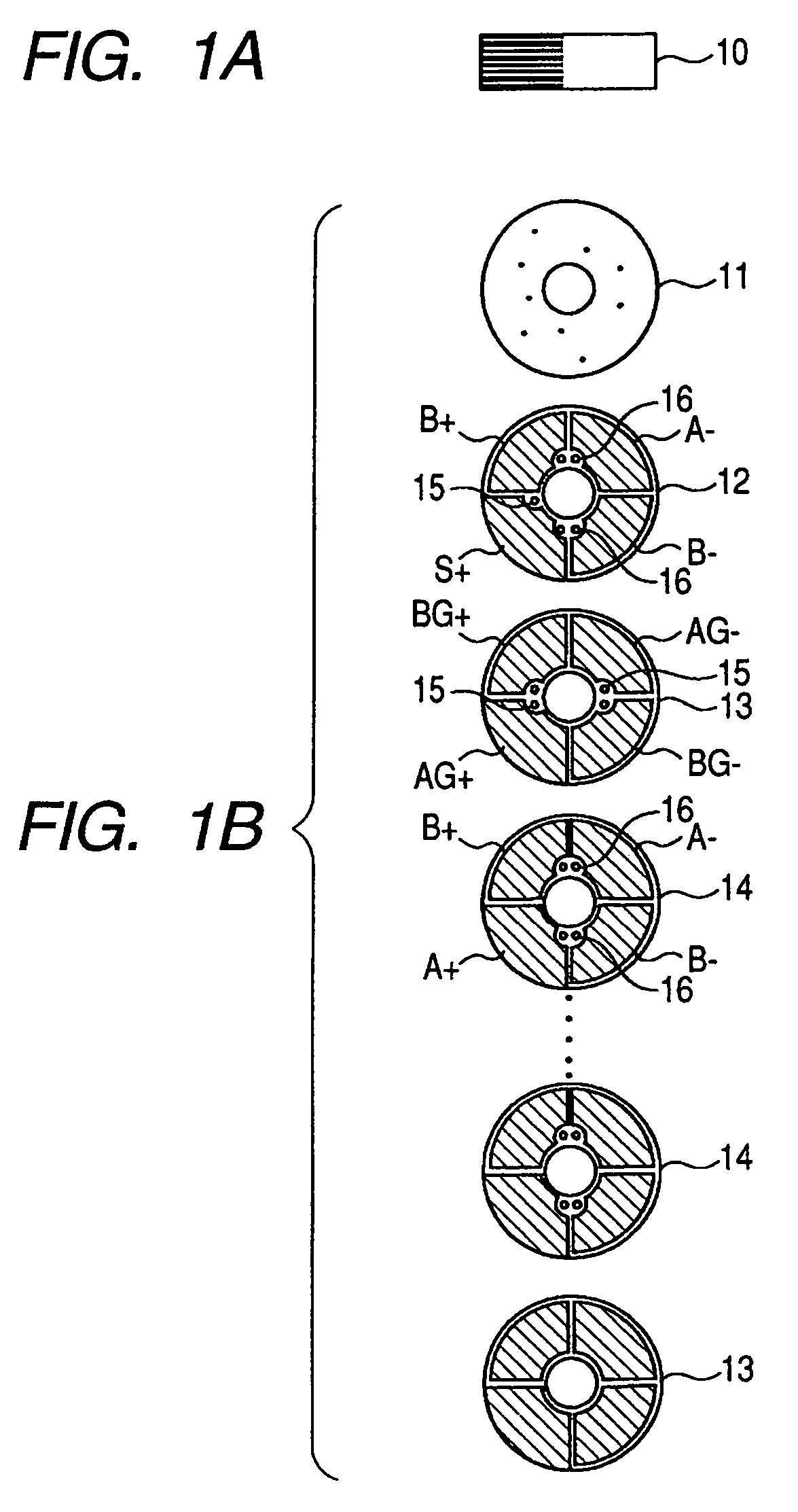

Stacked piezoelectric element, manufacturing method thereof and vibration wave driving apparatus

InactiveUS20070262679A1Suppress periodic dampingImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMiniaturizationWave motor

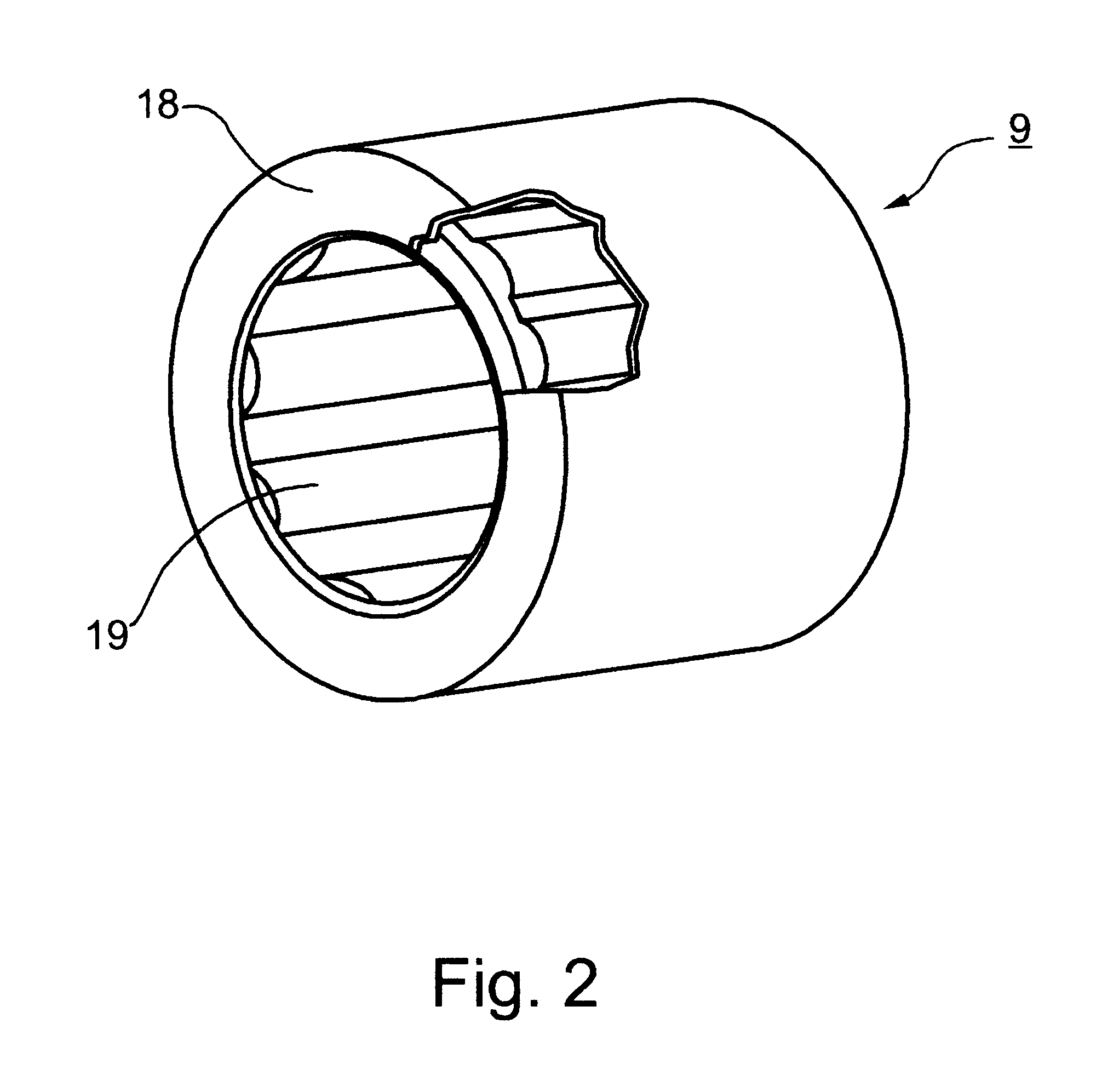

A stacked piezoelectric element comprising that can suppress periodic damping on miniaturization of a vibration wave motor and improve its performance. A stacked piezoelectric element comprises piezoelectric layers and electrode layers alternately stacked to have a shape of a cylinder. The electrode layers are divided into a plurality of electrode layer regions along a circumferential surface of the shape of a cylinder.

Owner:CANON KK

Ultrasonic wave motor and ultrasonic wave motor-equipped device

ActiveUS20150200610A1Piezoelectric/electrostriction/magnetostriction machinesMountingsWave motorRelative motion

Owner:CANON KK

Vibration wave motor and lens barrel

InactiveCN1780134AEasy to assembleImprove conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesMountingsTransducerEngineering

The vibration wave motor of the present invention includes: a housing; a rotor; a bearing member; a vibrator as an actuator having a support shaft and a driver; and a leaf spring having a pressing protrusion. The vibrator is held in a state where it is slidable in the opening of the case along the direction of the axis of rotation, and its support shaft is supported and inserted freely to rotate, and the driver is brought into contact with the above-mentioned driving member by the biasing force of the leaf spring. on the rotor. When the vibration wave is excited by the vibrator, the rotor is driven to rotate, the vibrator is held in the housing so as to be movable along the direction of the rotation axis, and the vibrator is pressed by the leaf spring, so that the vibrator abuts against the rotor. The side friction contact surface, so the vibrator can abut against the above-mentioned rotor evenly and perpendicularly to the contact friction surface, and a good driving state of the motor can be obtained.

Owner:OLYMPUS CORP

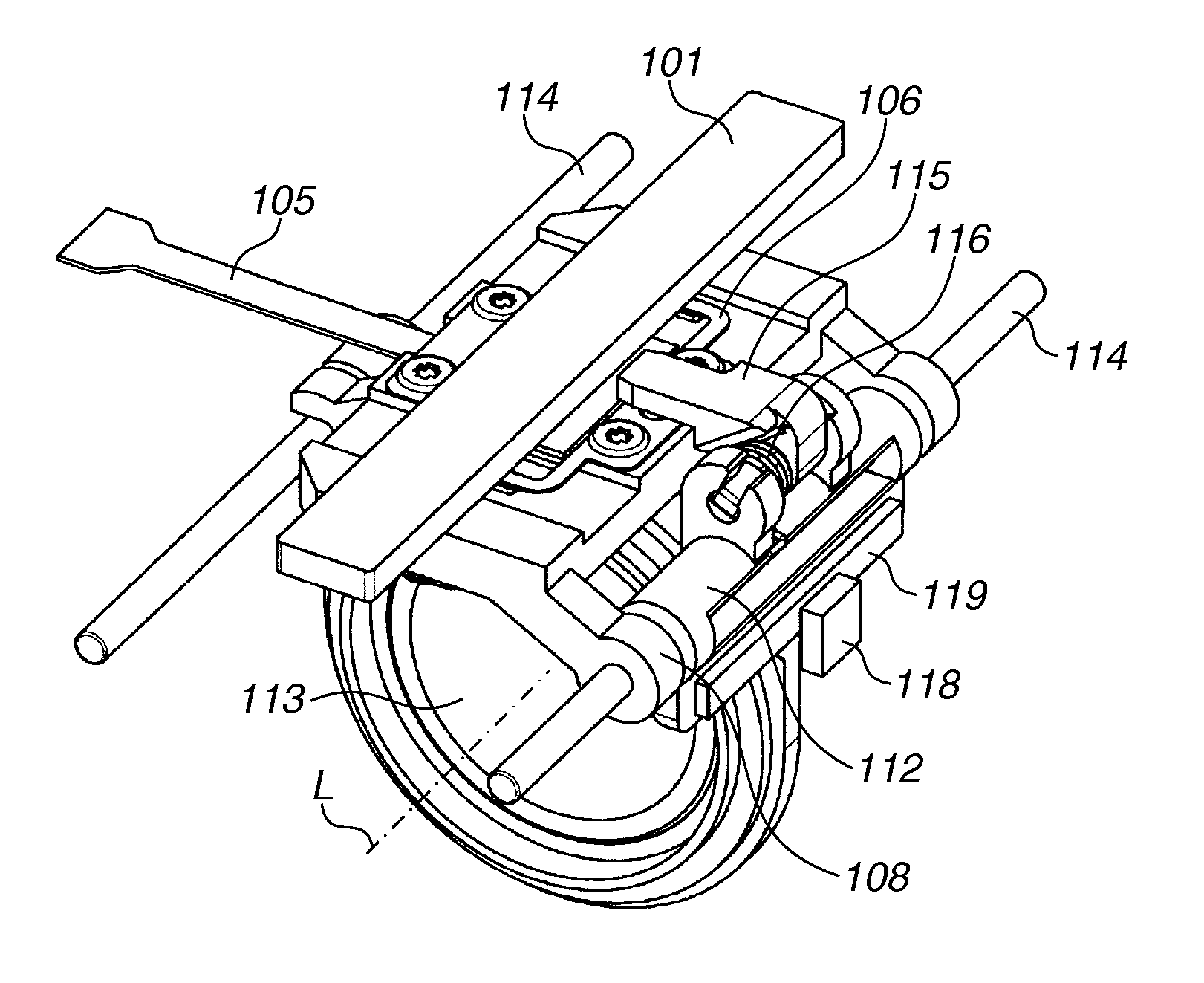

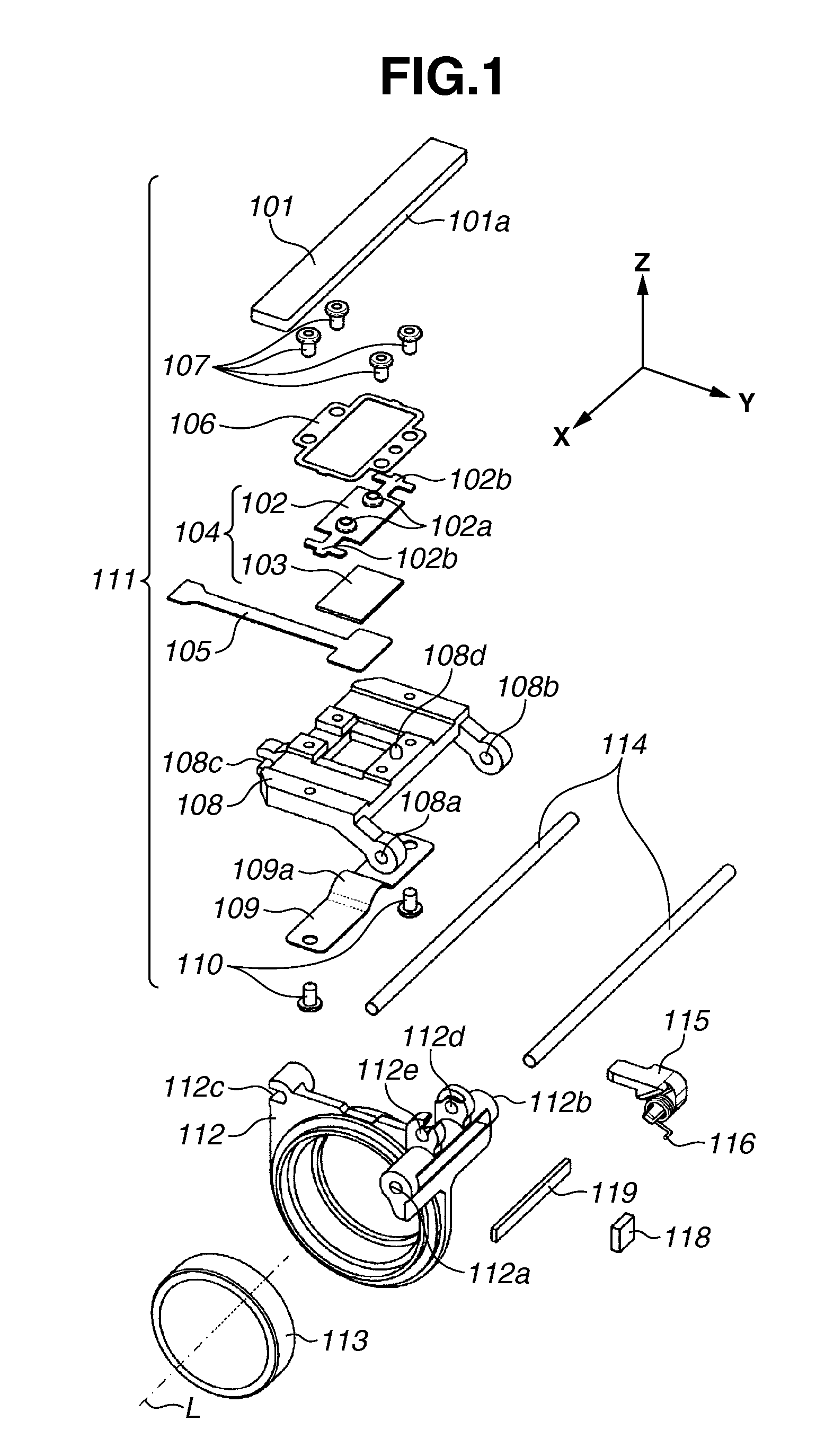

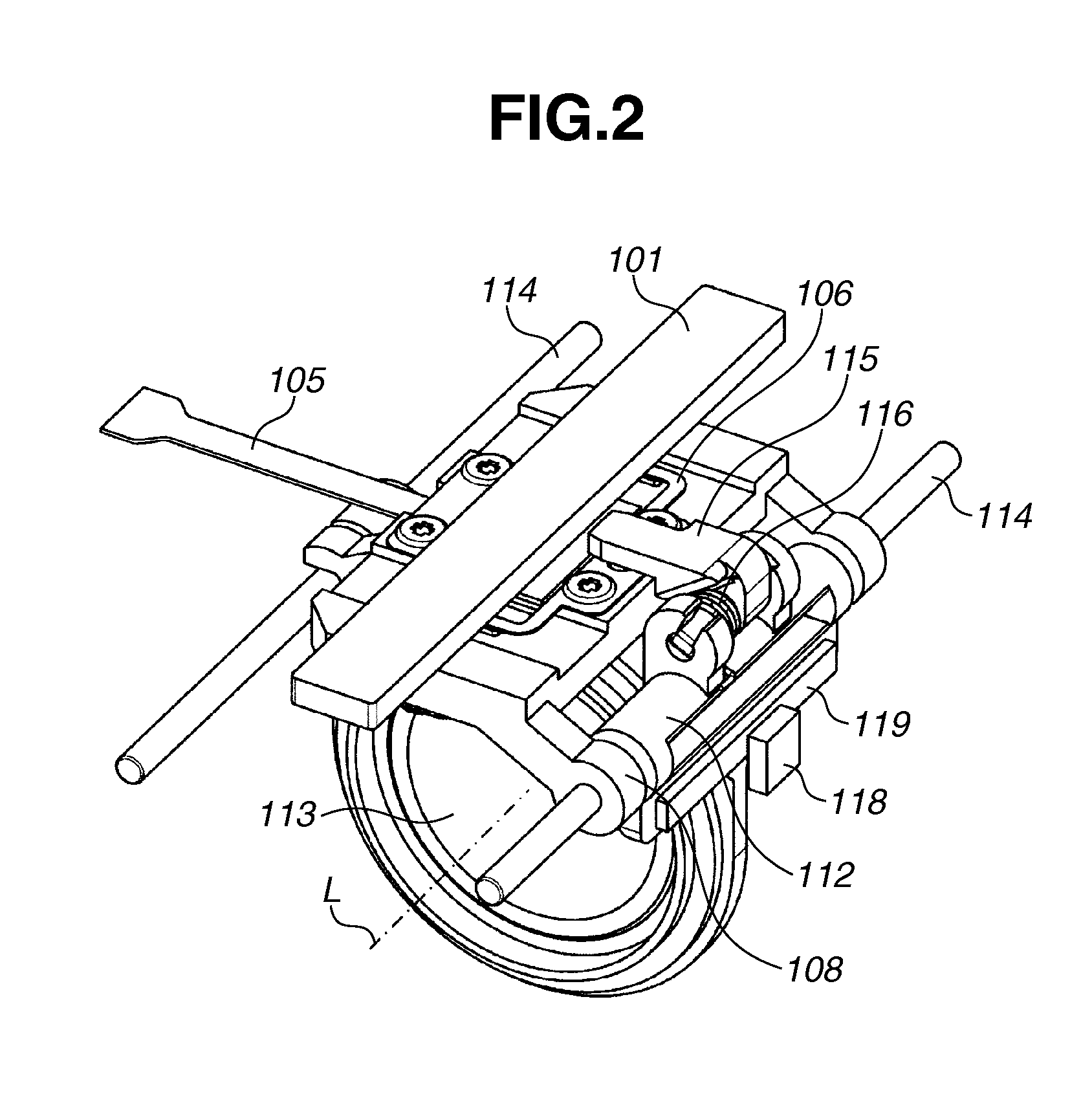

Vibration wave motor and lens driving apparatus

ActiveUS20170371125A1Small sizeIncrease in sizePiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCamera lensWave motor

Provided is a vibration wave motor including: a vibrator; a pressurizing member configured to pressurize the vibrator against a friction member; a holding member configured to hold the vibrator; and a buffering member provided between the vibrator and the holding member. The vibrator and the friction member are moved relatively to each other in a relative movement direction by vibration of the vibrator, and the holding member holds the vibrator in such a manner that an extending part extending in a pressurizing direction of the pressurizing member sandwiches the vibrator and the buffering member.

Owner:CANON KK

Piezoelectric wave motor

InactiveUS6518689B2Shear forces imposed upon the elements are minimized or eliminatedMaximizes deformationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesElectricityClassical mechanics

Owner:HONEYWELL FED MFG & TECHNOLOGI

Vibration wave motor and driving apparatus using the vibration wave motor

InactiveUS20160118913A1Small sizeDownsizing of a driving apparatusPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesWave motorTorsional vibration

A vibration wave motor includes: a vibrating plate having a rectangular surface; a piezoelectric device bonded to the vibrating plate, and configured to vibrate at high frequency; and a projection provided to the vibrating plate or the piezoelectric device. In the vibration wave motor, a natural vibration mode, which has a resonant frequency equal to or adjacent to a resonant frequency of torsional vibration in a natural vibration mode under a state in which the vibrating plate, the piezoelectric device, and the projection are integrated, is a natural vibration mode of bending vibration in a direction parallel to or orthogonal to a torsion center axis of the torsional vibration in the natural vibration mode. The projection is provided at a position closer to an antinode than to a node, which are in the direction orthogonal to the torsion center axis of the torsional vibration in the natural vibration mode.

Owner:CANON KK

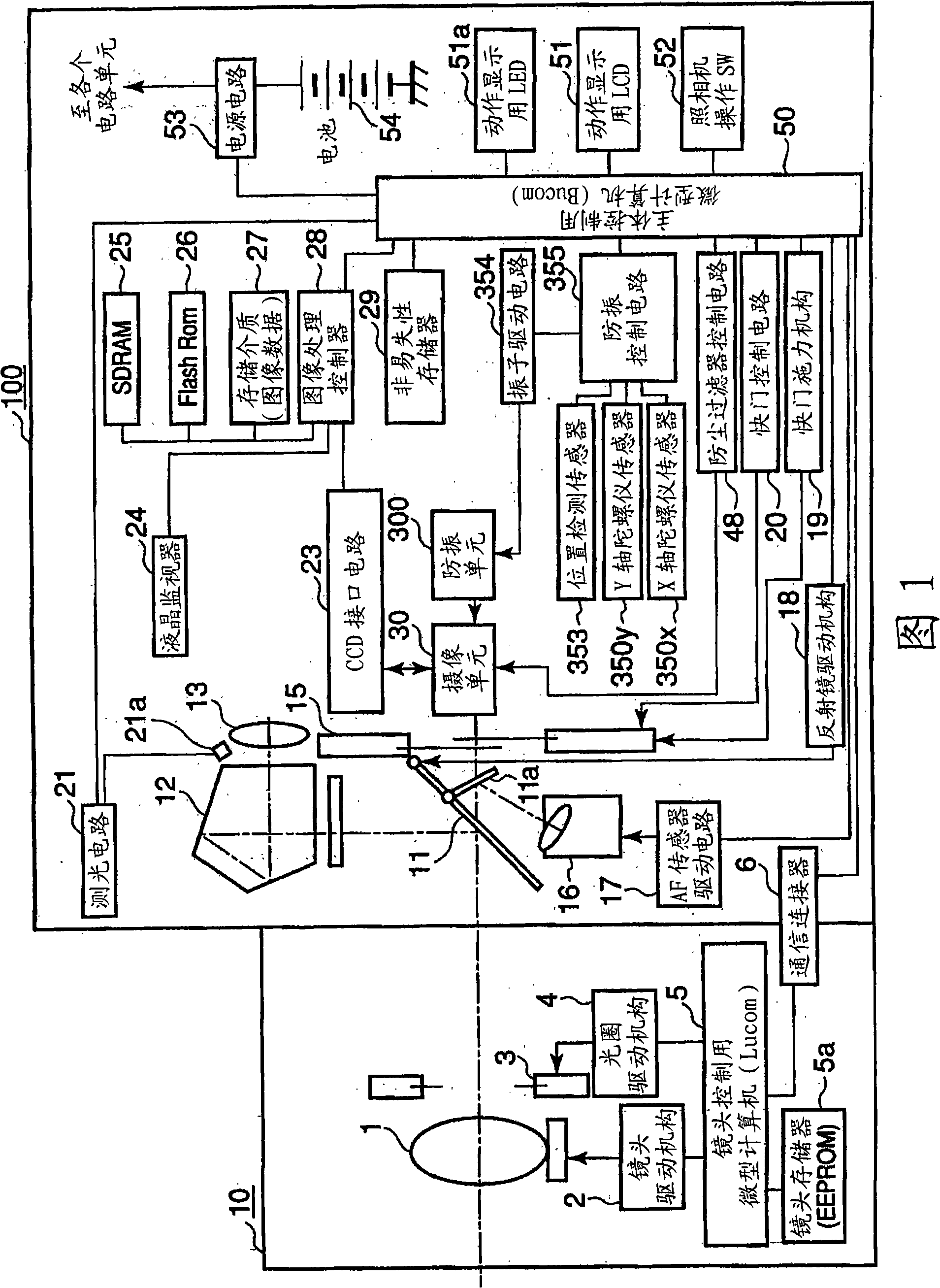

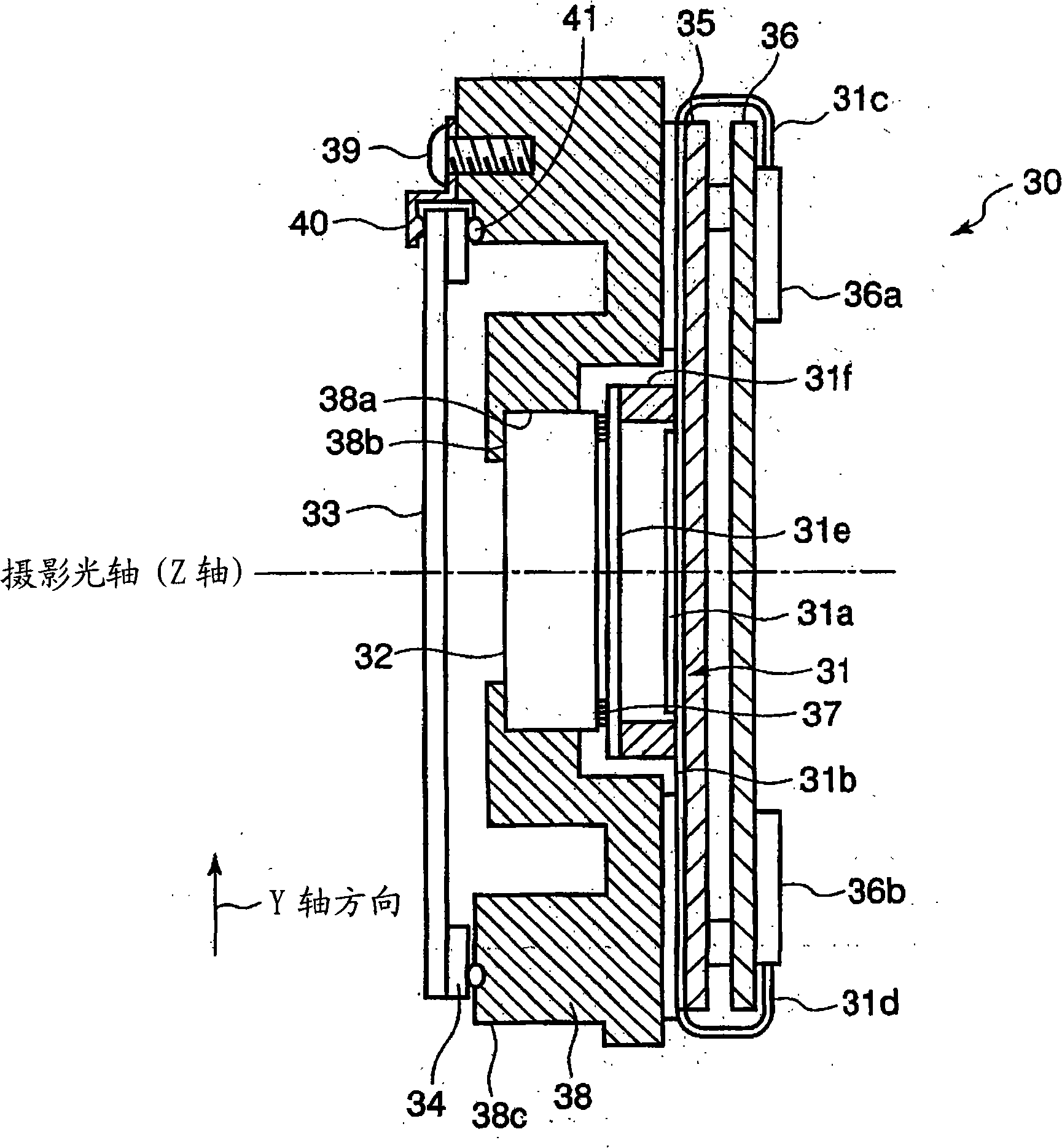

Imaging device

InactiveCN101334575AImprove convenienceEfficient replacementTelevision system detailsPrintersLocation detectionGyroscope

The present invention provides an obscurity correcting device which can shoot at any condition and uses a vibration wave motor, and a camera using the obscurity correcting device. The number that a deviation exceeds a preset threshold value is counted, wherein the deviation is a difference between a target drive position computed based on the obscure signals detected by an X axis gyroscope sensor (350x) and a Y axis gyroscope sensor (350y) and a position detection value detected in a position detecting sensor (353), if the count result reaches a preset count value, the obscurity correcting device is judged at unsteady state, and Tucom (402) executes control to stop the obscurity correction.

Owner:OLYMPUS CORP

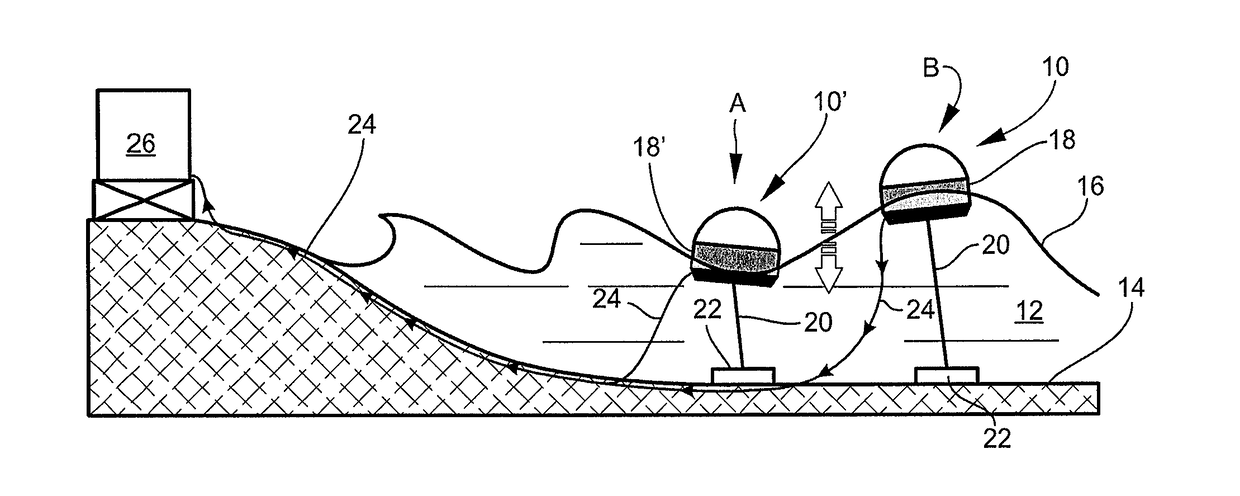

Wave motor and desalination system

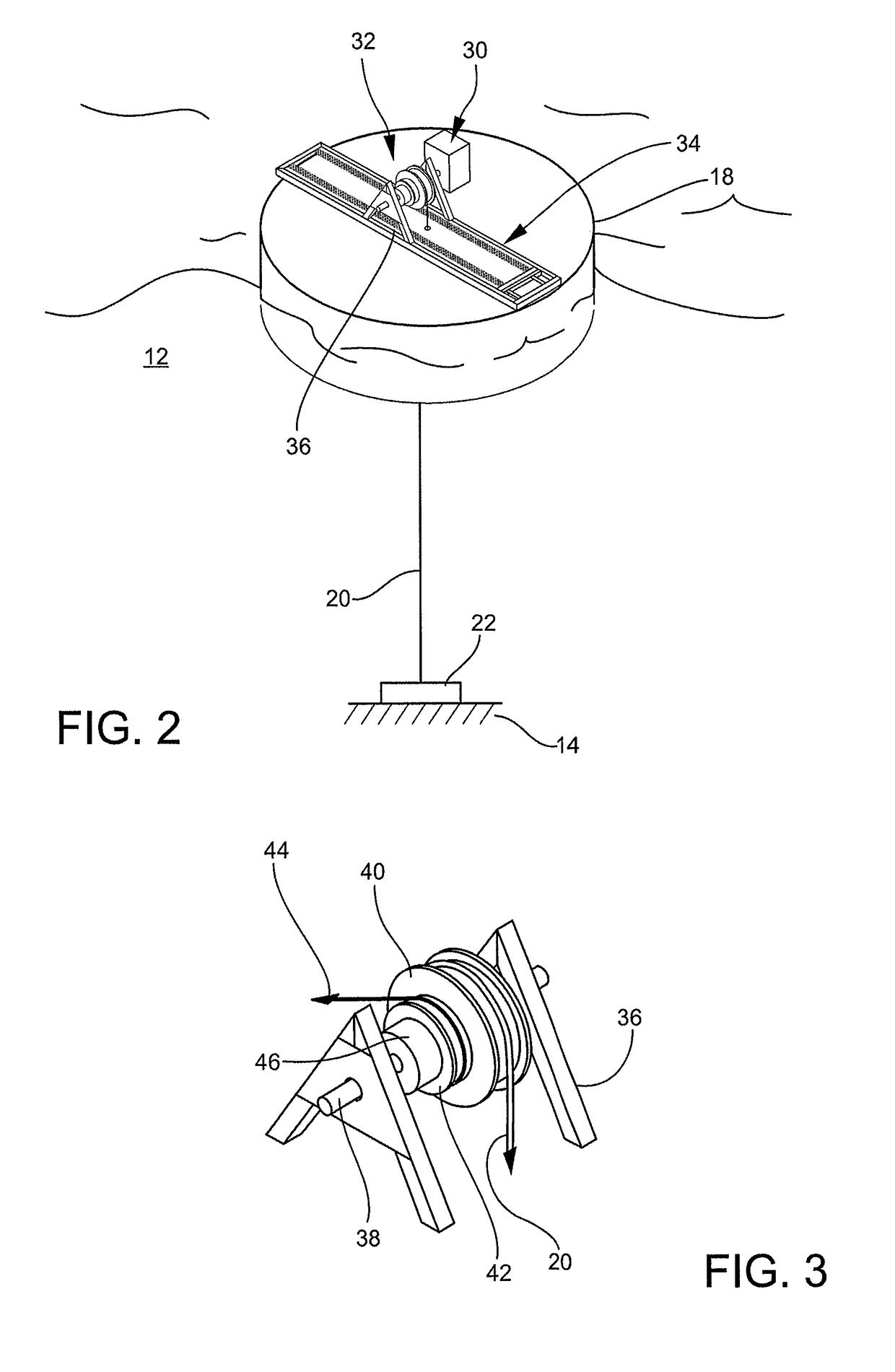

Wave energy is utilized by and / or seawater is desalinated by a point-absorber-type wave energy converter has: an anchor affixed to an ocean floor, a buoy is tethered to the anchor, and a machine is located on the buoy; the buoy includes a spool system and a recoil system, the spool system has a first spool and a second spool mounted together on a shaft, the recoil system includes a spring, a first line connects the first spool and the anchor, so that as the wave displaces the buoy, the shaft turns and drives the machine, and a second line connects the second spool and the recoil system, so that after the displacement of the buoy, the first line is recoiled onto the first spool.

Owner:ECOH2O INNOVATIONS LLC

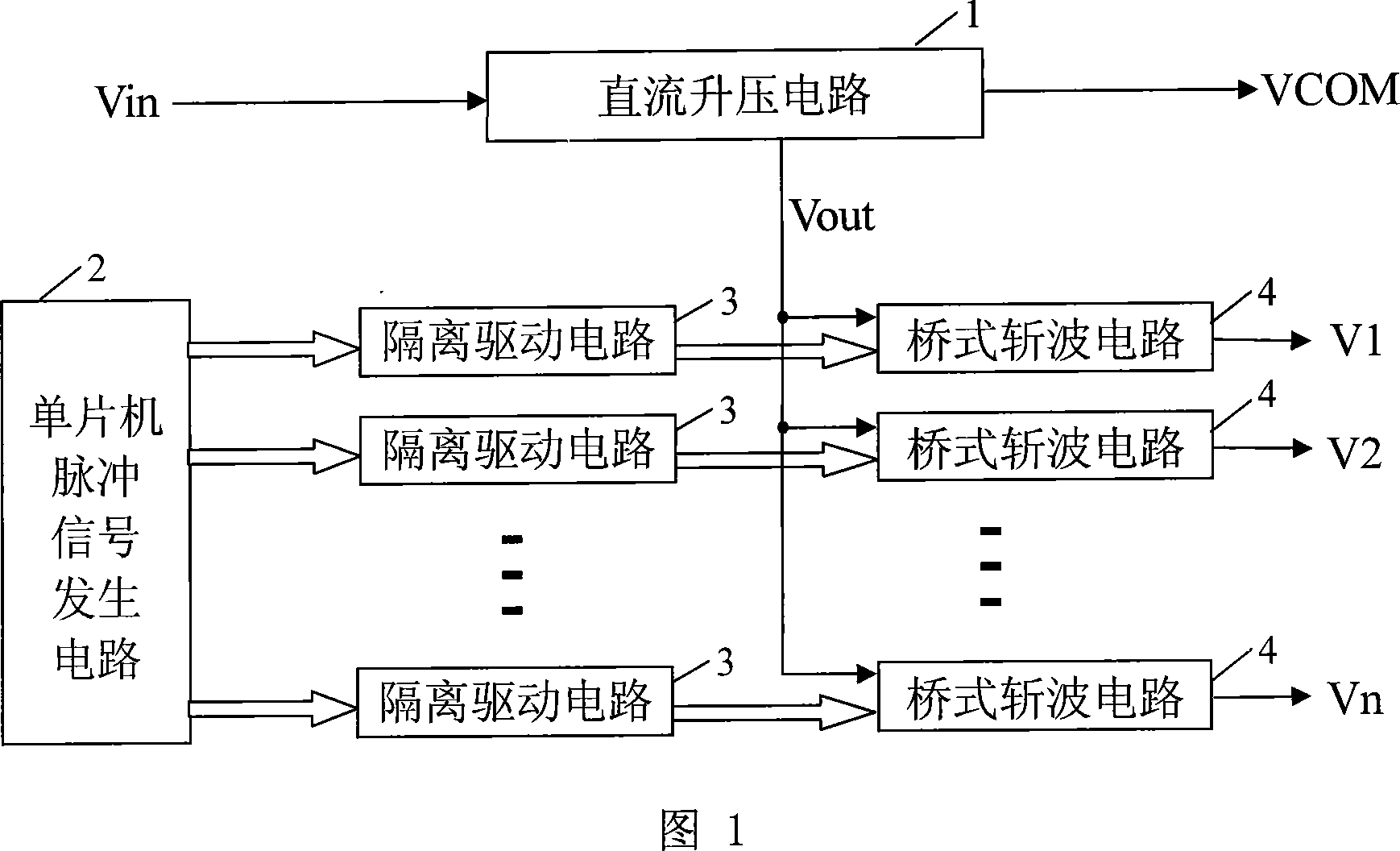

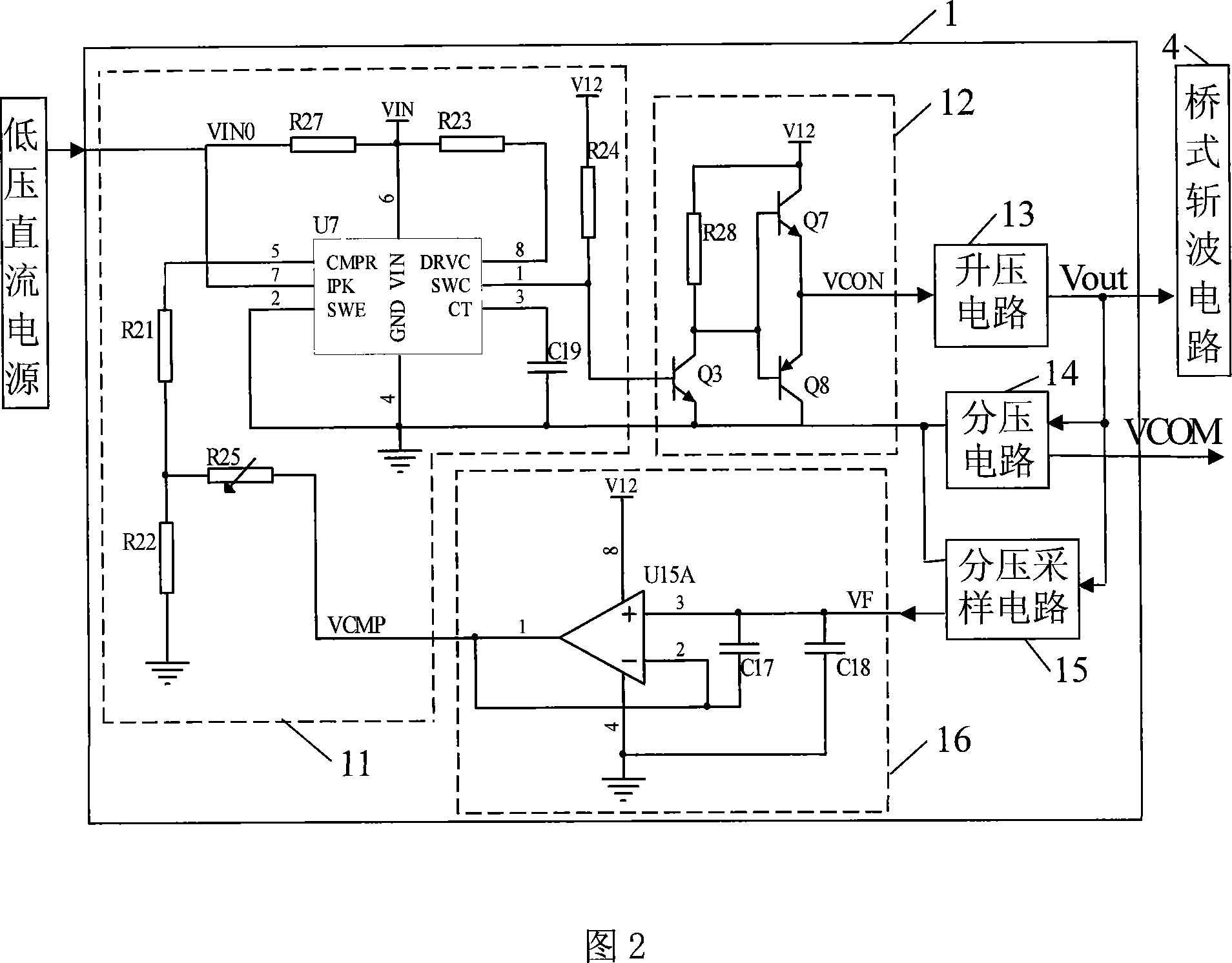

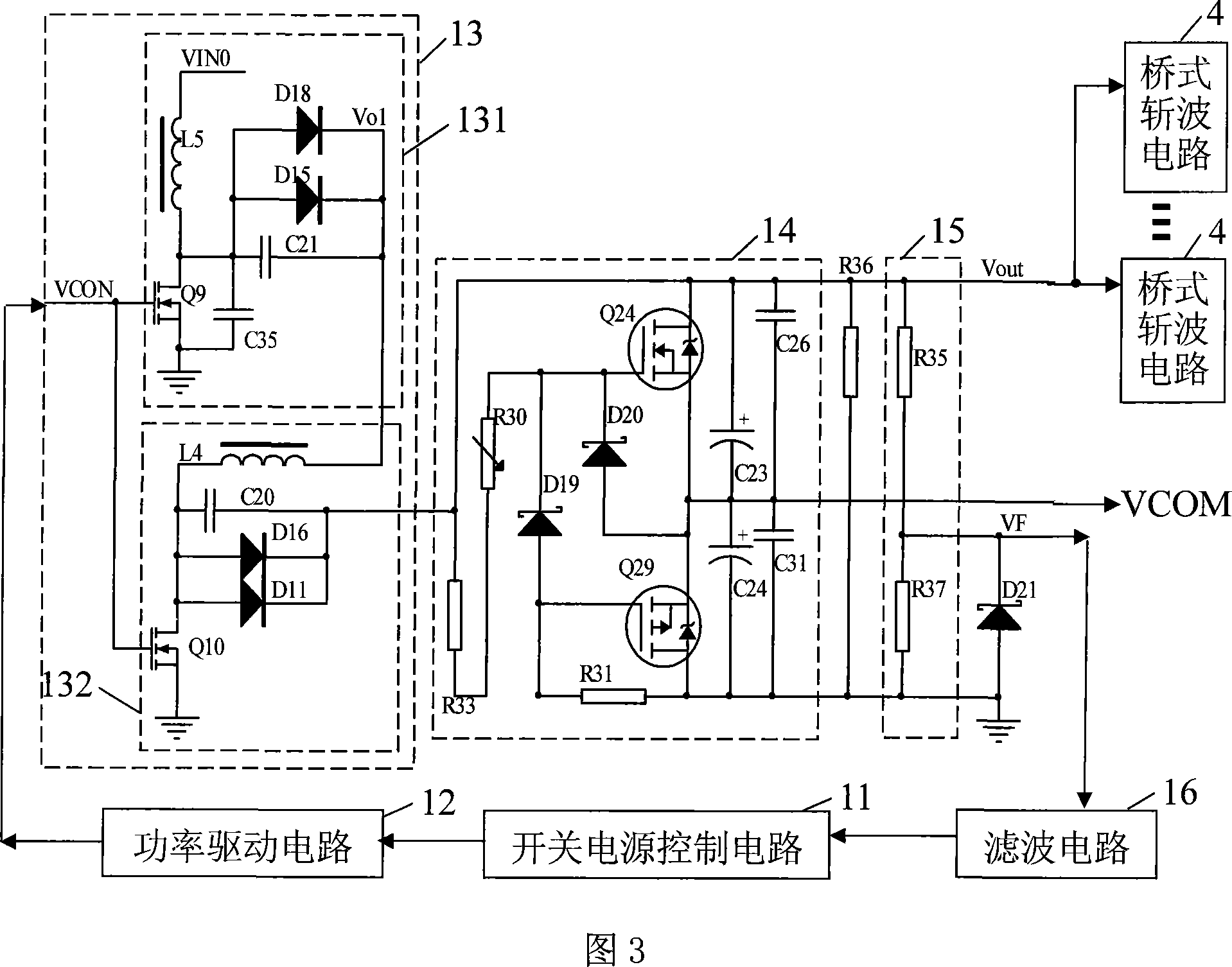

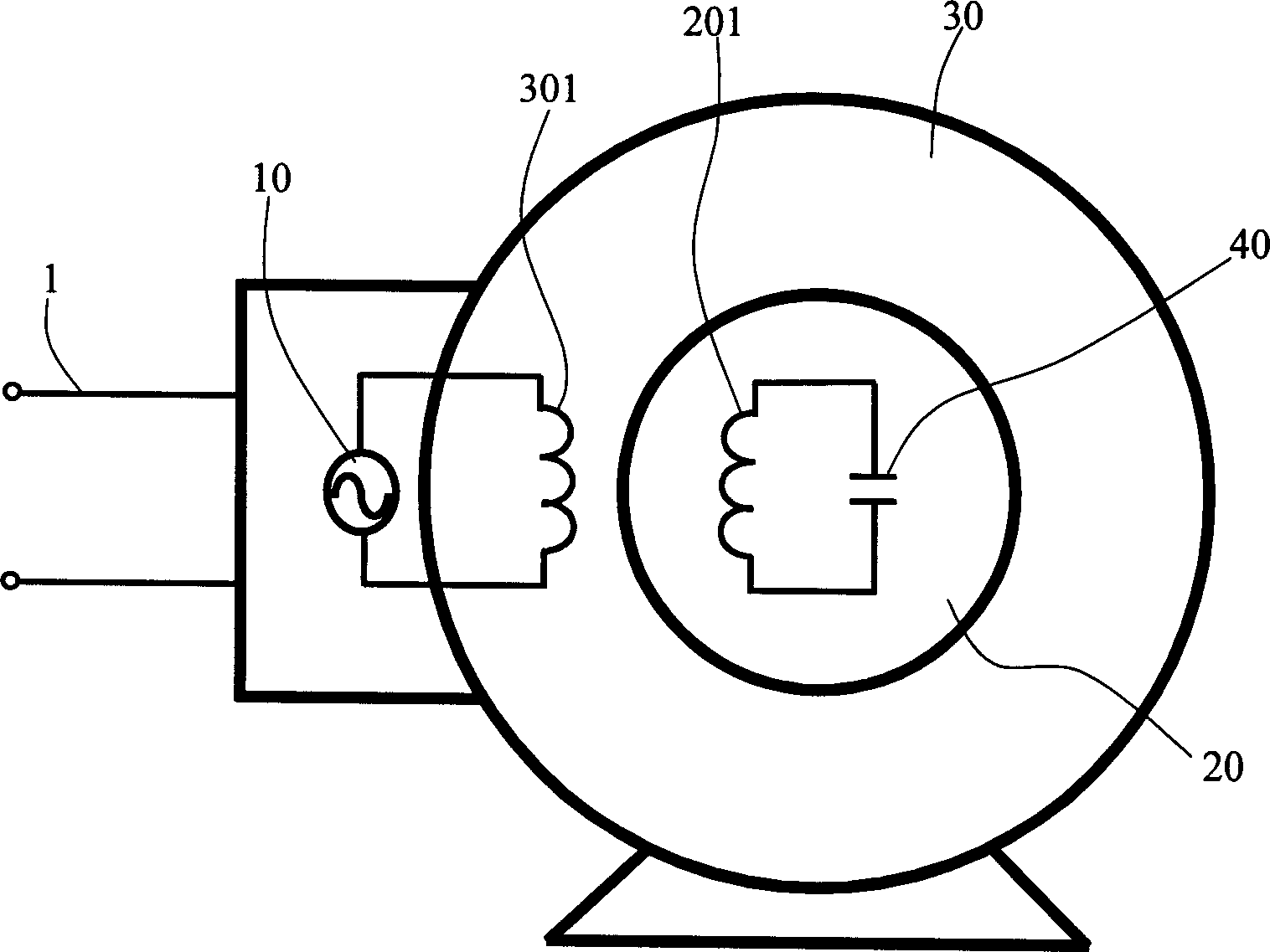

Transformer-free ultrasonic motor driver

InactiveCN101060291AStable output voltageFlexible frequency adjustmentPiezoelectric/electrostriction/magnetostriction machinesMicrocontrollerTransformer

The disclosed ultrasonic wave motor driver without transformer comprises: a SCM pulse signal generation circuit with signal output end connected with the input end of a multi-path isolation drive circuit, multi-path bridge chop circuit with control signal input end connected with the output end of the isolation drive circuit, and a dc boost-up circuit with dc drive voltage output end paralleling the two power ends of chop circuit with the power ground. This invention overcomes defects in current product, and has wide application.

Owner:HARBIN INST OF TECH

Vibration-wave motor

ActiveUS20180175747A1Smooth power transmissionPiezoelectric/electrostriction/magnetostriction machinesMountingsWave motorEngineering

A vibration-wave motor includes a vibrator, a first holding member configured to hold the vibrator, a second holding member configured to hold the first holding member, a plurality of pressing members arranged around the vibrator and configured to press the vibrator against a contacting member that contacts the vibrator, a movable plate disposed opposite to the vibrator with respect to the contacting member, and a coupling part configured to couple the second holding member and the movable plate with each other. The vibrator and the contacting member move relatively to each other due to a vibration generated by the vibrator. One of the second holding member and the movable plate includes a transmitting part configured to transmit a driving force of the vibration-wave motor to a driven member.

Owner:CANON KK

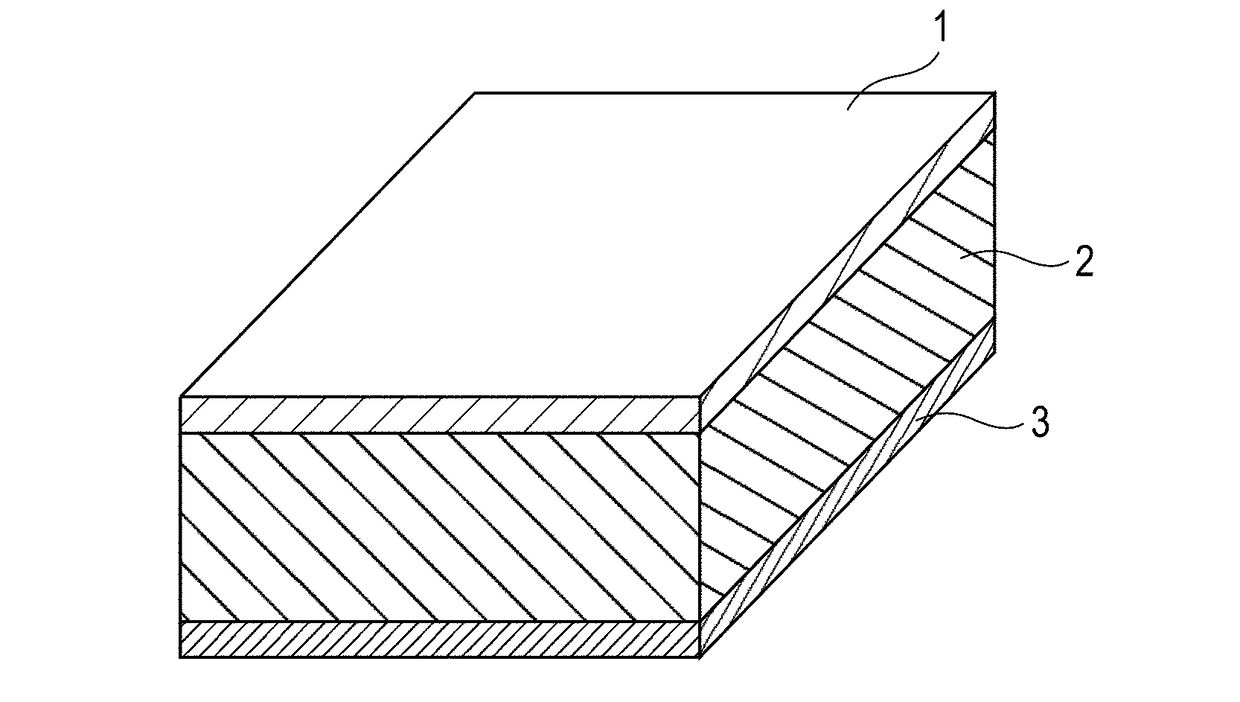

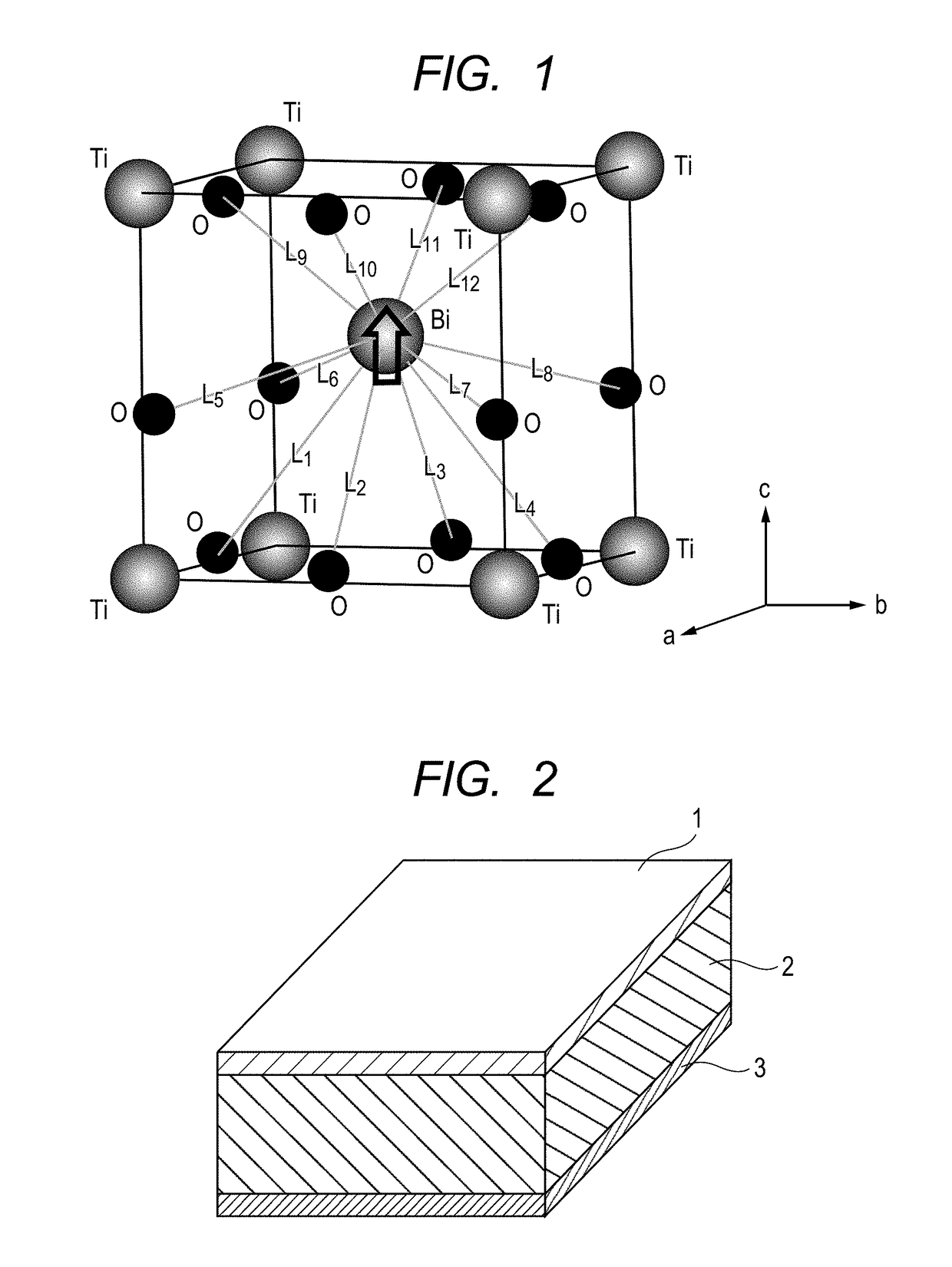

Piezoelectric material, piezoelectric element, liquid discharge head, liquid discharge apparatus, vibration wave motor, optical instrument, vibration apparatus, dust removing apparatus, imaging apparatus and electronic device

ActiveUS20170373244A1Television system detailsPiezoelectric/electrostriction/magnetostriction machinesWave motorOptical instrument

A piezoelectric material including a perovskite-type metal oxide represented by the following general formula (1); Bi; and Mn, wherein the content of Bi is 0.1-0.5 mol % with respect to 1 mol of the metal oxide, the content of Mn is 0.3-1.5 mol % with respect to 1 mol of the metal oxide, and the piezoelectric material satisfies (L4−L5) / L5≧0.05 and (L8−L9) / L9≧0.05 when the lengths of twelve Bi—O bonds with Bi that is located at a 12-fold site with respect to O in a perovskite-type unit cell as a starting point are taken to be L1 to L12 in length order:(Ba1-xM1x)(Ti1-yM2y)O3 (1)wherein 0≦x≦0.2, 0≦y≦0.1, and M1 and M2 are mutually different metal elements which have a total valence of +6 and are selected from other elements than Ba, Ti, Bi and Mn.

Owner:CANON KK

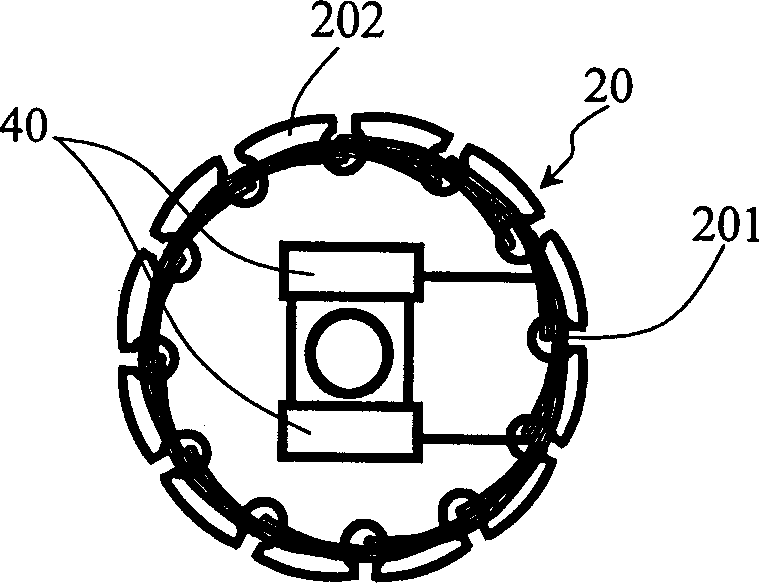

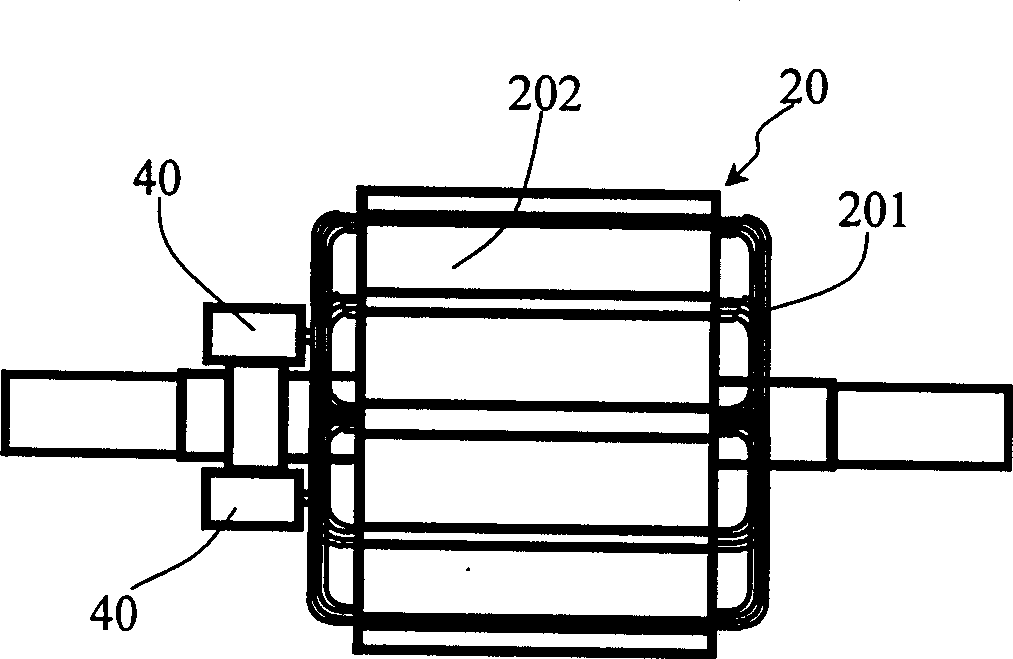

Water bucket type wave motor

The invention discloses a water bucket type wave motor. The water bucket type wave motor comprises a rotor and water buckets, wherein the rotor is cylindrical or annular, the water buckets are evenly distributed at the external circle of the rotor in the peripheral direction, each water bucket is of a water tank structure, openings of the water buckets are sequentially arranged along the periphery, the axis of a rotor shaft is slightly higher than the water surface and is parallel with the water surface, and the axis of the rotor shaft is roughly parallel with the bank. A one-way valve is installed on the lateral wall of each water bucket and corresponds to the opening of the corresponding water bucket, water can only enter through each one-way valve, and a water outlet is near the outer side of the bottom surface of each water bucket. Each water bucket is simple in structure, low in manufacturing cost and high in reliability. Due to the fact that the water bucket type wave motor directly collects and utilizes the potential energy of waves and floating force of water to drive the water buckets on the rotor to move for power generation, the wavy energy does not need a middle conversion procedure, and the utilization rate is high. If the geometric size of each water bucket is designed to be small, small broken waves can also be utilized.

Owner:CHONGQING UNIV +1

Wave generator power plant

InactiveUS7327049B2Cost effectiveReduce operating costsMachines/enginesEngine componentsWave power generationSea waves

The Wave Generator Power Plant converts the energy in sea waves into electricity. The wave motor portion of the power plant utilizes a buoyant, moving, semisubmerged, cone-shaped pontoon that is powered by the sea wave motion. The reciprocation is changed to rotary motion by a connecting rod and crankshaft. Then, through a gearbox, the rotary motion drives an electrical generator. The fully submerged, stationary, buoyant, ring-pontoon is anchored to the sea floor by sixteen (16) cables. Also, sixteen (16) columns connecting to it, support the upper above-water structure. The assembly, is a moving buoyant pontoon, reciprocating within an anchored ring-pontoon. Optimum operation takes place in sea waves of adequate height and period that can lift and drop the moving cone-shaped pontoon relative to the design mechanical requirements. Sea wave energy, through the design of this invention, is amassed to develop sixteen hundred (1600) horsepower and generate one ((1) mega-watt of electricity.

Owner:HAMBURG RON

Ultrasonic wave motor and ultrasonic wave motor-equipped device

ActiveUS9397586B2Piezoelectric/electrostriction/magnetostriction machinesMountingsEngineeringRelative motion

Owner:CANON KK

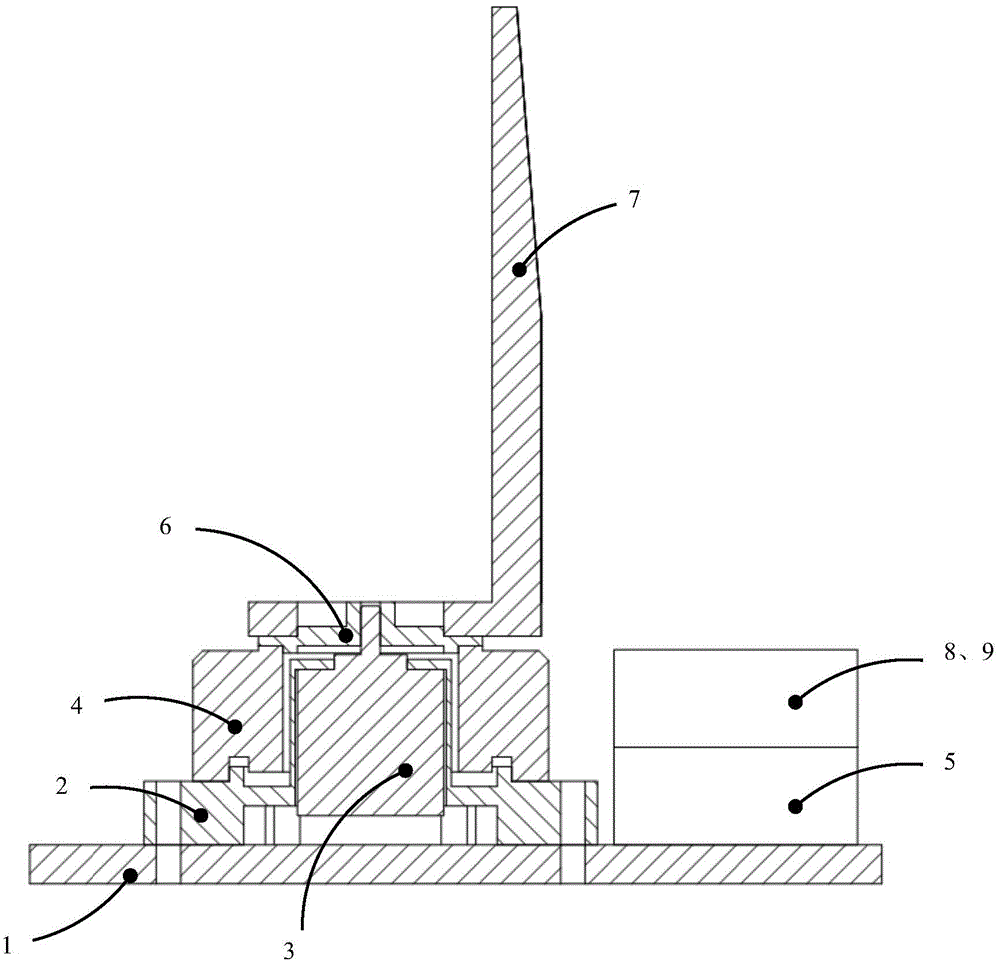

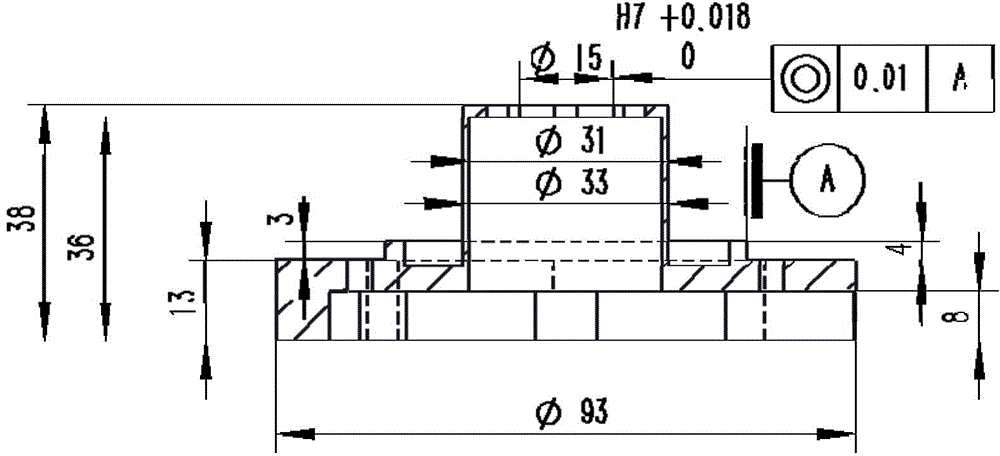

Indexing mechanism of ultrasonic wave motor based high-precision miniaturized fiber optic gyroscope north finder

The invention discloses an indexing mechanism of an ultrasonic wave motor based high-precision miniaturized fiber optic gyroscope north finder. According to the invention, the indexing mechanism of the fiber optic gyroscope north finder is designed by adopting a precise driving technique, and an ultrasonic motor is introduced for the first time to design the brand new indexing mechanism to replace the traditional complex mechanical type indexing mechanism and a locking mechanism, so that the structure of the indexing mechanism can be simplified greatly; the fiber optic gyroscope north finder formed by adopting the indexing mechanism can greatly reduce the size and weight of the north finder under the condition of not reducing the north finding precision, and fill the miniaturization and light weight technical blanks of the current indexing mechanism of the high-precision north finder.

Owner:ZHEJIANG UNIV

Vibrational wave motor, lens barrel and camera

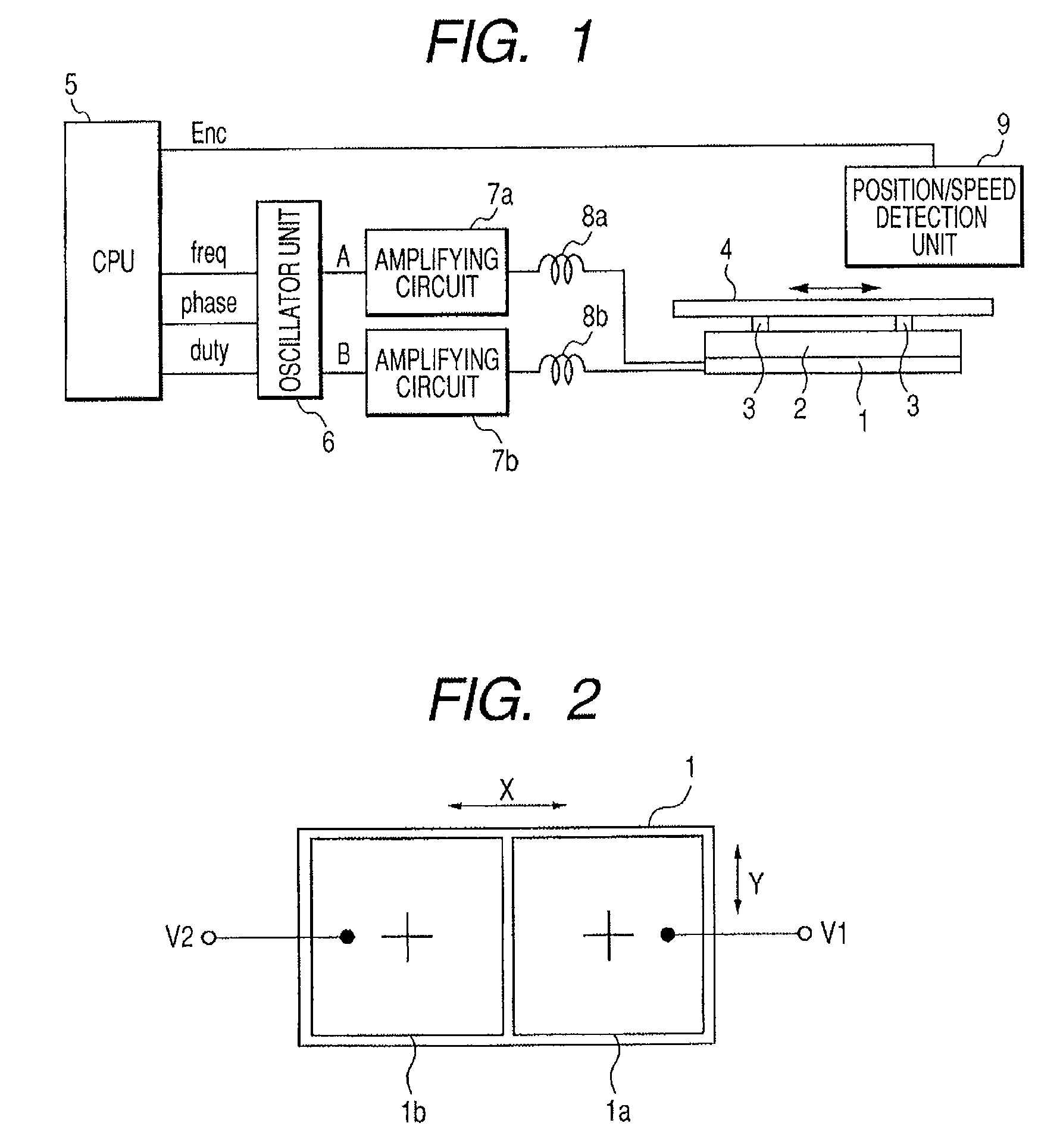

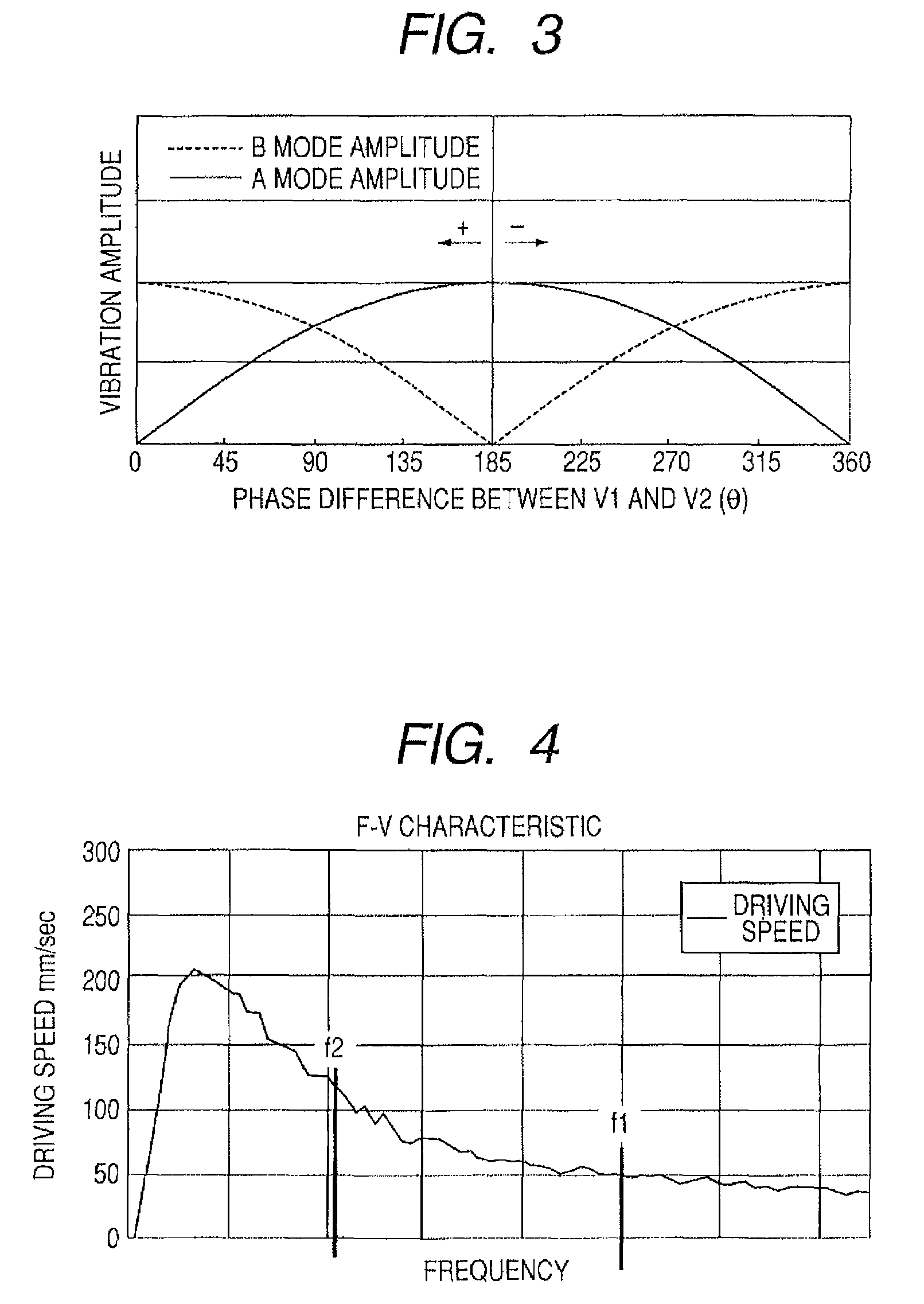

ActiveUS20110280559A1Suitable drive performanceDriven quietlyPiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementVibration amplitudeEngineering

A vibrational wave motor which can realize a suitable drive performance and can be driven quietly.A vibrational wave motor having: an electromechanical-conversion element excited by a driving signal; a vibrating element joined with the electromechanical-conversion element, and having a drive surface where a progressive vibrational wave is generated by the excitation; a relative motion member having a sliding surface pressure-contacting the drive surface of the vibrating element, and which is driven by the wave; and a driving device for providing the driving signal to the electromechanical-conversion element, wherein: the driving device provides the driving signal to the electromechanical-conversion element, the driving signal generating the wave satisfying a-value / λ≦0.00025 in the drive surface, where a vibration amplitude generated in the drive surface of the vibrating element is a-value, and a wavelength generated in the drive surface of the vibrating element is λ.

Owner:NIKON CORP

HF inducing motor and its speed controller

InactiveCN1417926ADirect speed display and controlSolve the problem of contact surface loss and output horsepower reductionAsynchronous induction motorsElectric motor speed/torque regulationMotor speedElectrical conductor

The present invention discloses HF inducing motor and its speed controller. Conducting winding is set in motor rotor and stator, and the rotor winding is connected to capacitor to form resonant loop.When HF alternate current is led into the stator winding, current will generate in the rotor by means of electric induction and electromagnetic resonance and interect with stator magnetic field to rotate motor to solve the friction problem of ultrasonic wave motor. The motor of the present invention can detect its rotation speed via stator winding. The low frequency component in winding voltage or current has frequency proportional directly with the rotation speed and is used in controlling and displaying rotation speed. The present invention also provides motor speed controller comprising simple analog and digital circuit.

Owner:林昌贤

Vibration wave motor

ActiveUS20160020712A1Increase speedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesVibration amplitudeResonance

A vibration wave motor includes a vibration plate having a flat plate portion and protruding portions, a piezoelectric element that performs high-frequency vibration, a friction member contacting the protruding portions, and a first natural vibration mode and a second natural vibration mode, which are excited in the vibration plate by the high-frequency vibration, the vibration plate and the friction member moving relatively to each other, maximum amplitude generated on tip ends of the protruding portions by the first natural vibration mode is larger than maximum amplitude generated on tip ends of the protruding portions by the second natural vibration mode, a resonance frequency of the first natural vibration mode is lower than a resonance frequency of the second natural vibration mode, and amplitudes of the first natural vibration mode and the second natural vibration mode in a frequency range at a time of drive substantially coincide with each other.

Owner:CANON KK

bucket wave engine

The invention discloses a water bucket type wave motor. The water bucket type wave motor comprises a rotor and water buckets, wherein the rotor is cylindrical or annular, the water buckets are evenly distributed at the external circle of the rotor in the peripheral direction, each water bucket is of a water tank structure, openings of the water buckets are sequentially arranged along the periphery, the axis of a rotor shaft is slightly higher than the water surface and is parallel with the water surface, and the axis of the rotor shaft is roughly parallel with the bank. A one-way valve is installed on the lateral wall of each water bucket and corresponds to the opening of the corresponding water bucket, water can only enter through each one-way valve, and a water outlet is near the outer side of the bottom surface of each water bucket. Each water bucket is simple in structure, low in manufacturing cost and high in reliability. Due to the fact that the water bucket type wave motor directly collects and utilizes the potential energy of waves and floating force of water to drive the water buckets on the rotor to move for power generation, the wavy energy does not need a middle conversion procedure, and the utilization rate is high. If the geometric size of each water bucket is designed to be small, small broken waves can also be utilized.

Owner:CHONGQING UNIV +1

Stacked type piezoelectric element and vibration wave motor

InactiveUS7608982B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesWave motorEngineering

Provided is a stacked type piezoelectric element including a surface electrode layer as a first layer and a piezoelectric layer as a second layer. A third layer to an N-th layer thereof are formed by alternately arranging piezoelectric layers and piezoelectric layers. A surface of the piezoelectric layer is provided with four-way split inner electrodes S+, B+, A−, and B−. A surface of the piezoelectric layer is provided with four-way split inner electrodes AG+, BG+, AG−, and BG−. A surface of the piezoelectric layer is provided with four-way split inner electrodes of A+, B+, A−, and B−. The piezoelectric layers are formed such that only the inner electrode S+ serving as a sensor phase and the inner electrodes A+ and AG+ being arranged in the same phase as the inner electrode S+ are exposed to an outside of the piezoelectric layer.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com