HF inducing motor and its speed controller

A speed control device, high-frequency induction technology, applied in the direction of motor speed or torque control, control system, electromechanical device, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

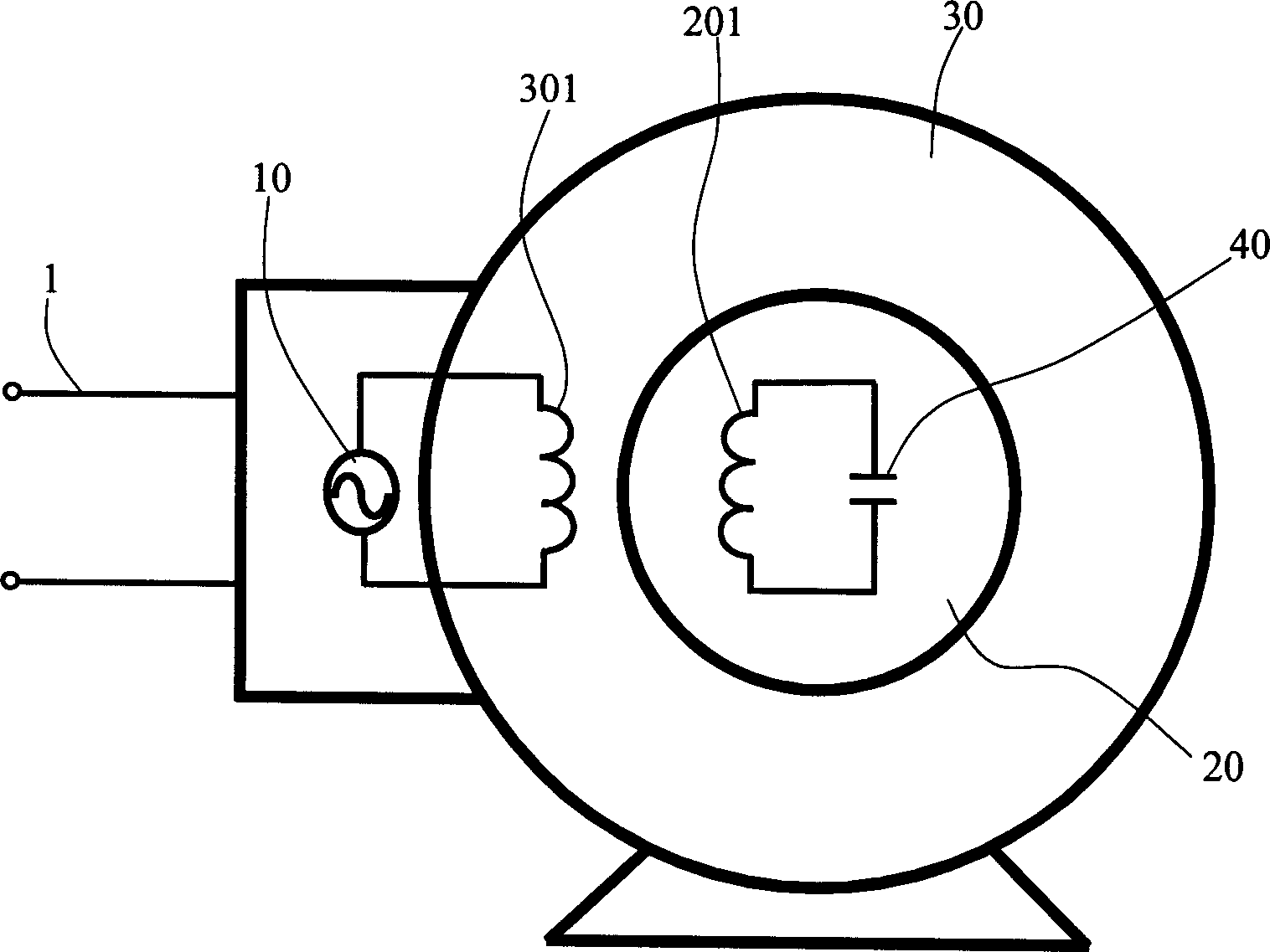

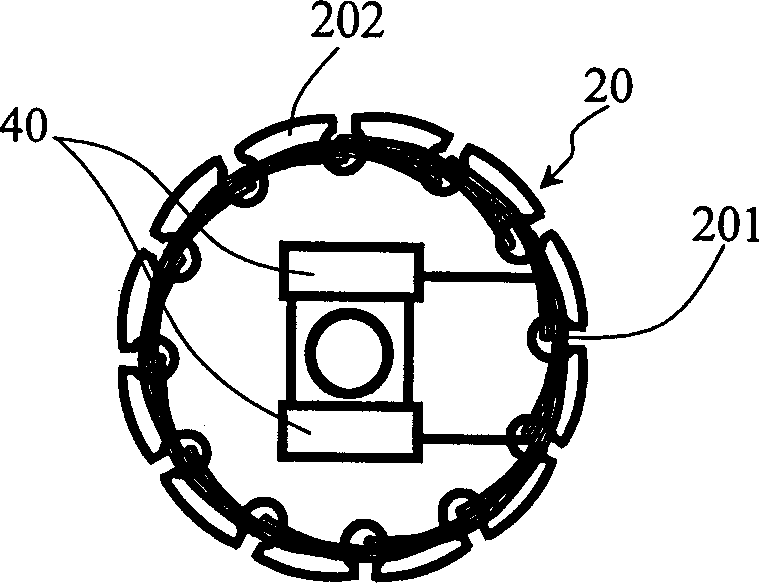

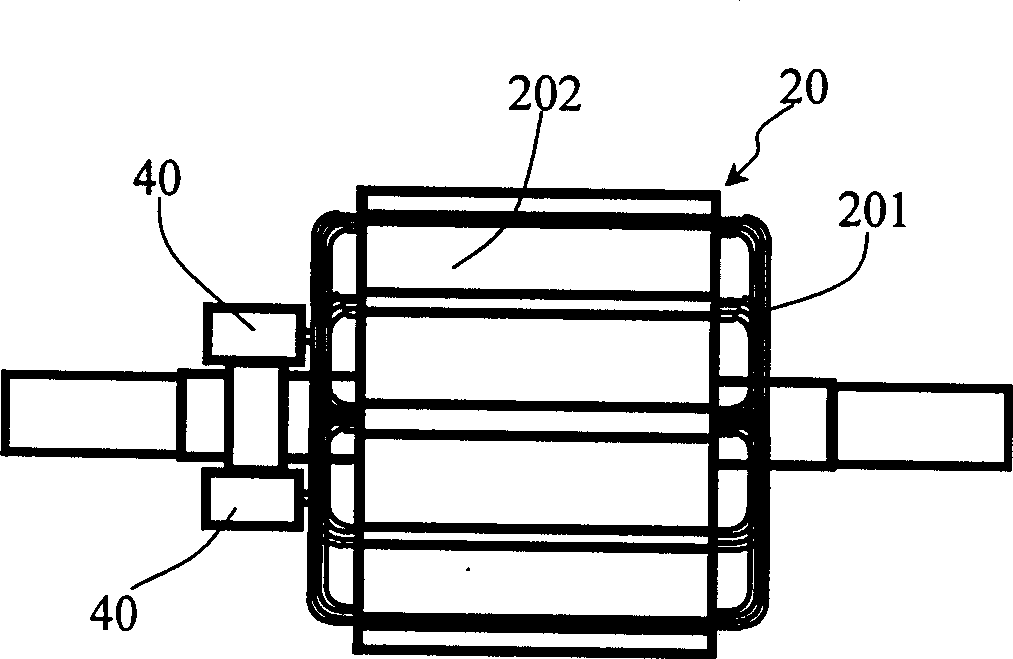

[0026] As shown in the first figure, the high-frequency induction motor of the present invention includes: a group of high-frequency alternating current generators (10), which convert the power supply (1) into high-frequency alternating current; a motor stator (30), which is wound with a conductor stator winding ( 301) (winding), and an inductance symbol is used to represent all stator windings (301); a rotor (20) is also wound with a conductor rotor winding (201), and is connected to a capacitor (40) to form an inductance-capacitance resonance loop. Named resonant tank or resonant tank circuit, this resonant tank is represented by a set of inductance-capacitance loops in Figure 1.

[0027] When the stator winding (301) is supplied with high-frequency alternating current, an alternating magnetic field is generated. When the magnetic field of the stator (30) changes rapidly due to high-frequency alternating current, and its changing frequency is just at or close to the resonanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com