Patents

Literature

31results about How to "Shorten vibration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

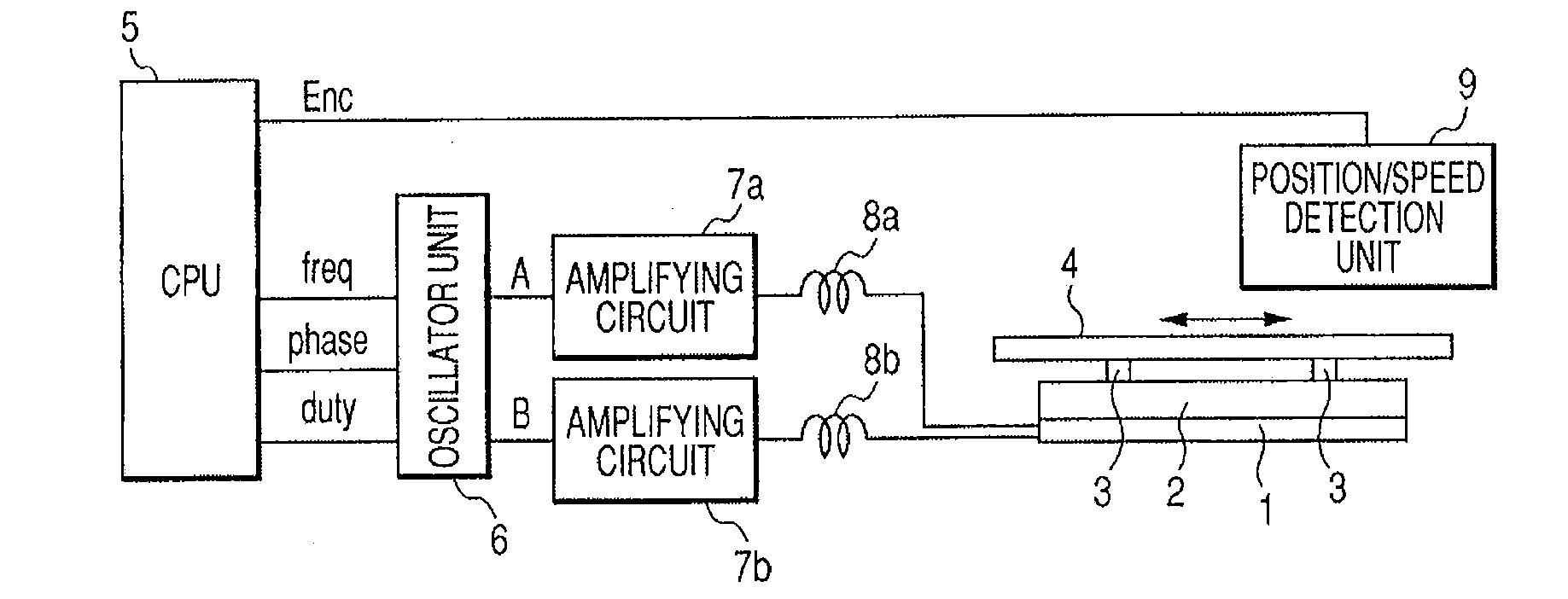

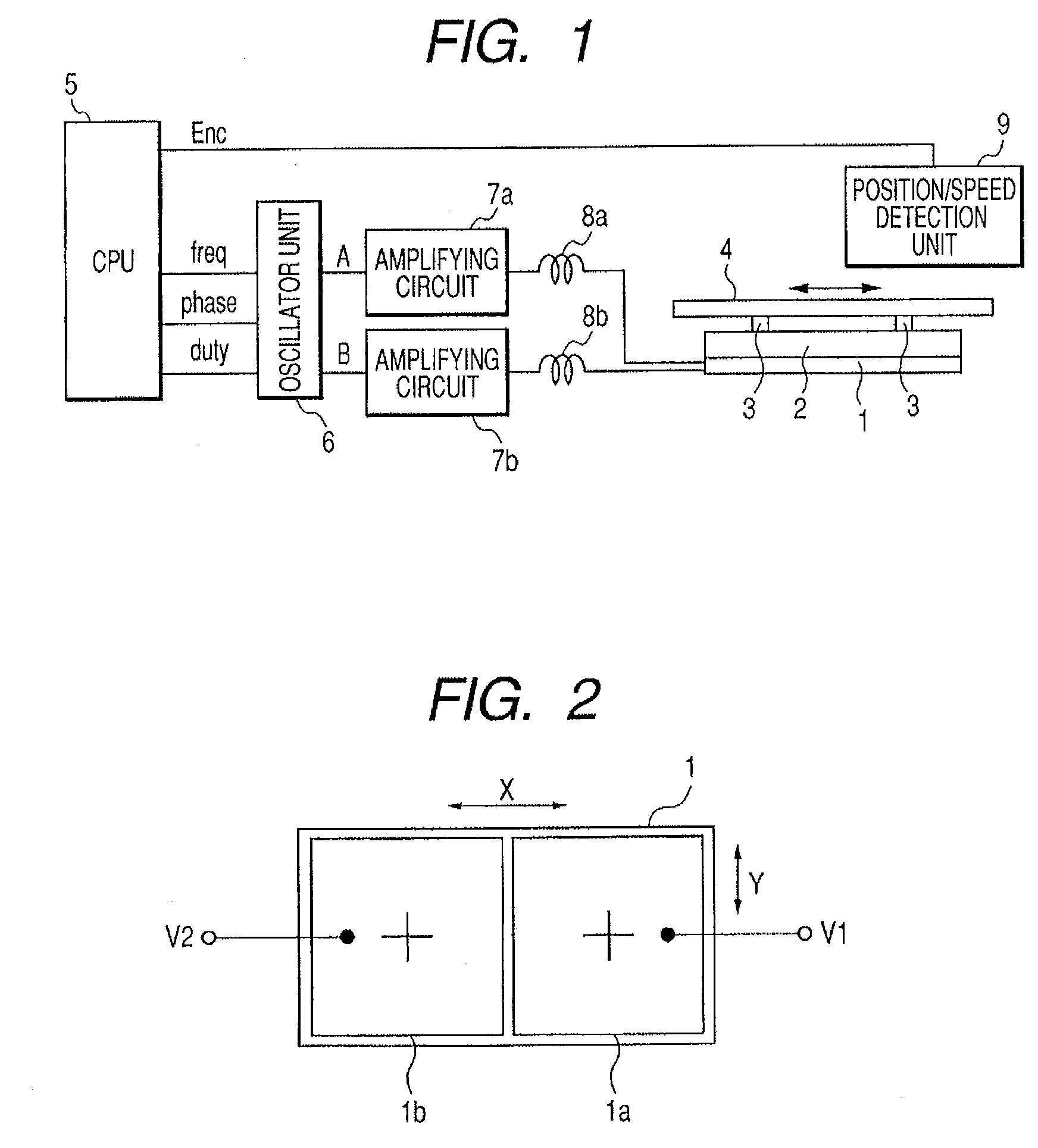

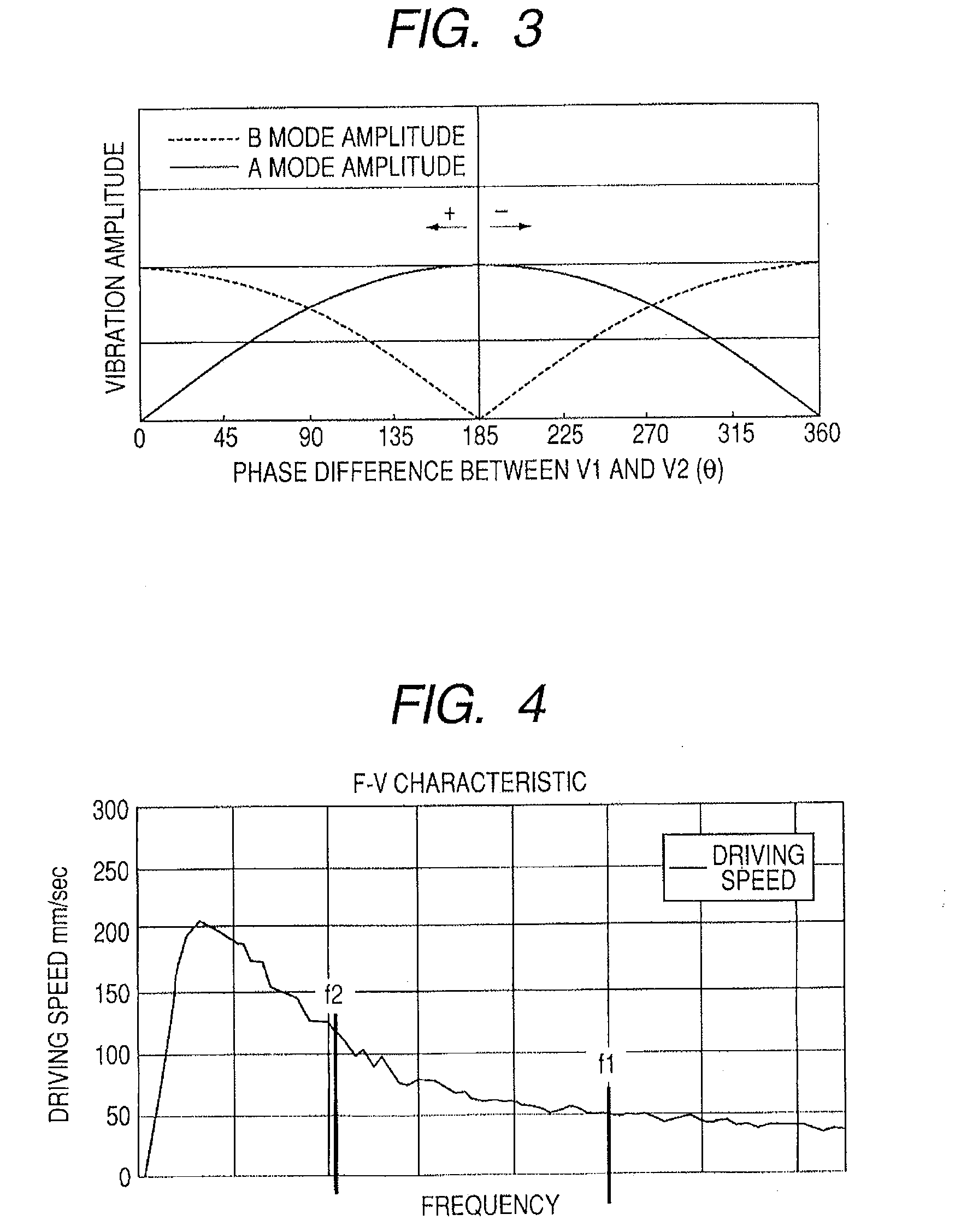

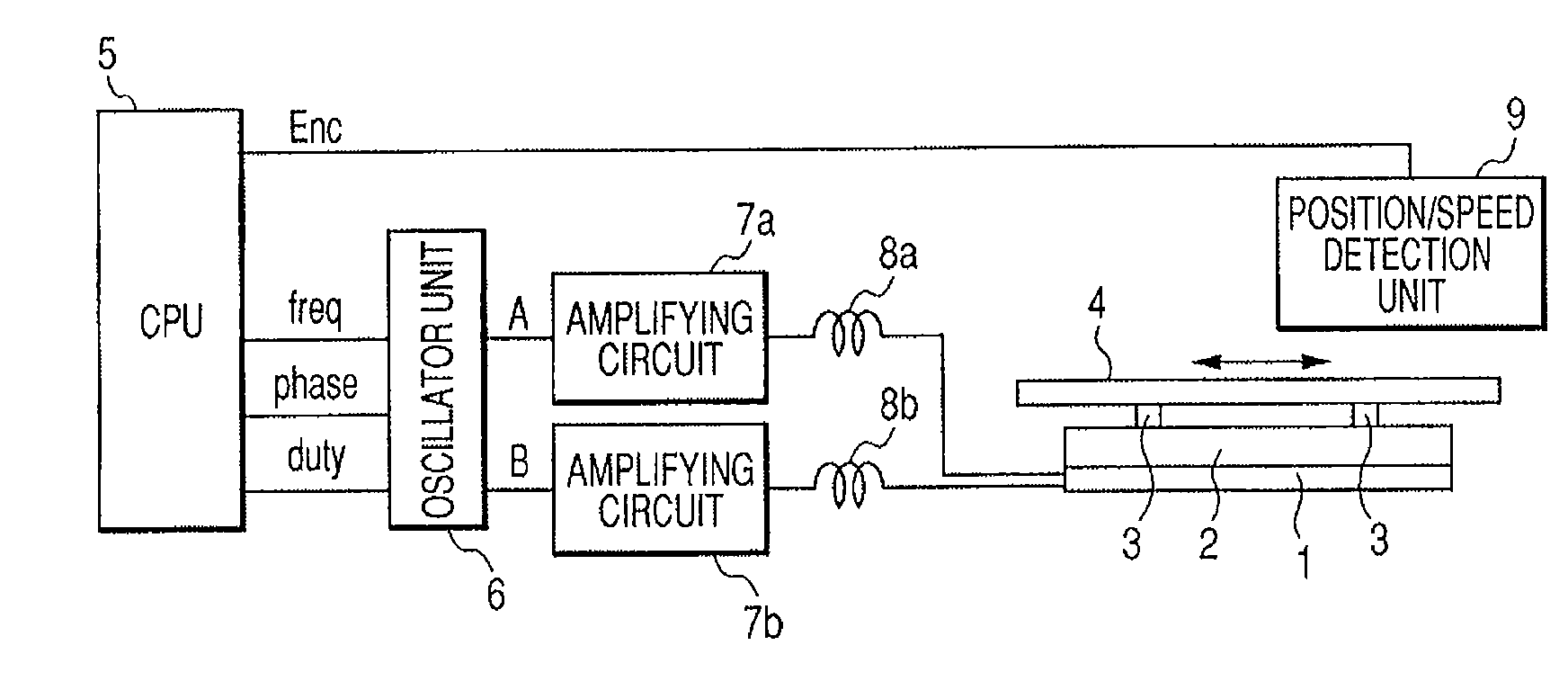

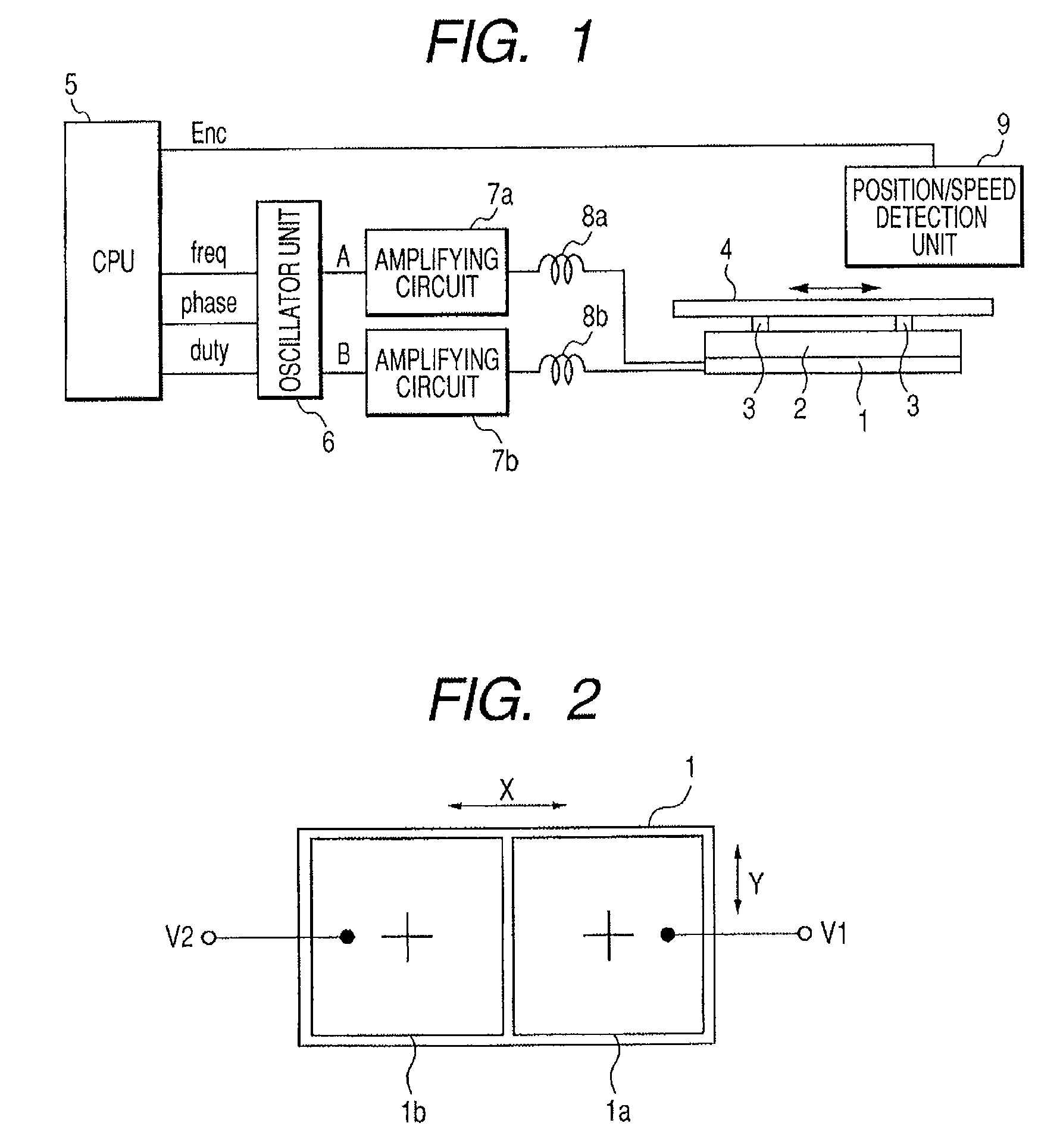

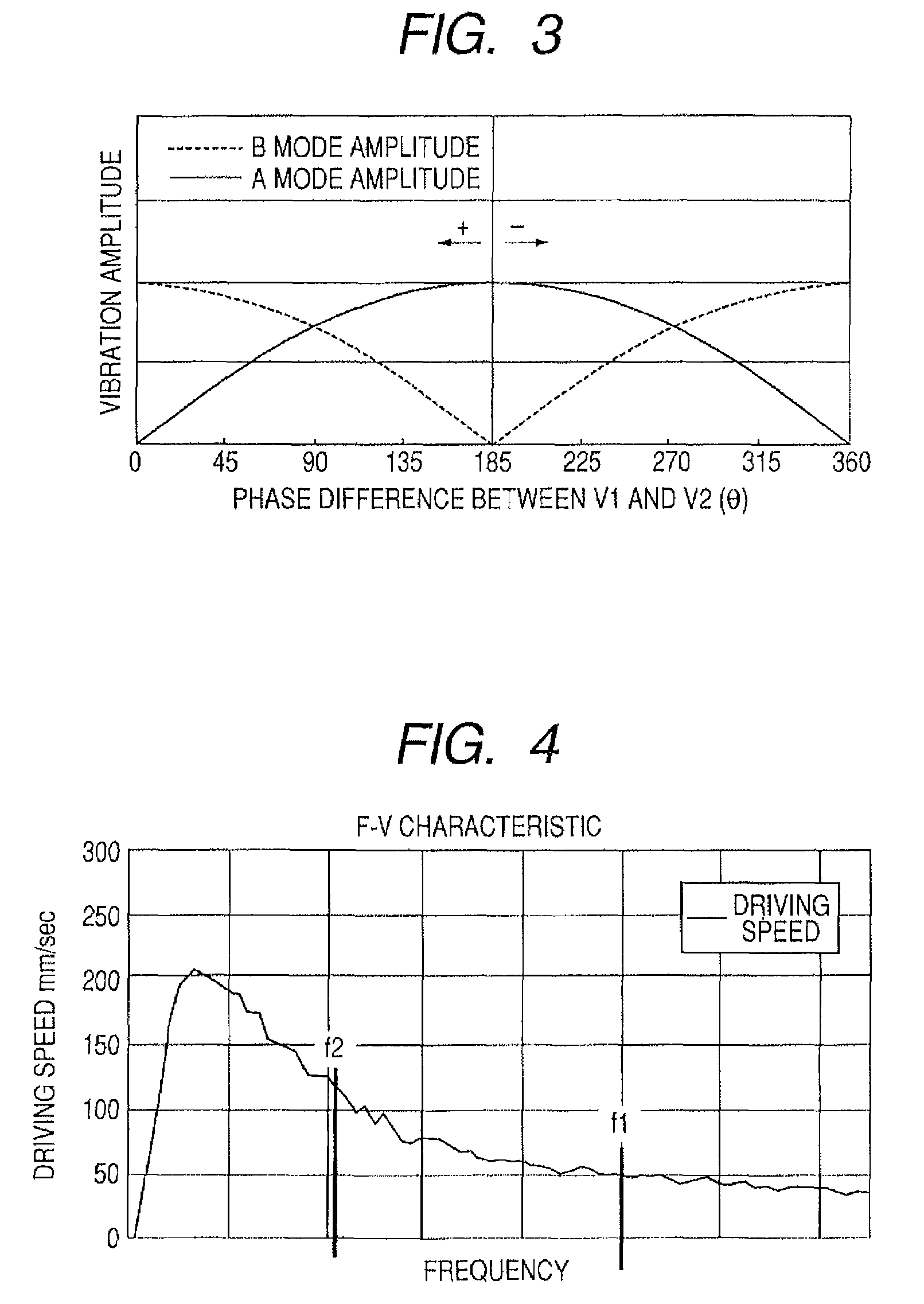

Motor driving method, program therefor, and motor driving apparatus

InactiveUS20070108870A1Start time be shortenSmoothly control movementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesWave motorStart time

Provided are a motor driving method, a program therefor, and a motor driving apparatus which can shorten starting time of a vibration wave motor. A driving circuit of the vibration wave motor includes a control unit. The control unit controls two-phase driving voltages applied to an electro-mechanical energy conversion element of the vibration wave motor. The control unit controls a phase difference between the two-phase driving voltages to drive a driven member at a predetermined speed in a fixed state of frequencies of the two-phase driving voltages. In this case, when the phase difference is set outside a predetermined range, the control unit changes the frequencies of the two-phase driving voltages.

Owner:CANON KK

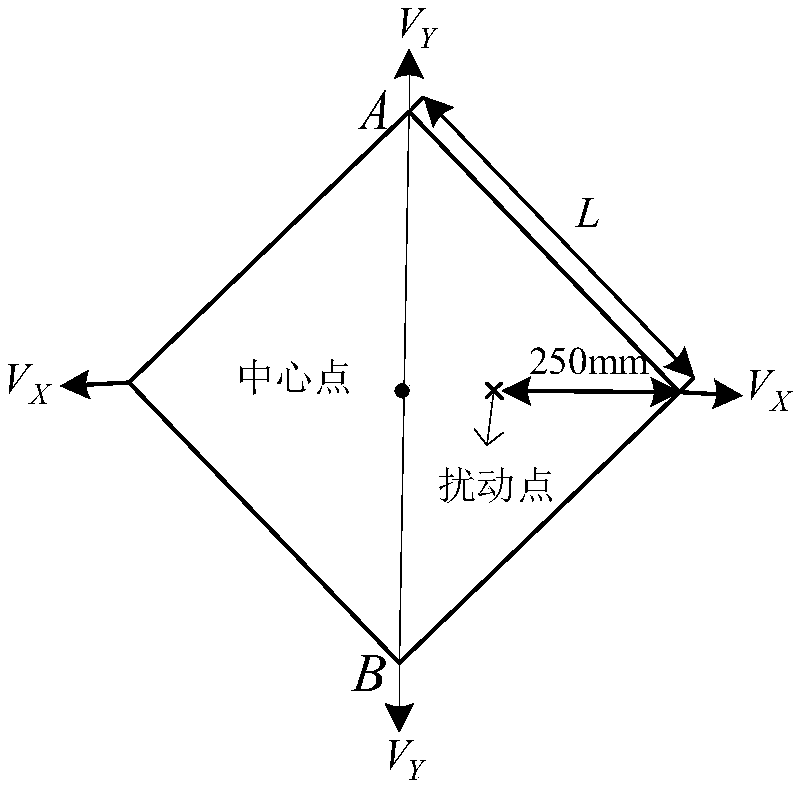

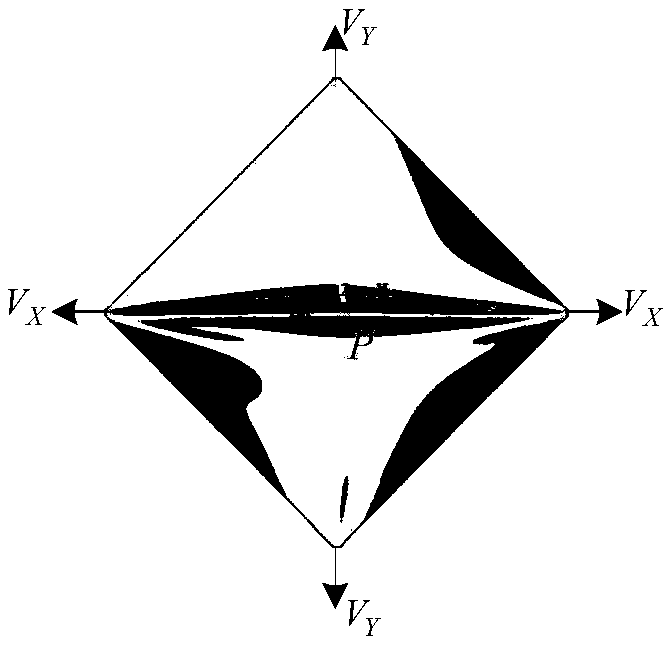

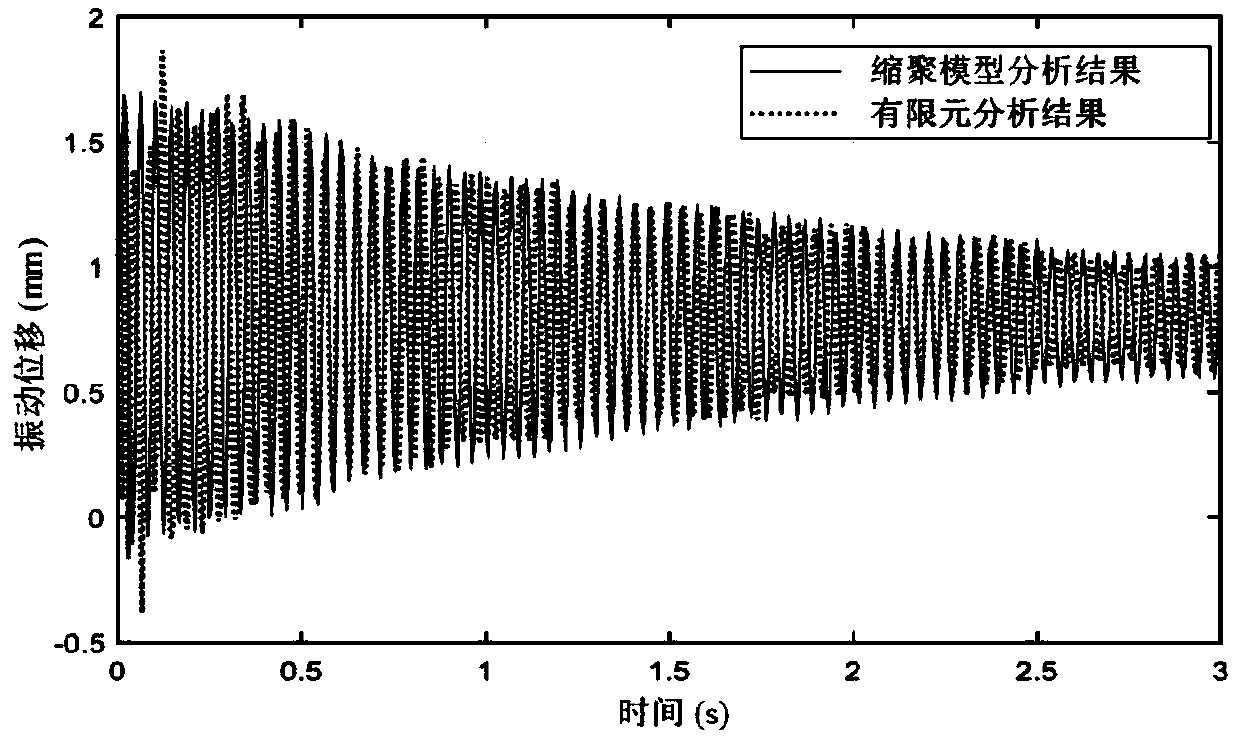

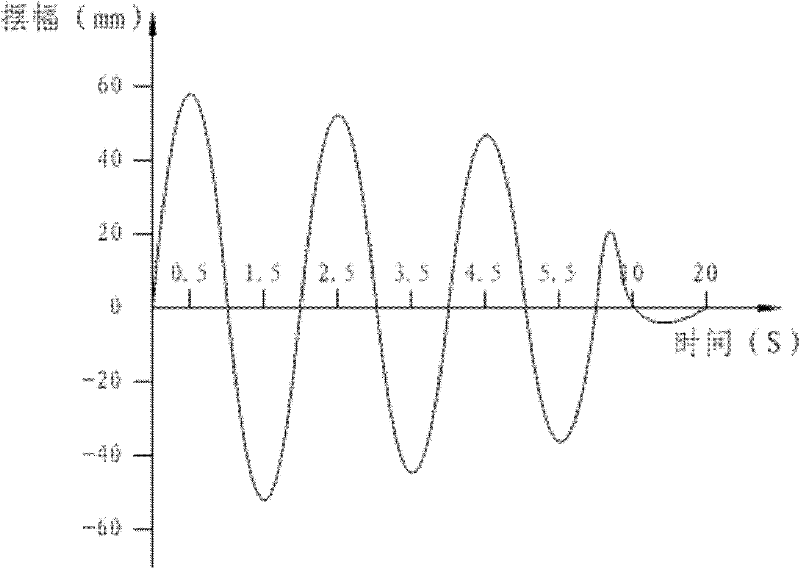

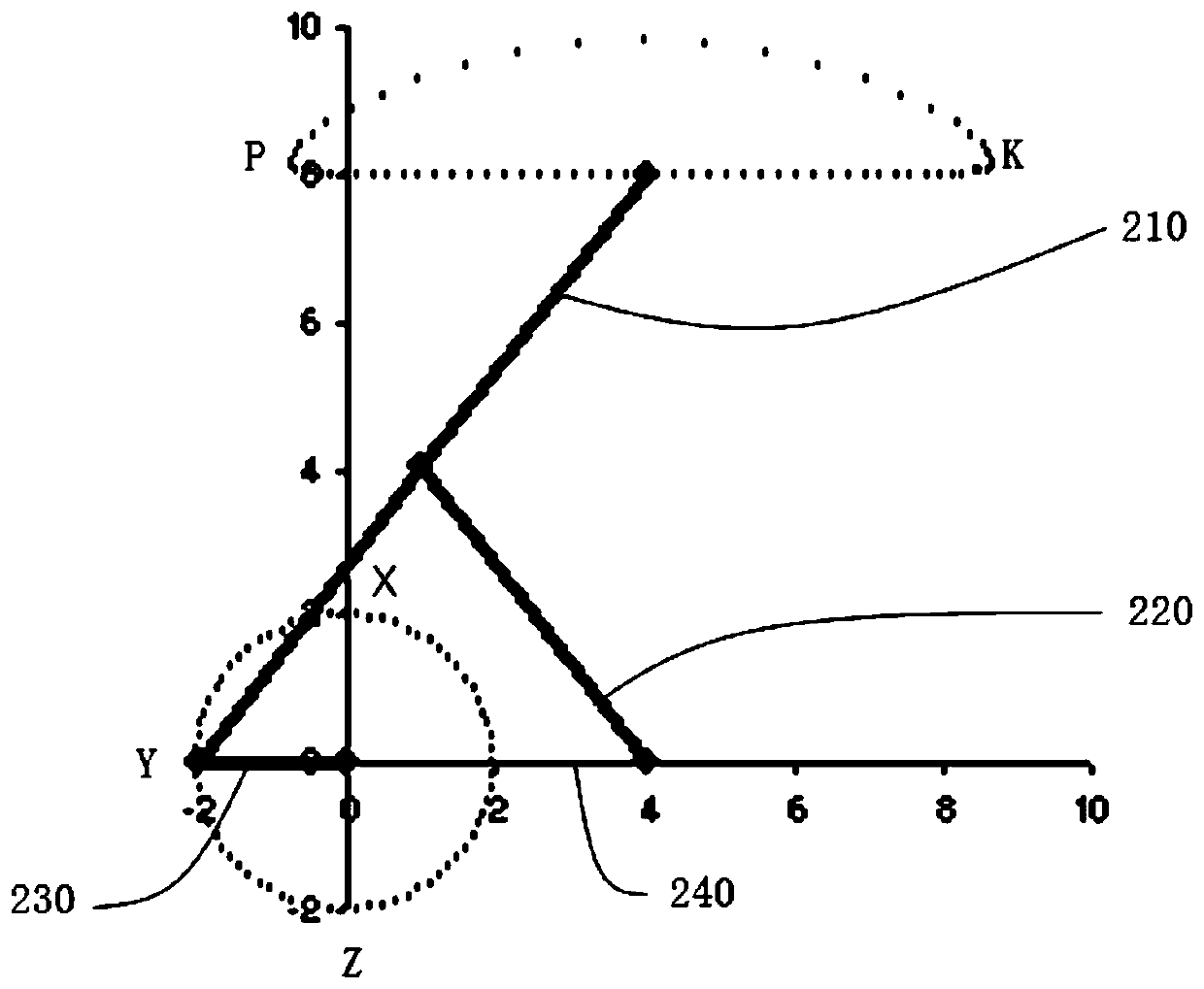

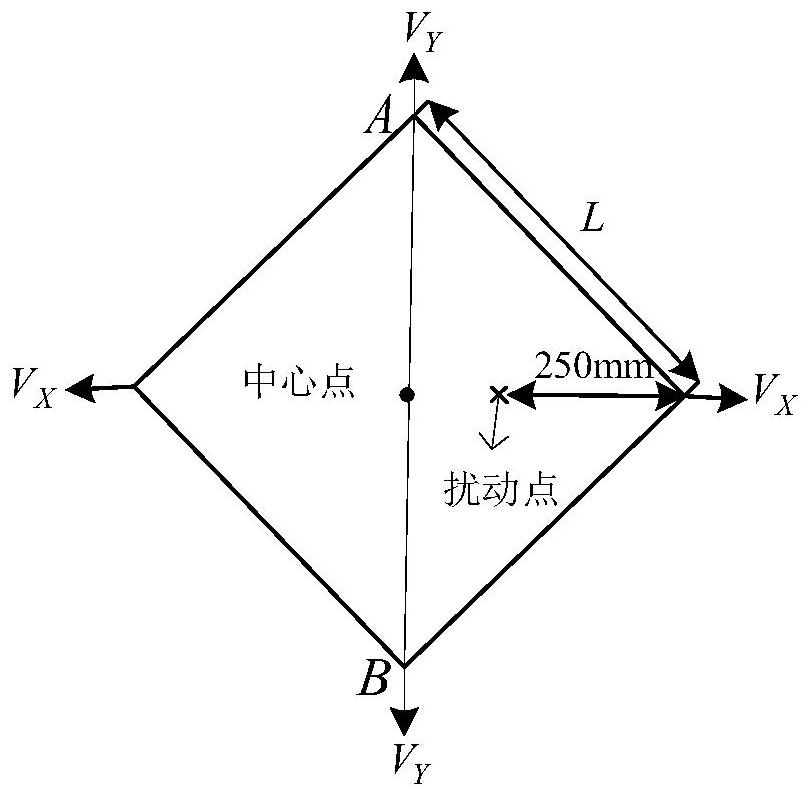

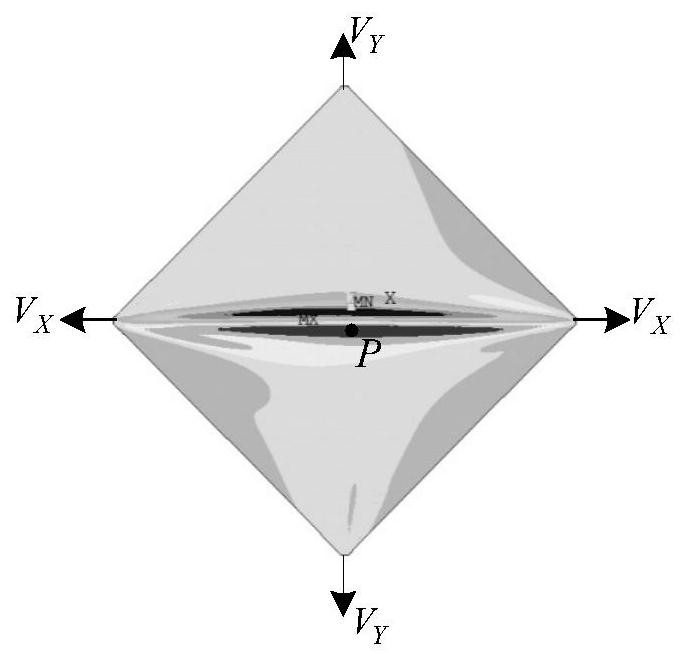

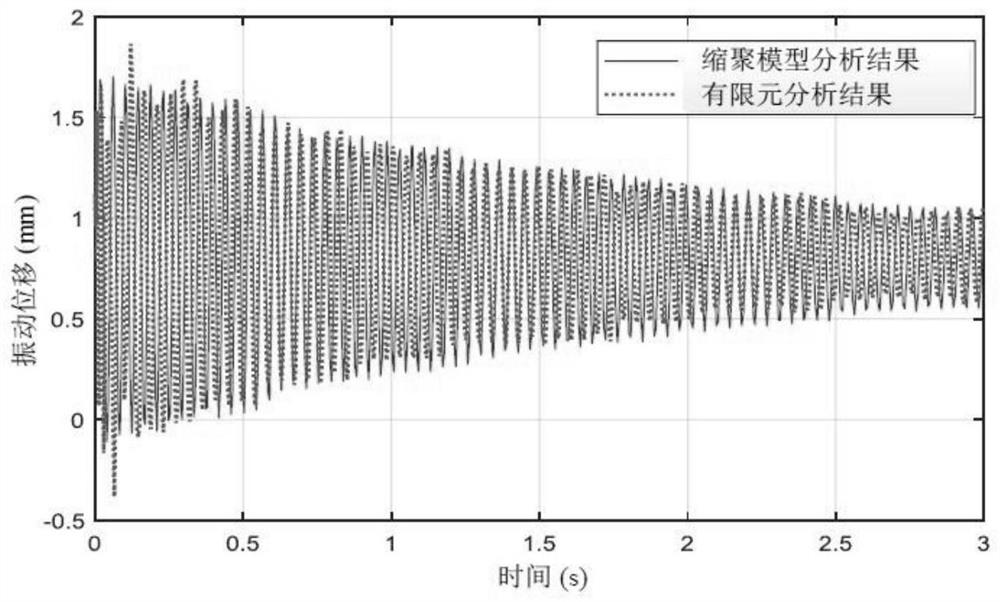

In-plane-control-based active vibration control method for wrinkled film

ActiveCN108897213AReduce vibrationImprove anti-disturbance abilityAdaptive controlControl orientedIn plane

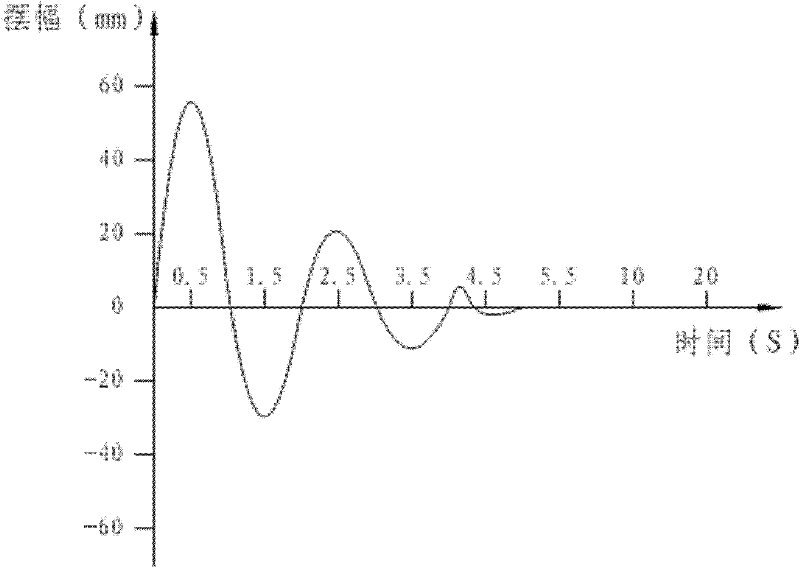

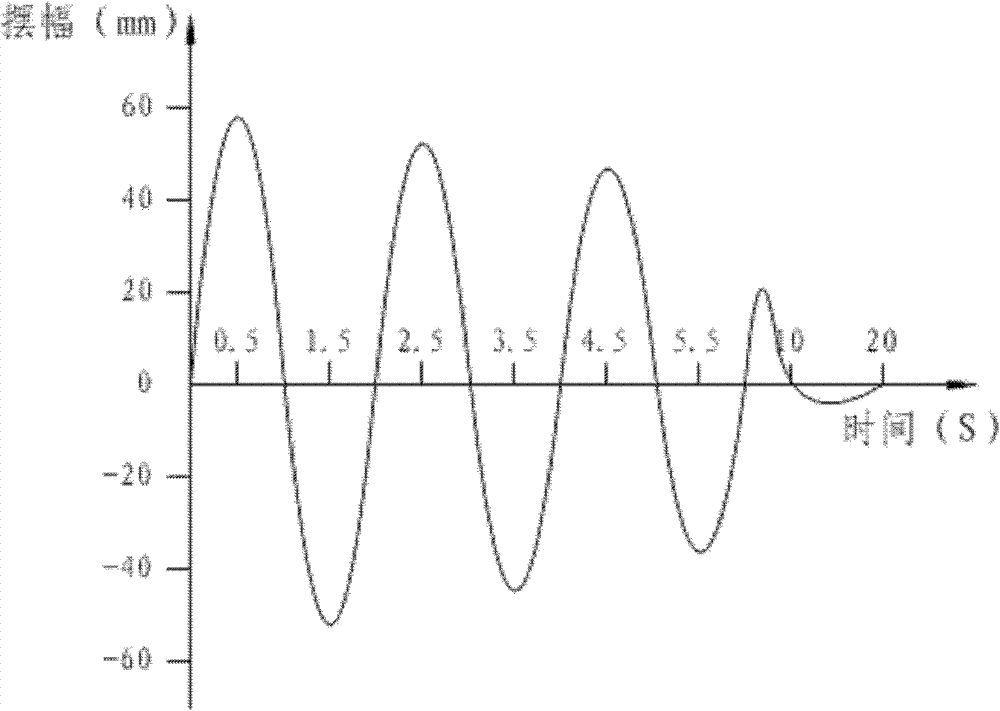

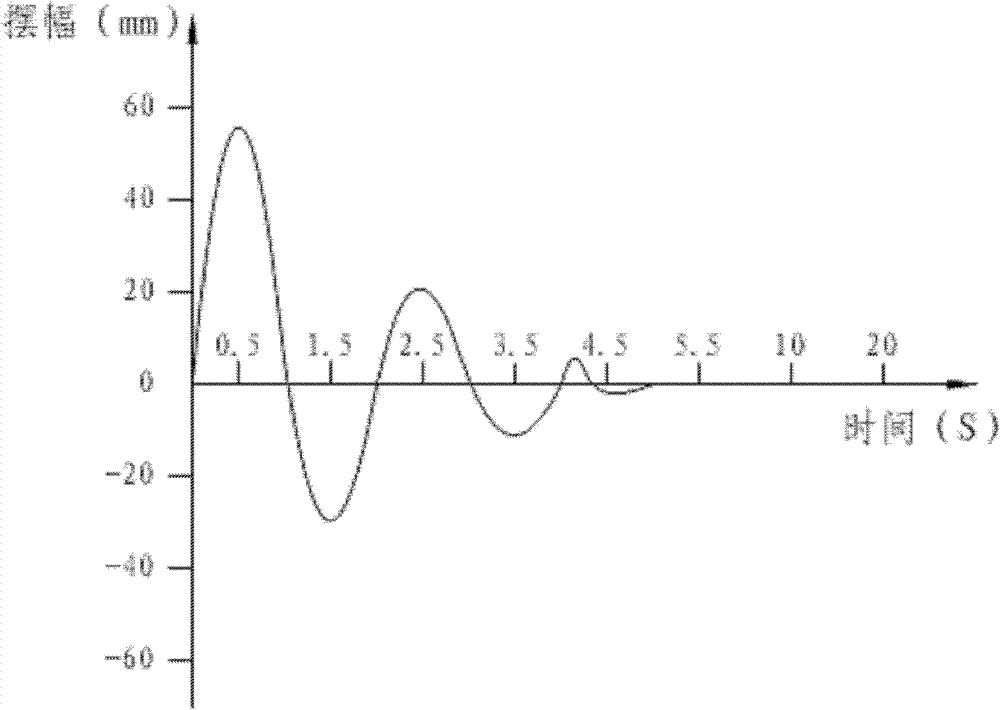

The invention relates to an in-plane-control-based active vibration control method for a wrinkled film. On the basis of the analysis on the influence on dynamic characteristics of a film structure bya wrinkle form, a dynamic model of a wrinkled film is established; according to a modal superposition method, a space vector based on a natural mode of vibration is obtained and dynamic models of thewrinkled film under different loads are established; condensation polymerization is carried out on the dynamic models according to contributions to system vibration deformation by all orders of modes,so that a control-oriented film structural dynamic model is established; and with a model reference adaptive controller, a PID-MRAC control method based on in-plane-control multi-model switching is proposed. According to the method provided by the invention, no actuator needs to be pasted on the surface of the film; the out-of-plane vibration of the film is suppressed effectively; the characteristics of the film are not affected; the high stability of the film structure is ensured; and compared with the conventional PID control method, the in-plane-control-based active vibration control method enables the vibration time to be shortened by about 39.7%.

Owner:BAOJI UNIV OF ARTS & SCI +1

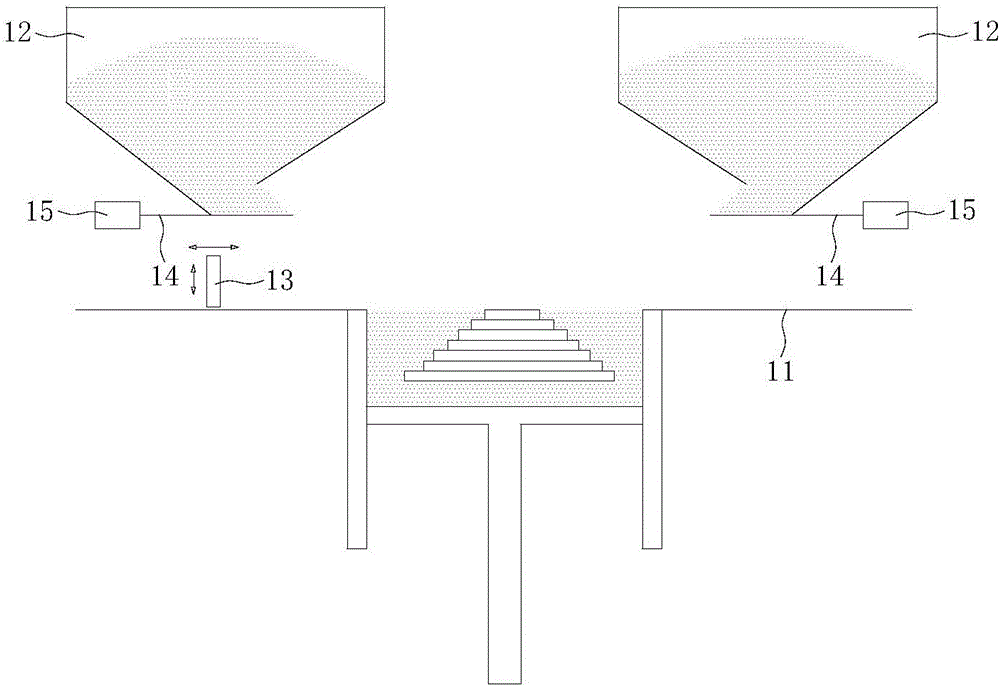

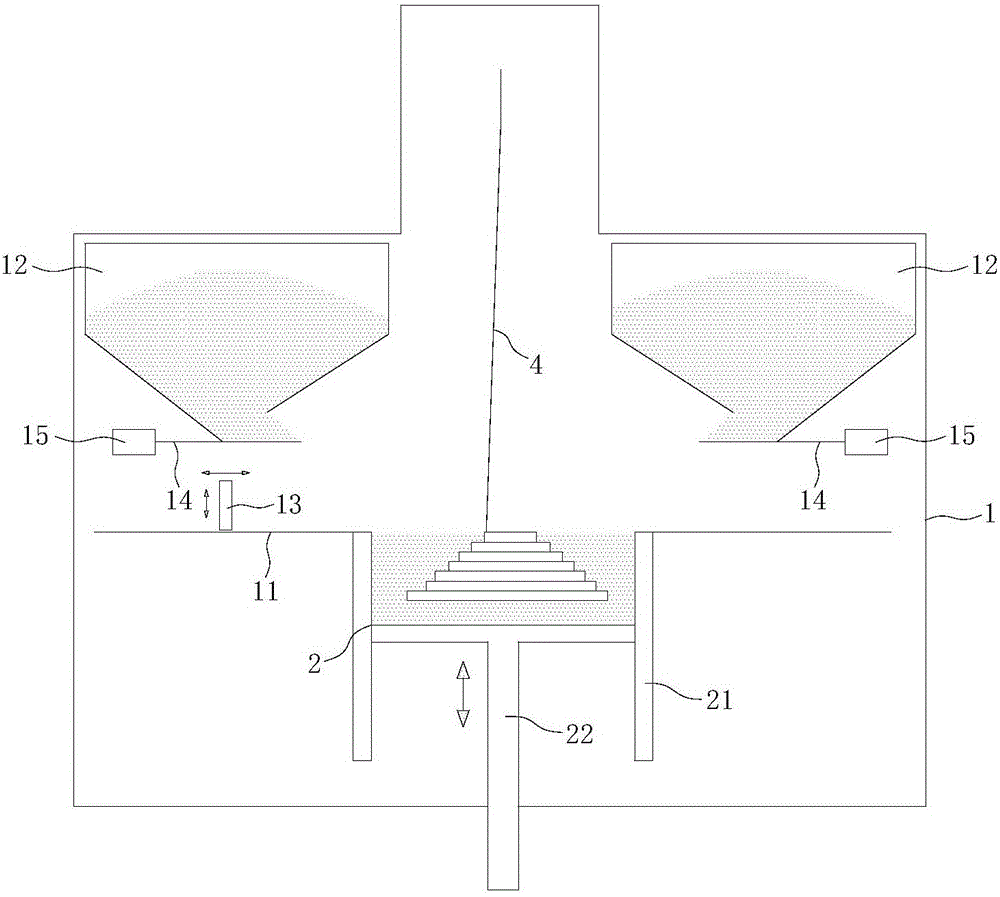

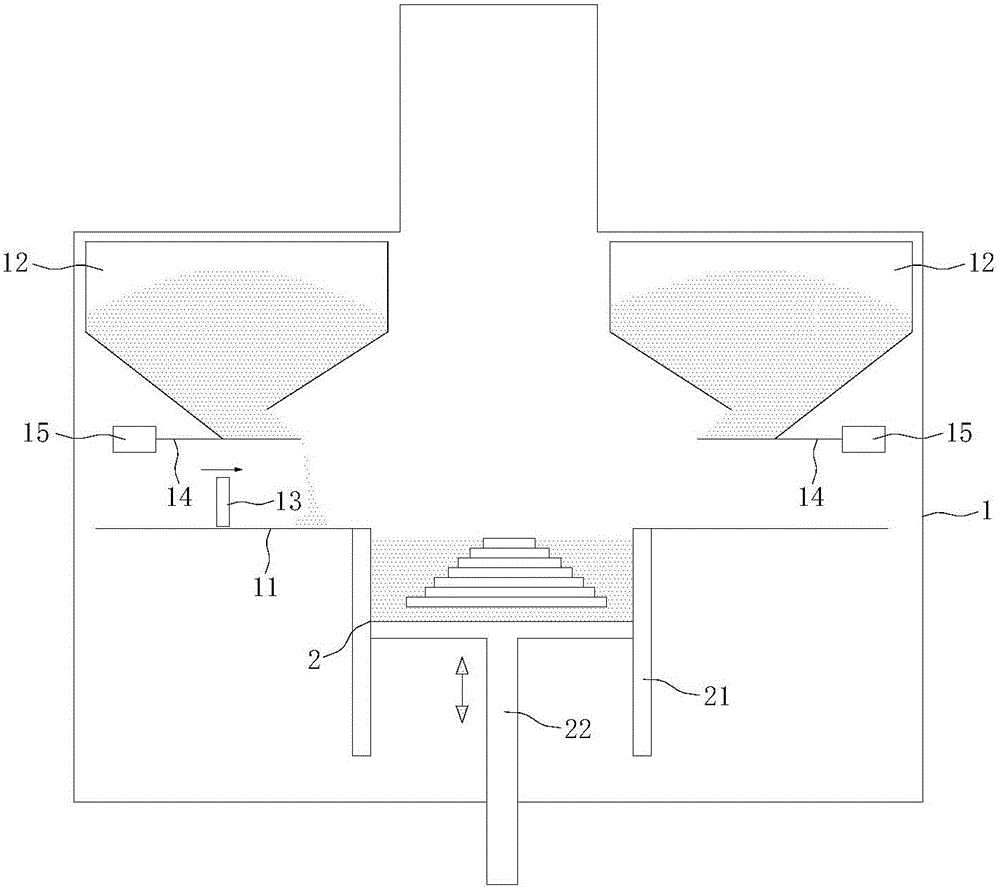

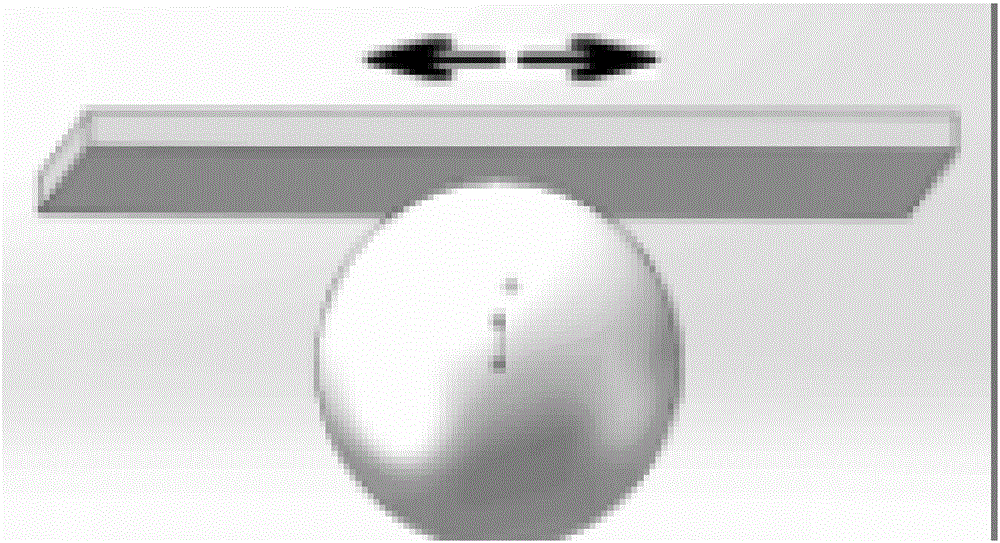

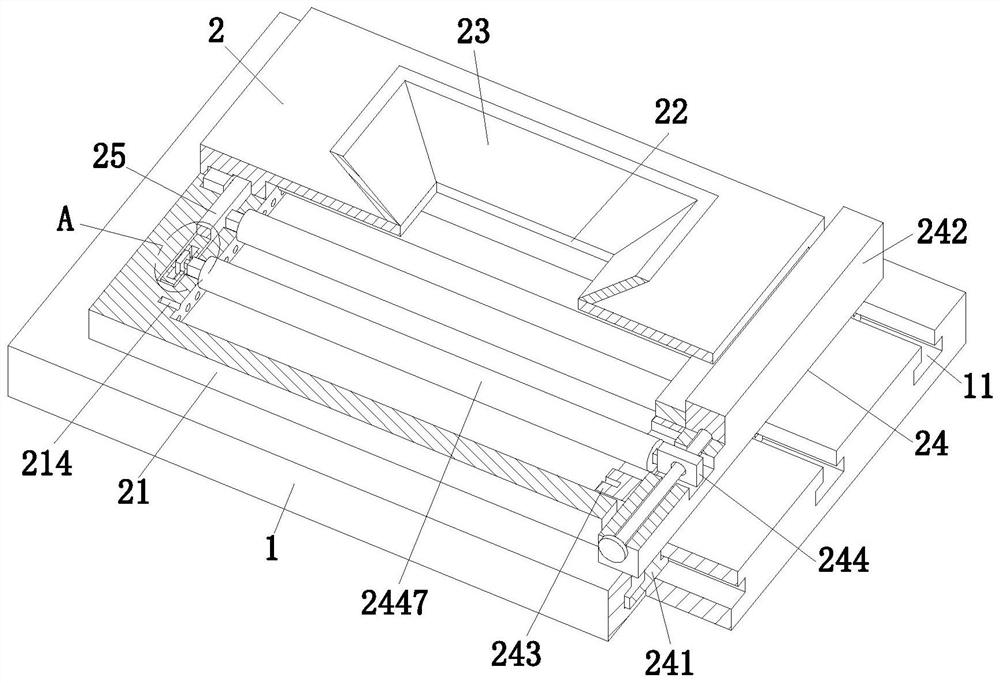

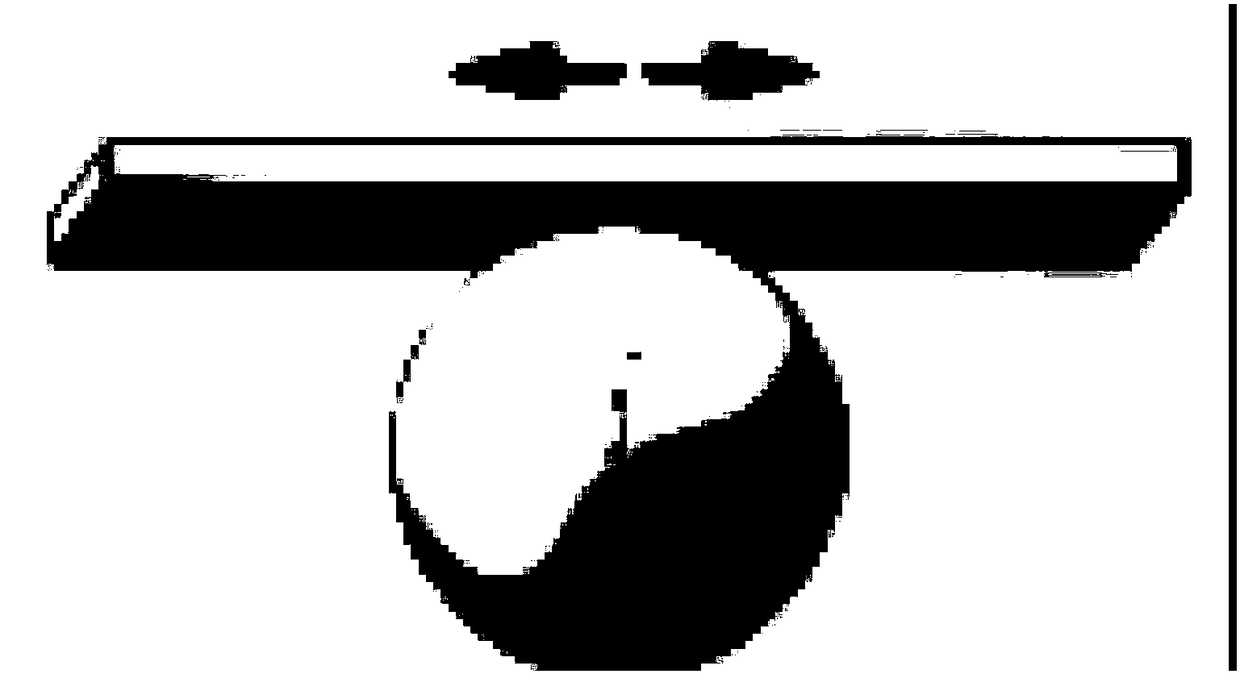

Powder distribution device and additive manufacturing device

InactiveCN105855548AUniform thicknessImprove spreading efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention belongs to the field related to additive manufacturing and discloses a powder distribution device and an additive manufacturing device. The powder distribution device comprises a powder spreading platform and hoppers arranged above two sides of the powder spreading platform, powder materials are placed in the hoppers, powder-material placing locations are arranged on the two sides of the powder spreading platform, the powder materials are transferred to the powder-material placing locations through the hoppers, scrapers vertically arranged above the powder spreading platform are allowed to move along the horizontal direction as well as the vertical direction, and the scrapers are respectively located on one sides of the powder-material placing locations when moving along the vertical direction. The powder distribution device is provided with the scrapers allowed to move along the horizontal direction as well as the vertical direction, two-way powder scraping is realized, thickness of powder layers is evener as compared with the existing one-way powder scraping, and powder spreading efficiency is improved. Further more, the scrapers are vertically arranged, so that two-way powder scraping can be better realized, and waste of the powder materials is avoided.

Owner:QUICKBEAM CO LTD +1

Motor driving method, program therefor, and motor driving apparatus

InactiveUS7701116B2Shorten vibration timeStable controlPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStart timeMotor drive

Provided are a motor driving method, a program therefor, and a motor driving apparatus which can shorten starting time of a vibration wave motor. A driving circuit of the vibration wave motor includes a control unit. The control unit controls two-phase driving voltages applied to an electro-mechanical energy conversion element of the vibration wave motor. The control unit controls a phase difference between the two-phase driving voltages to drive a driven member at a predetermined speed in a fixed state of frequencies of the two-phase driving voltages. In this case, when the phase difference is set outside a predetermined range, the control unit changes the frequencies of the two-phase driving voltages.

Owner:CANON KK

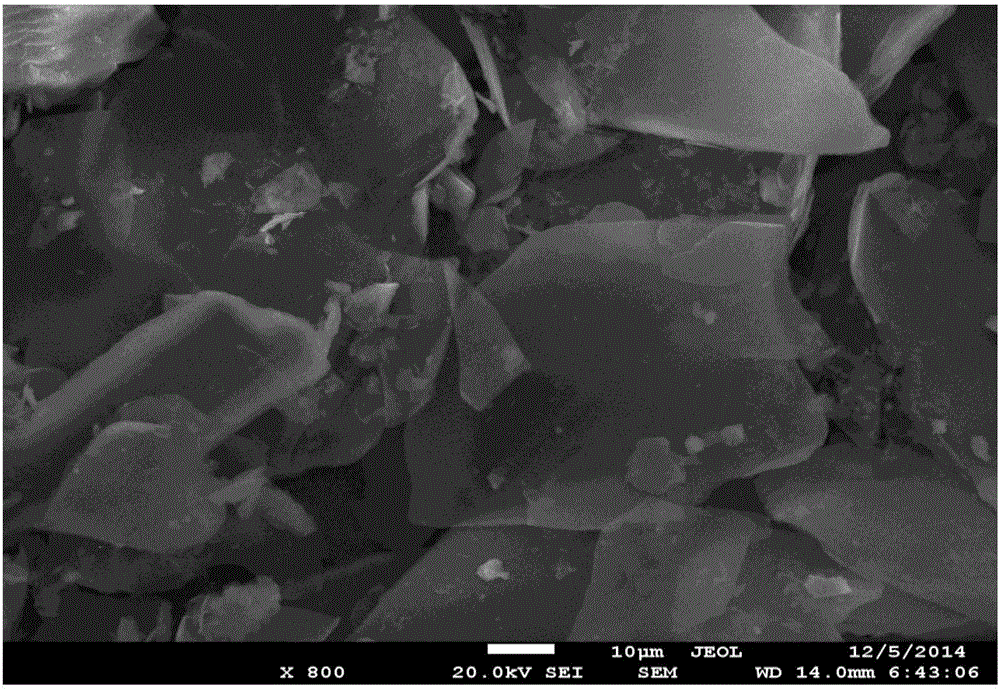

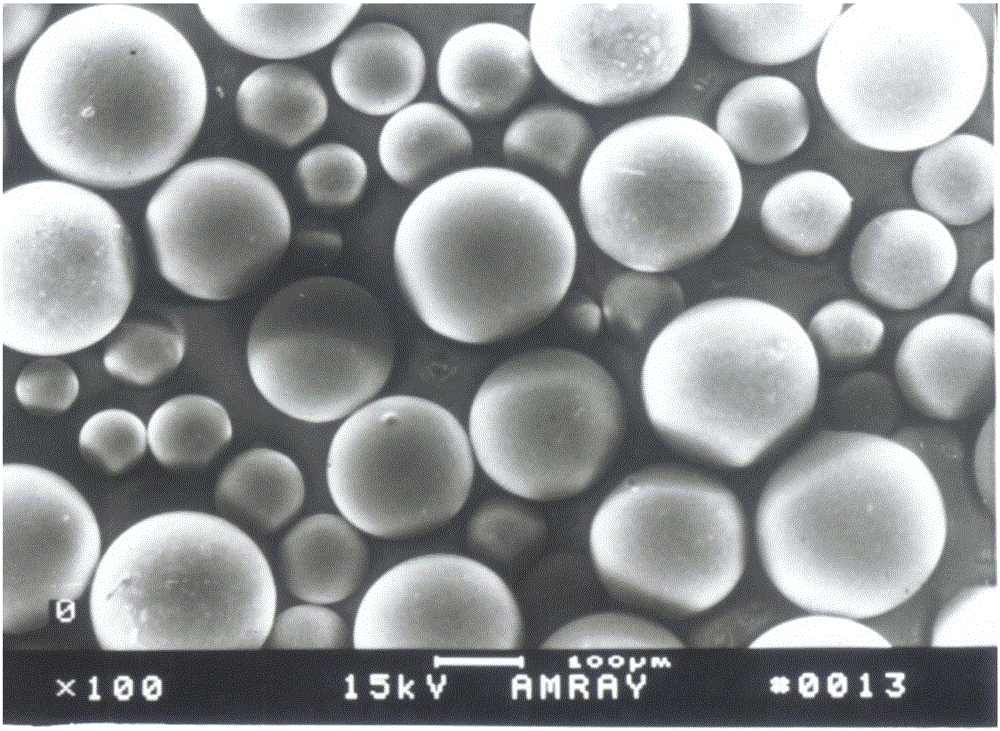

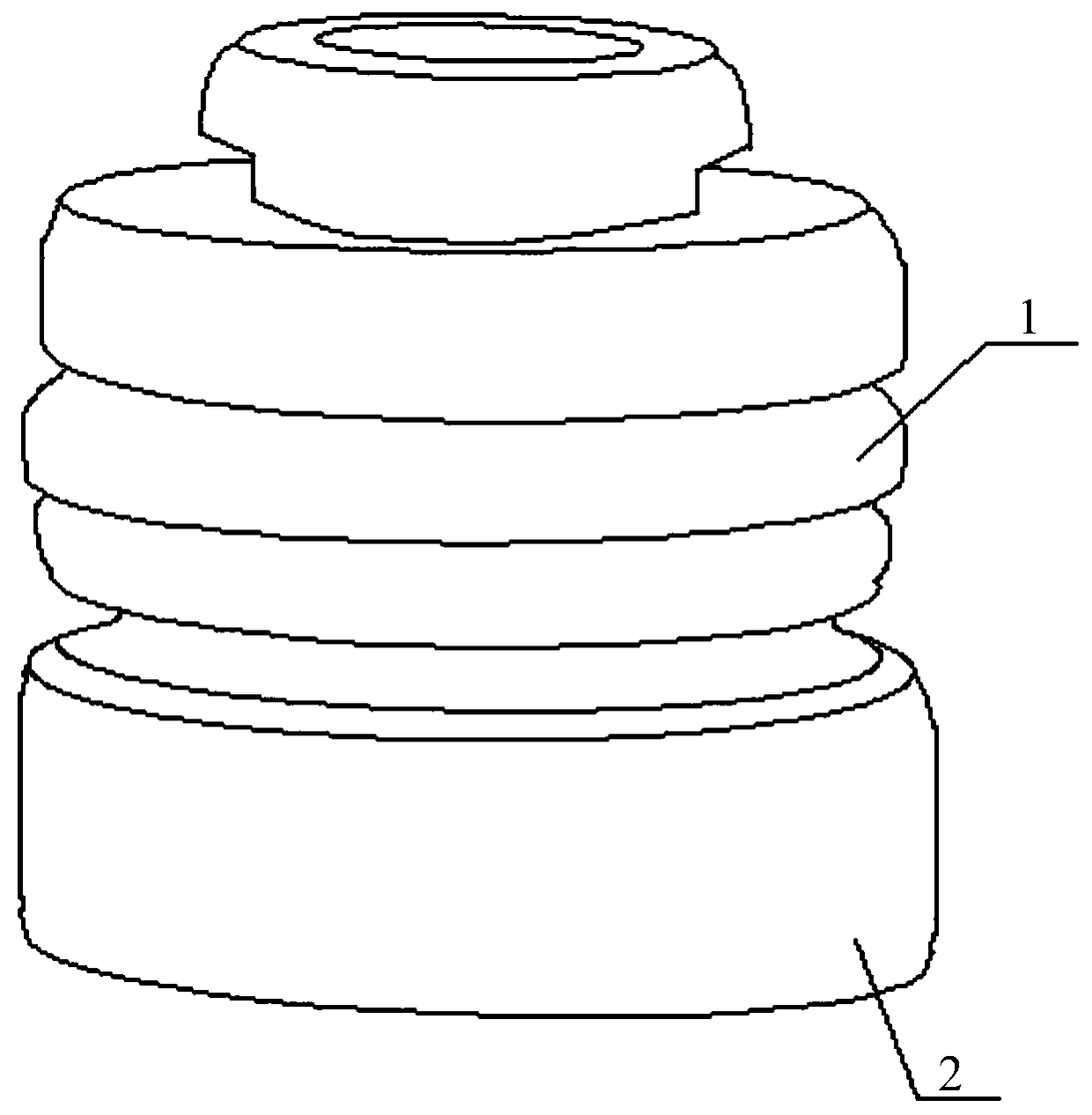

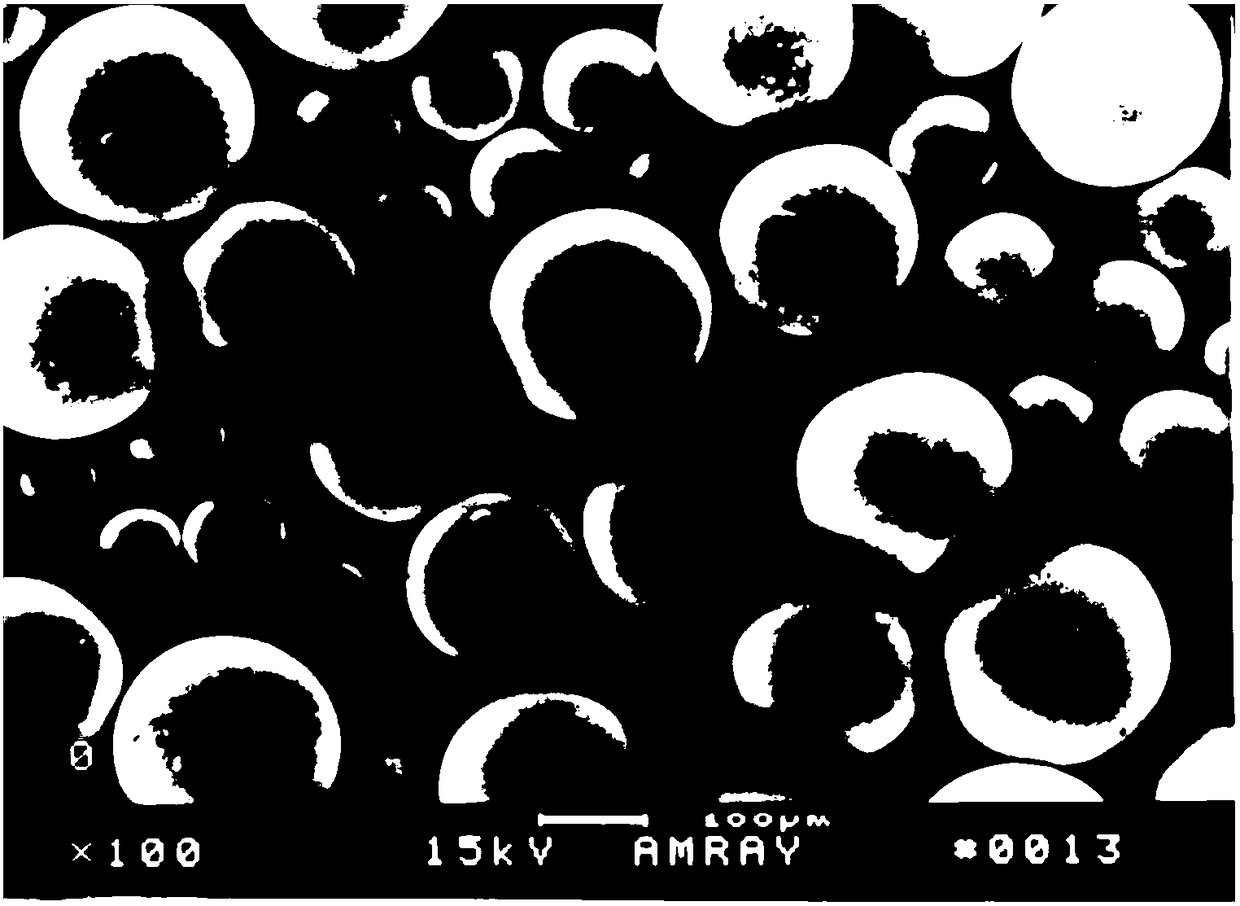

Damping material, preparation method thereof and piezoelectric ceramic ultrasonic probe

ActiveCN105907012AStable curing timeAvoid increased conductivityMaterial analysis using sonic/ultrasonic/infrasonic wavesDamping factorElectricity

The invention discloses a damping material, a preparation method thereof and a piezoelectric ceramic ultrasonic probe. The damping material comprises the following components in parts by weight: 60-120 parts of high-molecular polymer, 30-60 parts of inorganic fillers with sheet structure, 5-15 parts of inorganic fillers with ball structure, 0.5-5 parts of silane auxiliaries and 10-30 parts of solvents. The damping material provided by the invention can effectively prevent the long curing time and insufficient conduction caused by the increase of tungsten powder content as well as the interference to the ultrasonic signal caused by the middle layer formed by bonding the damping block with the piezoelectric ceramic wafer of the present damping material; the curing time is stable, the material is non-conducting and the damping coefficient is higher; a filling method is applied to the piezoelectric ceramic ultrasonic probe, so that the vibration damping of the piezoelectric ceramic wafer is greatly increased; the vibration time of the piezoelectric ceramic wafer is shortened; the absorption of the piezoelectric ceramic wafer for the echo signal is benefited; the definition of ultrasonic testing for multilayer gluing structure defect is increased.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Lost foam casting technology leading sands to be compacter

InactiveCN102218507AShorten vibration timeReduce energy consumptionFoundry mouldsFoundry coresDry sandMechanical engineering

The invention discloses a lost foam casting technology leading sands to be compacter, comprising the following steps of foaming and gluing or combining, wherein in the foaming process, EPS or STMMA beads are foamed and amplified by about 30 times by a foaming machine to form raw materials for producing the mold; the raw materials for producing the mold are arranged in the cavity of the mold; and the forming equipment heats the raw materials for producing the mold in the cavity of the mold, thus forming a mold sheet; in the gluing or combining step, when the mold sheet can not form a casting model directly, a plurality of mold sheets are bonded to form a casting model cluster; and a gating system and the casting model or the casting model cluster are bonded to form a whole; subsequently the casting model or the casting model cluster is dipped and roasted; the resistance parts, at which the sands can enter or fill the casting model or the casting model cluster easily, can be determined; then the structure of the casting model or the casting model cluster is improved; and finally the processed casting model or the casting model cluster is embedded in free dry sand and is vibrated to be compact, and the metal liquid is poured to form the casting. The lost foam casting technology can reduce the sand entering and filling resistance in the vibration procedure by changing part of the structure of lost foam casting model or the casting model cluster, thus leading the sand to be compacter.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

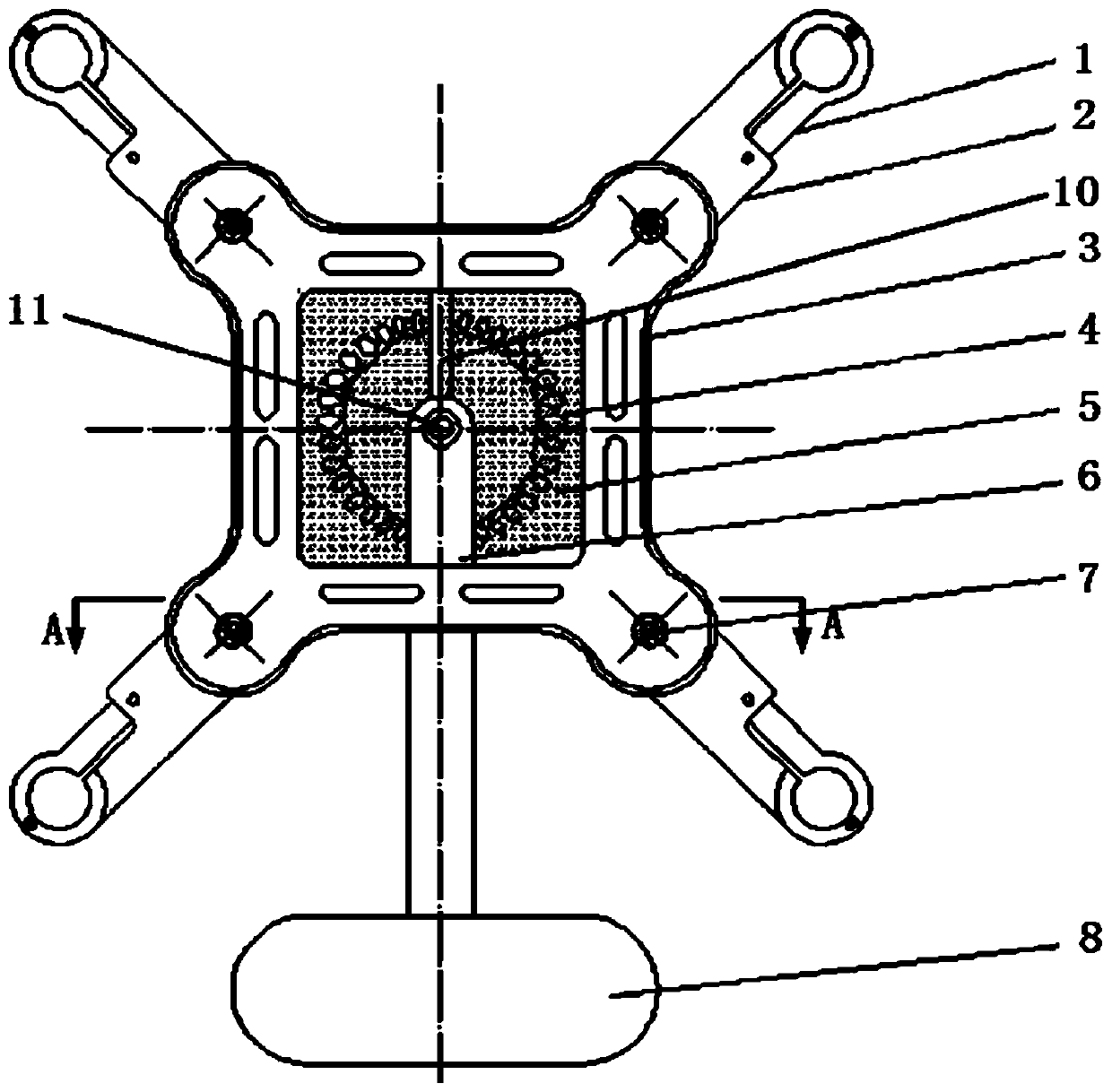

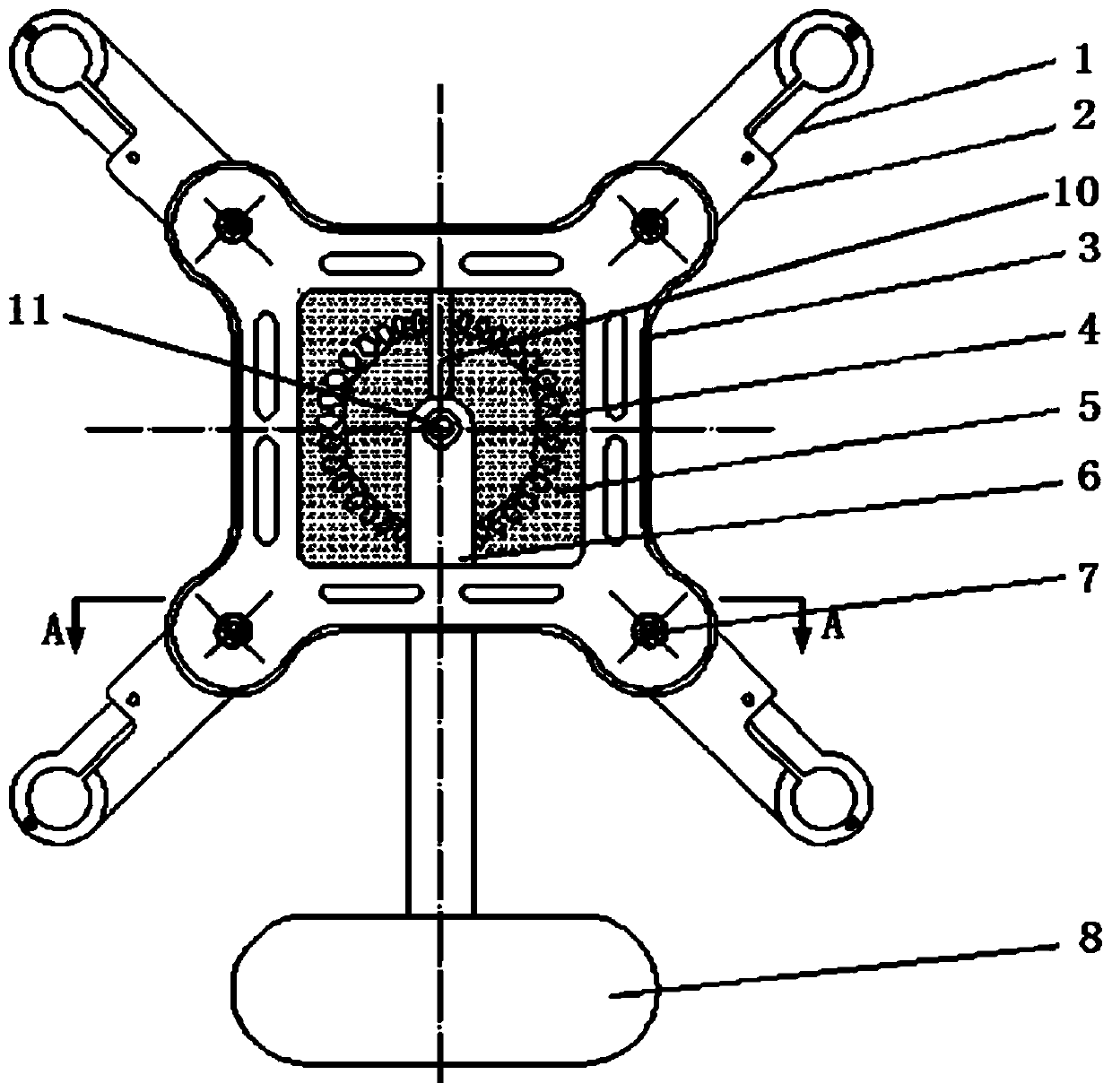

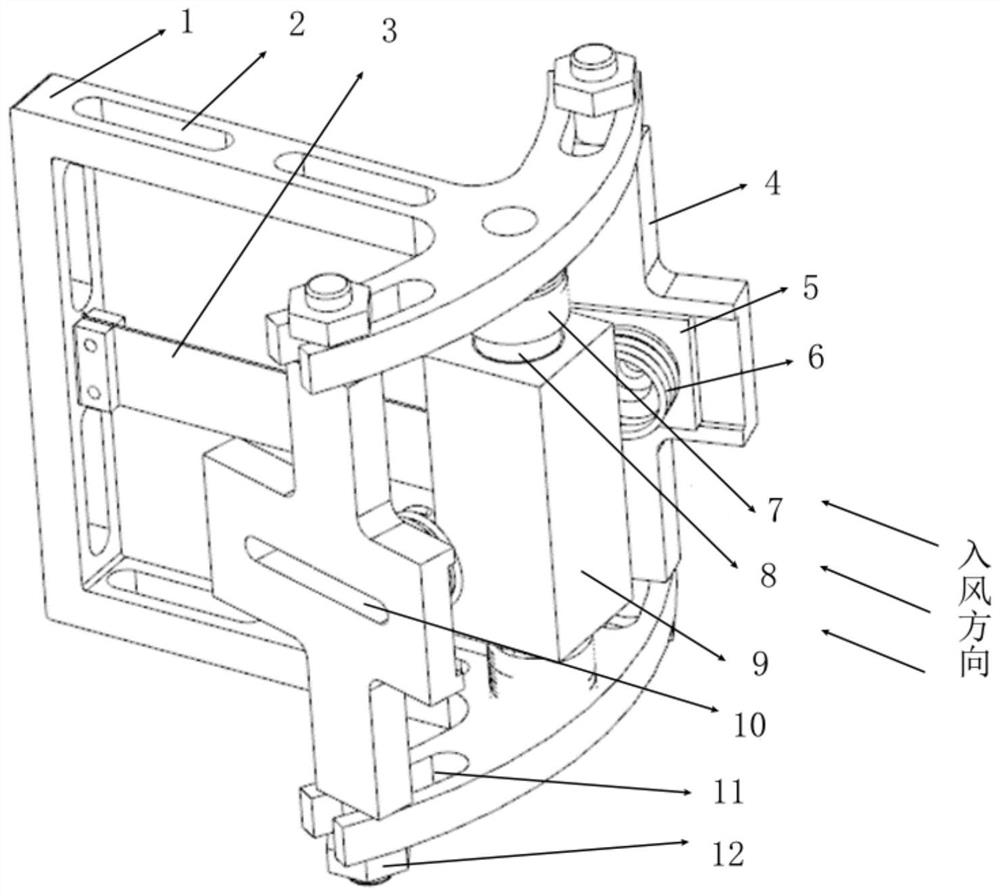

Multi-split conductor bundle deicing and overturning prevention device

ActiveCN109994979ASolve for uniformitySolving static twisting caused by asynchronous deicingMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsEngineeringStatic twisting

The invention provides a multi-split conductor deicing and overturning prevention device which comprises a spacer, a swing rod and a balancing weight. The spacer is clamped on the multi-split conductor bundle and is provided with a central shaft; the upper end of the swing rod enters the spacer and is hinged with the central shaft of the spacer, and the lower end of the swing rod is connected withthe balancing weight, so that the problems of static twisting and torsional vibration of the multi-split conductor caused by uneven ice coating and asynchronous deicing of the sub-conductors are solved, the vibration time is shortened, the vibration can be stopped quickly, and the damage to the sub-conductors, the sub-conductor spacer and the inter-phase spacer is avoided. The multi-split conductor deicing and overturning prevention device has simple structure, the deicing and overturning phenomena of the multi-split conductor can be well prevented and treated, and the condition that the sub-conductors and the spacer are damaged due to deicing and overturning of the multi-split conductor is avoided; and the multi-split conductor deicing and overturning prevention device is convenient to install, high in reliability, adjustable in rigidity of the spring, weight of the balancing weight and distance between the upper edge of the balancing weight and the lower edge of the middle frame ofthe spacer, and wide in range of application.

Owner:CHINA ELECTRIC POWER RES INST

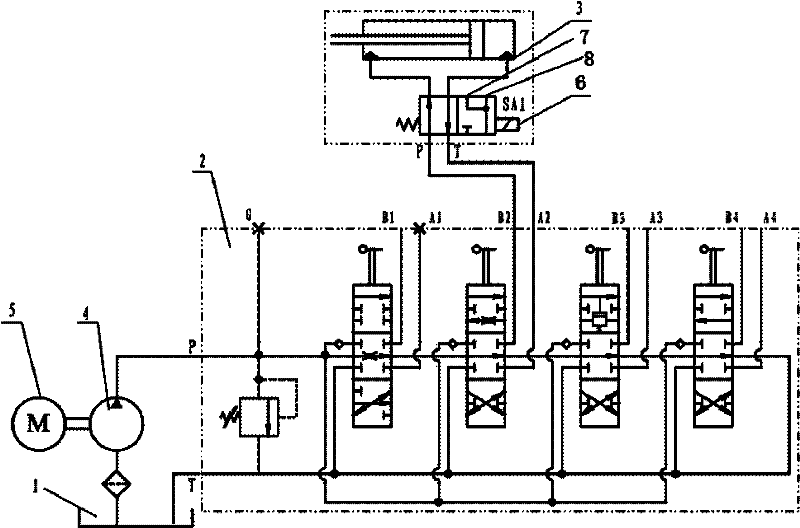

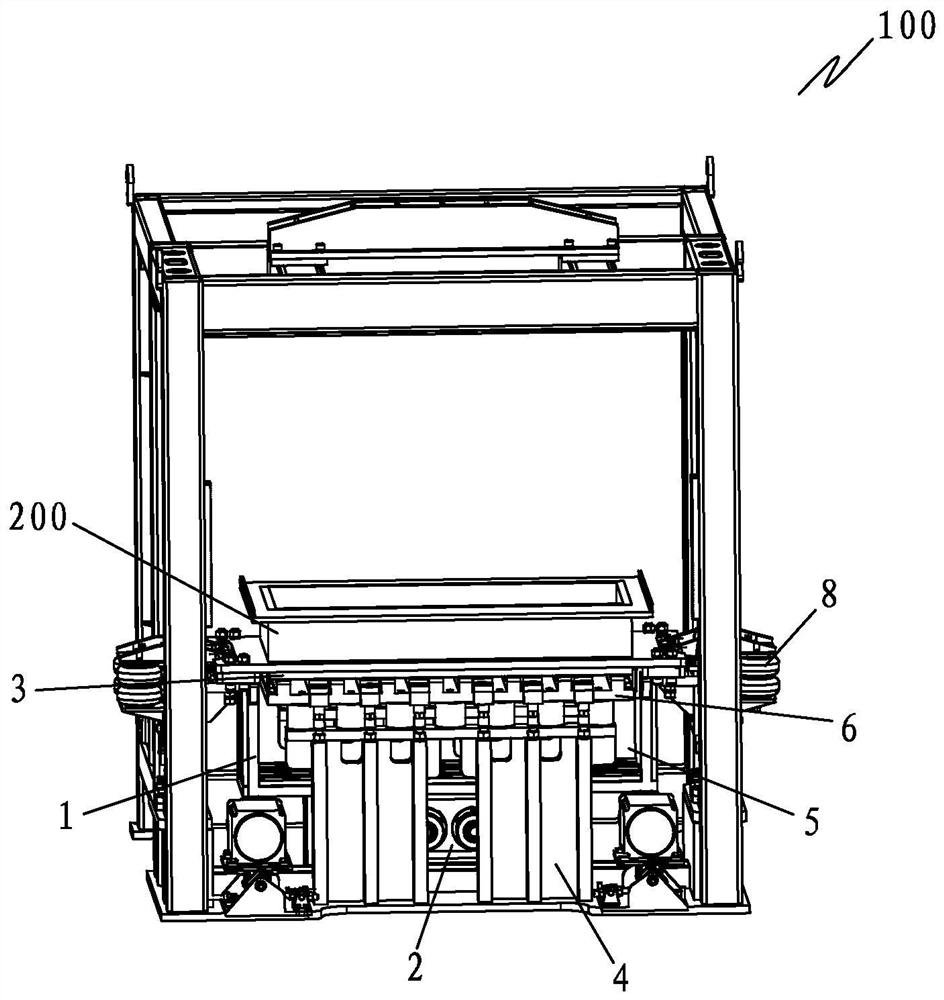

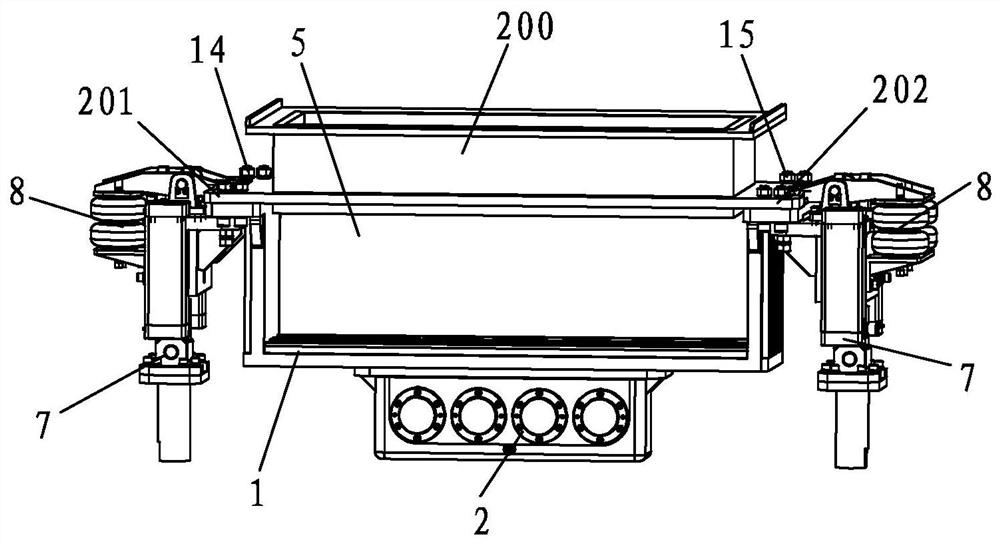

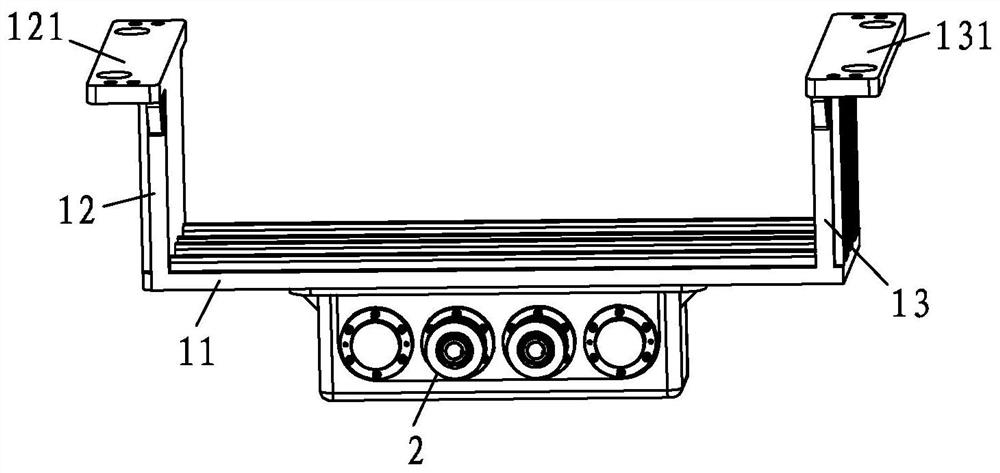

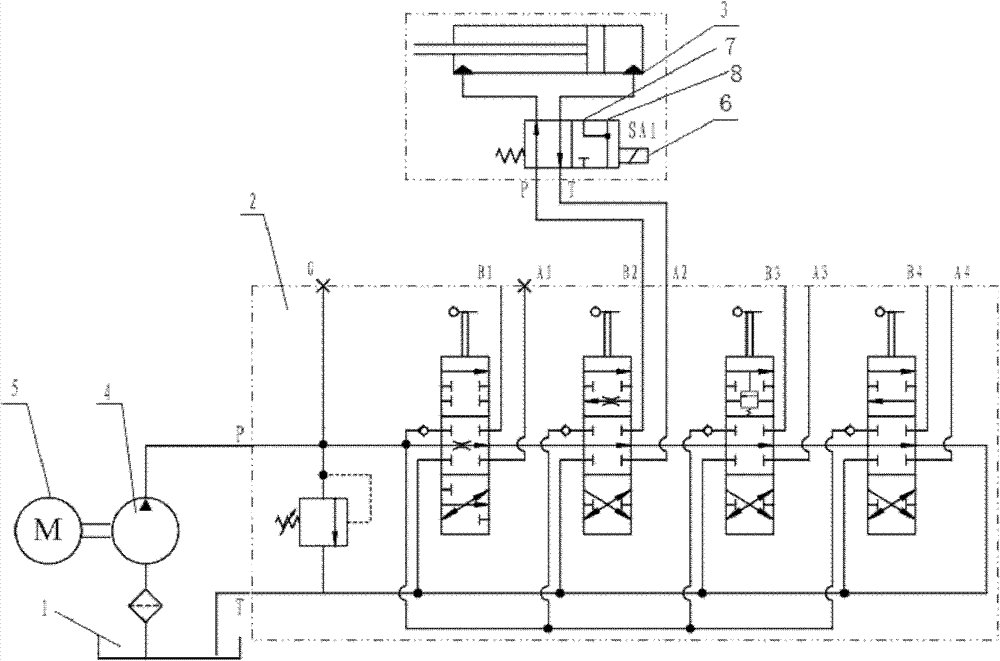

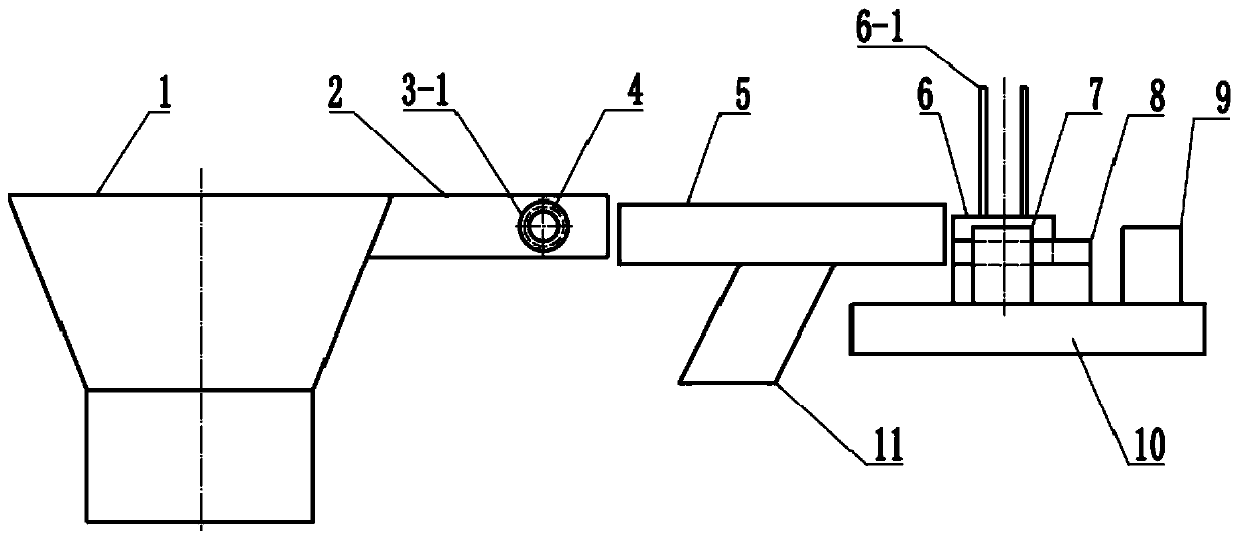

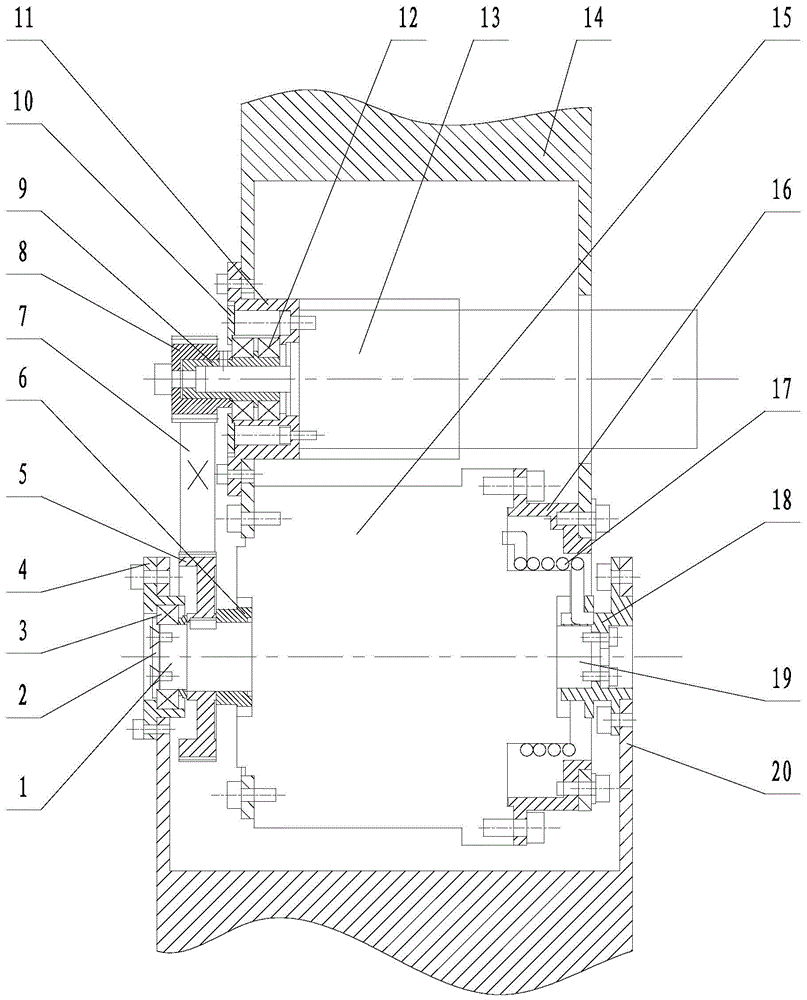

Damping system for forward gantry of electric forward forklift

ActiveCN102515064AReduce vibrationEliminate vibrationLifting devicesVibration suppression adjustmentsStorage efficiencyGear pump

The invention discloses a damping system for a forward gantry of an electric forward forklift, which comprises an oil tank connected with an oil inlet pipe and an oil return pipe, wherein the oil inlet pipe and the oil return pipe are both connected to a multi-way control valve which is externally connected with a forward cylinder, a gear pump is in external transmission connection with an electric motor and is arranged inside the oil inlet pipe, a two-position four-way solenoid valve is arranged inside a connecting pipeline between the multi-way control valve and the forward cylinder, a travel switch in control connection with the two-position four-way solenoid valve is arranged outside a piston rod of the forward cylinder, and when the two-position four-way solenoid valve is powered on, the two interfaces of the two-position four-way solenoid valve are communicated with each other. The problems of poor stacking safety and long storage time caused by the long-time vibration of the gantry of the electric forward forklift in the forward stacking operation process are solved. According to the damping system disclosed by the invention, the gantry can be quickly stabilized from vibration so that the amplitude of vibration can be quickly attenuated in an integrated mechanical-electrical-hydraulic manner on the basis of not influencing on the normal forward stacking operation of the electric forward forklift, so that the safety and storage efficiency of the forklift are greatly improved.

Owner:BANYITONG SCI & TECH DEVING

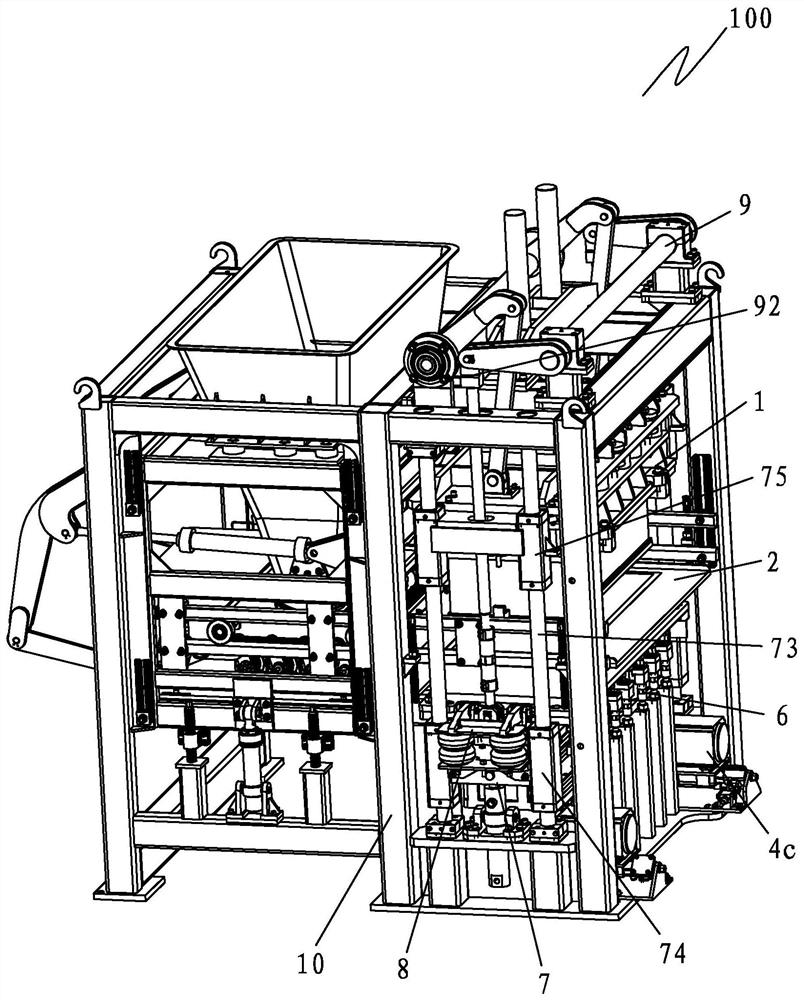

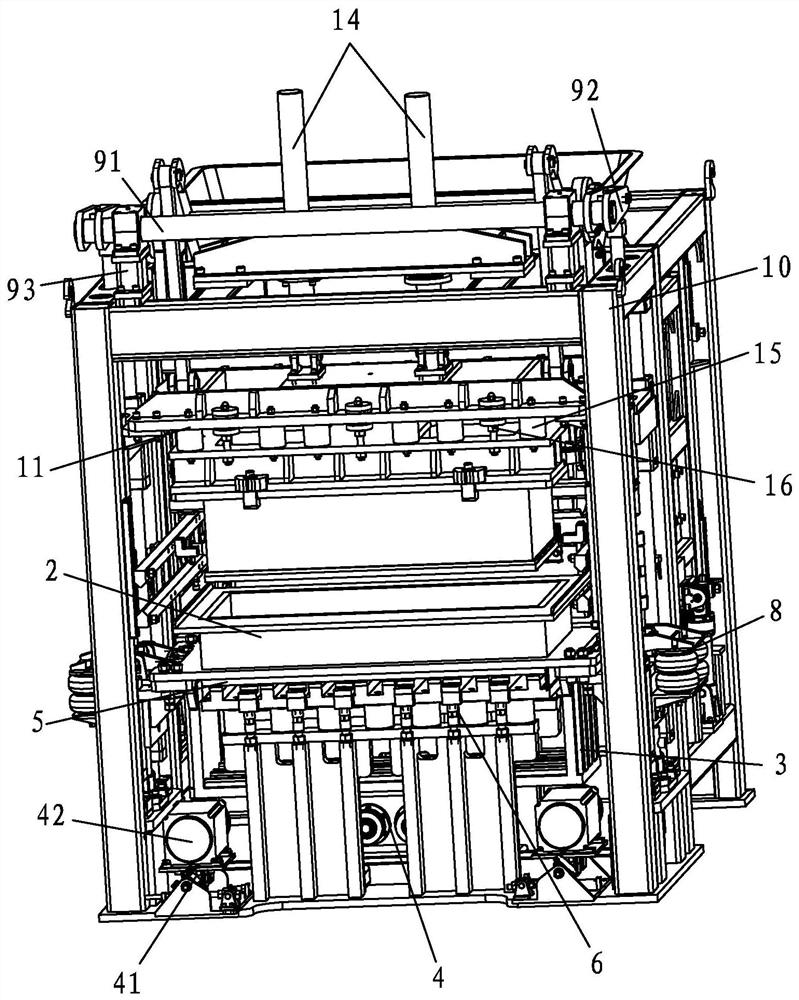

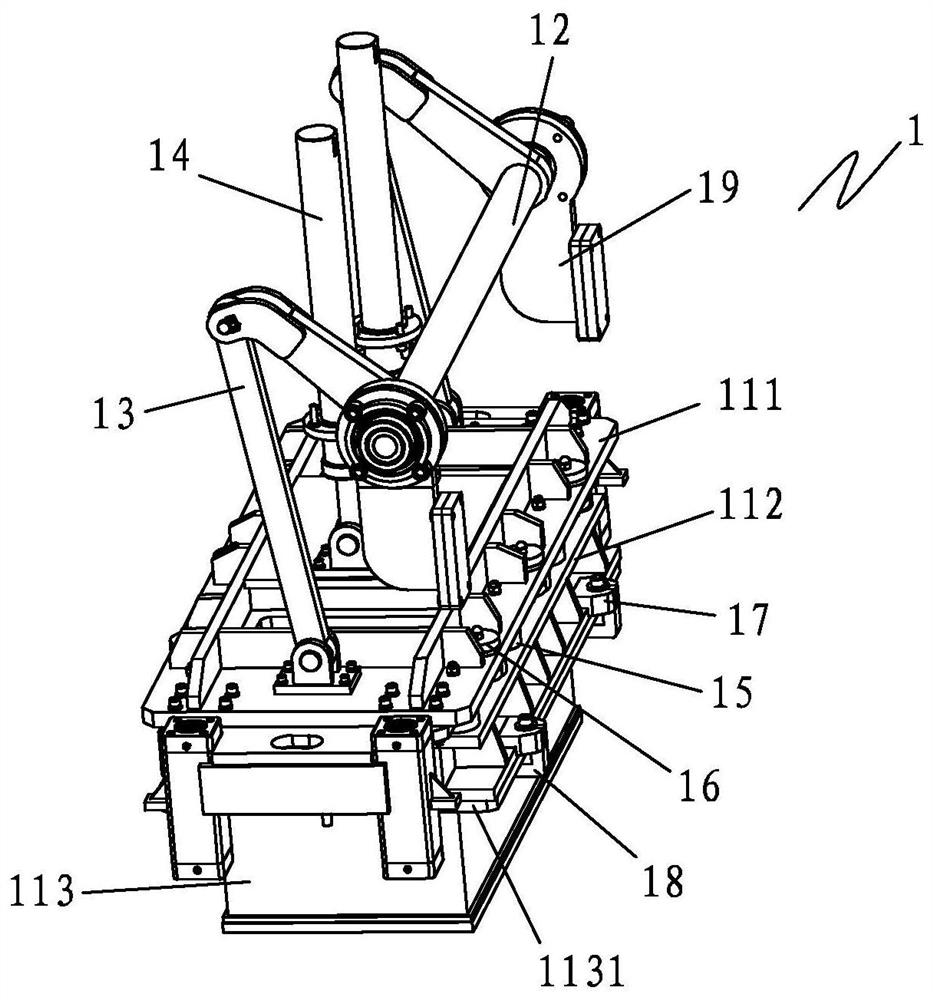

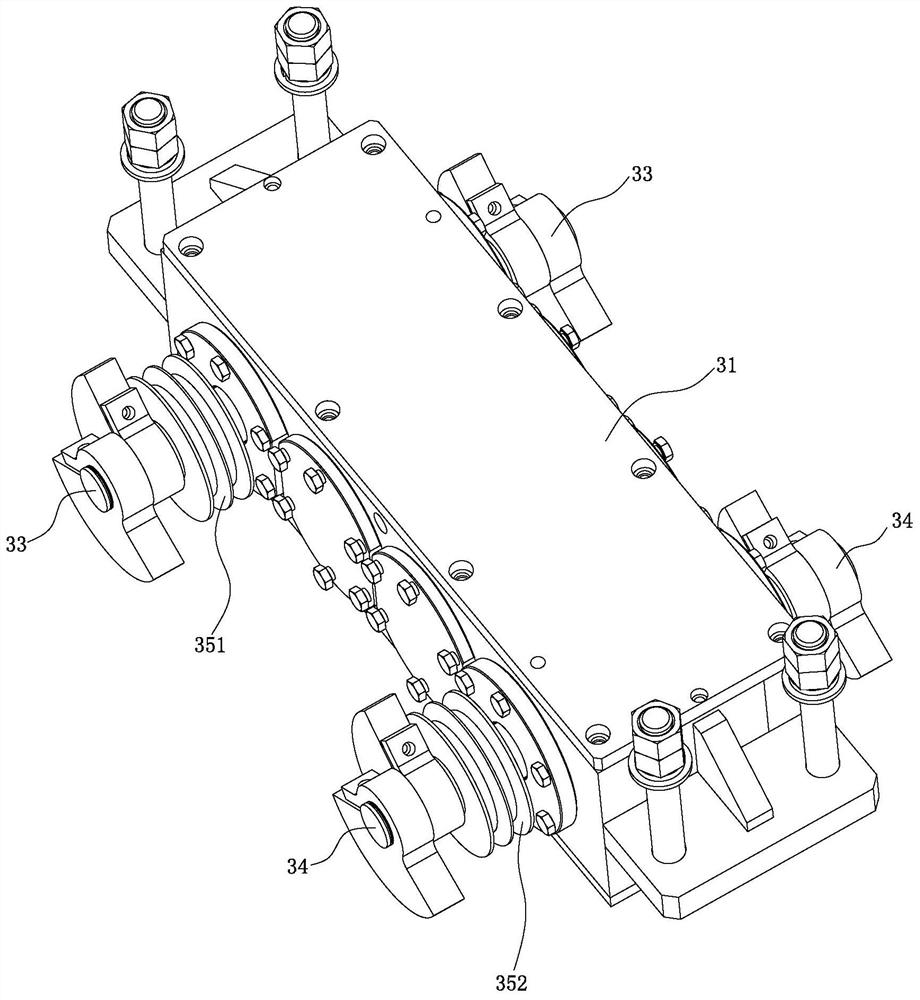

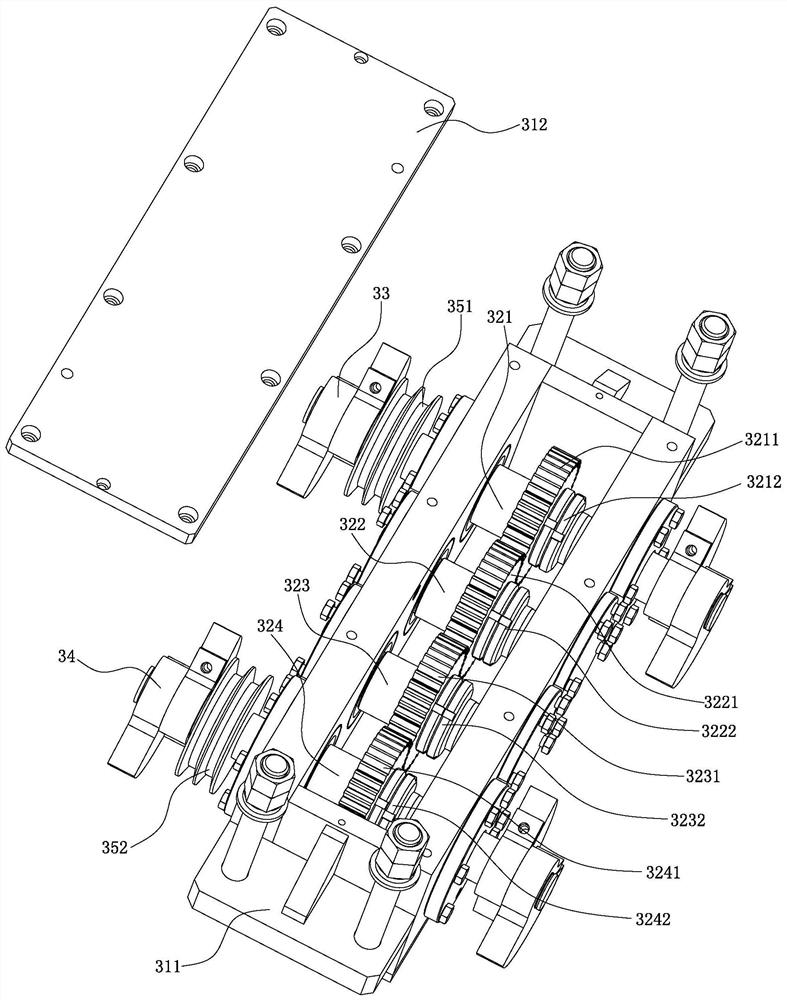

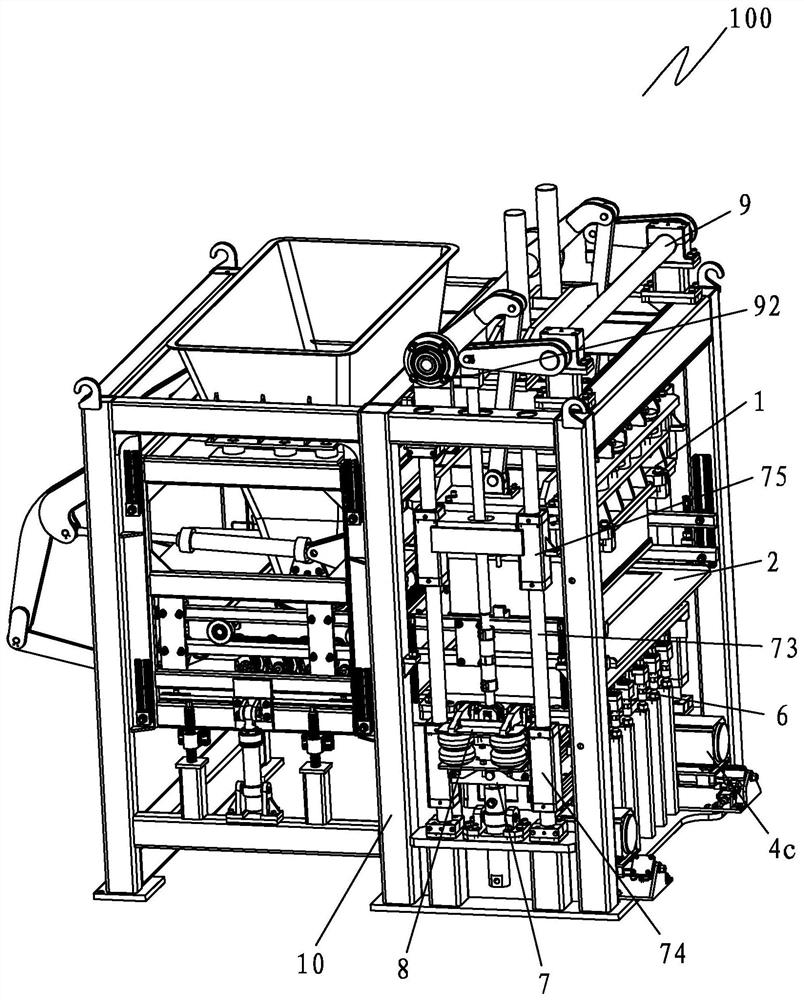

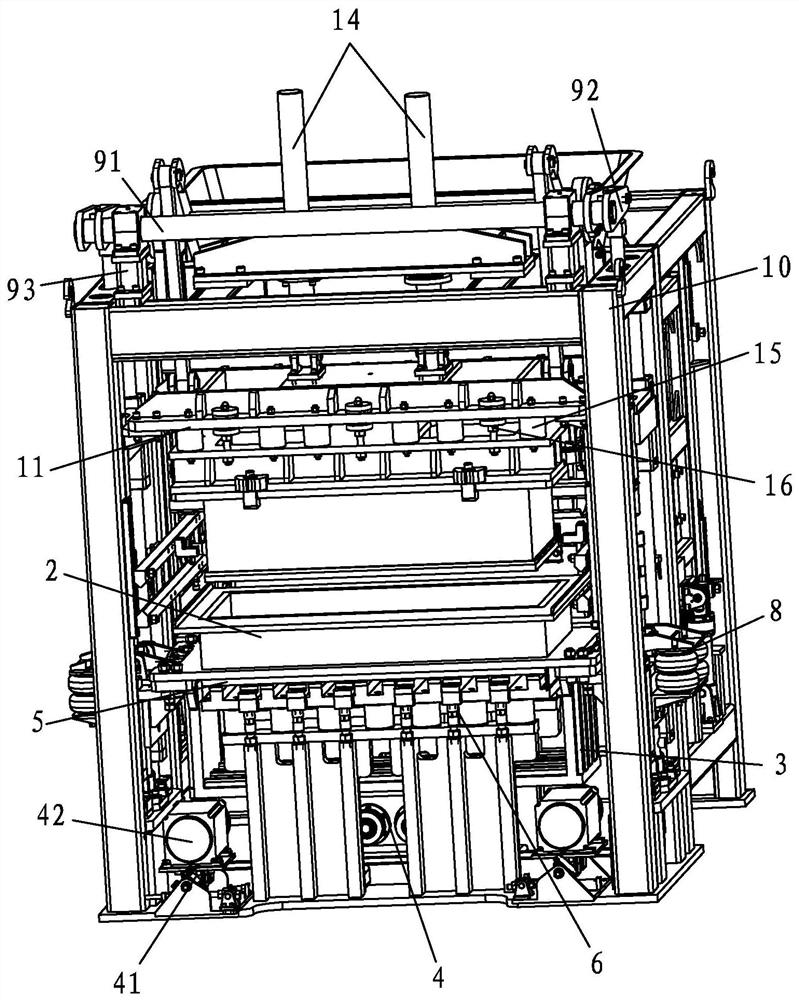

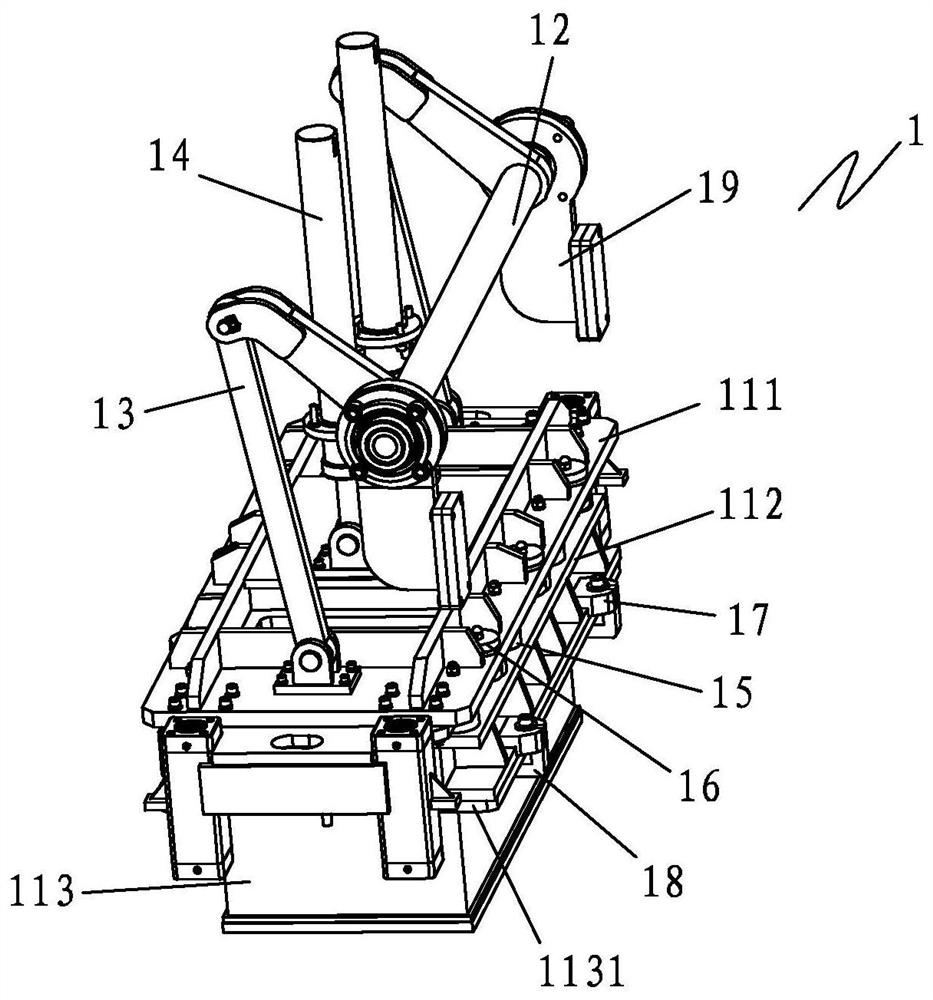

Concrete brick forming machine good in synchronism and low in noise

ActiveCN112248190AQuality assuranceReduce lossSolid waste managementNon-rotating vibration suppressionBrickMolding machine

The invention provides a concrete brick forming machine good in synchronism and low in noise. The synchronous brick forming machine comprises a synchronous pressing head mechanism used for achieving synchronous brick pressing, a concrete brick mold frame arranged below the synchronous pressing head mechanism, a vibration transmission connecting piece connected to the lower end of the concrete brick mold frame and used for directly transmitting vibration force to the concrete brick mold frame, a vibration mechanism fixedly arranged on the vibration transmission connecting piece and used for providing a vibration source, a concrete brick supporting plate arranged at the bottom of the concrete brick mold frame, a vibration reduction and knocking supporting mechanism arranged below the concrete brick supporting plate and used for supporting the concrete brick supporting plate and a lifting mechanism used for driving the concrete brick mold frame and the vibration transmission connecting piece to move up and down together. The concrete brick forming machine has the advantages that synchronism and the brick making effect are good; the filler vibration compaction effect is good, the quality of formed concrete bricks can be guaranteed, and the product percent of pass can be increased; the whole machine is low in working noise and beneficial to protecting the health of workers; and theforming speed is high, and high-efficiency and high-yield production can be realized.

Owner:FUJIAN QUNFENG MACHINERY

A vibration forming device and forming machine for forming low-noise concrete bricks

ActiveCN112223486BAids in rapid prototypingReduce vibration and working noiseSolid waste managementCeramic shaping apparatusLow noiseBrick

The invention provides a low-noise concrete brick forming vibration forming device and a forming machine. The vibration forming device comprises a connecting piece connected to a concrete brick formwork frame for directly transmitting vibration force to the concrete brick formwork frame, and a connecting piece fixed on the connecting piece. A vibrating mechanism used to provide a vibration source on the part. The advantages of the present invention are as follows: the vibration mechanism providing the vibration source is arranged on the connecting piece, and the connecting piece is directly connected with the concrete brick formwork frame. During operation, the vibration force of the vibration mechanism is directly transmitted to the concrete brick formwork frame through the connecting piece, which greatly improves the efficiency of the present invention. Reduce the energy loss in the vibration transmission process, so that the vibration mechanism does not need to work at a higher frequency; at the same time, it avoids the separation of the traditional concrete brick formwork frame and the vibration mechanism, resulting in the high-frequency collision of the two when the concrete brick is formed. ; Can reduce the vibration noise of the vibration forming device; can improve the vibration efficiency, reduce the vibration time, help the rapid forming of concrete bricks, and achieve high-efficiency and high-yield production.

Owner:FUJIAN QUNFENG MACHINERY

Damping system for forward gantry of electric forward forklift

ActiveCN102515064BReduce vibrationEliminate vibrationLifting devicesVibration suppression adjustmentsGear pumpSolenoid valve

The invention discloses a damping system for a forward gantry of an electric forward forklift, which comprises an oil tank connected with an oil inlet pipe and an oil return pipe, wherein the oil inlet pipe and the oil return pipe are both connected to a multi-way control valve which is externally connected with a forward cylinder, a gear pump is in external transmission connection with an electric motor and is arranged inside the oil inlet pipe, a two-position four-way solenoid valve is arranged inside a connecting pipeline between the multi-way control valve and the forward cylinder, a travel switch in control connection with the two-position four-way solenoid valve is arranged outside a piston rod of the forward cylinder, and when the two-position four-way solenoid valve is powered on, the two interfaces of the two-position four-way solenoid valve are communicated with each other. The problems of poor stacking safety and long storage time caused by the long-time vibration of the gantry of the electric forward forklift in the forward stacking operation process are solved. According to the damping system disclosed by the invention, the gantry can be quickly stabilized from vibration so that the amplitude of vibration can be quickly attenuated in an integrated mechanical-electrical-hydraulic manner on the basis of not influencing on the normal forward stacking operation of the electric forward forklift, so that the safety and storage efficiency of the forklift are greatly improved.

Owner:BANYITONG SCI & TECH DEVING

Automatic feeding device and control method for buzzer dispensing

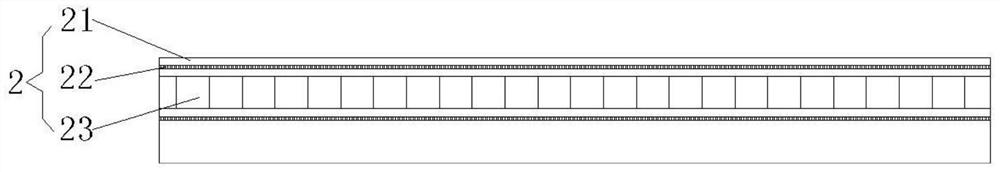

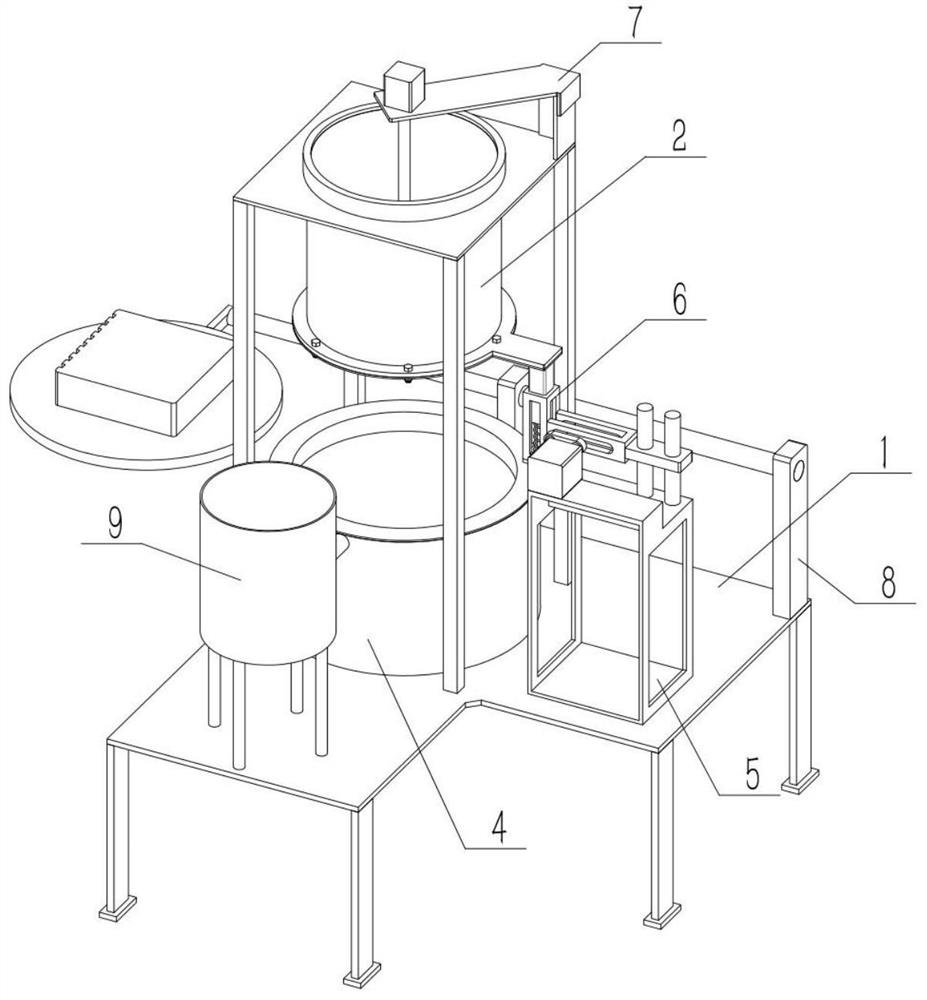

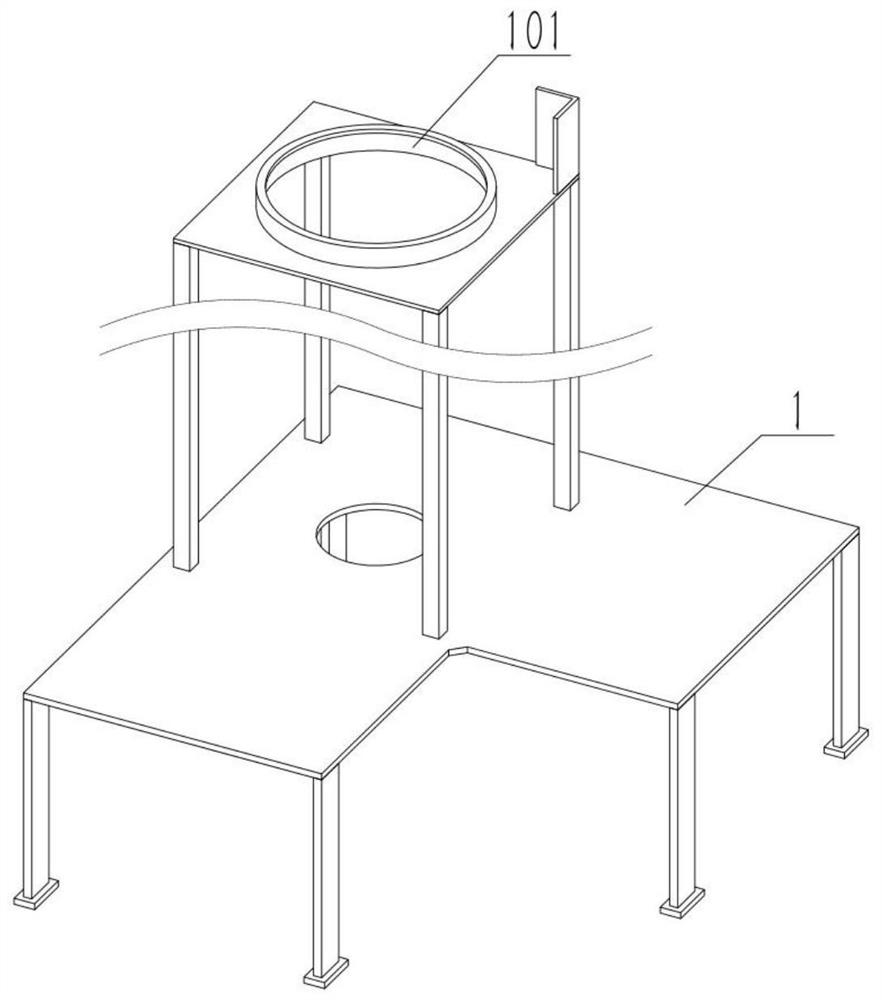

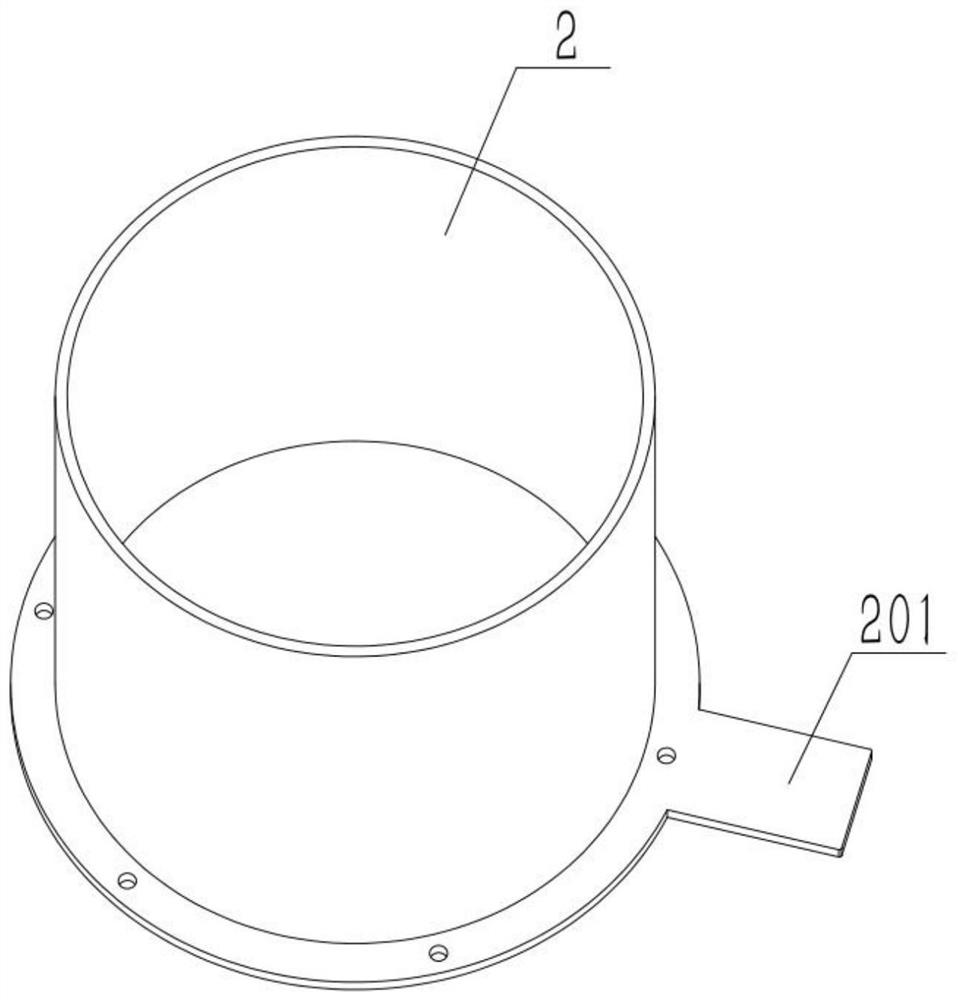

PendingCN110436127AGuaranteed continuityShorten vibration timeLiquid surface applicatorsControl devices for conveyorsLower limitMechanical engineering

The invention discloses an automatic feeding device and control method for buzzer dispensing. The device comprises a vibration conveying device and a dispensing positioning device. The vibration conveying device comprises a vibration plate, a first feeding guide rail, a second feeding guide rail and a direct vibration device. A first positioning convex strip and a second reflective photoelectric sensor are arranged on the side, in the direction opposite to the conveying direction of the second feeding guide rail, on a dispensing platform. A push mechanism is arranged at the end, in the direction perpendicular to the conveying direction of the second feeding guide rail, on the dispensing platform, and a second positioning convex strip and a first reflective photoelectric sensor are arrangedat the other end of the dispensing platform. By the adoption of the automatic feeding device for buzzer dispensing, whether the number of workpieces in the second feeding guide rail reaches the fullcapacity or not is judged according to a signal of an opposite-type optical fiber sensor, and the vibration disc is controlled to stop vibrating. When the number of workpieces in the second feeding guide rail reaches the set lower limit value, the vibrating plate is started, so that the continuity of the feeding is ensured, the vibration time of the vibrating plate is shortened, the energy is saved, the starting and stopping frequency of the vibrating plate is reduced, and the service life of the vibrating plate is prolonged.

Owner:江苏安澜万锦电子股份有限公司

Wind power generation device and mounting method thereof

PendingCN112160881AReduce vibration amplitudeShorten vibration timeMachines/enginesWind energy generationTransformerRelative motion

The embodiment of the invention discloses a wind power generation device and a mounting method thereof. The device comprises a large-mass element, a damping device and a generator set main structure,wherein the large-mass element is connected with the generator set main structure through a movable connecting piece and can move relative to the generator set main structure through the movable connecting piece, one end of the damping device is connected with the large-mass element, the other end of the damping device is connected with the generator set main structure or the movable connecting piece, and the damping device is used for slowing down the relative movement. Through the device, the dynamic characteristics of a whole wind generator set can be improved while the mounting and connecting requirements of a transformer and other components are met, and the effects of dissipating energy and reducing vibration also can be achieved during vibration of the generator set main structure.

Owner:MECAL(北京)工程技术有限公司

Acoustic insulating material for ultrasonic sensor and preparation method thereof

InactiveCN102176309AReduce remaining vibration timeShorten vibration timeSound producing devicesEpoxyPorosity

The invention discloses an acoustic insulating material for an ultrasonic sensor. The material is characterized by consisting of the following components in percentage by weight: 60 to 85 percent of epoxy resin, 3 to 10 percent of foaming agent, 5 to 15 percent of toughening agent, and 5 to 20 percent of curing agent. The method is simple, and the porosity of the acoustic insulating material for the ultrasonic sensor prepared by utilizing the method can reach 300 to 800 meshes, therefore, the acoustic insulating effect is good, the service life is long, and the stability is high.

Owner:BESTAR HLDG

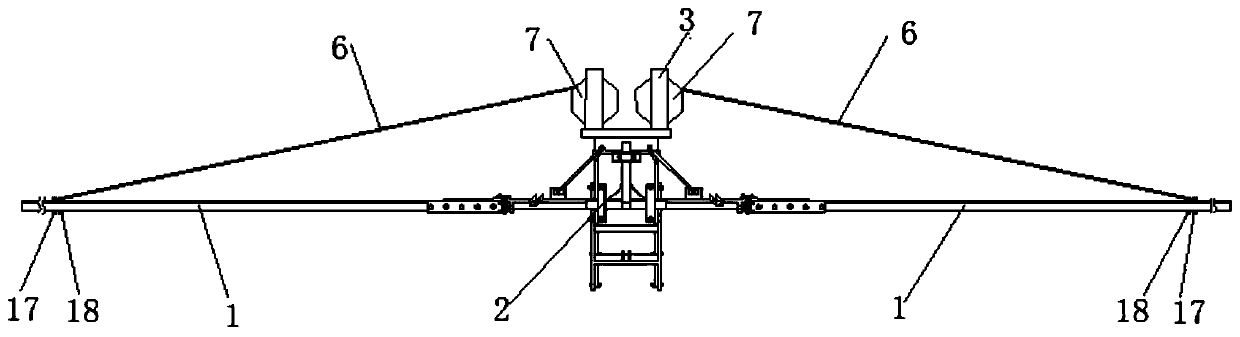

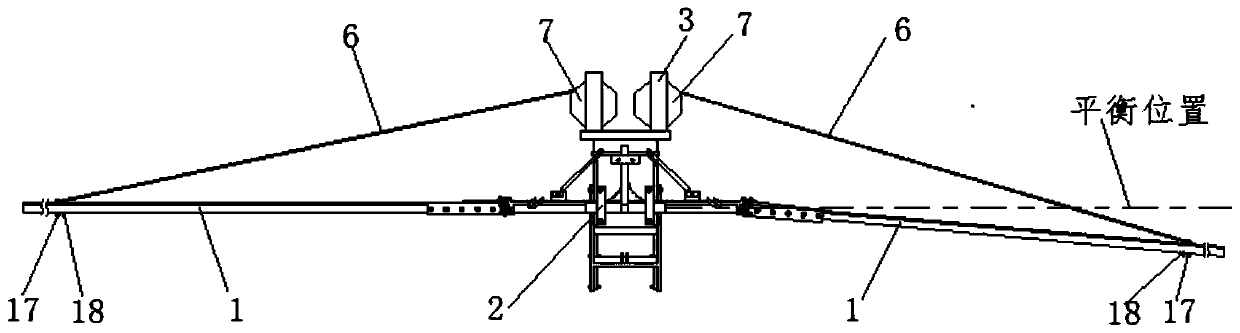

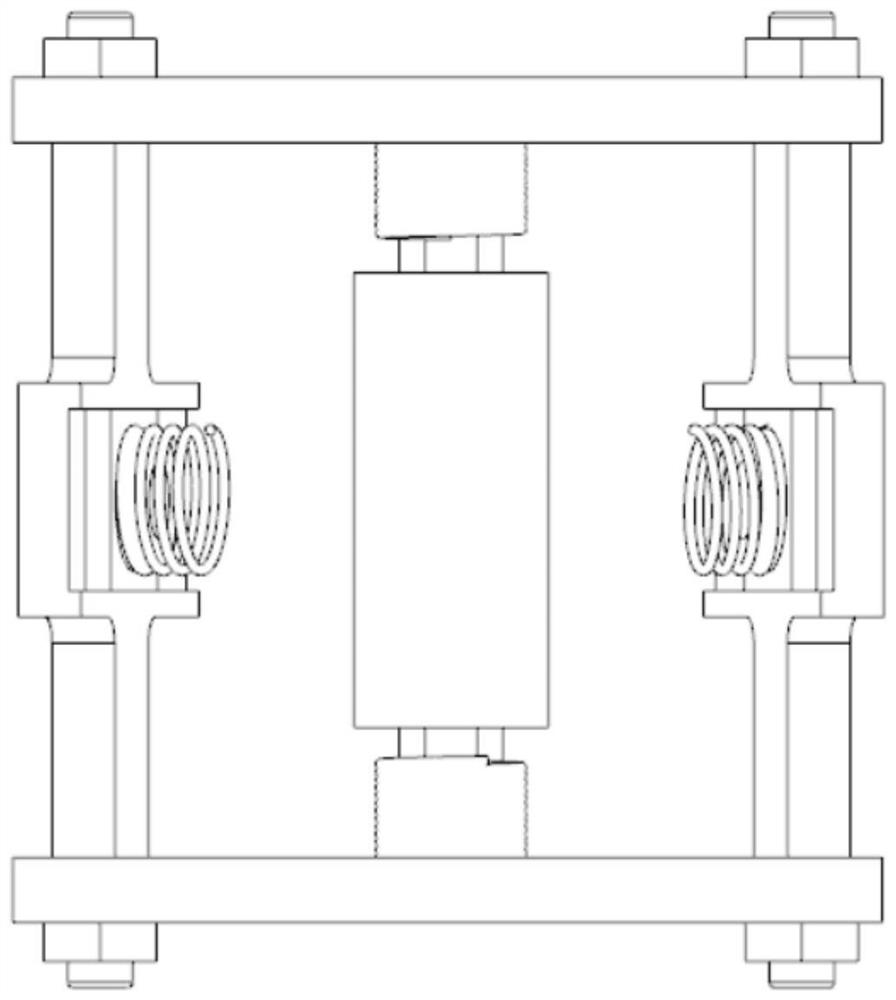

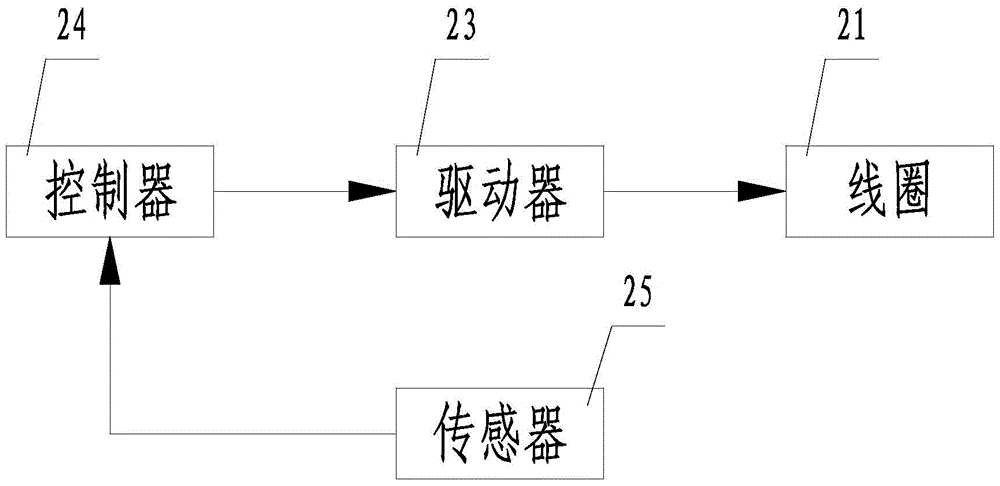

Balance control device for spray boom arms of high-ground-clearance boom sprayer

PendingCN111165459AReduce vibration time and vibration frequencyEliminate the effects ofInsect catchers and killersElectric machineryDrive motor

The invention discloses a balance control device for spray boom arms of a high-ground-clearance boom sprayer. The balance control device comprises: supports; supporting shafts, which are respectivelyarranged on the supports; a driving motor, which is used for driving the supporting shafts to rotate; cable recycling wheels and coil spring assemblies, which are respectively arranged on the supporting shafts; and circumferential limiting pieces, which are fixedly arranged on the supports and can circumferentially limit one ends of the coil spring assemblies, so the coil spring assemblies can berotated and tightened. According to the invention, cables are wound on the cable recycling wheels, and when the tail ends of the spray boom arms move downwards, the cables are pulled out, and the coilspring assemblies are gradually tightened to generate a force for preventing the spray boom arms from moving downwards; and when the tail ends of the spray boom arms move upwards, the driving motor drives the supporting shafts to rotate, and the cables are wound around the cable recycling wheels again. The balance control device provided by the invention can reduce the vibration frequency and vibration time of the spray boom arms, so the spray boom arms can be restored to a balance position as soon as possible; and the influence of vibration of a vehicle body on a pesticide application effectis reduced.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

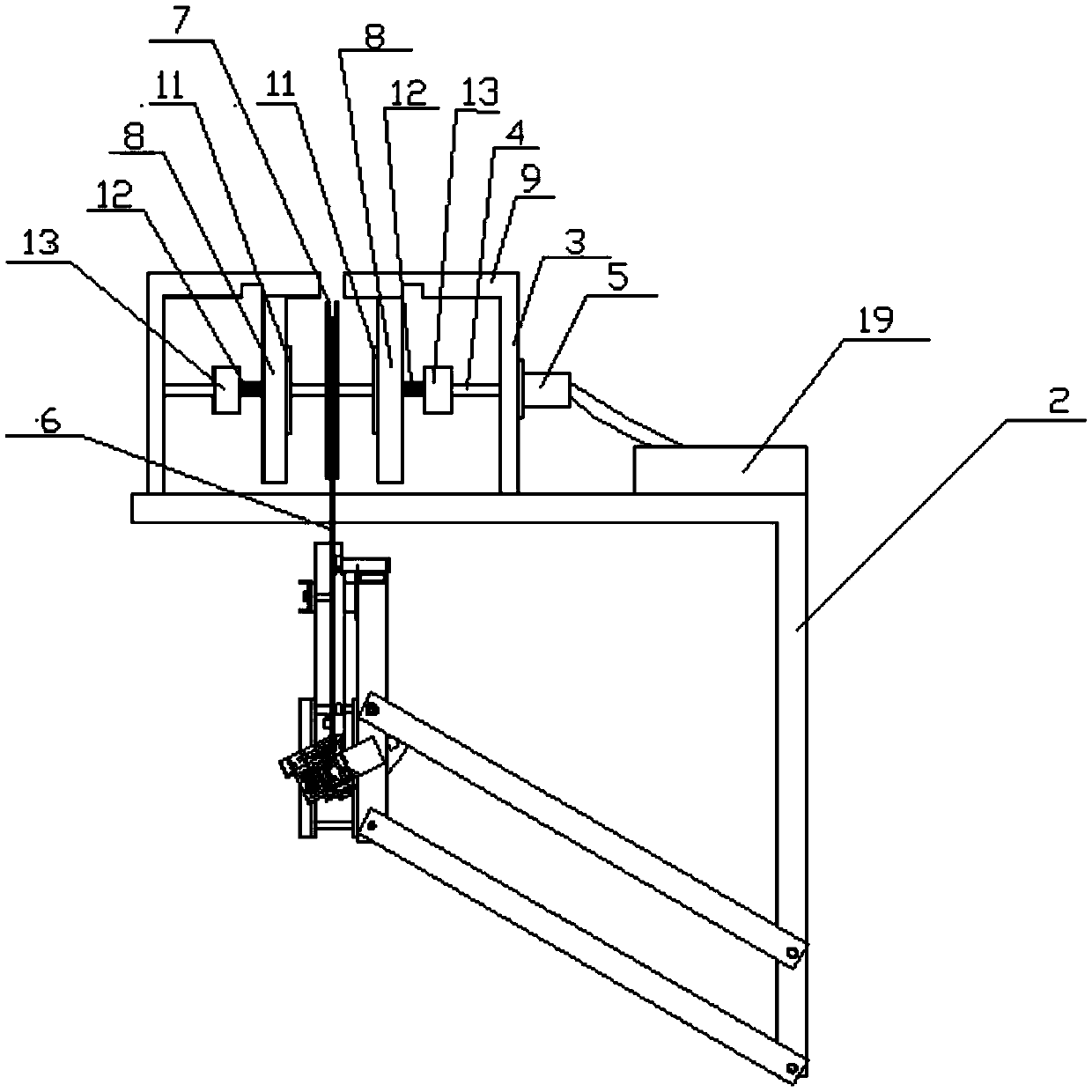

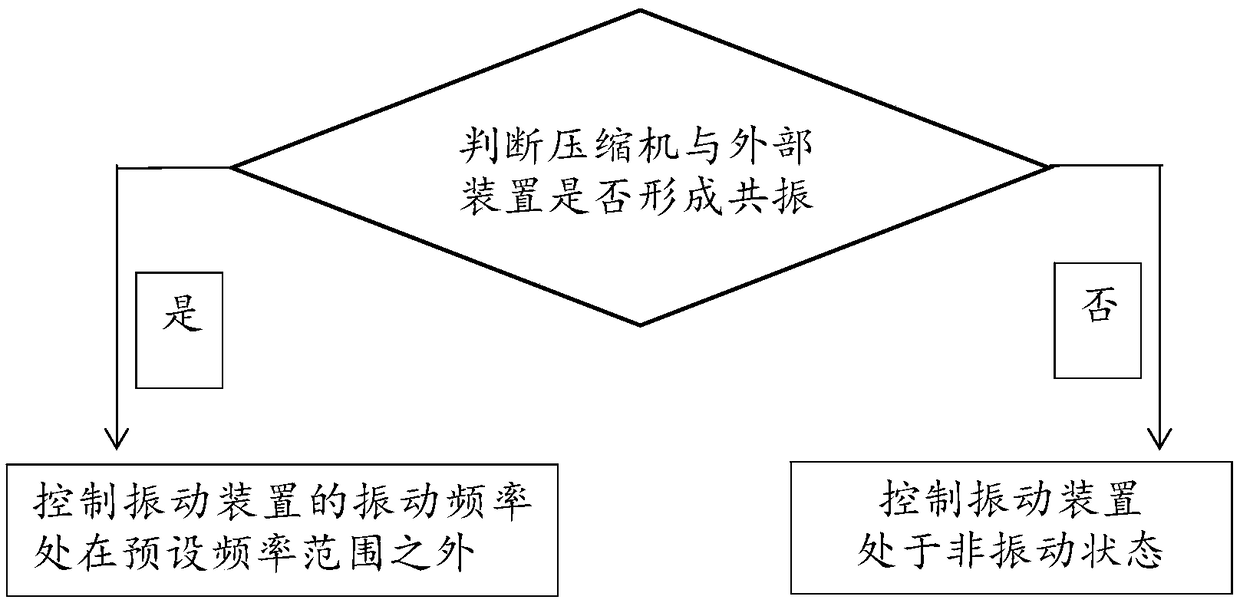

Compressor vibration damping method and system and electrical appliance product including system

PendingCN108869247AFix damageShorten vibration timePump testingPositive displacement pump componentsResonanceEngineering

The invention discloses a compressor vibration damping method and system and an electrical appliance product including the system and relates to the technical field of compressor vibration damping. The compressor vibration damping method is characterized in that a compressor is connected to a vibrating device used for driving the compressor to vibrate, and includes the steps of judging whether ornot resonance between the compressor and an external device occurs; if yes, controlling the vibration frequency of the vibrating device to be maintained beyond a preset frequency range in order to enable the compressor and the external device to stay in a non-resonance state, wherein the preset frequency range is a running frequency range of the compressor to cause resonance of the external device. In this way, by adding vibration of the vibrating device to prevent resonance between the compressor and the external device, the problem that a big noise is generated during resonance is solved, and the problem of damage of the compressor and external device due to resonance is also solved.

Owner:GREE ELECTRIC APPLIANCES INC

Variable-frequency vibration forming process for carbon electrodes

ActiveCN102672793AHigh densityShorten vibration timeShaping press ramVertical vibrationMechanical engineering

The invention relates to a variable-frequency vibration forming process for carbon electrodes and is applicable to vertical vibration forming of electrodes with diameters ranging from phi 800mm to phi 1400mm. The variable-frequency vibration forming process includes four stages including mold entering vibration, lower-frequency transformation, lower-frequency high pressure and high-frequency high pressure. Vibration time, compared with the prior art, is shortened by 5 to 8 minutes, green-pressing volume density of the processed electrode is improved from 1.68 g / cm<3> to 1.70g / cm<3>-1.72g / cm<3>, no internal quality defects and no breakage accidents are caused in use,, and producing efficiency and product quality are improved.

Owner:河北顺天电极有限公司

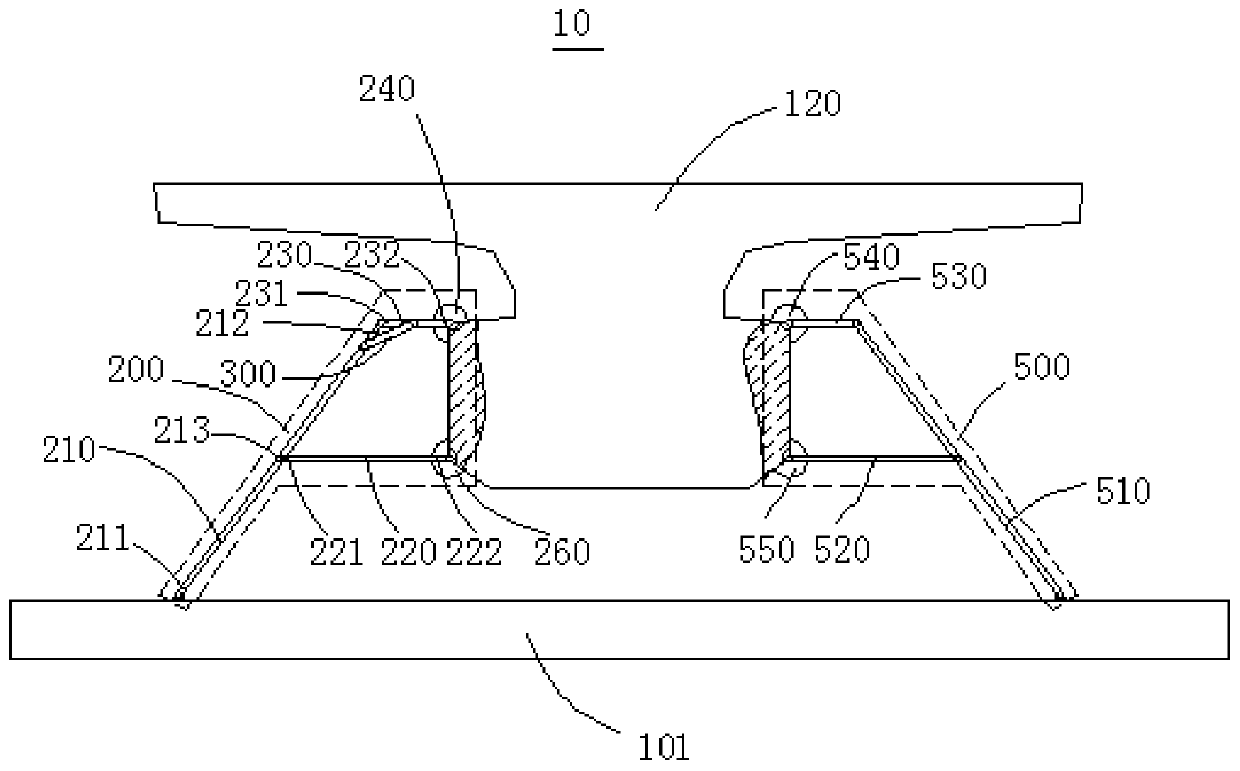

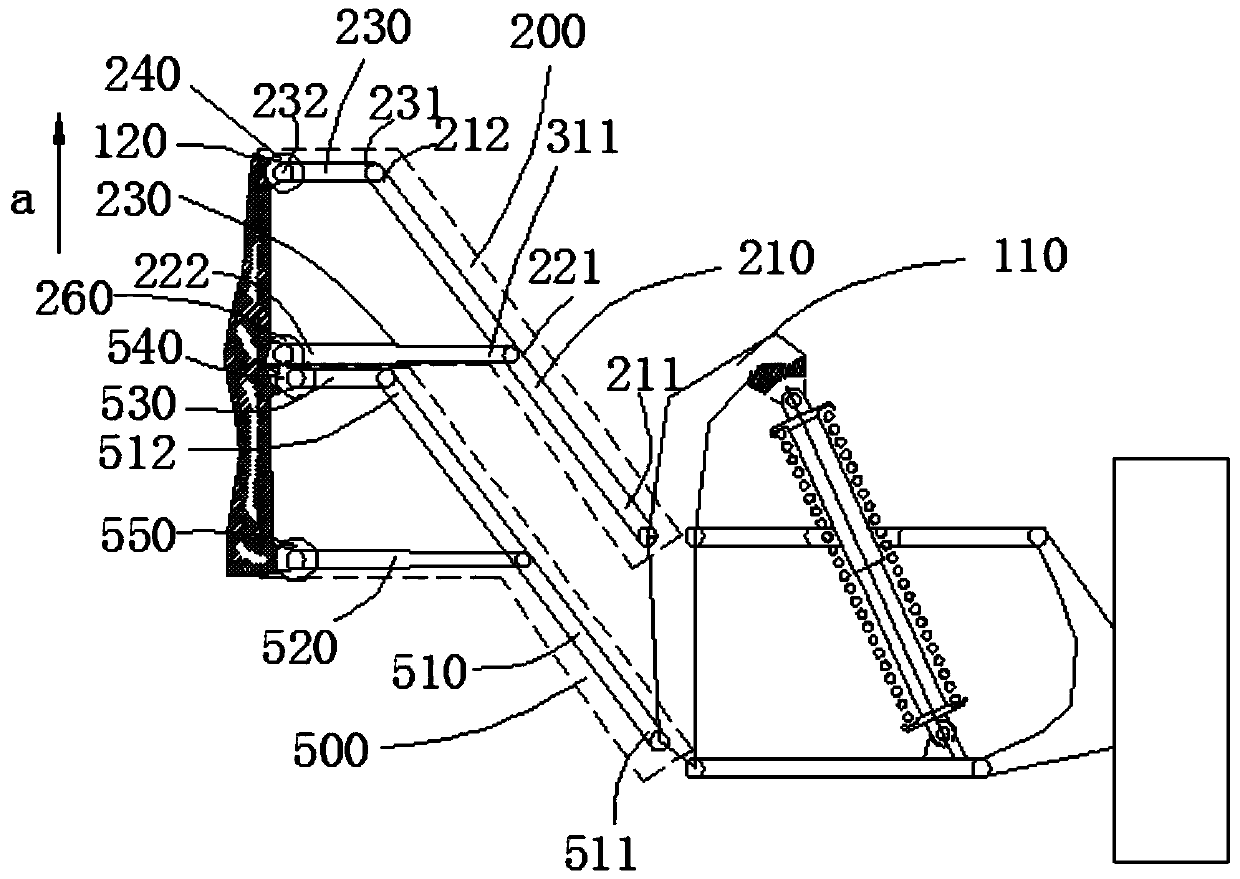

Active adjusting system for vehicle attitude and vehicle

PendingCN110722946AImprove vibration damping effectImprove stabilityResilient suspensionsVehicle frameCrank

The invention relates to an active adjusting system for a vehicle attitude and a vehicle. The active adjusting system for the vehicle attitude comprises a connecting rod mechanism which is co-definedby a first connecting rod, a first crank, a first rocking bar and a frame; the movement track of the first end of the first connecting rod is approximately a straight line. When the wheels bump up anddown in the vertical direction, the wheels drive an axle to move up and down, the axle drives the first end to move vertically, and the position of the frame is not changed. The active adjusting system for the vehicle attitude absorbs part of kinetic energy through the connecting rod mechanism, so that stability of the vehicle is improved. The active adjusting system for the vehicle attitude controls the rotation angle of the first crank through a first motor, so that a rotation angle of the first connecting rod and a rotation angle of the first rocking bar are controlled to reduce vibrationtime of the frame, and therefore, damping performance of the vehicle is improved, and stability of the vehicle is improved. Besides, the active adjusting system for the vehicle attitude further can adjust the vehicle attitude through the first motor, and improves comfort and safety.

Owner:TSINGHUA UNIV

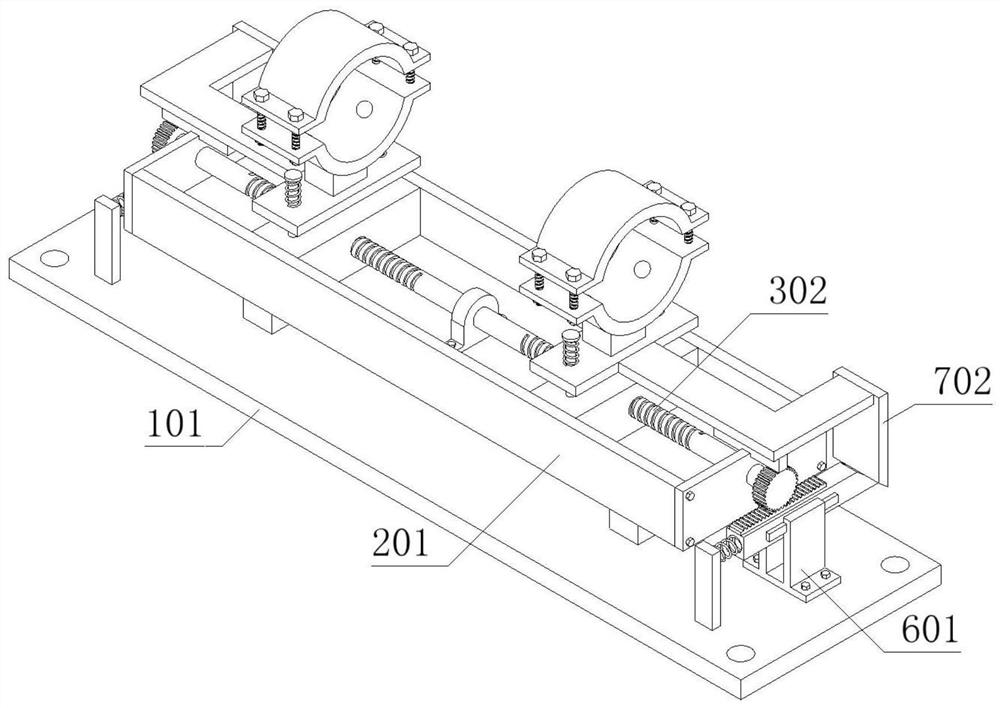

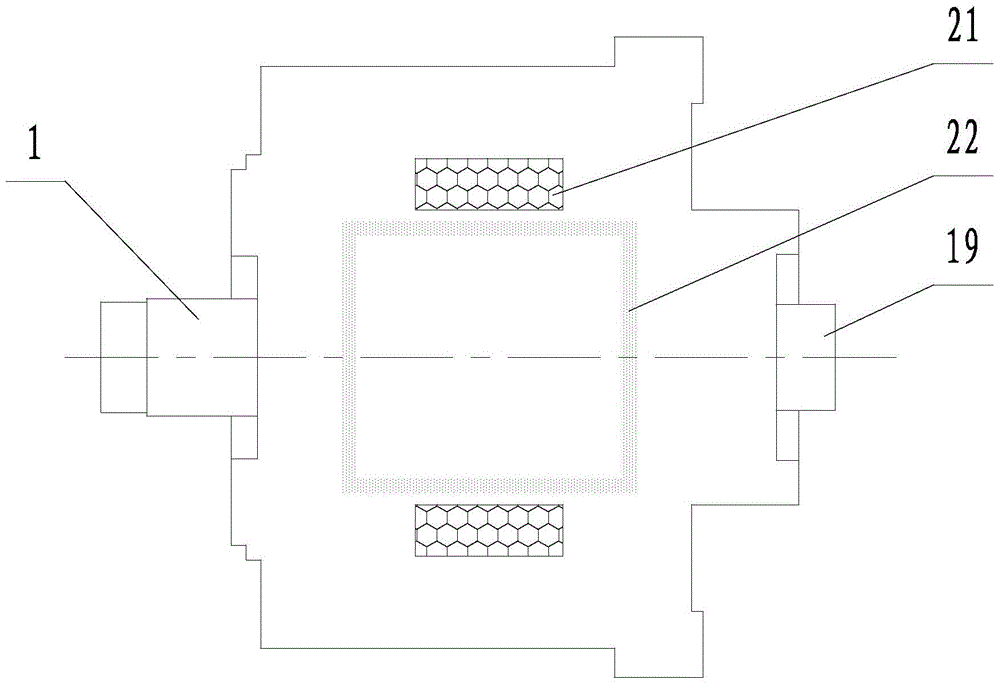

Anti-seismic support acting on installation of high-floor rainwater drainage pipe

ActiveCN113883336AShorten vibration timeAvoid damagePipe supportsPipe elementsDrainage tubesSeismic resistance

The invention provides an anti-seismic support acting on installation of a high-floor rainwater drainage pipe, and relates to the technical field of drainage pipe seismic resistance. The support comprises a fixing assembly; a mounting mechanism is mounted at the top of the fixing assembly, a driving part is mounted in the mounting mechanism, two groups of connecting devices are mounted inside the mounting mechanism, and a clamping mechanism is mounted at the tops of the two groups of connecting devices; the number of pushing parts is two, and the two pushing parts are installed at the top of the fixing assembly; and triggering devices are installed on the outer sides of the two groups of connecting devices. When the drainage pipe vibrates, the vibration time of the drainage pipe can be shortened while damping is conducted, the situation that the drainage pipe is damaged due to long-time vibration is avoided, and the service life of the drainage pipe is prolonged; and the problem that the drainage pipe is prone to being damaged due to long-time vibration is solved.

Owner:长春恒发房地产开发有限公司

An Active Vibration Control Method for Wrinkled Thin Films Based on In-Plane Regulation

ActiveCN108897213BChange propertiesFeature does not affectAdaptive controlControl orientedDynamic models

The invention relates to an active vibration control method for wrinkled membranes based on in-plane regulation. The dynamic model of wrinkled membranes is established mainly by analyzing the influence of wrinkle shape on the dynamic characteristics of the membrane structure; Based on the basic space vector, the dynamic model of the wrinkled membrane under different loads is established; according to the contribution of each order mode to the vibration deformation of the system, the dynamic model is condensed to establish a control-oriented dynamic model of the membrane structure; the model is adopted Referring to the adaptive controller, combined with the PID controller, a PID-MRAC control method based on in-plane regulation and multi-model switching is proposed. The method of the present invention does not need to paste actuators on the surface of the film, and can effectively suppress the out-of-plane vibration of the film. , will not affect the characteristics of the film itself, ensure the stability of the film structure, and shorten the vibration time by about 39.7% compared with the traditional PID control method.

Owner:BAOJI UNIV OF ARTS & SCI +1

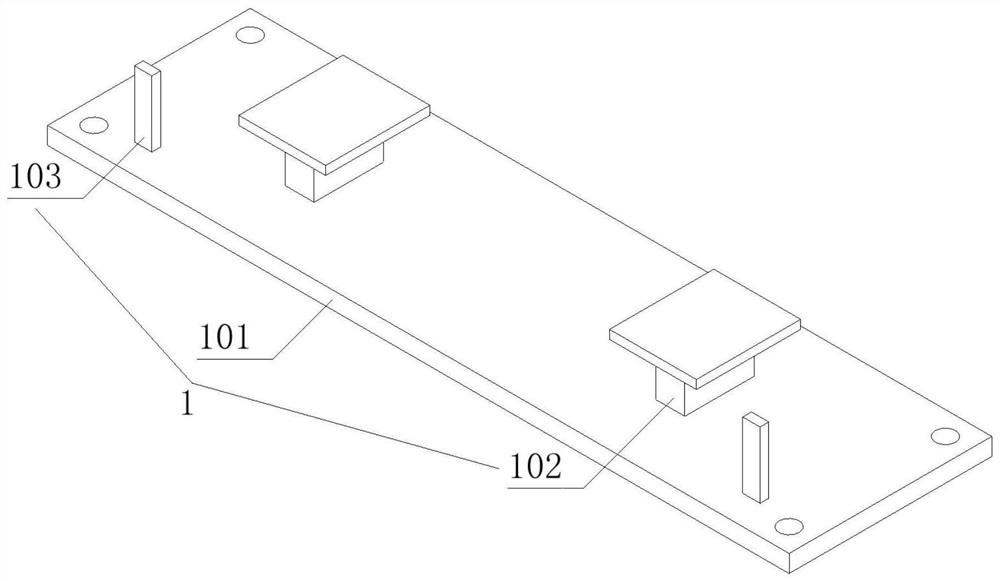

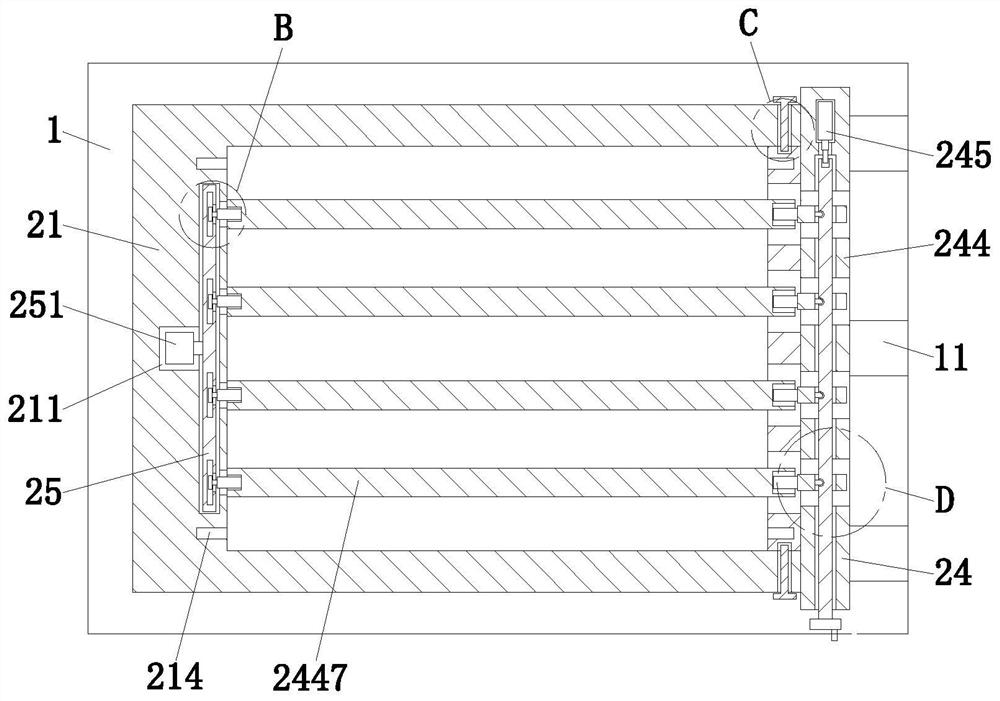

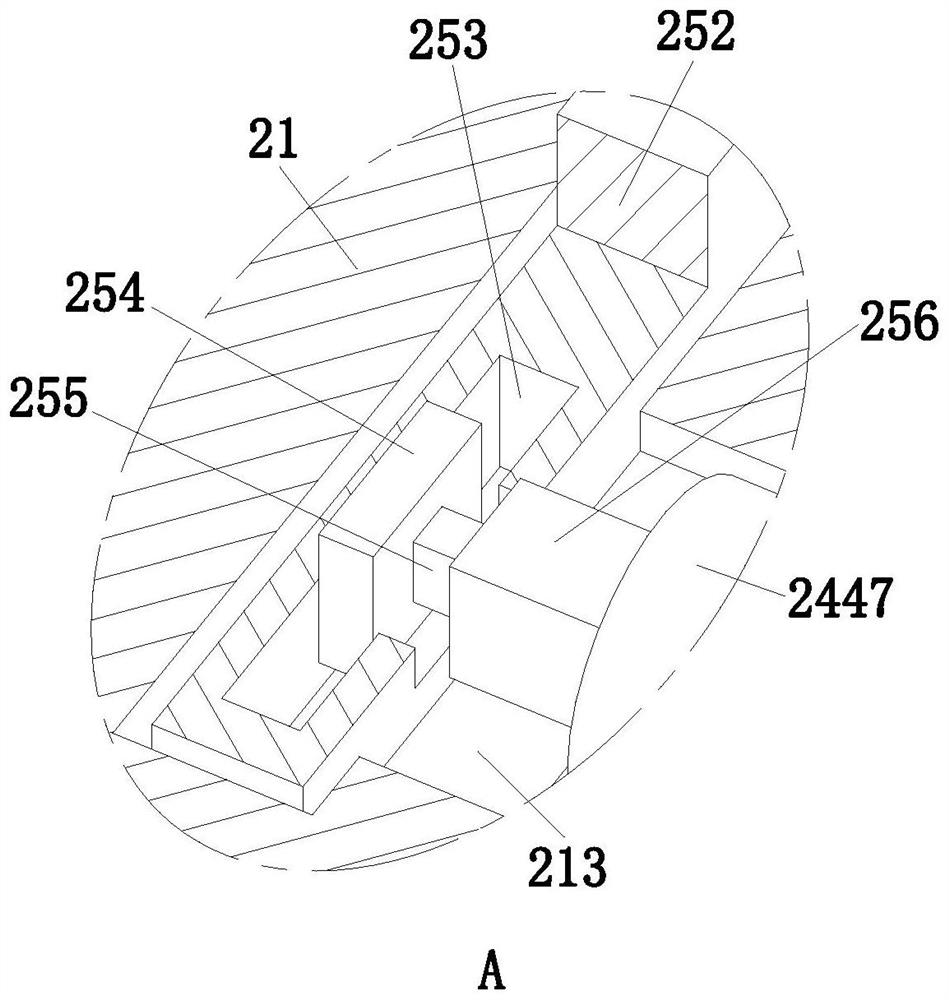

Hollow cement prefabricated slab forming mold

InactiveCN113305989AHigh strengthImprove the quality of useMouldsMould auxillary partsMolding machineStructural engineering

The invention provides a hollow cement prefabricated slab forming mold. The hollow cement prefabricated slab forming mold comprises a base and a forming device, convex sliding grooves are formed in the right end of the base from front to back at equal intervals, and the forming device is arranged at the upper end of the base. According to the hollow cement prefabricated slab forming mold, the problems that firstly, when traditional hollow cement prefabricated slabs are formed and processed, a pouring frame is usually placed on the ground, and then concrete is poured into the pouring frame through workers, so that vibration treatment cannot be carried out on the concrete, the concrete cannot be evenly mixed, bubbles are prone to being left in the concrete, then defects of hollow cement prefabricated slabs are caused, and therefore the later use quality of the hollow cement prefabricated slabs is influenced; and secondly, a few manufacturers adopt prefabricated slab forming machines when the hollow cement precast slabs are manufactured, and the machines cannot adjust the distance between pore channels of the hollow cement prefabricated slabs according to processing requirements, and therefore the applicability is low, and forming and processing can not be carried out on the hollow cement prefabricated slabs with different specifications are solved.

Owner:湖北嘉辉建工科技有限公司

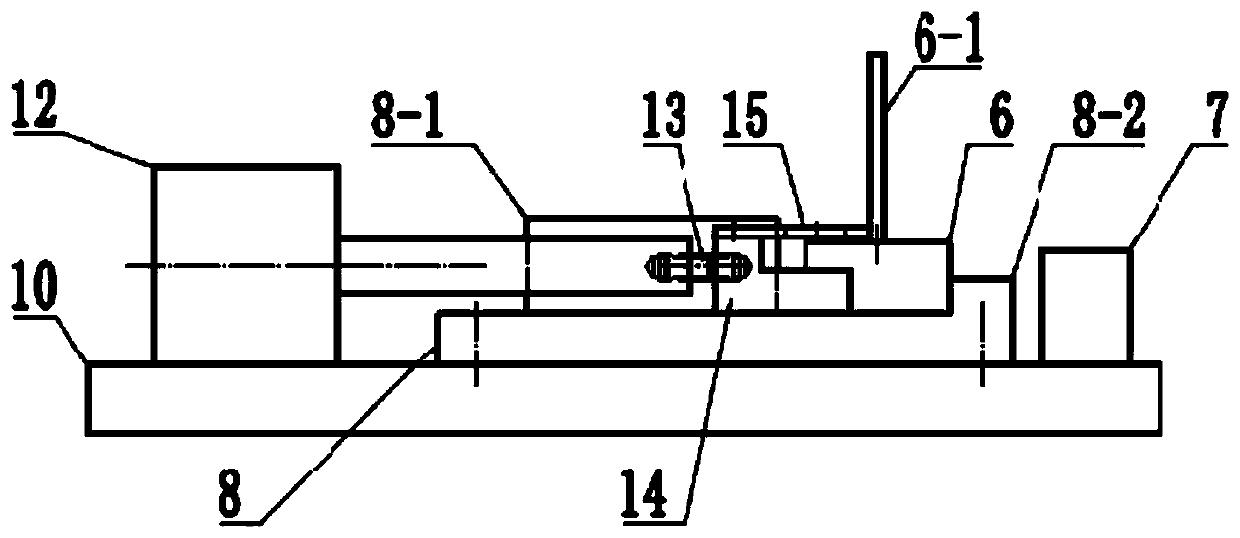

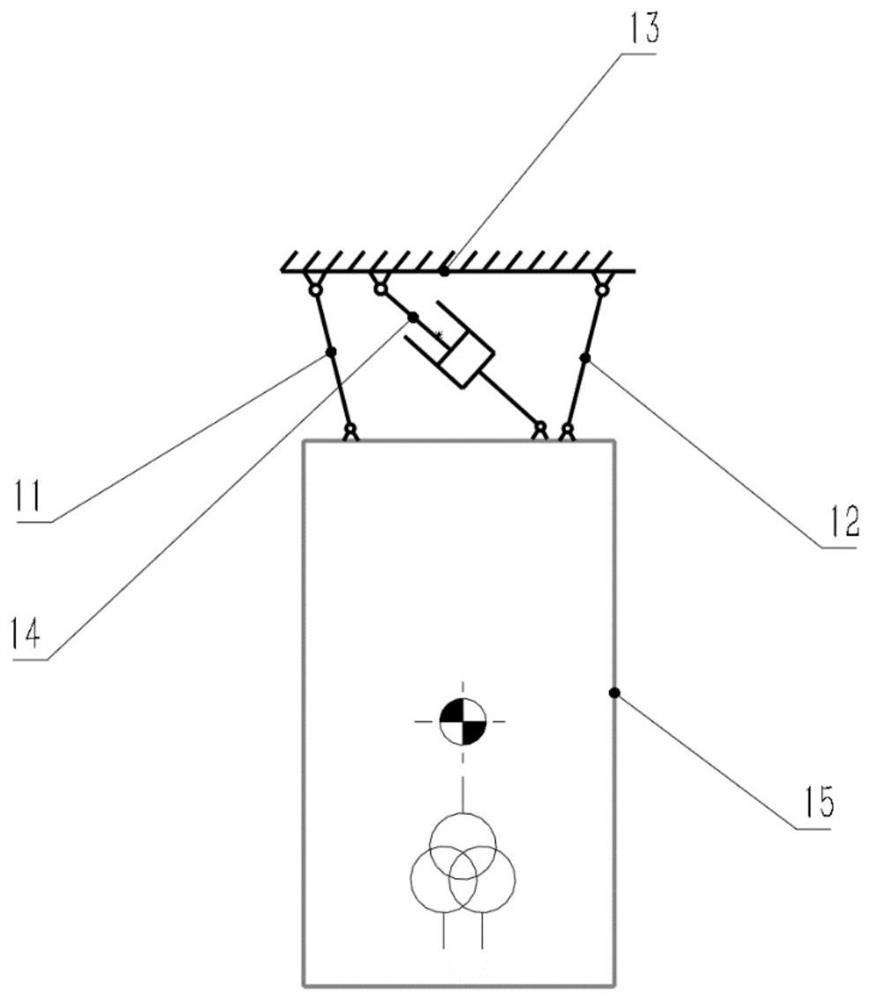

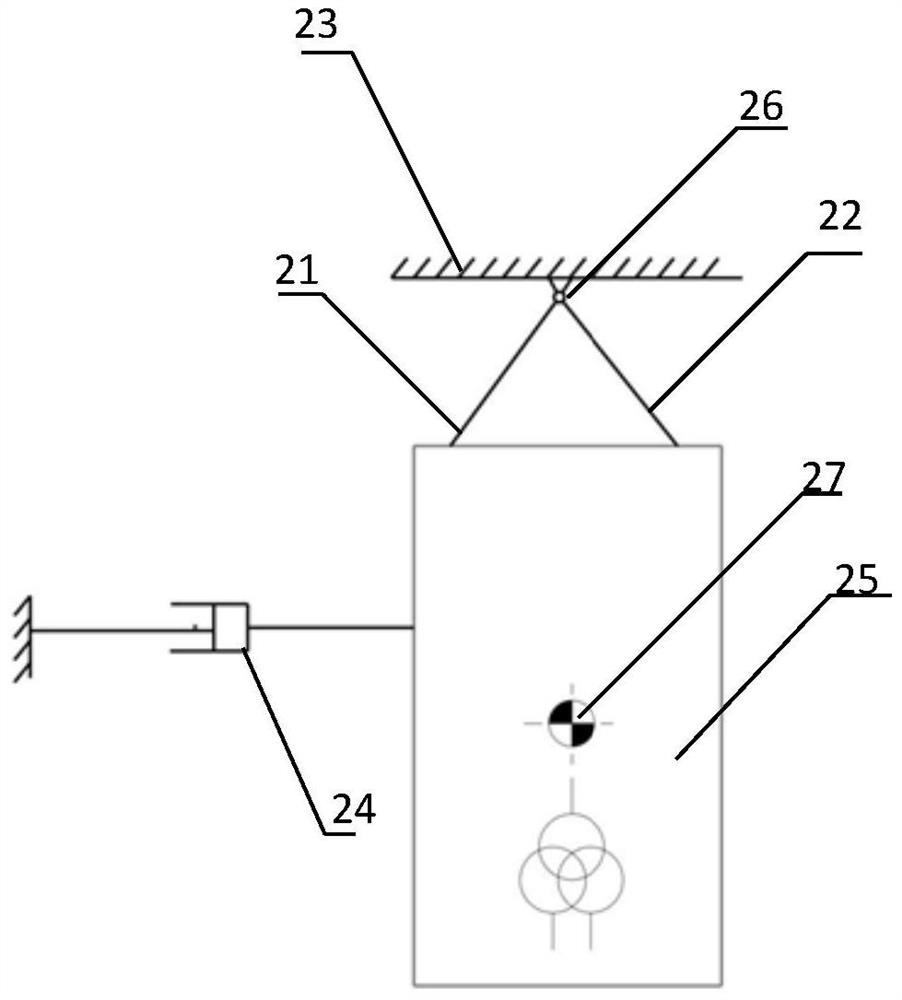

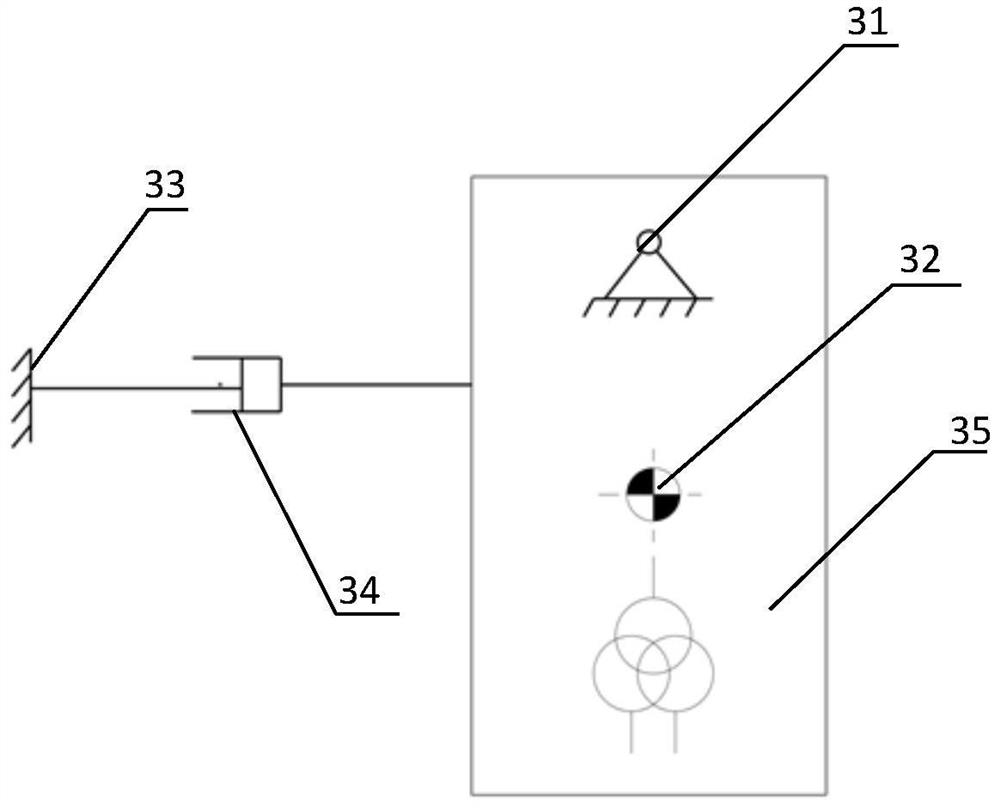

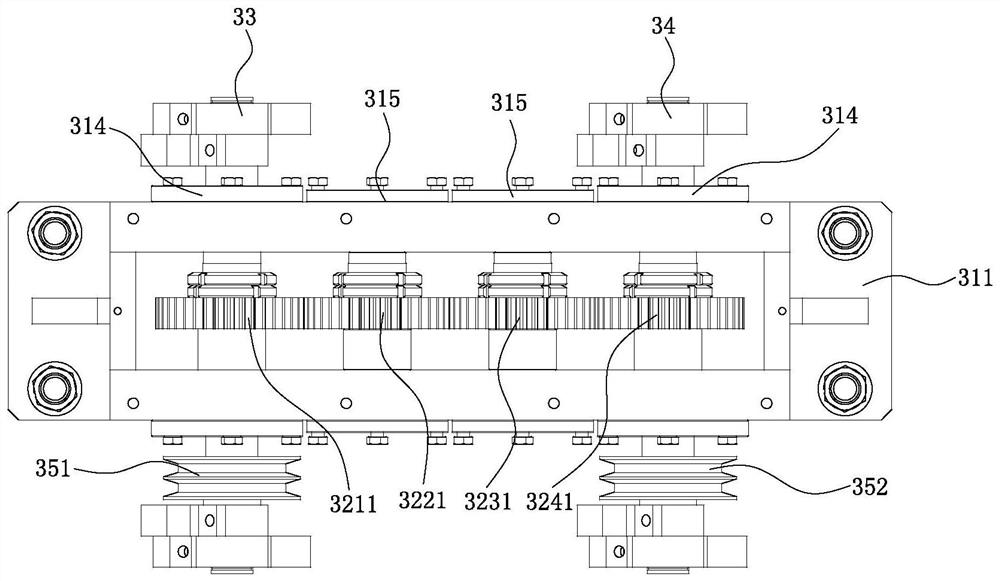

Four-shaft united excitation vibration power device

PendingCN112044721AIncrease contact areaShorten vibration timeMechanical vibrations separationVibration amplitudeDrive shaft

Owner:南阳市百斯特液压机械有限公司

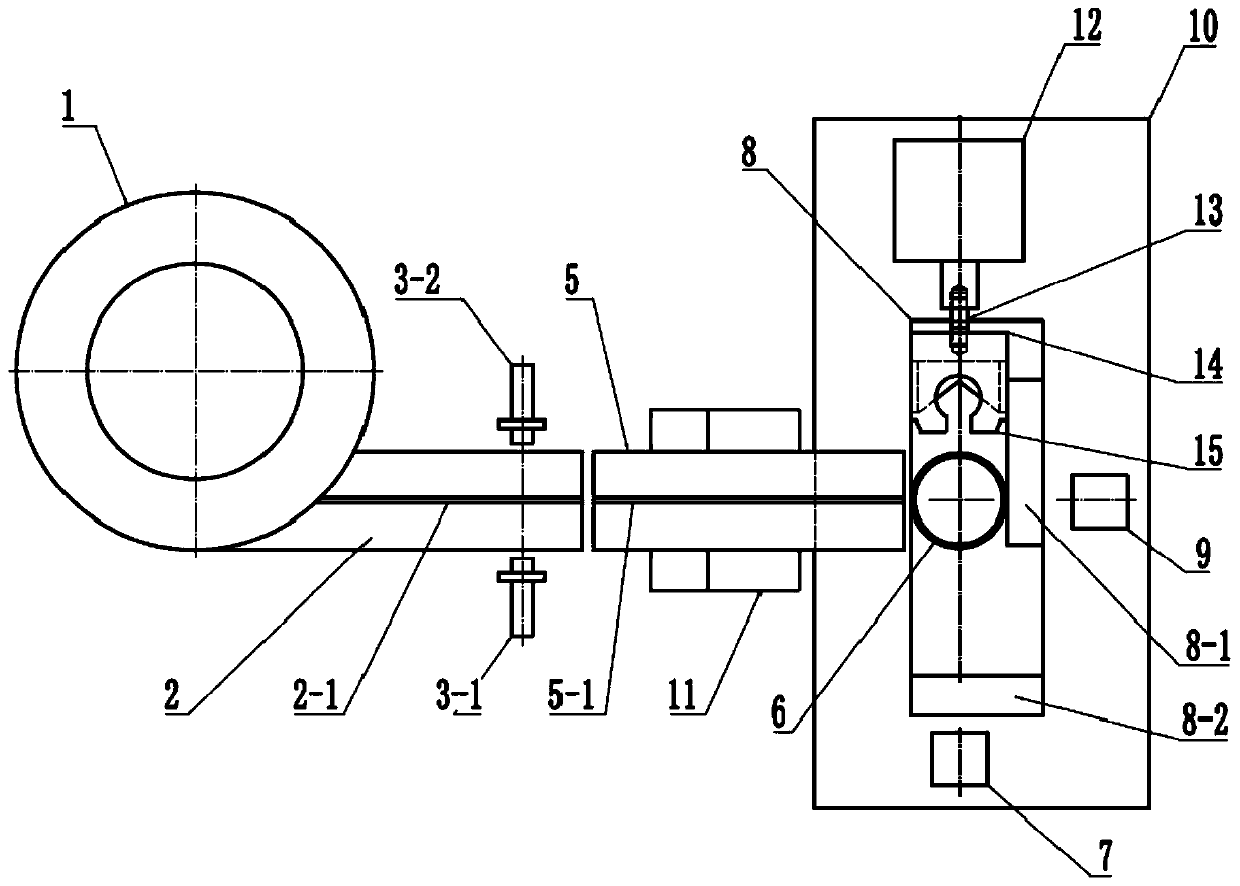

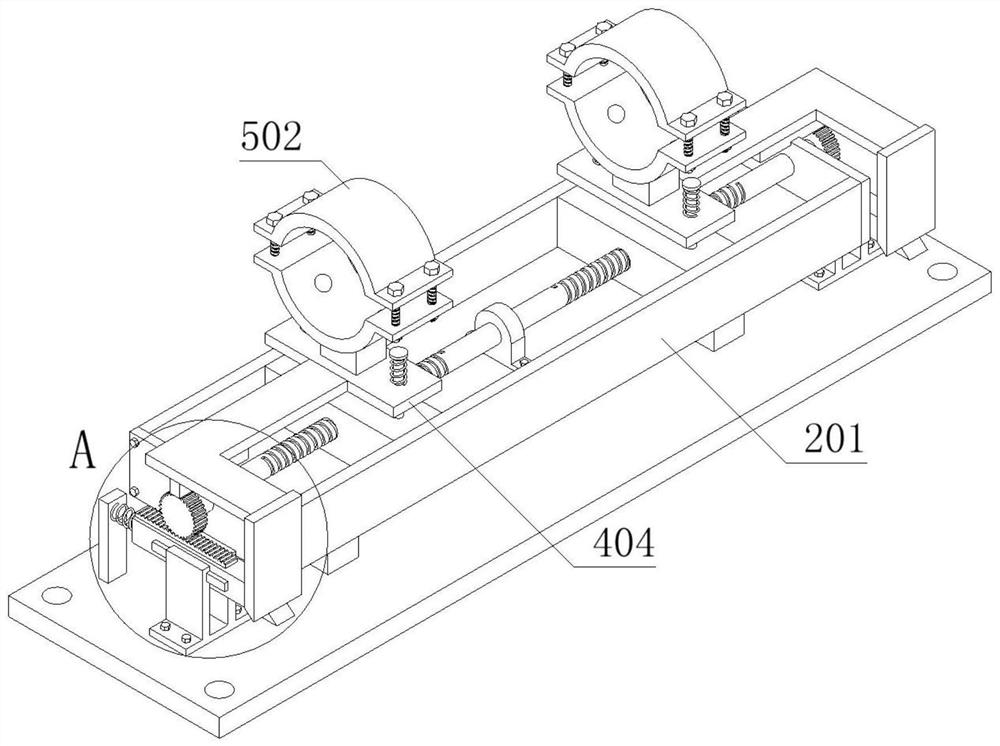

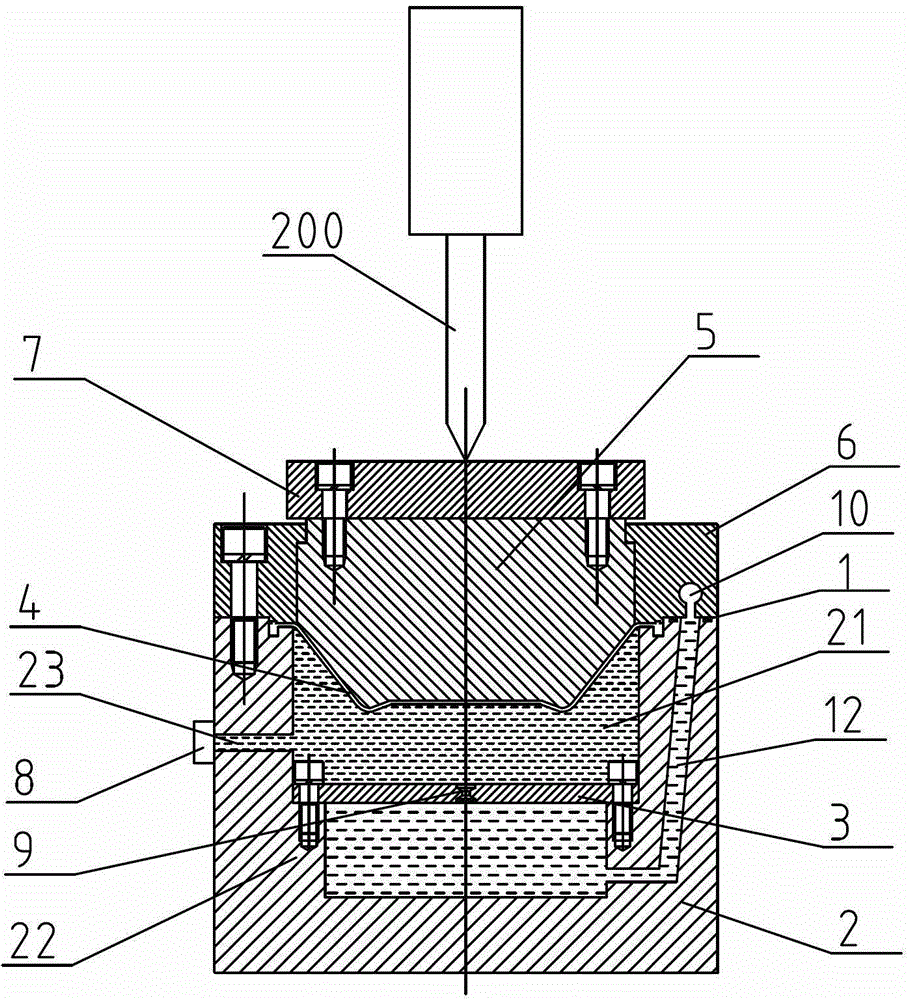

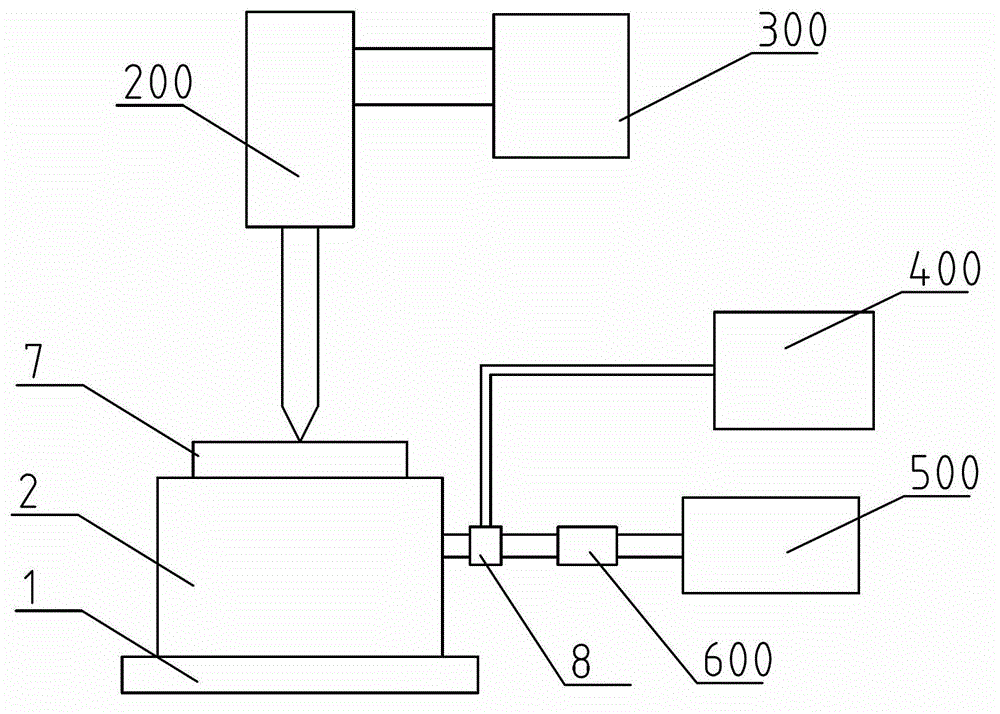

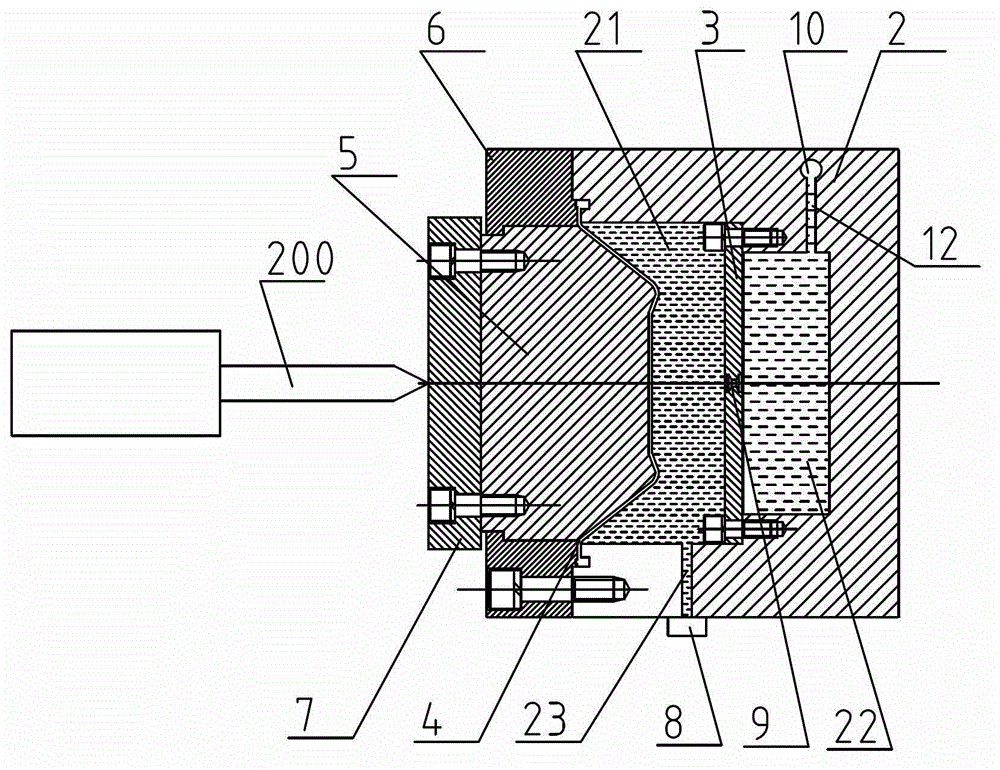

An impact testing device

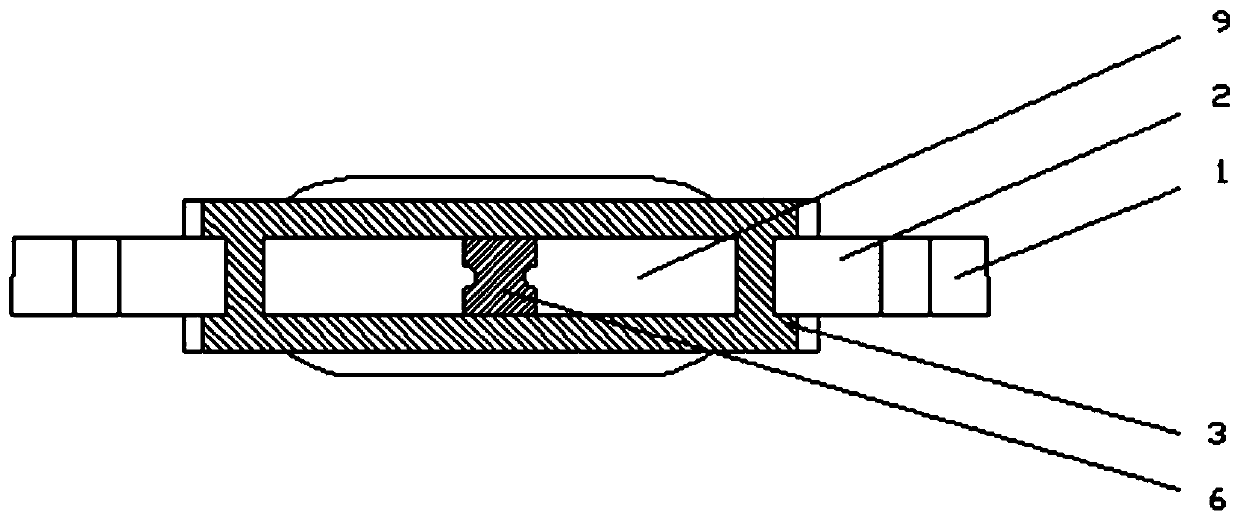

InactiveCN103048075BReduce vibration amplitudeShorten vibration timeApparatus for force/torque/work measurementShock testingElectricityDisplay device

The invention discloses an impact force testing device, which comprises an external power supply and a displaying device, wherein the external power supply is connected with the displaying device; the impact force testing device is characterized by comprising a cylinder body (2), wherein a holding cavity with a bottom and without a top is arranged in the cylinder body (2), and a rubber leather bowl (4) is arranged on the upper end of the holding cavity; a piston (5) is arranged on the rubber leather bowl (4); an upper cover (6) is arranged on the upper end of the cylinder body (2); a damping hole plate (3) is arranged in the holding cavity, and the damping hole plate (3) is used for dividing the holding cavity into a holding cavity I (21) and a holding cavity II (22) from top to bottom; and a sensor (8) is arranged on the side wall of the cylinder body (2), and the sensor (8) is connected with the external power supply and in signal connection with the displaying device.

Owner:ZHEJIANG UNIV +1

A concrete brick forming machine with good synchronization and low noise

ActiveCN112248190BQuality assuranceProtect your healthSolid waste managementNon-rotating vibration suppressionLow noiseBrick

The invention provides a concrete brick forming machine with good synchronization and low noise, comprising a synchronous pressing head mechanism for realizing synchronous pressing of bricks, a concrete brick mould frame arranged under the synchronous pressing head mechanism, and a concrete brick mould frame connected to the concrete brick mould frame. The lower end is used to transmit the vibration force directly to the vibration transmission connector of the concrete brick formwork frame, the vibration mechanism fixed on the vibration transmission connector to provide the vibration source, the concrete brick support plate set at the bottom of the concrete brick formwork frame, The vibration damping and knocking support mechanism arranged under the concrete brick support plate for supporting the concrete brick support plate and the lifting mechanism for driving the concrete brick formwork frame and the vibration transmission connecting piece to move up and down together. The advantages of the invention are: good synchronization, good brick-making effect; good vibration and compaction effect of filler, which can ensure the quality of formed concrete bricks and improve product qualification rate; low working noise of the whole machine is beneficial to protect the health of workers; High-efficiency and high-volume production can be achieved.

Owner:FUJIAN QUNFENG MACHINERY

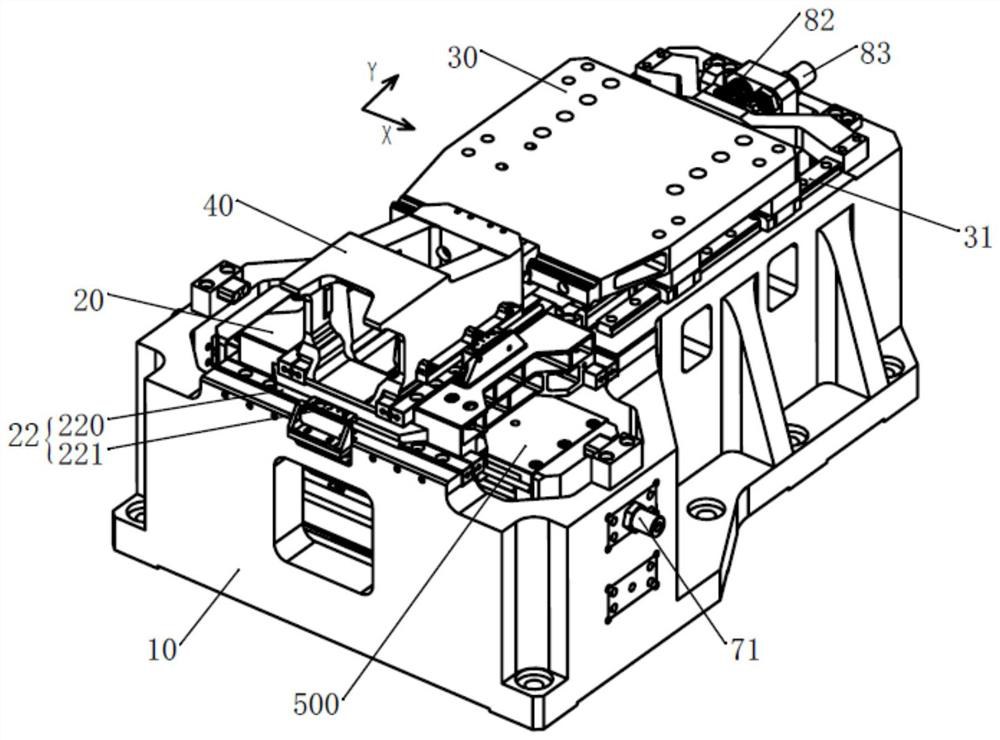

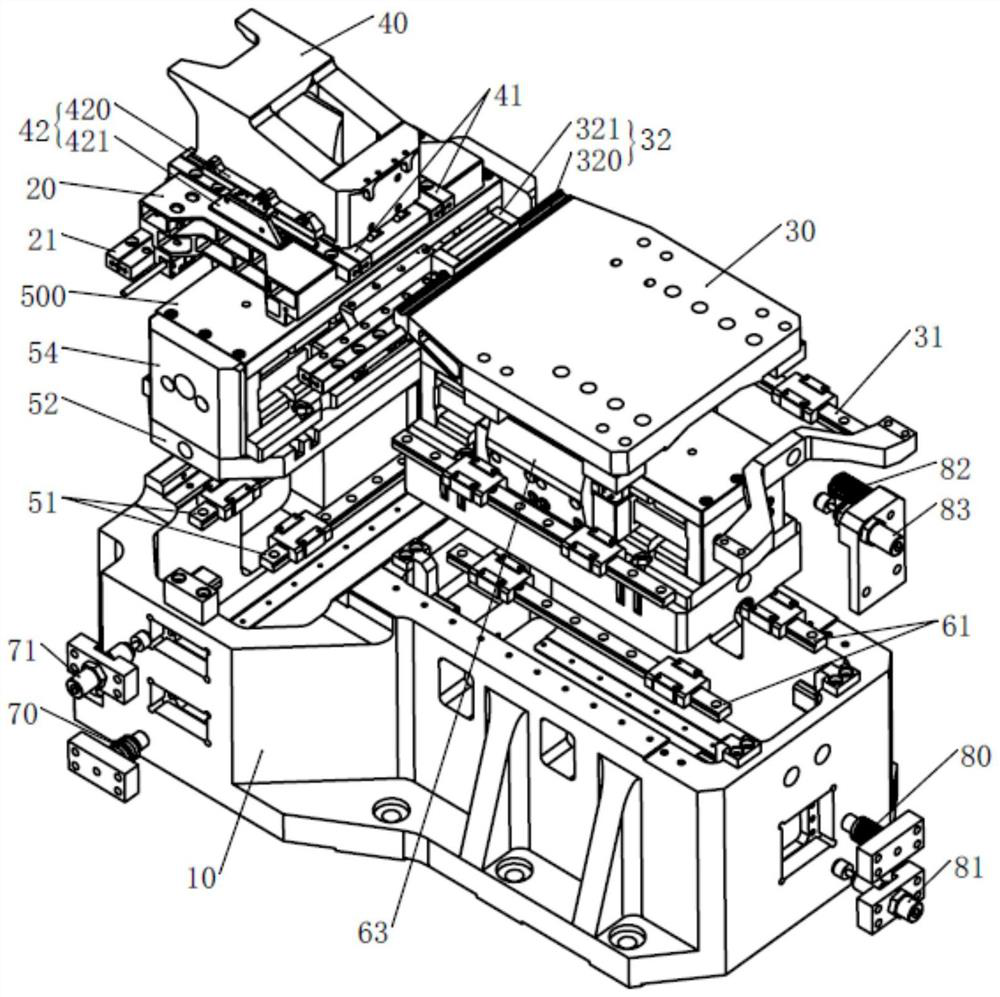

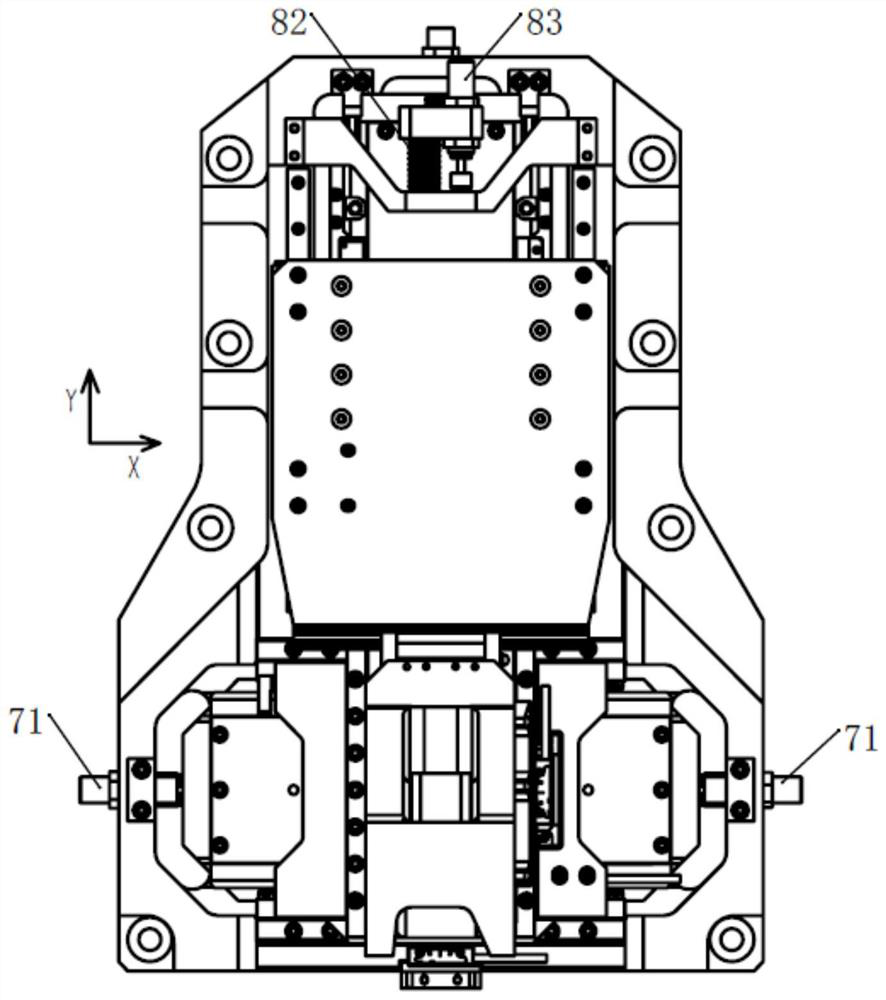

Two-dimensional motion platform

PendingCN114499102AGuaranteed uptimeReduce vibrationNon-rotating vibration suppressionSemiconductor/solid-state device manufacturingLinear motionElectric machine

The invention relates to the technical field of semiconductor packaging and manufacturing, and provides a two-dimensional motion platform which comprises a base, an X-direction motion platform, a Y-direction motion platform, a working motion platform, an X-direction driving linear motor and a Y-direction driving linear motor. The X-direction driving linear motor and the Y-direction driving linear motor can respectively drive the X-direction motion platform and the Y-direction motion platform to do linear motion and finally drive the working motion platform to do two-dimensional linear motion in an XY plane, and a linear motor stator of the two-dimensional linear platform is mounted on a motion platform base through a flexible device; therefore, the impact force of the linear motor stator on the motion platform base is reduced, the vibration of the motion platform is reduced, and the operation stability and positioning precision of the motion platform are improved; the impact of the motor stator on the base of the motion platform can be obviously reduced, the vibration of the motion platform and the base is reduced, the motion platform operates more stably, the stabilization time is obviously shortened when the motion platform stops, the vibration time is shortened, and the positioning precision is improved.

Owner:SHENZHEN DEVOL ADVANCED AUTOMATION CO LTD

Environment-friendly aviation skin damper

PendingCN112664609AReduce the strength of bending vibrationShorten vibration timeNon-rotating vibration suppressionFuselage bulkheadsAviationFatigue damage

The invention discloses an environment-friendly aviation skin damper, and relates to the technical field of aviation. The environment-friendly aviation skin damper comprises a steel plate, and the upper side surface of the steel plate is fixedly connected with a damping reinforcing patch. According to the environment-friendly aviation skin damper, the bending vibration strength of a metal component is weakened through the damping reinforcing patches, and when the metal component is bent and vibrates, vibration energy is rapidly transmitted to the damping reinforcing patches coated on the metal component, so that internal friction and mutual dislocation of the damping reinforcing patches are caused, then most of the vibration energy is changed into heat energy to be consumed, the noise energy radiated by bent vibration is reduced, meanwhile, the damping reinforcing patches can further shorten the excited vibration time of the metal component, equivalently, the total energy of noise radiated by the metal component is reduced, and therefore the problems of fatigue damage of aircraft structures and failure of electronic equipment due to the fact that multi-peak resonance of naval vessels, aircraft structures and electronic equipment thereof is frequently excited due to the fact that broadband vibration sources generated in the using process of existing aircrafts are too large are solved.

Owner:江苏汉龙航空科技发展有限公司

Traditional Chinese medicine mask preparation technology and traditional Chinese medicine mask

InactiveCN112660443AImprove filtering effectAvoid cloggingLiquid materialProcess engineeringMechanical engineering

The invention relates to mask processing, in particular to a traditional Chinese medicine mask preparation technology and a traditional Chinese medicine mask. The traditional Chinese medicine mask preparation technology comprises the following steps that Step 1, traditional Chinese medicine raw materials are ground and screened to obtain powder; Step 2, the powder is mixed with a liquid raw material to obtain paste; Step 3, the paste is added into a mask packaging bag, and the paste is hot-pressed in one area of the mask packaging bag; Step 4, a moisturizing stock solution is added into the mask packaging bag, and the moisturizing stock solution is hot-pressed into the other two areas of the mask packaging bag; compared with a facial mask towel, the paste mask can be used for flexibly wet-compressing the part to be wet-compressed.

Owner:哈尔滨禄远科技有限公司

Electromagnetic wind-induced galloping energy collection device

PendingCN114499097ASmall internal impedanceIncrease output powerReciprocating/oscillating/vibrating magnetic circuit partsElastic vibrationEngineering

The invention discloses an electromagnetic wind-induced galloping energy collection device which comprises a main frame, an elastic vibration beam, a coil, a permanent magnet, a choked flow vibrator and an amplitude limiting assembly. One end of the elastic vibrating beam is fixed on the main frame, and the other end of the elastic vibrating beam is fixedly provided with a choked flow vibrator; wherein the plane where the elastic vibration beam is located is arranged in the vertical direction, and the length direction of the flow choking vibrator is arranged in the vertical direction; the coil is fixed on the main frame, the permanent magnet is fixed at the end part of the choked flow vibrator, and the coil and the permanent magnet are opposite to each other but not in contact with each other; the two amplitude limiting assemblies are installed on the main frame and located on the two sides of the flow blocking vibrator respectively, and the amplitude limiting assemblies are used for limiting the amplitude of the flow blocking vibrator when the flow blocking vibrator does left-right reciprocating periodic motion. According to the invention, the problems of large internal impedance (megohm level), low energy conversion efficiency and small output power of a piezoelectric wind-induced vibration energy harvesting structure can be solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A robot flexible drive rotary joint with adjustable mechanical impedance parameters

ActiveCN104723354BAdjustable mechanical impedance parametersReduce impactJointsMagnetic currentElectric machine

The invention belongs to the field of flexible drive of robots, and particularly relates to a mechanical impedance parameter adjustable flexible-drive rotary joint of a robot. The mechanical impedance parameter adjustable flexible-drive rotary joint comprises a magnetorheological clutch, a motor, a first rod, a second rod, torsion springs and joint shaft end covers; the motor and the magnetorheological clutch are respectively mounted on the second rod, a magnetorheological clutch input shaft and a magnetorheological clutch output shaft are respectively mounted on two sides of the magnetorehological clutch, the magnetorheological clutch input shaft is connected with the output shaft of the motor through a driving mechanism, and the magnetorehological clutch output shaft is connected with the first rod; two ends of the torsion springs are respectively connected on the magnetorheological clutch and the joint shaft end covers. By the arrangement, the rotary joint can be transformed between the active and passive states with damp adjustable, and the damp and the torsion springs feature in a buffering function; under the passive state, the joint can be rotated passively along with rod pieces, impact energy is stored, energy efficiency is improved, and the flexible-drive rotary joint is used for flexible operations, requirements of active and passive adjustment or occasions where impact exists.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A damping material and preparation method thereof, and piezoelectric ceramic ultrasonic probe

ActiveCN105907012BStable curing timeAvoid increased conductivityMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityUltrasonic testing

The invention discloses a damping material, a preparation method thereof and a piezoelectric ceramic ultrasonic probe. The damping material comprises the following components in parts by weight: 60-120 parts of high-molecular polymer, 30-60 parts of inorganic fillers with sheet structure, 5-15 parts of inorganic fillers with ball structure, 0.5-5 parts of silane auxiliaries and 10-30 parts of solvents. The damping material provided by the invention can effectively prevent the long curing time and insufficient conduction caused by the increase of tungsten powder content as well as the interference to the ultrasonic signal caused by the middle layer formed by bonding the damping block with the piezoelectric ceramic wafer of the present damping material; the curing time is stable, the material is non-conducting and the damping coefficient is higher; a filling method is applied to the piezoelectric ceramic ultrasonic probe, so that the vibration damping of the piezoelectric ceramic wafer is greatly increased; the vibration time of the piezoelectric ceramic wafer is shortened; the absorption of the piezoelectric ceramic wafer for the echo signal is benefited; the definition of ultrasonic testing for multilayer gluing structure defect is increased.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com