Damping system for forward gantry of electric forward forklift

A vehicle door and vibration elimination technology, which is applied in the direction of vibration suppression adjustment, lifting device, spring/shock absorber, etc., can solve the problems of amplitude attenuation, poor stacking safety, long storage time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

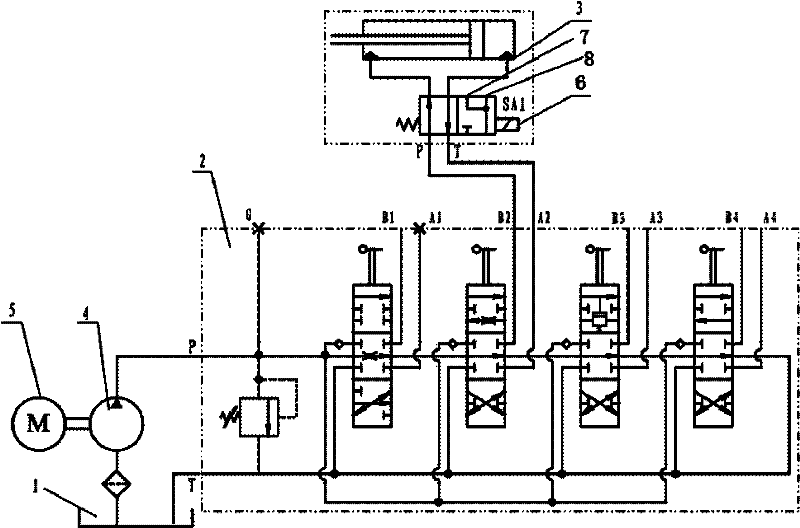

[0013] Referring to the accompanying drawings, a system for moving the mast forward of an electric forklift truck includes a fuel tank 1 connected with an oil inlet pipe and an oil return pipe connected to a multi-way control valve 2 respectively. A forward oil cylinder 3 is connected to the control valve, a gear pump 4 is provided in the oil inlet pipe, and an electric motor 5 is connected to the external transmission of the gear pump 4. The connecting pipe between the multi-way control valve and the forward oil cylinder is equipped with a two-position four-way solenoid valve. Valve 6, a travel switch is provided on the outside of the piston rod of the forward cylinder, and the travel switch is connected to the two-position four-way solenoid valve 6 for control. When the two-position four-way solenoid valve 6 is energized, the two ports 7, 8 are connected, and a delay circuit is provided in the control connection circuit between the travel switch and the two-position four-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com