A concrete brick forming machine with good synchronization and low noise

A concrete brick, low-noise technology, applied in ceramic forming machines, forming indenters, mechanical equipment, etc., can solve problems such as unfavorable health of workers, improve product qualification rate, poor equipment synchronization, etc., so as to avoid harm to physical health. , Improve the product qualification rate, the effect of low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

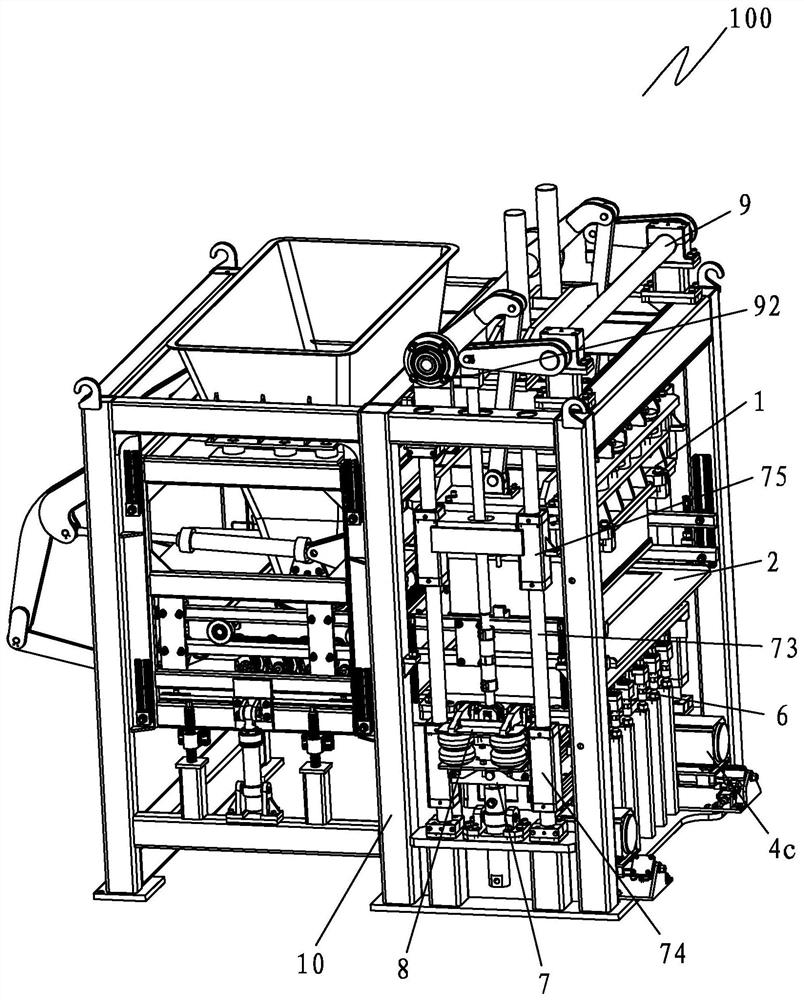

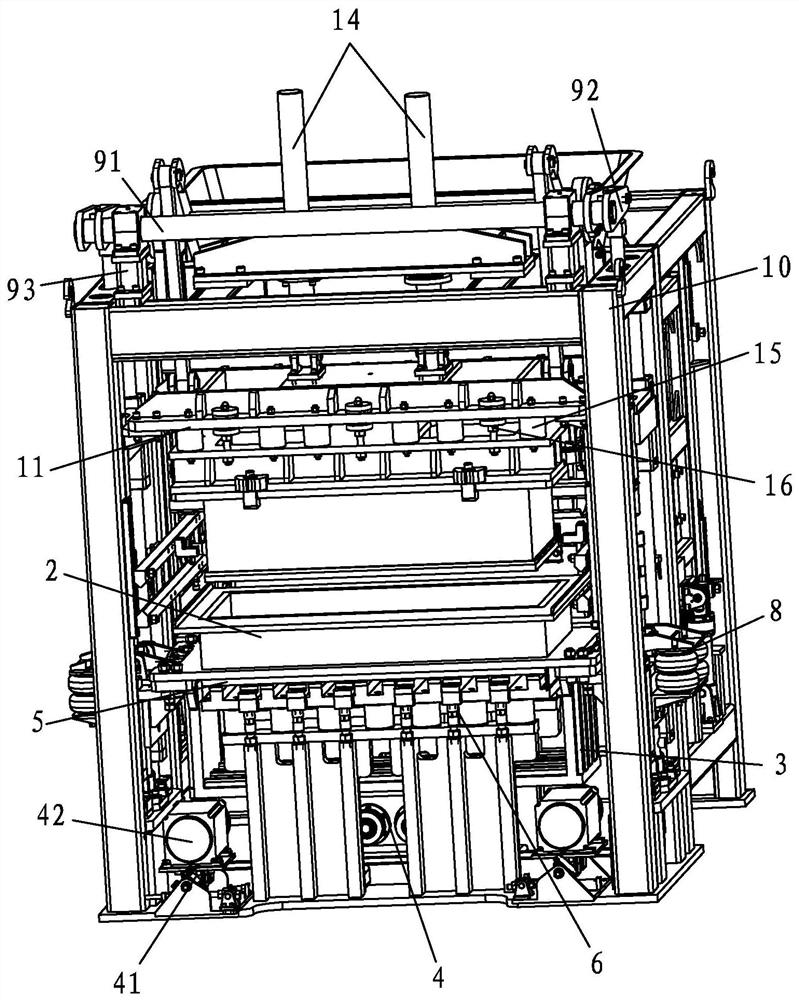

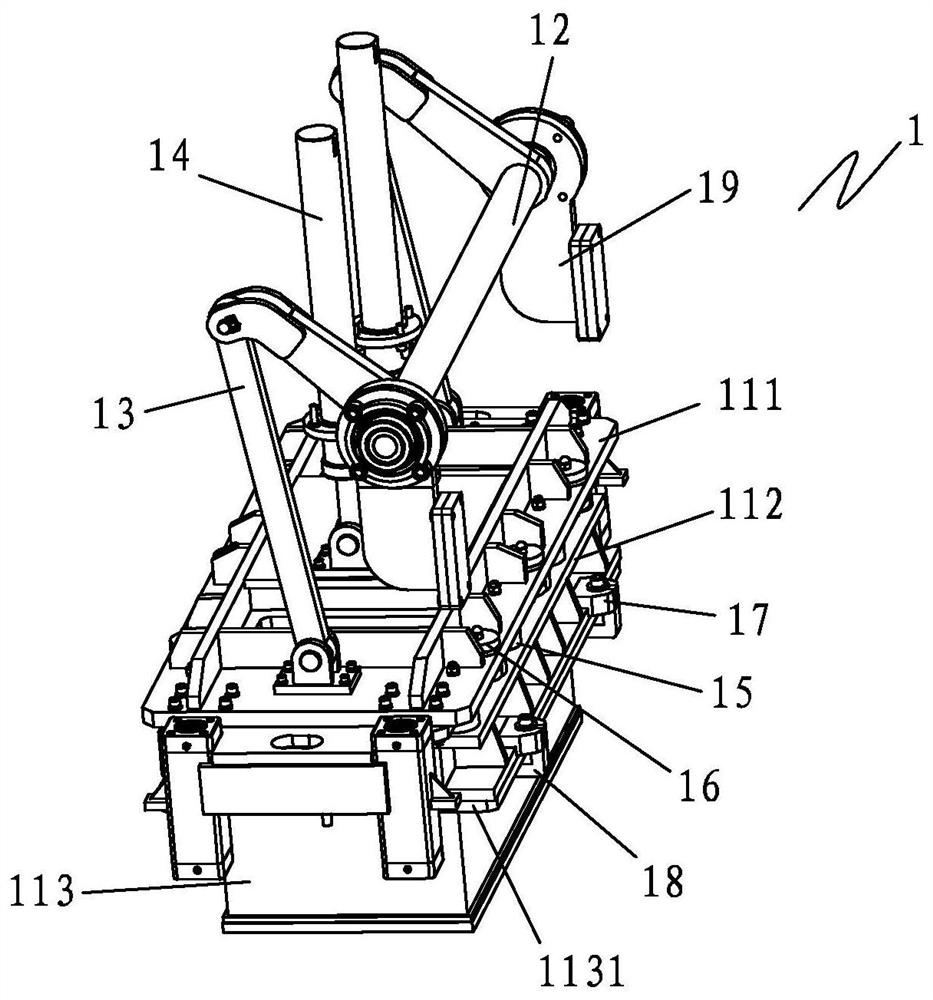

[0059] see Figure 1 to Figure 23 As shown, a preferred embodiment of a concrete brick forming machine 100 with good synchronization and low noise of the present invention includes a synchronous pressing head mechanism 1 for realizing synchronous pressing of bricks, and a concrete brick arranged under the synchronous pressing head mechanism 1. Mold frame 2, a vibration transmission connector 3 connected to the lower end of the concrete brick mold frame 2 for directly transmitting the vibration force to the concrete brick mold frame 2, and a vibration mechanism fixed on the vibration transmission connector 3 for providing a vibration source 4. The concrete brick support plate 5 arranged at the bottom of the concrete brick formwork frame 2, the vibration damping and knocking support mechanism 6 arranged under the concrete brick support plate 5 for supporting the concrete brick support plate 5, and connected to the vibration transmission connector 3 The lifting mechanism 7 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com