Hollow cement prefabricated slab forming mold

A technology of cement prefabricated panels and forming molds, which is applied in the direction of molds and mold auxiliary parts. It can solve the problems of inability to form hollow cement prefabricated panels, affect the quality of hollow cement precast panels, and fail to mix uniform concrete, etc., to achieve enhanced strength, Prevent bleeding and improve the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

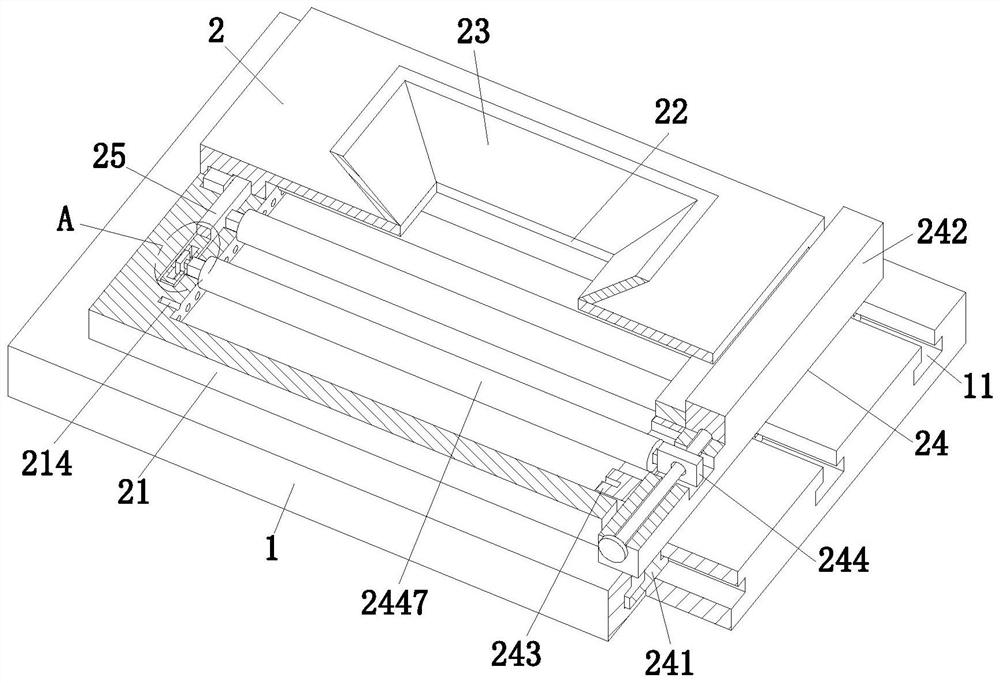

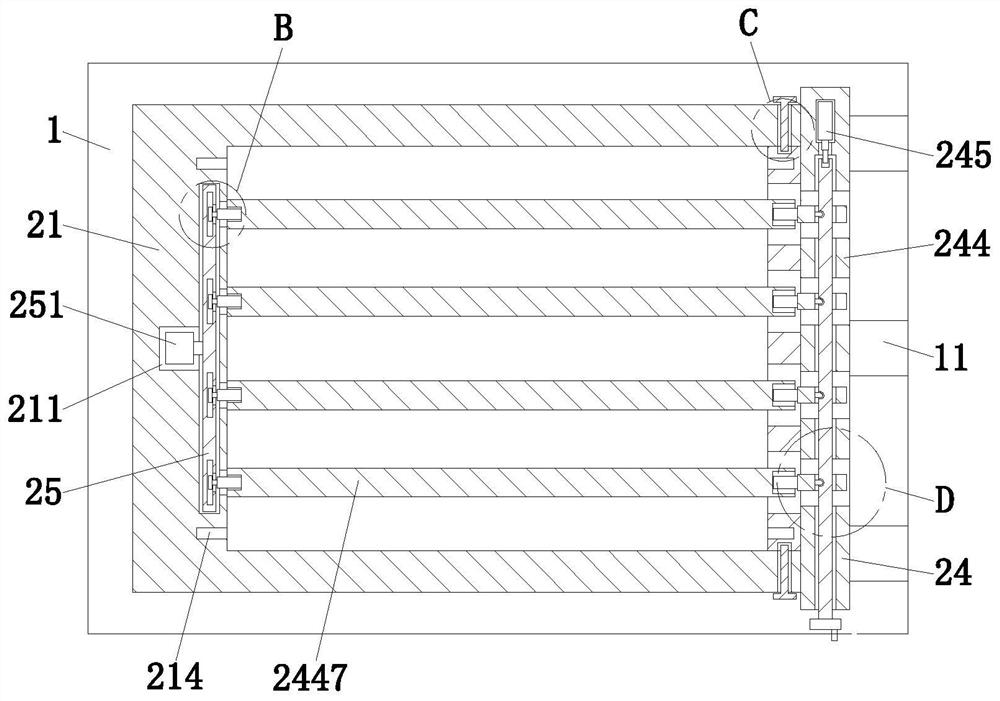

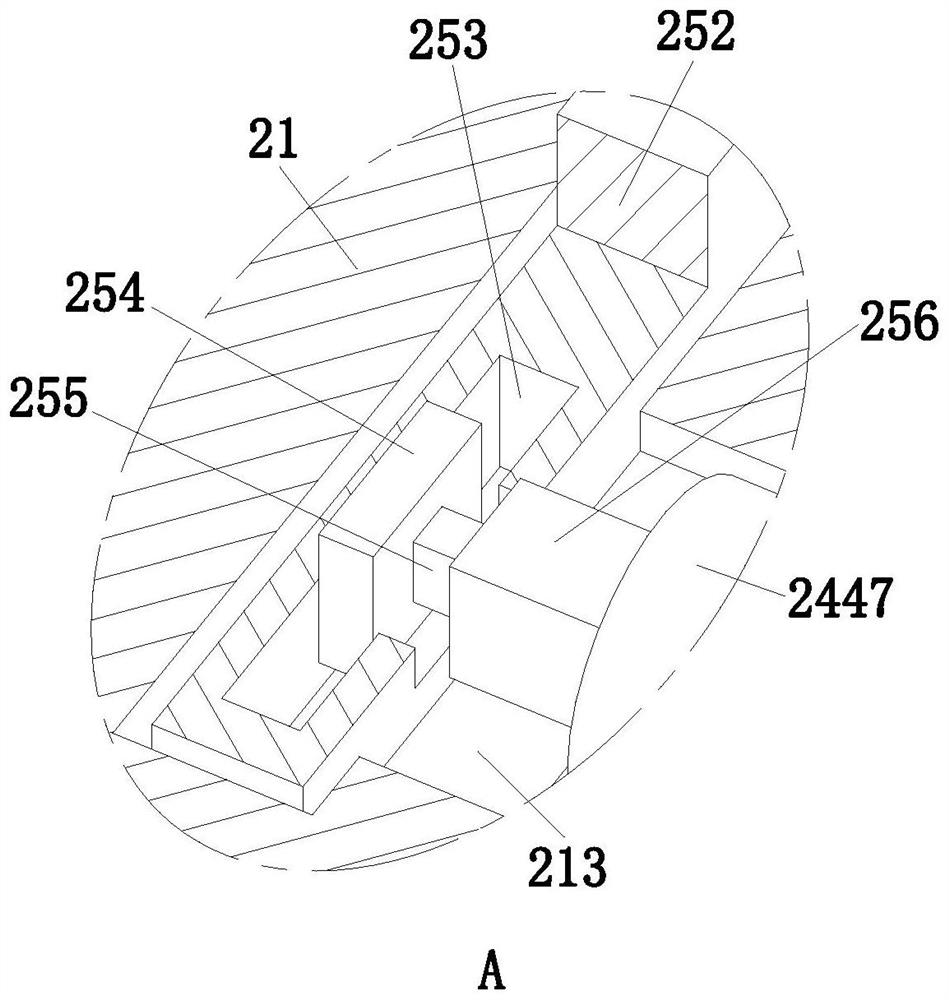

[0037] Such as Figure 1 to Figure 11 The hollow cement prefabricated panel forming mold shown includes a base 1 and a forming device 2. The right end of the base 1 is provided with convex chute 11 at equal intervals from front to back, and the upper end of the base 1 is provided with a forming device 2. in:

[0038] The forming device 2 includes a forming cylinder 21, a feed port 22, a hopper 23, a closing mechanism 24 and a vibrating mechanism 25, wherein: the forming cylinder 21 is fixedly installed on the upper end of the base 1 with the opening facing to the right, and the forming cylinder 21 can be spliced up and down. Disassemble the structure, the center of the upper end of the forming cylinder 21 is provided with a feed inlet 22, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com