Patents

Literature

164results about How to "Improve spreading efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

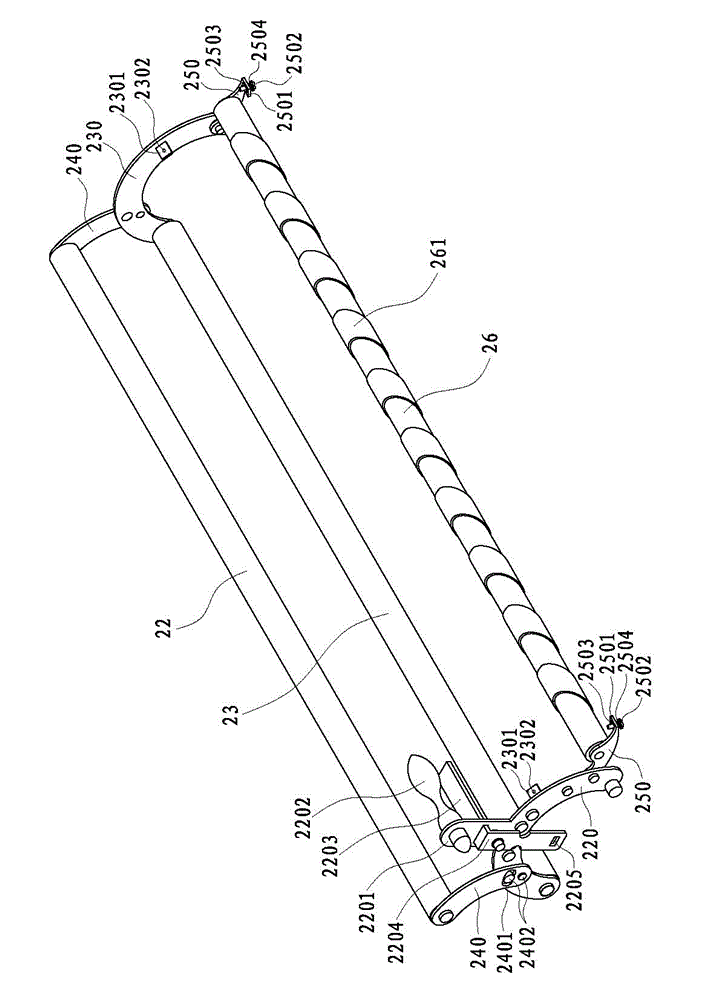

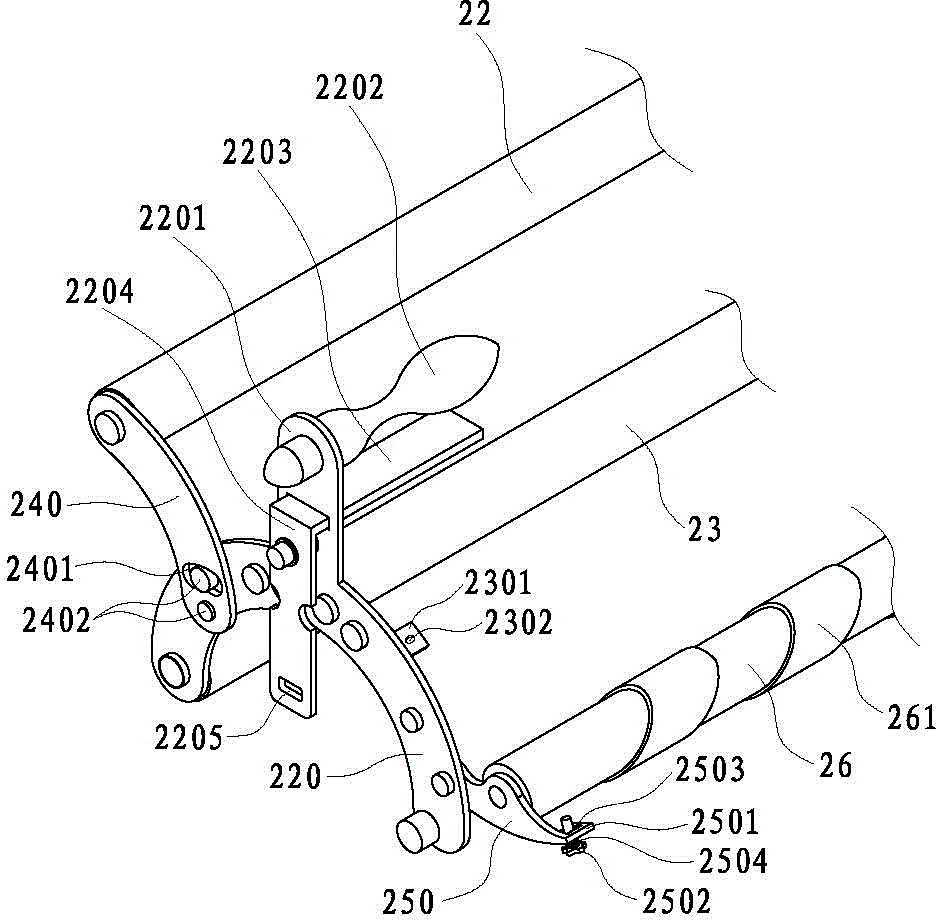

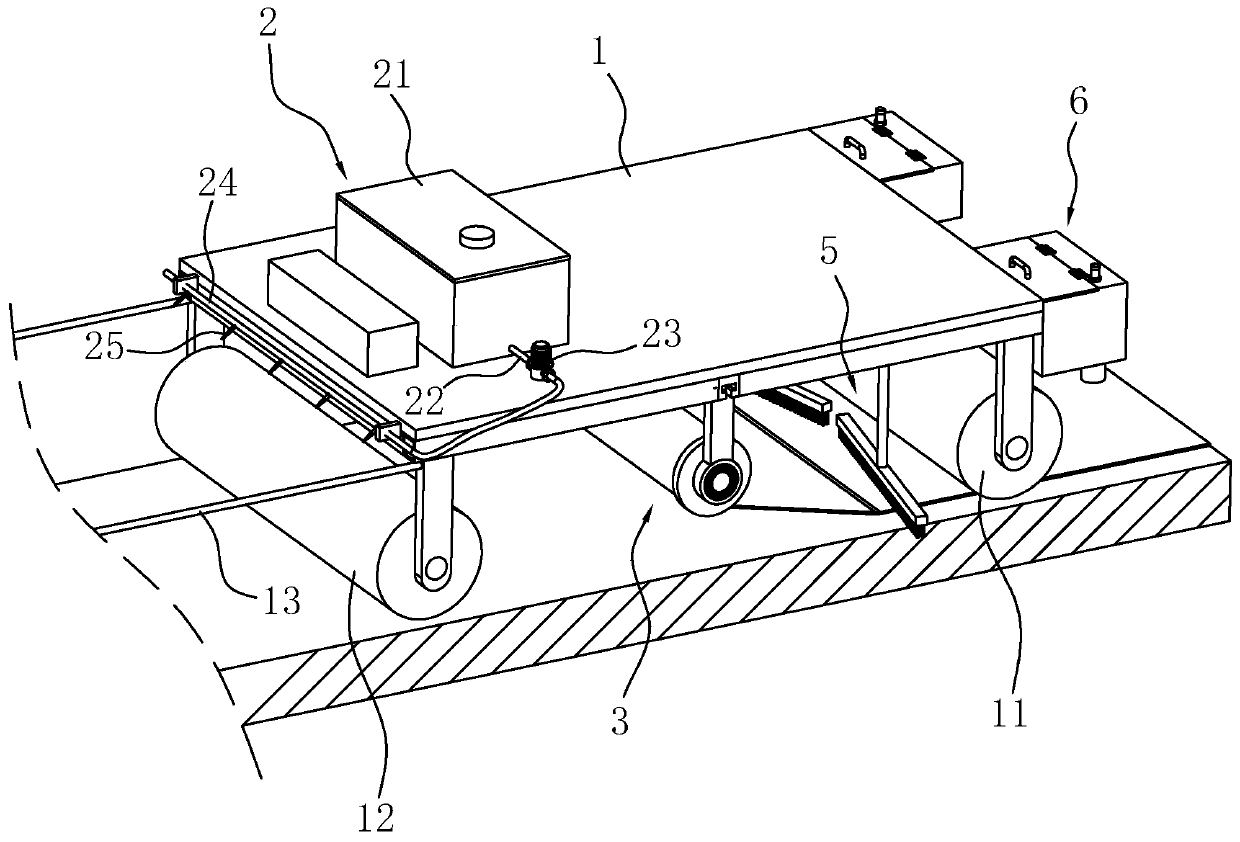

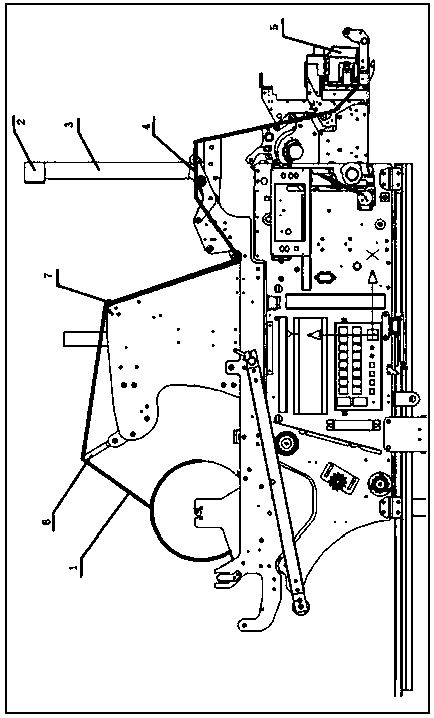

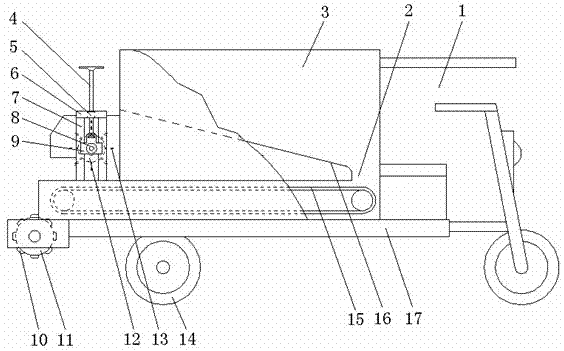

Cloth laying machine

ActiveCN104444559ACreases are effectively flattenedFlat cutUnfolding thin materialsMotor driveDrive wheel

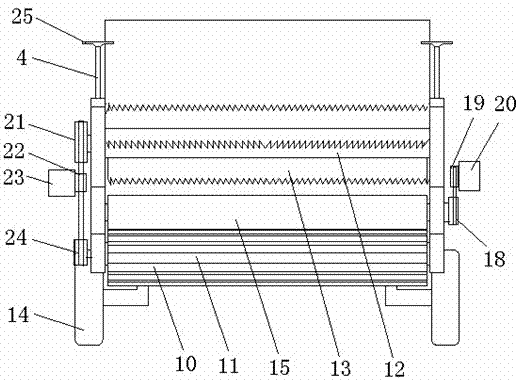

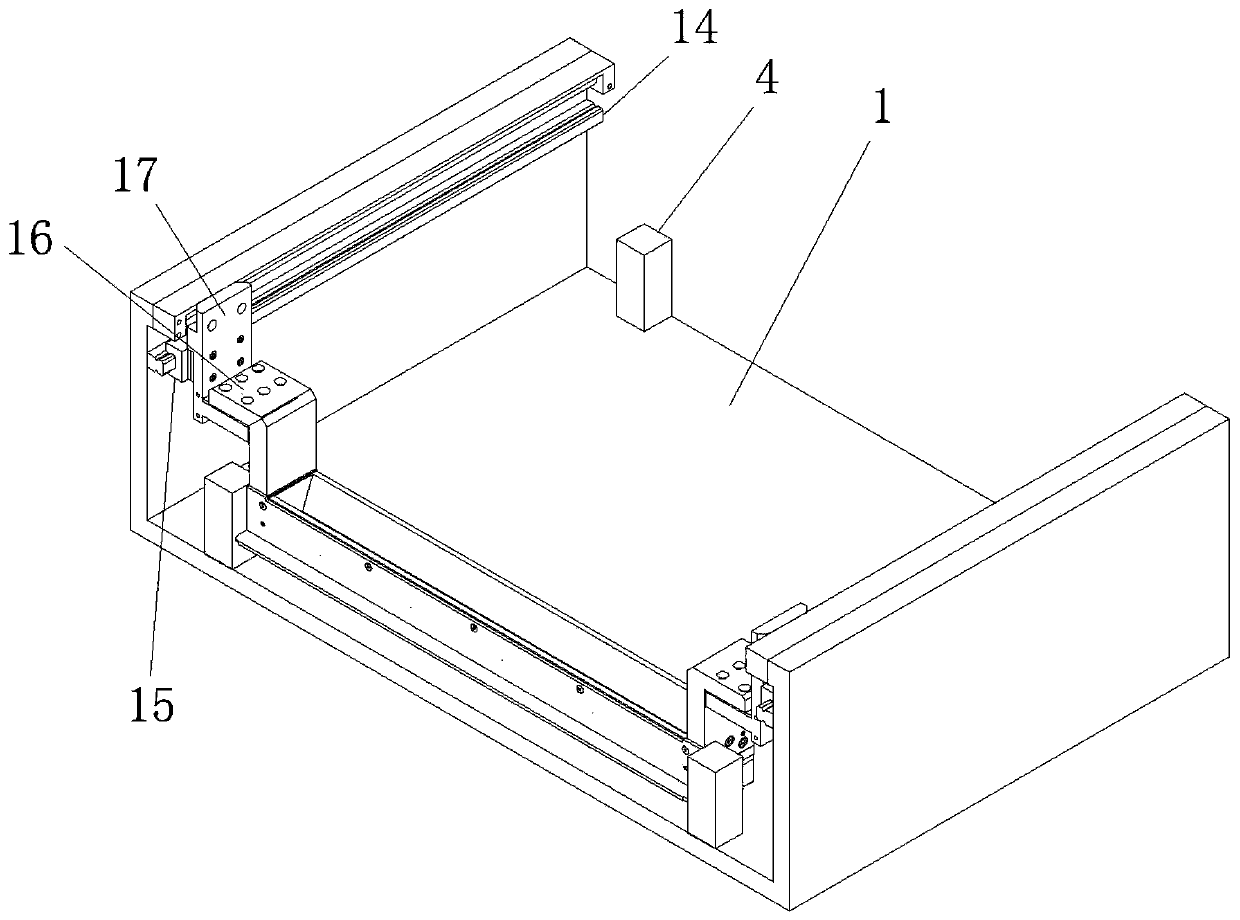

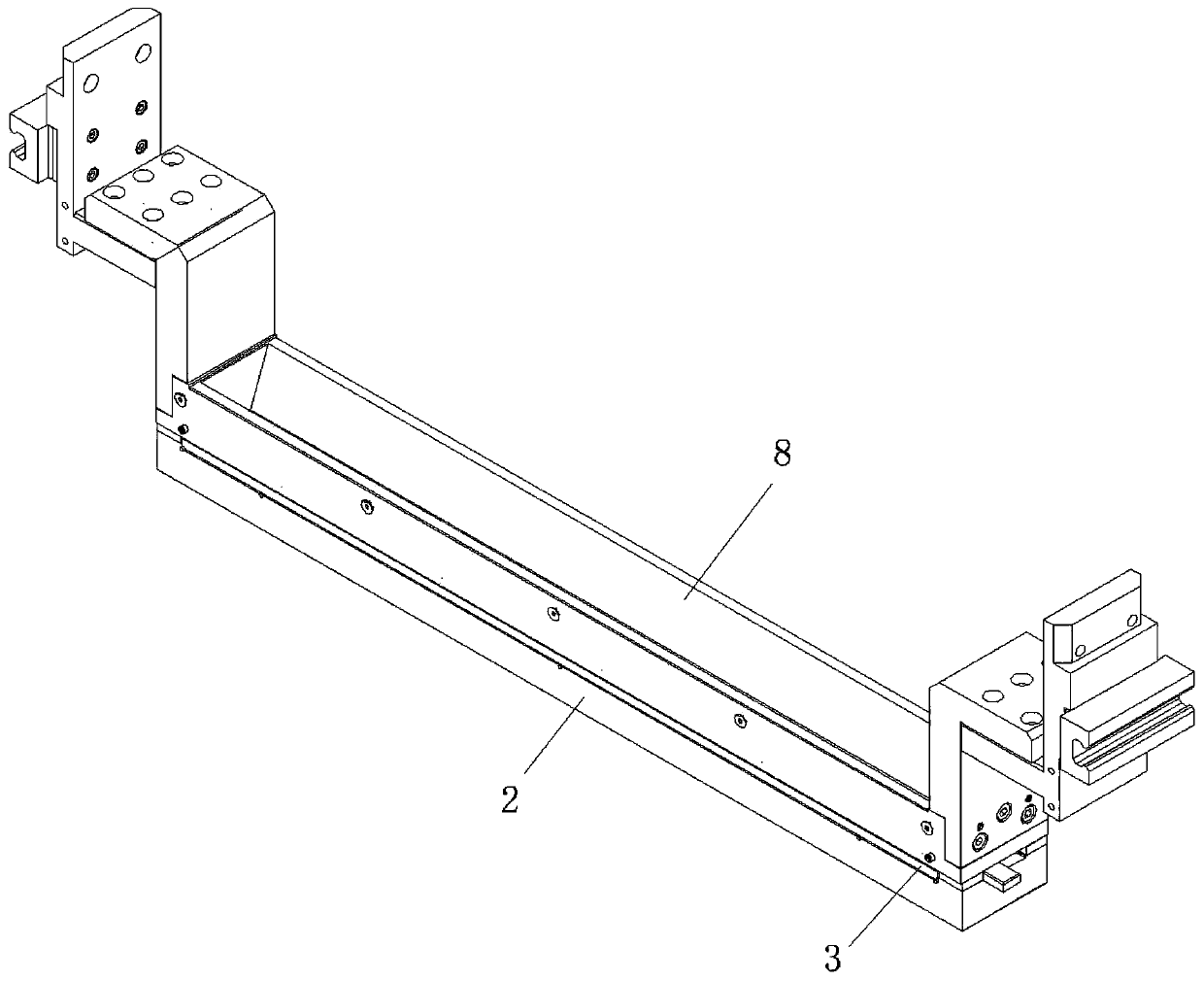

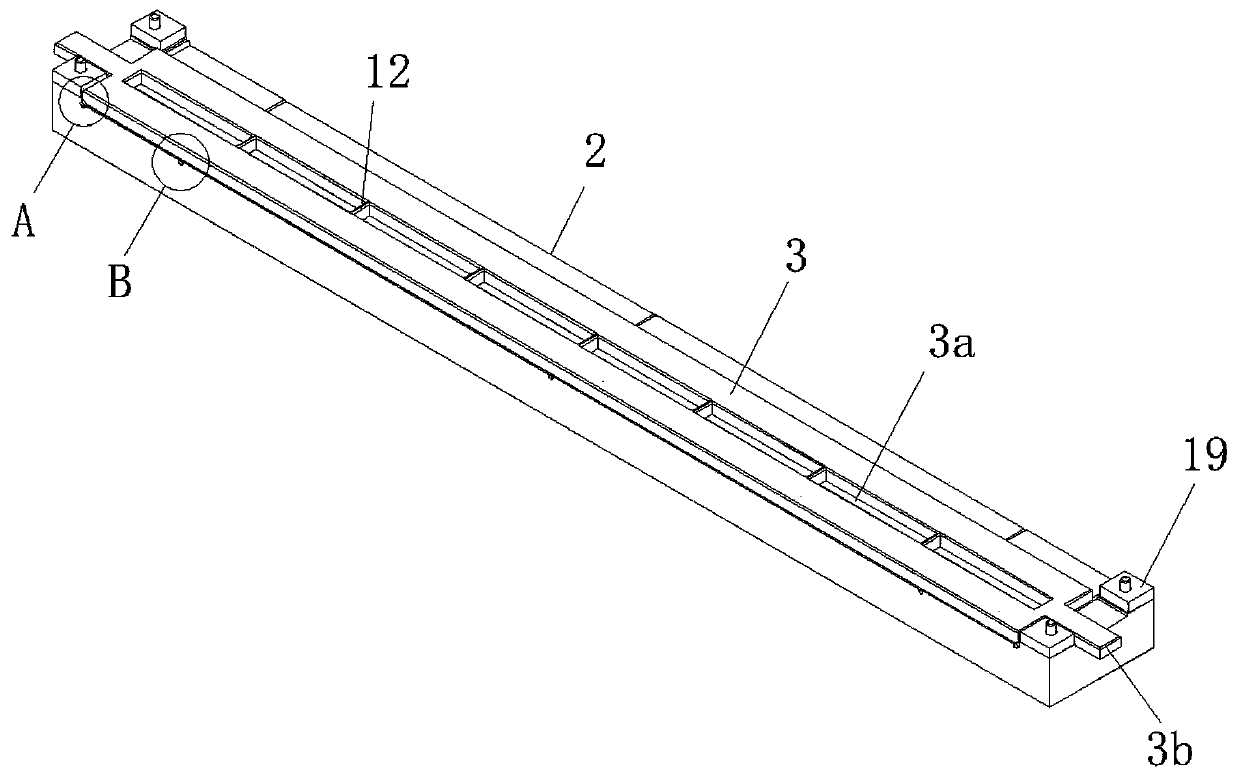

The invention discloses a cloth laying machine. The cloth laying machine comprises a machine frame, a cloth feeding device, a cloth spreading device and a cloth placing device, wherein the cloth feeding device, the cloth spreading device and the cloth placing device are arranged on the machine frame. The cloth spreading cloth comprises a movable cloth pressing roll, a cloth unwinding roll and two cloth spreading transmission mechanisms opposite in operating direction, wherein the movable cloth pressing roll and the cloth unwinding roll are arranged on the machine frame in parallel. The movable cloth pressing roll is located in the cloth path from the feeding device to the cloth unwinding roll. The cloth spreading transmission mechanisms are arranged on a platform of the machine frame and located in the cloth path from the movable cloth pressing roll to the cloth unwinding roll, and each comprise a driving wheel, a driven wheel, a second belt and a transmission motor driving the driving wheel to rotate. Through the structure, the cloth laying machine is high in cloth laying efficiency and good in cloth laying effect.

Owner:石狮市卓诚机械自动化设备有限责任公司

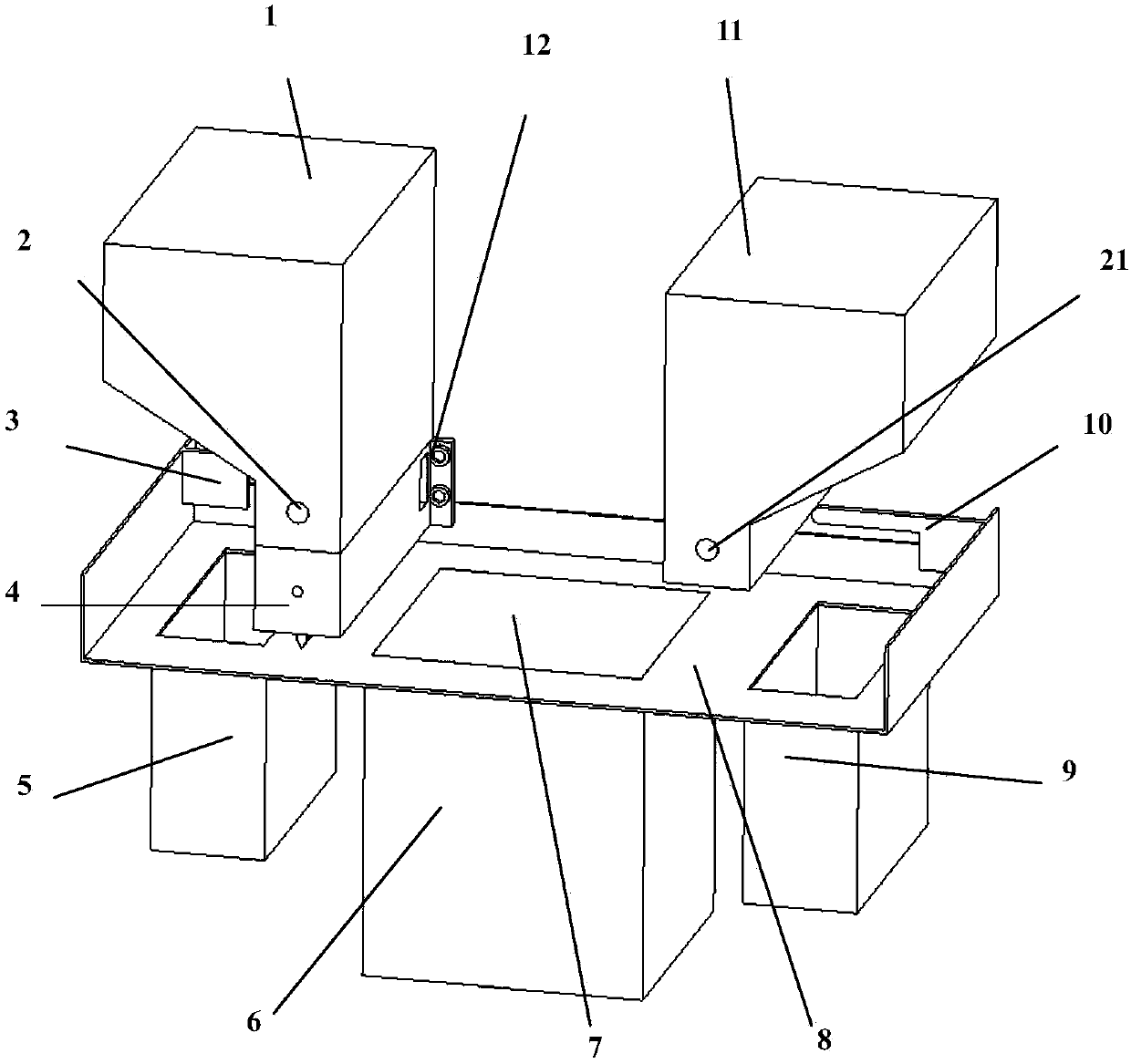

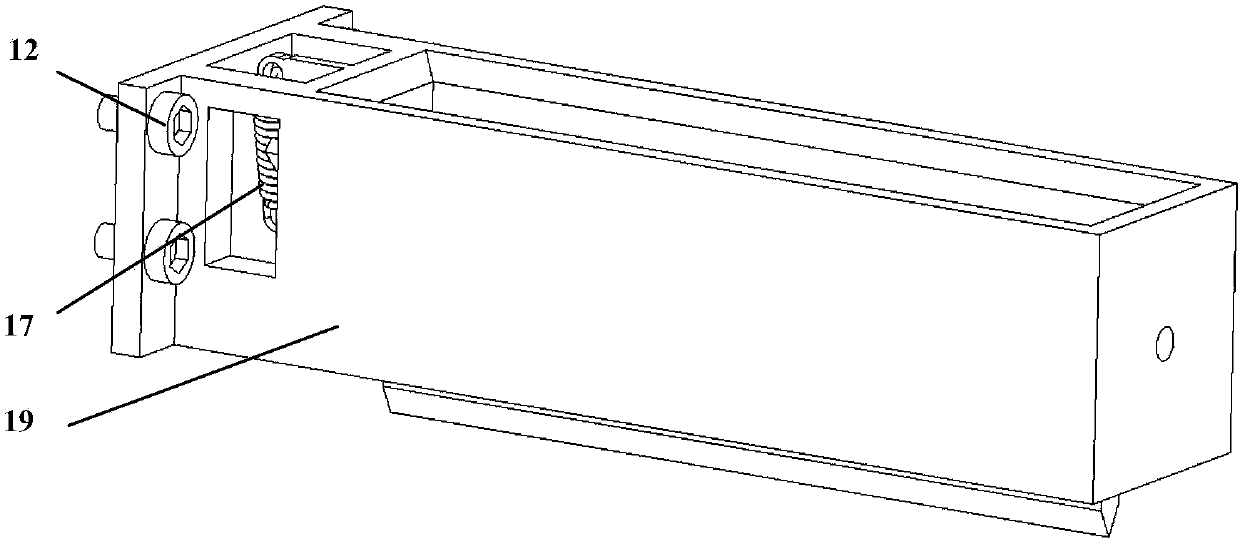

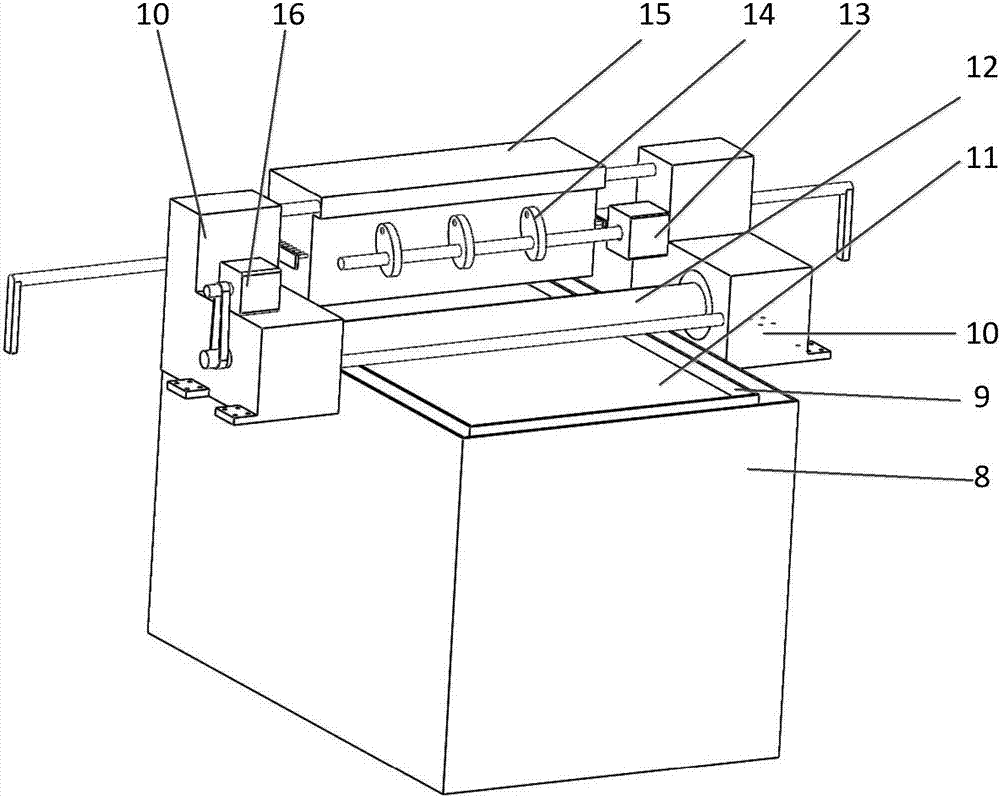

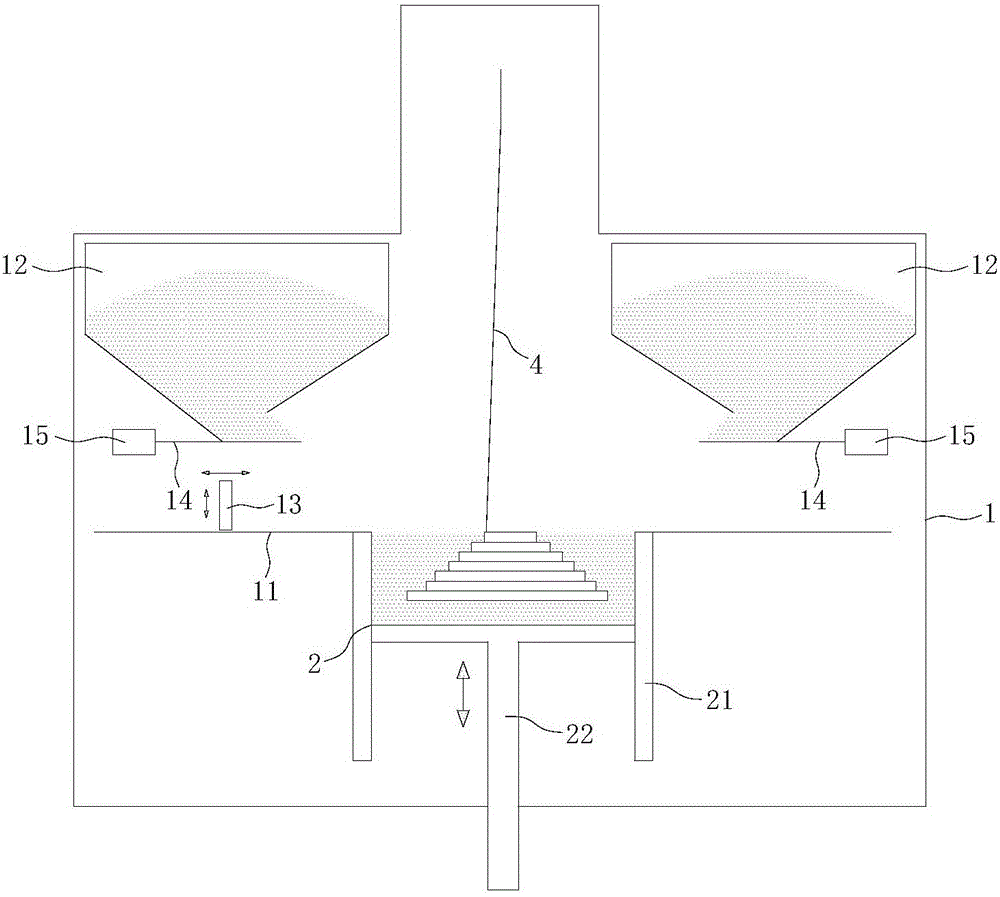

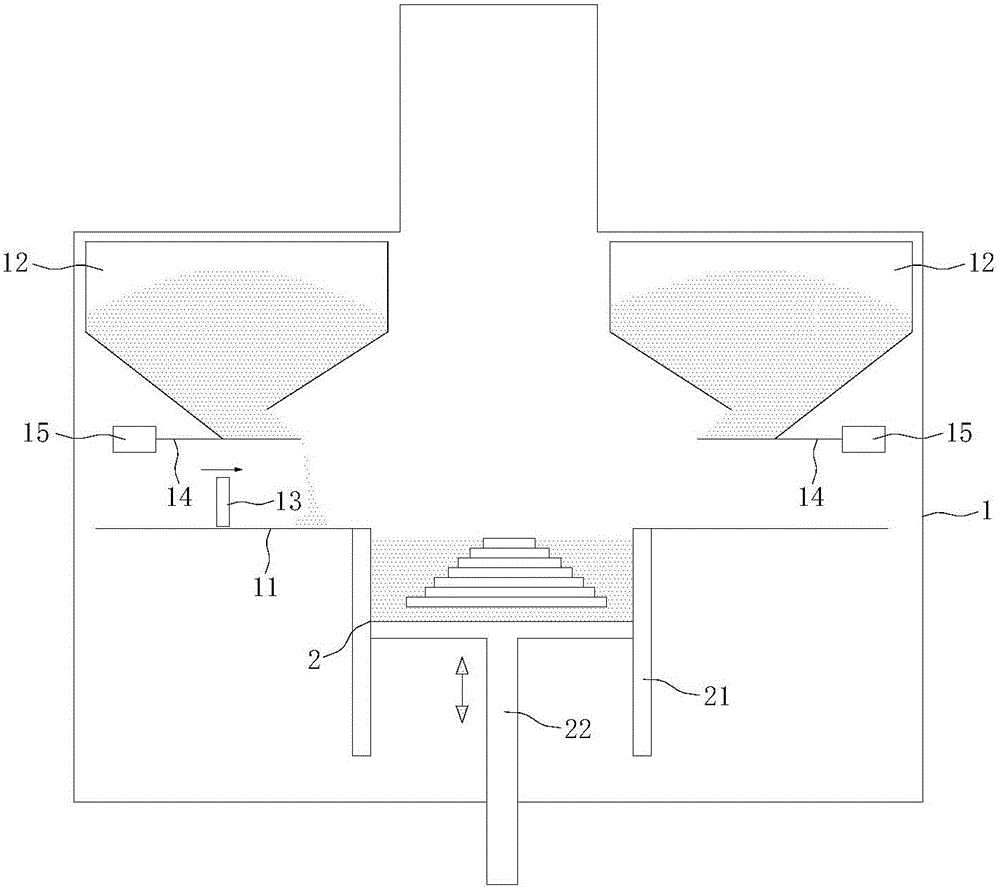

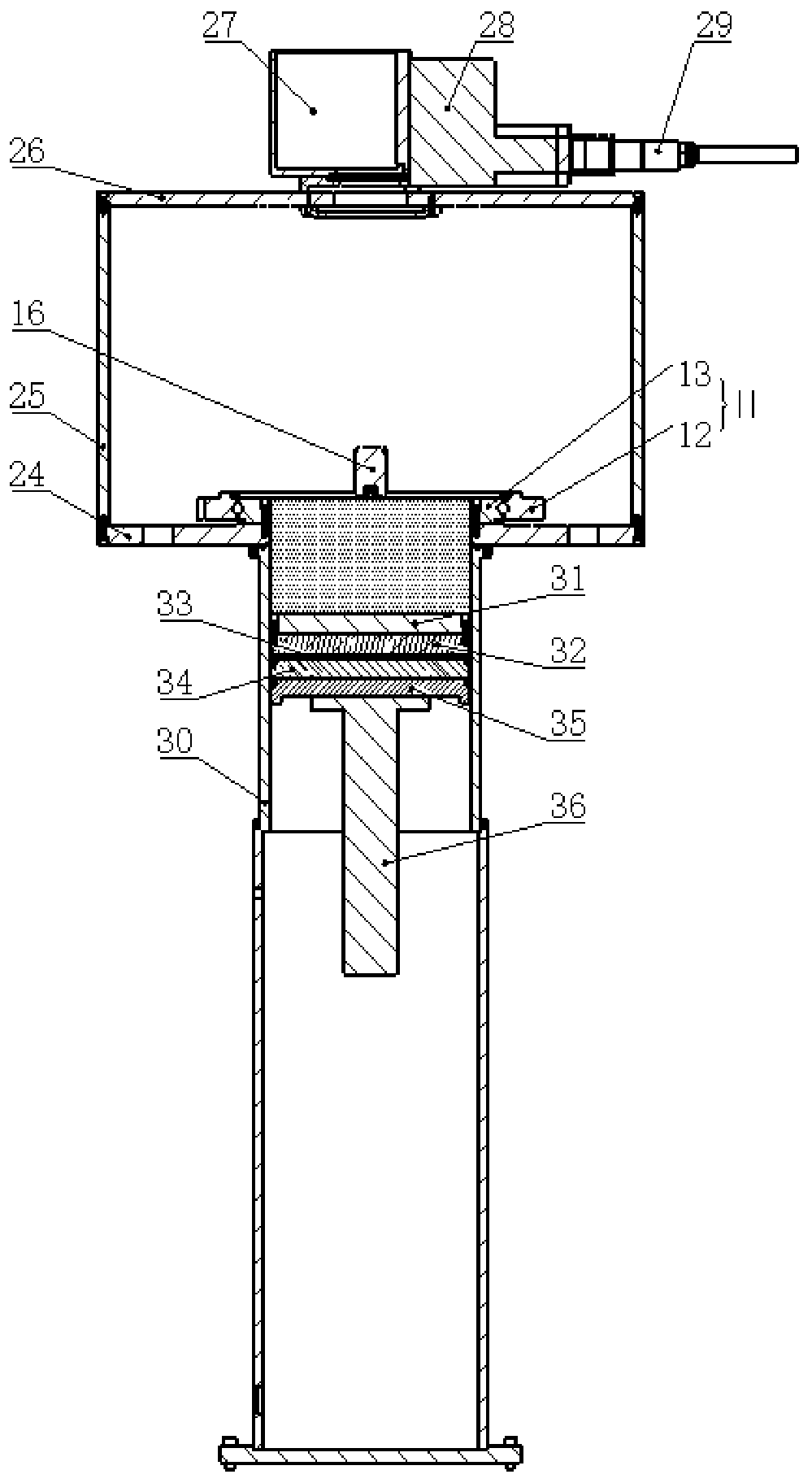

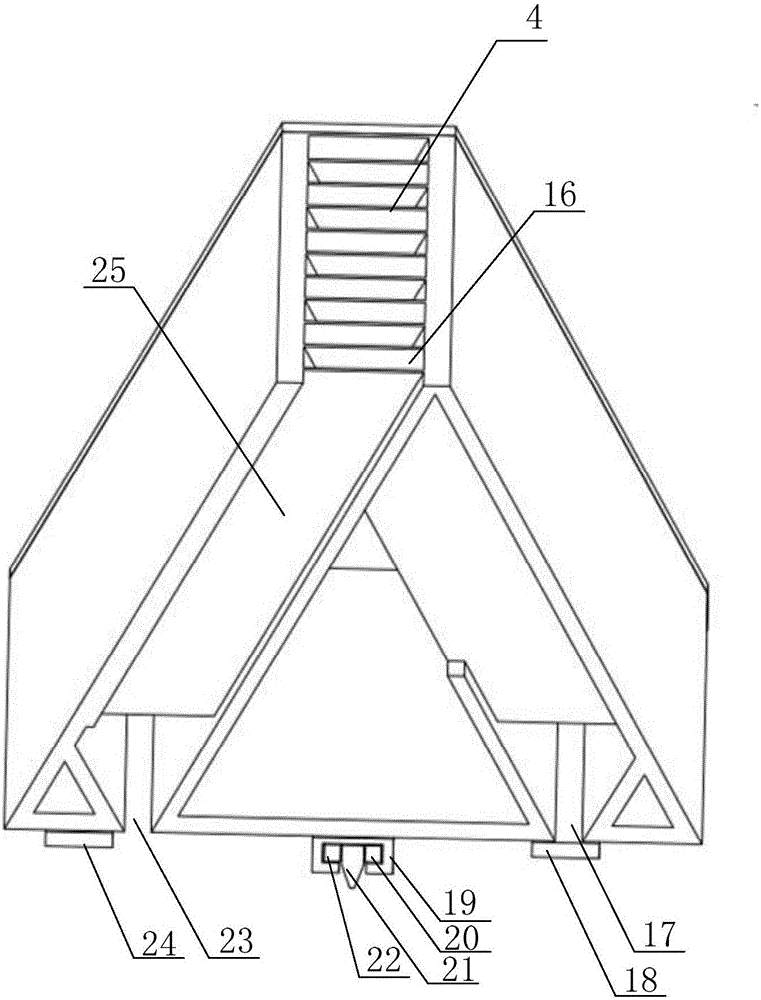

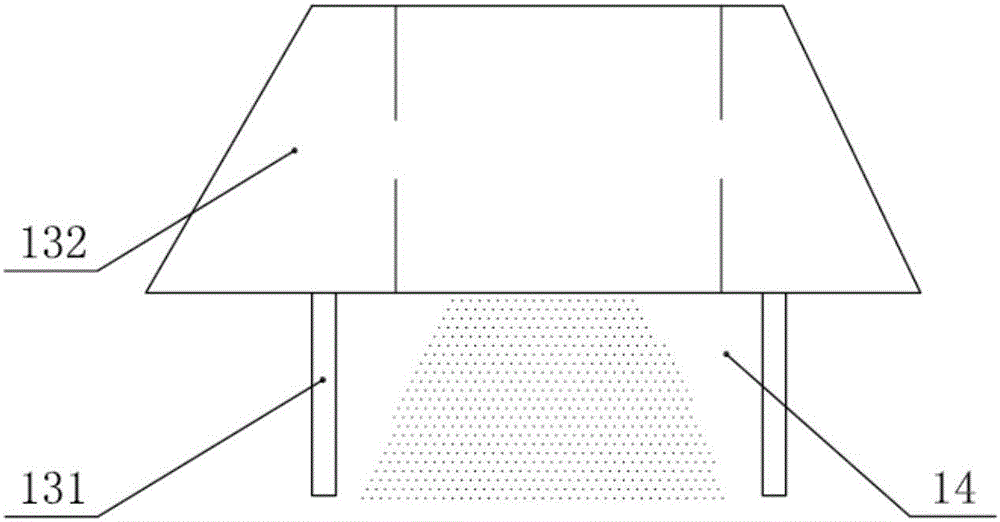

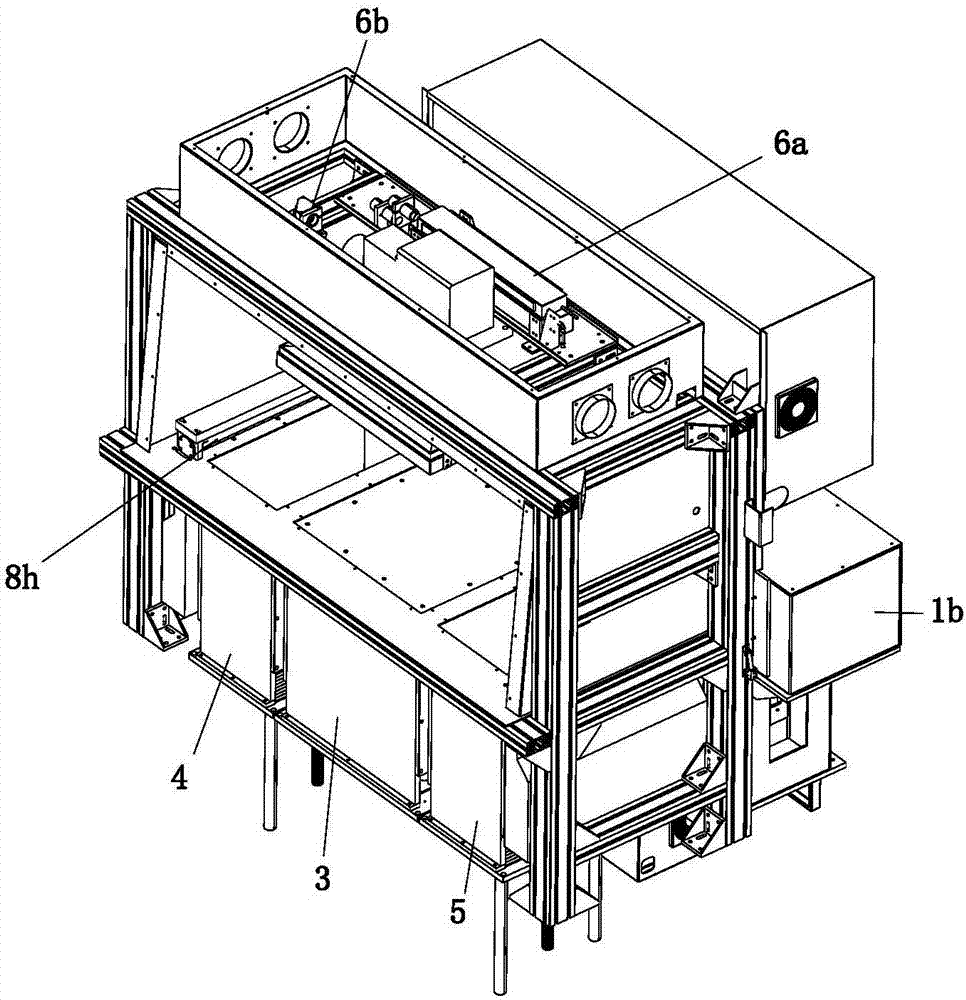

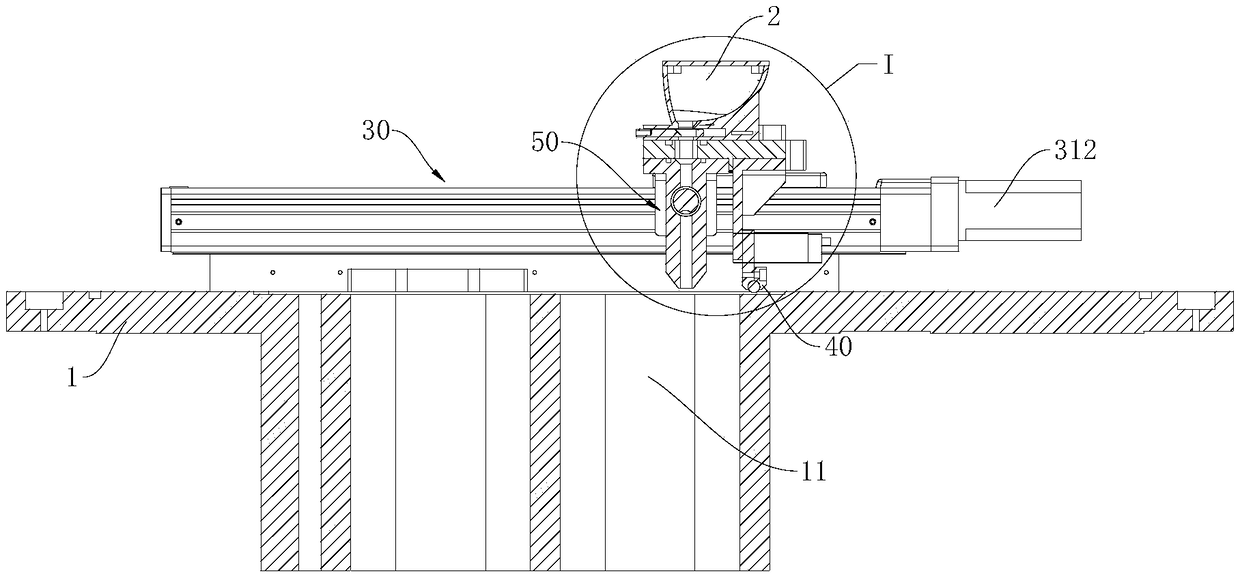

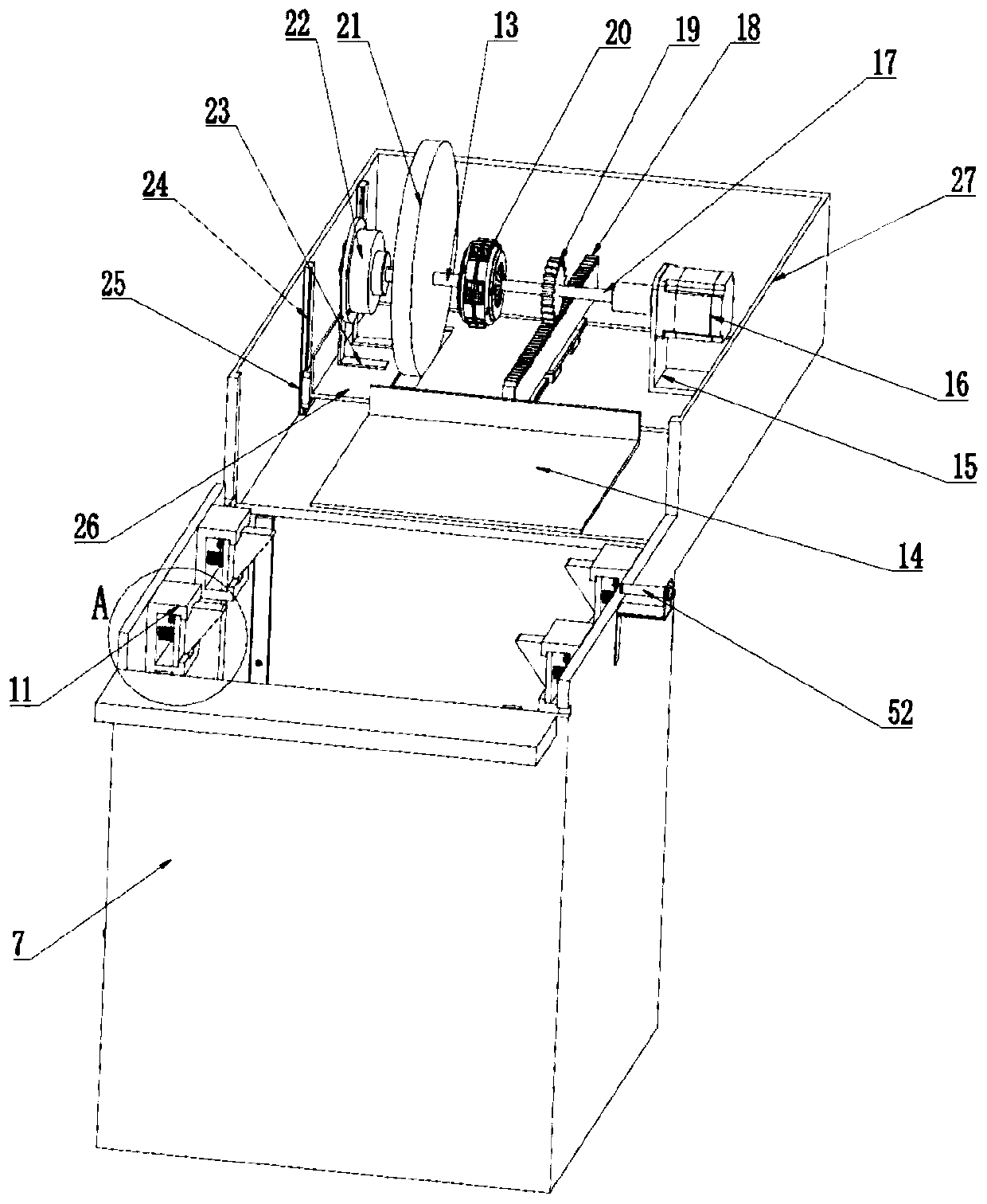

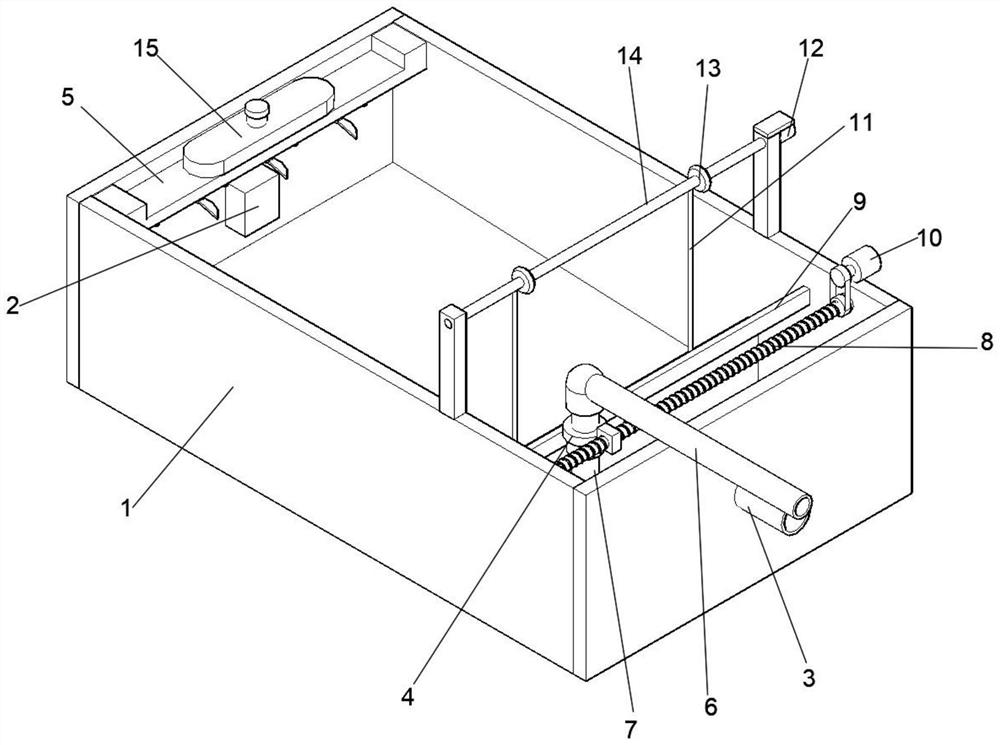

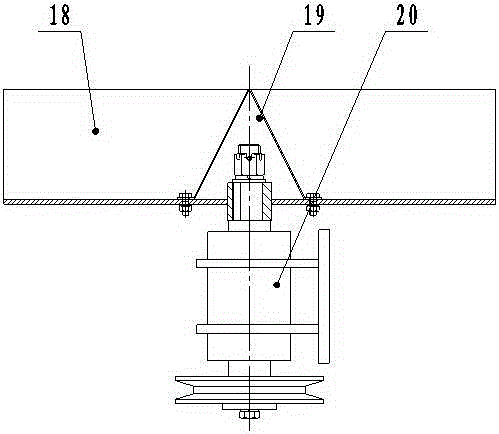

Single-scraper bidirectional powder-paving device for melting forming of laser selection area and method

ActiveCN107584120AEasy to cleanEasy maintenanceAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsForming processes

The invention relates to a single-scraper bidirectional powder-paving device and method for melting forming of a laser selection area. The structure is simple, the powder-paving efficiency is high, the powder-paving efficiency is guaranteed and the powder cleaning and maintenance are more convenient. The device comprises a forming platform, a left powder-conveying cabin, a right powder-conveying cabin and a powder paving slot; the powder paving slot comprises a slot tank, a scraper, a baffle and a reversing plate; a left reversing jacking pin and a right reversing jacking pin for driving the reversing plate to rotate and reverse are respectively arranged on the two sides of the forming platform; in a reversing process, the left reversing jacking pin or the right reversing jacking pin is incontact with the reversing plate before the powder paving slot moves to the left powder-conveying cabin or the right powder-conveying cabin, and besides, the rotation of the baffle under the drivingof the reversing plate is completed when the powder paving slot moves to the position under the powder-conveying cabin. According to the bidirectional powder-paving method provided by the invention, the bidirectional powder-paving device is utilized to complete the powder throwing in the melting forming process of the laser selection area, the powder paving operation is immediately performed afterthe melting forming of the laser selection area, the route is not wasted, the working time is not wasted, the comprehensive arrangement for the powder-paving and forming operations is realized and the efficiency is higher.

Owner:西安国宏天易智能科技有限公司

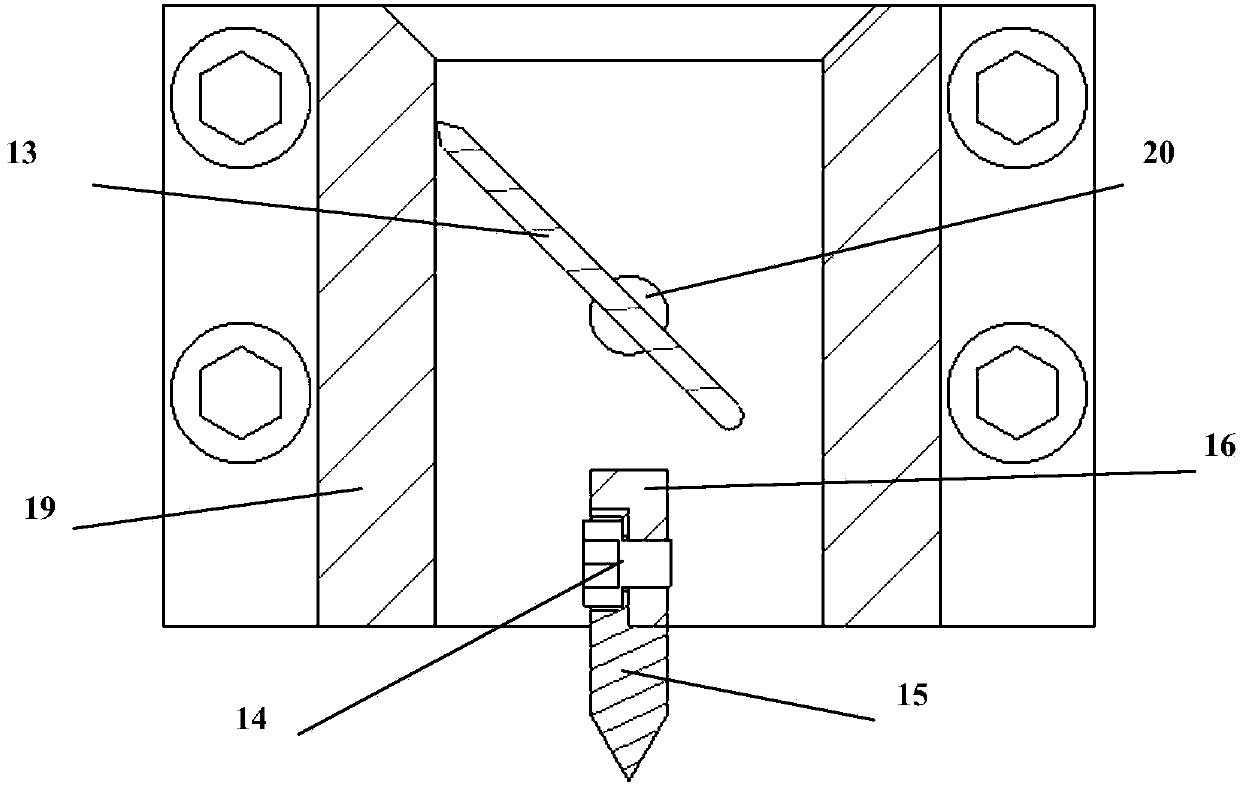

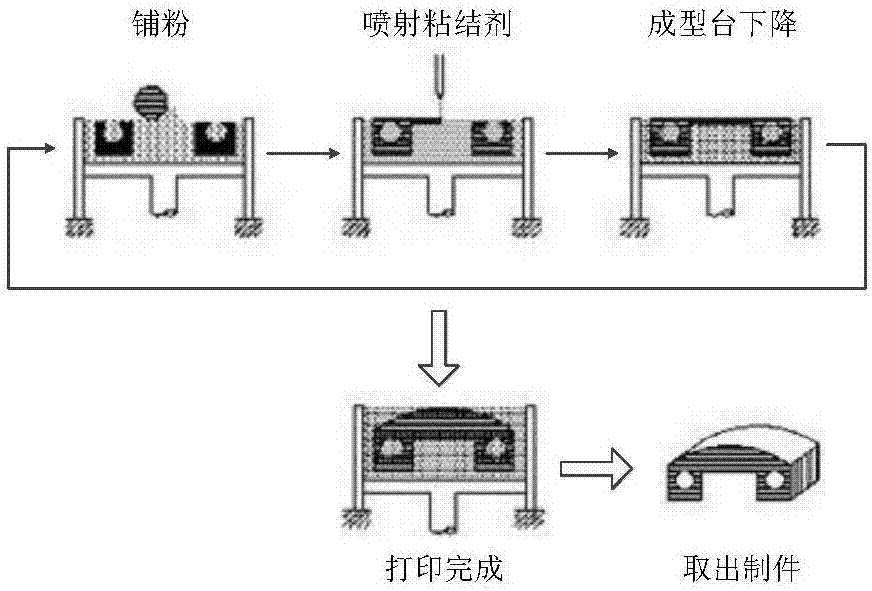

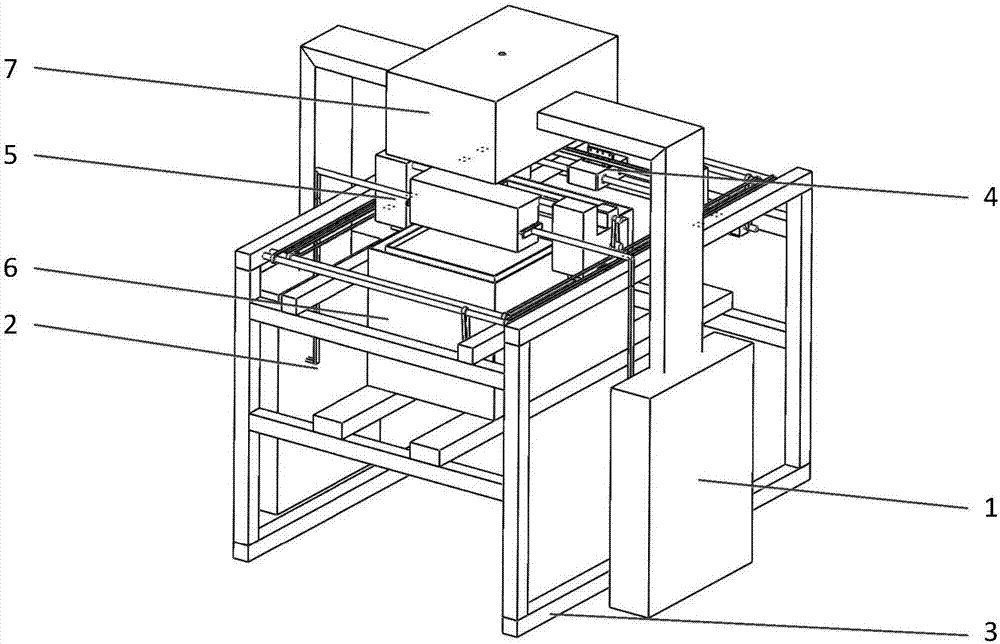

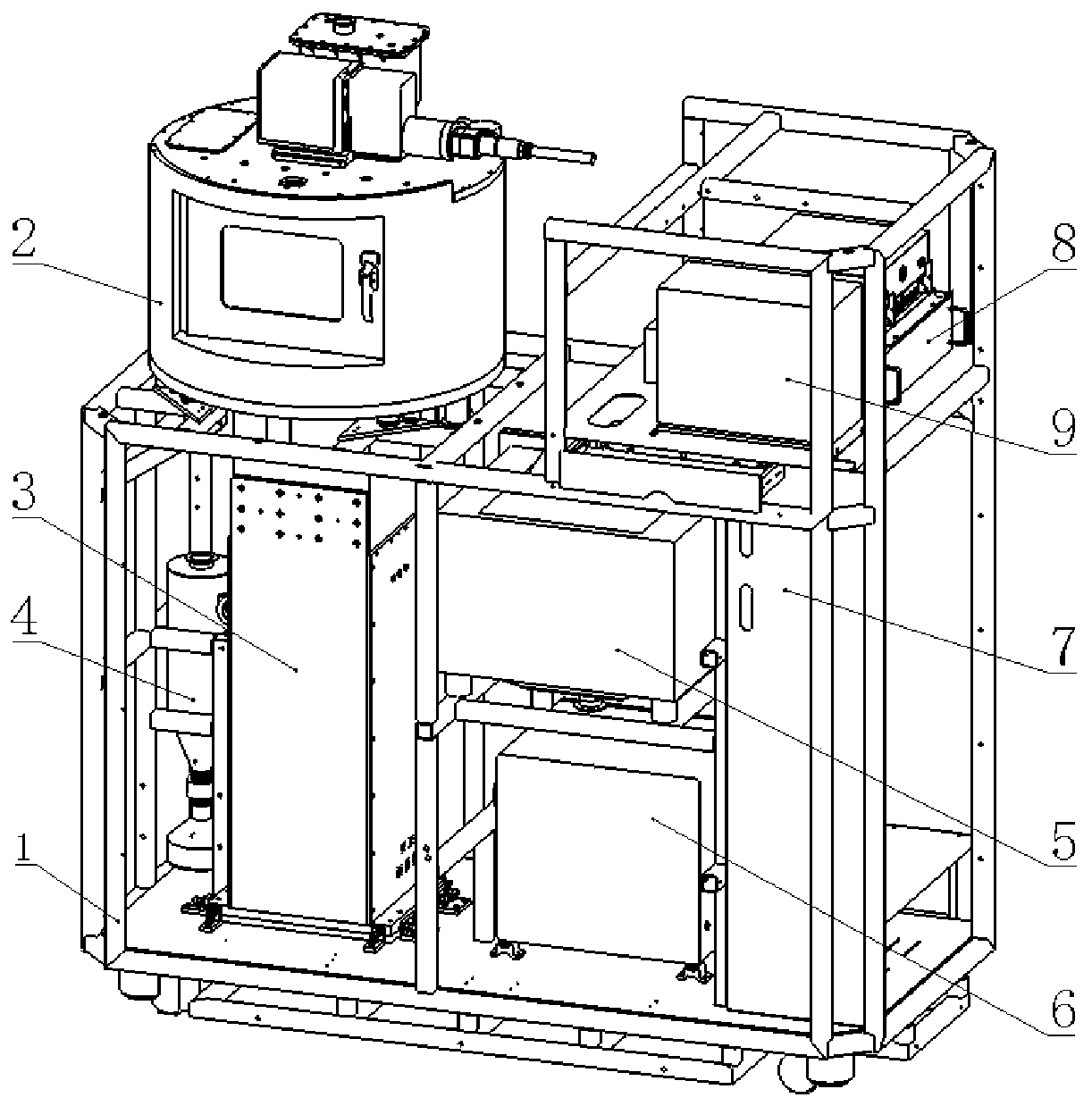

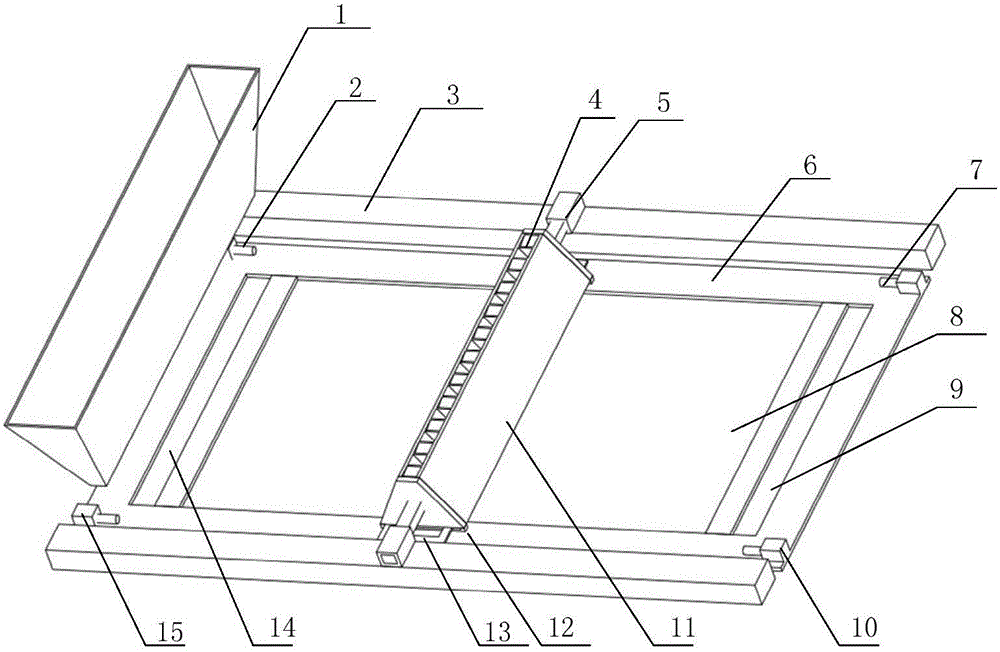

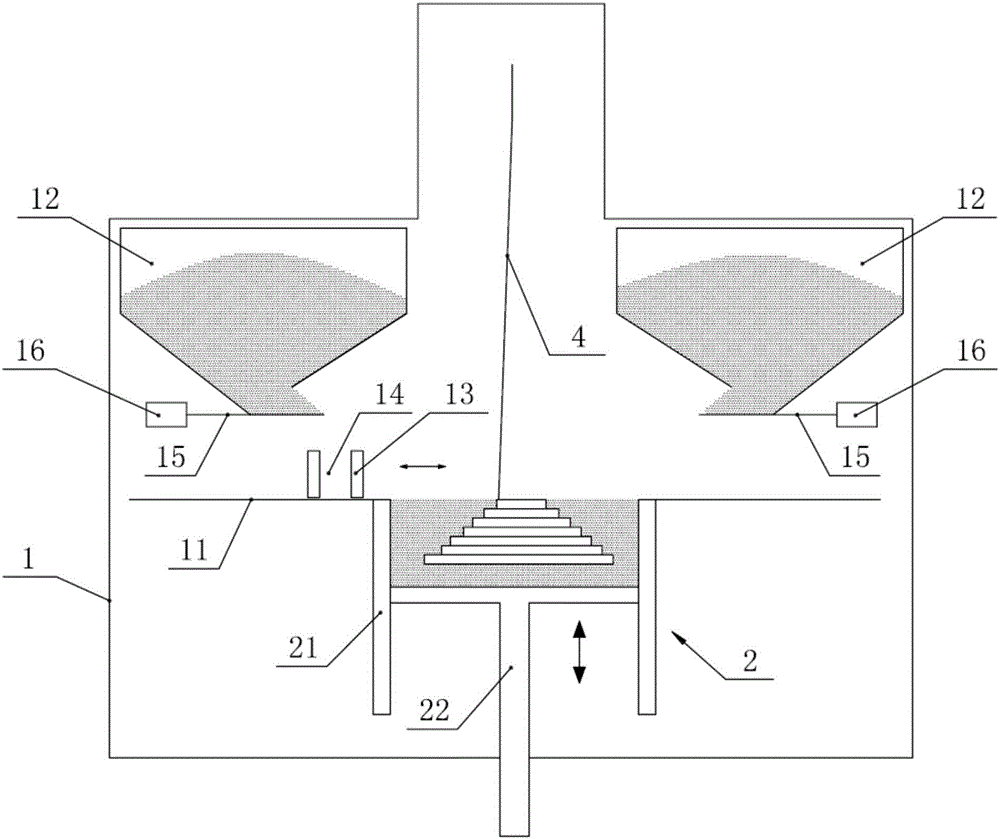

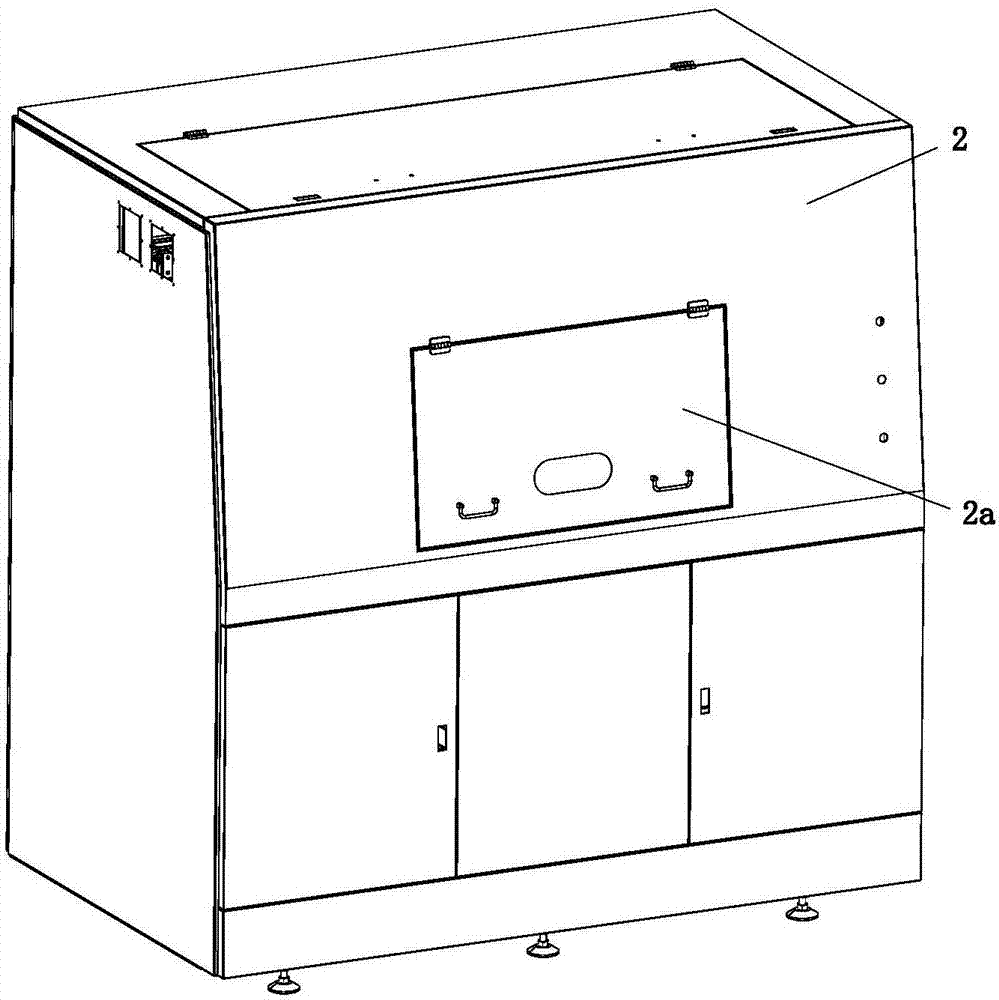

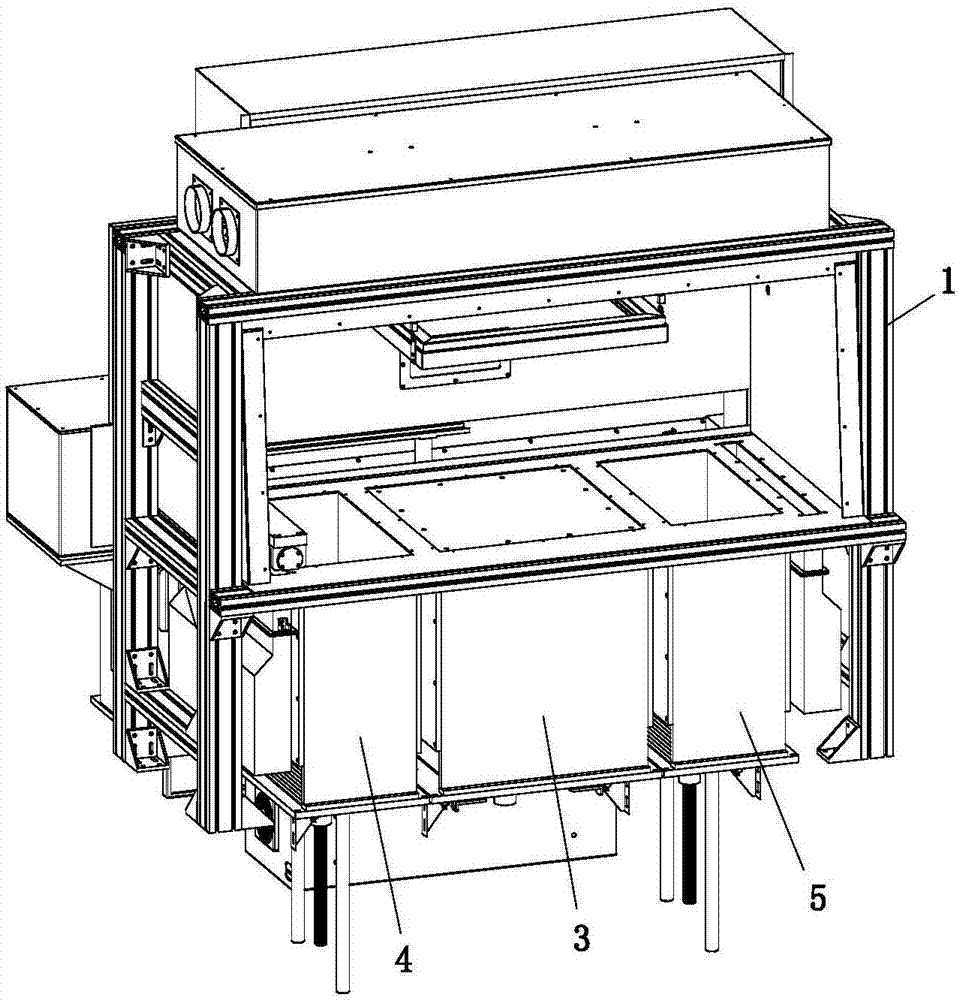

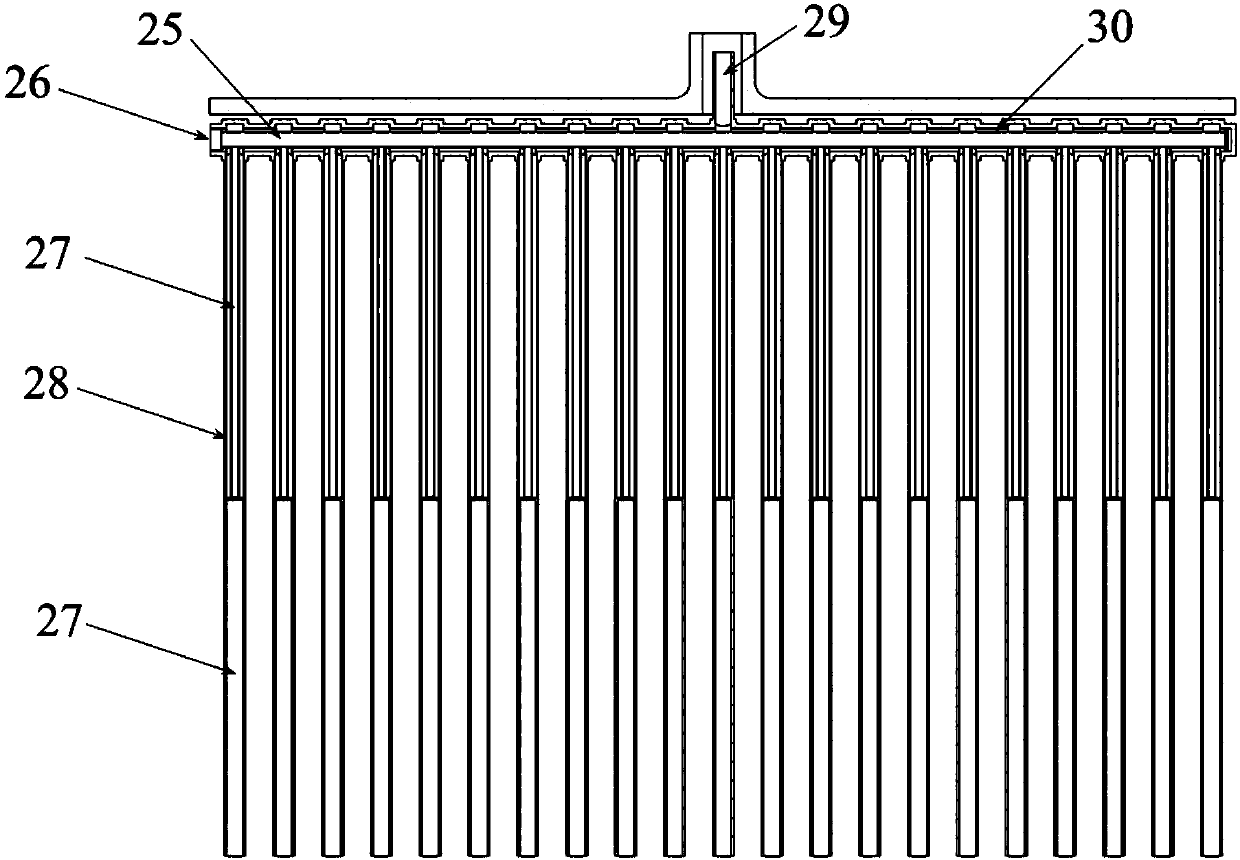

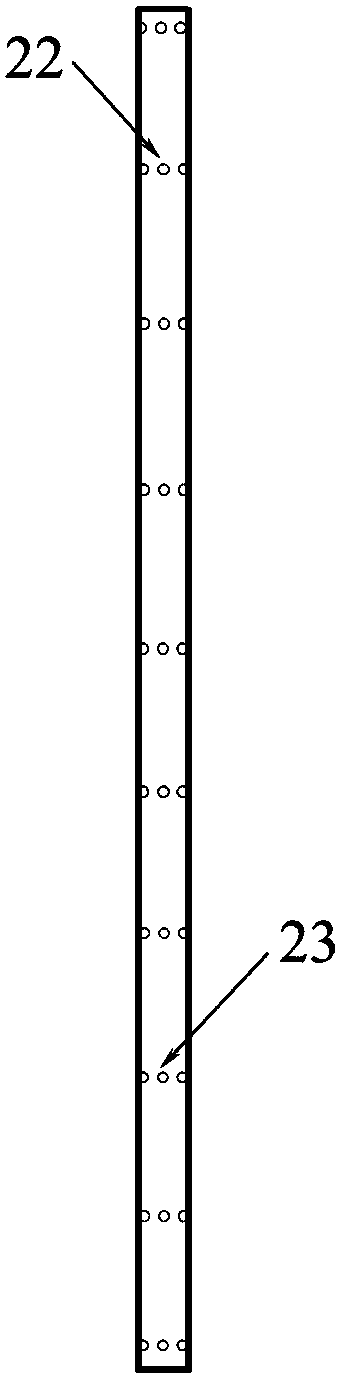

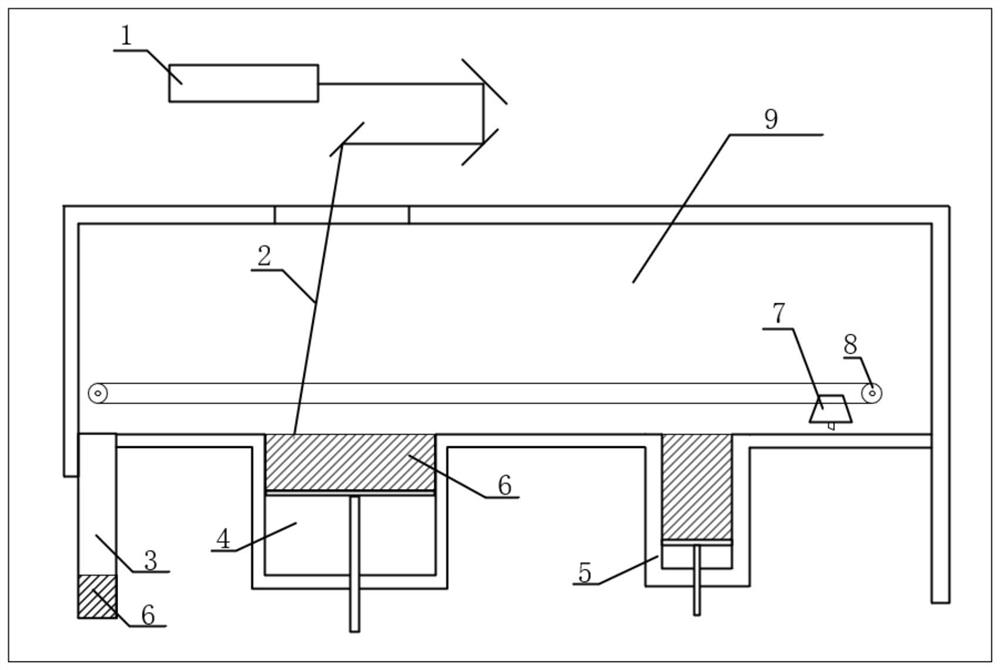

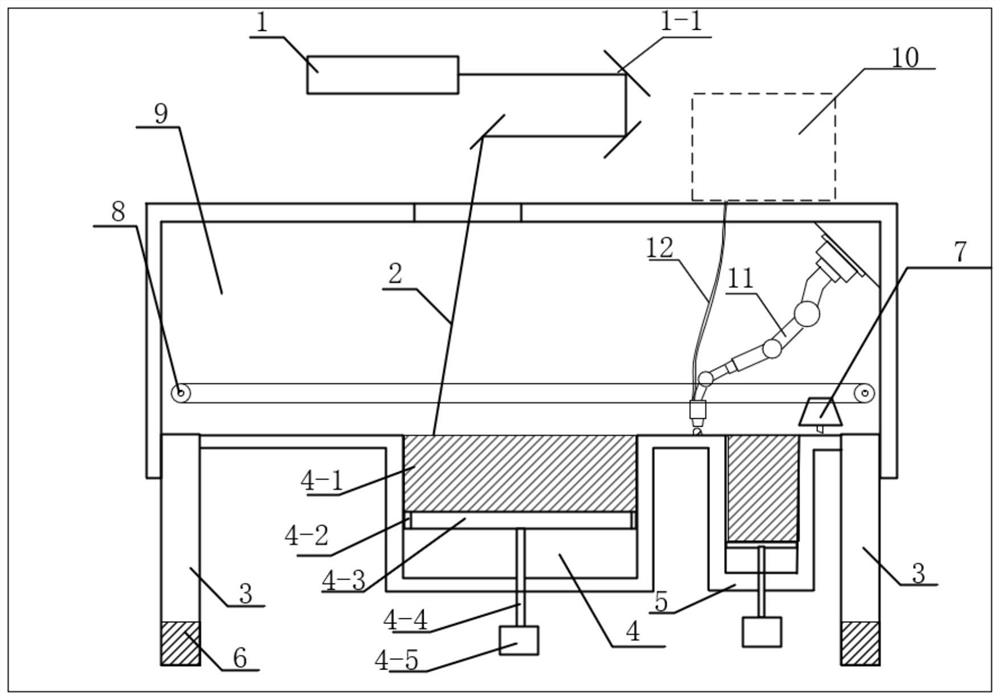

3DP process forming system and operation method thereof

ActiveCN108000870AAvoid cloggingExtend working life3D object support structuresAdditive mnaufacturing with solid and fluidEngineeringMetal

The invention discloses a 3DP process forming system and an operation method thereof. The 3DP process forming system comprises a rack of a metal frame structure. A modular forming cylinder is arrangedin the rack. A printing device and a powder feeding device are arranged at the position, on the upper portion of the modular forming cylinder, of the rack. The printing device and the powder feedingdevice are connected with Y-direction linear guide rails on the rack through sliding blocks and are used for moving on the Y-direction linear guide rails to carry out powder laying and printing. A part taking auxiliary device is arranged at the top of the rack. A physical curing device is arranged in the part taking auxiliary device. Powder storage boxes are arranged on the two sides of the rack.According to the 3DP process forming system and the operation method thereof, the problem that the uniformity of powder particles laid on a powder bed and the density of the powder bed cannot be guaranteed at the same time is solved, the problem of nozzle blocking caused by raising dust caused by laid powder motion is effectively avoided, and the equipment forming efficiency and the part taking efficiency are greatly improved.

Owner:XI AN JIAOTONG UNIV

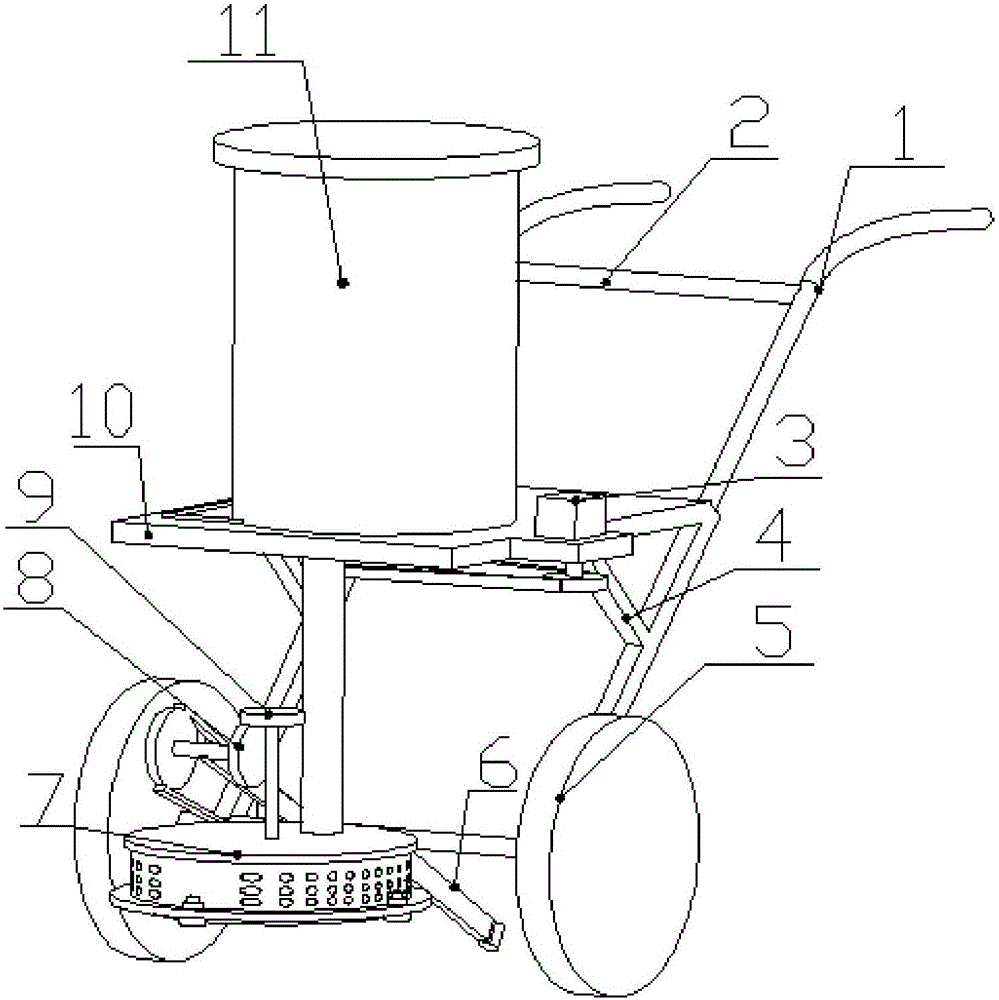

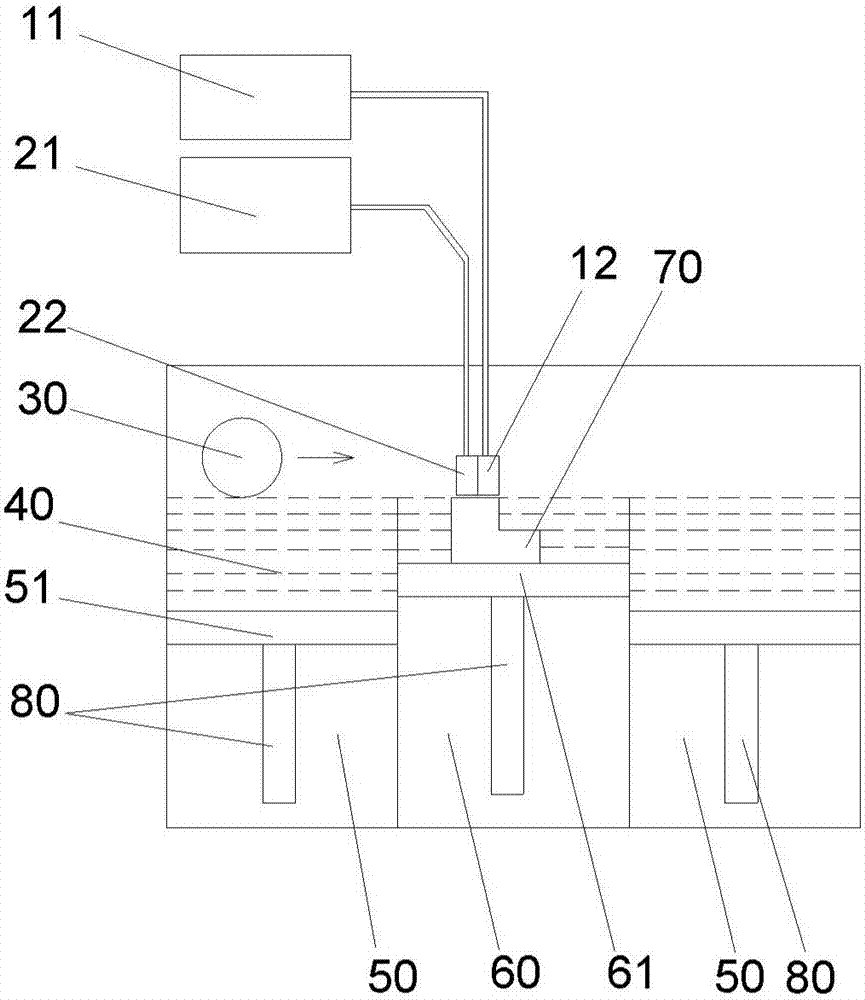

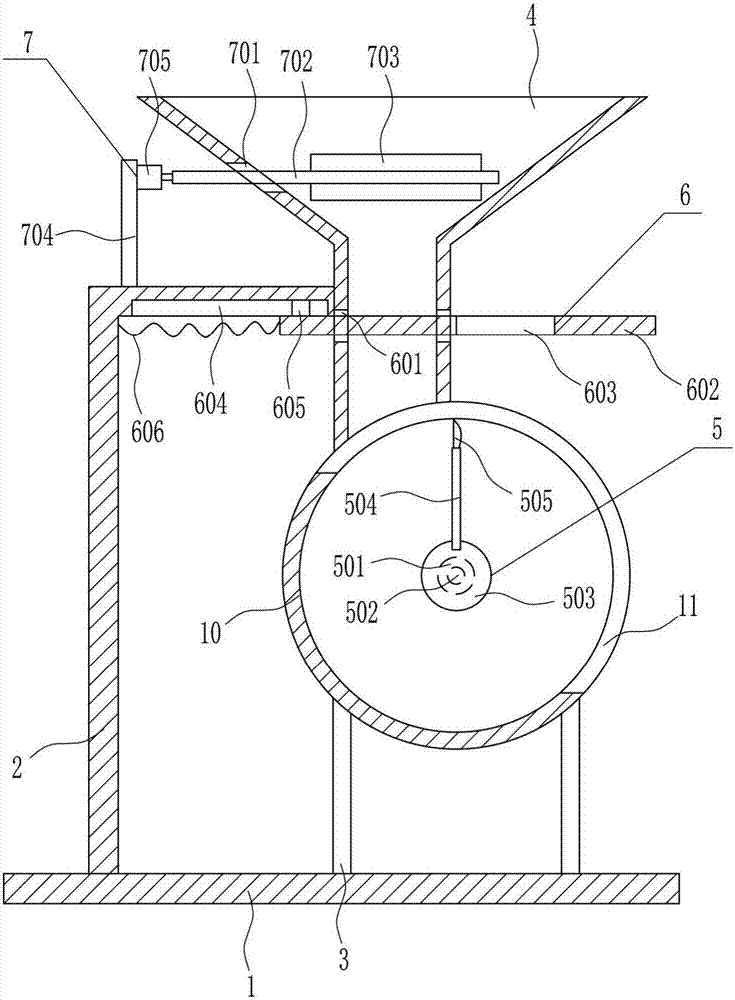

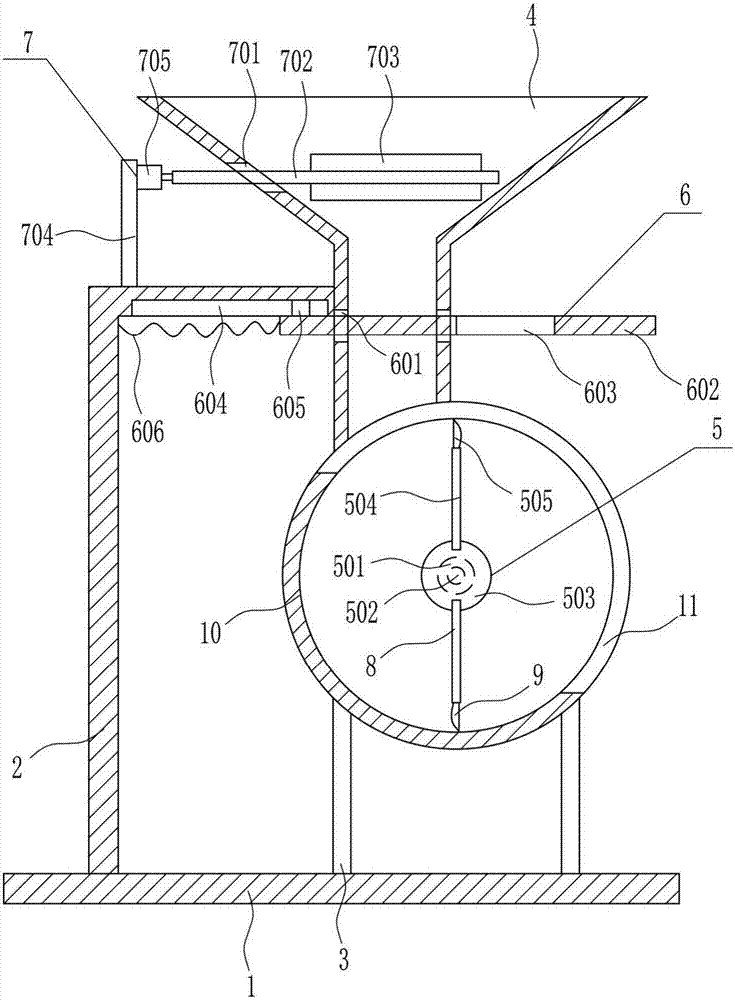

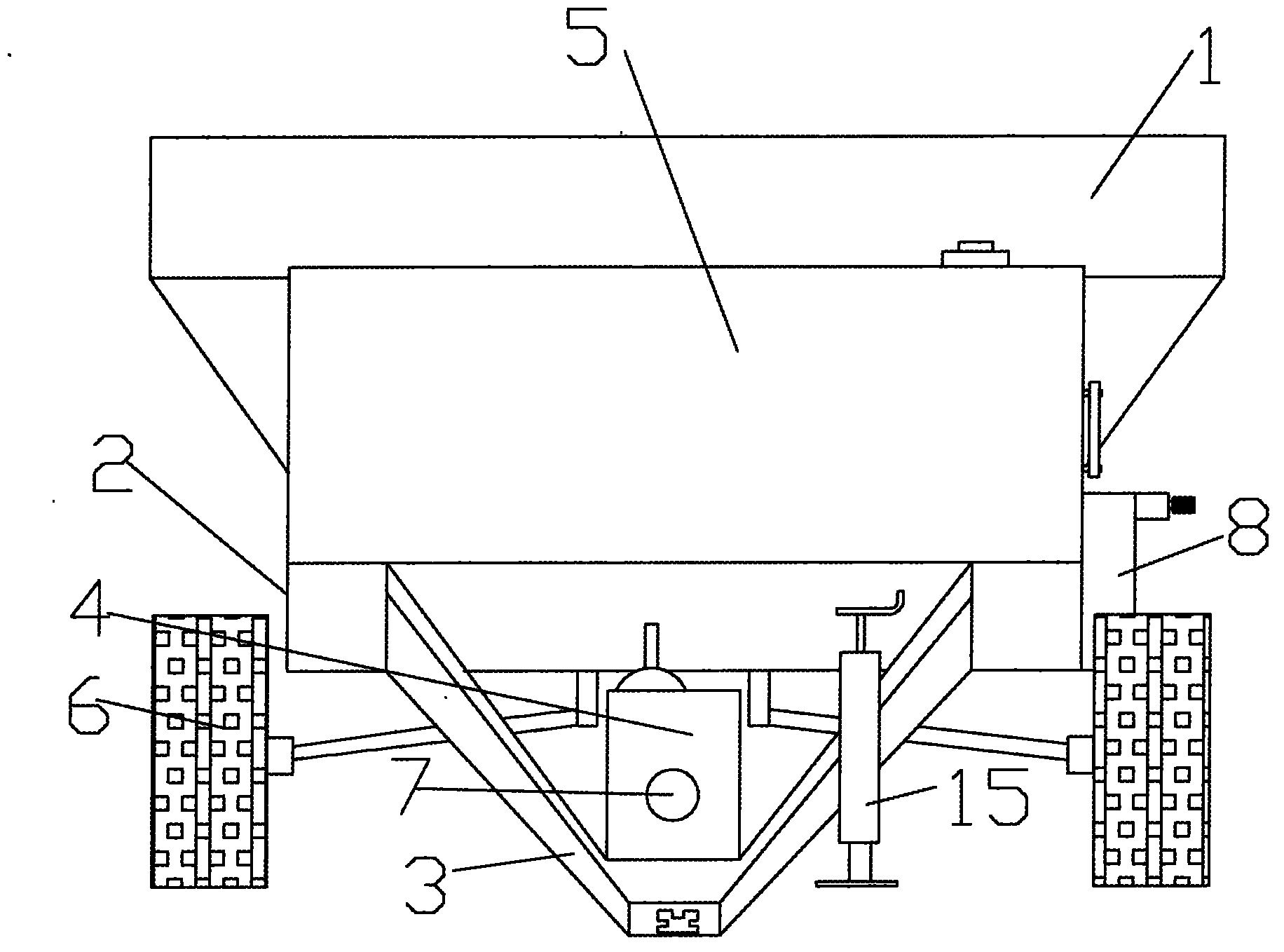

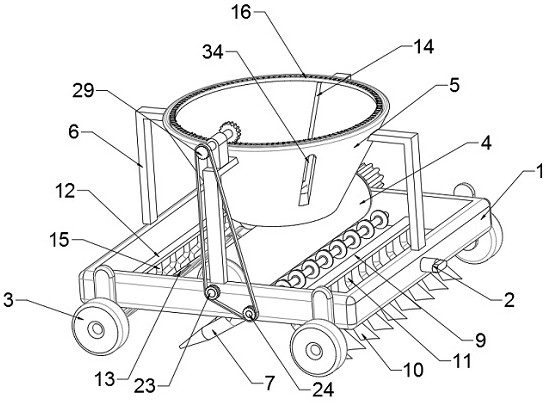

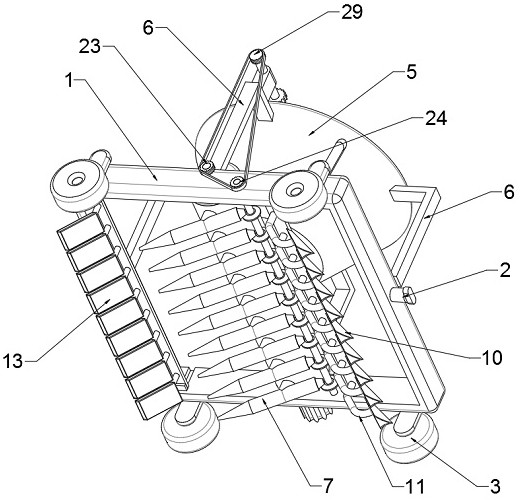

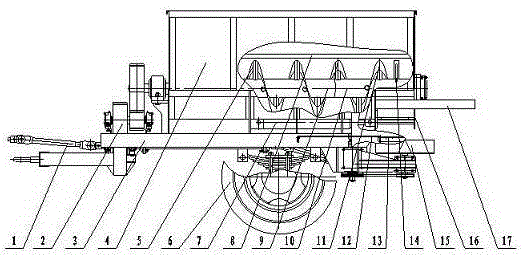

Agricultural centrifugal fertilizer-spreading device

ActiveCN106358544AAvoid manual crushingSpread evenlyFertiliser distributersCentrifugal wheel fertilisersMotor driveSpiral blade

The invention discloses an agricultural centrifugal fertilizer-spreading device, and belongs to the technical field of the agricultural machinery. The agricultural centrifugal fertilizer-spreading device uses a two-stage storing mode, and is composed of a spiral-type beating mechanism and a rotation centrifugal fertilizer-spreading mechanism. The agricultural centrifugal fertilizer-spreading device is characterized in that a motor drives spiral blades on an inner rotating disk to be rotated through a transmission mechanism, a large piece of the chemical fertilizer is smashed, a main rotation shaft connected on a wheel drives a rotation shaft to be rotated through the transmission mechanism, the rotation shaft passes through a connecting plate and is connected with a two-stage storing tank, a lot of small holes are opened around the two-stage storing tank so as to spread the fertilizer smoothly, five connecting holes are uniformly opened in the connecting plate, and the range of spreading the fertilizer can be controlled by connecting the different holes. The agricultural centrifugal fertilizer-spreading device is capable of automatically beating a large piece of the chemical fertilizer, uniformly spreading the fertilizer by the centrifugal rotation tank, and changing the spreading range, and is suitable for the particle-shaped and powder-shaped fertilizer.

Owner:黑龙江省樱田农机制造有限公司

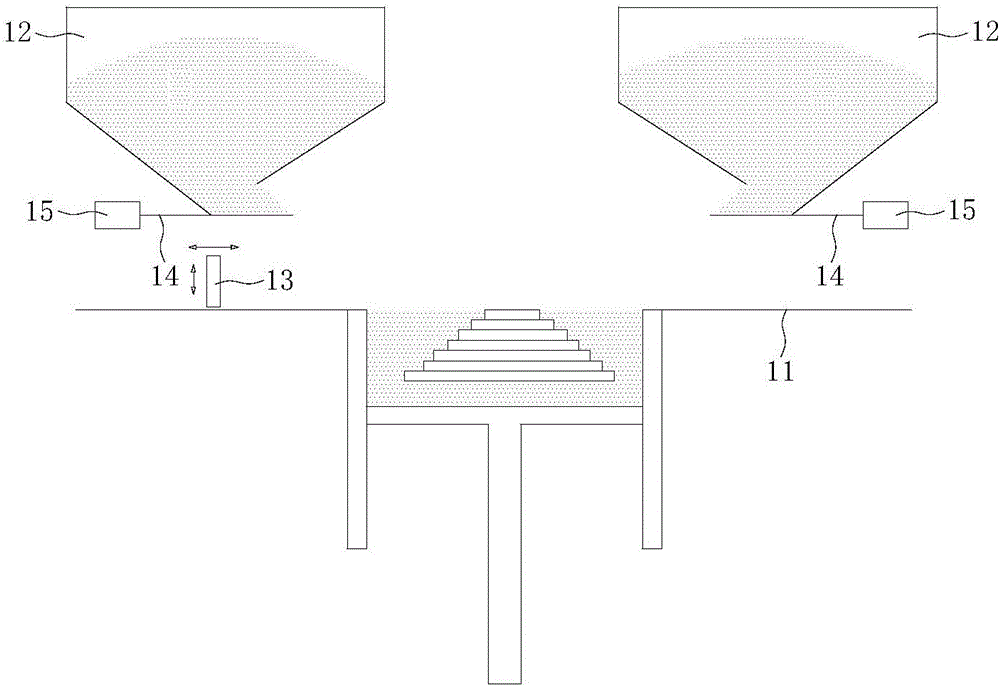

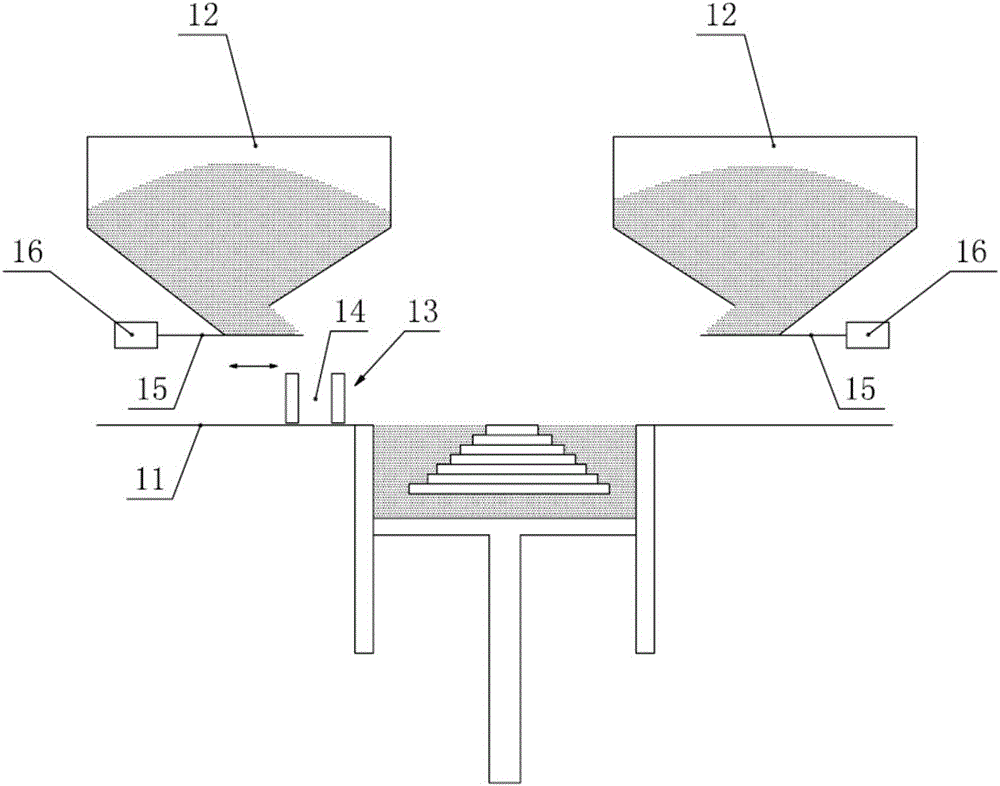

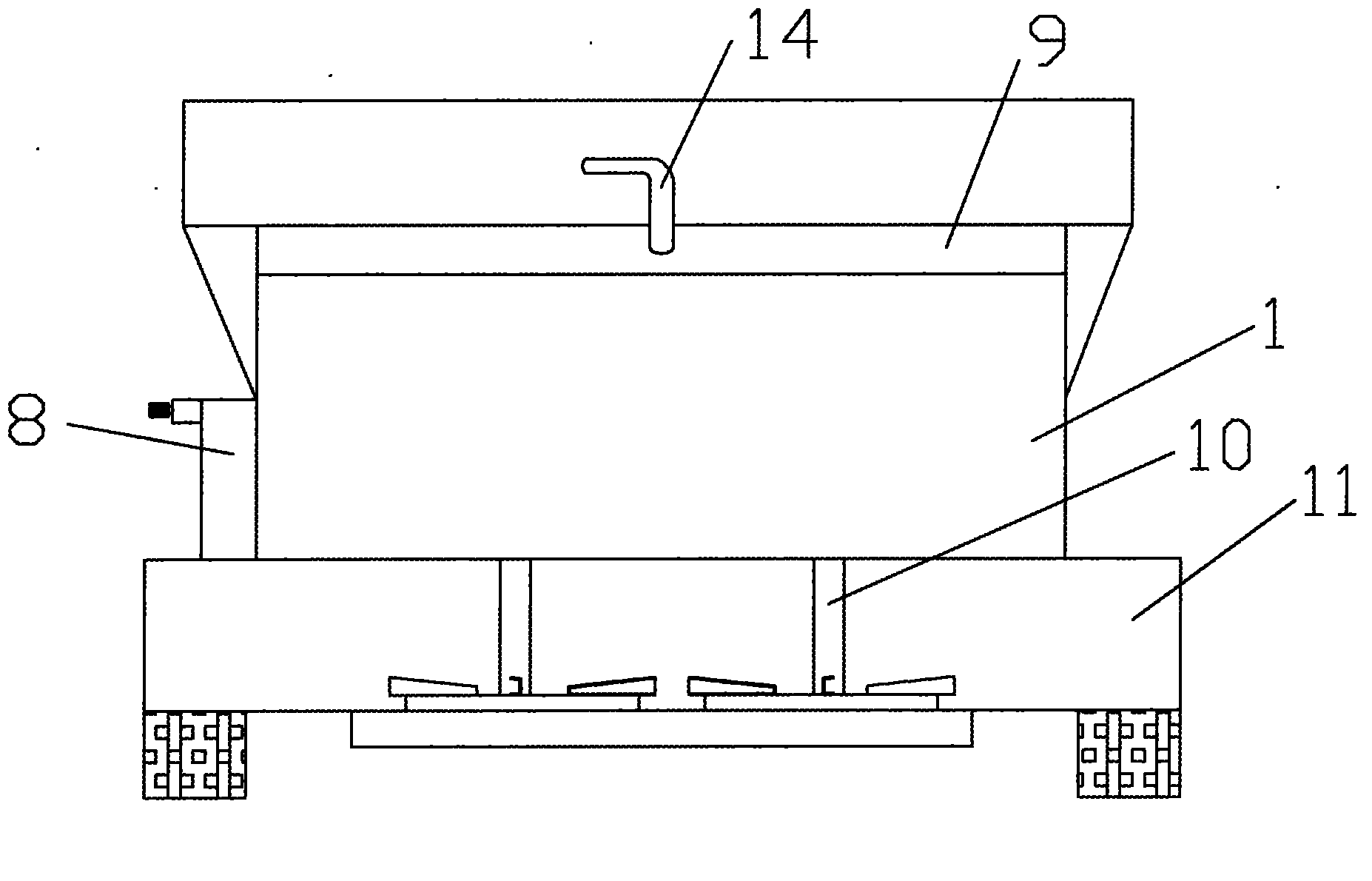

Powder distribution device and additive manufacturing device

InactiveCN105855548AUniform thicknessImprove spreading efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention belongs to the field related to additive manufacturing and discloses a powder distribution device and an additive manufacturing device. The powder distribution device comprises a powder spreading platform and hoppers arranged above two sides of the powder spreading platform, powder materials are placed in the hoppers, powder-material placing locations are arranged on the two sides of the powder spreading platform, the powder materials are transferred to the powder-material placing locations through the hoppers, scrapers vertically arranged above the powder spreading platform are allowed to move along the horizontal direction as well as the vertical direction, and the scrapers are respectively located on one sides of the powder-material placing locations when moving along the vertical direction. The powder distribution device is provided with the scrapers allowed to move along the horizontal direction as well as the vertical direction, two-way powder scraping is realized, thickness of powder layers is evener as compared with the existing one-way powder scraping, and powder spreading efficiency is improved. Further more, the scrapers are vertically arranged, so that two-way powder scraping can be better realized, and waste of the powder materials is avoided.

Owner:QUICKBEAM CO LTD +1

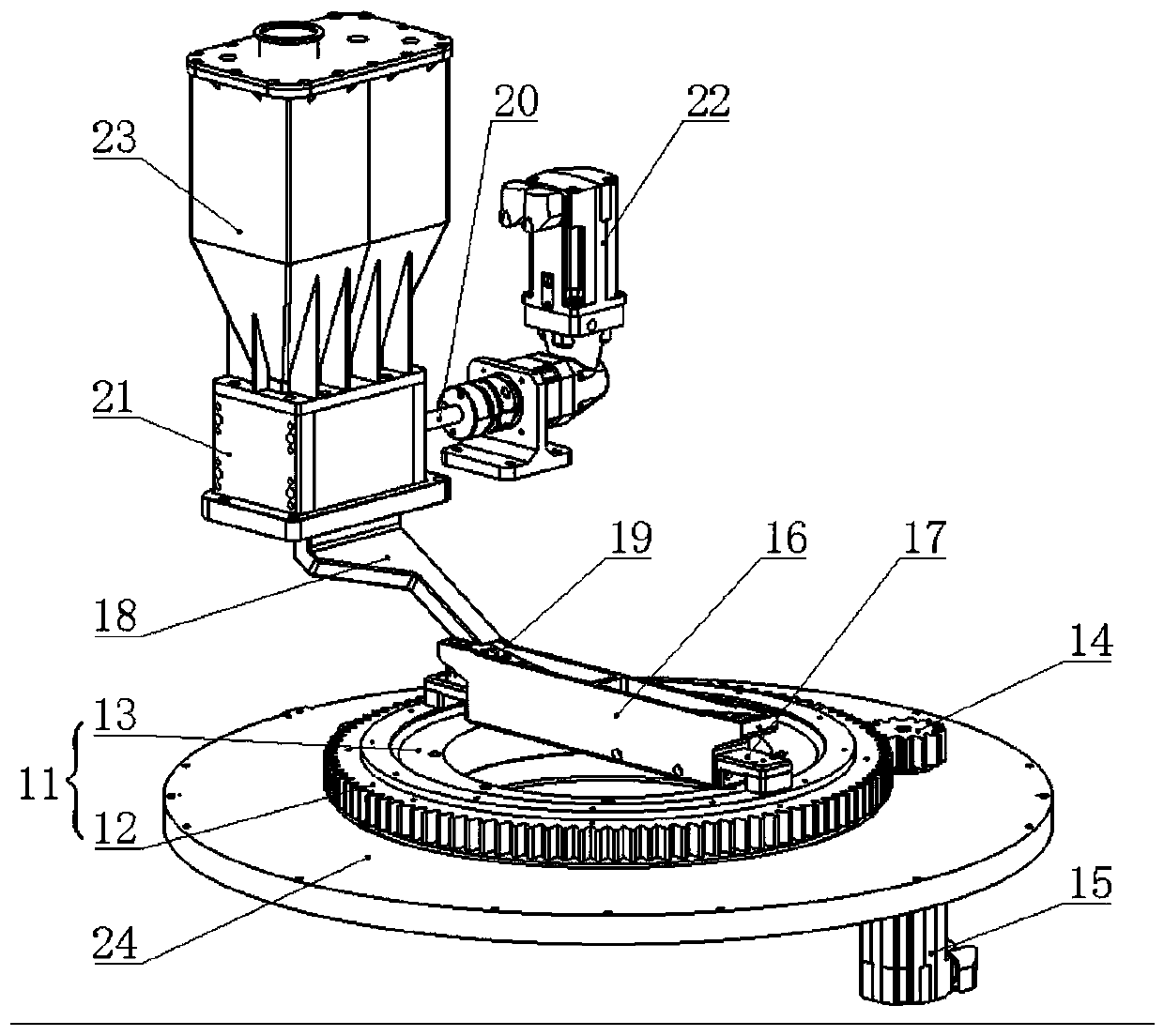

Continuous cyclic powder spreading structure and additive manufacturing molding equipment

PendingCN110560689AImprove forming efficiencyImprove powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsUtilization rate

The invention discloses a continuous cyclic powder spreading structure and additive manufacturing molding equipment. Side plates and a top plate are arranged on a bedplate. A printing molding cavity is formed by the bedplate and a cylinder body arranged at the lower end of the bedplate. The continuous cyclic powder spreading structure is arranged in the printing molding cavity, and continuous powder spreading in the printing molding process is achieved. Up-and-down movement of a printing substrate in the cylinder body is achieved by utilizing a driving device. Then the printing surface on theprinting substrate is printed and molded by utilizing a light path scanning structure arranged at the inner upper end of the printing molding cavity. Molding through holes are formed in a gear bearingand the middle of the bedplate correspondingly so that it is convenient for light path scanning structure laser and the printing surface on the printing substrate at the lower end of the bedplate tomold. The light path scanning structure is located at the upper end of the continuous cyclic powder spreading structure and can work simultaneously with a powder spreading scraper so that powder spreading and scanning molding are conducted, and that is to say, an efficient printing process that powder spreading is conducted while scanning is conducted can be achieved. By means of the continuous cyclic powder spreading structure and the additive manufacturing molding equipment, molding efficiency of parts is improved; and meanwhile, the printing substrate moves up and down in the cylinder body,the molding area is limited, and the utilization rate of powder is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

UV photo-cure 3D rapid forming system and printing method thereof

InactiveCN107415239AAvoid affecting the printing effectLow input costAdditive manufacturing apparatus3D object support structuresUV curingEngineering

The invention provides a UV photo-cure 3D rapid forming system and further provides a printing method of the UV photo-cure 3D rapid forming system. The UV photo-cure 3D rapid forming system comprises a printing curing device, a printing bin and a powder supply device. The printing curing device comprises a UV lamp curing unit and a UV glue bonding unit, the printing bin is provided with a work table for bonding and curing forming of printing powder, and the powder supply device is used for storing and conveying the printing powder to the printing bin and comprises a powder supply bin body and a powder laying roller. The UV photo-cure 3D rapid forming system and the printing method thereof have the advantages that according to the system, the UV photo-cure technology is applied to three-dimensional printing, the problems that a three-dimensional-printing forming workpiece is low in strength and needs secondary curing aftertreatment, for example, the workpiece is steeped by glue again are solved, the input cost is reduced, the production period is shortened, and the production efficiency is improved; operation is convenient, and the powder laying efficiency is high; and a powder layer is subjected to primary curing before UV curing and thus is better in supporting intensity than loose powder, the supporting effect on the subsequent cured workpiece is better, and forming is facilitated.

Owner:NANTONG INST OF TECH

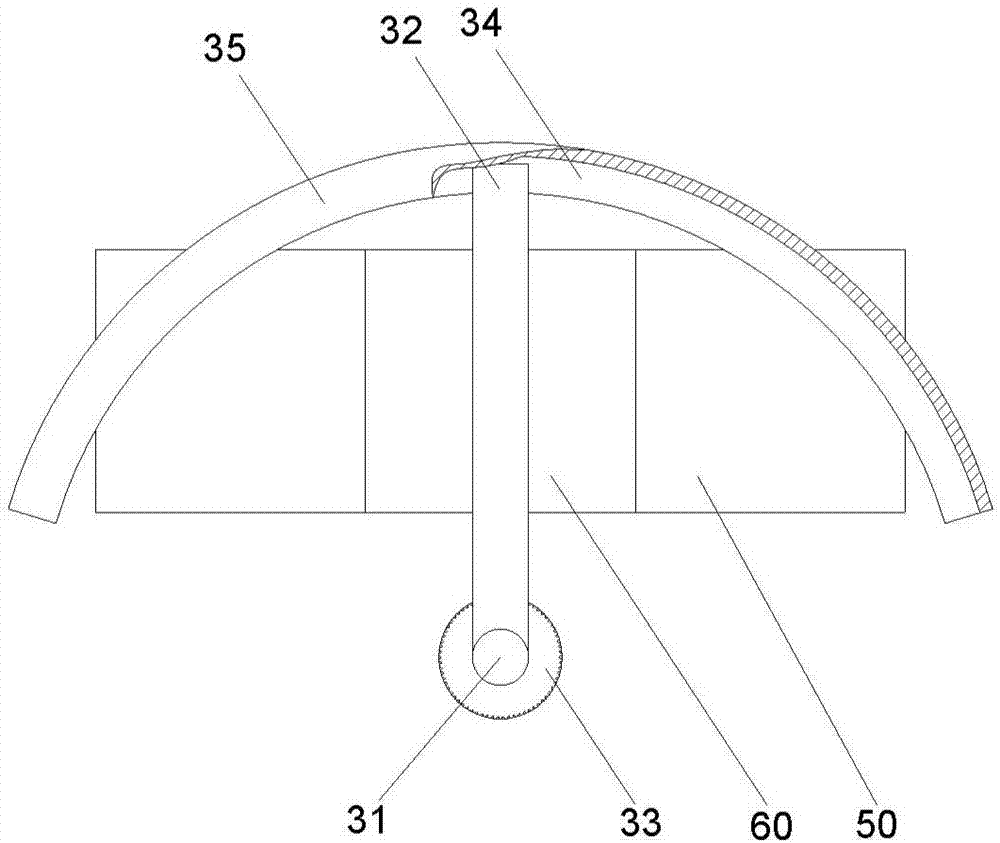

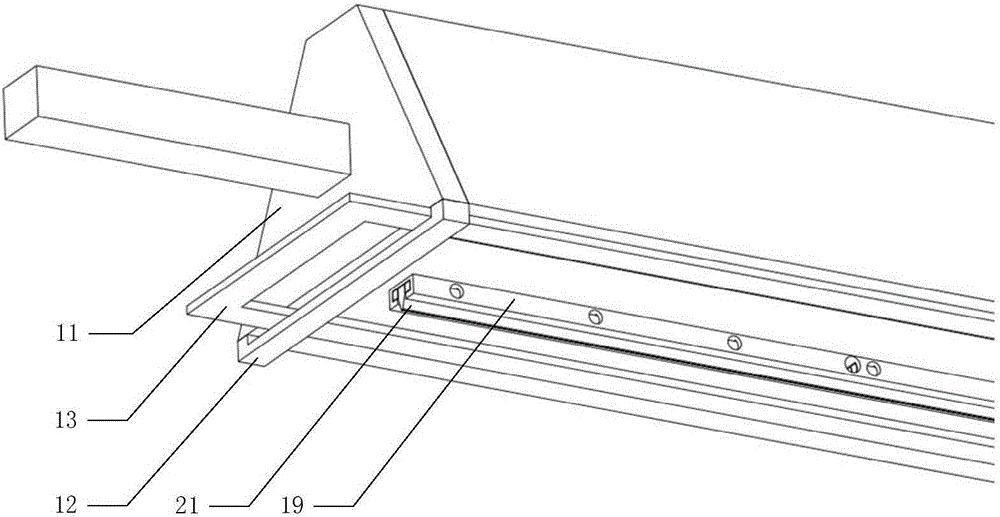

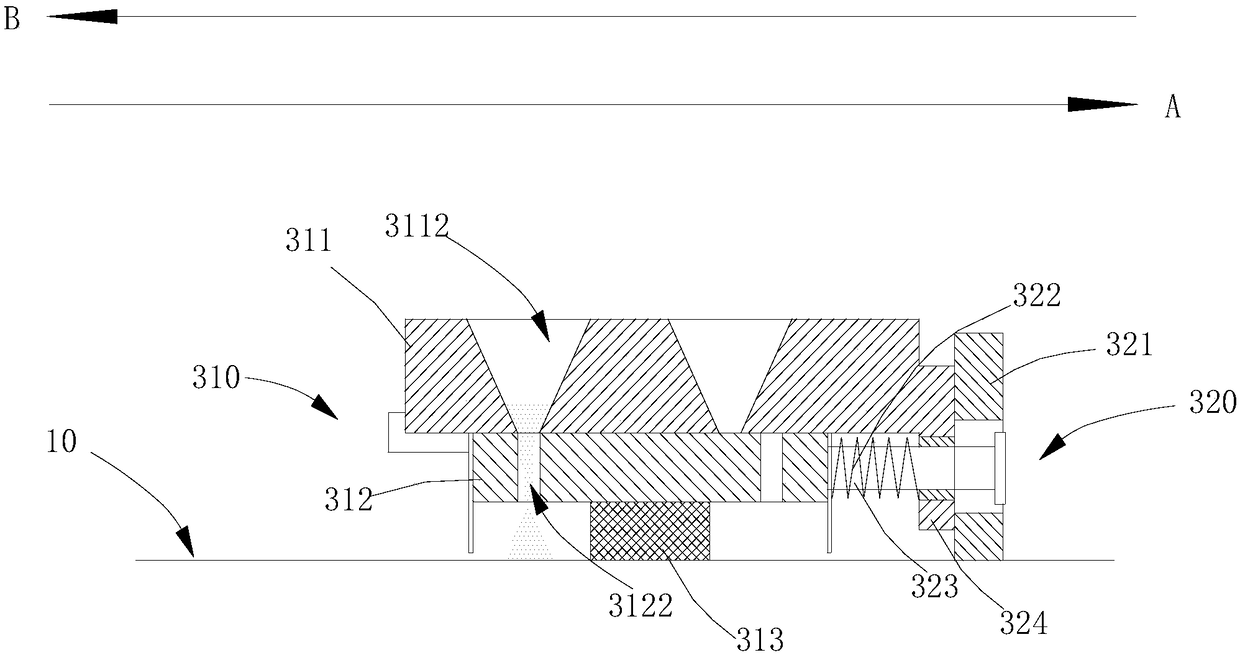

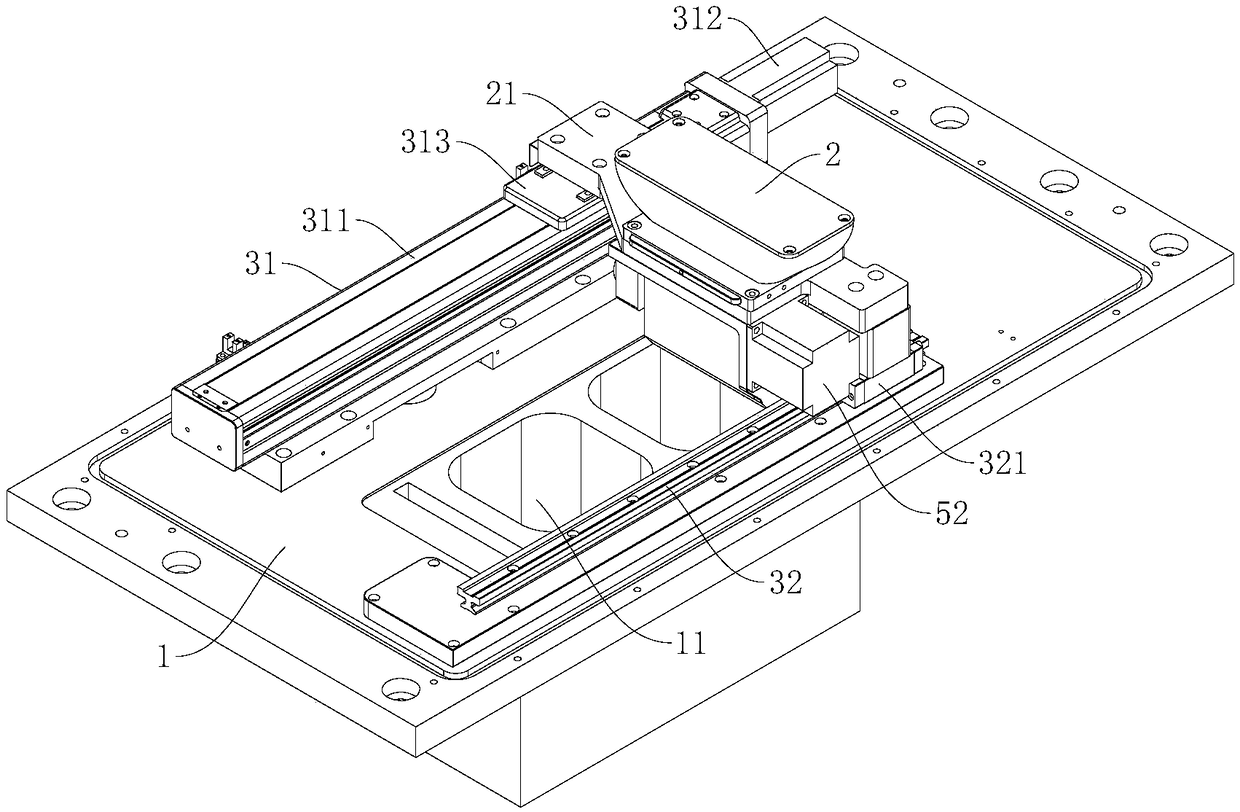

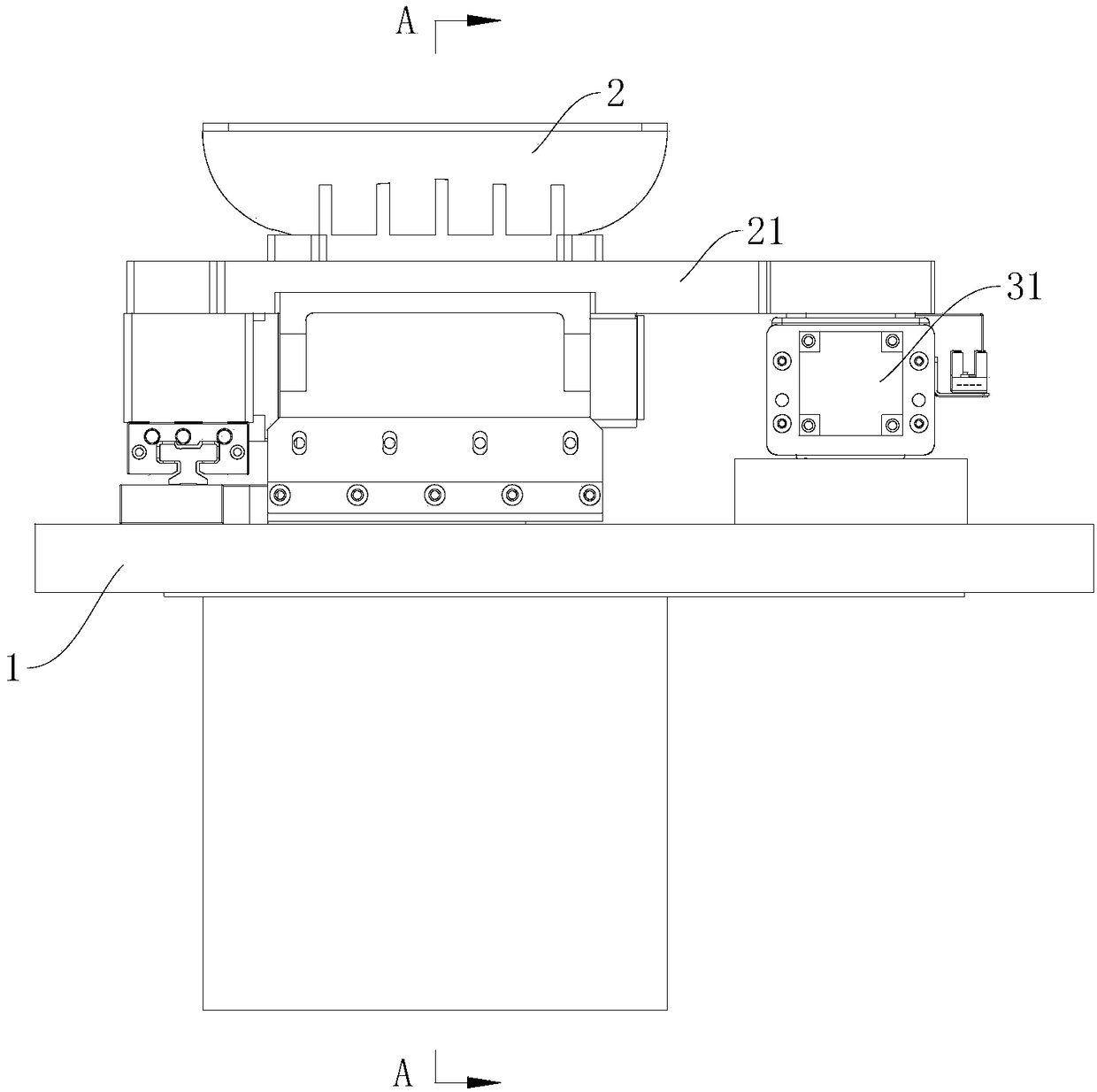

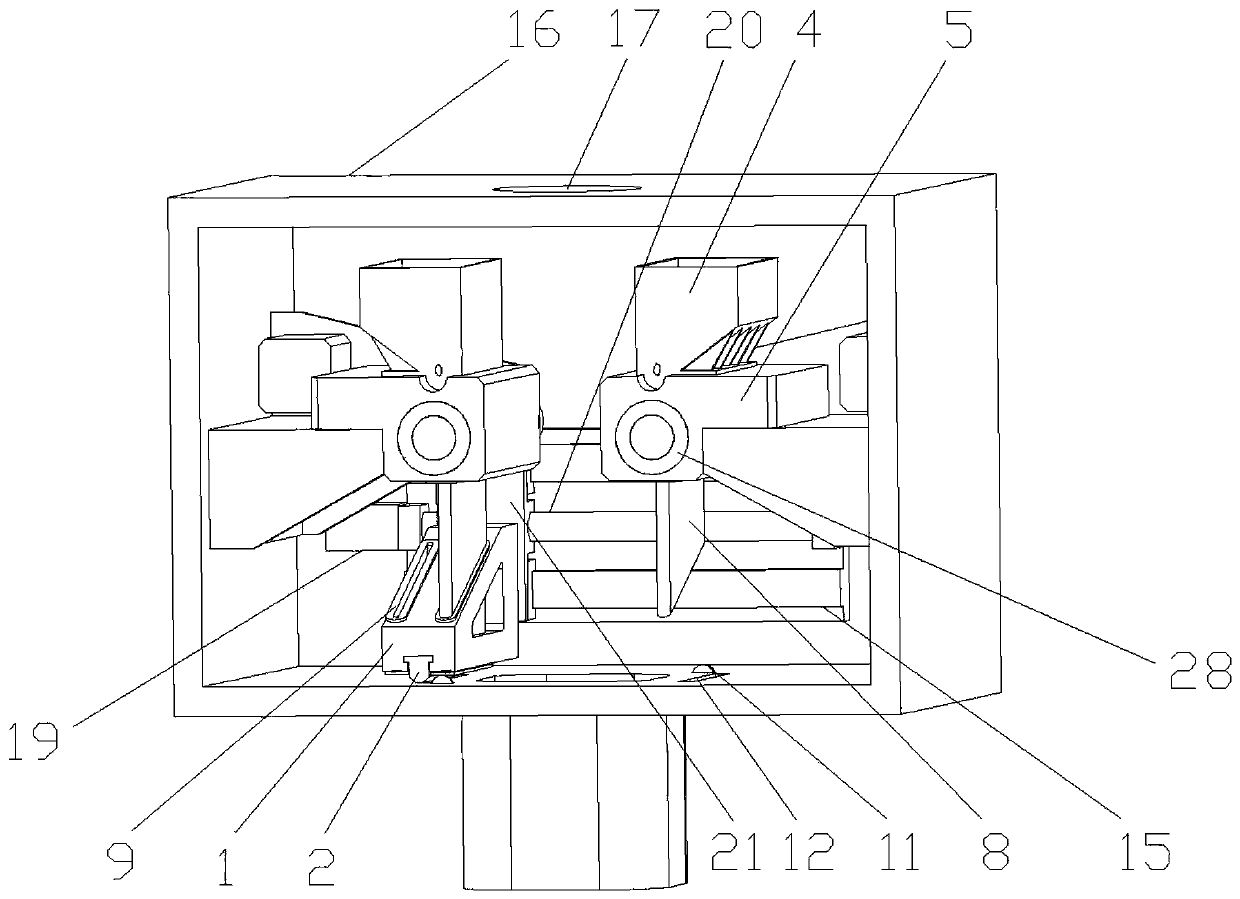

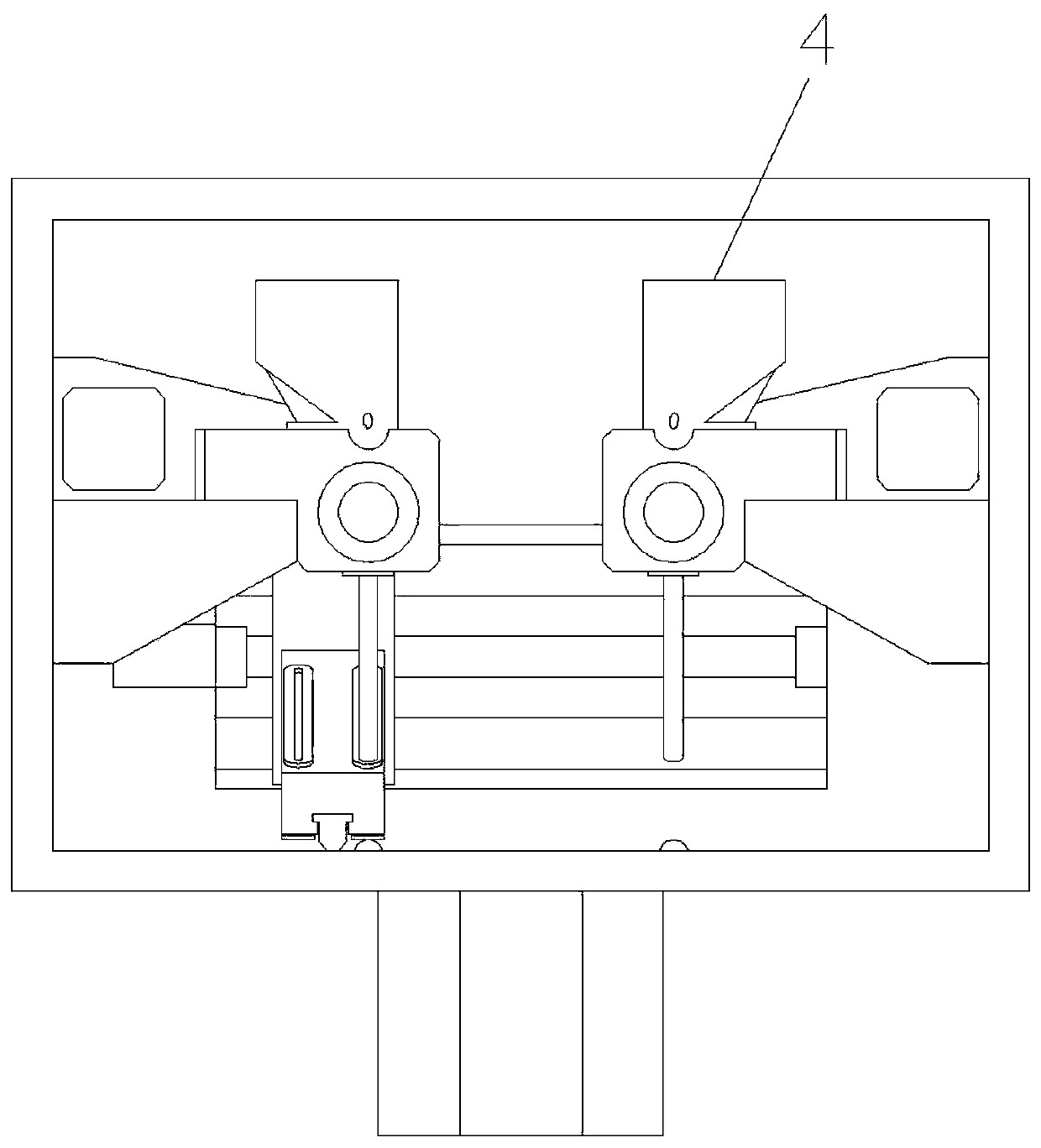

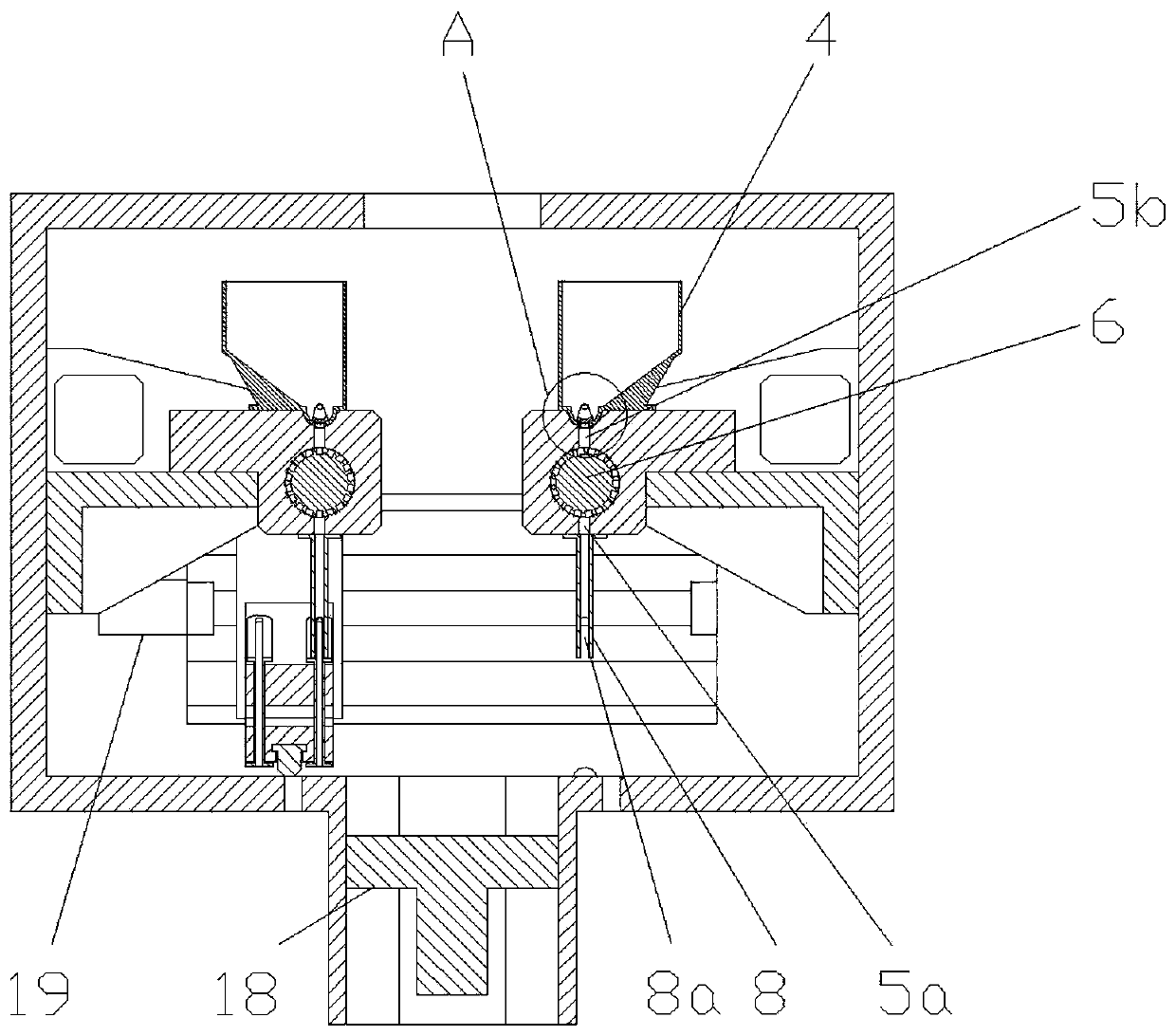

Mechanical contact-type bidirectional switching powder laying system based on powder bed

InactiveCN106312068ATo achieve powder storageWithout loss of precisionAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringContact type

The invention discloses a mechanical contact-type bidirectional switching powder laying system based on a powder bed. The mechanical contact-type bidirectional switching powder laying system comprises a forming horizontal plate, wherein linear guide rails are arranged on the forming horizontal plate; a bidirectional switching powder laying main body is erected on the linear guide rails; a linear motor slider is arranged on each of the left side and the right side of the bidirectional switching powder laying main body; and the bidirectional switching powder laying main body comprises a powder laying device powder inlet, limiting plates, a contact dual-rectangular sealing plate, powder laying and feeding openings and a scraper plate. According to the mechanical contact-type bidirectional switching powder laying system based on the powder bed, quantitative powder (twice powder laying quantity) is placed in a powder discharging hopper, the powder is placed in the powder laying device powder inlet through the powder discharging hopper under the gravity action, is uniformly distributed on two sides of a powder laying device under the action of left powder distributing openings and right powder distributing openings, the left powder distributing openings and the right powder distributing openings are in linear arrangement and equal in size and quantity, and powder feeding openings on two sides of the powder laying device are opened and closed to realize bidirectional powder feeding switching.

Owner:SOUTH CHINA UNIV OF TECH

Powder spreading device and additive manufacturing device

InactiveCN106424729AAvoid wastingImprove spreading efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturing3D printing

The invention belongs to the technical field of 3D printing, and discloses a powder spreading device and an additive manufacturing device. The powder spreading device comprises a powder spreading platform, hoppers and a scraper. The hoppers are located above two sides of the powder spreading platform, and are filled with powder materials. The scraper is arranged on the powder spreading platform, is vertically arranged and moves in the horizontal direction. A placing cavity communicating with the powder spreading platform is formed in the scraper. The powder materials in the hoppers are conveyed in the placing cavity, and are driven by the scraper to move. The additive manufacturing device comprises the powder spreading device. According to the powder spreading device, the scraper is vertically arranged and can move in the horizontal direction, so that bidirectional spreading of the powder materials can be realized; the placing cavity is formed in the scraper, the placing cavity is filled with the powder materials, and compared with a conventional additive manufacturing device for spreading powder bidirectionally, the scraper does not need to ascend, horizontally move and descend, and all that is needed is to horizontal move, bidirectional powder spreading can be completed, so that time waste is avoided, and the powder spreading efficiency is effectively improved.

Owner:QUICKBEAM CO LTD +1

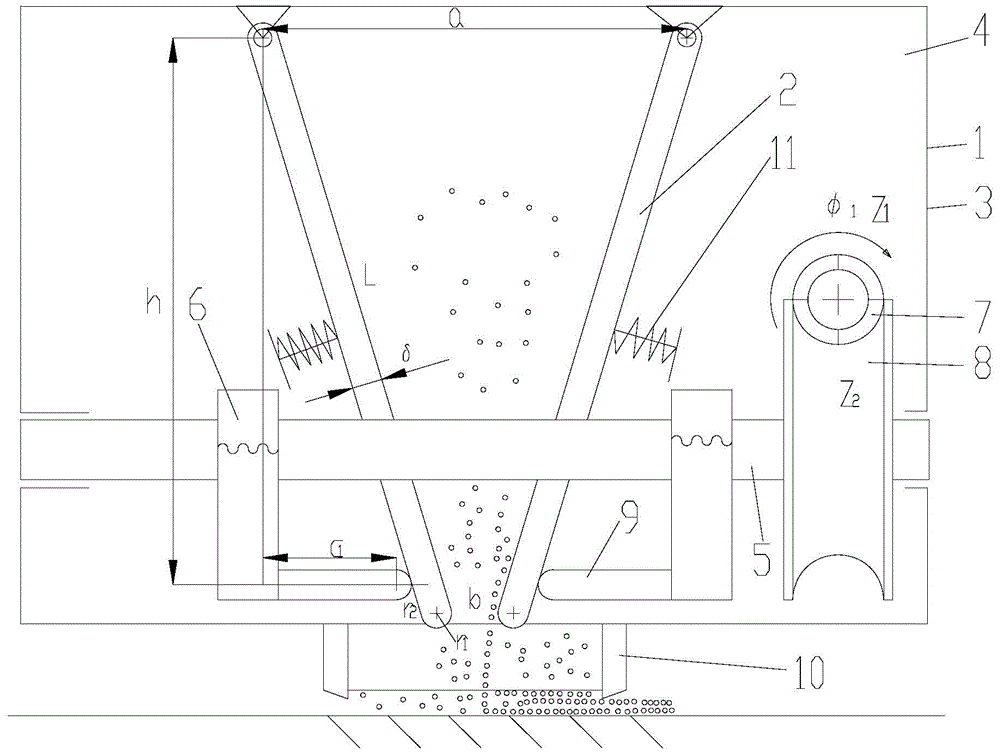

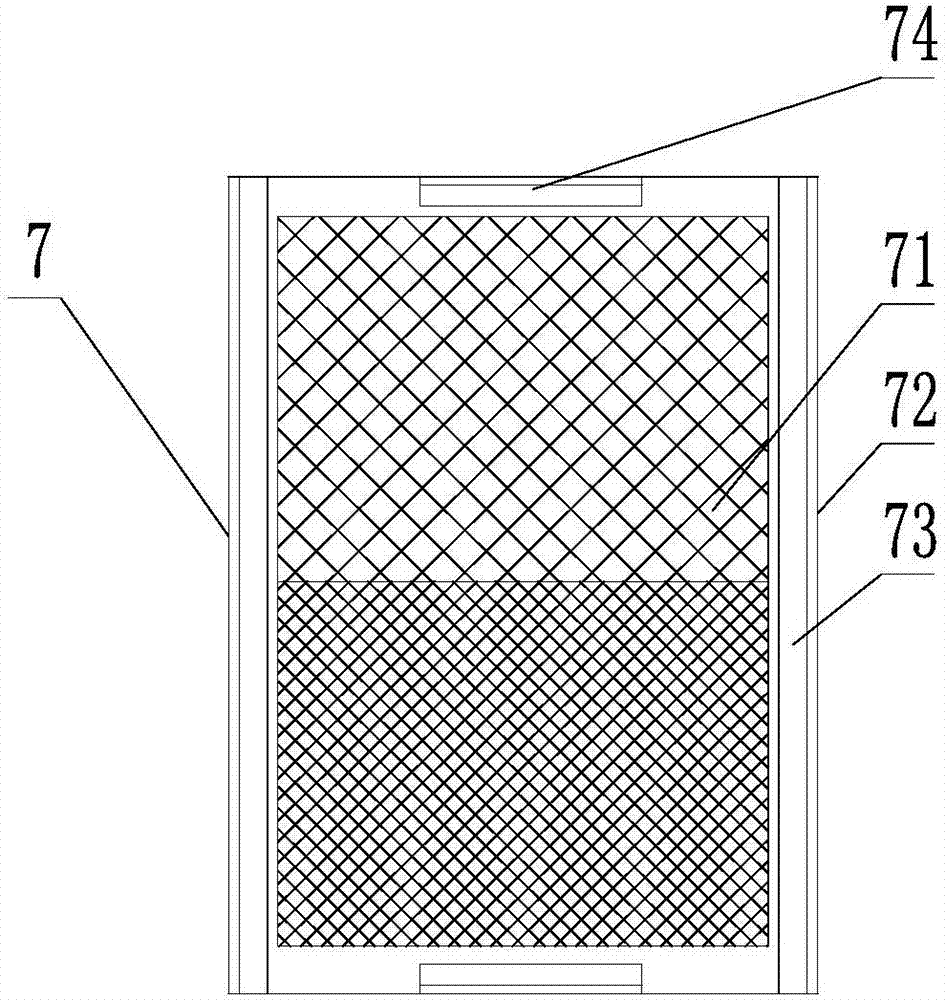

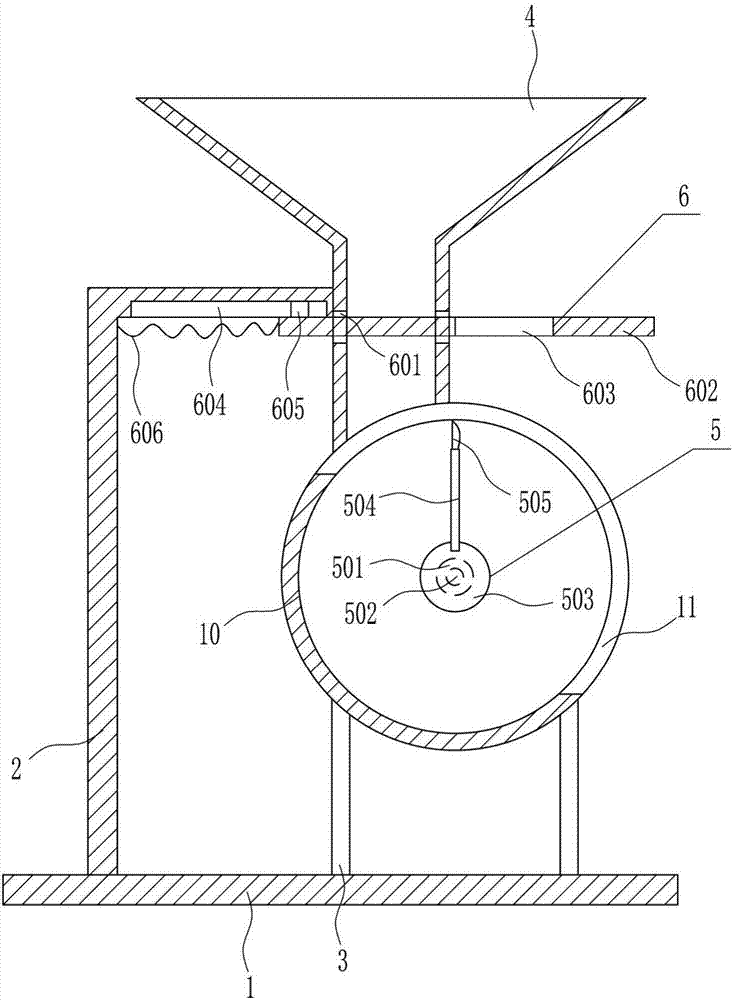

Powder spreading apparatus for selective laser melting

ActiveCN103911611ASave drive energyImprove molding qualityMetallic material coating processesSelective laser meltingSelective laser sintering

The invention discloses a powder spreading apparatus for selective laser melting. The apparatus comprises a funnel-type powder spreading bin used for holding powder to be spread and an adjusting device used for adjusting at least pressure of powder located at the powder outlet of the funnel-type powder spreading bin. According to the invention, the powder spreading bin with a funnel-type structure is employed and arranged along a vertical direction together with a processing platform; compared with the prior art, the powder spreading apparatus provided by the invention has a simple and compact structure, is free of idle stroke during round-trip powder spreading and can save driving energy needed in movement of the powder spreading apparatus, reduce energy consumption in powder spreading and improve powder spreading efficiency; powder at the bottom of the funnel-type powder spreading bin is used as a spreading powder source and has great pressure due to extrusion, so powder spreading compactness can be improved, thereby further improving part forming quality; the powder spreading bin can be also applied in research of powder fluidity and can effectively measure influence of a variety of factors on compactness of spread powder.

Owner:CHONGQING UNIV

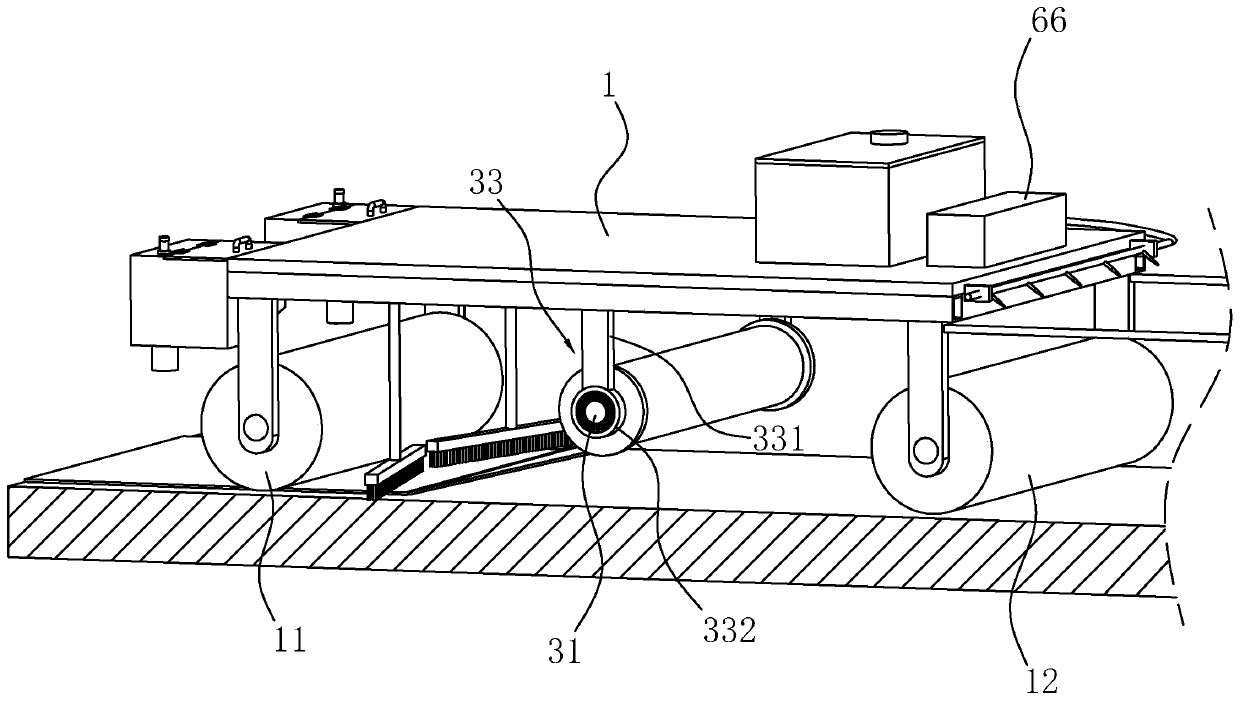

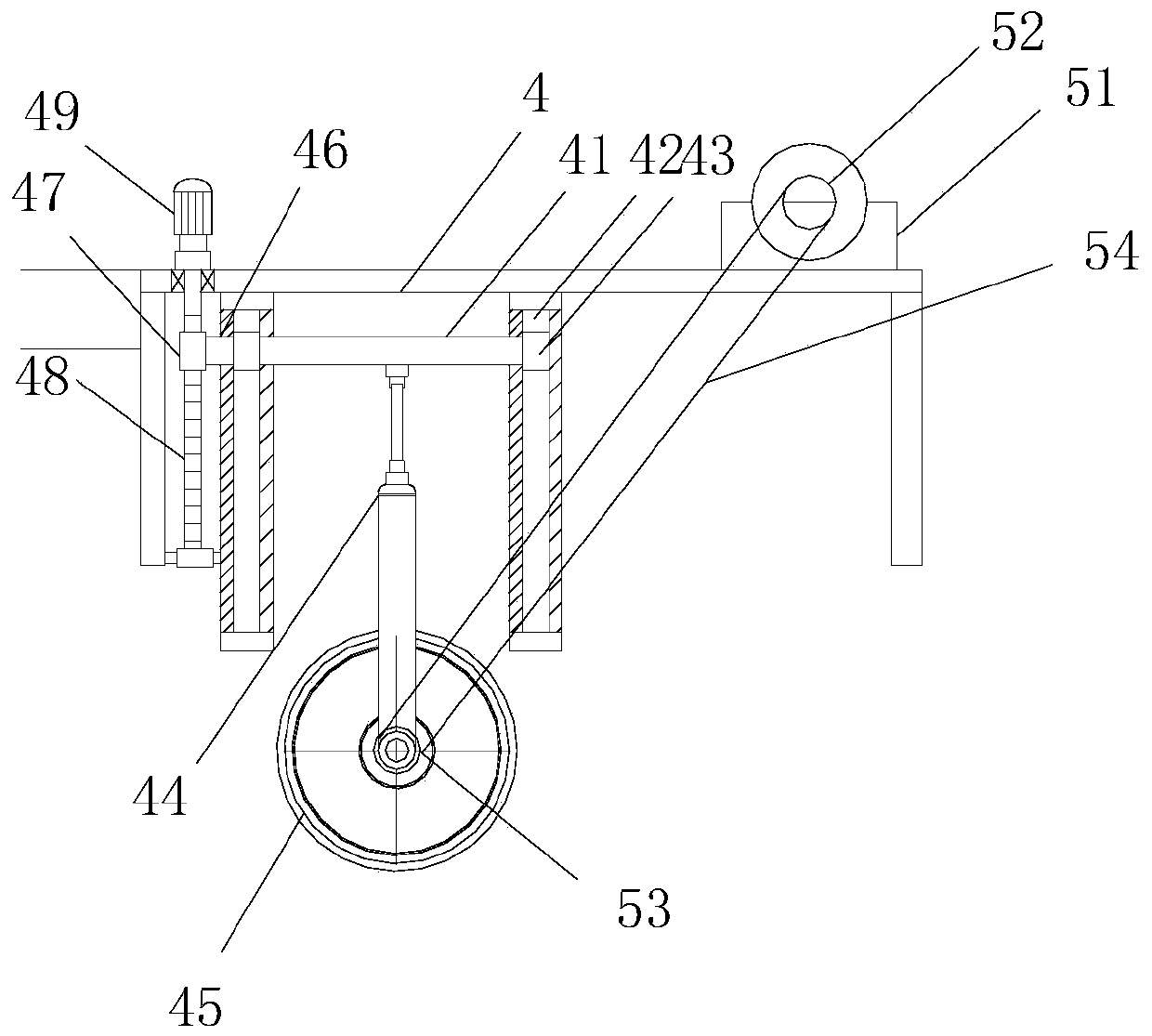

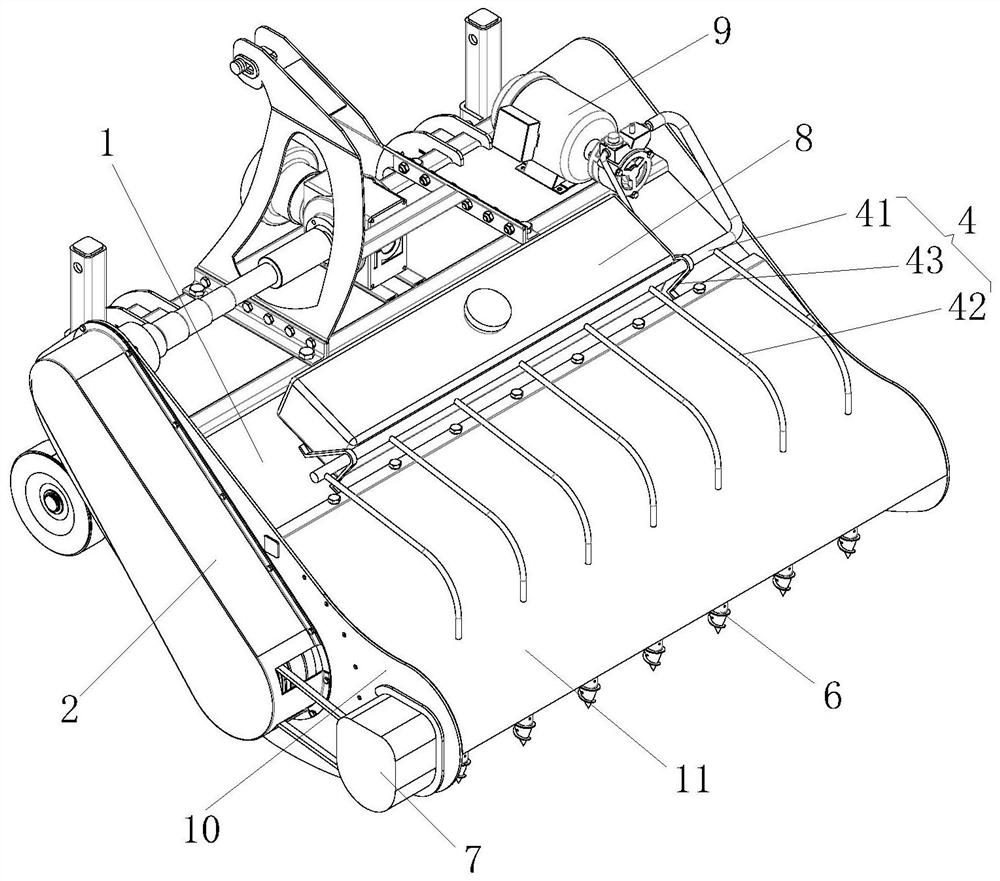

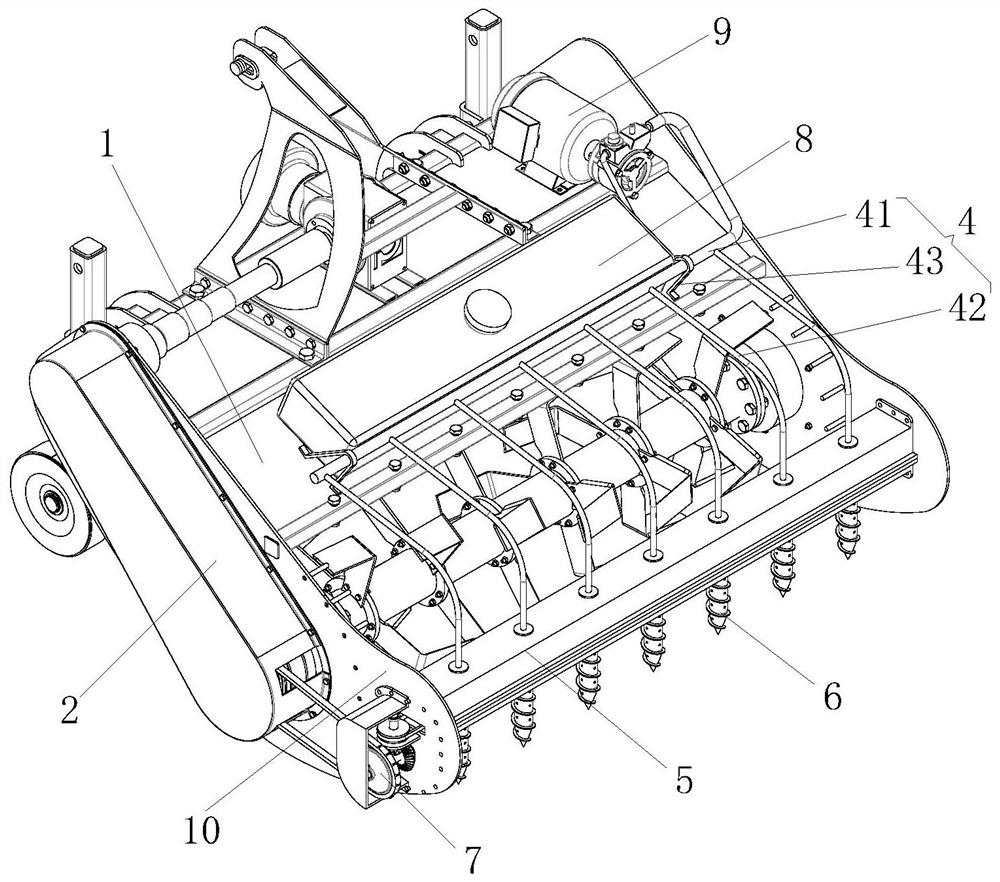

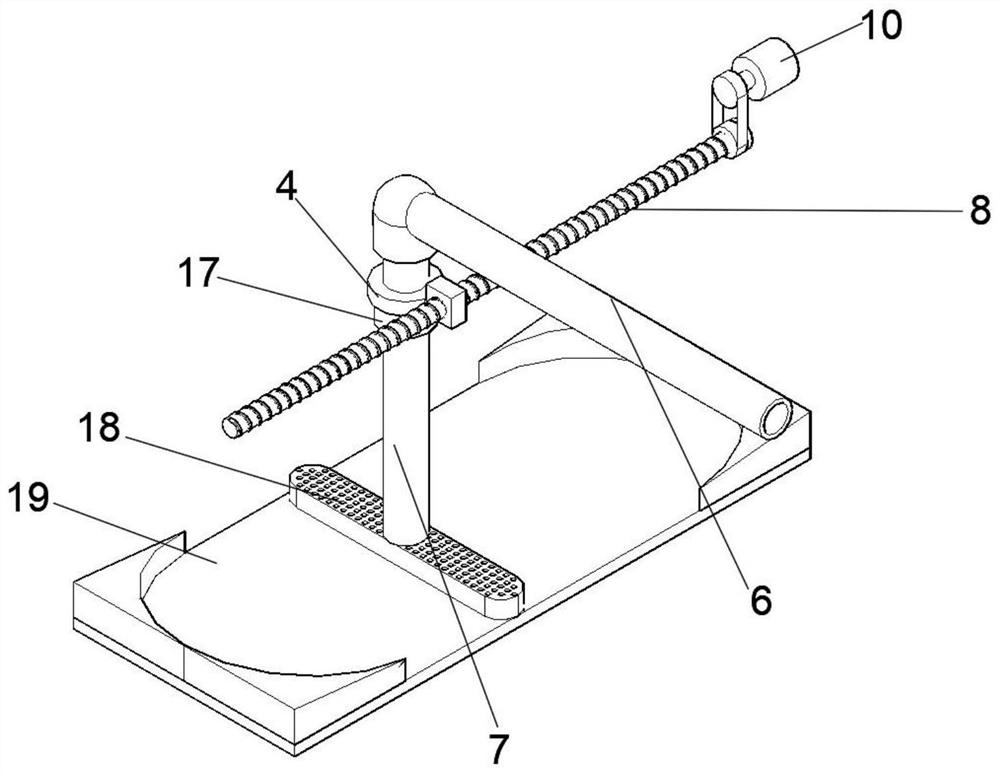

Mulching film machine for garden road construction

ActiveCN110055868AImprove laying efficiencyImprove spreading efficiencyRoads maintainencePlastic mulchEngineering

The invention discloses a mulching film machine for garden road construction. According to the technical scheme, the mulching film machine comprises a frame body, a first travelling roller and a second travelling roller, and the first travelling roller and the second travelling roller are arranged on the frame body, rotatably connected with the frame body, and parallel to each other; the frame body is provided with a mulching film paving device and a water spraying device, and a pulling rope driving the frame body to move is arranged on one side of the frame body; the mulching film paving device comprises a support roller erected on the frame body and a mulching film roll-collected on the circumferential surface of a support shaft, the support roller is rotatably connected with the frame body, and the support roller is further parallel to the first travelling roller; when the frame body is moved, the end part of the mulching film is pressed on the lower part of the first travelling roller; and the water spraying device comprises a water tank arranged on the frame body, a first water outlet pipe, a water pump, a second water outlet pipe and a spraying nozzle, the first water outletpipe, the water pump, the second water outlet pipe and the spraying nozzle are sequentially connected with the water tank, and the spraying nozzle is arranged on the second travelling roller and sprays towards the direction deviating from the first travelling roller. The mulching film machine for garden road construction has the advantages that water spraying and mulching film paving can be conducted simultaneously.

Owner:北京绿视点园林景观工程有限公司

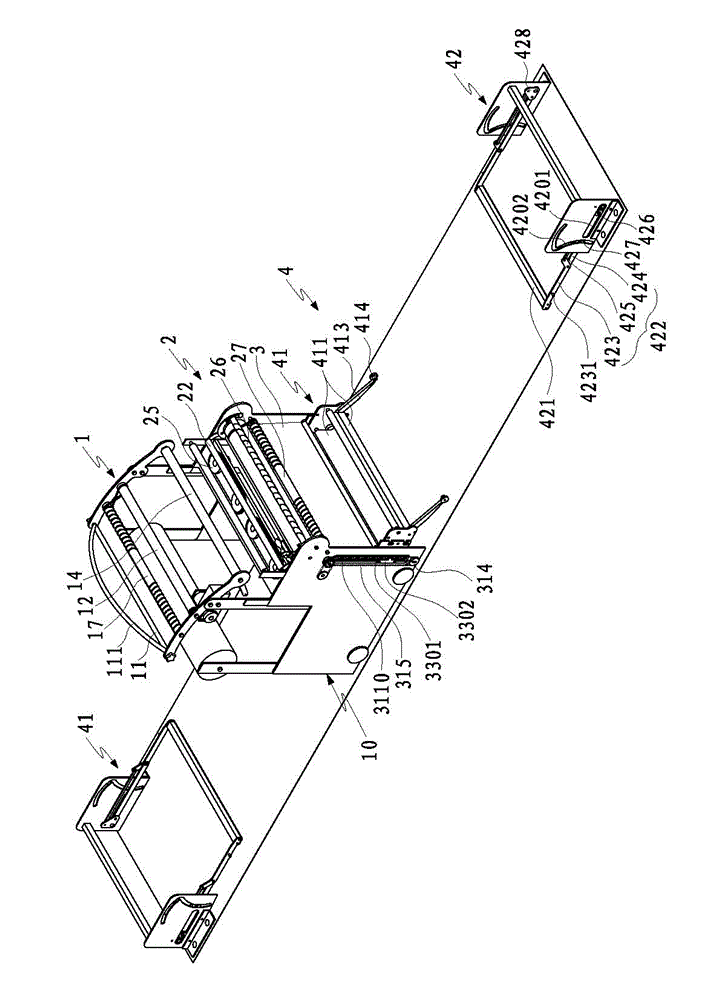

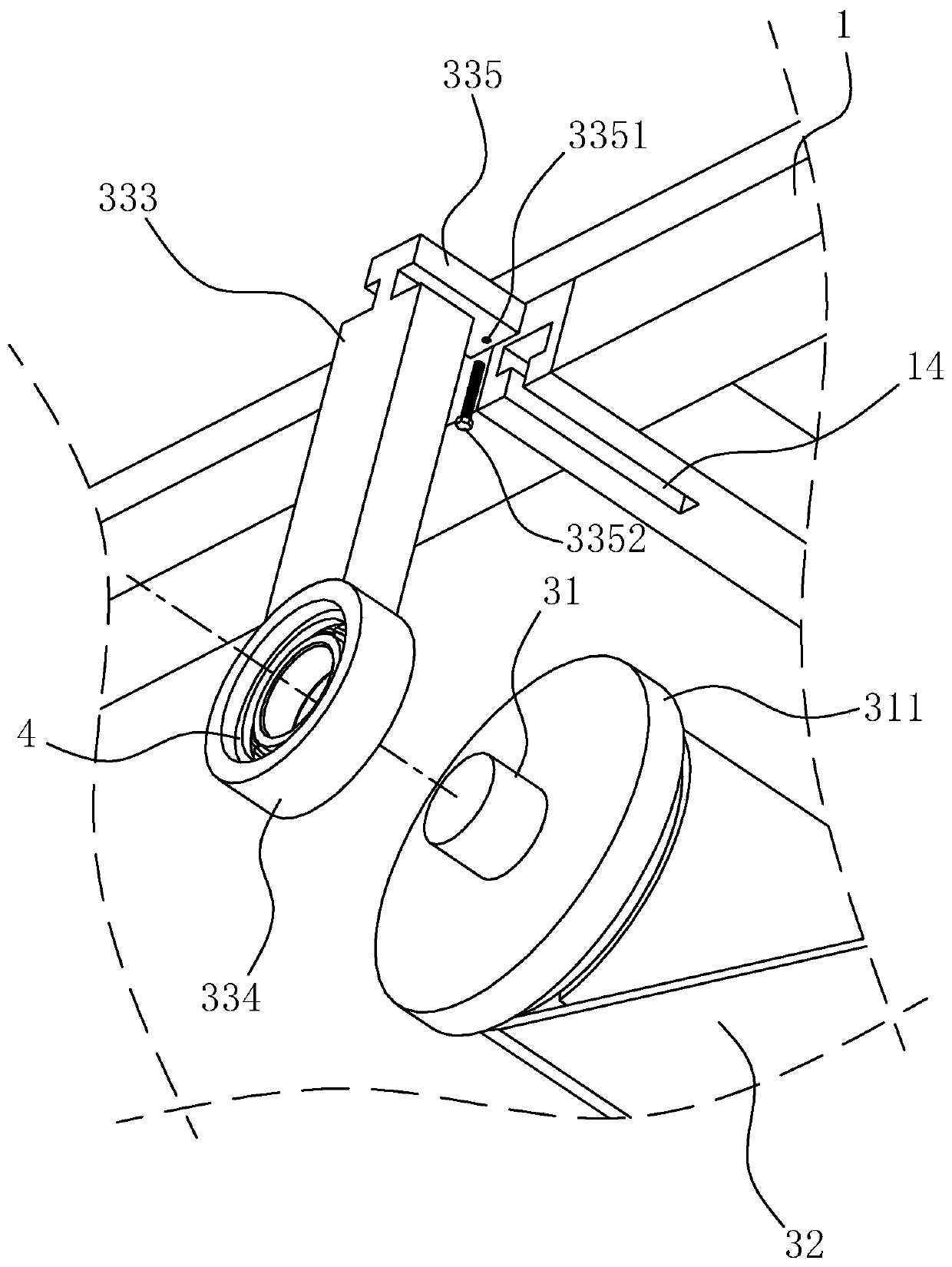

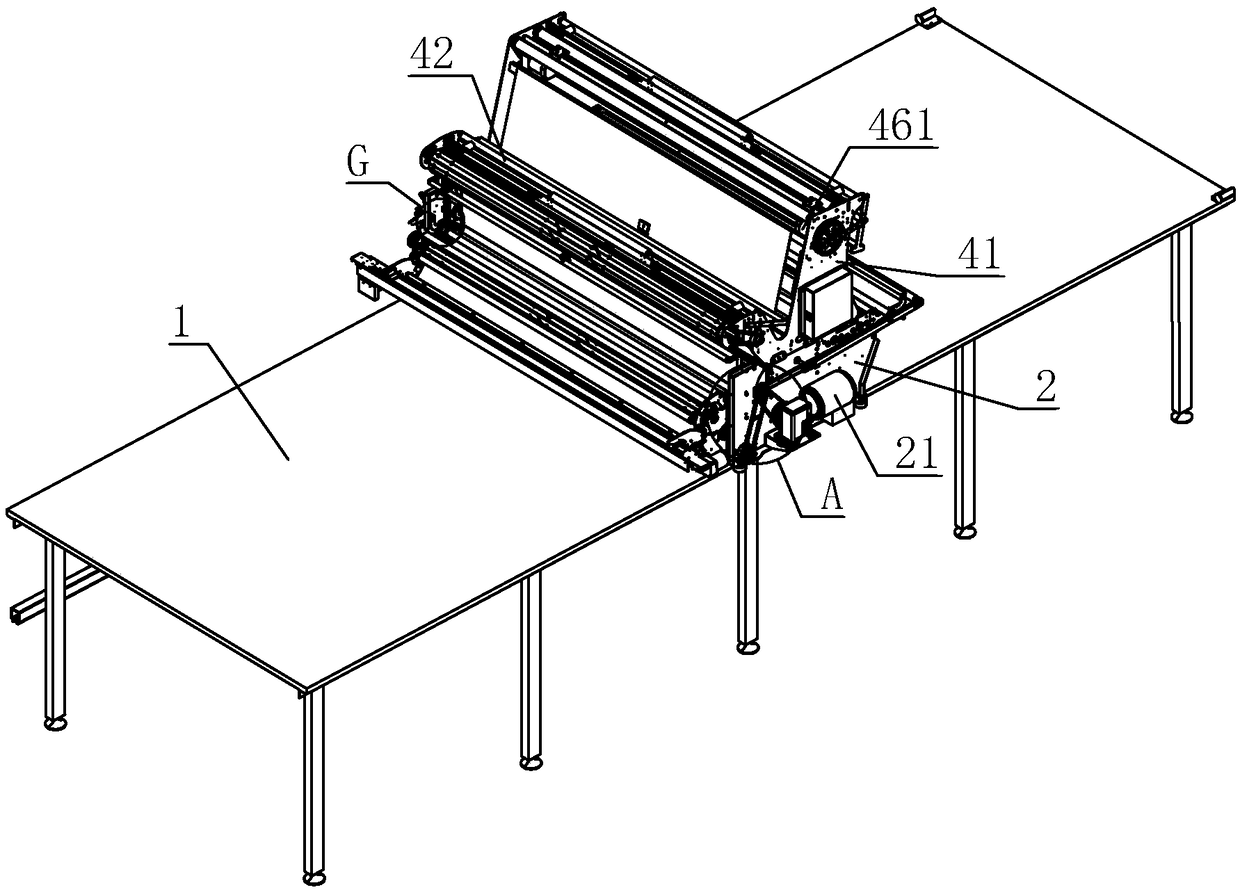

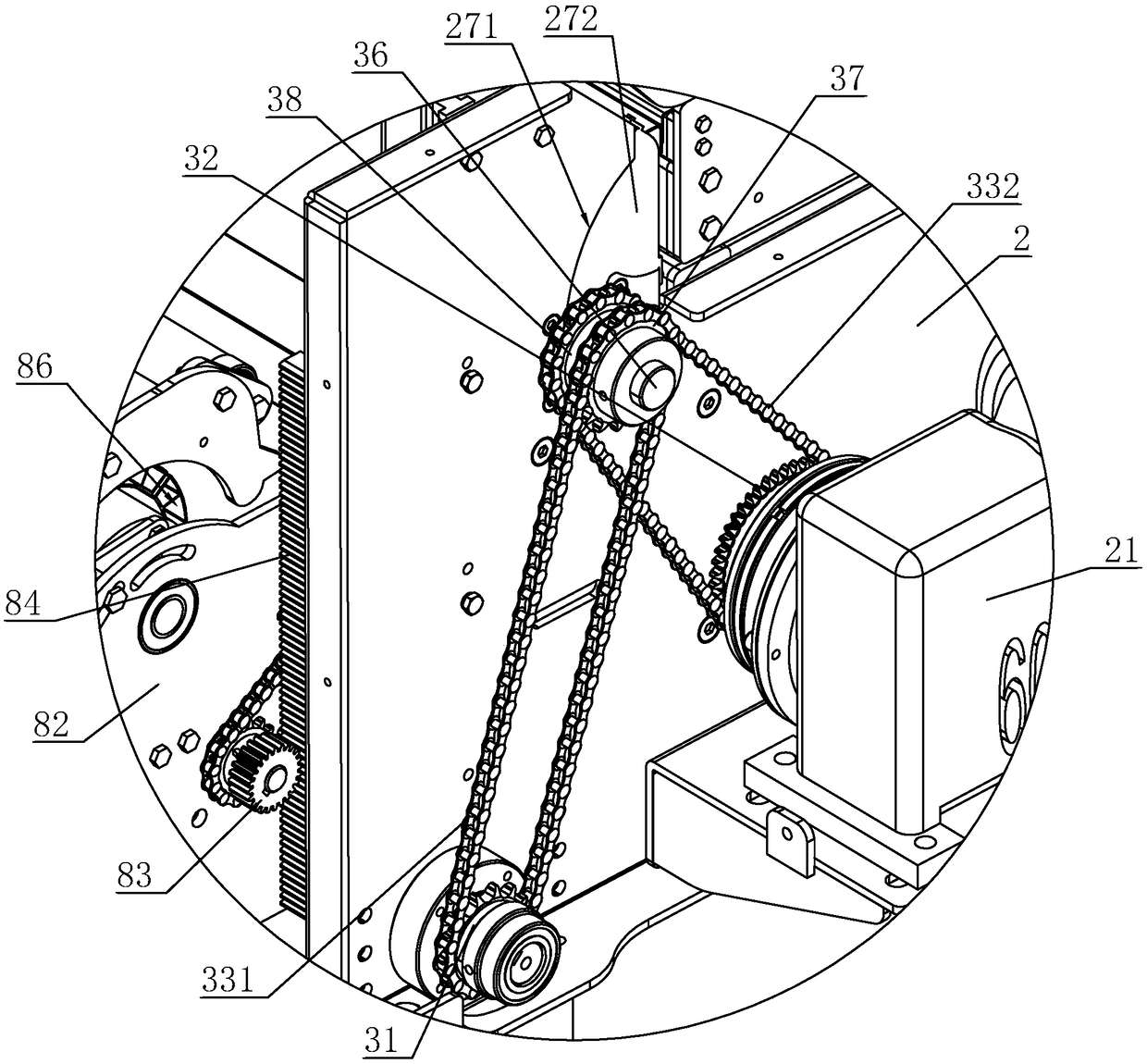

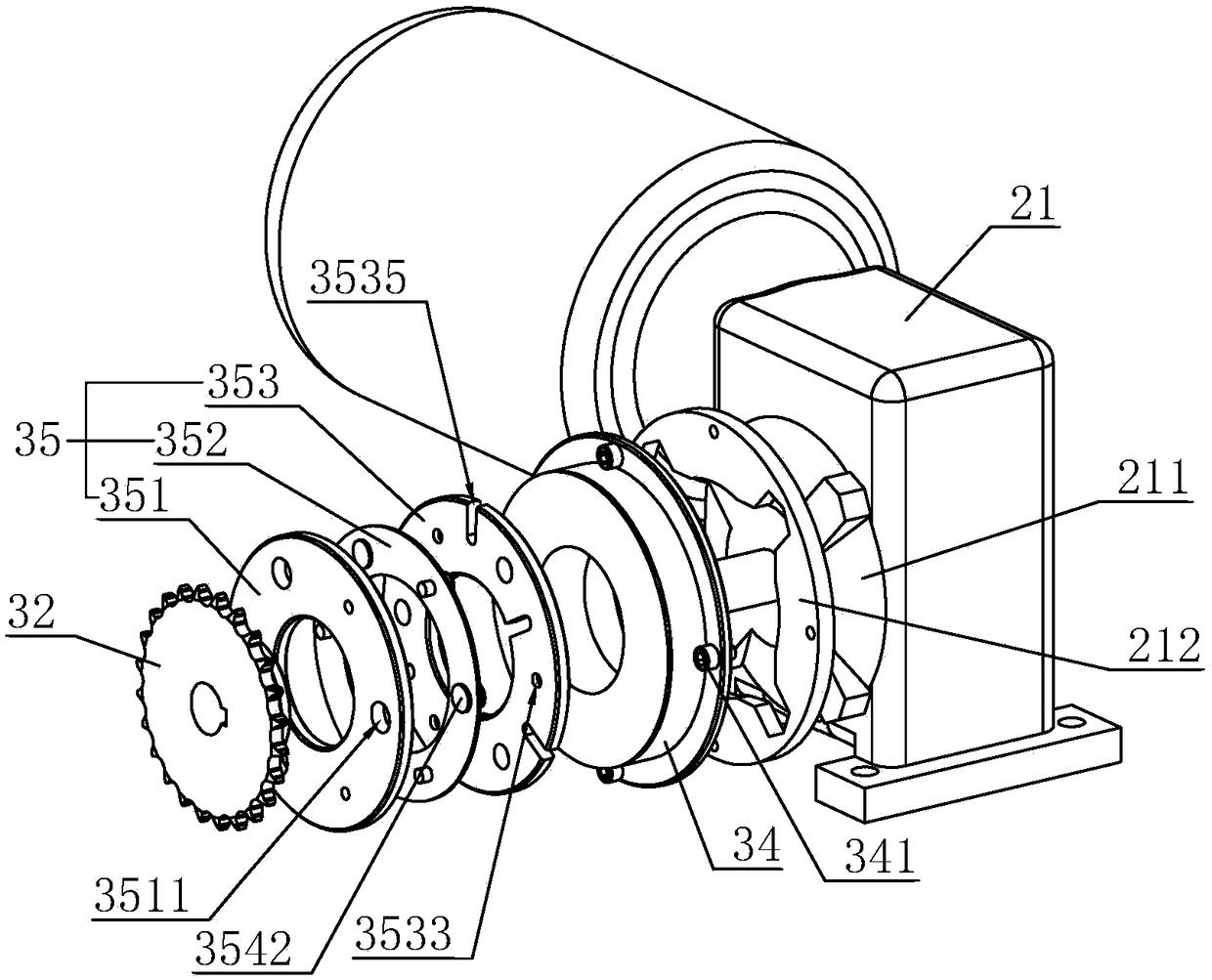

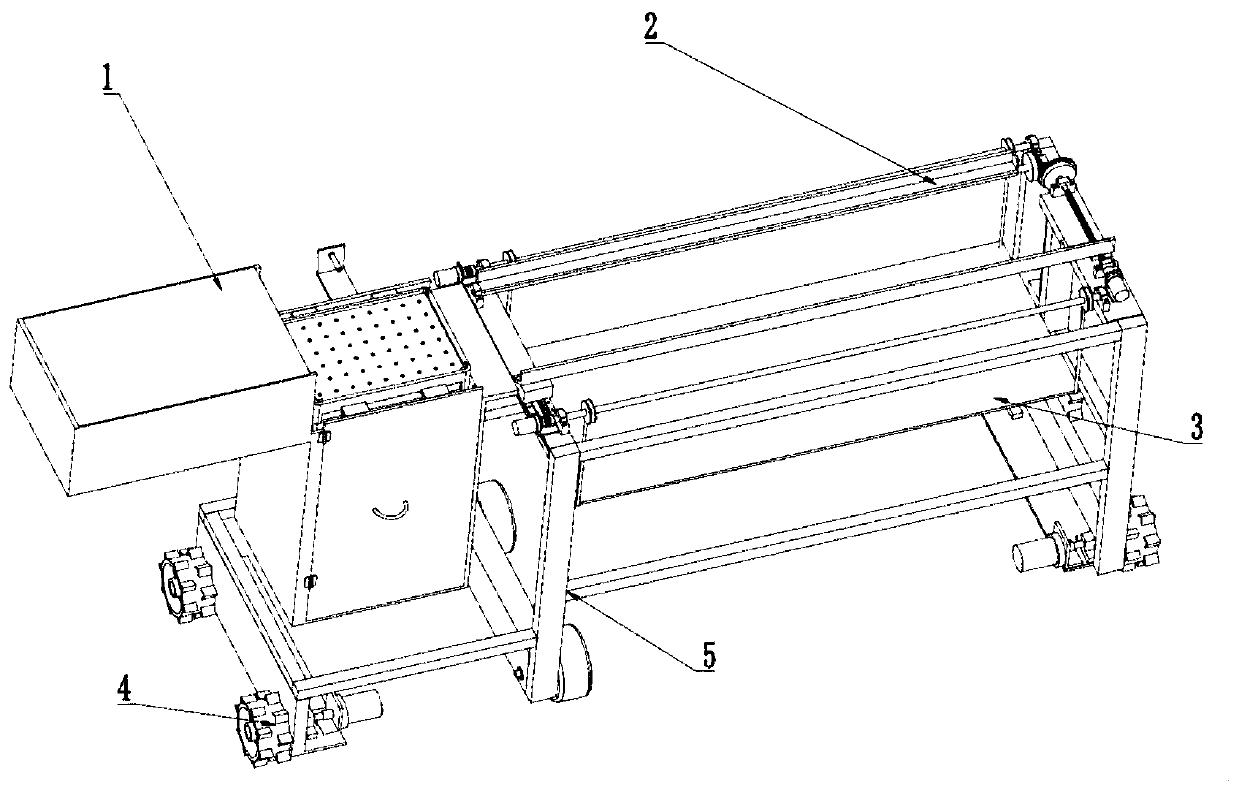

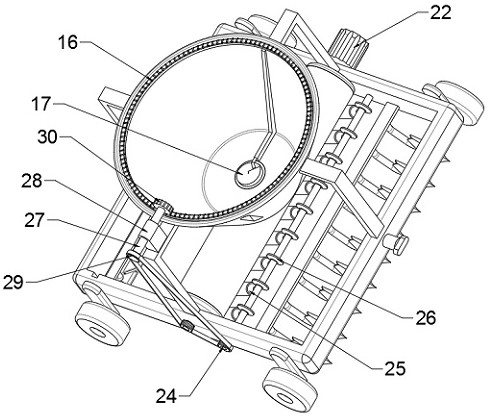

Knitting spreading machine and fabric spreading method thereof

PendingCN109132693AReduce slip distanceSmall length errorUnfolding thin materialsWebs handlingSprocketEngineering

The invention discloses a knitting spreading machine and a fabric spreading method thereof, relating to the technical field of garment processing equipment, comprising a fabric spreading platform, a frame which is rotatably provided with rollers and moves on the fabric spreading platform, and traveling motors which are installed on the frame and connected to the rollers and having brake mechanismsmounted thereon, wherein the brake mechanisms include first sprockets coaxially coupled to the rollers and second sprockets mounted on output shafts of the traveling motors, chain sets mounted on thefirst sprocket and the second sprocket, electromagnets mounted on the traveling motors and connected to a power source, and positioning assemblies mounted on the second sprockets and attracted by theelectromagnets. Through the positioning of the positioning assemblies and the electromagnets, the frame can be stopped rapidly, thereby greatly reducing the sliding distance of the frame, reducing the length error of the fabric spreading, and improving the accuracy of the fabric spreading.

Owner:浙江精力玛智能机械有限公司

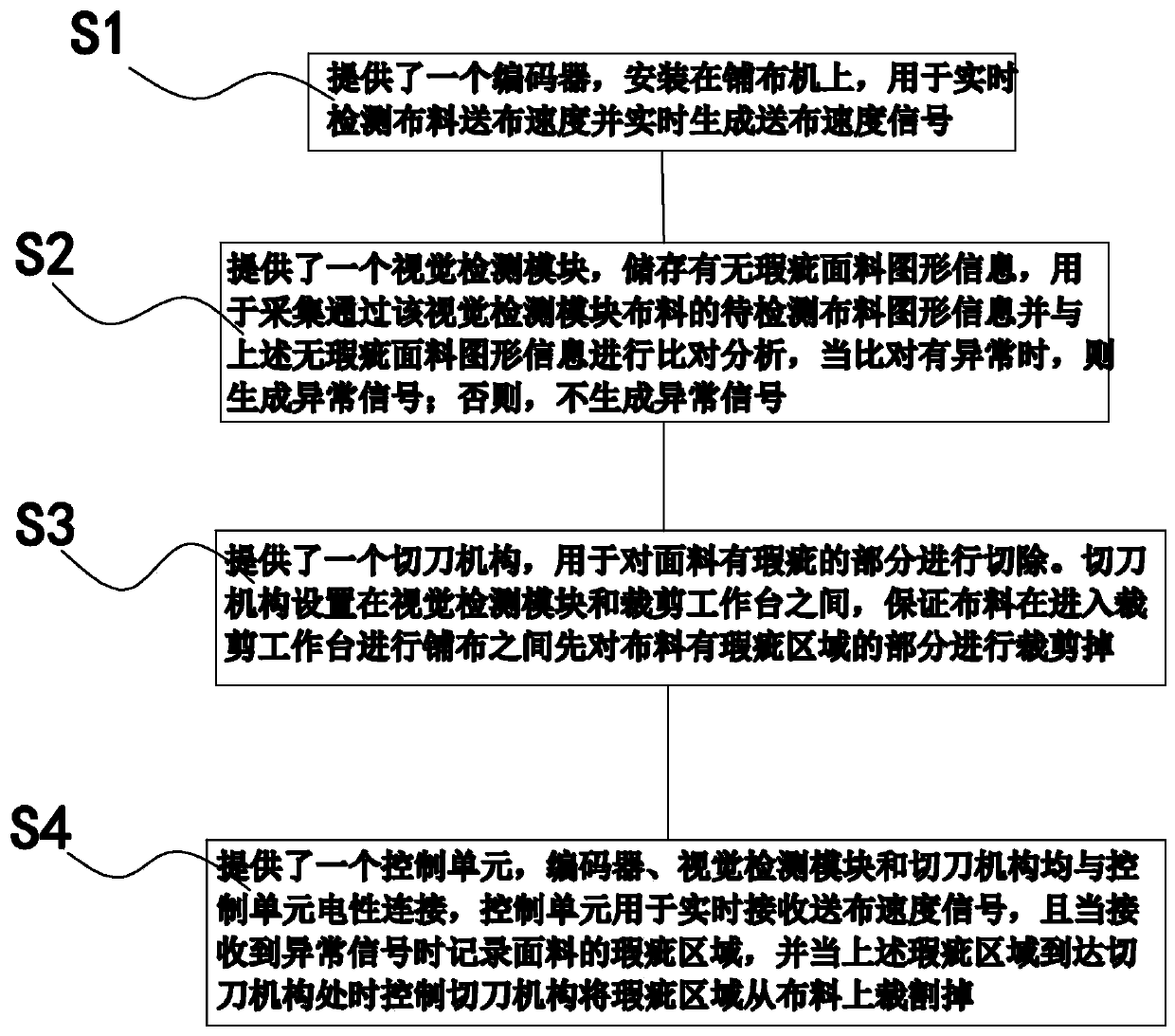

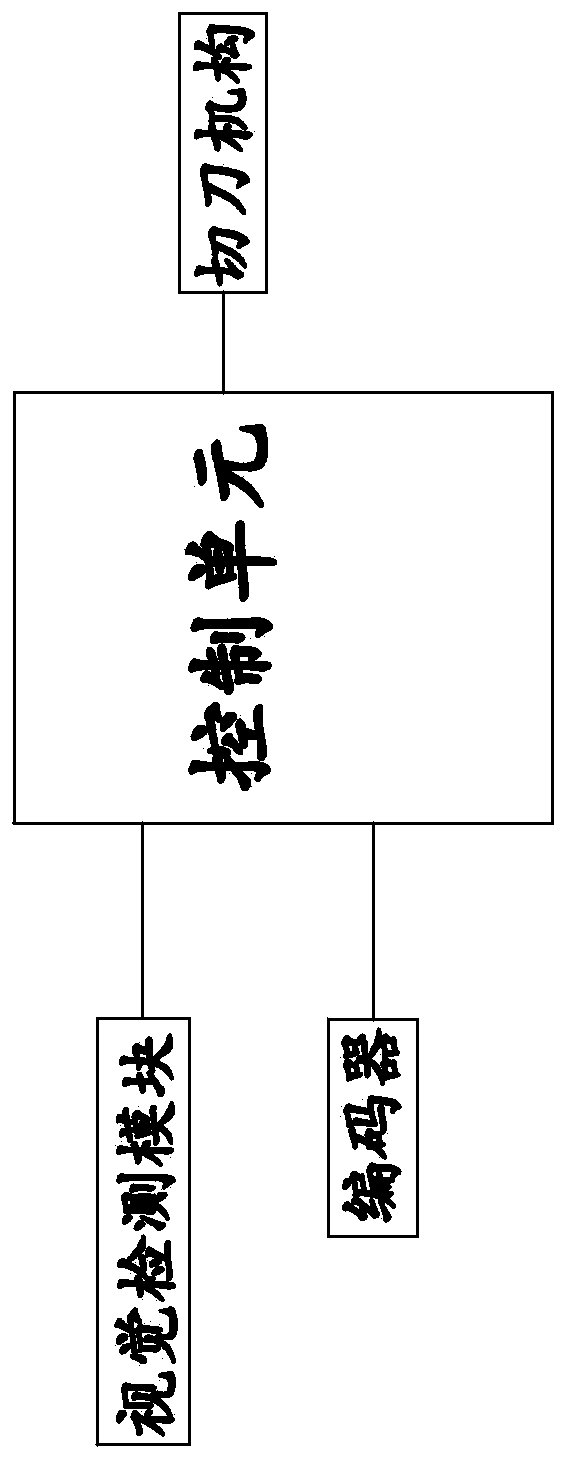

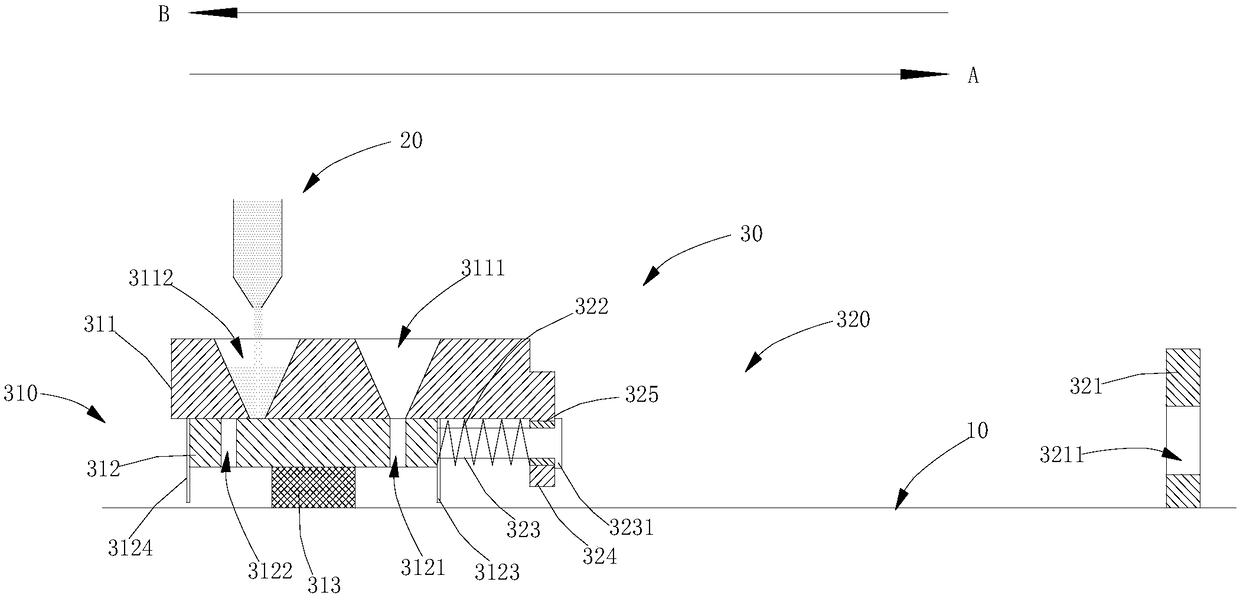

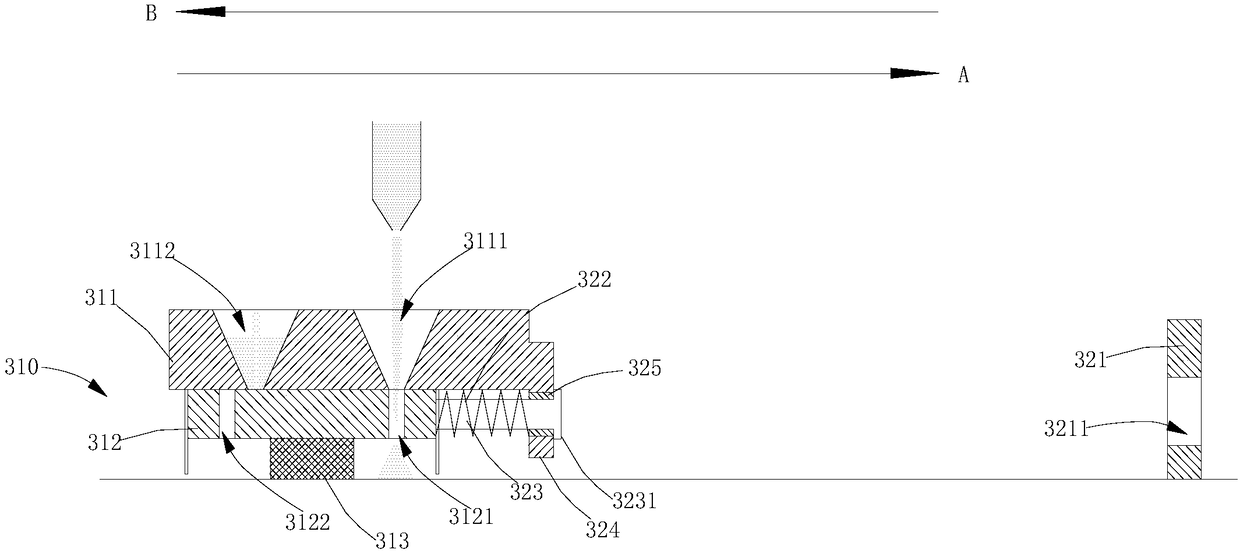

Cloth flaw detection control system on cloth spreading machine

InactiveCN110057832AAccurate cuttingImprove spreading efficiencyMaterial analysis by optical meansUnfolding thin materialsMachine controlControl system

The invention provides a cloth flaw detection control system on a cloth spreading machine and belongs to the field of cloth spreading machine control technologies. Through the system, the problems that in the prior art, cloth flaw detection efficiency is low, and accuracy is not high are solved. A cloth flaw detection control method comprises the steps that S1, an encoder is provided; S2, a visiondetection module is provided, wherein the vision detection module is used for collecting graphic information of to-be-detected cloth, performing comparative analysis and generating an anomaly signalwhen an anomaly is found through comparison; S3, a cutter mechanism is provided, wherein the cutter mechanism is used for cutting off a flawed part of the cloth; and S4, a control unit is provided, wherein the control unit is used for receiving a cloth-conveying velocity signal in real time, recording a flawed area of the cloth when receiving the anomaly signal and controlling the cutter mechanismto cut the flawed area off the cloth when the flawed area reaches the cutter mechanism. The cloth flaw detection control method has the advantages of high detection efficiency and high accuracy.

Owner:BULLMER ELECTROMECHANICAL TECH

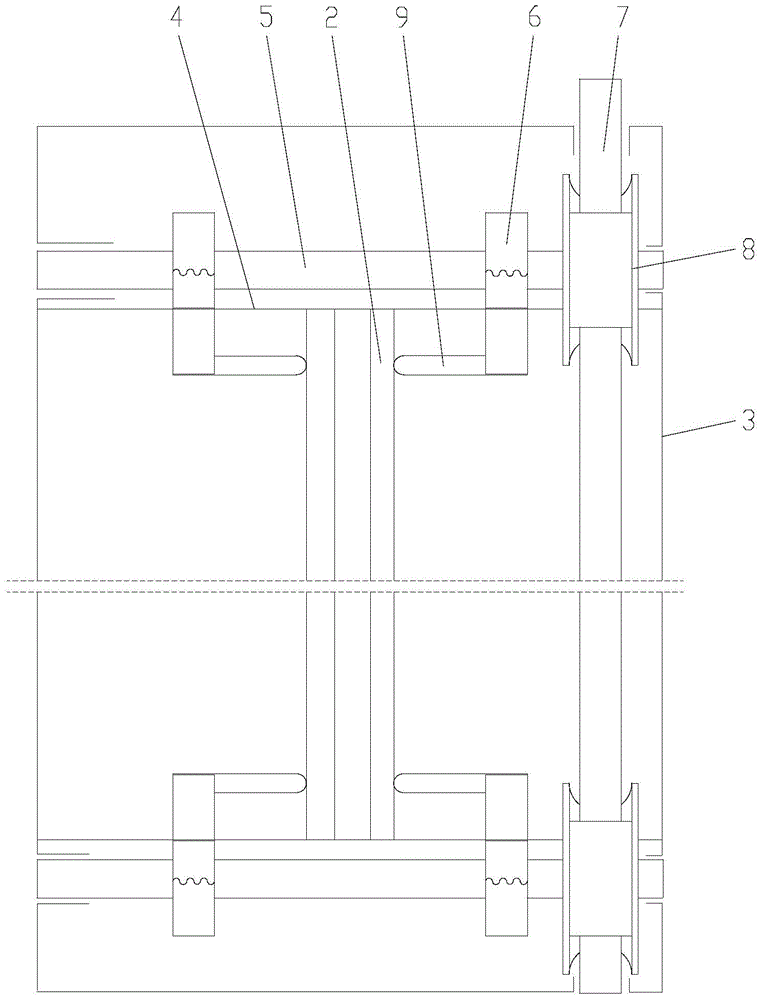

Bidirectional powder paving device, powder feeding and paving device and additive manufacturing device

PendingCN108544753ASimple structureLow input cost3D object support structuresAdditive manufacturing with solidsMetallurgyAdditive layer manufacturing

The invention relates to a bidirectional powder paving device. The bidirectional powder paving device comprises a powder paving mechanism, a driving mechanism and a adjusting mechanism; the powder paving mechanism comprises a powder feeding part, a scraper base and a scraper; the powder feeding part is arranged on the scraper base, and the scraper is fixed at the bottom of the scraper base; a forward powder feeding groove and a reverse powder feeding groove are formed in the powder feeding part, and the scraper base is provided with a forward powder falling hole and a reverse powder falling hole; the driving mechanism can drive the powder paving mechanism to reciprocate between a forward powder falling position and a reverse powder falling position along the powder paving path; and relative movement can be generated between the scraper base and the powder feeding part under the action of the adjusting mechanism to achieve switching between a forward conducting state and a reverse conducting state. According to the bidirectional powder paving device, twice powder falling and powder paving actions are realized when a scraper assembly drives a powder feeding plate to move back and forth in the length direction of a workbench, the powder paving efficiency is high, the structure is simple, and the device investment cost is low.

Owner:HUNAN FARSOON HIGH TECH CO LTD

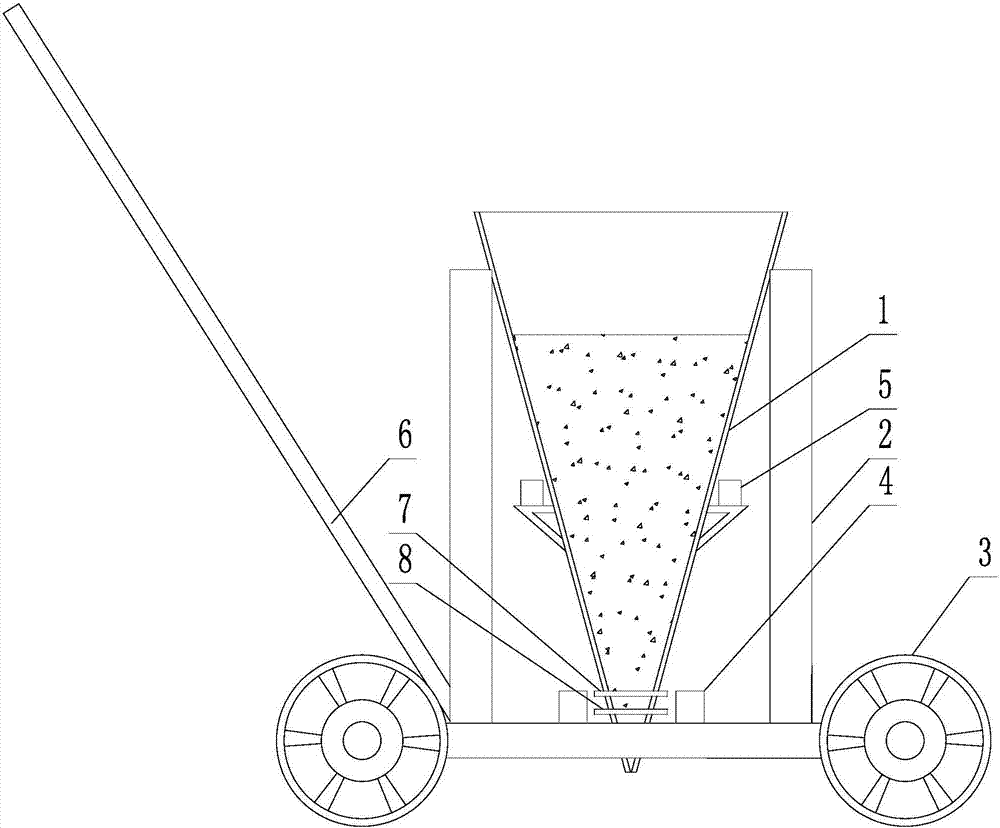

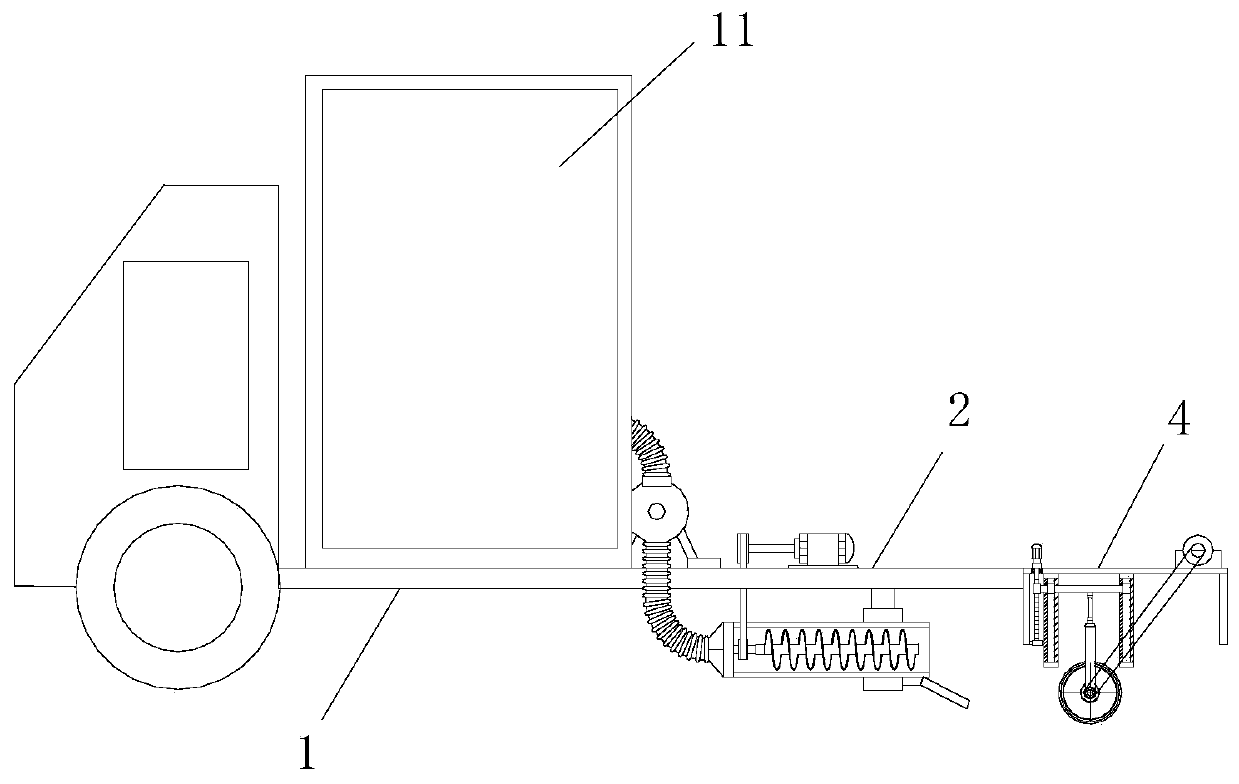

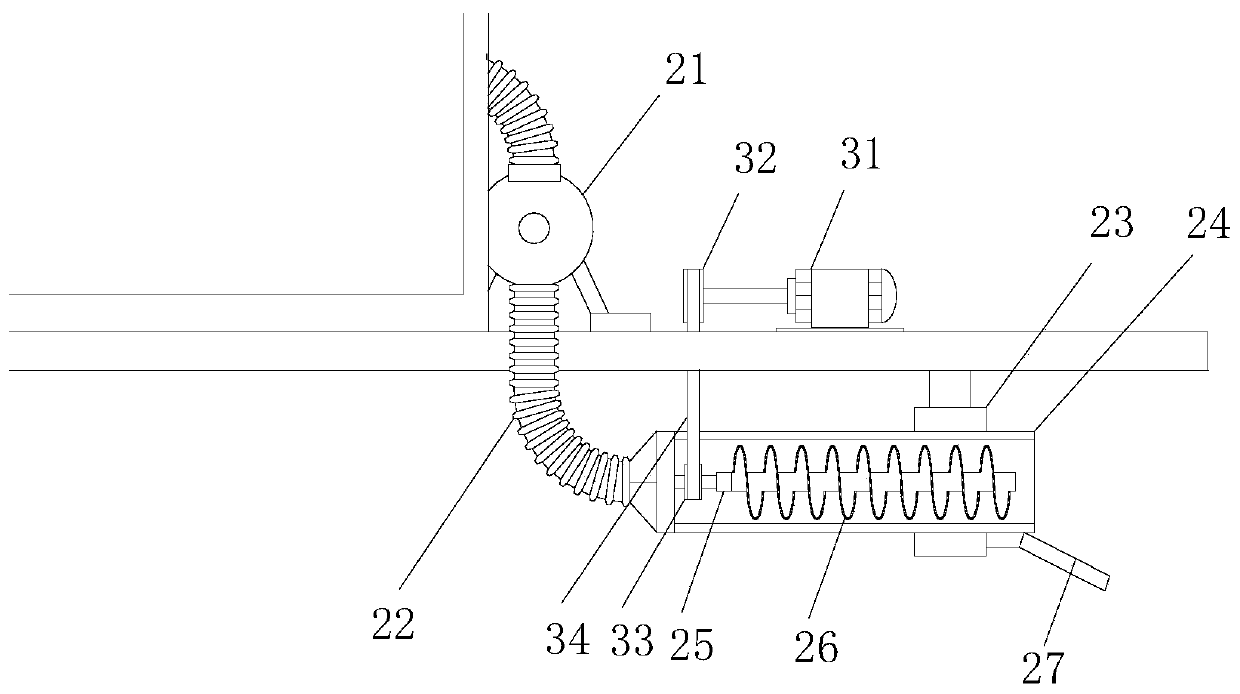

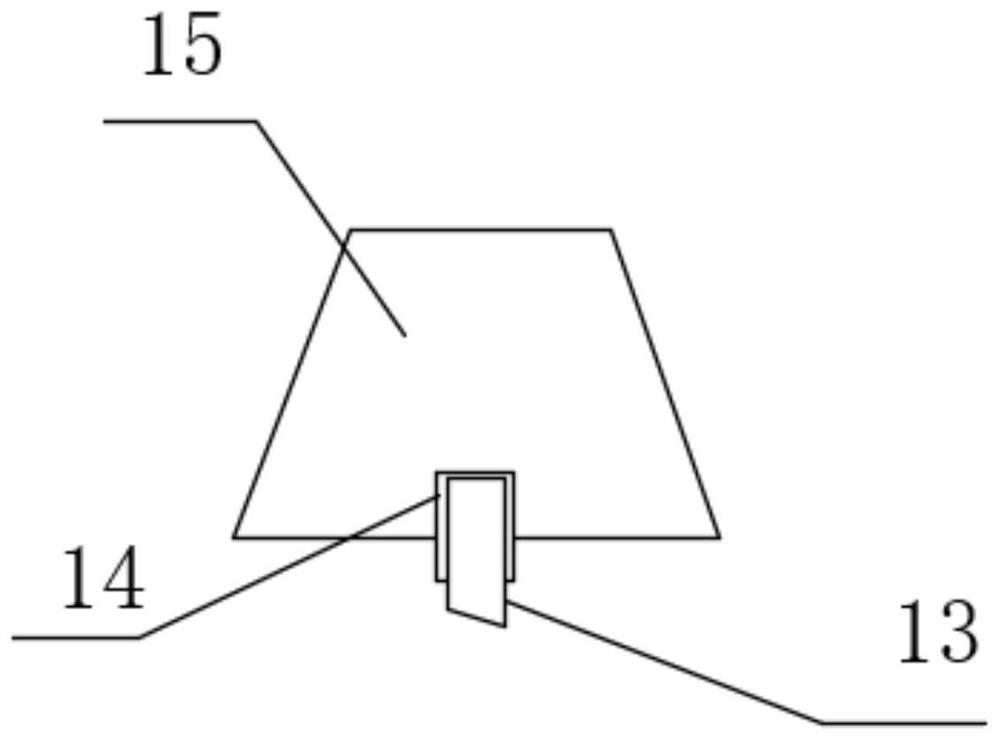

Carborundum aggregate distributor

PendingCN106906724AImprove spreading efficiencySimple structureRoads maintainenceVehicle frameDistributor

The invention discloses a carborundum aggregate distributor. The carborundum aggregate distributor comprise a vehicle frame, a hopper fixed on the vehicle frame, an outlet used for discharging carborundum arranged at the lower end of the hopper, the outlet is in a strop shape, the number of the wheel is at least two, the wheel is in a cylindrical shape, the projection of the outlet facing to any one of wheel axis is fallen between two ends of the wheels, and the outlet is positioned between any two wheels. The distributor has the advantages that the structure is simple, the aggregate distribution is uniform, and the spreading efficiency of carborundum terrace is increased.

Owner:CHINA MCC5 GROUP CORP

3d printer with double feeding cylinders

InactiveCN107263866AImprove spreading efficiencyImprove printing accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineering3d printer

The invention relates to the field of 3d printers, in particular to a 3d printer with double feeding cylinders. The 3d printer comprises a rack and a machine shell arranged outside the rack. A forming cylinder is arranged in the middle of the lower portion of the rack. The first material cylinder and the second material cylinder are arranged on the left side and the right side of the forming cylinder correspondingly. A laser emission mechanism is arranged in the position, located over the forming cylinder, of the rack. The rack is further provided with a powder feeding mechanism which can move back and forth above the first material cylinder, the forming cylinder and the second material cylinder. The first material cylinder is internally provided with a first lifting platform. The second material cylinder is internally provided with a second lifting platform. The forming cylinder is internally provided with a third lifting platform. Compared with the prior art, the laser emission mechanism of the 3d printer with the double feeding cylinders does not need to be moved, and the printing precision can be improved; and in addition, the 3d printer is simpler in structure, lower in manufacturing cost and higher in powder laying efficiency, so that the working efficiency is effectively improved.

Owner:安徽恒利增材制造科技有限公司

Cement troweling device for building foundation

InactiveCN110644332AAvoid uneven fallingImprove laying effectRoads maintainenceVehicle frameArchitectural engineering

The invention relates to the field related to construction, and particularly discloses a cement troweling device for a building foundation. The cement troweling device for the building foundation comprises a vehicle frame, a cement mixing barrel is mounted on the vehicle frame, a cement feeding mechanism and a cement troweling mechanism are mounted on the vehicle frame respectively, the cement feeding mechanism includes a cement conveying pump and a feeding rack, the feeding rack is provided with a feeding channel, a feeding roller shaft is mounted in the feeding channel in a built-in mode, aspiral feeding auger is mounted on the feeding roller shaft, a lifting frame is mounted in the cement troweling mechanism in a built-in mode, a work frame is mounted at the bottom of the lifting frame, a troweling roller is mounted on the work frame, the lifting frame is externally connected with an outer edge rod, a threaded sleeve is mounted at the rod end of the outer edge rod, a lifting screwis arranged at the side edge of the cement troweling mechanism, and the threaded sleeve is arranged on the lifting screw lifting in threaded fit in a sleeving mode. According to the cement troweling device for the building foundation, uniformity of spreading of cement can be improved, and the cement troweling device for the building foundation adapts to cement foundations of various heights

Owner:蔡新新

Feed spreading device for chicken and ducks in breeding industry

InactiveCN107114268AShorten the timeSpreading speed is fastTransportation and packagingRotary stirring mixersAgricultural scienceForage

Owner:王成志

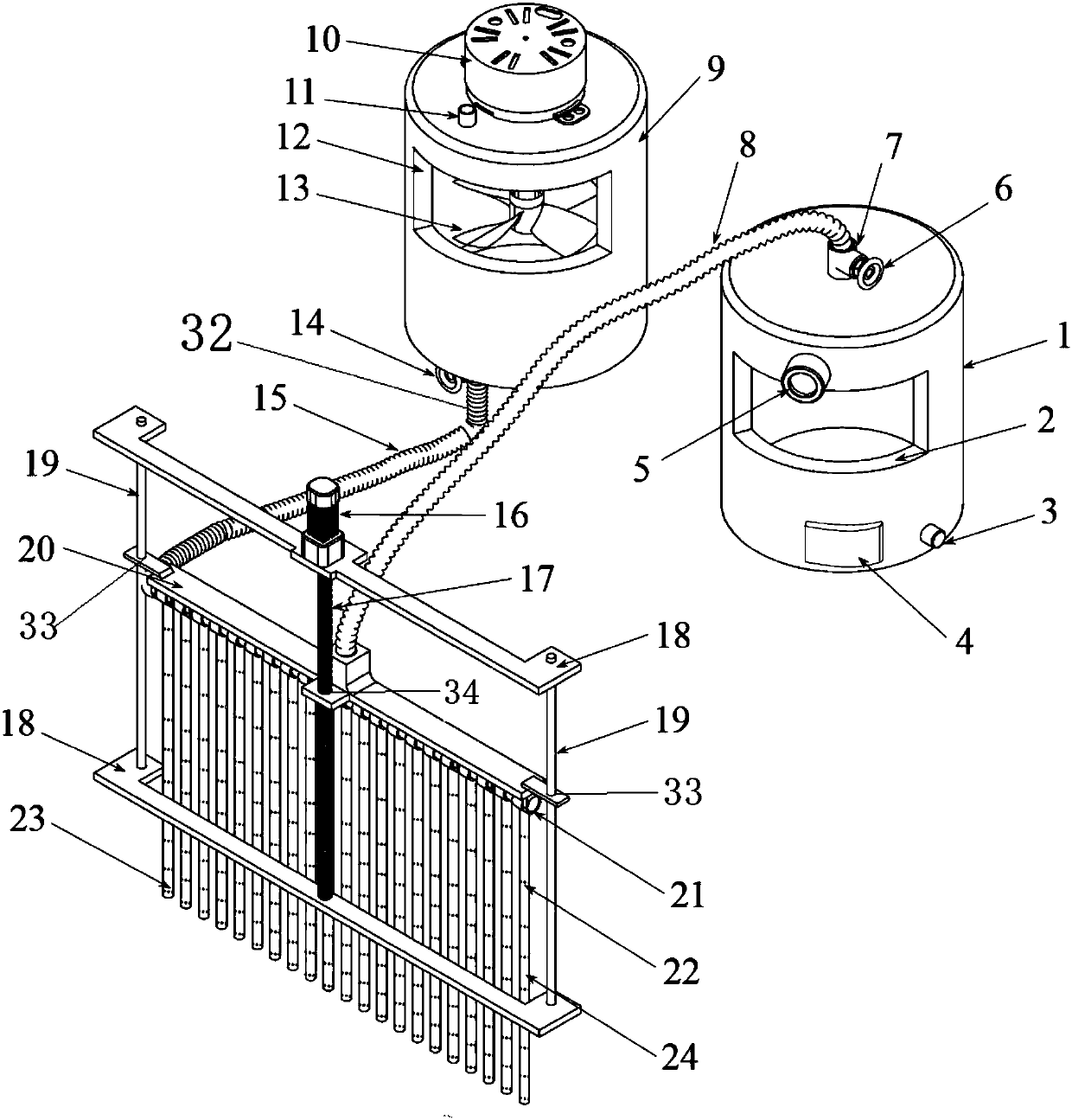

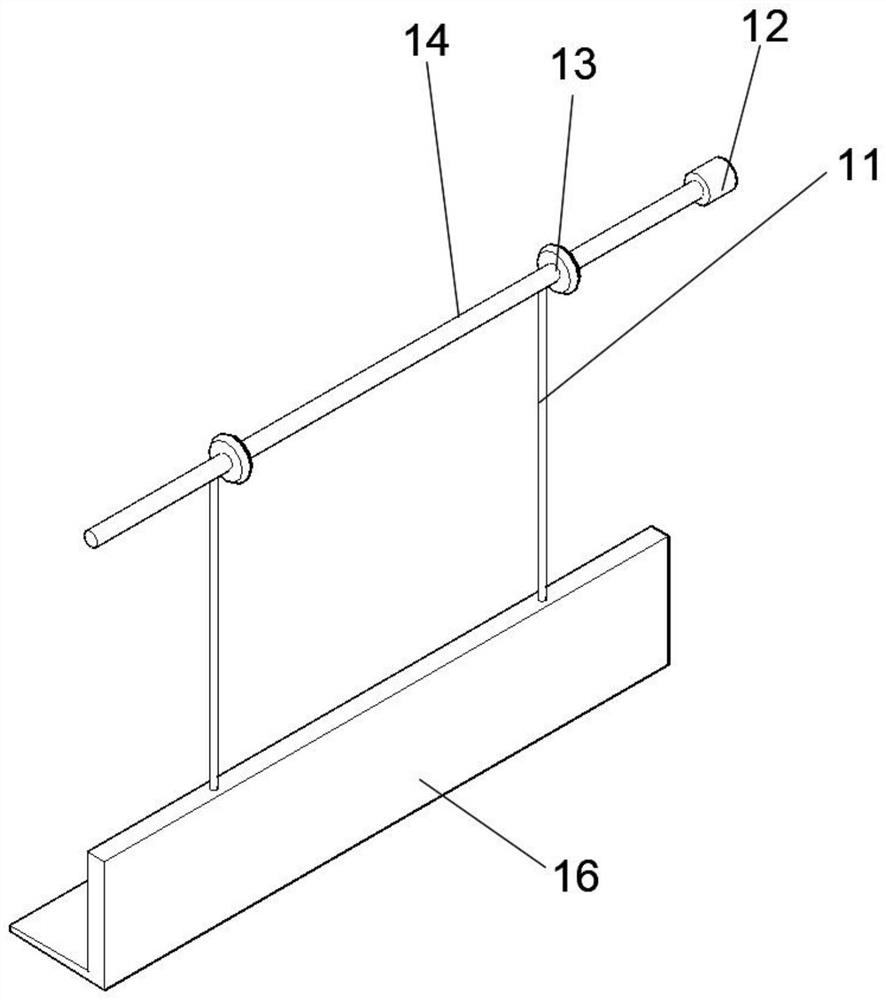

Tracer particle sowing device for two-phase flow field PIV measurement and operation method

ActiveCN107703325ARealize simultaneous spreadingRealize pressure releaseFluid speed measurementHolding tankSafety valve

The invention belongs to the field of fluid velocity field measurement, and relates to a tracer particle sowing device for two-phase flow field PIV measurement and an operation method. The problem that tracer particles cannot be effectively sowed in a two-phase flow field PIV measurement experiment at the same time in the prior art is solved. The device comprises a cylindrical pressure holding tank body, a tank body with a mixer, and a lifting particle release. The cylindrical pressure holding tank body comprises a first observation window, an air inlet, a safety valve, a pressure gauge, a first valve, an air outlet and a first hose. The tank body with the mixer comprises a first motor, a water inlet, a second observation window, the mixer, a second valve, a second hose and a water outlet.The lifting particle release comprises a second motor, a screw, a support frame, a connecting rod, a top steel plate, a horizontal pipe and a vertical circular pipe. The device provided by the invention has the advantages of wide application, simple operation and high reliability.

Owner:HARBIN ENG UNIV

Mobile tea tedding machine

ActiveCN104757152AGuaranteed uniformityEasy to tanPre-extraction tea treatmentEngineeringConveyor belt

The invention provides a mobile tea tedding machine which comprises a car body provided with wheels, a driving cab arranged at the front part of the car body, and a stock bin arranged at the rear part of the car body; the mobile tea tedding machine is characterized in that a conveyor belt is arranged under the stock bin; the output end of the conveyor belt is provided with a material raking mechanism and a material spreading mechanism; the material raking mechanism is arranged above the output end of the conveyor belt; the material raking mechanism comprises a raking roller which is horizontally arranged; a plurality of pieces of axial tooth rakes are arranged along the surface of the raking roller at intervals; the two ends of a roller shaft of the raking roller are respectively fixed on a bearing seat by a bearing; the bearing seat is directly fixed on the car body, or is fixed on the car body by an adjustment assembly. When the mobile tea tedding machine is used for tedding tea, the tea is evenly spread on a sunning ground only by driving a mobile car which is fully filled with the tea to the sunning ground. The mobile tea tedding machine not only is high in spreading efficiency, but also is capable of enabling the tea to be evenly spread and improving the tea sunning quality. The thickness of the spread tea can be adjusted by the raking roller, so that different types of tea can be conveniently tedded.

Owner:云南戎氏永德茶叶有限责任公司

Powder falling and powder spreading device for additive manufacturing equipment

ActiveCN109760313ASimple structureImprove uniformityApplying layer meansIncreasing energy efficiencyControl systemSingle degree of freedom

The invention discloses a powder falling and powder spreading device for additive manufacturing equipment. The powder falling and powder spreading device comprises a powder spreading operation table,a powder spreading assembly and a driving assembly. The powder spreading assembly is installed on the powder spreading operation table in a front-back single degree-of-freedom sliding mode. The driving assembly drives the powder spreading assembly to slide. The powder spreading assembly comprises a flow guide block, a powder falling opening switching plate and hitting blocks. The flow guide blockis connected to the powder spreading operation table in a front-back sliding mode and is used for powder falling. The powder falling opening switching plate is arranged above the flow guide block andcan slide front and back. The hitting blocks are installed on the powder spreading operation table, are located on the front and rear sides of the powder spreading assembly and are used for hitting the powder falling opening switching plate. The powder falling opening switching plate is provided with a powder falling switching groove extending left and right. The flow guide block is provided withtwo powder falling grooves formed front and back and extending left and right. According to the powder spreading assembly, automatic switching of the powder falling grooves is achieved through hittingin the sliding process, no special driving device needs to be arranged for switching the powder falling grooves in the structure, the structure of the powder spreading assembly is simplified, a control system is simplified, and cost of the additive manufacturing equipment is lowered.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

Mixed powder feeding device for three-dimensional printing equipment

PendingCN109226754ARealize simultaneous powder spreading functionImprove spreading efficiencyAdditive manufacturing apparatusIncreasing energy efficiency3d printedMaterials science

The present invention relates to the technical field of three-dimensional printing, and particularly discloses a mixed powder feeding device for three-dimensional printing equipment. The device comprises a molding cylinder, a moving powder cylinder, a driving assembly and a powder spreading assembly, wherein the molding cylinder is provided with a fixed powder cylinder, the moving powder cylinderis arranged on the molding cylinder, can slidably reciprocate on the molding cylinder and is located above the fixed powder cylinder, the driving assembly is used for driving the moving powder cylinder to slide, and the powder spreading assembly is arranged at the bottom of the moving powder cylinder; one side of the powder spreading assembly is provided with a powder leaking device arranged at the bottom of the moving powder cylinder and used for conveying powder in the moving powder cylinder to a molding face of the molding cylinder; the fixed powder cylinder is internally provided with a powder feeding device body used for conveying the powder in the fixed powder cylinder upward. The mixed powder feeding device for the three-dimensional printing equipment can achieve a function of alternative mixed powder spreading in two ways of moving powder spreading and fixed powder spreading, and also can achieve powder spreading of two materials, thereby being conductive to improving the powder spreading efficiency.

Owner:GUANGZHOU LEIJIA TECH CO LTD

Device and method for achieving multi-material additive manufacturing forming based on SLM equipment

ActiveCN112517923AGood formabilityWell mixedAdditive manufacturing apparatusIncreasing energy efficiencyRobotic armErbium lasers

The invention discloses a device and method for achieving multi-material additive manufacturing forming based on SLM equipment. The device comprises a forming chamber, a forming cylinder, a powder laying device, a powder supply bin, a laser and a powder supply system. The forming cylinder, the powder laying device and the powder supply bin are all arranged in the forming chamber, and the powder supply system is communicated with the powder supply bin through a powder conveying pipeline. The powder supply bin is installed at the tail end of a mechanical arm, and the powder laying device is arranged above the forming cylinder and is driven by a transmission device to horizontally move in the forming chamber. A powder supply device combining a traditional powder supply cylinder and the mechanical arm is adopted, when a single material is used, the traditional powder supply cylinder is used for supplying powder, when two or more materials are formed, a mechanical arm structure powder feeding device is used, and if the proportion of one material is larger than the sum of other materials, at the moment, the powder supply cylinder and mechanical arm structure combined powder supply mode can also be adopted, and due to the fact that the mechanical arm structure is simple and rapid in material replacement, the powder laying efficiency is improved.

Owner:XI AN JIAOTONG UNIV

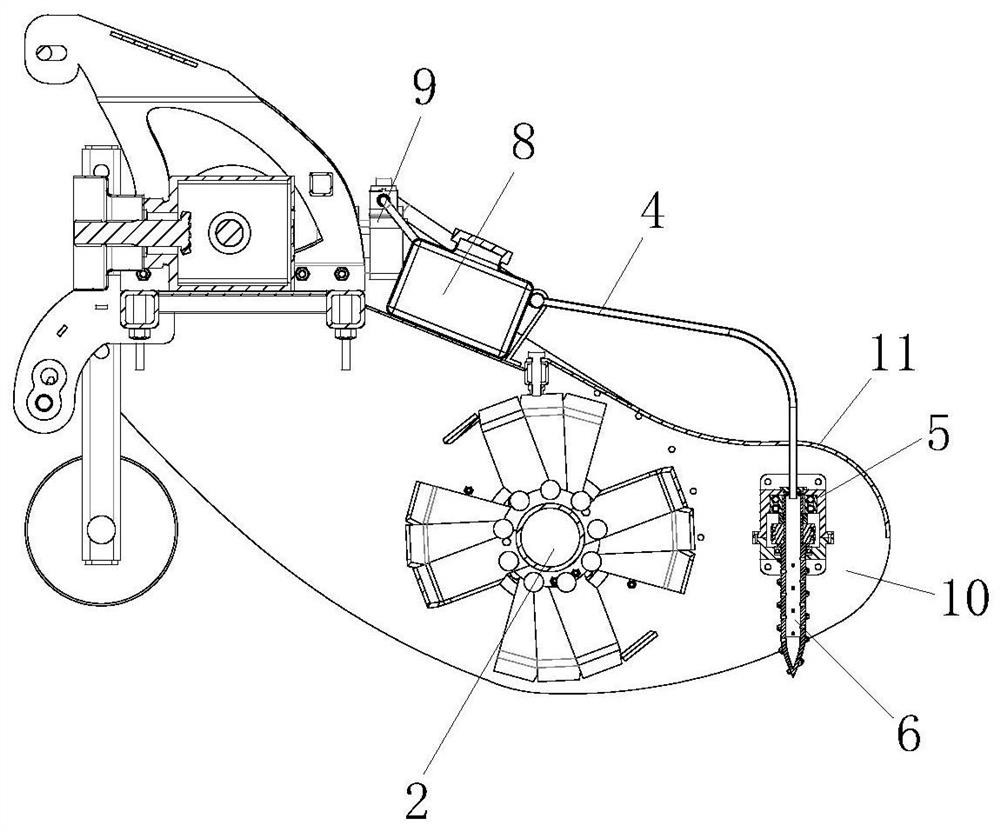

Soil pollution treatment device for environmental protection

InactiveCN111713192AGood effectWell mixedSpadesSoil lifting machinesPollution soilLiquid storage tank

The invention discloses a soil pollution treatment device for environmental protection. The soil pollution treatment device comprises a rotary cultivator rack, side plates, a transmission device and arotary blade assembly, wherein a truss is fixedly connected to the lower portions of the rear sides of the two side plates; a plurality of spraying assemblies are rotationally connected to the insideof the truss; a variable-speed reversing assembly is arranged on a side surface of each side plate; the power input end of each variable-speed reversing assembly is in transmission connection with the power output end of the transmission device; the variable-speed reversing assemblies drive the spraying assemblies to rotate synchronously; a liquid storage tank and a booster water pump are fixedlymounted on the top of the rotary cultivator rack; the water inlet end of the booster water pump communicates with the inside of the liquid storage tank through a water inlet pipe; and the water outlet end of the booster water pump communicates with the inside of each spraying assembly through a water outlet pipe assembly. The soil pollution treatment device can be integrated on an existing rotarycultivator, a chemical improver is uniformly fed into ploughed soil in a liquid form in a soil ploughing process, mixing of the chemical improver and the soil can be accelerated, and the spreading labor intensity of the chemical improver is reduced.

Owner:刘先超

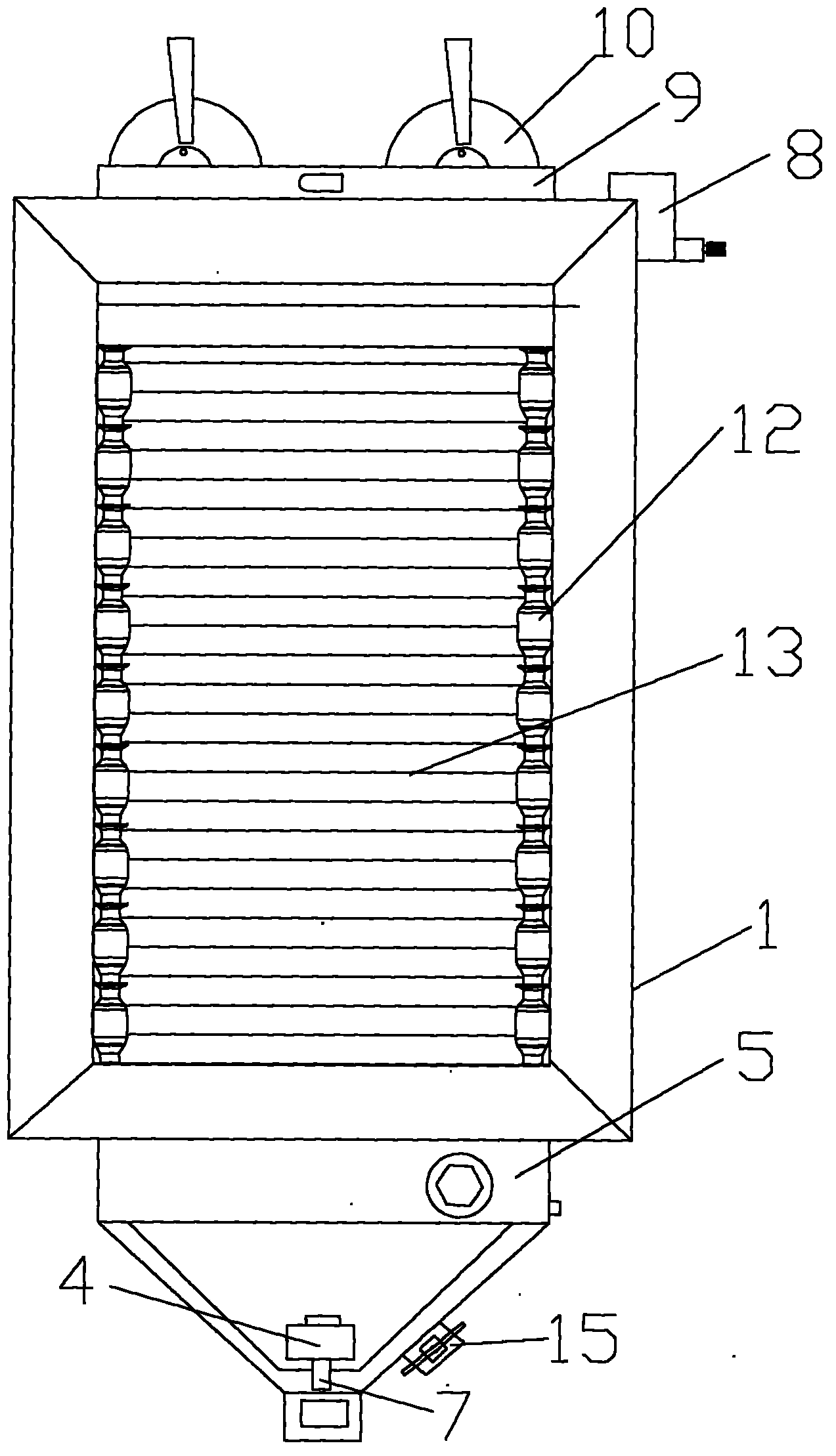

Fertilizer spreading machine

ActiveCN103283365AImprove spreading efficiencyImprove spreading qualityFertiliser distributersAgriculture gas emission reductionCircular discGear pump

The invention discloses a fertilizer spreading machine, relating to the technical field of agricultural machinery. The fertilizer spreading machine comprises a fertilizer tank, a chassis and a connection frame connected with a tractor, wherein a walking mechanism is arranged below the chassis; a gear pump is fixed on the connection frame; the gear pump is connected with a drive system of the tractor through a transmission shaft; a discharge door is arranged at the rear part of the fertilizer tank; the discharge door is lifted up and down through the opening / closing of the discharge door so as to control the fertilizer spreading quantity; multiple fertilizer spreaders are arranged below the discharge door; the fertilizer spreader comprises a disk, a rotary shaft arranged at the center of the disk and multiple fertilizer spreading slots uniformly distributed along the radial direction of the circumference of the disk; a gear shaft is arranged on the each of the two sides in the fertilizer tank; multiple transfer plates are arranged between the gear shafts; a speed reducer is arranged at the rear part of the fertilizer tank; the gear shafts are driven to run through the speed reducer. The fertilizer spreading machine disclosed by the invention realizes an automatic fertilizer spreading process, greatly improves the fertilizer spreading efficiency and the fertilizer spreading quality, and has the advantages of simplicity in operation, reliability in use, strong adaptability and high operation efficiency.

Owner:SHANDONG TIANSHENG MACHINERY

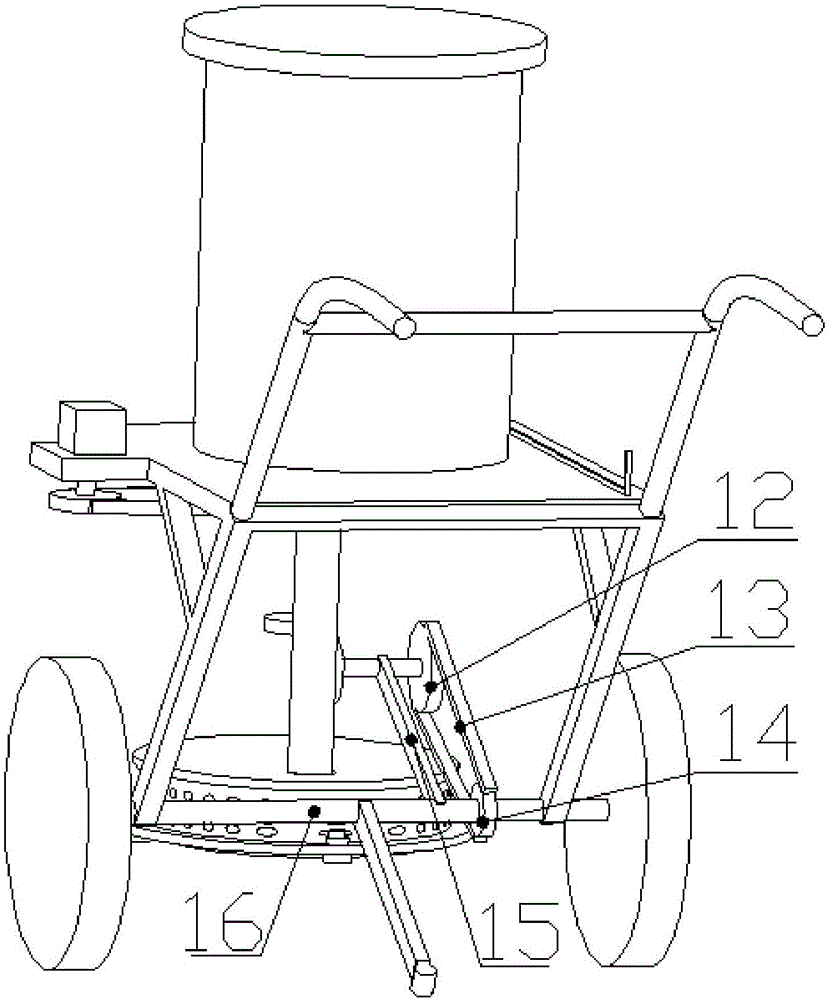

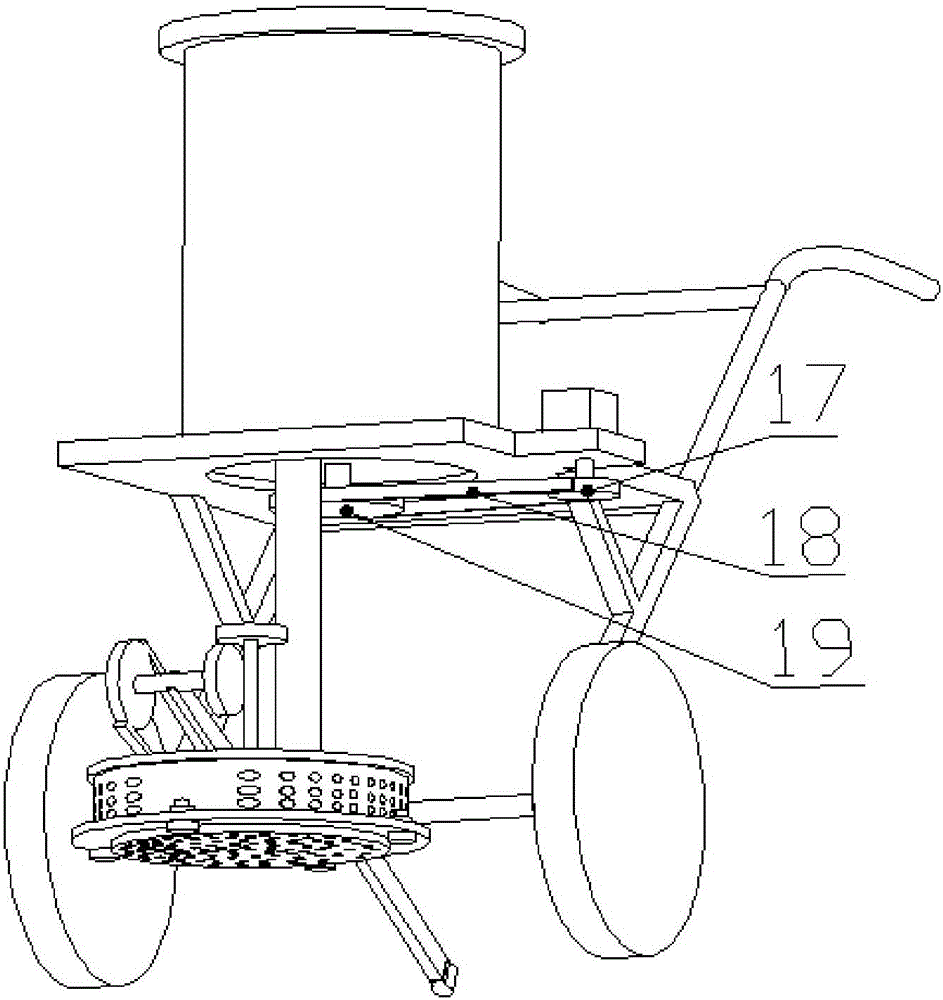

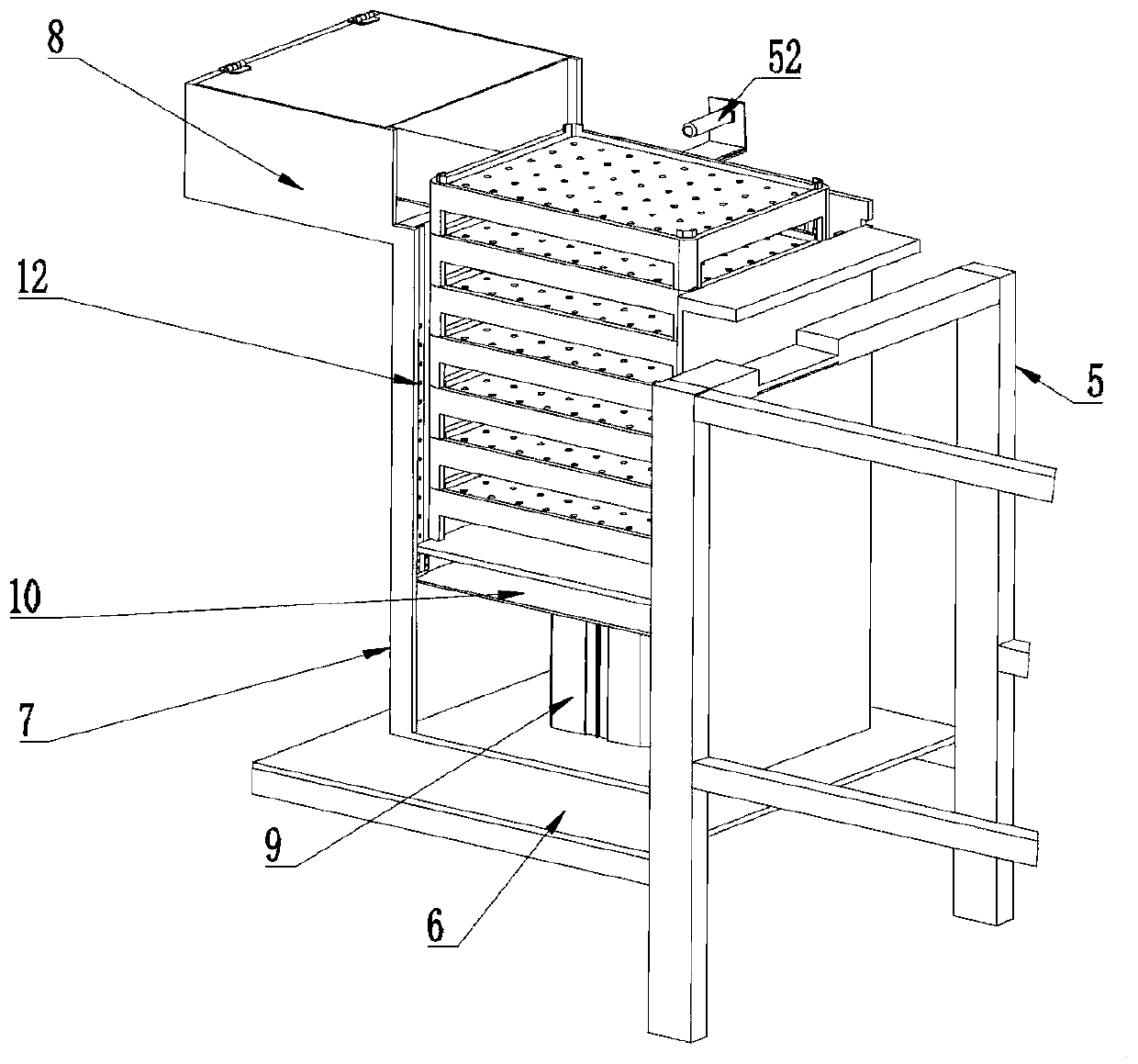

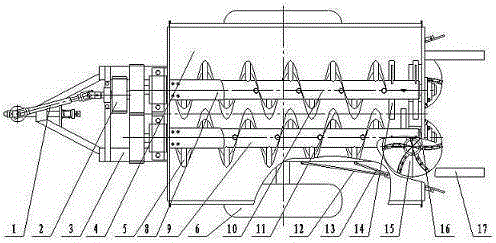

Automatic tray paving device with stacked tray separating function and tray paving method of device

ActiveCN109769521AAchieve one-by-one separationReduce workloadTransplantingFlower-pot fillingEngineeringWorkload

The invention discloses an automatic tray paving device with a stacked tray separating function and a tray paving method of the device. Existing tray paving equipment can complete seedling raising tray arrangement, but cannot supply a whole stack of trays, and the trays need to be supplied manually one by one in sequence. The high-automation-assisted tray paving device comprises a tray supply mechanism, a seedling tray temporary storage mechanism, a tray paving mechanism, a walking mechanism and a supporting frame. The supporting frame is driven by the walking mechanism to travel. The tray supply mechanism comprises a top tray assembly, a tray pushing assembly and seedling raising trays. The seedling tray temporary storage mechanism comprises a first rail, a third rotating shaft, a first bevel gear, a second bevel gear, a second rail, a second motor, a screw rod and a nut. The tray paving mechanism comprises a tray paving plate and two single-sided pull rope assemblies. Through the cooperation of the top tray assembly and the tray pushing assembly, the whole stack of seedling trays can be separated one by one, and then automatic tray supply is realized. Compared with a conventionaltray paving device which needs to supply the trays one by one, the workload of workers can be reduced.

Owner:ZHEJIANG TECH INST OF ECONOMY

Fertilizing material-spreading machine for agriculture

InactiveCN111742654AAvoid stickingImport smoothly and evenlyPlantingFertiliser distributersAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural fertilization, in particular to a fertilizing material-spreading machine for agriculture. The fertilizing material-spreading machine for agriculture comprises a movable frame, wherein one side of the movable frame is fixedly connected with a tractor, two sides of the movable frame are symmetrically equipped with four main wheels, the inside of the movable frame is horizontally provided with a dispersion cylinder, two ends of the dispersion cylinder are fixedly connected with the inner wall of the moving frame, the upper side of the dispersion cylinder is horizontally provided with a material placing bowl, the middle section of the dispersion cylinder is fixedly connected with and communicates with the material placing bowl through a connecting pipe, the inside of the dispersion cylinder is provided with a dispersion material-conveying assembly, a row of inclined cylinders are evenly distributed on the lower side of the dispersing cylinder in an inclined manner, the lower end of each inclined cylinder is tapered and is provided with a material outlet, the lower side of a first strip-shaped plate is evenly provided with groove openers, and the lower side of a second strip-shaped plate is evenly provided with a plurality of soil covering plates. The fertilizing material-spreading machine for agriculture adopts a novel material spreading manner, a fertilizer is directly spread at a certain depth position, and then the soil is covered. Firstly, the absorption of crops is convenient, and secondly, the fertilizer is noteasily washed away in rainy days. At the same time, the apparatus can realize even material-spreading, and the material-spreading efficiency is high.

Owner:陈存润

Water purification device for organic culture of mandarin fish

The invention discloses a water purification device for organic culture of mandarin fish. The water purification device comprises a pond body, the bottom of the pond body is obliquely arranged, and a sludge discharge mechanism and an impurity discharge mechanism are arranged in the pond body; the sludge discharging mechanism comprises a collecting groove, the collecting groove is formed in the lower end of the bottom of the pool body, a collecting pipe is arranged in the collecting groove, a plurality of sludge suction openings are formed in the collecting pipe, and the upper end of a control rod is rotationally connected with a rack through a fluted disc; and the residue discharge mechanism comprises a collecting frame, the collecting frame is of an L-shaped structure, the collecting frame is in a grid shape, the collecting frame is arranged on the side, close to the collecting groove, of the bottom of the pond body, and a lifting mechanism is arranged on the collecting frame. By arranging the collecting frame, some sundries are filtered, blockage is avoided, the sundries are discharged by lifting the collecting frame, cleaning and collecting are facilitated, sludge in the pond body can be collected and cleaned at any time, and efficiency is high.

Owner:安徽益丰生态农业开发有限公司

Spiral ring belt type barnyard manure crushing and scattering mechanism

ActiveCN105248026AOutput evenlySimple structureFertiliser distributersAgriculture gas emission reductionHydraulic cylinderDrive shaft

The invention provides a spiral ring belt type barnyard manure crushing and scattering mechanism and belongs to the technical field of agricultural machinery. The spiral ring belt type barnyard manure crushing and scattering mechanism comprises main parts including a rack, a manure box, spiral ring belts, crushing teeth, transmission shafts, a spiral support, a buffering beam, scattering discs, an unloading door, a hydraulic cylinder, a width adjusting plate, a hook and the like; the spiral ring belts and the crushing teeth are symmetrically mounted on the two parallel transmission shafts in the manure box in a staggered manner, and turning directions and rotary directions are opposite, so that the crushing and conveying of barnyard manure are guaranteed; the buffering beam is longitudinally distributed above the spiral ring belts so that shaft pressure is alleviated; the scattering discs are symmetrically mounted on the lower side of the unloading door; the transverse central lines of the two discs correspond to the central line of the unloading door; parabola-shaped throwing plates are mounted in the peripheral direction of the discs, and a conical flow guide cover is mounted in the middle of each disc, so that the manure can be uniformly and widely scattered; the width adjusting plate and the hook are hinged on the rack and the width can be adjusted; the manure box is in a reversed trapezoid shape, the bottom face of the manure box is W-shaped, and the central line of the manure box is overlapped with the central line of a corresponding shaft; materials are convenient to load and can be smoothly discharged, and no materials are remained; and the spiral ring belt type barnyard manure crushing and scattering mechanism has a simple structure, and high scattering efficiency and uniformity.

Owner:黑龙江省农业机械工程科学研究院齐齐哈尔分院

Two-way powder laying device for additive manufacturing

PendingCN109693376AAvoid empty tripsImprove spreading efficiencyAdditive manufacturing apparatus3D object support structuresEngineeringMechanical engineering

The invention discloses a two-way powder laying device for additive manufacturing. The two-way powder laying device for additive manufacturing comprises a working table, a powder laying mechanism anda first driving device, wherein the powder laying mechanism is slidably installed on the working table in a linear reciprocating left and right mode, and the first driving device is installed on the working table and used for driving the powder laying mechanism to slide. The powder laying mechanism comprises a scraper installation seat, a scraper and two powder laying channels, the reciprocating sliding scraper installation seat is driven by the first driving device, the scraper is installed at the bottom of the scraper installation seat, and the two powder laying channels are arranged on thescraper installation seat and located on the left side and the right side of the scraper. The two-way powder laying device for additive manufacturing can lay powder in both directions, empty stroke isavoided, two-way stroke is effectively used for performing the powder laying operation, and the efficiency of powder laying is improved.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com