Patents

Literature

58results about How to "Improve powder utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing paint-coat of metal surface, especially for gradient paint-coat

InactiveCN1405355ASimple production processLow costMetallic material coating processesAlloyIonization

The invention refers to a method of melting-covering coating of metal surface, especially a method of gradient coating. The steps: 1, pre-smear the mixing pwoder of Fe-, Co- or Ni-group alloying powder and ceramic powder; 2, use plasm produced by ionizing non-oxidizing gas in plasm moment to scan metal surface in order to produce melting-covering layer or gradient cost. It has positive effects.

Owner:山东科技大学机械电子工程学院

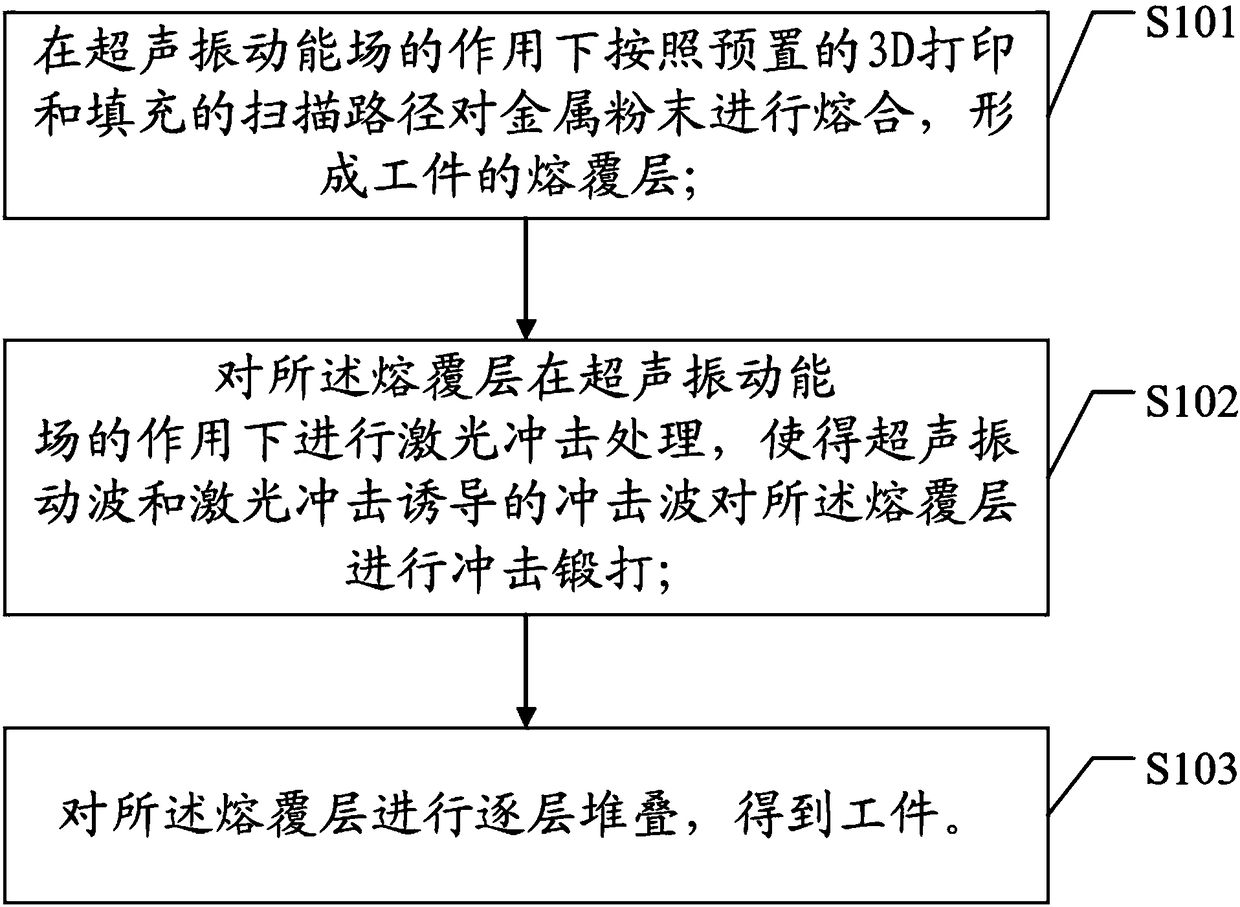

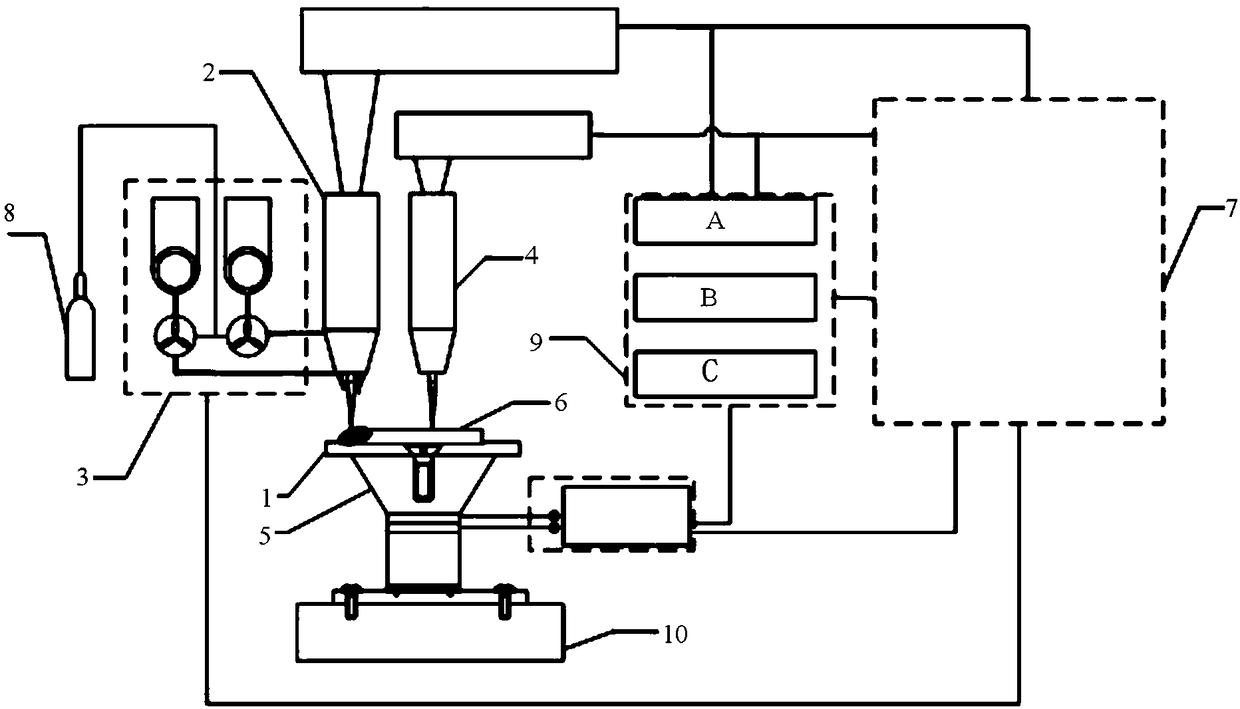

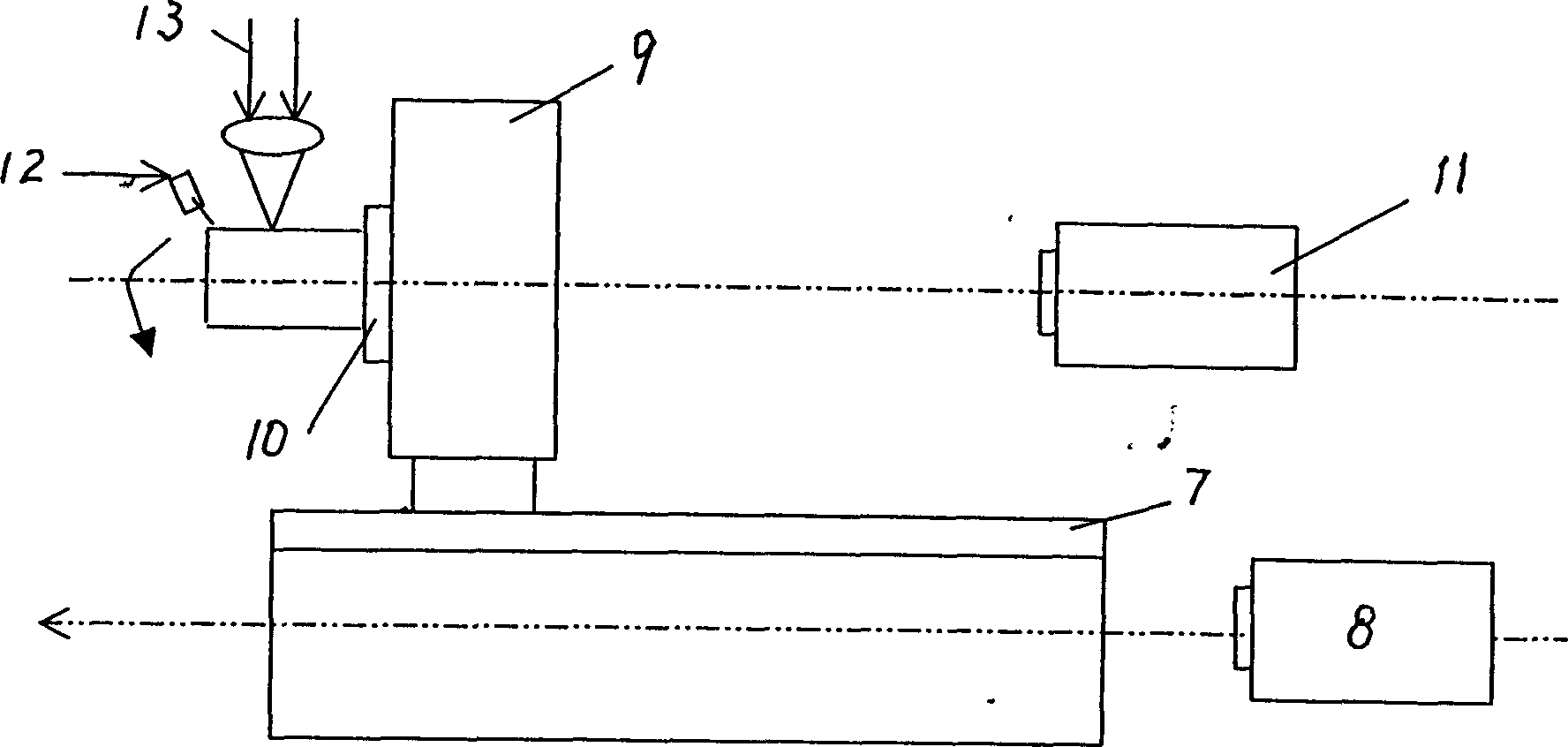

Method and device for carrying out 3D (Three-Dimensional) printing and composite manufacturing on metal

PendingCN108176857AImprove internal qualityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyShock waveUltrasonic vibration

The invention belongs to the technical field of 3D (Three-Dimensional) printing, and particularly relates to a method and a device for carrying out 3D printing and composite manufacturing on metal. The method for carrying out the 3D printing and the composite manufacturing on the metal comprises the following steps: S101, fusing metal powder under the action of an ultrasonic vibration energy fieldaccording to a preset 3D printing and filling scanning path, thus forming cladding layers of a workpiece; S102, simultaneously carrying out laser shock processing on the cladding layers under the action of the ultrasonic vibration energy field, and impacting and forging the cladding layers through ultrasonic vibration waves and shock waves induced by laser shock; S103, stacking the cladding layers layer by layer, thus obtaining the workpiece. Aiming at the problem existing when an existing metal 3D printing technology is used for manufacturing metal parts, the method disclosed by the invention has the advantages that internal defects of pores, poor fusion, shrinkage porosity and cracks of metal cladding layers and thermal stress can be removed to the maximum, the internal quality and themechanical dynamical comprehensive performance of the metal parts can be increased, and the problems of macroscopic deformation and cracking can be effectively controlled.

Owner:GUANGDONG UNIV OF TECH

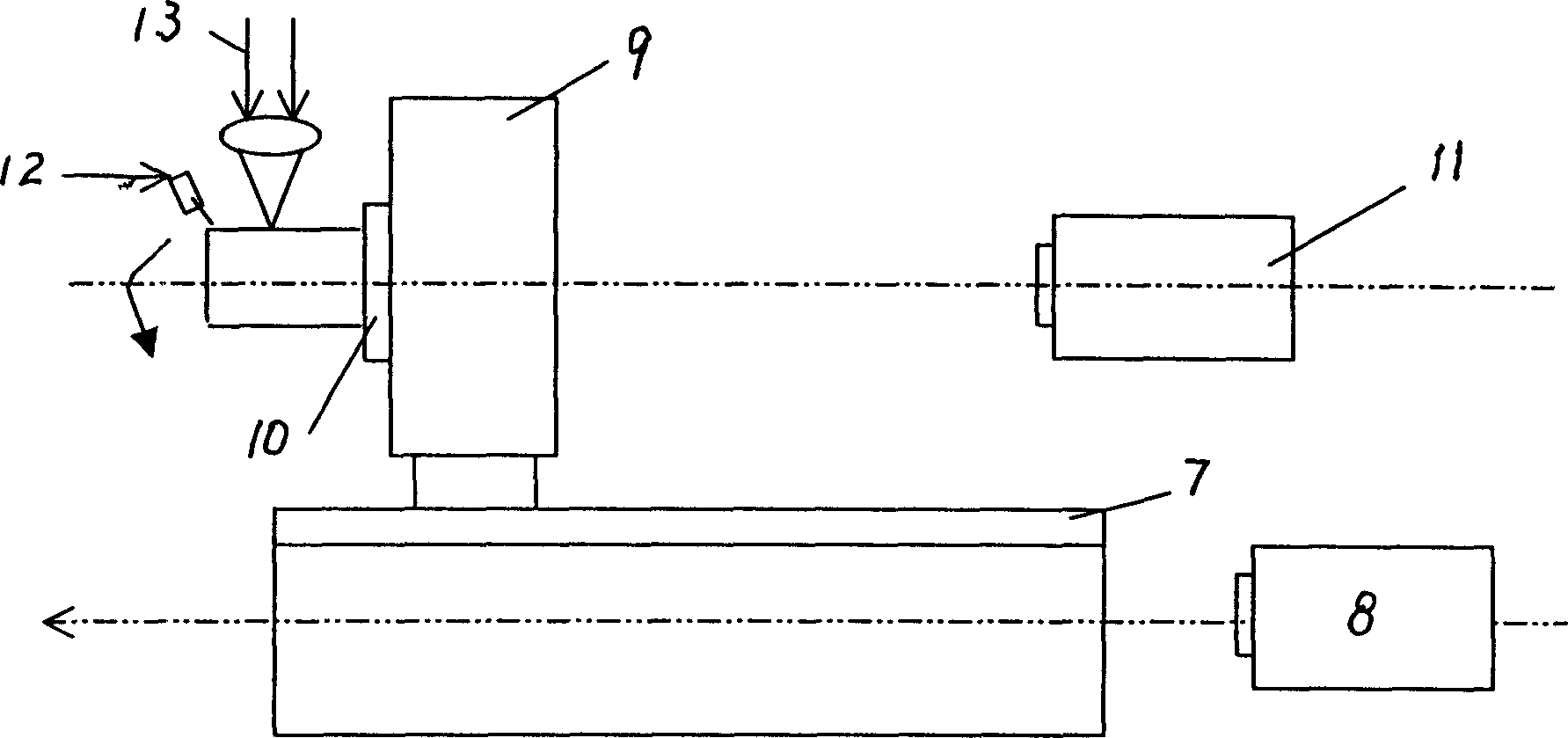

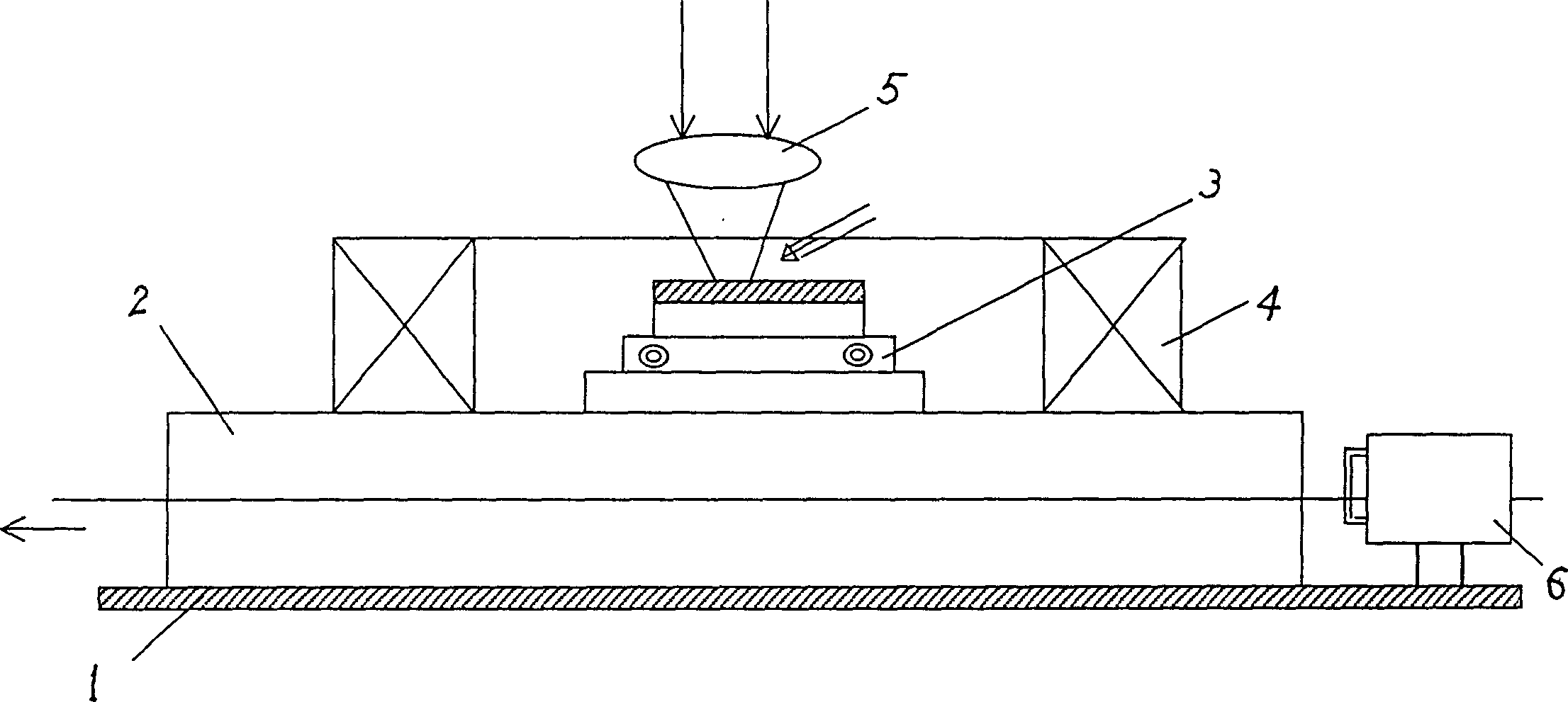

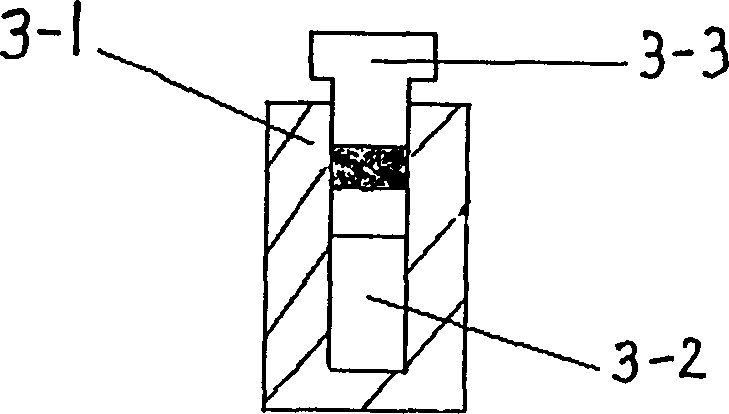

Method and its device for preparing cutter by laser coating composite ceramic layer

InactiveCN1554803AQuality improvementNo porosityMetallic material coating processesLaser beam welding apparatusFiberHeat-affected zone

The present invention relates to method and apparatus for making cutter with laser coated composite ceramic layer, belongs to the field of ceramic coating on metal surface, and aims at lowering cutter manufacturing cost while prolonging the service life of cutter. The cutter making process includes applying hard alloy powder to the surface of cutter base, applying mechanical pressure, preheating, and laser treating after or while applying the hard alloy powder. The cutter made may be chemical fiber cutter, milling cutter or trimming cutter. One of the cutter making apparatus includes bench, special fixture, electromagnetic coil and laser processing system. The other cutter making apparatus includes bench, chuck, powder blowing feeder and laser processing system. The present invention has high coating quality, less heat deformation, high production efficiency and other advantages.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for wear-resistant and corrosion-resistant composite coating layer

InactiveCN108611636AHigh hardnessAccelerated corrosionAdditive manufacturing apparatusMetallic material coating processesStellite alloySurface layer

The invention discloses a preparation method for a wear-resistant and corrosion-resistant composite coating layer. The preparation method specifically comprises the following steps: S1. carrying out pretreatment on a cladding matrix; S2. carrying out drying treatment on a cladding material; S3. melting the cladding material and the surface layer of the cladding matrix simultaneously through a laser device and in combination with a coaxial powder feeding method to form an alloy coating layer, that is, the high-hardness corrosion-resistant layer, wherein the cladding matrix in the step S1 is made from Q960 steel; and the cladding material in the step S2 is made from the mixture of tungsten carbide powder and Stellite 6 alloy powder. According to the preparation method disclosed by the invention, the composite coating layer is creatively prepared on the surface of the Q960 steel through a laser cladding technology; the tungsten carbide powder and the Stellite 6 alloy powder are mixed as the cladding material in a specific ratio; and the process parameters of the laser cladding technology are scientifically and reasonably designed, so that the problems of low hardness and short servicelife under the working condition of abrasive wear, of a laser cladding coating layer made from Stellite 6 cobalt alloy, are effectively solved.

Owner:HUNAN UNIV OF TECH +2

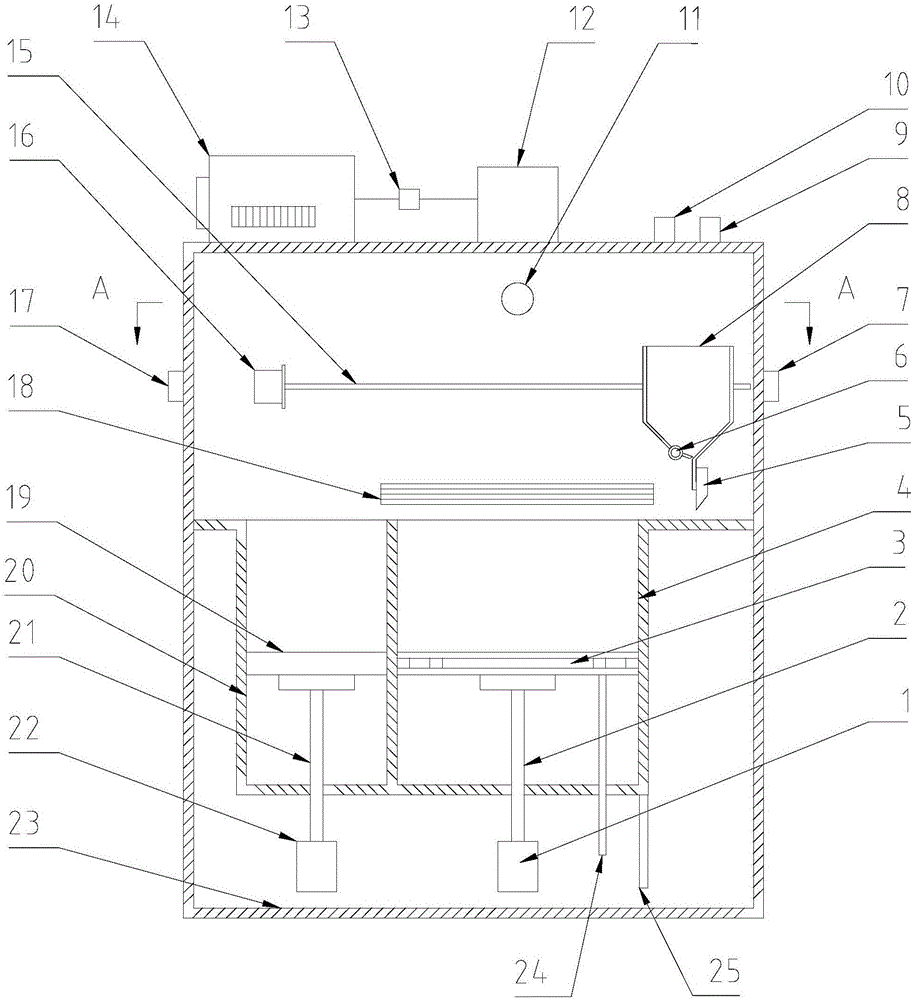

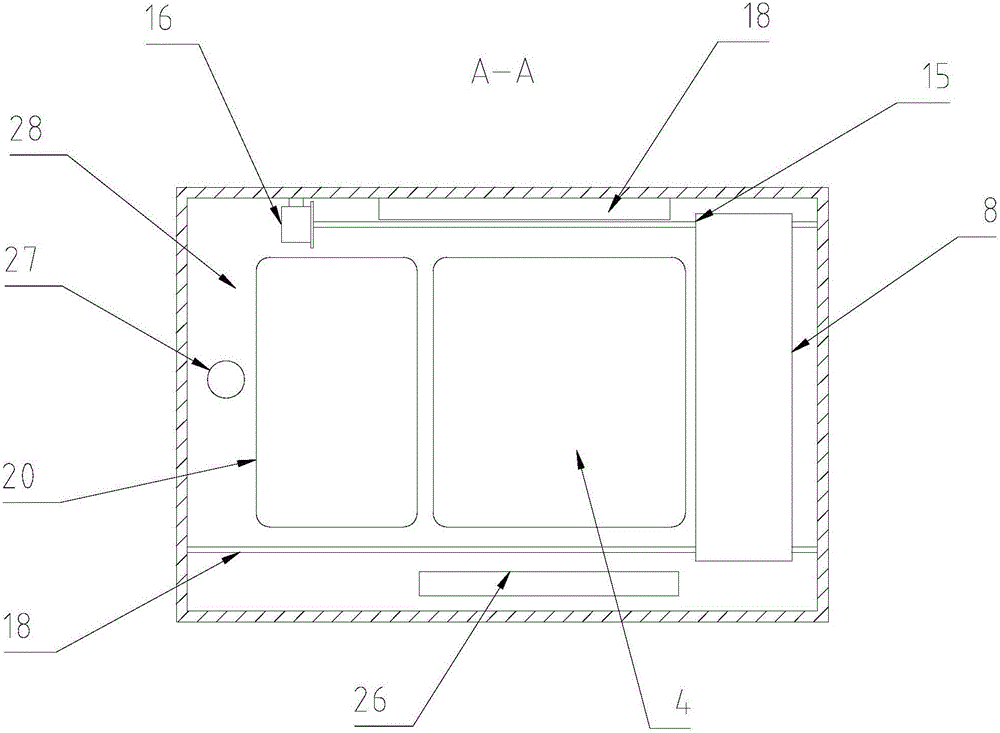

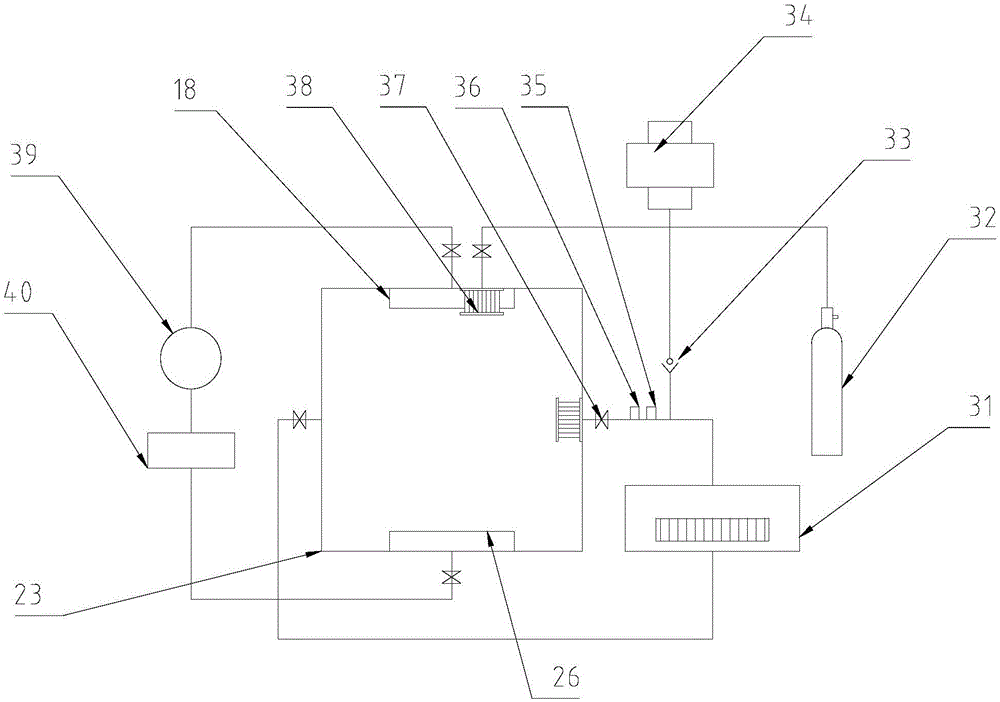

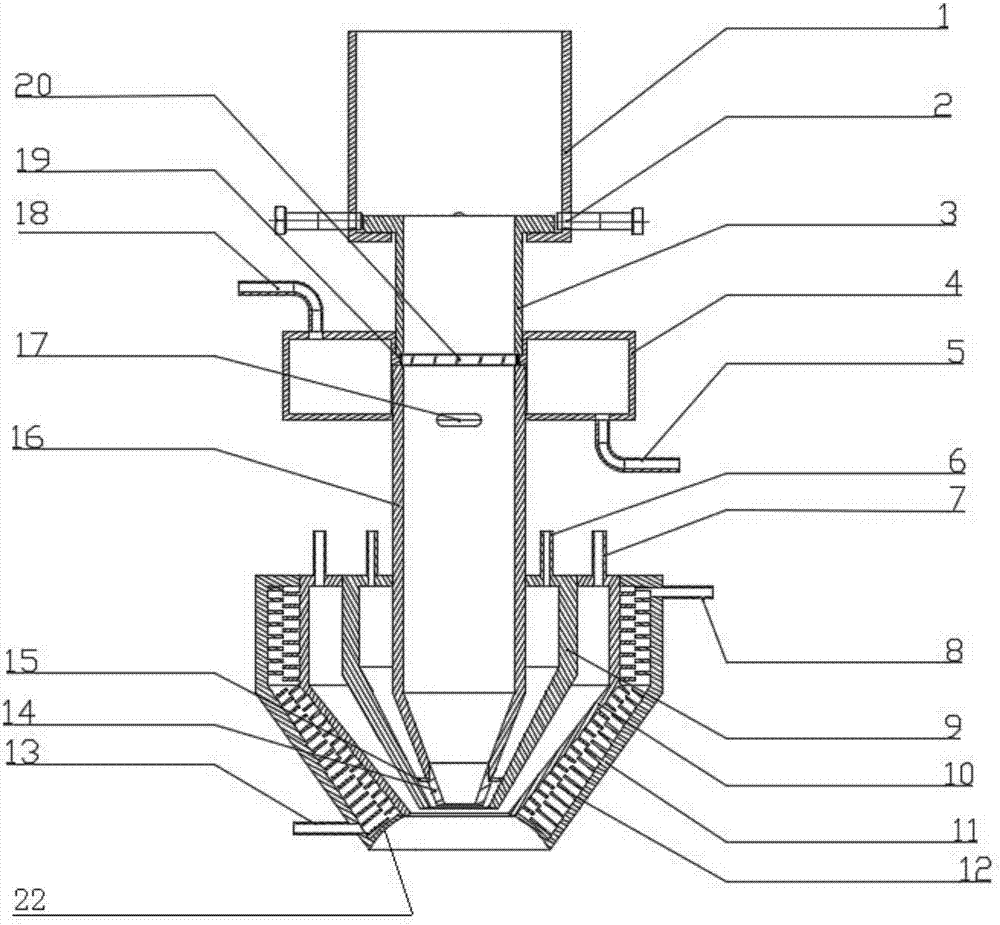

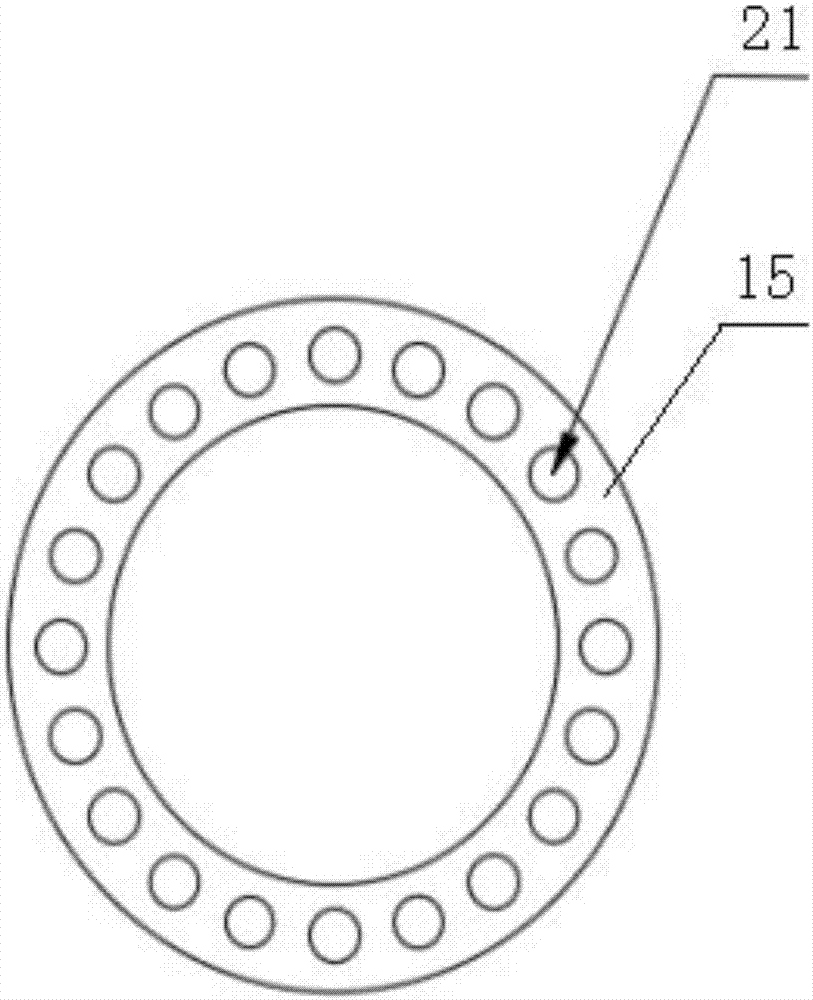

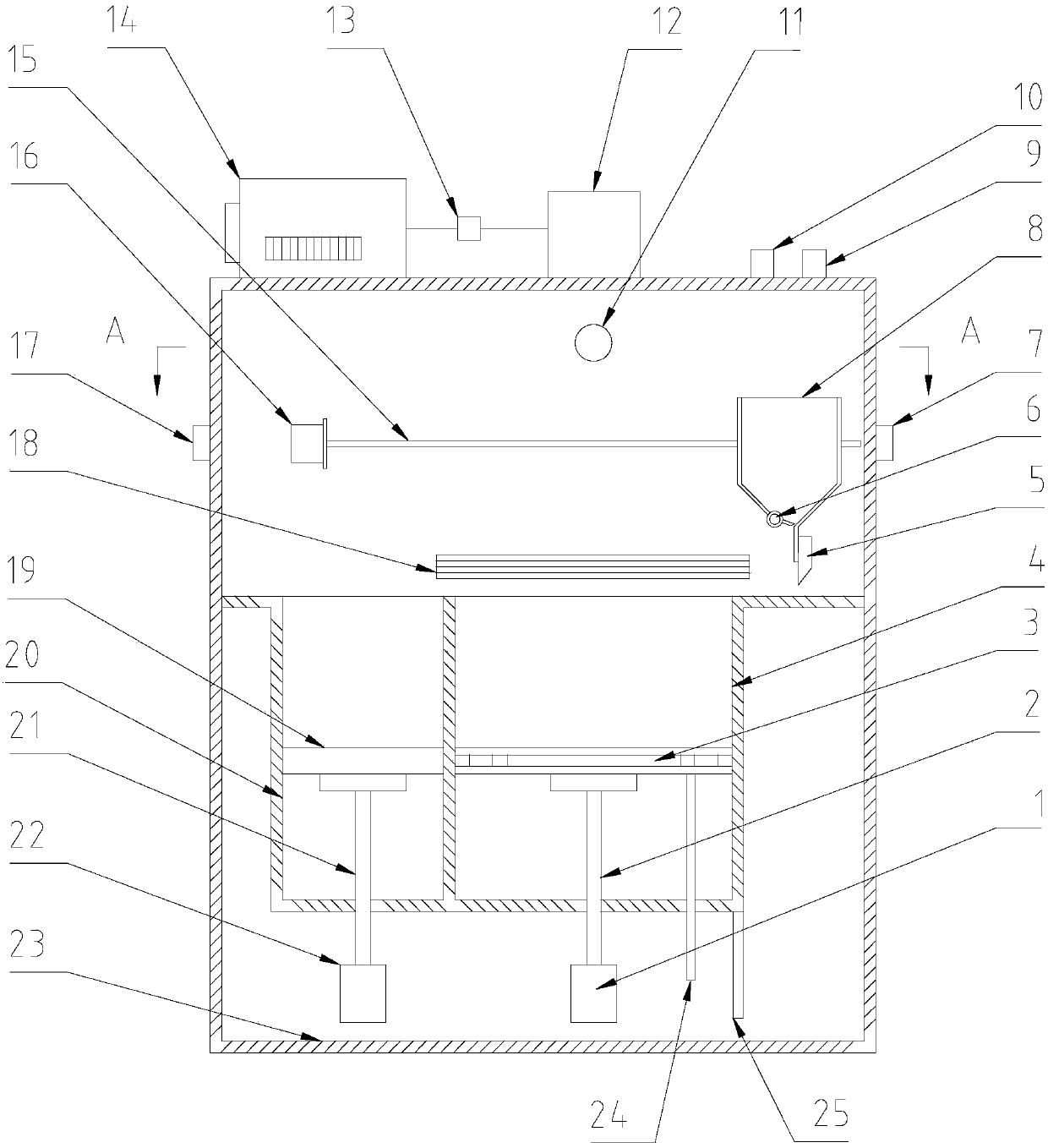

Special laser selecting area melting equipment for directly manufacturing metal orthopedics implant

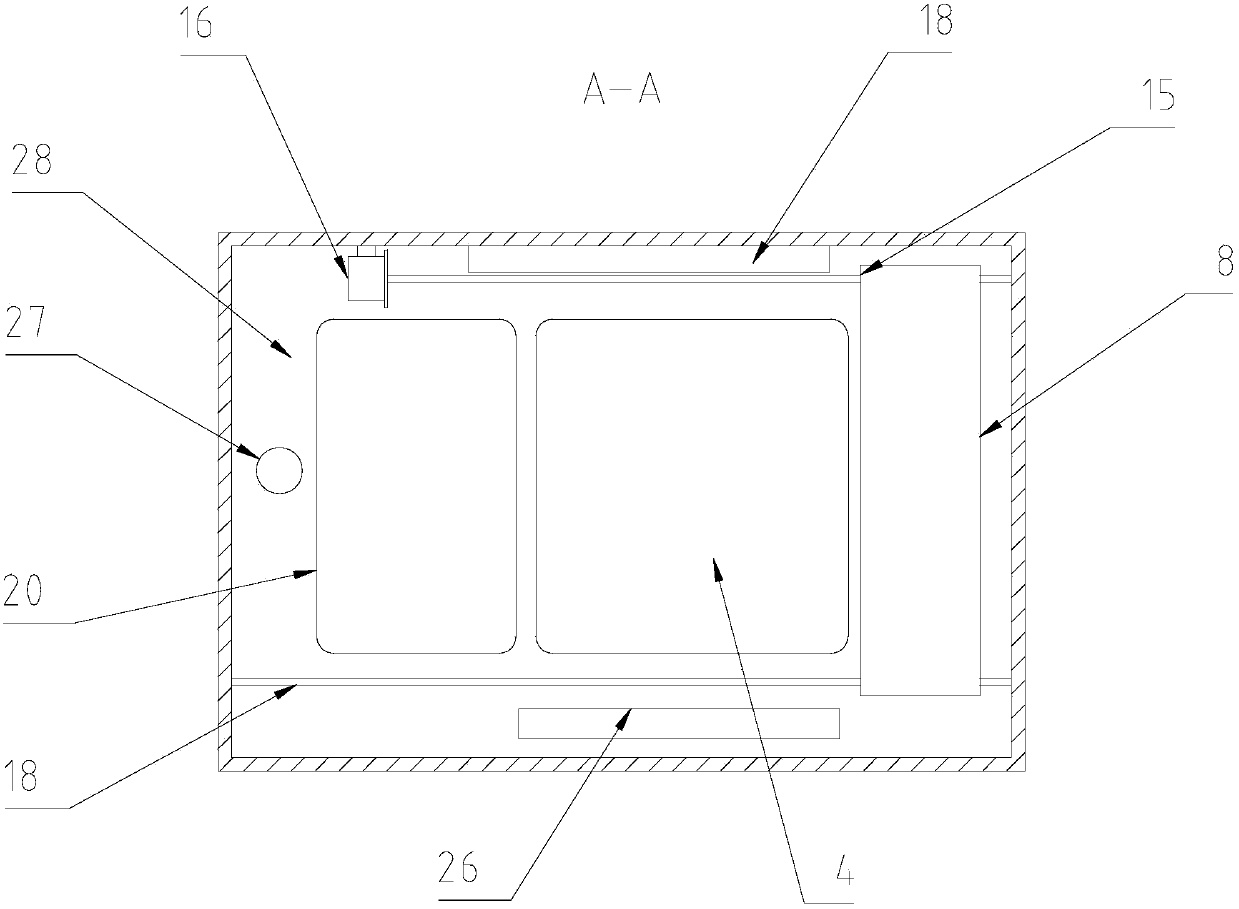

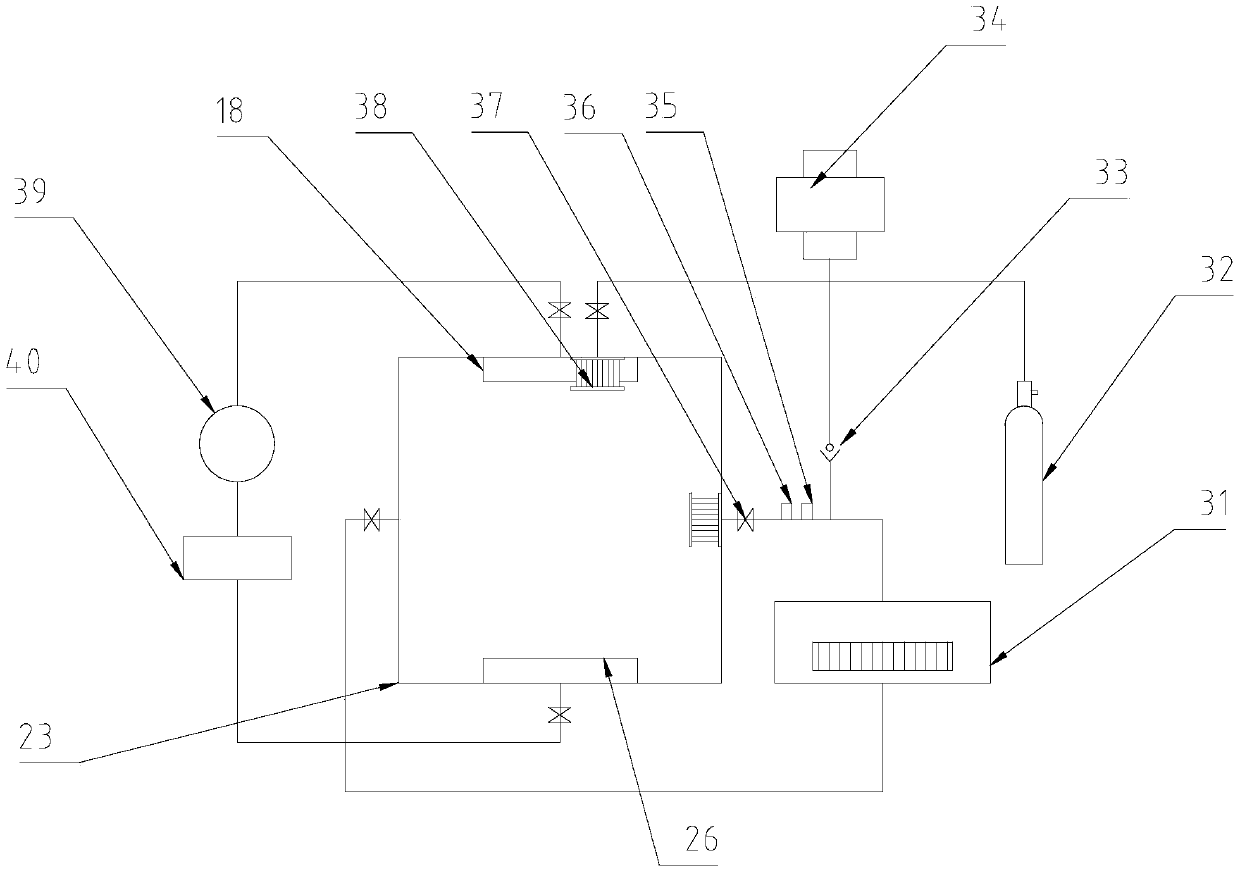

ActiveCN105945282AImprove powder utilizationImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyGratingOxygen

The invention discloses special laser selecting area melting equipment for directly manufacturing a metal orthopedics implant. The equipment is characterized by comprising a forming system, a powder recovery system, a powder paving system, a laser transmission system, a dust filter and water / oxygen purification double-circulation system, and a sealing cavity; the forming system, the powder recovery system and the powder paving system are all positioned in the sealing cavity; the laser transmission system is positioned at the upper part of the sealing cavity; the dust filter and water / oxygen purification double-circulation system is positioned out of the sealing cavity; the forming system includes a forming cylinder, a forming cylinder piston, a ball screw, a servo motor and a grating ruler; a heating copper plate, a water cooling system and a temperature sensor are arranged in the forming cylinder piston; the powder paving system paves powder by an upper powder paving mode; and the forming process is performed under argon protection, and is provided with the dust filter and water / oxygen purification double-circulation system. The equipment is high in atmosphere cleanness of the forming cavity and high in forming part size precision, can form such bionic structures as porous structures and biological channels, and is suitable for quick and personalized customization of artificial hip joints.

Owner:THYTEC SHANGHAI

Continuous cyclic powder spreading structure and additive manufacturing molding equipment

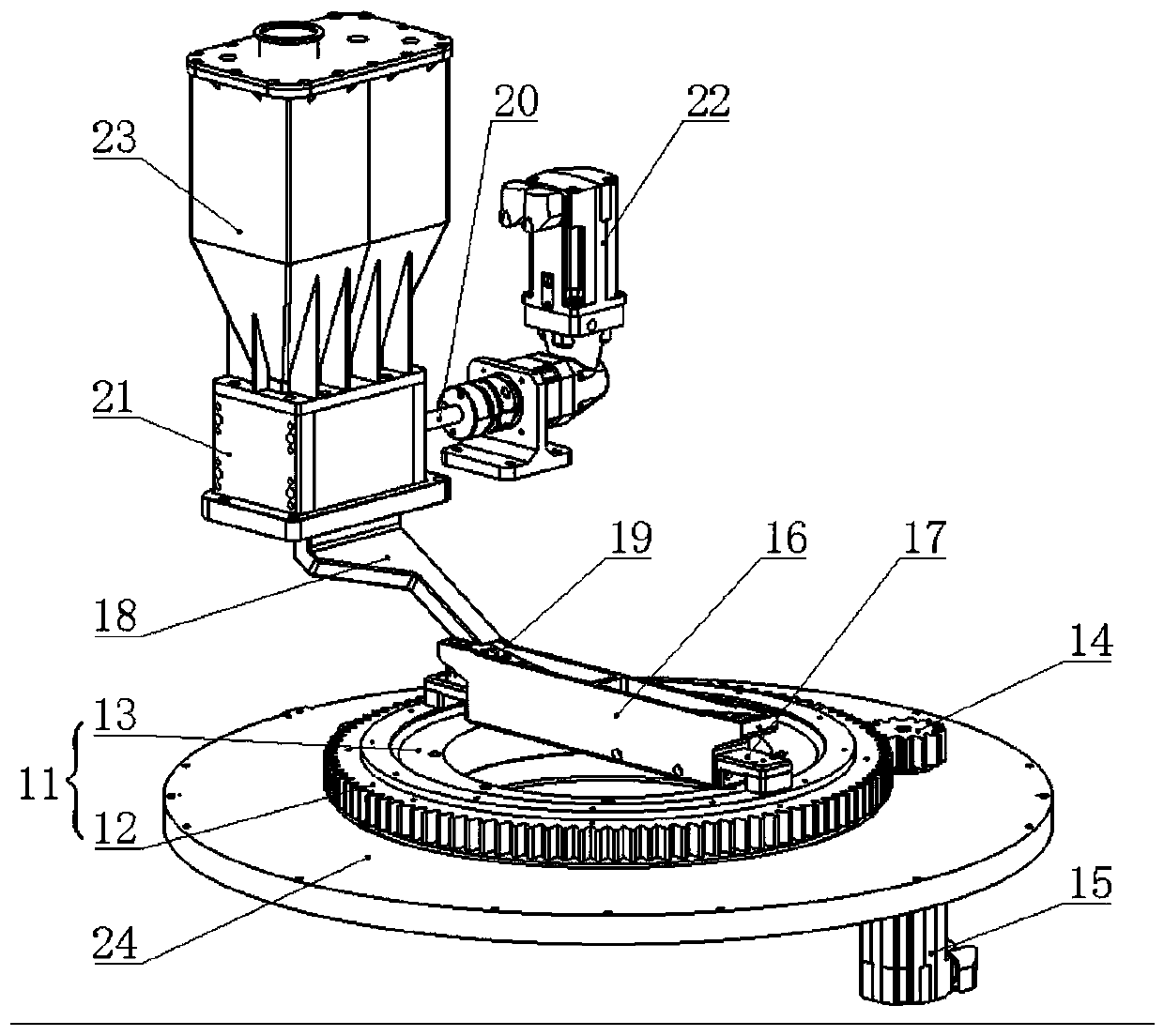

PendingCN110560689AImprove forming efficiencyImprove powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsUtilization rate

The invention discloses a continuous cyclic powder spreading structure and additive manufacturing molding equipment. Side plates and a top plate are arranged on a bedplate. A printing molding cavity is formed by the bedplate and a cylinder body arranged at the lower end of the bedplate. The continuous cyclic powder spreading structure is arranged in the printing molding cavity, and continuous powder spreading in the printing molding process is achieved. Up-and-down movement of a printing substrate in the cylinder body is achieved by utilizing a driving device. Then the printing surface on theprinting substrate is printed and molded by utilizing a light path scanning structure arranged at the inner upper end of the printing molding cavity. Molding through holes are formed in a gear bearingand the middle of the bedplate correspondingly so that it is convenient for light path scanning structure laser and the printing surface on the printing substrate at the lower end of the bedplate tomold. The light path scanning structure is located at the upper end of the continuous cyclic powder spreading structure and can work simultaneously with a powder spreading scraper so that powder spreading and scanning molding are conducted, and that is to say, an efficient printing process that powder spreading is conducted while scanning is conducted can be achieved. By means of the continuous cyclic powder spreading structure and the additive manufacturing molding equipment, molding efficiency of parts is improved; and meanwhile, the printing substrate moves up and down in the cylinder body,the molding area is limited, and the utilization rate of powder is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Rotating zirconium oxide target and preparation method thereof

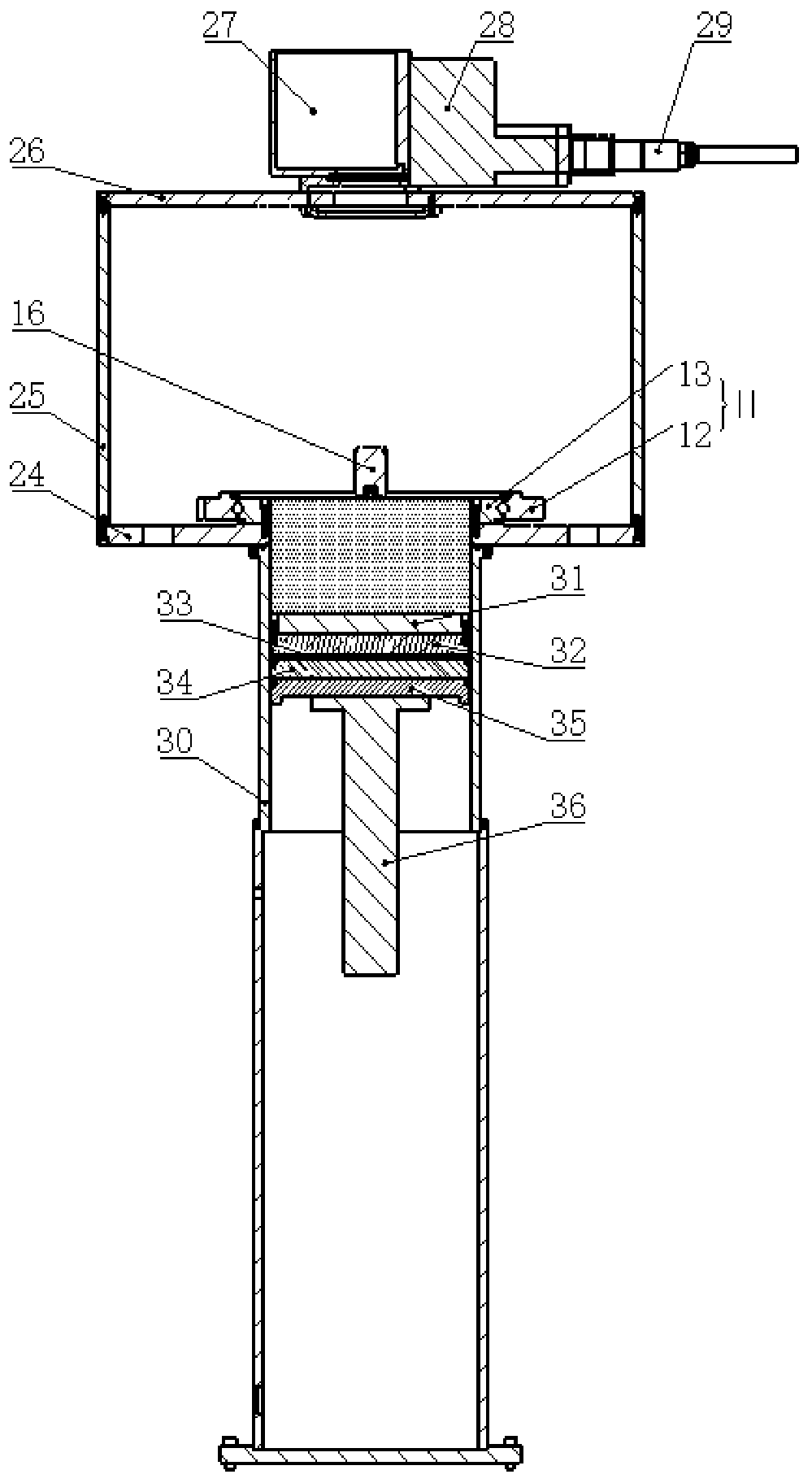

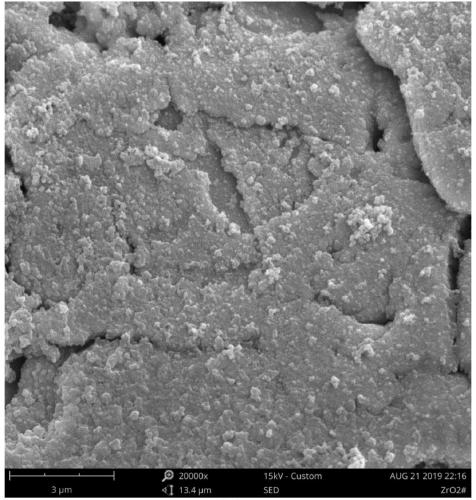

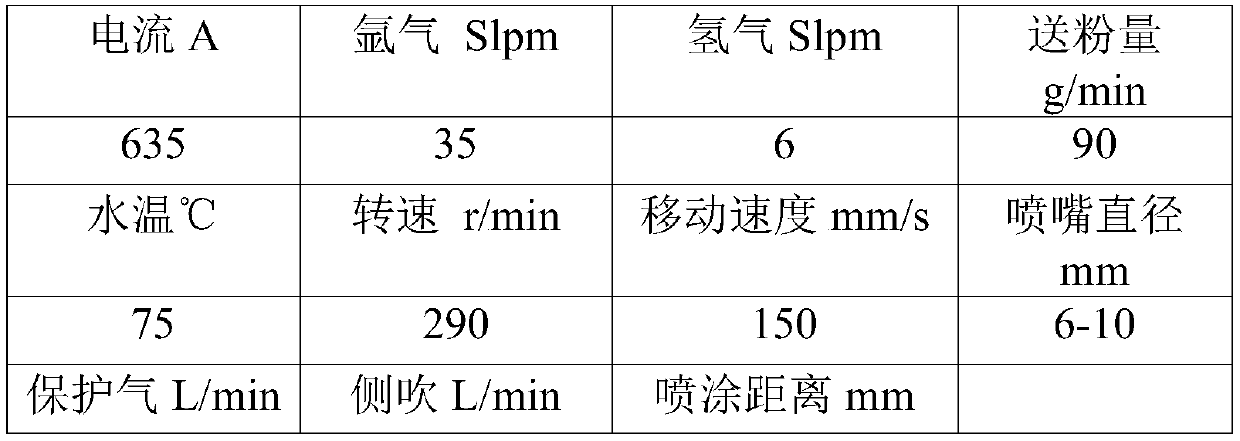

InactiveCN111041432AImprove uniformityReduce interventionMolten spray coatingVacuum evaporation coatingDopantMetallurgy

The invention discloses a rotating zirconium oxide target and a preparation method thereof. The rotating zirconium oxide target selects high-purity zirconium oxide free of any dopant as spraying powder; by conducting plasma spraying in a tank under gas protection, intervention of air and other impurities is reduced; the prepared target is low in electrical resistivity and high in uniformity, the purity is larger than or equal to 99.5%, the relative density is larger than or equal to 95%, the dimension of the target is free of limitation, the thickness can reach 3-9 mm, the maximum length can reach 4000 mm, the grain size is small, the product yield is high, the powder utilization ratio is high, and mass production is easy.

Owner:广州市尤特新材料有限公司

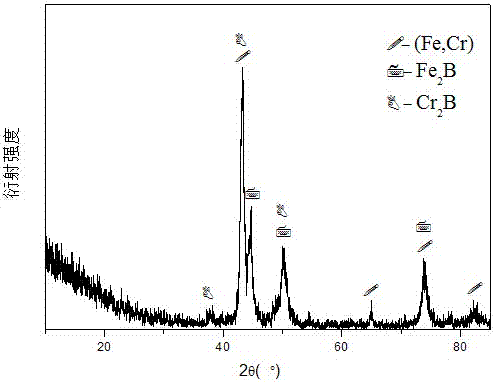

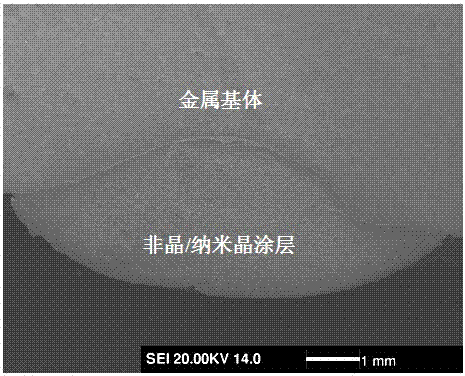

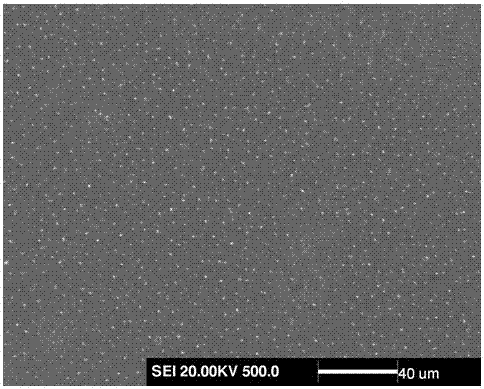

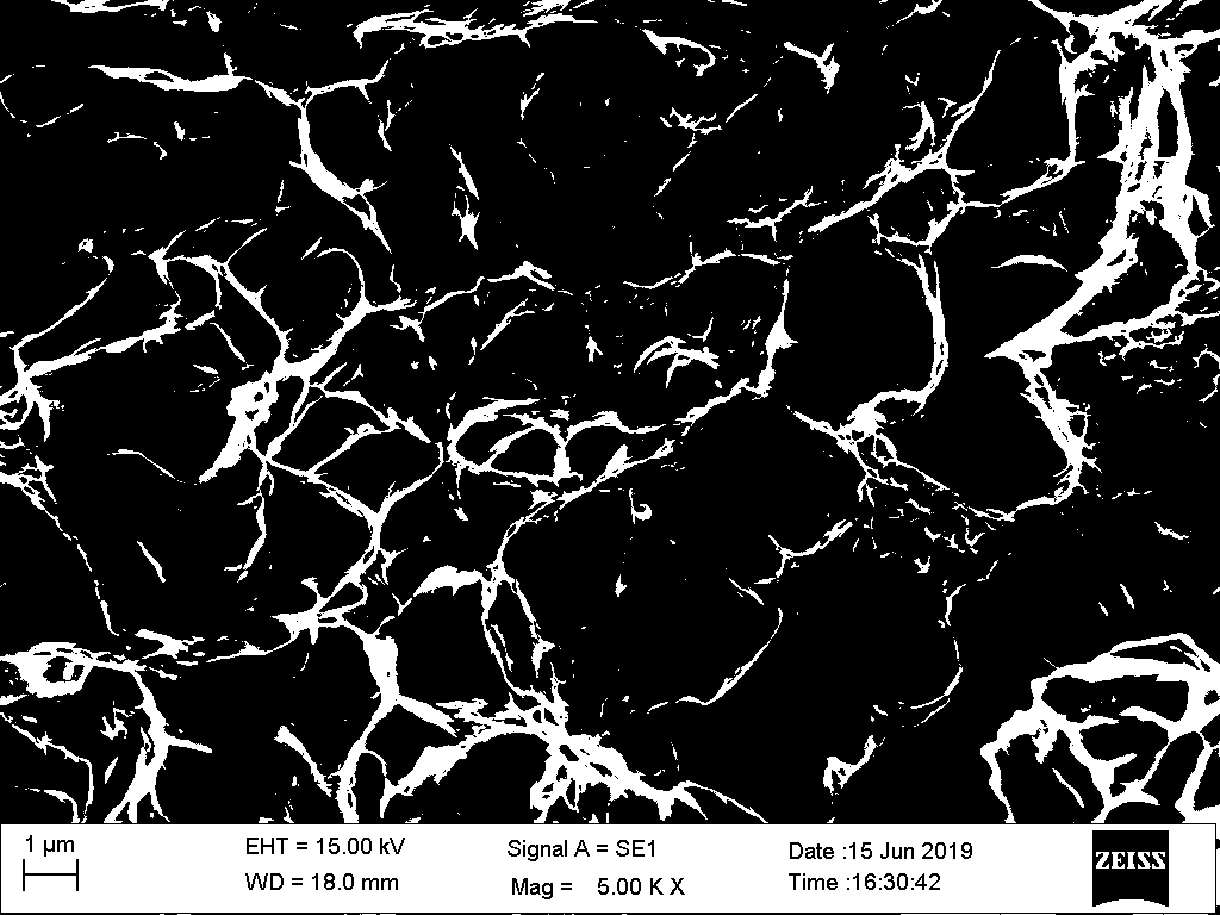

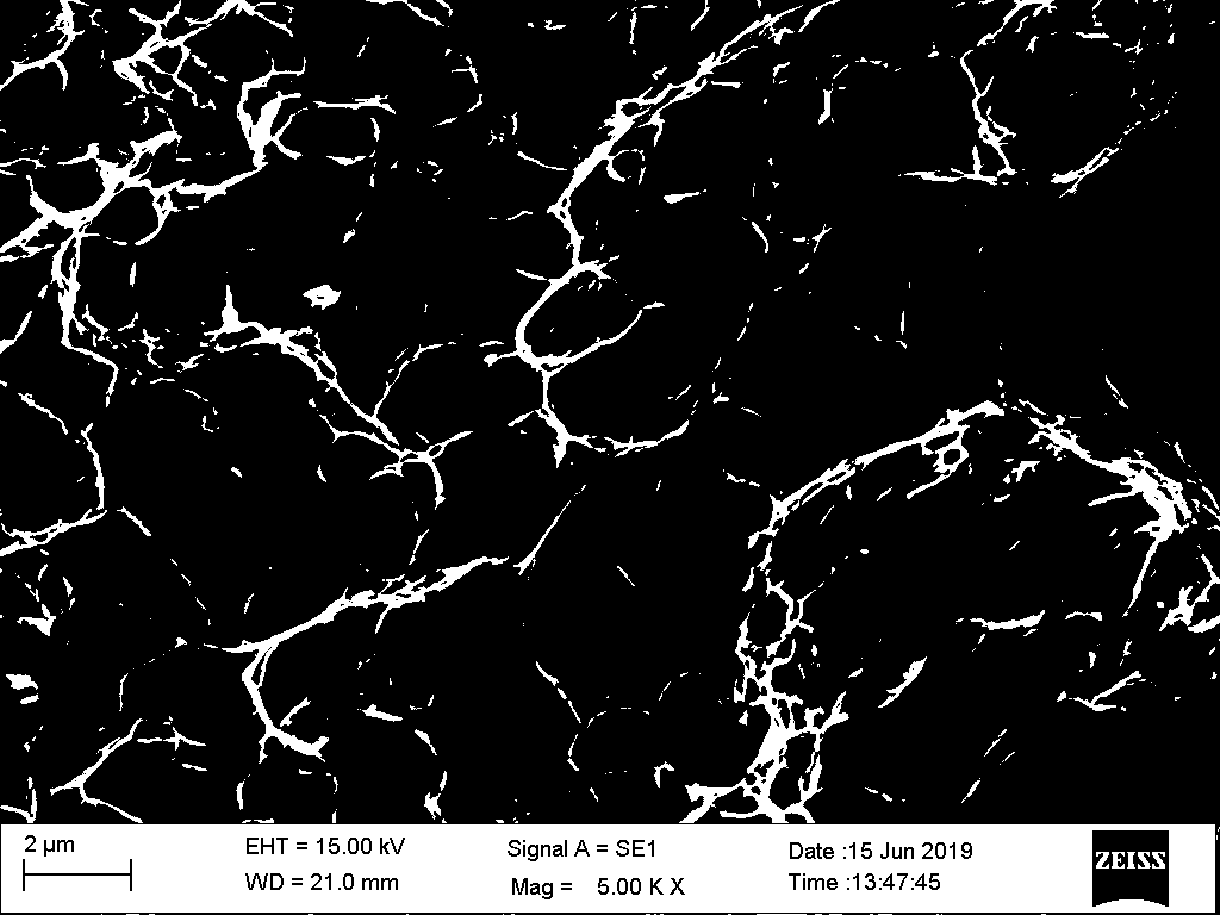

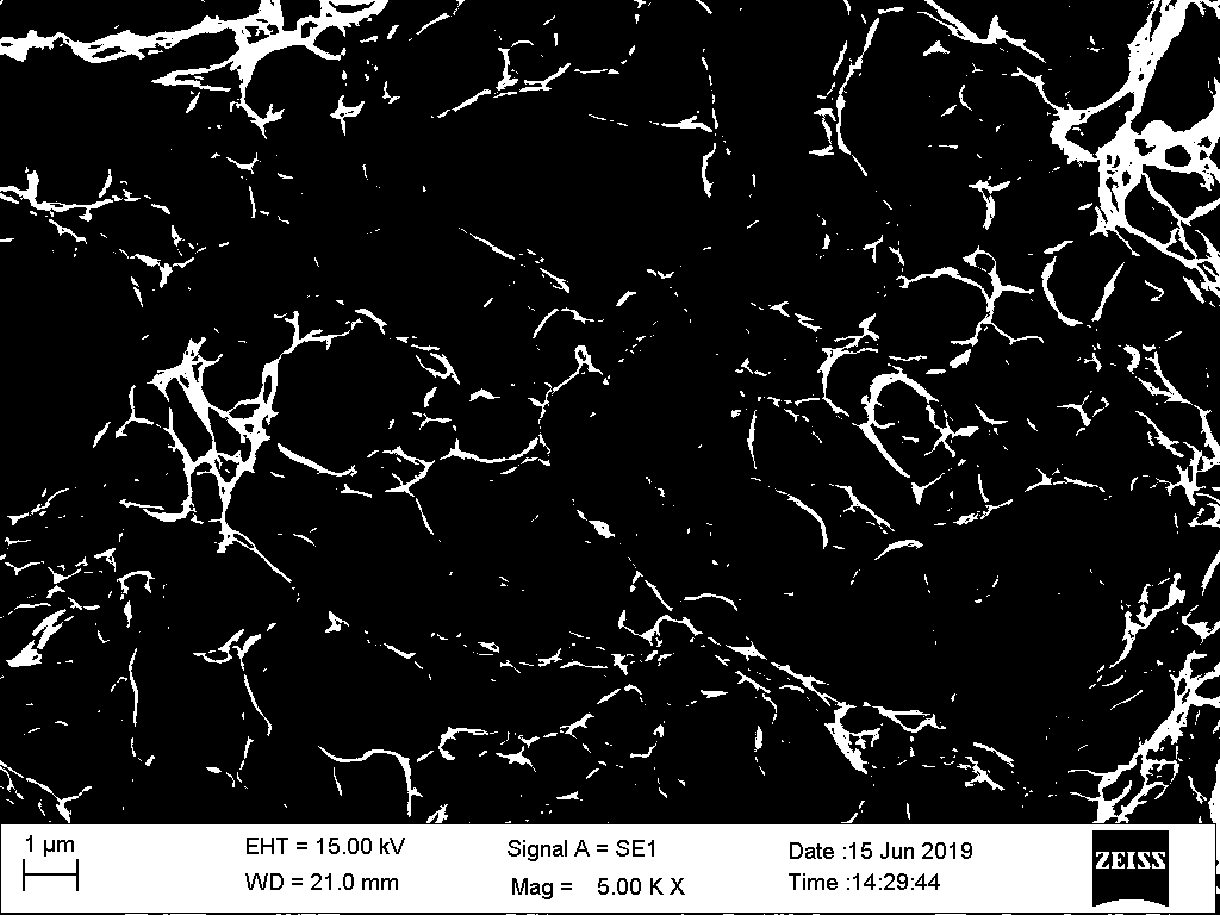

Method for preparing iron-based amorphous and nanocrystalline coating

ActiveCN106929845AImprove bindingEasy to operateTransportation and packagingMetal-working apparatusSurface engineeringNiobium

The invention provides a method for preparing an iron-based amorphous and nanocrystalline coating and belongs to the technical field of metal surface engineering. The method comprises the steps that elemental iron powder, chromium powder, boron powder, silicon powder and niobium powder are used as raw materials; the powder and hard alloy balls are put into a ball-milling tank to be subjected to ball milling and fully mixed; then an organic bonding agent is added; a mixture is pressed into a rod shape through a cylindrical mold to obtain a composite rod; the composite rod is naturally dried at the normal temperature and dried through a drying oven; and the composite rod is subjected to cladding through arc heat generated by an argon arc welding machine tungsten electrode, put on the surface of a metal substrate in a low-temperature tank and solidified to obtain the iron-based amorphous and nanocrystalline coating. The iron-based amorphous and nanocrystalline coating is well combined with the metal substrate, and nanocrystalline particles are uniformly distributed; the technological process is simple, easy to operate and low in equipment price; and compared with amorphous and nanocrystalline coatings prepared through laser cladding, the method for preparing the amorphous and nanocrystalline coating through argon arc cladding of the composite rod has the characteristics of being easy to operate, high in powder utilization rate, capable of reducing the production cost and the like.

Owner:无锡海韵新材料科技有限公司

Sieve hole built-in type annular laser cladding nozzle

ActiveCN107245715AGood pink matchEasy to replaceMetallic material coating processesProtective glassesEngineering

The invention discloses a sieve hole built-in type annular laser cladding nozzle which comprises a laser head connection part, a middle part sleeve part and a nozzle part; the laser head connection part is composed of an upper connection sleeve which is connected with a laser head; the middle part sleeve part is composed of a sliding sleeve which is connected with the upper connection sleeve; protective glass is arranged between the lower end of the sliding sleeve and the upper end of a center sleeve; a protective glass water cooled jacket is in threaded connection with the sliding sleeve and the center sleeve; a protective gas hole is formed in the center sleeve; a nozzle part is composed of a conical nozzle core which is connected with the center sleeve; and the outer side of each of the conical nozzle core and the center sleeve is sequentially provided with a powder inlet sleeve, a gas inlet sleeve and a water cooled jacket. The sieve hole built-in type annular laser cladding nozzle overcomes the disadvantages that the service life is short, a powder convergence diameter cannot be regulated, and the existing laser cladding nozzle cannot be suitable for powder particles in different sizes.

Owner:CHINA UNIV OF MINING & TECH

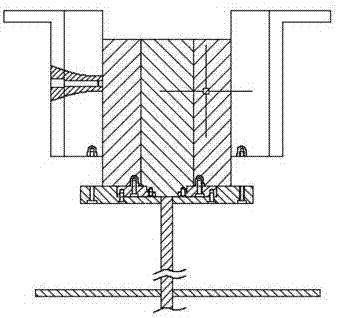

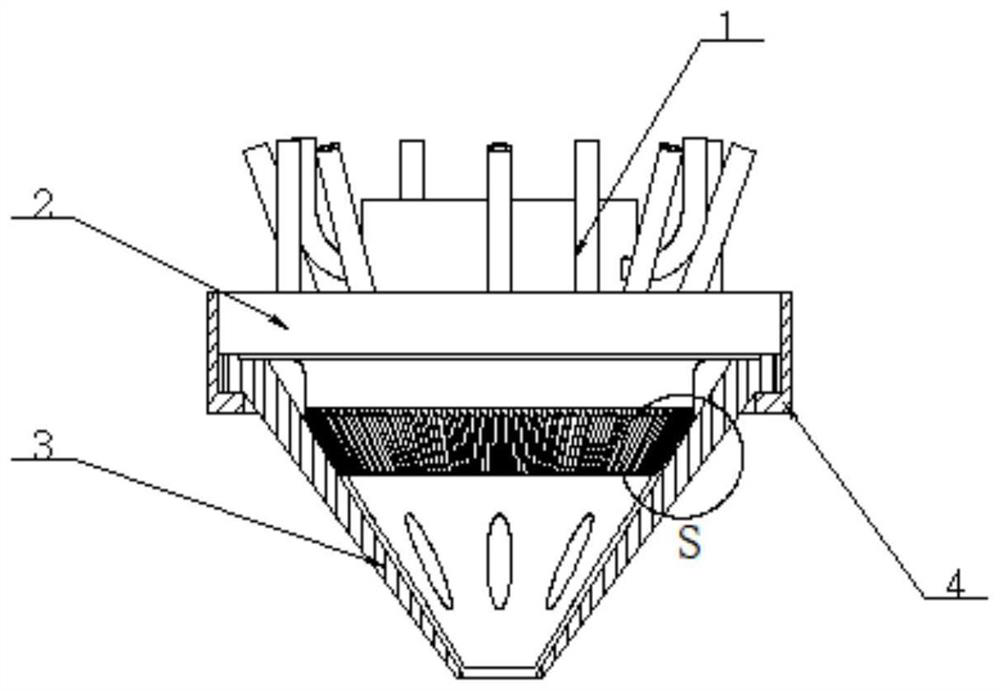

Forming cylinder for powder spreading type additive manufacturing equipment and in-cylinder piston body section adjusting method

ActiveCN107344237AImprove powder utilizationAvoid wasting powderAdditive manufacturing apparatusIncreasing energy efficiencyMachine partsEngineering

The invention discloses a forming cylinder for powder spreading type additive manufacturing equipment and an in-cylinder piston body section adjusting method. The forming cylinder comprises a cylinder body and a piston body arranged in the cylinder body, and the piston body is composed of a center piston body and at least one peripheral piston body, wherein the peripheral piston bodies sleeve on the center piston body and are distributed in the radial direction of the center piston body, and each peripheral piston body is provided with a first connecting part which is connected with the cylinder body and a second connecting part which is connected with the center piston body; and each peripheral piston body is disconnected with the cylinder body through the corresponding first connecting part and connected with the center piston body through the corresponding second connecting part, and then the variable-section piston body is formed by the peripheral piston bodies and the center piston body. According to the forming cylinder for the powder spreading type additive manufacturing equipment and the in-cylinder piston body section adjusting method, screw connection is adopted by the cylinder body, different piston bodies can do up-and-down telescoping motion along with an electric cylinder, and therefore the forming cylinder has forming spaces with three different sizes. When machining is conducted, the forming spaces with different sizes can be selected for machining parts with the corresponding sizes; and by means of the method, the powder spreading quantity can be greatly reduced, and the powder utilizing rate of the powder spreading type additive manufacturing equipment is increased.

Owner:NANJING ZHONGKE RAYCHAM TECH

Cobalt-based composite powder used for restoring rack of rolling mill and method for restoring rack of rolling mill

InactiveCN103817320AImprove repair effectImprove wear resistanceMetallic material coating processesCobaltLaser beams

The invention provides cobalt-based composite powder used for restoring a rack of a rolling mill and a method for restoring the rack of the rolling mill. The composite powder is composed of, by weight, 5 percent to 40 percent of chromium carbide and the balance of the cobalt-based powder, and the cobalt-based powder is composed of, by weight, 0.6 percent to 1 percent of C, 20 percent to 30 percent of Cr, 0.1 percent to 0.6 percent of Si, 0.1 percent to 0.5 percent of Mn, 5 percent to 10 percent of W, 0.5 percent to 3 percent of Fe, 5 percent to 12 percent of Ni and the balance of Co. According to the preparing process, the restored surface of the rack of the rolling mill is machined; nondestructive testing is performed on the restored surface; high-power semiconductor laser beams output by an optical fiber coupling are irradiated to the restored surface, reciprocating laser cladding machining is performed through programming of a robot, the composite powder is sintered to the base body of the rack of the rolling mill, and a cladding layer is obtained; the surface of the cladding layer is machined to meet the requirements for size accuracy and cleanliness of the surface; the method has the advantages of being short in restoring cycle, high in powder utilization rate, low in energy consumption and the like.

Owner:马海鹏

Aluminum rotary target material and manufacturing method thereof

InactiveCN109706422ASimple preparation processHigh densityVacuum evaporation coatingSputtering coatingThermal sprayingSand blasting

The invention provides a manufacturing method of an aluminum rotary target material. The method comprises S1, aluminum powder with the average grain diameter D50 of 10-80 micron is manufactured; S2, astainless steel tube or a titanium tube is taken as a target material base tube, and surface sand blasting treatment is conducted on the target material base tube; S3, cold spraying and forming are conducted, the manufactured aluminum powder is loaded into a cold spraying powder feeder, the processed target material base tube is installed on a transmission device to enable the target material base tube to rotate, a cold spraying gun and the target material base tube do relative motion in the horizontal direction to prepare the target material; and S4, the sprayed target material is machined into that with required size and precision, and a finished product is prepared. According to the method, the manufacturing process of the aluminum rotary target material is simple, the density of the manufactured aluminum rotary target material is far higher than that of a traditional thermal spraying technology, the relative density can reach 95-99%, the oxygen content is lower than that of the traditional thermal spraying technology, grain tissues are uniformly refined, the yield is high, the powder utilization rate is high and large-scale production is facilitated.

Owner:广州市尤特新材料有限公司

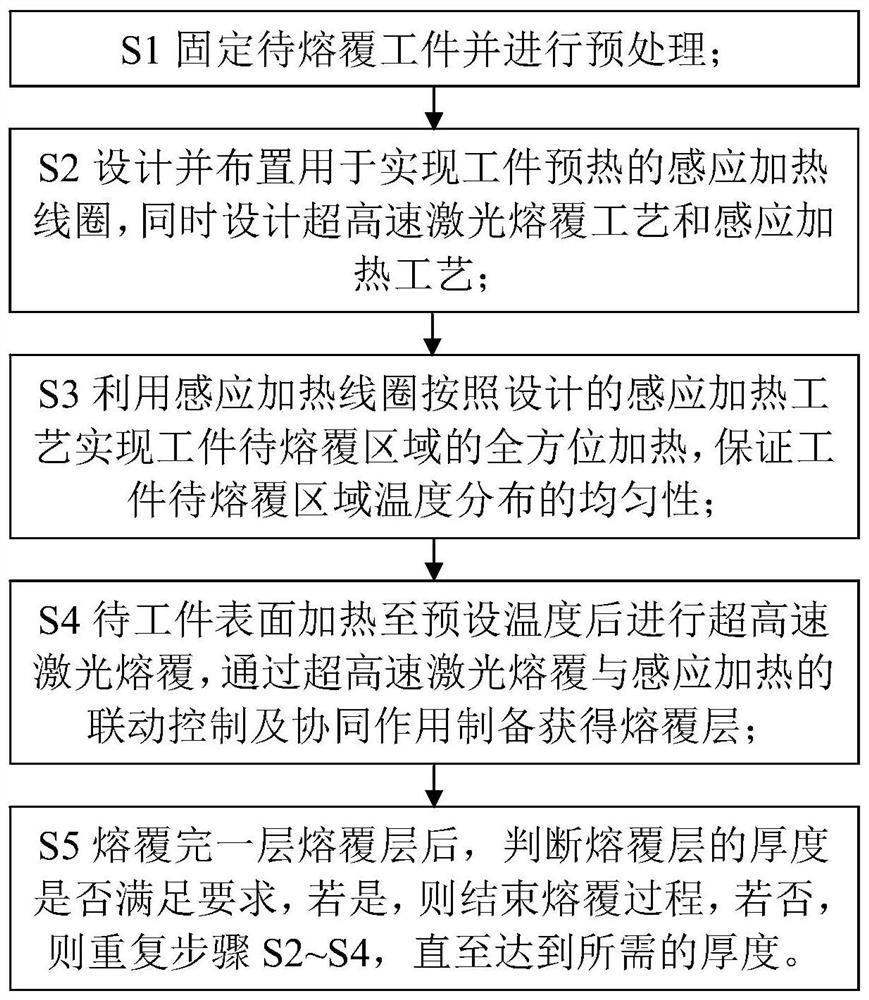

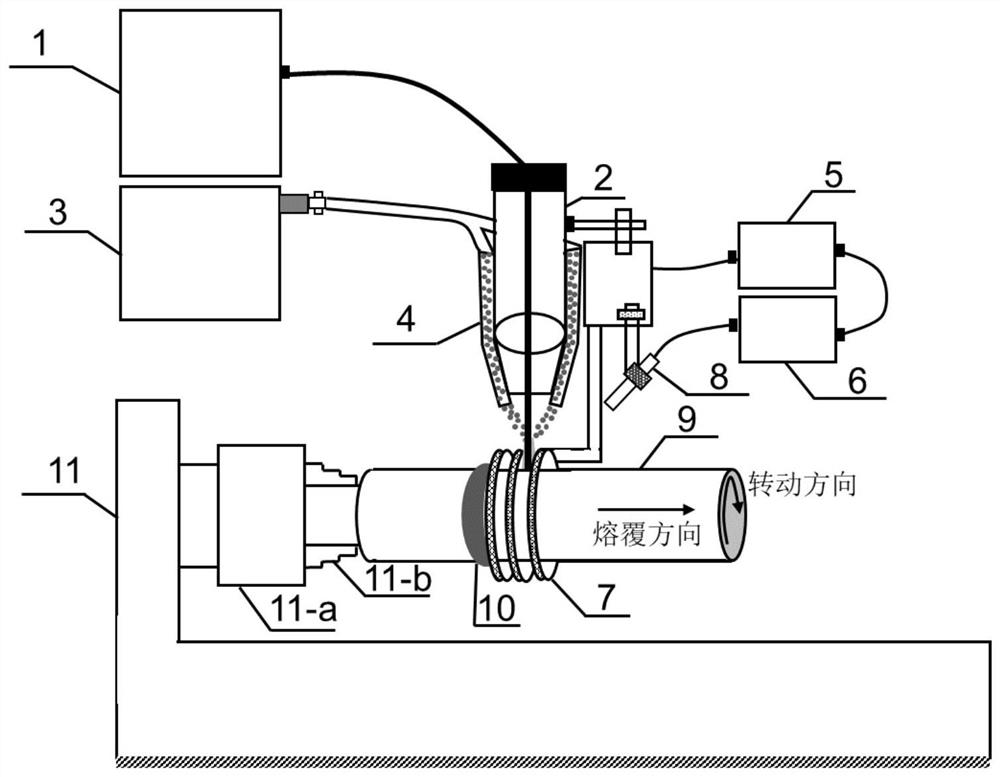

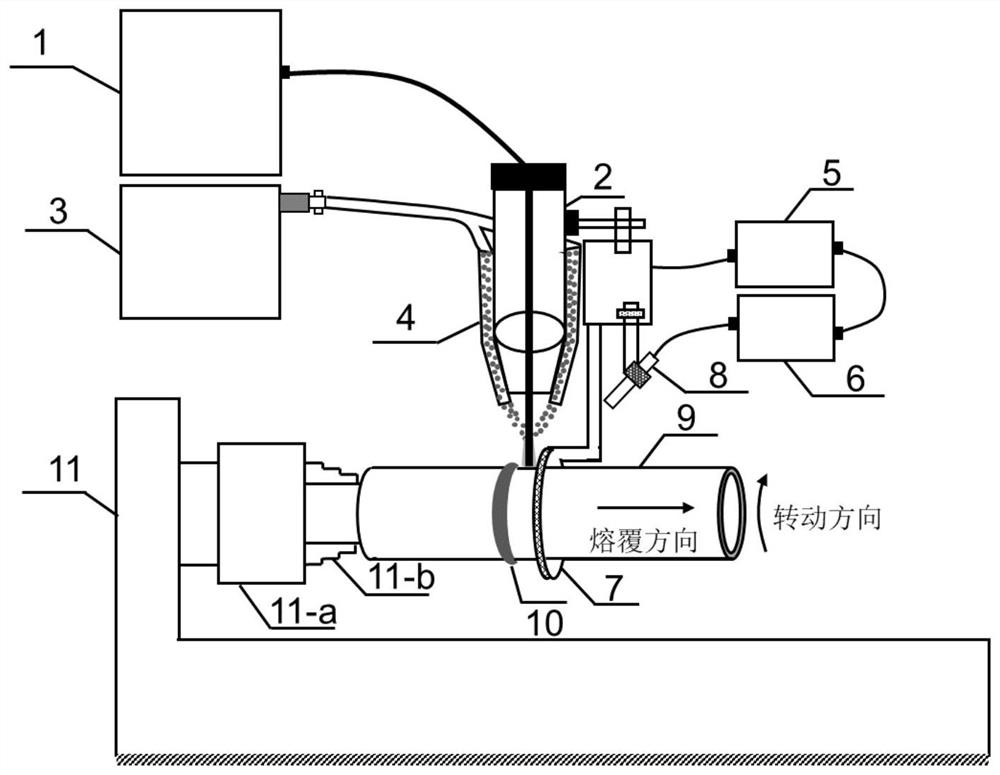

Ultrahigh-speed laser-induction composite cladding method and device

ActiveCN111676477AHigh precisionQuality improvementIncreasing energy efficiencyMetallic material coating processesUltra high speedAlloy

The invention belongs to the field of surface coating processing, and particularly discloses an ultrahigh-speed laser-induction composite cladding method and device. Aiming at a workpiece to be cladded as a processing object, the ultrahigh-speed laser-induction composite cladding device is provided with an induction heating coil used for realizing the fact of preheating the workpiece, the induction heating coil is arranged nearby the workpiece to be cladded, a area to be cladded of the workpiece is heated to a set temperature through the shape of the induction heating coil and the spatial arrangement of the induction heating coil relative to the workpiece to be cladded; and carrying out ultrahigh-speed laser-induction composite cladding above the area to be cladded of the workpiece by adopting ultrahigh-speed laser cladding and induction heating modes, so that interaction effect between a laser beam spot and a powder beam flow is carried out at a target position of a cladding area to heat a alloy powder to a molten drop or semi-molten drop state, and the alloy powder is sprayed to a micro molten pool on the preheated surface of the workpiece in a liquid or semi-solid form so as toprepare a required cladding layer. By means of the ultrahigh-speed laser-induction composite cladding method and device, high-precision, high-performance and metallurgical-defect-free ultra-efficientdeposition of the metal cladding layers of various materials can be achieved on the surface of a metal component.

Owner:武汉飞能达激光技术有限公司

Preparation method of AlFeCoNiCr high-entropy coating on surface of stainless steel

ActiveCN112281155AAchieve metallurgical bondingImprove bindingMetallic material coating processesSS - Stainless steelOxidation resistant

The invention discloses a preparation method of an AlFeCoNiCr high-entropy coating on the surface of stainless steel. The method comprises the following steps of 1, preparing materials; 2, mixing thematerials; 3, preparing mixed slurry; 4, coating the mixed slurry on the surface of the stainless steel and drying; 5, carrying out pre-sintering to form an AlFeCoNiC pre-sintered coating; and 6, preparing the AlFeCoNiC high-entropy coating on the surface of the stainless steel by adopting an electron beam cladding process. According to the preparation method, a powder pre-sintering method and anelectron beam cladding process are combined, metallurgical bonding of the AlFeCoNiCr high-entropy coating and a stainless steel base body is achieved, the bonding force of the AlFeCoNiCr high-entropycoating and the stainless steel base body is effectively improved, then the abrasion resistance, hardness, oxidation resistance and high-temperature corrosion resistance of the AlFeCoNiCr high-entropycoating on the surface of the stainless steel are improved, and the service life is prolonged. The preparation method is easy to implement and low in cost, and the adaptability of the AlFeCoNiCr high-entropy coating in an extreme environment is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

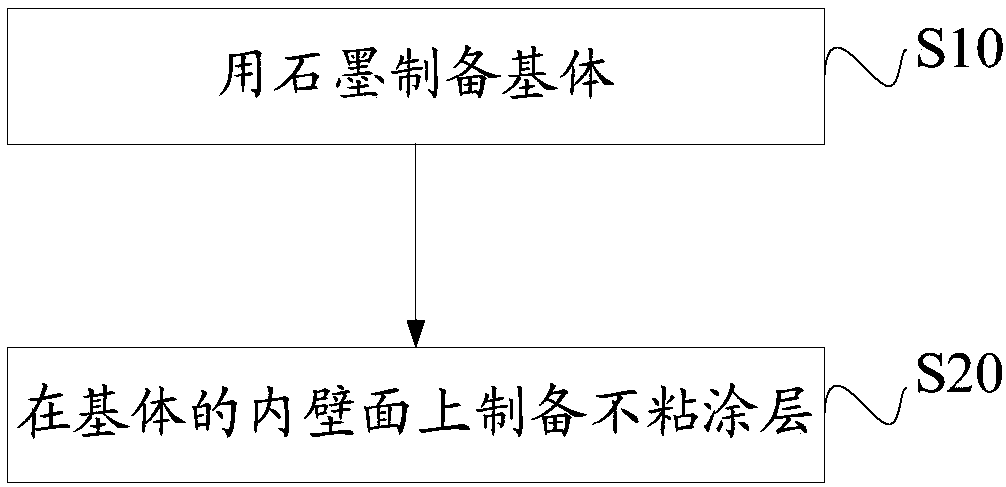

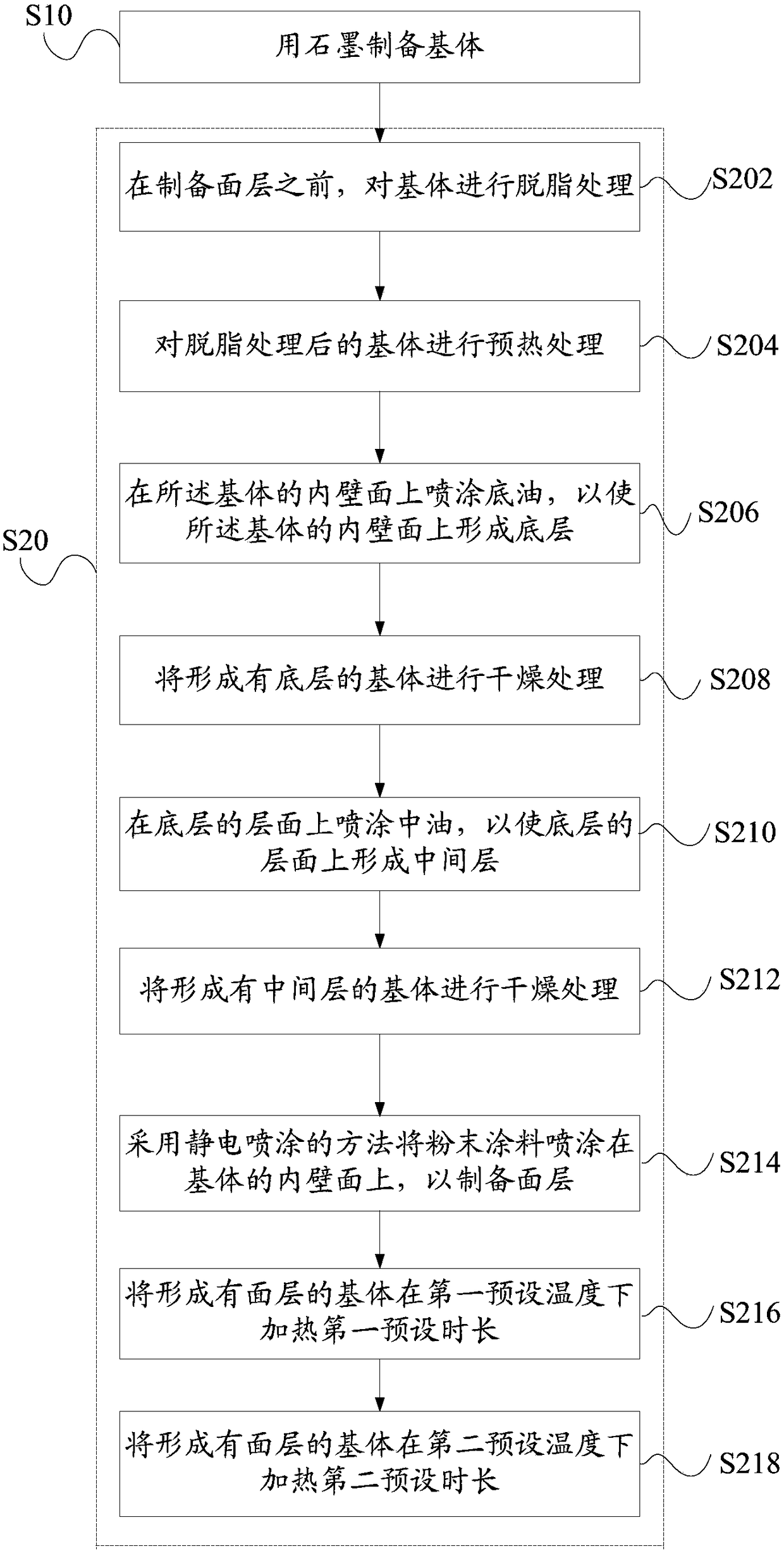

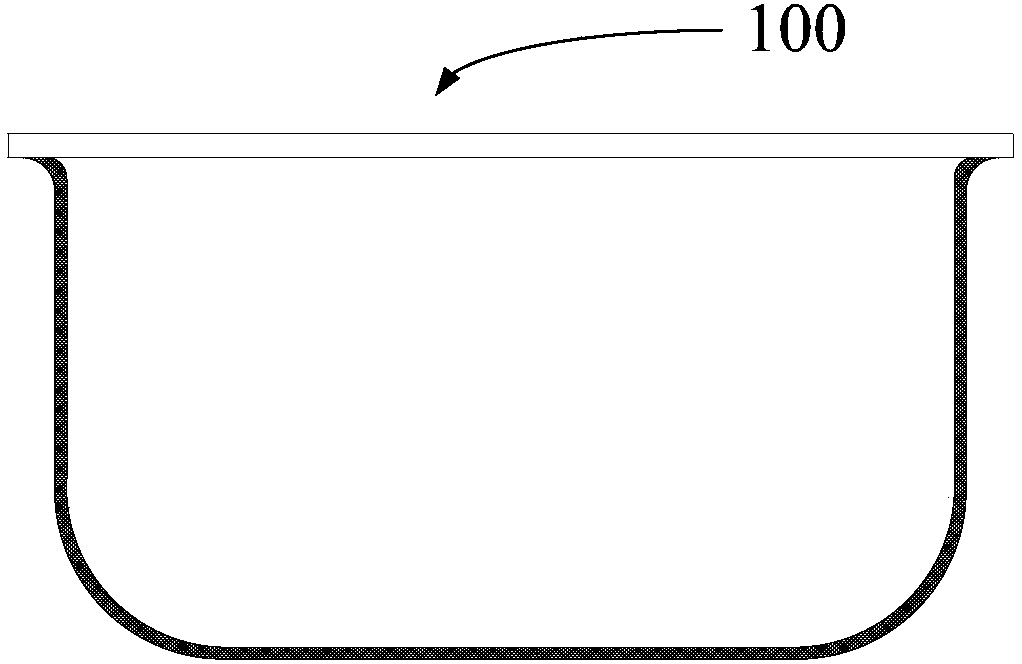

Cooking utensil and preparation method thereof

PendingCN108618633AReduce manufacturing costHeating evenlyCooking-vessel materialsLiquid surface applicatorsSurface layerGraphite

The invention provides a cooking utensil and a preparation method thereof. The preparation method of the cooking utensil comprises the steps that S10, graphite is used for preparing a base body; and S20, a non-sticking coating is prepared on the inner wall face of the base body, wherein the step S20 specifically comprises S214, namely powder coating is sprayed on the inner wall face of the base body by an electrostatic spraying method to prepare a surface layer. According to the preparation method of the cooking utensil, the electrostatic spraying method is used for prepare the surface layer on the graphite base body, so that the comfort of operation during spraying is improved, the working condition is improved, and the environment is not polluted; because of the good adsorption of the graphite base body, sandblasting treatment is not required before spraying, and the manufacturing cost of the cooking utensils is reduced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

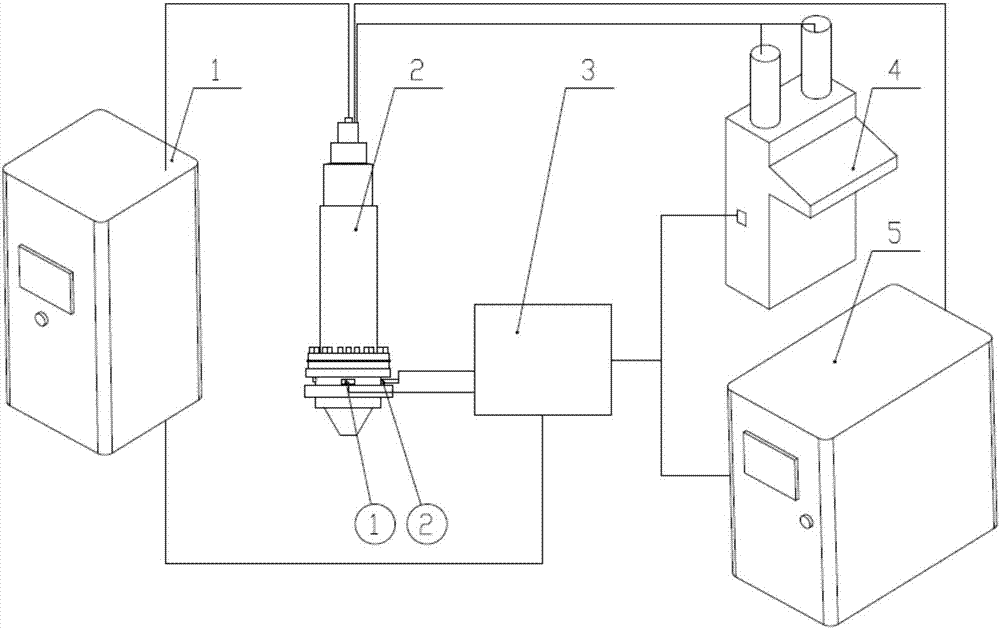

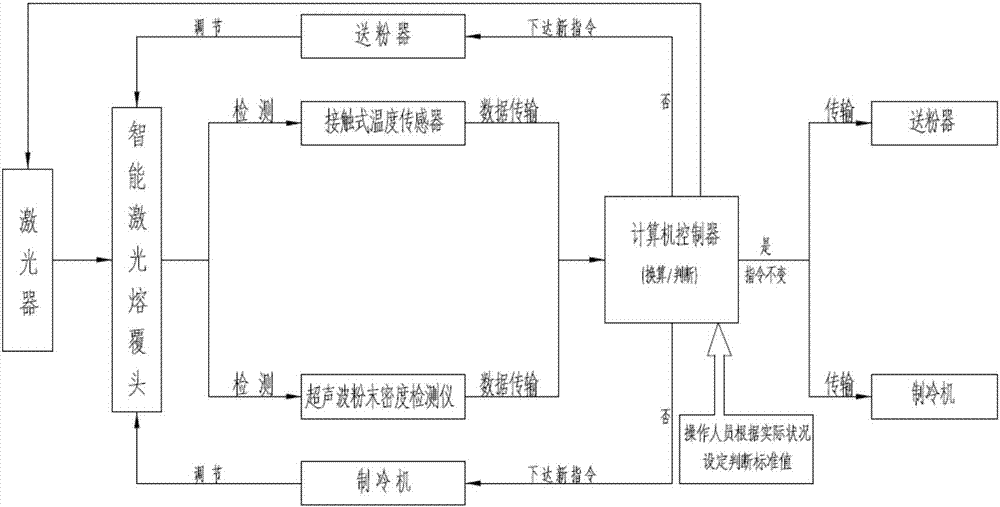

Intelligent laser cladding head with automatic temperature and powder feeding amount debugging function

InactiveCN107083550AAvoid powder accumulationImprove powder utilizationMetallic material coating processesData transmissionUltrasound

The invention discloses an intelligent laser cladding head with the automatic temperature and powder feeding amount debugging function. The laser cladding head comprises a base sleeve, a focus lens, a focus lens sleeve, a nozzle core, a cold water sleeve, a protection lens, a simple body and other basic components, and a contact type temperature sensor and an ultrasonic powder density detection instrument are further designed; in order to achieve the functions, except for the intelligent laser cladding head, a laser device, a cold water unit, a powder feeding device, a laser device and a control box are matched with the characteristics internally so that the functions are achieved, and a real-time effective closed-loop system is formed; under the normal work state of the laser device, the intelligent laser cladding head detects the real-time temperature of a laser cladding head through the contact type temperature sensor, data are transmitted to a computer controller, the computer controller carries out comparison according to rated value of the set program, judgment is carried out, according to the judgment result, a refrigeration command is issued to the cold water unit in real time, and the cold water unit regulates the refrigeration frequency according to the command; as well, the intelligent laser cladding head detects the real-time powder feeding density of the laser cladding head through a solid powder detection system, the data are transmitted to the computer controller, the computer controller carries out calculation according to the formula of the set program, the data are converted into the powder feeding amount, the data and the set value are compared, judgment is made, according to the judgment result, a powder feeding adjusting instruction is issued to the powder feeding device in real time, the set value of the powder feeding device is changed through the computer controller, and therefore the powder feeding amount is changed through the powder feeding device, and the optimal powder feeding effect is achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Surface treatment method for bathroom hardware

InactiveCN105855146AStrong adhesionUniform adhesionDuplicating/marking methodsPretreated surfacesEngineeringMaterials science

The invention discloses a surface treatment method for bathroom hardware. The surface treatment method for the bathroom hardware includes the following steps of (1) grinding; (2) cleaning and drying; (3) electrostatic spraying processing, specifically, the cleaned and dried bathroom hardware workpiece is put into a spraying chamber built by a high-voltage electrostatic generator, powdery paint is sprayed on the bathroom hardware workpiece through a spraying gun, and through electrostatic reaction, the powdery paint can be uniformly adsorbed to the bathroom hardware workpiece; (4) heating, drying and curing, specifically, the sprayed workpiece is put into a drier to be heated, the sprayed paint is solidified and hardened, and single-color surface spraying processing is realized; (5) pattern attaching, specifically, patterned paper printed with patterns is torn off a carrier, uniformly attached to the bathroom hardware workpiece heated, dried and cured in the step (4), and naturally dried for 1.5-3 h, and then a protective film on the patterned paper is torn off; and (6) baking and reinforcing, specifically, the bathroom hardware workpiece with the patterns attached is put into baking equipment, baked for 30-50 min at the high temperature of 120-180 DEG C, and cooled at normal temperature.

Owner:CHONGQING HUODUN BUILDING MATERIAL CO LTD

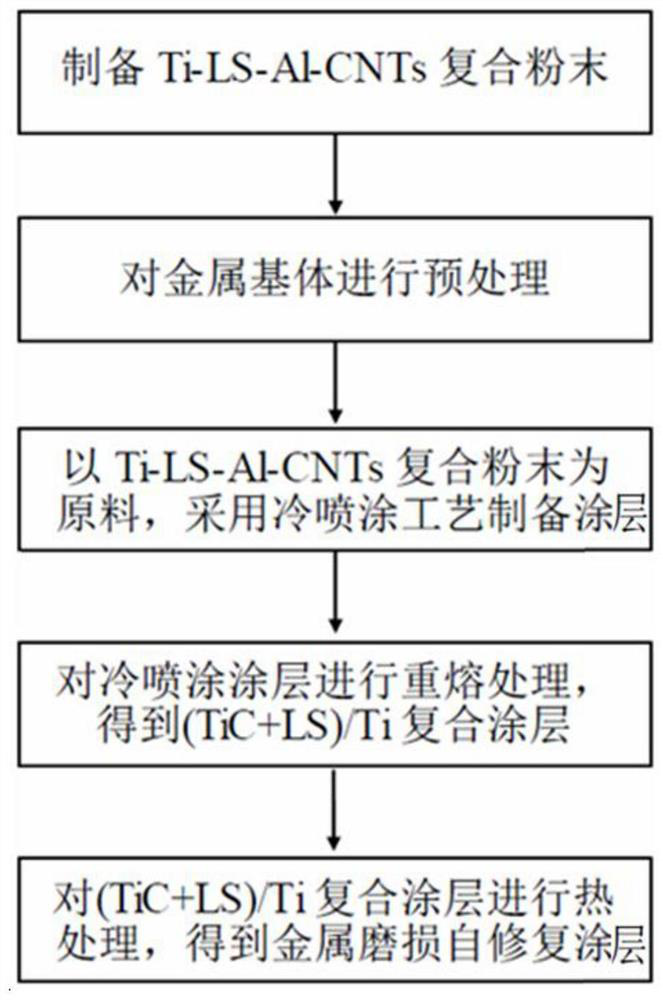

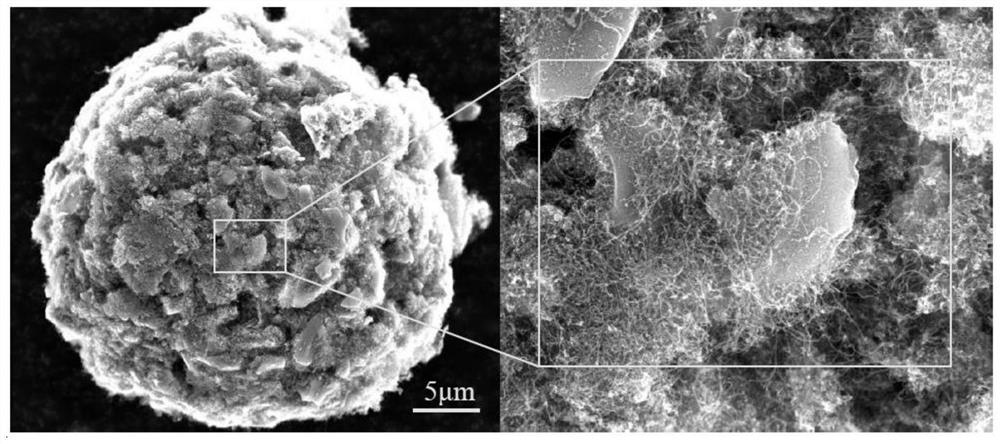

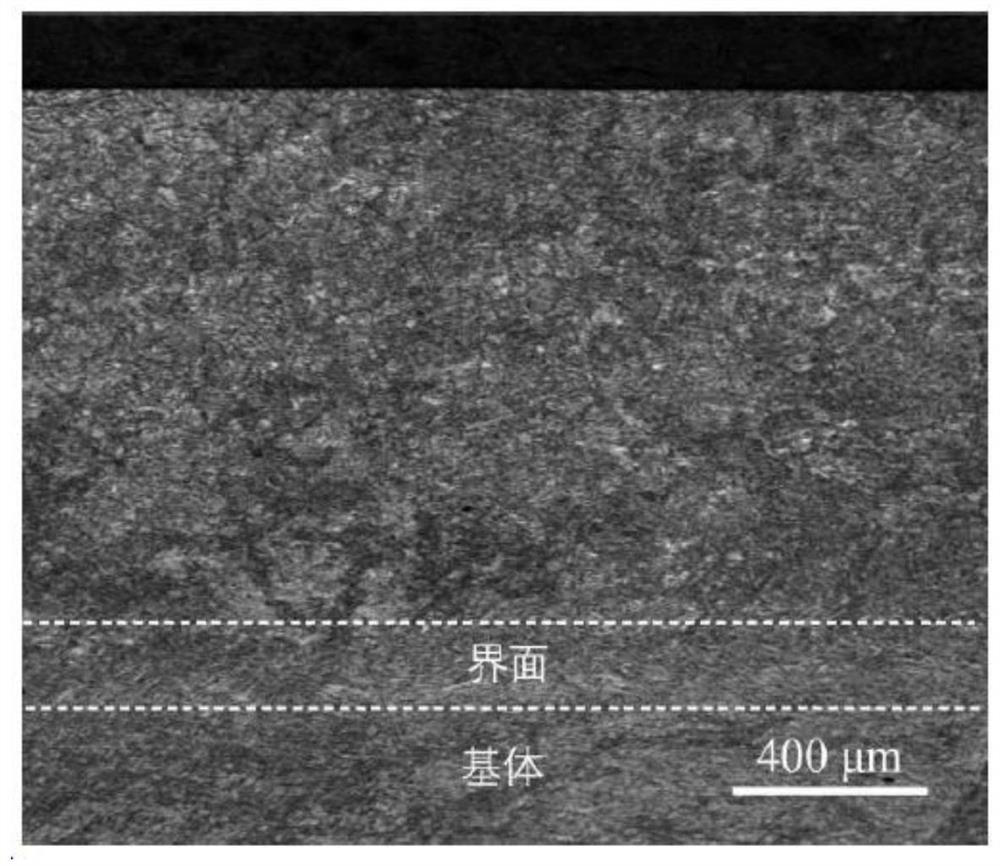

Composite powder for preparing self-repairing coating, preparation method of composite powder, titanium-based wear-resistant self-repairing coating and preparation method of titanium-based wear-resistant self-repairing coating

ActiveCN112974799AEvenly distributedHigh hardnessMaterial nanotechnologyTransportation and packagingAl powderCarbon nanotube

The invention provides composite powder for preparing a self-repairing coating, a preparation method of the composite powder, a titanium-based wear-resistant self-repairing coating and a preparation method of the titanium-based wear-resistant self-repairing coating. The preparation method of the composite powder comprises the following steps: firstly, mixing powder materials (layer silicate mineral powder, Al powder and Ti powder), a nitrate solution, a dispersing agent and a binder, and performing ball milling to obtain slurry; secondly, carrying out spray drying to obtain spherical composite powder particles; and finally, performing chemical vapor deposition treatment in an environment containing carbon source gas to form a carbon nanotube coating layer on the surface of the spherical composite powder, thereby obtaining spherical composite powder coated with carbon nanotubes (namely CNT). The composite powder is used as a raw material, and the wear-resistant self-repairing coating is prepared on the surface of a metal matrix through the steps of matrix surface pretreatment, cold spraying, re-melting treatment, heat treatment and the like. The titanium-based wear-resistant self-repairing coating provided by the invention has high hardness and good wear resistance, and has a wear self-repairing function in oil lubrication, dry friction and vacuum environments.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +1

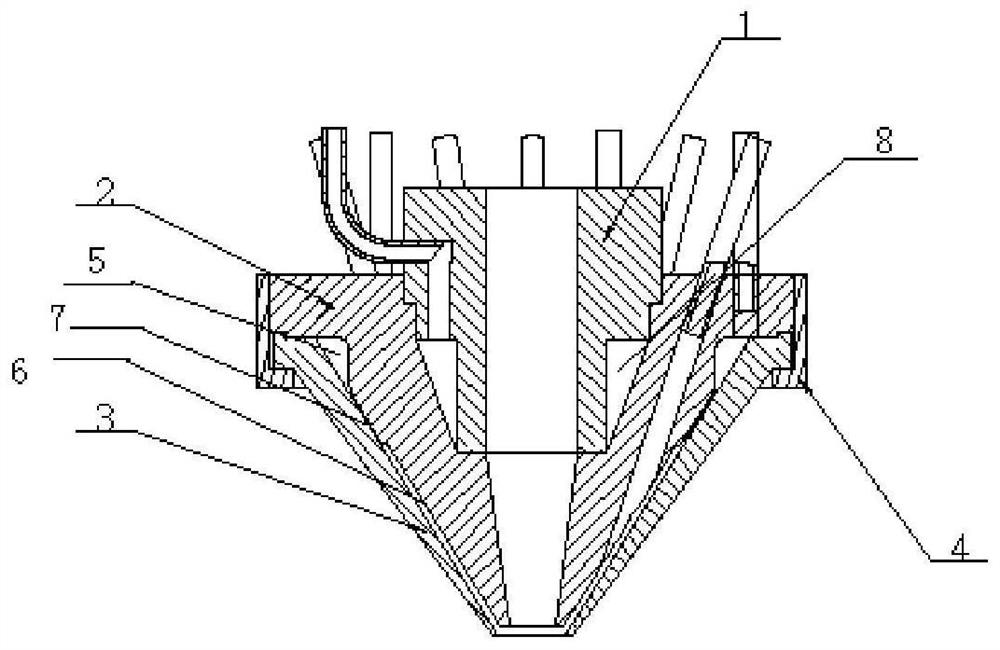

Multi-axis laser cladding anti-gravity deflection ring cone focusing powder feeding nozzle

PendingCN112030160AReduce deflectionImprove powder utilizationMetallic material coating processesShielding gasEngineering

The invention provides a multi-axis laser cladding anti-gravity deflection ring cone focusing powder feeding nozzle. The nozzle comprises a water-cooling connecting part, a gas-equalizing powder-conveying conical core, an outer thin converging conical cover, a conical cover locking ring, a protective gas annular cavity, a powder inverted-frustum-shaped annular seam converging cavity, a triangularinverted-cone-shaped annular equalizing gas channel and a cooling water annular cooling structure cavity; the water-cooling connecting part is fixedly installed in the middle of the nozzle; the gas-equalizing powder-conveying conical core and the outer thin converging conical cover are arranged on the outer side wall of the water-cooling connecting part from inside to outside; the conical cover locking ring is fixedly installed on the top end side walls of the gas-equalizing powder-conveying conical core and the outer thin converging conical cover; the cooling water annular cooling structure cavity is formed between the outer side wall of the water-cooling connecting part and the inner side wall of the gas-equalizing powder-conveying conical core; and the protective gas annular cavity, thetriangular inverted-cone-shaped annular equalizing gas channel and the powder inverted-frustum-shaped annular seam converging cavity are arranged on the outer side wall of the gas-equalizing powder-conveying conical core and the inner side wall of the outer thin converging conical cover from top to bottom. Compared with conventional technologies, the nozzle has the advantage that the problem of segregation of powder fed by the nozzle of a cladding head due to gravity during multi-axis laser cladding of a curved surface can be solved.

Owner:熔创金属表面科技(常州)有限公司

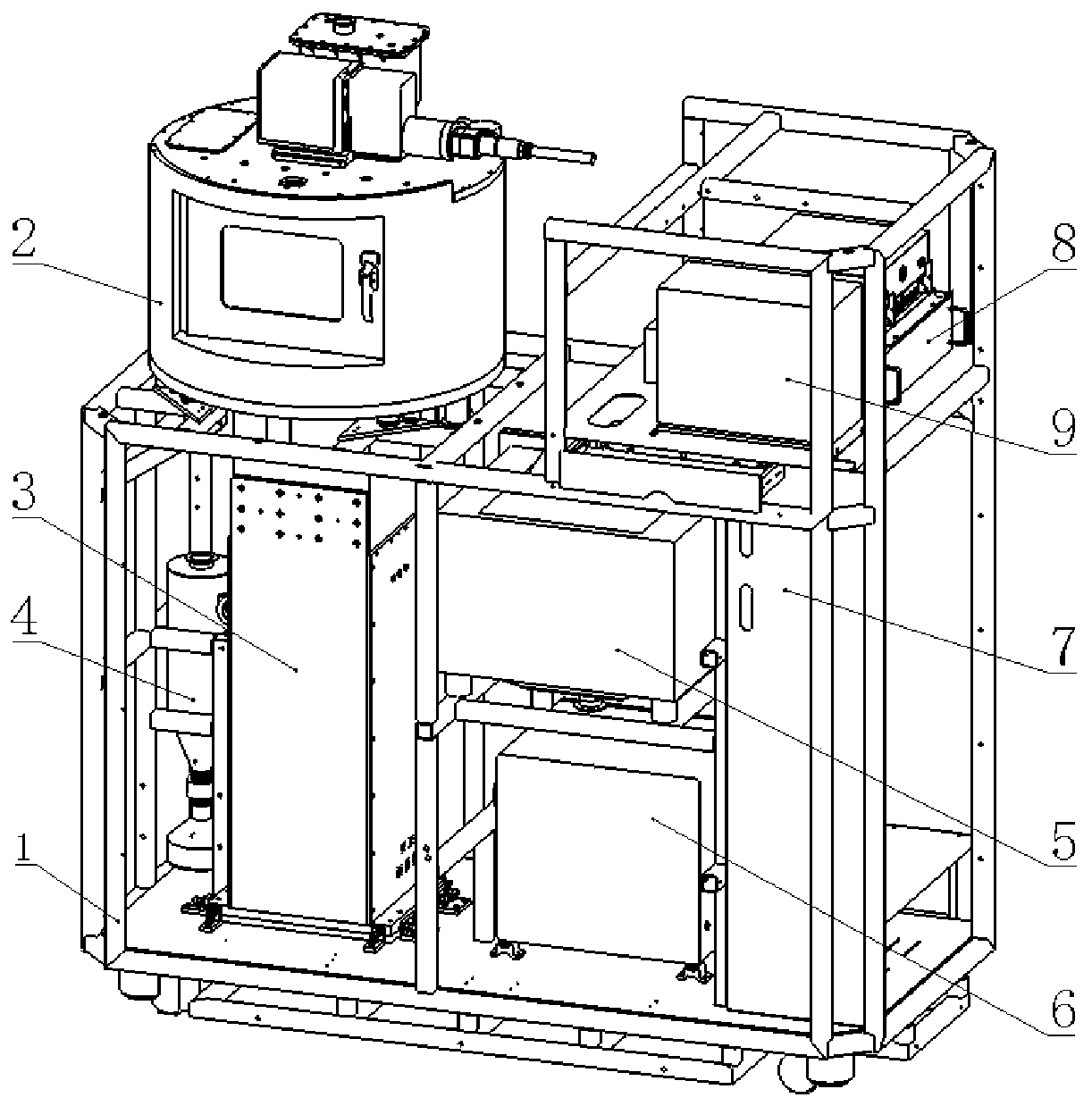

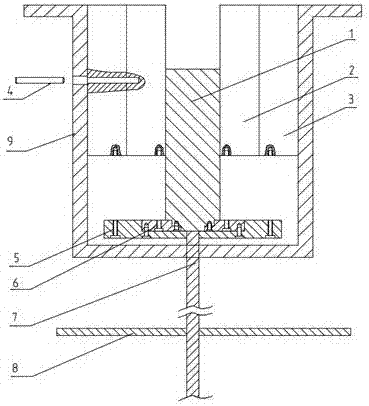

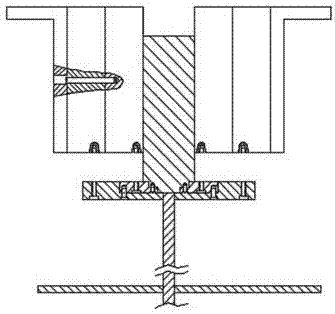

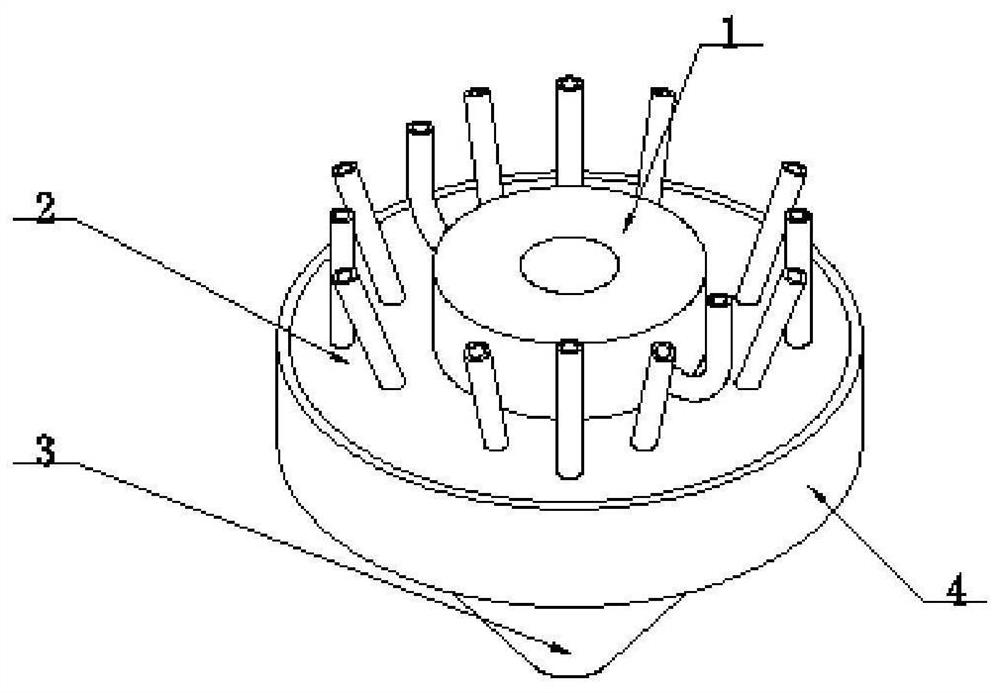

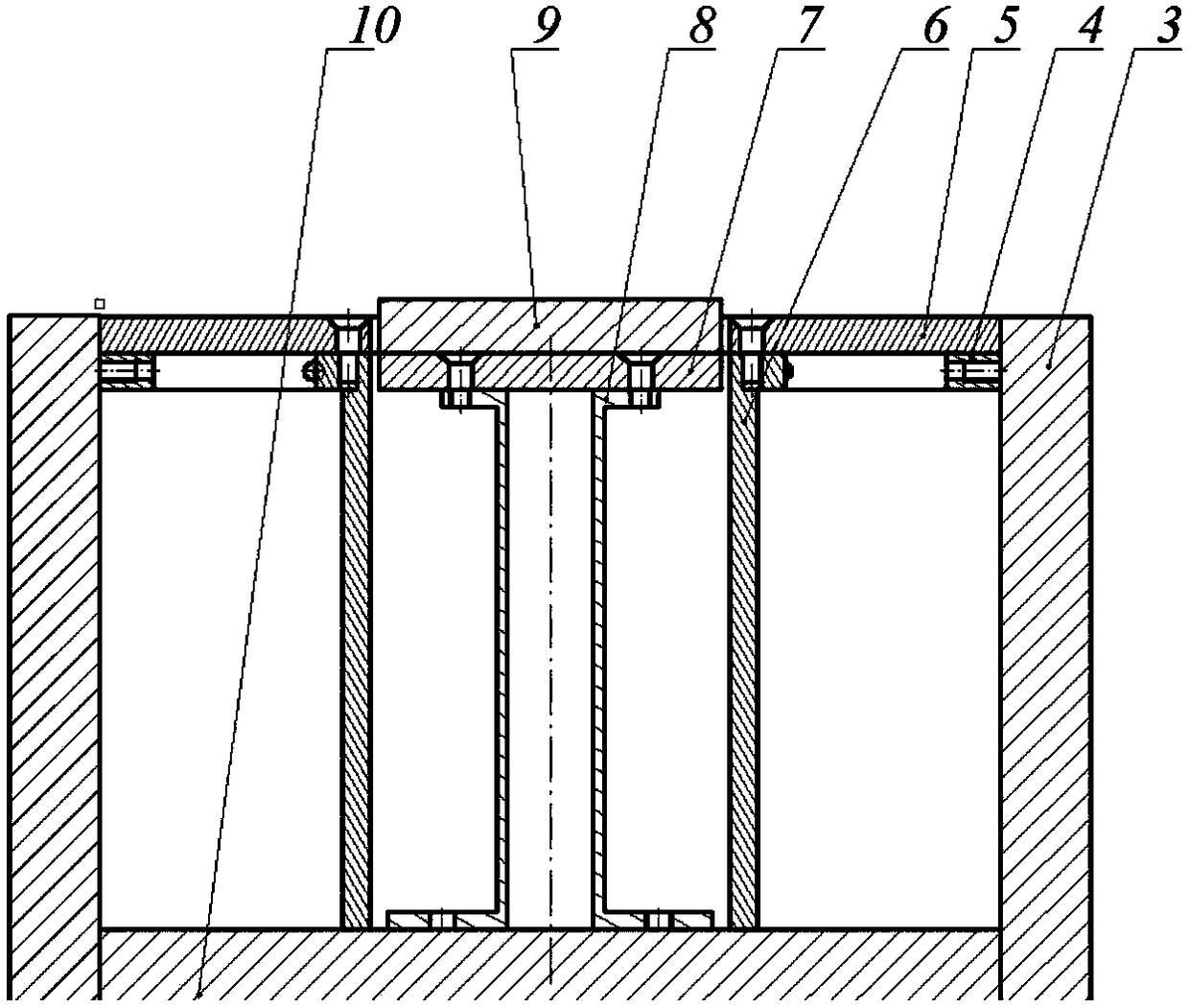

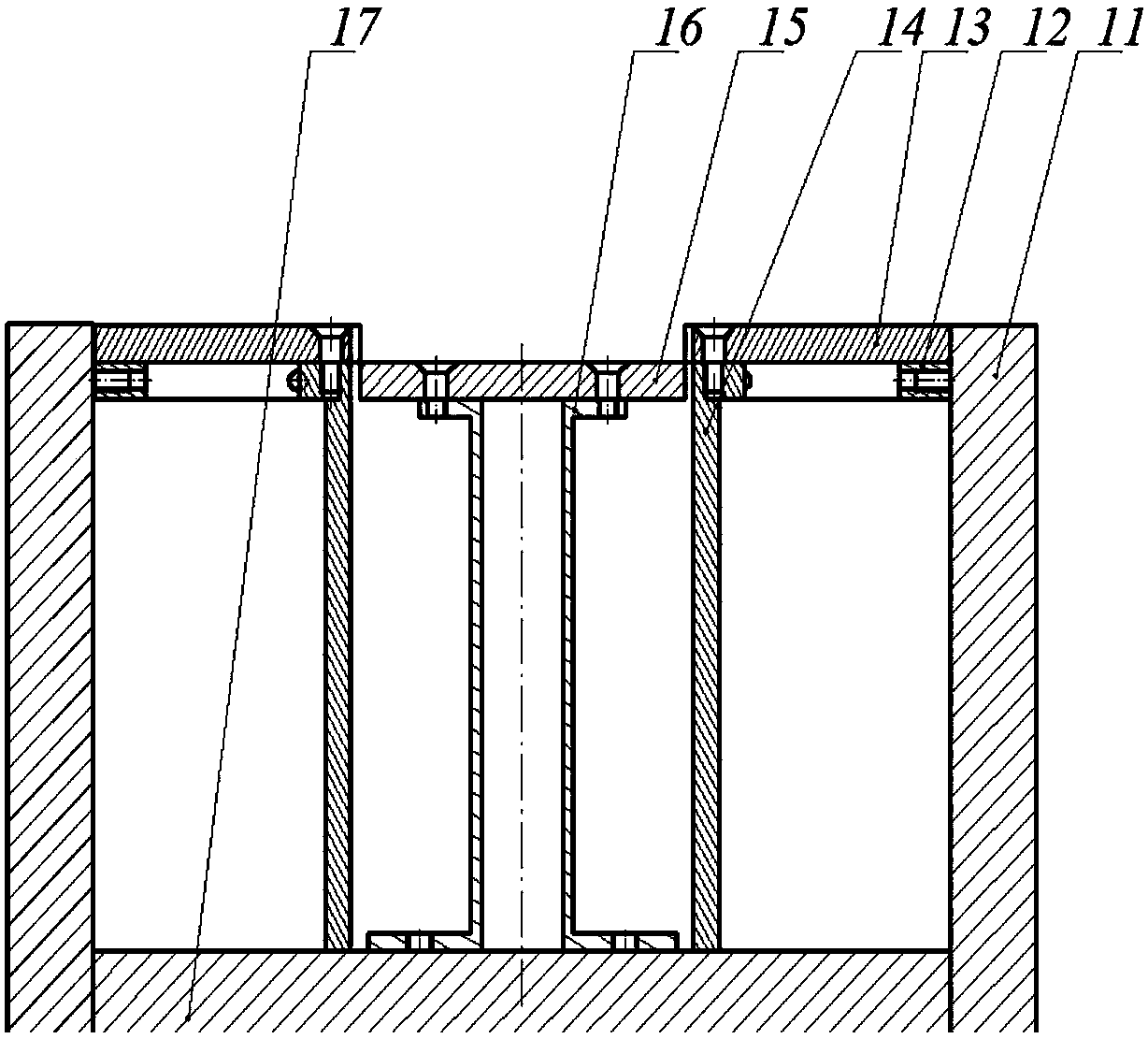

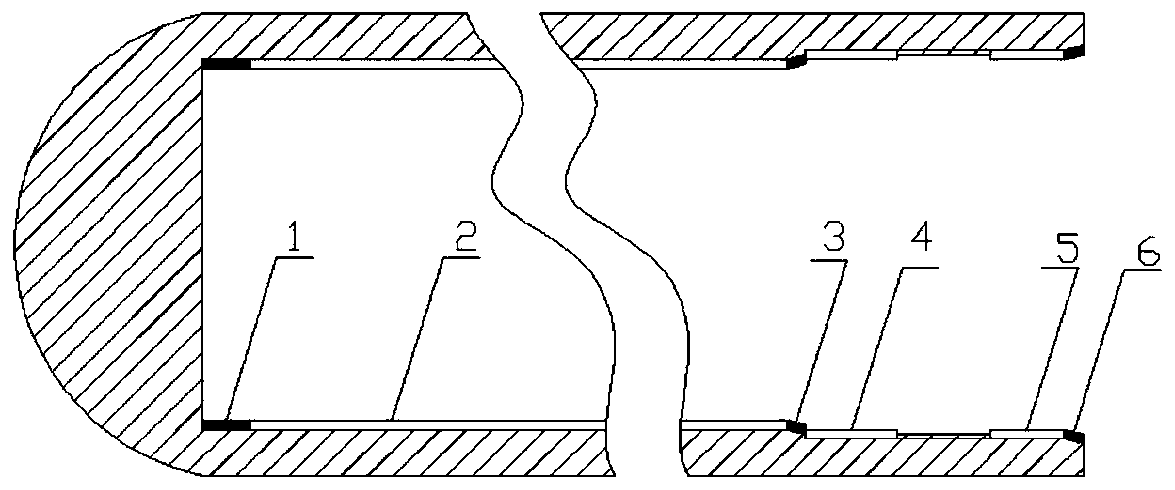

Base plate dimension adjustment device for powder feeding under double cylinders, and use method thereof

PendingCN108311699ASmall sizeImprove powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

The invention relates to a base plate dimension adjustment device for powder feeding under double cylinders. The base plate dimension adjustment device comprises a forming cylinder adjustment device (1) and a powder cylinder adjustment device (2), wherein the forming cylinder adjustment device (1) comprises a support frame I (4), a support plate I (5), an inner cylinder I (6), an inner cylinder bottom plate I (7), a connection rod I (8) and a base plate (9); the forming cylinder adjustment device is arranged in the outer cylinder (3) of a forming cylinder and located on the upper part of an outer cylinder bottom plate (10) of the forming cylinder; the powder cylinder adjustment device (2) comprises a support frame II (12), a support plate II (13), an inner cylinder II (14), an inner cylinder bottom plate II (15) and a connection rod II (16); and the powder cylinder adjustment device is arranged in the outer cylinder (11) of a powder cylinder and located on the upper part of an outer cylinder bottom plate (17) of the powder cylinder. The base plate dimension adjustment device disclosed by the invention increases the powder utilization rate of a powder spreading plane, reduces the powder use amount, and lowers the base plate expense and the powder use cost.

Owner:中航迈特粉冶科技(北京)有限公司

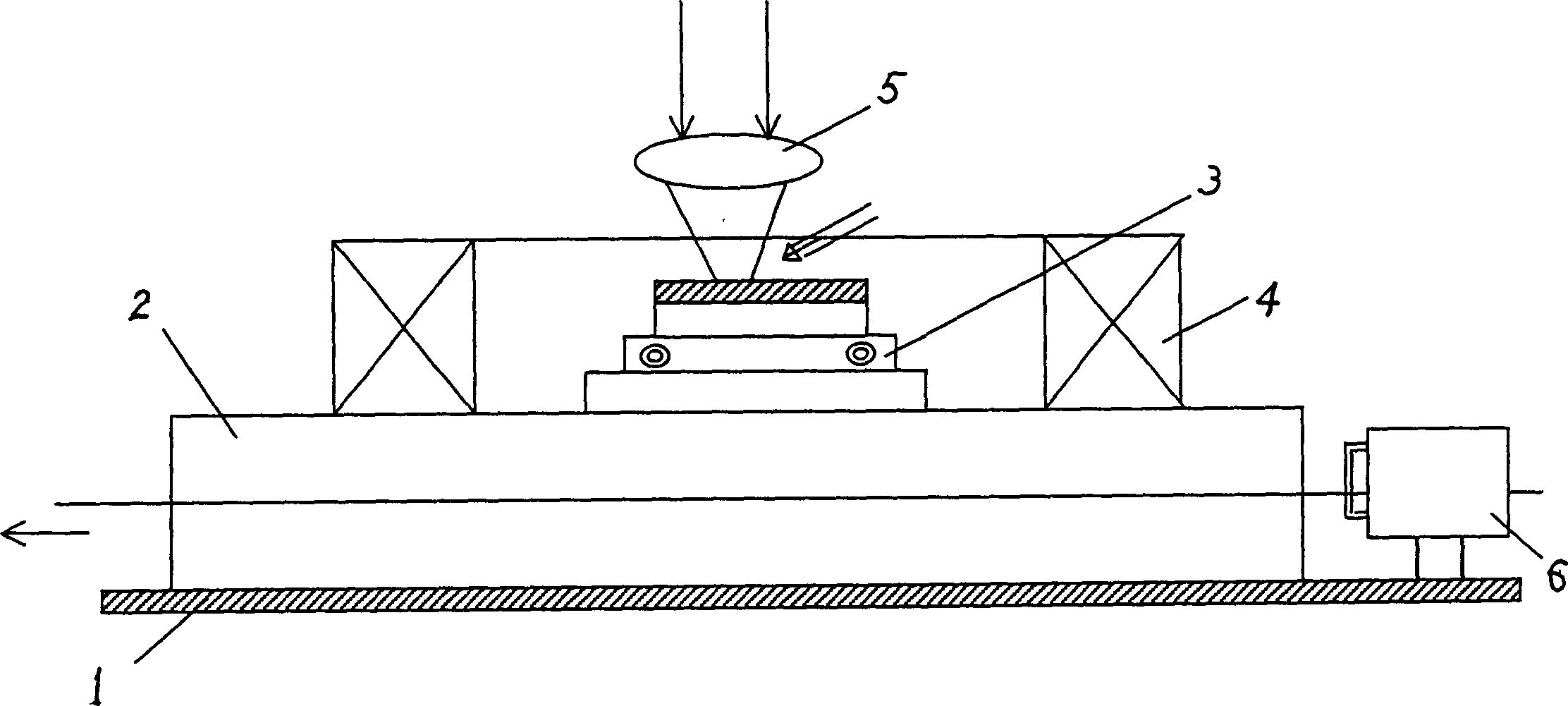

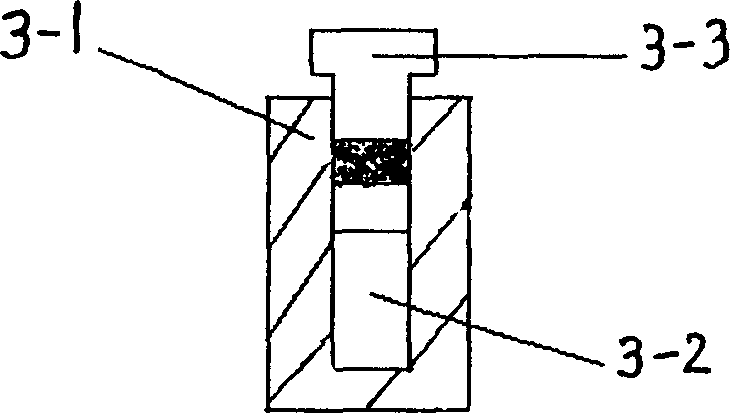

Method and its device for preparing cutter by laser coating composite ceramic layer

InactiveCN1259452CQuality improvementNo porosityMetallic material coating processesLaser beam welding apparatusFiberHeat-affected zone

The present invention relates to method and apparatus for making cutter with laser coated composite ceramic layer, belongs to the field of ceramic coating on metal surface, and aims at lowering cutter manufacturing cost while prolonging the service life of cutter. The cutter making process includes applying hard alloy powder to the surface of cutter base, applying mechanical pressure, preheating, and laser treating after or while applying the hard alloy powder. The cutter made may be chemical fiber cutter, milling cutter or trimming cutter. One of the cutter making apparatus includes bench, special fixture, electromagnetic coil and laser processing system. The other cutter making apparatus includes bench, chuck, powder blowing feeder and laser processing system. The present invention has high coating quality, less heat deformation, high production efficiency and other advantages.

Owner:HUAZHONG UNIV OF SCI & TECH

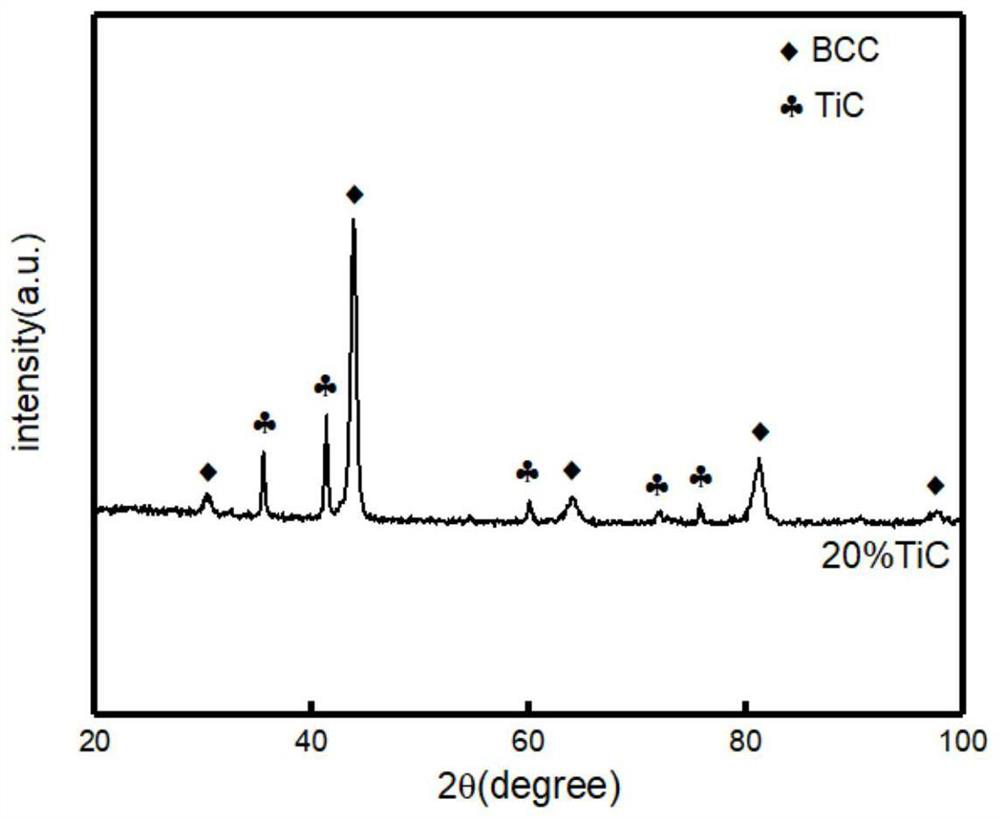

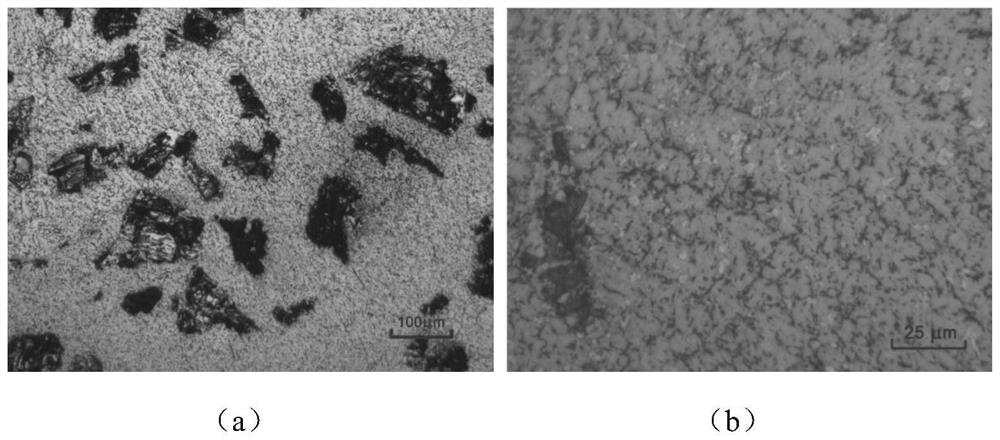

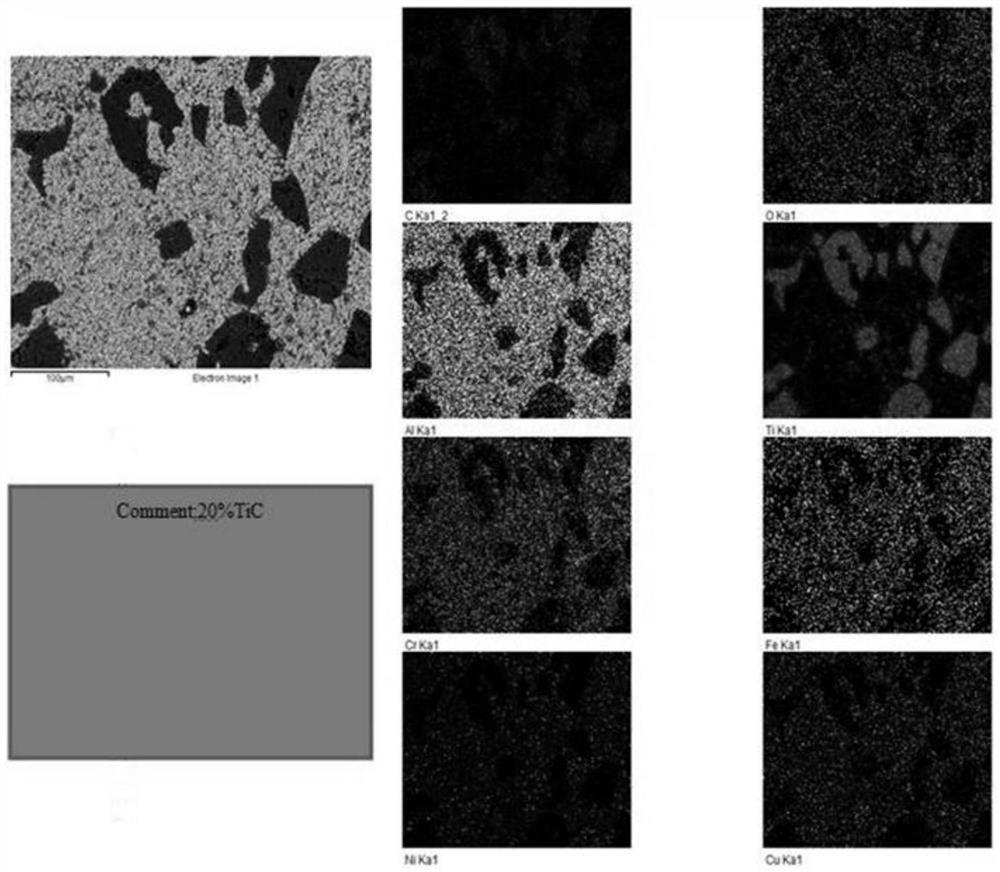

High-entropy alloy coating material with high wear resistance

PendingCN114574748AHigh hardnessImprove wear resistanceIncreasing energy efficiencyMetallic material coating processesHigh entropy alloysAlloy coating

The invention discloses a TiC reinforced high-entropy alloy coating material with high wear resistance. The TiC reinforced high-entropy alloy coating material comprises high-entropy alloy powder and 20wt% of TiC powder, the high-entropy alloy material comprises the following components in percentage by weight: 14.41% of Al, 15.41% of Cr, 18.84% of Cu, 16.55% of Fe and 34.79% of Ni. The method for preparing the high-entropy alloy coating by using the material through laser cladding comprises the following steps: preparing high-entropy alloy powder from the high-entropy alloy coating material through a gas atomization method, adding TiC powder, and carrying out ball milling and powder mixing; and uniformly mixed alloy powder is conveyed to the surface of the base body through a powder feeder, and a cladding coating combined with a base body material is obtained through laser cladding. The hardness and wear resistance of the material are improved by changing the content of TiC through the laser cladding technology, the performance requirements of key wear-resistant parts of agricultural machinery are met, and the material can be widely applied to high-end agricultural machinery.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

C-N-O supersaturated solid solution martensitic stainless steel powder, preparation method and cladding method

ActiveCN110938772AGood electrochemical corrosion performanceImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMartensitic stainless steel

The invention discloses a C-N-O supersaturated solid solution martensitic stainless steel powder, a preparation method and a cladding method, and relates to the technical field of laser additive and re-manufacturing. The elements contained in the powder comprise, by weight, 0.18-0.23 part of C, 0.09-0.12 part of N, 0.75-0.90 part of Si, 12.0-14.0 parts of Cr, 0.80-0.95 part of Mn, 1.30-1.80 partsof Ni, 0.45-0.55 part of Al, 0.22-0.30 part of V, 0.045-0.055 part of O, and 81.1-84.16 parts of Fe. After the above elements undergo vacuum melting according to a proportion, the C-N-O supersaturatedsolid solution martensitic stainless steel powder can be obtained by adopting high-purity nitrogen gas atomization. The method for cladding a laser forming layer based on the powder comprises the following steps that 1, raw material treatment is performed; 2, parameter setting is performed; and 3, cladding of the laser forming layer is performed. According to the C-N-O supersaturated solid solution martensitic stainless steel powder, the preparation method and the cladding method, laser fast cooling is used for inducing the non-equilibrium phase change, three interstitial atoms of C-N-O are dissolved in a body-centered structure in a supersaturated mode, then the martensite is formed, and a self-organizing interstitial atom short-range combined unit with the relatively lower energy stateis formed through short-range migration.

Owner:NANHUA UNIV

A special equipment for laser selective melting for direct manufacturing of metal orthopedic implants

ActiveCN105945282BImprove powder utilizationImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyArtificial hip jointsEngineering

A laser selective melting special equipment for directly manufacturing metal orthopedic implants, characterized in that it includes a forming system, a powder recovery system, a powder spreading system, a laser transmission system, a dust filtration and water / oxygen purification double circulation system, and a sealing cavity; the forming system, powder recovery system, and powder spreading system are all placed in the sealed cavity, the laser transmission system is placed on the upper part of the sealed cavity, and the dust filtration and water / oxygen purification double circulation system is placed outside the sealed cavity ; The forming system includes a forming cylinder, a forming cylinder piston, a ball screw, a servo motor and a grating scale; the inside of the forming cylinder piston is provided with a heating copper plate, a water cooling system and a temperature sensor; The way of powder spreading; the forming process is carried out under the protection of argon, and it is equipped with a double circulation system of dust filtration and water / oxygen purification. The invention has high cleanliness of the atmosphere in the forming chamber, high dimensional accuracy of the forming parts, can form bionic structures such as porous structures and biological channels, and is suitable for rapid and personalized customization of artificial hip joints.

Owner:THYTEC SHANGHAI

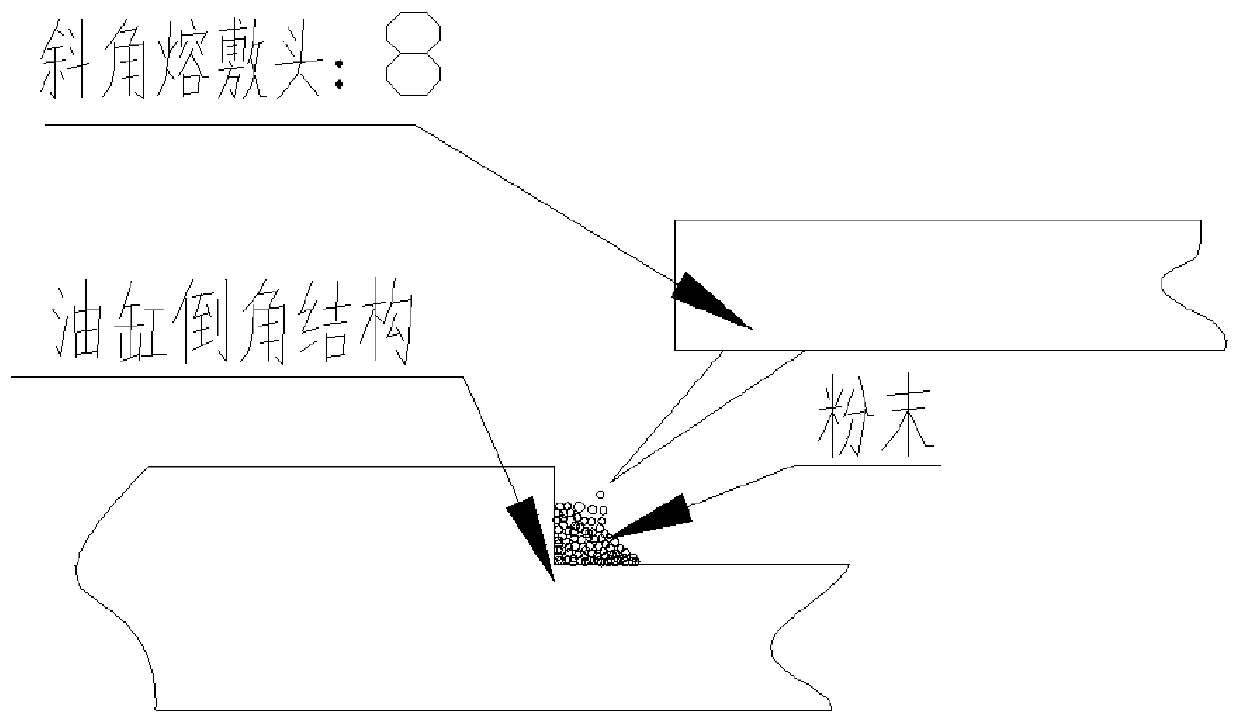

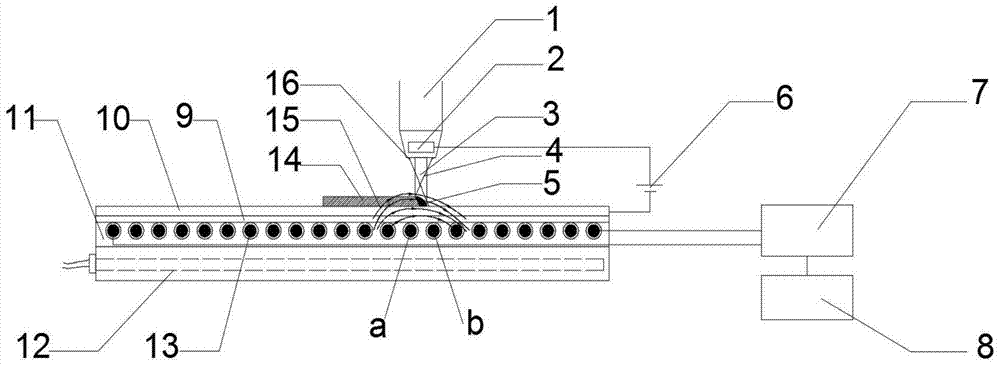

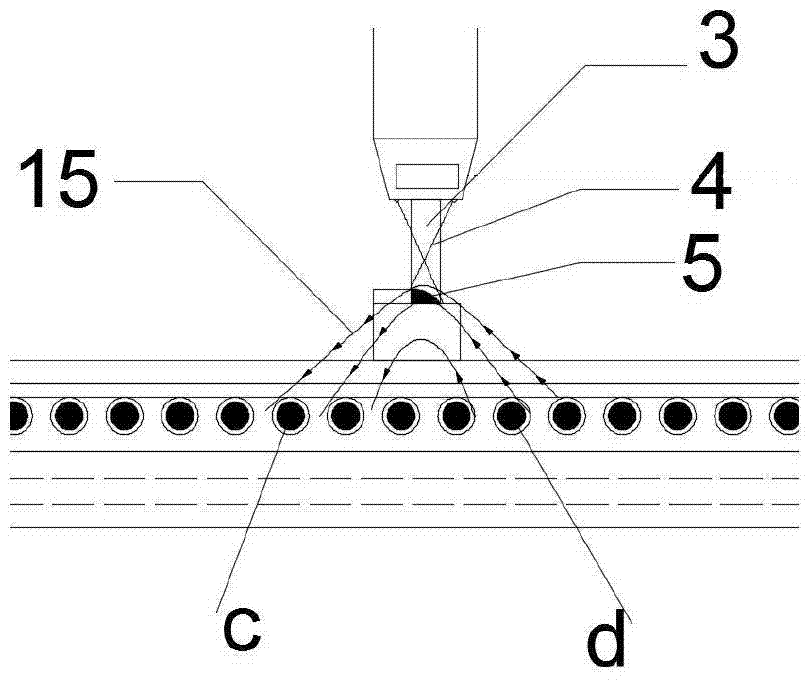

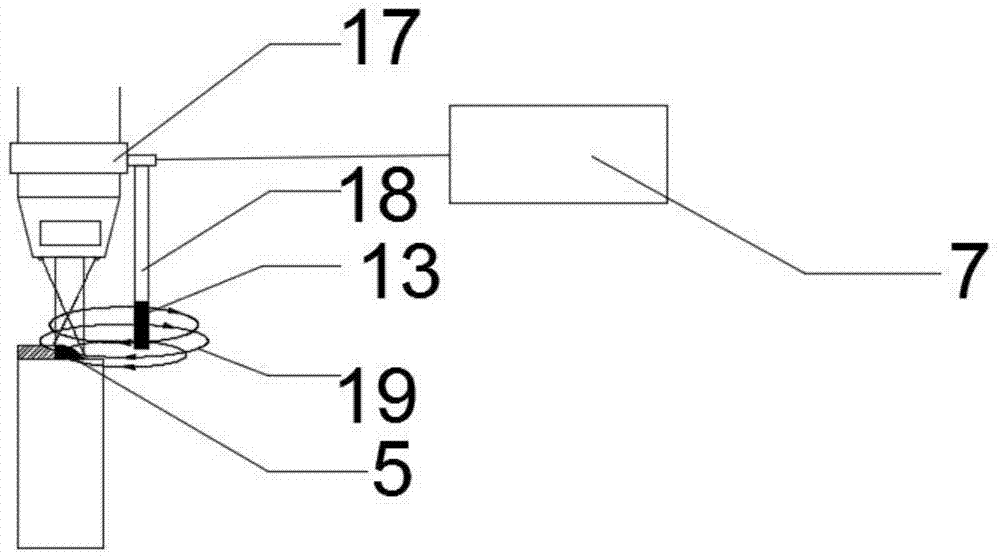

Laser cladding method for inner wall of hydraulic support oil cylinder

ActiveCN111593340AReduce manufacturing costImprove powder utilizationIncreasing energy efficiencyMetallic material coating processesBroadbandInner wall zone

The invention provides a laser cladding method for the inner wall of a hydraulic support oil cylinder. The laser cladding method comprises the following steps that step 1, defect machining treatment and cleaning treatment are conducted on the inner wall of the hydraulic support oil cylinder before cladding; step 2, laser cladding is conducted on a deep hole bottom end corner area and a chamfer structure area of the inner wall, treated in the first step, of the hydraulic support oil cylinder through an oblique angle coaxial powder feeding laser cladding device, and a cladding layer is formed; step 3, laser cladding is conducted on other inner wall areas, subjected to cladding in the second step, of the hydraulic support oil cylinder through a wide light spot paraxial broadband powder feeding laser cladding device, and a cladding layer is formed; and step 4, finished product aftertreatment machining is conducted on the inner wall, subjected to cladding in the third step, of the hydraulicsupport oil cylinder. According to the laser cladding method, the manner of combining two cladding technologies is adopted for conducting laser cladding treatment on the inner wall of the oil cylinder to be subjected to cladding, meanwhile, the beneficial effects of the wide light spot laser cladding technology and the beneficial effects of the oblique angle coaxial laser cladding technology areconsidered, and the production cost of cladding of the inner wall of the hydraulic support oil cylinder is reduced.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

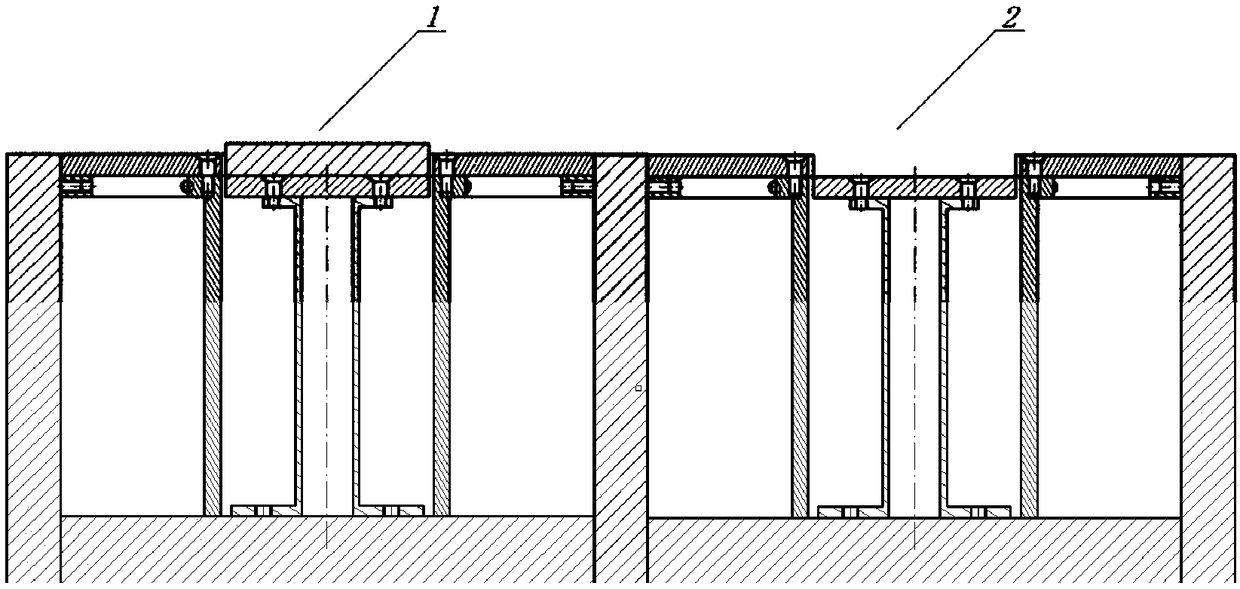

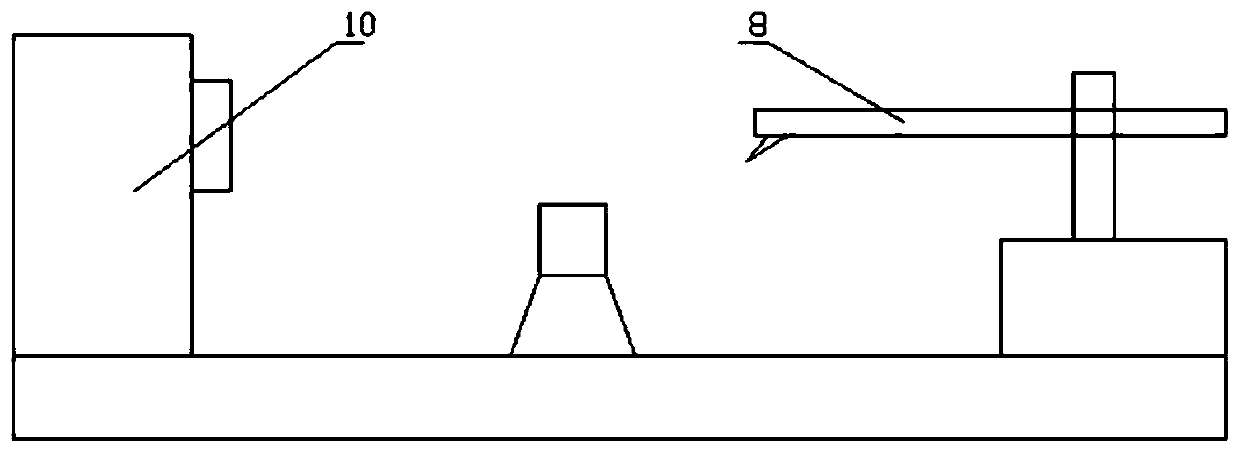

A device for electromagnetic field-assisted laser additive manufacturing

ActiveCN105522153BGuaranteed uniformityFine grainAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser additive manufacturing

The invention is a device for electromagnetic field-assisted laser additive manufacturing, which includes a laser head (1), which is composed of a base (10), an insulating heat dissipation layer (9), a magnetic field generating device (11), and a water cooling device (12). Manufacturing base, AC power supply (8), longitudinal magnetic field generator, DC power supply (6), controller (7); wherein, the manufacturing base is divided into 4 layers from top to bottom, the uppermost layer is the base, and the bottom of the base is The insulating heat dissipation layer is used to control the temperature of the substrate and prevent the substrate from communicating with the magnetic field generating device. The magnetic field generating device is located below the insulating heat dissipation layer (9); the magnetic field generating device is connected with the controller and is controlled by the controller, and the controller communicates with the AC The power supply is connected, and the AC power supply supplies power to the controller; a plurality of raw magnetic rods (13) are arranged in the magnetic field generating device, and a water cooling device (12) is arranged below the magnetic field generating device to keep the manufacturing substrate in an appropriate temperature range.

Owner:SOUTHEAST UNIV

Treatment method for improving abrasion resistance and toughness of rotary blade

ActiveCN110605532AImprove corrosion resistanceExtended service lifeMetallic material coating processesPlasma welding apparatusEnvironmental resistanceBrick

The invention belongs to the technical field of metal machining, in particular to a treatment method for improving abrasion resistance and toughness of a rotary blade, and belongs to the technical field of rotary blade machining. The treatment method has the advantages that the treatment method is simple, the cost is low, the rotary blade can be improved continuously without breaking and bending,wear resistance can be improved, the load of a tractor can be greatly reduced, the soil crushing capacity is high, the sharpness is high, the wear resistance is high, green and environmentally friendly and the like; and the requirement for fine tillage can be met, the working procedure interval is shortened, the replacement frequency of the rotary blade is reduced, and the working efficiency is improved, the strength is high, the toughness is good, the rotary blade is not only wear-resistant, but also does not break and bend when colliding hard objects such as bricks and stones.

Owner:安徽宏翔农业机械有限公司

Preparation method of electrical contact strengthened coating on metal surface

InactiveCN103114285AReduce pollutionReduce wasteMetallic material coating processesLiquid stateHardness

The invention discloses a preparation method of an electrical contact strengthened coating on a metal surface. The method is characterized by comprising the steps of: roughening and pre-cleaning the metal surface; selecting a wear-resisting and corrosion-resisting powder material as a coating material; preparing bonder slurry and coating powder material into liquid coating and spraying the coating on the metal surface; and strengthening the pre-coating by an electrical contact strengthening device. The coating is molten on the metal surface by the electrical contact strengthening technology, so that the coating with good surface quality, less inner defect, high hardness and high wear resistance and corrosion resistance can be obtained on the metal surface, and the service life of a workpiece is prolonged. The pre-coating is prepared by the pre-coating method of the liquid coating, so that the powder utilization ratio is improved, the operation is simplified and the cost is saved; and the method is beneficial for industrial popularization and application.

Owner:DONGHUA UNIV

Process for achieving laser cladding of silver layer on surface of high-current aluminum bus hardware terminal

ActiveCN110042389AUniform thicknessDense tissueMetallic material coating processesPower flowResidual oil

The invention discloses a process for achieving laser cladding of a silver layer on the surface of a high-current aluminum bus hardware terminal. The process comprises the following steps that 1, thesurface of the high-current aluminum bus hardware terminal is pretreated, surface oxide is removed through manual polishing, and it is ensured that the workpiece surface is exposed out of a matrix aluminum alloy material; 2, a supporting base plate is installed on the side, not to be clad with the silver layer, of the high-current aluminum bus hardware terminal, and a whole workpiece is installedon a workbench; 3, the portion to be clad with the silver layer is cleaned, residual oil contamination on the surface is removed, and it is ensured that the silver layer preparation face is sufficiently clean; 4, silver cladding treatment is carried out on one side of the high-current aluminum bus hardware terminal through laser cladding equipment; and 5, the two sides of different hardware terminals on a large-current aluminum bus are subjected to silver cladding treatment through the operation in the steps 2-4, and the place, clad with the silver layer, of the workpiece is polished, and treatment is complete. The obtained silver coating is compact, and has the good bonding effect with the matrix.

Owner:CHINA YANGTZE POWER +1

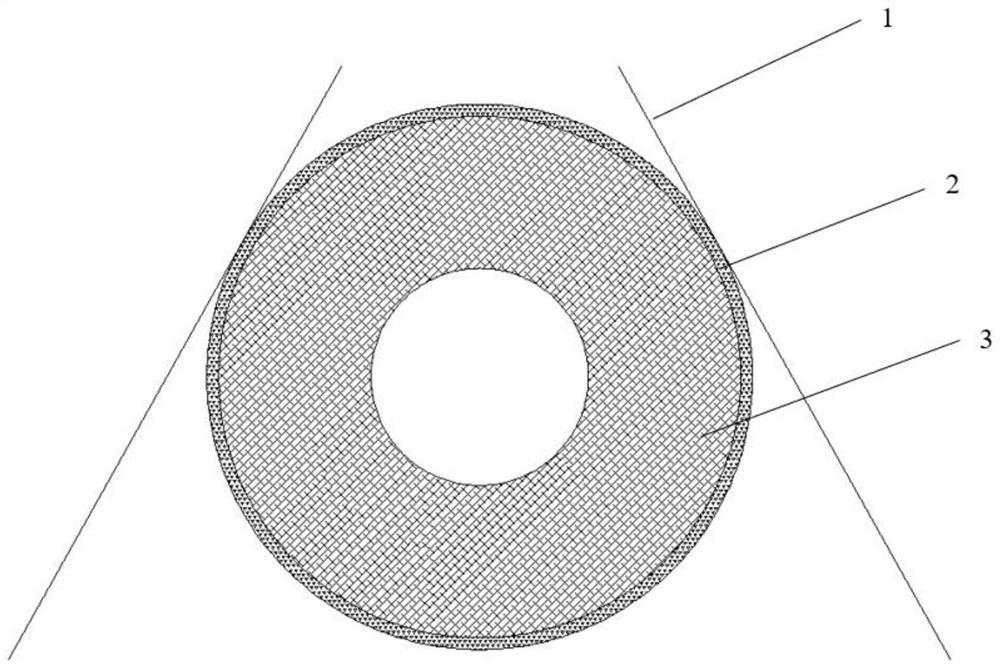

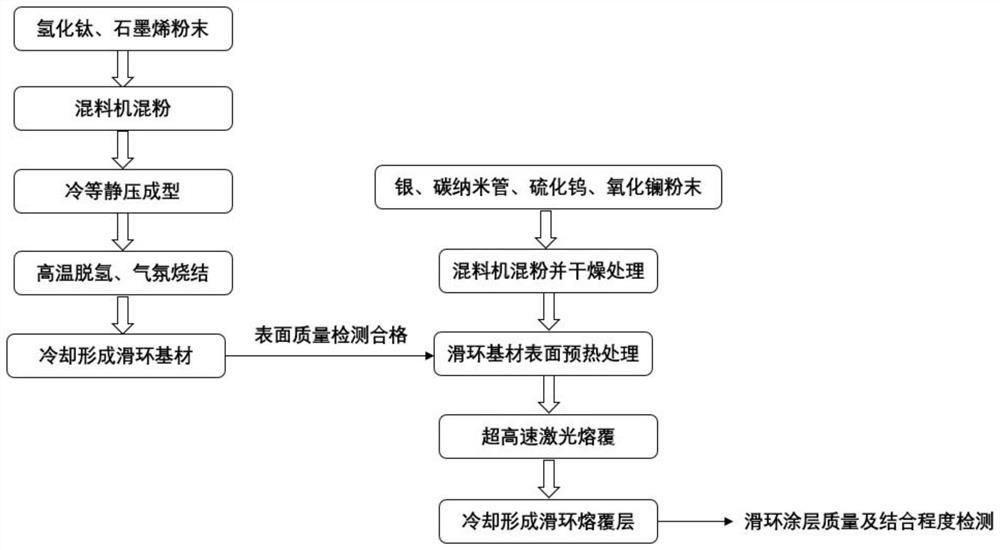

Light high-conductivity slip ring and preparation method thereof

PendingCN114069360AHigh strengthGood heat resistanceRotary current collectorMetallic material coating processesPowder metallurgyCarbon nanotube

The invention discloses a light high-conductivity slip ring and a preparation method. the light high-conductivity slip ring comprises a base material and a coating covering the base material; the base material comprises, by mass, 5-10% of graphene and 90-95% of titanium hydride; and the coating comprises, by mass, 0.5-1.3% of lanthanum oxide, 1-2% of tungsten sulfide and 7-12% of carbon nanotubes, and the balance is silver. The coating is cladded on the surface of the base material made of powder metallurgy through an ultra-high-speed laser cladding technology to form the coating of the slip ring. According to the conductive slip ring, light weight is achieved, the hardness and the arc corrosion resistance of the slip ring coating are enhanced, the antifriction and wear-resistant capacity of the working face of the slip ring is improved, the current-carrying performance is also improved compared with that of pure silver, the process is simple, and the manufacturing cost of the conductive slip ring for spaceflight is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com