Intelligent laser cladding head with automatic temperature and powder feeding amount debugging function

A technology of laser cladding and automatic debugging, which is applied in the direction of metal material coating process and coating, can solve the problems of laser cladding head damage, affecting the surface quality of substrates, etc., to reduce powder costs, prevent incomplete fusion, The effect of preventing powder accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

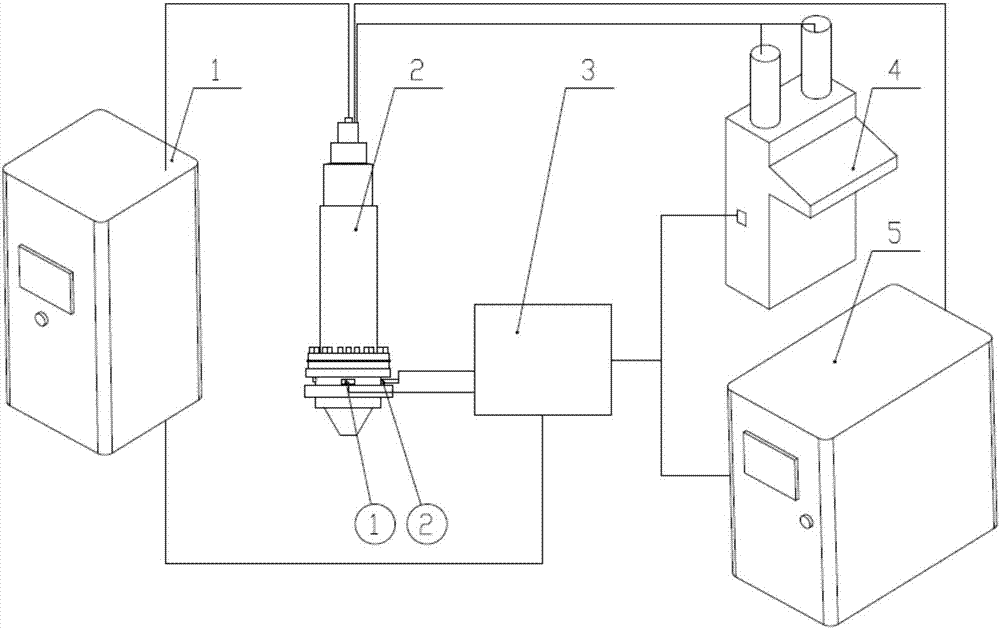

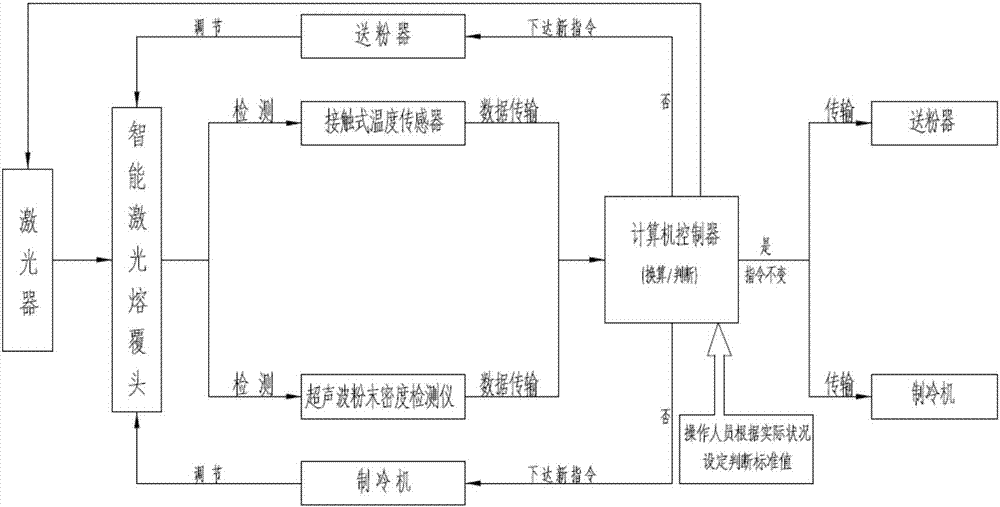

[0021] see figure 1 , an intelligent laser cladding head whose temperature and powder feeding amount can be automatically adjusted and its function realization method.

[0022] An intelligent laser cladding head that can automatically adjust the temperature and powder feeding amount. In addition to basic components such as base cover, focusing mirror, focusing mirror cover, nozzle core, cooling water jacket, protective mirror, and simplified body, it also includes a contact temperature sensor. ①. Ultrasonic powder density detector ②. The device required for its function realization method, in addition to the intelligent laser cladding head 2, also includes a laser 1, a refrigerator 5, a powder feeder 4, and a computer controller 3 to cooperate with its characteristics to form a real-time and ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com