Patents

Literature

43results about How to "Control cooling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

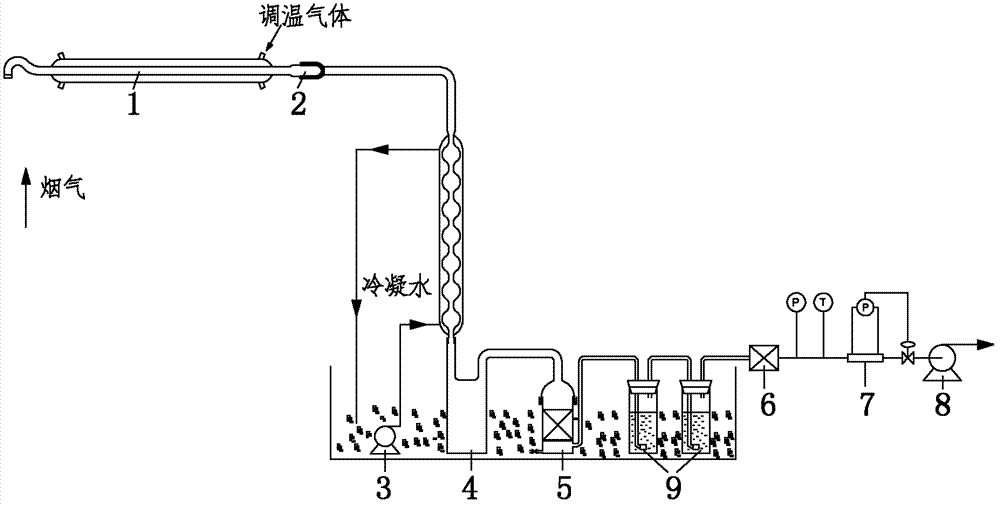

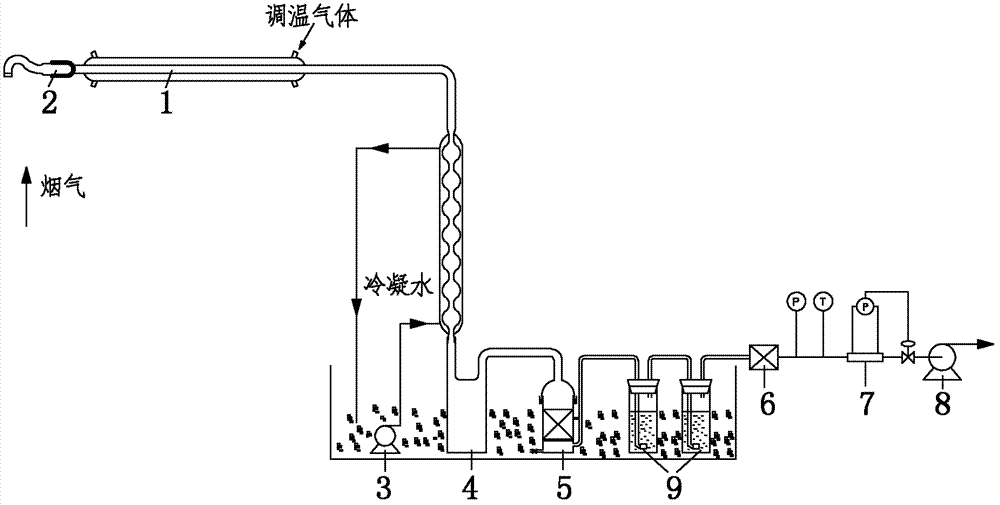

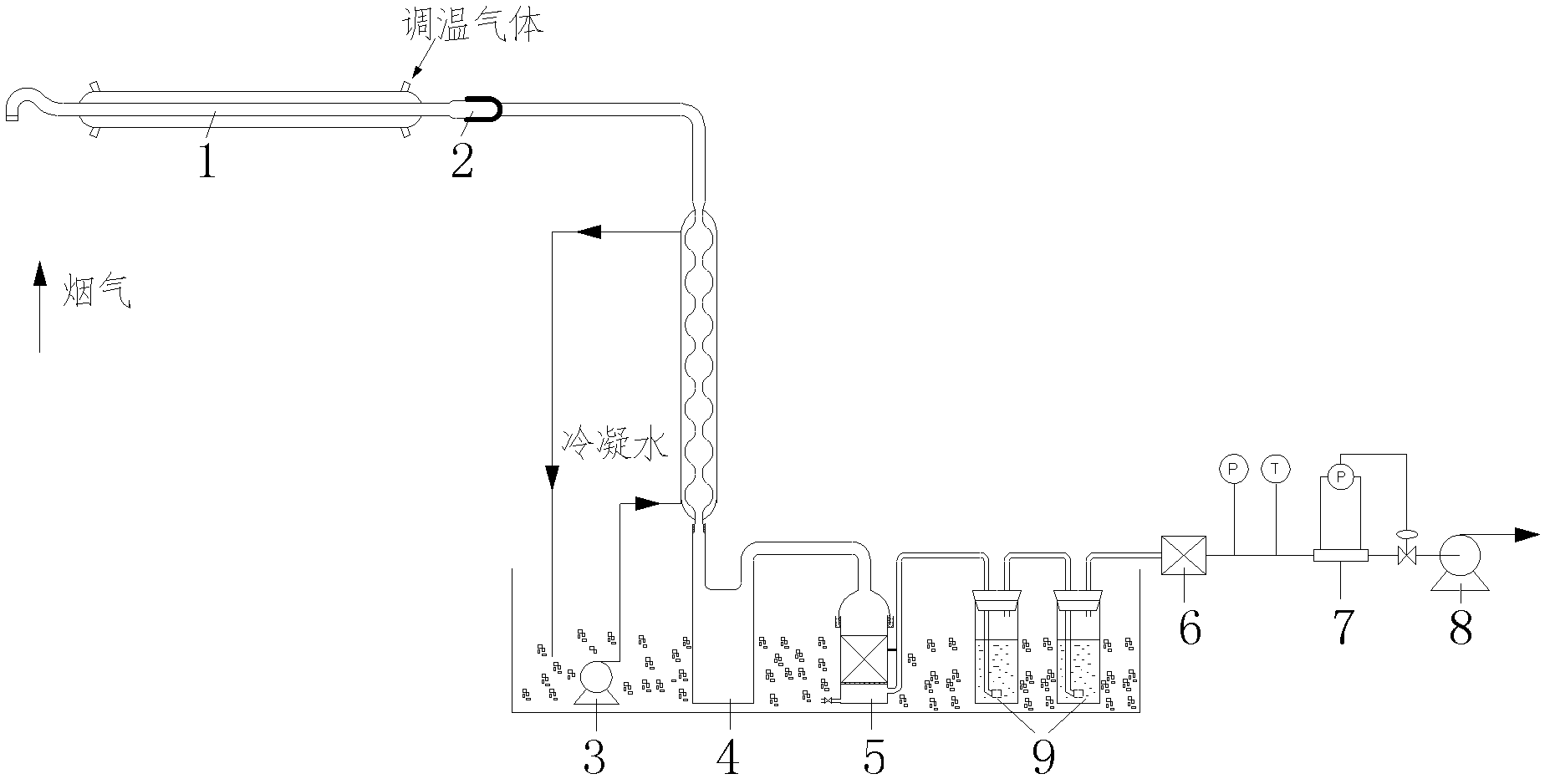

Method for sampling special organic gas in flue gas

The invention relates to a method for sampling a special organic gas in a flue gas. The method comprises the following steps: allowing the flue gas to enter through the inner tube of a sleeve from the inlet of a sampling gun, adjusting the temperature, intercepting particles by a filter cylinder, condensing the flue gas by a condensation device, allowing the obtained condensate liquid into a cooling and liquid removing bottle, trapping the cooled and dried gas by a trapping bottle to remove dioxin substances, further collecting by a washing bottle, and allowing the gas to go through a dryer, a gas flow meter, a thermometer and a sampling pump to complete the whole sampling process. A whole flue gas sampling pipeline adopting a full glass structure has the advantages of corrosion resistance, no chemical reaction, convenient cleaning, and prevention of the loss caused by the adsorption or contamination of the acquired sample by the wall surface of a tube wall utensil; the jacket glass sampling gun can heat or cool the acquired flue gas by hot or cold air entering through an external layer; the condensate liquid collection bottle having scales can rapidly judge whether there is severe gas leakage in the sampling process or not; and the flue gas is cooled, condensed, and dehydrated, and then adsorbs a sampling agent to guarantee a high sampling efficiency.

Owner:TONGJI UNIV

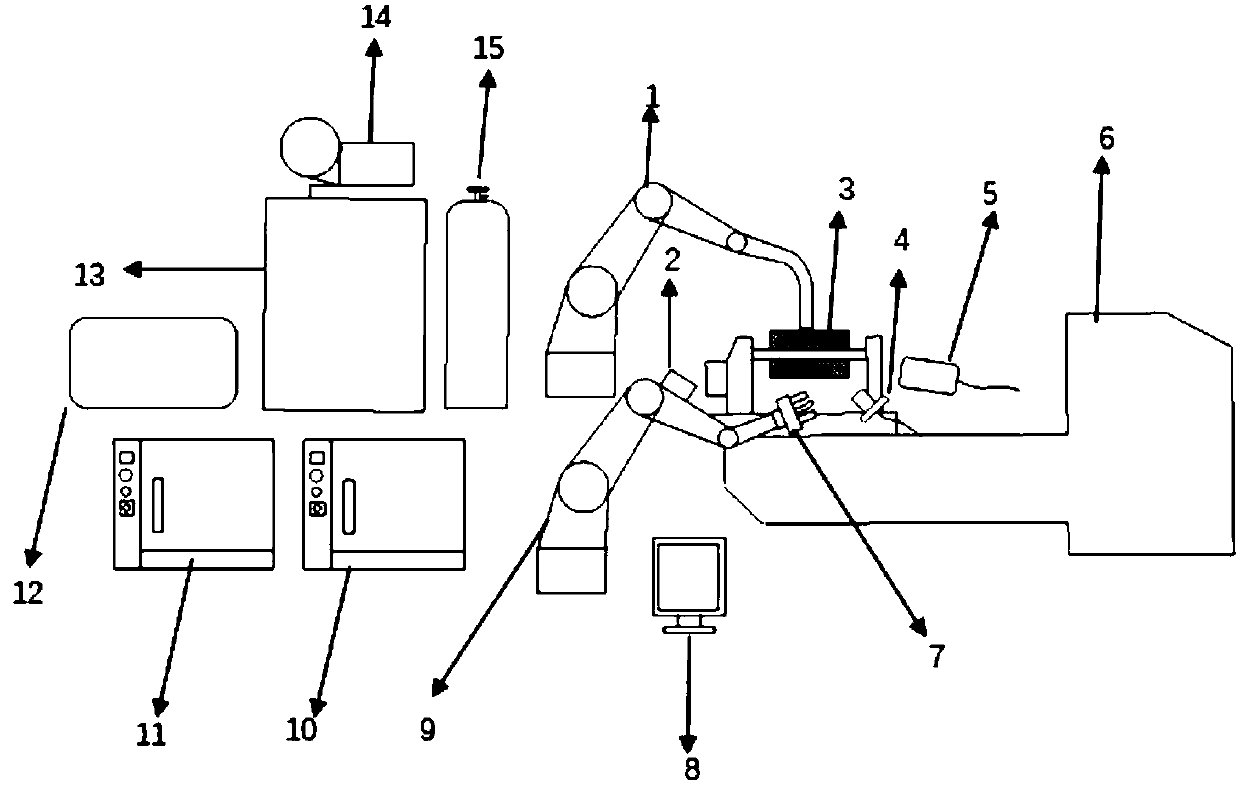

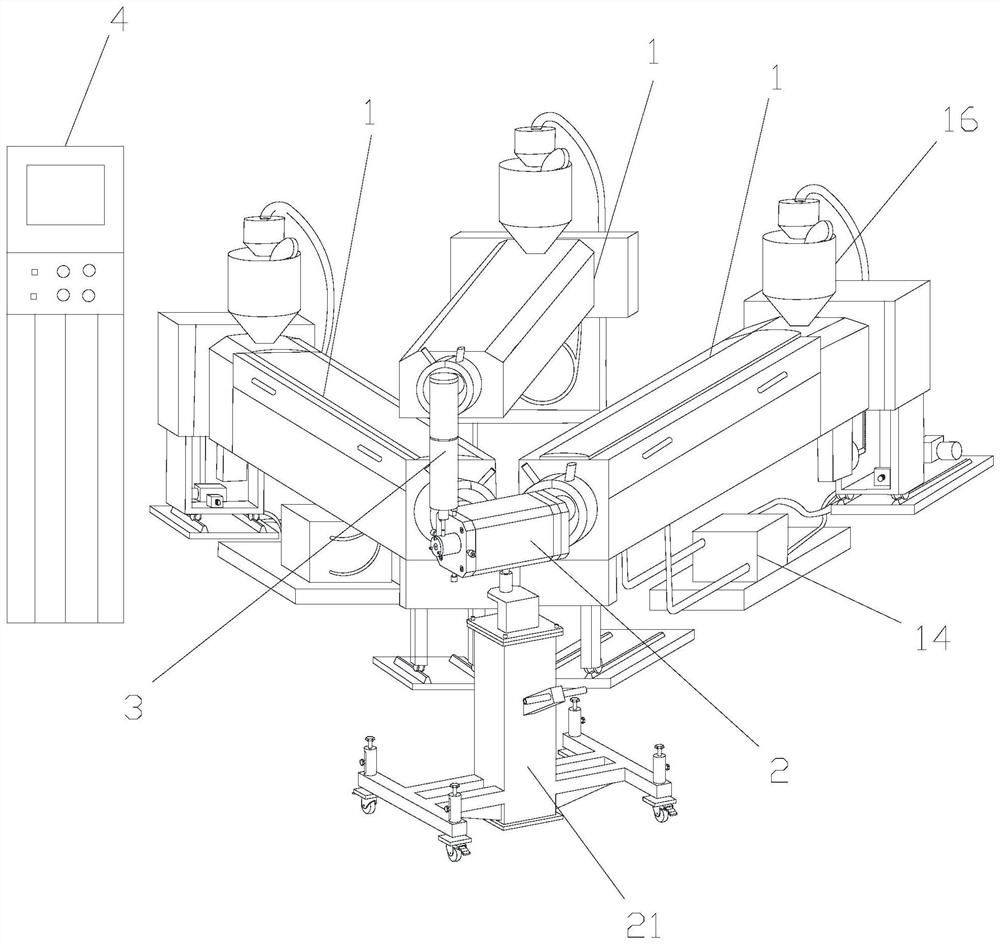

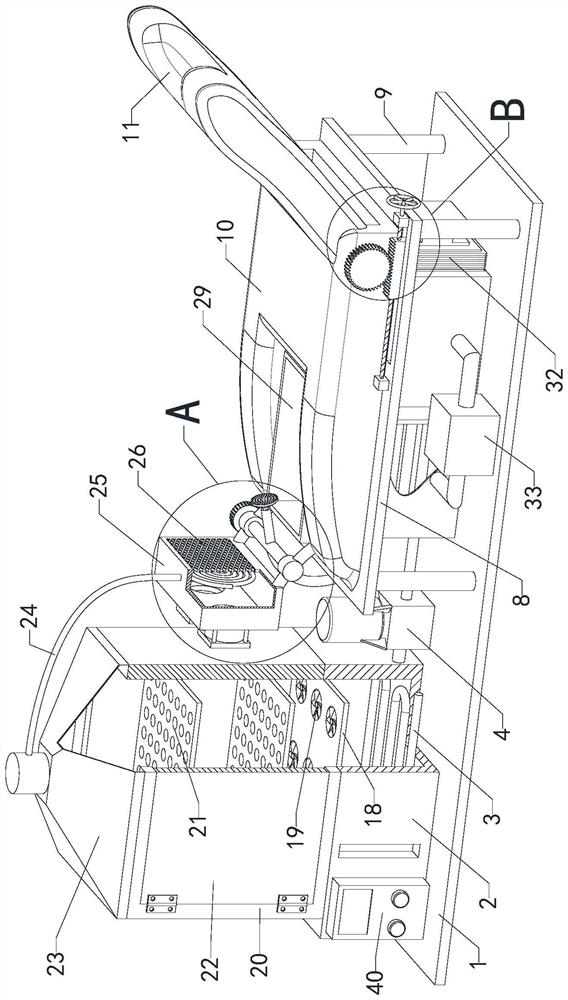

Material adding and reducing coordinated manufacturing method

ActiveCN109623105AImprove accuracy and qualityControl interlayer cooling temperatureOther manufacturing equipments/toolsPlasma welding apparatusThermal deformationElectric arc

The invention discloses a material adding and reducing coordinated manufacturing method. According to the method, model building is performed through CAD, and a computer is used for automatically generating a material adding trajectory; a power source is switched on, a base plate is installed and cleaned, and a material adding robot performs material adding on the front side of the base plate; thebase plate is overturned by 180 degrees; the material adding robot performs material adding on the front side of the base plate, and a material reducing robot performs material reducing on the back side of the base plate, air cooling is performed through an air gun, and an infrared thermometer monitors the back side temperature of the base plate in real time; overturning is performed again aftermachining of material adding and reducing and back side cooling are completed; and the steps are repeated till material adding manufacturing is completed. In the manufacturing method, material addingmanufacturing and material reducing machining are performed in a coordinated manner, the temperature of the base plate is monitored and controlled in real time, thermal deformation of the base plate is greatly reduced, the forming precision and quality of an obtained material adding structural part is improved, and the manufacturing period of electric arc material adding is shortened.

Owner:NANJING UNIV OF SCI & TECH

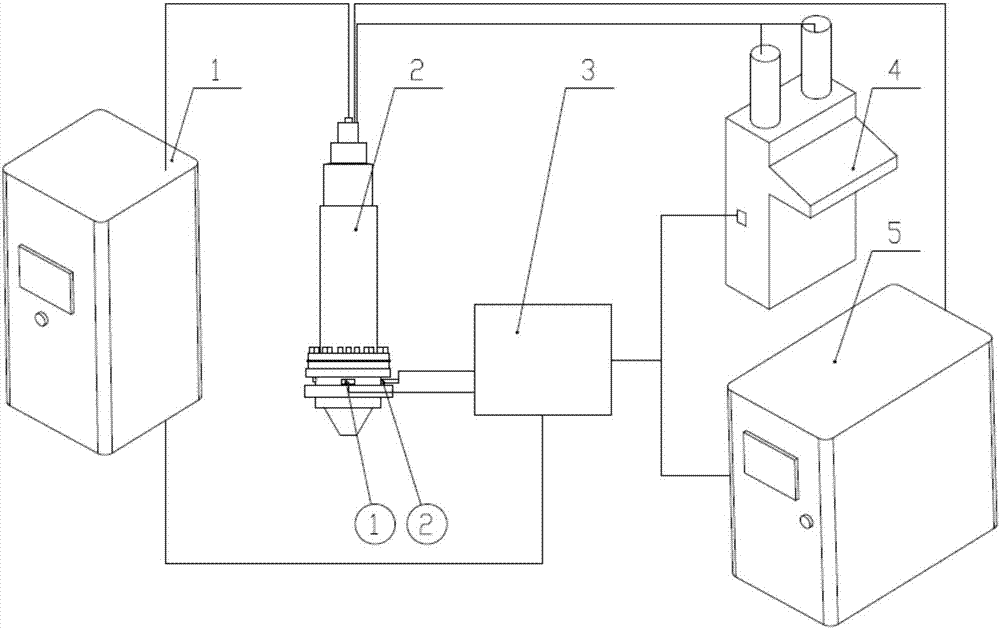

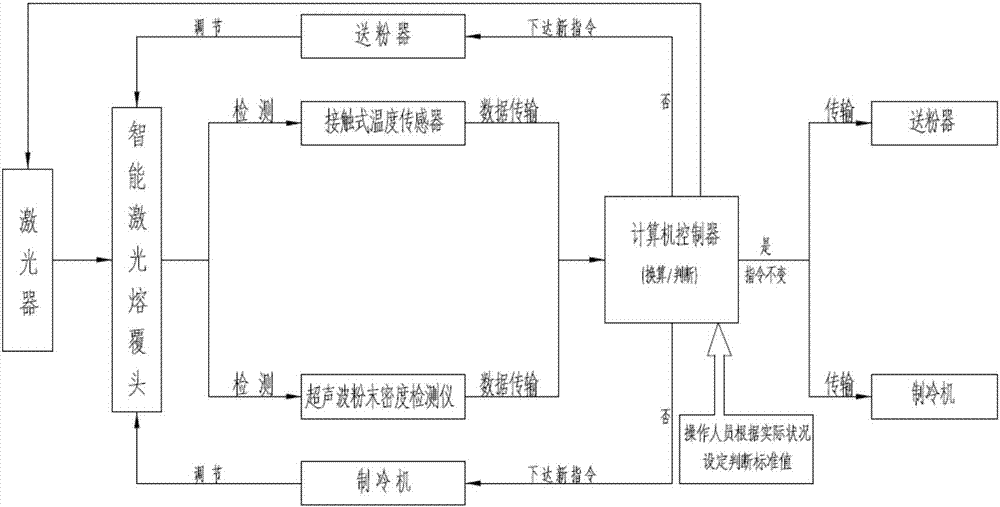

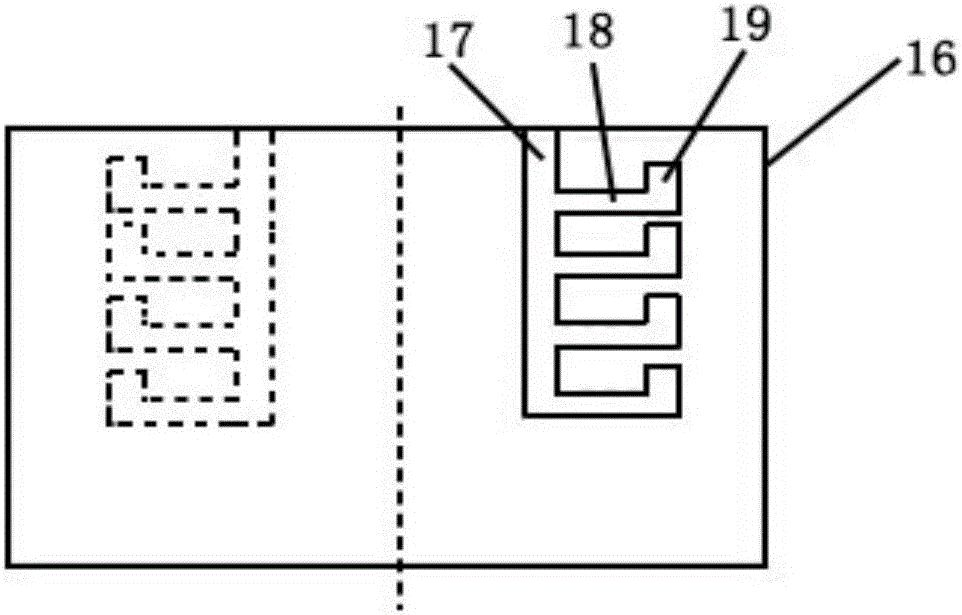

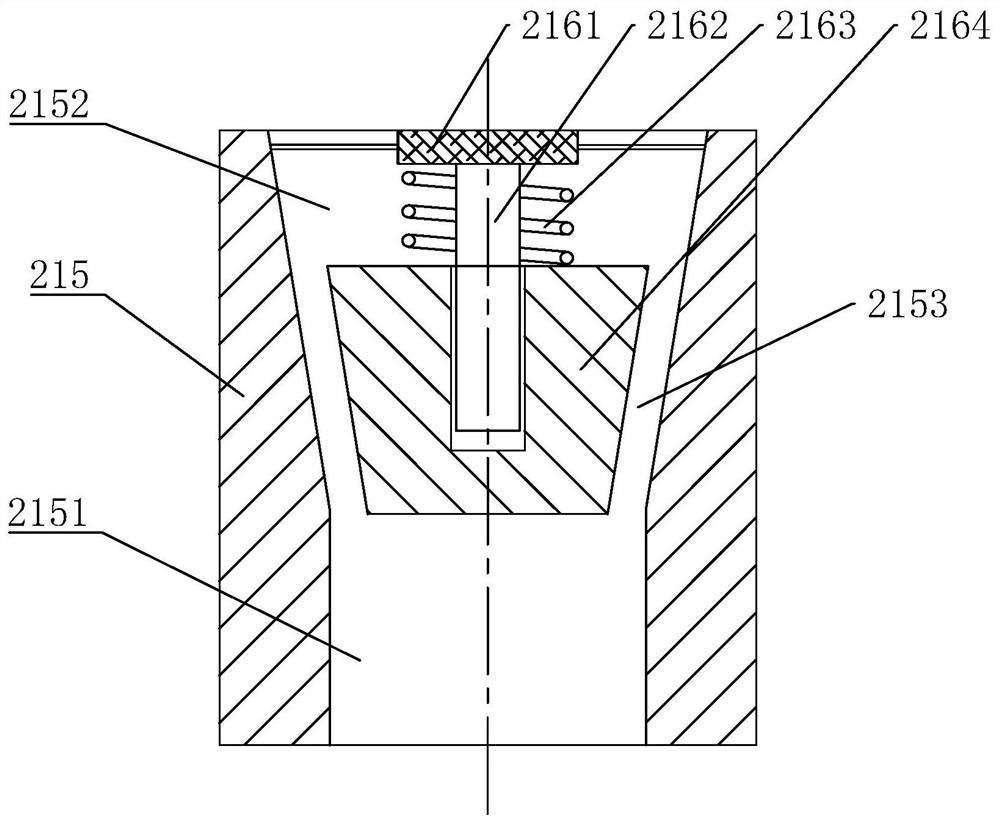

Intelligent laser cladding head with automatic temperature and powder feeding amount debugging function

InactiveCN107083550AAvoid powder accumulationImprove powder utilizationMetallic material coating processesData transmissionUltrasound

The invention discloses an intelligent laser cladding head with the automatic temperature and powder feeding amount debugging function. The laser cladding head comprises a base sleeve, a focus lens, a focus lens sleeve, a nozzle core, a cold water sleeve, a protection lens, a simple body and other basic components, and a contact type temperature sensor and an ultrasonic powder density detection instrument are further designed; in order to achieve the functions, except for the intelligent laser cladding head, a laser device, a cold water unit, a powder feeding device, a laser device and a control box are matched with the characteristics internally so that the functions are achieved, and a real-time effective closed-loop system is formed; under the normal work state of the laser device, the intelligent laser cladding head detects the real-time temperature of a laser cladding head through the contact type temperature sensor, data are transmitted to a computer controller, the computer controller carries out comparison according to rated value of the set program, judgment is carried out, according to the judgment result, a refrigeration command is issued to the cold water unit in real time, and the cold water unit regulates the refrigeration frequency according to the command; as well, the intelligent laser cladding head detects the real-time powder feeding density of the laser cladding head through a solid powder detection system, the data are transmitted to the computer controller, the computer controller carries out calculation according to the formula of the set program, the data are converted into the powder feeding amount, the data and the set value are compared, judgment is made, according to the judgment result, a powder feeding adjusting instruction is issued to the powder feeding device in real time, the set value of the powder feeding device is changed through the computer controller, and therefore the powder feeding amount is changed through the powder feeding device, and the optimal powder feeding effect is achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

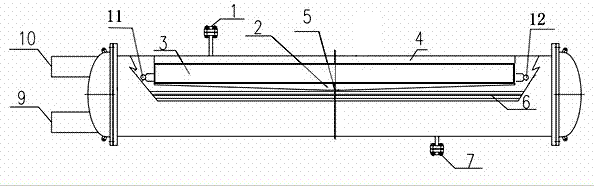

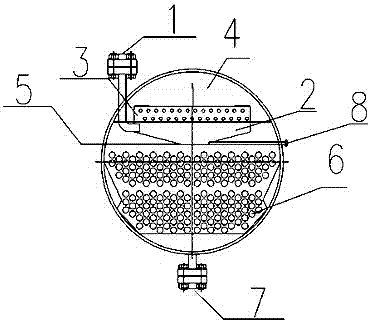

Condenser internally provided with oil separator

PendingCN106895612AImprove separation rateImprove heat transfer effectEvaporators/condensersLiquid stateOil separation

The invention discloses a condenser internally provided with an oil separator. The condenser comprises a condenser body and the oil separator. The oil separator is arranged inside the condenser body. The condenser internally provided with the oil separator is characterized in that an oil bath and a precooler are further arranged in the condenser body; the oil separator, the precooler and the oil bath are sequentially arranged in the condenser from top to bottom; the precooler and the oil separator are in seamless connection; a heat exchange device is arranged inside the condenser body; and after entering the condenser through a gas refrigerating fluid inlet in the surface of the condenser, gas refrigerating fluid flows out of the condenser via a liquid-state refrigerating fluid outlet after passing through the oil bath, the precooler, the oil separator and the heat exchange device in sequence. By means of the condenser internally provided with the oil separator, space is saved, cost is low and the oil separation rate is high. By adding the precooling structure, the cooling temperature can be reasonably controlled, refrigerant oil gas in the refrigerating fluid gas can be precipitated into liquid, and thus refrigerant oil can be separated from the refrigerating fluid gas.

Owner:刘焓

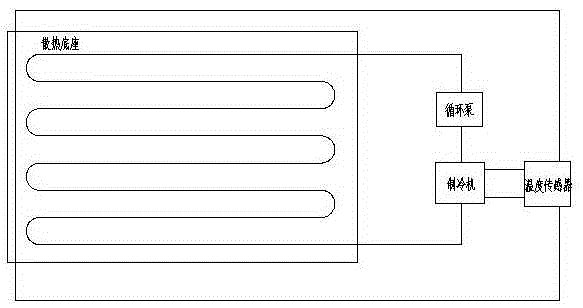

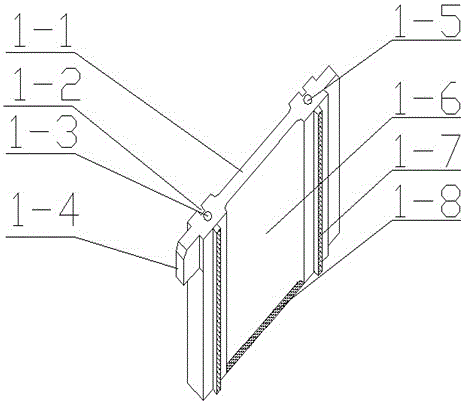

Cooling device for high-precision gear forging machining

InactiveCN105964874AAvoid deformationAvoid impuritiesPositive displacement pump componentsPumpsCold airCooling effect

The invention discloses a cooling device for high-precision gear forging machining. The cooling device comprises a cooling box, a cooling pipe, a circulating oil pump, a cooler, a refrigerating machine and a cooling nozzle; the cooling pipe is arranged on the four walls of the cooling box, one end of the cooling pipe is connected with an inlet of the circulating oil pump, and the other end of the cooling pipe is connected with an outlet of the cooler; one path of cold air generated by the refrigerating machine enters the cooler to cool hot oil, and the other path of the cold air generated by the refrigerating machine is guided into the cooling nozzle arranged on the upper portion of the cooling box; and cold oil cooled by the cooler is conveyed to the cooling pipe to cool a forging mold in the cooling box and then returns to the inlet of the circulating oil pump. According to the cooling device for high-precision gear forging machining, oil indirect cooling and air cooling are simultaneously adopted, and the cooling effect is good; the circulating oil amount can be precisely controlled, so that the cooling temperature is controlled; and the cooling device has the advantages of being good in heat dissipation condition, long in operation cycle, convenient to overhaul and the like.

Owner:董超超

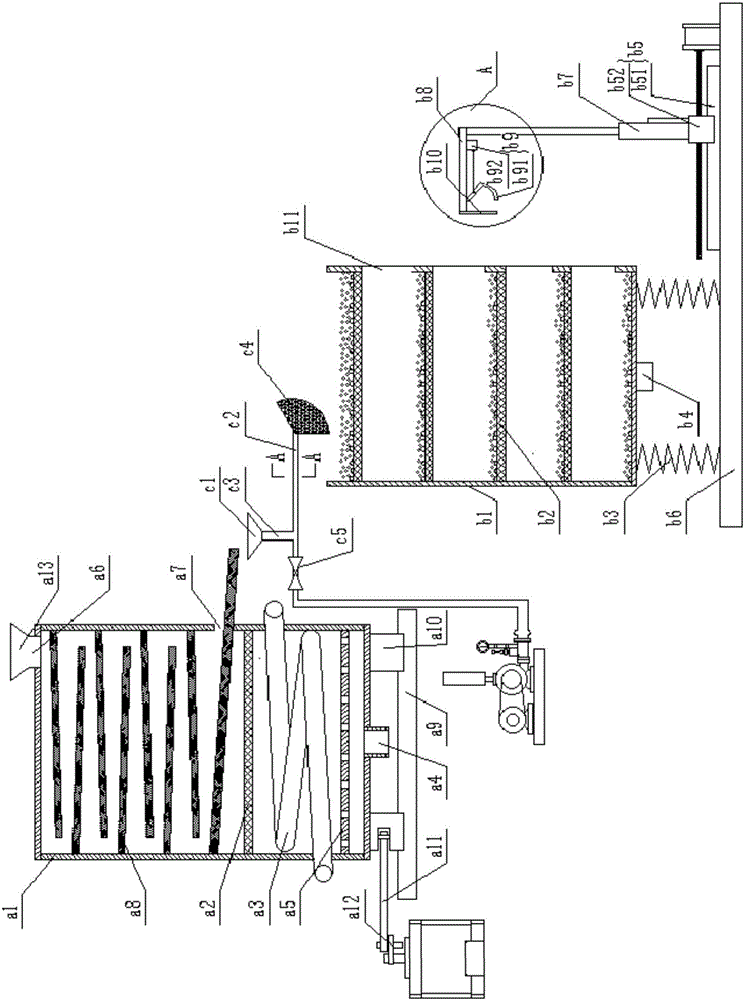

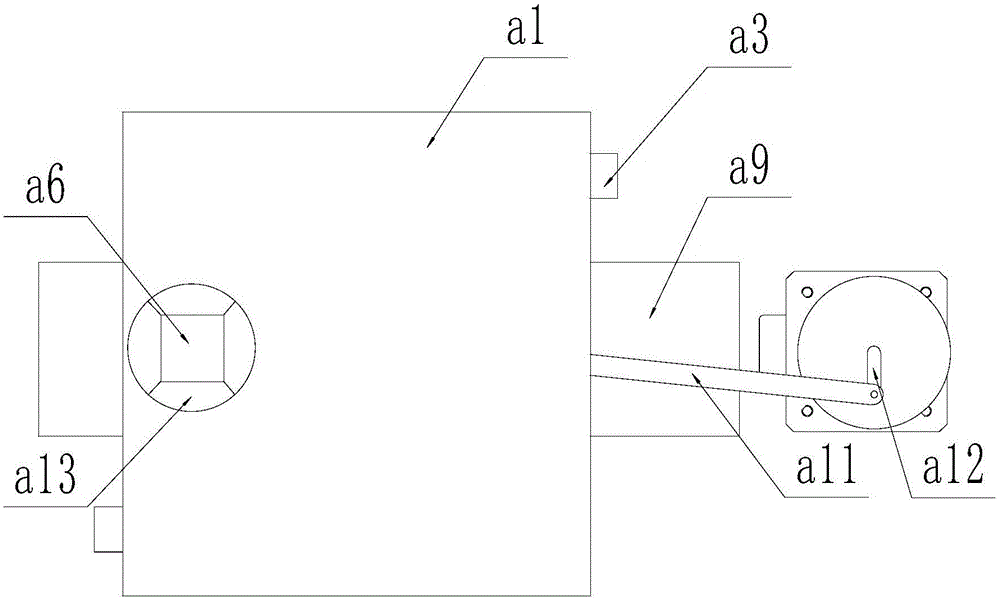

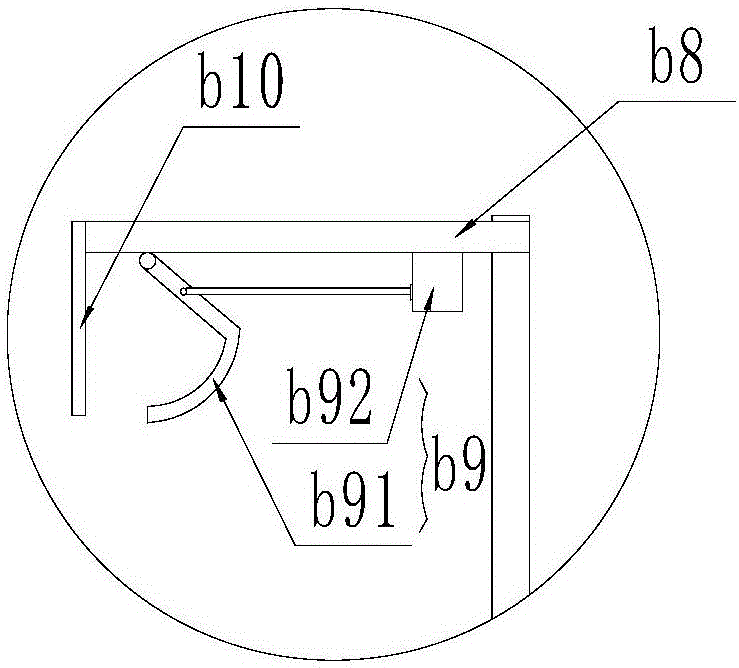

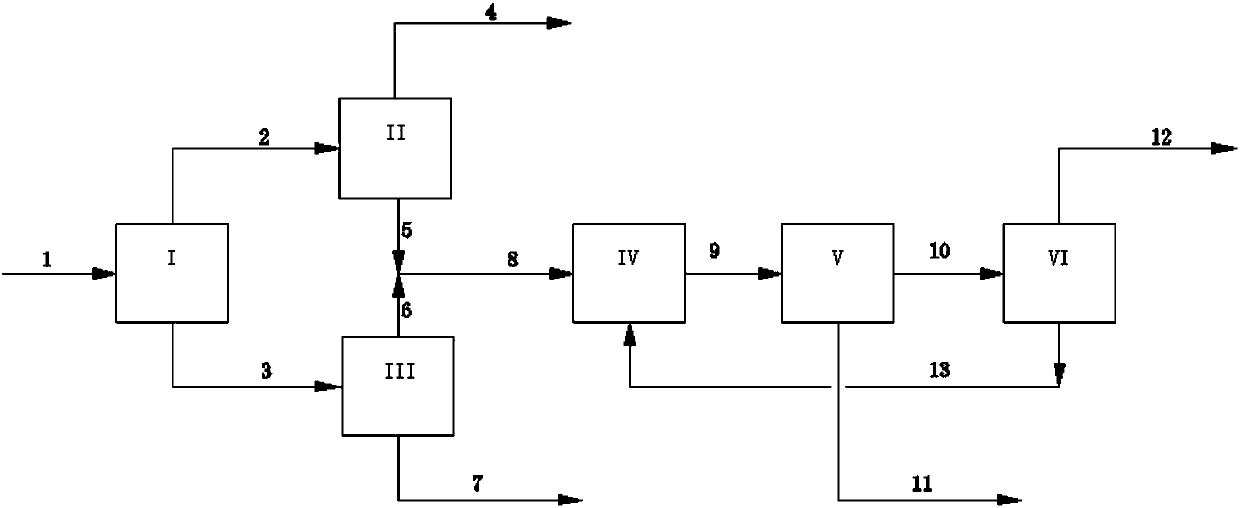

Determining system for original granularity of sintering mixture

PendingCN106404619AReduce labor intensityImprove the stability of analysis and detectionParticle size analysisGranularityUltimate tensile strength

The invention discloses a determining system for original granularity of a sintering mixture. The determining system comprises a cooling device, a detecting and sample sending device, a screening device and a microscope, wherein a discharging port of the cooling device communicates with a feeding port of the detecting and sample sending device, and the detecting and sample sending device is located between the cooling device and the screening device; the sintering mixture passes through the cooling device, the detecting and sample sending device and the screening device sequentially and is fed to the microscope for detection and observation. Compared with the prior art, the determining system has the advantages that the obtained mixture is not required to be classified during freezing of the sintering mixture, the granularity of the mixture is stable, manual stirring operation is not needed, and continuous feeding and recycling of a condensate can be realized; continuous and automatic sampling and feeding of mixture particles with different particle diameters are realized in a screening process, the stability, uniformity and reliability of sampling are improved, human unstable factors during sending are avoided, the labor intensity is reduced, the analysis and detection accuracy is improved, and the sample accuracy is effectively improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

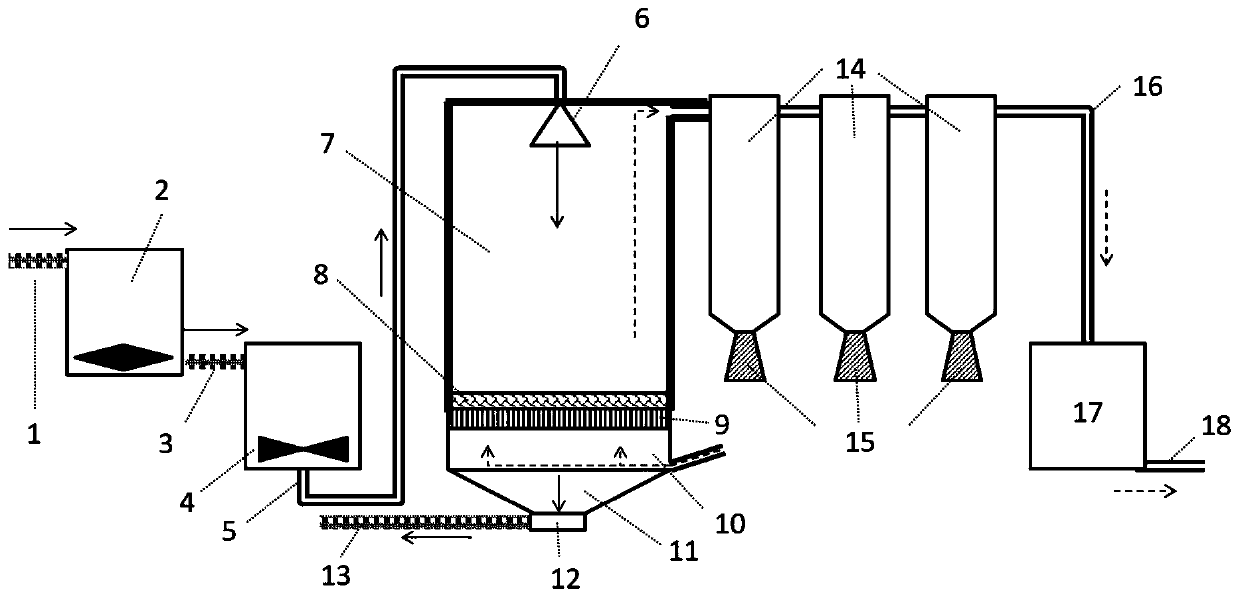

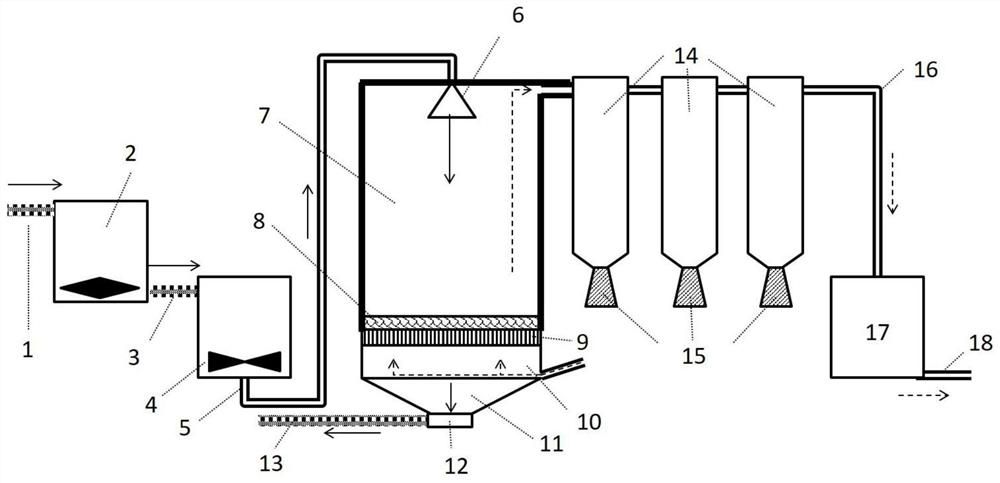

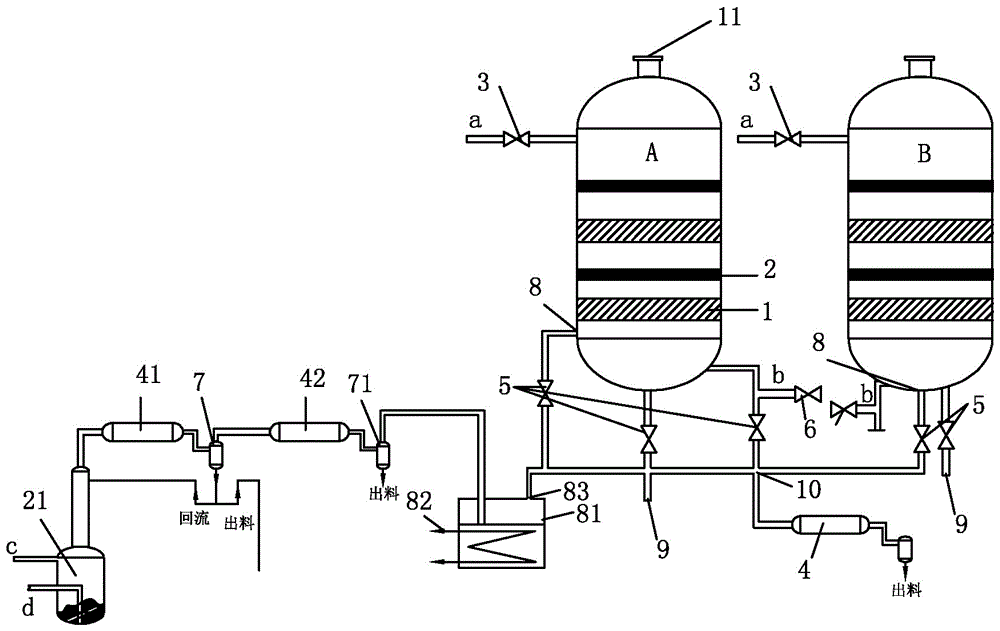

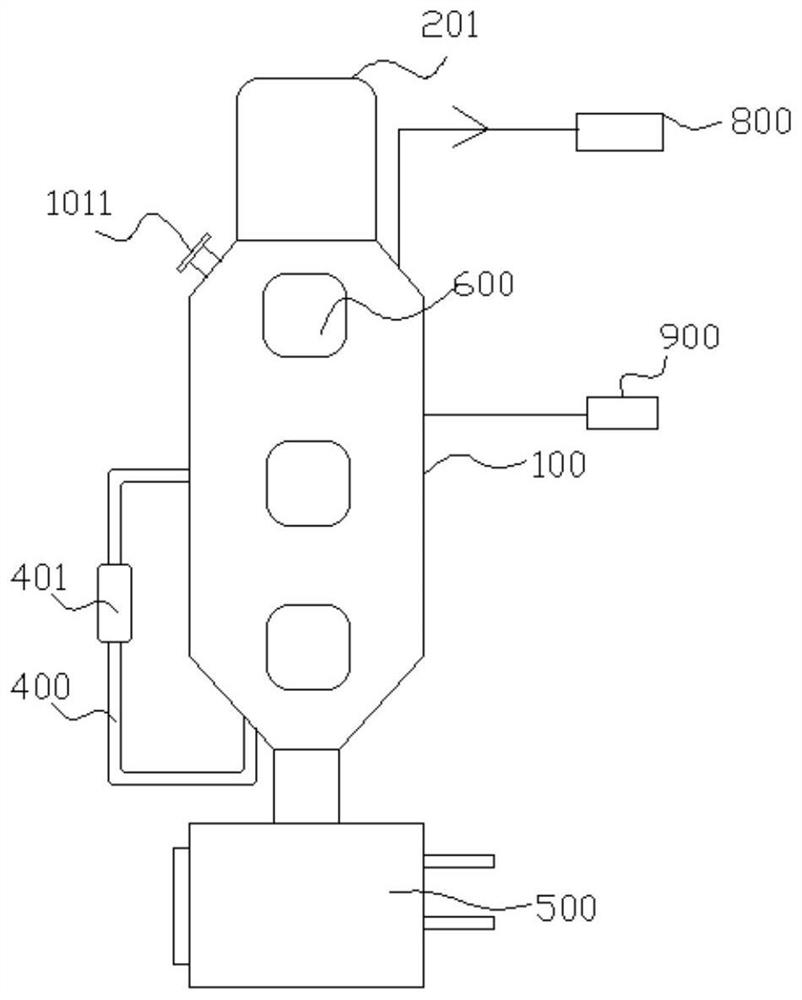

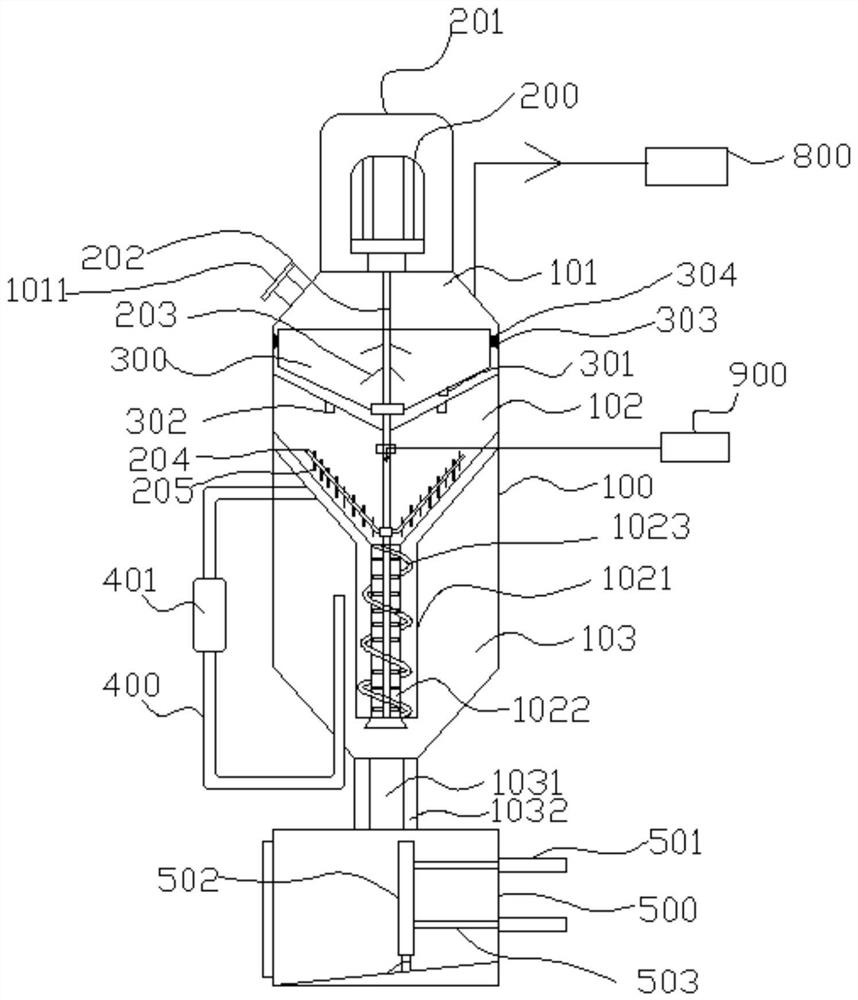

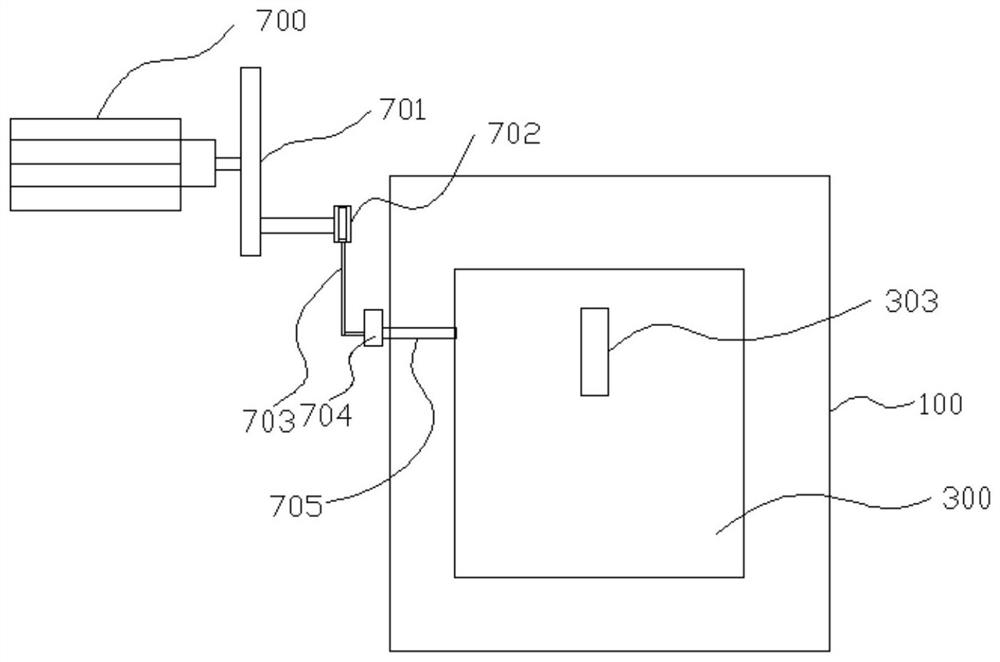

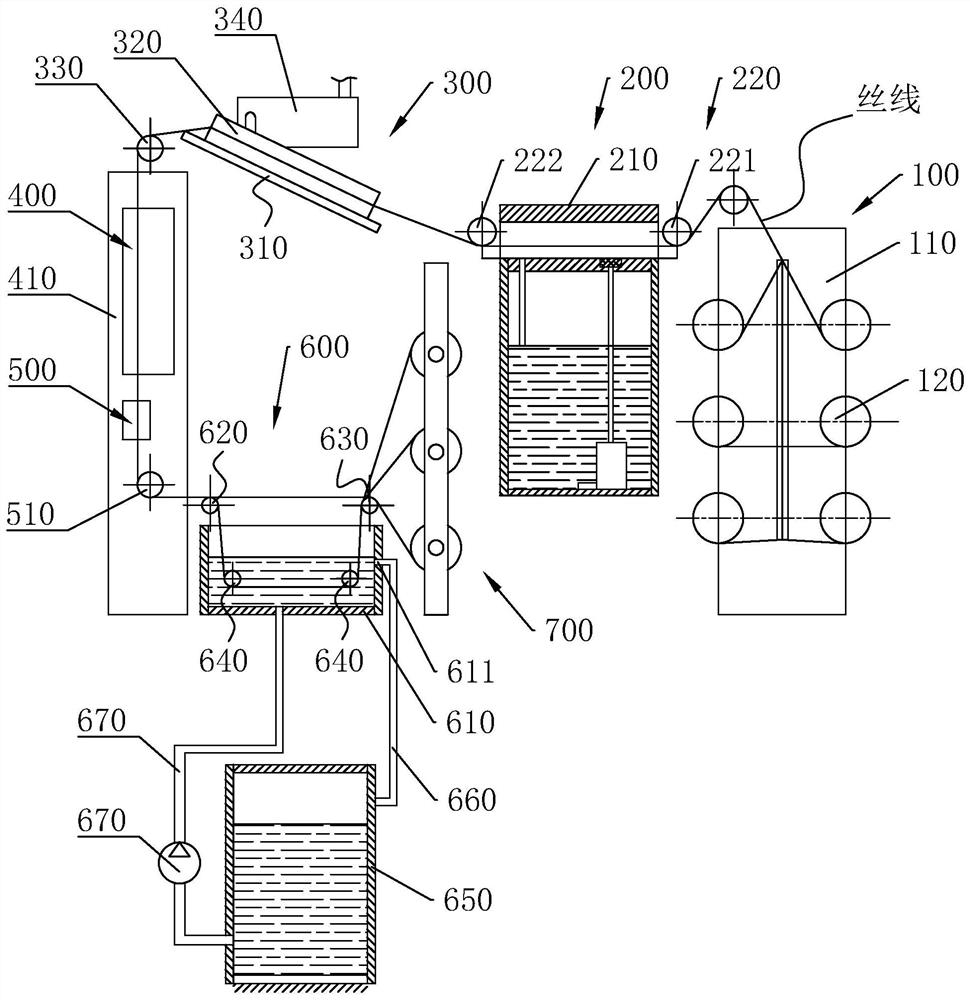

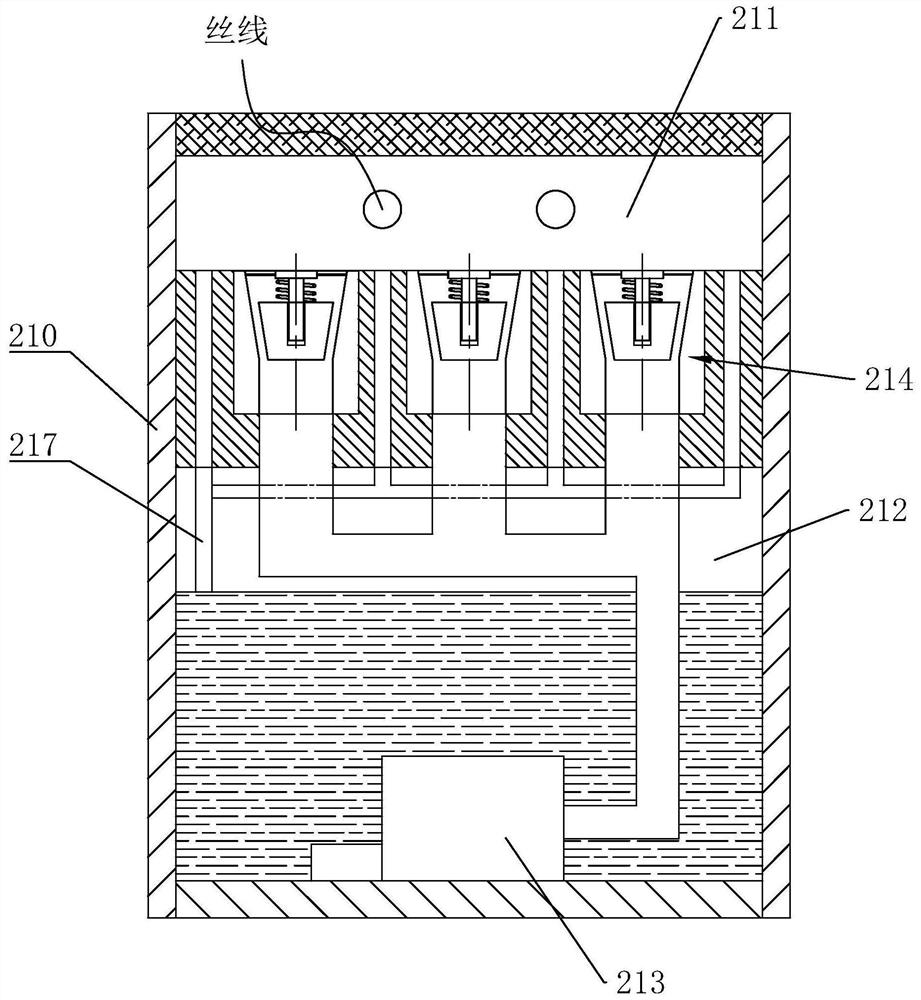

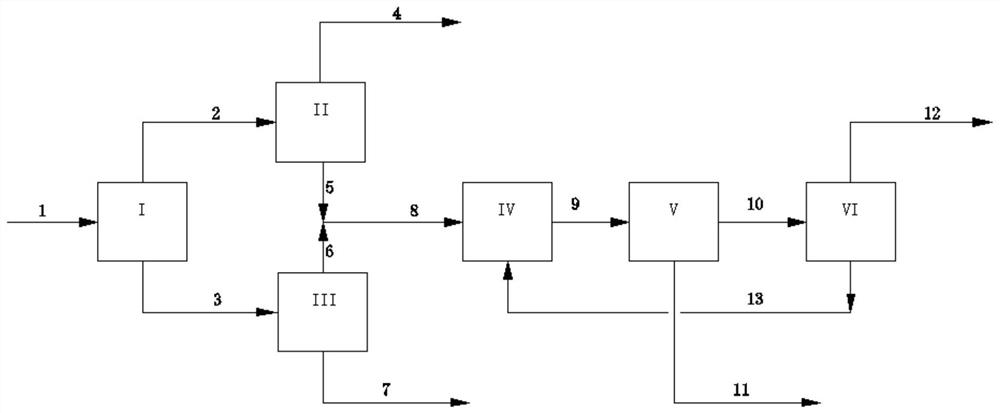

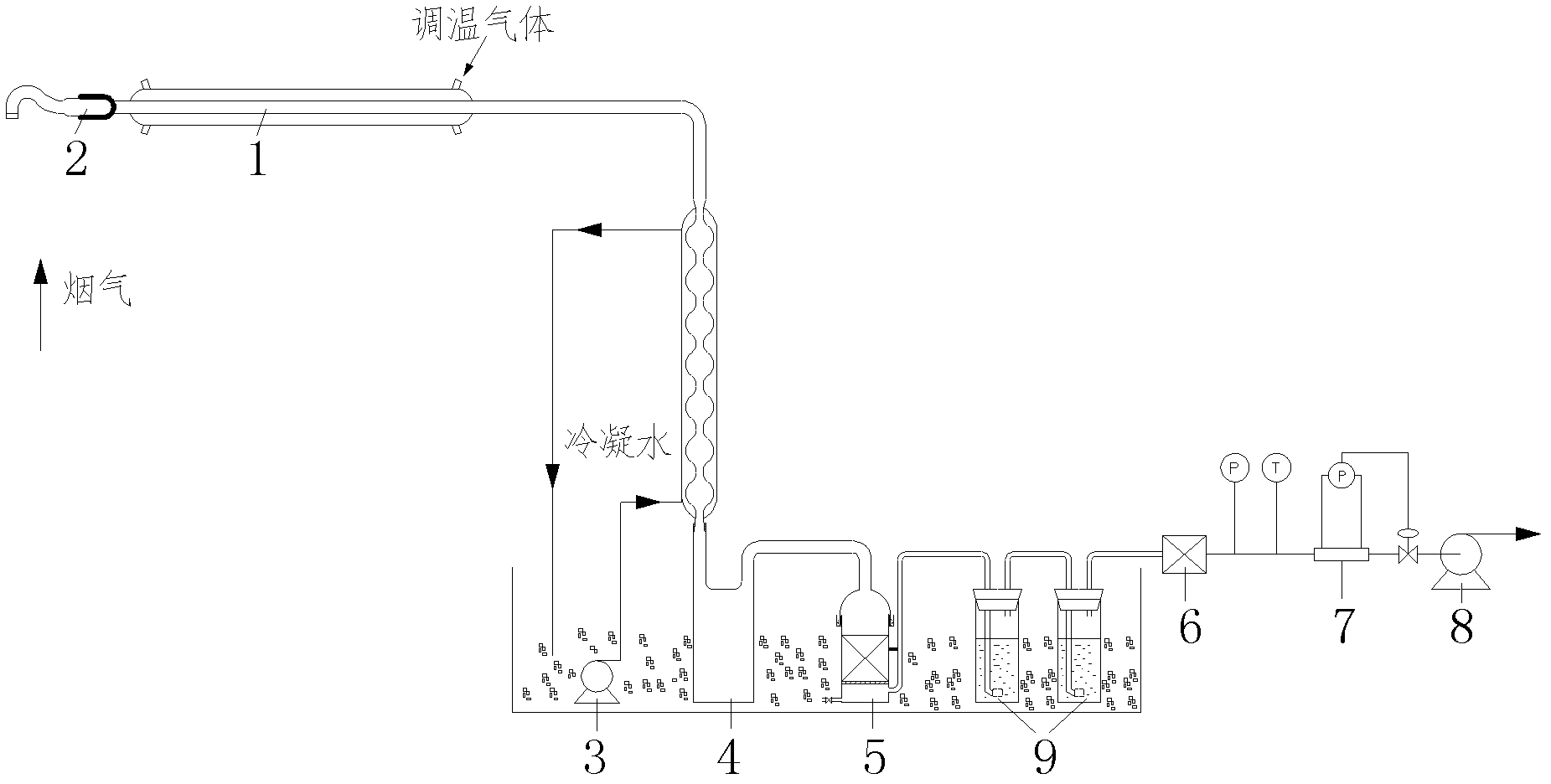

Organic waste pyrolysis oil production equipment and method based on self-sustaining smoldering

ActiveCN111394114AEfficient decompositionReduce energy consumptionMultiple-effect/fractional condensationLiquid hydrocarbon mixture productionFlue gasProcess engineering

The invention belongs to the related technical field of waste disposal, and discloses organic waste pyrolysis oil production equipment and method based on self-sustaining smoldering. The equipment comprises a material conveying assembly, a smoldering assembly, a condensation separation assembly and a flue gas purification assembly, and the material conveying assembly, the smoldering assembly, thecondensation separation assembly and the flue gas purification assembly are connected in sequence; the mixed material moves in the smoldering assembly from top to bottom; in the movement process, ashslag is formed through smoldering reaction and is discharged; meanwhile, a pyrolytic reaction is excited by heat generated by the smoldering reaction at the bottom of the smoldering assembly in the stacking process of the mixed material in the smoldering assembly; the generated pyrolysis gas moves to the condensation separation assembly along with the flue gas from bottom to top, the condensationseparation assembly and the flue gas purification assembly are used for sequentially condensing and purifying the flue gas from the smoldering assembly, and the obtained purified flue gas is discharged from the equipment. Two chemical processes of smoldering and pyrolysis are coupled so that the energy consumption is reduced and the integration level is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

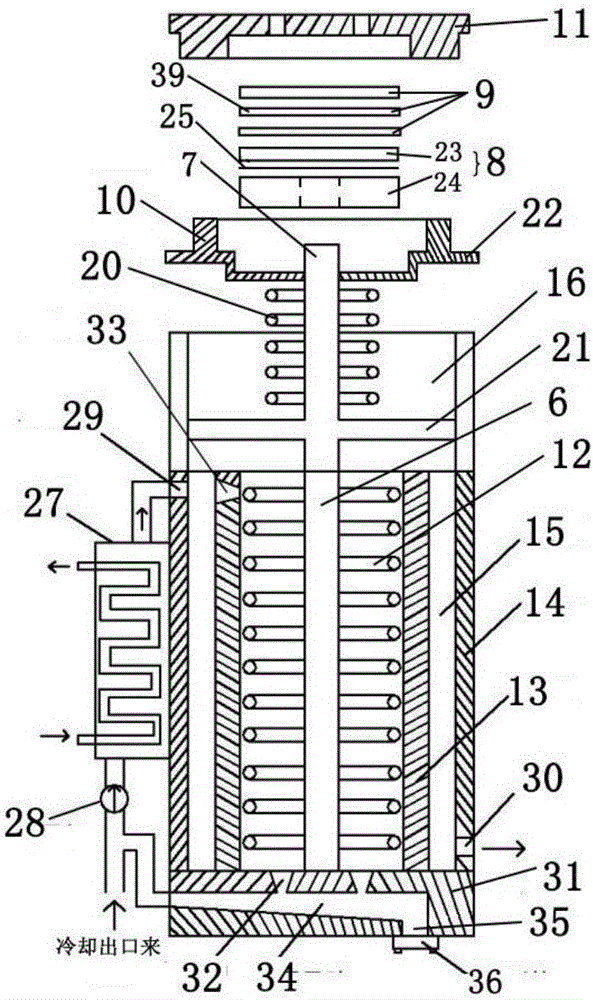

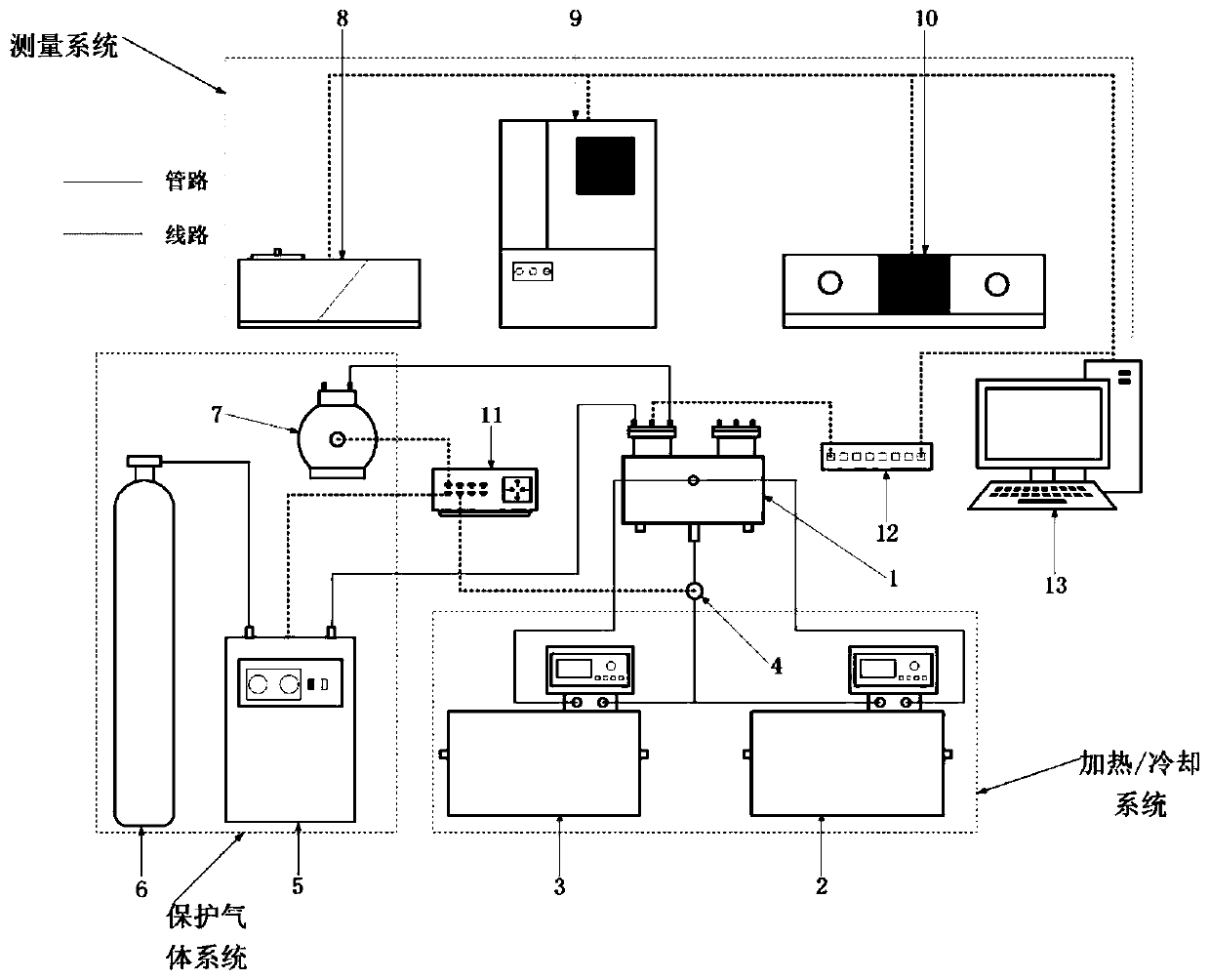

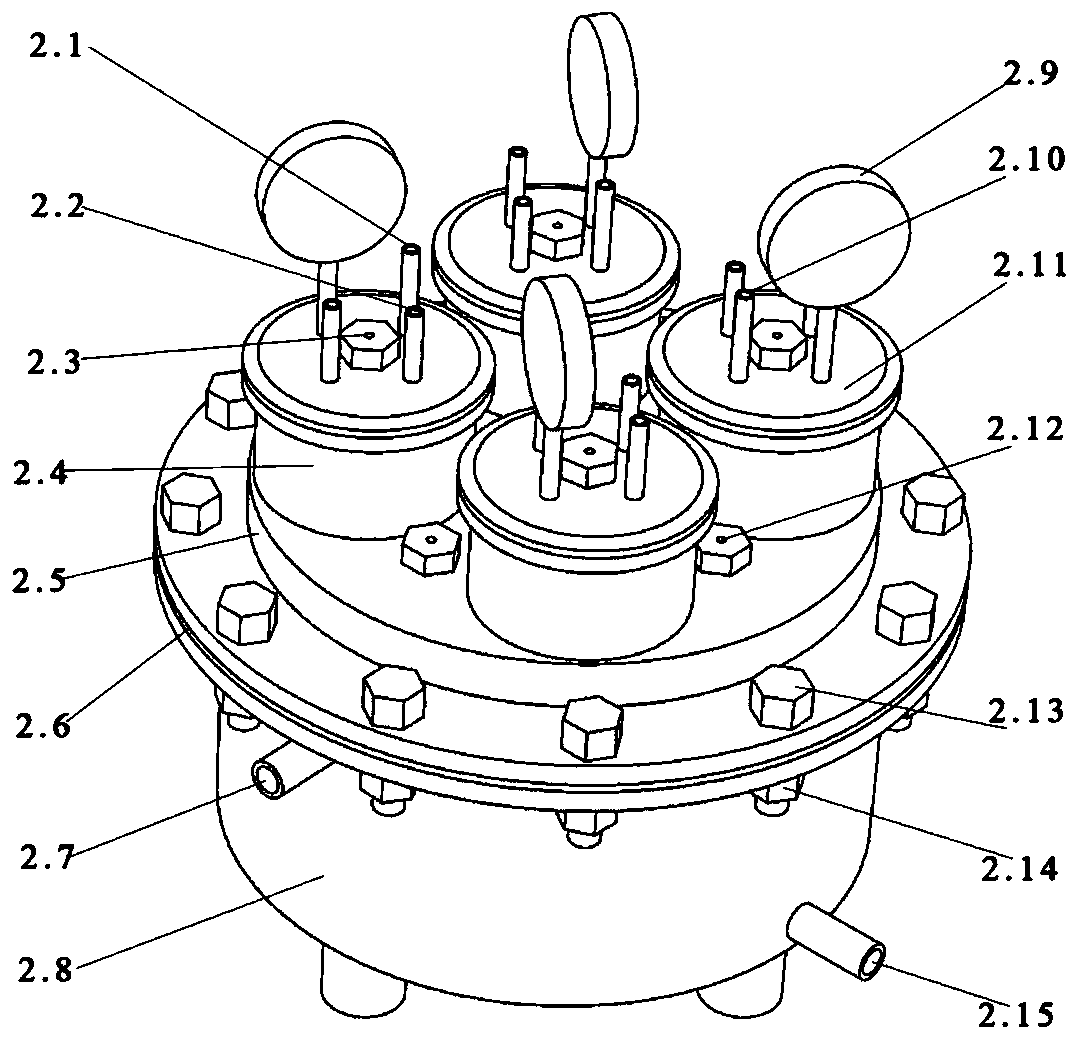

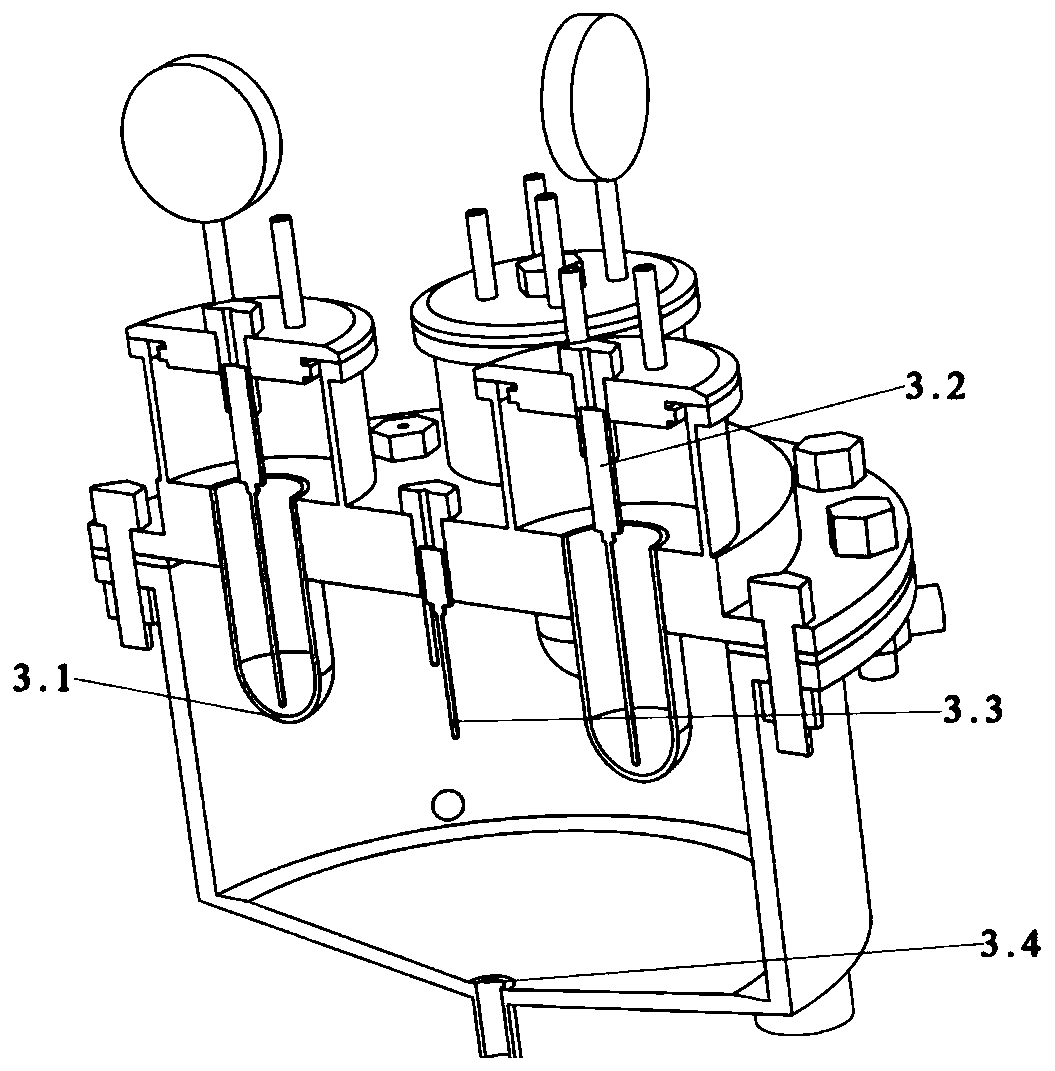

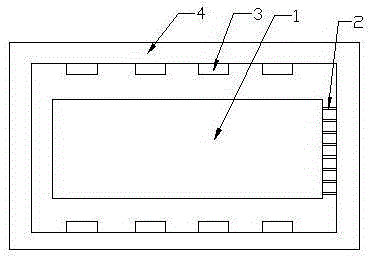

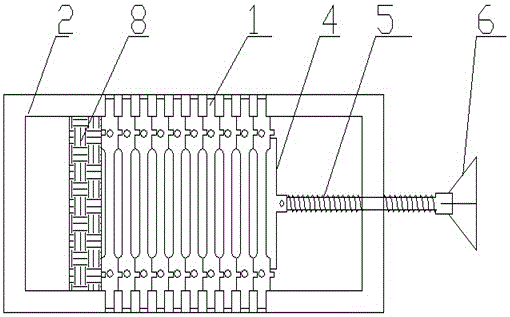

Integrated device for testing stability of phase change thermal storage material as well as method

ActiveCN109738476AControl heating temperatureControl cooling temperatureInvestigating phase/state changeMeasurement deviceProcess systems

The invention discloses an integrated device for testing stability of a phase change thermal storage material as well as a method. The device is applied to testing of the stability of the phase changethermal storage material. The device comprises a reaction kettle, a heating / cooling oil bath, an electromagnetic valve, a vacuum pump, a protective gas circulating pump, a protective gas tank, a DSC(differential scanning calorimeter), an X ray polycrystalline diffraction instrument, an infrared spectrometer, a console, a temperature acquisition card and a data acquisition and processing system.The reaction kettle is utilized for providing a test space; the heating / cooling oil bath is utilized for circularly melting and solidifying a material at a constant temperature; the vacuum pump, the protective gas circulating pump and the protective gas tank are utilized for providing a protective gas environment; the console is utilized for controlling a test cyclic process; the temperature acquisition card is utilized for recording temperature variation of the material in the cyclic process; a measuring device is utilized for measuring enthalpy of phase change, a phase change temperature, acrystal structure, a molecular structure and chemical composition of the material after being cycled for multiple times; and the data acquisition and processing system is utilized for processing datainformation returned back by a temperature information acquisition card and the measuring device.

Owner:ZHEJIANG UNIV

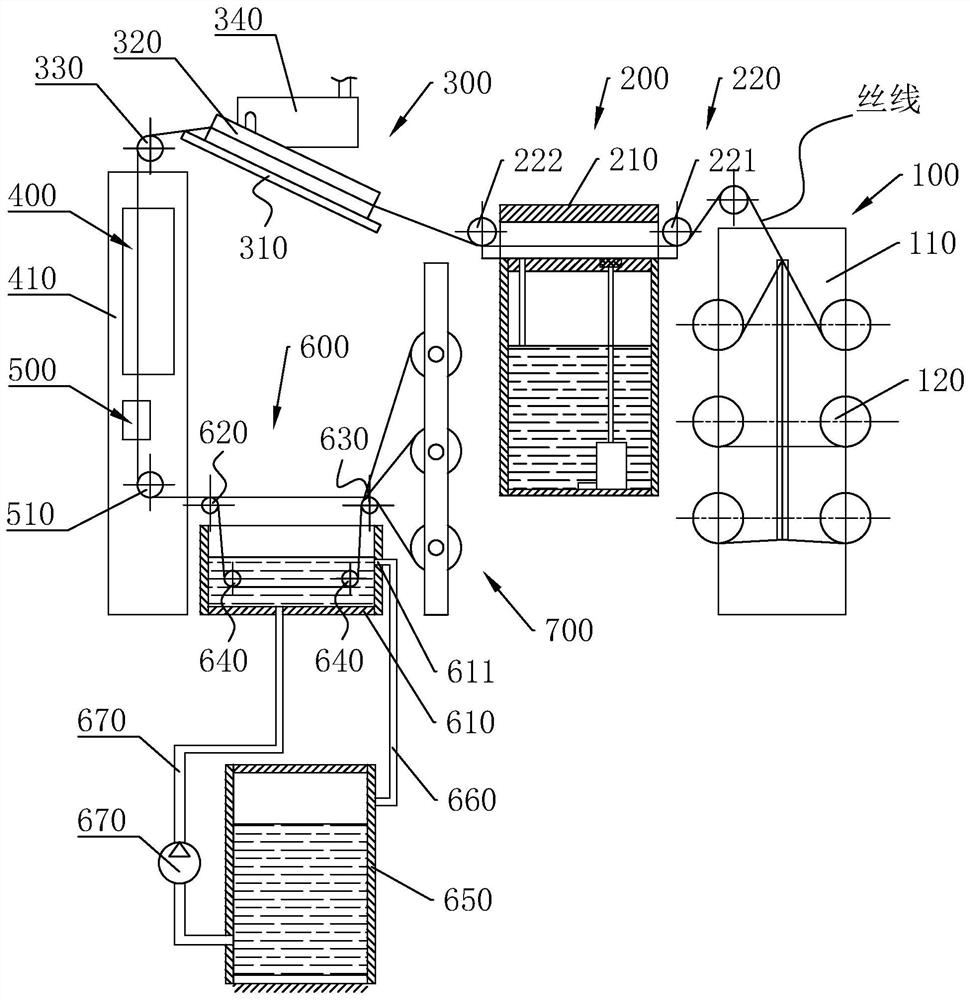

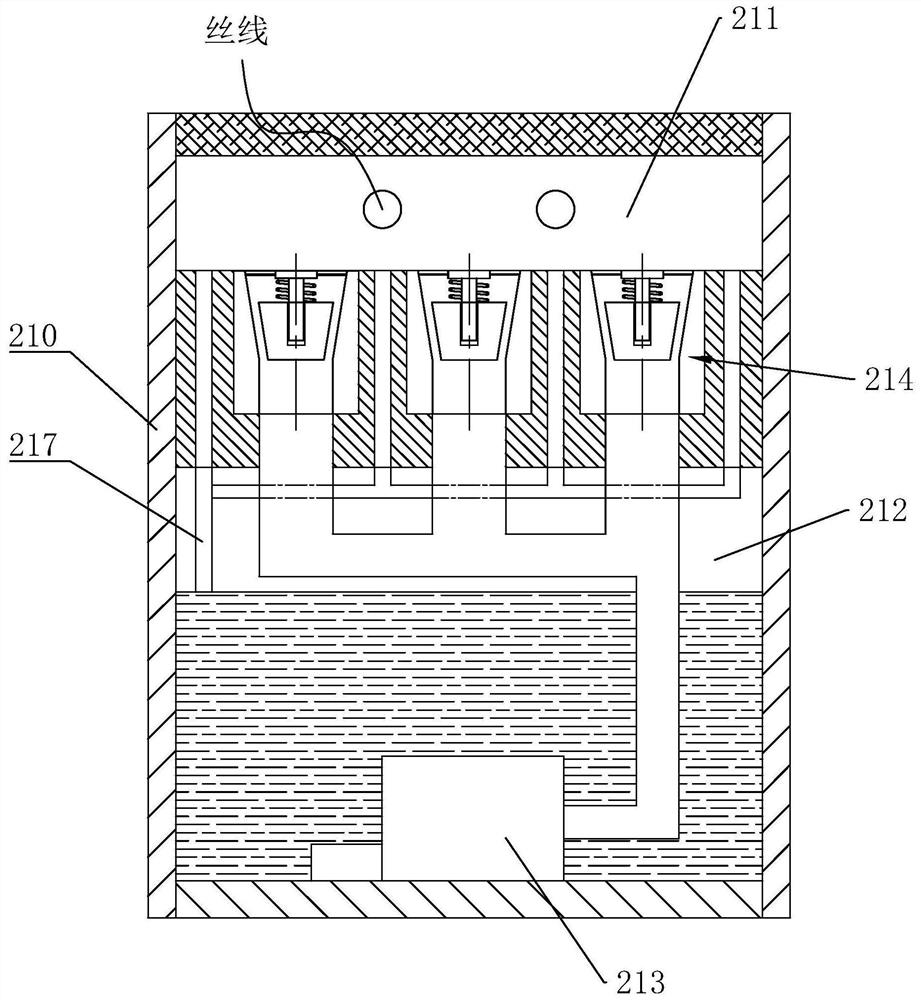

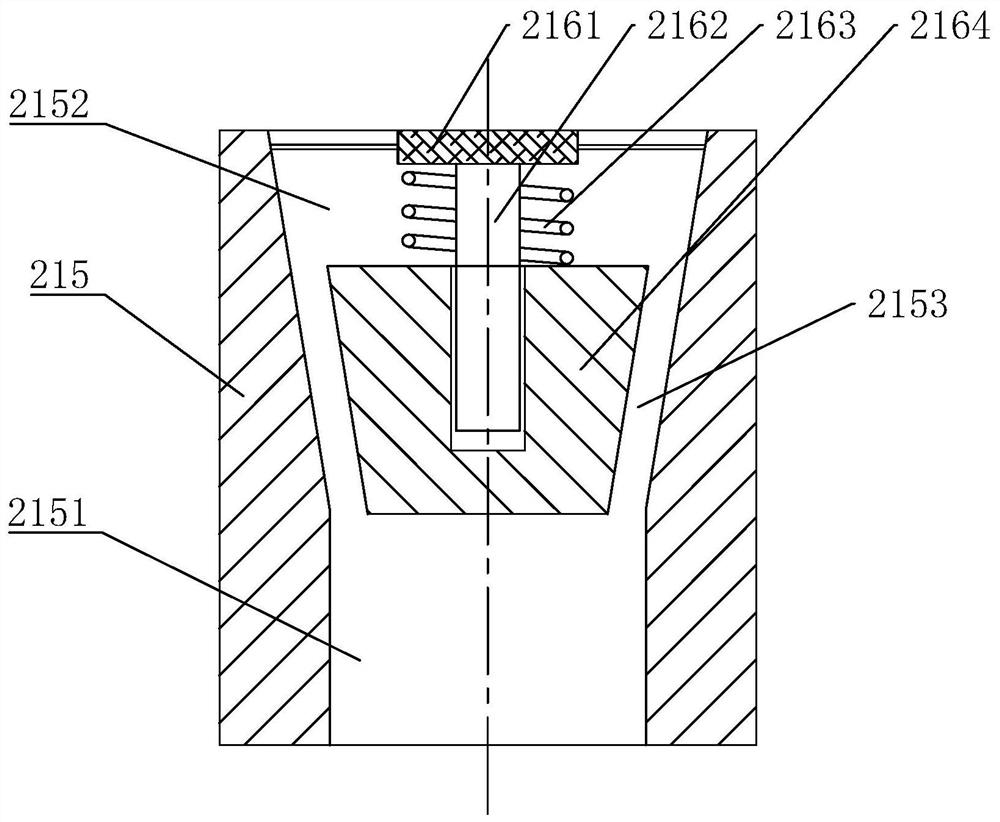

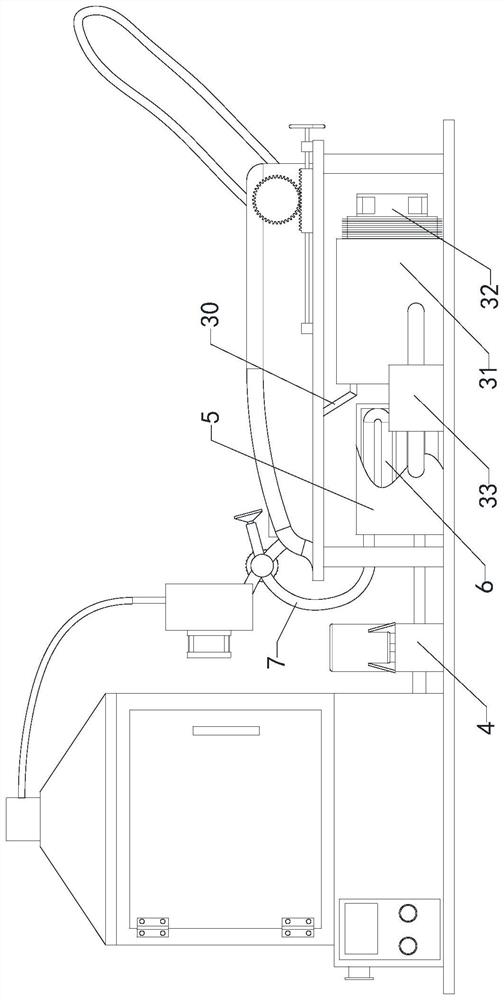

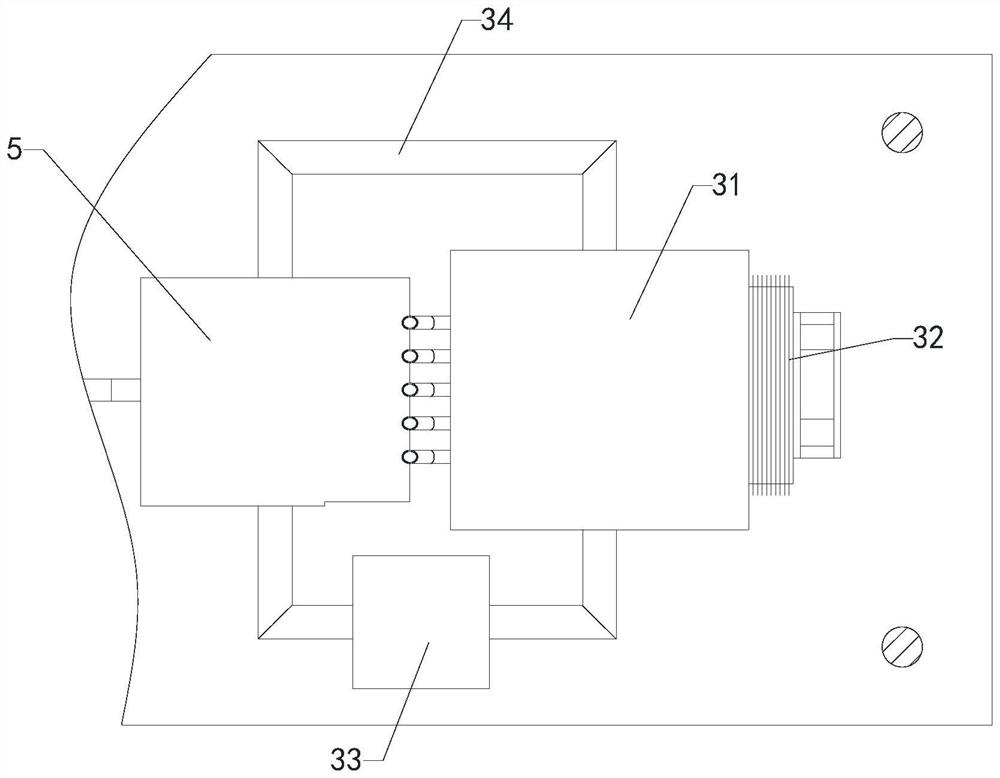

Chemical fiber spinning elasticizing device

ActiveCN112011866AImprove the lubrication effectShorten the production cycleLiquid/gas/vapor removalTextile treatment machine arrangementsYarnPolymer science

The invention belongs to the technical field of textile machinery, and particularly relates to a chemical fiber spinning elasticizing device which is characterized by comprising a yarn feeding system,a heating system, a cooling system, a false twister, an oiling system and a winding device which are arranged in sequence; the yarn feeding system is used for placing silk thread raw material and unwinding silk threads; the heating system is used for heating the unwound silk threads; the cooling system is used for cooling high-temperature silk threads; the false twister is used for false twistingof the silk threads; the oiling system is used for oiling and lubricating the silk threads; the winding device is used for winding the oiled silk threads; and an elasticizing device further comprisesa dyeing system which is located between the yarn feeding system and the heating system and used for dyeing the unwound silk yarn. Dyeing can be completed while the silk threads are elasticized, so that the production period is shortened, and the production cost is reduced.

Owner:诸暨市双冠化纤有限公司

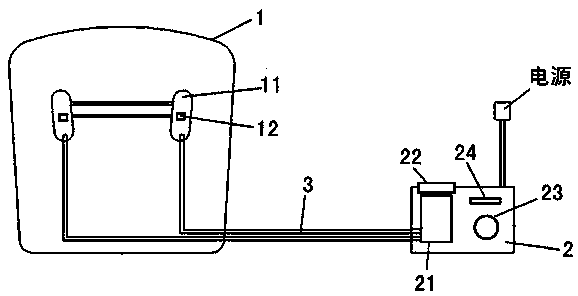

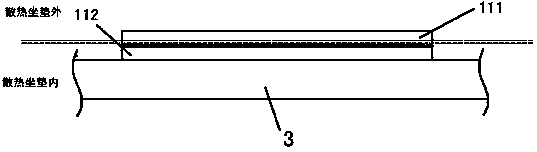

Fast cooling cushion

InactiveCN103818286AConvenient ArrangementIn line with the habitSeat heating/ventillating devicesNuclear engineeringRefrigeration

The invention relates to a fast cooling cushion. The fast cooling cushion comprises a heat conduction water pipe forming a closed loop, and the heat conduction water pipe is filled with liquid for heat conduction. A part of the heat conduction water pipe is arranged inside a heat radiator for dissipating heat, and a part of the rest heat conduction water pipe is arranged inside a heat dissipation cushion. The heat dissipation cushion is provided with heat exchangers which are connected with the heat conduction water pipe and used for rapidly transferring heat. The fast cooling cushion adopts a semiconductor refrigeration technology, carries out conversion through the heat exchangers, achieves the purpose of rapid cooling, meanwhile, is simple and compact in structure, simplifies the complex distribution of the heat conduction water pipe, saves cost, largely reduces weight and energy consumption, better controls cooling temperature, accords with habits of different users, and improves use experience.

Owner:李平红

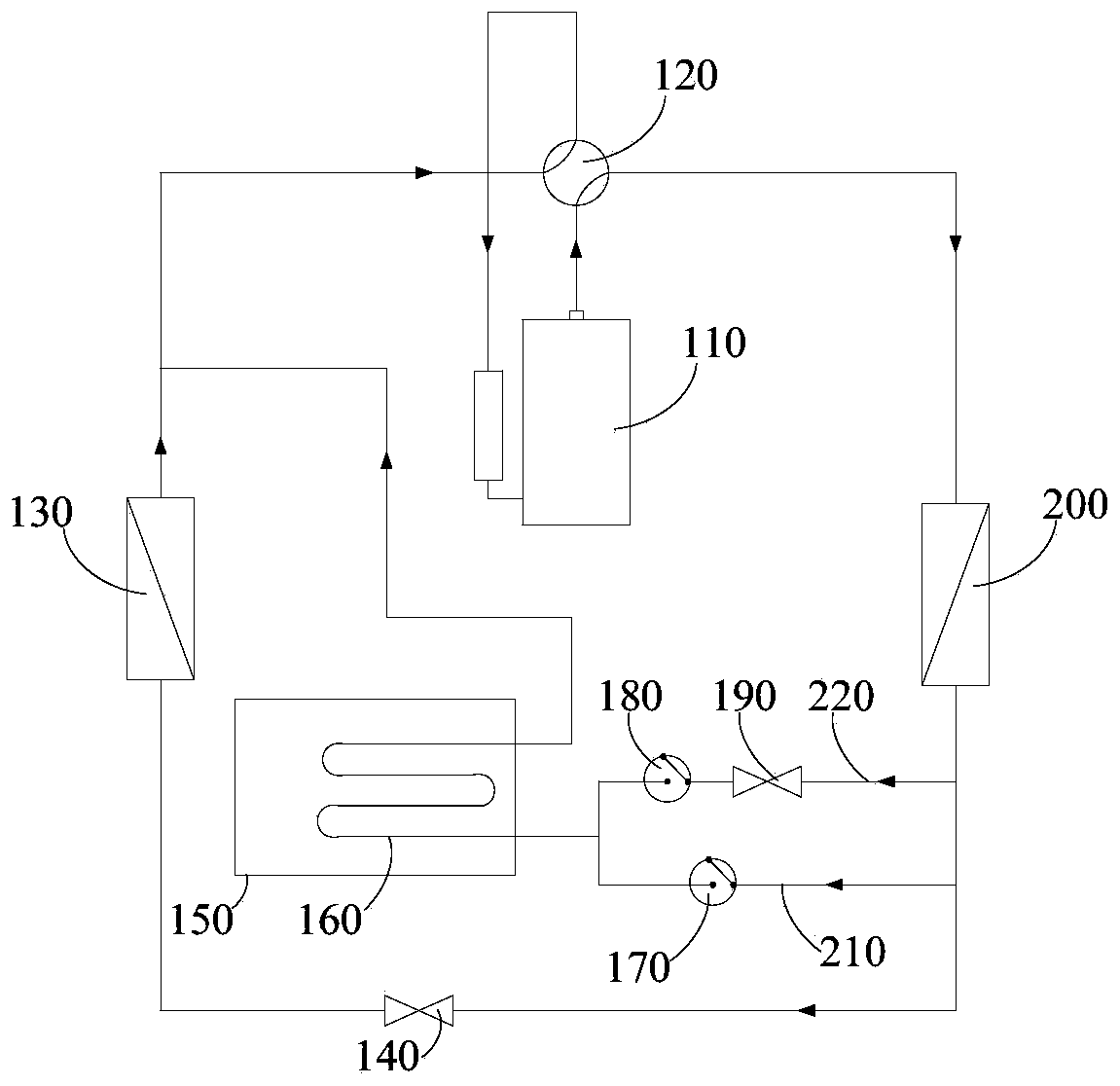

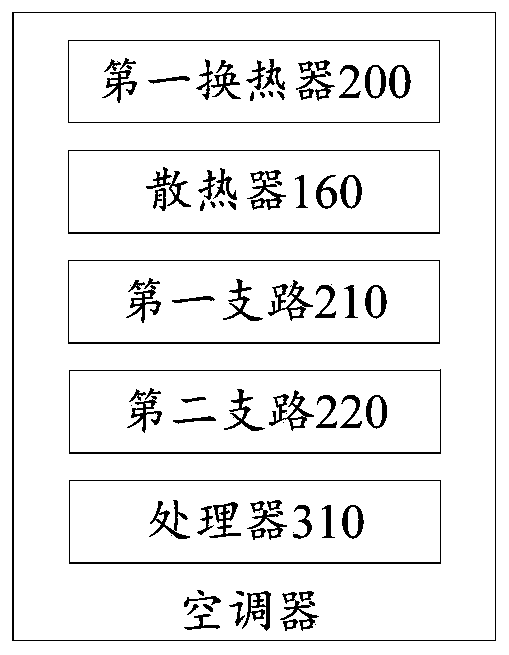

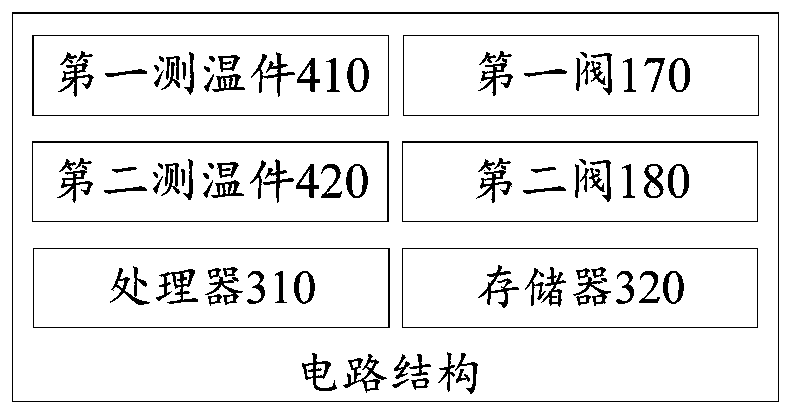

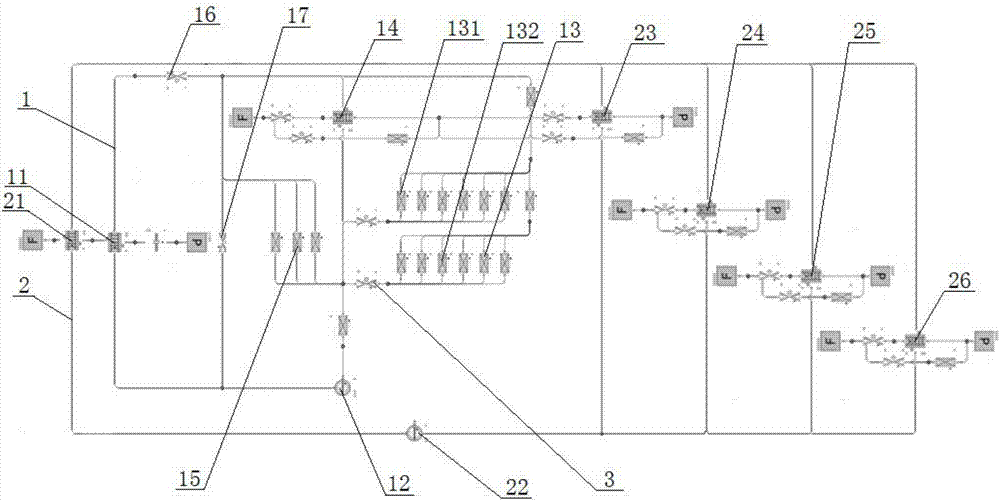

Air conditioner, control method and device thereof and computer readable storage medium

ActiveCN111442417AControl cooling temperatureMeet cooling and cooling needsMechanical apparatusCondensate preventionEngineeringMechanical engineering

The invention provides an air conditioner, a control method and device thereof and a computer readable storage medium. The air conditioner comprises a first heat exchanger, a radiator, a first throttling component and a processor, wherein the radiator is configured to be suitable for cooling a heat dissipation object; a first branch and a second branch are formed in the air conditioner; the firstbranch is connected with the first heat exchanger and the radiator; the second branch is connected with the first heat exchanger and the radiator; the first throttling component is formed as at leastone part of the second branch; and the processor is configured to be suitable for controlling the on / off of the first branch and the on / off of the second branch respectively. Through the adoption of the air conditioner provided by the scheme, the heat dissipation and cooling temperatures of the heat dissipation object can be flexibly controlled, so that the heat dissipation and cooling requirements of the heat dissipation object are better met, and the heat dissipation efficiency and the anti-condensation requirement of the heat dissipation object are guaranteed at the same time.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

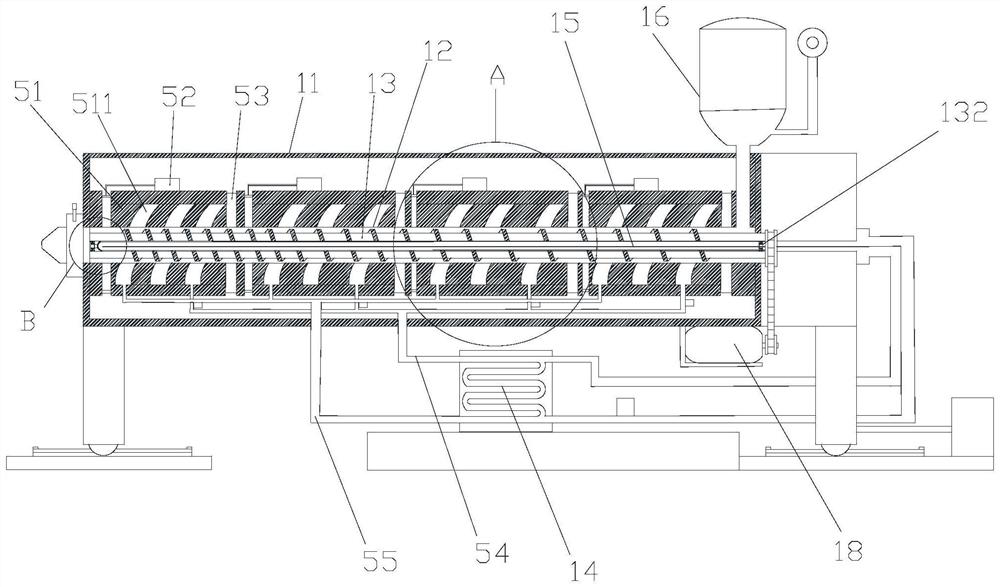

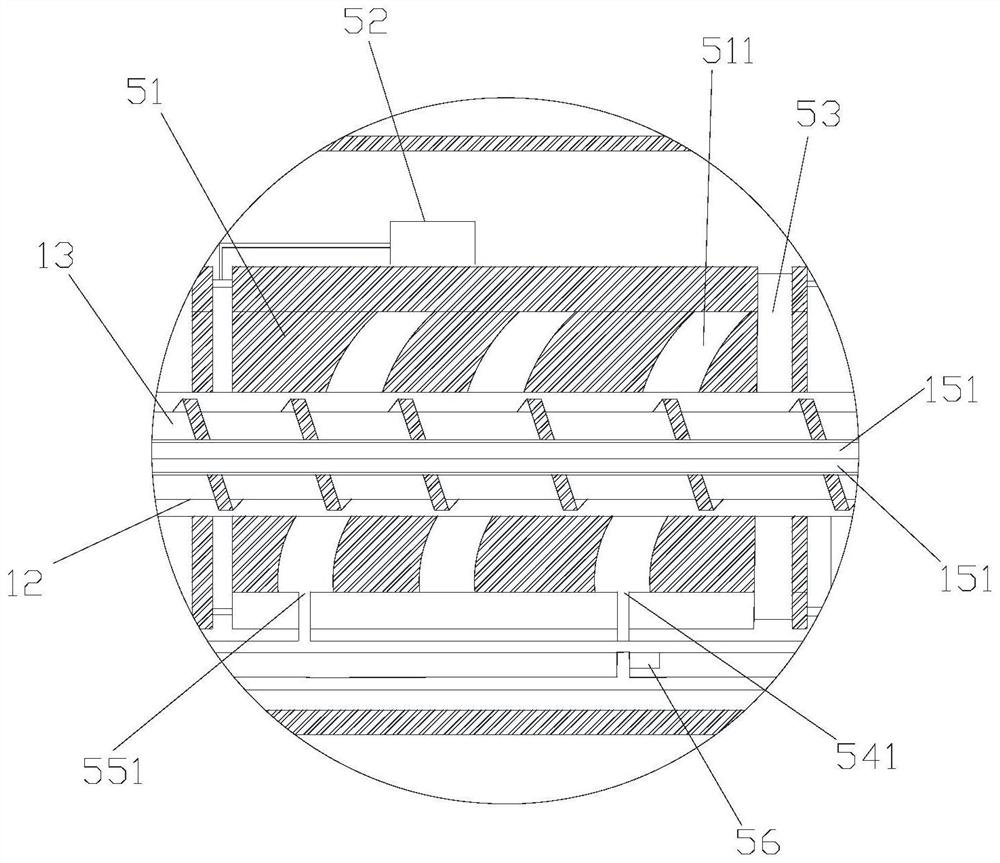

Cable three-layer supply forming equipment

PendingCN114454455AFirmly connectedIncrease productivityCoatingsInsulating conductors/cablesTemperature controlHeat balance

The cable three-layer supply forming equipment comprises an extruder and a mold machine head, the extruder comprises a machine shell and a threaded sleeve installed in the machine shell, one end of the threaded sleeve extends out of the machine shell to form an extrusion opening, the interior of the threaded sleeve is hollowed out to form an inner cavity, and a feeding box for feeding materials into the inner cavity is installed on the machine shell; the step-by-step temperature control device can carry out step-by-step temperature control on the extrusion screw and accurately control the extrusion temperature of raw materials at each stage, so that the extrusion speed can be accelerated, and as friction heat and shearing heat generated during high-speed operation of the extruder can destroy heat balance, the step-by-step temperature control device sometimes is difficult to lower the temperature, so that the extrusion speed is increased. The cooling circulating device installed in the cooling tank can strengthen the cooling force and improve the adjustability of the temperature of raw materials, the raw materials enter the forming cavity from the middle-layer discharging port and the inner-layer feeding port to wrap the wire, the outer-layer raw materials are guided into the extrusion gap through the material guiding tank to wrap the inner-layer raw materials and the middle-layer raw materials, and therefore the inner-layer raw materials and the middle-layer raw materials are wrapped. The three layers of raw materials are integrally formed on the wire, and the production efficiency is improved.

Owner:江西华缆科技有限公司

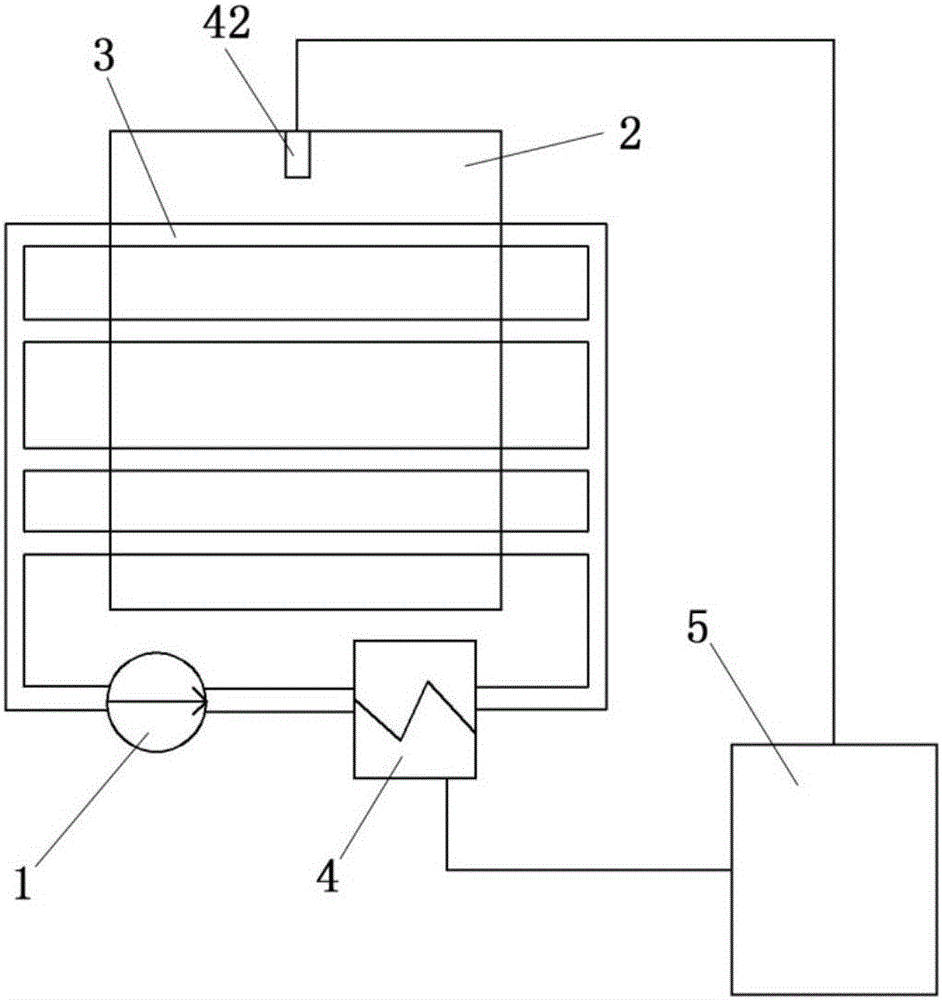

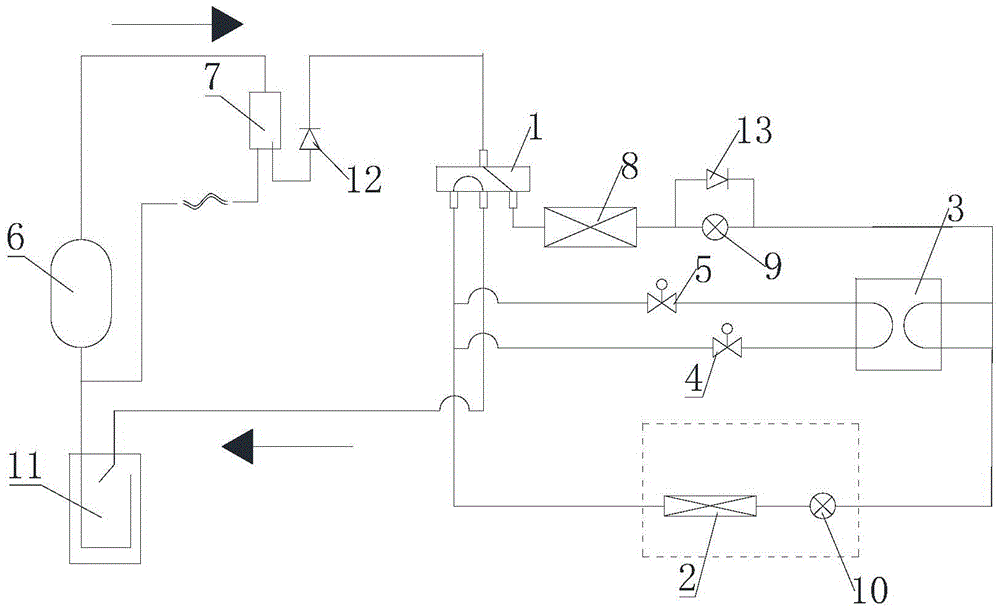

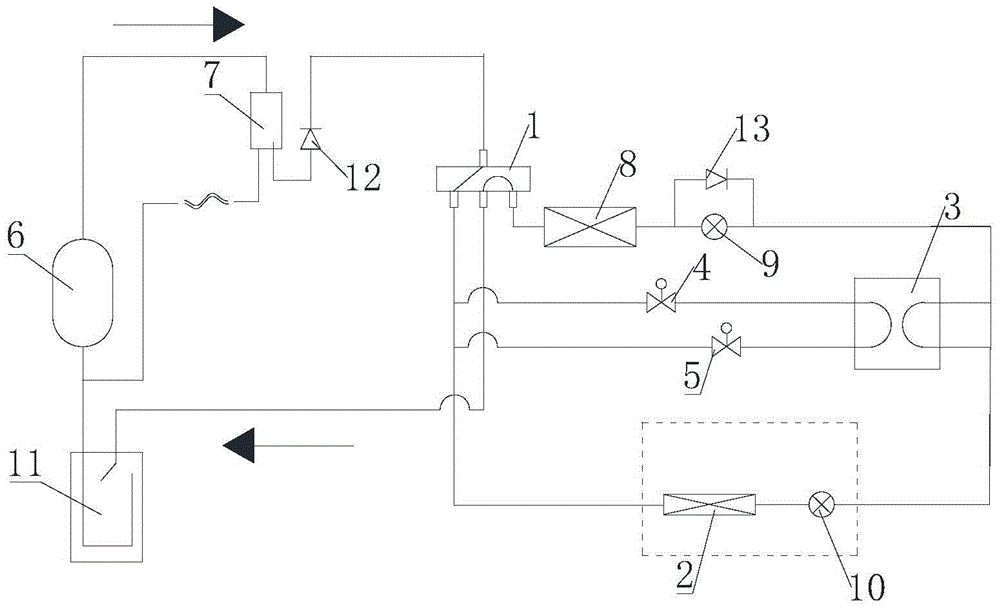

Air-conditioner and control method thereof

ActiveCN105465975AControl cooling temperatureSolve condensationMechanical apparatusSpace heating and ventilation safety systemsCooling temperatureEngineering

The invention discloses an air-conditioner and a control method thereof. The air-conditioner comprises a compressor driver board, a coolant cooling module, a first electromagnetic valve, a second electromagnetic valve and a controller; a liquid inlet on one side of the coolant cooling module is connected with a connecting pipeline through the first electromagnetic valve, while a liquid outlet on one side of the coolant cooling module is connected with the same connecting pipeline through the second electromagnetic valve; the controller controls the openings of the first electromagnetic valve and the second electromagnetic valve according to a temperature of the compressor driver board, thereby controlling the temperature of the compressor driver board within a predetermined range. By means of the technical solution, the air-conditioner is capable of controlling the openings of the first electromagnetic valve and the second electromagnetic valve according to the temperature of the compressor driver board, thereby controlling a quantity of a coolant entering the coolant cooling module and achieving a purpose of controlling a cooling temperature of the compressor driver board.

Owner:GREE ELECTRIC APPLIANCES INC

Engine cooling management system

PendingCN107956569AControl cooling temperatureEffective control of cooling temperatureLiquid coolingCoolant flow controlEngineeringAir compressor

An engine cooling management system comprises a high-temperature cooling circulation system and a low-temperature cooling circulation system. The high-temperature cooling circulation system comprisesa high-temperature heat dissipation water tank, a high-temperature cooling water pump, an engine body, an EGR first-stage cooler and an air compressor. The low-temperature cooling circulation system comprises a low-temperature heat dissipation water tank, a low-temperature cooling water pump, an EGR second-stage cooler, a supercharger, an engine oil cooler and an air conditioner. Through the design, the cooling temperatures of all parts in the cooling system are precisely controlled.

Owner:DONGFENG COMML VEHICLE CO LTD

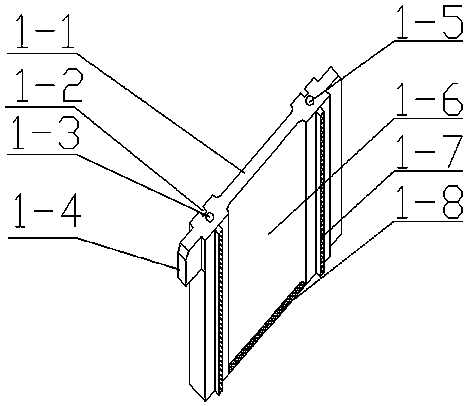

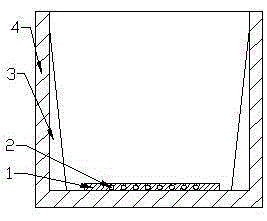

Heat treatment method for re-sorbitizing steel wires or steel strips

ActiveCN105506234ASmall sizeControl cooling temperatureFurnace typesHeat treatment furnacesMartensite transformationRoom temperature

The invention discloses a heat treatment method for re-sorbitizing steel wires or steel strips. The heat treatment method comprises the following steps: heating the steel wires or steel strips to austenite temperature, quickly cooling the austenitized isothermal steel wires or steel strips to the temperature range more than the martenitic transformation point of a material or the temperature range of 200-450 DGE C, then sending the steel wires or steel strips into an insulation sleeve for standing and heat preservation, and thus completing sorbite phase transformation; controlling the temperature of the sleeve to any temperature point between the room temperature and 500 DEG C. The method for sorbitizing the steel wires or steel strips does not need isothermal equipment of lead bath and salt bath and does not need special isothermal devices. The cool temperature is controlled by changing the cooling speed, and therefore the size of sorbite structures is controlled.

Owner:GUIZHOU GUDA CABLE CO LTD

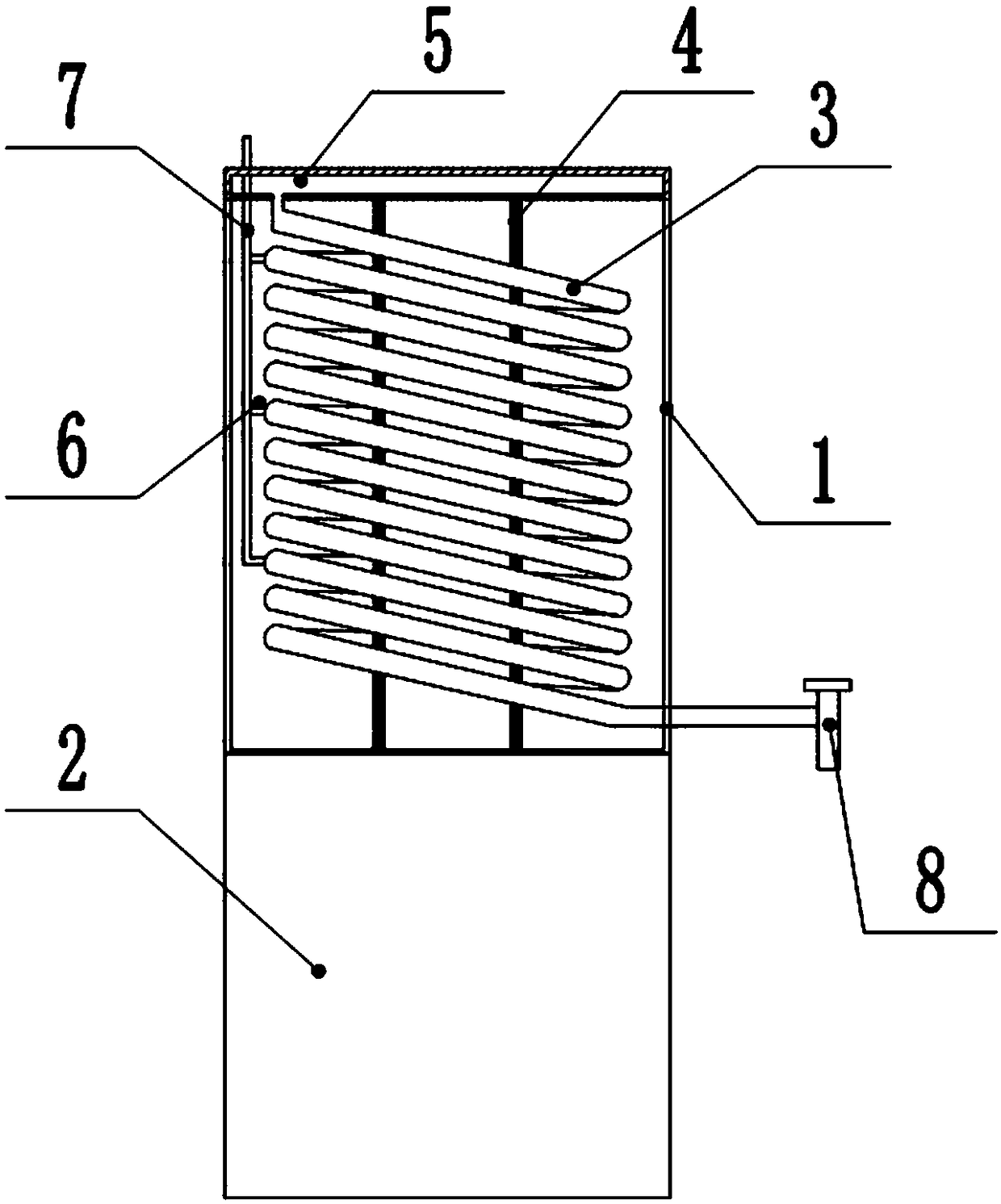

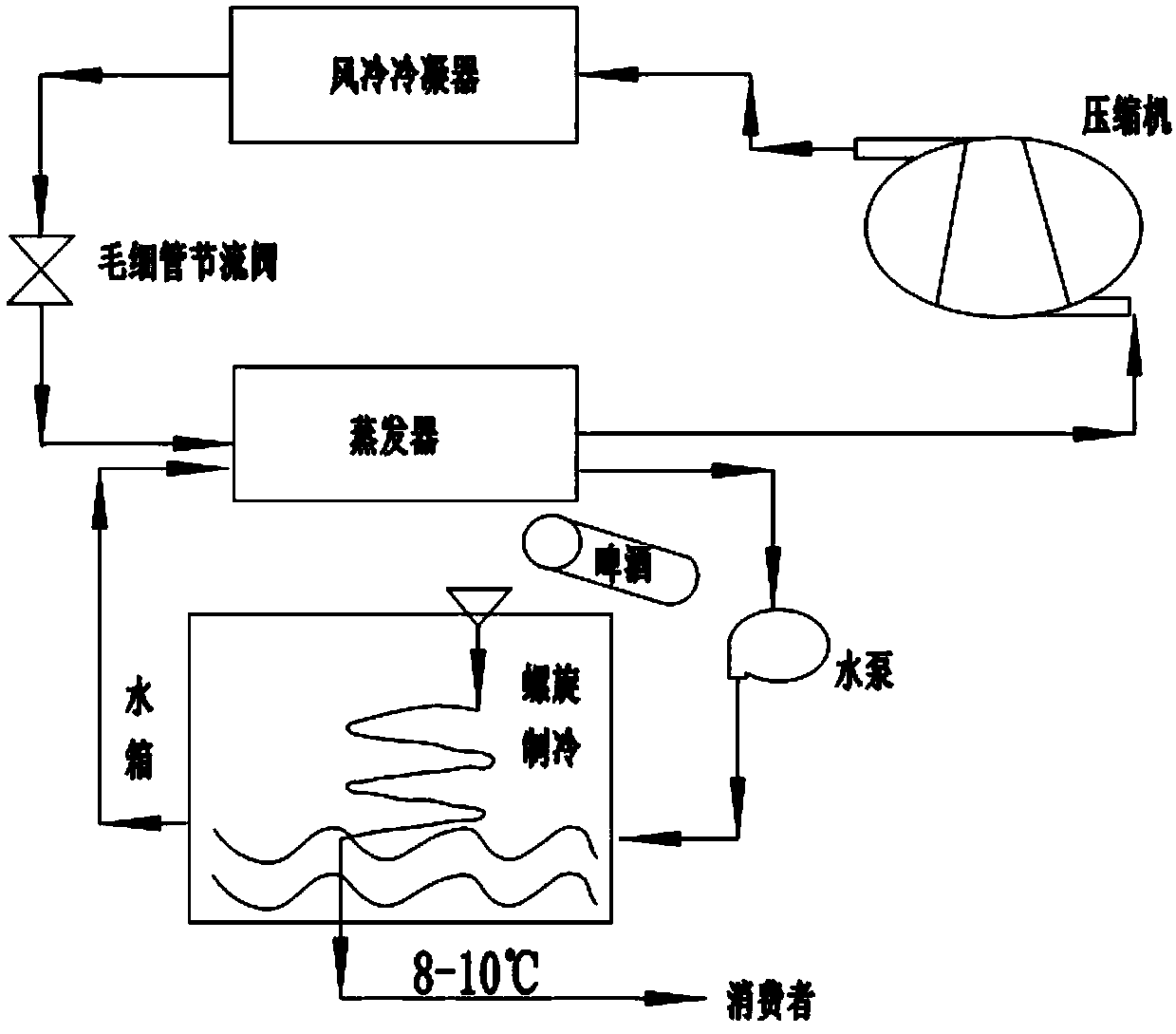

Instantaneous refrigeration beer machine

PendingCN108387065AControl cooling temperatureSimple structureDomestic cooling apparatusLighting and heating apparatusEngineeringBottle

The invention discloses an instantaneous refrigeration beer machine which comprises a water tank. A spiral coil heat exchanger is arranged in the water tank in the height direction; an opening in theupper end of the spiral coil heat exchanger is connected with a beer injecting container on the upper portion of the spiral coil heat exchanger; an outlet in the bottom end of the spiral coil heat exchanger extends out of the water tank, and a faucet is arranged to control opening and closing of the outlet; and a cooling liquid inlet and a cooling liquid outlet are formed in the bottom in the water tank, wherein the cooling liquid inlet is connected with an output end opening of a liquid refrigeration device, and the cooling liquid outlet is connected with an input end opening of the liquid refrigeration device. The instantaneous refrigeration beer machine has the characteristics that instantaneous and convenient effects are achieved, the cooling temperature of beer can be controlled, cooling of beer bottles is omitted, and energy saving and environmental protection are achieved.

Owner:GUIZHOU UNIV

A self-sustaining smoldering organic waste pyrolysis oil production equipment and method

ActiveCN111394114BEfficient decompositionReduce energy consumptionMultiple-effect/fractional condensationLiquid hydrocarbon mixture productionThermodynamicsFlue gas

The invention belongs to the technical field of waste disposal, and discloses a self-sustaining smoldering organic waste pyrolysis oil-making equipment and method. The equipment includes a material conveying component, a smoldering component, a condensation separation component and a flue gas purification component. The material conveying component, the smoldering component, the condensation separation component and the flue gas purification component are connected in sequence; the mixed material moves from top to bottom in the smoldering component, and is discharged as ash through the smoldering reaction during the movement. During the process of material accumulation in the smoldering component, the pyrolysis reaction is stimulated by the heat generated by the smoldering reaction at the bottom of the smoldering component, and the generated pyrolysis gas moves from bottom to top with the flue gas to the condensation separation component. And the flue gas purification component is used to condense and purify the flue gas from the smoldering component in sequence, and the purified flue gas obtained is discharged from the equipment. The invention couples two chemical processes of smoldering and pyrolysis, reduces energy consumption and improves integration.

Owner:HUAZHONG UNIV OF SCI & TECH

Controlled rolling and cooling method for PSB830 fine rolled threaded steel

InactiveCN108971242AControl cooling temperatureRaise the slow temperatureTemperature control deviceWork treatment devicesSurface layerMetallurgy

The invention discloses a controlled rolling and cooling method for PSB830 fine rolled threaded steel. The controlled rolling and cooling method comprises the steps that (1) a PSB830 steel billet is heated and then is subjected to rough rolling, intermediate rolling and finish rolling in sequence; (2) the rolled PSB830 steel is subjected to through-water cooling through a first through-water cooling area, a second through-water cooling area, a third through-water cooling area, a fourth through-water cooling area and a fifth through-water cooling area in sequence; and (3) air cooling is conducted after tempering, the water pressure of cooling water in the first through-water cooling area is 0.7-1.1 MPa, the water pressure of the second through-water cooling area is 0.8-1.2 MPa, the water pressure of the third through-water cooling area is 1.0-1.4 MPa, the water pressure of the fourth through-water cooling area is 1.0-1.4 MPa, and the water pressure of the fifth through-water cooling area is 0.7-1.1 MPa. The effects that a surface layer quenching martensitic structure is effectively avoided, transformation of the structure type is achieved, and meanwhile, good uniformity of the surface layer and the core temperature is ensured are achieved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Plastic film production process

The invention relates to a plastic and rubber production process, in particular to a plastic film production process. The plastic film production process is characterized by comprising the following technical steps that (1) raw materials are screened, specifically, plastic particles are screened with a screen of 20-200 meshes, and the plastic particles are polylactic acid particles; (2) melting is carried out, specifically, the target particles obtained after screening in the step (1) are added into a reactor, the temperature is controlled to be 170-190 DEG C, and the target particles are melted to be in a molten state under the stirring condition; (3) modification is carried out, specifically, a modified material is added into the molten liquid in the step (2) and evenly mixed with the molten liquid under the vacuum stirring condition, and the modified material is a mixture of magnesium aluminum hydrotalcite, ammonium polyphosphate and cobalt powder with the mixing ratio being 3:2:2; (4) extrusion casting is carried out, specifically, the mixed molten liquid in the step (3) is extruded by a T-shaped port film casting machine to form a molten film; and (5) cooling is carried out, specifically, the molten film extruded in the step (4) is tightly attached to a cooling roller to be cooled.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Method for treating and recycling tail gas produced during benzaldehyde production

ActiveCN106621695ASignificantly diluted displacementDilution displacementGas treatmentDispersed particle separationActivated carbonBenzaldehyde

The invention discloses a method for treating and recycling tail gas produced during benzaldehyde production. Benzaldehyde tail gas produced in a dibenzyl ether oxidizing process is subjected to the treatment of tail gas dilution, tail gas condensation, tail gas water washing and tail gas adsorption. The tail gas is introduced into a plurality of active carbon adsorption devices to perform multi-layer adsorption, thereby emitting purified tail gas without peculiar smell; steam resolution active carbon is adopted periodically for recycling, so that recycling of active carbon is realized, and the tail gas is adsorbed by the adsorption devices; meanwhile, active carbon in other adsorption devices is resolved and recycled, and the adsorption devices work alternatively, so that continuous adsorption of the adsorption devices is ensured, the working efficiency is increased, the production cost is lowered, and the problem of environmental influence caused by the tail gas is solved.

Owner:HUBEI GREENHOME MATERIALS TECH INC

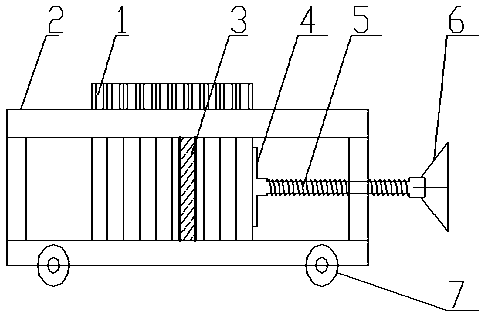

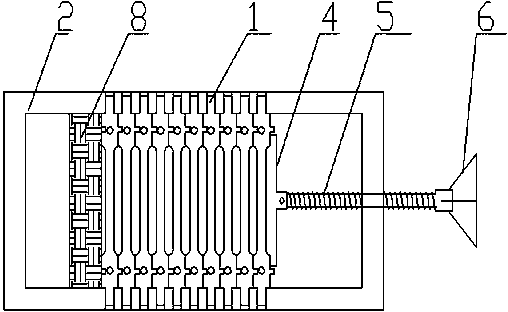

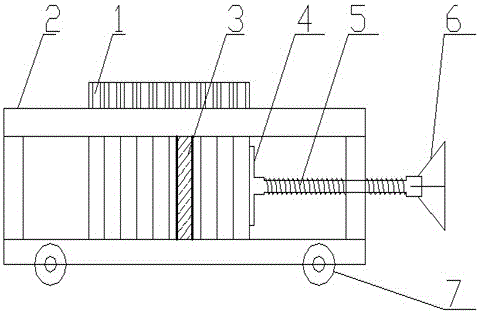

Bismuth ingot die

InactiveCN104275451AImprove ingot casting speed and production efficiencyImprove product qualityEngineeringBismuth preparation

A bismuth ingot die is composed of more than two die components and a casting frame. A casting cavity is formed between the die components. The casting frame comprises a support, a fixed beam, a retaining plate, a screw, a die pushing plate and a screw rotating ring. The fixed beam is arranged on a front frame rod and a rear frame rod of the support, the retaining plate is arranged on the frame rods at the top and the bottom of the support, the screw is arranged on the right side of the support, the left end of the screw is connected with the die pushing plate, the right side of the screw is connected with the screw rotating ring, and the die components are arranged on the support. The die components are fastened by pushing the die pushing plate via the screw. The bismuth ingot die has the advantages that ingot casting speed is increased, production efficiency and bismuth ingot quality are improved, several bismuth ingots can be cast at the same time, and the bismuth ingot die is simple in structure, low in cost and convenient to use.

Owner:耒阳市诚松有色金属再生有限公司

High-vacuum low-temperature crystallization equipment for potassium perchlorate production and using method thereof

InactiveCN111939590AClear in timePlay the role of stirringPerchloratesSolution crystallizationPhysical chemistryPotassium chlorate

The invention discloses high-vacuum low-temperature crystallization equipment for potassium perchlorate production, which belongs to the field of chemical equipment and comprises a tank body, a vacuumevaporation area, a crystallization area and a settling separation area are sequentially arranged in the tank body from top to bottom, and the vacuum evaporation area communicates with the crystallization area through a spraying device. The crystallization area communicates with the settling separation area through a material releasing pipe; a stirring shaft penetrating through the vacuum evaporation area and the crystallization area and a first driving device used for driving the stirring shaft to rotate are arranged in the tank body; a first stirring blade and a second stirring blade are arranged on the stirring shaft, hollow cavities which communicate with each other are formed in the stirring shaft and the second stirring blade in the crystallization area, air guide pipes connected with a cooling air source are arranged in the hollow cavities, and the hollow cavities are filled with cooling liquid; an air injection assembly is arranged on the second stirring blade; and the evaporation speed of the vacuum evaporation area is high, the production efficiency is improved, and the invention further discloses a using method of the equipment.

Owner:江西永宁科技有限责任公司

Multifunctional flushing device for nursing in obstetrics and gynecology department

ActiveCN113713200AControl cooling temperatureEasy to operateCannulasEnemata/irrigatorsEngineeringGynecology department

The invention relates to the technical field of medical instruments, in particular to a multifunctional flushing device for nursing in the obstetrics and gynecology department. The multifunctional flushing device can prevent a patient from squatting or sitting and lying during flushing, reduce the tearing phenomenon and automatically clean and blow-dry the private parts of the patient, traditional manual cleaning and towel wiping are replaced, so that breeding and spreading of germs are reduced, and the working efficiency and reliability of the device are improved. The multifunctional flushing device comprises a bottom plate, a water tank, heating pipes, a suction pump, a cooling box body, a cooling pipe, a hose, a fixing plate, a supporting column, a soft cushion, a backrest, two sets of supporting bent rods, two sets of damping shaft sleeves, a rotating pipe, a fixing pipe, a shower head, a rotary knob, a steam sterilization assembly, a drying assembly, a sewage collection assembly, an adjusting assembly and a cooling circulation assembly. The sewage collection assembly is mounted on the right part of the upper end face of the bottom plate, the water tank is fixedly mounted on the left part of the upper end face of the bottom plate, the steam sterilization assembly is mounted on the upper end face of the water tank in a communicating mode, and the heating pipes are laid in the bottom plate.

Owner:莒县人民医院

A chemical fiber spinning texturing device

ActiveCN112011866BImprove the lubrication effectShorten the production cycleLiquid/gas/vapor removalTextile treatment machine arrangementsYarnPolymer science

The invention belongs to the technical field of textile machinery, and particularly relates to a chemical fiber spinning elasticizing device which is characterized by comprising a yarn feeding system,a heating system, a cooling system, a false twister, an oiling system and a winding device which are arranged in sequence; the yarn feeding system is used for placing silk thread raw material and unwinding silk threads; the heating system is used for heating the unwound silk threads; the cooling system is used for cooling high-temperature silk threads; the false twister is used for false twistingof the silk threads; the oiling system is used for oiling and lubricating the silk threads; the winding device is used for winding the oiled silk threads; and an elasticizing device further comprisesa dyeing system which is located between the yarn feeding system and the heating system and used for dyeing the unwound silk yarn. Dyeing can be completed while the silk threads are elasticized, so that the production period is shortened, and the production cost is reduced.

Owner:诸暨市双冠化纤有限公司

A mold cooler

The invention discloses a mold radiator. The invention realizes the cooling of the mold or the metal workpiece through a clamping mechanism made of flexible metal and a circulating liquid cooling system, and realizes the clamping of the mold through the flexible metal arranged on both sides of the composite body. And combination, because of its own physical properties, flexible metal can tightly combine molds of different widths and edge shapes, and the liquid cooling system installed at the bottom and around, through the adjustment of the flow rate of the heat transfer liquid of the liquid cooling system and heat dissipation The adjustment of the device probability can conveniently set the cooling parameters of the mold or workpiece, so that the workpiece or mold can be cooled uniformly at a suitable temperature.

Owner:WUJIANG LILI JIANXING CASTING FACTORY

Method for producing aromatics by mixing light hydrocarbons

ActiveCN108017493BReduce hydrogen contentGuaranteed selectivityHydrocarbon by hydrocarbon condensationDehydrogenationPhysical chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

A bismuth ingot mold

A bismuth ingot die is composed of more than two die components and a casting frame. A casting cavity is formed between the die components. The casting frame comprises a support, a fixed beam, a retaining plate, a screw, a die pushing plate and a screw rotating ring. The fixed beam is arranged on a front frame rod and a rear frame rod of the support, the retaining plate is arranged on the frame rods at the top and the bottom of the support, the screw is arranged on the right side of the support, the left end of the screw is connected with the die pushing plate, the right side of the screw is connected with the screw rotating ring, and the die components are arranged on the support. The die components are fastened by pushing the die pushing plate via the screw. The bismuth ingot die has the advantages that ingot casting speed is increased, production efficiency and bismuth ingot quality are improved, several bismuth ingots can be cast at the same time, and the bismuth ingot die is simple in structure, low in cost and convenient to use.

Owner:耒阳市诚松有色金属再生有限公司

Method for preparing aromatic hydrocarbon from mixed light hydrocarbon

ActiveCN108017494AReduce contentReduce methane contentLiquid hydrocarbon mixtures productionHydrocarbon by hydrocarbon condensationHydrogenGas phase

The invention relates to a method for preparing an aromatic hydrocarbon from a mixed light hydrocarbon. In the prior art, the energy consumption for recycling ethylene in the mixed light hydrocarbon raw material is high. A purpose of the present invention is mainly to solve the problem in the prior art. The technical scheme of the present invention comprises that 1) a light hydrocarbon raw material is subjected to cooling separation to obtain hydrogen-rich gas and a hydrogen-depleted liquid; 2) the hydrogen-rich gas is separated by a methane removing unit to obtain methane-hydrogen mixing gasand a methane removing stream; 3) the hydrogen-depleted liquid is subjected to rectification separation to obtain a heavy removing stream and a first aromatic hydrocarbon stream; 4) the methane removing stream and the heavy removing stream are converged, and the converged stream is fed into a light hydrocarbon aromatization reactor, and is converted into an aromatization product; 5) the aromatization product is subjected to cooing separation to obtain a gas phase product and a second aromatic hydrocarbon stream; 6) the gas phase product is compressed, and the compressed product is fed into anethane removing tower to obtain ethane gas and a circulation stream; and 7) the circulation stream returns the light hydrocarbon aromatization reactor. With the technical scheme, the problem in the prior art is well solved. The method of the present invention can be used in the industrial production of light hydrocarbon aromatization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for sampling special organic gas in flue gas

The invention relates to a method for sampling a special organic gas in a flue gas. The method comprises the following steps: allowing the flue gas to enter through the inner tube of a sleeve from the inlet of a sampling gun, adjusting the temperature, intercepting particles by a filter cylinder, condensing the flue gas by a condensation device, allowing the obtained condensate liquid into a cooling and liquid removing bottle, trapping the cooled and dried gas by a trapping bottle to remove dioxin substances, further collecting by a washing bottle, and allowing the gas to go through a dryer, a gas flow meter, a thermometer and a sampling pump to complete the whole sampling process. A whole flue gas sampling pipeline adopting a full glass structure has the advantages of corrosion resistance, no chemical reaction, convenient cleaning, and prevention of the loss caused by the adsorption or contamination of the acquired sample by the wall surface of a tube wall utensil; the jacket glass sampling gun can heat or cool the acquired flue gas by hot or cold air entering through an external layer; the condensate liquid collection bottle having scales can rapidly judge whether there is severe gas leakage in the sampling process or not; and the flue gas is cooled, condensed, and dehydrated, and then adsorbs a sampling agent to guarantee a high sampling efficiency.

Owner:TONGJI UNIV

A heat treatment method for re-sorbitizing steel wire or steel strip

ActiveCN105506234BSmall sizeControl cooling temperatureFurnace typesHeat treatment furnacesMartensite transformationRoom temperature

The invention discloses a heat treatment method for re-sorbitizing steel wires or steel strips. The heat treatment method comprises the following steps: heating the steel wires or steel strips to austenite temperature, quickly cooling the austenitized isothermal steel wires or steel strips to the temperature range more than the martenitic transformation point of a material or the temperature range of 200-450 DGE C, then sending the steel wires or steel strips into an insulation sleeve for standing and heat preservation, and thus completing sorbite phase transformation; controlling the temperature of the sleeve to any temperature point between the room temperature and 500 DEG C. The method for sorbitizing the steel wires or steel strips does not need isothermal equipment of lead bath and salt bath and does not need special isothermal devices. The cool temperature is controlled by changing the cooling speed, and therefore the size of sorbite structures is controlled.

Owner:GUIZHOU GUDA CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com