Determining system for original granularity of sintering mixture

A sintering mixture and particle size measurement technology, which is applied in particle size analysis, measuring devices, and analysis materials, etc., can solve the problem of unsuitable large-scale freezing treatment dosage and safe operation, poor repeatability of mixture particle measurement results, and labor intensity of manual sample delivery. Large and other problems, to achieve the effect of improving the conversion efficiency of cold air, prolonging the freezing time, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

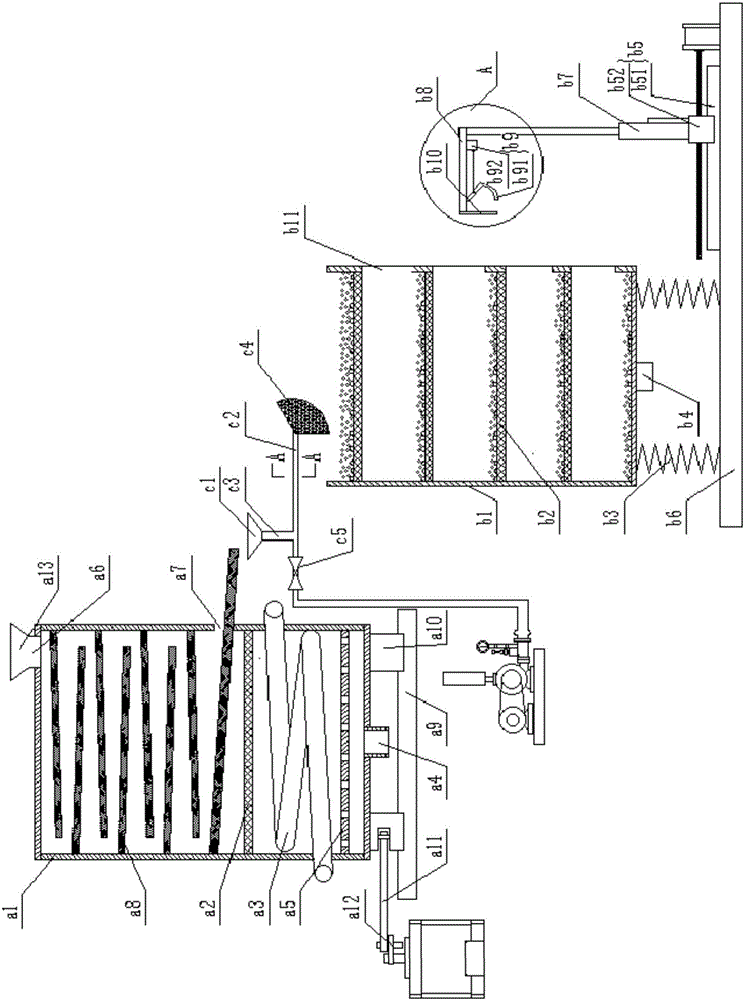

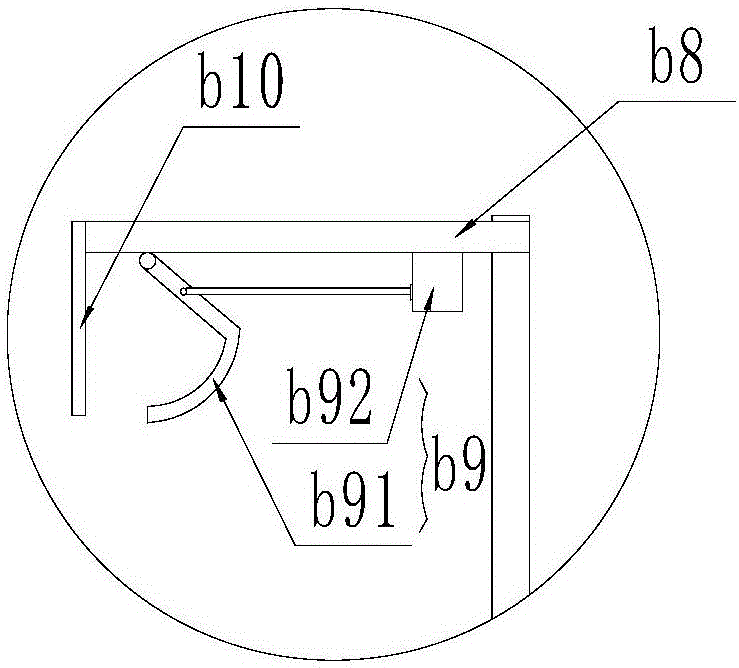

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1As shown in -6, a system for measuring the original particle size of a sintered mixture includes a cooling device a, a screening device b, a detection sample delivery device c and a microscope, wherein the outlet of the cooling device a is connected to the detection sample delivery device c The feeding port is connected, the detection and sample delivery device c is located between the cooling device a and the screening device b, and the sintered mixture passes through the cooling device a, detection and sample delivery device c and screening device b in sequence, and is sent to The microscope is used for detection and observation;

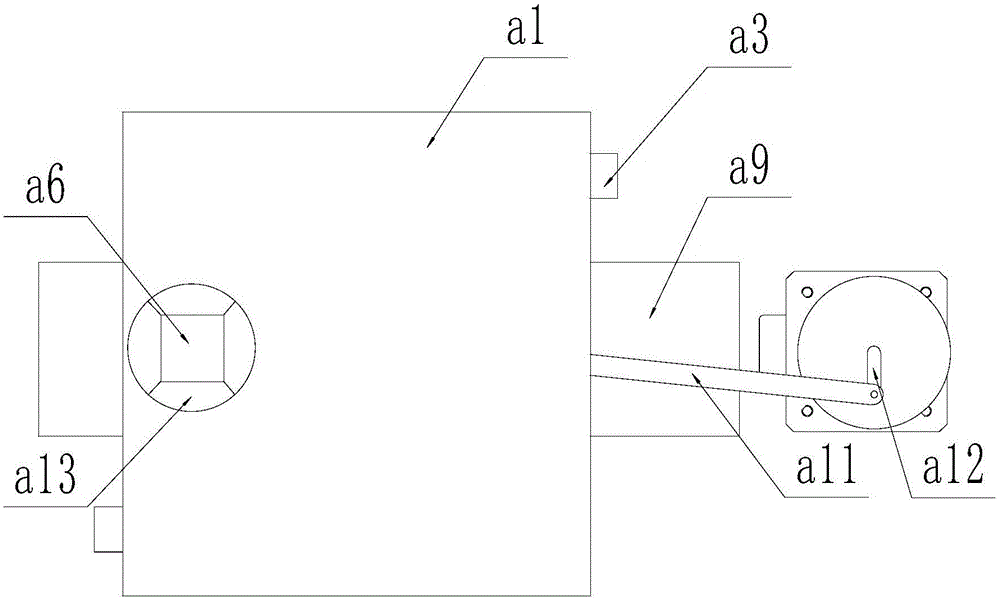

[0034] The cooling device a includes a cooling box body a1, and a breatha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com