Integrated device for testing stability of phase change thermal storage material as well as method

A phase change heat storage material and technology of heat storage materials, which are applied in the field of performance testing of phase change heat storage materials, can solve the problem of no strict control of the test gas atmosphere, no cycle stability of the phase change heat storage material, thermal stability and chemical stability. performance, and the problems of constant temperature heating and constant temperature cooling are not realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

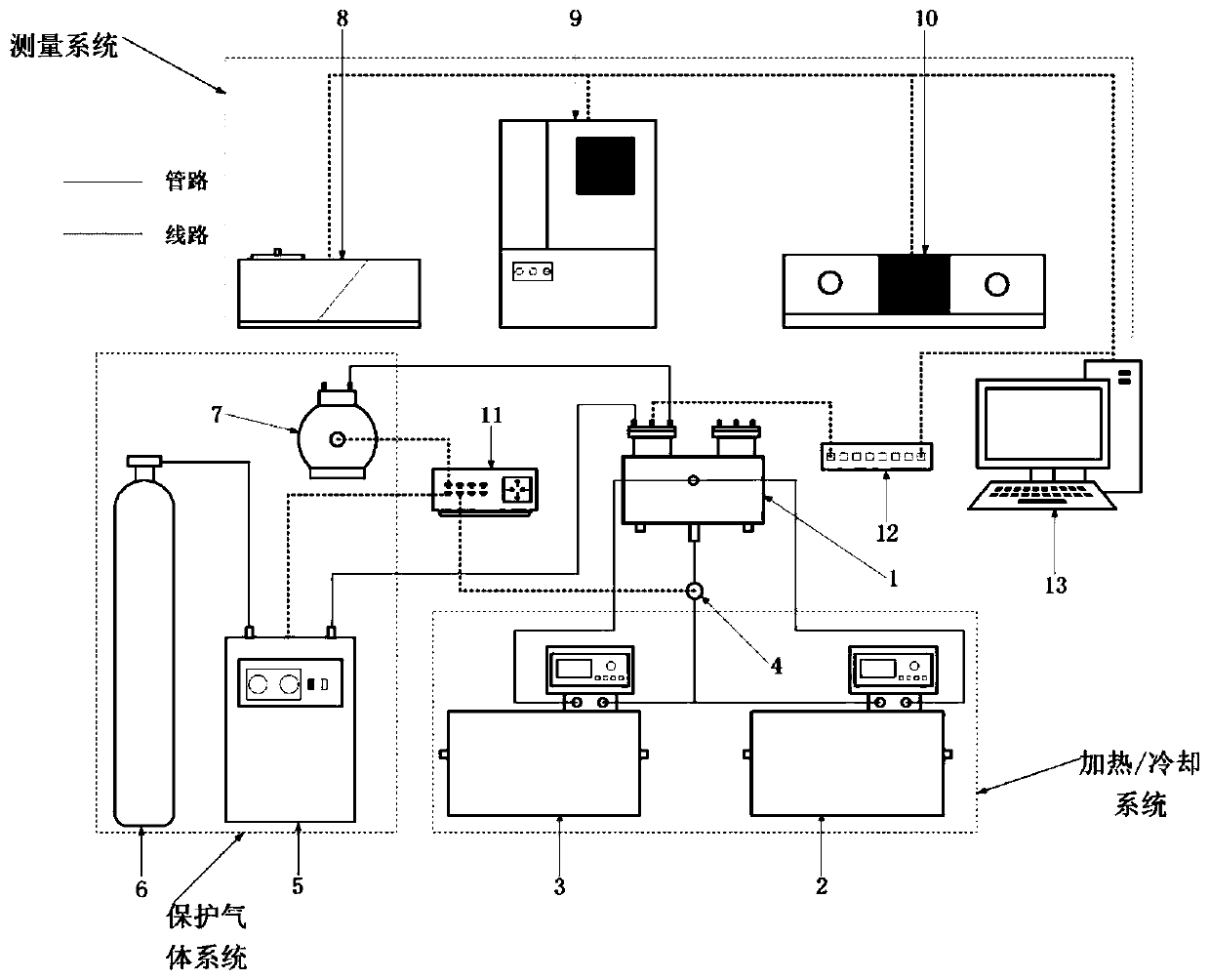

[0029] Such as figure 1 As shown, in a specific embodiment of the present invention, an integrated device for testing the stability of phase change heat storage materials is characterized by including a reactor 1, a heating oil bath 2, a cooling oil bath 3, a solenoid valve 4, and a protective gas Circulating pump 5, protective gas tank 6, vacuum pump 7, DSC differential scanning calorimeter 8, X-ray polycrystalline diffractometer 9, infrared spectrometer 10, console 11, temperature acquisition card 12 and data acquisition and processing system 13;

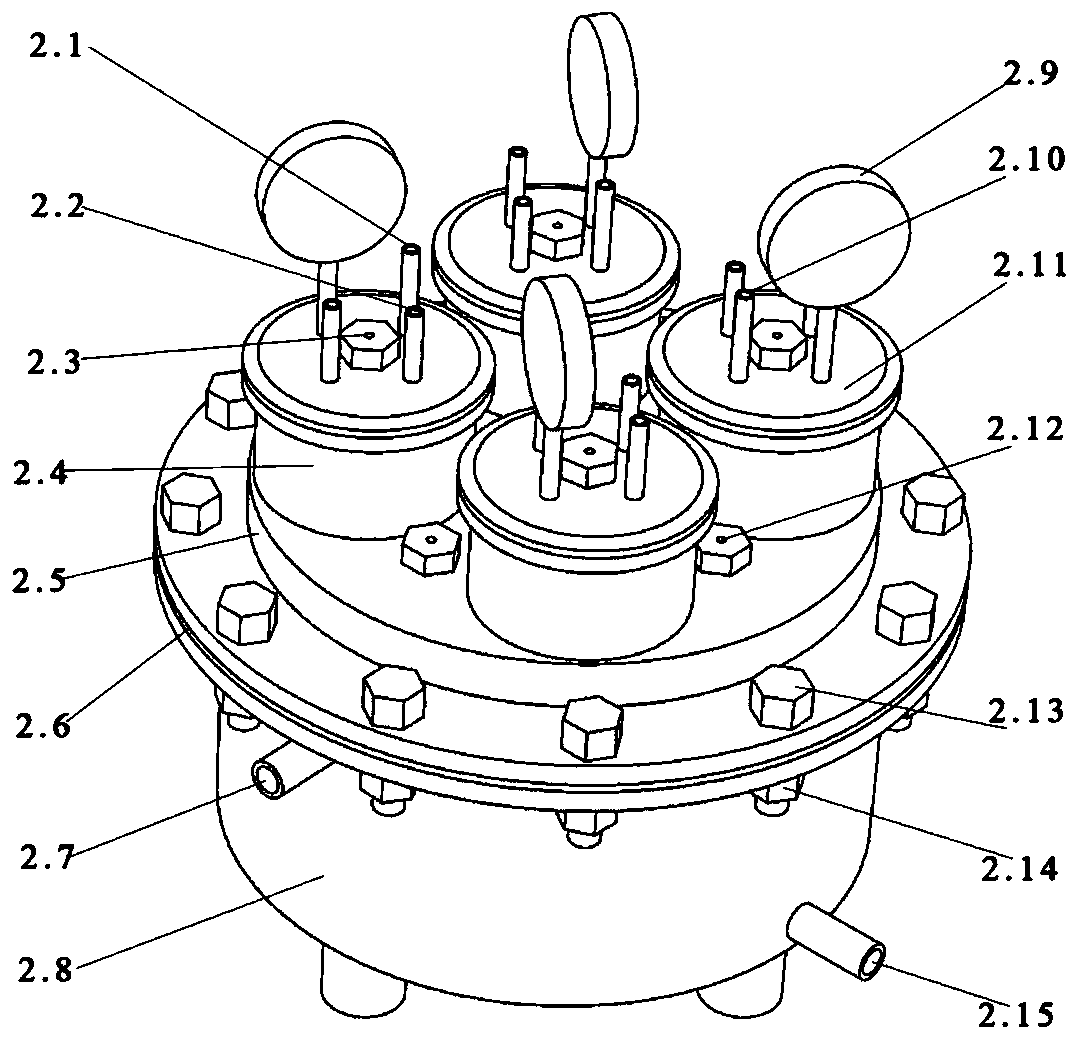

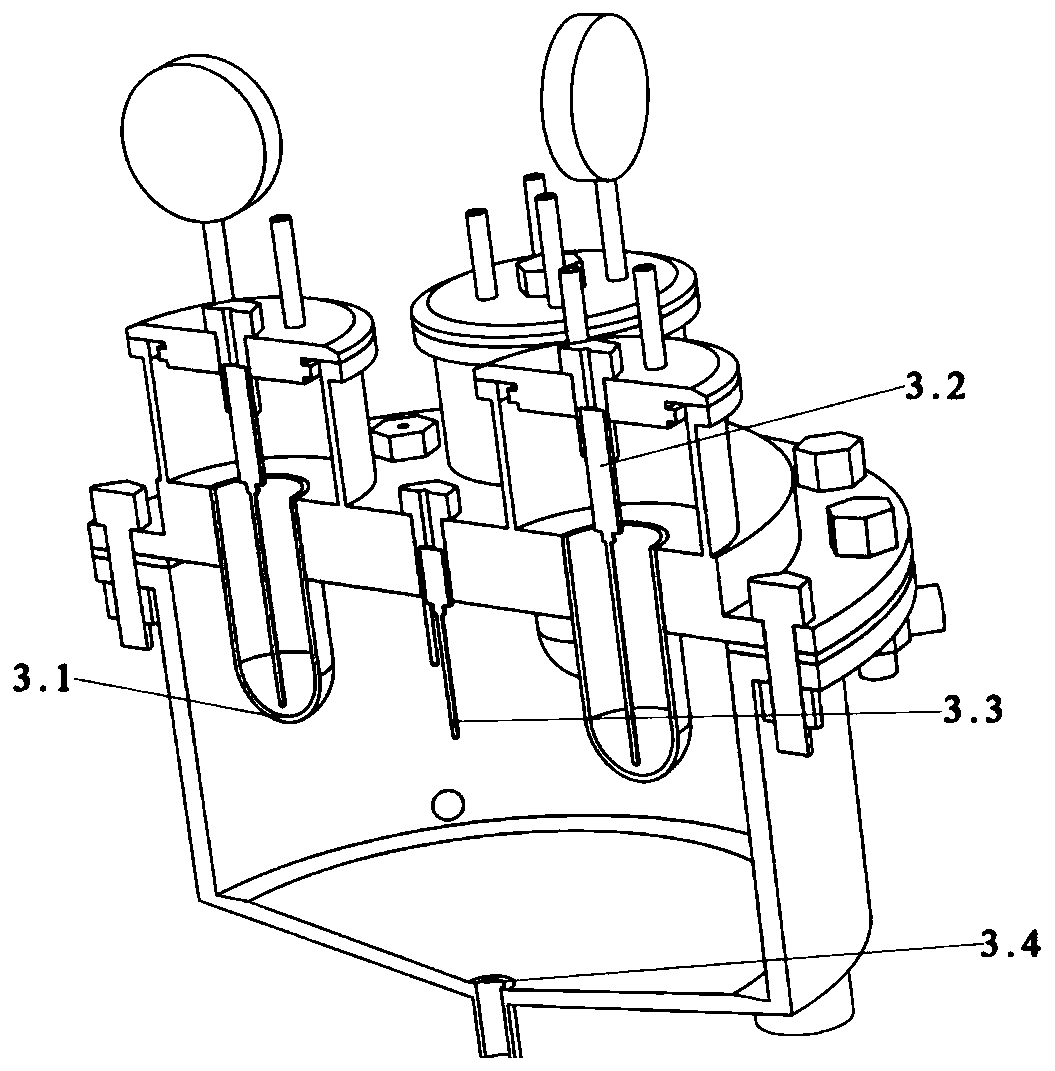

[0030] The reaction kettle 1 is provided with several vacuum chambers. The bottom of the vacuum chamber is provided with a test tube for loading phase change heat storage materials, and the test tubes are loaded with phase change heat storage materials; the heating oil bath 2 and cooling oil bath 3 are connected to the electromagnetic through the pipeline The valve 4 is connected; the solenoid valve 4 is connected to the oil chamber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com