High-resolution high-temperature metallographic structure analyzer

A metallographic structure, high-resolution technology, applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of uncontrollable cooling speed, uncontrollable heating temperature, single function, etc., to achieve a wide range of applications, The effect of preventing oxidation and expanding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

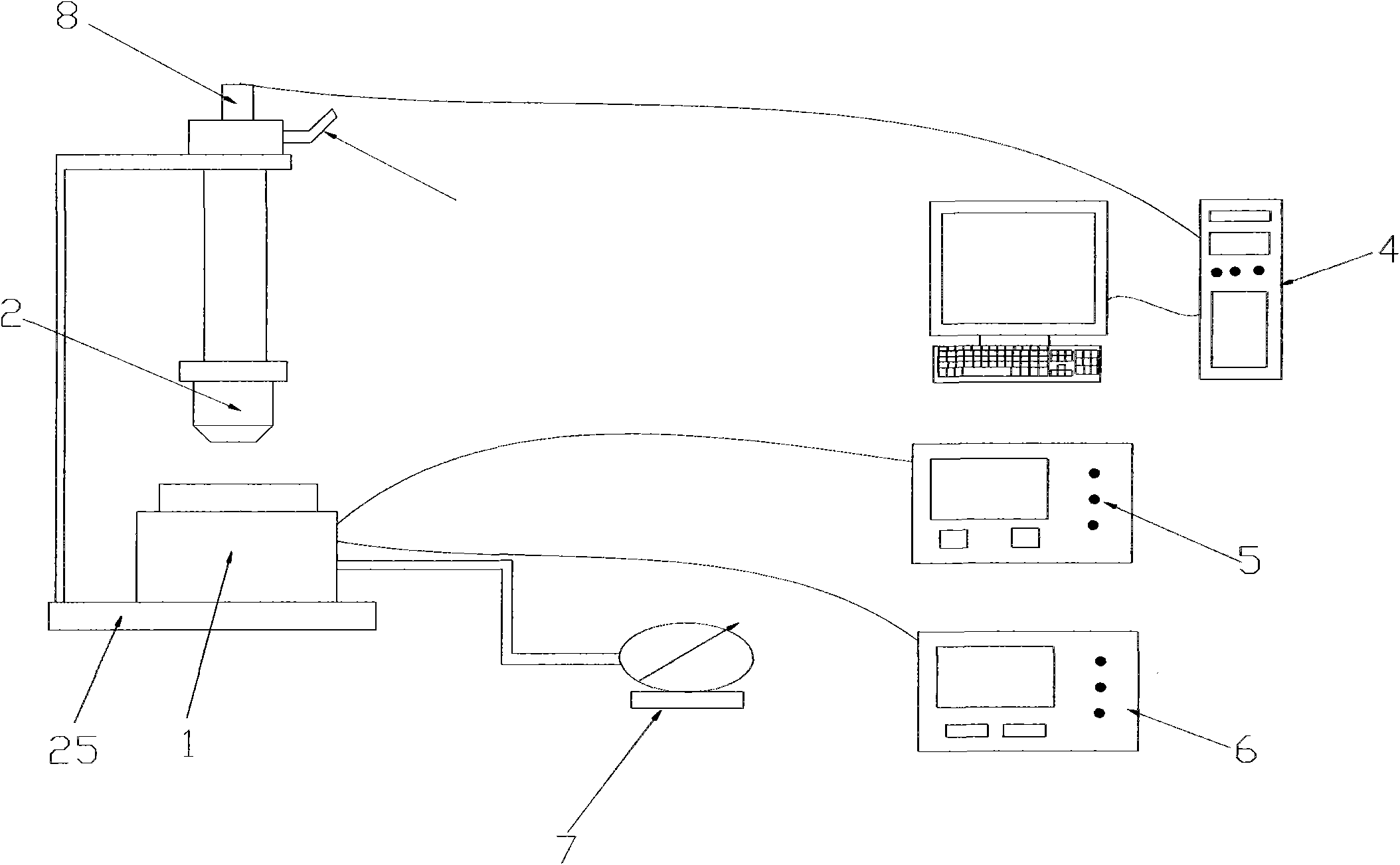

[0022] The metallographic microscope adopts the long focal length objective lens 2, and the metallographic microscope is provided with a digital camera 8, the camera of the digital camera 8 is connected with the lens barrel, and forms an optical path perpendicular to the sample plane, and the sample can be observed by adjusting the focal length of the camera The magnification of the digital camera device 8 is adjusted, the signal output end of the digital camera device 8 is connected to the image signal input end of the microcomputer 4, and the microcomputer is embedded with an image analysis system, and the image analysis system mainly includes Shanghai Changfang Optical Instrument Co., Ltd. CF-2000 A series of metallographic structure analysis software and other tissue analysis software.

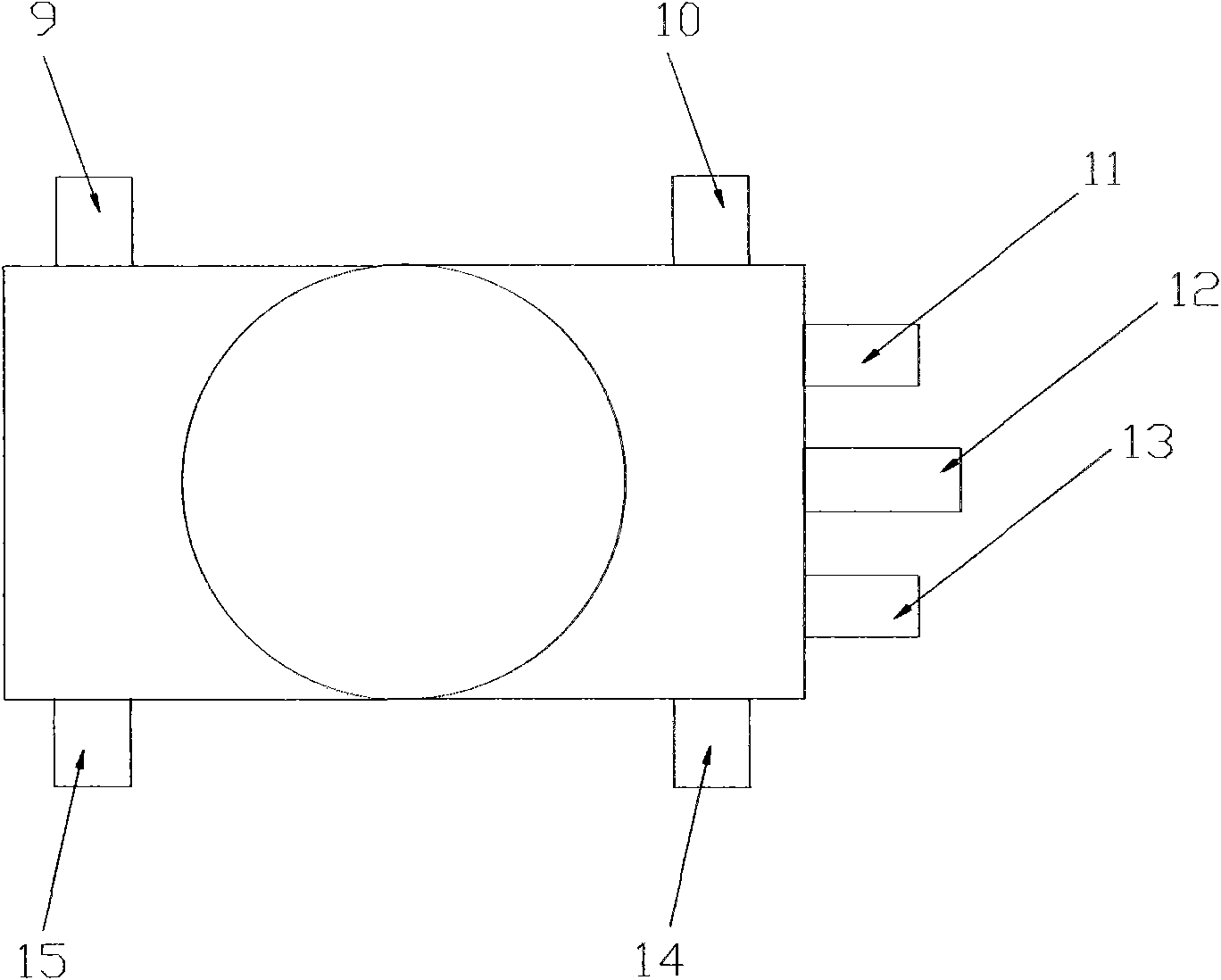

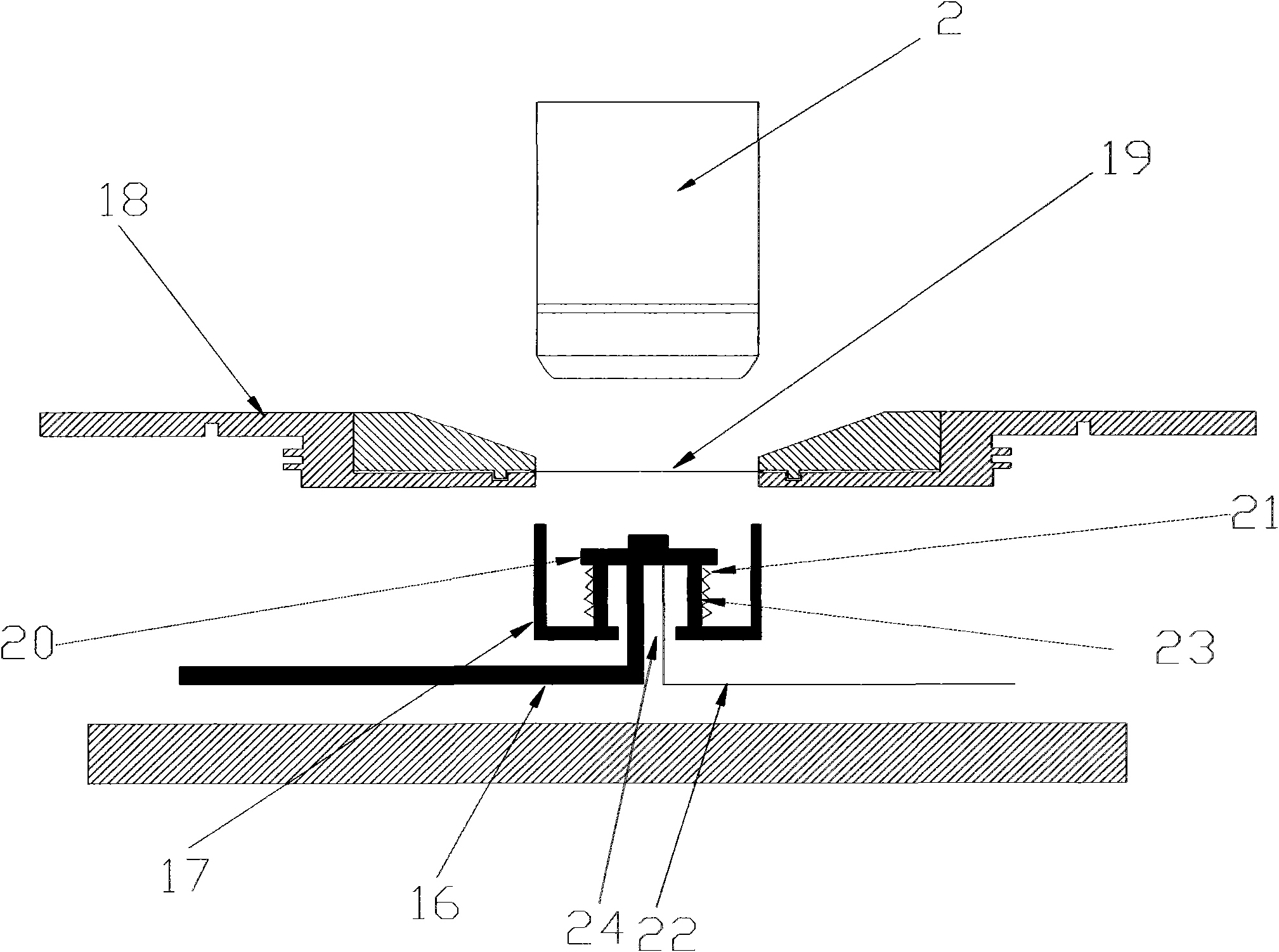

[0023] The hot stage 1 is fixed on the base 25 of the metallographic microscope. The left and right ends of the rear side on the outer wall of the hot stage 1 are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com