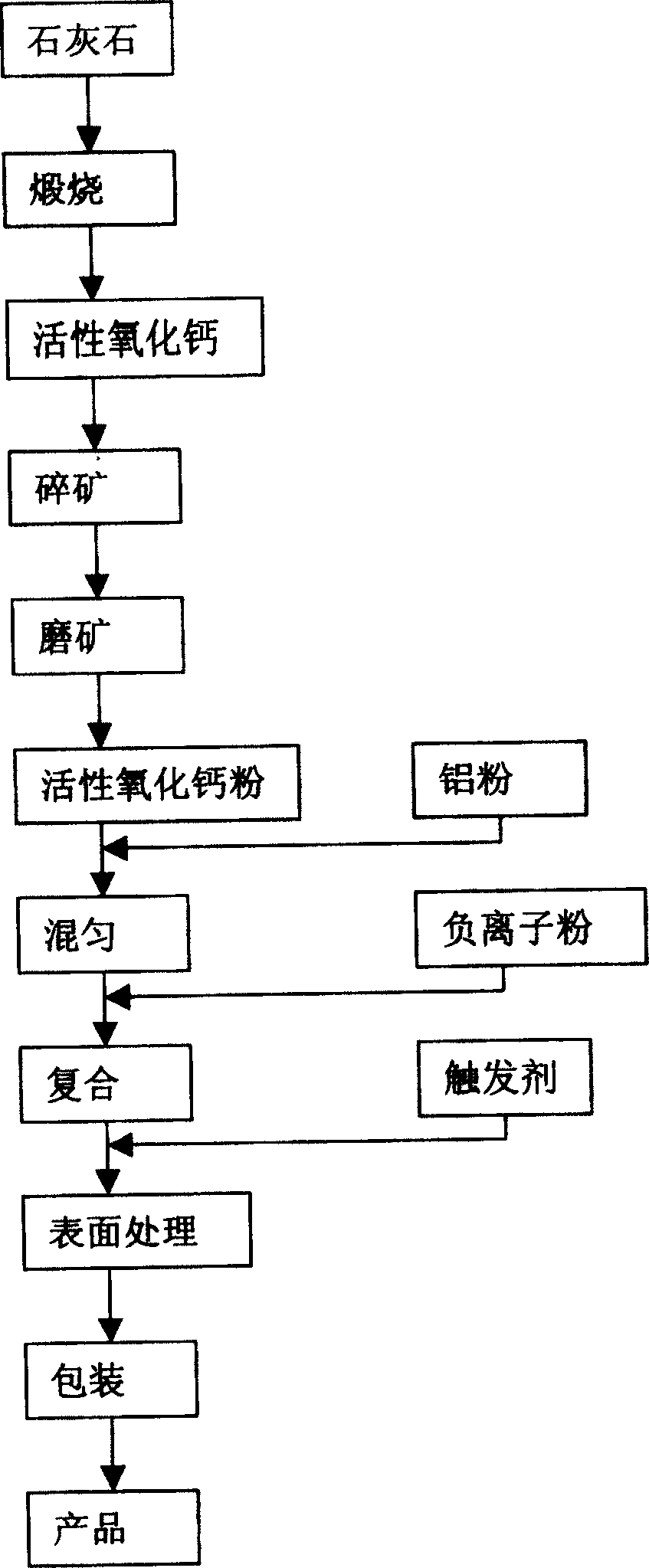

Preparation process of mineral heating agent

A technology of exothermic agents and minerals, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of short temperature duration, slow heating rate of exothermic agents, and high heating temperature, and achieve long duration and fast heating rate. , the effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]First, block limestone (with a particle size range of 100-300mm) is calcined in a muffle furnace at 950°C for 2.5 hours to produce activated calcium oxide; then, the activated calcium oxide is crushed to a size below 5mm by a jaw crusher; The activated calcium oxide is ground to a particle size of ≤0.076mm with a Raymond mill to obtain activated calcium oxide powder; then, the activated calcium oxide powder and aluminum powder with a particle size of ≤0.076mm are mixed at room temperature at a low speed (600r / min) and mix for 1 min; then add negative ion powder, heat up to 45°C and compound for 3 minutes; pass the compounded mixed powder and trigger agent through high-energy mechanical force and shear force in a universal pulverizer under high-speed conditions (1000r / min) , impact force, etc., make the mixed powder get surface modification 20S, and then pack it to form a product. Trigger agent required particle size: ≤0.15mm; composed of caustic soda (NaOH purity above ...

Embodiment 2

[0049] First, block limestone (with a particle size range of 100-300mm) is calcined in a muffle furnace at 1000°C for 2 hours to produce activated calcium oxide; then, the activated calcium oxide is crushed to a size below 5mm by a jaw crusher; The activated calcium oxide is ground to a particle size of ≤0.076mm with a Raymond mill to obtain activated calcium oxide powder; then, the activated calcium oxide powder and aluminum powder with a particle size of ≤0.076mm are mixed in a heat mixer at a low speed (200r / min) and mix for 5 minutes; then add negative ion powder, heat up to 50°C and compound for 1 minute; pass the compounded mixed powder and trigger agent through high-energy mechanical force and shear force in a universal pulverizer under high-speed conditions (1200r / min). , impact force, etc., make the mixed powder get surface modification 15S, and then pack it to form a product. Trigger agent required particle size: ≤0.15mm; composed of caustic soda (NaOH purity above ...

Embodiment 3

[0052] First, block limestone (with a particle size range of 100-300mm) is calcined in a muffle furnace at 900°C for 2 hours to produce activated calcium oxide; then, the activated calcium oxide is crushed to a size below 5mm by a jaw crusher; The activated calcium oxide is ground to a particle size of ≤0.076mm with a Raymond mill to obtain activated calcium oxide powder; then, the activated calcium oxide powder and aluminum powder with a particle size of ≤0.076mm are mixed in a heat mixer at a low speed (400r / min) and mix for 0.5min; then add negative ion powder, heat up to 40°C and compound for 5 minutes; pass the compounded mixed powder and trigger agent under high-speed conditions (800r / min) in a universal pulverizer through high-energy mechanical force, shear Under the action of compound forces such as force and impact force, the mixed powder is surface-modified for 30S, and then packaged to form a product. Trigger agent required particle size: ≤0.15mm; composed of caust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com