Patents

Literature

32results about How to "Control the heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel

ActiveCN102676766AReduce plasticityReduce toughnessHeat treatment process controlFragilityPerformance index

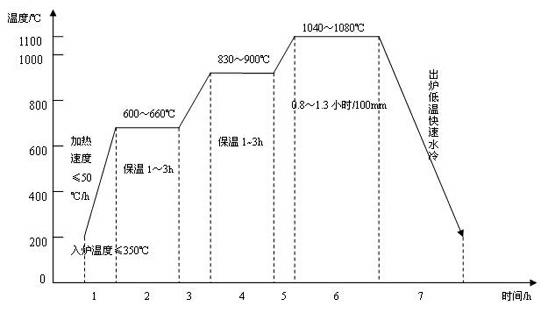

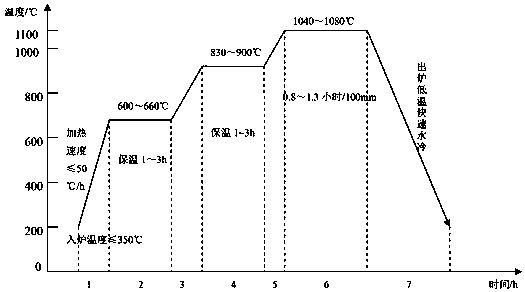

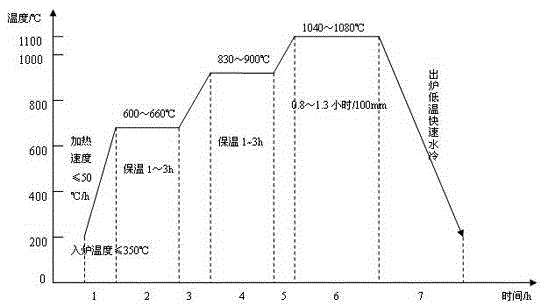

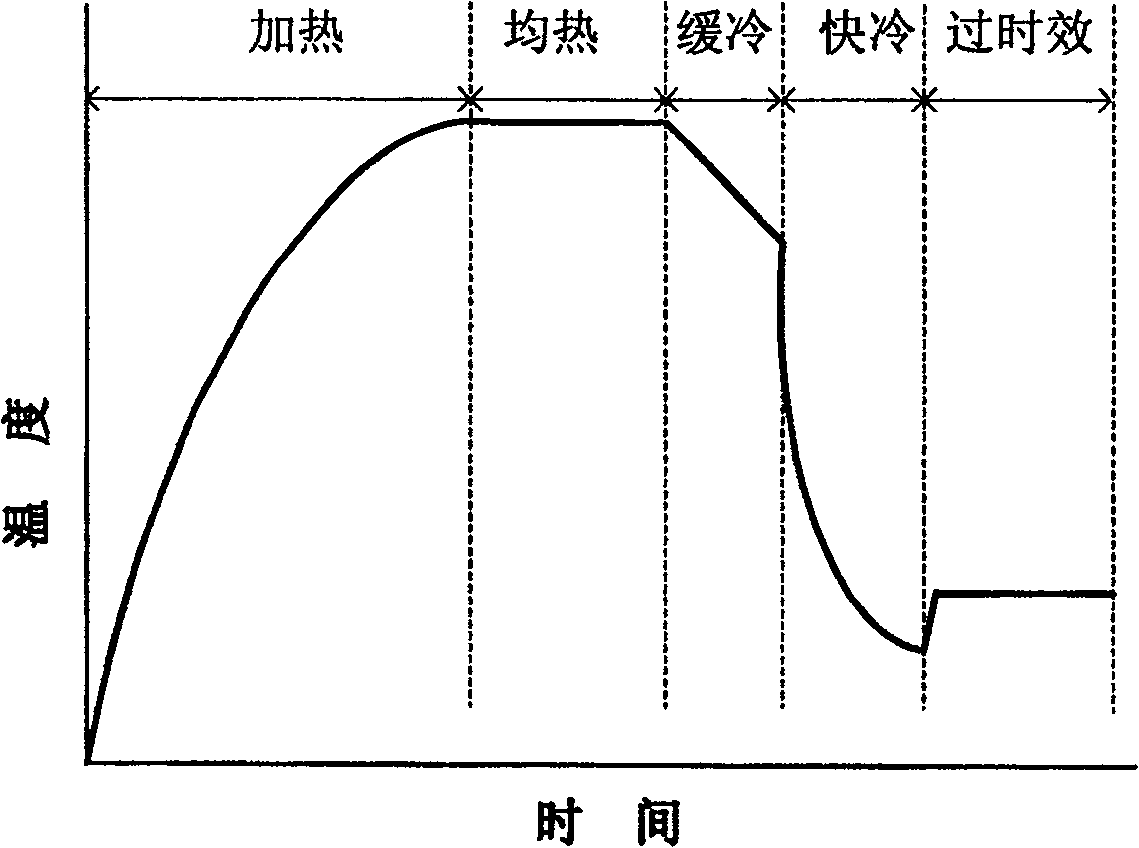

The invention belongs to the technical field of production of duplex stainless steel products used at low temperature and particularly relates to a thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel with high requirements for performance indexes. The thermal treatment method comprises the steps: feeding forged austenite-ferrite stainless steel into a furnace at the feeding temperature of not greater than 350 DEG C and performing twice preheating; performing solution treatment; performing cooling, feeding the austenite-ferrite stainless steel into clear water with the initial temperature smaller than 10 DEG C, and retaining the austenite-ferrite stainless steel for 20 minutes at the cooling speed of 4-6 seconds / mm. An austenite-ferrite stainless steel solution treatment process comprises the steps of (1) heating, namely controlling heating speed, preheating temperature, solid solution temperature and retaining time at a low-temperature section, reducing thermal stress and simultaneously obtaining good duplex structural proportion and (2) cooling, namely adopting a quick low-temperature long-time water-cooling mode to prevent precipitation due to fragility phase and remarkably reducing the plasticity and the toughness of the steel.

Owner:HENAN ZHONGYUAN HEAVY FORGING

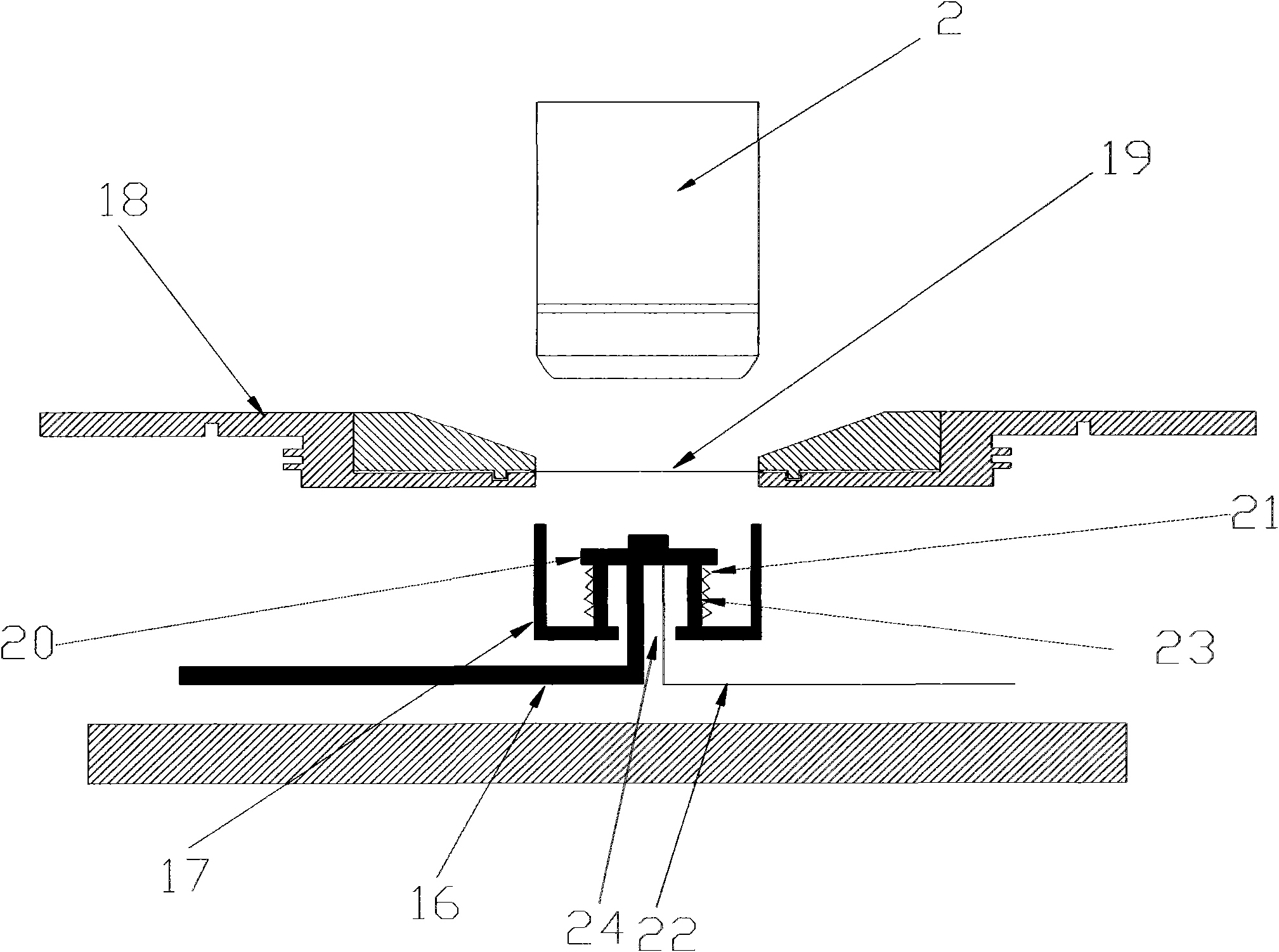

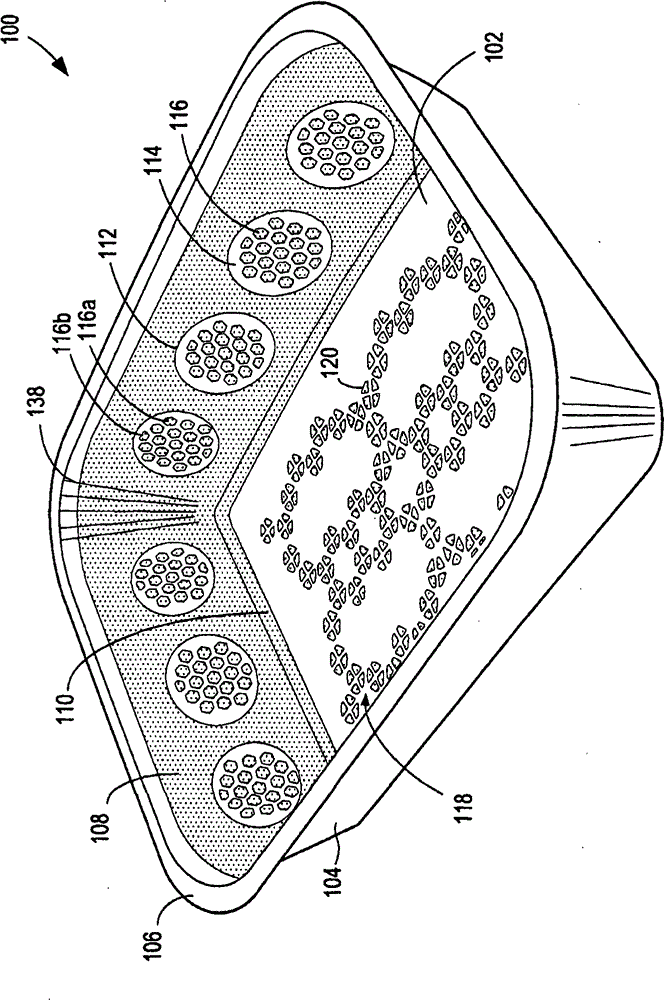

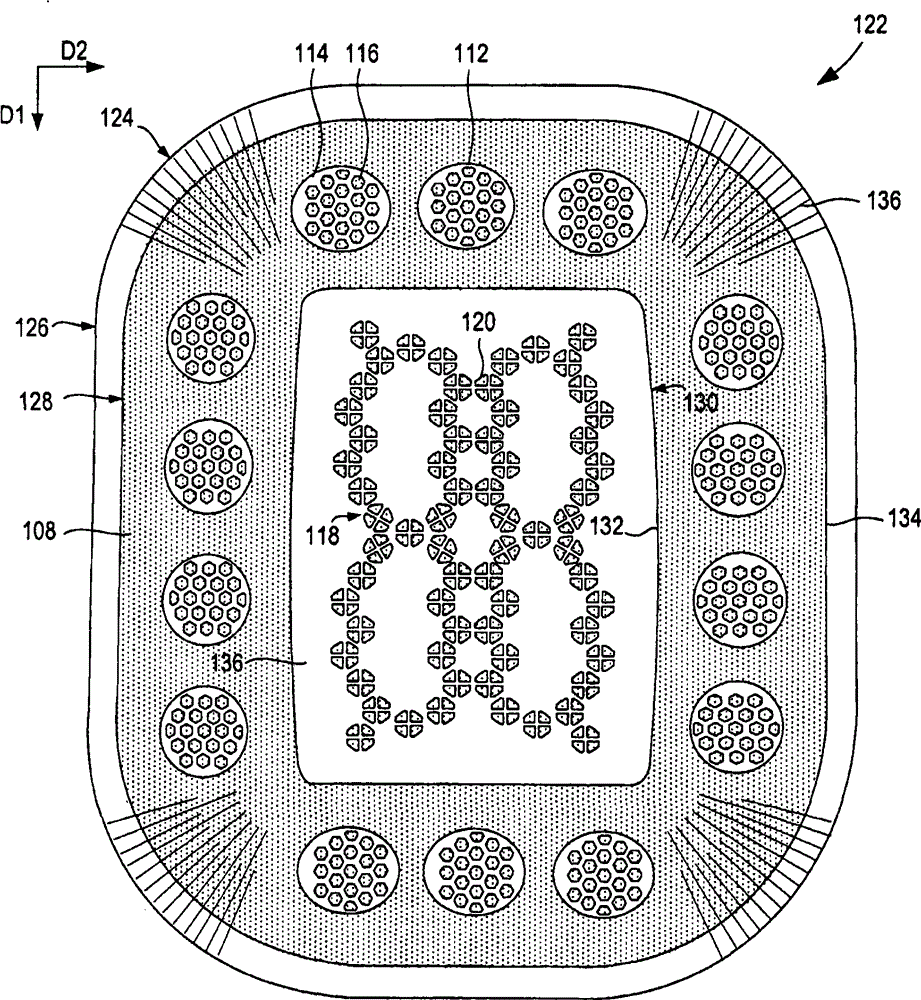

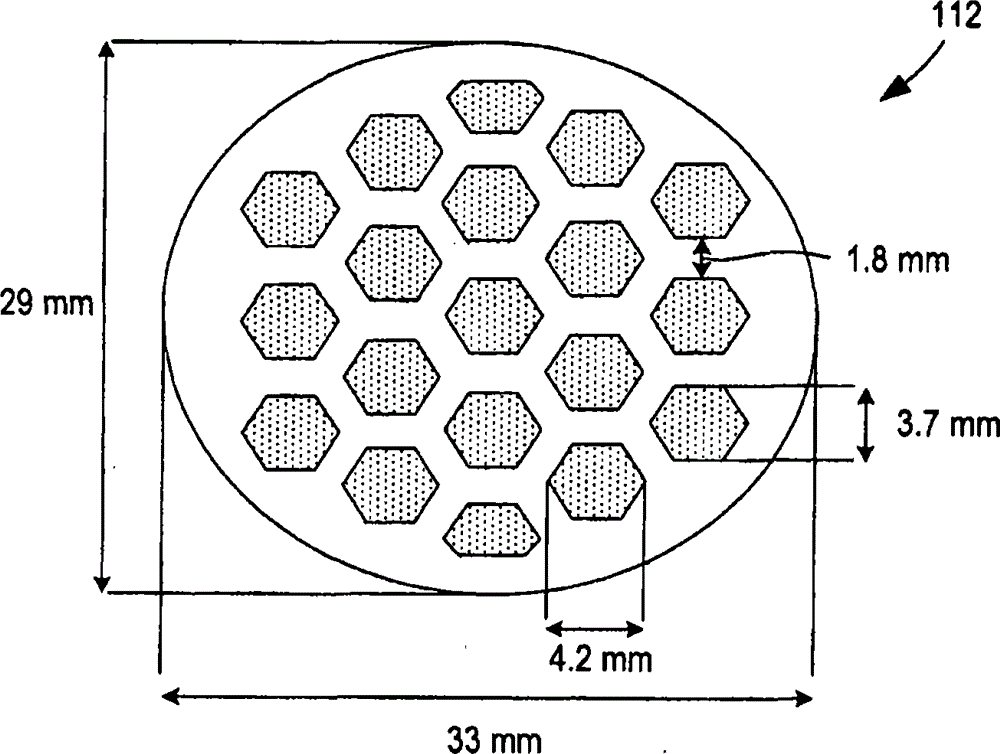

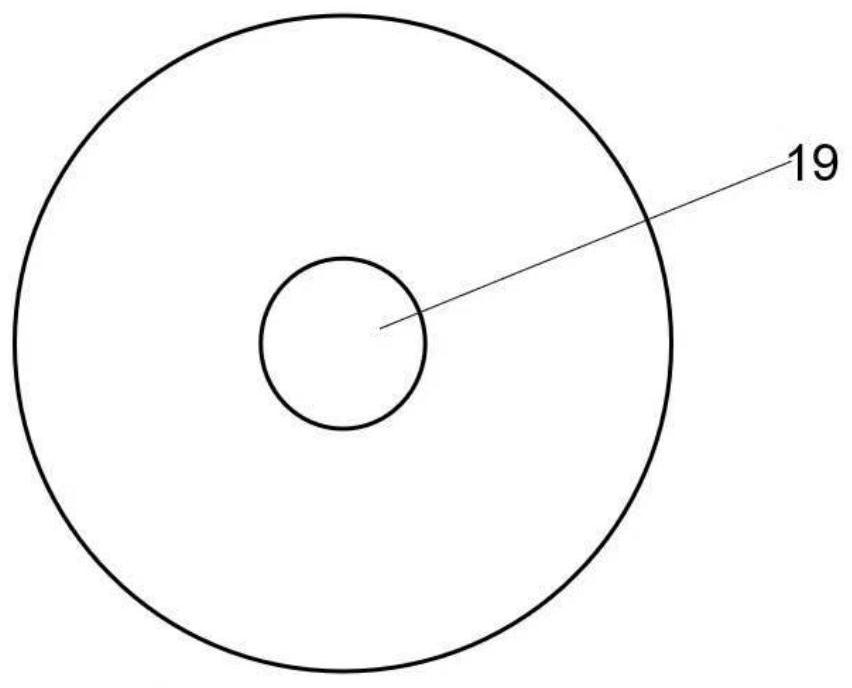

Even heating microwavable container

InactiveCN101636620AControl the heating rateMinimize scorchingDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenProcess engineering

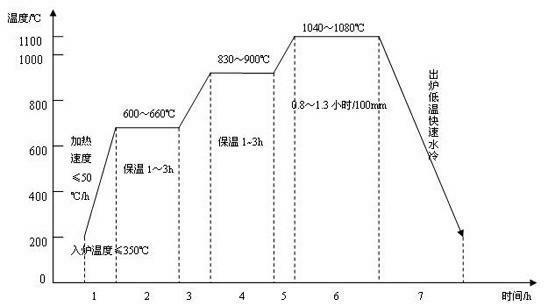

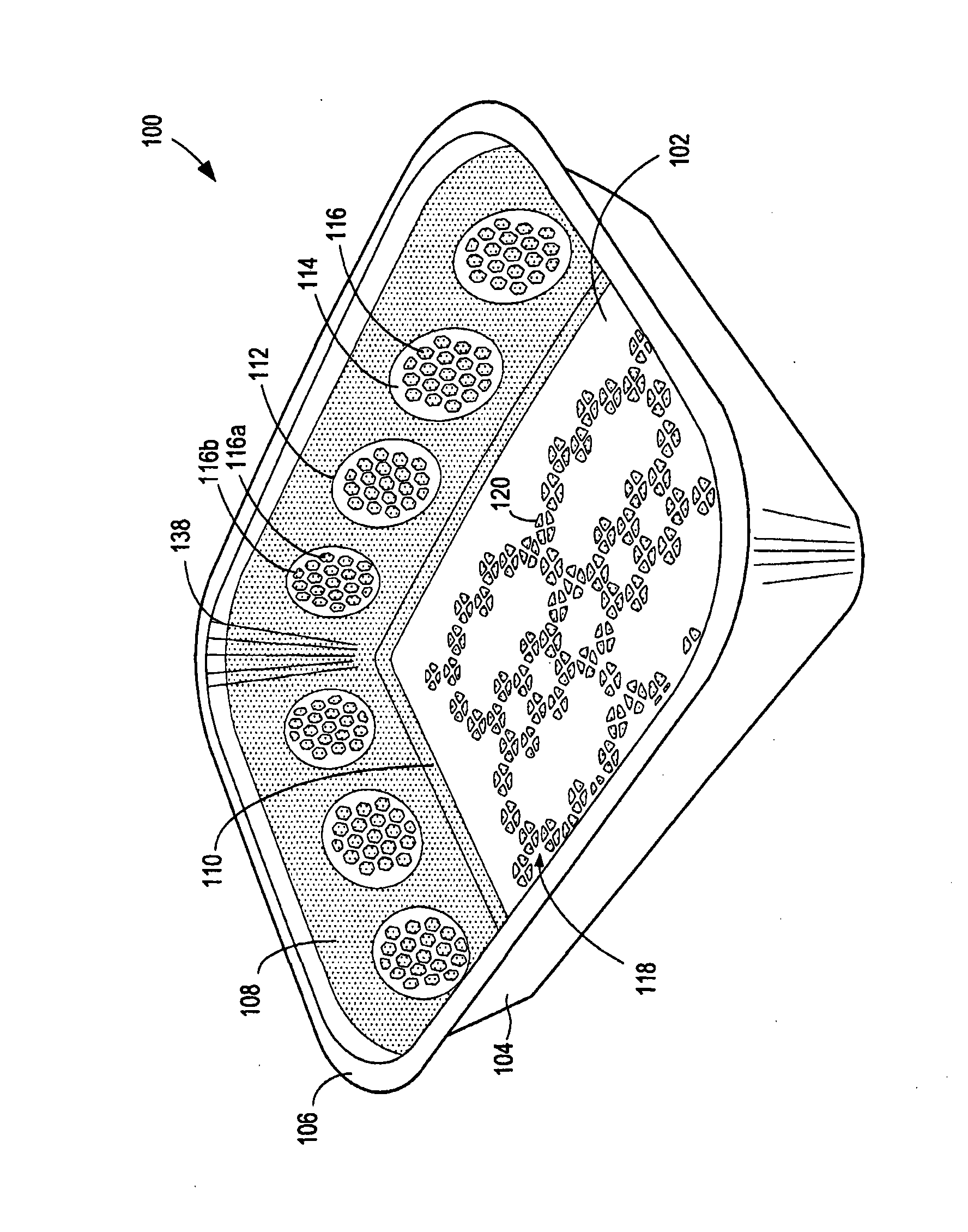

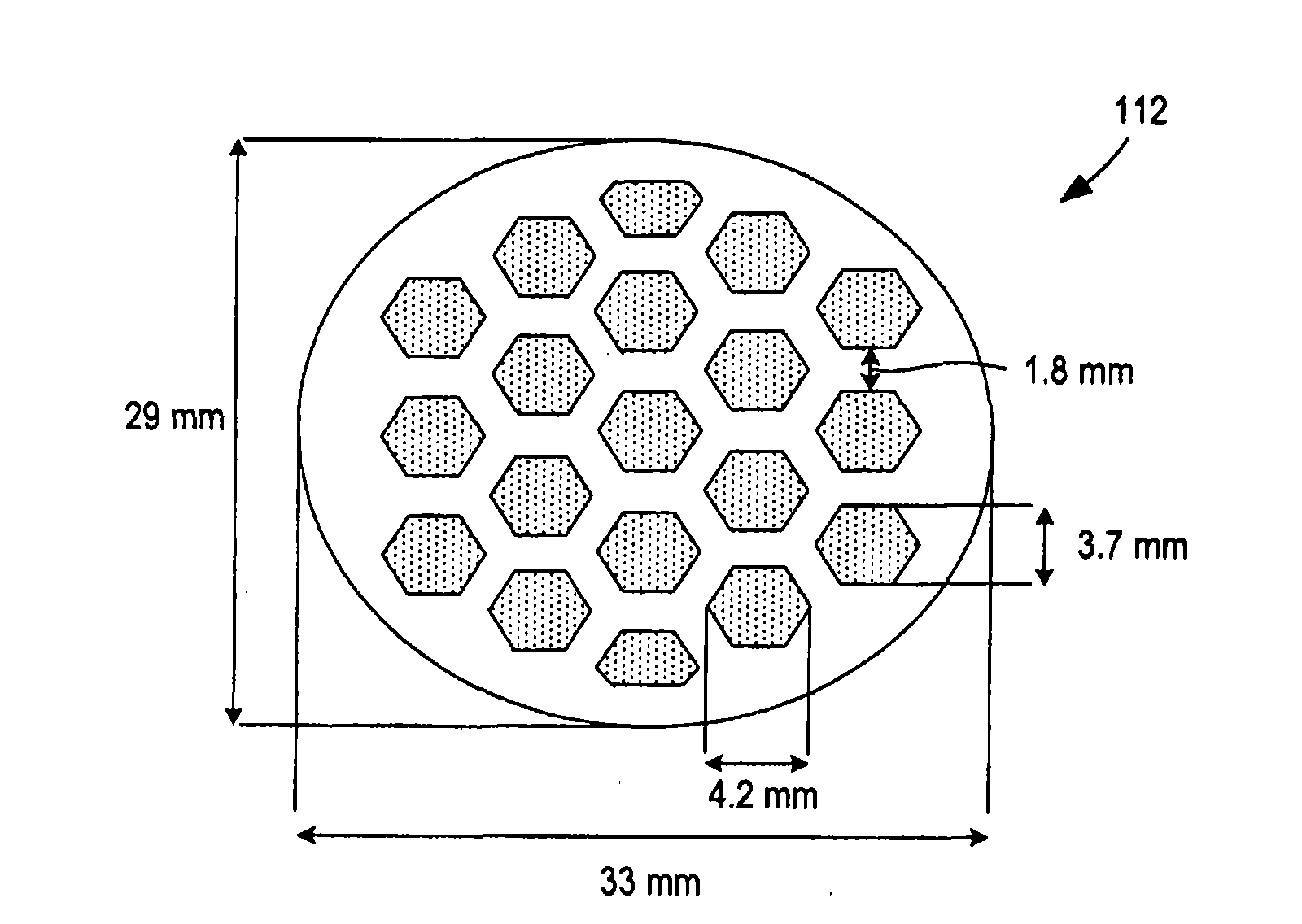

A construct for heating a food item in a microwave oven comprises a base (102), a wall (104) extending upwardly from the base (102), a microwave energy shielding element (108) overlying at least a portion of the wall (104), and a microwave energy diffusing element (112) circumscribed by the microwave energy shielding element (108), where the microwave energy diffusing element (112) includes a plurality of microwave energy reflective elements (116) within a microwave energy transparent area (114).

Owner:GRAPHIC PACKAGING INT

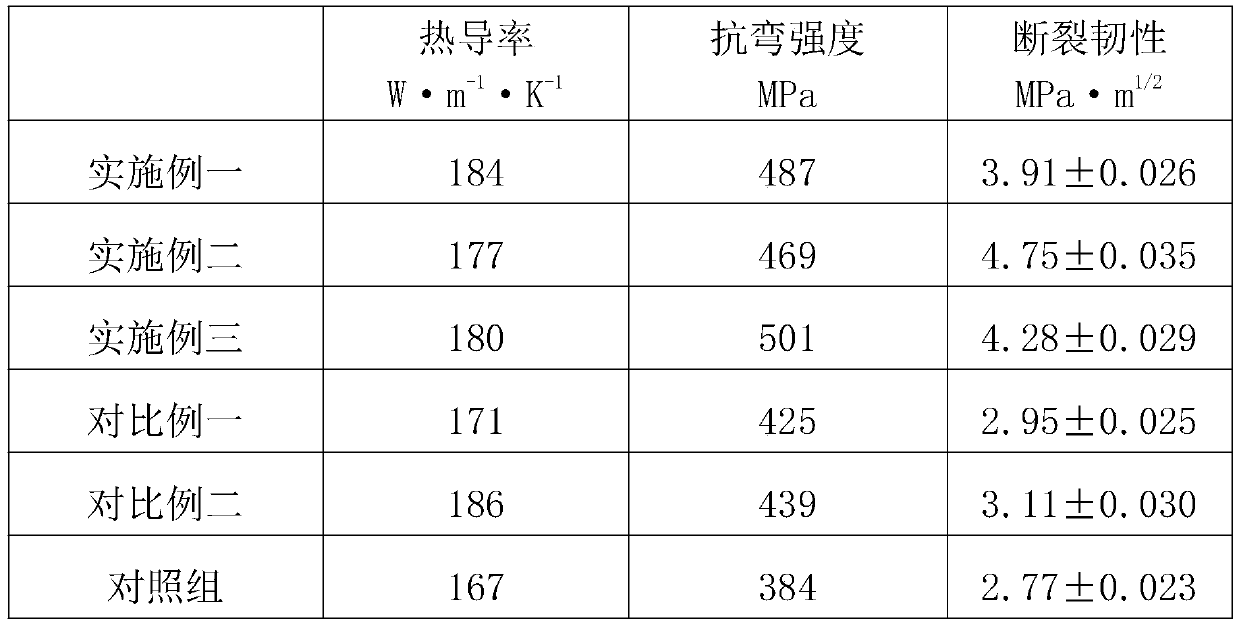

Particle dispersion toughened aluminum nitride ceramic substrate and preparation method thereof

The invention relates to the technical field of preparation of aluminum nitride ceramic substrates, provides a particle dispersion toughened aluminum nitride ceramic substrate and a preparation methodthereof, and solves the problem that an aluminum nitride ceramic has insufficient fracture toughness and cannot satisfy high requirements for material performance in the application field in the prior art. The aluminum nitride ceramic is prepared from the following raw material components: 75-90 parts of aluminum nitride powder, 3-6 parts of a sintering auxiliary agent, 2-4 parts of hafnium carbide, 3-5 parts of zirconium oxide, 0.5-1 part of aluminum oxide, 5-10 parts of polyimide, 1-3 parts of bis(2-ethylhexyl) phthalate, and 4-8 parts of an antifoaming agent. The method provided by the invention adopts a composite toughening manner to modify an aluminum nitride ceramic substrate, and the fracture toughness of the ceramic substrate is obviously superior to that of an aluminum nitride ceramic substrate prepared by single toughening modification.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

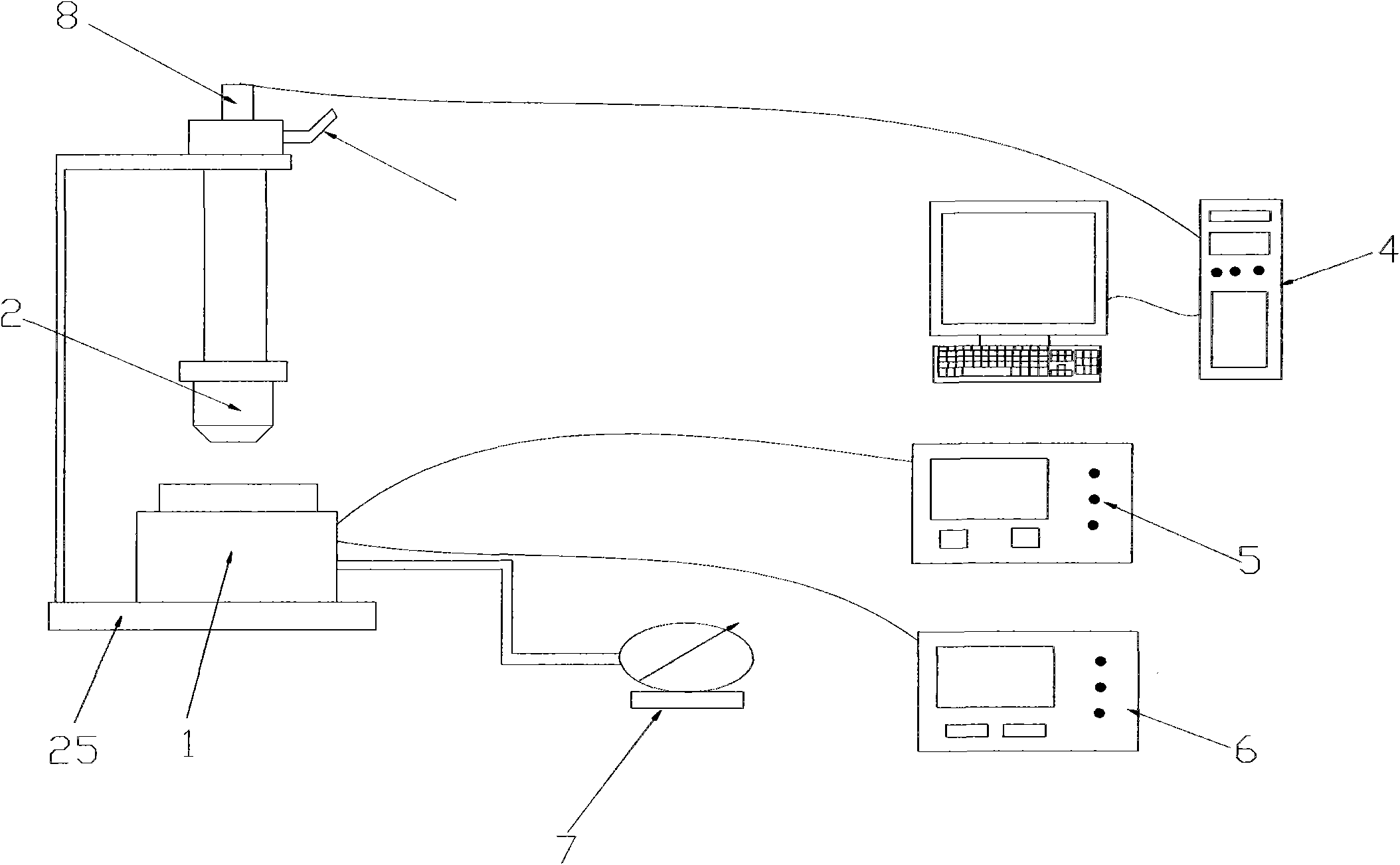

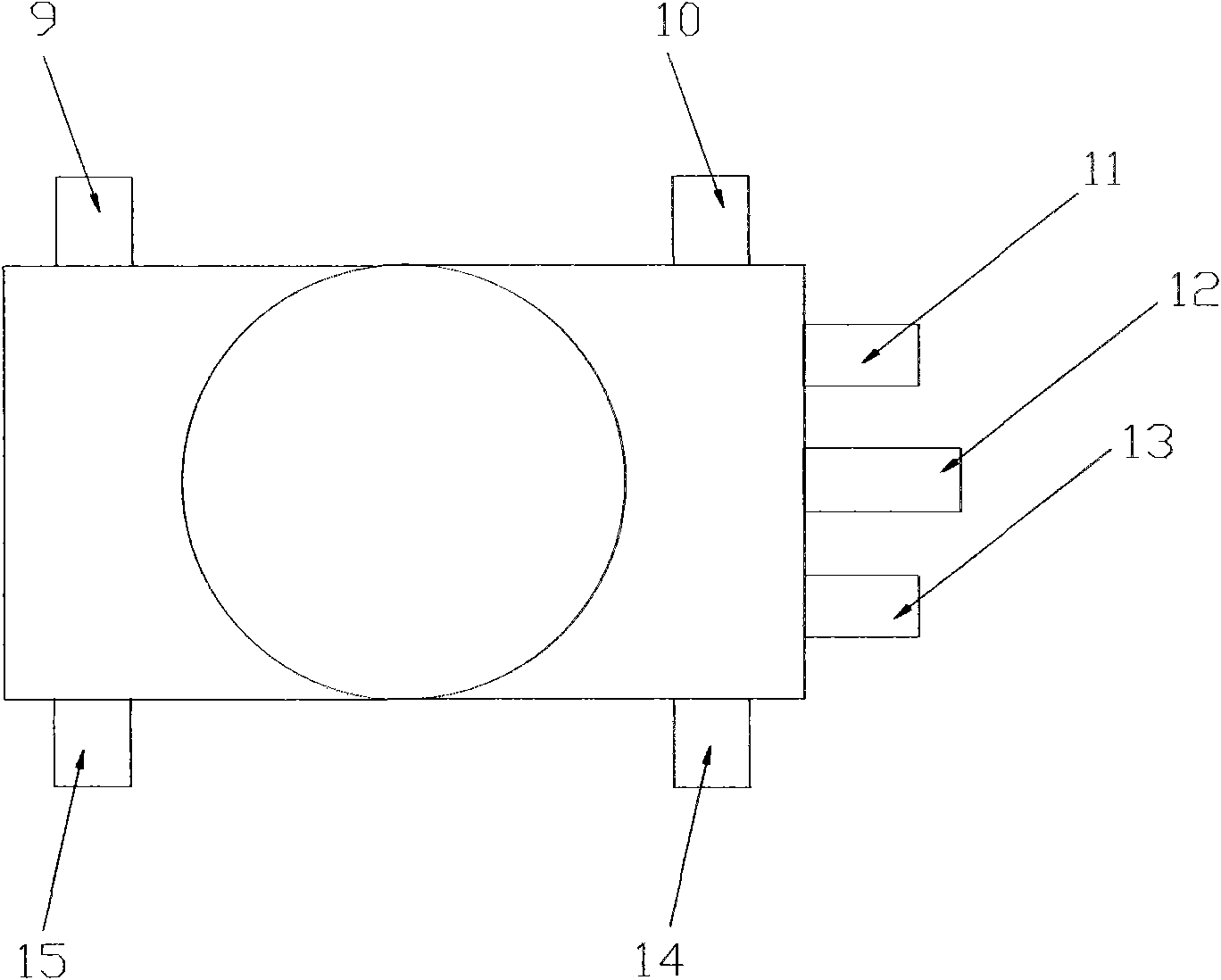

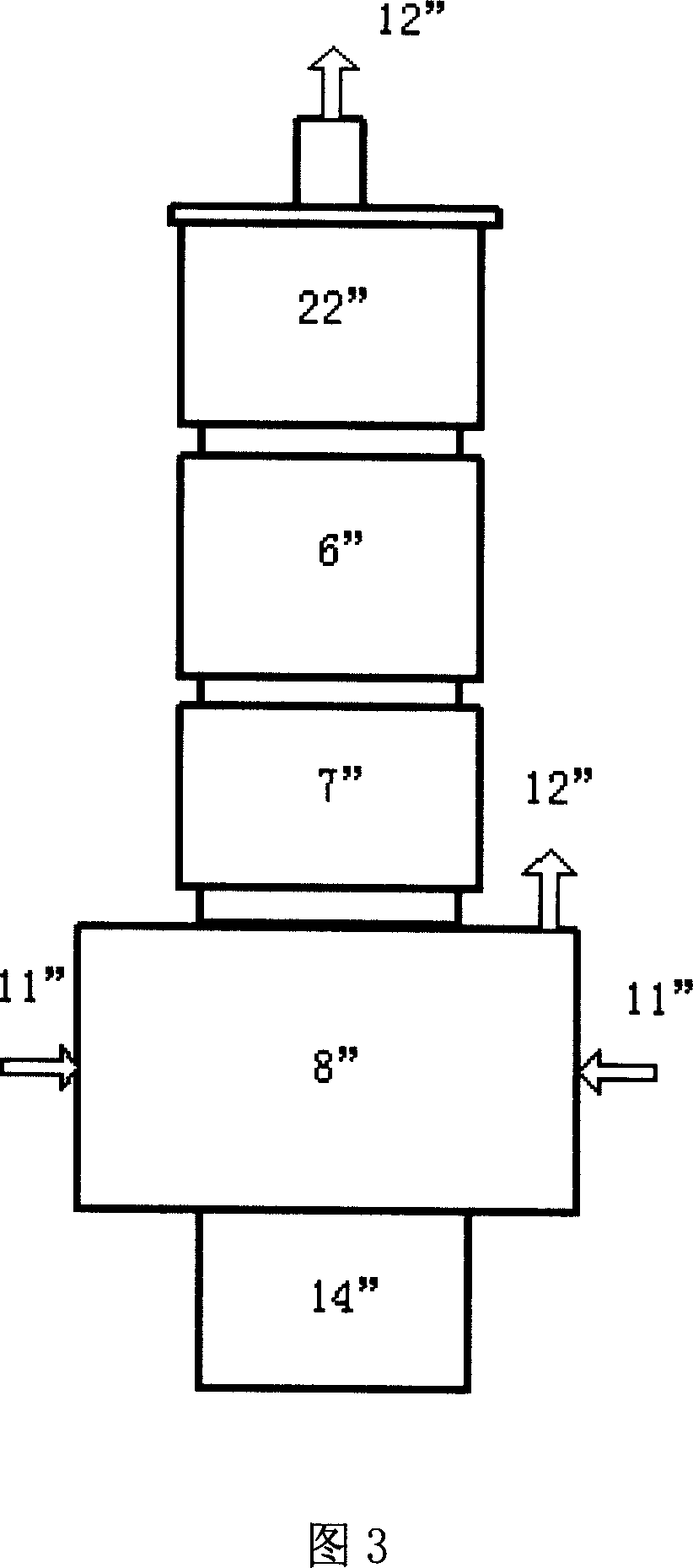

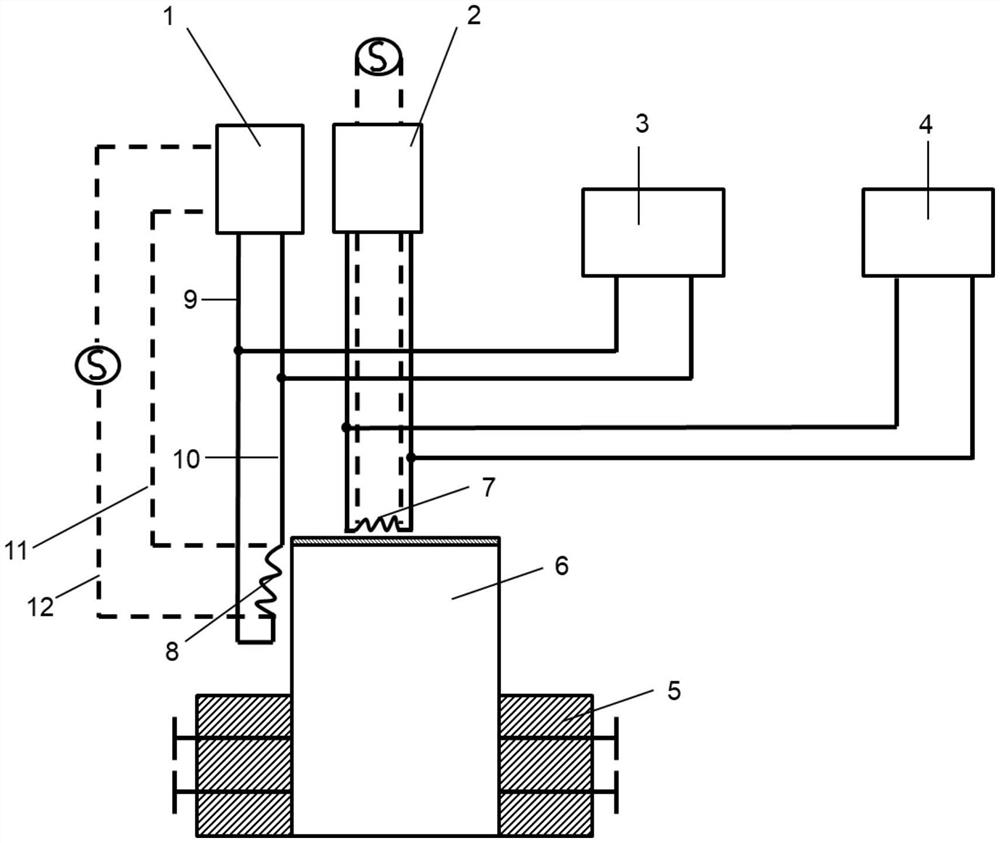

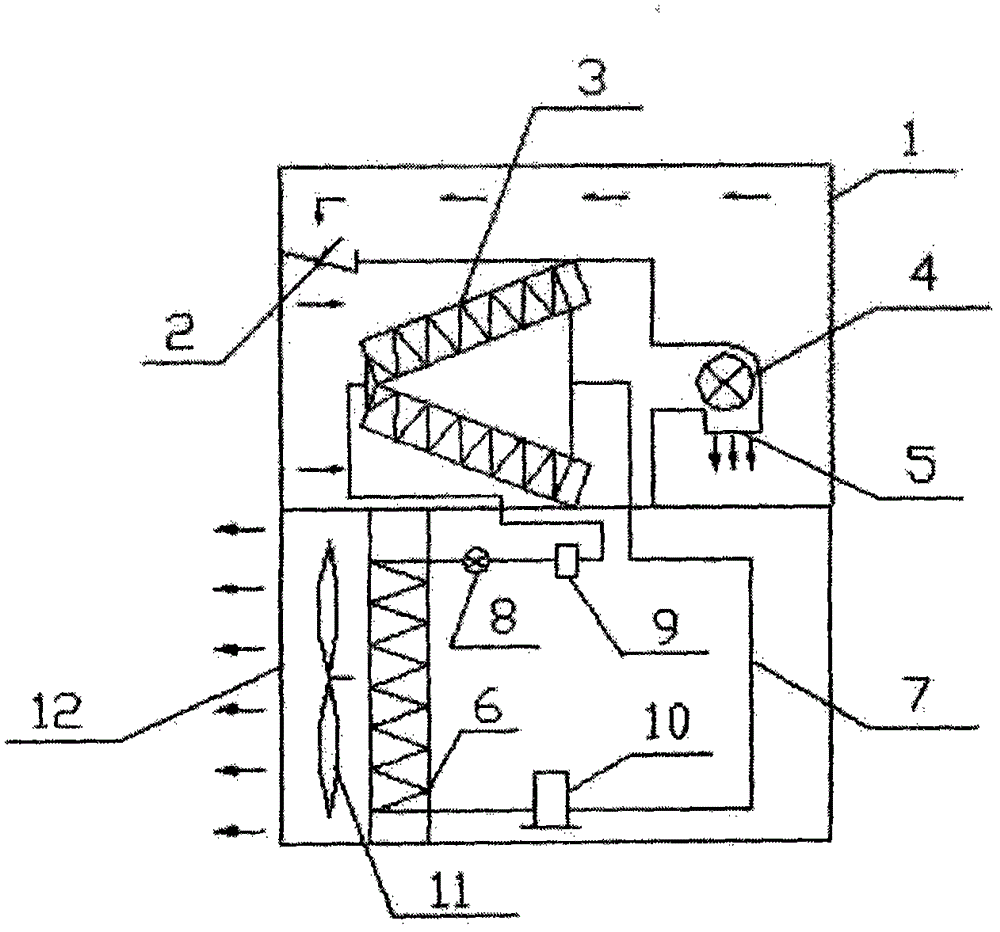

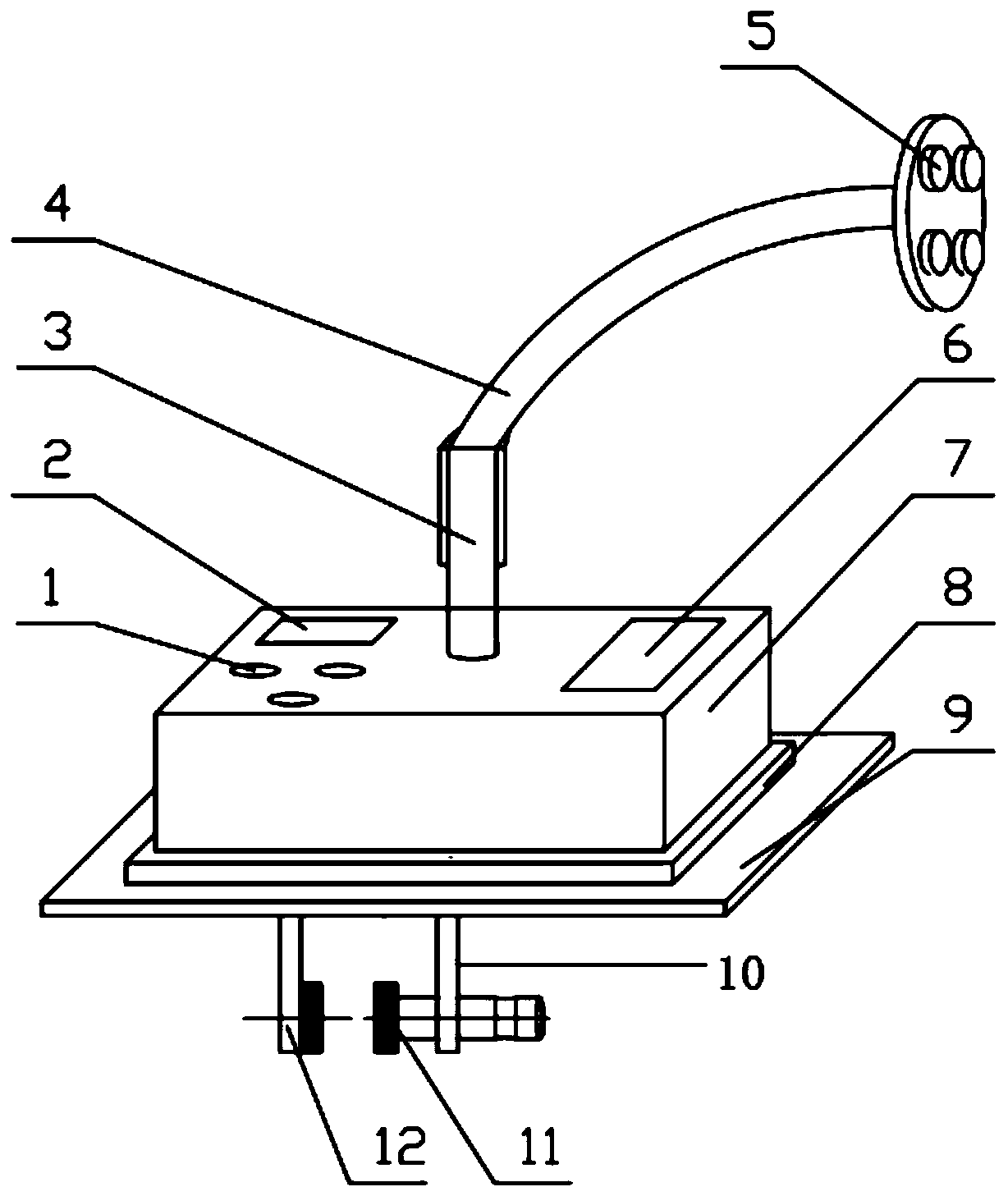

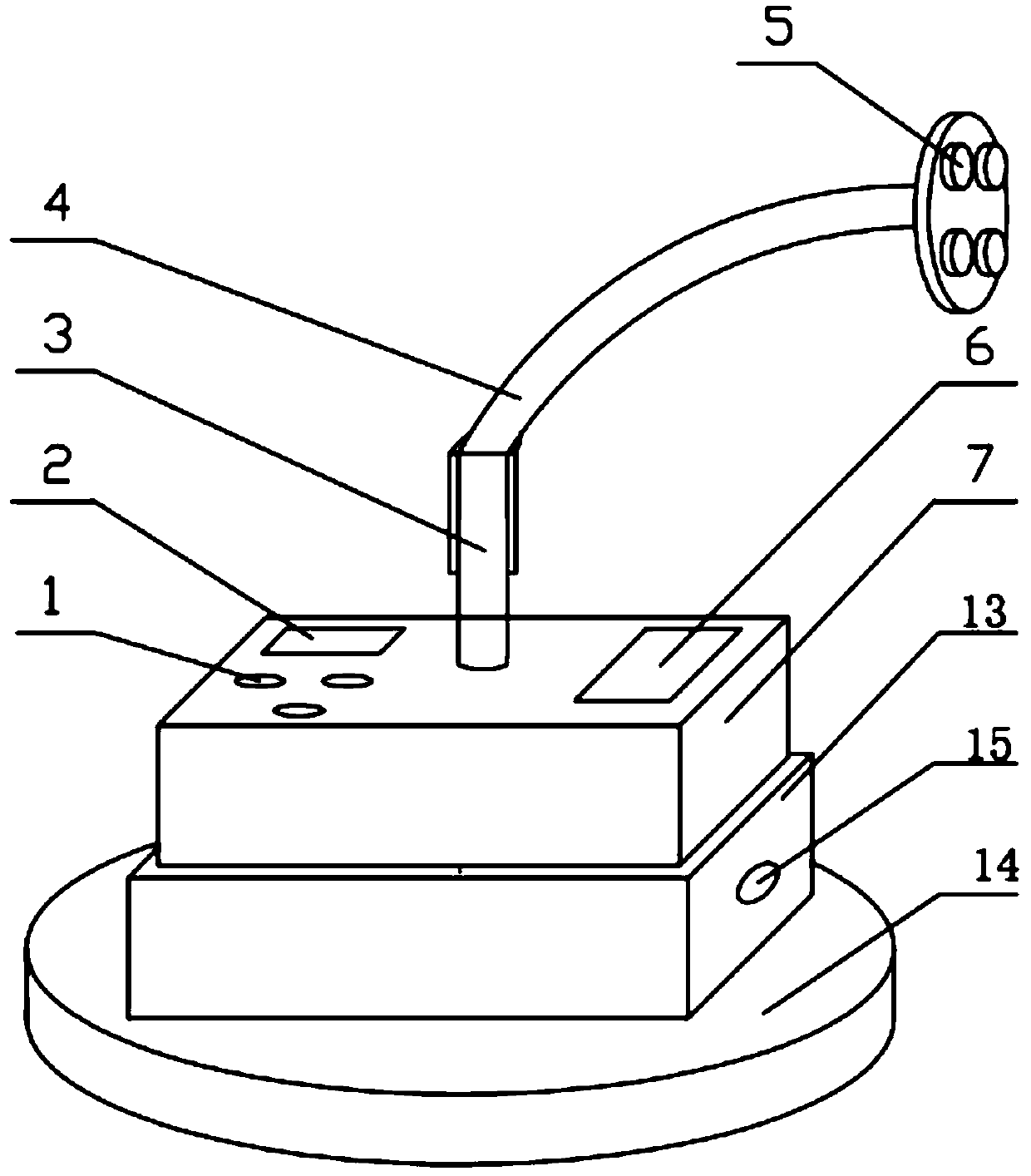

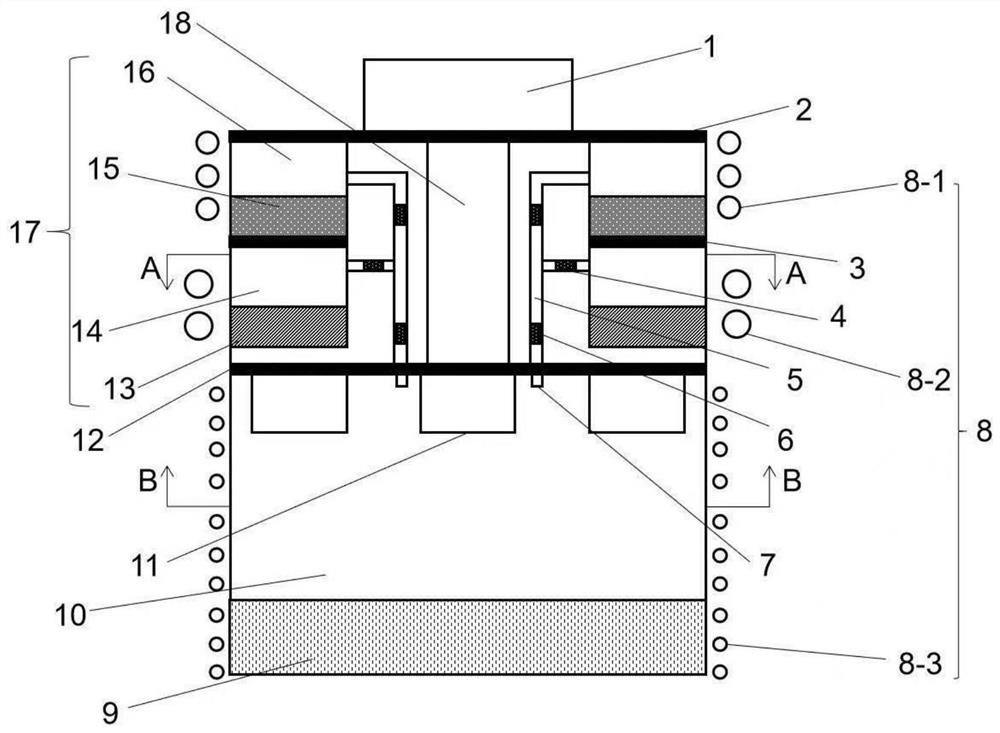

High-resolution high-temperature metallographic structure analyzer

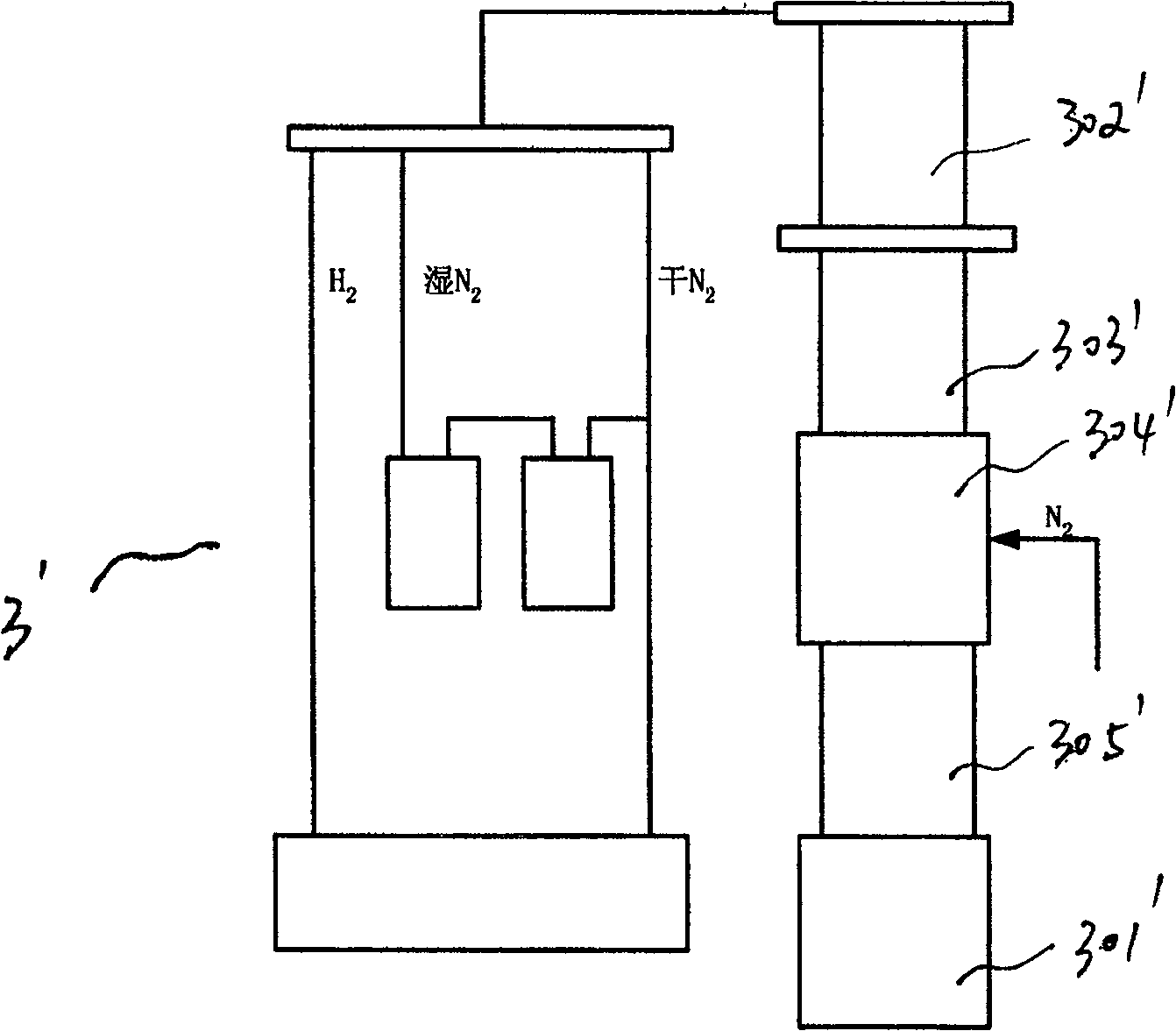

InactiveCN101839846AControl the heating rateControl heating temperatureMaterial analysis by optical meansWater circulationImage analysis

The invention relates to the technical field of metalloscopes, in particular to a high-resolution high-temperature metallographic structure analyzer which comprises a metalloscope equipped with a digital camera head, a hot stage, a cooling water circulation system of a window, a cooling water circulation system of a warm stage upper cover and a microcomputer embedded with an image analysis system. The analyzer is characterized in that the signal output end of the digital camera head is connected with the signal input end of the microcomputer, and the outer wall of the hot stage is respectively provided with a cooling water inlet, a liquid nitrogen cooling opening, a vacuum interface, a heating power supply interface, a thermocouple interface, a cooling water outlet and a reserved function interface. Compared with the prior art, by the invention, cooling speed and heating speed can be shown by numerical values and can be controlled more visually and conveniently; and in addition, the flow rate of the cooling water can be controlled in an intelligent way. The internal vacuum degree of the hot stage of the device can reach 10-3Pa, which can prevent a metal sample from being oxidized at high temperature. The reserved function interface of the device greatly widens the application scope of the high-temperature metalloscope.

Owner:SHANGHAI UNIV OF ENG SCI

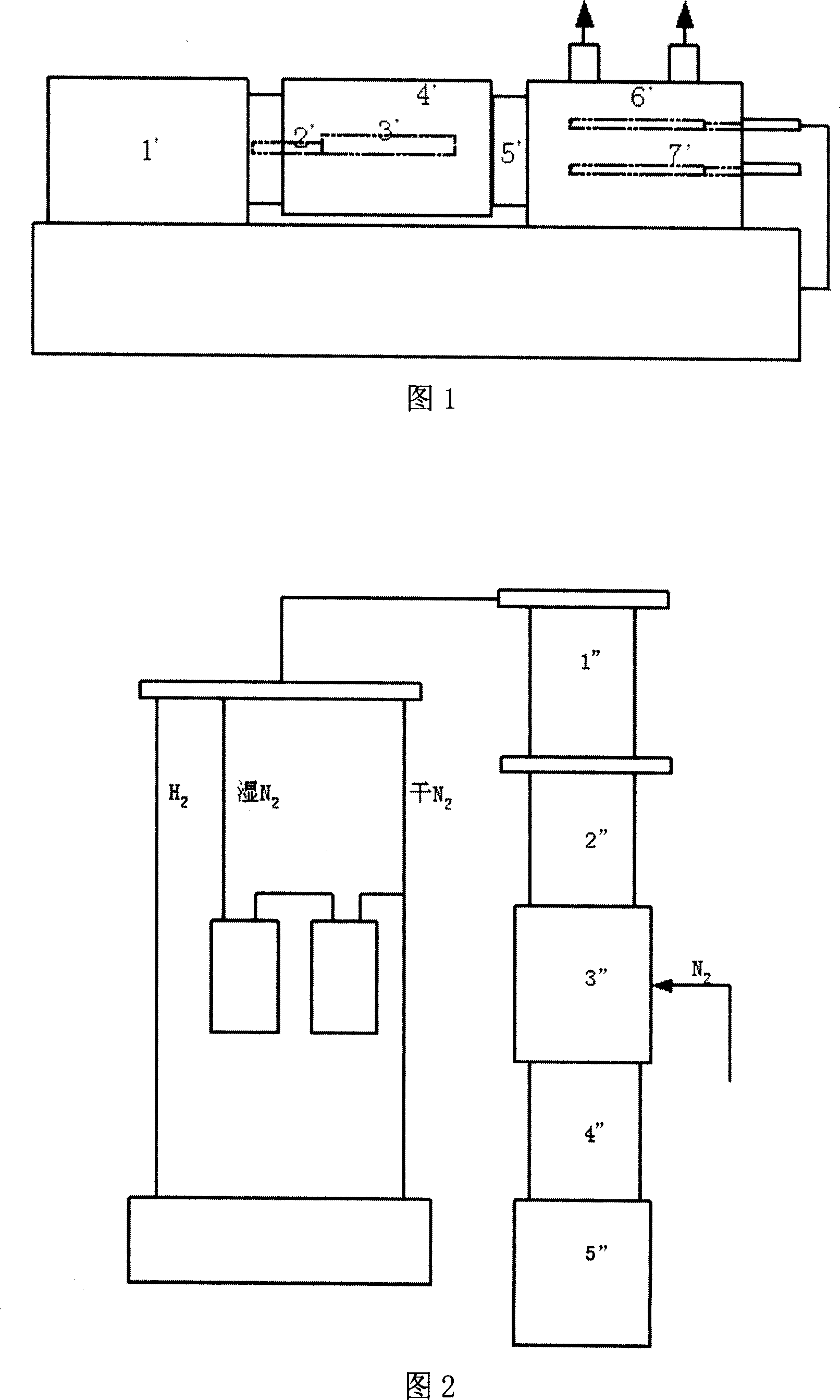

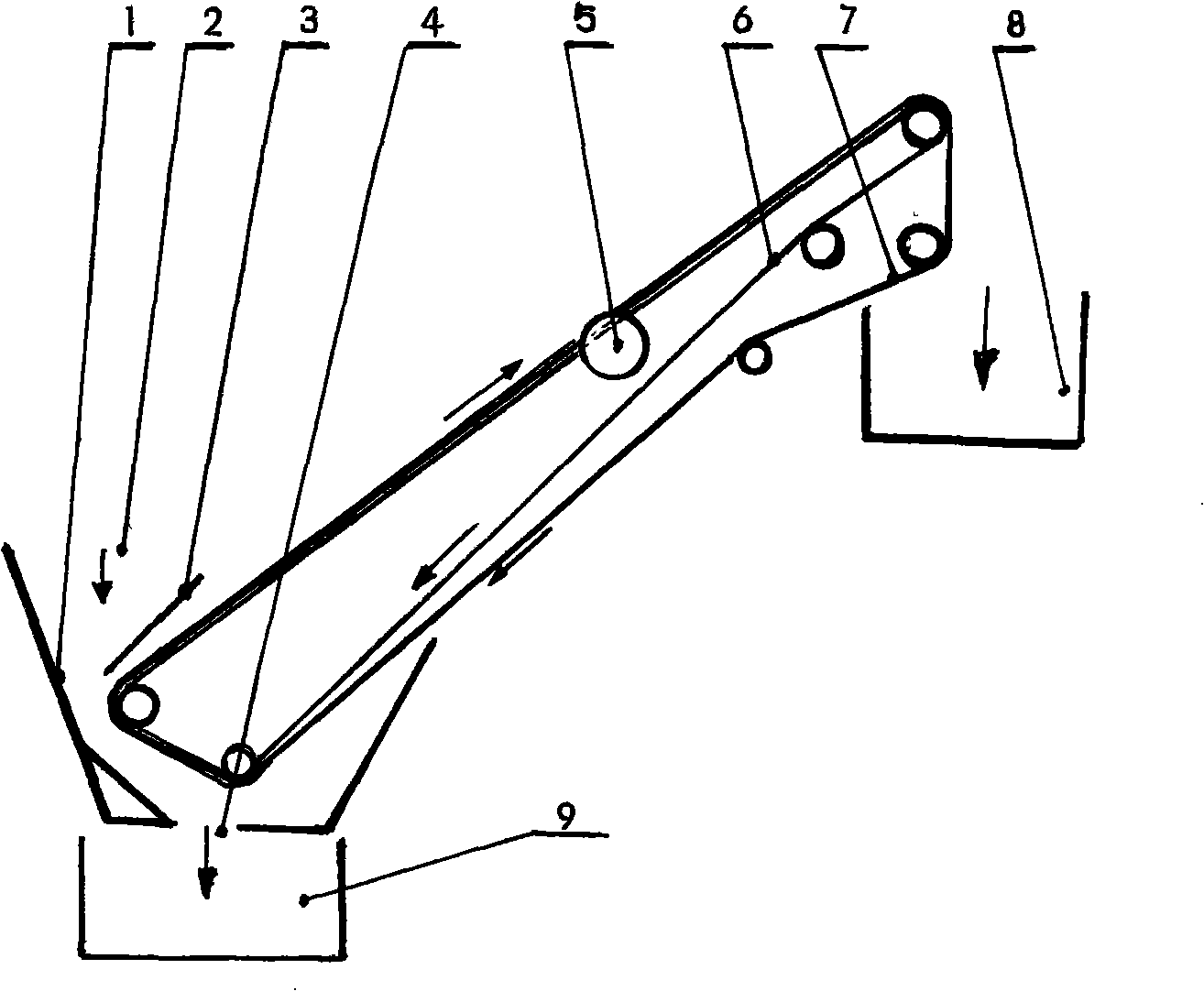

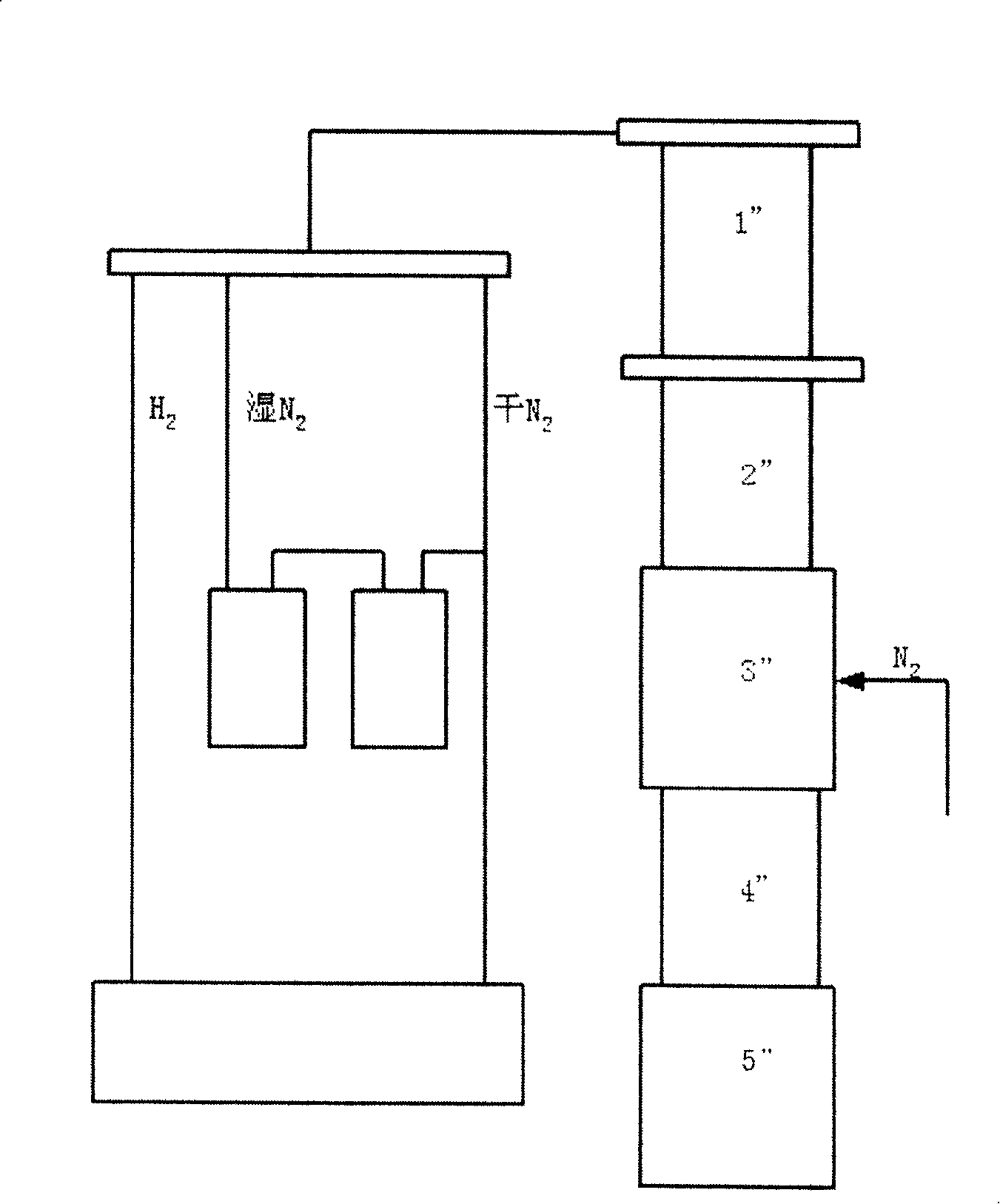

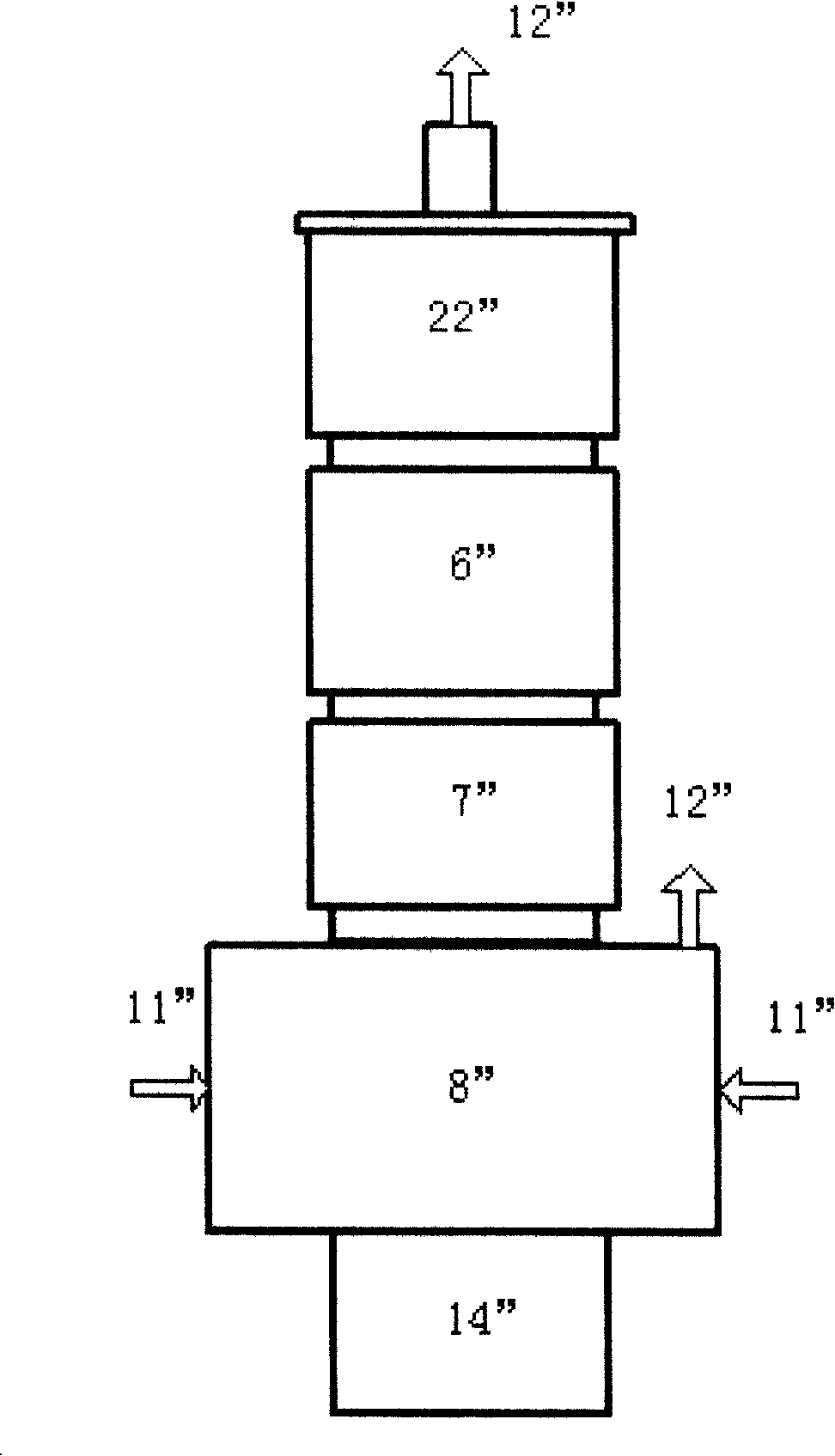

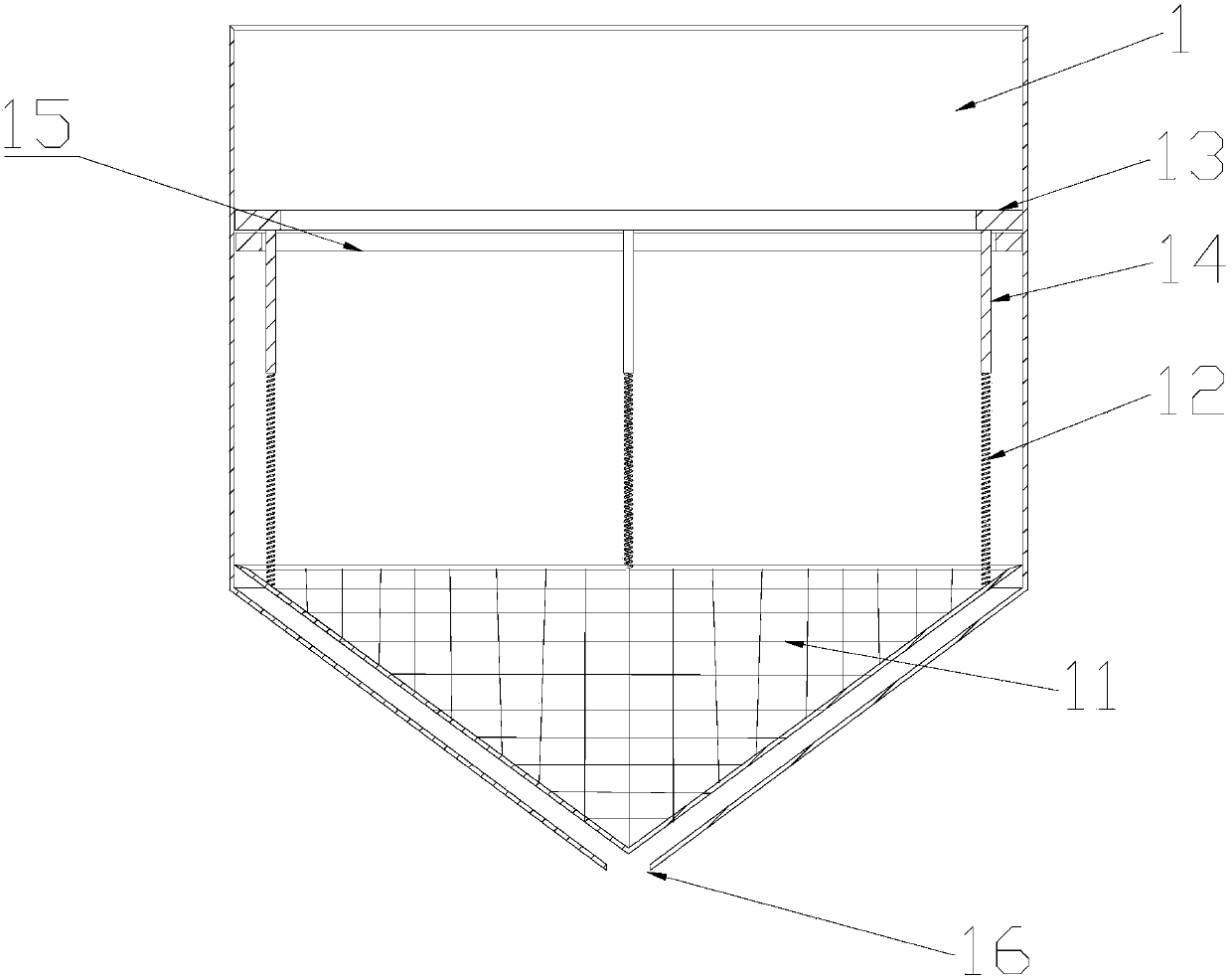

Quick cooling test plant for disk type band steel, and method of use

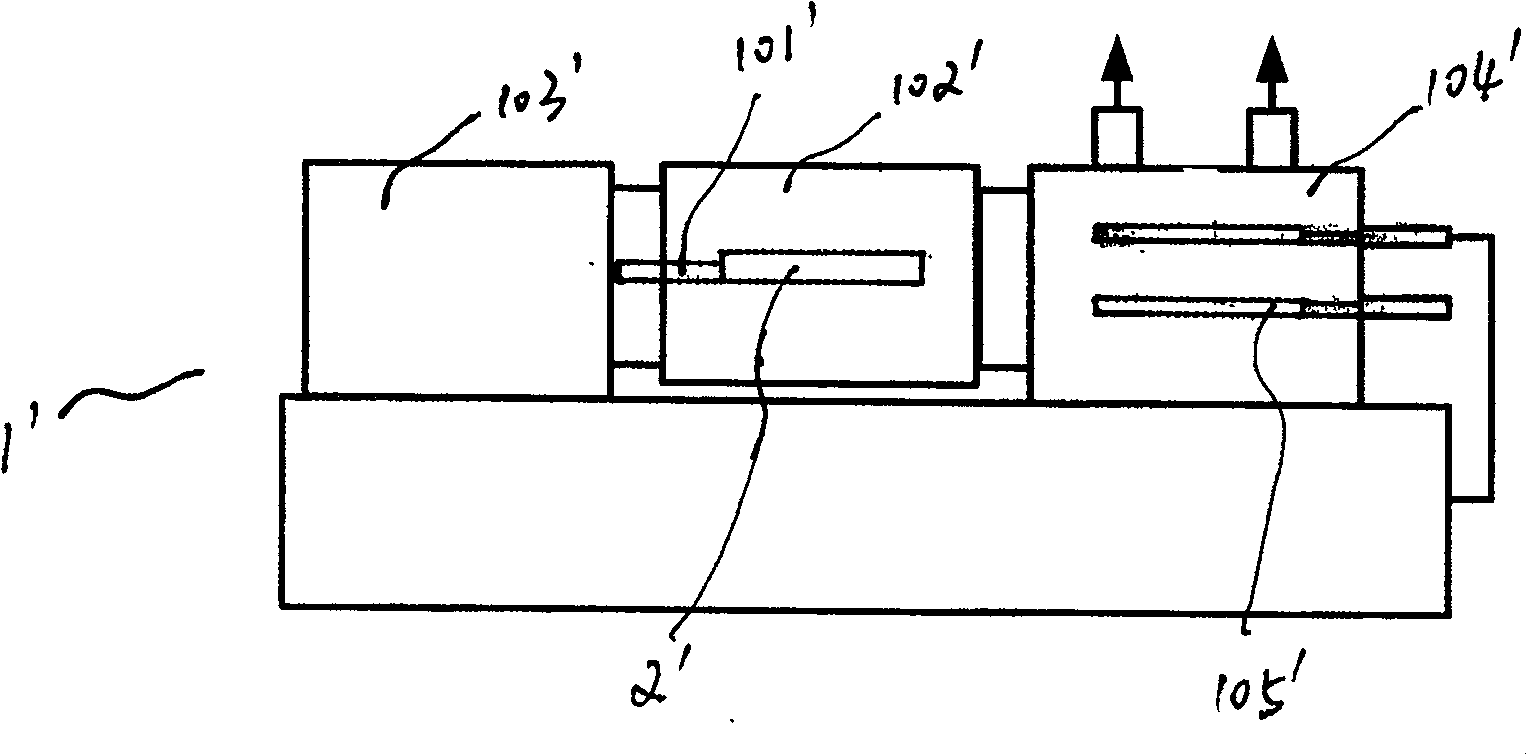

InactiveCN101092660AEliminate fragileEliminate deformationFurnace typesHeat treatment furnacesFixed frameStrip steel

This invention relates to disk-type strip steel rapid cooling test apparatus for stimulating annealing process requirement of continuous annealing of strip steel, and its usage method. The apparatus comprises: a disk-type case, a disk-type sample fixing frame and a compensating wire that can rotate around a core axis in the case, a sample loading / unloading chamber, a heating / homogenizing chamber, a slow cooling / over-aging chamber, a spray cooling chamber and a water quenching chamber. When used, the compensating wire is connected to the surface of the sample, and then the sample is introduced into the above chambers in sequence. This invention has such advantages of large sample size, a wide variety of cooling methods, high cooling speed, simple apparatus, and low malfunction rate.

Owner:BAOSHAN IRON & STEEL CO LTD

Treating method for improving steel toughness

The invention belongs to the technical field of production of duplex stainless steel products used at low temperature, and in particular relates to a treatment method for improving the toughness of steel. 1) After the steel is forged, the furnace is charged at a furnace temperature not higher than 350°C and preheated twice. ; then solid solution treatment; then cooling, put into clear water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 4-6 seconds / mm. The steel solution treatment process includes the following steps: ① heating, Control the heating rate, preheating temperature, solid solution temperature and holding time in the low temperature section to reduce thermal stress and obtain a better two-phase structure ratio; The precipitation will significantly reduce the plasticity and toughness of steel.

Owner:孙超

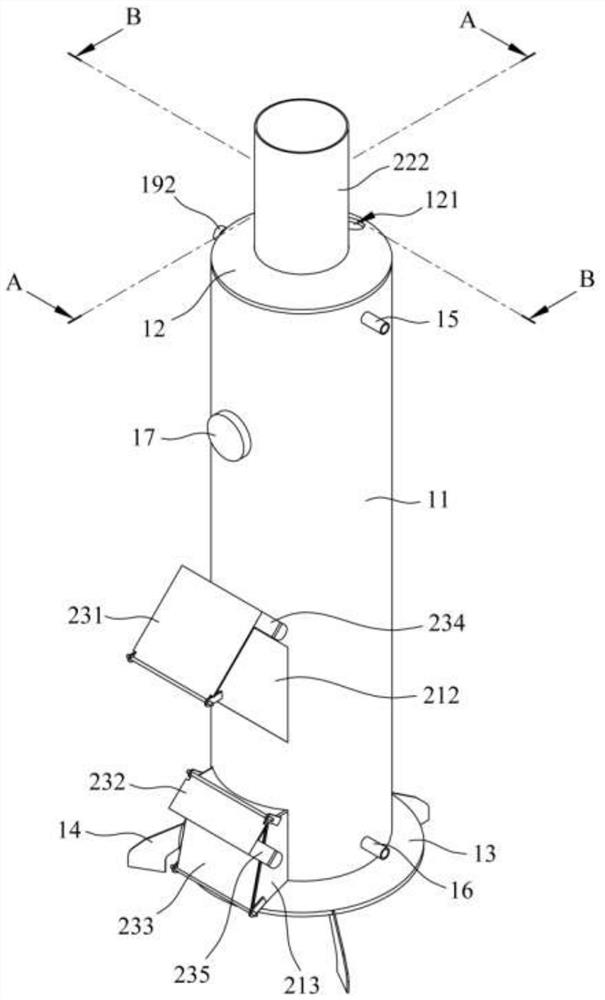

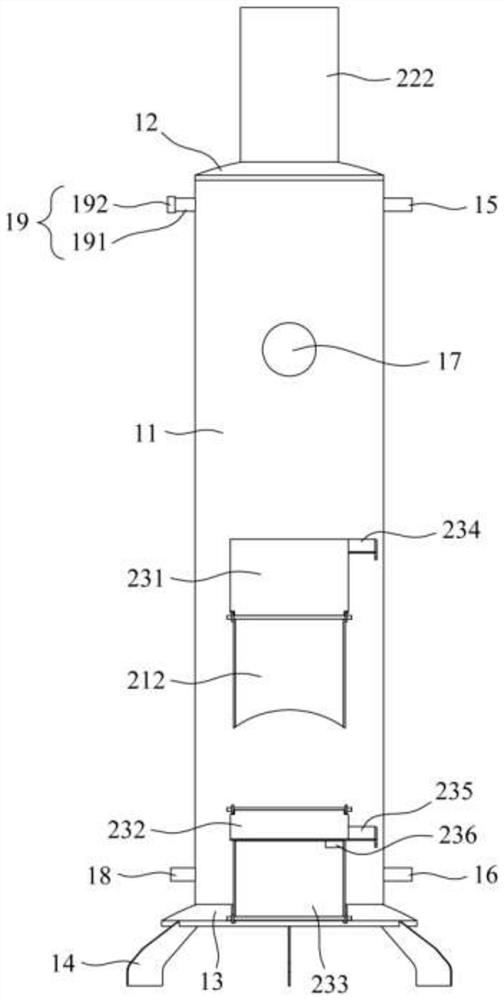

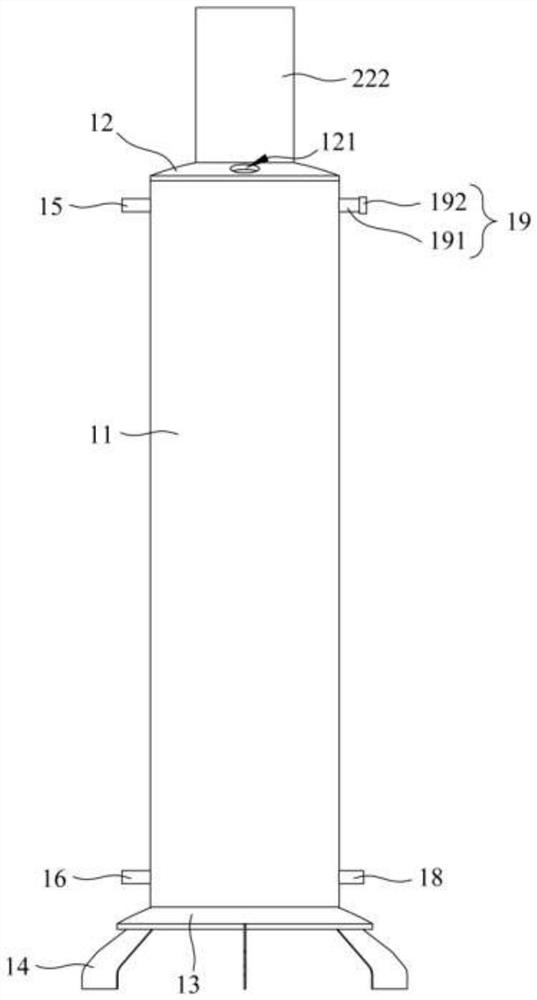

Novel vacuum induction melting furnace

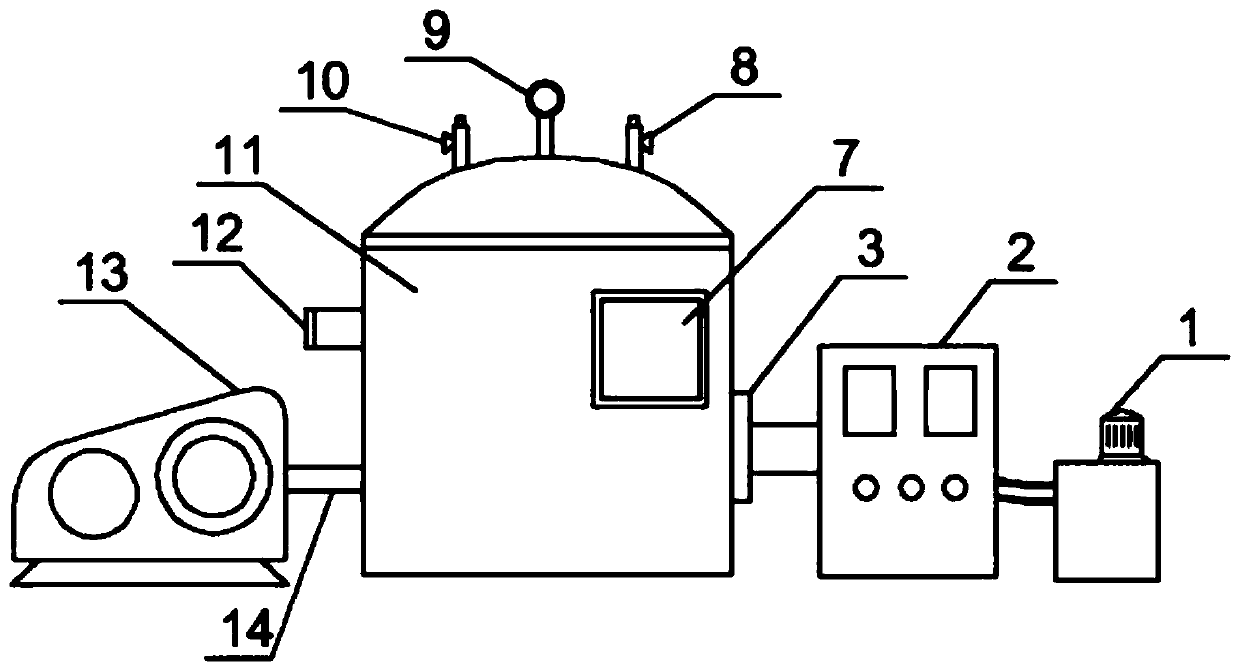

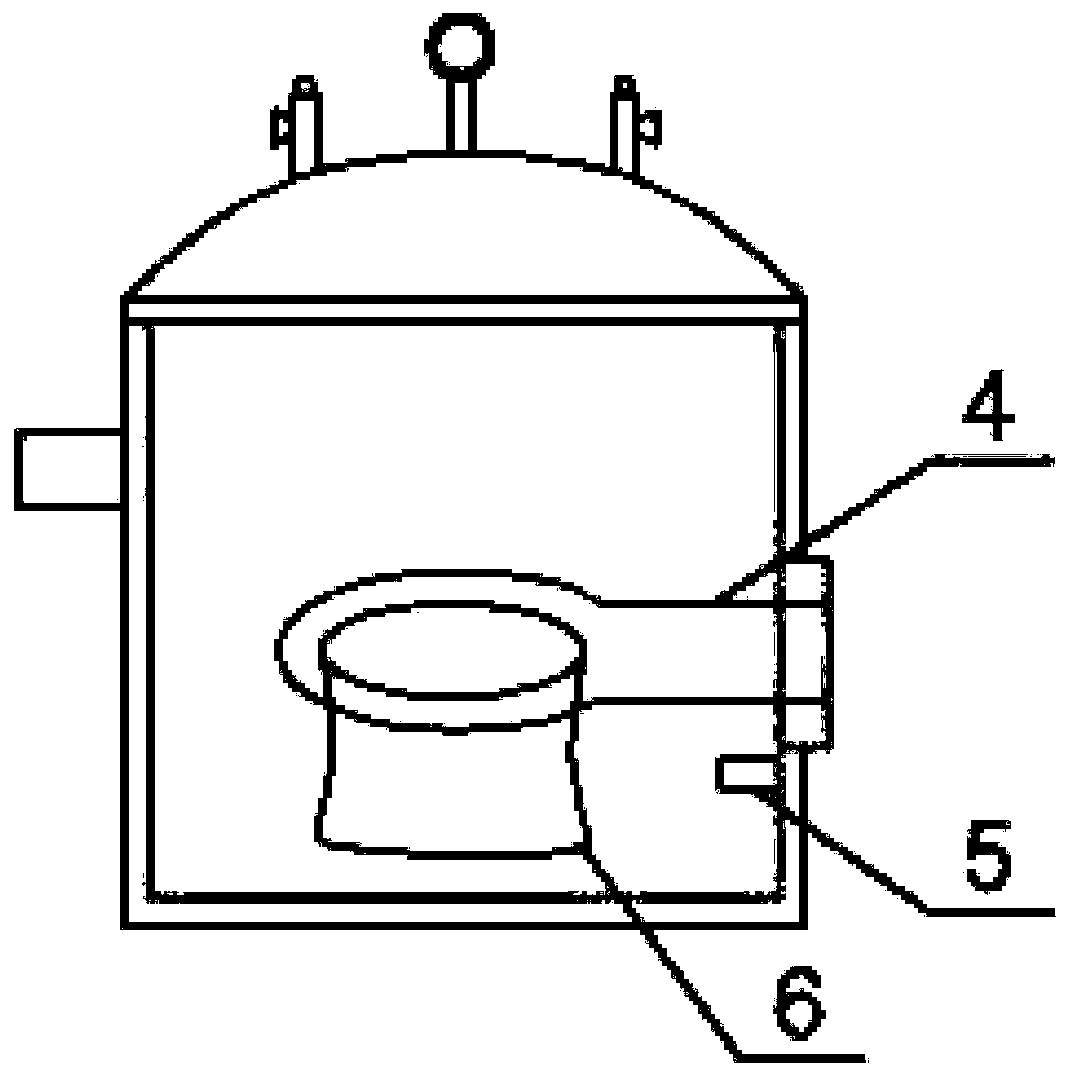

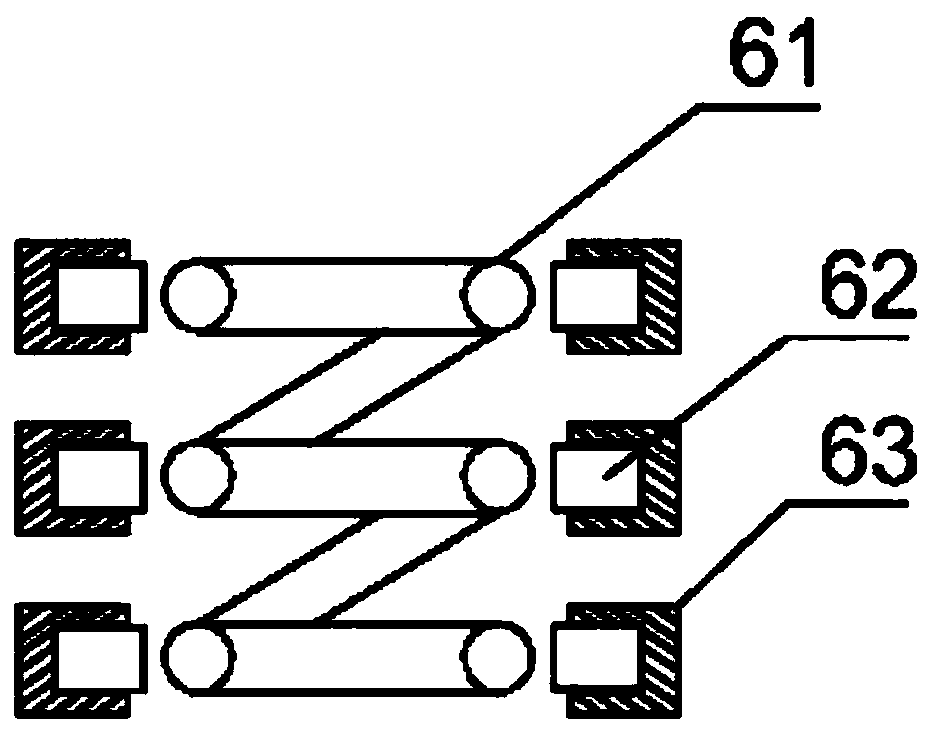

InactiveCN110470137AAvoid equipment damageExtended service lifeFurnace componentsCrucible furnacesWater pipeHeating efficiency

The invention provides a novel vacuum induction melting furnace. The novel vacuum induction melting furnace comprises a cooling system, a high frequency induction machine, an insulating partition plate, a high frequency induction heating coil, a temperature detector, a crucible, a temperature display screen, an air inlet valve, a vacuum gauge, an air inlet valve, a vacuum heating furnace, an observation window, a vacuum pump and a vacuum bellows. The cooling system is connected to the high frequency induction machine through a cooling water pipe; the insulating partition plate is installed onthe side part of the vacuum heating furnace; the high frequency induction heating coil penetrates through the insulating partition plate and enters into the vacuum heating furnace; and the temperaturedetector is disposed in the vacuum heating furnace. The high frequency induction heating coil, the temperature detector and the cooling system are arranged, the novel vacuum induction melting furnacehas reasonable structure and low unit energy consumption, effectively improve the heating efficiency of a NdFeB magnet raw material, facilitate the control of the heating temperature, effectively protect the heating device, and facilitate the market promotion and application.

Owner:JIANGXI YG MAGNET CO LTD

Duplicating machine and laser printer color toner manufacturing technique

Disclosed is a color toner production technology for copiers and laser printers; the color of the toner has three primary colors of red, blue, yellow, and black color; the toner can change the raw materials and displays the fluorescent color; or the same powder of the toner can be displayed as two colors from different point of views; the toner of the invention can print a variety of color presswork with bright and fluorescent color and has anti-counterfeiting function; as the toner has small particle size, small inner layer proportion and less using amount, the toner enables the presswork to be clearly printed and is especially suitable for printing micro-data and images; through magnetic separation technology, the semi-finished products are provided with soft (or hard) magnetic properties and can be fully utilized; the tacky (fixing) temperature is 36-38 DEG C lower than that of the current toner; moreover, the toner of the invention has low energy consumption and short fixing time, and can extend the service life of the equipment and improve the printing and copying speed, which is an ideal upgrade product for the existing toner.

Owner:孙先明

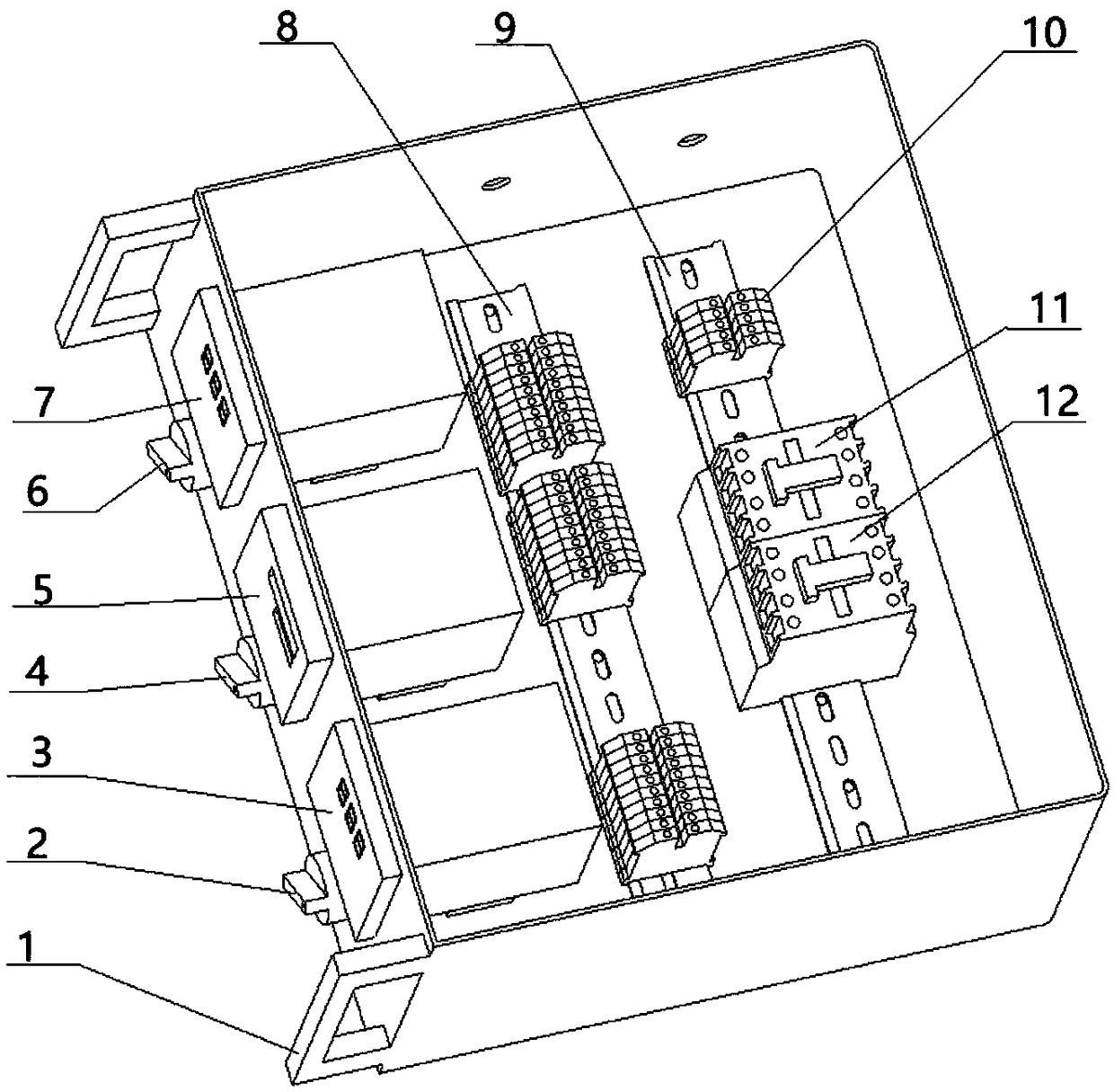

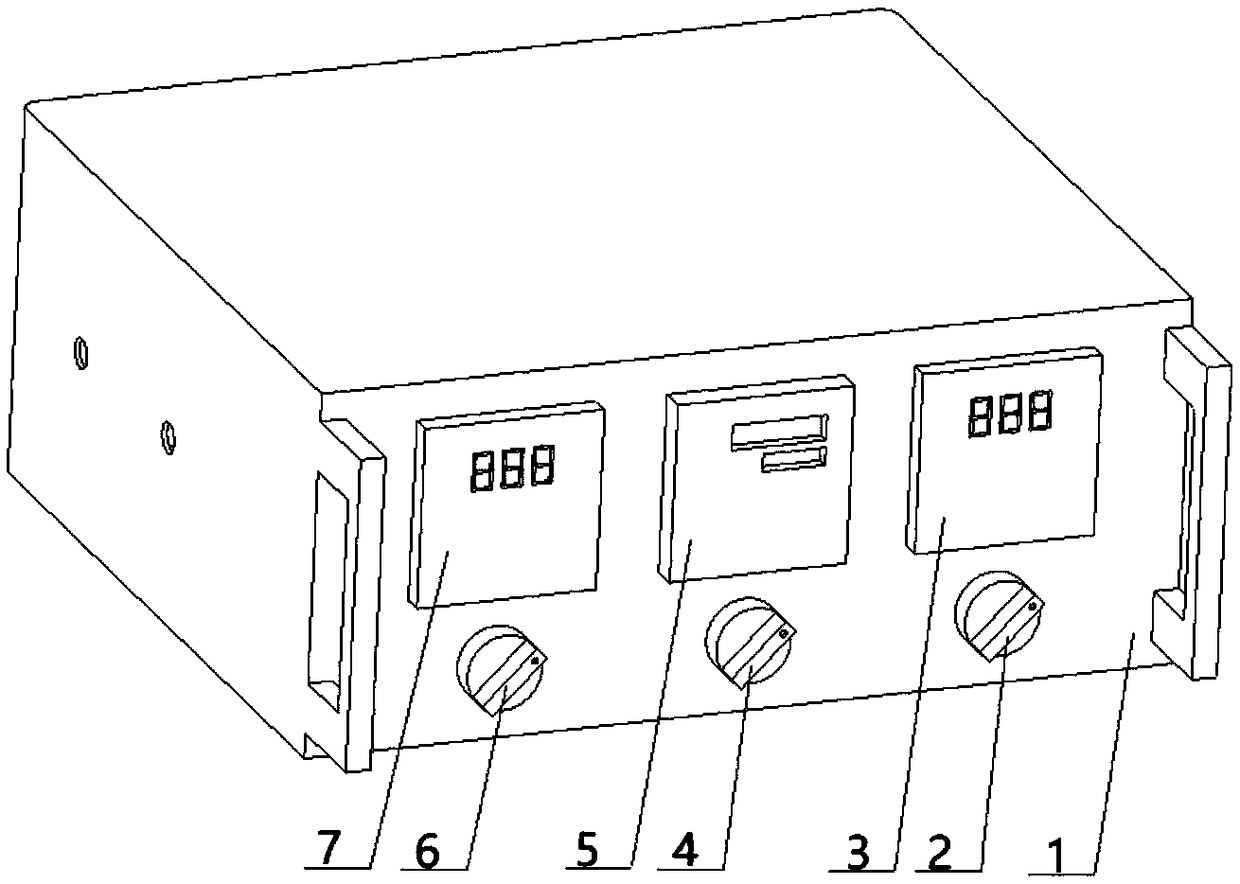

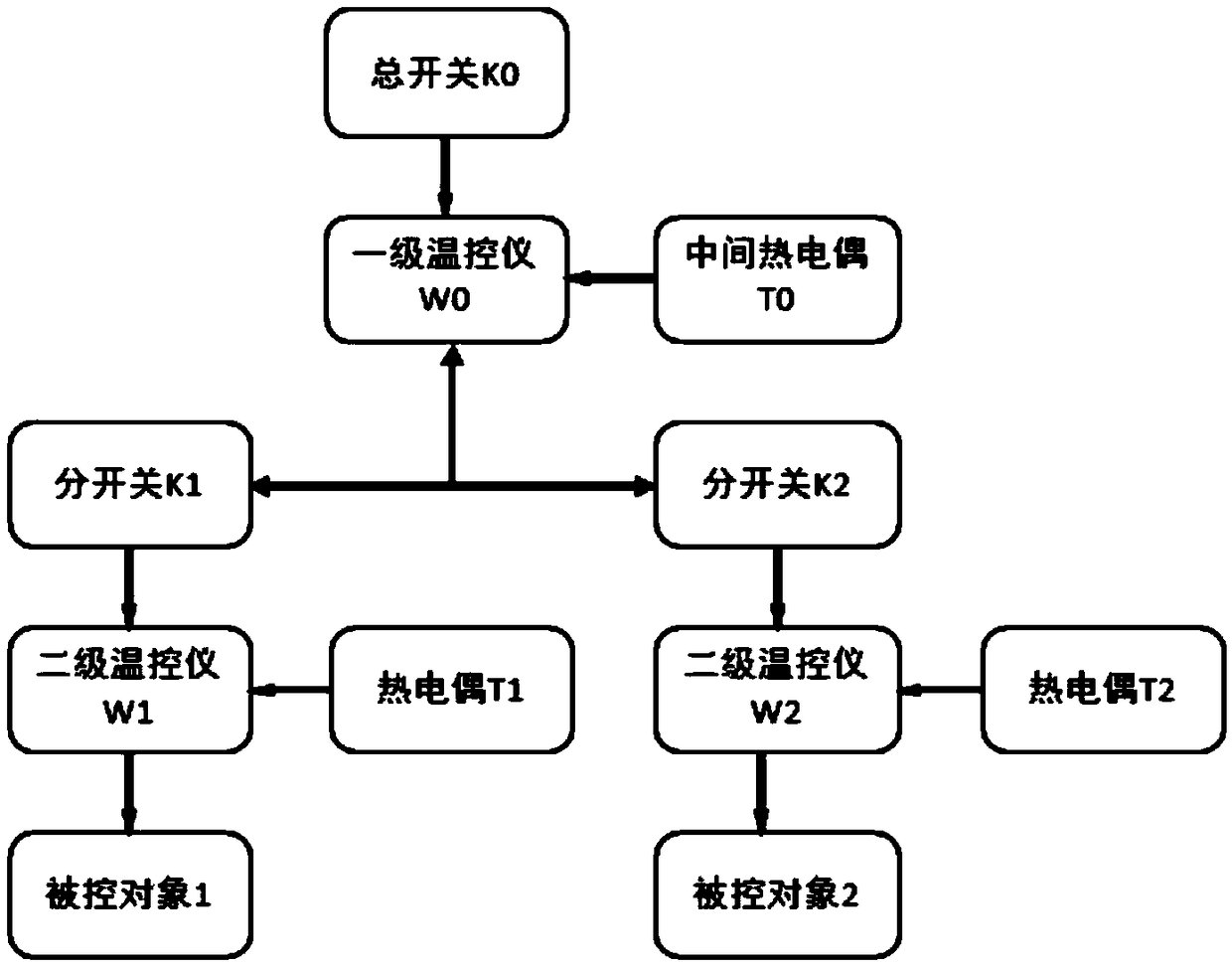

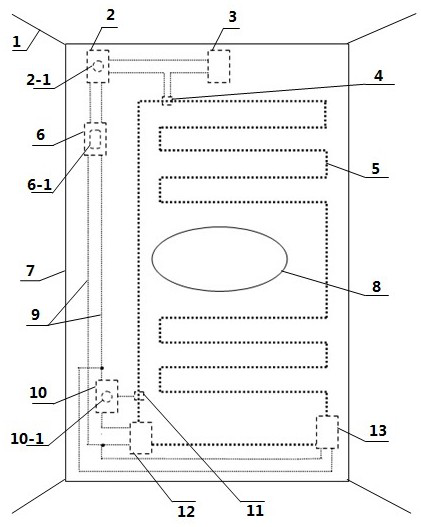

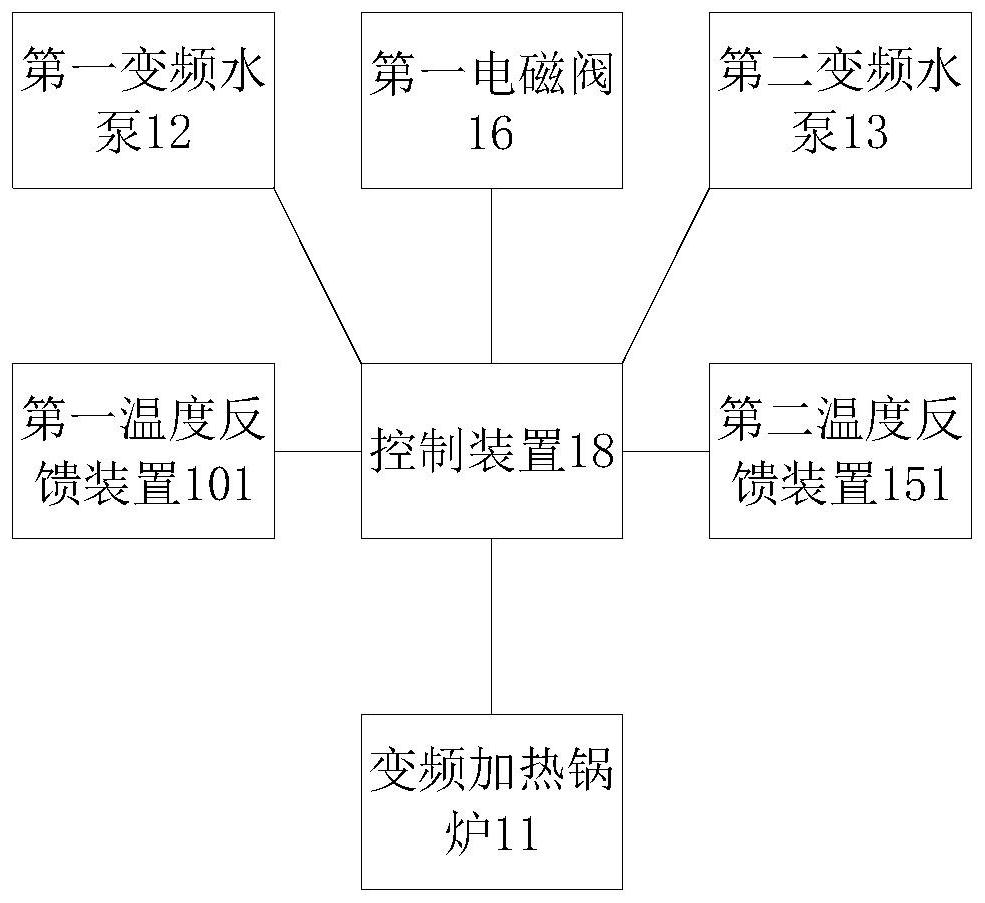

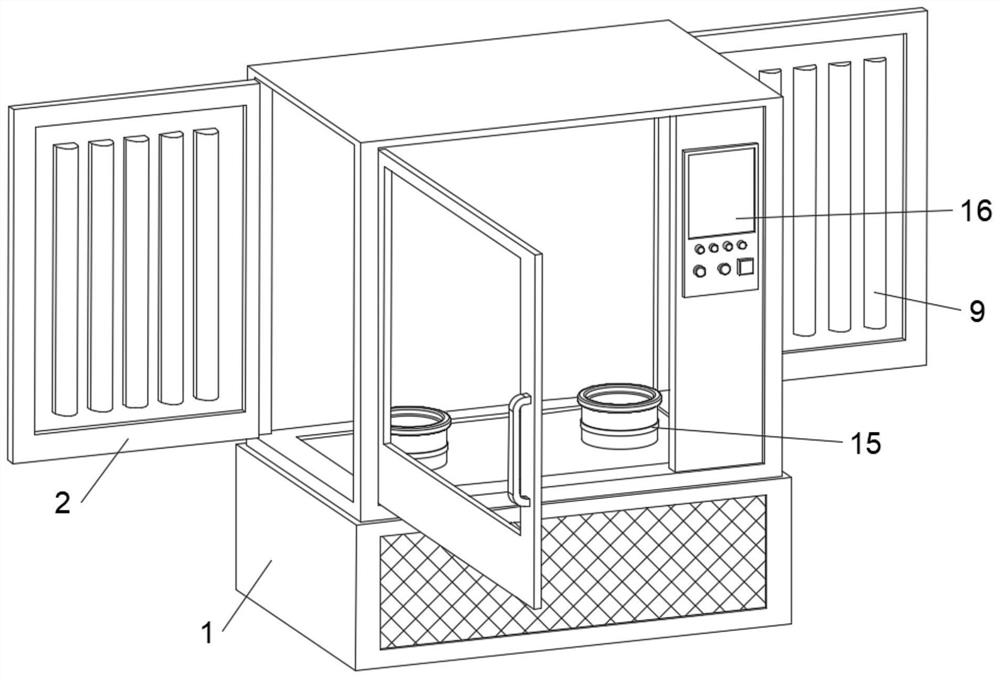

A heating box control system and control cabinet for observing thermal deformation of piezoelectric devices

ActiveCN107300937BControl heating temperatureControl the heating rateAuxillary controllers with auxillary heating devicesThermodynamicsControl signal

The invention discloses a heating box control system for observing the thermal deformation of a piezoelectric device, and a control cabinet. The control system comprises a main switch which is configured to control the on / off of a first-stage temperature controller control signal circuit of a whole heating box. The first-stage temperature controller control signal circuit is configured to collecting the temperature of a central thermocouple in the heating box, and controls the on / off of two independent second-stage temperature controller control signal circuits connected with the first-stage temperature controller control signal circuit according to a collection value. Each second-stage temperature controller control signal circuit comprises a branch switch, an AC contactor circuit of a second-stage temperature controller and an AC contactor circuit of a heating plate, wherein the AC contactor circuits are controlled by the branch switch. Through the control of the connection of the two AC contactors, the system achieves the operation of the heating plate in the heating box or an object. Meanwhile, the signals of the thermocouples on the two heating plates are fed back to the corresponding second-stage temperature controllers, so as to feed back and adjust the heating temperature of the heating plates.

Owner:SHANDONG UNIV

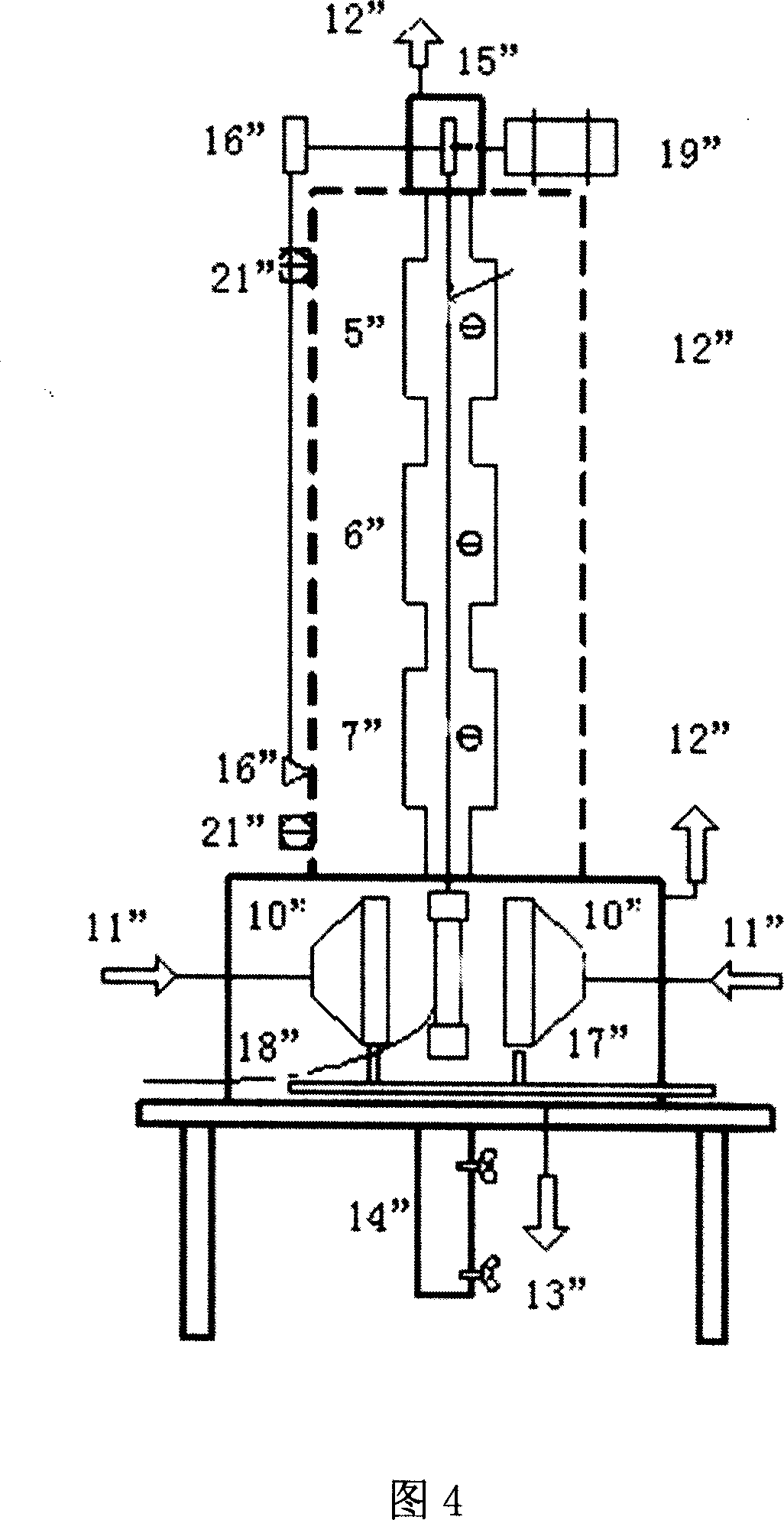

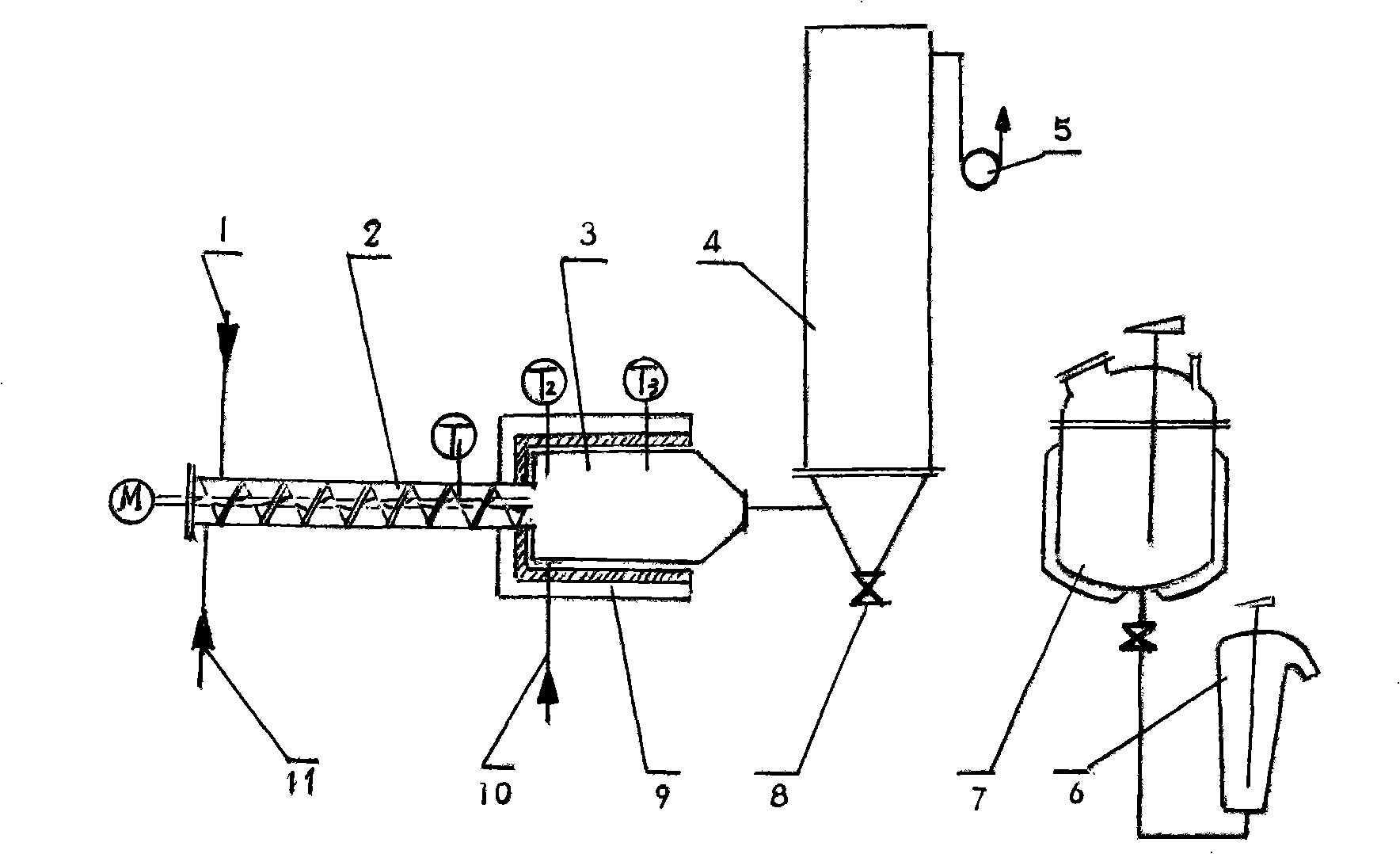

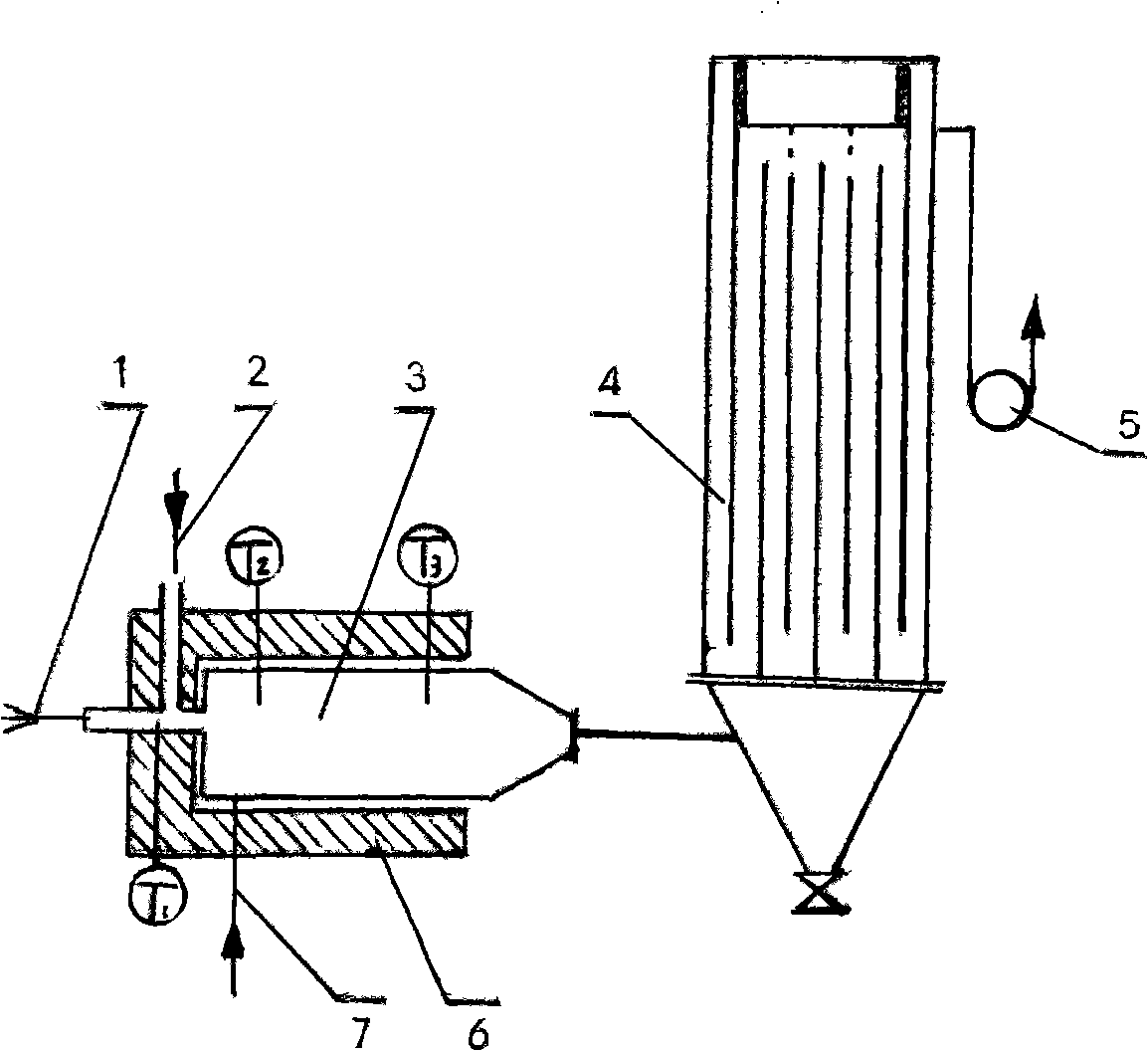

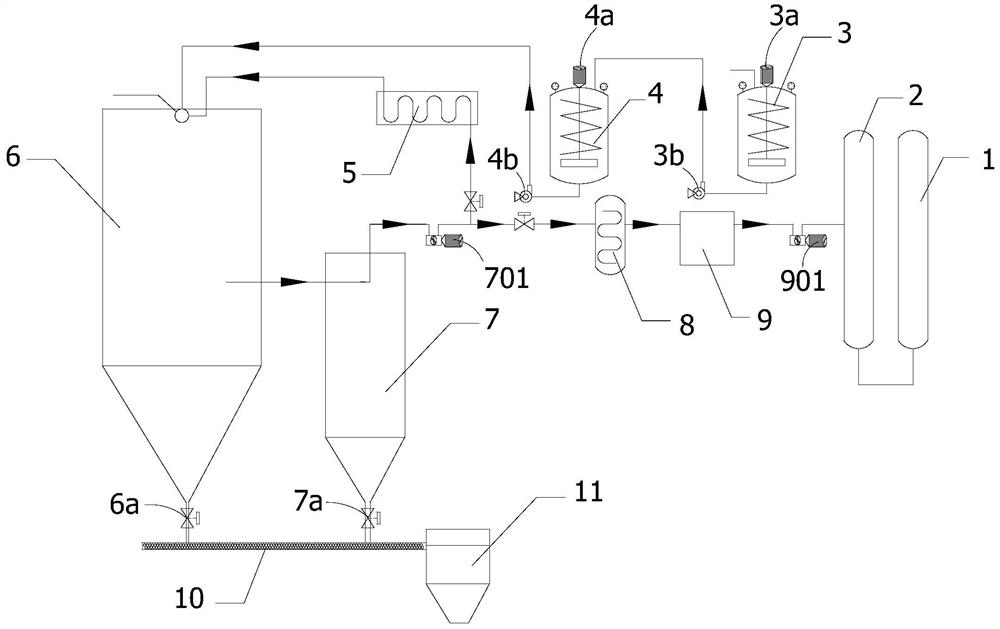

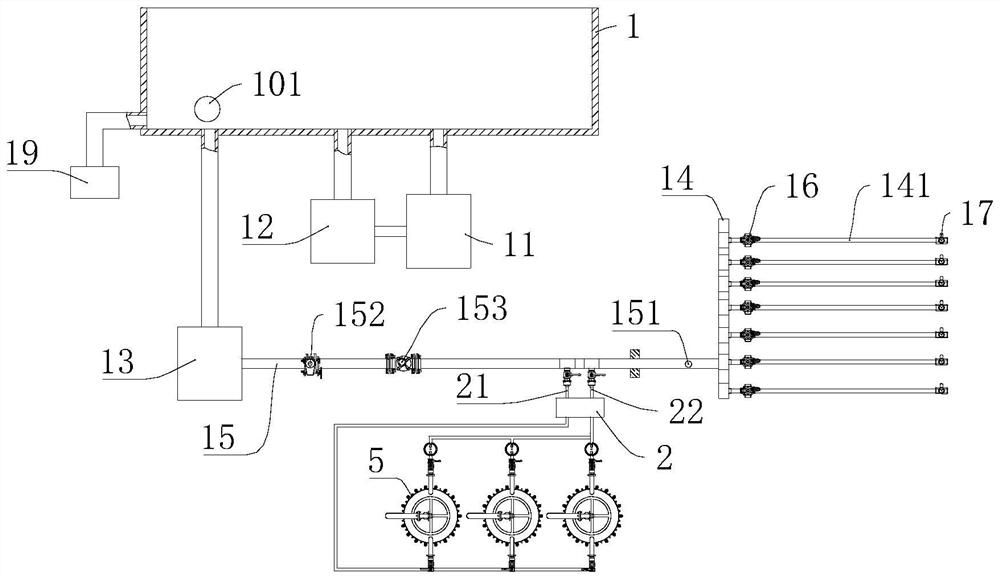

A method and device system for recovering nitric acid by nitrate pyrolysis

ActiveCN109721038BControl the heating rateHigh thermal decomposition efficiencyOxide/hydroxide preparationChemical industryNitrate saltsPhysical chemistry

The invention discloses a method for recovering nitric acid by pyrolyzing nitrate. The method comprises the following steps: (1) conveying the nitrate into at least two preheaters, heating the nitrateto firstly liquefy the nitrate, and then heating the nitrate to a temperature less than decomposition temperature in order to obtain a nitrate hot fluid; (2) conveying the nitrate hot fluid into a decomposer, and heating the nitrate hot fluid with a high temperature gas to maintain the internal temperature of the decomposer at 500-800 DEG C in order to decompose the nitrate into a mixed gas and asolid powder; and (3) separating mixed gas and the solid powder, conveying a part of the mixed gas into a nitric acid recovery tank, heating the remaining mixed gas to 500-800 DEG C, and then returning the heated remaining mixed gas into the decomposer to heat the nitrate hot fluid in order to thermally decompose the nitrate hot fluid. The method for recovering nitric acid has the advantages of less corrosion damages to devices, no introduction of other impurity components and no interference in the heating process, good decomposition speed and decomposition rate of the nitrate, and high recycling rate of the nitric acid.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

Quick cooling test plant for disk type band steel, and method of use

InactiveCN100447260CEliminate fragileEliminate deformationFurnace typesHeat treatment furnacesFixed frameStrip steel

This invention relates to disk-type strip steel rapid cooling test apparatus for stimulating annealing process requirement of continuous annealing of strip steel, and its usage method. The apparatus comprises: a disk-type case, a disk-type sample fixing frame and a compensating wire that can rotate around a core axis in the case, a sample loading / unloading chamber, a heating / homogenizing chamber, a slow cooling / over-aging chamber, a spray cooling chamber and a water quenching chamber. When used, the compensating wire is connected to the surface of the sample, and then the sample is introduced into the above chambers in sequence. This invention has such advantages of large sample size, a wide variety of cooling methods, high cooling speed, simple apparatus, and low malfunction rate.

Owner:BAOSHAN IRON & STEEL CO LTD

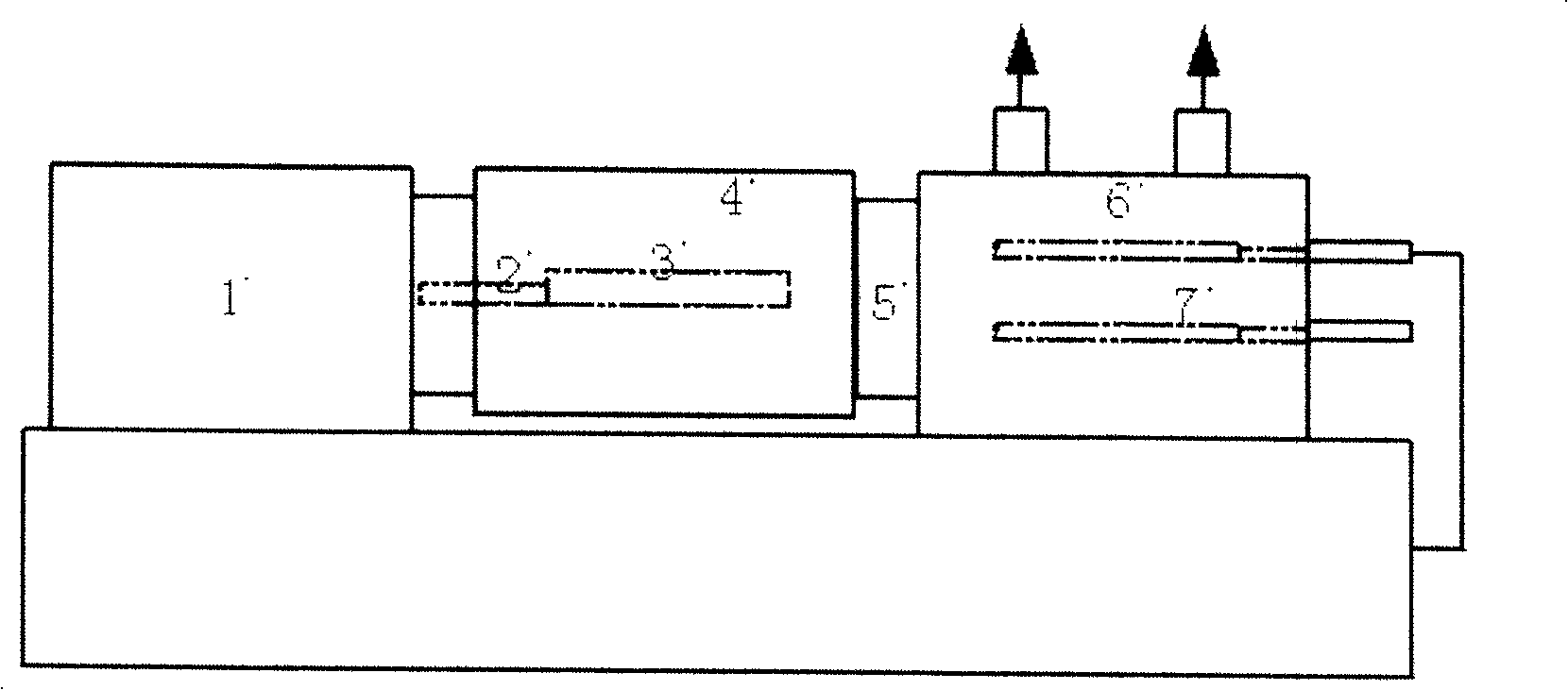

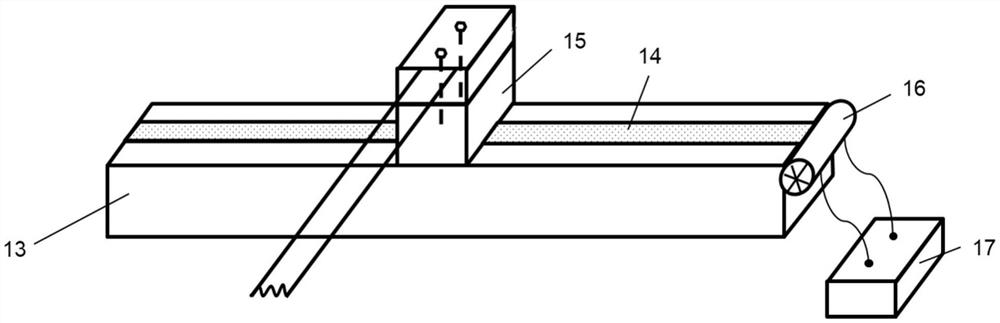

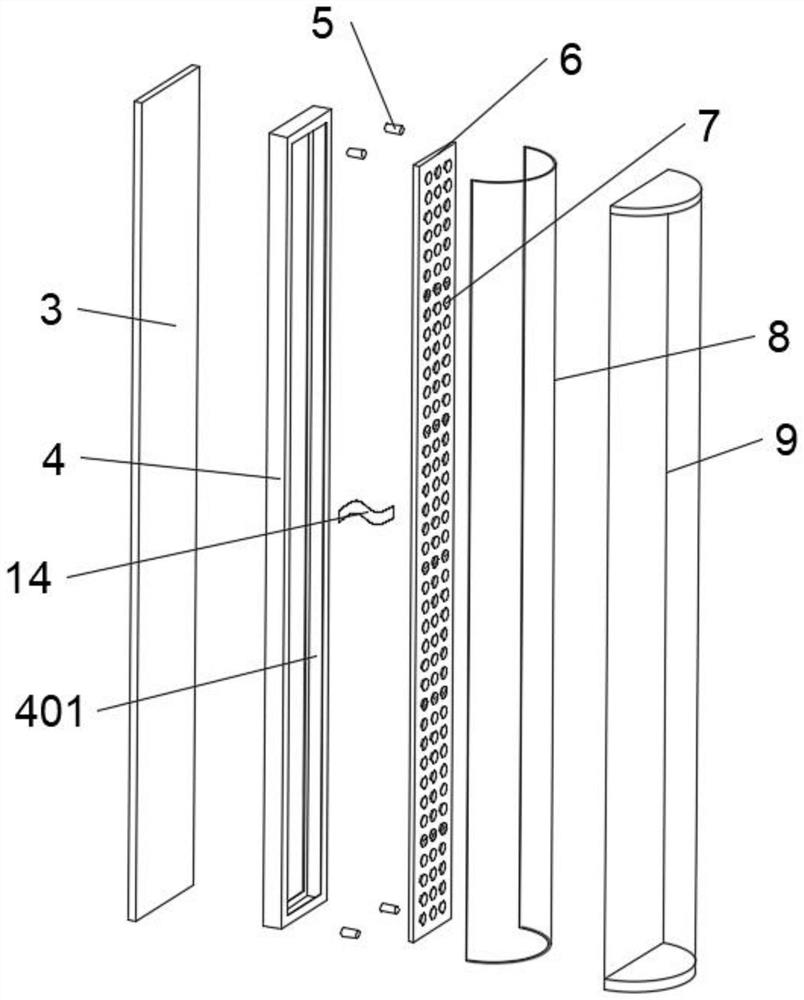

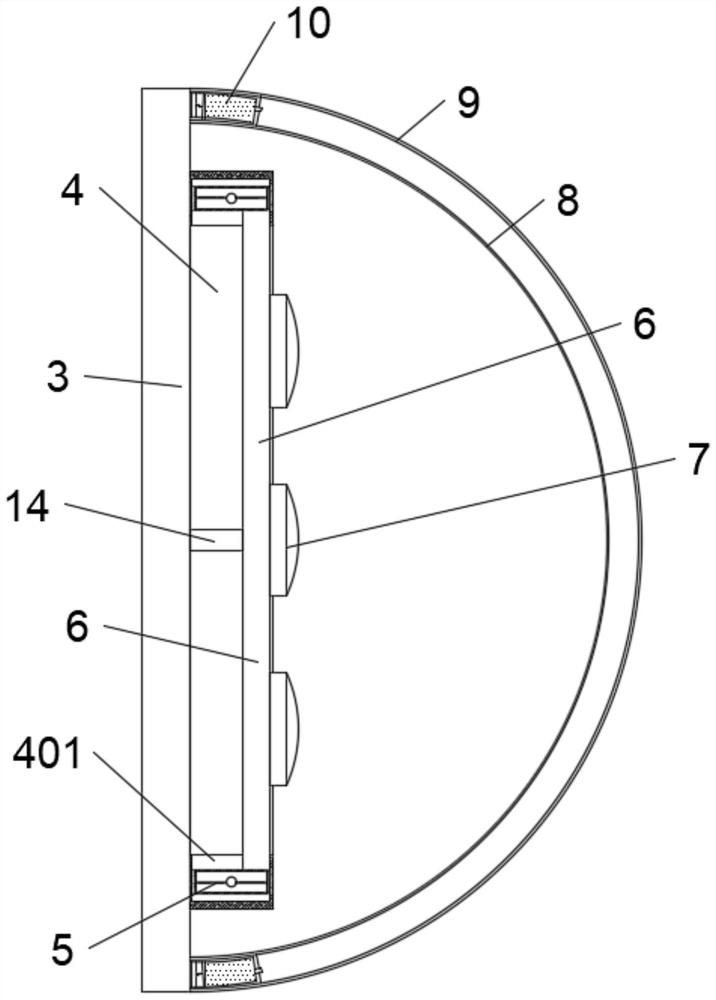

Blade tip cutting coating preparation system with residual stress relieving effect and using method

ActiveCN112267110AReduce residual stressAlleviate the effect of residual stressMetallic material coating processesRefrigerationSurface modification

The invention discloses a blade tip cutting coating preparation system with a residual stress relieving effect and a using method thereof, and belongs to the technical field of material surface modification and coatings. The blade tip cutting coating preparation system with the residual stress relieving effect comprises a blade fixing module, a first induction heating head and a second induction heating head, wherein the first induction heating head and the second induction heating head are located over the blade fixing module and on the side face of the blade fixing module. By controlling thedistance between the first induction heating head and a blade base body and the distance between the second induction heating head and the blade base body, gradient preheating of different temperatures is achieved on different portions of the blade base body, residual stress is relieved, and the mechanical behavior of a blade is prevented from being affected by overheating. In addition, a refrigeration module can protect a circuit control module, the first induction heating head and the second induction heating head from being burnt out.

Owner:XI AN JIAOTONG UNIV

Thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel

ActiveCN102676766BReduce plasticityReduce toughnessHeat treatment process controlFragilityPerformance index

The invention belongs to the technical field of production of duplex stainless steel products used at low temperature and particularly relates to a thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel with high requirements for performance indexes. The thermal treatment method comprises the steps: feeding forged austenite-ferrite stainless steel into a furnace at the feeding temperature of not greater than 350 DEG C and performing twice preheating; performing solution treatment; performing cooling, feeding the austenite-ferrite stainless steel into clear water with the initial temperature smaller than 10 DEG C, and retaining the austenite-ferrite stainless steel for 20 minutes at the cooling speed of 4-6 seconds / mm. An austenite-ferrite stainless steel solution treatment process comprises the steps of (1) heating, namely controlling heating speed, preheating temperature, solid solution temperature and retaining time at a low-temperature section, reducing thermal stress and simultaneously obtaining good duplex structural proportion and (2) cooling, namely adopting a quick low-temperature long-time water-cooling mode to prevent precipitation due to fragility phase and remarkably reducing the plasticity and the toughness of the steel.

Owner:HENAN ZHONGYUAN HEAVY FORGING

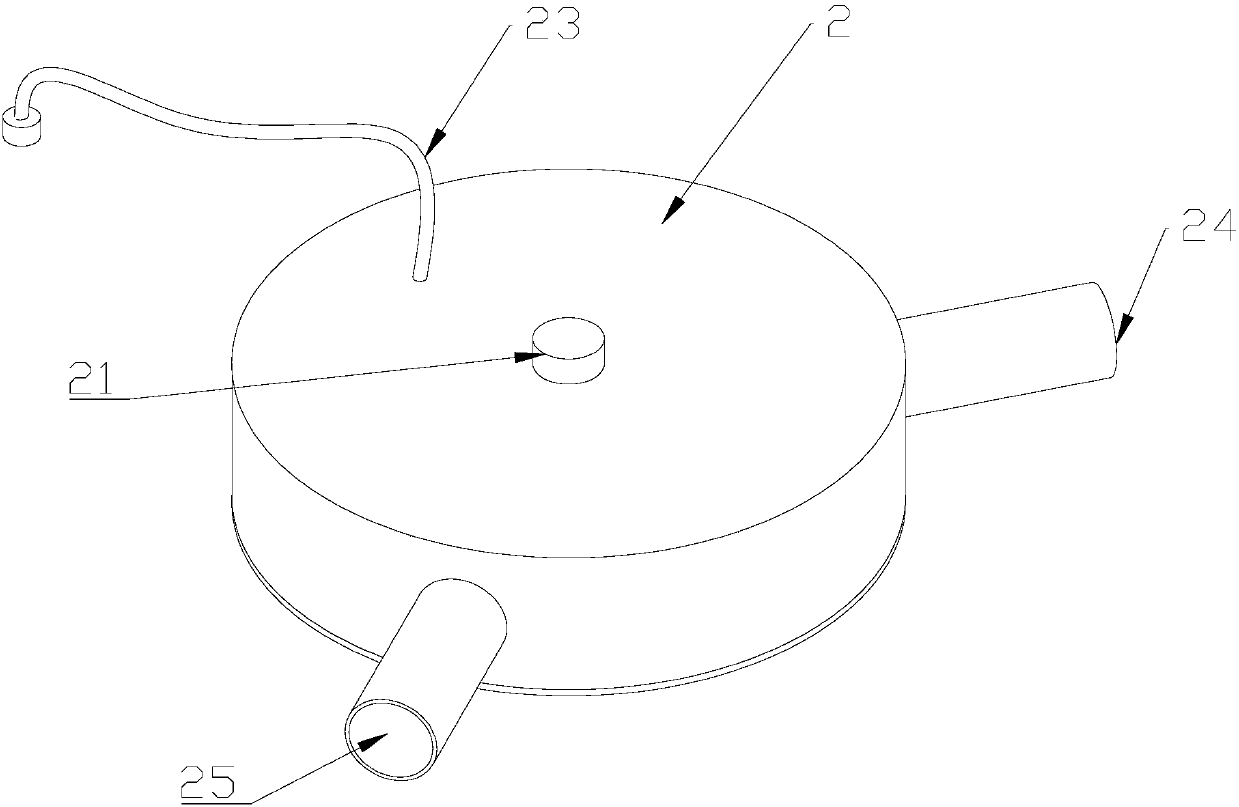

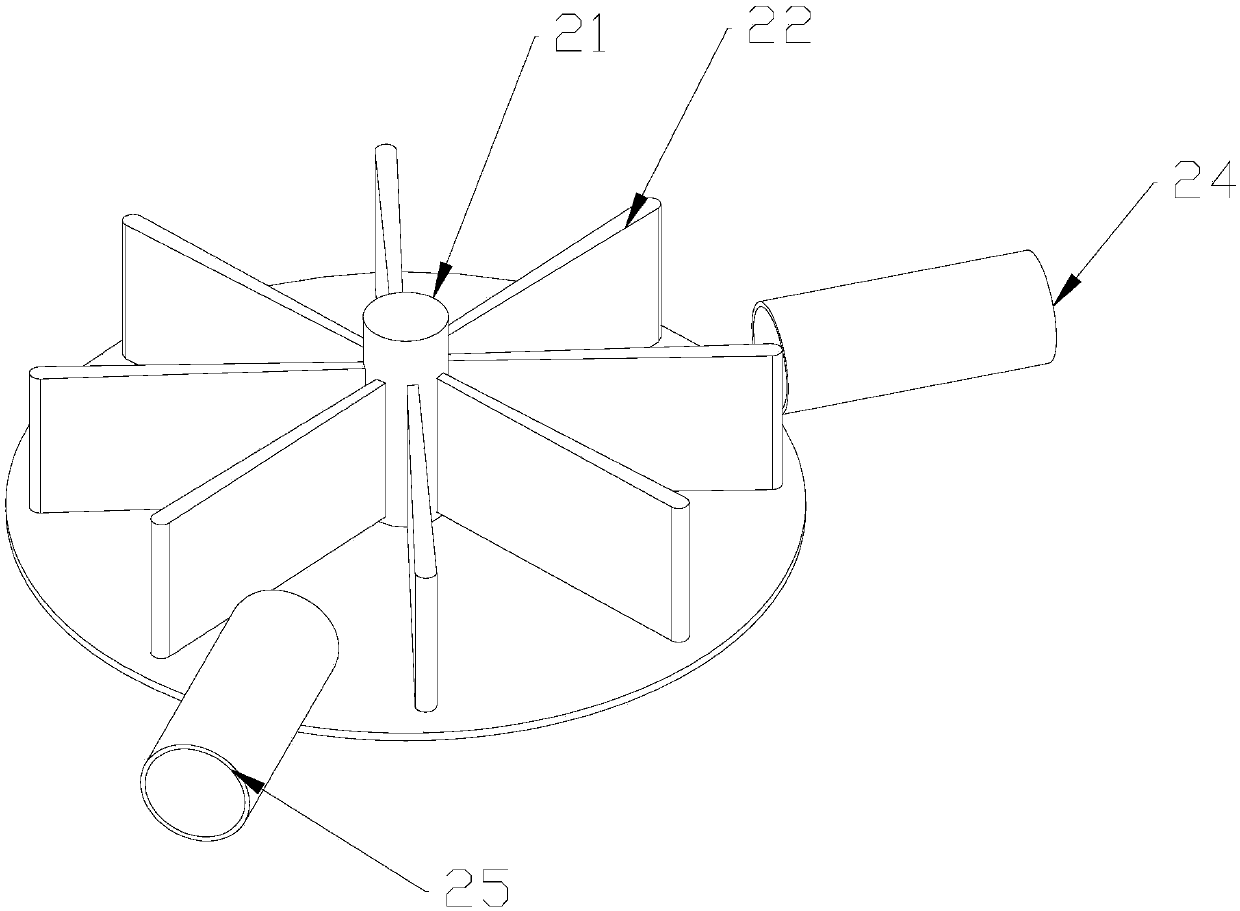

Liquid heater with filtering function

PendingCN107726618AAvoid depositionDoping EliminationStorage heatersMoving filtering element filtersEngineeringThermal efficiency

The invention provides a liquid heater with a filtering function. The liquid heater comprises a filtering mechanism and a heating mechanism; the filtering mechanism comprises a filtering box and a filtering screen; the filtering screen is cone-shaped, a detachable bracket is arranged at the upper end of the filtering screen, and a vibrating spring is connected between the filtering screen and thedetachable rack; the heating mechanism comprises a heating box, a rotating shaft is arranged in the heating box, and a plurality of heating plates are arranged on the rotating shaft; and the top of the heating box is connected to a vacuum pipe. The liquid heater with the filtering function provided by the invention achieves the effects of being high in heating efficiency and long in service life.

Owner:TIANJIN LANKE MACHINERY CO LTD

Steam hot water boiler

InactiveCN111829171AControl the heating rateEasy to igniteSteam generation using pressureWater heatersThermodynamicsMechanics

The invention discloses a steam hot water boiler. The steam hot water boiler comprises a cooker and a stove, wherein the stove comprises a combustion device and an adjusting module; the combustion device comprises a combustion cylinder, a feeding pipe and an air inlet pipe; the adjusting module comprises a first door plank, a second door plank and a third door plank; the flow of external air entering a combustion space of the combustion cylinder through the feeding pipe is adjusted by controlling the opening degree of the first door plank; and the flow of external air entering the combustion space of the combustion cylinder through the air inlet pipe is adjusted by controlling the opening degree of the second door plank and the third door plank. Therefore, by adjusting the flow of the external air entering the combustion space of the combustion cylinder through the feeding pipe and the air inlet pipe in a multi-section mode, the effect of adjusting the firepower in a multi-section modeis achieved, and then the heating speed on cold water can be controlled.

Owner:陈正雄

Green constant-temperature clothes

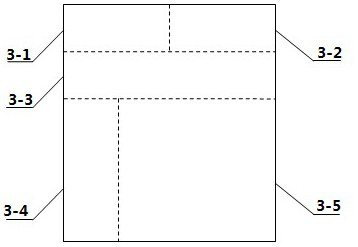

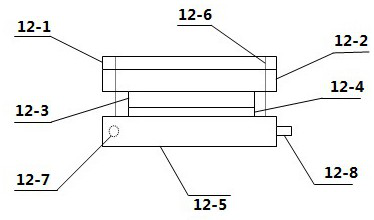

PendingCN114073346AAchieve constantSimple structureGarment special featuresBatteries circuit arrangementsEngineeringMechanical engineering

The invention discloses clothes which can keep a constant temperature, can control the constant temperature speed and does not need to be charged. The invention belongs to household articles for daily use. The green constant-temperature clothes overcome the technical defects that the constant-temperature speed of the constant-temperature clothes in the prior art cannot be controlled so that the temperature of the clothes is suddenly high or low, heating or cooling is frequently started, and charging is needed. The clothes mainly comprise a power supply device (3), a heating and refrigerating speed regulator (2), a reversing switch (6), a mechanical temperature controller (10), a temperature changing box (12), a pump (13), a rubber hose (5), a component bearing medium (7), a lead (9), a liquid (which is not marked in the rubber hose (5) and a water tank (12-5)) and the like. According to the green constant-temperature clothes, the liquid is cooled or heated according to the refrigerating and heating principle of the semiconductor cooling piece (12-4), and then the liquid is circulated in cycles through the pump (13) and the rubber hose (5). And the constant-temperature comfort is successfully kept for people.

Owner:李绪章

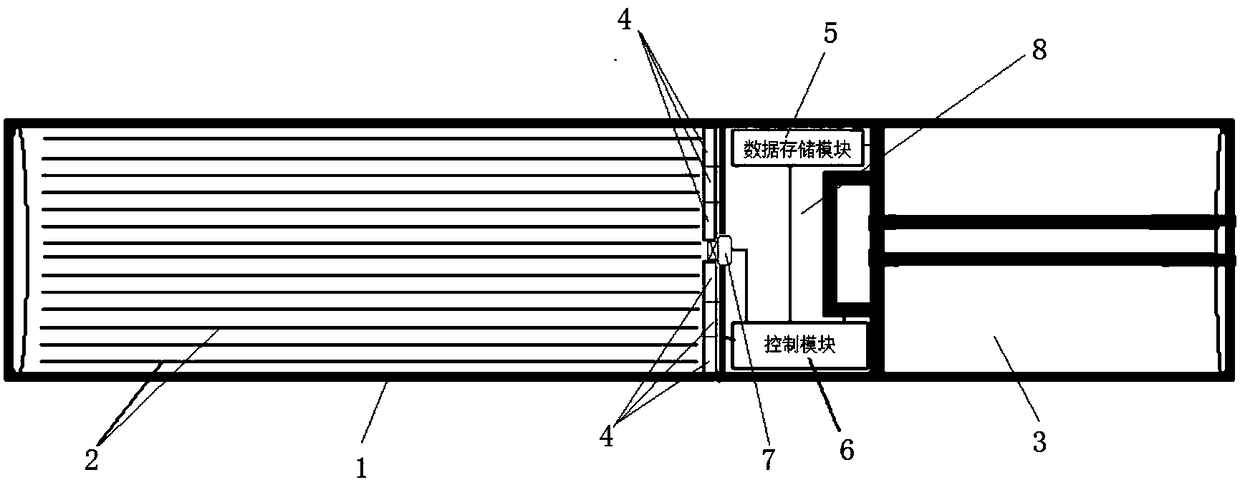

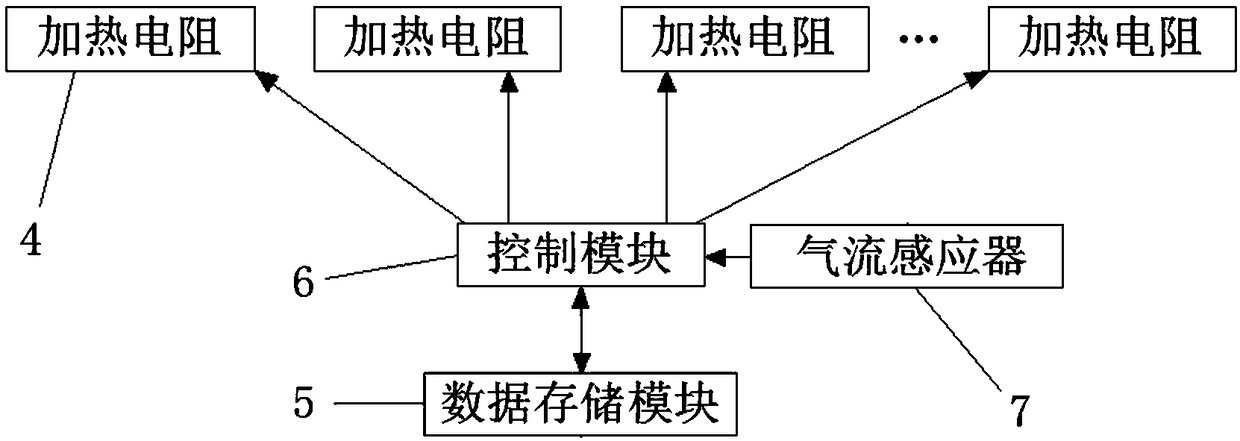

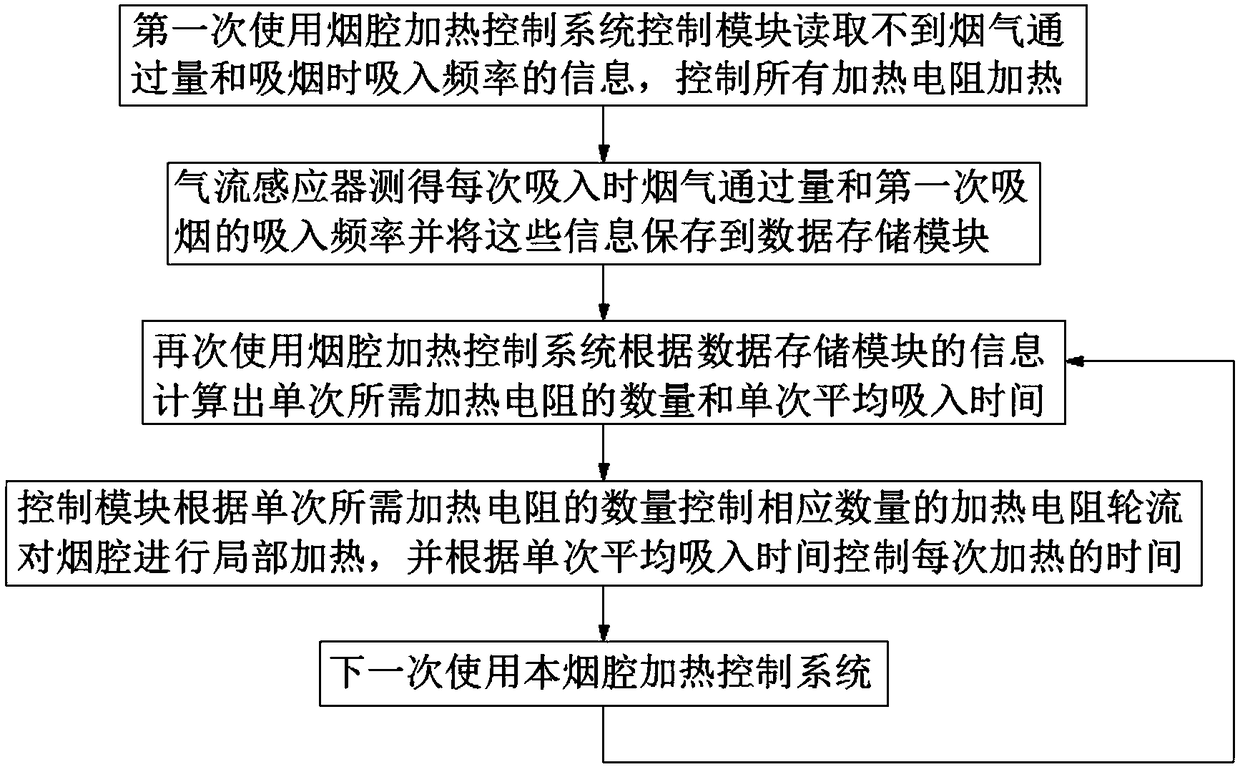

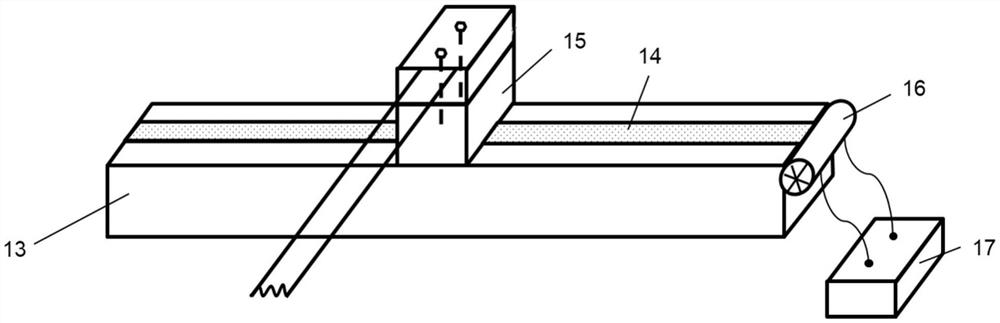

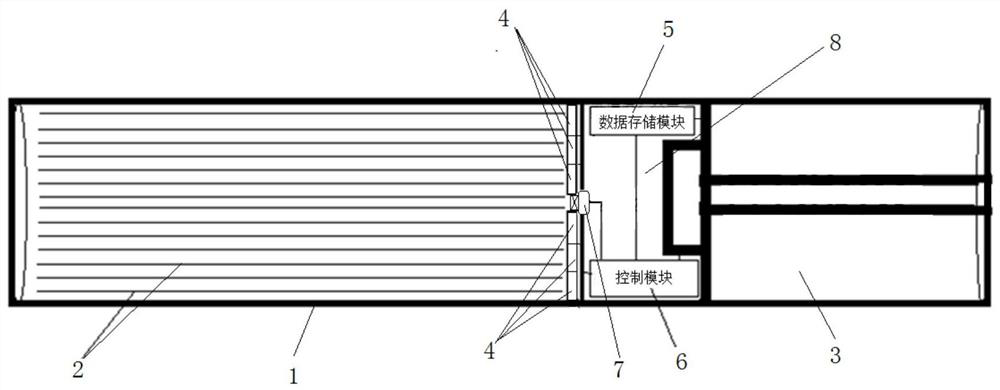

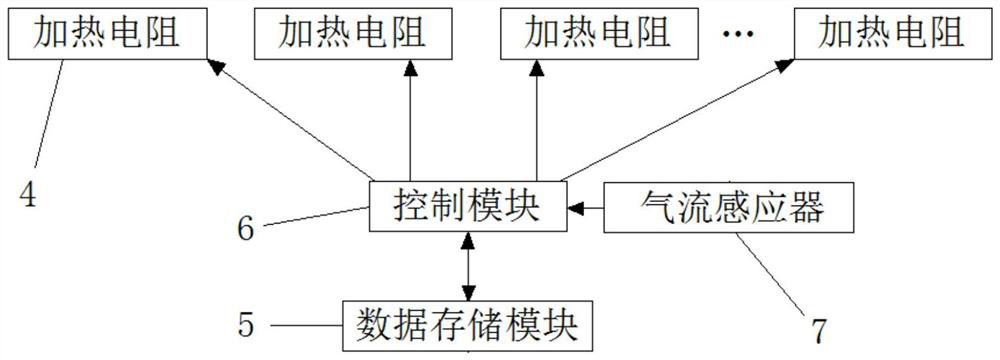

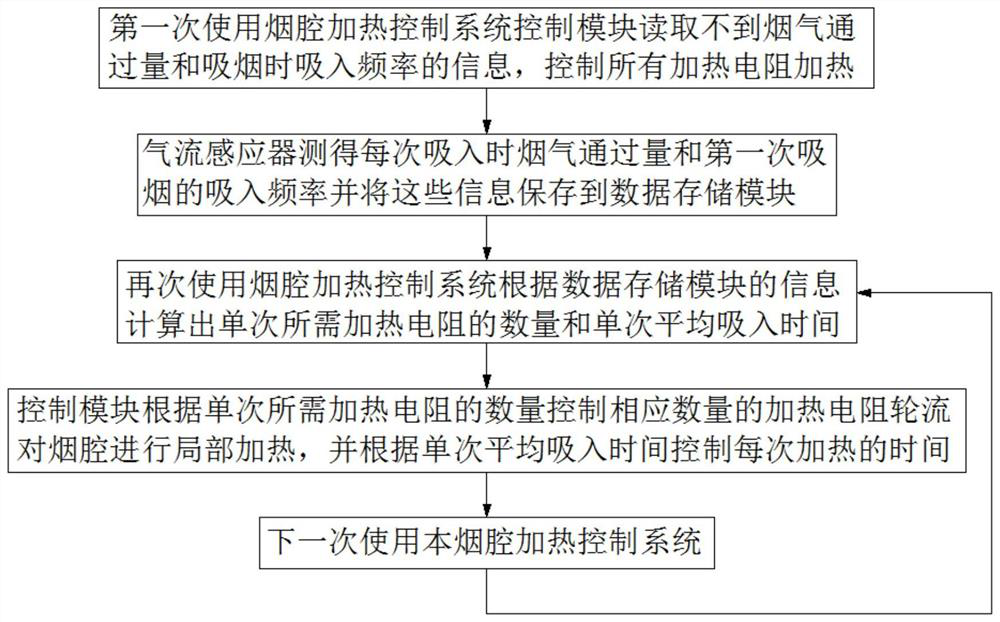

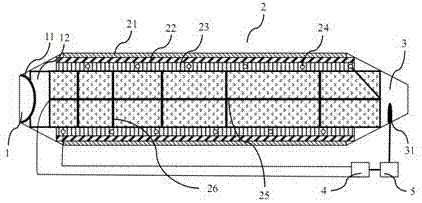

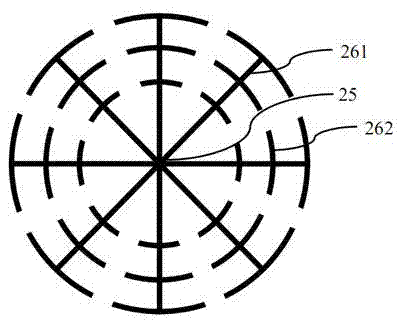

Control method of intelligent cigarette cavity heating control system for lower-temperature cigarette

ActiveCN109043666AControl the heating rateHeating carefullyTobacco devicesElectricityElectrical resistance and conductance

The invention discloses a control method of an intelligent cigarette cavity heating control system for a lower-temperature cigarette. The cigarette cavity heating control system comprises multiple heating needles, multiple heating resistors, a temperature sensor, an airflow sensor, a data storage module, a control module and a battery. The heating needles are stabbed into a cigarette cavity containing tobacco, the heating needles are connected to all the heating resistors, and the airflow sensor is arranged at a suction port of the bottom of the cigarette cavity; the control module is electrically connected to all the heating resistors separately, the airflow sensor is in signal connection with the control module, and the data storage module is in signal connection with the control module.The control module reads information of the suction frequency during previous use, the smoke amount generated by the heating resistors per unit and the smoke passing amount through multi-time suctionto calculate the number of heating resistors required by single time and average suction time of single time. The heating area and heating time are controlled by all the heating resistors. Therefore,according to habits of smokers, the heating speed of tobacco shreds is controlled, and the situation is avoided that since tobacco shreds cannot be sufficiently used, tobacco shreds and electric energy are wasted.

Owner:芜湖启迪睿视信息技术有限公司

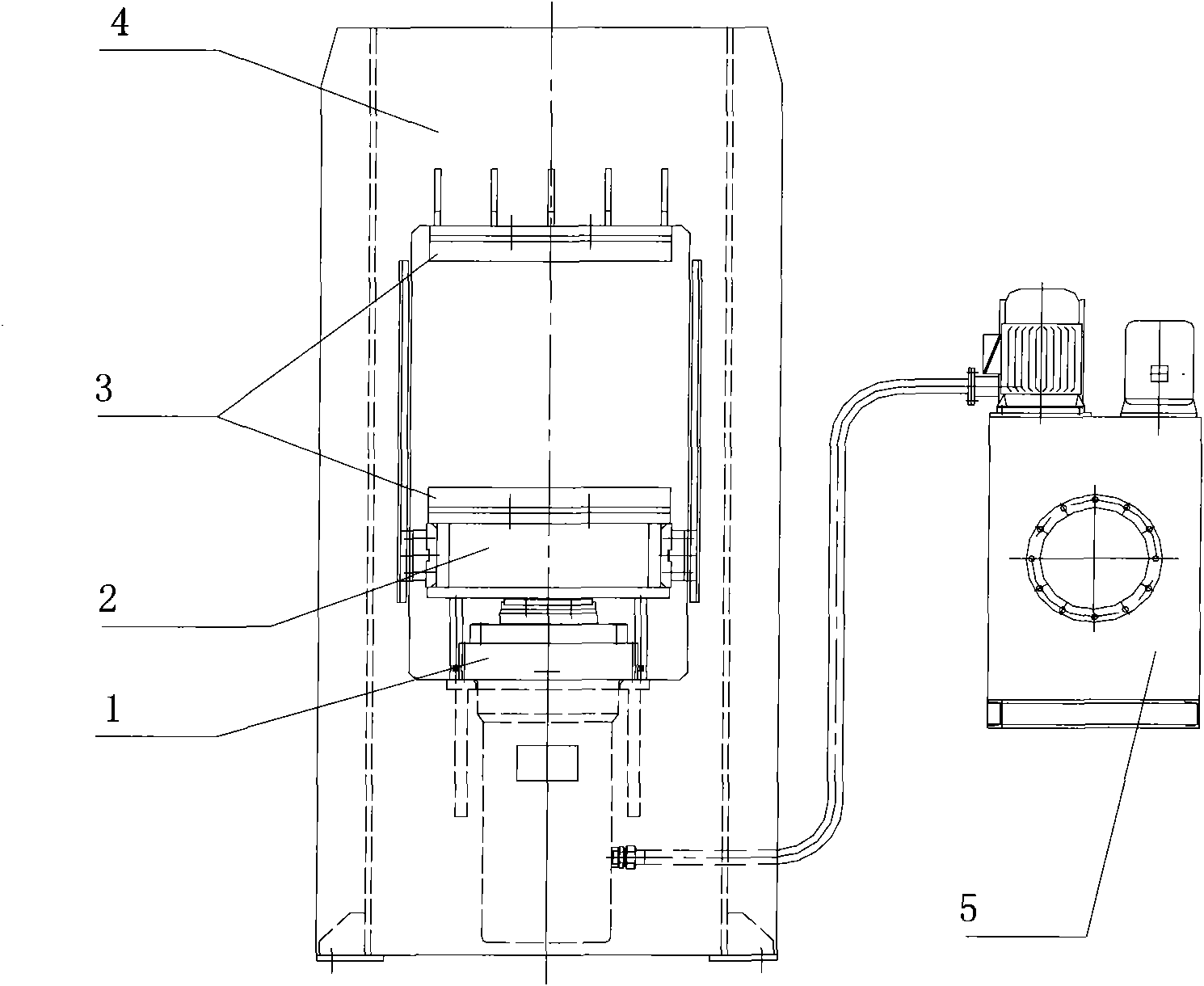

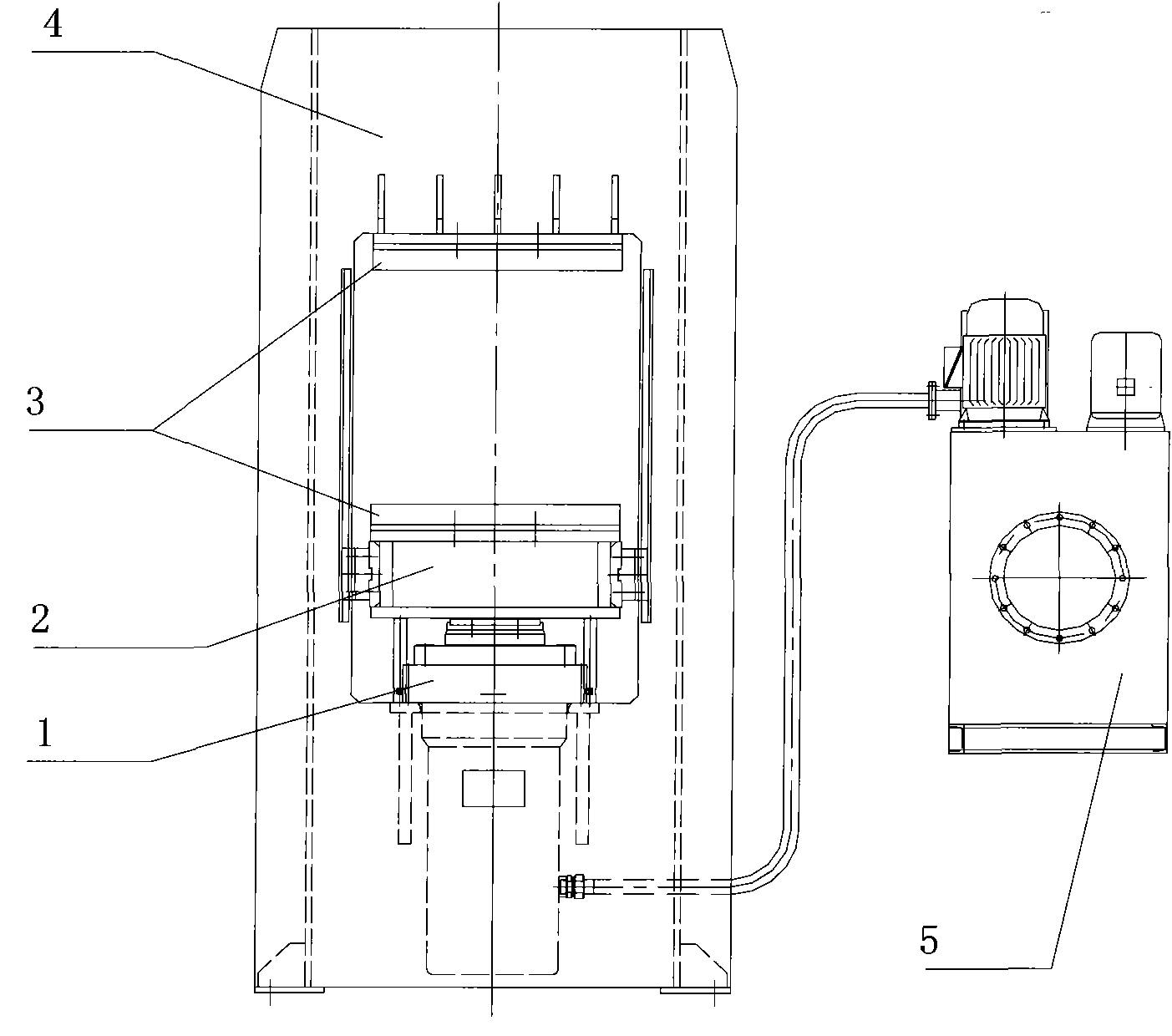

Artificial stone testing press

The invention discloses an artificial stone testing press which is used for experiments of artificial stone process, and comprises a press main body, a hydraulic station, a proportional temperature control device and an electric control device, wherein the press main body comprises a framework, an oil cylinder, a movable cross beam and hot press plates, and the oil cylinder is mounted at the bottom part of the main body; the movable cross beam is placed on the oil cylinder and can slide up and down on a peripheral guide device; and one hot press plate is fixed on the movable cross beam, the other hot press plate is fixed on a frame on the upper surface, and the two hot press plates are in contact when the oil cylinder is lifted to the top part. The device is convenient to operate and reliable to work, thereby being an ideal testing device.

Owner:SUZHOU XINXIELI MACHINE MFG

Even heating microwavable container

InactiveCN101636620BControl the heating rateMinimize scorchingDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenProcess engineering

Means for heating food in a microwave oven comprising a microwave energy of at least a portion of the bottom (102), the wall (104) extending upwardly from said bottom (102), the covering wall (104) of the shield element (108) , and by the microwave energy shielding element (108) surrounded by the microwave energy diffusing element (112), wherein the microwave energy diffusing element (112) comprises a plurality of reflective elements within a microwave energy (114) in the microwave energy permeable areas (116).

Owner:GRAPHIC PACKAGING INT

Direct heating type constant-temperature dryer

InactiveCN104634090AIncrease the heating areaImprove securityHeat pumpsDrying gas arrangementsAir volumeFresh air

The invention discloses a direct heating type constant-temperature dryer. The direct heating type constant-temperature dryer comprises an air inlet, an electric adjusting valve arranged at the tail end of the air inlet, condensers arranged below the right portion of the electric adjusting valve, a centrifugal fan arranged at the right side of the condensers, an air outlet arranged below the centrifugal fan, an evaporator arranged below the condensers, circulating conveying pipes connected with the two ends of the condensers and the two ends of the evaporator, a draught fan arranged at the left side of the condensers and a dehumidifying port arranged at the left side of the draught fan. According to the direct heating type constant-temperature dryer, since the two condensers are obliquely arranged, the heating area of fresh air is enlarged, the air supply volume of the fresh air is adjusted in combination with the electric adjusting valve, the heating speed of the condensers on the air is controlled, the heating speed is high, the heating effect is good, the energy ratio of the working effect of a main engine is increased, and the energy saving effect is achieved; compared with the traditional technology, cyclic heating of the air is not needed, and the air outlet can be externally connected with a heat conveying pipe to form a certain distance, so a fire can be prevented, and the safety of operation is enhanced.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

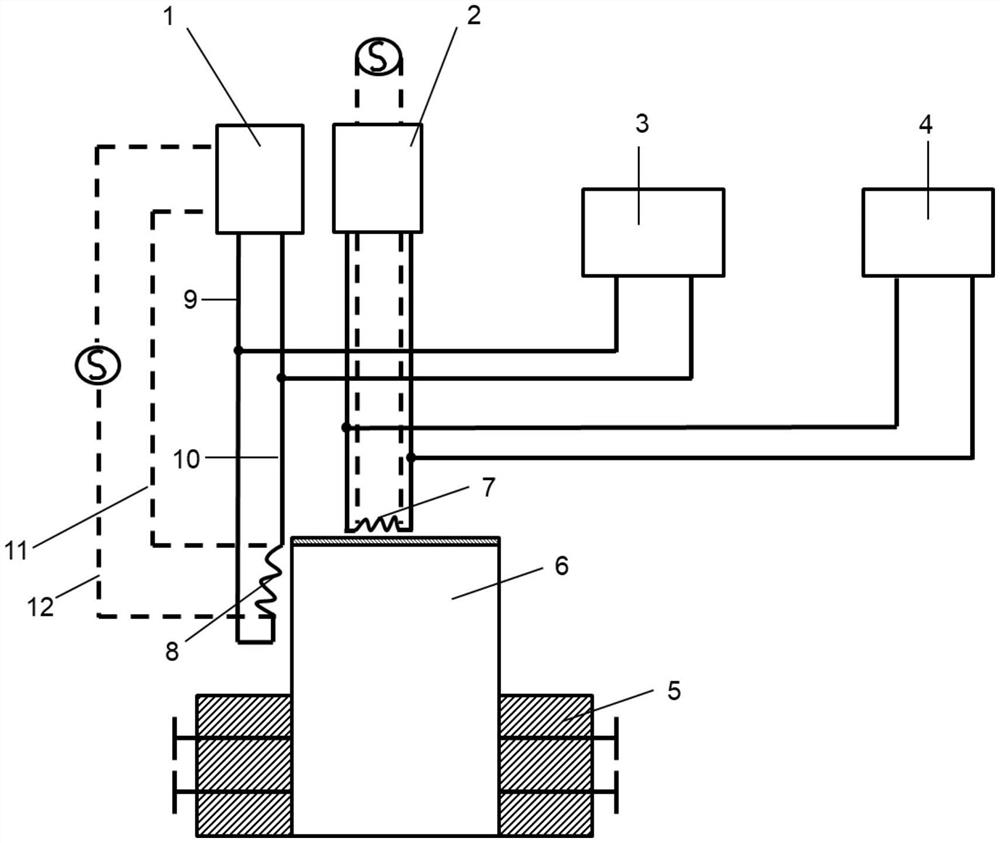

Constant-temperature irrigation system

PendingCN114667877AControl the heating rateControl heating powerClimate change adaptationPressurised distribution of liquid fertiliserSoil scienceAgricultural irrigation

A constant-temperature irrigation system relates to the technical field of agricultural irrigation and is used for solving the problem of low temperature of irrigation water in winter in the prior art. A constant-temperature irrigation system is characterized in that the constant-temperature irrigation system comprises a buffer water tank, a variable-frequency electric heating boiler, a first variable-frequency water pump, a second variable-frequency water pump, a water and fertilizer all-in-one machine, a water distribution device and a plurality of irrigation pipelines distributed in different sunlight greenhouses, all irrigation water paths are connected with the water outlet end of the water distribution device, and the water and fertilizer all-in-one machine comprises a water inlet pipe and a fertilizer injection pipe; the first variable-frequency water pump, the variable-frequency electric heating boiler and the buffer water tank are connected in series, so that water in the water tank is circularly heated through the variable-frequency electric heating boiler. The constant-temperature irrigation device has the advantage of being beneficial to constant-temperature irrigation.

Owner:寿光恒蔬无疆农业发展集团有限公司

A blade tip cutting coating preparation system and application method capable of alleviating residual stress

ActiveCN112267110BReduce residual stressAlleviate the effect of residual stressMetallic material coating processesCoating systemStructural engineering

Owner:XI AN JIAOTONG UNIV

Simulating device for strip steel continuous annealing process

InactiveCN100535663CReduce the impact of cooling effectsUniform temperatureTesting metalsCooling chamberEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

Plant illumination system based on laser pulse

ActiveCN114557209AAdjust the degree of transparencyIncrease profitSaving energy measuresHorticulture methodsLight irradiationEngineering

The invention discloses a plant illumination system based on laser pulses, and belongs to the field of plant cultivation equipment.The plant illumination system based on the laser pulses comprises an illumination incubator body and side illumination fan blades symmetrically and rotatably connected to the illumination incubator body, and a plurality of power-on bottom plates are fixedly installed on the side illumination fan blades; a fine adjustment frame is fixedly mounted at the front end of the electrified bottom plate, light direction adjusting assemblies are symmetrically and fixedly mounted on the inner wall of the fine adjustment frame, and through cooperative use of the light direction adjusting assemblies and the shunting supporting plate, the light irradiation direction of the pulsed accent light can be finely adjusted, and the accuracy of the illumination direction is effectively improved; the illumination utilization rate is effectively improved, the illumination requirement of plant cultivation is met, the photosynthesis efficiency of plants is improved, the growth of cultivated plants is facilitated, and the light-transmitting adjusting assembly is used in the built-in heat absorption protection layer and the external transparent protection cover.

Owner:ZHEJIANG UNIV

Temperature measuring device for aluminum vehicle body maintenance

PendingCN111579104AReduce labor costsAchieve damage-free connectionThermometer detailsThermometer applicationsMechanical engineeringAutomotive engineering

The invention discloses a temperature measuring device for aluminum vehicle body maintenance, which comprises a detection device used for measuring the temperature of an aluminum vehicle body; and a fixing assembly arranged on the detection device and used for fixing the detection device onto the aluminum vehicle body. According to the temperature measuring device for maintenance of the aluminum vehicle body, the detection device is fixed to the aluminum vehicle body through the fixing assembly for temperature measurement, the two hands of maintenance personnel can be liberated, and thereforethe labor cost of maintenance is reduced.

Owner:HUNAN AUTOMOTIVE ENG VOCATIONAL COLLEGE

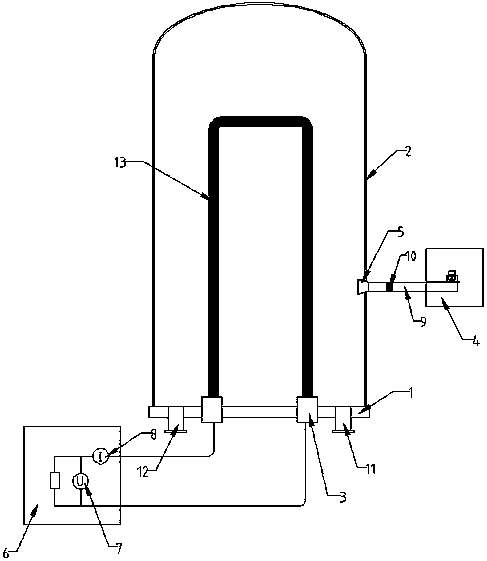

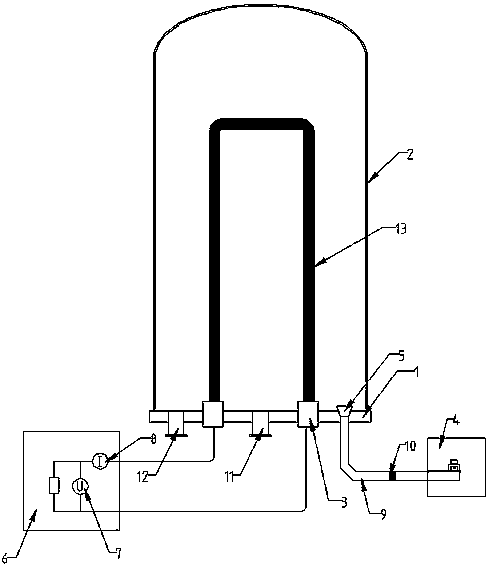

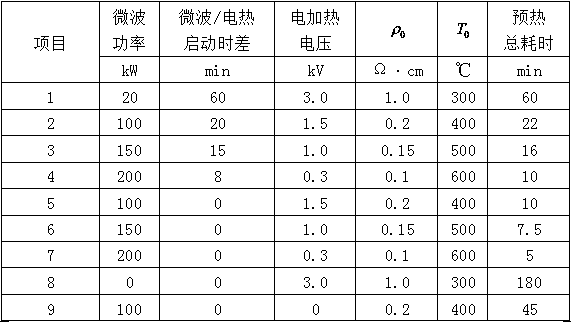

Novel polycrystalline silicon production preheating method and novel polycrystalline silicon production preheating device

PendingCN111072029AEffective heatingShorten heating timeChemical industryFurnace typesHigh energyThermal efficiency

The invention discloses a novel polycrystalline silicon production preheating device, which comprises a chassis and a furnace cover which are connected with each other, wherein an electrode is arranged on the chassis, and is connected with an electric heating power supply, and the furnace cover is also connected with a microwave generator. According to the invention, a silicon core is heated by combining microwave irradiation heating and electric heating, and is mainly non-metallic in a normal temperature state, the microwave heating efficiency is high at this time, and the electric heating efficiency is continuously improved along with the reduction of the resistivity of the silicon core, the enhancement of the metallicity and the reduction of the heating efficiency of microwave irradiation, so that the advantages of microwave heating and electric heating are both achieved, the defects of high energy consumption, low heating efficiency, complicated operation and the like in the priorart are overcome, the production efficiency of polycrystalline silicon can be effectively improved, and good economic benefits are achieved.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

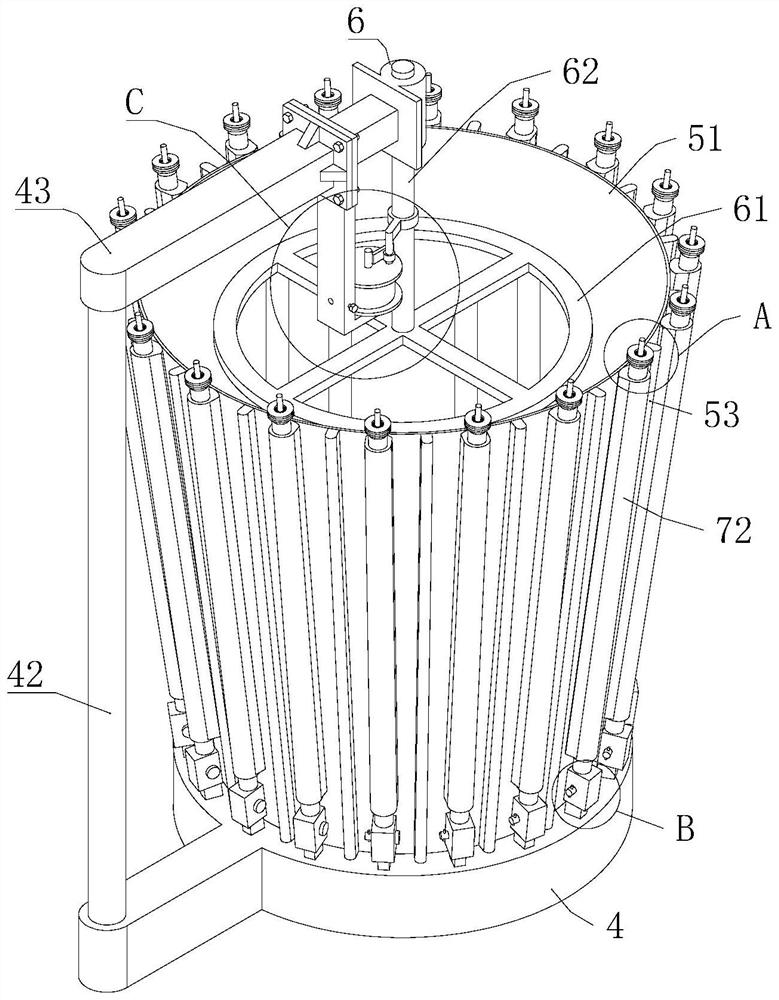

Device for simultaneous growth of multiple silicon carbide single crystals

InactiveCN113249783ASolve the \"competition\"Solve problemsPolycrystalline material growthFrom condensed vaporsCarbide siliconSingle crystal

The invention discloses a device for simultaneous growth of a plurality of silicon carbide single crystals. The device comprises a graphite crucible, an induction heating coil and a driving mechanism. The driving mechanism is located above the outside of the graphite crucible, the induction heating coil is located outside the graphite crucible, and the graphite crucible is cylindrical and comprises a main chamber located at the lower part and an auxiliary chamber located at the upper part. The bottom of the main chamber is filled with silicon carbide source powder. The auxiliary chamber comprises a first auxiliary material groove with the bottom filled with the silicon carbide source powder and a second auxiliary material groove with the bottom filled with halide auxiliary materials. Through the special design of the structure of the growth device, the corresponding requirements on the growth environment in the growth process of a plurality of silicon carbide single crystals are met, and a plurality of high-quality silicon carbide single crystals are obtained in the same batch, so that the growth efficiency of the current silicon carbide single crystals is remarkably improved.

Owner:中科汇通(内蒙古)投资控股有限公司

A control method for an intelligent low-temperature smoke chamber heating control system

The invention discloses a control method for an intelligent low-temperature smoke chamber heating control system. The smoke chamber heating control system includes a heating needle, a heating resistor, a temperature sensor, an airflow sensor, a data storage module, a control module and a battery. The heating acupuncture Enter the smoke chamber filled with tobacco. There are several heating resistors. Each heating resistor is connected to several heating needles. The airflow sensor is located at the suction port at the bottom of the smoke chamber. The control module is electrically connected to each heating resistor. The airflow sensor The sensor signal is connected to the control module, and the data storage module signal is connected to the control module. The control module reads the inhalation frequency during previous use, the amount of smoke generated by a unit heating resistor and the amount of smoke passed through several inhalations, and calculates the number of heating resistors required for a single time and the average inhalation time of a single time. The invention The heating area and heating time are controlled by each heating resistor. In this way, the heating speed of the cut tobacco can be controlled according to the smoker's habits, thereby avoiding the failure to fully utilize the cut tobacco and wasting the cut tobacco and electric energy.

Owner:芜湖启迪睿视信息技术有限公司

Air electrical heating device

InactiveCN107461924AControl the heating rateReasonably adjust the wind speedAir heatersElectricityTemperature control

The invention provides an air electrical heating device which comprises an air inlet segment, a heating segment and an air outlet segment. The air inlet segment is provided with a buffering membrane which is used for lowering the flowing speed of the air, and an air buffering cavity is formed between the buffering membrane and the heating segment; the air outlet segment is provided with a temperature sensor, and the temperature sensor is in electric connection with a temperature analyzer; the heating segment is of a round barrel shape and comprises a shell body, a thermal-insulation layer, a heating layer and a multihole heating ceramic material from outside to inside in sequence; the heating layer is internally provided with a screwy heating wire, the multihole heating ceramic material is internally provided with a plurality of plate-shaped heating patterns, wherein the multiple plate-shaped heating patterns are connected through a heating rod; the heating rod is in electric connection with the heating wire and is electrically connected to an external controller; and the controller is in electric connection with the temperature analyzer, and the electrical heating power of the heating wire and the heating rod is controlled by testing the temperature of the air outlet segment.

Owner:JIANGSU ZHONGKUANG HEAVY EQUIP CO LTD

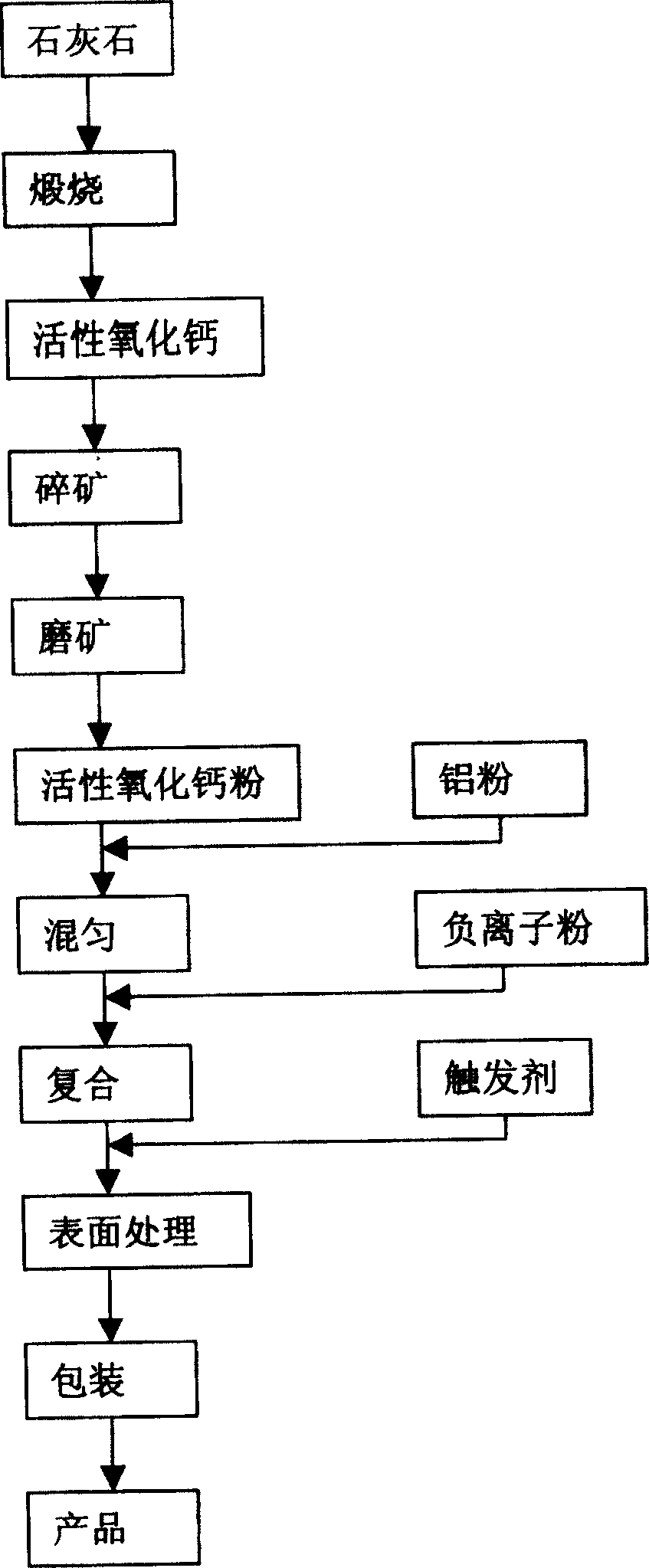

Preparation process of mineral heating agent

InactiveCN100362076CControl the heating rateFast feverHeat-exchange elementsAluminium powderMaterials science

A process of the mineral exothermic compound is the compound-surface treatment. The block limestone is calcined for 2-4h under 900-1000DEG C to make the active calcium oxide which is broken to 5mm, then the active calcium oxide is grinded to less than 0.076mm, next to mix the active calcium oxide powder and the aluminium powder which the particle size is less than 0.076mm for 0.5-5min; Then the anion powder is added into and compound them for 1-5min under 40-50DEG C. The compound powder and the catalyst are modified on surface for 15-30s with mixing at a high speed. The product has the high exothermic speed and releases the anion, so it can be used for the tourist to heat the food and the drinks.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com