Artificial stone testing press

A technology of artificial stone and press, applied in the field of artificial stone, can solve the problems of waste of manpower and material, and achieve the effect of high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

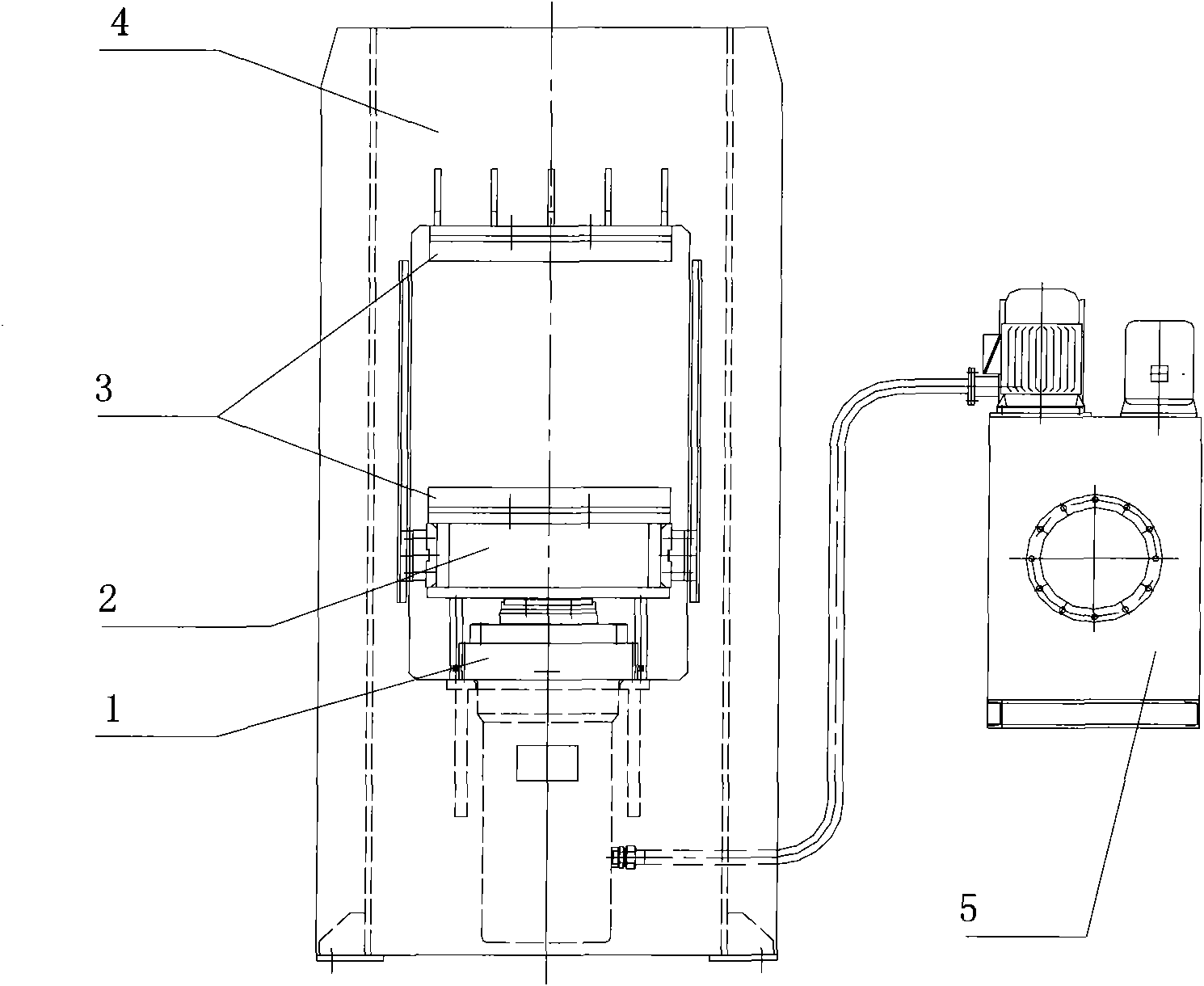

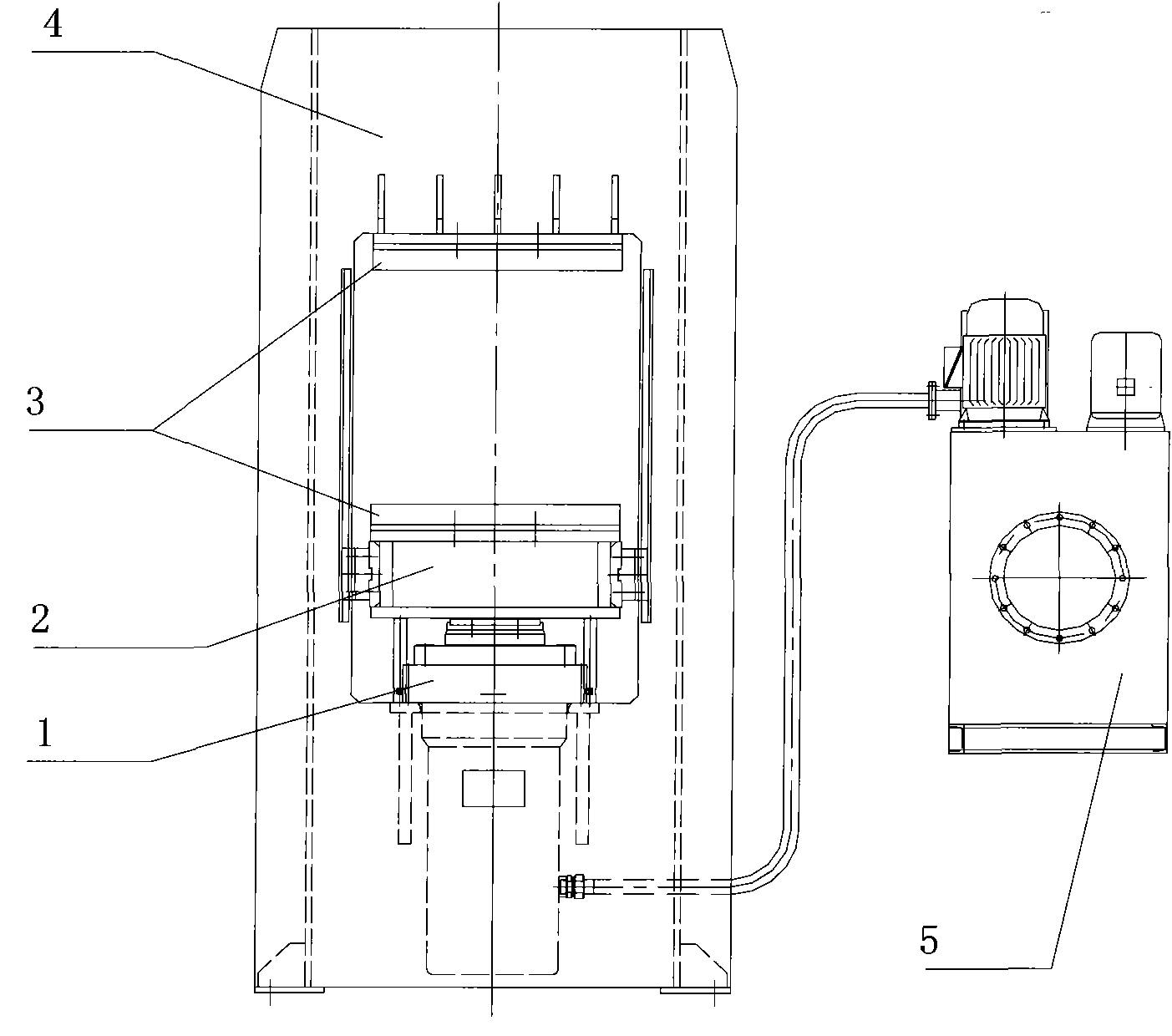

[0019] Such as figure 1 A kind of artificial stone test press shown is used for the experiment of artificial stone technology, including press main body, hydraulic station 5, proportional temperature control device, electric control device, it is characterized in that, described press main body is made up of frame, oil cylinder 1. The movable beam 2 and the hot pressing plate 3 are composed of the oil cylinder 1 installed at the bottom of the main body; the movable beam 2 is placed on the top of the oil cylinder 1 and slides up and down on the surrounding guide device; the hot pressing plate 3 is fixed on the movable beam 2, The other one is fixed on the frame 4 above, and when the oil cylinder 1 rose to the top, two heat press plates 3 contacted.

[0020] Among them, the proportional temperature control device is composed of a steam flow prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com